Page 1

Model CFB2 shown

Models covered

• CFB1

• CFB2

• CFB3

Wilbur Curtis Co., inC.

Service Manual – Frozen Beverage Dispenser

Important Safeguards/Symbols

Symbols:

WARNING/CAUTION – To advise about conditions that may result in property damage,

personal injury or death

IMPORTANT - Notes about proper operation

WARNING:

• This equipment is designed for commercial use only.

• To reduce the risk of re or electric shock, DO NOT open service panels. There are no user

serviceable parts inside. Any servicing other than cleaning and routine maintenance should

be performed by an authorized Wilbur Curtis Co., Inc. service technician. Refrigeration

equipment must be serviced by a licensed, certied, refrigerant technician.

• Do not install a damaged unit or a unit with a damaged power cord.

• Clean this appliance according to the CLEANING section of this manual before using it for

the rst time. Clean this appliance daily according to the CLEANING section.

• Keep hands and other items away from moving parts during operation.

• Dispose of refrigeration equipment and refrigerants in accordance with current local

environmental protection regulations and laws. This applies to an appliance that is being

replaced and to this unit, when it has reached the end of its service life. DO NOT dispose of

refrigeration equipment in a landll or urban waste. Contact your local governing authorities

for information on disposal requirements.

WARNING:

Read and follow the

setup instructions

before attempting to use this

appliance. Failure to follow these

instructions can result in injury

and/or void the warranty.

EXCESSIVE WEIGHT

WARNING: Due

to weight, this unit

requires a minimum of two

people to lift or reposition.

IMPORTANT: Installer:

Observe all codes and

ordinances.

WILBUR CURTIS CO., INC.

Montebello, CA 90640

For the latest information go to

www.wilburcurtis.com

Phone: 800-421-6150

SETUP INSTRUCTIONS

System Requirements

• Electrical: See the WIRING DIAGRAMS in this

manual or visit www.wilburcurtis.com for your

model. The electrical outlet must be in a location

that allows the unit to be easily disconnected for

service or cleaning.

• Operating Temperature: 68 to 90°F (20 to 32°C).

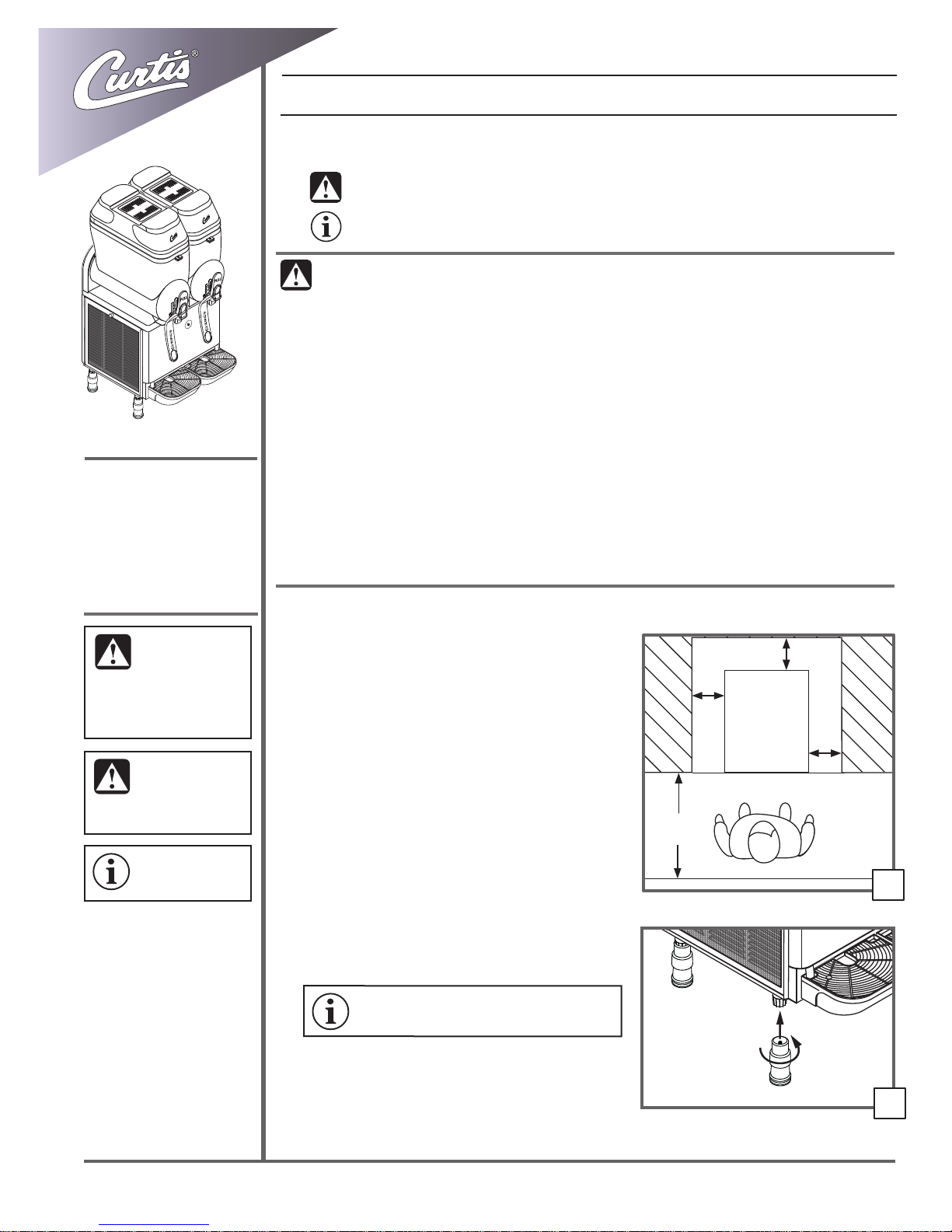

1. Select the location. The unit must be installed

indoors away from sources of moisture and heat.

The clearances shown are the minimum distances

from obstructions, between CFB units and other

equipment, required for proper operation. Do not

obstruct the ventilation grills on the back and sides.

Locate the unit on a secure, level surface. Install the

unit for easy removal if service is needed.

2. Unpack the unit. Keep the original packaging

materials in the event the unit needs to be returned

to the manufacturer.

IMPORTANT: RMAs will not be accepted unless the unit

is packaged in the original packaging material.

