Curtis Instruments PMC 1200, PMC 1209B, PMC 1221C, PMC 1231C, PMC 1221B Series Manual

1209B/1221B

1221C/1231C

© 1999 CURTIS INSTRUMENTS, INC.

DESIGN OF CURTIS PMC 1200 SERIES

CONTROLLERS PROTECTED BY U.S.

PATENT NO. 4626750.

MOTOR CONTROLLERS

1209B/1221B/1221C/1231C Manual

p/n 98827, Rev. D: August 1999

MANUAL

CURTIS PMC

235 East Airway Boulevard

Livermore, California 94568 USA

Tel: 925-961-1088

Fax: 925-961-1099

www.curtisinst.com

1209B / 1221B / 1221C / 1231C Manual

p/n 98827, Rev. D: August 1999

© 1999 CURTIS INSTRUMENTS, INC.

This electronic version of the 1209B/1221B/1221C/1231C manual is offered as a

convenience to our customers. You may download any or all of it.

If you would like a hard copy of the published manual, please order it by part number from

the Curtis office nearest you.

The electronic version of the manual is identical to the printed version published in August

1999. Bookmarks have been added to the electronic version to speed the process of going

directly to a particular part of the document.

CURTIS INSTRUMENTS, INC.

200 KISCO AVENUE

MOUNT KISCO, NEW YORK 10549 USA

☎

914-666-2971 FAX 914-666-2188

■ CURTIS PMC

235 EAST AIRWAY BOULEVARD

LIVERMORE, CALIFORNIA 94550 USA

☎

925-961-1088 FAX 925-961-1099

■

ADDITIONAL OFFICES located in

Bulgaria, China, England, France, Germany,

India, Italy, Japan, Netherlands, Puerto Rico,

Russia, Sweden, and Switzerland

Curtis PMC 1209B/1221B/1221C/1231C Manual iii

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

234567890

1

CONTENTS

1. OVERVIEW .......................................................................1

2. HARDWARE INSTALLATION ....................................... 3

Controller .................................................................... 3

Throttle ........................................................................ 5

Other Hardware ...........................................................8

Main contactor ................................................... 10

Forward/reverse contactors .................................. 11

Forward/reverse switches ..................................... 11

Keyswitch and interlocks .....................................11

Keyswitch relay ................................................... 11

Polarity protection diode ..................................... 12

Control wiring fuse ............................................. 12

Power wiring fuse ................................................ 12

3. WIRING ........................................................................... 13

Connections: Low Current ......................................... 13

Connections: High Current ....................................... 13

Wiring: Typical Installation ....................................... 14

KSI wiring .......................................................... 15

Forward/reverse wiring ........................................ 16

Plug braking ................................................ 16

Freewheeling ................................................16

Throttle wiring ................................................... 17

Standard potbox wiring ...............................17

Pots for twist-grip throttles .......................... 18

Electronic throttle wiring ............................. 19

Reduced speed operation ............................. 20

Throttle ramp shaping ................................. 21

Installation Checkout ................................................. 22

CONTENTS

Curtis PMC 1209B/1221B/1221C/1231C Manual iv

CONTENTS

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

23456789

0

4. MAINTENANCE AND ADJUSTMENT ....................... 24

Controller .................................................................. 24

Potbox ........................................................................ 25

5. TROUBLESHOOTING AND BENCH TESTING ....... 27

Operational Notes ......................................................27

In-Vehicle Diagnostic Tests (Troubleshooting) .......... 28

Bench Testing ............................................................ 34

6. GLOSSARY: FEATURES AND FUNCTIONS .............. 37

APPENDIX A Functional Description ................................ A-1

APPENDIX B Pulse Width Modulation ............................. B-1

APPENDIX C Electrical Specifications ................................ C-1

Curtis PMC 1209B/1221B/1221C/1231C Manual v

FIGURES

FIG. 1: Curtis PMC 1209B full-feature

motor controller ......................................................... 1

FIG. 2: Mounting dimensions,

Curtis PMC 1209B/1221B/1221C controllers ........... 3

FIG. 3: Mounting dimensions,

Curtis PMC 1231C controller ................................... 4

FIG. 4: Mounting dimensions,

Curtis PMC potboxes PB-5, -6, -9, and -10 ............... 6

FIG. 5: Mounting dimensions, Curtis PMC footpedal ........... 6

FIG. 6: Mounting dimensions,

Curtis electronic throttle (ET series) ........................... 7

FIG. 7: Typical installation,

1209B/1221B/1221C controllers ............................... 8

FIG. 8: Typical installation, 1231C controller ........................9

FIG. 9: Basic wiring configuration,

1209B/1221B/1221C controllers ............................. 14

FIG. 10: Basic wiring configuration, 1231C controller ........... 15

FIG. 11: Control wiring for inhibiting plug braking,

in order to allow freewheeling .................................. 17

FIG. 12: Standard throttle pot, 0–5kΩ ................................... 17

FIG. 13: Bi-directional twist-grip throttle with

a standard 20 kΩ pot and a controller

with the optional 5kΩ–0 throttle input .................... 18

FIGURES

Curtis PMC 1209B/1221B/1221C/1231C Manual vi

FIGURES/TABLES

FIG. 14: Curtis electronic throttle (ET series)

with a controller having the optional

0–5V throttle input .................................................. 19

FIG. 15: Reduced speed operation (with standard

(0–5kΩ pot) ............................................................. 20

FIG. 16: Throttle ramp shapes ................................................21

FIG. 17: Adjustment pots ....................................................... 25

FIG. 18: Guide to troubleshooting procedures ....................... 29

FIG. 19: Setup for bench testing ............................................. 35

FIG. A-1: Block diagram, Curtis PMC

1209B/1221B/1221C/1231C controllers ............... A-1

FIG. B-1: Pulse width modulation.......................................... B-1

TABLES

TABLE 1: Recommended precharge resistors ......................... 10

TABLE C-1: Electrical specifications, 1209B/1221B ............... C-1

TABLE C-2: Electrical specifications, 1221C/1231C ............... C-2

Curtis PMC 1209B/1221B/1221C/1231C Manual

1

OVERVIEW

OVERVIEW

Curtis PMC Model 1209B/1221B and 1221C/1231C electronic motor speed

controllers are designed to provide smooth, silent, cost-effective control of motor

speed and torque on a wide variety of electric vehicles. The 1209B/1221B

controllers are designed primarily for material handling applications, and the

1221C/1231C controllers for on-road vehicles.

