Page 1

March 2008

10250T Series

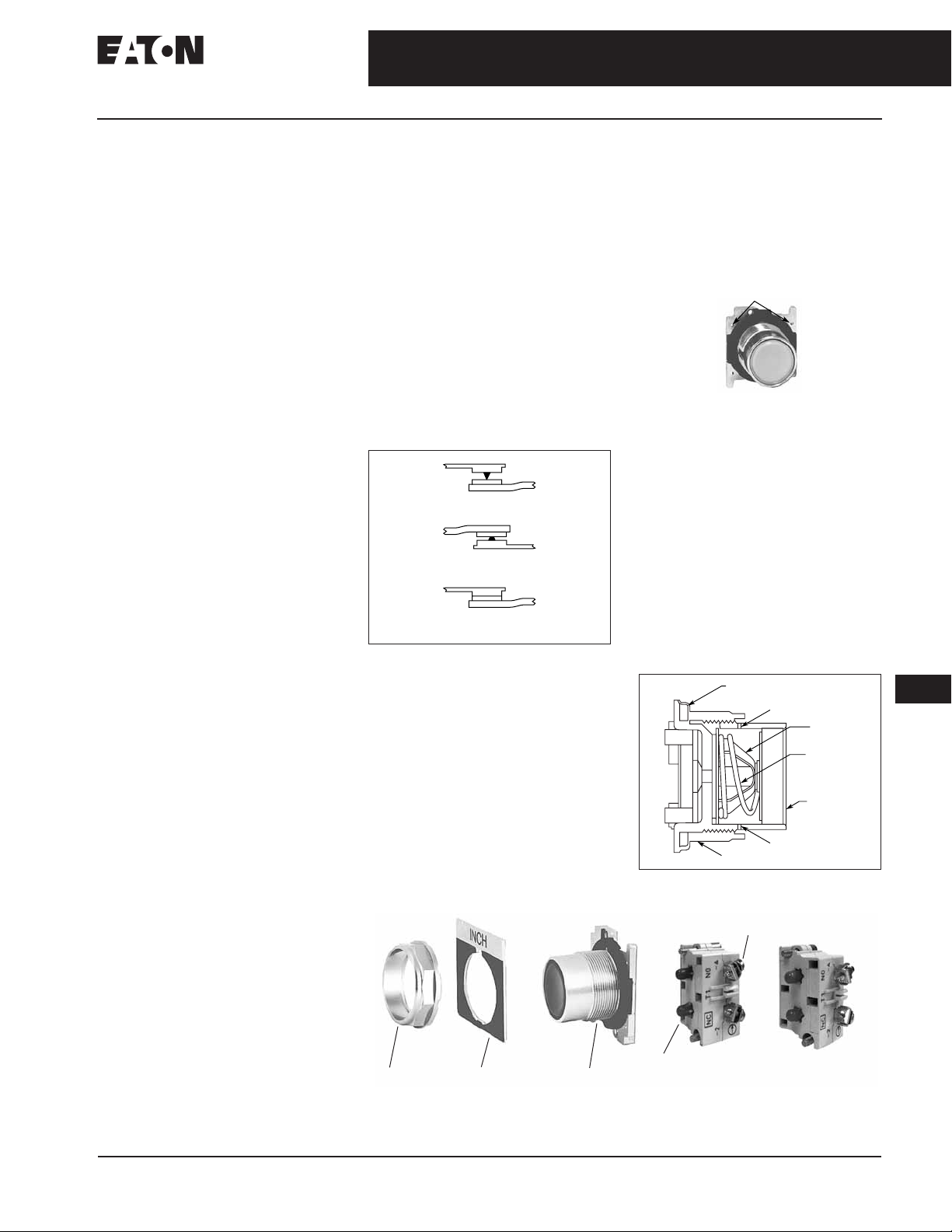

Mounting Nut Legend Plate Operator

Terminal Clamps Shipped

Ready to Wire

Stackable Contact

Blocks up to 12

Circuits per Operator

Color Coded Plungers

Red = NC Green = NO

Pushbuttons & Indicating Lights

30.5 mm Heavy-Duty Watertight/Oiltight

10250T Series

47-115

Contents

Description Page

Product Description . . . . . . . . 47-115

Features . . . . . . . . . . . . . . . . . . 47-116

Benefits . . . . . . . . . . . . . . . . . . 47-116

Contact Operation . . . . . . . . . 47-116

Standards and

Certifications. . . . . . . . . . . . . 47-116

Technical Data and

Specifications . . . . . . . . . . . . 47-116

Point-of-Purchase

Packaging . . . . . . . . . . . . . . . 47-117

Product Selection

Non-illuminated

Momentary Pushbutton

Units . . . . . . . . . . . . . . . . . 47-118

Pushbuttons . . . . . . . . . . . . 47-119

Illuminated Momentary

Pushbutton Units. . . . . . . 47-122

Indicating Light Units . . . . 47-123

Illuminated Pushbuttons

and Indicating Lights. . . . 47-124

Push-Pull Units. . . . . . . . . . 47-125

Illuminated Push-Pull

Units . . . . . . . . . . . . . . . . . 47-126

Potentiometers. . . . . . . . . . 47-128

Push-Pulls . . . . . . . . . . . . . . 47-129

Selector Switch Units . . . . 47-132

Selector Switch

Selection . . . . . . . . . . . . . 47-133

Selector Switch

Operators . . . . . . . . . . . . . 47-135

Illuminated Selector

Switch Operators. . . . . . . 47-138

Joysticks Units . . . . . . . . . . 47-139

Joystick . . . . . . . . . . . . . . . . 47-139

Roto-Push

Roto-Push Operators . . . . . 47-143

Contact Blocks . . . . . . . . . . 47-148

Options

Legend Plates . . . . . . . . . . . 47-151

Enclosures . . . . . . . . . . . . . 47-153

Accessories . . . . . . . . . . . . . . . 47-155

Renewal Parts . . . . . . . . . . . . . 47-157

Mounting . . . . . . . . . . . . . . . . . 47-159

Dimensions . . . . . . . . . . . . . . . 47-160

Ordering Complete

Devices . . . . . . . . . . . . . . . . . 47-163

Catalog Number

Structure . . . . . . . . . . . . . . . . 47-164

®

Units. . . . . . . . 47-142

Product Description

The 30.5 mm pushbutton line features

a zinc die cast construction with

chrome-plated housing and mounting

nut. The same durable construction is

also available with the corrosive resistant E34 line of pushbuttons. See E34

section on Pages 47-166 – 47-189.

Reliability Nibs

Eaton’s Cutler-Hammer® contact

blocks feature enclosed silver contacts

with pointed “reliability nibs” for reliable performance from logic level up

