Page 1

Definite Purpose Contactors and Starters

25–60A, Single- and Three-Phase—A25, B25

Incomplete catalog number

A25CNC30 A

Magnet coil suffix

Starters

4.3

25–60A, Single- and Three-Phase—A25, B25

Product Description

A25 and B25 Definite

Purpose Starters from Eaton’s

Electrical Sector combine the

features and flexibility of the

C25 Definite Purpose

Contactors and Freedom

Series Bi-metallic Ambient

Compensated Overload

Relays mounted on a common

mounting plate.

Features and Benefits

Overload Relay

●

Selectable manual or

automatic reset operation

●

Interchangeable heater

packs adjustable ±24% to

match motor FLA and

calibrated for use with 1.0

and 1.15 service factor

motors

●

Class 10 or 20 heater packs

●

Bimetallic, ambient

compensated operated.

Trip free mechanism

●

Electrically isolated NO-NC

contacts (pull RESET

button to test)

●

Overload trip indication

●

Shrouded or fingerproof

terminals to reduce

possibility of electrical

shock

●

Single-phase sensitivity

Contents

Description Page

25–60A, Single- and Three-Phase—A25, B25

Product Selection . . . . . . . . . . . . . . . . . . . . . . . V5-T4-24

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-26

Technical Data and Specifications . . . . . . . . . . V5-T4-27

Trip Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-28

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-28

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-29

15–45A, Single- and Three-Phase—A27, B27 . . . . V5-T4-30

15–75A, Single- and Three-Phase—A30, B30 and

C440/XT Electronic Overload Relay . . . . . . . . . . V5-T4-38

Standards and Certifications

●

UL Recognized

Components UL File

#E-1491, Guide NLDX2

●

CSA Certified Components

File #LR353, Guide

380W-1.14 Class 3211 04

Catalog Number Selection

25–60A, Single- and Three-Phase—A25, B25

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

When Ordering Specify

●

Catalog number plus magnet coil suffix, see Page V5-T4-24

Example, order catalog number A25CNC30A

●

Heater packs for specific FLA of motor,

see Pages V5-T4-26 and V5-T4-27

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-23

4

4

4

4

4

4

4

Page 2

4.3

A25 Starter

Product Selection

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Definite Purpose Contactors and Starters

Starters

Single- and Three-Phase Starters—Open Type

Single-Phase

Ampere Rating

Inductive

Full Load

25 115 150 2 — 1.5 — B25CNC25_ B25SNC25_ A25CNC25_ A25SNC25_

30 115 180 2 — 1.5 — B25CNC30_ B25SNC30_ A25CNC30_ A25SNC30_

40 115 240 3 — 2.2 — B25CNE40_ B25SNE40_ A25CNE40_ A25SNE40_

50 115 300 — — — — N/A N/A A25CNE50_ A25SNE50_

60 115 360 — — — — N/A N/A A25CNE60_ A25SNE60_

Line

Voltage

230 150 3 7-1/2 2.2 5.5 B25CNC25_ B25SNC25_ A25CNC25_ A25SNC25_

460 125 — 10 — 7.5 B25CNC25_ B25SNC25_ A25CNC25_ A25SNC25_

575 100 — 10 — 7.5 B25CNC25_ B25SNC25_ A25CNC25_ A25SNC25_

230 180 5 10 3.7 7.5 B25CNC30_ B25SNC30_ A25CNC30_ A25SNC30_

460 150 — 15 — 11 B25CNC30_ B25SNC30_ A25CNC30_ A25SNC30_

575 120 — 15 — 11 B25CNC30_ B25SNC30_ A25CNC30_ A25SNC30_

230 240 7-1/2 10 5.5 7.5 B25CNE40_ B25SNE40_ A25CNE40_ A25SNE40_

460 200 — 20 — 15 B25CNE40_ B25SNE40_ A25CNE40_ A25SNE40_

575 160 — 20 — 15 B25CNE40_ B25SNE40_ A25CNE40_ A25SNE40_

230 300 — 15 — 11 N/A N/A A25CNE50_ A25SNE50_

460 250 — 30 — 22 N/A N/A A25CNE50_ A25SNE50_

575 200 — 30 — 22 N/A N/A A25CNE50_ A25SNE50_

230 360 — 20 — 15 N/A N/A A25CNE60_ A25SNE60_

460 300 — 40 — 30 N/A N/A A25CNE60_ A25SNE60_

575 240 — 40 — 30 N/A N/A A25CNE60_ A25SNE60_

Locked

Rotor

Maximum Motor

(hp)

SinglePhase

ThreePhase

Maximum Motor

(kW)

SinglePhase

ThreePhase

Common

Control

Catalog

Number

12

Separate

Control

Catalog

3

Number

3

Three-Phase

Common

Control

Catalog

Number

1

Separate

Control

Catalog

3

Number

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Magnet Coil Suffix

Voltage

60 Hertz 50 Hertz Coil Suffix

4

AC

12 12 R 12 1R

24 24 T 24 1T

5

110–120

208–240 208–240 B 120 1A

6

240

277 — H

— 380–415 L

440–480 440–480 C

550–600 550–600 D

Notes

1

Starters do not include heater packs. Select heater pack from tables, see Pages V5-T4-26 and V5-T4-27.

2

Set of three heater packs required for single-phase applications.

3

Incomplete catalog number. Replace underscore (_) with magnet coil suffix from table above.

4

Class H AC coils available as option for 15A–50A contactor. Add 2 before AC coil suffix letter.

5

104–120V 50/60 Hz for 60A contactor.

6

Available through 50A.

7

Starters with DC coils include an early breaking auxiliary contact, C320KGD1. See Page V5-T4-62 for more detail.

5

110–120

220 J

A 48 1W

Voltage

60 Hertz Coil Suffix

7

DC

V5-T4-24 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 3

Definite Purpose Contactors and Starters

AD

CB

1. 0

Service

Factor

1. 15

Service

Factor

Starters

4.3

Overload Relay

General

Overload relays are provided

to protect motors, motor

control apparatus and motorbranch circuit conductors

against excessive heating

due to motor overloads and

failure to start. This definition

does not include: 1) motor

circuits over 600 volts, 2)

short-circuits, 3) ground faults

and 4) fire pump control.

(NEC Art. 430-31)

Time Current

Characteristics

The time-current

characteristics of an overload

relay is an expression of

performance which defines

its operating time at various

multiples of its current

setting. Tests are run at

Underwriters Laboratory (UL)

in accordance with NEMA

Standards and the NEC.

UL requires—

●

When tested at 100

percent of its current

rating, the overload relay

shall trip ultimately

●

When tested at 200

percent of its current

rating, the overload relay

shall trip in not more than 8

minutes

●

When tested at 600

percent of its current

rating, the overload relay

shall trip in not more than

10 or 20 seconds,

depending on the Class of

the relay or heater packs

“Current Rating” is defined

as the minimum current at

which the relay will trip. Per

NEC, an overload must

ultimately trip at 125% of FLA

(Full Load Amperes) current

(heater) setting for a 1.15

service factor motor and

115% FLA for a 1.0 service

factor motor.“Current

Setting” is defined as the

FLA of the motor and thus

the overload heater pack

setting.

Example: 600% of current

rating is defined as 750%

(600 x 1.25) of FLA current

(heater) setting for a 1.15

service factor motor. A 10

ampere heater setting must

trip in 20 seconds or less at

75 amperes motor current for

a Class 20 relay.

Overload Relay Setting

FLA Dial Adjustment—

For motors having a 1.15

service factor, rotate the FLA

adjustment dial to correspond

to the motor’s FLA rating.

Estimate the dial position

when the motor FLA falls

between two letter values as

shown in the example.

For motors having a 1.0

service factor, rotate the FLA

dial single-half position

counterclockwise (CCW).

Manual/Automatic Reset—

The overload relay is factory

set at M for manual reset

operation. For automatic

reset operation, turn the reset

adjustment dial to the A

position as shown in the

illustration.

Automatic reset is not

intended for two-wire control

devices.

Test for Trip Indication—

To test overload relay for trip

indication when in manual

reset, pull out the blue RESET

button. An orange flag will

appear indicating that the

device has tripped. Push

RESET button in to reset.

