ASSEMBLY AND INSTALLATION

INSTRUCTIONS

A4S

20 / 15 / 10 MeterBeam

C O R P O R A T I O N

951279 (8/98)

A4S

WARNING

THIS ANTENNA IS AN ELECTRICAL CONDUCTOR. CONTACT WITH POWER LINES CAN RESULT IN DEATH, OR SERIOUS

INJURY. DO NOT INSTALL THIS ANTENNA WHERE THERE IS ANY POSSIBILITY OF CONTACT WITH OR HIGH VOLTAGE ARCOVER FROM POWER CABLES OR SERVICE DROPS TO BUILDINGS. THE ANTENNA, SUPPORTING MAST AND/OR TOWER

MUST NOT BE CLOSE TO ANY POWER LINES DURING INSTALLATION, REMOVAL OR IN THE EVENT PART OF THE SYSTEM

SHOULD ACCIDENTALLY FALL. FOLLOW THE GUIDELINES FOR ANTENNA INSTALLATIONS RECOMMENDED BY THE U.S.

CONSUMER PRODUCT SAFETY COMMISSION AND LISTED IN THE ENCLOSED PAMPHLET.

Your Cushcraft A4S Yagi antenna is designed and manufactured to give trouble free service. This antenna will perform as specified if the

instructions and suggestions in this manual are followed and care is used in the assembly and installation. When checking the components

received in your antenna package use the parts listed beside each diagram. There is a master parts list on page 2. If you are unable to locate

any tube or component, check the inside of all tubing. IMPORTANT: Save the weight label from the outside of the carton. Each antenna is

weighed at the factory to verify the parts count. If you claim a missing part, you will be asked for the weight verification label.

Plan your installation carefully. If you use volunteer helpers be sure that they are qualified to assist you. Make certain that everyone involved

understands that you are the boss and that they must follow your instructions. If you have any doubts at all, employ a professional antenna

installation company to install your antenna.

LOCATION

PLANNING

Location of the antenna is very important. Surrounding objects such as trees, power lines, other antennas, etc. will seriously reduce efficiency.

To minimize the effects of surrounding objects, mount the antenna as high and in the clear as possible. If metal guy wires are used, they should

be broken with strain insulators. EXTREME CARE MUST BE USED FOR YOUR SAFETY. YOU MUST INSURE THAT WHILE THE A4S IS

IN OPERATION NEITHER PEOPLE OR PETS CAN COME IN CONTACT WITH ANY PORTION OF YOUR ANTENNA. DEADLY VOLTAGES

AND CURRENTS MAY EXIST. ALSO, SINCE THE EFFECTS OF EXPOSURE TO RF FIELDS ARE NOT FULLY UNDERSTOOD, LONG TERM

EXPOSURE TO INTENSE RF FIELDS IS NOT RECOMMENDED. THERE IS A WARNING STICKER WHICH MUST BE ATTACHED TO THE

BOOM AS SHOWN IN FIGURE I.

MOUNTING

The mast mount bracket will accommodate up to a 2" (5.1 cm) mast. A 1-1/2" OD (3.8 cm) or larger heavy wall tubing mast should be used. A

good heavy duty antenna rotator will provide the best service and longest life. Often it is desirable to mount several antennas on one mast.

To keep possible interaction to a minimum, place your antennas as far apart as you can.

SYSTEM GROUNDING

Direct grounding of the antenna, mast and tower is very important. This serves as protection from lightning strikes and static buildup, and from

high voltage which is present in the radio equipment connected to the antenna. A good electrical connection should be made to one or more

ground rods (or other extensive ground system) directly at the base of the tower or mast, using at least #10AWG ground wire and non-corrosive

hardware. For details and safety standards, consult the National Electrical Code. You should also use a coaxial lightning arrester. Cushcraft

offers several different models, such as LAC-1, LAC-2 and the LAC-4 series.

ASSEMBLY

Assemble your antenna by following the directions and illustrations in steps 1 through 5. After the antenna is completely assembled, verify

dimensions and element spacings for accuracy. Then, return to the section below for final tuning.