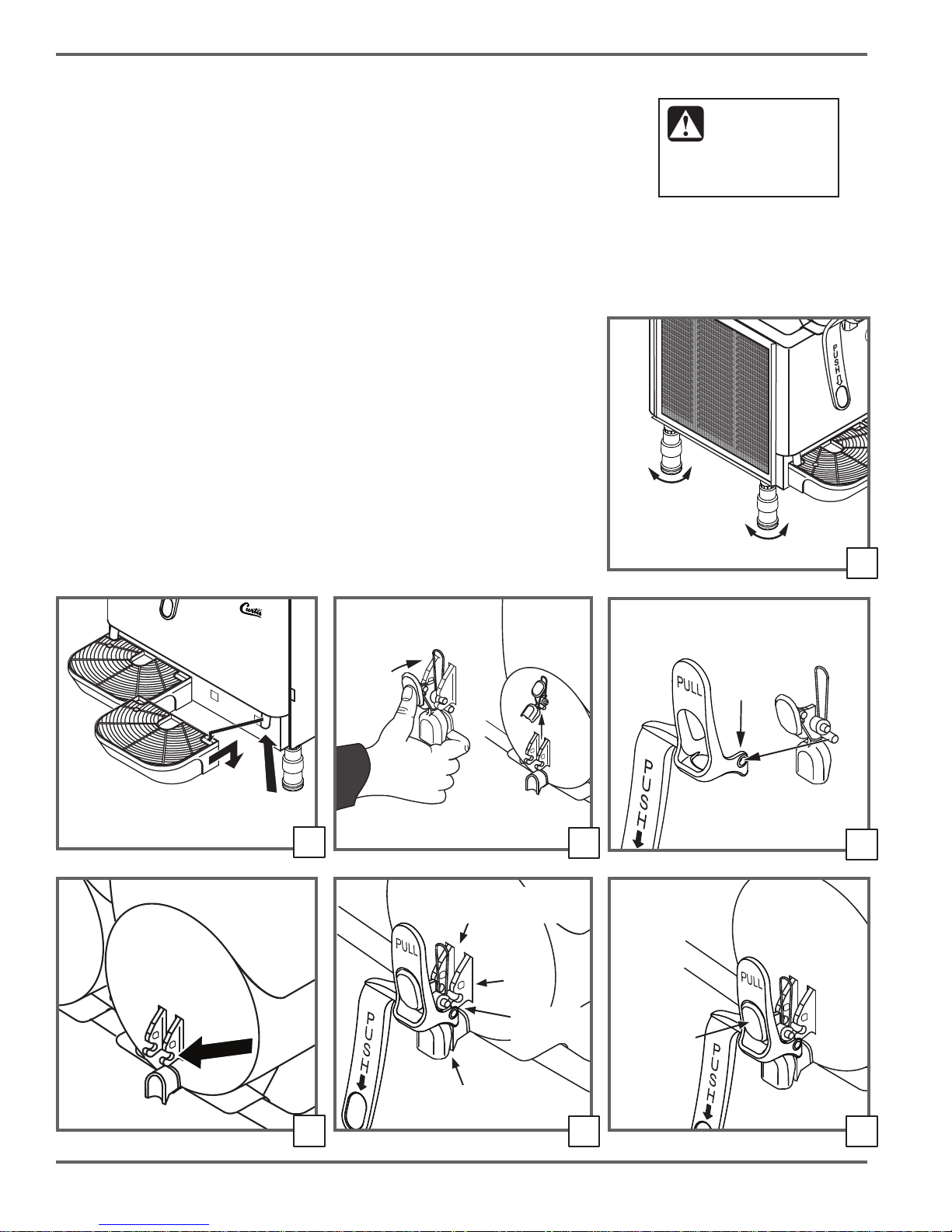

3. Locate the legs, packaged inside the bowls. Thread

them into the mounts on the bottom of the unit.

Hand tighten into place.

continued...

4" min.*

(10 cm)

CFB

frozen

beverage

dispenser

(10 cm)

4" min.*

60" min.

(150 cm)

*9" (23 cm) recommended

4" min.*

(10 cm)

1

3

READ AND SAVE THESE INSTRUCTIONS

Page 1

Page 2

Wilbur Curtis Co., Inc.

SETUP INSTRUCTIONS (CONT.)

4. Level the unit left to right and front to back by rotating the feet on the bottom of

the legs.

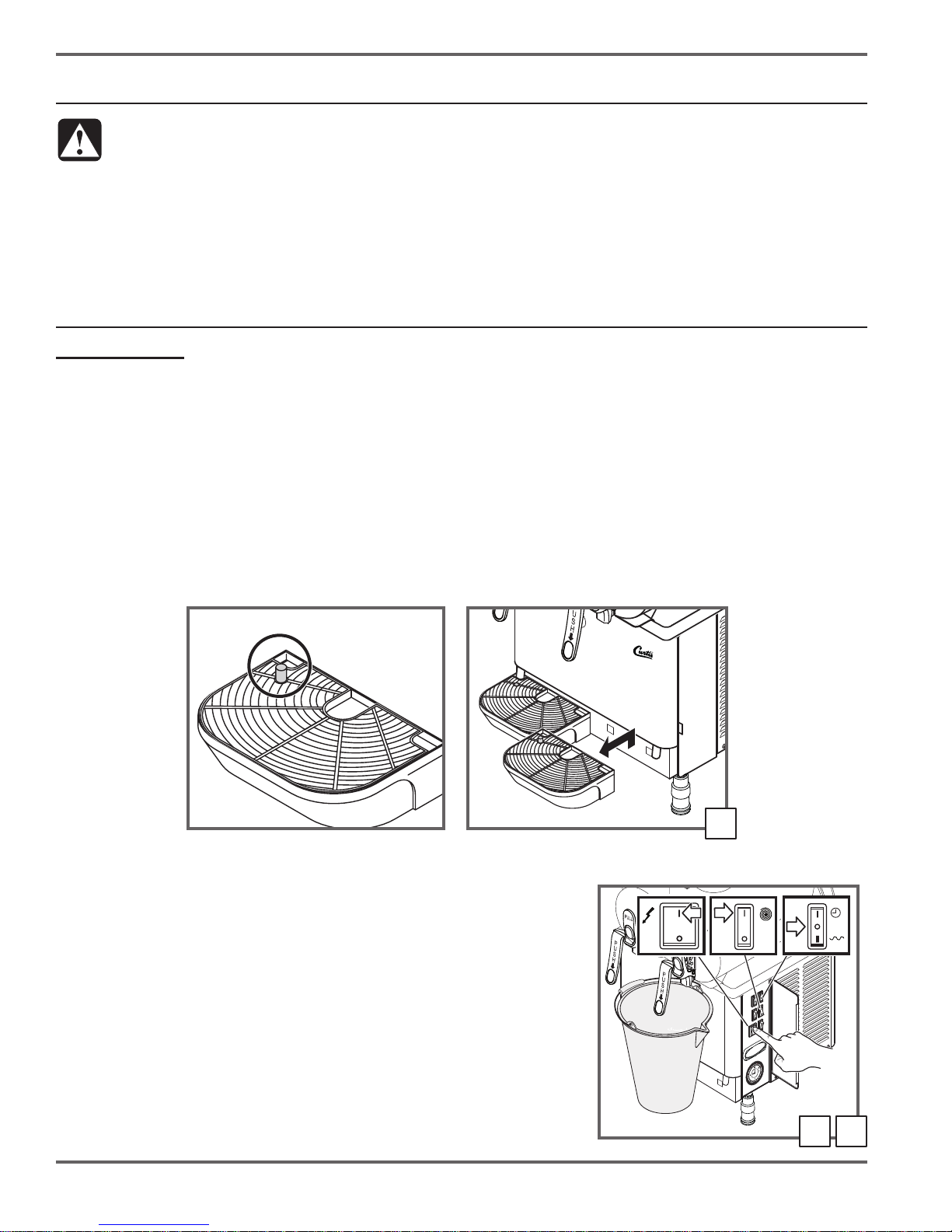

5. Locate the drip trays, packaged inside the bowls. Position the drain hose in the

opening in the top of each tray. Then, insert the tabs on the back of the drip tray

into the holes on the front of the chassis. Push down gently to secure in place.

