Custom Brackets Digital PRO-M, Digital PRO-E, Digital PRO-SV, QRS-H2, QRS-E2 Instructions For Use Manual

...Page 1

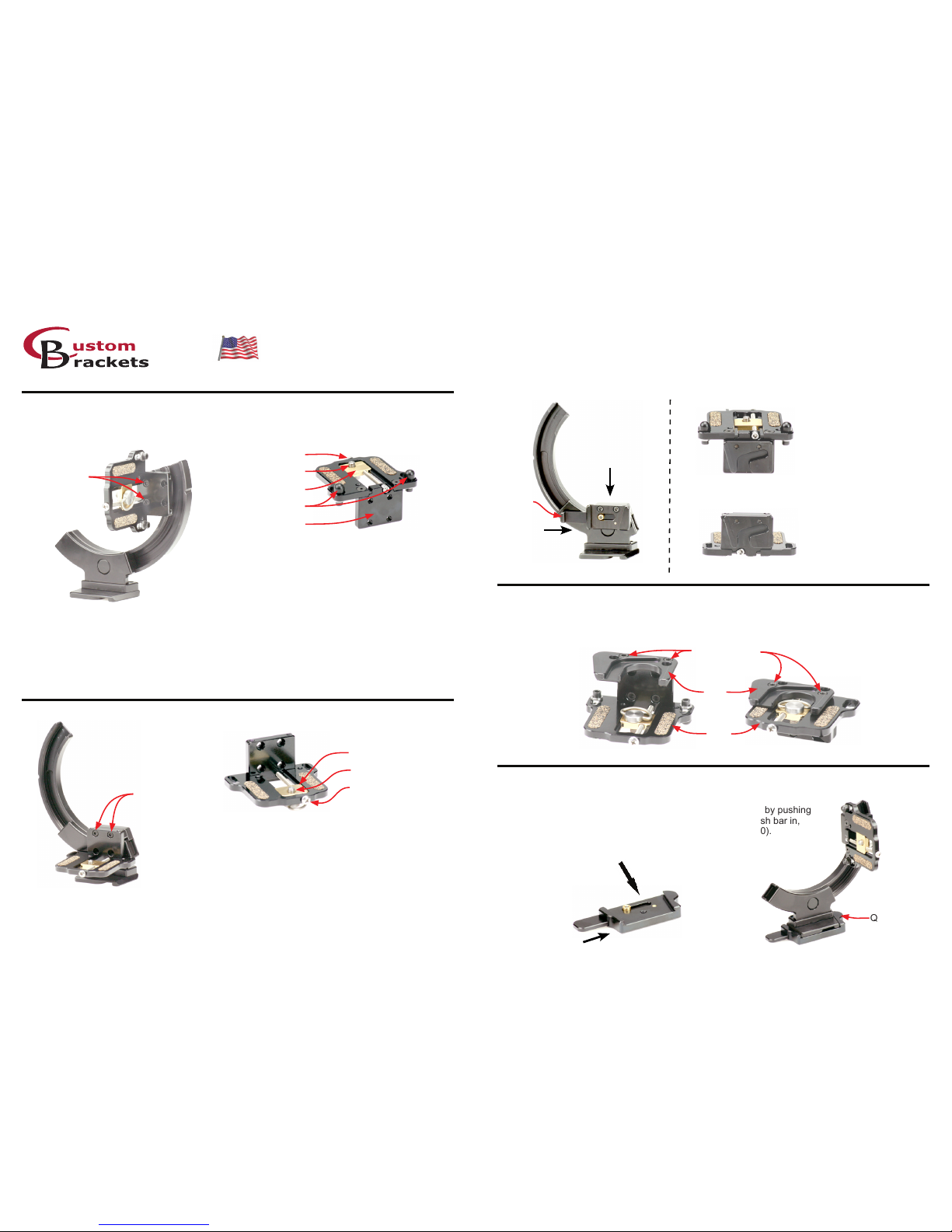

Figure #3

Two screws for

mounting CMP

Attaching your camera to the CMP

Camera with add on vertical grips or battery packs

Remove the anti-twist posts using the Allen

wrench (9/64”) provided with the bracket. Refer

to picture at the top of this page (gure #4).

