Page 1

Upright lock knob

Folding the bracket for storage

RF-PRO (Rapid Fire) INSTRUCTIONS

Innovative Camera Mount Accessories

Made in U SA

32 Alpha Park

Cleveland, Ohio 44143

phone: 440.446.0819

toll free: 800.530.2289

website: www.custombrackets.com

email: info@custombrackets.com

Bracket in

storage position

Fold-out leg

Remove your camera and ash prior to storage. It is not necessary to remove a ash cord if attached to the ash

mounting plate. Loosen the upright lock knob and rotate upright backward to lower until at. Fold in the leg.

Note:

The upright knob may be tightened when the bracket is in the storage (at) position. The upright lock knob must

be loosened prior to rotating the upright or damage may occur and warranty will be void.

Attaching the bracket to a tripod or monopod

Attach the RF-PRO to a tripod / monopod’s 1/4”-20 mounting stud and tighten until rmly attached.

Optional Accessories - Sold Separately

RF-WT

wireless ash operation

WFM-1

wireless transmitters

RF-CB

(Custom Brackets style)

Locking shoe mount with anti-twist for

Locking shoe mount with anti-twist for

Bottom tripod quick release plate

Refer to instructions included with accessory for attaching to bracket

RF-C1

RF-C2

RF-C3

Connector for Spider Camera Holster™ - Carry Speed

Connector for Black Rapid™ ConnectR

Connector for Sun Sniper

™ -

Custom SLR

™ -

Joby

USA 5 Year Warranty

For a period of ve (5) years from date of purchase, Custom Brackets will repair or replace free of charge, any defect in material or

workmanship. Warranty does not cover repairs due to customer abuse, negligence, impact or any modications made by the customer.

Warranty service is available by returning the RF-PRO (shipping prepaid) to Custom Brackets. All returns must include a return authorization

(RA) number (contact Custom Brackets to obtain), letter explaining the problem, and a copy of the sales receipt.

International 5 Year Limited Warranty

For a period of ve (5) years from date of purchase, Custom Brackets will repair or replace free of charge, any defect in material or

workmanship. Warranty does not cover repairs due to customer abuse, negligence, impact or any modications made by the customer.

Limitation to the warranty - after one year shipping charges are not covered. Warranty service is available by returning the RF-PRO

(shipping prepaid) to Custom Brackets. All returns must include a return authorization (RA) number (contact Custom Brackets to obtain),

letter explaining the problem, and a copy of the sales receipt.

Repair

Repair service is available by returning the RF-PRO (shipping prepaid) to Custom Brackets. All returns must include a return authorization

(RA) number (contact Custom Brackets to obtain), letter explaining the problem, and a copy of the sales receipt. A repair cost will be issued

and must be approved prior to any repairs. Shipping charges are the responsibility of the customer.

Maintenance

The only maintenance necessary on the RF-PRO is to clean the inside track of the rotator (back side) periodically with a clean cloth and

WD-40 to remove any dust or dirt that may have accumulated to keep it working at it’s best. The rotation tension is factory set. Attempting

to adjust the tension will void the warranty and may result in damage to the camera, lens or ash.