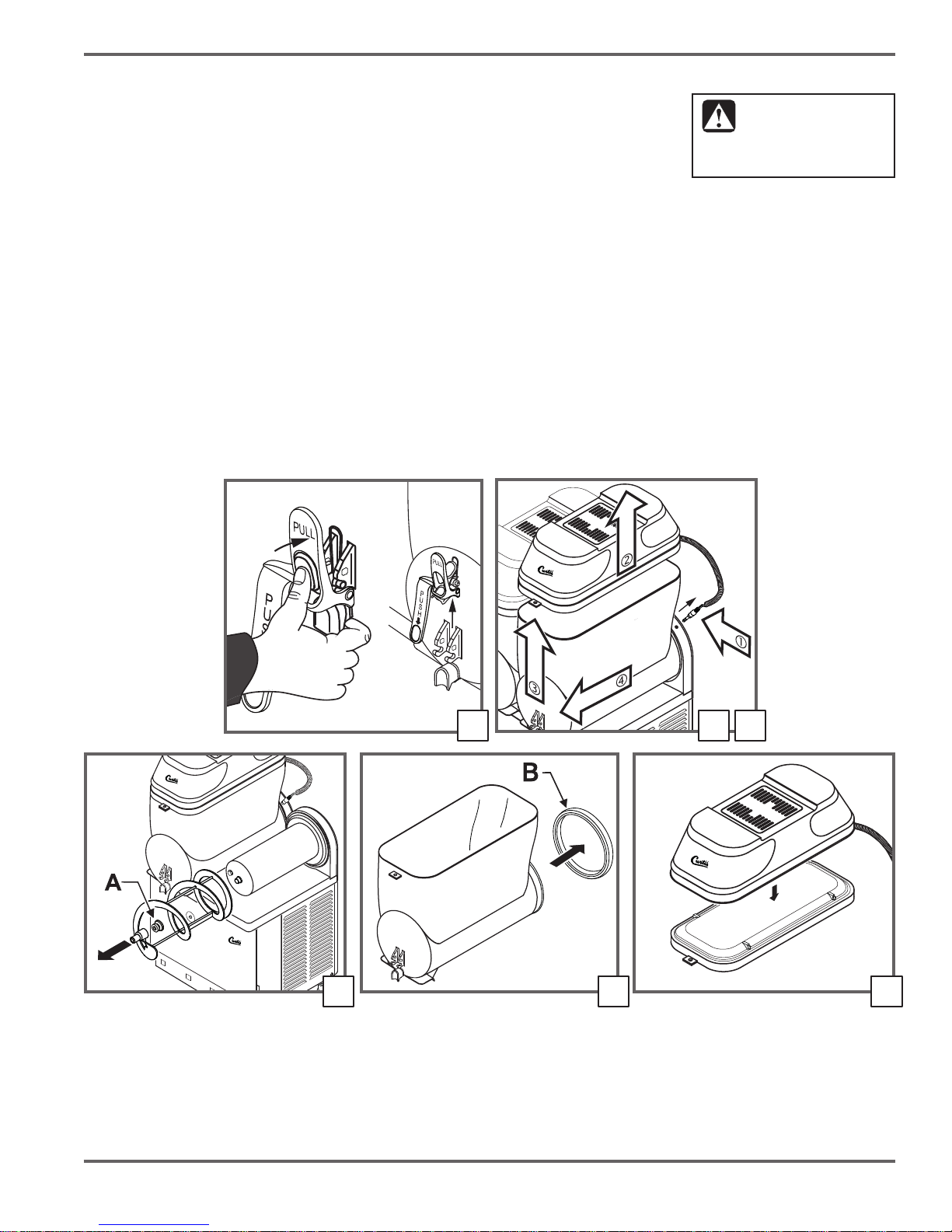

6. Prepare to install the dispensing levers by removing the handles from the taps.

Push in on the top of the handle with your thumb while pulling up on the bottom

with your index nger.

7. Locate the dispensing levers, packaged inside the bowls. Install them on the tap

handles. While pulling outward on both sides of the base of the dispensing lever,

insert the pins on the bottom of the handle into the base holes on the lever.

8. Lubricate the tap mounting slots using food grade lubricant.

9. Prepare the tap handle assembly for attachment. Lubricate the red rubber gasket

on the back of the tap handle assembly with food grade lubricant and insert it into

the tap hole on the bottom of the bowl. Line up the middle pins on the handle with

the mounting slots.

10. Attach the tap handle assembly. Push in with your thumb on the center of the

handle until the tap handle assembly pops into place.

WARNING: Use the

leveling legs to level

the dispenser only. Do

not use them to adjust unit height.

Do not extend them higher than

necessary.

Drain hose

4

Base

Lever

5

Spring must be

between mounts

Mount

6

Handle

7

8

Page 2

Red plug

(lubricate)

Line up as

shown

9

Push here

10

Page 3

Service Manual - Frozen Beverage Dispenser

11. Open the control panel door (on the right side) and make sure the

main power switch is in the OFF (O) position.

12. Set the timer clock according to the

instructions below.

13. Connect the unit to a grounded,

3-prong, electrical outlet with the

IMPORTANT: The unit

may not operate as

desired if the timer is not

set properly.

appropriate amperage rating. The circuit

must be protected by a suitably rated circuit breaker. Do not use an

extension cord or any type of adapter.

14. Turn ON (|) the main power switch.

15. Clean and sanitize the unit before using it for the rst time as

instructed in the CLEANING section. Verify that the unit is operating

properly according to the operating instructions.

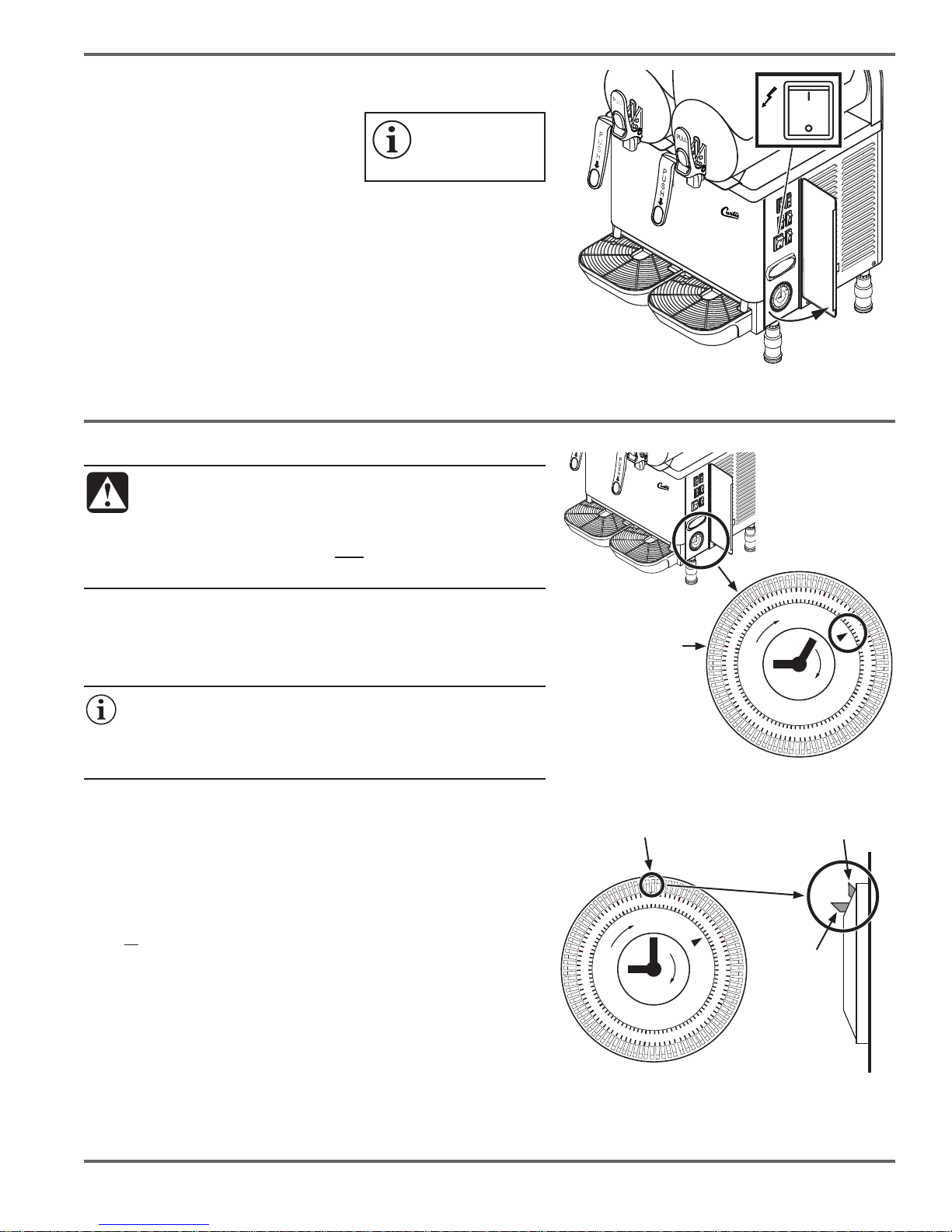

SETTING THE TIMER CLOCK*

CAUTION:

• Set the timer only with the main power switch in the

OFF (O) position.

• Turn the timer wheel only in the clockwise direction.

• Do not set the timer using any kind of tool.

1. With the main power switch off, turn the outer wheel on the timer

clockwise until the correct time (AM or PM) lines up with the arrow on

the clock face.

2. Turn on the main power switch to start the clock.

IMPORTANT: The clock/timer is equipped with a backup circuit

and continues to keep time for 10 to 15 minutes after power is

interrupted. If the power cord is disconnected or the main power

switch is turned off for a longer period of time, the clock will need

to be reset when power is restored.