Like all Curtis PMC 1200 series controllers, the 1209B/1221B/1221C/1231C

models offer superior operator control of the vehicle’s motor drive speed. Key

features of these controllers include:

✓ Infinitely variable drive and brake control

✓ Power MOSFET design provides high efficiency (for reduced motor and

battery losses) and silent operation

✓ High pedal disable (HPD) function monitors throttle status during turn-on

and prevents operation until throttle has been returned to neutral [optional

feature]

✓ Thermal protection and compensation circuit provides both

undertemperature and overtemperature cutback, as well as steady current limit

throughout the entire operating range

More Features

☞

1

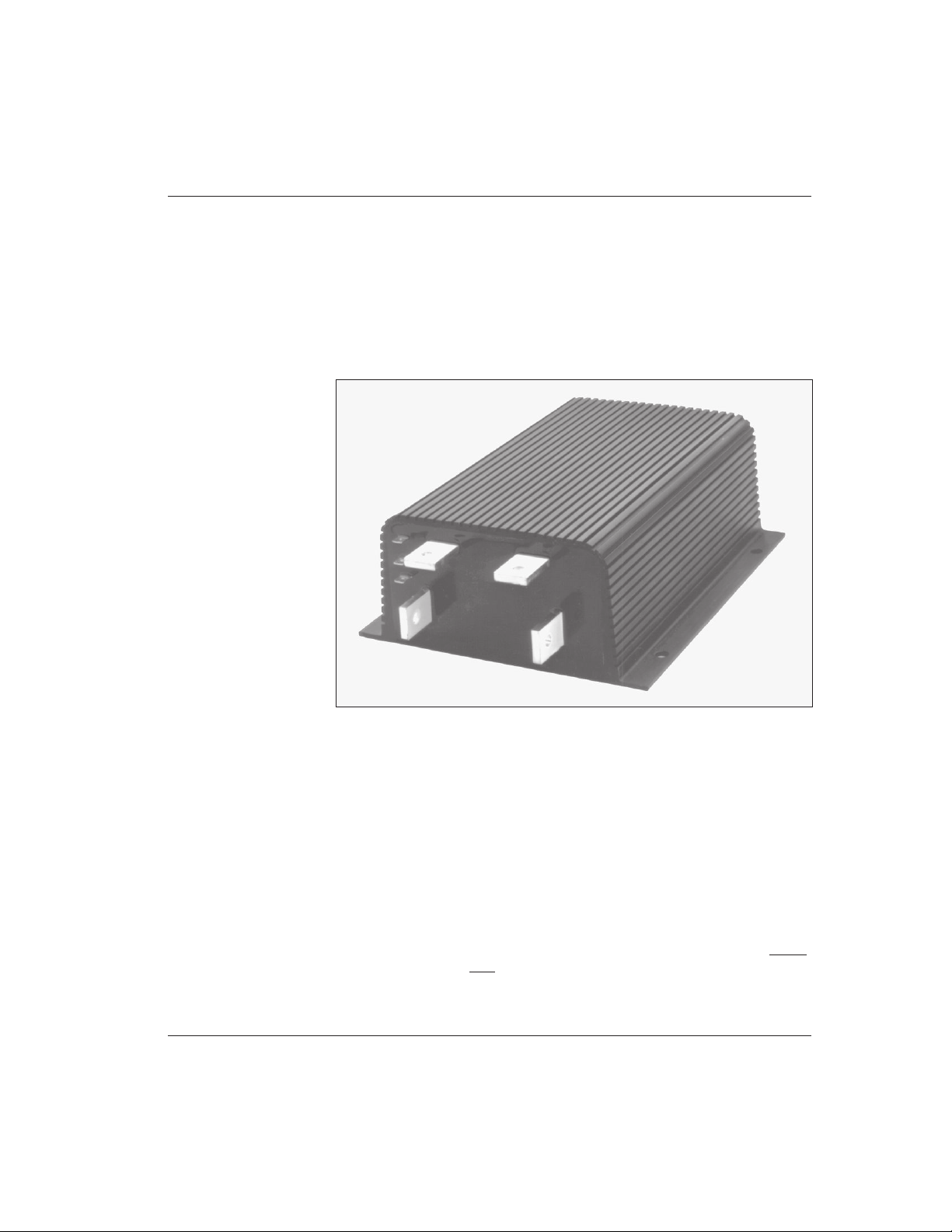

Fig. 1 Curtis PMC

1209B full-feature

electronic motor

controller.

Models 1221B, 1221C,

and 1231C have

similar external

connections.

Curtis PMC 1209B/1221B/1221C/1231C Manual

2

OVERVIEW

Working on electric vehicles is potentially dangerous. You should protect

yourself against runaways, high current arcs, and outgassing from lead acid

batteries:

RUNAWAYS — Some fault conditions could cause the vehicle to run out of

control. Jack up the vehicle and get the drive wheels off the ground before

attempting these procedures or any other work on the motor control

circuitry.

HIGH CURRENT ARCS — Electric vehicle batteries can supply very high power,

and arcs can occur if they are short circuited. Always open the battery circuit

before working on the motor control circuit. Wear safety glasses, and use

properly insulated tools to prevent shorts.