4

4

4

4

4

4

4

4

4

4

4

4

4

4

FLA Dial Adjustment Reset Adjustment Dial

A

M

Example of 12.0 FLA

setting for heater pack

number H2011B showing

position for 1.0 or 1.15

service factor motors.

Replacement Overload with Connectors

Starter Size Overload Part Number

25 and 30A 10-7125

40 and 50A 10-7132

60A 10-7131

Example of setting for manual

reset.

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-25

Page 4

Definite Purpose Contactors and Starters

Locking Cover

4.3

Accessories

4

Contactor Accessories, see Pages V5-T4-11 and V5-T4-12.

Locking Cover for Overload Relay

4

Snap-on transparent or opaque plastic panel for covering access port to the overload relay trip

setting dial—helps prevent accidental or unauthorized changes to trip and reset setting.

4

4

4

4

4

4

4

Separate Enclosures

4

4

4

Starters

Locking Cover for Overload Relay

Minimum Order

Description

Clear cover, no accessibility 50 C320PC3

Gray cover, no accessibility, with auto only nib 50 C320PC4

Gray cover, no accessibility, with manual only nib 50 C320PC5

Gray cover with FLA dial accessibility, A, B, C, D positions

and auto only nib

Gray cover with FLA dial accessibility, A, B, C, D positions

and manual only nib

Separate Enclosures—NEMA 1

Application Catalog Number

25 and 30A C799B11

40, 50 and 60A C799B13

Quantity

(Std. Pkg.) Catalog Number

50 C320PC6

50 C320PC7

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Heater Packs

Fast Trip—Class 10 Heater Packs

Manual or Automatic Reset

Heater packs are shipped three to a carton.

Catalog numbers listed below are for three heater packs.

Fast Trip Ratings

Motor Full Load Ampere Rating

Dial Position

ABCD

0.26 0.313 0.367 0.42 H2101B-3

0.384 0.464 0.543 0.623 H2102B-3

0.57 0.688 0.806 0.924 H2103B-3

0.846 1.02 1.2 1.37 H2104B-3

1.28 1.55 1.83 2.1 H2105B-3

1.92 2.33 2.74 3.15 H2106B-3

2.3 2.79 3.28 3.77 H2107B-3

3.38 4.1 4.82 5.54 H2108B-3

4.96 6.03 7.09 8.16 H2109B-3

7.07 8.58 10.1 11.6 H2110B-3

9.6 11.2 12.8 14.4 H2111B-3

14.4 17.5 20.7 23.8 H2112B-3

18.7 21.8 25 28.1 H2113B-3

23.5 27.3 31 34.8 H2114B-3

28.3 32.6 37 41.3 H2115B-3

36.6 42.3 48.1 53.8 H2116B-3

53.8 60.8 67.9 74.9 H2117B-3

Trip Curves, see Page V 5-T4-28.

Notes

1

For motor full load amperes between listed values, adjust dial clockwise for higher or counterclockwise for lower motor currents. The currents listed are for 1.5 service factor motors.

A position adjustment is provided for 1.0 service factor motors.

2

Set of three heater packs are required for both single- and three-phase applications.

1

Catalog Number

(Includes Three Heater

Packs)

2

V5-T4-26 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 5

Definite Purpose Contactors and Starters

Starters

4.3

Standard Trip—Class 20 Heater Packs

Manual or Automatic Reset

Heater packs are shipped three to a carton.

Catalog numbers listed below are for three heater packs.

Standard Trip Ratings

Motor Full Load Ampere Rating

Dial Position

ABCD

0.254 0.306 0.359 0.411 H2001B-3

0.375 0.452 0.53 0.607 H2002B-3

0.56 0.676 0.791 0.907 H2003B-3

0.814 0.983 1.15 1.32 H2004B-3

1.2 1.45 1.71 1.96 H2005B-3

1.79 2.16 2.53 2.9 H2006B-3

2.15 2.6 3.04 3.49 H2007B-3

3.23 3.9 4.56 5.23 H2008B-3

4.55 5.5 6.45 7.4 H2009B-3

6.75 8.17 9.58 11 H2010B-3

9.14 10.8 12.4 14 H2011B-3

14 16.9 19.9 22.8 H2012B-3

18.7 22.7 26.7 30.7 H2013B-3

23.5 28.5 33.5 38.5 H2014B-3

29 34 39.1 44.1 H2015B-3

39.6 45.5 51.5 57.4 H2016B-3

53.9 60.9 67.9 74.9 H2017B-3

Trip Curves, see Page V5-T4-28.

1

Catalog Number

(Includes Three Heater

Packs)

4

4

4

2

4

4

4

4

4

4

4

4

4

4

4

4

Technical Data and Specifications

Terminal Wire Sizes

Line Side (Contactor)

Terminal Type Power Terminals Coil Terminals

Screw/pressure plate 8–14 AWG 12–16 AWG

Box lug: 25–50A 4–14 AWG 12–16 AWG

Box lug: 60A 3–14 AWG 12–16 AWG

Power Terminals—Load—Cu Only (Stranded or Solid)

Terminal Range Torque Rating

25 and 30A 14–6 AWG 20 lb-in (14–10 AWG)

40, 50 and 60A 14–2 AWG 35 lb-in (14–10 AWG)

Control Terminals—Cu Only

12–16 AWG stranded, 12–14 AWG solid

Notes

1

For motor full load amperes between listed values, adjust dial clockwise for higher or counterclockwise for lower motor currents. The currents listed are for 1.5 service factor motors.

A position adjustment is provided for 1.0 service factor motors.

2

Set of three heater packs are required for both single- and three-phase applications.

3

Line side (contactor) torque ratings can be found on Page V5-T4-14.

3

Wire Range—Solid or Stranded

40 lb-in (8 AWG)

45 lb-in (6–4 AWG)

50 lb-in (3–2 AWG)