Main Power Switch Location

Turn outer wheel

clockwise to set

1

12

2

3

4

5

AM

7

9

8

9

10

11

11

12

12

10

9

8

3

5

6

1

4

3

2

Clock Set to 9:05 PM

7

PM

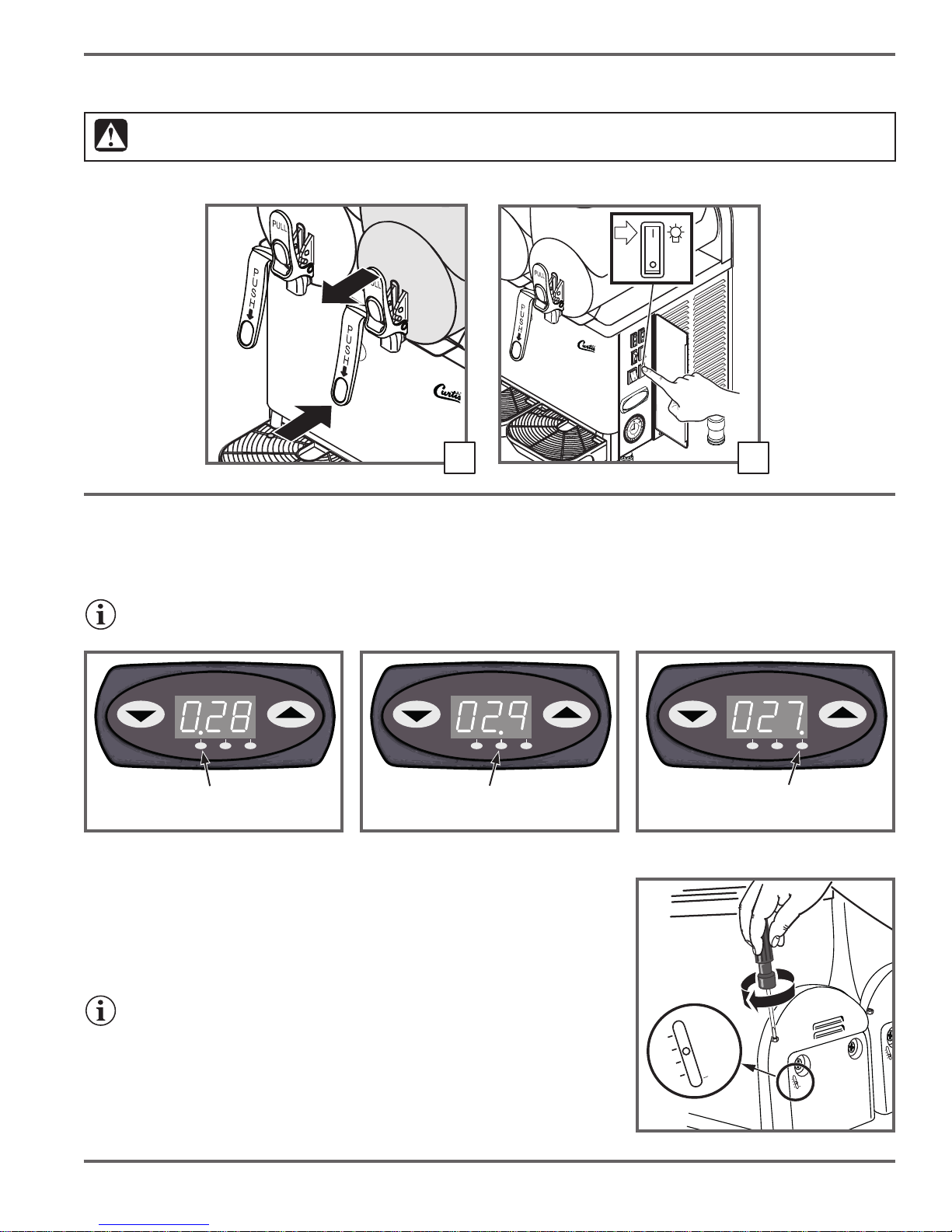

TIMER OPERATION*

Use the timer to start the unit automatically. This feature allows you to pour

the mix in ahead of time and have the frozen beverage ready to serve at

the programmed time (unattended operation). The timer determines when

the unit is in standby (night) mode or freeze mode. In standby mode the

mixture is kept cool, but does not freeze.

The unit comes from the factory set for manual (non-timer) operation.

When all of the timer tabs are ipped outward (see diagram, right),

the timer is disabled and the unit will freeze the mixture any time the

refrigeration switch is set to ON (|).

Setting Up the Timer

1. With the main power switch off, ip the timer tabs next to the time

marks on the timer to either the standby or freeze position. The unit

will operate in the mode selected during the corresponding time

period.

2. Check to make sure the clock is set to the current time, then turn ON

(|) the main power switch.

*Models CFB2 and CFB3 only.

Timer tabs

2

3

4

5

AM

7

9

8

9

10

11

Timer tab in

freeze position

1

12

11

12

12

10

9

8

7

PM

Timer tab

in standby

(night)

position

3

5

6

1

4

3

2

Timer Side View

Page 3

Page 4

OPERATING INSTRUCTIONS

WARNING:

• Keep body parts and other items clear of the inside of the mixing bowl when the main power switch is

ON (|). Keep the mixing switch in the OFF (O) position whenever the mixing bowl lid is removed.

• Do not use the machine to freeze water alone.

• Use only slush mixtures with the required sugar content (see below).

• Do not use this unit with milk/dairy based mixes unless it is equipped

with a temperature display. Do not leave milk/dairy based mixtures in

the unit without the main power switch on and the refrigeration switch

set to standby (|) or freeze (||).

• Never pour hot liquids (above 77°F/25°C) into the mixing bowl.

• Do not ll the mixing bowl higher than the MAX LEVEL indicator.

Wilbur Curtis Co., Inc.

Temperature

display

Concentrate

Water

MAX

LEVEL

1. If using the unit to dispense a slush type frozen beverage, dilute and mix the

slush concentrate with water in a clean container. Follow the concentrate

manufacturer’s directions. THE MIXTURE OBTAINED MUST HAVE A

MINIMUM SUGAR CONTENT OF 13°Bx and less than 22°Bx (11 to 20% sugar

by weight). The capacity of each mixing bowl is 3 gallons (12 liters). If using the

unit to dispense a milk/dairy based frozen beverage, use the mix according to

the instructions on the package.

2. With the mixing switch in the OFF (O) position, remove the

mixing bowl lid from the desired bowl and hang it on the side.

Pour in the mix up to, or below the MAX LEVEL indicator. The

minimum level is just above the plastic mixing auger.

3. Replace the mixing bowl lid.

1

4. Make sure that the main power switch is ON (|). Push (|) on

the mixing switch for the desired mixing bowl to turn on the

mixer.

5. Push (|) on the refrigeration switch for the desired mixing

bowl to begin freezing. NOTE: On units equipped with a

timer, when the refrigeration switch is in position (|), the unit

will freeze the mixture provided the timer is set to freeze

for the current time (see Setting the Timer). Standby mode,

position (||) on the refrigeration switch, may be used to put

the unit in standby mode manually. This mode saves energy,

keeping the mixture cool without freezing.

Mixing

Refrigeration

2

3

Page 4

4

5

Page 5

Service Manual - Frozen Beverage Dispenser

MAX

6. Once the mixture is frozen (40 to 90 minutes), pull out on the top of the dispenser lever or push the bottom of the lever to

dispense.

CAUTION: If the tank is lled with a milk or dairy based mix, dispense a small amount of the product from the tap into a separate

container before dispensing the serving for the customer.

7. Push (|) on the light switch to turn on the integral lid lights.

or

6

7

How to Read the Digital Temperature Display (Some Versions)

The temperature display indicates the temperature in the mixing bowls. The display changes every three seconds to show

the temperature in a different bowl. The dot at the bottom of the display indicates the bowl temperature that is currently being

displayed. See the diagrams below for more information. The bowls are numbered 1, 2 and 3*, left to right, facing the front.

NOTE: If the display shuts off, it can be reset by pushing the down arrow button (▼).

1 2 3 1 2 31 2 3

Bowl 1 display

indicator

Bowl 2 display

indicator

Bowl 3 display

indicator*

*CFB3 only

Adjusting Beverage Thickness

Use the adjustment screws at the back of each mixing bowl to adjust beverage

thickness. The recommended (factory default) setting is 2. Insert a at blade

screwdriver into the adjustment hole as shown and turn to adjust. The indicator on the

back will move to indicate the thickness level. The higher the number the thicker the

frozen beverage will be.

IMPORTANT: When the thickness level is set to higher levels, (around 4) the lid

should be fastened to prevent it from coming off during operation.

1

2

Periodic maintenance

Have the unit checked periodically (at least once a year) by a qualied technician to

ensure proper operation.

3

MAX

4

1

2

3

MAX

4

Back

1

2

3

4

Page 5

Page 6

Wilbur Curtis Co., Inc.

CLEANING

WARNING:

• To avoid personal injury, disconnect the power cord before cleaning. Wear protective glasses and

gloves.

• Never spray water on the unit to clean it.

