Cutler Hammer, Div of Eaton Corp 9000X AF Drives Application Information

9000X AF Drives

Application Manual

Effective August 2010

Supersedes January 2010

August 2010

Important Notice — Please Read

The product discussed in this literature is subject to terms and conditions outlined in Eaton

Electrical Inc. selling policies. The sole source governing the rights and remedies of any

purchaser of this equipment is the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE

OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton

Electrical Inc. be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability or otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

Cover Photo: Eaton’s Series 9000X AF Drives.

9000X AF Drives

MN04004001E

For more information visit: www.eaton.com

i

9000X AF Drives

Table of Contents

CHAPTER — LIST OF FIGURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

CHAPTER — LIST OF TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

CHAPTER — SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Cautions and Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

CHAPTER 1 — BASIC APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Basic Application — Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

CHAPTER 2 — STANDARD APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Standard Application — Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

CHAPTER 3 — LOCAL/REMOTE CONTROL APPLICATION. . . . . . . . . . . . . . . . . . . . . . . . 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Local/Remote Control Application — Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . 3-3

CHAPTER 4 — MULTI-STEP SPEED CONTROL APPLICATION . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Multi-Step Speed Control Application — Parameter Lists . . . . . . . . . . . . . . . . . . . . 4-3

CHAPTER 5 — PID CONTROL APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

PID Control Application — Parameter Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

CHAPTER 6 — MULTI-PURPOSE CONTROL APPLICATION . . . . . . . . . . . . . . . . . . . . . . . 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

“Terminal To Function” (TTF) Programming Principle . . . . . . . . . . . . . . . . . . . . . . . 6-3

Parameter Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Fieldbus Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

CHAPTER 7 — PUMP AND FAN CONTROL APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Control I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Short Description of Function and Essential Parameters . . . . . . . . . . . . . . . . . . . . . 7-5

Parameter Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Input Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

August 2010

ii For more information visit: www.eaton.com

MN04004001E

August 2010

Table of Contents, continued

CHAPTER 8 — DESCRIPTION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Keypad Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-86

APPENDIX A — ADDITIONAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

External Brake Control with Additional Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Closed Loop Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Parameters of Motor Thermal Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Parameters of Stall Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Parameters of Underload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Fieldbus Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

9000X AF Drives

MN04004001E

For more information visit: www.eaton.com

iii

9000X AF Drives

List of Figures

Defining Input/Output — Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Defining Input/Output — Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Screenshot of 9000X Drive Programming Tool; Entering the Address Code . . . . . . . . . 6-4

2-Pump Autochange System Principal Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

3-Pump Autochange System Principal Control Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Example of the Function of the PFC Application with Three Aux. Drives . . . . . . . . . . . . 7-8

Example of 2-Pump Autochange, Main Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Example of 3-Pump Autochange, Main Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Linear and Squared Change of Motor Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Programmable V/Hz Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

PID Controller Function as I-Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

PID Output Curve with the Values of Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

PID Output Curve with the Values of Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Start Forward/Start Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Start, Stop and Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Start Pulse/Stop Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

DIN3 as DC-Brake Command Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

With and Without Reference Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Reference Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Reference Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Analog Output Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Analog Output Invert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Analog Output Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Output Frequency Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

DC Braking Command (Selection 12) Selected for DIN2 . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

AI1 No Signal Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

AI1 Signal Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

AI1 Signal Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Analog Input AI2 Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Examples of Actual Value Signal Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Control Place B with and without Reference Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

External Brake Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

An Example of On/Off-Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Scaling of Max. Motor Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Reduction of DC Braking Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Reduction of Acceleration and Deceleration Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Reduction of Torque Supervision Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Place B Start Forward/Start Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Place B Start, Stop, Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Place B Start Pulse/Stop Pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

PID Sum Point Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

An Example of Joystick Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

Example of Sleep Limit Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Joystick Hysteresis with Minimum Frequency at 35 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Scaling of DC-Braking Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

August 2010

iv For more information visit: www.eaton.com

MN04004001E

August 2010

List of Figures, continued

Reducing Acceleration and Deceleration Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

Reducing Torque Supervision Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

Digital Outputs 1 and 2, On- and Off-Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

An Example of Adjust Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-50

Acceleration/Deceleration (S-shaped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-51

DC-Braking Time when Stop Mode = Coasting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-53

DC-Braking Time when Stop Mode = Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

Example of Skip Frequency Area Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-55

Ramp Speed Scaling between Skip Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

Motor Thermal Current IT Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-63

Motor Temperature Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-64

Stall Characteristics Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-65

Stall Time Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-65

Setting of Minimum Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-66

Underload Time Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-67

Example of Automatic Restarts with Two Restarts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-68

Example of Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-75

Reference Steps after Starting Auxiliary Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-76

Frequency Converter Sleep Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-77

Example of Adjustable Frequency Drive and

Two Auxiliary Drives with Bypassed PID Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-79

Input and Output Pressure Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-80

Output Pressure Behavior Depending on

Input Pressure and Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-80

Frequency Drop and Increase Delays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-81

Autochange Applied to Auxiliary Drives Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-82

Autochange with All Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-82

Autochange Interval and Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-83

Actual Value Special Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-84

Brake Control with Additional Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Brake Control Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