2 -

Attach your camera with lens toward vertical plate. Once the “D” style camera screw is tightened,

loosen 1/2 turn.

Turn the adjusting screw counterclockwise with a Phillips screwdriver to move the camera screw

plate forward until the camera touches the vertical plate. Then turn an additional 1/4 turn.

Tighten the “D” style camera screw completely.

4 -

5 -

6 -

Remove the “D” style camera screw and install from opposite side as shown.

3 -

Camera without add on vertical grips or battery packs

Attach your camera with lens toward the

anti-twist posts. Once the “D” style camera

screw is tightened, loosen 1/2 turn (gure #2).

Turn the adjusting screw counterclockwise using a Phillips screwdriver to move the camera

screw plate forward until the camera touches one of the anti-twist posts. Then turn an additional

1/4 turn (make sure camera is facing straight forward).

Tighten the “D” style camera screw completely.

Camera screw plate

Adjusting Screw

“D” style camera screw

Vertical plate

2 -

3 -

4 -

(2) Anti-twist posts

Loosen second anti-twist post (if it is not touching the camera) using the same Allen wrench

(9/64”) and move it until it touches the camera and then tighten.

5 -

Attach the camera plate (CMP) to the bracket using the two screws (8-32 thread x 1/2” long socket

head) and Allen wrench (9/64”) supplied with your

bracket (gure #1).

1 -

Figure #1

Two screws for

mounting CMP

Camera screw plate

Adjusting Screw

“D” style camera screw

Attach the camera plate (CMP) to the bracket using the two screws (8-32 thread x 1/2” long socket

head) and Allen wrench (9/64”) supplied with your

bracket (gure #3).

1 -

Figure #2

Figure #4

Digital PRO-M, Digital PRO-E, Digital PRO, Digital PRO-SV

QRS-H2, QRS-E2, QRS-2

BRACKET INSTRUCTIONS

U.S. Patent 6,354,544

Attaching the camera quick release (QR-C kit, QR-C, C-SP)

Attach the camera quick release (QR-C) to the bracket using the two screws (8-32 thread x 1/2” long

socket head screw) and Allen wrench (9/64”) supplied with your bracket (gure #5)

C-SP attached to CMP

for tall cameras and

cameras with vertical

grips / battery packs

C-SP attached to CMP

for short cameras and

cameras without vertical

grips / battery packs

Figure #6

Figure #7

Figure #5

Push bar

2 - Slide C-SP in

from above

1 - Push the

push bar in

Attaching the camera bottom plate (CBP)

Attach the camera bottom plate (CBP) to the CMP using the two screws (8-32 thread x 1/2” long

socket head screw) supplied with your CBP and Allen wrench (9/64”) supplied with your bracket.

Figures #8 and #9 are showing the CMP up-side-down with the CBP attached

CBP attached

to CMP for tall

cameras and

cameras with

vertical grips /

battery packs

CBP attached

to CMP for short

cameras and

cameras without

vertical grips /

battery packs

Figure #8

Figure #9

CMP

CBP

Two screws for

mounting CBP

Attach the camera subplate (C-SP) to the camera mounting plate (CMP) using the two screws

(8-32 thread x 5/16” long socket head screw) supplied with the C-SP and Allen wrench (9/64”)

supplied with your bracket per either gure #6 or #7.

Attach your camera per the CMP instructions.

While pushing in the push bar on the QR-C (step 1 in gure #5), slide the C-SP (attached to the CMP)

downwards into the QR-C (attached to the bracket) (step 2 in gure #5). The push bar on the QR-C

needs to be pushed in when attaching and detaching the C-SP.

Attaching the bracket to the tripod quick release (QR)

Figure #10

Figure #11

Attach the tripod quick release (QR) to any tripod by screwing the QR

onto the 1/4-20 bolt on the tripod. Attach the bracket to the QR by pushing

in the push bar (step 1 in gure #10), and while holding the push bar in,

slide the bracket into the QR from the front (step 2 in gure #10).

Figure #11 shows the bracket in the quick release.

