Page 1

AC Motor Controller with VCL

Motor Controllers

www.curtisinstruments.com

www.curtisinstruments.com

1

Page 2

The Ultimate Class III Truck Control System: Superb Performance and Value

The Curtis Model AC F2-A Motor Controller provides accurate speed and torque control of 3-phase AC induction and

PMAC motors.

Model AC F2-A is fully optimized for use as a traction controller on 1.0 ton-2.0 ton Class III pedestrian-operated powered

pallet trucks. It provides vehicle designers with the ability to fully dene and control the detailed dynamic performance

of their vehicle’s drivetrain, and also provides comprehensive vehicle management and CAN capabilities. Model AC F2-A

is also suitable for traction or hydraulic pump control on other types of battery powered vehicles.

Together with the Curtis model 3141 CAN LCD display and the user-friendly Curtis Integrated Toolkit, the Curtis model

AC F2-A is the ultimate Class III truck control system.

FEATURES

Fit for Purpose

▶ Compact, rugged housing with very small ‘footprint’

for its power rating.

▶ Heavy duty M6 busbars for motor and battery

connectors.

▶ Sealed, 23-pin AMPseal I/O connector.

▶ Impervious to most oils, solvents, degreasers and other

chemicals often encountered by industrial vehicles.

▶ IP65 and IP67 environmental protection as per IEC 60529.

▶ Exceeds latest global conformance requirements for

functional safety, electrical safety and EMC.

▶ CE marked as a programmable safety device.

▶ UL583 recognized component.

Motors

▶ Easily configured to work with any AC induction or

PMAC motor.

▶ Improved motor auto-characterization setup allows

simple on-truck pairing with different Induction

motor types.

You Feel It When You Drive It—

Maximum Torque, Minimum Losses, Full control

▶ The latest implementation of Curtis’ renowned field-

oriented control algorithms and our advanced PWM

switching technology assure maximum motor output

torque and highest possible system efficiency across

the entire torque/speed spectrum.

▶ Smooth and predictable drive control that only Curtis

can deliver.

▶ Comprehensive library of AC motor types stored

controller memory.

www.curtisinstruments.com

2

Page 3

FEATURES continued

Get More Out of Your Battery—

Regardless of the Technology

▶ High-efficiency means more of your battery’s energy

is converted to motor output power.

▶ Fully configurable over- and under-voltage

protection parameters.

▶ Wide operating voltage range allows use with the

latest cell chemistries such as lithium ion.

▶ Configurable CANbus and VCL allows easy integration

with the BMS (Battery Management Systems)

typically found on lithium battery packs.

Powerful, High Performance Dual Microprocessors

▶ Dual-micro architecture achieves up to PL=D,

category 2 functional safety under

EN ISO 13849-1 / EN1175-1:1998+A1:2010.

▶ Ultra-fast processor speeds allows highly accurate

control and regulation of voltage, frequency and current.

▶ Hardware ‘ready’ for the forthcoming EN1175:2020.

Customize Your Vehicle with VCL

▶ The Curtis VCL (Vehicle Control Language) allows

Curtis AC motor controllers to perform as ‘vehicle

managers,’ eliminating the need for costly, additional

system controllers.

Comprehensive CAN Capabilities

▶ Configurable 11 or 29 bit protocol support for

CANopen or J1939 use.

▶ ‘Plug and Play’ support for Curtis CAN displays and a

variety of CAN tiller heads from leading

manufacturers FREI and REMA.

▶ Fully compliant with CANopen protocol CiA 301.

▶ Capable of acting as ‘CAN interpreter’ allowing 3rd

party CAN devices with differing profiles to work on

the same CAN network.

Improved Diagnostics

▶ Integrated, high visibility status LED with simplified flash

code sequence for at-a-glance system troubleshooting.

▶ Thermal cutback, warning, and automatic shutdown

provide protection to motor and controller.

▶ Improved error logging and fault history tables with

CAN Emergency Messages.

CAN-based Programming

▶ Model AC F2-A is programmable over the CANbus.

This allows simpler ‘vehicle level’ communication with

many of the CAN-based service tools used by the

major industrial truck manufacturers worldwide.

▶ Allows use of the Curtis Integrated Toolkit.

Highly Flexible I/O

▶ All I/O pins are multi-function, and can be configured

to provide up to:

– 17 Digital Inputs

– 9 Analog Inputs

– 2 Potentiometer sources

– 5 Output drivers, including proportional valve driver

– Quadrature encoder input

– Sine/Cosine sensor input

www.curtisinstruments.com

3

Page 4

SYSTEM ACCESSORIES

Curtis Model 3141

A cost-effective, CAN-based LCD vehicle

status display in a rugged 52mm

diameter housing is the ideal partner

to model AC F2-A.

▶ Large, easy-to-read

16-segment format LCD.

▶ Battery Discharge Indicator, Service

(Hours) Counter and Diagnostic/

Message Center functions.