9000X AF Drives

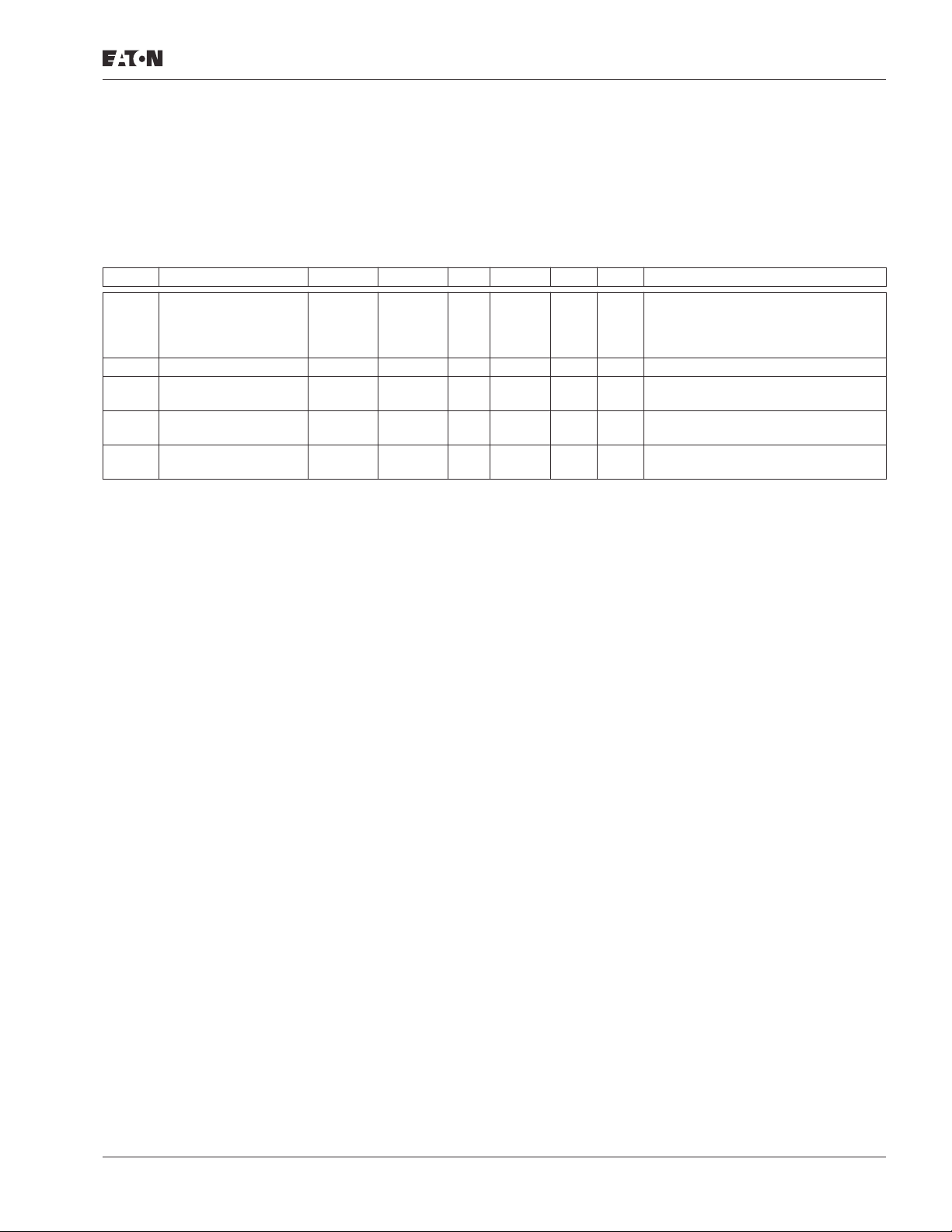

List of Tables

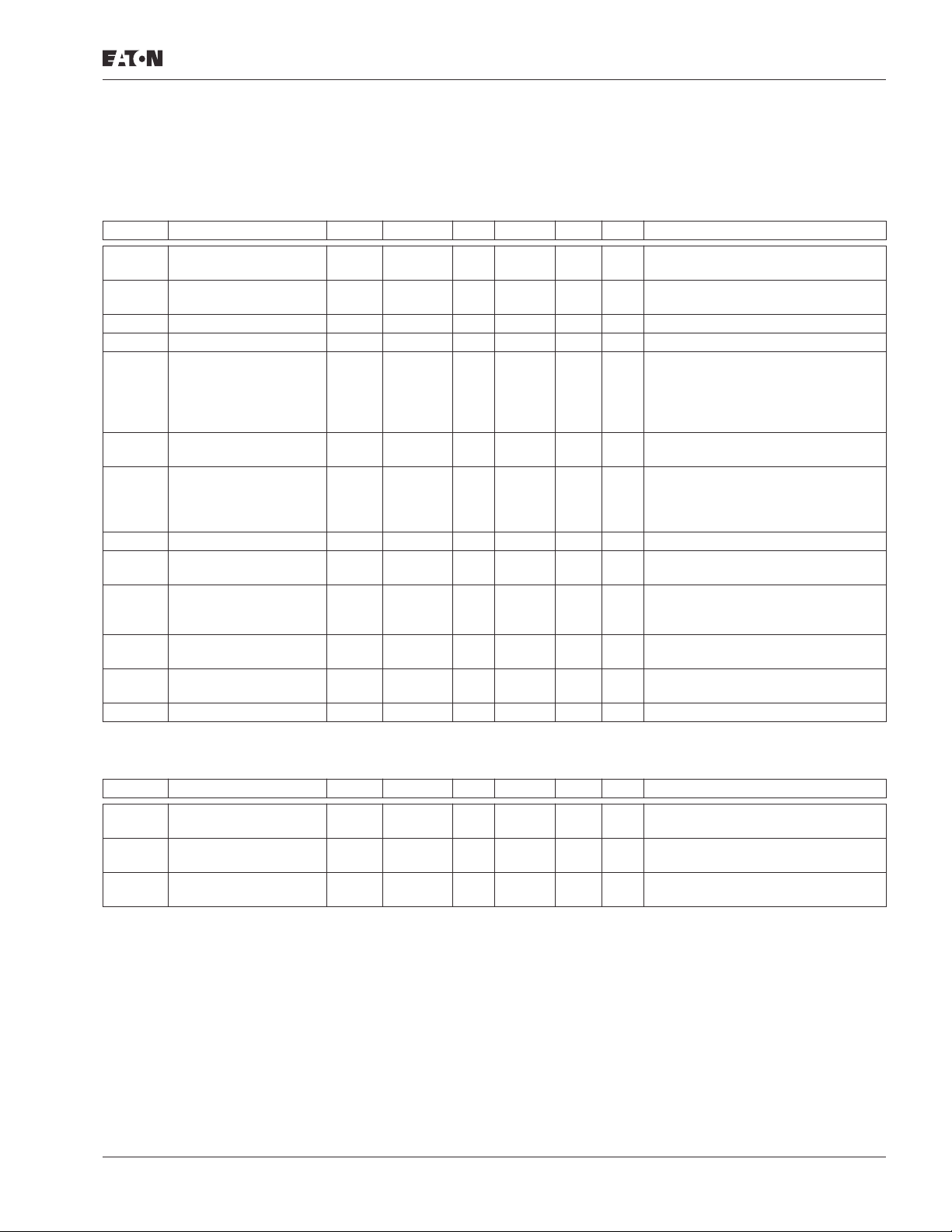

Table 1-1: Basic Application Default I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-3: Basic Parameters — G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-4: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

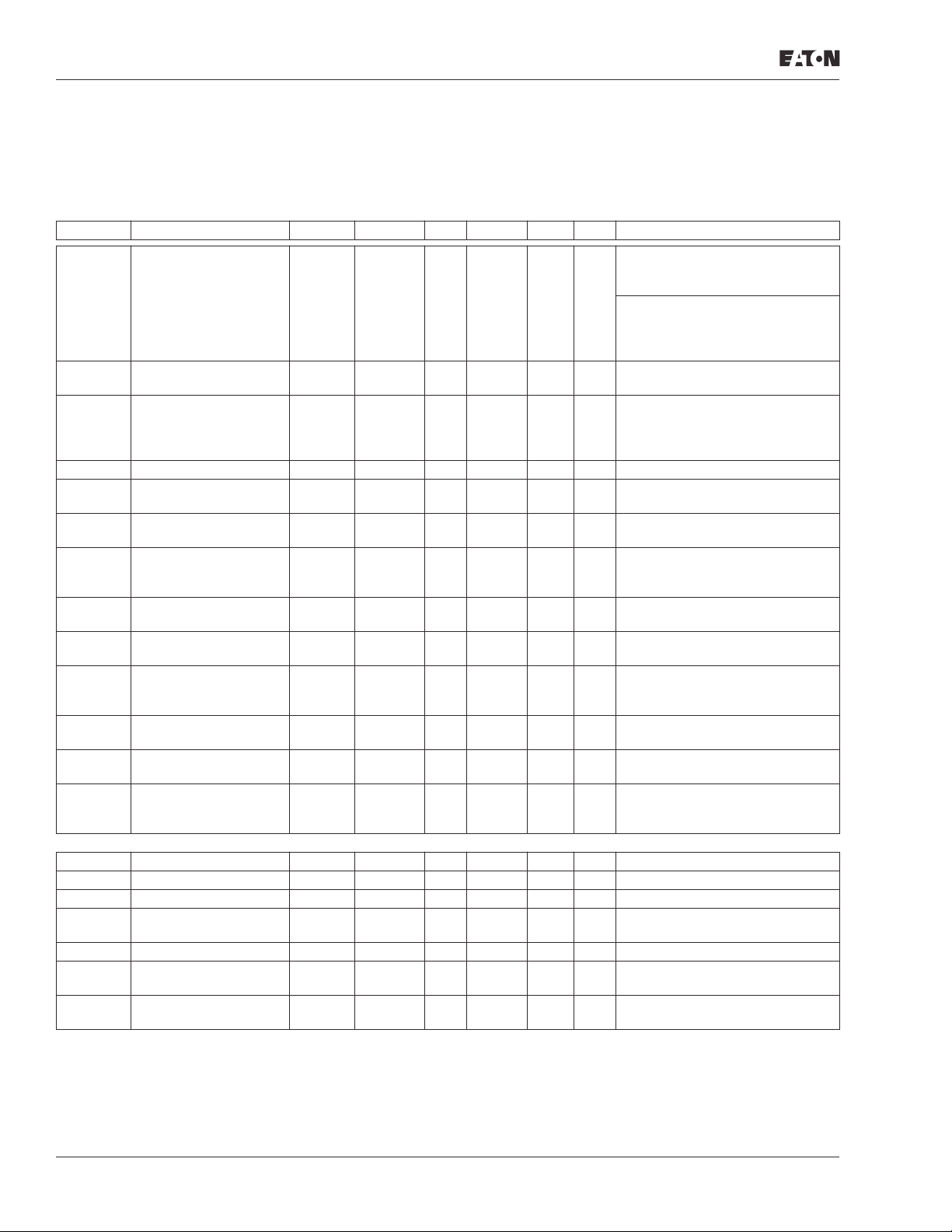

Table 2-1: Standard Application Default I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-3: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table 2-4: Input Signals — G1.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-5: Output Signals — G1.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-6: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-7: Skip Frequency Parameters — G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-8: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2-9: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Table 2-10: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Table 2-11: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

MN04004001E

For more information visit: www.eaton.com

v

9000X AF Drives

List of Tables, continued

Table 3-1: Local/Remote Application Default I/O Configuration . . . . . . . . . . . . . . . . . . . 3-2

Table 3-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-3: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-4: Input Signals — G1.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-5: Output Signals — G1.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Table 3-6: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Table 3-7: Skip Frequency Parameters — G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table 3-8: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Table 3-9: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Table 3-10: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Table 3-11: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Table 4-1: Multi-Step Speed Control Application Default I/O Configuration . . . . . . . . . 4-2

Table 4-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 4-3: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Table 4-4: Input Signals — G1.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Table 4-5: Output Signals — G1.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 4-6: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-7: Skip Frequency Parameters — G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 4-8: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Table 4-9: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Table 4-10: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Table 4-11: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Table 5-1: PID Application Default I/O Configuration (with 2-wire transmitter) . . . . . . . 5-2

Table 5-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-3: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-4: Input Signals — G1.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 5-5: Output Signals — G1.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-6: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Table 5-7: Skip Frequency Parameters — G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Table 5-8: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Table 5-9: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Table 5-10: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Table 5-11: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Table 6-1: Multi-Purpose Control Application Default I/O Configuration and

Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 6-2: Monitoring Values, SPX Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Table 6-3: Operate Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 6-4: Fixed Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Table 6-5: Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Table 6-6: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 6-7: Input Signals: Basic Settings — G1.2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Table 6-8: Analog Input 1 Parameters — G1.2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Table 6-9: Analog Input 2 Parameters — G1.2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Table 6-10: Analog Input 3 Parameters — G1.2.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Table 6-11: Analog Input 4 Parameters — G1.2.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Table 6-12: Free Analog Input Signal Selection — G1.2.6 . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Table 6-13: Digital Input Signals — G1.2.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Table 6-14: Delayed Digital Output 1 Parameters — G1.3.1 . . . . . . . . . . . . . . . . . . . . . . . 6-14

Table 6-15: Delayed Digital Output 2 Parameters — G1.3.2 . . . . . . . . . . . . . . . . . . . . . . . 6-14

Table 6-16: Digital Output Signals — G1.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Table 6-17: Limit Settings — G1.3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Table 6-18: Analog Output 1 Parameters — G1.3.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Table 6-19: Analog Output 2 Parameters — G1.3.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Table 6-20: Analog Output 3 Parameters — G1.3.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

August 2010

vi For more information visit: www.eaton.com

MN04004001E

August 2010

List of Tables, continued

Table 6-21: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Table 6-22: Skip Frequency Parameters — G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Table 6-23: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Table 6-24: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Table 6-25: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Table 6-26: Fieldbus Parameters — G1.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Table 6-27: Torque Control Parameters — G1.10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Table 6-28: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Table 7-1: Pump and Fan Control Application Default I/O Configuration and

Connection Example (with 2-wire transmitter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-2: Monitoring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Table 7-3: Basic Parameters — G1.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Table 7-4: Input Signals, Basic Settings — G1.2.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Table 7-5: Input Signals, Analog Input 1 — G1.2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Table 7-6: Input Signals, Analog Input 2 — G1.2.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Table 7-7: Input Signals, Analog Input 3 — G1.2.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Table 7-8: Input Signals, Analog Input 4 — G1.2.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Table 7-9: Input Signals, Digital Inputs — G1.2.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Table 7-10: Output Signals, Digital Outputs — G1.3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Table 7-11: Output Signals, Limit Settings — G1.3.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Table 7-12: Output Signals, Analog Output 1 — G1.3.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Table 7-13: Output Signals, Analog Output 2 — G1.3.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Table 7-14: Output Signals, Analog Output 3 — G1.3.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Table 7-15: Drive Control Parameters — G1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Table 7-16: Skip Frequencies— G1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Table 7-17: Motor Control Parameters — G1.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Table 7-18: Protections — G1.7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Table 7-19: Autorestart Parameters — G1.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Table 7-20: Pump and Fan Control Parameters — G1.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Table 7-21: Keypad Control Parameters — M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Table 8-1: Preset Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table 8-2: Preset Speeds 3 to 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-3: Multi-Step Speed Selections with Digital Inputs DIN3, DIN4,

DIN5 and DIN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Table 8-4: Selections for ID143 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Table 8-5: Selections for ID171 and ID172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Table 8-6: Selections for ID173, ID174 and ID175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Table 8-7: Analog Output Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Table 8-8: Output Signals Via DO1 and Output Relays RO1 and RO2 . . . . . . . . . . . . . . . 8-19

Table 8-9: Selections for ID320 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Table 8-10: Selections for Parameter ID325 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Table 8-11: Selections for ID332 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Table 8-12: Size-Dependent Switching Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-57

Table 8-13: Typical Monitored Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-73

Table 8-14: Selectable Wake-Up Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-78

9000X AF Drives

MN04004001E

For more information visit: www.eaton.com

vii

9000X AF Drives

Safety

Definitions and Symbols

This symbol indicates high voltage. It calls your attention to items

or operations that could be dangerous to you and other persons

operating this equipment. Read the message and follow the

instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of

two signal words: CAUTION or WARNING, as described below.

