Page 1

CURTIS DECANTER BREWER

TROUBLESHOOTING GUIDE

Service & Sales

1-800-421-6150

www.wilburcurtis.com

Page 2

Page 3

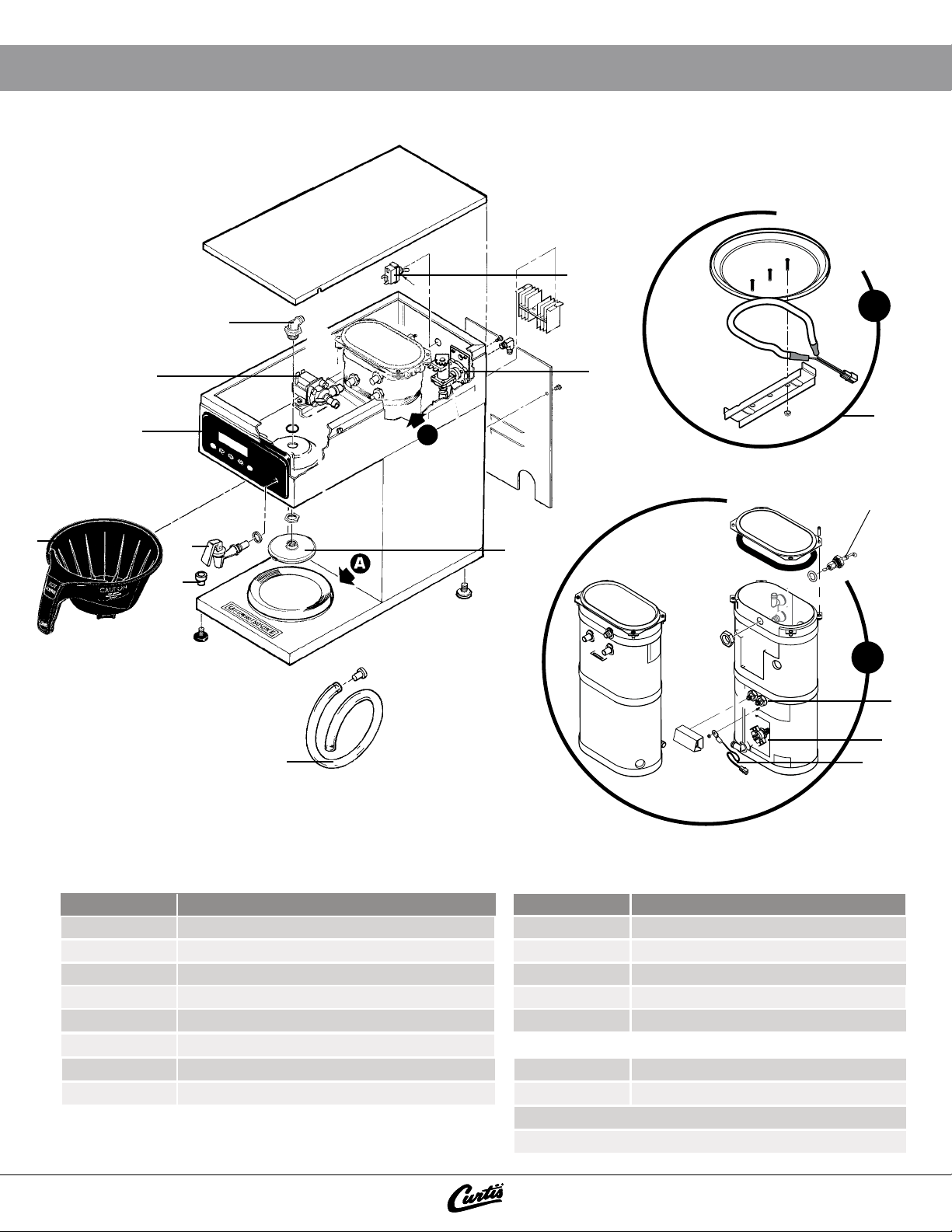

BREWER PARTS IDENTIFICATION

15

9

3

1

12

14

B

2

7

5

4

6

B

10

11

A

8

9

WATER RELATED HEAT RELATED

PART #

1. WC- 826L VALVE, INLET 1.0 GPM 120V

2. WC-5527K KIT, PROBE WATER LVL FITTING, ORING, NUT

3. WC- 889 VALVE, DUMP LEFT 120V 12W

4. WC-29025 SPRAYHEAD, PURPLE ADVANCE FLOW

5. WC-37252 KIT, HOT WATER FAUCET REPLACEMENT

6. WC-1806 SEAT CUP, SILICONE

7. WC-3621-101

8. WC-5310 TUBING, SILICONE

Service & Sales

Service & Sales

1-800-421-6150

1-800-421-6150

DESCRIPTION

BREW CONE, COFEE

PART #

9. WC-1438-101 SENSOR, TEMPERATURE TANK

10. WC- 917-04 HEATING ELEMENT

11. WC- 523 THERMOSTAT, HI LIMIT HEATER

12. WC- 972-102 BREW WARMER

13. WC-6193-0 TRIAC, 40A 600V (NOT ILLUSTRATED)

MASTER CONTROL

14A. WC-37061

14B. WC-37062

14C. WC-37063

15. WC- 102 SWITCH, TOGGLE DPST 25A 125/25OVAC

DESCRIPTION

KIT, LABEL & UCM ALPHA 1GT

KIT, LABEL & UCM ALPHA 2GT

KIT, LABEL & UCM ALPHA 3GT

www.wilburcurtis.com

www.wilburcurtis.com

Page 4

PARTS IMAGES

1

WC-826L

VALVE, INLET 1.0 GPM 120V

2 3

WC-5527K

KIT, PROBE WATER LVL

FITTING, ORING, NUT

5 6 7

WC-37252

KIT, HOT WATER FAUCET

REPLACEMENT

WC-1806

SEAT CUP, SILICONE

VALVE, DUMP LEFT 120V 12W

WC-889

WC-3621-101

BREW CONE, COFEE

4

WC-29025

SPRAYHEAD, PURPLE

ADVANCE FLOW

8

WC-5310

TUBING, SILICONE

9

WC-1438-101

SENSOR, TEMPERATURE TANK

13

WC-6193-0

TRIAC, 40A 600V

10

WC-917-04

HEATING ELEMENT

14

WC-37061, WC-37062

WC-37063

KIT, LABEL & UCM

11

WC-523

THERMOSTAT, HI LIMIT HEATER

