Page 1

Manual

Electronic Code Switch

Module (ECS)

» Software Device Profile 1.2.0.0 «

Curtis Instruments, Inc.

200 Kisco Avenue

Mt. Kisco, NY 10549

www.curtisinstruments.com

Read Instructions Carefully!

Specications are subject to change without notice.

© 2021 Curtis Instruments, Inc. ® Curtis is a registered trademark of Curtis Instruments, Inc.

© The design and appearance of the products depicted herein are the copyright of Curtis Instruments, Inc. 53241 RevA March 2021

Page 2

TABLE OF CONTENTS

CHAPTERS

1: OVERVIEW ......................................................................................................................................1

USING THIS MANUAL .................................................................................................................... 2

CONVENTIONS .............................................................................................................................. 2

NUMERAL SYSTEM NOTATION ................................................................................................ 2

MISCELLANEOUS CONVENTIONS ............................................................................................ 2

2: KEYPAD, LEDS, AND BUZZER .......................................................................................................... 3

KEYPAD ........................................................................................................................................ 3

LEDS ............................................................................................................................................ 3

BUZZER ........................................................................................................................................ 4

3: USER OPERATION ........................................................................................................................... 5

OPERATE A VEHICLE .....................................................................................................................5

USER MANAGEMENT MENU .......................................................................................................... 5

SPECIFY THE PIN CODE, TAG, AND/OR USER NAME CODE.............................................................. 6

4: INSTALLATION AND WIRING ............................................................................................................8

INSTALLING THE ECS .................................................................................................................... 8

I/O CONNECTOR ........................................................................................................................... 9

I/O PINS ....................................................................................................................................... 10

WIRING DIAGRAM ........................................................................................................................ 10

BATTERY CONNECTIONS .............................................................................................................. 11

PRECHARGE ................................................................................................................................ 11

RELAY OUTPUT ............................................................................................................................ 12

INTERLOCK .................................................................................................................................. 13

CANBus ....................................................................................................................................... 13

CALIBRATE THE ANTENNA............................................................................................................ 13

pg. ii

Curtis Electronic Code Switch Module (ECS) – March 2021

Page 3

TABLE OF CONTENTS cont’d

5: THE ECS SUPERVISOR AND USERS.................................................................................................14

USER STATUSES .......................................................................................................................... 14

6: PROGRAMMABLE PARAMETERS .................................................................................................... 15

LOGON USER MANAGEMENT MENU ............................................................................................. 17

LOGON USER SETUP MENU ......................................................................................................... 18

SUPERVISOR MANAGEMENT MENU .............................................................................................. 19

USER INFORMATION MENU .......................................................................................................... 20

REGISTERED USER LIST MENU .............................................................................................. 20

APPLICATION SETUP MENU ..........................................................................................................21

CONTROL MENU .................................................................................................................... 21

RELAY MENU ......................................................................................................................... 22

CAN INTERFACE MENU .......................................................................................................... 23

PDO SETUPS MENUS AND PDO MAPPING MENUS ..................................................................24

MISC MENU ........................................................................................................................... 27

PASS THROUGH MODE MENU ...................................................................................................... 28

7: SYSTEM MONITOR MENU ..............................................................................................................29

STATE MENU ...............................................................................................................................30

INPUTS MENU .............................................................................................................................. 31

SWITCH STATUS MENU ..........................................................................................................31

VOLTAGE MENU ..................................................................................................................... 31

FAULT HISTORY MENU ................................................................................................................. 32

8: DIAGNOSTICS AND FAULTS ............................................................................................................ 33

PROGRAMMING DEVICE DIAGNOSTICS ......................................................................................... 33

LEDS AND FAULT CODES ............................................................................................................. 34

FAULT RECORDS .......................................................................................................................... 34

FAULT CODES .............................................................................................................................. 35

Curtis Electronic Code Switch Module (ECS) – March 2021

pg. iii

Page 4

TABLE OF CONTENTS cont’d

9: CANOPEN COMMUNICATIONS ........................................................................................................ 37

BYTE AND BIT SEQUENCE ORDER ................................................................................................ 37

CAN PROGRAMMING CONSIDERATIONS ....................................................................................... 37

MESSAGE CAN-IDS ...................................................................................................................... 38

NMT STATE CONFIGURATION ....................................................................................................... 38

EMERGENCY MESSAGES AND FAULTS ......................................................................................... 38

EXPEDITED SDOS ........................................................................................................................ 39

PDOS ........................................................................................................................................... 40

PDO TIMING .......................................................................................................................... 40

PDO MAPPING OBJECTS ........................................................................................................ 40

PDO DATA BYTES .................................................................................................................. 41

MAP CAN OBJECTS TO A PDO ............................................................................................... 41

PDO1 .................................................................................................................................... 42

PDO2 .................................................................................................................................... 44

STANDARD CANOPEN OBJECTS ................................................................................................... 45

ERROR HISTORY OBJECT (1003H) ......................................................................................... 46

10: SUPERVISOR OPERATION WITH THE KEYPAD ................................................................................ 47

SUPERVISOR MANAGEMENT MENU .............................................................................................. 47

LOG ONTO THE SUPERVISOR MANAGEMENT MENU .....................................................................48

MANAGE THE SUPERVISOR’S PIN CODE, RFID TAG, AND USER NAME CODE ................................. 49

MANAGE USERS .......................................................................................................................... 50

USER STATUSES AND THE LEDS ............................................................................................ 50

ADD/DELETE USERS MENU ................................................................................................... 50

ADD AND DELETE PIN CODES, RFID TAGS, AND USERS .......................................................... 51

pg. iv

Curtis Electronic Code Switch Module (ECS) – March 2021

Page 5

TABLE OF CONTENTS cont’d

PROGRAM PARAMETERS WITH THE KEYPAD ................................................................................ 53

ACCESS THE PROGRAMMING MENU ...................................................................................... 53

CHANGE THE BAUD RATE PARAMETER .................................................................................. 54

CHANGE THE NODE ID PARAMETER ....................................................................................... 54

CHANGE THE INTERLOCK TYPE PARAMETER .......................................................................... 55

CHANGE THE LOGOFF TIME PARAMETER ............................................................................... 55

CHANGE THE MUTE ENABLE PARAMETER .............................................................................. 55

CHANGE THE RELAY WORK MODE PARAMETER .....................................................................56

SHOW THE LAST USER’S ID ......................................................................................................... 56

FIND THE FIRST AVAILABLE USER ID ............................................................................................ 57

CALIBRATE THE ANTENNA............................................................................................................ 57

11: MANAGE USERS WITH CURTIS PROGRAMMING DEVICES .............................................................. 58

USE THE SUPERVISOR MANAGEMENT MENU ...............................................................................58

USE THE LOGON USER SETUP MENU ...........................................................................................59

APPENDIX A: CURTIS PROGRAMMING DEVICES .................................................................................. 60

APPENDIX B: SPECIFICATIONS ........................................................................................................... 62

Curtis Electronic Code Switch Module (ECS) – March 2021

pg. v

Page 6

TABLE OF CONTENTS cont’d

FIGURES

FIGURE 1 MOUNTING DIMENSIONS ..................................................................................................... 8

FIGURE 2 WIRING DIAGRAM ............................................................................................................... 10

FIGURE 3 RELAY CONTACTS — MAXIMUM SWITCHING CURRENT ...................................................... 12

FIGURE 4 FAULT HISTORY DETAILS — CIT ......................................................................................... 32

FIGURE 5 FAULT HISTORY DETAILS — 1313 PROGRAMMER .............................................................. 32

FIGURE 6 ACTIVE FAULTS — CIT ........................................................................................................ 33

FIGURE 7 ACTIVE FAULTS — 1313 PROGRAMMER ............................................................................. 33

TABLES

TABLE 1 MATING CONNECTOR PARTS — IP40 PROTECTION ............................................................... 9

TABLE 2 MATING CONNECTOR PARTS — IP54 PROTECTION ............................................................... 9

TABLE 3 ECS PINS ............................................................................................................................. 10

TABLE 4 USER STATUSES .................................................................................................................. 14

TABLE 5 PDO SETUP MENUS .............................................................................................................24

TABLE 6 PDO MAPPING MENUS ......................................................................................................... 24

TABLE 7 PDO PARAMETERS’ CAN INDEXES AND DEFAULT VALUES ..................................................... 25

TABLE 8 FAULT CODES ......................................................................................................................35

TABLE 9 MAPPED PDO BYTES ...........................................................................................................40

pg. vi

Curtis Electronic Code Switch Module (ECS) – March 2021

Page 7

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

1 — OVERVIEW

e Curtis Electronic Code Switch (ECS) is an operator identication keypad. e ECS ensures

that only authorized users can operate a vehicle. e ECS supervisor denes the authorized users.

Authorized users can log on by entering a user ID and PIN code or by swiping an RFID tag.

e ECS can be integrated into vehicle systems with or without a CANbus. e ECS is designed for

use in applications such as material handling vehicles, MEWP (Mobile Elevating Work Platforms),

golf carts, ICE vehicles, and many others.

e following list summarizes the ECS’s key features:

• A Normally Open (NO) relay that is opened and closed by CAN messages or by users logging

on and o.

• Machine power control through authorized RFID tag and PIN code access or CAN commands.

• Easy to integrate with vehicle systems:

– CAN-based systems: CANopen implementation with an optionally connected CAN

termination resistor. Supports CAN baud rates from 100 Kbps to 1 Mbps.

– Non-CAN systems: e output relay changes state when an authorized user logs onto

the ECS.

• Pass-through mode, which is for applications in which another CAN device can receive

keypad entries and RFID tag swipes.

• Supports ISO 14443A RFID tags.

• Allows up to 100 users.

• Status LEDs and a buzzer conrm keypad entries and provide diagnostic information.

• Automatic log o based on the interlock state and a congurable timer.

• You can use the Curtis Integrated ToolkitTM (CIT) or the Curtis 1313 handheld programmer

to change parameters, monitor real-time data, review and clear the fault history, update

rmware, and perform other diagnostic and application development tasks.

• Operates in demanding conditions, with an operational temperature range of –40° to +70°C

and electronic components sealed to IP65.

• CE compliance, UL recognition, and ROHS 3 compliance ensure compatibility with global

regulatory safety.

Note: For technical support, contact the Curtis distributor or the Curtis sales and support oce in

your region.

1 — OVERVIEW

pg. 1

Page 8

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

USING THIS MANUAL

• Vehicle operators only need to read the following chapters:

– Keypad, LEDs, and Buzzer

– User Operation

• e ECS supervisor should also read the following chapters:

– e ECS Supervisor and Users

– Supervisor Operation with the Keypad

– Manage Users with Curtis Programming Devices

• Users who install, congure, and troubleshoot the ECS should also read the chapters

applicable to their tasks.

CONVENTIONS

e following topics describes terms and notations used in this manual.

Numeral System Notation

e following table describes how this manual denotes decimal, binary, and hexadecimal numbers.

Note: e letter n in the Format column represents a digit.

Numeral System Format Example

Either of the following:

Decimal

Hexadecimal

Binary nnnb 101b

• nnn

• nnnd

Either of the following:

• nnnh

• 0xnnn

• 127

• 127d

• 62Ah

• 0x62A

In addition, some CANopen examples have hexadecimal values without notation. ose examples

are formatted with a monospace font and with the bytes delimited by spaces, as shown in the

following example:

21 FF 01 11 22 01 00 00

Miscellaneous Conventions

pg. 2

• RO means read-only.

• RW means read-write.

• N/A means not applicable.

• e word tag is used to describe RFID cards, keys, fobs, etc.

1 — OVERVIEW

Page 9

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

2 — KEYPAD, LEDs, AND BUZZER

e following topics describe the ECS’s keypad, LEDs, and buzzer.