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-27

4

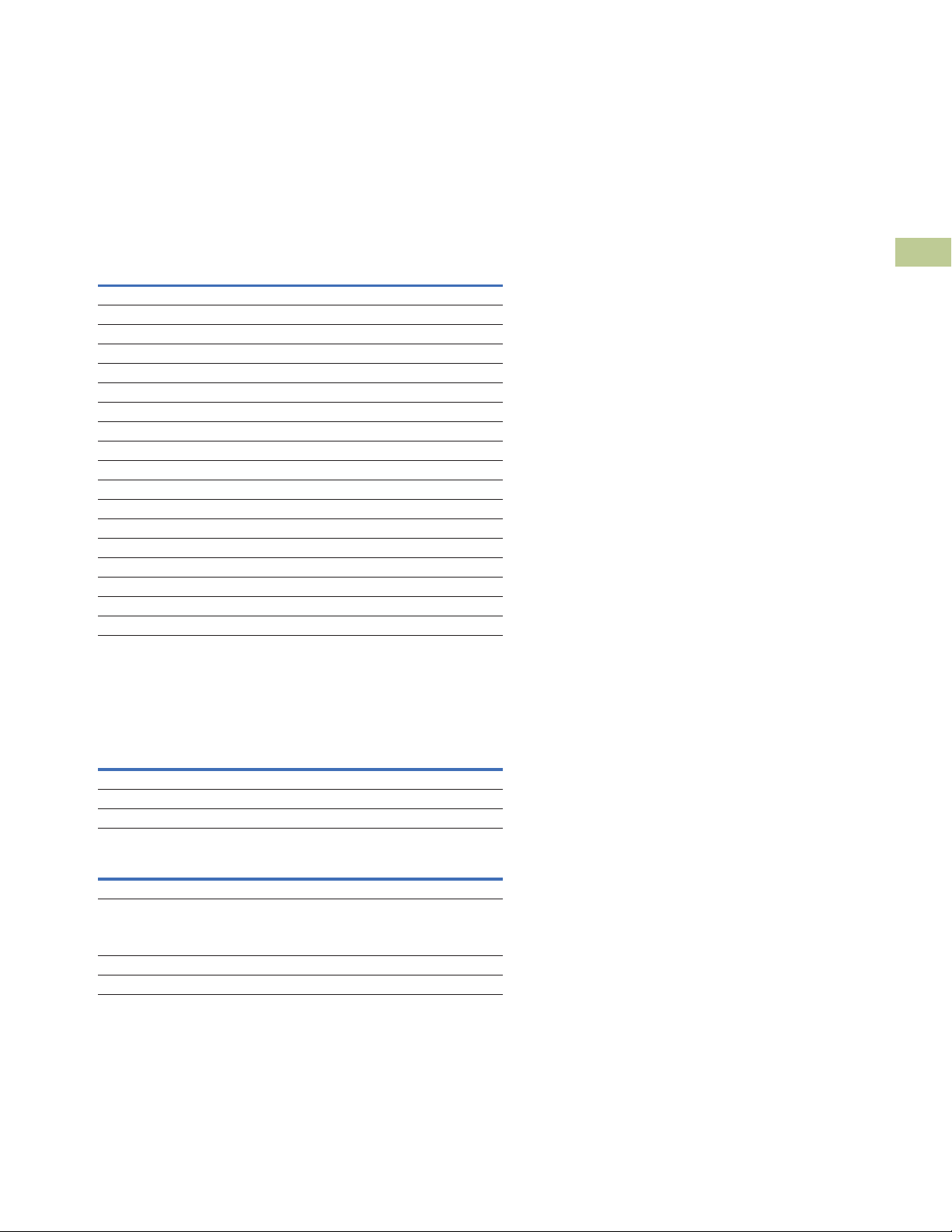

Page 6

Definite Purpose Contactors and Starters

0

1

2

3

4

5

10

20

30

40

50

100

200

300

400

500

1000

2000

3000

4000

5000

10,000

246810

From

Hot Start

From

Cold Start

Multiples of Current Setting

Trip Time

(Seconds)

0

1

2

3

4

5

10

20

30

40

50

100

200

300

400

500

1000

2000

3000

4000

5000

10,000

246810

From

Hot Start

From

Cold Start

Multiples of Current Setting

Trip Time

(Seconds)

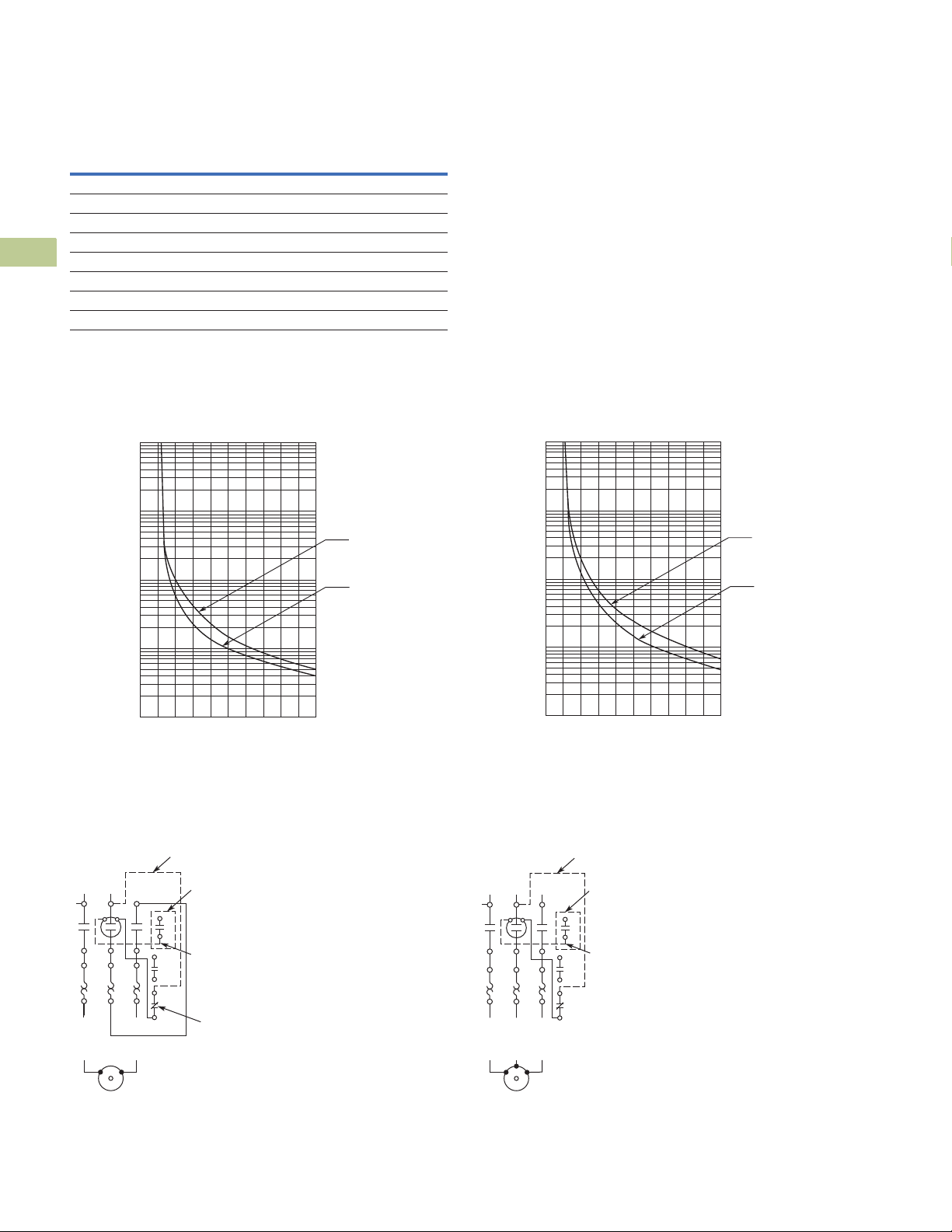

1NO Aux. Contact

(When Supplied)

Reset

Wire “D”

(Supplied with

1NO Aux. Contact)

Wire “C”

(Supplied with Common Control)

1

13

14

L1 L2

T1

4/T22/T1

T2

AC Motor

98

97

96

95

4.3

Overload Relay UL/CSA Contact Ratings Control Circuit

4

AC Volts 120V 240V 480V 600V

NC Contact B600

4

Make and break 30A 15A 7.5A 6A

Break 3A 1.5A 0.75A 0.6A

4

Continuous 5A 5A 5A 5A

4

NO Contact C600

Make and break 15A 7.5A 3.375A 3A

4

Break 1.5A 0.75A 0.375A 0.3A

Continuous 2.5A 2.5A 2.5A 2.5A

4

4

Trip Curves

4

Bimetallic Ambient Compensated Overload Relay—25°C Open Rating

Class 10 Overload Relay Class 20 Overload Relay

4

4

4

Starters

4

4

4

4

4

4

4

4

Wiring Diagrams

4

Single-Phase Connections Three-Phase Connections

4

4

4

4

4

4

4

4

4

4

V5-T4-28 Volume 5—Motor Control and Protection CA08100006E—August 2018

T2

6/T32/T1 4/T2

T3

Wire “C”

1NO Aux. Contact

13

14

98

97

96

95

(When Supplied)

Wire “D”

(Supplied with

1NO Aux. Contact)

(Supplied with Common Control)