Set the element lengths for the portion of the band you want to favor, by using Chart 1 and Figure B. Your A4S is now ready for use. Because

of variations in trap caps, the overall dimensions D-1, 2, 3, 4 may vary as much as 1 inch from the individual dimensions. This will not affect

performance. Always use the individual dimensions when adjusting your antenna.

You may check the VSWR in order to confirm assembly was done properly. The easiest place to check the antenna is likely to be in its final

mounting configuration. Orient the antenna such that it is pointing straight up. The back of the antenna should be at least 2 feet (.6 m) off the

ground.

Run the coax cable from your transmitter to the area in which the antenna is to be tested. The length of this cable or your feedline is not critical.

Connect a good quality VSWR bridge to the end of this cable. Connect a short length of cable [10 ft. (305 cm) or less] from the VSWR bridge

to the antenna under test. Set the transmitter to your center operating frequency and measure the VSWR while taking care not to effect the

measurement with your body. A VSWR of 2:1 or less is satisfactory and will not degrade the performance. If the VSWR is greater than 2:1,

check all dimensions and connectors.

ADD-ON KIT

Adding 30 or 40 meters to your A4S beam is a breeze with the spectacular A744 add on kit. Your'll be on the air quickly operating on your new

band because the A744 easily clamps to your A4S. You can operate on 40 meters or with a simple adjustment 30 meters.

The kit comes complete with reinforced insulator, teflon® proteced high power traps, all hardware and non-stretch lamcord® support line. Cushcraft

makes it easy to add more excitement to your hobby.

TUNING PROCEDURE

A4S

MASTER PARTS LIST

KEY PAR T# QTY

BA Aluminum tubing 2" x 72" x .058 drilled and 1

BB Aluminum tubing 2" x 75-1/4" x .058 swagged and drilled 2

one end

EA Aluminum tubing 1-1/8" x 72" (2.9 x 182.9 cm) drilled 1

EB Aluminum tubing 1-1/8" x 36" (2.9 x 91.4 cm) drilled one 2

EC Aluminum tubing 7/8" x 36" x .058 drilled for U-bolt slotted 1

ED Aluminum tubing 1" x 65" (2.5 x 165.1 cm) slotted 2

EE Aluminum tubing 1" x 46-1/2" (2.5 x 188.1 cm) slotted 2

EF Aluminum tubing 1" x 5-1/4" (2.5 x 13.3 cm) slotted 4

EG Aluminum tubing 1/2" x 35-7/8" ( 1.3 x 91.1 cm) 4

EH Aluminum tubing 3/4" x 48" (1.9 x 121.9 cm) slotted 2

EJ Aluminum tubing 5/8" x 48" (1.6 x 121.9 cm) 2

EK Aluminum tubing 1-1/8" x 24" (2.9 x 61.0 cm) drilled 1

EL Aluminum tubing 1-1/4" x 50" (3.2 x 127 cm) slotted 2

EM Aluminum tubing 1-1/8" x 72" (2.9 x 182.9 cm) slotted 2

EN Aluminum tubing 1" x 24" (2.5 x 61.0 cm) slotted 2

EP Aluminum tubing 1/2" x 48" (1.3 x 121.9 cm) 2

slotted both ends

for U-bolt, slotted both ends.