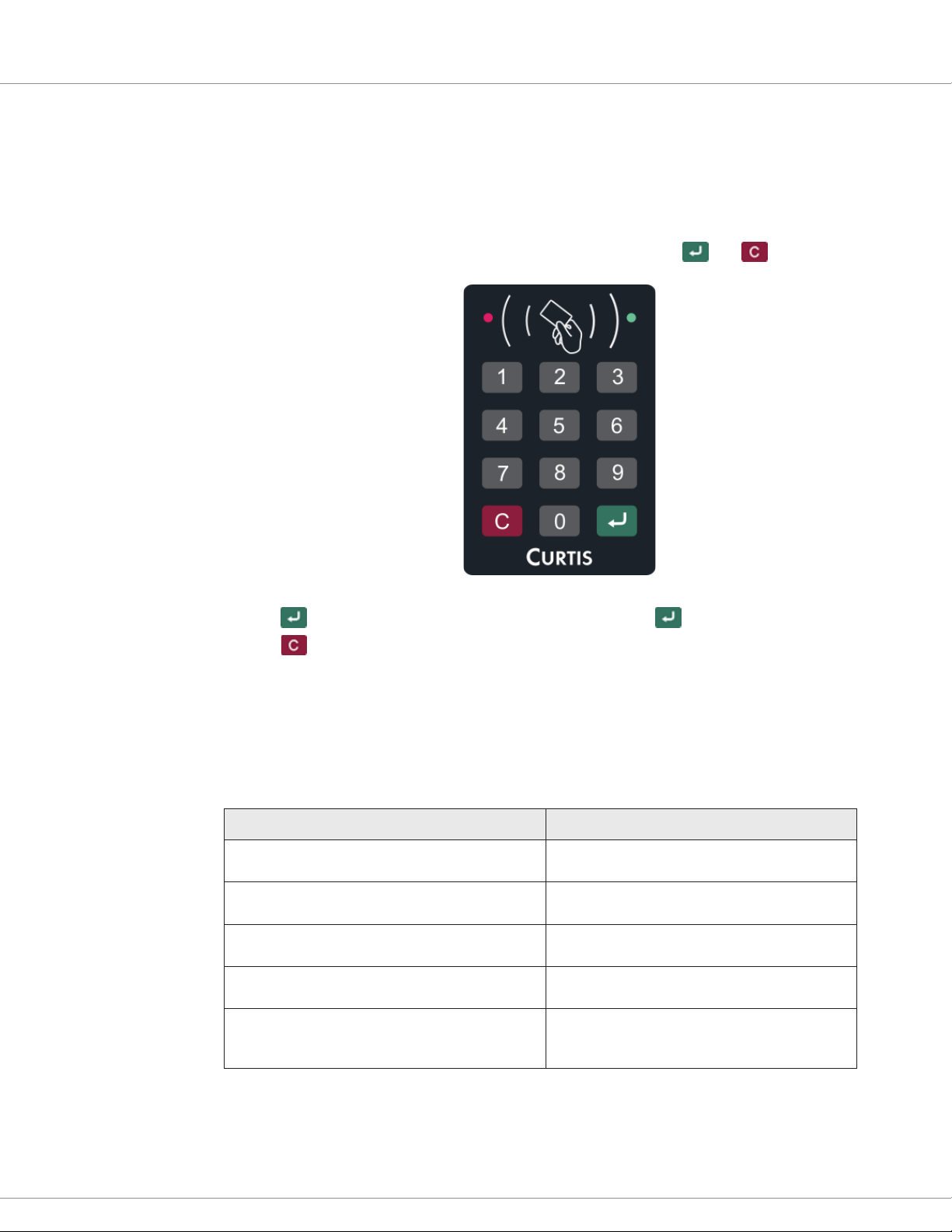

KEYPAD

e ECS keypad consists of buttons for the numbers 0–9, as well as and buttons:

• e button is used to submit entries. For example, press aer you enter a menu number.

• e button is used to perform various tasks such as logging on and o, clearing data, and

returning to the previous menu.

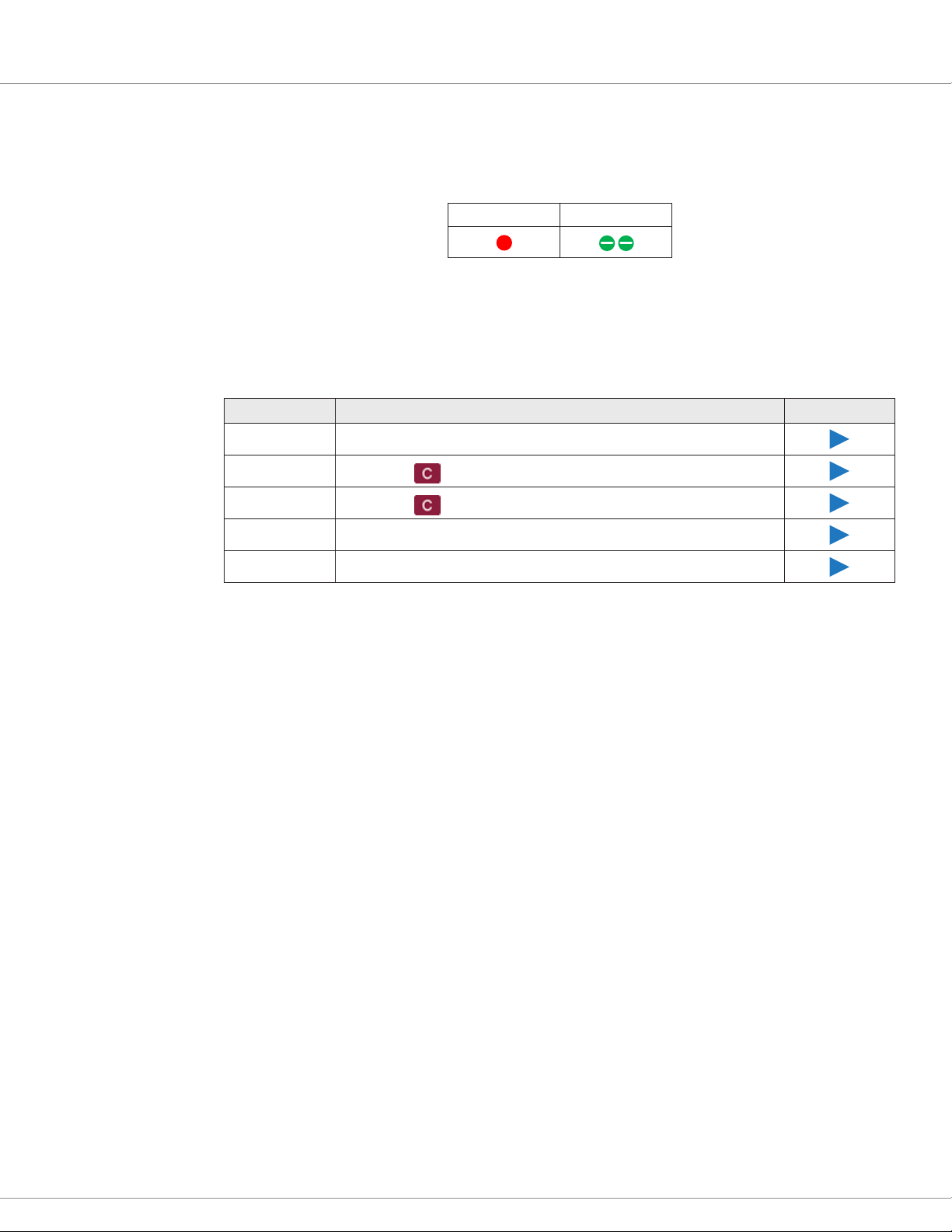

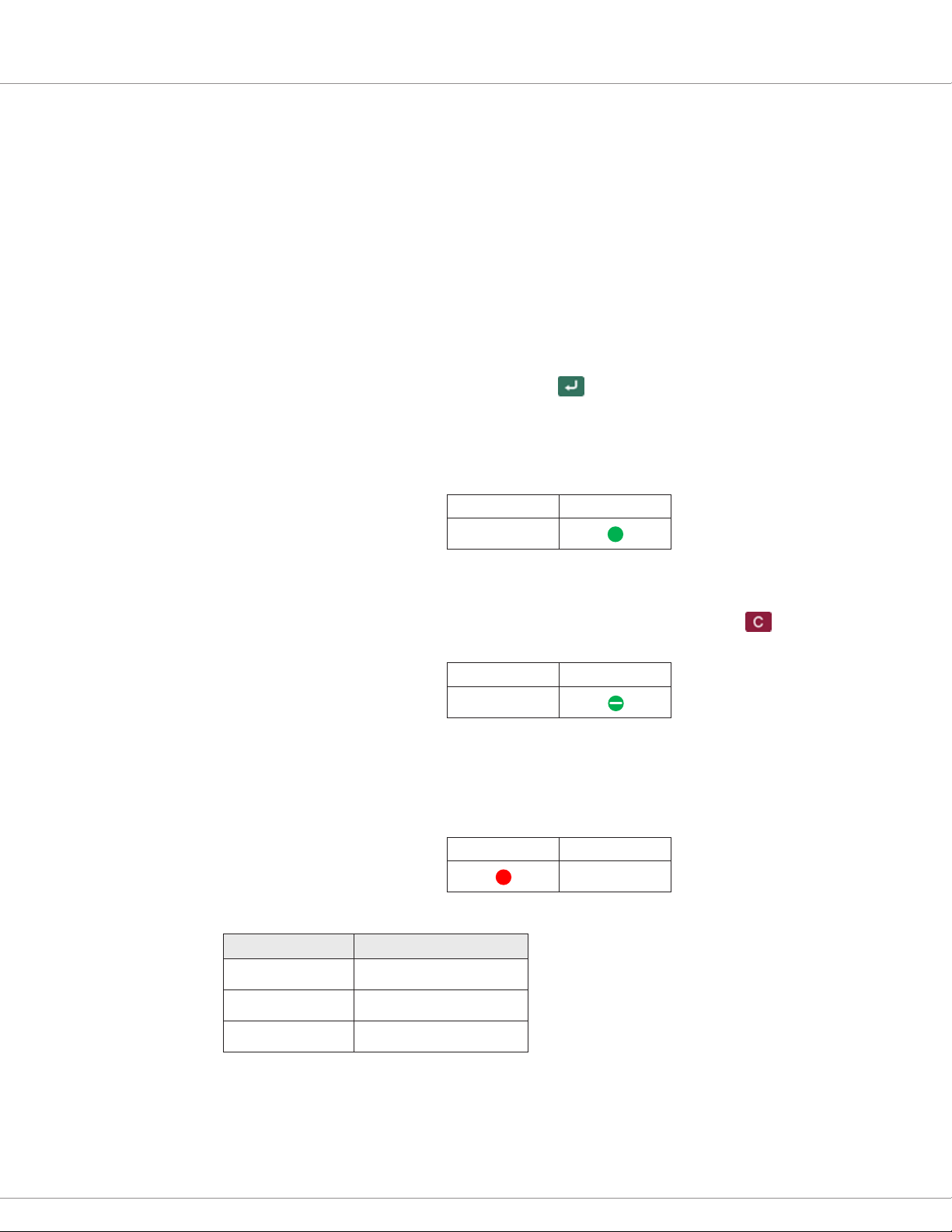

LEDs

e ECS has green and red LEDs that indicate information such as the current menu, status, and

fault codes. e following table summarizes the typical usages of the LEDs:

ECS Operation LEDs

The ECS is idle.

A user is logged on to operate the vehicle.

A fault occurs.

The supervisor is on the Supervisor Management

menu or a user is on the User Management menu.

The supervisor or a user is working with a submenu

of the Supervisor Management menu or User

Management menu.

The green LED ashes once per two seconds and

the red LED is off.

The red LED is off and the green LED remains on

without ashing.

The LEDs ash the fault code. Faults typically are

handled by a technician.

The red LED remains on without ashing and the

green LED is off.

The information indicated by the LEDs depends

upon the menu or submenu.

2 — KEYPAD, LEDs, AND BUZZER

pg. 3

Page 10

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

In this manual, LED ash sequences are described with tables that contain red and green circles.

When an LED periodically ashes, the number of ashes are indicated with striped circles. In the

following example, the red LED remains on without ashing and the green LED ashes twice per

two seconds:

Red Green

When an LED is o, the table will not include a circle for the LED.

BUZZER

e ECS has a buzzer that indicates whether user entries and RFID tag swipes are valid. e following

table describes the buzzer sounds.

Sound Description

Pushbutton You pressed a button.

Clear Data

Return

Error You entered invalid data or an invalid menu number.

Success You logged on, entered valid data, or pressed a valid menu number.

You pressed to clear data that you entered while working on a menu.

You pressed to return to the previous menu or to log off.

Play Audio

Note: If you don’t hear the buzzer, it means that the Mute Enable parameter is set to On.

pg. 4

2 — KEYPAD, LEDs, AND BUZZER

Page 11

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

3 — USER OPERATION

e ECS ensures that only authorized users can access a vehicle. If you are authorized, the ECS

supervisor will provide you with a user ID and PIN code, an RFID tag, or both.

e following sections describe how to use the ECS to operate a vehicle and to create or change your

tag, PIN code, and/or user name code.