Indicates a potentially hazardous situation which, if not avoided,

can result in serious injury or death.

August 2010

WARNING

WARNING

Indicates a potentially hazardous situation which, if not avoided,

can result in minor to moderate injury, or serious damage to the

product. The situation described in the CAUTION may, if not

avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING).

Hazardous High Voltage

Motor control equipment and electronic controllers are connected

to hazardous line voltages. When servicing drives and electronic

controllers, there may be exposed components with housings or

protrusions at or above line potential. Extreme care should be taken

to protect against shock.

Stand on an insulating pad and make it a habit to use only one

hand when checking components. Always work with another

person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure

equipment is properly grounded. Wear safety glasses whenever

working on electronic controllers or rotating machinery.

CAUTION

WARNING

viii For more information visit: www.eaton.com

MN04004001E

August 2010

Cautions and Notices

Read this manual thoroughly and make sure you understand the procedures before you

attempt to install, set up, or operate this 9000X AF Drives from Eaton’s electrical sector.

Cautions

Notices

9000X AF Drives

CAUTION

Be ABSOLUTELY sure not to connect two functions to one and

same output in order to avoid function overruns and to ensure

flawless operation.

CAUTION

The calculated model does not protect the motor if the airflow to

the motor is reduced by blocked air intake grill.

Notice

The inputs, unlike the outputs, cannot be changed in RUN state.

MN04004001E

For more information visit: www.eaton.com

ix

9000X AF Drives

August 2010

x For more information visit: www.eaton.com

MN04004001E

August 2010

Chapter 1 — Basic Application

Introduction

The Basic Application is easy to use with a minimum number of parameters. It operates like

the default setup of the Standard Application. It is the default setting on delivery from the

factory. If any configuration changes are needed, select the Standard Application in menu

M5. Fieldbus control is not available in the Basic Application, but fieldbus monitoring is the

same as the Standard Application.

The parameters of the Basic Application are explained in Chapter 8 of this manual. The

explanations are arranged according to the individual ID number of the parameter.

Motor Protection Functions in the Basic Application

The Basic Application provides almost all the same protection functions as the other

applications:

● External fault protection

● Input phase supervision

● Undervoltage protection

9000X AF Drives

● Output phase supervision

● Earth fault protection

● Motor thermal protection

● I

reference fault (auto reset)

in

Unlike the other applications, the Basic Application does not provide any parameters for

choosing the response function or limit values for the faults. The motor thermal protection

is explained in more detail on Page A-4 in Appendix A.

MN04004001E

For more information visit: www.eaton.com

1-1

9000X AF Drives

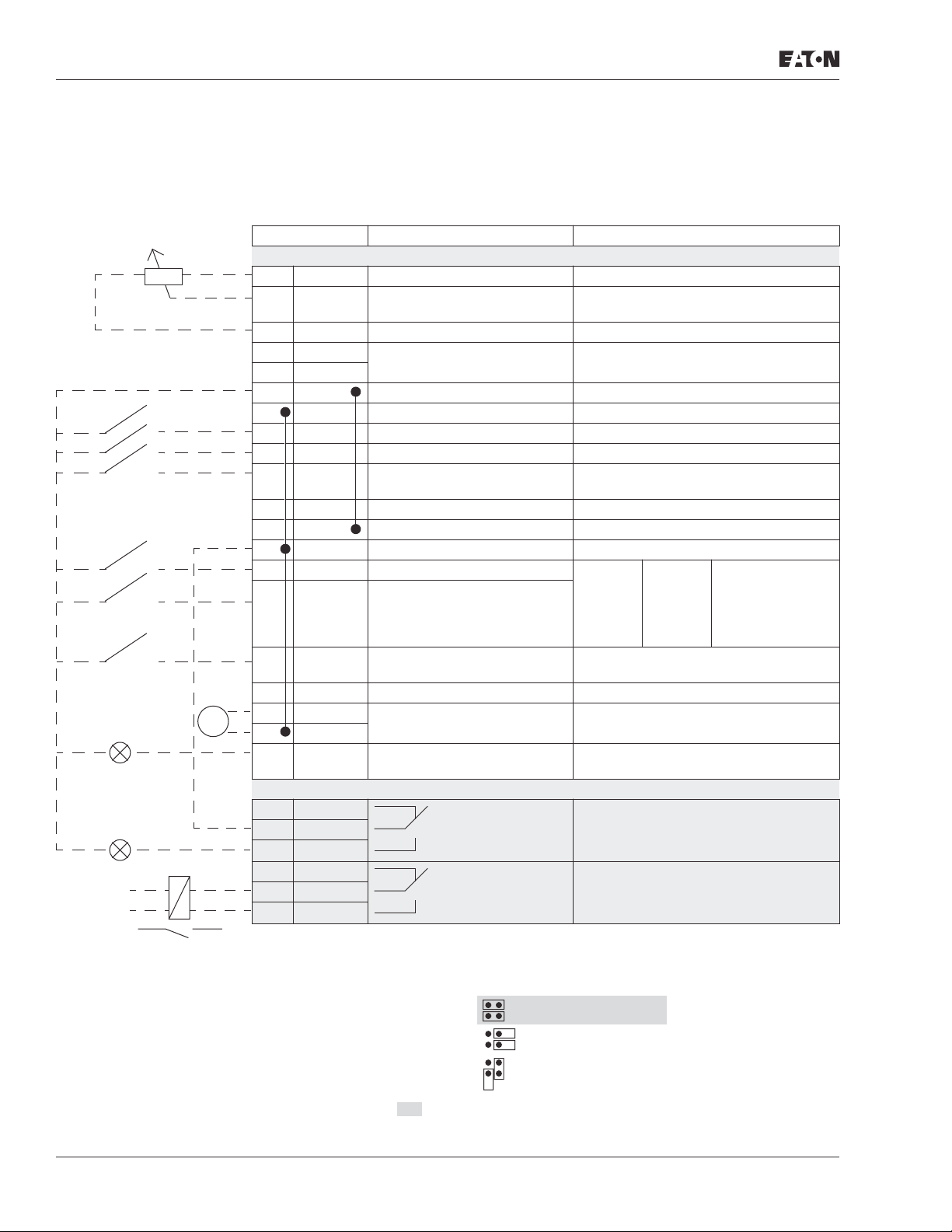

Control I/O

August 2010

Basic Application

Reference potentiometer

1 – 10 kW

mA

READY

RUN

220V

AC

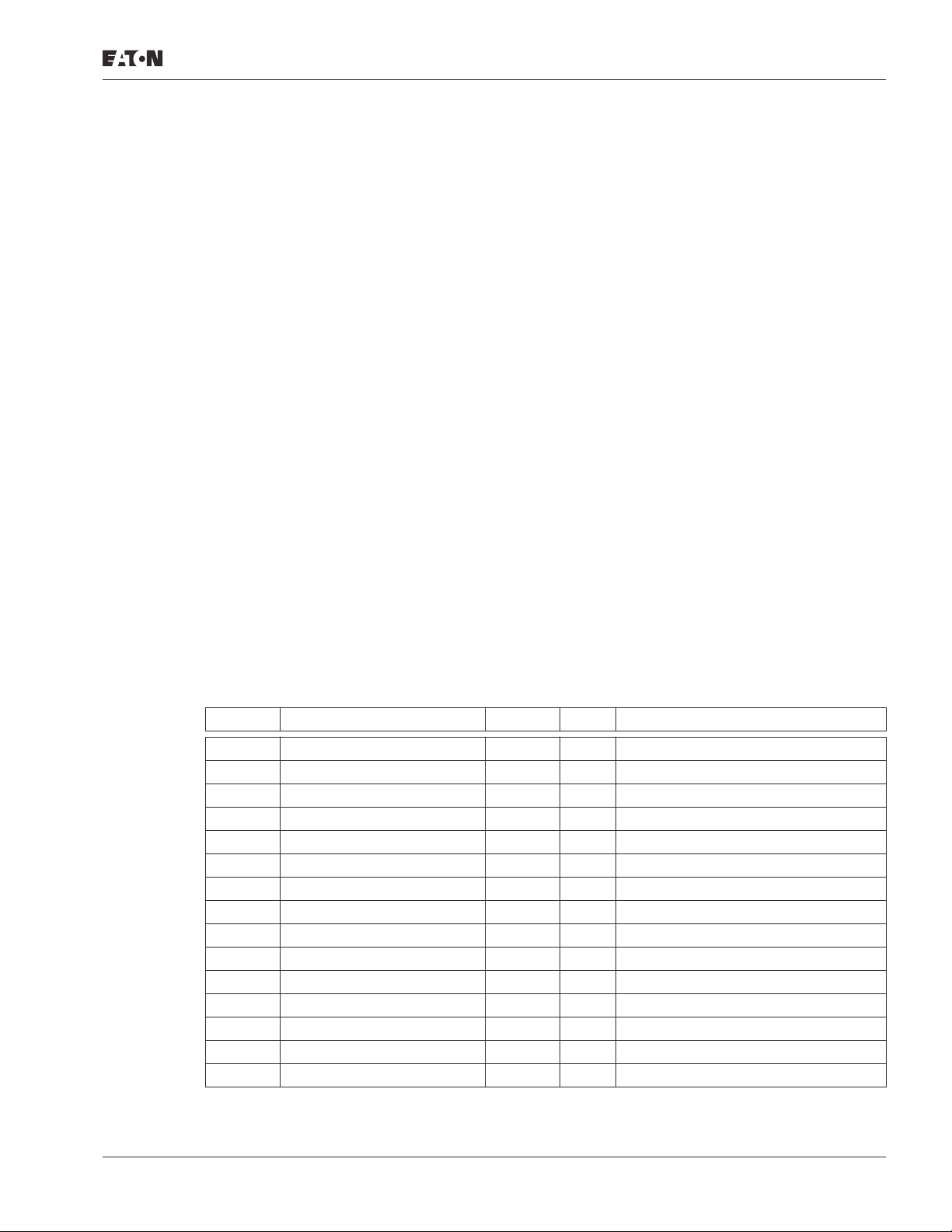

Table 1-1: Basic Application Default I/O Configuration

Terminal Signal Description

OPTA1

1 +10V

2 AI1+ Analog input, voltage range

3 AI1- I/O Ground Ground for reference and controls

4 AI2+ Analog input, current range

5 AI26 +24V Control voltage output Voltage for switches. etc. max 0.1A

7 GND I/O ground Ground for reference and controls

8 DIN1 Start forward Contact closed = start forward

9 DIN2 Start reverse Contact closed = start reverse

10 DIN3 External fault input

11 CMA Common for DIN1 – DIN3 Connect to GND or +24V

12 +24V Control voltage output Voltage for switches (see #6)