to 600V. To ensure reliable switching,

nibs bite through oxide which can form

on silver contacts, eliminating the

need for expensive logic level blocks

for most applications.

Dry Circuit

Medium Duty

Heavy-Duty

Figure 47-90. Reliability Nibs

Reliability nibs improve performance

in dry circuit, corrosive, fine dust and

other contaminated atmospheres.

Under normal environmental conditions, the minimum operational voltage

is 5V and the minimum operational

current is 1 mA, AC/DC. For operation

under a wider range of environmental

conditions, logic level contact blocks

with inert palladium tipped contacts

are recommended.

Grounding Nibs

10250T line operators have “grounding

nibs” — four metal points on the operator casting designed to bite through

most paints and other coatings on

metal panels to enhance the ground

connection when the operator is

securely tightened.

Grounding

Nibs

Grounding Nibs

Diaphragm Seal with Drainage Holes

Liquid Drainage

Eaton’s Cutler-Hammer pushbutton

operators offer front of panel drainage

via holes in the operator bushing. Hidden from view by the mounting nut,

these holes prevent buildup of liquid

inside the operator, which can prevent

operation in freezing environments.

The holes also provide a route for

escaping liquid in high pressure washdowns, effectively relieving pressure

from the internal diaphragm seal,

ensuring reliable sealing in applications even beyond NEMA 4.

Foam Neoprene

Panel Sealing Gasket

Mounting Nut

Figure 47-91. Diaphragm Seal

Drainage Hole

Flexible

Diaphragm

Stainless

Steel

Operating

Spring

Colorfast

Molded

Button

Drainage Hole

47

CA08102001E For more information visit: www.eaton.com

Page 2

47-116

Pushbuttons & Indicating Lights

30.5 mm Heavy-Duty Watertight/Oiltight

March 2008

10250T Series, Technical Data and Specifications

47

Features

■ Heavy-duty zinc die cast construction

■ Enclosed silver contacts with

reliability nibs

■ Diaphragm seals with drainage

holes

■ Grounding nibs on the operator

casing

Benefits

■ Reliability nibs improve contact

reliability even under dry circuit and

fine dust conditions

■ Drainage holes prevent buildup of

liquid inside the operator which

can prevent operation in freezing

environments

■ Grounding nibs bit through paint

and other coatings to provide

secure ground

Contact Operation

Slow make and break. All normally

closed contacts have positive opening

operation, i.e., normally closed contacts

are forced open in the event of contact

weld or spring breakage.