OPERATE A VEHICLE

To operate a vehicle equipped with the ECS, log on by taking one of the following steps:

• Place your user tag in front of the ECS.

• Enter your user ID and PIN code, then press .

Note: If your user ID is 1–9, enter 0 before the digit. For example, if the user ID is User 3, enter 03.

If your tag or your user ID and PIN code are valid, the buzzer sounds the Success sound and the

green LED remains on without ashing. You can now operate the vehicle.

Red Green

You remain logged on until you either log off, the interlock switch is off for longer than the

programmed timeout interval, or another operator swipes a tag.

Once you have nished operating the vehicle, log o by pressing and holding until you hear the

Return sound and the green LED starts ashing.

Red Green

USER MANAGEMENT MENU

e User Management menu allows you to add or change your PIN code, tag, and/or user name

code. When you are on the User Management menu, the red LED remains on without ashing and

the green LED is o.

Red Green

e User Management menu contains the following menus. To access a menu, press its menu number:

Menu Number Description

1 Change PIN code.

2 Change tag.

3 — USER OPERATION

3 Change user name code.

When you select a menu, the red LED remains on without ashing and the green LED ashes the

menu number every two seconds.

pg. 5

Page 12

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

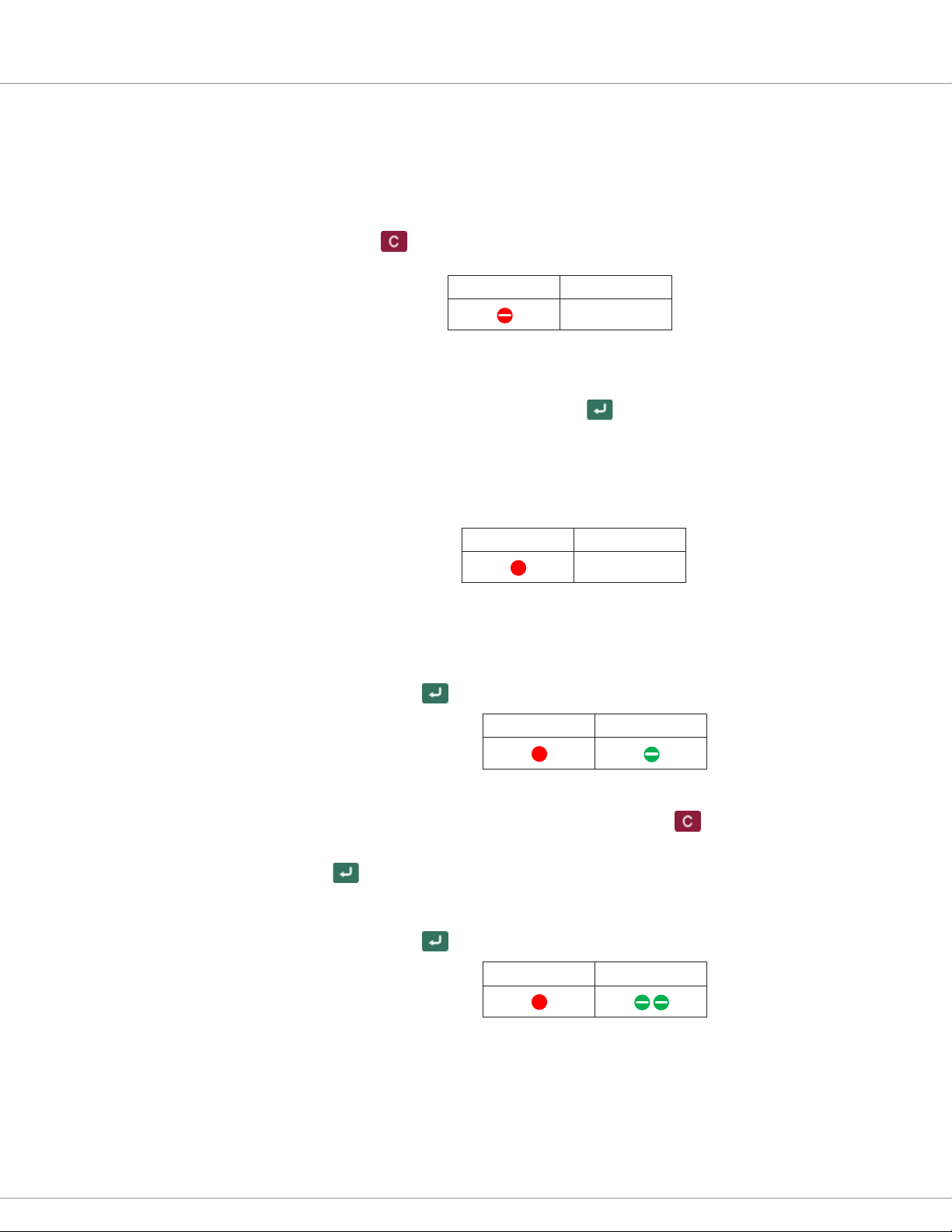

SPECIFY THE PIN CODE, TAG, AND/OR USER NAME CODE

Take the following steps to access the User Management menu and add or change your PIN code,

tag, and/or user name code.

Note: If the ECS doesn’t detect keypad activity for 60 seconds, the ECS automatically logs o.

1. Press and hold the button for two seconds, until you hear the Pushbutton sound twice and

the red LED starts ashing.

Red Green

2. Perform one of the following steps:

– Place your user tag in front of the ECS.

– Enter your user ID and PIN code, then press .

Note: If your user ID is 1–9, enter 0 before the digit. For example, if the user ID is User 3,

enter 03.

The buzzer sounds the Success sound, indicating that you have accessed the User

Management menu.

Red Green

You can now perform any or all of the tasks listed in the following headings. e tasks can be

performed in any order:

Add or Change the PIN Code

a. Press 1, then press .

Red Green

b. Enter the PIN code, which must be between 2–6 digits.

Tip: If you need to clear the digits you’ve entered, press . You can then enter the new

PIN code.

c. Press to save the PIN code and return to the User Management menu.

Add or Replace the Tag

a. Press 2, then press .

Red Green

pg. 6

b. Place the tag in front of the ECS until you hear the Success sound. e ECS returns to the

User Management menu.

Note: Replacing a tag invalidates any tags previously created for the user ID.

3 — USER OPERATION

Page 13

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

Add or Change the User Name Code

a. Press 3, then press .

Red Green

b. Enter the user name code, which can be any number between 0–9999.

Note: e user name code is not your user ID, is not required, and is not used to log on to

the ECS. e user name code can be used for information such as an alias or an employee ID.

c. Press to save the user name code and return to the User Management menu.

3. Press to log o.

Red Green

3 — USER OPERATION

pg. 7

Page 14

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

4 — INSTALLATION AND WIRING

This chapter explains how to install and wire the ECS and how to configure the inputs and

outputs (I/Os).

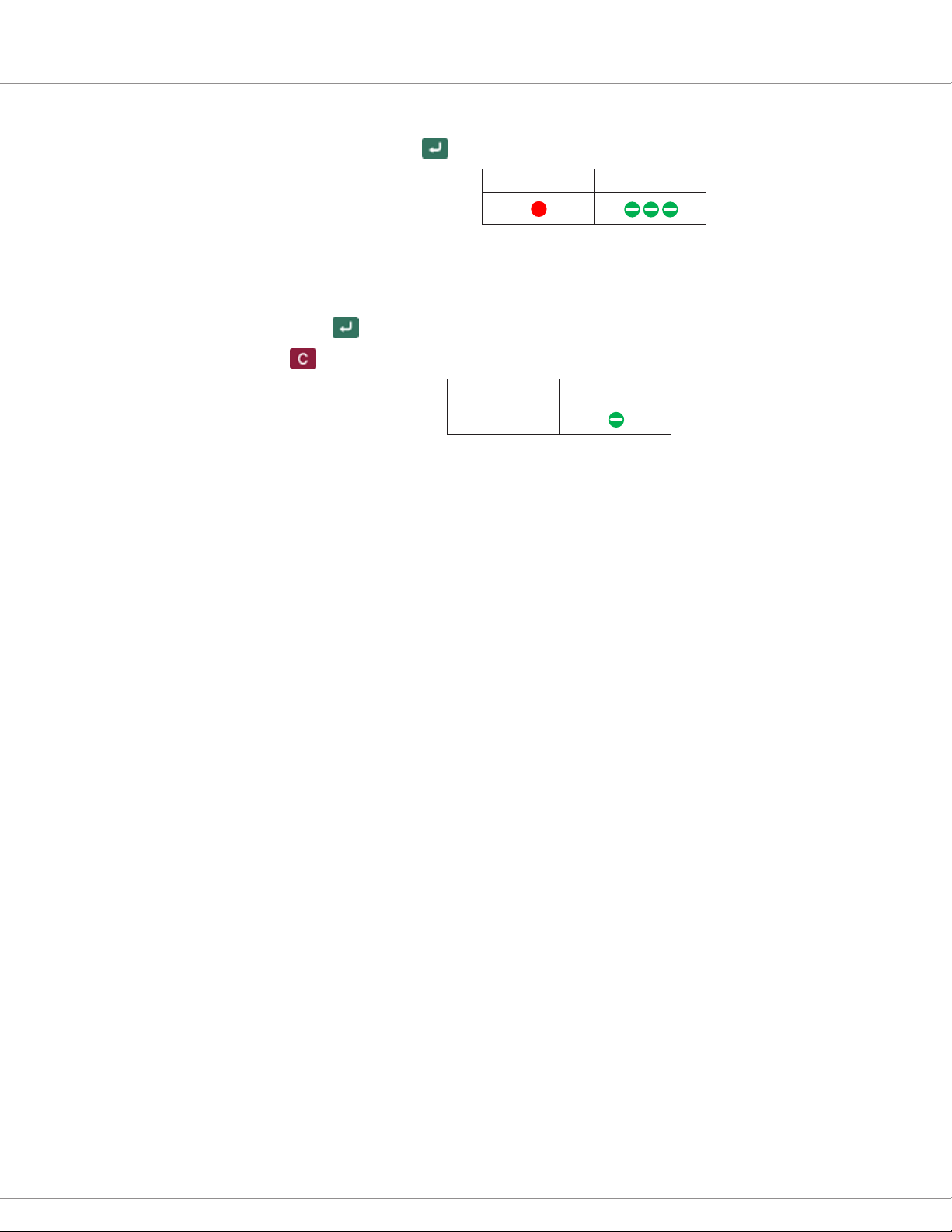

INSTALLING THE ECS

To install the ECS, snap-fit it into the desired location, using 2.0–4.0 mm snap-in fingers.

The location should be carefully chosen to keep the ECS clean and dry. Figure 1 shows the

mounting dimensions:

Figure 1

Mounting

Dimensions

4X R7

70.0

LED

2PLS

64.0

4X R5.5

102.0

34.0

4.3

92.0

40.0

pg. 8

Note: The panel hole size is 92.3 3 64.3 mm, with a tolerance of +0.7 mm for both the length

and width.

4 — INSTALLATION AND WIRING

Page 15

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

I/O CONNECTOR

e ECS provides an 8-pin connector for the I/Os.

14

8

5

e mating connector is an 8-pin Mini-Universal MATE-N-LOK housing plug from TE Connectivity.

e front of the ECS is sealed to IP65. e rear of the ECS is sealed to IP65 for electronic components

and to IP40 for the connector. You can increase the connector’s protection to IP54 by using the parts

listed in Table 2.

e following tables list the TE Connectivity parts for IP40 and IP54 protection.

Table 1 Mating Connector Parts — IP40 Protection

Part TE Connectivity Part Number

Connector Housing 770579-1

Terminal (18–22 AWG) 770904-X

Table 2 Mating Connector Parts — IP54 Protection

Part TE Connectivity Part Number

Connector Housing 794821-1

Terminal (18–22 AWG) 770904-X

Interface Seal 794772-8

Single Wire Seal or Gang Seal • Single: 794758-1

• Gang: 1586359-8

Cavity Plug Seal (for unused terminal positions) 794995-1

4 — INSTALLATION AND WIRING

pg. 9

Page 16

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

120Ω CAN BUS TERMINATION

KEYSWITCH

I/O PINS

e following table describes the I/O pins.