13 GND I/O ground Ground for reference and controls

14 DIN4 Multi-step speed select 1 DIN4 DIN5 Frequency ref.

15 DIN5 Multi-step speed select 2 Open

16 DIN6 Fault reset Contact open = no action

17 CMB Common for DIN4 – DIN6 Connect to GND or +24V

18 AO1+ Output frequency

19 AO120 DO1 Digital output

OPTA2

21 RO1 Relay output 1

22 RO1

23 RO1

24 RO2 Relay output 2

25 RO2

26 RO2

Reference output Voltage for potentiometer, etc.

ref

Voltage input frequency reference

0 – 10V DC

Current input frequency reference

0 – 20 mA

Contact open = no fault

(programmable)

Contact closed = fault

Open

Closed

Open

Closed

Open

Closed

Closed

Contact closed = fault reset

Programmable

Analog output

Range 0 – 20 mA/R

L

Programmable

READY

Open collector, I ≤ 50 mA, U ≤ 48V DC

RUN

FAULT

Ref.U

in

Multi-step ref.1

Multi-step ref.2

RefI

in

, max. 500W

Note: For more information on jumper selections, see the 9000X AF Drives User

Manual, Chapter 4.

= Factory default.

Jumper Block X3:

CMA and CMB Grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally connected

together, isolated from GND

1-2 For more information visit: www.eaton.com

MN04004001E

August 2010

Basic Application

Basic Application — Parameter Lists

On the next pages you will find the lists of parameters within the respective parameter

groups. The parameter descriptions are given in Chapter 8.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter

= Parameter value can only be changed after the drive has been stopped

= Use TTF method to program these parameters. See Page 6-3.

9000X AF Drives

Monitoring Values (Control Keypad: Menu M7)

The monitoring values are the actual values of parameters and signals as well as statuses

and measurements. Monitoring values cannot be edited.

See 9000X AF Drives User Manual, Chapter 5 for more information.

Table 1-2: Monitoring Values

Code Parameter Unit ID Description

V1.1 Output frequency Hz 1 Output frequency to motor

V1.2 Frequency reference Hz 25 Frequency reference to motor control

V1.3 Motor speed rpm 2 Motor speed in rpm

V1.4 Motor current A 3

V1.5 Motor torque % 4 In % of Motor nominal torque

V1.6 Motor power % 5 Motor shaft power

V1.7 Motor voltage V 6

V1.8 DC Bus voltage V 7

V1.9 Unit temperature ∞C 8 Heatsink temperature

V1.10 Motor temperature % 9 Calculated motor temperature

V1.11 Voltage input V 13 AI1

V1.12 Current input mA 14 AI2

V1.13 DIN1, DIN2, DIN3 15 Digital input statuses

V1.14 DIN4, DIN5, DIN6 16 Digital input statuses

V1.15 DO1, RO1, RO2 17 Digital and relay output statuses

V1.16 Analog I

M1.17 Multimonitoring items Displays three selectable monitoring

out

mA 26 AO1

values

MN04004001E

For more information visit: www.eaton.com

1-3

9000X AF Drives

Basic Application

Basic Parameters (Control Keypad: M1 ➔ G1.1)

Table 1-3: Basic Parameters — G1

Code Parameter Min. Max. Unit Default Cust ID Note

P1.1 Min frequency 0.00 Par. 1.2 Hz 0.00 101

P1.2 Max frequency Par. 1.1 320.00 Hz 60.00 102 NOTE: If f

synchronous speed, check

suitability for motor and drive

system.

P1.3 Acceleration time 1 0.1 3000.0 s 3.0 103

P1.4 Deceleration time 1 0.1 3000.0 s 3.0 104

P1.5 Current limit 0.1 x I

P1.6

Nominal voltage of the

180 690 V P: 230V

motor

2 x I

H

H

AI

L

P: 460V

107

110 Check the rating plate of the

motor.

P: 575V

P1.7 Nominal frequency of

the motor

P1.8

Nominal speed of the

motor

30.00 320.00 Hz 60.00 111 Check the rating plate of the

motor.

300 20 000 rpm 1720 112 Check the rating plate of the

motor. The default applies for a

4-pole motor and a nominal size

frequency converter.

P1.9

Nominal current of the

motor

0.1 x IH2 x I

H

AI

H

113 Check the rating plate of the

motor.

P1.10 Preset speed 1 0.00 Par 1.1.2 Hz 10.00 105 Speeds preset by operator

P1.11 Preset speed 2 0.00 Par 1.1.2 Hz 40.00 106 Speeds preset by operator

P1.12 Input phase

supervision

0 3 730 0 = No action

1 = Working

2 = Fault

3 = Fault, coast

> than the motor

max

August 2010

1-4 For more information visit: www.eaton.com

MN04004001E

9000X AF Drives

August 2010

Basic Application

Keypad Control (Control Keypad: Menu M2)

The parameters for the selection of control place and direction on the keypad are listed

below. See the Keypad Control Menu in the 9000X AF Drives User Manual.

Table 1-4: Keypad Control Parameters — M2

Code Parameter Min. Max. Unit Default Cust ID Note

R1.1 Keypad reference Par. 1.1 Par. 1.2 Hz 60.00

P1.2 Direction (on keypad) 0 1 0 123 Reverse request activated from the

R1.3 Stop button 0 1 1 114 0 = Limited function of Stop button

P2.4 Operate menu hide 0 1 0 1688 0 = No

System Menu (Control Keypad: Menu M5)

For parameters and functions related to the general use of the drive, such as application

and language selection, customized parameter sets or information about the hardware and

software, see Chapter 5 in the 9000X AF Drives User Manual.

panel

1 = Stop button always enabled

1 = Yes

Expander Boards (Control Keypad: Menu M6)

The M6 menu shows the expander and option boards attached to the control board and

board-related information. For more information, see Chapter 5 in the 9000X AF Drives

User Manual.

MN04004001E

For more information visit: www.eaton.com

1-5

9000X AF Drives

August 2010

1-6 For more information visit: www.eaton.com

MN04004001E

August 2010

Chapter 2 — Standard Application

Introduction

Select the Standard Application in menu M5. See Chapter 5 of the 9000X AF Drives

User Manual.

The Standard Application is typically used in pump and fan applications and conveyors

for which the Basic Application is too limited but where no special features are needed.

● The Standard Application has the same I/O signals and the same control logic as the

Basic Application.

● Digital input DIN3 and all the outputs are freely programmable.

Additional functions:

● Programmable Start/Stop and Reverse signal logic

● Reference scaling

● One frequency limit supervision

● Second ramps and S-shape ramp programming

9000X AF Drives

● Programmable start and stop functions

● DC-brake at stop

● One skip frequency area

● Programmable V/f curve and switching frequency

● Autorestart

● Motor thermal and stall protection: Programmable action; off, warning, fault

The parameters of the Standard Application are explained in Chapter 8 of this manual.

The explanations are arranged according to the individual ID number of the parameter.