• Do not use cleaning liquids, compounds or powders containing chlorine (bleach), solvents, scouring

powder,

ammable materials or corrosives. These products promote corrosion and will damage the

surfaces. USE OF THESE PRODUCTS WILL VOID THE WARRANTY.

• DO NOT immerse the unit or parts in water or any other liquid, unless specically instructed to do so.

Do not wash any of the components in a dishwasher. Hand or air dry the parts only.

Daily Cleaning

Clean and sanitize all of the bowl assemblies at least once a day according to the following steps. These operations may need to

be performed more frequently based on the mix used. Contact the concentrate/mix supplier for more details. If the machine is not

used continuously throughout the day, wipe the tap areas with a clean cloth and sanitizing uid. If the dispenser has not been used

for a long period of time, clean the unit before returning it to use.

1. For cleaning, prepare a mild solution of detergent and warm water.

Empty the Drip Trays

The drip trays should be emptied and cleaned every day and drained every time the red full indicator pops up. They must also be

removed before emptying the bowl.

2. Lift each drip tray up and out.

3. Wash the trays and grills with the detergent solution. Hand dry all of the components, then reinstall the grills. Set the trays aside

and reinstall at the end of the daily cleaning process.

Full indicator

2

Empty the Bowl

Empty each bowl before cleaning (if already empty, skip to step 7).

4. Place a large empty container under each dispenser tap.

5. Turn the main power switch to the ON (|) position. Turn the mixing switches to

the ON (|) and the refrigeration switches to the OFF (O) position. Pull out on each

dispenser lever to drain the contents out of each bowl. NOTE: If the beverage

mixture is not frozen, hold the container up to the bottom of the tap to reduce

splashing.

6. Once the bowls are empty, switch the main power switch OFF (O). Unplug the

power cord from the electrical outlet.

Page 6

54

Page 7

Service Manual - Frozen Beverage Dispenser

Remove the Mixing Bowls and Lids

7. Remove the handle assembly from the bowl tap by pushing in on the top of the handle with

your thumb while pulling up on the bottom with your index nger.

8. Disconnect the lid light plugs from the sockets behind the mixing bowl. Make sure that the

plugs do not come into contact with liquids while removed. Lift off the lids.

9. Raise the front part of each bowl to release. Remove each bowl from its seat by pushing and

tapping lightly on the rear.

NOT immerse the top portion of

the lid in uids of any kind.

CAUTION:

To prevent damage, DO

Clean the Mixing Bowl Parts

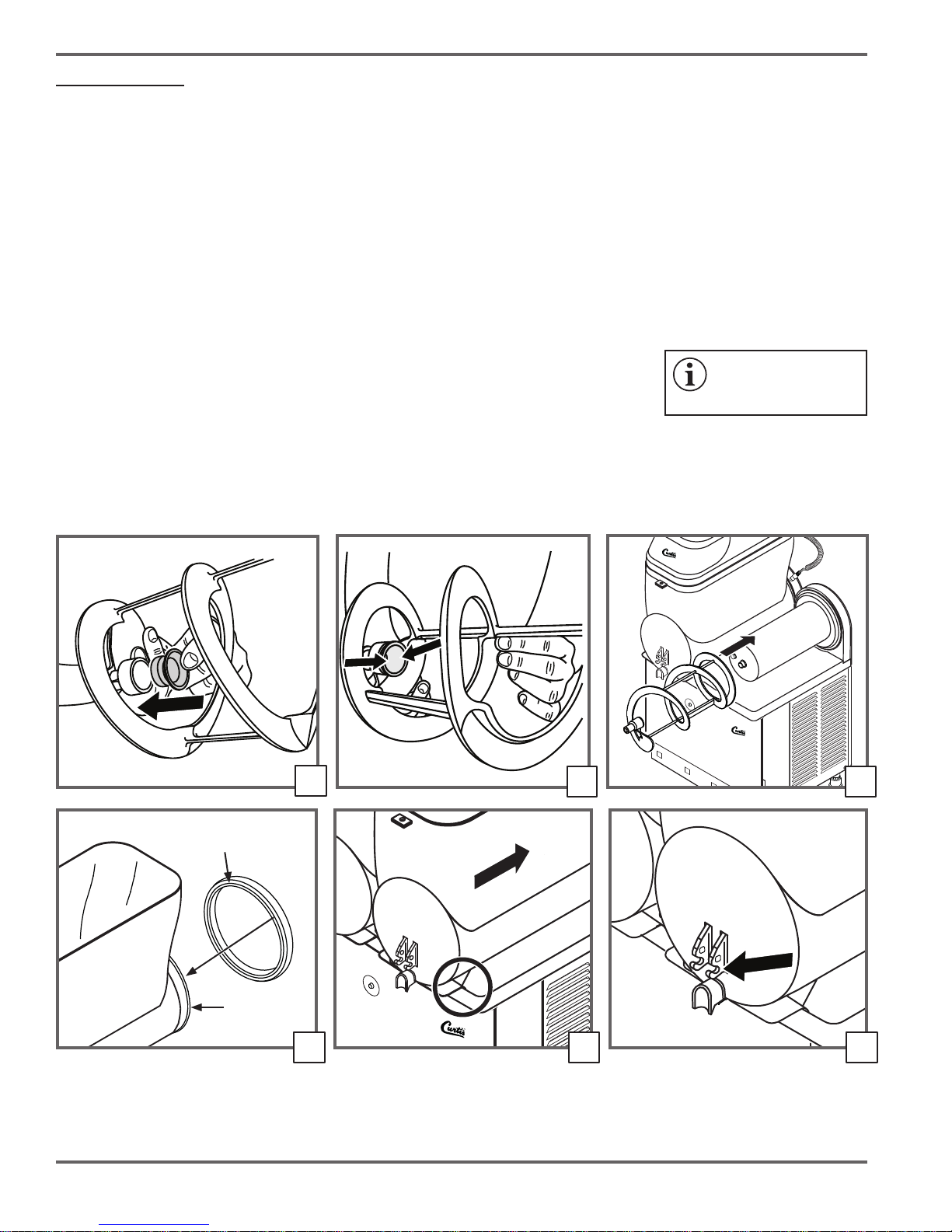

10. Pull forward on each auger to remove it from the evaporator. Remove the auger seal (A).

11. Pull the bowl seal (B) off of the back of the bowl.

12. Pull the bottom part of the lids free from the top parts.

13. Soak the bottom part of the lids, removed in step 12, and the tap parts and auger in detergent solution and scrub with a soft

cloth. Rinse in fresh water.

14. To clean the top portions (lighted part) of the lids, use a clean, damp cloth soaked with detergent solution. Using a clean, damp

cloth, wipe clean the outside portion of the lid top. Wipe with a clean, damp cloth soaked in fresh water.

15. Clean the mixing bowls and evaporators with a clean damp cloth soaked with detergent solution. Wipe with a clean, damp cloth

soaked in fresh water.

continued...

987

10 11 12

Page 7

Page 8

Wilbur Curtis Co., Inc.

Daily Cleaning (Cont.)

Sanitizing

16. Fill a container with a sanitizer solution mixed in water (2% of sodium hypoclorite mixed in water).

17. Using a sponge dipped in sanitizing solution, sanitize the underside of the bottom portion of the lids. Allow 30 minutes for the

solution to act.

18. Rinse the underside of the lid bottoms with a clean sponge soaked in fresh water. Place the lids on a clean surface and hand

dry, rst the underside, then the outside, using a clean cloth.

19. Thoroughly wash the bowl and evaporator with a sponge soaked in the sanitizer solution. Rinse thoroughly with clean water.

20. Fill another container with sanitizer solution and submerge the tap parts, augers and seals in the sanitizer solution. Leave them

to soak in the solution for 30 minutes. Rinse thoroughly with clean water, then air dry.

Reassemble the Unit

21. Check the seals before reinstalling. Replace worn seals with new ones before reinstalling. Replace all seals and gaskets at

least once a year.

22. Install each auger seal on each auger.

23. Using food grade lubricant, lubricate the inside of the auger seal.

24. Reinstall the augers. Rotate each auger until it engages completely.

25. Install an evaporator seal on the back of each bowl. The circular lip on the back of the bowl ts into the groove on the seal.

26. Set the mixing bowls back in place. Make sure that the lip on the bottom of each bowl rests inside the front trim on the top of

the chassis.

27. Lubricate the tap mounting slots on the front of each mixing bowl with food grade lubricant.

gaskets may result in leaks.