end, slotted both ends

both ends

one end

one end

both ends

one end

for U-bolt

both ends

one end

one end

KEY PART# QTY

TB 15 meter director trap 2

TC 15 meter driv. & refl. trap 4

TD 10 meter driv. trap 2

TE 10 meter director trap 2

11 010011 #8-32 hex nut 6

27 050027 5/8" Black plastic cap 2

41 011941 #8 Split lock washer 6

53 050053 1/2" Black plastic caps 6

63 170063 2-1/2" Machined aluminum V-blocks 4

95 122095 1" x 10" O.D. Fiberglass insulator drilled for U-bolt 1

99 050099 2" Black plastic caps 2

118 010118 5/16" (.8 cm) hex nut 16

119 010119 5/16" (.8 cm) lock washer 16

123 010123 #8-32 x 1-1/2" (3.8 cm) machine screw 2

130 190130 6" x 6" Aluminum mounting plate 1

156 190156 2" x 1-1/8" Formed aluminum brackets 4

232 010232 8-32 x 2-1/2" (6.4 cm) Round head slotted machine screw 2

326 290326 Danger label 1

404 010404 2 1/8" x 3" (5.4 x 7.6 cm) U-bolt 4

405 010405 2 1/8" x 4" (5.4 x 10.2 cm) U-bolt 4

409 030409 11/16" (1.7 cm) Worm clamp 8

410 030410 1" (2.5 cm) Worm clamp 16

411 030411 1-1/8" (2.9 cm) Worm clamp 8

412 030412 1-1/2" (3.8 cm) Worm clamp 4

414 030414 2-1/4" (5.7 cm) Worm clamp 2

453 100453 Terminal 2

and element screw

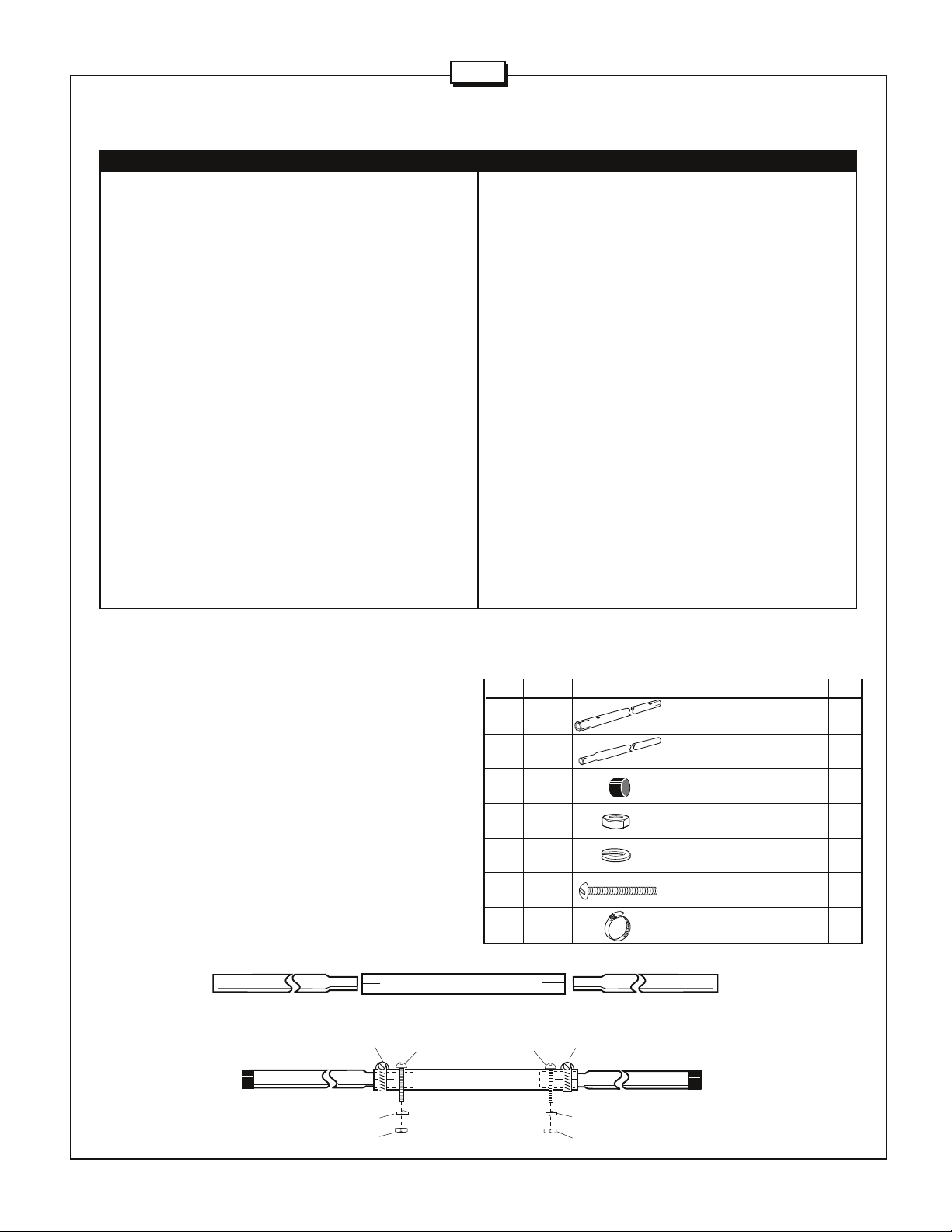

#1 - BOOM ASSEMBLY

Place worm clamps (414) over the slotted endes of tube BA. Slide

both BB sections into BA (Figure A). Rotate them as required to align

the holes for the 2-1/2" screws (232). Place the lock washer (41) and

the hex nut (11) on the screws and tighten them. Tighten the worm

clamps. Place the plastic caps (99) on the ends of the boom assembly.

FIGURE

A

BB

414

BB

99

232

KEY P/N DISPLAY DESC SIZE QTY

BA ALUM 2" x 72" 1

BB ALUM 2" x 75-1/4" 2

99 050099 PLASTIC 2" 2

11 010011 HEX 8-32 2

41 011941 SPLIT LOCK #8 2

232 010232 MACHINE 8-32 x 2-1/2" 2

414 030414 WORM 2-1/4" 2

BA

BA

232

414

BB

TUBE (5.1 x 182.9 cm)