▶ Sealed to IP65 (IP67 optional).

▶ 12–48V nominal operating

voltage range.

▶ CE compliant, UL583

recognized component.

▶ Optional backlight and heater.

The Curtis Integrated Toolkit

A fully integrated suite of development and diagnostic tools for use on

CAN systems using Curtis and other 3rd party CAN-based products. It is

comprised of the following tools that run in a shared environment:

▶ Launchpad

Starting point and project editor.

▶ Programmer

Used to congure parameters,

view monitor values, and view

active faults and the fault history.

▶ TACT

Improved version of the

stand-alone oscilloscope/

datalogging tool.

The Curtis Integrated Toolkit is compatible with many leading

USB>CAN interface dongles from Peak, Kvaser, iFAC, Sontheim,

etc. Contact your local Curtis Sales office for further information.

▶ VCL Studio

Editor and Compiler for

VCL software.

▶ Menu Editor

Tool to create and modify

programming menus.

▶ Package & Flash

Downloader tool to load your

software into the CAN device.

MODEL CHART

Model

AC F2-A 12-120-001 12V 120Arms 40Arms Yes

AC F2-A 24-120-001 24V 120Arms 40Arms Yes

AC-F2-A 24-200-001 24V 200Arms 67Arms Yes

AC-F2-A 24-240-001 24V 240Arms 80Arms Yes

AC F2-A 24-240-001 24V 240Arms* 84Arms* Yes

AC F2-A 48-150-001 36-48V 150Arms* 50Arms* Yes

AC F2-A 48-240-001 36-48V 240Arms* 80Arms* Yes

*Subject to change, please contact your Curtis sales representative for more information.

All models are also available without internal 120Ω CAN termination

www.curtisinstruments.com

Nominal Battery

Voltage

Maximum Current:

[S2-1 minute]

Maximum Current:

[S2-60 minute]