Table 3 ECS Pins

Pin Signal Name Description

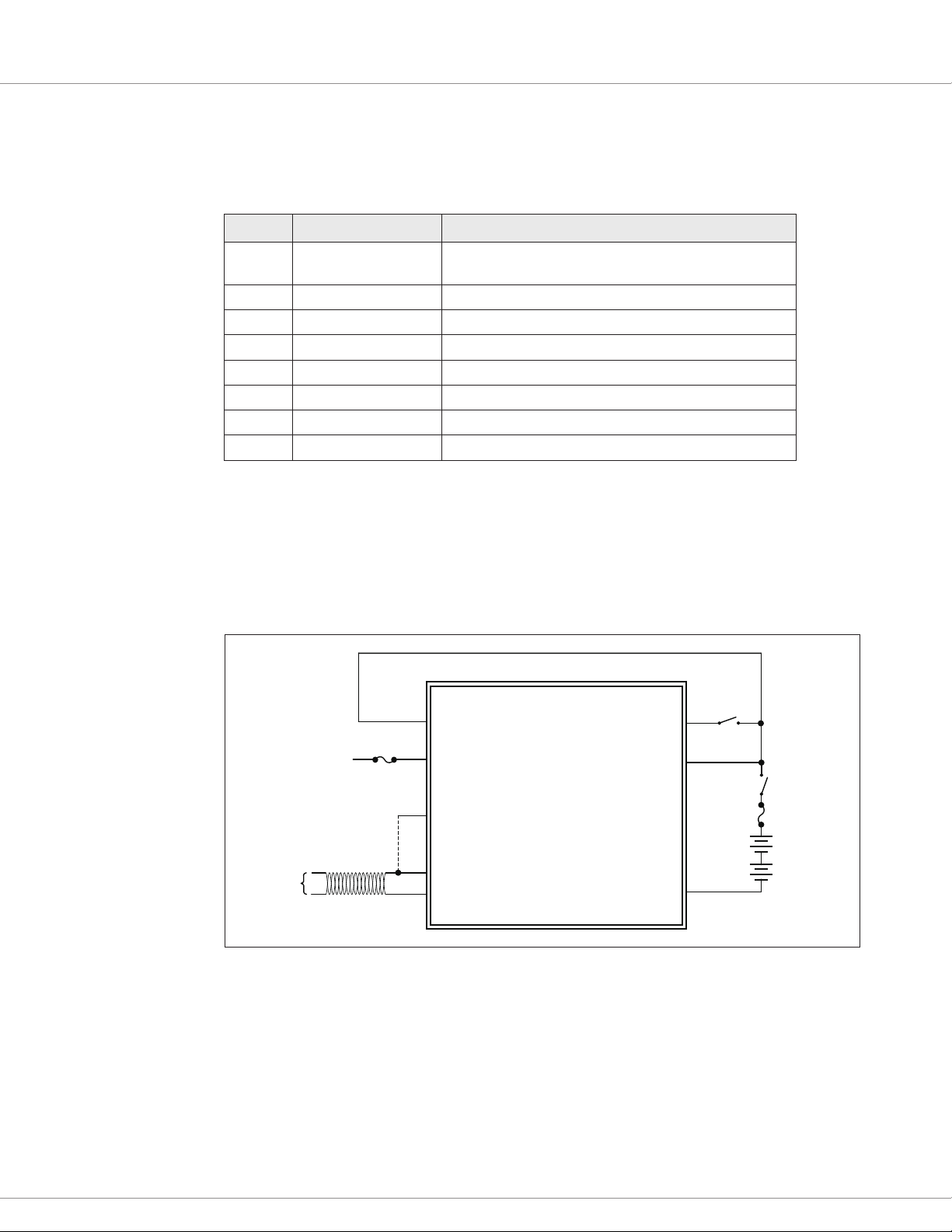

Figure 2

Wiring Diagram

J1-1 CAN Term

CAN terminating 120Ω resistor.

Note: To enable the resistor, connect this pin to pin J1-6.

J1-2 Interlock Input Active high; 12–96V

J1-3 Relay COM Power to relay; 12– 96V

J1-4 Relay NO Relay output

J1-5 CAN Low

J1-6 CAN High

J1-7 B+ Battery Positive

J1-8 B– Battery Common

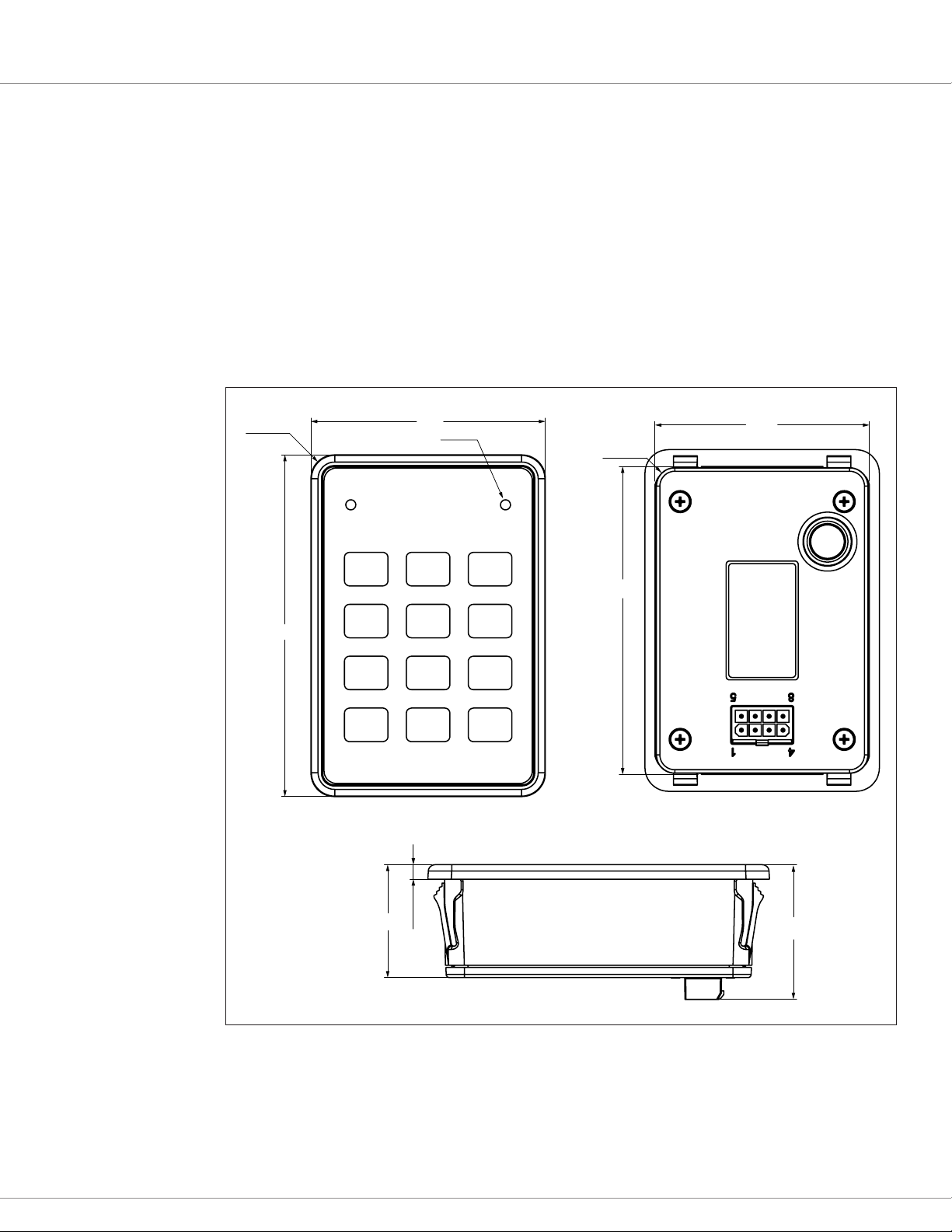

WIRING DIAGRAM

The following diagram illustrates a configuration in which the ECS is connected to an

interlock switch.

J1-3

RELAY COM INTERLOCK INPUT

FUSE

CONNECTED

TO LOAD

CONNECT J1-1 TO J1-6 FOR

CAN

PORT

J1-4

J1-1

J1-6

J1-5

RELAY N.O.

CAN TERM

CAN HIGH

CAN LOW

Note: Use fuses that are appropriately sized for your application.

B+

J1-2

J1-7

FUSE

BATTERY

(12-96V)

J1-8

B-

pg. 10

4 — INSTALLATION AND WIRING

Page 17

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

Current Limit (A)

Relay COM Voltage

BATTERY CONNECTIONS

Connect the battery to the B+ and B– pins (pins 7–8, respectively). e following table describes the

B+ pin’s operating voltage:

Minimum Nominal Maximum

9VDC 12–96VDC 120VDC

Note: All voltages listed in this manual are DC voltages.

e following table describes the B+ pin’s operating current:

B+ Voltage Operating Current

12V 248mA

24V 114mA

36V 70mA

48V 52mA

60V 44mA

72V 37mA

80V 32mA

96V 33mA

PRECHARGE

To suppress arcing across the relay contacts when the relay closes, the ECS uses a current-limited

precharge circuit to power the devices connected to Relay NO. e relay closes when the Relay NO

voltage reaches 90% of the Relay COM voltage; if the relay doesn’t close, a Precharge Fault occurs.

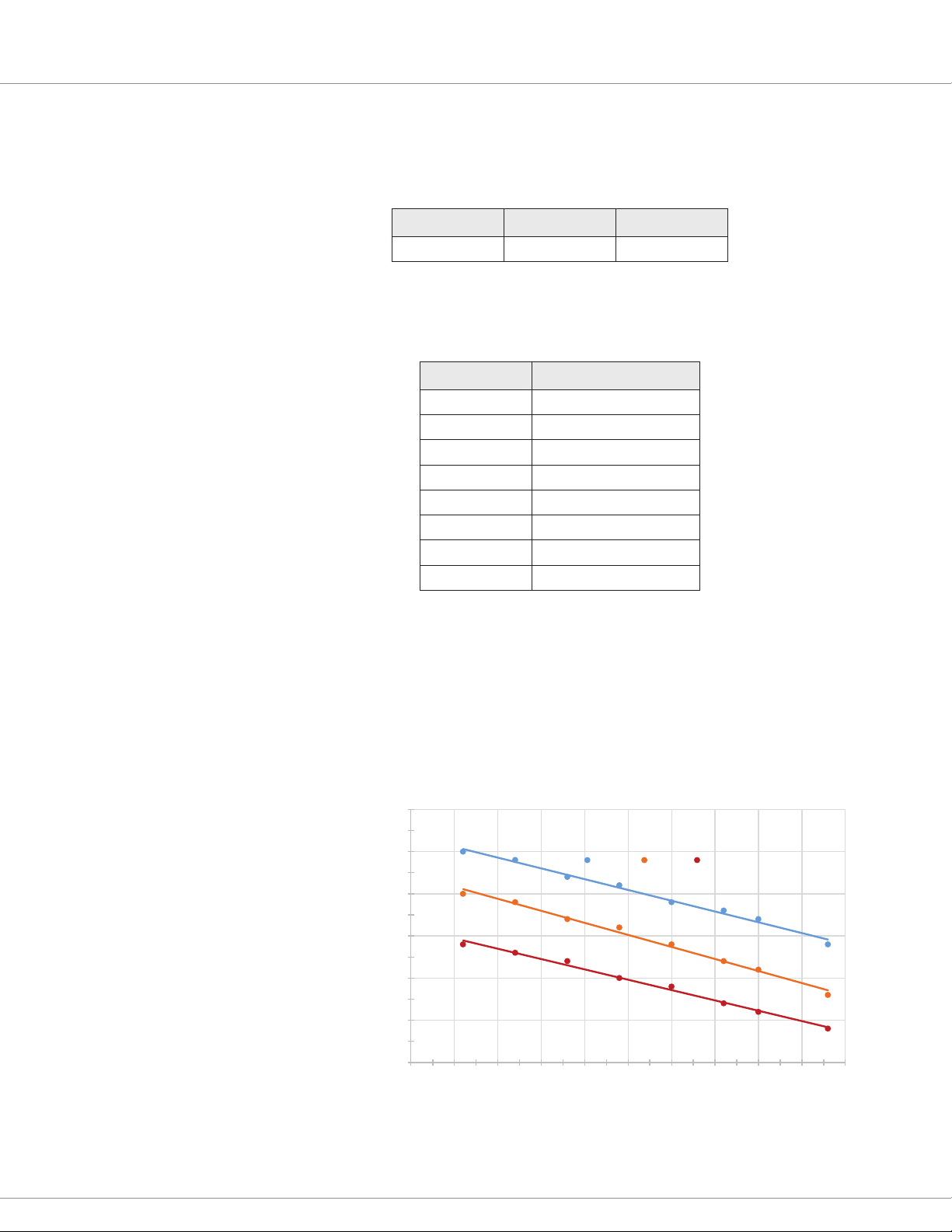

The following chart shows the precharge current limits for Relay COM voltages at various

ambient temperatures:

3 .0

2 .5

2 .0

Precharge

1 .5

1 .0

0 .5

0 .0

0 10 20 30 40 50 60 70 80 90 100

-4 0°C 2 5 °C 7 0°C

4 — INSTALLATION AND WIRING

pg. 11

Page 18

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

Contact Current (A)

200

Contact Voltage (V)

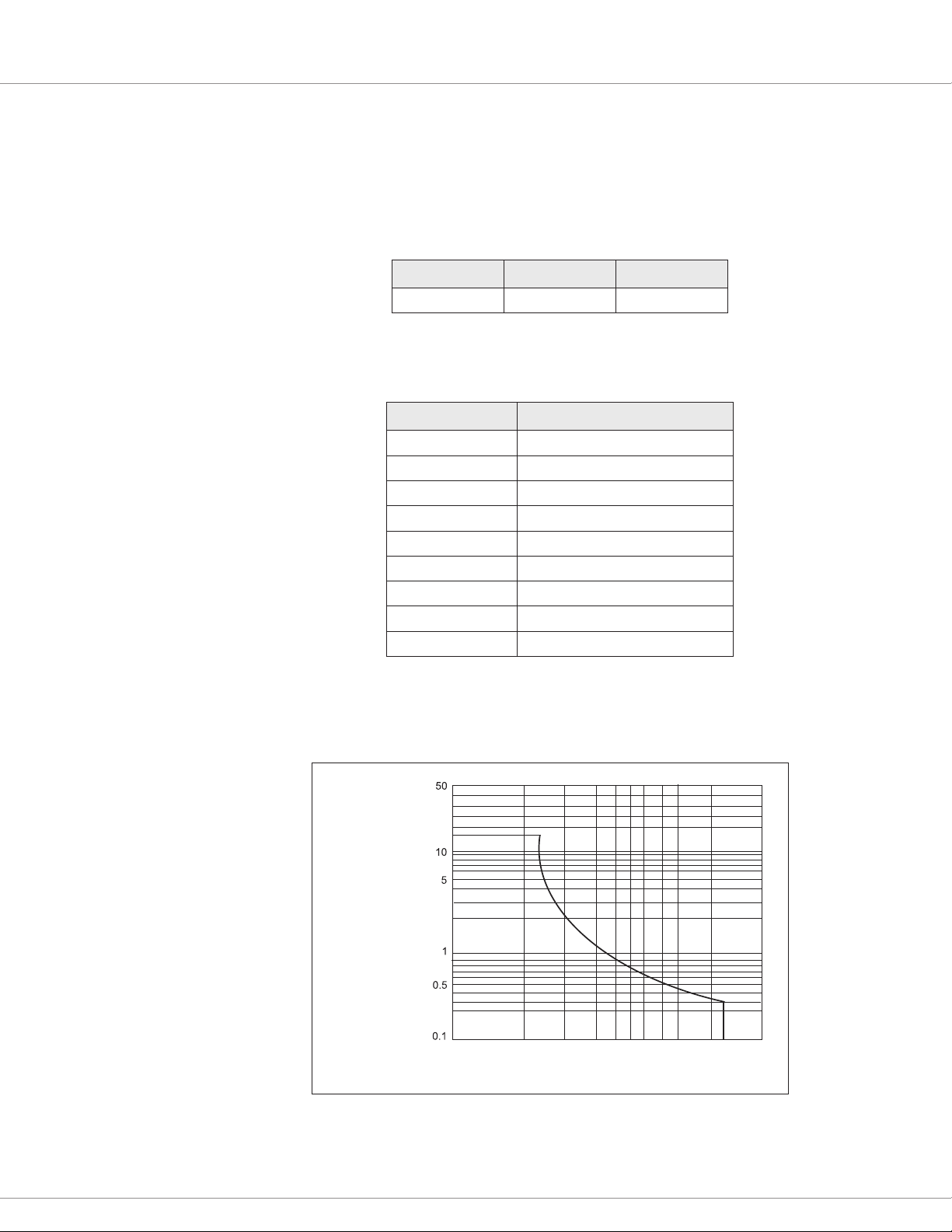

RELAY OUTPUT

e ECS uses a normally open (NO) relay as an output driver. When the relay engages, Relay NO

(pin 4) outputs the power provided by the power source. Connect Relay COM (pin 3) in series with

the power source, and connect Relay NO to the load.

e following table describes the Relay COM operating voltage:

Nominal Minimum Maximum

12–96V 9V 120V

e following table and Figure 3 describe the maximum switching current for various voltages when

a resistive load is connected:

Contact Voltage Maximum Switching Current

12V 16.0A

24V 16.0A

36V 1.5A

48V 0.9A

60V 0.7A

72V 0.6A

80V 0.5A

96V 0.3A

120V 0.3A

pg. 12

Figure 3

Relay Contacts — Maximum

Switching Current

1005040302010

4 — INSTALLATION AND WIRING

Page 19

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

When the ECS commands the relay to close or open, the Relay State parameter indicates the

relay’s state:

• When the relay closes, the Relay State value changes in this order: 0, 1, 2, 3, 4, 5.

• When the relay opens, the Relay State value changes in this order: 5, 6, 8, 0.

e Relay Work Mode parameter species whether logging on or CAN commands engage the relay.

ere also are parameters for conguring the relay’s pull-in and holding voltages; see Relay Menu.

INTERLOCK

When the interlock state is o and the logo interval has expired, the ECS automatically logs the

user o. e logo interval is specied with the Logo Time parameter.

Note: e automatic logo can be disabled by setting Logo Time to 0.

e interlock signal can be controlled with either a switch, such as a seat switch, or RPDO1. e

Interlock Type parameter species the interlock signal’s source.

If the vehicle uses an interlock switch, connect the switch to pin 2. When a switch is used, the

interlock’s input voltage ranges from 0V to the B+ voltage. e interlock input is active high; the

interlock state is o when the interlock input’s voltage is below the voltage specied with the Interlock

High reshold parameter.

Note: For information on the interlock parameters, see Control Menu.

CANbus

To connect the ECS to the CANbus, connect CAN Low and CAN High to pins 5 and 6, respectively.

Use twisted-pair wiring to minimize the likelihood of picking up a voltage bias on only one signal.

Pin 1 provides access to an internal 120Ω terminating resistor. To enable the resistor, connect CAN

High (pin 6) to pin 1.

e ECS includes parameters for items such as the baud rate, heartbeat rate, node ID, and PDOs. For

more information, see CAN Interface Menu and CANopen Communications.

CALIBRATE THE ANTENNA

Aer the ECS is installed, calibrate the antenna so that the ECS automatically detects the best channel

for RFID recognition. You can calibrate with either of the following:

• e AM Base Calibration parameter.

• e keypad; see the Calibrate the Antenna section.

4 — INSTALLATION AND WIRING

pg. 13

Page 20

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

5 — THE ECS SUPERVISOR AND USERS

e ECS supervisor is responsible for authorizing users to log on to the ECS. e supervisor authorizes

users by creating PIN codes and/or tags for user IDs. Aer the supervisor creates a user, the user can

log onto the ECS by swiping the tag or entering the user ID and PIN code.

e supervisor can delete users. When a user is deleted, the user’s PIN code and/or RFID tag are

deactivated and the user can no longer log on to the ECS.

e ECS provides 100 user IDs. e supervisor’s user ID is 00. e remaining user IDs, which range

from 01 through 99, are for users.

The default supervisor PIN code is 123456. For security reasons, change the supervisor’s PIN code

CAUTION

as soon as possible.

e following considerations apply to supervising users:

• e default PIN code for users is 1234. Aer the supervisor creates a PIN code for a user ID,

the user should specify a dierent PIN code.

• Aer the supervisor creates a tag for a user ID, the user can create a PIN code.

• Aer the supervisor creates a PIN code for a user ID, the user can create a tag.

• e supervisor can remove a user’s tag while preserving the user’s PIN code, and vice versa.

• e supervisor logs on with the ECS keypad.

• e supervisor manages users with the keypad or with a Curtis programming device, as

described in the following topics:

– Supervisor Operation with the Keypad

– Manage Users with Curtis Programming Devices

Note: e supervisor can also use the keypad to update some parameters and calibrate the

antenna eld strength level.

USER STATUSES

Each user ID has a user status. e user status indicates whether and how the user can access the

ECS. User statuses are identied by numbers and are described in the following table:

Table 4 User Statuses

User Status Description

1 The user is not authorized to access the ECS.

2 The user only has a PIN code.

3 The user only has a tag.

4 The user has both a PIN code and a user tag.

pg. 14

5 — THE ECS SUPERVISOR AND USERS

Page 21

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

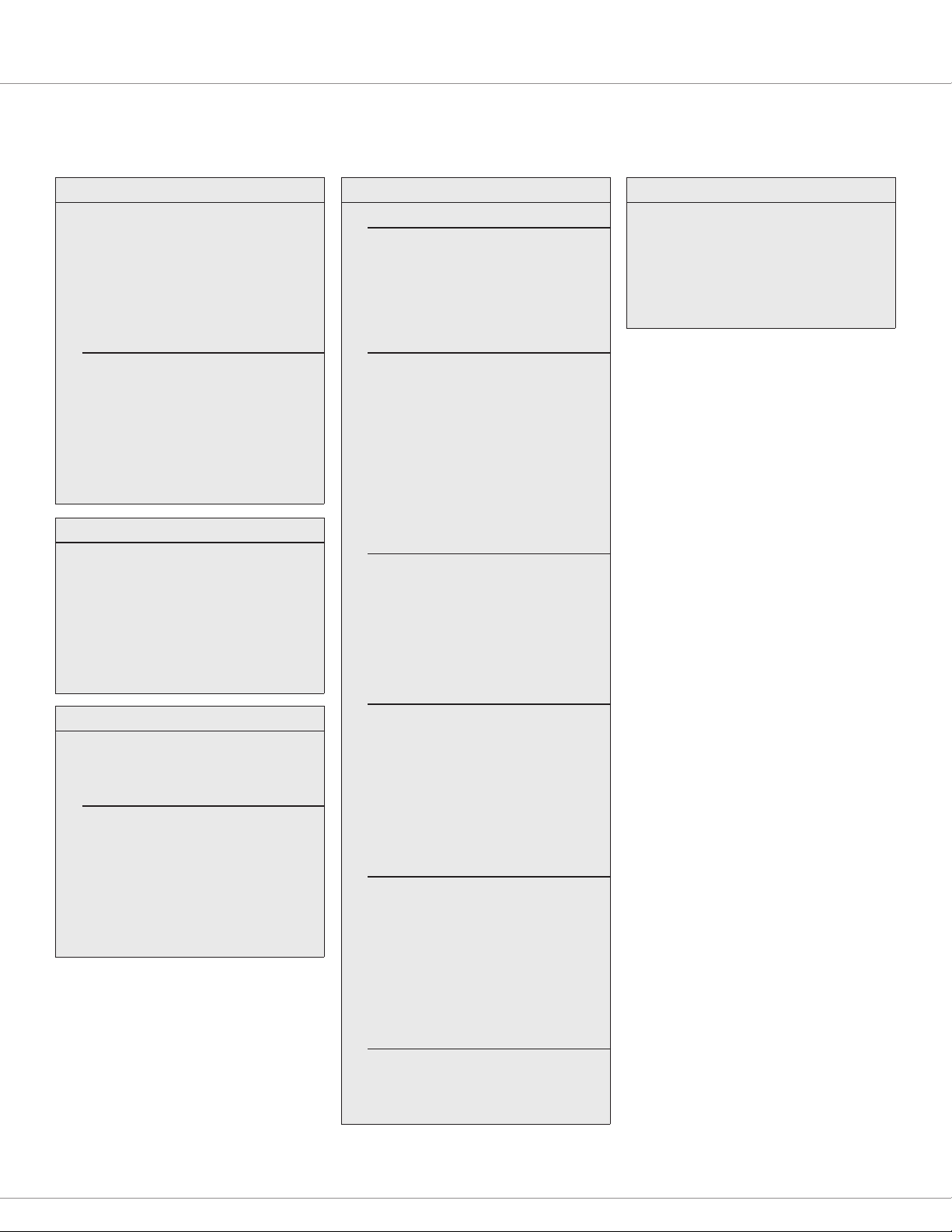

6 — PROGRAMMABLE PARAMETERS

LOGON USER MANAGEMENT MENU..... p.1 7

— Logon User ID

— Logon User Name Code

— Logon RFID 1

— Logon RFID 2

— Logon RFID 3

LOG ON USER SETUP MENU......... p.18

— New PIN Code

— Save New PIN Code

— New RFID Tag

— Delete RFID Tag

— New Name Code

— Save New Name Code

SUPERVISOR MANAGEMENT MENU..... p.19

— First Free User ID

— Target User ID

— Target User State

— Create Target User PIN Code

— Create Target User RFID Tag

— Delete Target User

USER INFORMATION MENU............... p.20

— Last Logon User ID

— Total Registered Users

REGISTERED USER LIST MENU.... p.20

SUPERVISOR MENU................ p.20

— User Status

— User Name Code

USER 01—USER 99 MENUS... p.20

— User Status

— User Name Code

APPLICATION SETUP MENU............... p.21

CONTROL MENU........................... p.21

— Interlock Type

— Interlock High Threshold

— Mute Enable

— Logoff Time

RELAY MENU................................ p.22

— Relay Work Mode

— Pull-in Voltage

— Holding Voltage

— Open Delay

— Relay Driver

— Relay Driver PWM

— Relay Driver Feedback

CAN INTERFACE MENU................. p.23

— Baud Rate

— Node ID

— Heartbeat Rate

— Auto Operation

— CAN NMT State

RPDO1—RPDO4 SETUPS MENUS.... p.24

— RPDOn Event Time

— RPDOn COB ID

RPD O1—RPDO4 SETUPS

MENUS.............................. p.24

— Length

— Map 1 through Map 8

TPDO1—TPDO4 SETUPS MENUS.... p.24

— TPDOn Event Time

— TPDOn COB ID

TPD O1—TPDO4 MAPPING

MENUS.............................. p.24

— Length

— Map 1 through Map 8

MISC MENU.................................. p.27

— Restore Parameters

— AM Base Calibration

— Pass Through Switch

PASS THROUGH MODE MENU........... p.28

— Input PushButton Value

— Clear PushButton Value

— RFID 0

— RFID 1

— RFID 2

6 — PROGRAMMABLE PARAMETERS

pg. 15

Page 22

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

The programmable parameters allow you to configure the ECS so that it meets your application’s

requirements. Curtis programming devices provide a user-friendly way to read and write to

the parameters.

Note: You can change some parameters with the keypad; see Program Parameters with the Keypad.

Restart the ECS after you change a parameter marked as [PCF]. If the ECS is not restarted, a

Parameter Change fault will occur.

e parameters are grouped into menus and are described in the following topics. e following

columns in the parameter description tables contain multiple types of information:

• Parameter and CAN Index: e parameter name, followed by the CAN index and sub-index.

is column also identies parameters marked as [PCF].

Note: CAN indexes and sub-indexes are delimited by colons. For example, a parameter with

an index of 0x4E46 and a sub-index of 0x00 would be represented as 0x4E46:00.

• Val ue s and Raw Values: e allowed values as displayed in Curtis programming devices,

followed by allowed values in raw units suitable for CAN messages.

• Data Size and Read/Write. e parameter’s data size, followed by whether the parameter is

writable (RW) or read-only (RO).

• Access Level and Default Value. e parameter’s access level for Curtis programming devices,

followed by the default value.

Note: Curtis programming device licenses provide dierent access levels to parameters.

pg. 16

6 — PROGRAMMABLE PARAMETERS

Page 23

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

LOGON USER MANAGEMENT MENU

e Logon User Management parameters indicate information about the logged-on user. e Logon

User Management menu also contains the Logon User Setup menu.

Note: e Logon RFID 1, Logon RFID 2, and Logon RFID 3 parameters cannot be accessed through

the CANbus.

LOGON USER MANAGEMENT MENU

PARAMETER

CAN INDEX

Logon User ID

0x3804:00

Logon User Name Code

0x3805:00

Logon RFID 1 0–4294967295

Logon RFID 2 0–4294967295

Logon RFID 3 0–4294967295

VALUES

RAW VALUES

–1 to +99

–1 to +99

0–99999

0–99999

0–4294967295

0–4294967295

0–4294967295

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RO

32-bit

RO

32-bit

RO

32-bit

RO

32-bit

RO

Field Basic Indicates the user ID of the logged-on user.

Note: –1 indicates that no one is logged on. The

supervisor user ID is 0.

Field Basic Indicates the user name code of the logged-on user.

Field Basic Indicates the rst four bytes of the UID of the logged-

on user’s RFID tag.

Field Basic Indicates the second set of bytes of the RFID tag's

UID. The value depends upon the tag’s cascade level:

• Cascade level 2: Three bytes

• Cascade level 3: Four bytes

Field Basic For cascade level 3 tags, indicates the last two bytes

of the RFID tag's UID.

6 — PROGRAMMABLE PARAMETERS

pg. 17

Page 24

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

LOGON USER SETUP MENU

e following table describes the Logon User Setup menu. e parameters let the logged-on user

create or change the user’s PIN code, RFID tag, and user name code.

e Logon User Setup Menu is visible only when the supervisor is logged on to manage users or the

vehicle operator is logged on to manage the user’s credentials. In addition, the menu’s parameters

can be accessed through the CANbus only if the supervisor or vehicle operator is logged on.

LOGON USER SETUP MENU

PARAMETER

CAN INDEX

New PIN Code

0x3828:00

Save New PIN Code

0x3829:00

New RFID Tag

0x3827:00

Delete RFID Tag

0x382C:00

New Name Code

0x382A:00

Save New Name Code

0x382B:00

VALUES

RAW VALUES

0–999999999

0–999999999

Off/On

0–1

Off/On

0–1

Off/On

0–1

0–99999

0–99999

Off/On

0–1

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

32-bit

RW

8-bit

RW

8-bit

RW

8-bit

RW

32-bit

RW

32-bit

RW

Field Basic Indicates a new PIN code for the logged-on user.

Specify 9 as a control word, followed by the PIN code.

For example, if the PIN code is 3579, specify 93579.

The new PIN code is activated by setting the Save

New PIN Code parameter to On.

Field Basic Activates the New PIN Code.

Field Basic Adds or changes an RFID tag for the logged-on user.

To add the tag, set the parameter to On, then place

the tag in front of the ECS until the buzzer sounds

the Success sound.

Field Basic Deletes the RFID tag of the logged-on user. To delete,

set the parameter to On.

Field Basic Indicates a new user name code. Specify 9 as a control

word, followed by the user name code. For example, if

the user name code is 2468, specify 92468.

The new user name code is activated by setting the

Save New Name Code parameter to On

Field Basic Activates the New Name Code.

pg. 18

6 — PROGRAMMABLE PARAMETERS

Page 25

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

SUPERVISOR MANAGEMENT MENU

e Supervisor Management menu allows the supervisor to add and delete authorized users. is

menu is visible when the supervisor has logged on to manage users.

Note: e First Free User ID parameter cannot be accessed through the CANbus. Data for the other

parameters can be downloaded and uploaded only when the supervisor is logged on to manage users.

Adding a user involves creating an RFID tag and/or a PIN code for a user ID. When a PIN code or

an RFID tag is added or a user is deleted, the buzzer sounds the Success sound. For steps on using

this menu, see Use the Supervisor Management Menu.

e following table describes the Supervisor Management parameters.

SUPERVISOR MANAGEMENT MENU

PARAMETER

CAN INDEX

First Free User ID 0–99

Target User ID

0x3830:00

Target User State

0x3831:00

Create Target User

PIN Code

0x3833:00

Create Target User

RFID Tag

0x3832:00

Delete Target User

0x3834:00

VALUES

RAW VALUES

0–99

1–99

1–99

1–5

1–5

Off/On

0–1

Off/On

0–1

Off/On

0–1

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RO

8-bit

RW

8-bit

RO

8-bit

RW

8-bit

RW

8-bit

RW

Field Basic Indicates the rst user ID for which neither a PIN Code

nor a user tag has been added.

Field Basic Species the user ID to be managed.

Field Basic Indicates the user status of the Target User ID.

1 = The user is not authorized to access the ECS.

2 = The user only has a PIN Code.

3 = The user only has an RFID tag.

4 = The user has both a PIN Code and an RFID tag.

5 = An error has occurred.

Field Basic Activates the PIN code for the Target User ID. To

activate, set the parameter to On.

The default PIN code is 1234. It’s recommended that

the user change the PIN code.

If the supervisor attempts to create a new PIN code

for a Target User ID that already has a PIN code, the

buzzer will sound the Error sound. To create a new

PIN code, delete the user, then create a PIN code for

the same user ID.

Field Basic Activates the RFID tag for the Target User ID. To

activate, set the parameter to On, then place the

tag in front of the ECS until the buzzer sounds the

Success sound.

If the supervisor attempts to create a new tag for a

Target User ID that already has a tag, the buzzer will

sound the Error sound. To create a new tag, delete

the user, then create a tag for the same user ID.

Field Basic Deletes the Target User ID. To delete, set the

parameter to On.

6 — PROGRAMMABLE PARAMETERS

pg. 19

Page 26

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

USER INFORMATION MENU

e following table describes the User Information parameters. e menu also contains the Registered

User List menu.

Note: e User Information parameters cannot be accessed through the CANbus.

USER INFORMATION MENU

PARAMETER

CAN INDEX

Last Logon User ID 0–99

Total Registered Users 0–100

VALUES

RAW VALUES

0–99

0–100

Registered User List Menu

e Registered User List menu contains the Supervisor menu and the User 01–99 menus, which are

described in the following topics.

Supervisor Menu

e following table describes the parameters on the Supervisor menu. e supervisor’s user ID is 00.

Note: e Supervisor menu parameters cannot be accessed through the CANbus.

USER INFORMATION MENU — SUPERVISOR MENU

PARAMETER

CAN INDEX

User Status 1–5

User Name Code 0–99999

VALUES

RAW VALUES

1–5

0–99999

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RO

8-bit

RO

Field Basic Indicates the user ID of the last user to log onto

the ECS.

OEM Dealer Indicates the number of registered users.

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RO

32-bit

RO

Field Basic Indicates the supervisor’s user status. The user

statuses are represented by the same values as the

Target User State parameter’s allowed values.

Field Basic Indicates the supervisor’s user name code.

pg. 20

User 01–99 Menus

Each user ID has a User n menu, where n represents the user ID. The User n menus contain

parameters with the same names, allowed values, data sizes, descriptions, etc. e following table

describes the User n menu parameters.

Note: e User n menu parameters cannot be accessed through the CANbus.

USER INFORMATION MENU — USER 01–99 MENUS

PARAMETER

CAN INDEX

User Status 1–5

User Name Code 0–99999

VALUES

RAW VALUES

1–5

0–99999

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RO

32-bit

RO

Field Basic Indicates the user’s status. The user statuses are

represented by the same values as the Target User

State parameter’s allowed values.

Field Basic Indicates the user name code.

6 — PROGRAMMABLE PARAMETERS

Page 27

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

APPLICATION SETUP MENU

e Application Setup menu contains the following menus:

• Control menu

• Relay menu

• CAN Interface menu

• Misc menu

ese menus are used to congure the ECS, and are described in the following topics.

Control Menu

e following table describes the parameters on the Control menu.

APPLICATION SETUP MENU — CONTROL MENU

PARAMETER

CAN INDEX

Interlock Type

0x3705:00

Interlock High Threshold

0x3323:00

Mute Enable

0x3701:00

Logoff Time

0x3702:00

VALUES

RAW VALUES

0–1

0–1

2.00–30.00V

200–3000

Off/On

0–1

0–255

0–255 min

DATA SIZE

READ/WRITE

8-bit

RW

16-bit

RW

8-bit

RW

8-bit

RW

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer0Indicates whether the interlock signal is controlled by

the interlock input or RPDO1:

0 = Interlock input (pin 2)

1 = RPDO1

OEM Dealer

8.00V

Field Basic

Off

Field Basic

30 min

Indicates the high level threshold for the

interlock input.

Indicates whether the buzzer is muted:

Off = Audible

On = Muted

Indicates the automatic logoff time. If the interlock

signal has been off for the specied time, the ECS

automatically logs the user off.

To disable the automatic logoff, specify 0.

6 — PROGRAMMABLE PARAMETERS

pg. 21

Page 28

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

Relay Menu

e following table describes the parameters on the Relay menu.