LEAD ACID BATTERIES — Charging or discharging generates hydrogen gas,

which can build up in and around the batteries. Follow the battery

manufacturer’s safety recommendations.

Wear safety glasses.

✓ Undervoltage cutback function protects against low battery voltage, includ-

ing low voltage caused by external loads

✓ Throttle pot fault circuitry shuts off the motor in the event of an open circuit

fault in the throttle or its wiring, to prevent runaway conditions

✓ Frequency shifting feature provides improved control of current limit at low

duty cycles [“C” models only]

✓ Simple installation with no adjustments required

✓ Tin-plated solid copper bus bars

✓ Push-on connectors for control wiring

Familiarity with your Curtis PMC controller will help you to install and operate

it properly. We encourage you to read this manual carefully. If you have

questions, please contact the Curtis office nearest you.

☞

C A U T I O N

Curtis PMC 1209B/1221B/1221C/1231C Manual

3

HARDWARE INSTALLATION

HARDWARE INSTALLATION

CONTROLLER

The controller can be oriented in any position, but the location should be

carefully chosen to keep the controller as clean and dry as possible. If a clean,

dry mounting location cannot be found, a cover must be used to deflect dirt

and water splash.

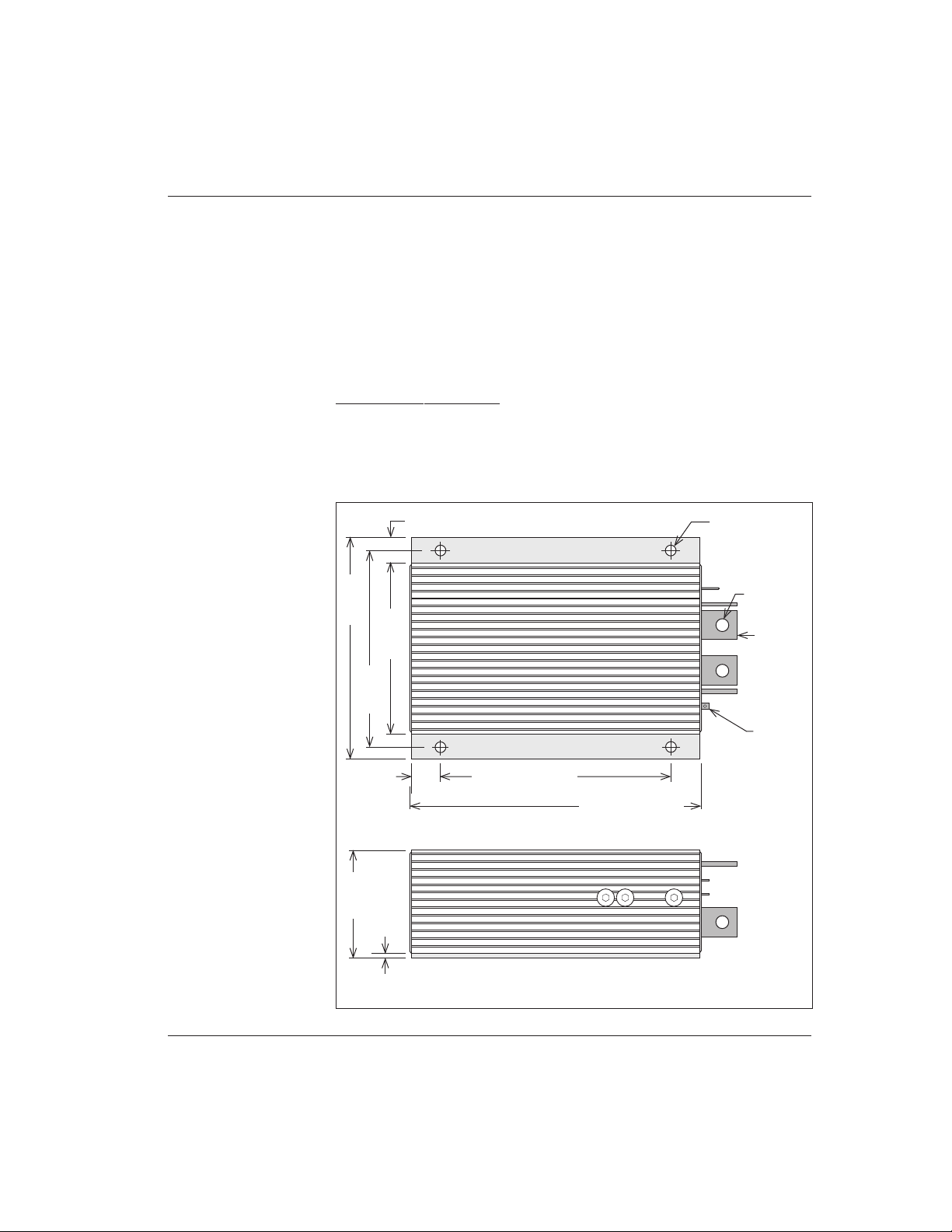

1209B, 1221B, and 1221C

The controller should be fastened with four screws to a clean, flat metal surface

that provides an adequate heat sink. The mounting surface is an integral part of

the overall heatsinking of the controller, and affects its ability to dissipate heat.

The case outline and mounting dimensions are shown in Figure 2.

2

Fig. 2 Mounting

dimensions, Curtis PMC

1209B/1221B/1221C

controllers.

6 (0.25)

male push-on,

2 plcs

7 (0.28) dia.

15 (0.60)

MODEL

1209:

231 (9.1)

MODEL

1221:

282 (11.1)

3.3

(0.13)

80 (3.15)

37 (1.45)

Dimensions in millimeters and (inches)

MODEL

1209:

152 (6.0)

MODEL

1221:

203 (8.0)

180 (7.1)

165 (6.5)

143 (5.6)

8.4 (0.33) dia.