L1 L2 L3

1

T1

AC Motor

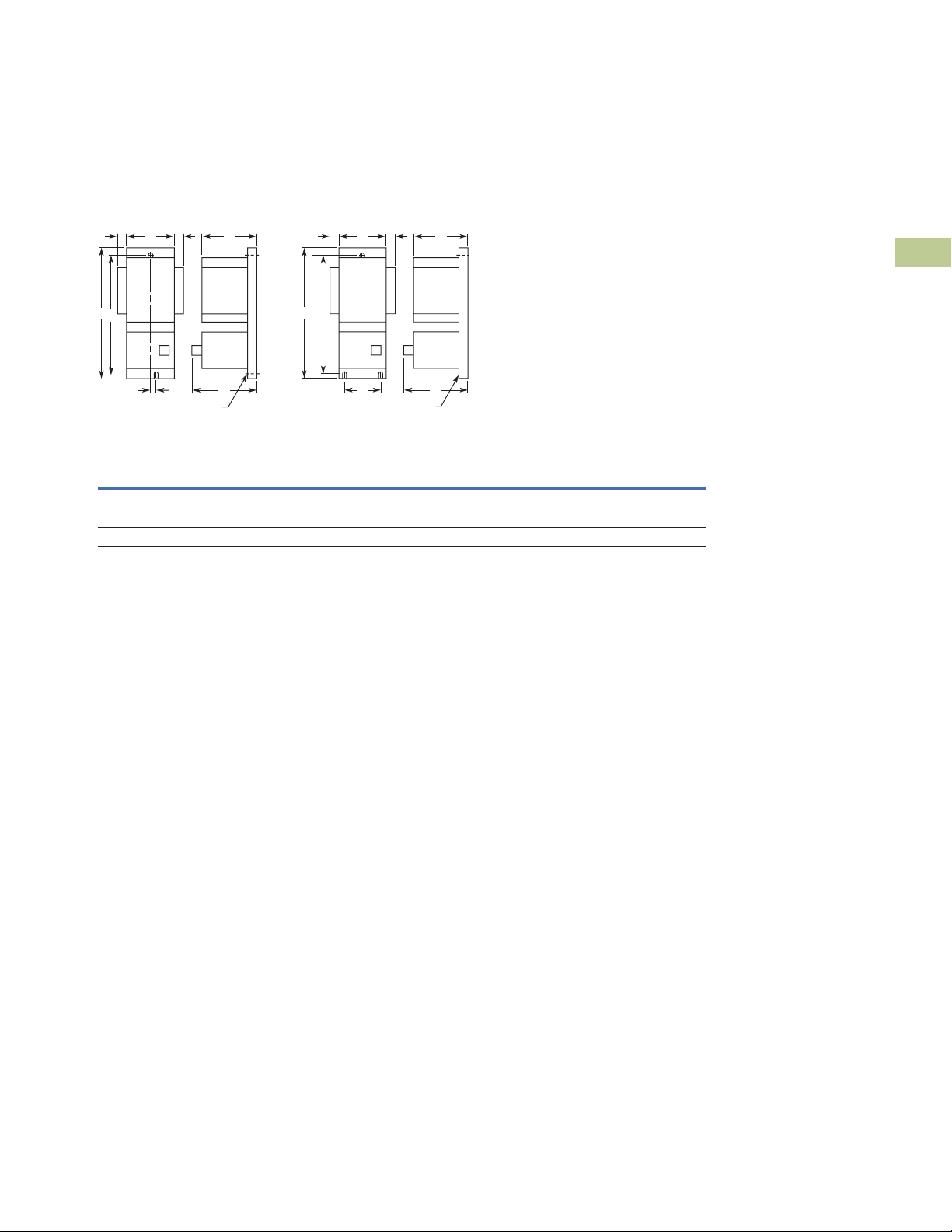

Page 7

Definite Purpose Contactors and Starters

G D

C

Mtg. for #10-32 Screw

AHH

B

E

Starters

4.3

Dimensions

Approximate Dimensions in Inches (mm)

A25 and B25 Starers—Open Type

25 and 30 Ampere

Dimensions and Shipping Weights

Ampere Size

25 and 30 2.50 (64.0) 7.14 (181.0) 3.56 (90.4) 3.69 (93.7) 6.55 (166.0) 0.20 (5.1) 0.54 (13.7) 1.8 (0.8)

40 2.56 (65.0) 8.08 (205.0) 3.50 (89.0) 3.66 (93.0) 7.50 (190.5) 2.00 (51.0) 0.54 (13.7) 1.8 (0.8)

50 and 60 2.56 (65.0) 8.08 (205.0) 4.15 (105.0) 3.66 (93.0) 7.50 (190.5) 2.00 (51.0) 0.54 (13.7) 3.6 (1.6)

Wide

A

High

B

40, 50 and 60 Ampere

B

E

Mtg. for #10-32 Screw

Deep

C

G D

Deep

D

CAHH

MountingEMounting

G

Auxiliary

Contact Adder

H

Shipping

Weight

Lbs (kg)

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-29

Page 8

4.3

15–45A, Single- and Three-Phase—A27, B27

Incomplete catalog number

A27CNE30 A

Magnet coil suffix

040

Overload relay suffix

Definite Purpose Contactors and Starters

Starters

4

4

4

4

4

4

4

4

4

4

4

15–45A, Single- and Three-Phase—A27, B27

Product Description

4

A27 and B27 Definite

Purpose Starters from

4

Eaton’s Electrical Sector

combine the features and

4

flexibility of the C25 Definite

Purpose Contactors and XT

4

Series Bi-metallic Ambient

Compensated Overload

4

Relays.

4

Features and Benefits

●

●

●

●

●

4

4

●

Selectable manual or

automatic reset operation

Class 10 trip class

Bimetallic, ambient

compensated operated.

Trip free mechanism

Electrically isolated NO-NC

contacts (pull TEST button

to test)

Shrouded or fingerproof

terminals to reduce

possibility of electrical

shock

Single-phase sensitivity

Contents

Description Page

25–60A, Single- and Three-Phase—A25, B25 . . . . V5-T4-23

15–45A, Single- and Three-Phase—A27, B27

Product Selection . . . . . . . . . . . . . . . . . . . . . . . V5-T4-31

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-33

Technical Data and Specifications . . . . . . . . . . V5-T4-33

Trip Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-36

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . V5-T4-36

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-37

15–75A, Single- and Three-Phase—A30, B30 and

C440/XT Electronic Overload Relay . . . . . . . . . . V5-T4-38

Standards and Certifications

●

UL Recognized

Components UL File

#E-1491, Guide NLDX2

●

CSA Certified Components

File #LR353, Guide 3

80W-1.14 Class 3211 04

●

IEC/EN 60947

●

VDE 0660

●

UL

●

CSA

●

CE

4

4

4

4

4

4

4

4

4

4

4

V5-T4-30 Volume 5—Motor Control and Protection CA08100006E—August 2018

Catalog Number Selection

15–45A, Single- and Three-Phase—A27, B27

When Ordering Specify

●

Catalog number plus magnet coil suffix plus overload relay

suffix, see Page V5-T4-32

Example, order catalog number A27CNE30A040

Page 9

Definite Purpose Contactors and Starters

A27 Starter

Starters

4.3

Product Selection

Three-Phase Starter—Open Type

Common Control Separate Control

Ampere Rating

Inductive

Full Load

15 115 90 — — A27CNC15_ A27CRC15_ A27SNC15_ A27SRC15_

25 115 150 — — A27CNC25_ A27CRC25_ A27SNC25_ A27SRC25_

30 115 180 — — A27CNE30_ A27CRE30_ A27SNE30_ A27SRE30_

40 115 240 — — A27CNE40_ A27CRE40_ A27SNE40_ A27SRE40_

45 115 270 — — A27CNE45_ A27CRE45_ A27SNE45_ A27SRE45_

Note

1

Incomplete catalog number. Replace underscore (_) with magnet coil suffix and overload relay suffix from Page V5-T4-32.

Line

Voltage

230 90 3 2.2 A27CNC15_ A27CRC15_ A27SNC15_ A27SRC15_

460 75 5 3.7 A27CNC15_ A27CRC15_ A27SNC15_ A27SRC15_

575 60 5 3.7 A27CNC15_ A27CRC15_ A27SNC15_ A27SRC15_

230 150 7-1/2 5.5 A27CNC25_ A27CRC25_ A27SNC25_ A27SRC25_

460 125 10 7.5 A27CNC25_ A27CRC25_ A27SNC25_ A27SRC25_

575 100 10 7.5 A27CNC25_ A27CRC25_ A27SNC25_ A27SRC25_

230 180 10 7.5 A27CNE30_ A27CRE30_ A27SNE30_ A27SRE30_

460 150 15 11 A27CNE30_ A27CRE30_ A27SNE30_ A27SRE30_

575 120 15 11 A27CNE30_ A27CRE30_ A27SNE30_ A27SRE30_

230 240 10 7.5 A27CNE40_ A27CRE40_ A27SNE40_ A27SRE40_

460 200 20 15 A27CNE40_ A27CRE40_ A27SNE40_ A27SRE40_

575 160 20 15 A27CNE40_ A27CRE40_ A27SNE40_ A27SRE40_

230 270 15 11 A27CNE45_ A27CRE45_ A27SNE45_ A27SRE45_

460 225 30 22 A27CNE45_ A27CRE45_ A27SNE45_ A27SRE45_

575 180 30 22 A27CNE45_ A27CRE45_ A27SNE45_ A27SRE45_

Locked

Rotor

Maximum

Motor (hp)