APPLICATION SETUP MENU — RELAY MENU

PARAMETER

CAN INDEX

Relay Work Mode [PCF]

0x3706:00

Pull-in Voltage

0x34C8:00

Holding Voltage

0x34C6:00

Open Delay

0x34CA:00

Relay Driver

0x34CC:00

Relay Driver PWM

0x34CD:00

Relay Driver Feedback

0x34CE:00

VALUES

RAW VALUES

0–2

0–2

60.0–100.0%

2457–4095

60.0–100.0%

2457–4095

0–4000ms

0–1000

Off/On

0–1

0–100.0%

0–16384

Off/On

0–1

DATA SIZE

READ/WRITE

8-bit

RW

16-bit

RW

16-bit

RW

16-bit

RW

8-bit

RO

16-bit

RO

8-bit

RO

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer1Indicates how the relay is engaged and disengaged:

0 = Disable relay output. The relay remains open

even if an authorized user logs in.

1 = Engage and disengage the relay when an

authorized user logs on or off.

2 = Engage and disengage the relay with the

Control CAN State object. For more information,

see RPDO1.

OEM Dealer

100.0%

OEM Dealer

75.0%

OEM Dealer

40ms

Field Basic

N/A

OEM Dealer

N/A

OEM Dealer

N/A

Indicates the initial voltage when the relay driver is

rst turned on.

The ECS allows a high initial voltage to ensure the

relay closes. After 1 second, the voltage decreases to

the Holding Voltage.

Indicates the reduced voltage that the ECS applies to

the relay after it has closed.

Specify a voltage that is high enough to ensure the

relay remains closed under all shock and vibration

conditions the vehicle is expected to encounter.

Indicates how long the relay remains closed after a

user logs off or a CAN command opens the relay.

Indicates whether the relay driver is on.

Indicates the relay coil’s PWM duty cycle.

Indicates whether the relay coil is energized:

Off = Not energized

On = Energized

pg. 22

6 — PROGRAMMABLE PARAMETERS

Page 29

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

CAN Interface Menu

e following table describes the parameters on the CAN Interface menu.

APPLICATION SETUP MENU — CAN INTERFACE MENU

PARAMETER

CAN INDEX

Baud Rate [PCF]

0x2001:01

Node ID [PCF]

0x2000:01

Heartbeat Rate

0x1017:00

Auto Operation

0x32BC:00

CAN NMT State

0x32A4:00

VALUES

RAW VALUES

–1 to +4

–1 to +4

1–7Fh

1–7Fh

16–200ms

4–50

Off/On

0–1

0–127

0–127

DATA SIZE

READ/WRITE

8-bit

RW

8-bit

RW

16-bit

RW

8-bit

RW

8-bit

RO

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer0Species the CAN baud rate:

–1 = 100 Kbps

0 = 125 Kbps

1 = 250 Kbps

2 = 500 Kbps

3 = 800 Kbps

4 = 1 Mbps

OEM Dealer

46h

OEM Factory

100ms

OEM Dealer

Off

Field Basic

N/A

Species the ECS’s node ID.

Note: Node ID 127 is reserved for Curtis

programming devices.

Specifies the cyclic rate of the ECS's

heartbeat messages.

Species the ECS’s NMT state after it has

powered up:

On = Operational

Off = Pre-operational

Indicates the ECS’s NMT state:

0 = Initialization

4 = Stopped

5 = Operational

127 = Pre-operational

e CAN Interface menu contains the RPDO Setups and TPDO Setups menus. e PDO Setups

menus contain the RPDO Mapping and TPDO Mapping menus, which specify the objects for which

the PDOs transmit and receive data.

6 — PROGRAMMABLE PARAMETERS

pg. 23

Page 30

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

PDO Setups Menus and PDO Mapping Menus

e ECS provides four RPDOs and four TPDOs. e PDO Setups menus contain the PDOs’ Event

Time and COB-ID parameters.

Note: PDO1 and PDO2 are precongured to communicate with devices on the CANbus; see PDO1

and PDO2. PDO3 and PDO4 are not precongured.

e parameters on the PDO Setups menus contain similar names; the names’ rst words correspond

to the parameters’ PDOs. For example, the parameter for RPDO1’s event time is named RPDO1

Event Time. e PDO Mapping menus each contain a Length parameter and the Map 1 through

Map 8 parameters.

The parameters on these menus contain the same allowed values, descriptions, etc.; the only

dierences are the parameters’ CAN indexes and default values. e following tables describe the

menus’ parameters, followed by a table that lists the parameters’ CAN indexes and default values.

Table 5 PDO Setup Menus

VALUES

PARAMETER

RDPOn Event Time 0–65535ms

TDPOn Event Time 0–65535ms

RPDOn COB ID and

TPDOn COB ID

RAW VALUES

0–65535

0–65535

0–FFFFFFFFh

0–FFFFFFFFh

Table 6 PDO Mapping Menus

VALUES

PARAMETER

Length 0–8

Map 1 0–FFFFFFFFh

Map 2 0–FFFFFFFFh

Map 3 0–FFFFFFFFh

Map 4 0–FFFFFFFFh

Map 5 0–FFFFFFFFh

Map 6 0–FFFFFFFFh

Map 7 0–FFFFFFFFh

Map 8 0–FFFFFFFFh

RAW VALUES

0–8

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

0–FFFFFFFFh

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

16-bit

RW

16-bit

RW

32-bit

RW

OEM Dealer Species the RPDO’s timeout. If the RPDO does

not receive data before the timeout elapses, a PDO

Timeout fault will occur.

To disable the timeout, specify 0.

OEM Dealer Species the cyclic rate of the TPDO’s messages.

OEM Factory Species the PDO’s COB-ID.

DATA SIZE

READ/WRITE ACCESS LEVEL DESCRIPTION

8-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

32-bit

RW

OEM Factory Species the number of objects mapped to the PDO.

OEM Factory Species the rst mapped object.

OEM Factory Species the second mapped object.

OEM Factory Species the third mapped object.

OEM Factory Species the fourth mapped object.

OEM Factory Species the fth mapped object.

OEM Factory Species the sixth mapped object.

OEM Factory Species the seventh mapped object.

OEM Factory Species the eighth mapped object.

pg. 24

Note: For information on mapping objects, see Map CAN Objects to a PDO.

6 — PROGRAMMABLE PARAMETERS

Page 31

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

Table 7 PDO Parameters' CAN Indexes and Default Values

MENU PARAMETER CAN INDEX DEFAULT VALUE

RPDO1 Setups RPDO1 Event Time

RPDO1 Setups RPDO1 COB ID

RPDO1 Mapping Length

RPDO1 Mapping Map 1

RPDO1 Mapping Map 2

RPDO1 Mapping Map 3

RPDO1 Mapping Map 4

RPDO1 Mapping Map 5

RPDO1 Mapping Map 6

RPDO1 Mapping Map 7

RPDO1 Mapping Map 8

TPDO1 Setups TPDO1 Event Time

TPDO1 Setups TPDO1 COB ID

TPDO1 Mapping Length

TPDO1 Mapping Map 1

TPDO1 Mapping Map 2

TPDO1 Mapping Map 3

TPDO1 Mapping Map 4

TPDO1 Mapping Map 5

TPDO1 Mapping Map 6

TPDO1 Mapping Map 7

TPDO1 Mapping Map 8

RPDO2 Setups RPDO2 Event Time

RPDO2 Setups RPDO2 COB ID

RPDO2 Mapping Length

RPDO2 Mapping Map 1

RPDO2 Mapping Map 2

RPDO2 Mapping Map 3

RPDO2 Mapping Map 4

RPDO2 Mapping Map 5

RPDO2 Mapping Map 6

RPDO2 Mapping Map 7

RPDO2 Mapping Map 8

TPDO2 Setups TPDO2 Event Time

TPDO2 Setups TPDO2 COB ID

TPDO2 Mapping Length

TPDO2 Mapping Map 1

TPDO2 Mapping Map 2

TPDO2 Mapping Map 3

TPDO2 Mapping Map 4

TPDO2 Mapping Map 5

TPDO2 Mapping Map 6

TPDO2 Mapping Map 7

TPDO2 Mapping Map 8

RPDO3 Setups RPDO3 Event Time

0x1400:05

0x1400:01

0x1600:00

0x1600:01

0x1600:02

0x1600:03

0x1600:04

0x1600:05

0x1600:06

0x1600:07

0x1600:08

0x1800:05

0x1800:01

0x1A00:00

0x1A00:01

0x1A00:02

0x1A00:03

0x1A00:04

0x1A00:05

0x1A00:06

0x1A00:07

0x1A00:08

0x1401:05

0x1401:01

0x1601:00

0x1601:01

0x1601:02

0x1601:03

0x1601:04

0x1601:05

0x1601:06

0x1601:07

0x1601:08

0x1801:05

0x1801:01

0x1A01:00

0x1A01:01

0x1A01:02

0x1A01:03

0x1A01:04

0x1A01:05

0x1A01:06

0x1A01:07

0x1A01:08

0x1402:05

200ms

246h

1

37800010h

0

0

0

0

0

0

0

40ms

400001C6h

4

38000008h

4E020008h

37070010h

38040008h

0

0

0

0

0ms

346h

1

38100008h

0

0

0

0

0

0

0

40ms

400002C6h

6

38140008h

38040008h

38130008h

38110008h

38120010h

38030008h

0

0

40ms

6 — PROGRAMMABLE PARAMETERS

pg. 25

Page 32

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

Table 7 PDO Parameters' CAN Indexes and Default Values, cont’d

MENU PARAMETER CAN INDEX DEFAULT VALUE

RPDO3 Setups RPDO3 COB ID

RPDO3 Mapping Length

RPDO3 Mapping Map 1

RPDO3 Mapping Map 2

RPDO3 Mapping Map 3

RPDO3 Mapping Map 4

RPDO3 Mapping Map 5

RPDO3 Mapping Map 6

RPDO3 Mapping Map 7

RPDO3 Mapping Map 8

TPDO3 Setups TPDO3 Event Time

TPDO3 Setups TPDO3 COB ID

TPDO3 Mapping Length

TPDO3 Mapping Map 1

TPDO3 Mapping Map 2

TPDO3 Mapping Map 3

TPDO3 Mapping Map 4

TPDO3 Mapping Map 5

TPDO3 Mapping Map 6

TPDO3 Mapping Map 7

TPDO3 Mapping Map 8

RPDO4 Setups RPDO4 Event Time

RPDO4 Setups RPDO4 COB ID

RPDO4 Mapping Length

RPDO4 Mapping Map 1

RPDO4 Mapping Map 2

RPDO4 Mapping Map 3

RPDO4 Mapping Map 4

RPDO4 Mapping Map 5

RPDO4 Mapping Map 6

RPDO4 Mapping Map 7

RPDO4 Mapping Map 8

TPDO4 Setups TPDO4 Event Time

TPDO4 Setups TPDO4 COB ID

TPDO4 Mapping Length

TPDO4 Mapping Map 1

TPDO4 Mapping Map 2

TPDO4 Mapping Map 3

TPDO4 Mapping Map 4

TPDO4 Mapping Map 5

TPDO4 Mapping Map 6

TPDO4 Mapping Map 7

TPDO4 Mapping Map 8

0x1402:01

0x1602:00

0x1602:01

0x1602:02

0x1602:03

0x1602:04

0x1602:05

0x1602:06

0x1602:07

0x1602:08

0x1802:05

0x1802:01

0x1A02:00

0x1A02:01

0x1A02:02

0x1A02:03

0x1A02:04

0x1A02:05

0x1A02:06

0x1A02:07

0x1A02:08

0x1403:05

0x1403:01

0x1603:00

0x1603:01

0x1603:02

0x1603:03

0x1603:04

0x1603:05

0x1603:06

0x1603:07

0x1603:08

0x1803:05

0x1803:01

0x1A03:00

0x1A03:01

0x1A03:02

0x1A03:03

0x1A03:04

0x1A03:05

0x1A03:06

0x1A03:07

0x1A03:08

0x80000446

0

0

0

0

0

0

0

0

0

40ms

0xC0003C6

0

0

0

0

0

0

0

0

0

40ms

0x80000546

0

0

0

0

0

0

0

0

0

40ms

0xC00004C6

0

0

0

0

0

0

0

0

0

pg. 26

6 — PROGRAMMABLE PARAMETERS

Page 33

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

Misc Menu

e following table describes the parameters on the Misc menu.

APPLICATION SETUP MENU — MISC MENU

PARAMETER

CAN INDEX

Restore

Parameters [PCF]

0x4E46:00

AM Base

Calibration [PCF]

0x3612:00

Pass Through Switch

0x3712:00

VALUES

RAW VALUES

Off/On

0–1

Off/On

0–1

0–1

0–1

DATA SIZE

READ/WRITE

8-bit

RW

8-bit

RW

8-bit

0

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer

Off

OEM Dealer

Off

OEM Dealer0Indicates whether the ECS is running in pass-through

Resets all parameters to their default values. To

reset, specify On.