25

×

19 × 5

(1.0

×

0.75 × 0.187)

Curtis PMC 1209B/1221B/1221C/1231C Manual

4

HARDWARE INSTALLATION

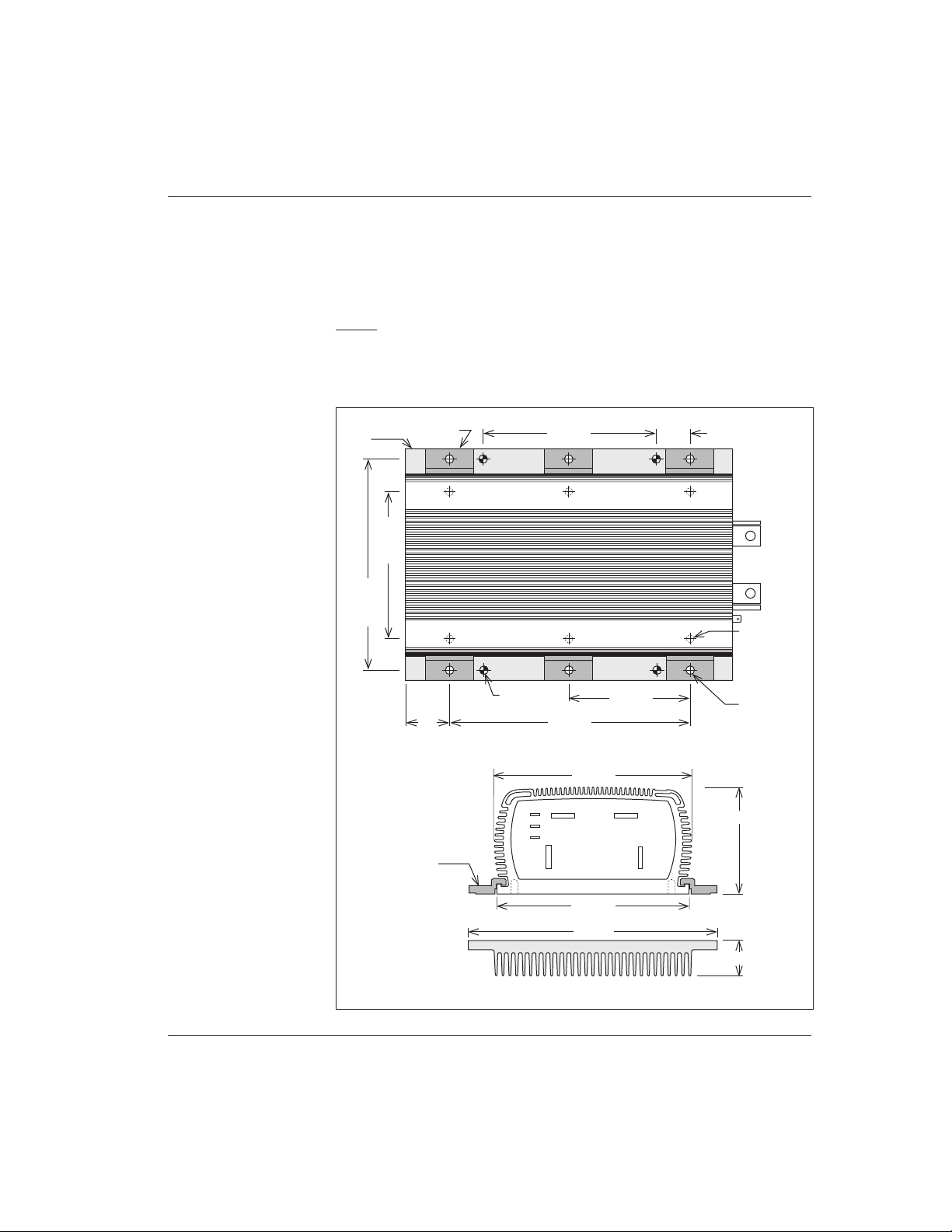

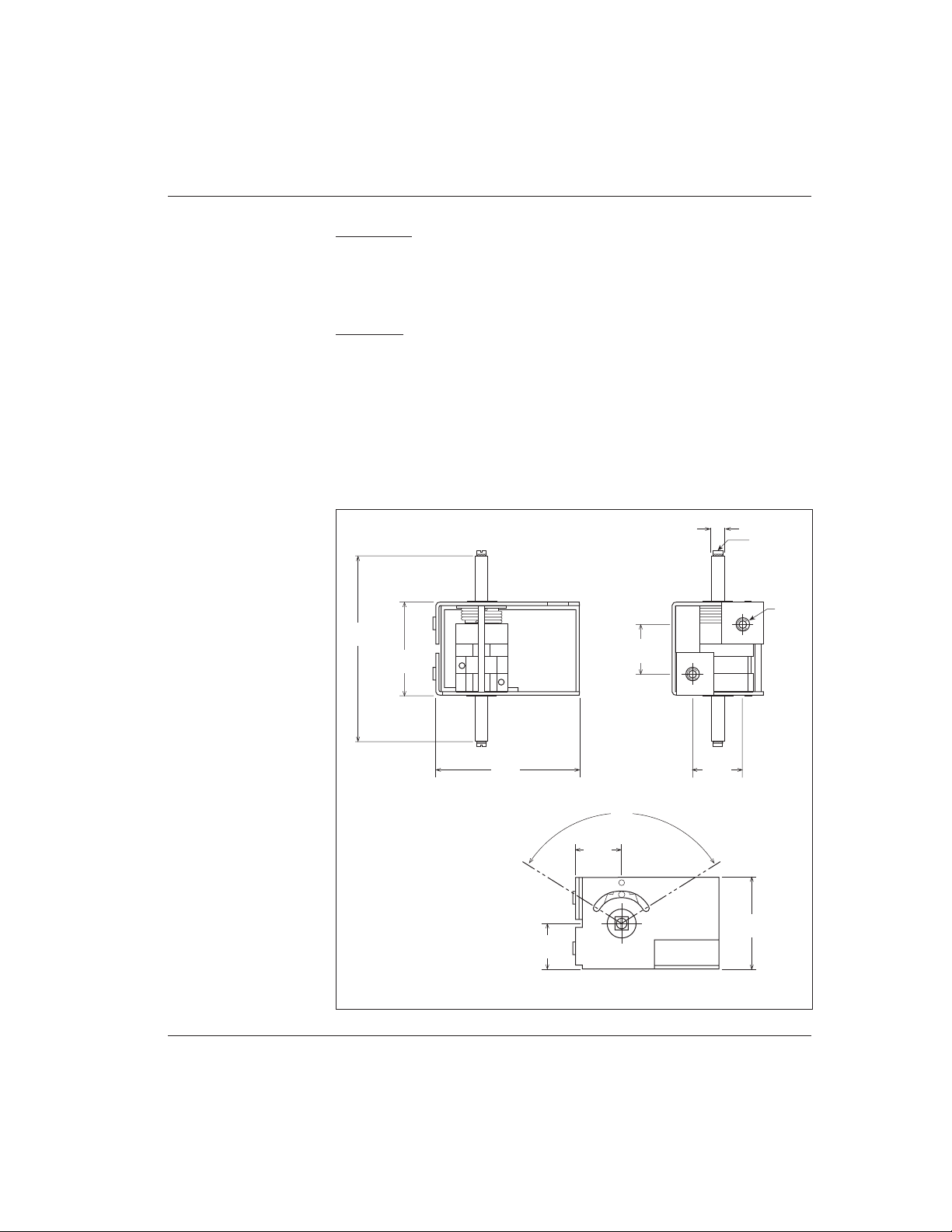

Fig. 3 Mounting

dimensions, Curtis PMC

1231C controller.

Be sure to mount the 1209B/1221B/1221C controller so as to allow access

to the adjustment screws. Although not usually necessary, a thermal joint

compound can be used to improve heat conduction from the case to the

mounting surface.

1231C

The controller should be fastened to a clean, flat metal surface that provides an

adequate heat sink. The mounting surface is an integral part of the overall

heatsinking of the controller, and affects its ability to dissipate heat.

B-

O P T I O N A L H E A T S I N K B A S E

B+

A2

M-

Dimensions in millimeters and (inches)

175 (6.9)

173 (6.8)

220 (8.6)

Mounting Clamp

(6 supplied)

94 (3.7)

Mounting

Clamp

(1/4-20 UNC),

6 places

(1/4-20 UNC)

×

8 (5/16),

6 places

229 (9.0)

114 (4.5)

165 (6.5)

32 (1.25)

200 (7.9)

140 (5.5)

Optional

Heatsink

Base

30 (1.2)

7 (9/32) dia.,

4 places

40

(1.6)

Curtis PMC 1209B/1221B/1221C/1231C Manual

5

HARDWARE INSTALLATION

Six mounting clamps are provided, which can be used to attach the control-

ler to its matching heatsink (Curtis PMC p/n 16421001) or to some other

surface. An alternative mounting method is provided by six tapped holes on the

bottom of the controller. The case outline, heatsink outline, and mounting

dimensions are shown in Figure 3.

Be sure to mount the 1231C controller so as to allow access to the adjust-

ment screws. Although not usually necessary, a thermal joint compound can be

used to improve heat conduction from the case to the mounting surface.

THROTTLE

0–5kΩ Input

The standard controller throttle input is 0–5kΩ. Curtis PMC potboxes (PB-5,

-6, -9, -10) are designed to match this input. Some of these potboxes have a builtin microswitch, eliminating the need to install a separate pedal-actuated