Maximum

Motor (kW)

Metal

Mounting Plate

Catalog

1

Number

DIN Rail

Adapter

Catalog

Number

Metal

Mounting Plate

1

Catalog

Number

1

DIN Rail

Adapter

Catalog

Number

4

4

4

1

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-31

Page 10

Definite Purpose Contactors and Starters

4.3

Single-Phase Starter—Open Type, B27

4

4

Ampere Rating

Inductive

Full Load

4

15 115 90 3/4 0.4 B27CNC15_ B27CRC15_ B27SNC15_ B27SRC15_

4

4

25 115 150 2 1.5 B27CNC25_ B27CRC25_ B27SNC25_ B27SRC25_

4

4

4

30 115 180 2 1.5 B27CNE30_ B27CRE30_ B27SNE30_ B27SRE30_

4

4

40 115 240 3 2.2 B27CNE40_ B27CRE40_ B27SNE40_ B27SRE40_

4

4

45 115 270 3 2.2 B27CNE45_ B27CRE45_ B27SNE45_ B27SRE45_

4

4

4

Magnet Coil Suffix

4

Voltage

60 Hertz 50 Hertz Coil Suffix

4

4

4

4

4

4

4

4

4

4

4

4

4

2

AC

12 12 R 12 1R

24 24 T 24 1T

110–120 110–120 A 48 1W

208–240 208–240 B 120 1A

3

240

277 — H

— 380–415 L

440–480 440–480 C

550–600 550–600 D

Notes

1

Incomplete catalog number. Replace underscore (_) with magnet coil suffix and overload

relay suffix from tables above.

2

Class H AC coils available as option. Add 2 before AC coil suffix letter.

3

Available through 45A.

4

Starters with DC coils include an early breaking auxiliary contact, C320KGD1.

See Page V5-T4-62 for more detail.

220 J

Starters

Common Control Separate Control

Metal

Mounting Plate

Line

Voltage

230 90 2 1.5 B27CNC15_ B27CRC15_ B27SNC15_ B27SRC15_

460 75 — — B27CNC15_ B27CRC15_ B27SNC15_ B27SRC15_

575 60 — — B27CNC15_ B27CRC15_ B27SNC15_ B27SRC15_

230 150 3 2.2 B27CNC25_ B27CRC25_ B27SNC25_ B27SRC25_

460 125 — — B27CNC25_ B27CRC25_ B27SNC25_ B27SRC25_

575 100 — — B27CNC25_ B27CRC25_ B27SNC25_ B27SRC25_

230 180 5 3.7 B27CNE30_ B27CRE30_ B27SNE30_ B27SRE30_

460 150 — — B27CNE30_ B27CRE30_ B27SNE30_ B27SRE30_

575 120 — — B27CNE30_ B27CRE30_ B27SNE30_ B27SRE30_

230 240 7-1/2 5.5 B27CNE40_ B27CRE40_ B27SNE40_ B27SRE40_

460 200 — — B27CNE40_ B27CRE40_ B27SNE40_ B27SRE40_

575 160 — — B27CNE40_ B27CRE40_ B27SNE40_ B27SRE40_

230 270 7-1/2 7.5 B27CNE45_ B27CRE45_ B27SNE45_ B27SRE45_

460 225 — — B27CNE45_ B27CRE45_ B27SNE45_ B27SRE45_

575 180 — — B27CNE45_ B27CRE45_ B27SNE45_ B27SRE45_

Locked

Rotor

Maximum

Motor (hp)

Voltage

60 Hertz Coil Suffix

4

DC

Maximum

Motor (kW)

Catalog

1

Number

Overload Relay Suffix

Motor Full Load Amperes Suffix Code

Frame C

0.1–0.16 P16 15–25A

0.16–0.24 P24 15–25A

0.24–0.4 P40 15–25A

0.4–0.6 P60 15–25A

0.6–1 001 15–25A

1–1.6 1P6 15–25A

1.6–2.4 2P4 15–25A

2.4–4 004 15–25A

4–6 006 15–25A

6–10 010 15–25A

10–16 016 15–25A

16–24 024 15–25A

24–32 032 15–25A

Frame D

6–10 010 30–45A

10–16 016 30–45A

16–24 024 30–45A

24–40 040 30–45A

40–57 057 30–45A

DIN Rail

Adapter

Catalog

Number

Metal

Mounting Plate

1

Catalog

Number

1

DIN Rail

Adapter

Catalog

1

Number

For use with Contactor

Ampere Range

4

V5-T4-32 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 11

Definite Purpose Contactors and Starters

Starters

4.3

Renewal Parts

Overload Relays

Motor Full

Load Amperes Suffix Code

Frame C

0.1–0.16 P16 15–25A XTOBP16CC1DP

0.16–0.24 P24 15–25A XTOBP24CC1DP

0.24–0.4 P40 15–25A XTOBP40CC1DP

0.4–0.6 P60 15–25A XTOBP60CC1DP

0.6–1 001 15–25A XTOB001CC1DP

1–1.6 1P6 15–25A XTOB1P6CC1DP

1.6–2.4 2P4 15–25A XTOB2P4CC1DP

2.4–4 004 15–25A XTOB004CC1DP

4–6 006 15–25A XTOB006CC1DP

6–10 010 15–25A XTOB010CC1DP

10–16 016 15–25A XTOB016CC1DP

16–24 024 15–25A XTOB024CC1DP

24–32 032 15–25A XTOB032CC1DP

Frame D

6–10 010 30–45A XTOB010DC1DP

10–16 016 30–45A XTOB016DC1DP

16–24 024 30–45A XTOB024DC1DP

24–40 040 30–45A XTOB040DC1DP

40–57 057 30–45A XTOB057DC1DP

For use with

Contactor

Ampere Range

Overload Relay

Catalog Number

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Technical Data and Specifications

Terminal Wire Sizes

Line Side (Contactor)

Terminal Type Power Terminals Coil Terminals

Screw/pressure plate 8–14 AWG 12–16 AWG

Box lug: 15–45A 4–14 AWG 12–16 AWG

Note

1

Line side (contactor) torque ratings can be found on Page V5-T4-14.

1

Wire Range—Solid or Stranded

Power Terminals—Load—Cu Only (Stranded or Solid)

Terminal Range Torque Rating

15 and 25A 14–8 AWG 16 lb-in (14–8 AWG)

30, 40 and 45A 14–2 AWG 31 lb-in (14–2 AWG)

Control Terminals—Cu Only

12–16 AWG stranded, 12–14 AWG solid

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-33

4

Page 12

Definite Purpose Contactors and Starters

4.3

Overload Relays

4

These tripping characteristics are the mean values of the spread at 20°C ambient temperature

in a cold state.

4

Tripping time depends on response current. With devices at operating temperature, the

tripping time of the overload relay reduces to approximately 25% of the read off value.

4

Specific characteristics for each individual setting range can be found in MN03402001E.

4

Overload Relays

4

Description

General

4

Climatic proofing Damp heat, constant, to IEC 60068-2-78;

4

Ambient temperature range

Temperature compensation Continuous Continuous

4

Mechanical shock resistance (IEC/EN 60068-2-27)

Half-sinusoidal shock 10 ms 10g 10g

4

Degree of protection IP20 IP20

4

Protection against direct contact when actuated

from front (IEC 536)

Insulation voltage (U

4

Overvoltage category/pollution degree III/3 III/3

4

Impulse withstand voltage (U

Operational voltage (U

4

Safe isolation to VDE 0106 Part 101 and Part 101/A1

Between auxiliary contacts and main contacts (Vac) 440 440

4

Between main contacts (Vac) 440 440

Overload relay setting range 0.1–32A 6–75A

4

Temperature compensation residual error >20°C (%/K)

4

Current heat loss (3 conductors)

Lower value of setting range, W 2.5 3

4

Upper value of setting range, W 6 7.5

Terminal capacity 2 x (1–6) 2 x (1–6)

4

Solid, mm

Flexible with ferrule, mm

4

Solid or stranded, AWG 14-8 14-2

4

Terminal screw M4 M6

Tightening torque Nm (lb-in) 1.8 (16) 3.5 (31)

4

Too ls

Pozidrive screwdriver Size 2 Size 2

4

Standard screwdriver 1 x 6 1 x 6

Notes

4

1

Ambient temperature operating range to IEC/EN 60947, PTB: –5° to 50°C [23° to 122°F].

