Curtron CFD-TQ-2-36-1, CFD-TQ-2-42-1, CFD-TQ-2-48-1, CFD-TQ-2-60-1, CFD-TQ-3-60-1 Installation Manual

...Page 1

800•833•5005

Curtron Products • 5350 Campbells Run Road • Pittsburgh, PA 15205-9738 • 412.787.9750

• Fax: 412.787.3665 • Web Site: www.curtronproducts.com • E-Mail: info@curtronproducts.com

OTHER

CURTRON

PRODUCTS

POLAR-PRO™

SWINGING DOORS

CASER

COOLER CURTAINS

CURTRONIZER

™

STRIP DOORS

TEMP KEEPERS™

COOL KEEPERS

™

STRIP DOORS

Make Food Products

Your Number One Priority!

RACK COVERS

MODEL ENCLOSED:

❏ CFD-TQ-2-36-1

❏ CFD-TQ-2-42-1

❏ CFD-TQ-2-48-1

❏ CFD-TQ-2-60-1

❏ CFD-TQ-3-60-1

❏ IBD-TQ-2-36-1

❏ IBD-TQ-2-42-1

❏ IBD-TQ-2-48-1

❏ IBD-TQ-2-60-1

❏ IBD-TQ-3-60-2

❏ CFD-HH-2-36-1-3S

❏ CFD-HH-2-42-1-3S

❏ CFD-HH-2-48-1-3S

❏ CFD-HH-2-60-1-3S

❏ CFD-HH-3-60-1-3S

INSTALLATION INSTRUCTIONS

AIR DOORS

Make Food Products

Your Number One Priority!

Copyright © 2007 Curtron Products Catalog No. CFD/IBDAD 06-07

Page 2

2

3

Thank you for choosing a Curtron quality product.

UNCRATING

Carefully examine the carton(s) for damage before opening. If the carton is

damaged, immediately notify the shipping company.

• Remove all protective packaging.

• Remove the cover housing by lifting vertically.

Enclosed is a packet of self-tapping screws which will be used to attach the

cover housing to the mounted chassis.

CAUTION: LIFT THE UNIT BY GRASPING THE INLET RINGS ON THE

BLOWER HOUSING WITHOUT TOUCHING THE BLOWER WHEELS.

Excess weight on the blower wheels may cause improper alignment and balance of the motor shaft and blower wheels.

WARNING:TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you

have any questions, contact the manufacturer.

B. Before servicing or cleaning unit, switch power off at the service panel

and lock service panel to prevent power from being switched on accidentally.

C. Installation work and electrical wiring must be done by a qualified person

in accordance with all applicable codes and standards, including firerated construction.

D. When cutting or drilling into wall or ceiling, do not damage electrical wiring

and other hidden utilities.