After the parameters have been reset, the value

reverts to Off.

Calibrates the antenna eld strength level so that the

ECS automatically detects the best channel for RFID

recognition. To calibrate, specify On.

After calibration has nished, the value reverts to Off.

mode. 0 indicates that pass-through mode is off.

Note: If the value is 1, the Pass Through Mode menu

is visible.

6 — PROGRAMMABLE PARAMETERS

pg. 27

Page 34

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

PASS THROUGH MODE MENU

e Pass rough Mode menu is visible if the ECS is operating in pass-through mode. Pass-through

mode is designed for applications in which another CAN device can receive keypad entries and RFID

tag swipes. Pass-through mode has the following characteristics:

• Users cannot log on.

• e ECS remains in the idle state.

• e Input PushButton Value parameter stores the keys that were entered before the button

was pressed. e parameter is reset to 0 if the Clear PushButton Value parameter is set to On

or an RFID tag is swiped.

• e RFID parameters store the UIDs of swiped tags. ese parameters are reset to 0 if the user

presses numeric keys and then presses the button.

To enable pass-through mode, set the Pass rough Switch parameter to 1.

e following table describes the Pass rough Mode parameters.

PASS THROUGH MODE MENU

PARAMETER

CAN INDEX

Input PushButton Value

0x5902:00

Clear PushButton Value

0x5902:01

RFID 0

0x5901:00

RFID 1

0x5901:01

RFID 2

0x5901:02

VALUES

RAW VALUES

0–999999999

0–999999999

Off/On

0–1

0–4294967295

0–4294967295

0–4294967295

0–4294967295

0–4294967295

0–4294967295

DATA SIZE

READ/WRITE

32-bit

RO

8-bit

RW

32-bit

RO

32-bit

RO

32-bit

RO

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer

N/A

OEM Dealer0Sets the Input PushButton Value parameter to 0

OEM Dealer

N/A

OEM Dealer

N/A

OEM Dealer

N/A

Indicates the keys that were pressed before the

button was pressed.

9 is prepended to the key numbers. For example, if the

3579 keys were pressed, the value would be 93579.

Note: If more than eight keys have been pressed, the

buzzer sounds the Error sound to indicate that the

maximum value was exceeded.

when On is specied.

Indicates the rst four bytes of the RFID tag’s UID.

Indicates the second set of bytes of the RFID tag's

UID. The value depends upon the tag’s cascade level:

• Cascade level 2: Three bytes

• Cascade level 3: Four bytes

For cascade level 3 tags, indicates the last two bytes

of the tag's UID.

pg. 28

6 — PROGRAMMABLE PARAMETERS

Page 35

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

7 — SYSTEM MONITOR MENU

SYSTEM MONITOR MENU................. p.29

ECS STATE

STATE MENU................................ p.30

— Interlock State

— Relay State

— Buzzer State

INPUTS MENU.............................. p.31

SWITCH STATUS MENU........... p.31

— Interlock Switch

VOLTAGE MENU....................... p.31

— Battery Voltage

— Relay COM Voltage

— Interlock Voltage

FAULT HISTORY MENU................. p.32

— Clear History

PARAMETER

CAN INDEX

ECS State

0x3801:00

e System Monitor menu contains read-only parameters that display real-time data. You can use

these parameters to congure and troubleshoot the ECS. e System Monitor menu includes menus

that contain parameters, as well as the ECS State parameter.

e System Monitor menu also contains the Fault History menu, which lists the fault history and

provides a parameter to clear the history.

e following table describes the ECS State parameter.

SYSTEM MONITOR MENU

VALUES

RAW VALUES DATA SIZE ACCESS LEVEL DESCRIPTION

0–4

0–4

8-bit Field Basic Indicates the ECS’s operational state:

0 = Idle

1 = PIN code or RFID tag validation. For example,

the ECS is in this state when a user presses and

holds for two seconds before entering a

user ID and PIN code or swiping an RFID tag.

2 = Supervisor management. The supervisor is

logged on to manage users.

3 = User management. A user is logged on to

manage the PIN code and/or user name.

4 = Logged on. A user is logged on to drive the vehicle.

e following topics describe the System Monitor menus.

7 — SYSTEM MONITOR MENU

pg. 29

Page 36

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

STATE MENU

e following table describes the parameters on the State menu.

STATE MENU

PARAMETER

CAN INDEX

Interlock State

0x3322:00

Relay State

0x34C9:00

Buzzer State

0x4E20:00

VALUES

RAW VALUES DATA SIZE ACCESS LEVEL DESCRIPTION

Off/On

0–1

0–9

0–9

Off/On

0–1

8-bit Field Basic Indicates whether the interlock signal is active:

Off = Inactive

On = Active

8-bit Field Basic Indicates the relay operation state:

0 = Relay is open

1 = Precharge

2 = Relay Welded fault check

3 = Closing delay. The relay has closed but its status

is being conrmed.

4 = Missing check. The ECS is verifying whether the

relay has closed.

5 = Relay is closed

6 = Delay. The relay has received the open command

but remains closed until the Open Delay expires.

7 = Reserved

8 = Open delay. The relay is open but is within a

96ms delay before the relay can be closed again.

9 = Fault

8-bit Field Basic Indicates whether the buzzer is sounding a notication:

Off = Buzzer is silent

On = Buzzer is sounding

pg. 30

7 — SYSTEM MONITOR MENU

Page 37

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

INPUTS MENU

The Inputs menu contains the Switch Status and Voltage menus, which are described in the

following topics.

Switch Status Menu

e Switch Status menu contains the Interlock Switch parameter:

INPUTS MENU — SWITCH STATUS MENU

PARAMETER

CAN INDEX

Interlock Switch

0x3320:00

PARAMETER

CAN INDEX

Battery Voltage

0x3393:00

Relay COM Voltage

0x34C5:00

Interlock Voltage

0x34AF:00

VALUES

RAW VALUES DATA SIZE ACCESS LEVEL DESCRIPTION

Off/On

0–1

8-bit Field Basic Indicates whether the interlock input is on.

Voltage Menu

e following table describes the parameters on the Voltage menu.

INPUTS MENU — VOLTAGE MENU

VALUES

RAW VALUES DATA SIZE ACCESS LEVEL DESCRIPTION

0–150.00V

0–15000

0–150.00V

0–15000

0–35.00V

0–3500

16-bit Field Basic Indicates the B+ input’s voltage.

16-bit Field Basic Indicates the Relay COM input’s voltage.

16-bit OEM Dealer Indicates the interlock input’s voltage.

Note: If the input’s voltage exceeds 35V, the parameter

value will be clamped to 35V.

7 — SYSTEM MONITOR MENU

pg. 31

Page 38

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

FAULT HISTORY MENU

e Fault History menu lists the history of the ECS’s faults. Each fault’s history includes the Count,

Time, First Time, and Type parameters, as shown in the following screenshots from the Curtis

Integrated ToolkitTM (CIT) and the Curtis 1313 handheld programmer:

Figure 4

Fault History Details — CIT

Figure 5

Fault History Details —

1313 Programmer

e menu also provides the Clear History parameter:

PARAMETER

CAN INDEX

Clear History

0x20F0:01

VALUES

RAW VALUES

Off/On

0–1

FAULT HISTORY MENU

DATA SIZE

READ/WRITE

16-bit

RW

ACCESS LEVEL

DEFAULT VALUE DESCRIPTION

OEM Dealer

Off

Clears the fault history. To clear the history,

specify On.

After the fault history has been cleared, the value

reverts to Off.

pg. 32

7 — SYSTEM MONITOR MENU

Page 39

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

8 — DIAGNOSTICS AND FAULTS

The ECS provides diagnostic information to help technicians troubleshoot. You can view the

diagnostic information with Curtis programming devices and the status LEDs.

PROGRAMMING DEVICE DIAGNOSTICS

e following list describes how Curtis programming devices display diagnostic information:

• Real-time data such as the statuses of inputs and outputs are displayed in the System

Monitor menu.

• A history of faults is displayed in the Fault History menu.

• Active faults are displayed above the parameter menus. e following examples from CIT and

the Curtis 1313 handheld programmer show that a Parameter Change fault is active:

Figure 6

Active Faults — CIT

Figure 7

Active Faults — 1313

Programmer

Tip: To see a fault’s fault type in CIT, expand the fault. To see a fault’s fault type in the 1313

programmer, select the fault.

8 — DIAGNOSTICS AND FAULTS

pg. 33

Page 40

Curtis Electronic Code Switch Module (ECS) – March 2021 Return to TOC

LEDs AND FAULT CODES

When one or more faults are active, the red and green LEDs indicate the faults in the following ash

sequence:

1. e red LED indicates the fault code’s rst digit by ashing n times, where n is the digit.

2. e green LED indicates the fault code's second digit by ashing n times, where n is the digit.

For example, if the fault code is 34, the red LED ashes three times, then the green LED ashes

four times.

Red Green

3. A delay occurs.

4. If more than one fault is active, the previous steps occur for each fault.

5. e sequence repeats as long as there are active faults.

When a fault occurs, the ECS transmits a CANopen emergency message that includes the fault code.

See Emergency Messages and Faults.

FAULT RECORDS

Each ECS fault is represented by a Fault Record. Fault Records are identied by the CAN indexes

listed in Table 8. e following table describes the sub-indexes of Fault Records:

FAULT HISTORY

SUB-INDEX

01h N/A The status of the fault:

02h N/A Reserved. N/A N/A

03h Count The number of times the fault has occurred

04h Time The time, in seconds, of the fault’s most recent

05h First Time The time, in seconds, of the fault’s rst

06h Type The fault’s fault type.

PARAMETER DESCRIPTION READ / WRITE

RO 0–255

• 00h = The fault has never occurred.

• 01h = The fault is not active.

• 03h = The fault is active.

RO 0–4294967295

since the fault history was cleared.

RO 0–4294967295

occurrence since the fault history was cleared.

To calculate the number of seconds, divide the

value by 10.

RO 0–4294967295

occurrence since the fault history was cleared.

To calculate the number of seconds, divide the

value by 10.

RO 0–4294967295

If multiple instances of the fault have occurred

and the instances have different fault types,

sub-index 06h contains the most recent

instance’s fault type.

VALUES

DATA SIZE

8-bit

32-bit

32-bit

32-bit

32-bit

pg. 34

Note: Sub-indexes 03h through 06h correspond to the parameters contained by the faults in the Fault

History menu. e Fault History Parameter column lists the parameters’ names.

8 — DIAGNOSTICS AND FAULTS

Page 41

Return to TOC Curtis Electronic Code Switch Module (ECS) – March 2021

FAULT CODES

When the ECS detects a fault, it operates in a manner that is safe in the presence of that fault.

Depending on a fault’s severity, a fault’s eect can range from no action to shutting down operation.

Some faults have multiple causes. e ECS uses fault types to distinguish these causes. All faults have

a fault type of 1; faults with multiple causes have additional fault types.

e following table describes the fault codes.

Table 8 Fault Codes

FAULT CODE

CAN INDEX

13

0x2223

21

0x2222

22

0x2221

23

0x2220

32

0x2591

NAME

FAULT ACTIONS

Precharge Failed

Disengage relay

Shut down

Relay Driver Fault

Disengage relay

Shut down

Relay Did Not Close

Disengage relay

Shut down

Relay Welded

Disengage relay

Shut down

Hardware Fault

Disengage relay

Shut down

POSSIBLE CAUSES

• Incorrect Relay COM voltage

• Defective precharge circuit

Defective relay driver 1 Relay driver feedback is low

• Open relay coil

• Defective relay driver

Incorrect Pull-in Voltage

parameter value.

Defective relay 2 With the relay on, the

Defective relay 1 Before the ECS turns on the

Defective keypad button 1 A button on the keypad was

FAULT

TYPE

1 • After 500ms of

2 The Relay COM voltage

2 Relay driver feedback is

1 96ms after the relay driver

SET CONDITION CLEAR CONDITION

precharging, the Relay NO

voltage is less than 90%

of the Relay COM voltage.

• After 40ms of

precharging, the Relay

NO voltage is less

than the larger of the

following voltages:

• 2V

• 90% of the Relay

COM voltage.

is less than 4V for 40ms

and the Relay Work Mode

parameter value is not 0.

with the relay driver signal

off for 100ms.