MN04004001E

For more information visit: www.eaton.com

2-1

9000X AF Drives

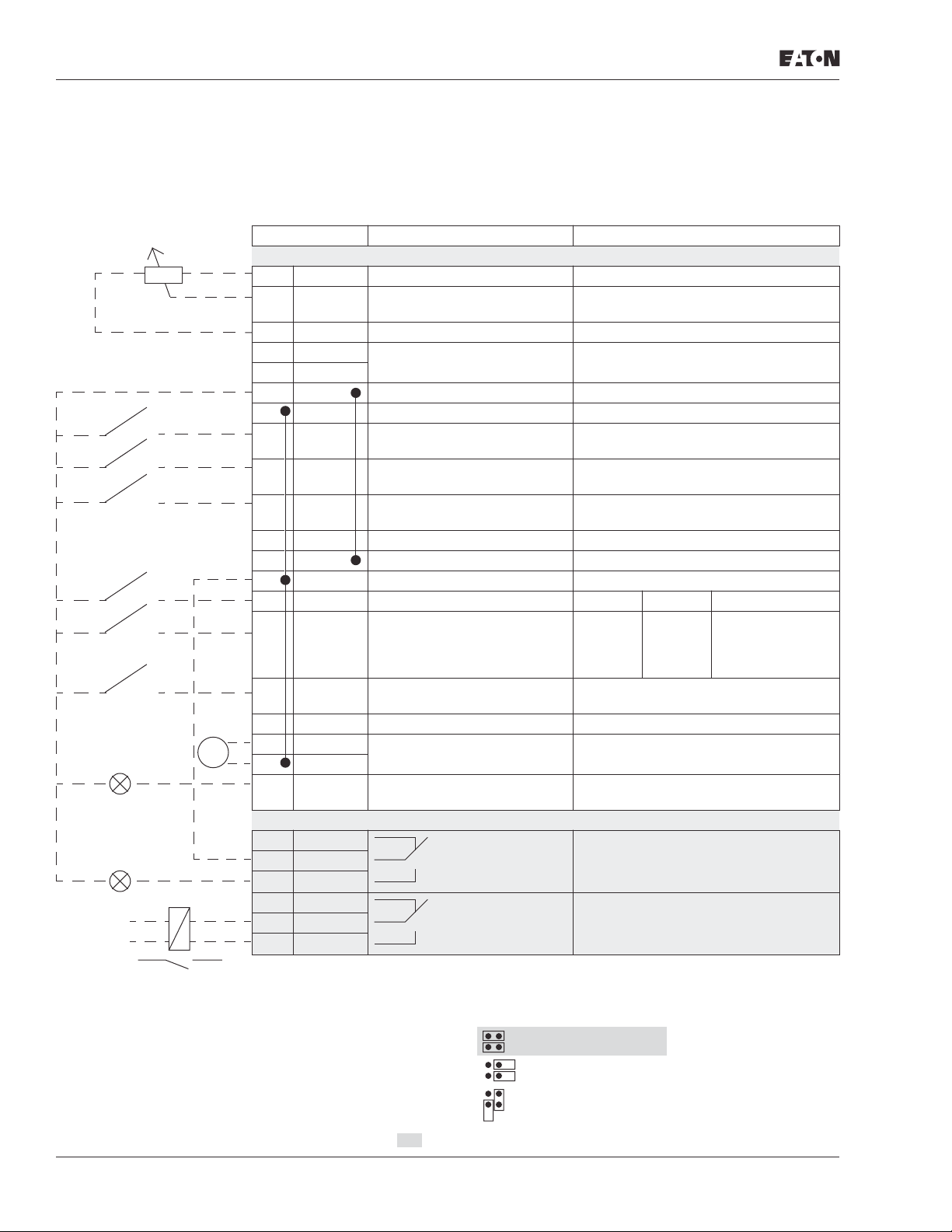

Control I/O

Reference potentiometer

1 – 10 kW

mA

READY

RUN

220V

AC

August 2010

Standard Application

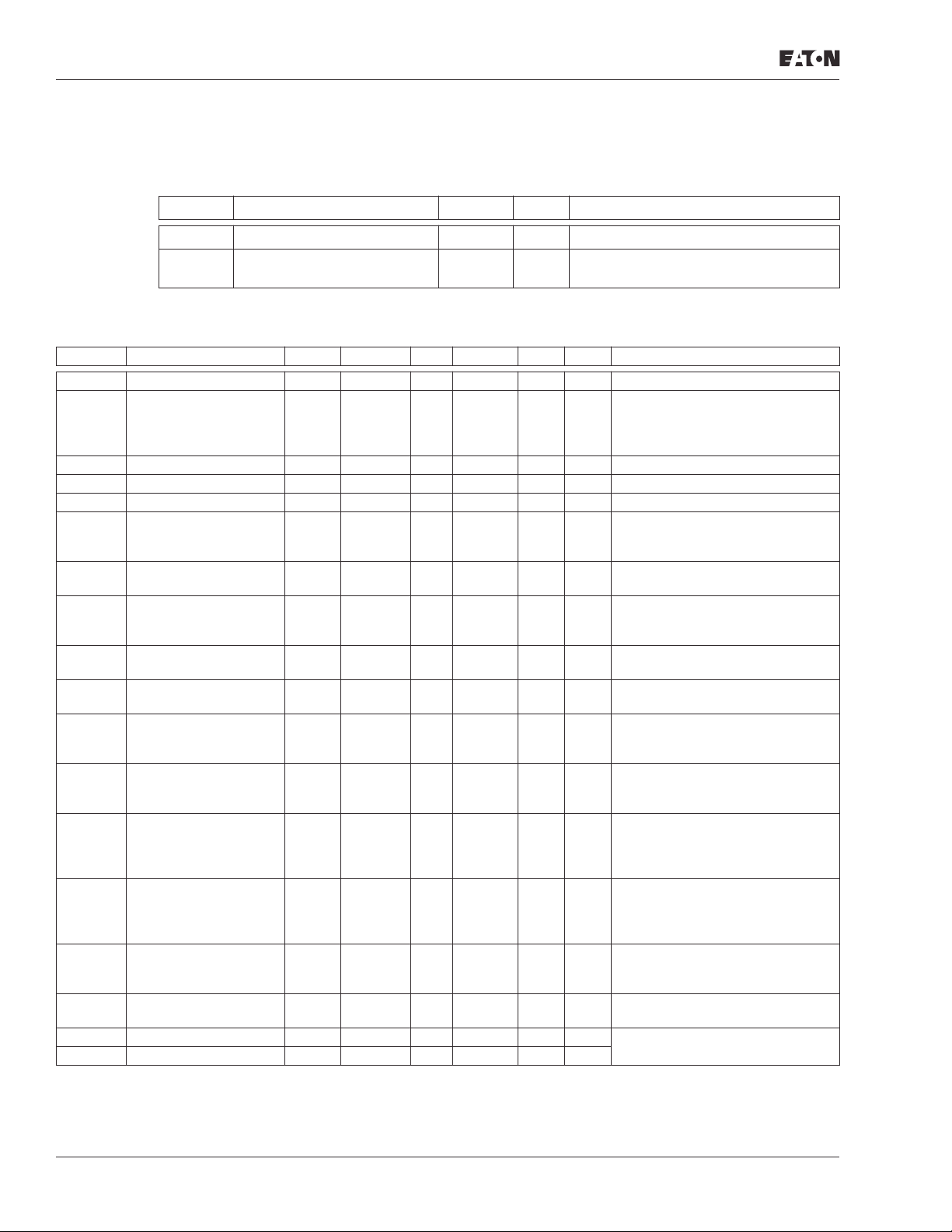

Table 2-1: Standard Application Default I/O Configuration

Terminal Signal Description

OPTA1

1 +10V

2 AI1+ Analog input, voltage range

3 AI1- I/O Ground Ground for reference and controls

4 AI2+ Analog input, current range

5 AI26 +24V Control voltage output Voltage for switches, etc. max 0.1A

7 GND I/O ground Ground for reference and controls

8 DIN1 Start forward

9 DIN2 Start reverse

10 DIN3 External fault input

11 CMA Common for DIN1 – DIN3 Connect to GND or +24V

12 +24V Control voltage output Voltage for switches (see #6)

13 GND I/O ground Ground for reference and controls

14 DIN4 Multi-step speed select 1 DIN4 DIN5 Frequency ref.

15 DIN5 Multi-step speed select 2 Open

16 DIN6 Fault reset Contact open = no action

17 CMB Common for DIN4 – DIN6 Connect to GND or +24V

18 AO1+ Output frequency

19 AO120 DO1 Digital output

OPTA2

21 RO1 Relay output 1

22 RO1

23 RO1

24 RO2 Relay output 2

25 RO2

26 RO2

Reference output Voltage for potentiometer, etc.

ref

Voltage input frequency reference

0 – 10V DC

Current input frequency reference

0 – 20 mA

Contact closed = start forward

(programmable)

Contact closed = start reverse

(programmable)

Contact open = no fault

(programmable)

Contact closed = fault

Open

Closed

Open

Closed

Open

Closed

Closed

Contact closed = fault reset

Programmable

Analog output

Range 0 – 20 mA/R

L

Programmable

READY

Open collector, I ≤ 50 mA, U ≤ 48V DC

RUN

FAULT

Ref.U

in

Multi-step ref.1

Multi-step ref.2

Ref.I

in

, max. 500W

Note: For more information on jumper selections, see the 9000X AF Drives User

Manual, Chapter 4.

= Factory default.

Jumper Block X3:

CMA and CMB Grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally connected

together, isolated from GND

2-2 For more information visit: www.eaton.com

MN04004001E

August 2010

Standard Application

Standard Application — Parameter Lists

On the next pages you will find the lists of parameters within the respective parameter

groups. The parameter descriptions are given in Chapter 8. The descriptions are arranged

according to the ID number of the parameter.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter

= Parameter value can only be changed after the drive has been stopped.

= Use TTF method to program these parameters. See Page 6-3.

9000X AF Drives

Monitoring Values (Control Keypad: Menu M7)

The monitoring values are the actual values of parameters and signals as well as statuses

and measurements. Monitoring values cannot be edited.

See 9000X AF Drives User Manual, Chapter 5 for more information.

Table 2-2: Monitoring Values

Code Parameter Unit ID Description

V1.1 Output frequency Hz 1 Output frequency to motor

V1.2 Frequency reference Hz 25 Frequency reference to motor control

V1.3 Motor speed rpm 2 Motor speed in rpm

V1.4 Motor current A 3

V1.5 Motor torque % 4 In % of the nominal motor torque

V1.6 Motor power % 5 Motor shaft power

V1.7 Motor voltage V 6

V1.8 DC Bus voltage V 7

V1.9 Unit temperature ∞C 8 Heatsink temperature

V1.10 Motor temperature % 9 Calculated motor temperature

V1.11 Analog input 1 V 13 AI1

V1.12 Analog input 2 mA 14 AI2

V1.13 DIN1, DIN2, DIN3 15 Digital input statuses

V1.14 DIN4, DIN5, DIN6 16 Digital input statuses

V1.15 DO1, RO1, RO2 17 Digital and relay output statuses

MN04004001E

For more information visit: www.eaton.com

2-3

9000X AF Drives

August 2010

Standard Application

Table 2-2: Monitoring Values (Continued)

Code Parameter Unit ID Description

V1.16 Analog I

out

mA 26 AO1

M1.17 Monitoring items Displays three selectable monitoring

values

Basic Parameters (Control Keypad: Menu M1

➔

G1.1)