TUBE (5.1 x 191.1 cm)

CAP (5.1 cm)

NUT

WASHER

SCREW (6.4 cm)

CLAMP (5.7 cm)

BB

99

41

11

41

11

EB

95

41

11

123

A4S

A4S

#2 Element Assembly

Assembly of elements is straight forward as shown in

Figure B. Arrows on the traps point to the center of the

element. Element #3 has a fiberglass insulator at its

center which is joined to tubes EB with a worm clamp

(411) and pinning screws (123) as shown in Figure C.

Set dimensions to the desired band using Chart 1 and

Chart 2. Tighten all clamps.

FIGURE C

#1 Reflector

B1 C1 D1 A2 D2 A3 B3 C3 D3 A4 B4 C4 D4

Phone

Center

CW

125-1/2" 46-1/2" 30' 8-1/4" 106-1/2" 17' 9" 78" 5-3/4" 38-1/4" 24' 2-1/2" 72-1/2" 7" 34-3/4" 22' 10-3/4"

3.188 m 1.181 m 9.354 m 2.705 m 5.41 m 1.981 m 14.6 cm 97.2 cm 7.379 m 1.842 m 17.8 cm 88.3 cm 6.979 m

128" 46-1/2" 31' 1-1/4" 107 1/2" 17' 11" 79" 5-3/4" 38-1/4" 24' 5-1/2" 74-1/2" 7" 34-3/4" 23' 3"

3.251 m 1.181 m 9.481 m 2.73 m 5.46 m 2.007 m 14.6 cm 97.2 cm 7.455 m 1.892 m 17.8 cm 88.3 cm 7.087 m

129-1/2" 46-1/2" 31' 4-1/2" 108-1/2" 18' 1" 82-1/2" 6-3/4" 38-1/4" 25' 1-1/2" 76-1/2" 7-1/2" 34-3/4" 23' 8"

3.289 m 1.181 m 9.563 m 2.756 m 5.51 m 2.09 m 17.1 cm 97.2 cm 7.658 m 1.943 m 19.0 cm 88.3 cm 7.214 m

#1

53

#3

#4

#2 Reflector

FIGURE B

D1

EP

C1

409

TC

EN

EM

B1

412

EL

412

EK

412

EL

411410

412

B1

EM

411 410

EN

TC

D2

#2

A2

409

EJ

27

EH

410

410

EC

EH

A2

409

EJ

27

D3

C3

EF

410

TD

410

409

TC

EG

53

410

ED

A3

411

EB

411

411

95

EB

A3

411

410

ED

B3

410

TD

B3

EF

410

TC

D4

B4

411

A4

EE

410

C4

EF

EG

53

409

TB

410

TE

410

410

EE

A4

411

EA

Center

Line

Chart 1

#3 Driven Element

#4 Director

B4

EF

TE

410

410

TB

409

Chart 2

BAND 20M 15M 10M

Phone 14.25 21.325 28.60

Center 14.170 21.275 28.40

CW 14.10 21.15 28.15

C1

EP

409

53

C3

EG

409

53

C4

EG

53

Center Frequency

(MHz)