QR

2 - Slide bracket in

from front side

1 - Push the

push bar in

Push Bar

phone 440-446-0819

Toll Free 800-530-2289

website: www.custombrackets.com

email: info@custombrackets.com

32 Alpha Park

Cleveland, Ohio 44143

Made in USA

Innovative Camera Support s

Page 2

FCN

Use the examples below to set your FCN. Screw cord onto plate and adjust the plastic piece so that

it is next to the cord.

Nikon SC-29

Nikon SC-28 &

Canon Cords

Canon

Off-Camera Cord 2

Off-Camera Cord OC-E3

Flash Screw

Flash Cord Here

Nikon SC-17

Nikon SC-28

Flash Cord Here

Flash Cord Here

Nikon SC-29

Attaching your ash cord to the FCN

Using the ash lock on the

Digital PRO-M, Digital PRO, QRS-H2, QRS-E2, QRS-2

The ash lock knob will lock the ash in any tilt position desired.

1 - Loosen the ash lock knob, tilt the ash to the desired position. Then retighten the ash lock knob.

Digital PRO-M &

Digital PRO Bottom Upright

Flash lock knob

Flash receiver

QRS-H2, QRS-E2

& QRS-2 Upright

**QRS-2 not shown

Flash lock knob

Flash receiver

Attaching the ash plate (FCN) to the bracket

Loosen the ash receiver knob. Slide the ash

plate onto the ash receiver until it stops. Then

retighten the ash receiver knob.

(Shown with Nikon SC-17 cord)

Flash receiver

Flash receiver knob

Flash plate

Attaching your ash cord to the Digital PRO-E

Use the steps below to set your anti-twist plates (rst time installation only).

Attaching accessories (AP, MC, FT-JR)

Figure #19

Figure #14

MC

MC attached

to AP

MC

FT-JR

FT-JR

AP

MC

AP

AP

Figure #18

Figure #17

Figure #15

Figure #16

MC

Digital PRO-M (gure #15, #17)

Digital PRO-E (gure #19)

QRS-H2 and QRS-E2 (gure #14)

QRS-2 (gure #14) (Shown from back)

AP

Digital PRO-M (gure #16, #17)

Digital PRO-E (gure #19)

QRS-H2 and QRS-E2 (gure #14)

QRS-2 (gure #14) (Shown from back)

FT-JR

Digital PRO-M (gure #18)

Digital PRO-E (gure #19)

Important information for Digital PRO-M and Digital PRO

For a period of one year from date of purchase, Custom Brackets will repair or replace free of charge,

any defect in material or workmanship. Warranty does not cover repairs due to customer abuse,

negligence, impact or any modications made by the customer. Warranty service is available by

returning the Bracket (prepaid) to Custom Brackets. All returns must include a return authorization

(RA) number (contact Custom Brackets to obtain), letter explaining the problem, and a copy of the

sales receipt.

Repair service is available by returning the Bracket (prepaid) to Custom Brackets. All returns must

include a return authorization (RA) number (contact Custom Brackets to obtain) and letter explaining

the problem. A repair cost will be issued and must be approved prior to any repairs.

The Bracket was designed to be completely maintenance free. The rotation tension is factory set.

Adjusting the tension will void the warranty and may damage the bracket.

The adjustable upright has a safety stop installed to prevent the ash mounting plate from hitting the

top of the camera. If the upright lock knob is backed out, it will clear the safety stop and allow the

upright to be retracted completely into the grip for storage.

Warranty

Repair

Maintenance

The ash tilt has a lock knob for locking the angle of ash. When the lock knob is released, tilt the

ash to a different position. The tension of the tilt is factory set, adjusting it may cause damage to

the camera, ash, and / or bracket.

Important information for Digital PRO-M, QRS-H2, QRS-E2 and QRS-2

Canon off-camera cord II, Canon Cord 3, Nikon SC-17, Nikon SC-28, SC-29 Cords

1-

234-

Attach cord with screw, do not tighten completely (Nikon cords will be set in nal position in step 3).

**Canon cords come out front, Nikon cords come out left side (towards upright).

Slide right anti-twist plate (away from upright side) to cord and tighten anti-twist screw.

Remove cord (Canon users skip this step) and repeat step 1 with cord coming out right side.

Slide left anti-twist (upright side) to cord and tighten anti-twist screw.

Tighten ash screw to cord.

5-

MC

Loading...

Loading...