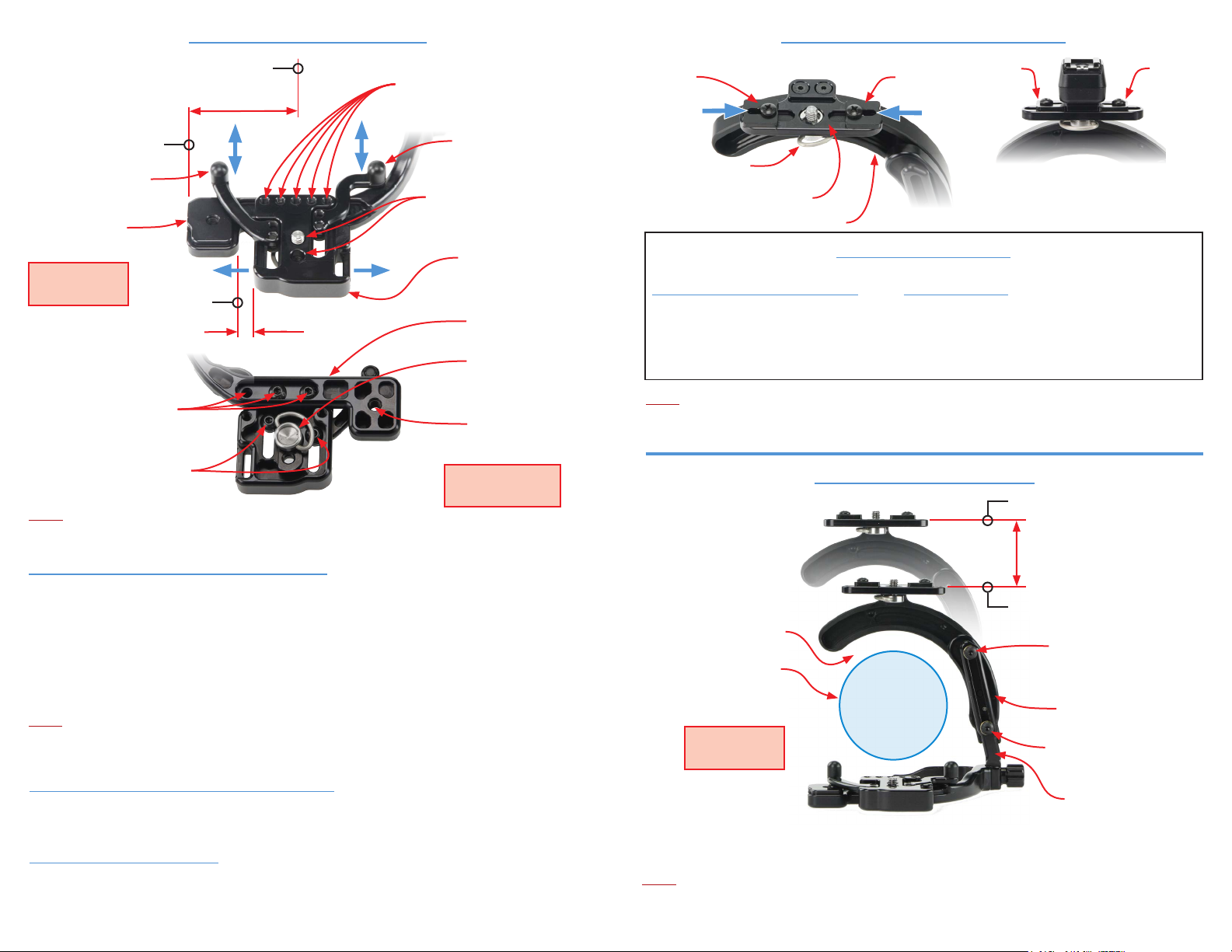

Shown with

short camera

Shown with

tall camera

™

™

Captive ash screw

“D” clip stainless steel

1/4” x 20 thread

Flash rotator

Flash anti-twist (2)

Camera screw

“D” style stainless steel

1/4” x 20 thread

Upright screw

on backside

Camera plate

Camera position holes (2)

for positioning camera

front to back

Strap slot

Camera plate position holes (5)

for positioning camera

left to right

Tripod hole

1/4” x 20 thread

Backside of

bracket shown

Flash rotator

base

Upright

Connector Mounting Hole

Captive upright

lock knob

Fold-out leg

Must be completely folded

in or out to rotate ash

Parts of the RF-PRO

For accessories RF-C1, RF-C2, RF-C3

Camera Anti-Twist (2)

Adjustable front to back

Page 2

Attaching the camera to the bracket

Attaching the ash cord to the ash mount

Center of Lens

Camera plate position holes (5)

1-11/16”

End of support

for positioning camera

left to right

Camera anti-twist

Adjustable front to back

Camera anti-twist

Adjustable front to back

Support

Camera position holes (2)

for positioning camera

front to back

Camera plate

Top view of

camera plate

Support position holes (3)

for positioning camera

left to right

Camera anti-twist screws (2)

Left position

5/16”

Support

Camera screw

“D” clip stainless steel

1/4” x 20 thread

Tripod hole

1/4” x 20 thread

Bottom view of

camera plate

Note:

- Prior to attaching the camera, raise the ash rotator to the up position (see: back view of bracket).