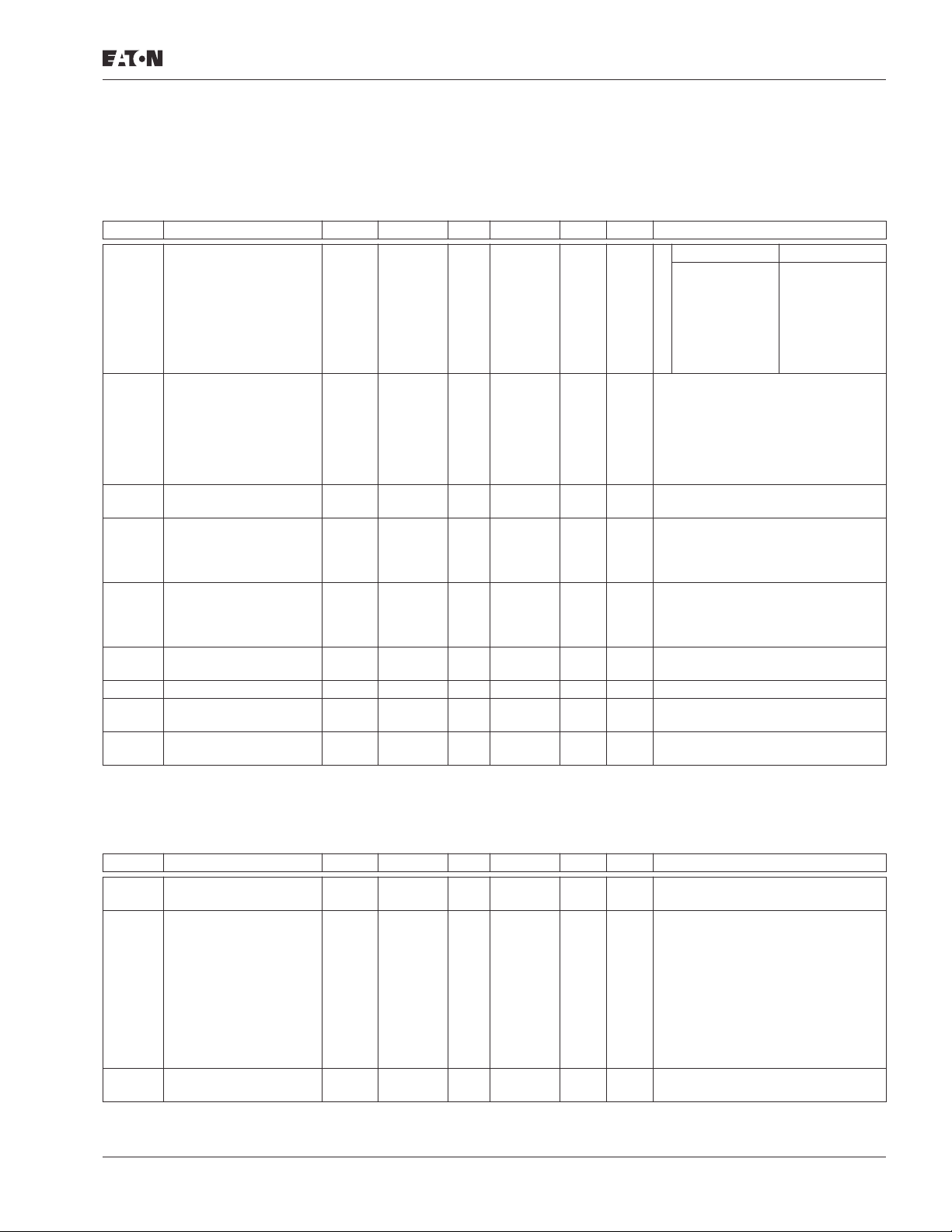

Table 2-3: Basic Parameters — G1.1

Code Parameter Min. Max. Unit Default Cust ID Note

P1.1.1 Min frequency 0.00 Par. 1.1.2 Hz 0.00 101

P1.1.2 Max frequency Par.

1.1.1

P1.1.3 Acceleration time 1 0.1 3000.0 s 3.0 103

P1.1.4 Deceleration time 1 0.1 3000.0 s 3.0 104

P1.1.5 Current limit 0.1 x I

P1.1.6

Nominal voltage of the

180 690 V P: 230V

motor

P1.1.7

Nominal frequency of

30.00 320.00 Hz 60.00 111 Check the rating plate of the

the motor

P1.1.8

Nominal speed of the

300 20 000 rpm 1720 112 The default applies for a 4-pole

motor

P1.1.9

Nominal current of the

0.1 x IH2 x I

motor

P1.1.10

P1.1.11 Local Control

Power Factor 0.30 1.00 0.85 120 Check the rating plate of the

1 3 2 171 1 = I/O Terminal

Place

P1.1.12 Remote Control

1 3 1 172 1 = I/O Terminal

Place

P1.1.13

P1.1.14

Local reference 0 3 2 173 0 = AI1

Remote reference 0 3 0 174 0 = AI1

P1.1.15 Identification 0 2 0 631 0 = Not used

P1.1.16 V/Hz Opt 0 1 0 109 0 = Not used

P1.1.17 Preset speed 1 0.00 Par. 1.1.2 Hz 10.00 105 Speeds preset by operator.

P1.1.18 Preset speed 2 0.00 Par. 1.1.2 Hz 40.00 106

320.00 Hz 60.00 102 NOTE: If f

synchronous speed, check

suitability for motor and drive

system.

2 x I

H

H

AI

L

107

110

P: 460V

P: 575V

motor.

motor and a nominal size

frequency converter.

H

AI

H

113 Check the rating plate of the

motor.

motor.

2 = Keypad

3 = Fieldbus

2 = Keypad

3 = Fieldbus

1 = AI2

2 = Keypad

3 = Fieldbus

1 = AI2

2 = Keypad

3 = Fieldbus

1 = V/Hz

2 = V/Hz with boost

1 = Automatic torque boost

> than the motor

max

2-4 For more information visit: www.eaton.com

MN04004001E

August 2010

Standard Application

Input Signals (Control Keypad: Menu M1 ➔ G1.2)

Table 2-4: Input Signals — G1.2

Code Parameter Min. Max. Unit Default Cust ID Note

P1.2.1

P1.2.2

P1.2.3 Current reference

P1.2.4 Reference scaling

P1.2.5 Reference scaling

P1.2.6 Reference inversion 0 1 0 305 0 = Not inverted

P1.2.7 Reference filter time 0.00 10.00 s 0.10 306 0 = No filtering

P1.2.8

P1.2.9

Rising edge required to start.

CP = control place.

Start/Stop logic 0 6 0 300 DIN1 DIN2

Start fwd

0

Start/Stop

1

Start/Stop

2

Start pulse

3

4

5

6

DIN3 function 0 7 1 301 0 = Not used

Fwd

Start /Stop

Start

/Stop

1 = Ext. fault. closing cont.

2 = Ext. fault. opening cont.

3 = Run enable

4 = Acc./Dec. time select.

5 = Force CP to Remote

6 = Rvs (if par. 1.2.1 = 3)

0 1 1 302 0 = 0 – 20mA

offset

1 = 4 – 20mA

0.00 Par. 1.2.5 Hz 0.00 303 Selects the frequency that

minimum value

corresponds to the min.

reference signal

0.00 = No scaling

0.00 320.00 Hz 0.00 304 Selects the frequency that

maximum value

corresponds to the max.

reference signal

0.00 = No scaling

1 = Inverted

AI1 signal selection A.1 377 TTF programming method used.

See Page 6-3.

AI2 signal selection A.2 388 TTF programming method used.

See Page 6-3.

9000X AF Drives

Start rvs

Rvs/Fwd

Run enable

Stop pulse

Rvs

Rvs/Fwd

Run enable

Output Signals (Control Keypad: Menu M1 ➔ G1.3)

Table 2-5: Output Signals — G1.3

Code Parameter Min. Max. Unit Default Cust ID Note

P1.3.1

Analog output 1 signal

selection

P1.3.2 Analog output

function

P1.3.3 Analog output filter

time

MN04004001E

0 A.1 464 TTF programming method used.

See Page 6-3.

0 8 1 307 0 = Not used

1 = Output freq. (0 – f

2 = Freq. reference (0 – f

3 = Motor speed (0 – Motor

nominal speed)

4 = Motor current (0 – I

5 = Motor torque (0 – T

6 = Motor power (0 – P

7 = Motor voltage (0 – U

8 = DC-Bus volt (0 – 1000V)

0.00 10.00 s 1.00 308 0 = No filtering

For more information visit: www.eaton.com

max

nMotor

nMotor

nMotor

)

)

max

nMotor

)

)

)

)

2-5

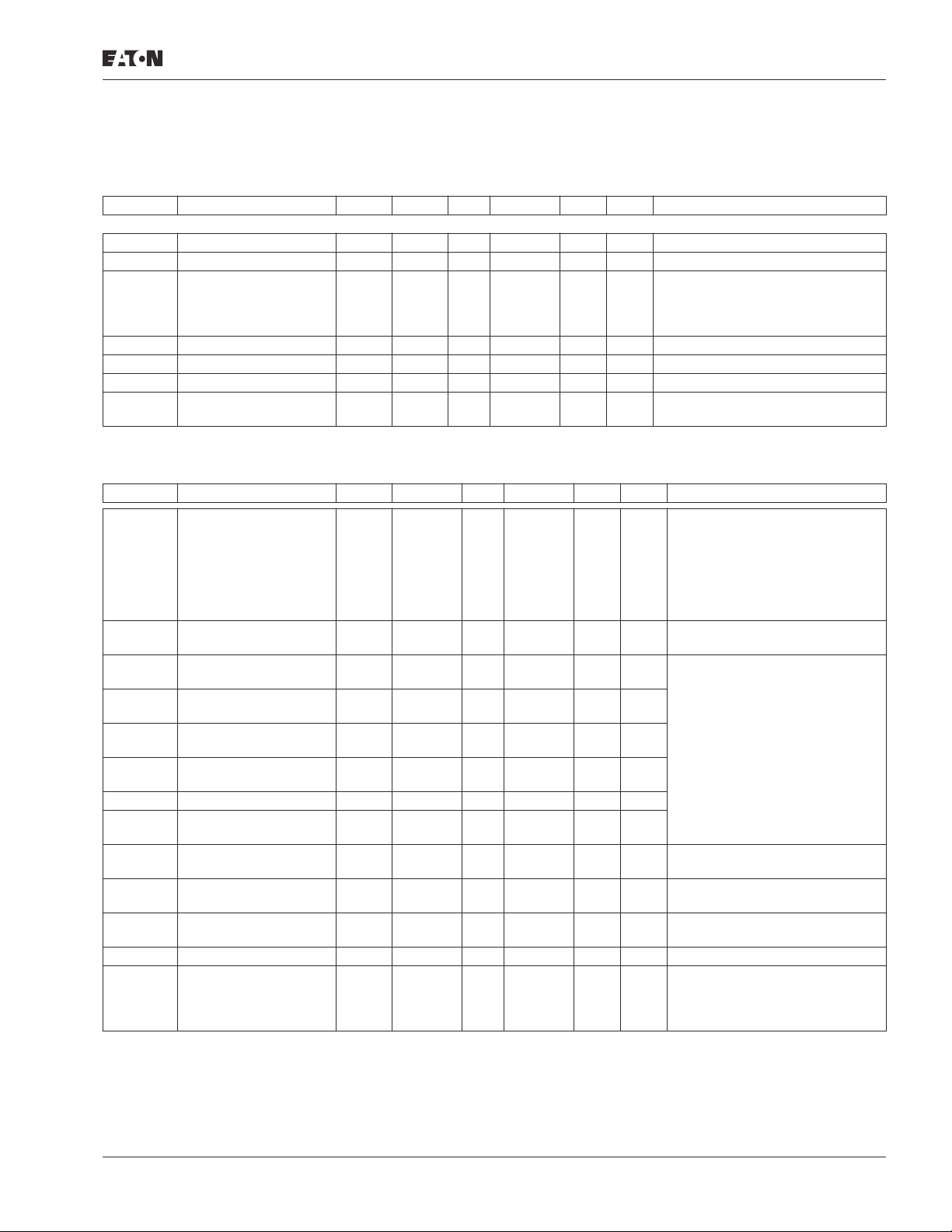

9000X AF Drives

Standard Application

Table 2-5: Output Signals — G1.3 (Continued)