KEY P/N DISPLAY DESC SIZE QTY

EA ALUMINUM 1-1/8" x 72" 1

EB ALUMINUM 1-1/18" x 36" 2

EC ALUMINUM 7/8" x 36"" 1

ED ALUMINUM 1" x 65" 2

EE ALUMINUM 1" x 46-1/2" 2

EF ALUMINUM 1" x 5-1/4" 4

EG ALUMINUM 1/2" x 35-7/8" 4

EH ALUMINUM 3/4" x 48" 2

EJ ALUMINUM 5/8" x 48" 2

EK ALUMINUM 1-1/8" x 24" 1

EL ALUMINUM 1-1/4" x 50" 2

EM ALUMINUM 1-1/8" 72" 2

EN ALUMINUM 1" x 24" 2

EP ALUMINUM 1/2" x 48" 2

TB DIRECTOR 15 METER 2

TC DRIV & REFL 15 METER 4

TD DRIV. 10 METER 2

TE DIRECTOR 10 METER 2

11 010011 HEX #8-32 2

27 050027 BLK PLASTIC 5/8" 2

41 011941 SPLIT LOCK #8 2

53 050053 BLK PLASTIC 1/2" 6

95 122095 FIBERGLASS 10" 1

123 010123 SS MACHINE 8-32 x 1-1/2" 2

409 030409 SS WORM 11/16" 8

410 030410 SS WORM 1" 16

411 030411 SS WORM 1-3/8" 8

412 030412 SS WORM 1-1/2" 4

TB

TC

TD

TE

TUBING (2.9 x 182.9cm)

TUBING (2.9 x 91.4cm)

TUBING (2.2 x 91.4cm)

TUBING (2.5 x 165.1cm)

TUBING (2.5 x 188.1cm)

TUBING (2.5 x 13.3cm)

TUBING (1.3 x 91.1cm)

TUBING (1.9 x 121.9cm)

TUBING (1.6 x 121.9 cm)

TUBING (2.9 x 121.9 cm)

TUBING (3.2 x 127 cm)

TUBING (2.9 x 189.9 cm)

TUBING (2.5 x 61.0 cm)

TUBING (1.3 x 121.9 cm)

TRAP

TRAP

TRAP

TRAP

NUT

CAP (1.6 cm)

WASHER

CAP (1.3 cm)

INSULATOR (2.54 cm)

SCREW (3.81)

CLAMP (1.7 cm)

CLAMP (2.5 cm)

CLAMP (3.5 cm)

CLAMP (3.8 cm)

3

4

A4S

KEY P/N DISPLAY DESC SIZE QTY

118 010118 SS HEX 5/16" 8

119 010119 SS LOCK 5/16" 8

156 190156 ALUMINUM 2" X 1-1/8" 4

405 010405 U-BOLT 2-1/8" x 4" 4

FIGURE D

NUT (.8 cm)

WASHER (.8 cm)

BRACKET (5.08 X 2.86 cm)

(5.4 x 10.2cm)

(5.1 cm)

2"

Important: Drain holes in traps

should all be facing the ground

TC

TD

#3 - ELEMENT MOUNTING

Attach elements according to Figures E and F. Check all dimensions

for proper placement of elements on the boom. Level the elements

and tighten all the nuts on the U-bolts that hold the elements on the

boom. See Figure G for fine tuning the level of the elements. Check

all traps to make sure that the arrows are pointed towards the boom

and the drain holes are facing the ground so that moisture will not

build up in the traps.

TCTC

108"

(2.73m)

TD

TC

1

40 "

2

(102.8 cm)

1

76 "

2

(194.3 cm)

156

FIGURE E

Boom

119

118

1

94 "

2

(240.0 cm)

TB

TE

TE

TB

FIGURE F

405

118

119

Element

156

BOOM

BOOM

405

ELEMENT

95

119

118

FIGURE G

ELEMENT

ELEMENT

A4S

#4 - R F CHOKE

A feedline should be prepared as shown in Figure H using the

solder terminals (453) provided. A 1:1 balun may be installed

at the feedpoint but it is not required. We recommend using

an RF choke made from 8 turns of RG8U coaxial cable with 6

inch (15.2 cm) diameter.

coax for your RF Choke because when the coax is wound in

a coil the center conductor may migrate away from the center

and detune your choke.

element using washers (41) and nuts (11) as shown in Figure

H. Be sure to tape and seal the feedline against water at the

point where the center dielectric and braid separate. Tape the

feedline, between the feedpoint and the RF choke to the boom.