2

4

6 mm2 flexible with ferrules to DIN 46228.

3

Main contact terminal capacity, solid and stranded conductors with ferrules: When using two conductors use identical cross-section.

4

) Vac 690 690

i

e

2

Starters

XTOB … CC1

Specification

Damp heat, cyclic, to IEC 60 068-2-30

1

) Vac 6000 6000

imp

) Vac 690 690

2

–25° to 50°C [–13° to 122°F] –25° to 50°C [–13° to 122°F]

Finger and back of hand proof Finger and back of hand proof

<

0.25

2 x (1–4) 1 x 25

2

2 x (1–6)

XTOB … DC1

Specification

Damp heat, constant, to IEC 60068-2-78;

Damp heat, cyclic, to IEC 60 068-2-30

<

0.25

3

2 x (1–10)

4

4

4

4

4

V5-T4-34 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 13

Definite Purpose Contactors and Starters

Starters

4.3

Overload Relays, continued

Description

Auxiliary and Control Circuit Connections

Impulse withstand voltage (U

Overvoltage category/pollution degree III/3 III/3

Terminal capacity

2

2 x (0.75–4) 2 x (0.75–4)

Solid, mm

Flexible with ferrule, mm

Solid or stranded, AWG 2 x (18–12) 2 x (18–12)

Terminal screw M3.5 M3.5

Tightening torque Nm (lb-in) 0.8–1.3 (7–11.5) 0.8–1.3 (7–11.5)

Too ls

Pozidrive screwdriver Size 2 Size 2

Standard screwdriver 1 x 6 1 x 6

Auxiliary circuit rated insulation voltage (U

Rated operational voltage (U

Safe isolation to VDE 0106 Part 101 and Part 101/A1

Between the auxiliary contacts (Vac) 240 240

Conventional thermal current, I

Rated operational current—AC-15

NO contact

120V 1.5 1.5

240V 1.5 1.5

415V 0.5 0.5

500V 0.5 0.5

NC contact

120V 1.5 1.5

240V 1.5 1.5

415V 0.9 0.9

500V 0.8 0.8

Rated operational current—DC-13 L/R

NO contact

24V 0.9 0.9

60V 0.75 0.75

110V 0.4 0.4

220V 0.2 0.2

Short-circuit rating without welding maximum fuse, A gG/gL 6 6

Note

1

Rated operational current: Making and breaking conditions to DC-13, L/R constant as stated.

) Vac 6000 6000

imp

2

2 x (0.75–2.5) 2 x (0.75–2.5)

) Vac 500 500

i

) Vac 500 500

e

th

1

<

15 ms

XTOB … CC1

Specification

66

XTOB … DC1

Specification

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-35

4

4

4

4

4

4

4

Page 14

4.3

2h

100

60

40

20

10

6

4

2

1

40

20

10

6

4

2

1

0.6

XTOB...CC1,

XTOB...DC1

1 1.5 2 3 4 68 10 15 20

x Setting Current

2-Phase

Seconds

Minutes

3-Phase

1NO Aux. Contact

(When Supplied)

Reset

Wire “D”

(Supplied with

1NO Aux. Contact)

Wire “C”

(Supplied with Common Control)

1

13

14

L1 L2

T1

4/T22/T1

T2

AC Motor

98

97

96

95

Trip Curv e

4

Overload Relay

4

4

4

4

4

4

4

4

4

4

Definite Purpose Contactors and Starters

Starters

4

Wiring Diagrams

Single-Phase Connections Three-Phase Connections

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

V5-T4-36 Volume 5—Motor Control and Protection CA08100006E—August 2018

T2

6/T32/T1 4/T2

T3

Wire “C”

1NO Aux. Contact

13

14

98

97

96

95

(When Supplied)

Wire “D”

(Supplied with

1NO Aux. Contact)

(Supplied with Common Control)

L1 L2 L3

1

T1

AC Motor

Page 15

Definite Purpose Contactors and Starters

D

CAH

B

E

D

C

AH

B

E

Starters

4.3

Dimensions

Approximate Dimensions in Inches (mm)

A27 and B27 Starters—Open Type

15 and 25 Ampere

Dimensions and Shipping Weights

Ampere Size

15 and 25 (metal plate) 2.40 (61.0) 5.50 (139.0) 3.35 (85.0) 3.70 (94.0) 3.13 (82.6) — 0.54 (13.7) 1.6 (0.7)

15 and 25 (DIN rail mount) 2.23 (56.5) 5.20 (133.0) 3.35 (85.0) 3.70 (94.0) — — 0.54 (13.7) 1.6 (0.7)

30, 40 and 45 (metal plate) 2.40 (61.0) 6.00 (152.0) 3.35 (85.0) 3.90 (98.0) 3.13 (82.6) — 0.54 (13.7) 1.11 (0.9)

30, 40 and 45 (DIN rail mount) 2.23 (56.5) 5.70 (145.0) 3.35 (85.0) 3.90 (98.0) — — 0.54 (13.7) 1.11 (0.9)

Wide

A

High

B

Deep

C

30, 40 and 45 Ampere

Deep

D

Mounting

E

Mounting

G

Auxiliary

Contact AdderHShipping Weight

Lbs (kg)

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-37

4

Page 16

4.3

15–75A, Single- and Three-Phase—A30, B30 and

C440/XT Electronic Overload Relay

Definite Purpose Contactors and Starters

Starters

4

4

4

4

4

4

4

4

4

4

4

15–75A, Single- and Three-Phase—A30, B30 and

C440/XT Electronic Overload Relay

4

Product Description

4

A30 and B30 Starters

A30 and B30 Definite

4

Purpose Starters from Eaton’s

Electrical Sector combine the

features and flexibility of the

4

C25 Definite Purpose

Contactors and C440

4

Electronic Overload Relays.

4

C440 Overload

C440 is the most compact,

4

high-featured, economical

product in its class.

4

C440 is a self-powered

electronic overload relay

4

available up to 100A as a

self contained unit. With

4

external CTs, C440 can

protect motor up to

1500 FLA. Available add-on

4

accessories include remote

reset capability and

4

communication modules

with I/O for DeviceNet,

4

PROFIBUS, and Modbus.

4

Features

A30 and B30 Starters

●

Standard version:

selectable trip class

(10A, 10, 20, 30) with

selectable manual or

auto reset

●

Current adjustment

range: 5:1

●

Self-powered design—will

accept AC voltages from

12 to 690V 50/60 Hz

●

Ambient temperature

compensation

●

Low heat generation

●

Phase loss protection

●

Phase unbalance

protection

●

Electrically isolated

1NO-1NC contacts

(push-to-test)

●

Trip status indicator

Contents

Description Page

25–60A, Single- and Three-Phase—A25, B25 . . . . V5-T4-23

15–45A, Single- and Three-Phase—A27, B27 . . . . V5-T4-30

15–75A, Single- and Three-Phase—A30, B30 and

C440/XT Electronic Overload Relay

Standards and Certifications . . . . . . . . . . . . . . V5-T4-39

Catalog Number Selection . . . . . . . . . . . . . . . . V5-T4-39

Product Selection . . . . . . . . . . . . . . . . . . . . . . . V5-T4-40

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . V5-T4-42

Technical Data and Specifications . . . . . . . . . . V5-T4-43

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . V5-T4-45

C440 Overload

●

Reliable, accurate,

electronic motor protection

●

Easy to select, install and

maintain

●

Compact size

●

Flexible, intelligent design

●

Global product offering—

available with NEMA, IEC

and DP power control

Motor Control

●

Two B600 alarm (NO) and

fault (NC) contacts

●

Test/Trip button

Motor Protection

●

Thermal overload

●

Phase loss

●

Selectable (ON/OFF)

phase unbalance

●

Selectable (ON/OFF)

ground fault

User Interface

●

Large FLA selection dial

●

Trip status indicator

●

Operating mode LED

●

DIP switch selectable trip

class, phase unbalance and

ground fault

●

Selectable Auto/Manual

reset

Feature Options

●

Remote reset

●

120 Vac

●

24 Vac

●

24 Vdc

●

Tamper-proof cover

4

4

4

4

4

V5-T4-38 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 17

Definite Purpose Contactors and Starters

Designation

A = Three-phase starter

B = Single-phase starter

Type

30 = Non-reversing

Control

C = Common control

S = Separate control

Enclosure Type

N = Open with metal mounting plate

R = Open with DIN rail mounting adapter

(two- and three-pole, 15–50A contactors only)