IMPORTANT: Failure to

properly lubricate seals/

22

Seal

groove

Lip

25 26 27

Page 8

23 24

Page 9

Service Manual - Frozen Beverage Dispenser

28. Prepare the tap handle assembly for attachment. Check the red rubber gasket on the back of each tap assembly for wear.

Replace if necessary. Lubricate each tap gasket with food grade lubricant. Insert the gasket into the tap hole on the bottom of

the bowl. Line up the middle pins on the handle with the mounting slots.

29. Attach the tap handle assembly. Push in with your thumb on the center of the handle until the handle assembly pops into place.

30. Reassemble and reinstall each lid and insert the light plug into the socket behind each mixing bowl.

Rinse the Unit

Before starting up the unit again after cleaning, rinse it out as follows:

31. Connect the power cord to the electrical outlet.

32. Fill the mixing bowls with clean water;

33. Turn the main power switch to the ON (|) position. Push (|) on the mixing switches for all of the mixing bowls. Make sure the

refrigeration switches are OFF (O).

34. Leave the unit on for ve minutes.

35. Drain the water from each of the mixing bowls by placing a container under the tap and pulling the lever.

Reinstall the Drip Trays and Wipe Up

36. Position the drain hose in the opening

in the top of each tray. Then, insert the

tabs on the back of the drip tray into

the holes on the front of the chassis.

Push down gently to secure in place.

37. Wipe any dust or debris from the

exterior surfaces of the unit with a

damp cloth. Wipe up any spills/liquids

in the surrounding area.

Spring must be

between mounts

Mount

Line up as

shown

Push here

Red gasket

(lubricate)

Weekly Cleaning

1. Make sure the main power switch is in the OFF (O) position.

2. Lift the lter* up and out of the slot on the left side of the unit.

3. Clean the lter and the ventilation louvers on the outside of the unit with a

vacuum or soft bristled brush.

4. Replace the lter.

*Model CFB1 is not equipped with a lter.

28

3533

29

Drain hose

3630

Page 9

Page 10

TROUBLESHOOTING

Wilbur Curtis Co., Inc.

Unit Does Not Turn ON

1. Make sure that the circuit breaker for the electrical

outlet is not tripped and is turned on.

2. Make sure that the power cord is properly

connected to the electrical outlet.

3. Make sure that the main power switch is on.

Mixture Does Not Freeze

1. Make sure that the refrigeration switch is in the (|)

position.

2. If using a slush mixture, make sure that it is properly

diluted. Proper sugar content is 11 - 20%.

3. Make sure that the clock is set to the current time

and that the timer is set to freeze at the current time.

See "SETTING THE TIMER CLOCK" (CFB2 and

CFB3 only).

4. Make sure that the thickness setting is not set too

low. See "Adjusting Beverage Thickness".

5. See "Check for Proper Ventilation" section on the

facing page.

6. Check to see if the compressor reset switch inside

the control panel is "popped out" (CFB2 and CFB3

without temperature display only). Push in to reset

(see diagram below) and allow the sealed system

to cool before restarting the unit. If the reset switch

continues to pop out, call for service.

Tap Leaks

1. Make sure that the (red) tap gasket is properly

lubricated and is not worn out.

2. Make sure that the tap handle assembly is properly

seated.

Beverage Does Not Come Out of Tap

This problem is usually caused by a mixture that is too

thick or ice chunks forming in the bowl.

1. If using a slush mixture, make sure that it is properly

diluted. Proper sugar content is 11 - 20%.

2. Make sure the thickness setting on the back of unit

is not set too high.

Leak at Back of Mixing Bowl

1. Make sure that the mixing bowl seal is properly

lubricated and is not worn out.

2. Make sure that the mixing bowl is properly seated.

Auger Does Not Turn or is Noisy

1. Make sure the mixing switch is turned on.

2. If using a slush mixture, make sure that it is

properly diluted. Proper sugar content is 11 - 20%.

An improperly diluted slush mixture can cause

ice chunks that can interfere with proper auger

operation.

3. Make sure the auger seal is properly installed and

lubricated.

Compressor Reset (some models)

Page 10

High Pressure/Temperature Light On

CFB2 and CFB3 only. Turn

off the main power switch*

and check the following:

1. See "Check for Proper

Ventilation" section on

the facing page.

2. If the light still comes

on during operation,

turn off the main power

switch and call for

service.

* On units equipped with a temperature display, the

system is designed to reset itself automatically after the

main power switch has been off for 5 minutes.

High pressure/

temperature light

Page 11

Service Manual - Frozen Beverage Dispenser

TROUBLESHOOTING

Numeric Code (Alarm) Appears on Display

CFB2 and CFB3 with temperature display only. See list

below to determine possible problem.

Error

Code

A1

A2

A3

A4

A5

A6

Problem Remedy

Temperature probe

for bowl 1

disconnected

Bowl 1 too hot or

temperature probe

shorted

Temperature probe

for bowl 2

disconnected

Bowl 2 too hot or

temperature probe

shorted

Temperature probe

for bowl 3 (CFB3

only) disconnected

Bowl 3 (CFB3 only)

too hot or tempera-

ture probe shorted

See "Check for Proper

ventilation is OK, call

See "Check for Proper

ventilation is OK, call

See "Check for Proper

ventilation is OK, call

Call for service

Ventilation". If

for service..

Call for service

Ventilation". If

for service.

Call for service

Ventilation". If

for service.

Check for Proper Ventilation:

1. The unit will not function properly if there is not

sufcient air space (4 inches minimum on back and

sides).

2. Make sure that the lter (CFB2 and CFB3 only) is

clean and that all ventilation grills are not blocked or

dirty. See the CLEANING section.

3. Make sure that the unit is not close to sources of

heat that could affect proper operation (heaters,

cooking grills, etc.).

REFRIGERANT SPECIFICATIONS

For reference only. Check the serial number label on the product for the refrigerant specications for the unit being serviced.

CFB1 CFB3

Refrigerant type R404A

Amount 7.05 ounces

High design pressure 397 psig

Low design pressure 175 psig

CFB2

Refrigerant type R404A

Amount 12.84 ounces

High design pressure 397 psig

Low design pressure 175 psig

Refrigerant type R404A

Amount 16.68 ounces

High design pressure 397 psig

Low design pressure 175 psig

Page 11

Page 12

ROUGH-IN DIAGRAMS

CFB1

Wilbur Curtis Co., Inc.

11.75”

(29.8 cm)

SIDE VIEW

8.82”

(22.4 cm)

35.51”

(90.2 cm)

FRONT VIEW

TOP VIEW

20.48”

(52.0 cm)

8.15”

(20.7 cm)

4.21”

(10.7 cm)

5.91”

(15.0 cm)

CFB2

11.74”

(29.8 cm)

SIDE VIEW

35.51”

(90.2 cm)

FRONT VIEW

TOP VIEW

19.53”

(49.6 cm)

16.49”

(41.9 cm)

4.21”

(10.7 cm)

11.69”

(29.7 cm)

Page 12

12.60”

(32.0 cm)

Page 13

ROUGH-IN DIAGRAMS

CFB3

Service Manual - Frozen Beverage Dispenser

11.75”

(29.8 cm)

SIDE VIEW

11.69”

(29.7 cm)

35.51”

(90.2 cm)

FRONT VIEW

9.76”

(24.8 cm)

4.21”

(10.7 cm)

10.71”

(27.2 cm)

11.30

(28.7 cm)

TOP VIEW

19.57”

(49.7 cm)

24.53”

(62.3 cm)

Page 13

Page 14

WIRING DIAGRAMS

Wilbur Curtis Co., Inc.