microswitch. Curtis PMC also offers a self-contained footpedal unit (FP-2) that

eliminates the need for fabricating and installing a pedal-potbox linkage. Mounting dimensions for the potboxes and for the footpedal unit are shown in Figures

4 and 5.

Any potbox that provides a nominal 0–5kΩ output (controller output

begins at ≈300 ohms, full output is ≈4400 ohms) will work with the standard

throttle input. For other types, contact your Curtis office.

If a Curtis PMC potbox is used, it must be mounted so as to allow

connection between the potbox lever arm and the vehicle accelerator linkage.

The lever arm provides a series of holes so that the accelerator pedal “throw” can

be converted into the correct amount of potentiometer rotation. Use of a second

return spring on the pedal, in addition to the potbox return spring, is required to

prevent an uncontrollable full-on throttle input (which could happen if there was

a single spring, and it broke). If the self-contained potbox spring is insufficient to

return the pedal by itself, two additional pedal return springs must be used.

It is also required that the accelerator pedal hit a mechanical stop at its full-

on position just before (≈1 mm [1/32"–1/16"]) the potbox lever hits its own fullon stop. This mechanical stop will prevent the potbox lever arm from bending if

undue force is put on the pedal. Protection of the potbox from water and dirt will

help avoid problems of corrosion and electrical leakage.

After the potbox has been mounted, operation of the pot can be tested by

measuring the resistance between the two wires with an ohmmeter. With the

pedal not applied, the resistance should be less than 50 ohms. As the pedal is

applied, the resistance should rise smoothly until it reaches a value between 4500

and 5500 ohms. Values below 4500 ohms may cause a reduction in efficiency

and top speed. Values above 7000 ohms indicate a defective potbox, and will

cause controller shutdown.