Code Parameter Min. Max. Unit Default Cust ID Note

P1.3.4 Analog output

P1.3.5 Analog output

P1.3.6 Analog output scale 10 1000 % 100 311

P1.3.7 Digital output 1

P1.3.8 Relay output 1

P1.3.9 Relay output 2

P1.3.10 Output frequency limit

P1.3.11 Output frequency limit

P1.3.12

P1.3.13 Analog output 2

P1.3.14 Analog output 2 filter

P1.3.15 Analog output 2

P1.3.16 Analog output 2

P1.3.17 Analog output 2

inversion

minimum

function

function

function

1 supervision

1; Supervised value

Analog output 2 signal

selection

function

time

inversion

minimum

scaling

0 1 0 309 0 = Not inverted

1 = Inverted

0 1 0 310 0 = 0 mA

1 = 4 mA

0 16 1 312 0 = Not used

1 = Ready

2 = Run

3 = Fault

4 = Fault inverted

5 = FC overheat warning

6 = Ext. fault or warning

7 = Ref. fault or warning

8 = Warning

9 = Reversed

10 = Preset speed 1

11 = At speed

12 = Mot. regulator active

13 = OP freq. limit 1 superv.

14 = Remote Control Active

15 = Thermistor fault/warng

16 = Fieldbus input data

0 16 2 313 Same as parameter 1.3.7

0 16 3 314 Same as parameter 1.3.7

0 2 0 315 0 = No limit

1 = Low limit supervision

2 = High limit supervision

0.00 320.00 Hz 0.00 316

0 0.1 471 TTF programming method used.

See Page 6-3.

0 8 4 472 Same as parameter 1.3.2

0.00 10.00 s 1.00 473 0 = No filtering

0 1 0 474 0 = Not inverted

1 = Inverted

0 1 0 475 0 = 0 mA

1 = 4 mA

10 1000 % 100 476

August 2010

2-6 For more information visit: www.eaton.com

MN04004001E

August 2010

Standard Application

Drive Control Parameters (Control Keypad: Menu M1 ➔ G1.4)

Table 2-6: Drive Control Parameters — G1.4

Code Parameter Min. Max. Unit Default Cust ID Note

P1.4.1 Ramp 1 shape 0.0 10.0 s 0.0 500 0 = Linear

P1.4.2 Ramp 2 shape 0.0 10.0 s 0.0 501 0 = Linear

P1.4.3 Acceleration time 2 0.1 3000.0 s 10.0 502

P1.4.4 Deceleration time 2 0.1 3000.0 s 10.0 503

P1.4.5

Brake chopper 0 4 0 504 0 = Disabled

P1.4.6 Start function 0 1 0 505 0 = Ramp

P1.4.7 Stop function 0 3 1 506 0 = Coasting

P1.4.8 DC braking current 0.00 I

P1.4.9 DC braking time at

0.00 600.00 s 0.00 508 0 = DC brake is off at stop

L

A 0.7 x I

H

stop

P1.4.10 Frequency to start DC

0.10 10.00 Hz 1.50 515

braking during

ramp stop

P1.4.11 DC braking time

0.00 600.00 s 0.00 516 0 = DC brake is off at start

at start

P1.4.12 Flux brake 0 1 0 520 0 = Off

P1.4.13 Flux braking current 0.1 x I

HIL

AI

H

>0 = S-curve ramp time

>0 = S-curve ramp time

1 = Used when running

2 = External brake chopper

3 = Used when stopped/running

4 = Used when running (no testing)

1 = Flying start

1 = Ramp

2 = Ramp+Run enable coast

3 = Coast+Run enable ramp

507

1 = On

519

9000X AF Drives

Skip Frequency Parameters (Control Keypad: Menu M1 ➔ G1.5)

Table 2-7: Skip Frequency Parameters — G1.5

Code Parameter Min. Max. Unit Default Cust ID Note

P1.5.1 Skip frequency

range 1 low limit

P1.5.2 Skip frequency

range 1 high limit

P1.5.3 Skip frequency

acc./dec. ramp

MN04004001E

0.00 Par. 1.5.2 Hz 0.00 509

0.00 Par. 1.1.2 Hz 0.0 510 0 = Skip frequency range 1 not used

0.1 10.0 1.0 518

For more information visit: www.eaton.com

2-7

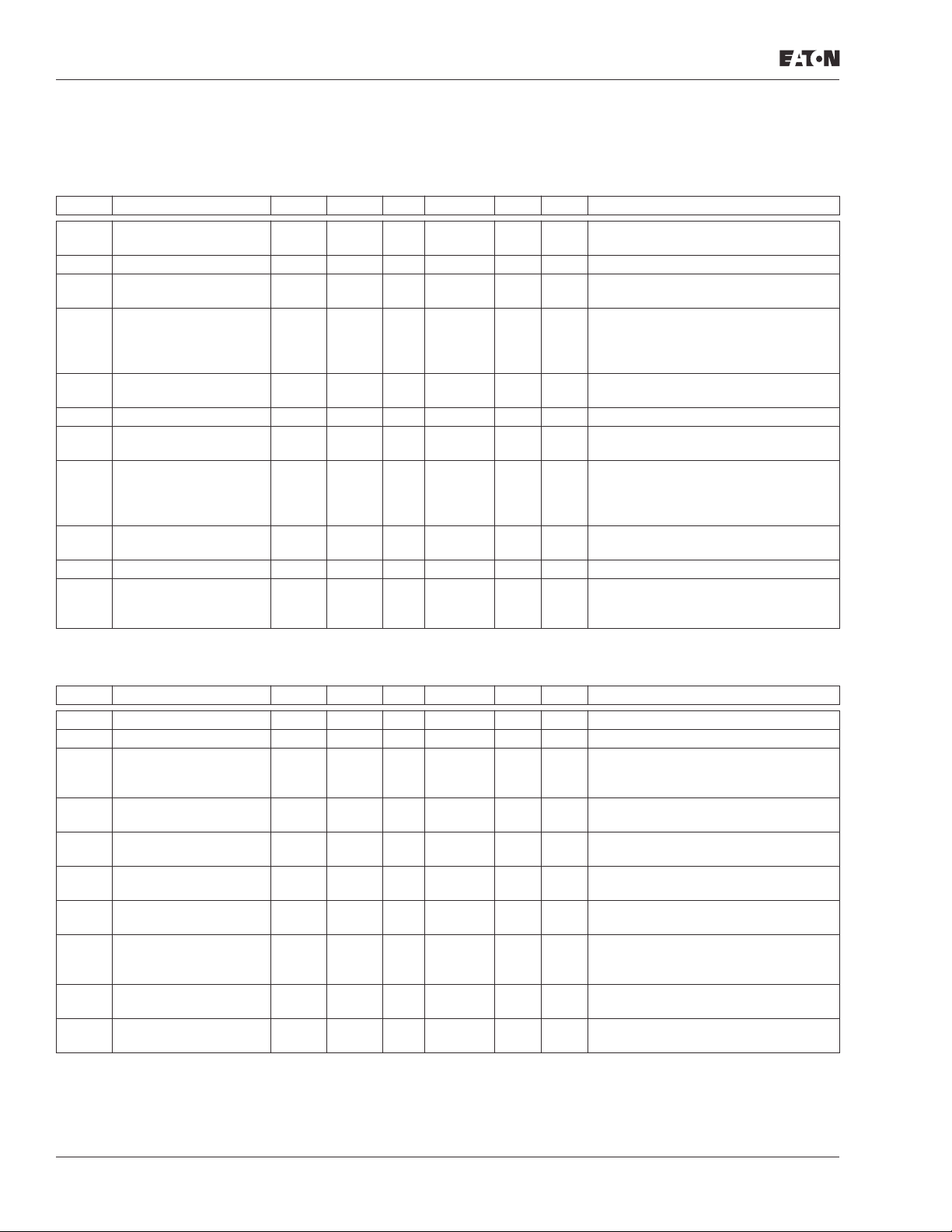

9000X AF Drives

August 2010

Standard Application

Motor Control Parameters (Control Keypad: Menu M1 ➔ G1.6)