T ape the RF choke to the mast. If you plan to install the antenna

in a salty or corrosive environment, you may want to consider

coating all elements with a clear marine varnish or its equivalent

after it is assembled.

KEY P/N DISPLAY DESC SIZE QTY

11 010011 HEX #8-32 2

41 011941 SPLIT LOCK #8 2

453 100453 TERMINAL 2

Important- Do not use foam dielectric

Attach th RF choke to the driven

NUT

WASHER

453

FIGURE H

BOOM

453

41

11

Electrical

T ape

41

11

4"

(10.16 cm)

Electrical

T ape

Warning: Do not use foam

dielectic coax cable.

8 Turns

6"

(15.2 cm)

#5 - BOOM TO MAST ASSEMBLY

KEY P/N DISPLAY DESC SIZE QTY

63 170063 V-BLOCK 2" 4

118 010118 HEX 5/16" 8

119 010119 LOCK 5/16" 8

404 010404 U-BOLT 2-1/8 x 3" 4

130 190130 MOUNTING 3/16" x 6" x 6" 1

326 290326 DANGER 1

(fits 404 U-Bolt) (5.1 cm)

NUT (.8 cm)

WASHER (.8 cm)

(5.4 x 7.6 cm)

PLATE (.48 x 15.2 x 15.2 cm)

LABEL

Attach the boom to your mast as shown in Figure I. First attach the

mounting plate (130) to the BA section of the boom using U-bolts

(404), washers (119), nuts (118), and V-blocks (63). Attach the

mounting plate to the mast using the U-bolts (404), V-block (63),

washers(119) and nuts (118). Return to the tuning section on page

1 for final checkout and tuning procedure.

118

MAST

FIGURE I

119

63

130

119

118

119

119

63

404

118

119

63

404

118

119

63

326

404

118

118

SPECIFICATIONS

Model A4S

Frequency Ranges 28, 21, 14

Forward Gain, dBd 8.9

Front to Back Ratio, dB 25

2:1 Bandwidth KHz >500

Power Rating, Watts PEP 2000

3 dB Beam Width, Deg. E Plane 58

Boom Length 18(5.48)

Boom Diameter, In (cm) 2 (5.10)

Longest Element, ft (m) 32 (9.75)

Element Center Dia, In (cm) 1.25 (3.18)

Turning Radius, ft (m) 18.4 (5.49)

Mast Size Range, In (cm) 1.25-2 (3.18-5.08)

Wind Load, ft

Weight, lb (kg) 37 (16.8)

2

2

(m

) 5.50 (0.51)

Cushcraft Corporation, P.O. Box 4680, Manchester, New Hampshire 03108, warrants to the original purchaser for one year

LIMITED WARRANTY

from date of purchase that each Cushcraft antenna is free of defects in material or workmanship. If, in the judgement of

Cushcraft, any such antenna is defective, then Cushcraft Corporation will, at its option, repair or replace the antenna at

its expense within thirty days of the date the antenna is returned (at purchasers expense) to Cushcraft or one of its

authorized representatives. This warrranty is in lieu of all other expressed warranties, any implied warranty is limited in

duration to one year. Cushcraft Corporation shall not be liablefor any incidental or consequential damages which may

result from a defect. Some states do not allow limitations on how long an implied warranty lasts or exclusions or limitations

of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. This warranty does not extend

to any products which have been subject the misuse, neglect, accident or improper installation. Any repairs or alterations

outside of the Cushcraft factory will nulify this warranty.

C O R P O R A T I O N

TELEPHONE: 603-627-7877 • FAX: 603-627-1764 • E-mail: techsup@cushcraft.com

48 PERIMETER ROAD, MANCHESTER, NH 03108 USA

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Loading...

Loading...