Curtis PMC 1209B/1221B/1221C/1231C Manual

6

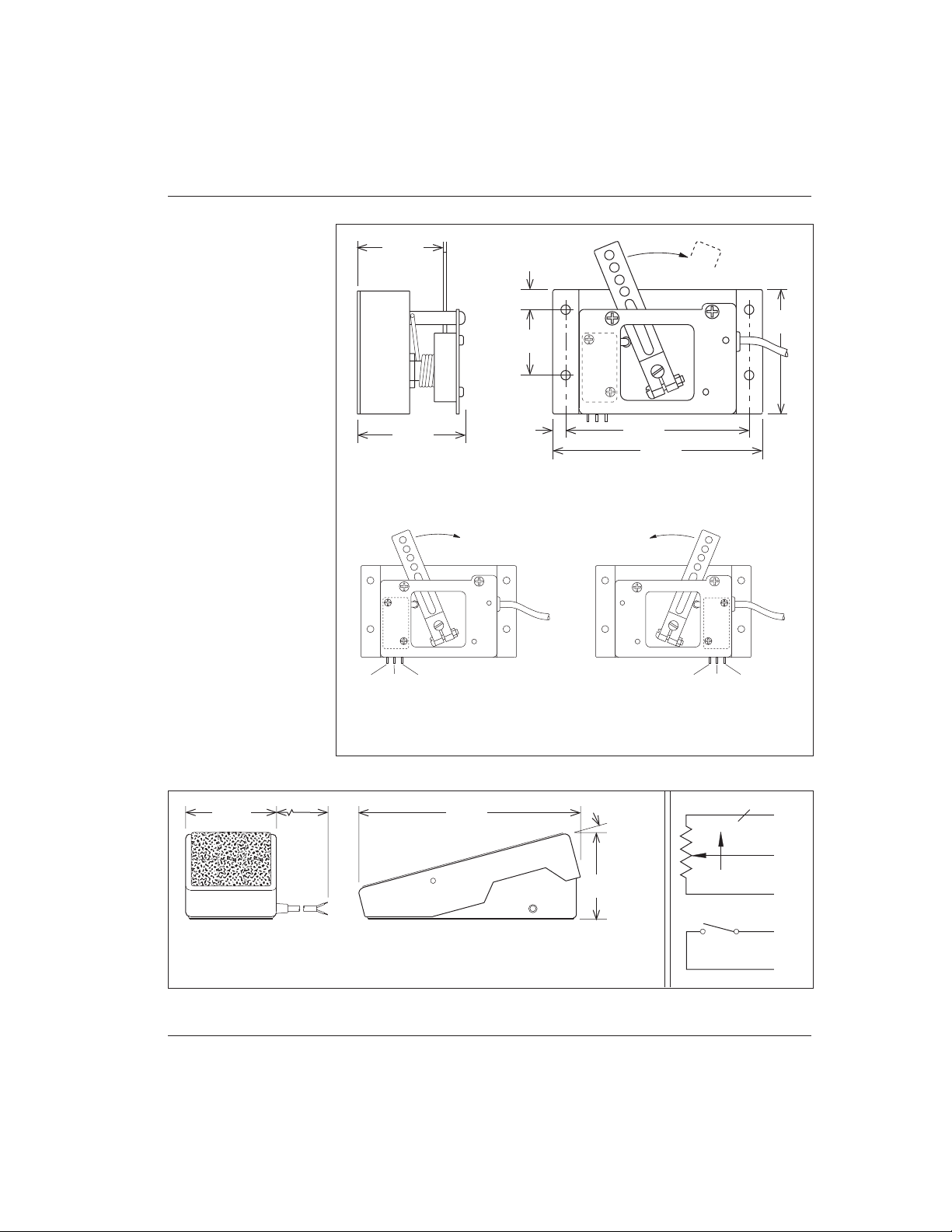

Fig. 4 Mounting

dimensions,

Curtis PMC potboxes

PB-5, -6, -9, and -10.

HARDWARE INSTALLATION

10 (0.38)

32

(1.25)

6

(0.25)

89 (3.5)

60

(2.37)

102 (4.0)

45

°

Dimensions in millimeters and (inches)

RIGHT-HAND OPERATION LEFT-HAND OPERATION

COM. N.O. N.C.

N.C. N.O. COM.

WITH MICROSWITCH: PB-6

WITHOUT MICROSWITCH: PB-5

WITH MICROSWITCH: PB-9

WITHOUT MICROSWITCH: PB-10

42 (1.65)

52 (2.06)

Fig. 5 Curtis PMC footpedal FP-2.

Dimensions in millimeters and (inches)

≈15°

244 (9.6)

112 (4.4)

112

(4.4)

1.8 m

(6 ft)

WIRING:

BLACK

= throttle input

BLUE

= switch, common (Note: The green wire is not used with

WHITE

= throttle input

ORANGE

= switch, normally open 1209B/1221B/1221C/1231C controllers)

BLK

ON

GRN

(not used)

WHT

ORG

BLU

COM.N.O.

Curtis PMC 1209B/1221B/1221C/1231C Manual

7

HARDWARE INSTALLATION

5kΩ–0 Input

The 1209B/1221B/1221C/1231C controllers are also available with 5kΩ–0

throttle inputs. Using this throttle type, controller output begins at ≈4400 ohms

with full output at less than 300 ohms.

0–5V Input

A 0–5V throttle input option is also available for these controllers. The negative

side of the 5V source should be referenced to B- and must be capable of driving

an input impedance of 5kΩ.

Curtis offers two bi-directional, wigwag electronic throttle assemblies designed for use with the 0–5V input: the ET series and the CH series. They

require a 24–36V supply voltage.

The ET-XXX throttle assembly provides a 0–5V output and forward/reverse

relay coil drivers. Dimensions for the ET-series throttles are shown in Figure 6.

Dimensions in millimeters and (inches)

99

(3.90)

44

(1.73)

69

(2.72)

24

(0.94)

VIS TC 3×12

6 × 6 (0.24 × 0.24)

24

(0.94)

∅ M5

22

(0.87)

22

(0.87)

116

°

44

(1.73)

Fig. 6 Mounting

dimensions,

Curtis electronic throttle

(ET series).