Standards and Certifications

■ CE EN60947-5-1

■ UL 508 — File No. 131568

■ CSA C22.2 No. 14 — File No. LR68551

Ingress Protection

When mounted in similarly rated

enclosure —

■ Standard Indicating Lights

❑ UL (NEMA) Type 1, 2, 3, 3R, 3S, 4,

4X, 12, 13

❑ IEC IP65

■ All Other Operators

❑ UL (NEMA) Type 1, 2, 3, 3R, 4, 4X,

12, 13

❑ IEC IP65

Technical Data and

Specifications

Mechanical Ratings

■ Frequency of operation

❑ All pushbuttons:

6000 operations/hr.

❑ Key and lever selector switches:

3000 operations/hr.

❑ Auto-latch devices:

1200 operations/hr.

■ Life

❑ Pushbuttons: 10 x 10

❑ Contact blocks: 10 x 10

❑ PresTest units: 10 x 10

❑ Lever and key selector switches:

0.25 x 10

❑ Twist to release pushbuttons:

0.3 x 10

■ Shock resistance

❑ Duration: 20 mS ≥ 5g

6

operations

6

operations

6

operations

6

operations

6

operations

Electrical Ratings

■ Insulation: Ui = 660V AC or DC

■ Thermal: lth = 10A

Short Circuit Coordination to

IEC/EN 60947-5-1

■ Rated conditional short circuit cur-

rent: 1 kA

■ Fuse type: GE Power Controls TIA

10, Red Spot Type gG, 10A,

660V AC, 460V DC, BS88-2,

IEC 60269-2-1

Climate Conditions

■ Operating Temperature: 1° to 150°F

(-17° to 66°C)

■ Storage Temperature: -40° to 176°F

(-40° to 80°C)

■ Altitude: 6,562 ft. (2,000m)

■ Humidity: Max. 95% RH @ 60°C

Terminals

■ Marking

❑ NC-NO on the contact block to meet

the NEMA requirements. Dual

marking system 1 – 2 for normally

closed, 3 – 4 for normally open to

meet BS5472 (Cenelec EN50 005)

■ Clamps

❑ Terminals are saddle clamp type

for 1 x 22 AWG (0.34 mm

AWG (2.5 mm

■ Torque = 7 lb-in (0.8 Nm)

■ Degree of protection against

2

) conductors

2

) to 2 x 14

direct electrical contact: IP2X

with fingerproof shroud

Light Units

■ Transformers: will withstand short

circuit for 1 hour per IEC 60997-5-1

■ Bulbs — average life

❑ Transformer type: 20,000 hrs.

❑ Resistor/direct voltage type:

2500 hrs. minimum @ rated V

❑ LED: 60,000 to 100,000 hrs.

■ UL rating: A600, P600

❑ AC load life duty cycle

1200 operations/hour

– 10A: 110V pf 0.4 – 1 x 10

operations

– 5A: 250V pf 0.4 – 1 x 10

operations

– 2A: 660V pf 0.4 – 1 x 10

operations

■ Switching capacity

❑ AC15 rated make/break

(11 x le at 1.1 x Ue)

– 6A: 120V pf 0.3

– 4A: 240V pf 0.3

– 2A: 660V pf 0.3

❑ DC13 rated make/break

(1.1 x le at 1.1 x Ue)