E. Do not operate this fan with any solid state speed control device.

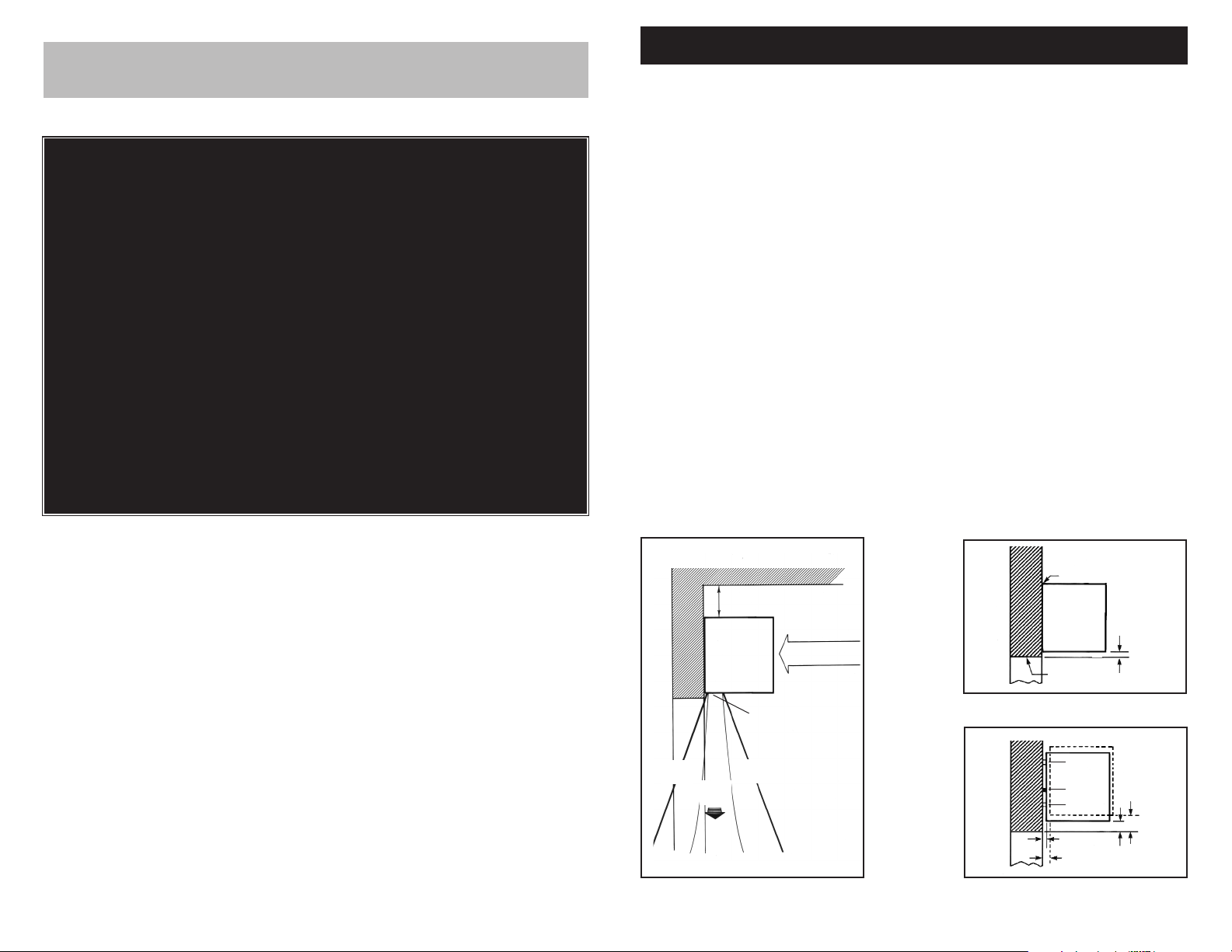

INDOOR AND OUTDOOR MOUNTING FOR CURTRON AIR DOORS

INDOOR MOUNTING - Environmental/Insect/ Dust Control

OUTDOOR MOUNTING - Insect/ Dust Control

NOTE: The air door is weatherproof; therefore, no special covering is required

for outdoor mounting.

IMPORTANT: A minimum of 4” is required above the top of the air door for the

installation and removal of the cover housing.

1. Install the air door so that nothing interferes with the air stream when it is

deflected 20° to either side. If the air stream strikes any obstruction, for

example, the top edge of the doorway, a structural beam or a door opening

device, its efficiency will be reduced. See Figure 1. On electrically heated

units there should be a minimum clearance of at least 4” between the side

of the unit and any combustible material, if the unit is enclosed in the ceiling

or a decorative cover.

2. The outlet nozzle should be no more than 1” above the top of the doorway

opening. See Figure 2A.

If the air door must be mounted higher, then it should be spaced out from

the wall 3/8” for every inch the unit is moved up above the doorway opening. Any void between the air door and the wall must be sealed (use foam,

plastics or similar packing) for best performance. See Figure 2B.

Figure 1

Figure 2B

Figure 2A

FLUSH MOUNT

AIR

DOOR

1”

TOP OF

DOORWAY

3”

2”

SPACER

SEAL

SPACER

3/8”

3/4”

4” MINIMUM SPACE REQUIRED

AIR INTAKE

AIR

DOOR

AIR

FLOW

MAX.