Curtis PMC 1209B/1221B/1221C/1231C Manual

8

HARDWARE INSTALLATION

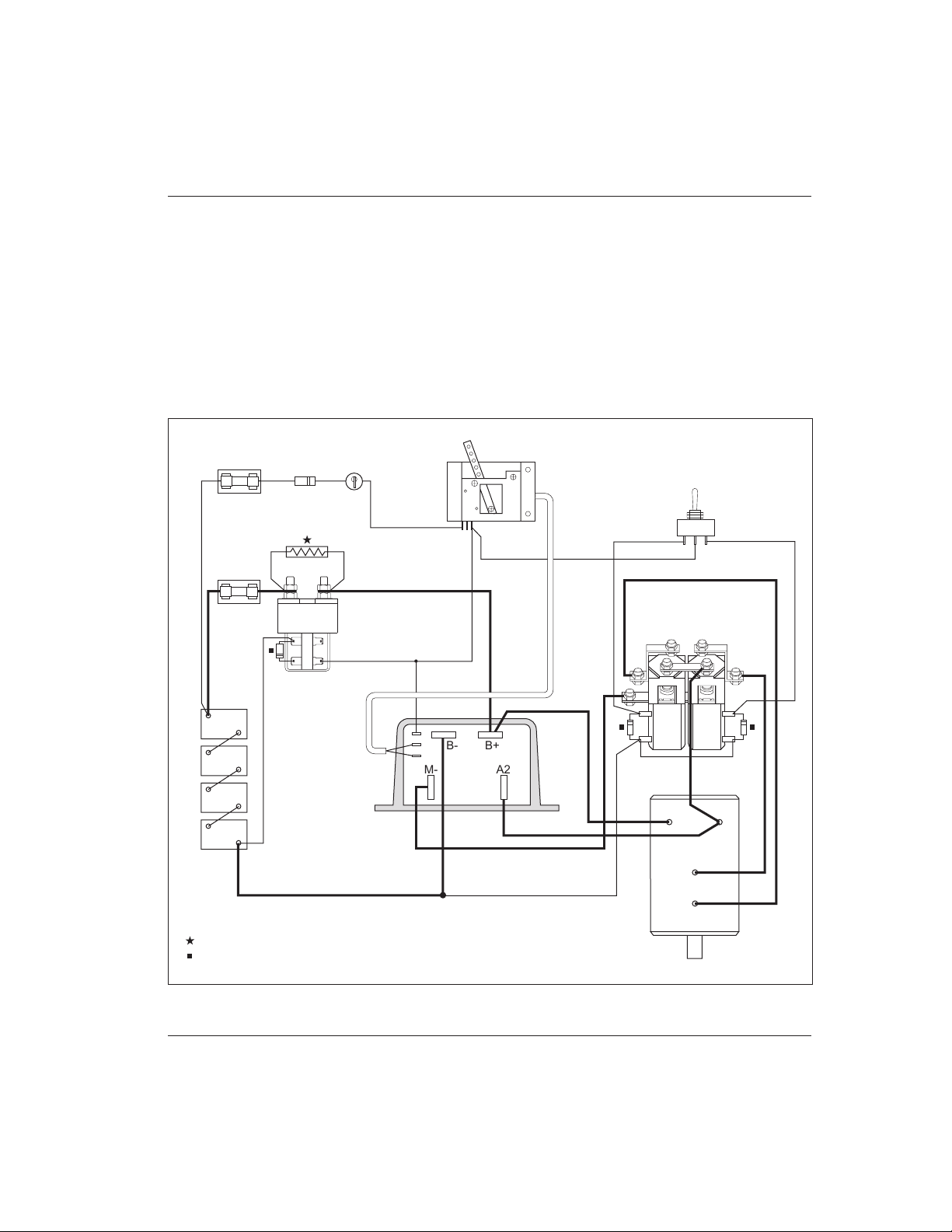

Fig. 7 Typical installation, Curtis PMC 1209B/1221B/1221C controllers.

The CH-XXX is a complete control head assembly, consisting of an ET-XXX

throttle integrated into a molded steel and plastic assembly designed for mounting directly to the tiller stem of material handling lifts. For more information

about ET and CH products, call your local dealer or Curtis office.

OTHER HARDWARE

The recommended hardware for a typical 1209B, 1221B, or 1221C controller

installation is shown in Figure 7, and for a 1231C installation in Figure 8.

CONTROL

WIRING

FUSE

POWER

WIRING

FUSE

POLARITY

PROTECTION

DIODE

KEYSWITCH

POTBOX

FORWARD/REVERSE SWITCH

(SPDT, center off)

F R

FORWARD/REVERSE

CHANGEOVER CONTACTOR

(Albright SW202 shown)

MAIN

CONTACTOR

(Albright SW200

shown)

A1

A2

S1

S2

SERIES

MOTOR

BATTERY

B-

B+

PRECH ARGE RE SISTOR (see Table 1 , page 1 0, for re commen ded siz e)

COIL S UPPRES SION DI ODE (se e text, page 10 , for rec ommend ed size )

FWD REV

A2M-

B-

B+

COM.

N.C.