1

N

Power Consumption:

115 Vac, 60 Hz., 8.1 A

2 3

M

9

M

WIRING DIAGRAM - MODEL CFB1

M

6

FA3

5

FA2

7

11

8

tº

12

10

M

4

13

Page 14

Nº Description

1 Main power switch

2

Auger motor

3 Fan motor

4 Tank cover light

5 Relay

6 Micro regulation

7 Refrigeration switch

Nº Description

8 Thermostat

9 Fan motor

10 Compressor

11 Tank lights switch

12 Transformer

13 Fuse

LEGEND - MODEL CFB1

Page 15

WIRING DIAGRAMS

1

L

P

24

Service Manual - Frozen Beverage Dispenser

11

10

17

23

3

N

Power Consumption:

115 Vac, 60 Hz., 12.4 A

M

2

67

M

13

5

M

4

14

15

16

12

M

8 8

tº tº

WIRING DIAGRAM - MODEL CFB2 WITHOUT TEMPERATURE DISPLAY

18 9

M

19

20

21

22

Nº Description

1 Main power switch

2

Fuse

3 Compressor

4 Fan motor

5 Transformer

6 Tank cover light

7 Fuse

8 Relay

9 Timer

10 Tank lights switch

11 Left mixing switch

12 Left refrigeration switch

LEGEND - MODEL CFB2 WITHOUT TEMPERATURE DISPLAY

Nº Description

13 Left auger motor

14 Left thermostat

15 Left micro regulation

16 Left electrovalve

17 Right mixing switch

18 Right refrigeration switch

19 Right auger motor

20 Right thermostat

21 Right micro regulation

22 Right electrovalve

23 Relay

24 Compressor cutoff (reset) switch

Page 15

Page 16

WIRING DIAGRAMS

1

F

T

FA3

COM

23

NO

FA1 FA2

3

M

Wilbur Curtis Co., Inc.

24

10

2

7

5

6

M

4

M

11

12

13

8

tº tº

14

M

20

17

19

18 9

M

8

tº

25

N

Power Consumption:

115 Vac, 60 Hz., 12.4 A

Nº Description

1 Main power switch

Fuse holder

2

3 Compressor

4 Fan motor

5 Transformer

6 Tank cover light

7 Fuse

8 Relay

9 Timer

10 Tank lights switch

11 Left mixing switch

12 Left refrigeration switch

13 Left auger motor

15

16

21

22

WIRING DIAGRAM - MODEL CFB2 WITH TEMPERATURE DISPLAY

Nº Description

14 Left thermostat

15 Left micro regulation

16 Left electrovalve

17 Right mixing switch

18 Right refrigeration switch

19 Right auger motor

20 Right thermostat

21 Right micro regulation

22 Right electrovalve

23 Electronic Regulator

24 Thermal Protector

25 Temperature Display

tº

LEGEND - MODEL CFB2 WITH TEMPERATURE DISPLAY

Page 16

Page 17

WIRING DIAGRAMS

1

L

30

P

29

3

M

2

M

4

M

Service Manual - Frozen Beverage Dispenser

23

24

M

8

25

26

9

M

8

12

17

18

M

19

8

20

11

10

7

31

6

M

13

5

tº tº tº

14

N

Power Consumption:

115 Vac, 60 Hz., 14.8 A

15

16

21

22

WIRING DIAGRAM - MODEL CFB3 WITHOUT TEMPERATURE DISPLAY

Nº Description

1 Main power switch

2 Fan motor 1

3 Compressor

4 Fan motor 2

5 Transformer

6 Tank cover light

7 Fuse

8 Relay

9 Timer

10 Tank lights switch

11 Left mixing switch

12 Left refrigeration switch

13 Left auger motor

14 Left thermostat

15 Left micro regulation

Nº Description

17 Middle mixing switch

18 Middle refrigeration switch

19 Middle auger motor

20 Middle thermostat

21 Middle micro regulation

22 Middle electrovalve

23 Right mixing switch

24 Right refrigeration switch

25 Right auger motor

26 Right thermostat

27 Right micro regulation

28 Right electrovalve

29 Relay

30 Compressor cutoff (reset) switch

31 Fuse

16 Left electrovalve

27

28

LEGEND - MODEL CFB3 WITHOUT TEMPERATURE DISPLAY

Page 17

Page 18

WIRING DIAGRAMS

1

L

T

30

FA3

COM

29

NO

FA1 FA2

3

M

M

2

4

M

Wilbur Curtis Co., Inc.

11

10

6

7

31

12

M

13

5

tº

14

17 23

M

19

8

tº tº

20

18

M

8

26

24

25

9

M

8

tº

32

N

Power Consumption:

115 Vac, 60 Hz., 14.8 A

Nº Description

1 Main power switch

2 Fan motor 2

3 Compressor

4 Fan motor 1

5 Transformer

6 Tank cover light

7 Fuse

8 Relay

9 Timer

10 Tank lights switch

11 Left mixing switch

12 Left refrigeration switch

13 Left auger motor

14 Left thermostat

15 Left micro regulation

16 Left electrovalve

15

16

21

22

27

28

WIRING DIAGRAM - MODEL CFB3 WITH TEMPERATURE DISPLAY

Nº Description

17 Middle mixing switch

18 Middle refrigeration switch

19 Middle auger motor

20 Middle thermostat

21 Middle micro regulation

22 Middle electrovalve

23 Right mixing switch

24 Right refrigeration switch

25 Right auger motor

26 Right thermostat

27 Right micro regulation

28 Right electrovalve

29 Electronic regulator

30 Thermal protector

31 Fuse holder

32 Temperature Display

tº

tº

LEGEND - MODEL CFB3 WITH TEMPERATURE DISPLAY

Page 18

Page 19

20

23

5

16

27A

40A

33

35

34

37

41

32

15

29

44

38

42

43A

45A

30

8

11

12

6

25A

48

17

24

18

49

24

51

4

14

19

26

28A

22

EXPLODED VIEW - CFB1

Service Manual - Frozen Beverage Dispenser

Page 19

Page 20

16

32

33

30

29

43B

42

38

20

44

41

37

35

34

40B

28A

50

54

56

27B

48

17

49

24

19

18

45B

51

21

24

36

39

31

15

25B

53

14

10

9

7

55A

13

23

47A

47B

46A

46B

22

8

11

12

6

26

EXPLODED VIEW - CFB2

Wilbur Curtis Co., Inc.

Page 20

Page 21

10

20

43B

25

42

41

38

44

35

34

37

15

31

29

30

33

32

16

9

28B

47A

55B

47B

25B

51

21

13

39

36

7

17

18

24

49

24

48

53

23

52

19

46C

46D

40C

27C

5

45B

8

11

12

6

14

26

22

54

56

EXPLODED VIEW - CFB3

Service Manual - Frozen Beverage Dispenser

Page 21

Page 22

Wilbur Curtis Co., Inc.

PARTS LIST

ITEM PART # DESCRIPTION

a

1

a

2

a

3

4 WC-100151 ELECTRONIC REGULATOR (CFB1)

5 WC-100129 FAN MOTOR 120X120X38 115V CFB3 (ALSO USED ON CFB1)

6 WC-100005 TRANSPARENCY (CFB1, CFB2, CFB3)

a

7

a

8

a

9

a

10

a

11

12 WC-100011 DISPENSING LEVER PUSH - BLACK (CFB1, CFB2, CFB3)

a

13

a

14

a

15

a

16

a

17

a

18

a

19

20 WC-4916 LUBRICANT, GREASE HEAVY DUTY PC'S 4oz (CFB1, CFB2, CFB3)

a

21

22 WC-100024 BOWL COVER SET GT - BLACK (COMPLETE) (CFB1, CFB2, CFB3)

a

23

a

24

25A WC-100147 COMPLETE TRANSFORMER (CFB1)

25B WC-100079 COMPLETE TRANSFORMER (CFB2, CFB3)

a

26

a

27A

a

27B

a

27C

a

28A

a

28B

a

29

a

30

a

31

a

32

a

33

a

34

a

35

a

36

a

37

a

38

a

39

40A WC-100143 COMPRESSOR (CFB1)

40B WC-100071 COMPRESSOR (CFB2)

40C WC-100119 COMPRESSOR (CFB3)

a

Recommended parts to stock

WC-100130 TUNE UP KIT 1 BOWL (NOT SHOWN, INCLUDES ITEMS 11, 29 AND 32)

WC-100127 TUNE UP KIT 2 BOWLS (NOT SHOWN, INCLUDES ITEMS 11, 29 AND 32)

WC-100128 TUNE UP KIT 3 BOWLS (NOT SHOWN, INCLUDES ITEMS 11, 29 AND 32)

WC-100103 MECHANICAL TIMER (CFB2, CFB3)

WC-100001 TAP SET GNW - BLACK (ADA-LONG HANDLE) (CFB1, CFB2, CFB3)

WC-100097 CUT OFF PRESSURE CFB (CFB2, CFB3 WITHOUT TEMPERATURE DISPLAY)

WC-100094 FILTER EXT. CONDENS. COMP. USA 05 CFB (CFB2, CFB3)

WC-100010 TAP RUBBER GASKET - RED (CFB1, CFB2, CFB3)