20°

MAX.

20°

OUTLET NOZZLE

Page 3

4

5

MOTOR /BLOWER MOUNTING

Drill and install the mounting hardware (supplied by others). The keyhole slots in the backplate accommodate 1/4” mounting hardware.

See Figure 4.

3. Do not fully tighten the mounting screws.

4. Lift the motor/blower assembly by the sheet

metal frame over the door with the outlet

nozzle facing down. DO NOT LIFT BY THE

BLOWER WHEELS.

5. Slip the motor/blower

assembly over the 4

mounting screws.

6. Tighten the 4 mounting screws for a

secure attachment.

See Figure 5.

7. Replace cover with

sheet metal screws.

AIR DOOR

BACKPLATE

8 KEYHOLE

MOUNTING SLOTS

Figure 3

Select and mark two vertical holes on each end of the backplate. See Figure 3.

The mounting holes and hardware must be capable of supporting a minimum

of three times the net weight of the air door.

See Table 1.

If sufficient support is not available, go to Optional Mounting.

AMBIENT ELECTRIC

MODEL NET WEIGHT NET WEIGHT

LBS. LBS.

TABLE 1

CFD-TQ-2-36-1 70 75

CFD-TQ-2-42-1 80 85

CFD-TQ-2-48-1 82 87

CFD-TQ-2-60-1 97 102

CFD-TQ-3-60-1 110 115

1/4”

1/4”

Figure 5

LINE-UP KEYHOLES ON

ALL 4 SCREWS

PUSH

BACKPLATE

TOWARD WALL

SLIDE BACKPLATE DOWN

TIGHTEN ALL

4 SCREWS

If the location of the keyhole slots on the backplate do not provide suitable

support, locate and mark the best alternative location on the wall.

Transfer the marks to the backplate of the air door.

Before drilling holes in the backplate of the air door, check to make sure the

new holes will not interfere with the internal components of the air door.

Drill the 4 holes in the wall and 4 holes in the backplate.

Lift the motor/blower assembly by the sheet metal frame over the door with

the outlet nozzle facing down. DO NOT LIFT BY THE BLOWER WHEELS.

Install the 4 mounting screws (supplied by others).

OPTIONAL MOUNTING

ELECTRIC WIRING

CAUTION: Electrical Shock Hazard

Disconnect power source whenever working on unit. WARNING: To

reduce risk of fire or electric shock, DO NOT use this fan with any

solid state speed control device.

1. Make sure the correct voltage, as marked on the unit, is used.

2. Connect the proper size conductor wire (supplied by others) to the pigtail

leads in the junction box.

See Figure 6. For motor amp ratings see Table 2.

3. Connect conductor wire to power source.

4. An optional knock-out is supplied on the left-hand side of the cover housing to connect wiring from the left-hand side.

Figure 6

Table 2

Weights are the same for comparable

length units in CFD-HH and IBD-TQ Series

Figure 4

JUNCTION BOX

Standard Amps for Amps for

Motor Voltages1/2 Motor3/4 Motor

120, 1ø, 60 hz 7.2 7.5

208, 1ø, 60 hz 4.0 3.8

240, 1ø, 60 hz 4.0 3.8

460, 1ø, 60 hz N/A 1.8

Page 4

6

The heater circuit may be controlled by a remote

thermostat or a remote mounted three position fan only/off/fan with heat. See Figure 7.

Connect the proper wires (located in the junction

box) to the terminals of the thermostat or three

position switch. See wiring diagram located in

the inside of the cover housing. See Figure 8.

Overheating protection is provided by thermal

cutouts built into the heater coil assembly.

ELECTRICALLY HEATED MODELS

Remote Thermostat Or

Remote Three Position

Switch

Figure 7

Figure 8

IMPORTANT: All electrical wiring

should be performed by qualified

personnel and done in accordance

with local codes and regulations.

CAUTION: Disconnecting more than one power supply

may be required to de-energize the unit.