Curtis PMC 1209B/1221B/1221C/1231C Manual

9

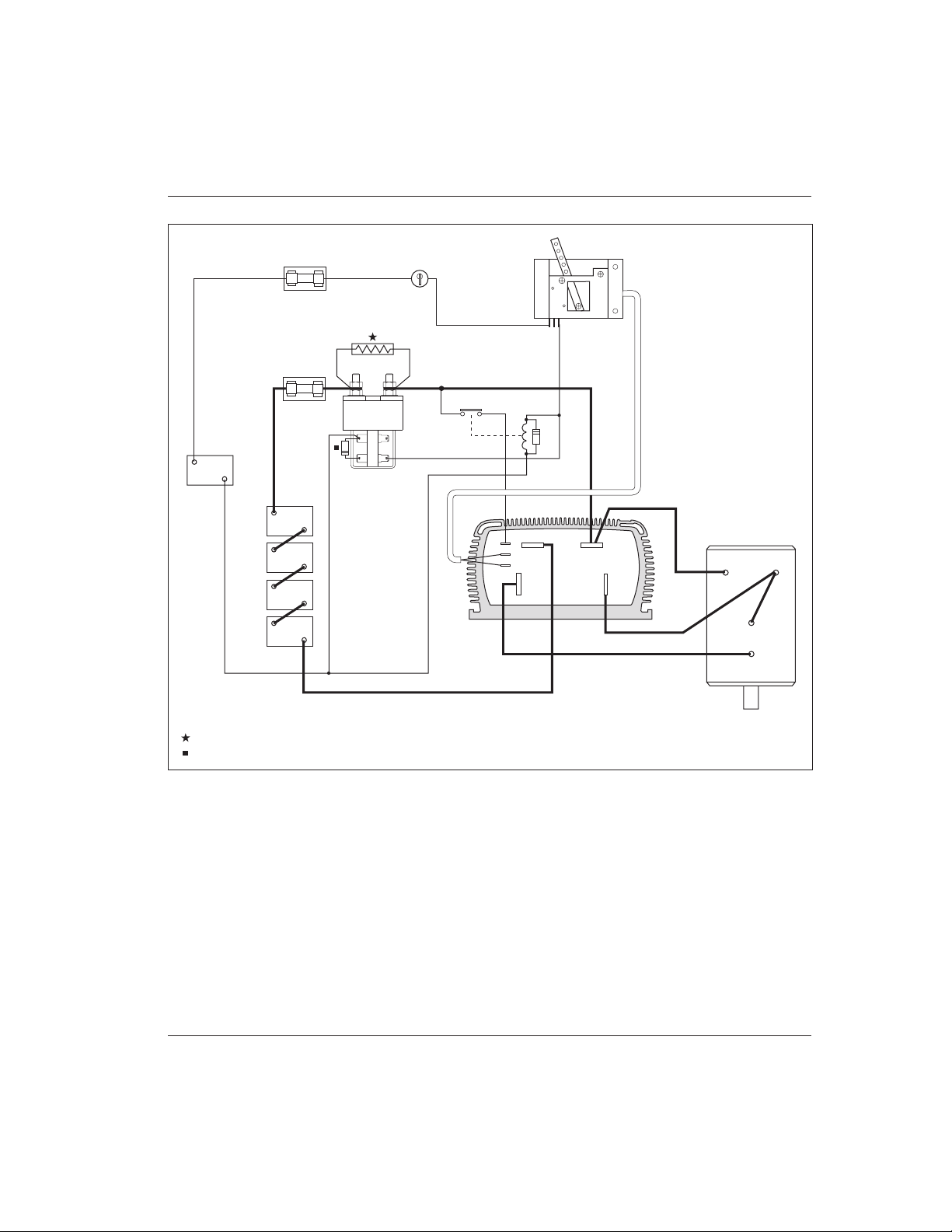

Fig. 8 Typical installation, Curtis PMC 1231C controller.

Contactors should be mounted in a clean, dry location. If such a location is

unavailable, a cover should be used to deflect dirt and water splash.

The precharge resistor and coil suppression diode connected to the main

contactor (and the coil suppression diodes connected to the forward/reverse

contactors in “B” applications) are somewhat delicate components. Care should

be taken to prevent damaging them during installation.

HARDWARE INSTALLATION

CONTROL

WIRING

FUSE

POWER

WIRING

FUSE

KEYSWITCH

POTBOX

MAIN

CONTACTOR

(Albright SW200

shown)

TRACTION BATTERY

B-

B+

PRECH ARGE RE SISTOR (see Table 1 , page 1 0, for re commen ded siz e)

COIL S UPPRES SION DI ODE (se e text, page 10 , for rec ommend ed size )

A1

A2

S1

S2

SERIES

MOTOR

12V

AUXILIARY

BATTERY

B+

B-

KSI RELAY

B- B+

A2

M-

COM.

N.C.

Curtis PMC 1209B/1221B/1221C/1231C Manual

10

HARDWARE INSTALLATION

Main Contactor

Most applications use a main contactor in series with the battery positive (B+)

cable to disconnect all power when the system is turned off, as shown in Figures

7 and 8. A heavy-duty single-pole, single-throw (SPST) contactor with silveralloy contacts is recommended, such as an Albright SW200 (available from

Curtis).

A coil suppression diode should be used on the contactor coil. Curtis PMC

p/n MP-1 (which is rated at 100 volts, 3 amps) is appropriate in systems up to

72V. In systems with nominal voltage greater than 72V where the contactor coils

are energized from the battery pack, a diode with a breakdown voltage of at least

200 volts should be used.

The rapid charging of the controller’s internal filter capacitors causes a high

inrush current to flow briefly when the contactor closes. To extend contact life,

a precharge resistor is recommended; the resistor precharges the capacitors and

reduces the inrush current through the contacts. If an inexpensive “can” type

solenoid is used, the resistor is mandatory to prevent contact welding.

The recommended precharge resistance values and power ratings are listed

in Table 1. These resistors will provide the maximum precharge voltage while

being capable of dissipating the power generated by the full battery voltage

without failure. NOTE: A resistor with a lower power rating may catch on fire if a

system fault applies the full battery voltage across it.

Table 1 RECOMMENDED PRECHARGE RESISTORS

CONTROLLER RESISTANCE POWER RATING

MODEL NUMBER (Ω) (W)

1209B -46XX 270 5

-55XX 270 10

-64XX 620 10

-6A5XX 620 10

-72XX 750 20

1221B -48XX 270 5

-57XX 270 10

-66XX 620 10

-6A7XX 620 10

1221C -74XX 750 20

1231C -77XX 750 20

-86XX 750 25

Loading...

Loading...