– 1.0A: 125V L/R ≥ 0.95 at 300 mS

– .55A: 250V L/R ≥ 0.95 at 300 mS

– .1A: 660V L/R ≥ 0.95 at 300 mS

– 10A: 110V pure resistive

■ Maximum ratings for logic level

and hostile atmosphere application

❑ Maximum amperes: 0.5A

❑ Maximum volts: 120V AC/DC

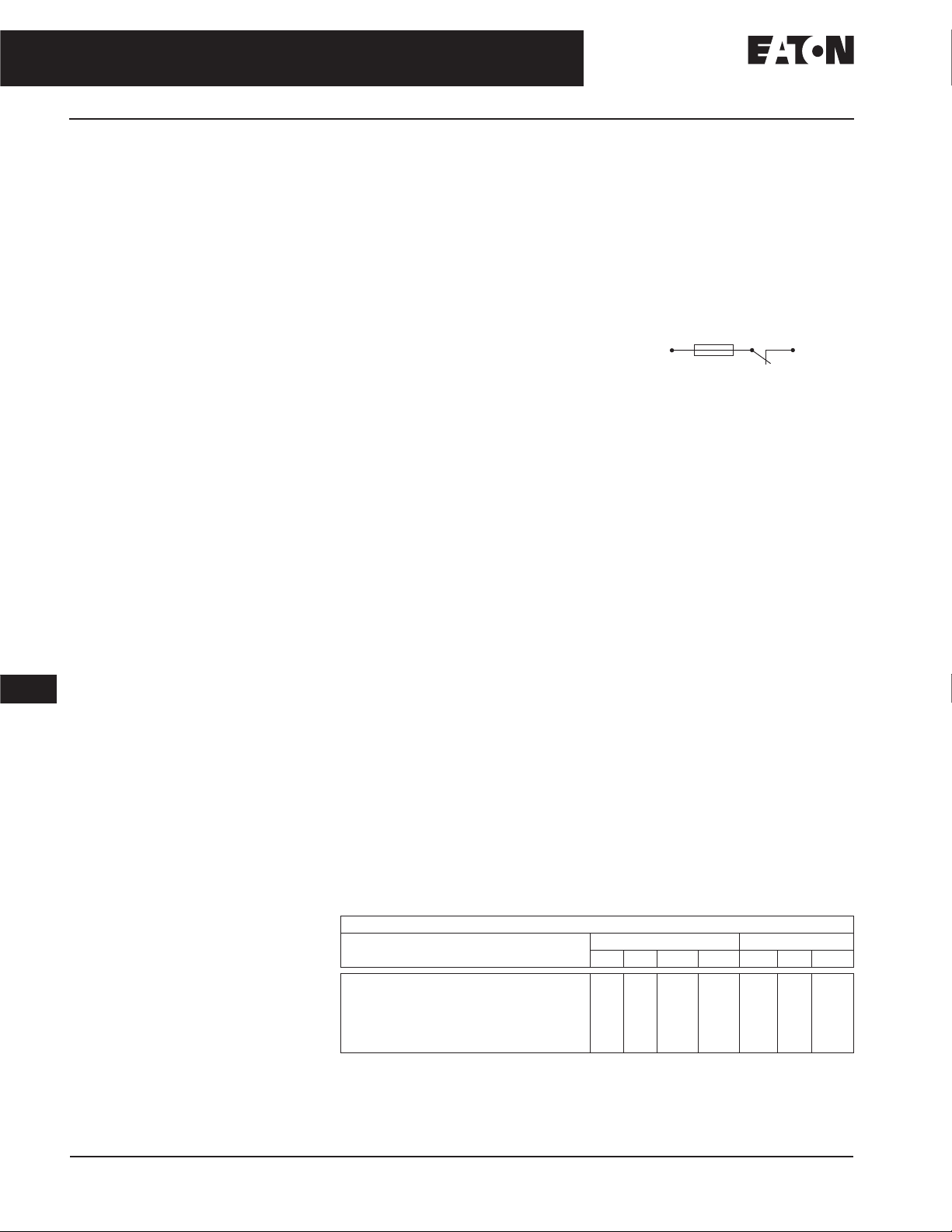

Table 47-171. Contact Block

Meet or Exceed NEMA Rating Designations A600, A300 and B300 for AC and P600 for DC

Description Volts AC 50 or 60 Hz Volts DC

120 240 480 600 24/28 125 250

Make and Emerg. Interrupting Capacity (Amp)

Normal Load Break (Amp)

Thermal Current (Amp)

Voltamperes:

Make and Emerg. Interrupting Capacity

Normal Load Break

7200

720

60

30

6

3

10

10

7200

7200

720

720

Fuse

15

12

1.5

10

7200

720

5.7

1.2

5.7

10

5.0

138

138

138

138

1.1

1.1

5.0

6

6

6

0.55

0.55

5.0

138

138

For more information visit: www.eaton.com CA08102001E

Loading...

Loading...