Table 3

Aluminum

Cover Housing

Bottom 4

Housing

Screws

Motor/Blower

Assembly

Power

Source

Wires

Top 4 Housing Screws

AMP DRAW OF ELECTRIC HEAT

Voltage

7.5 kw 10 kw 15 kw

208v 1ø - 60 hz 36.1 48.0 72.0

240v 1ø - 60 hz 31.4 41.7 62.5

208v 3ø - 60 hz 20.9 27.8 41.6

240v 3ø - 60 hz 18.1 24.1 36.1

480v 3ø - 60 hz 9.0 12.0 18.0

Note: When amp draw of motors and heaters are in

excess of 48 amps, two power supplies are required.

7

AIR DIRECTIONAL VANES ADJUSTMENT

AIR FLOW ADJUSTMENTS

Adjustment of the air directional vanes may be made by grasping each vane with

pliers or channel locks and twisting. It is recommended to place a rag or newspaper between the plier jaws and the vanes to prevent scratching.

If the vanes will not twist with a pair of pliers, it may be necessary to remove the

cover housing and loosen the 2 vane mounting screws located on each end of the

outlet nozzle. ALWAYS DISCONNECT THE POWER SOURCE BEFORE

REMOVING THE COVER.

1. With the air door operating and door in its full open position, check to

see that nothing is obstructing the air flow at the discharge nozzle.

2. Find the air stream split location. Hold a handkerchief, by the corner,

approximately 12” above the floor. Gently move the handkerchief back

and forth in the doorway. Make sure the air is being directed to both the

inside and outside. See Figure 9. The split location is indicated when the

handkerchief is vertical with minimal or no fluttering. See Figure 9.

3. FOR INDOOR MOUNTING - The split location should be approximately

3” outside the doorway and 12” above the floor. See Figure 10.

4. FOR EXTERIOR MOUNTING - The split location should be approxi-

mately 6” outside the doorway and 12” above the floor. See Figure 11.

OUTSIDE INSIDE

12” Minimum

Figure 9 Figure 10

Figure 11

INSIDE

INSIDE

OUTSIDE

OUTSIDE

12” Above

Floor

12” Above

Floor

3”

6”

Page 5

8

OPTIONAL CONTROLS

If an automatic door switch (rated at 22 amps) or a start/stop push button station (rated at 24 amps) is used, refer to the wiring diagram found on the inside

of the housing for proper wiring.

CAUTION: disconnect the main power supply before installing the cover.

When the installation of the motor/blower section and wiring is complete, slide the

cover over the assembly and fasten with the 8 screws that are provided: 4 on the

top and 4 on the bottom. finally, connect the main power supply. See Figure 8.

WARNING: The motor has internal self-resetting thermal overload protection. Always disconnect the power source before servicing.

MOTOR /BLOWER WHEEL ASSEMBLY/COVER HOUSING

To keep your Curtron Air Door operating at peak efficiency, semi-annual

cleaning of the blower wheels and cover housing is recommended. The

housing can easily be removed for access to the motor/blower assembly by

removing the cover housing screws. See Figure 8. Remove dust and dirt

build-up from the blower wheels and housing. The motor is totally enclosed

and permanently lubricated, and does not require any additional lubrication.

Re-install the cover housing and housing screws after maintenance is complete.

ALUMINUM AIR FILTER

Every Curtron Air Door comes with a built-in re-usable Aluminum Air Filter

which should be cleaned twice a year. Simply remove the intake grill mounting screws and detach the grill from the cover housing. The filter can then

be easily lifted out of the frame. Clean with soap and water and allow to dry

before placing the filter back into the frame. Replace the intake grill and

mounting screws. See Figure 12.

NOTES:

MAINTENANCE AND CLEANING

Model No.

Serial No.

Date of Purchase

INTAKE GRILL

MOUNTING

SCREWS

INTAKE GRILL

MOUNTING SCREWS

INTAKE GRILL

RE-USABLE

ALUMINUM AIR FILTER

COVER

HOUSING

Figure 12

Loading...

Loading...