G = NEMA Type 1 enclosed

Power Terminals

15–40A Contactor

A = Binding head screws without quick connect terminals

B = Binding head screws with quick connect terminals

C = Pressure plate without quick connect terminals

D = Pressure plate with quick connect terminals

E = Lugs without quick connect terminals

F = Lugs with quick connect terminals

50–75A Contactor

E = Lugs without quick connect terminals

F = Lugs with quick connect terminals

Auxiliary Contacts (Side Mount)

A = 1NO pressure plate

B = 1NC pressure plate

C = 1NO-1NC pressure plate

D = 2NO pressure plate

E = 2NC pressure plate

F = 1NO pressure plate and QC

G = 1NC pressure plate and QC

H = 1NO-1NC pressure plate and QC

J = 2NO pressure plate and QC

K = 2NC pressure plate and QC

L = 1NO-1NC snap switch QC only

M = 2NO-2NC snap switch QC only

X =None

AC Coil Codes

T = 24V

A = 110/120V

B = 208/240V

C = 440/480V

D = 550/600V

H = 277V

L = 380/415V

J = 240V/60 Hz; 220V/50 Hz

(Available through 50A)

Current Ratings

25 =25A

30 =30A

40 =40A

45 =45A

60 =60A

75 =75A

A 3 0 C N C 2 5 A X 5 E 0 0 5

OLR Model Designation

5C = C440 with ground fault

5E = Standard C440 OLR SEL Reset, SEL Class

Overload Range

DP Starters with C440 Electronic Overload

15A–75A Contactor

005 = 1–5A

020 = 4–20A

045 = 9–45A

100 = 20–100A

Starters

4.3

Standards and Certifications

A30 and B30 Starters

●

UL Listed Components

●

CSA Certified Components

●

IEC EN 60947-4-1, EN

60947-5-1

●

CE Certified Components

●

CCC Certified Components

●

RoHS Certified Components

Catalog Number Selection

A30 and B30 Definite Purpose Starters

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-39

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Page 18

4.3

A30 Starter

Product Selection

4

When Ordering Specify

●

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Catalog number plus AC coil code, auxiliary contact code, OLR model designation and overload

range code, see below

Definite Purpose Contactors and Starters

Starters

Three-Phase Starters—Open Type A30 with C440 Electronic Overload

Ampere Rating

Inductive

Full Load

25 115 150 — — A30CNC25_ A30CRC25_ A30SNC25_ A30SRC25_

30 115 180 — — A30CNE30_ A30CRE30_ A30SNE30_ A30SRE30_

40 115 240 — — A30CNE40_ A30CRE40_ A30SNE40_ A30SRE40_

45 115 300 — — A30CNE45_ A30CRE45_ A30SNE45_ A30SRE45_

60 115 360 — — A30CNE60_ — A30SNE60_ —

75 115 450 — — A30CNE75_ — A30SNE75_ —

Note

1

Incomplete catalog number. Replace underscore (_) with suffix, see Page V5-T4-41.

Line

Voltage

230 150 7-1/2 5-1/2

460 125 10 7-1/2

575 100 10 7-1/2

230 180 10 7-1/2

460 150 15 11

575 120 15 11

230 240 10 7-1/2

460 200 20 15

575 160 20 15

230 300 15 11

460 250 30 22

575 200 30 22

230 360 20 15

460 300 40 30

575 340 40 30

230 450 20 18-1/2

460 375 50 37

575 300 50 37

Locked

Rotor

Maximum

Motor (hp)

Maximum

Motor (kW)

Common Control Separate Control

Metal

Mounting Plate DIN Rail Adapter

Catalog Number

1

Catalog Number 1Catalog Number 1Catalog Number

Metal

Mounting Plate DIN Rail Adapter

1

4

4

4

4

4

4

4

4

4

4

V5-T4-40 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 19

Definite Purpose Contactors and Starters

C440/XT Electronic

Overload Relay

Starters

4.3

When Ordering Specify

●

Catalog number plus AC coil code, auxiliary contact code, OLR model designation and overload

range code, see below

Single-Phase Starters—Open Type, B30 with C440 Electronic Overload

Ampere Rating

Inductive

Full Load

25 115 150 2 1.5 B30CNC25_ B30CRC25_ B30SNC25_ B30SRC25_

30 115 180 2 1.5 B30CNE30_ B30CRE30_ B30SNE30_ B30SRE30_

40 115 240 3 2.2 B30CNE40_ B30CRE40_ B30SNE40_ B30SRE40_

45 115 300 3 2.2 B30CNE45_ B30CRE45_ B30SNE45_ B30SRE45_

Line

Voltage

230 150 3 2.2

460 125 — —

575 100 — —

230 180 5 3.7

460 150 — —

575 120 — —

230 240 7-1/2 5.5

460 200 — —

575 160 — —

230 300 10 7.5

460 250 — —

575 200 — —

Locked

Rotor

Maximum

Motor (hp)

Maximum

Motor (kW)

Common Control Separate Control

Metal

Mounting Plate DIN Rail Adapter

Catalog Number

1

Catalog Number 1Catalog Number 1Catalog Number

Metal

Mounting Plate DIN Rail Adapter

4

4

4

4

1

4

4

4

4

4

4

4

4

4

4

C440 Electronic Overload Relay for Integrated Use with DP Contactors

C440 Overload Relay for Integrated Use with DP Contactors by Feature Set

FLA Range

(Amps)

Frame D

1–5 25–50A 005 C440A1A005SDD C440A2A005SDD

4–20 25–50A 020 C440A1A020SDD C440A2A020SDD

9–45 25–50A 045 C440A1A045SDD C440A2A045SDD

Frame F

20–100 60–75A 100 C440B1A100SDF C440B2A100SDF

Note

1

Incomplete catalog number. Replace underscore (_) with suffix, see table above.

DP Contactor

Rating

Suffix

Code

Overload Relay Catalog

Number (Standard)

Overload Relay Catalog

Number (Ground Fault)

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-41

4

4

Page 20

4

Safety Cover

Reset Bar

Remote Reset

4

4

4

4

4

4.3

Accessories

CT Kits

Definite Purpose Contactors and Starters

Starters

Accessories

Description Catalog Number

Safety Cover

Clear Lexan cover that mounts on top of the FLA dial and DIP switches when closed. ZEB-XSC

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Reset Bar

Assembles to the top of the overload to provide a larger target area for door

mounted reset operators.

Remote Reset

Remote reset module (24 Vdc)

Remote reset module (120 Vac)

Remote reset module (24 Vac)

Note

1

Customer can wire remote mounted button to reset module (that is, 22 mm pushbutton, catalog number M22-D-B-GB14-K10).