- The camera plate has been factory set for small cameras with the camera mounting hole on center of the lens.

(1) Setting the camera plate position - Left to Right

The camera plate has ve (5) position holes (5/16” apart) for positioning the camera plate left to right.

Two (2) screws are provided to attach the camera plate to the bracket. Once the correct left to right position has

been determined, use any two support position holes which line up with the camera plate position holes to attach

the camera plate using the 1/8” Allen wrench provided with bracket.

For smaller cameras, or those without add-on vertical grips / battery packs, position the camera plate with a

distance of 5/16” from left position.

For taller cameras, or those with add-on vertical grips / battery packs with the camera mounting hole on center

with the lens, position the camera plate to left position.

Note:

Some add-on vertical grips / battery packs have the mounting screw hole off center to the lens. Determine the

correct position to mount the camera plate to the support which locates the center of the lens as close to 1-11/16”

from the end of the support.

(2) Setting the camera plate position - Front to Back

The camera plate has two (2) camera screw holes for locating the camera front to back. Attach the camera using

one of the camera screw holes. Position of the camera is a customer preference on how comfortable it feels

when holding the bracket in the horizontal and vertical positions.

(3) Setting the camera anti-twist

Once the camera is positioned properly, adjust the two (2) camera anti-twists to contact the front of the camera.

Tighten the two (2) camera anti-twist screws located on the bottom side of the camera plate using the 1/8” Allen

wrench provided with bracket..

An additional hole in the anti-twist is provided if the camera screw “D” clip interferes with the anti-twist screws.

Anti-twist

Captive ash screw

“D” clip

Flash mounting plate

Anti-twist

Anti-twist

Shown with Canon

Off Camera cord II attached

Anti-twist

Flash rotator

Flash anti-twist procedure

Canon off-camera cord II, Canon Cord 3,

Nikon SC-17 cords (rst time installation)

1-

Attach cord with ash screw

2-

Slide one anti-twist to cord

Slide other anti-twist to cord

34-

Tighten ash screw to cord

(do not tighten completely)

(tighten anti-twist screw)

(tighten anti-twist screw)

Nikon SC-28, SC-29 Cords

(rst time installation)

1-

Attach cord (reversed) with ash screw

2-

Slide left anti-twist to cord

Remove cord and install normal

34-

Slide right anti-twist to cord

Tighten ash screw to cord

5-

(tighten anti-twist screw)

(tighten anti-twist screw)

(do not tighten completely)

Note:

Do not rotate the ash rotator unless a ash cord or the

to the ash mounting plate and “D” clip of the screw is folded down. Rotating without one of these attached

may cause damage to the rotator and void warranty.

RF-FT

(mount for wireless ash operation) is attached

Adjusting the ash rotator height

Up position

Height Adjustment

Down position

Equal space around lens

Upright screw

Lens outside diameter

Up position

(shown for reference)

Position rotator

for equal space

around lens

Back view of

bracket

Flash rotator base

Upright screw

Down position

Upright

The ash rotator is adjustable to work with short or tall cameras.

Adjust by loosening the upright screw, then position the rotator to be centered around the lens of the camera.

After desired position of rotator is set, lock upright screw using the 1/8” Allen wrench provided with bracket.

Note:

- Rotating without equal space around lens may cause damage to the lens or bracket.

- The leg must be completely folded in or out to rotate ash to avoid damage to the bracket.

Loading...

Loading...