15

WC-103

SWITCH, TOGGLE DPST

25A 125/25OVAC

12

WC- 972-102

BREW WARMER

Service & Sales

1-800-421-6150

www.wilburcurtis.com

Page 5

TROUBLESHOOTING INSTRUCTIONS

POWER ISSUES

The unit will not turn on:

Check if the panel breaker is turned on. If it

1

is, proceed to STEP 2.

Check the voltage at the receptacle it should

2

read: L1-N = 120v, N-G = 0v. Proceed to

STEP 3 if accurate.

Check if the power cord is properly con-

3

nected to the receptacle. If it is, proceed to

STEP 4.

Check the toggle switch if it is in the ON

4

position. If it is ON, proceed to STEP 5.

Not heating:

LCD reads “Heating”

Yes:

Verify 120 volts between #2 & #4 on both

sides of the Manual Reset Thermostat.

If no, reset or replace the Manual Reset

Thermostat.

Verify 120 volts across the Toggle Switch.

Yes:

If no, replace the toggle switch.

Check the voltage at the power block, it

5

should read: L1-N = 120v, N-G = 0v.

Check the voltage at the reset thermostat, it

6

should read 120v.

Check the voltage at the toggle switch, it

7

should read 120v.

Verify 120v between pins #8 and #16 on

8

molex connector at UCM.

If all steps were taken and the unit still does

9

not turn on, replace the UCM.

HEATING ISSUES

Overheating/Steaming:

LCD reads “Heating”

Verify that the resistance on the Temperature

Sensor is less than 10k ohms with a hot tank

(200+ degrees) If no, verify correct mounting

and that the walls of the tank are free of mineral deposits. If yes, bypass the sensor using a

jumper with a 5k ohm resistor. If the LCD reads

“ready” and the unit stops heating, replace the

temperature sensor, if not, replace the UCM.