Internal 120Ω

CAN Termination

4

Page 5

DIMENSIONS

120.0

106.0

STATUS

LED

155.0

2X ø7.5

141.0

7.0

7.0

2X ø7.0

5X M6X1.0 - 6H 18

www.curtisinstruments.com

53.0

55.0

11.0

5

Page 6

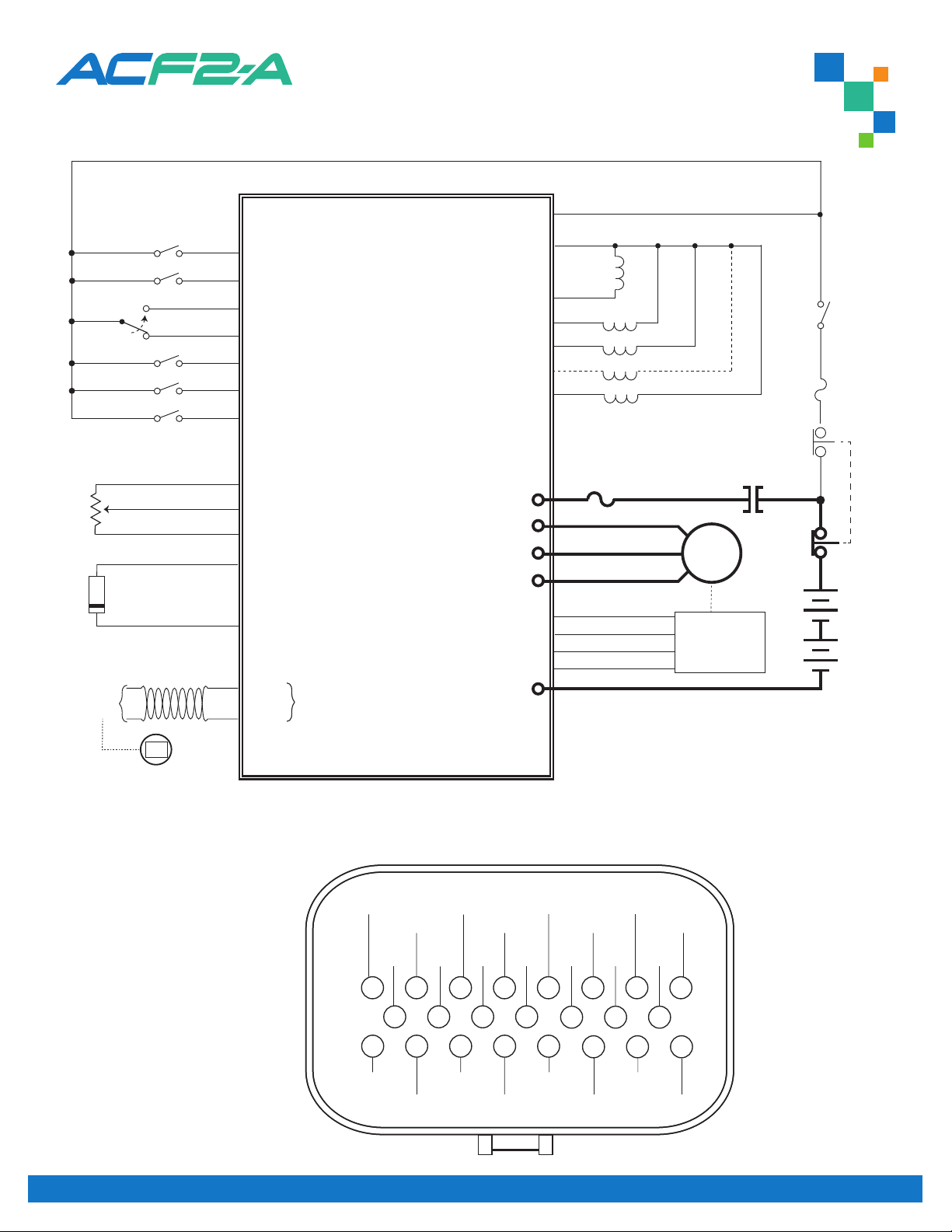

CONNECTOR WIRING

LIFT

LOWER

EMR_N.O.

EMERG. REV.

EMR_N.C.

REVERSE

FORWARD

INTERLOCK

J1-23

J1-22

J1-21

J1-19

J1-15

J1-14

J1-8

SWITCH 14 / ANALOG 14 / +12V

SWITCH 13

SWITCH 12

SWITCH 11 / ENC1_C

SWITCH 8 / ANALOG 8

SWITCH 7 / ANALOG 7

SWITCH 5 / ANALOG 5

KSI

KSI COIL RETURN

DRIVER 3 / SWITCH 23

DRIVER 2 / SWITCH 22

DRIVER 5 / SWITCH 25

DRIVER 4 / SWITCH 24

DRIVER 1 / SWITCH 21

J1-1

J1-2

J1-5

J1-4

J1-3

J1-6

J1-7

MAIN

BRAKE

PUMPEM

PROP

VALVE

KEYSWITCH

FUSE

THROTTLE

WIPER

MOTOR

TEMPERATURE

SENSOR*

CAN

PORT

Curtis 3141 CAN-based Gauge

*NOTE: KTY sensor shown. The banded end must be connected to I/O Ground.

PINOUT CHART

J1-10

SWITCH 6 / ANALOG 6 / POT HI

J1-11

SWITCH 1 / ANALOG 1 / POT WIPER

J1-12

I/O GROUND

J1-9

ANALOG 2 / SWITCH 2 / MOTOR TEMP

J1-12

I/O GROUND

J1-13

J1-20

CAN H

CAN L

INTERNAL 120Ω

TERMINATION ON

MODELS –x01

SWITCH

14 /+12V

SWITCH

SWITCH

8

13

SWITCH

SWITCH

7

I/O GROUND

12

CANHI/O

ENC1_A

ENC1_B

CAN

L

B+

U

V

W

B−

GND

+5V

SWITCH

11

J1-16

J1-17

J1-18

J1-12

WIPER

ENC

B

FUSE

POT

HI

PHASE-A

PHASE-B

GND

ENC

A

MOTOR

TEMP

MAIN

EMERGENCY

STOP

AC

MOTOR

5V

ROTOR

POSITION

ENCODER

BATTERY

+5V

www.curtisinstruments.com

231622 21

15 9

14 13 12 11 10

8

7

SWITCH

5

DRIVER

DRIVER

1

6 5

4

DRIVER

20

3

19 18

4 3

DRIVER

2

DRIVER

5

17

2

COIL

RETURN

1

KSI

6

Page 7

SPECIFICATIONS

Nominal Input Voltage 12V 24V 36/48V

Minimum Voltage 9V 12V 18V

Brownout Voltage 8.3V 8V 12V

Maximum Voltage 15V 30V 63V

PWM Frequency 10Khz

Maximum Controller Output Frequency 800Hz

Electrical Isolation to Heatsink 500Vac

Storage Ambient Temperature –40°C to 95°C

Operating Ambient Temperature –40°C to 50°C

Controller linearly reduces maximum current limit with an internal heatsink

Thermal Cutback

temperature from 85°C (185°F) to 95°C (203°F); complete

cutoff occurs above 95°C (203°F) and below –40°C (–40°F).

Design Life 8000 hours

Operating Duration at Maximum Current 1 Minute

Package Environmental Rating IP65/IP67

Weight 1.1Kg (2.2lbs)

Dimensions W x L x H 120mm x 155mm x 53mm

EMC Designed to the requirements of EN 12895:2015

Designed to the requirements of EN1175-1:1998+A1: 2010,

EN ISO 13849-1:2015

WARRANTY

Safety

UL UL recognized component per UL583

Two year limited warranty from time of delivery.

www.curtisinstruments.com

Specifications subject to change without notice 50304 REV G 11/20©2020 Curtis Instruments, Inc. is a trademark of Curtis Instruments, Inc.

7

Loading...

Loading...