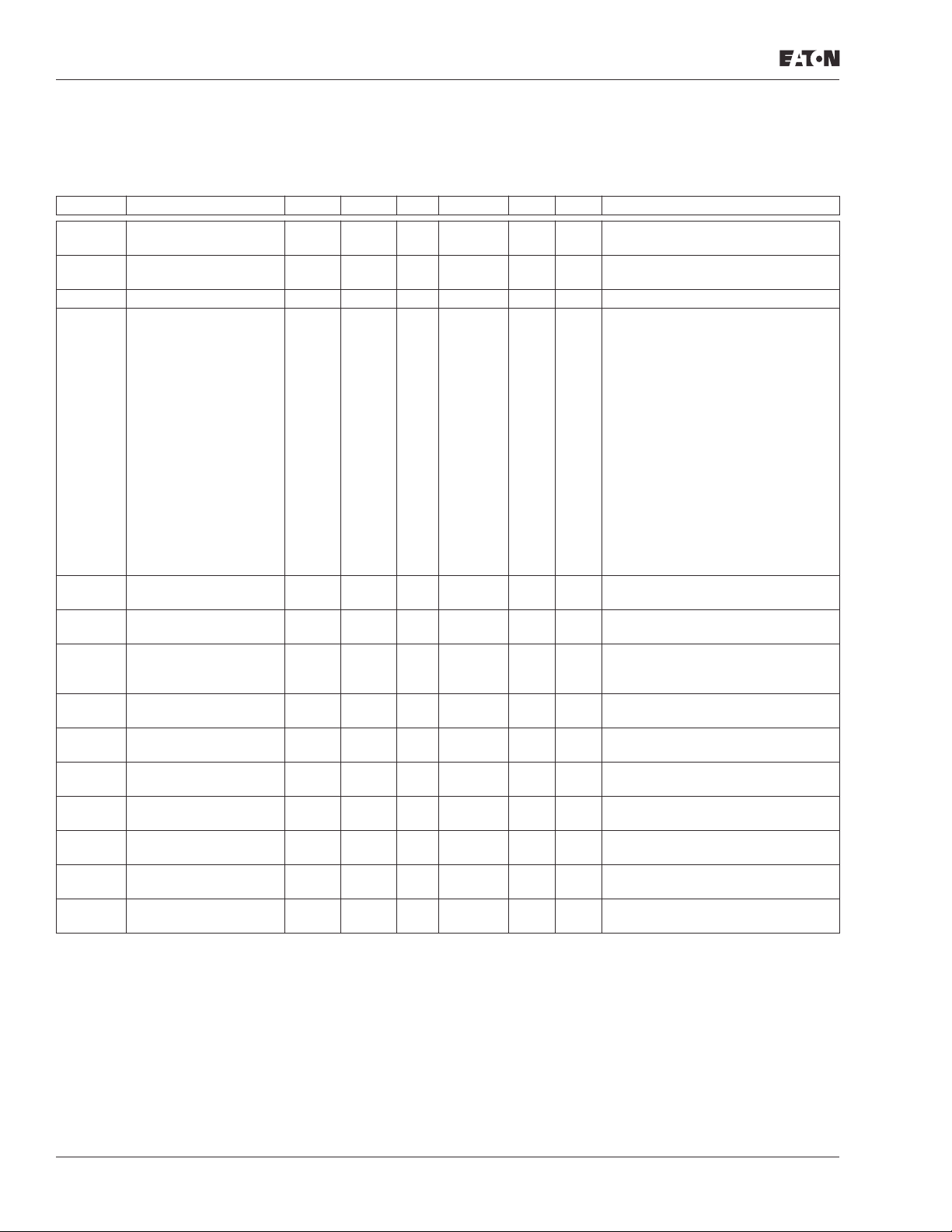

Table 2-8: Motor Control Parameters — G1.6

Code Parameter Min. Max. Unit Default Cust ID Note

P1.6.1

P1.6.2

P1.6.3

P1.6.4

P1.6.5

P1.6.6 V/Hz curve midpoint

P1.6.7

P1.6.8

P1.6.9 Switching frequency 1.0 Varies kHz Varies 601 See Table 8-12 on Page 8-57 for

P1.6.10 Overvoltage controller 0 2 1 607 0 = Not used

P1.6.11 Undervoltage

P1.6.12 Load Drooping 0.00 100.00 0.00 620 Drooping % of nominal speed at

P1.6.13 Identification 0 1 0 631 0 = Not used

Closed Loop parameter group 1.6.14 (SPX only)

P1.6.14.1 Magnetizing current 0.00 100.00 A 0.00 612

P1.6.14.2 Speed control P gain 0 1000 30 613

P1.6.14.3 Speed control I time 0.0 500.0 ms 30.0 614

P1.6.14.5 Acceleration

P1.6.14.6 Slip adjust 0 500 % 100 619

P1.6.14.7 Magnetizing current at

P1.6.14.8 Magnetizing time at

Motor control mode 0 1/6 0 600 SVX:

0 = Frequency control

1 = Speed control

Additionally for SPX:

2 = Torque control

3 = Closed loop speed ctrl

4 = Closed loop torque ctrl

V/Hz optimization 0 1 0 109 0 = Not used

1 = Automatic torque boost

V/Hz ratio selection 0 3 0 108 0 = Linear

1 = Squared

2 = Programmable

3 = Linear with flux optim.

Field weakening point 8.00 320.00 Hz 60.00 602

Voltage at field

10.00 200.00 % 100.00 603 n% x U

weakening point

0.00 Par. 1.6.4 Hz 60.00 604

frequency

V/Hz curve midpoint

voltage

0.00 100.00 % 100.00 605 n% x U

Parameter max. value =

par. 2.6.5

Output voltage at zero

0.00 40.00 % 1.30 606 n% x U

frequency

exact values

1 = Used (no ramping)

2 = Used (ramping)

0 1 1 608 1 = Yes

controller

2 = No

nominal torque

1 = OL v/f Ratio

2 = OL v/f and Boost

0.00 300.00 s 0.00 626

compensation

start

MotCurr

Min

MotCurr

Max

A 0.00 627

0.0 600.0 s 0.0 628

start

nmot

nmot

nmot

2-8 For more information visit: www.eaton.com

MN04004001E

August 2010

Standard Application

Motor Control Parameters — G1.6

Code Parameter Min. Max. Unit Default Cust ID Note

Closed Loop parameter group 1.6.14 (SPX only) (Continued)

P1.6.14.9 0-speed time at start 0 32000 ms 100 615

P1.6.14.10 0-speed time at stop 0 32000 ms 100 616

P1.6.14.11 Start-up torque 0 3 0 621 0 = Not used

P1.6.14.12 Start-up torque FWD -300.0 300.0 s 0.0 633

P1.6.14.13 Start-up torque REV -300.0 300.0 s 0.0 634

P1.6.14.15 Encoder filter time 0 1000 ms 0 618

P1.6.14.17 Current control

P gain

0.00 100.00 % 40.00 617

Protections (Control Keypad: Menu M1 ➔ G1.7)

Table 2-9: Protections — G1.7

Code Parameter Min. Max. Unit Default Cust ID Note

P1.7.1 Response to

reference fault

P1.7.2 Reference fault

frequency

P1.7.3 Response to external

fault

P1.7.4 Input phase

supervision

P1.7.5 Response to

undervoltage fault

P1.7.6 Output phase

supervision

P1.7.7 Earth fault protection 0 3 2 703

P1.7.8 Thermal protection of

the motor

P1.7.9 Motor ambient

temperature factor

P1.7.10 Motor cooling factor at

zero speed

P1.7.11 Motor thermal time

constant

P1.7.12 Motor duty cycle 0 100 % 100 708

P1.7.13 Stall protection 0 3 0 709 0 = No response

0 6 6 700 0 = No response

0.00 Par. 1.1.2 Hz 0.00 728

0 3 2 701 0 = No response

0 3 3 730

1 3 0 727

0 3 2 702

0 3 2 704

-100.0 100.0 % 0.0 705

0.0 150.0 % 40.0 706

1 200 min 45 707

1 = Torque memory

2 = Torque reference

3 = Start-up torque fwd/rev

1 = Warning

2 = Warning+Previous Freq.

3 = Wrng+PresetFreq 1.7.2

4 = Fault.stop acc. to 1.4.7

5 = Fault.stop by coasting

6 = Fault, Restart

1 = Warning

2 = Fault.stop acc. to 1.4.7

3 = Fault.stop by coasting

1 = Warning

2 = Fault.stop acc. to 1.4.7

3 = Fault.stop by coasting

9000X AF Drives

MN04004001E

For more information visit: www.eaton.com

2-9

9000X AF Drives

Standard Application

Table 2-9: Protections — G1.7 (Continued)

Code Parameter Min. Max. Unit Default Cust ID Note

P1.7.14 Stall current 0.1 I

P1.7.15 Stall time limit 1.00 120.00 s 15.00 711

P1.7.16 Stall frequency limit 1.0 Par.

P1.7.17 Underload protection 0 3 0 713 0 = No response

P1.7.18 Field weakening area

load

P1.7.19 Zero frequency load 5.0 150.0 % 10.0 715

P1.7.20 Underload protection

time limit

P1.7.21 Response to

thermistor fault

P1.7.22 Response to fieldbus

fault

P1.7.23 Response to slot fault 0 3 2 734 See P1.7.21

P1.7.24 FB MCW Bit 15 0 2 0 771 0 = No action

10 150 % 50 714

2 600 s 20 716

0 3 2 732 0 = No response

0 3 2 733 See P1.7.21

nMotor

x 2

1.1.2

AI

L

Hz 25.0 712

710

1 = Warning

2 = Fault.stop acc. to 1.4.7

3 = Fault.stop by coasting

1 = Warning

2 = Fault.stop acc. to 1.4.7

3 = Fault.stop by coasting

1 = Fault low

2 = Fault high

August 2010

Autorestart Parameters (Control Keypad: Menu M1 ➔ G1.8)

Table 2-10: Autorestart Parameters — G1.8

Code Parameter Min. Max. Unit Default Cust ID Note

P1.8.1 Wait time 0.10 10.00 s 0.50 717

P1.8.2 Trial time 0.00 60.00 s 30.00 718

P1.8.3 Start function 0 2 0 719 0 = Ramp

P1.8.4 Number of tries after

undervoltage trip

P1.8.5 Number of tries after

overvoltage trip

P1.8.6 Number of tries after

overcurrent trip

P1.8.7 Number of tries after

reference trip

P1.8.8 Number of tries after

motor temperature

fault trip

P1.8.9 Number of tries after

external fault trip

P1.8.10 Number of tries after

underload fault trip

0 10 0 720

0 10 0 721

0 3 0 722

0 10 0 723

0 10 0 726

0 10 0 725

0 10 0 738

1 = Flying start

2 = According to par. 1.4.6

2-10 For more information visit: www.eaton.com

MN04004001E

9000X AF Drives

August 2010

Standard Application

Keypad Control (Control Keypad: Menu M2)

The parameters for the selection of control place and direction on the keypad are listed

below. See the Keypad control menu in the 9000X AF Drives User Manual.

Table 2-11: Keypad Control Parameters — M2

Code Parameter Min. Max. Unit Default Cust ID Note

P2.1 Control place 0 3 0 1685 0 = Keypad L/R

R2.1 Keypad reference Par. 1.1.1 Par. 1.1.2 Hz

P2.3 Direction (on keypad) 0 1 0 123 0 = Forward

P2.4 Stop button 0 1 1 114 0 = Limited function of Stop button

P2.5 Operate menu hide 0 1 0 1688 0 = No

System Menu (Control Keypad: Menu M5)

For parameters and functions related to the general use of the drive, such as application

and language selection, customized parameter sets or information about the hardware and

software, see Chapter 5 in the 9000X AF Drives User Manual.

1 = Local

2 = Remote

3 = I/O force

1 = Reverse

1 = Stop button always enabled

1 = Yes

Expander Boards (Control Keypad: Menu M6)

The M6 menu shows the expander and option boards attached to the control board and

board-related information. For more information, see Chapter 5 in the 9000X AF Drives

User Manual.

MN04004001E

For more information visit: www.eaton.com

2-11

9000X AF Drives

August 2010

2-12 For more information visit: www.eaton.com

MN04004001E

Loading...

Loading...