1

1

1

ZEB-XRB

C440-XCOM

ZEB-XRR-120

ZEB-XRR-24

4

4

4

4

4

4

4

4

4

4

V5-T4-42 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 21

Definite Purpose Contactors and Starters

Starters

4.3

Technical Data and Specifications

Electronic Overload Relays up to 1500A

Specification

Description 45 mm 55 mm

Electrical Ratings Range Range

Operating voltage (three-phase) and frequency 690 Vac (60/50 Hz) 690 Vac (60/50 Hz)

FLA Range

0.33–1.65A

1–5A

4–20A

9–45A

Use with Contactors

XT IEC frames B, C, D F, G

Freedom NEMA sizes 00, 0, 1, 2 3

DP contactors 25–50A 60, 75A

Tri p C l as s

10A, 10, 20, 30

Selectable

Motor Protection

Thermal overload setting 1.05 x FLA: does not trip

Feature Range Range

Phase loss Fixed threshold 50% Fixed threshold 50%

Phase unbalance (selectable: enable/disable) Fixed threshold 50% Fixed threshold 50%

Ground fault (selectable: enable/disable) 50% of FLA dial setting

Reset Manual/automatic Manual/automatic

Indicators

Trip status Orange flag Orange flag

Mode LED One flash: Overload operating properly

Options

Remote reset Yes Yes

Reset bar Yes Yes

Communication expansion module Yes Yes

Communication adapter Yes Yes

Capacity

Load terminals

Terminal capacity 12–10 AWG (4–6 mm

Tightening torque 20–25 lb-in (2.3–2.8 Nm)

Input, auxiliary contact and remote reset terminals

Terminal capacity 2 x (18–12) AWG 2 x (18–12) AWG

Tightening torque 5.3 lb-in (0.8–1.2 Nm) 5.3 lb-in (0.8–1.2 Nm)

Vol t age s

Insulation voltage U

Insulation voltage U

Rated impulse withstand voltage 6000 Vac 6000 Vac

Overvoltage category/pollution degree III/3 III/3

(three-phase) 690 Vac 690 Vac

i

(control) 500 Vac 500 Vac

i

1.15 x FLA: overload trip

>150% = 2 sec

>250% = 1 sec

Two flashes: Current is above FLA dial setting—pending trip

2

)

2

8–6 AWG (6–16 mm

25–30 lb-in (2.8–3.4 Nm)

)

20–100A

10A, 10, 20, 30

Selectable

1.05 x FLA: does not trip

1.15 x FLA: overload trip

50% of FLA dial setting

>150% = 2 sec

>250% = 1 sec

One flash: Overload operating properly

Two flashes: Current is above FLA dial setting—pending trip

6–1 AWG (16–50 mm

25–30 lb-in (2.8–3.4 Nm)

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

2

)

4

4

4

4

4

4

4

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-43

4

4

Page 22

Definite Purpose Contactors and Starters

4.3

Electronic Overload Relays up to 1500A, continued

4

Description 45 mm 55 mm

4

Auxiliary and Control Circuit Ratings

Conventional thermal continuous current 5A 5A

4

Rated operational current—IEC AC-15

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Make contact (1800 VA)

120V 15A 15A

240V 15A 15A

415V 0.5A 0.5A

500V 0.5A 0.5A

Break contact (180 VA)

120V 1.5A 1.5A

240V 1.5A 1.5A

415V 0.9A 0.9A

500V 0.8A 0.8A

IEC DC-13 (L/R F 15 ms1)

0–250V 1.0A 1.0A

Rated operational current—UL B600

Make contact (3600 VA)

120V 30A 30A

240V 15A 15A

480V 7.5A 7.5A

600V 6A 6A

Break contact (360 VA)

120V 3A 3A

240V 1.5A 1.5A

480V 0.75A 0.75A

600V 0.6A 0.6A

R300—Vdc ratings (28 VA)

0–120V 0.22A 0.22A

250V 0.11A 0.11A

Short-Circuit Rating without Welding

Maximum fuse 6A gG/gL 6A gG/gL

Environmental Ratings

Ambient temperature (operating) –13° to 149°F (–25° to 65°C) –13° to 149°F (–25° to 65°C)

Ambient temperature (storage) –40° to 185°F (–40° to 85°C) –40° to 185°F (–40° to 85°C)

Operating humidity UL 991 (H3) 5% to 95% non-condensing 5% to 95% non-condensing

Altitude (no derating) NEMA ICS1 2000m 2000m

Shock (IEC 600068-2-27) 15g any direction 15g any direction

Vibration (IEC 60068-2-6) 3g any direction 3g any direction

Pollution degree per IEC 60947-4-1 3 for product (2 for pcb) 3 for product (2 for pcb)

Ingress protection IP20 IP20

Protection against direct contact when actuated from front (IEC 536) Finger- and back-of-hand proof Finger- and back-of-hand proof

Mounting position Any Any

Climatic proofing Damp heat, constant to IEC 60068-2-30 Damp heat, constant to IEC 60068-2-30

Starters

Specification

4

4

4

V5-T4-44 Volume 5—Motor Control and Protection CA08100006E—August 2018

Page 23

Definite Purpose Contactors and Starters

1NO Aux. Contact

(When Supplied)

Reset

Wire “D”

(Supplied with

1NO Aux. Contact)

Wire “C”

(Supplied with Common Control)

1

13

14

L1 L2

T1

4/T22/T1

T2

AC Motor

98

97

96

95

Starters

4.3

Electronic Overload Relays up to 1500A, continued

Specification

Description 45 mm 55 mm

Electrical/EMC

Radiated emissions

IEC 60947-4-1-Table 15

EN 55011 (CISPIR 11) Group 1, Class A, ISM

Conducted emissions

IEC 60947-4-1-Table 14

EN 55011 (CISPIR 11) Group 1; Class ISM

ESD immunity

IEC 60947-4-1 (Table 13)

Radiated immunity

IEC 60947-4-1

IEC 61000-4-3

Conducted immunity

IEC 60947-4-1, IEC 61000-4-6

Fast transient immunity

IEC 60947-4-1 (Table 13)

IEC 61000-4-4

Surge immunity

IEC 60947-4-1 (Table 13)

IEC 61000-4-5 a Class 4

Power freq. magnetic field immunity

IEC 60947-4-1, IEC 61000-4-8

Electromagnetic field

IEC 60947-4-1 Table 13, IEC 61000-4-3

Distortion IEEE 519 5% THD max., 5th harmonic 3% max. 5% THD max., 5th harmonic 3% max.

Electrostatic discharge (ESD)

IEC 61000-4-2, EN 61131-2

Electrical fast transient (EFT)

IEC 61000-4-4, EN 61131-2

Surge immunity

IEC 61000-4-5, EN 61131-2

30 MHz to 1000 MHz 30 MHz to 1000 MHz

0.15 MHz to 30 MHz 0.15 MHz to 30 MHz

±8 kV air, ±6 kV contact ±8 kV air, ±6 kV contact

10V/m 80 MHz–1000 MHz

3V/m from 1.4 to 2.7 GHz

80% amplitude modulated

1 kHz sine wave

140 dub (10V rms)

150 kHz–100 MHz

±4 kV using direct method

with accessory installed in expansion bay

±2 kV using direct method

Three-phase power inputs:

±4 kV line-to-line (DM)

±4 kV line-to-ground (CM)

With accessory installed in expansion bay:

±2 kV line-to-line (DM) –>1.2/50 us;

2 kV line-to-earth, 1 kV line-to-line

±4 kV line-to-ground (CM)

30A/m, 50 Hz 30A/m, 50 Hz

10 V/m 10 V/m

4 kV contact

8 kV air discharge

±2 kV using direct method ±2 kV using direct method

±2 kV line-to-ground (CM) ±2 kV line-to-ground (CM)

10V/m 80 MHz–1000 MHz

3V/m from 1.4 to 2.7 GHz

80% amplitude modulated

1 kHz sine wave

140 dub (10V rms)

150 kHz–100 MHz

±4 kV using direct method

with accessory installed in expansion bay

±2 kV using direct method

Three-phase power inputs:

±4 kV line-to-line (DM)

±4 kV line-to-ground (CM)

With accessory installed in expansion bay:

±2 kV line-to-line (DM) –>1.2/50 us;

2 kV line-to-earth, 1 kV line-to-line

±4 kV line-to-ground (CM)

4 kV contact

8 kV air discharge

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Wiring Diagrams

Single-Phase Connections Three-Phase Connections

T2

6/T32/T1 4/T2

T3

Wire “C”

1NO Aux. Contact

13

14

98

97

96

95

(When Supplied)

Wire “D”

(Supplied with

1NO Aux. Contact)

(Supplied with Common Control)

L1 L2 L3

1

T1

AC Motor

Volume 5—Motor Control and Protection CA08100006E—August 2018 V5-T4-45

4

4

4

4

4

4

4

4

4

4

4

4

Loading...

Loading...