Verify 120 volts across the Heating Ele-

Yes:

ment. If yes, replace the Heating Element.

If no, verify 120 volts between the Triac

gate, Neutral, and L1. If yes, replace the

Triac, if no, replace the UCM.

Verify that the panel breaker is turned on

No:

and the receptacle has 120 volts. If not,

consult an electrician.

WARMER ISSUES

No power to any warmer:

Verify correct programming: (Model number).

Not heating:

Verify 120v at heating element.

Yes: Replace heating element.

No: Verify that the connections and wirings

are good. If OK, replace UCM.

Service & Sales

1-800-421-6150

LCD reads “Ready to Brew”

Check the triac for continuity across A1 & A2,

if continuity is present, replace the triac, if no

continuity, replace UCM.

Ensure that the temperature is adjusted to compensate

i

for high elevation. The factory setting is 200 degrees.

The temperature setting will need to be reduced Two

degrees for every One Thousand feet of elevation.

Constantly hot, even when turned off:

Ensure proper resistence value on the heating

element between 140-170 ohm.

Ensure wiring is not shorted to ground.

Replace UCM.

www.wilburcurtis.com

Page 6

TROUBLESHOOTING INSTRUCTIONS

TANK FILLING ISSUES

Not lling:

Yes:

Does the LCD read “Water Level

Error”?

Yes:

Verify the ow rate to be a minimum of 1

gpm from outlet of the water lter. If not,

ensure that the inlet side of the water

lter is receiving a minimum of 1 gpm. If

yes, replace the water lter. If not, con-

sult a plumber.

No:

Remove the orange wire from the probe.

Does the tank start lling?

Yes:

Replace water level probe

No:

Replace the UCM

BREWING ISSUES

LCD does not read “Brewing”:

If the LCD reads “Ready to Brew” and no

response when Brew Button is pressed, replace

the UCM.

LCD reads “Brewing”:

No water ow from the sprayhead:

Does water ow from the hot water faucet? If

yes, verify 120 volts at the dump valve coil. If

voltage is present at the dump valve coil, replace

the dump valve. If 120 volts is not present at

the dump valve coil, conrm continuety of wiring

between molex connector and Dump Valve. If

okay, replace the UCM. (Verify the resistance on

the dump valve coil to be open in one direction,

and under 2k ohm in the other direction BEFORE

REPLACING THE UCM) If water does not ow

from the hot water faucet, replace the Water Level Probe.

Brewing Short Pots:

Verify that the Hot Water Tank is lling correctly.

(See Tank Filling issues)

Overlling:

Turn OFF toggle switch.

Does the tank continue to ll?

Yes: Replace water inlet valve

No: Ground the probe wire to chassis.

Does the tank continue to still ll?

Yes: Replace the UCM

No: Replace Water Level Probe

Before replacing any parts, verify the

i

following:

Verify that the Dump Valve outlet tting on the tank,

the tubing between the tank outlet and the Sprayhead

tting, the Sprayhead, and Dump Valve are clear of

obstructions.

Ensure correct alignment of the sprayhead tting and

that the tubing is routed properly to allow for maximum

water ow. (No Kinks)

Overowing the Pot:

• Ensure that the Sprayhead has not been removed. Replace as needed.

• Ensure that the Hot Water Tank is not over-

owing (See Tank Filling Issues)

• Ensure that hot water is not owing from the

Dump Valve when the toggle switch is turned

off. If it is, replace the dump valve.

• Ensure Cold Brew Lock is set to 5 degrees

Service & Sales

1-800-421-6150

www.wilburcurtis.com

www.wilburcurtis.com

Page 7

NOTES

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Service & Sales

1-800-421-6150

www.wilburcurtis.com

Page 8

Wilbur Curs Co., Inc.

6913 Acco Street, Montebello CA 90640

Customer Service: 800.421.6150 | 323.837.2300

csrassistance@wilburcurs.com

Tech Support: 800.995.0417

www.wilburcurs.com

APR/2015 M111_TS_WC_Alpha_revNC

Loading...

Loading...