WC-100109 RELE FINDER 60.63 110V/60HZ (10A) (CFB2, CFB3 WITHOUT TEMPERATURE DISPLAY)

WC-100013 TAP LOCK ROD - BLACK (CFB1, CFB2, CFB3)

WC-100088 FUSE 5A (CFB1, CFB2, CFB3)

WC-100015 SPIRAL SHOVEL (CFB1, CFB2, CFB3)

WC-100087 SWITCH PROTECTION 22 X 30 (CFB1, CFB2, CFB3)

WC-100086 SWITCH PROTECTION 11 X 30 (CFB1, CFB2, CFB3)

WC-100018 DRIPPING TRAY+GRATING GT BLACK (CFB1, CFB2, CFB3)

WC-100023 RELAY (30 AMP) (CFB2, CFB3)

WC-100025 COMMAND COVER+ TECH SUPPORT ADH + HINGES+ SCREWS (CFB1, CFB2, CFB3)

WC-100084 SWITCH-BLACK (CFB1, CFB2, CFB3)

WC-100028 BOWL SET GNW (CFB1, CFB2, CFB3)

WC-100146 COMPRESSOR RELAY (CFB1)

WC-100076 COMPRESSOR RELAY (CFB2)

WC-100120 COMPRESSOR RELAY CFB3

WC-100075 POWER CABLE (CFB1, CFB2)

WC-100171 POWER CABLE (CFB3)

WC-100031 TANK JOINT (CFB1, CFB2, CFB3)

WC-100106 WATERTIGHT 2 M6+OR EVAP GHZ-GB (COMES WITH O-RINGS INSTALLED) (CFB1, CFB2, CFB3)

WC-100074 FAN MOTOR 16W 115/60 (CFB2, CFB3)

WC-100034 WATERTIGHT SHAFT JOINT SIL. TRANSLU. (SEAL) (CFB1, CFB2, CFB3)

WC-100035 UPPER TRAY CAP - BLACK (CFB1, CFB2, CFB3)

WC-100036 REGULATION SYSTEM SUBJECTION (ADJUSTMENT PIN RETAINER) (CFB1, CFB2, CFB3)

WC-100037 REGULATION ROD (CFB1, CFB2, CFB3)

WC-100073 SPECIAL NUT TYPE CWP M4 (CFB2, CFB3)

WC-100039 REGULATION SYSTEM SPRING GUIDE (CFB1, CFB2, CFB3)

WC-100040 GEAR MOTOR ELCO MONO 115/60HZ (CFB1, CFB2, CFB3)

WC-100072 FAN MOTOR BLADES Ø250 X 28º (CFB2, CFB3)

Page 22

Page 23

Service Manual - Frozen Beverage Dispenser

PARTS LIST (CONT.)

ITEM PART # DESCRIPTION

a

41

a

42

43A WC-100136 EVAPORATOR SUPPORT SET PZ-1+ PZ-2 - BLACK (CFB1)

43B WC-100045 EVAPORATOR SUPPORT SET PZ-1+ PZ-2 - BLACK (CFB2, CFB3)

a

44

45A WC-100141 CONDENSER + FILTER (CFB1)

45B WC-100069 CONDENSER + FILTER (CFB2, CFB3)

46A WC-100065 DOUBLE ELECTROVALVE OLAB 115V/60HZ (CFB2)

46B WC-100066 DOUBLE ELECTROVALVE CEME 115V/60HZ) (CFB2)

46C WC-100115 TRIPLE ELECTROVALVE CEME 115V/60HZ CFB3

46D WC-100116 TRIPLE ELECTROVALVE OLAB 115V/ 60HZ CFB3

47A WC-100063 GAS ELECTROVALVE BOBBIN OLAB 1 (CFB2, CFB3)

47B WC-100064 GAS ELECTROVALVE BOBBIN CEME 1 115V 60HZ (CFB2, CFB3)

a

48

a

49

a

50

a

51

52 WC-100123 COMPRESSOR OPERATION BOX (CFB3)

53 WC-100100 DRAIN RACOR (DRAIN PIPE FITTING) (CFB1, CFB2, CFB3)

54 WC-100187 ELECTRONIC REGULATOR (CFB2, CFB3 WITH TEMPERATURE DISPLAY)

55A WC-100191 ELECTRONIC TEMPERATURE VISUAL DISPLAY (CFB2 WITH TEMPERATURE DISPLAY)

55B WC-100192 ELECTRONIC TEMPERATURE VISUAL DISPLAY (CFB3 WITH TEMPERATURE DISPLAY)

56 WC-100186 THERMAL PROTECTOR (CFB2, CFB3 WITH TEMPERATURE DISPLAY)

a

Recommended parts to stock

WC-100043 REGULATION SPRING (CFB1, CFB2, CFB3)

WC-100044 TRANSMISSION SHAFT SET (CFB1, CFB2, CFB3)

WC-100046 MINIRRUPTOR (CONTROL SWITCH) (CFB1, CFB2, CFB3)

WC-100061 GREEN MAIN SWITCH (CFB1, CFB2, CFB3)

WC-100060 SWITCH-BLACK (CFB1, CFB2, CFB3)

WC-100078 COMPRESSOR CAPACITOR (CFB2)

WC-100057 MECHANICAL THERMOSTAT (CFB1, CFB2, CFB3 WITHOUT TEMPERATURE DISPLAY)

Page 23

Page 24

Product Warranty

Wilbur Curtis Co., Inc. certies that its products are free from defects in material and workmanship under normal use. The following limited warranties

and conditions apply:

5 years, parts and 1 year labor, from the original date of purchase on compressors on refrigeration equipment

3 years, parts and labor, from original date of purchase on digital control boards

2 years, parts, from original date of purchase on all other electrical components, ttings and tubing

1 year, labor, from original date of purchase on all other electrical components, ttings and tubing

Additionally, Wilbur Curtis Co., Inc. warrants its grinding burrs for forty (40) months from the date of purchase or 40,000 pounds of cof fee, whichever

comes rst. Stainless steel components are warranted for two (2) years from the date of purchase against leaking or pitting. Replacement parts

are warranted for ninety (90) days from the date of purchase or for the remainder of the limited warranty period of the equipment in which the

component is installed.

All in-warranty service calls must have prior authorization. For authorization, call the Technical Support Department at 800-995-0417.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. Wilbur Curtis Co., Inc., assumes no responsibility for substitute replacement parts

installed on Curtis equipment that have not been purchased from Wilbur Curtis Co., Inc. Wilbur Curtis Co., Inc. will not accept any responsibility if

the following conditions are not met. The warranty does not cover:

• Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

• Replacement of items subject to normal use and wear: This shall include, but is not limited to, spray heads, light bulbs, shear disks,

“O” rings, gaskets, silicone tubing, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

The warranty is void under the following circumstances:

• Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

• Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

• Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

• Improper water supply: This includes, but is not limited to, excessive or low water pressure and inadequate or uctuating water ow rate.

• Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

• Abuse or neglect (including failure to periodically clean or remove lime accumulations): The manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

Repairs and/or Replacements are subject to Curtis’ decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by delays,

waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the equipment.

This includes institutional and correctional facilities. Wilbur Curtis Co., Inc. will allow up to 100 miles, round trip, per in-warranty service call.

Return Merchandise Authorization (RMA): All claims under this warranty must be submitted to the Wilbur Curtis Technical Support Department

prior to performing any repair work or return of this equipment to the factory. All returned equipment must be properly re-packaged in the

original carton and received by Curtis within 45 days following the issuance of a RMA. No units will be accepted if they are damaged in

transit due to improper packaging. NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION

(RMA). THE RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL. All warranty claims must be submitted within

60 days of service. Invoices will not be processed or accepted without a RMA number. Any defective parts must be returned in order

for warranty invoices to be processed and approved. All in-warranty service calls must be performed by an authorized service agent. Call the

Wilbur Curtis Technical Support Department to nd an agent near you.

ECN 19783 Rev F 01/29/18 @ 10.4

Wilbur Curtis Co., Inc.

Mail: 6913 Acco Street, Montebello, CA 90640-5403 U.S.A.

Phone: 800-421-6150 │ Fax: 323-837-2410 │ Technical Support Phone: 800-995-0417 (M-F 5:30

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

a.m. - 4:00 p.m. PST) │ Email: techsupport@wilburcurtis.com │ www.wilburcurtis.com

Printed in U.S.A. 01/18 F-4043 RevF

Loading...

Loading...