Washing

The washing instructions below apply to the cleaning of all CurTec

packaging products that are made of polyethylene and

polypropylene:

Best results will be achieved with a washing installation that is

equipped with spray nozzles or a so-called Ultra-Sonic installation.

Best qualified detergent is a low-foaming alkaline substance with

a PH-value of 10 to 12 (solvents.)

The recommended temperature of the washing water lies

between 40°C and 50°C.

The temperature of the rinsing water can only be up to 65°C.

Washing at maximum temperature can only take up to 35 seconds

and rinsing at maximum temperature only up to 20 seconds. It

prevents the plastic from warming up and shrinking.

Increased drying of products can be effected by means of applying

cold air. If warm air will be used the drying can only last up to 30

seconds at a maximum temperature of 65°C.

The blowing and drying part of the installation needs to be

adjusted to the product, so those difficult spots of the kegs can

also be dried.

For specific technical information CurTec would like to refer to the

various suppliers of washing installations.

Attention! Check the thermostat and programmed times of your

equipment regularly.

0807

01 Close

The UN marking on a drum is only valid if the

following closing instruction is applied.

1. Put the lid on the drum and turn it clockwise until it is tight.

2. Turn the lid 30° clockwise using a tool. Only now the drum is

closed liquid tight and the UN marking is valid.

3. After closing the drum you can make the container tamper

evident. For that purpose the lid and the container have sealing

loops. CurTec advises you to use Unisto Compact seals.

Put the tail of the sealing strip into the sealing loops of the lid and

drum. Push the tail trough the eye of the sealing strip and pull

close.

Vaten gebruiksaanwizjing 2020-7

4. The drum is now sealed.

Remark: Sealing the drum is not a requirement for the validity of

the UN marking

Vaten gebruiksaanwizjing 2020-7

02 Open

1. In case a drum is sealed, tear the seal and remove it from the

loops.

2. Turn the lid counter-clockwise to open.

Unstacking

Due to the weight of the stack on top, the rubber gasket can get

compressed and needs time to recover. After unstacking, CurTec

strongly advises users to leave the drums in an upright position for

at least 15 minutes prior to opening. This allows the rubber gasket

to return to its original shape and guarantee an optimal closure.

Drums manual 2020-7

03 Use

Filling

The temperature of the content cannot exceed 70°C. The content

has to cool down to 30°C before the container can be closed. The

drum can be closed according to instruction 1.

Lifting

Depending on the type of drum, you can lift the container by using

the large handgrips on the body or the handgrips on the lid.

Attention! Please consider the HSE regulations regarding weight

and frequency restrictions for lifting

Charging the handgrip

The mounted handgrips have been designed for manual

displacement of drums only. They are are not suitable for

mechnical handling, such as lifting a drum with a hoist. The

handgrip is suited for a brief, controlled charge of maximum 80 kg

and a couple of minutes, during which the handgrip canot be

torqued.

Freezing

The drums are made of plastic which is resistant to a minimum

temperature of -25°C. As of -5°C, shock load on the drums should

be avoided.

Attention! The volume of drums filled with water-based contents

can increase by 10%. The chances that drums will distort is real

and it will reduce the stability of a drum stack on a pallet. Please

maintain a maximum filling level of 90% and test the stability of a

pallet stacking.

Drums manual 2020-7

Air transport

During air transport, the pressure drops inside a plane’s cargo

hold, which causes air inside a package wanting to escape. After

landing, normal atmospheric pressure prevails again which,

depending on the amount of escaped air*, can cause the drum

wall to cave in.

CurTec packaging has not been designed to compensate pressure

differences. The construction is such that a correctly closed

packaging alllows air to escape relatively fast, but does not allow it

to return easily.

Since CurTec has no influence on the use of its packaging by end

users, they advise to test each transport mode.

It remains the responsibility of end users to verify whether a

package and content comply with relevant transport regulations.

CurTec refers to the regulations mentioned in the UN certificates.

* The quantity depends on the content type (the shape and air between) and the

filling degree/ level

Drums manual 2020-7

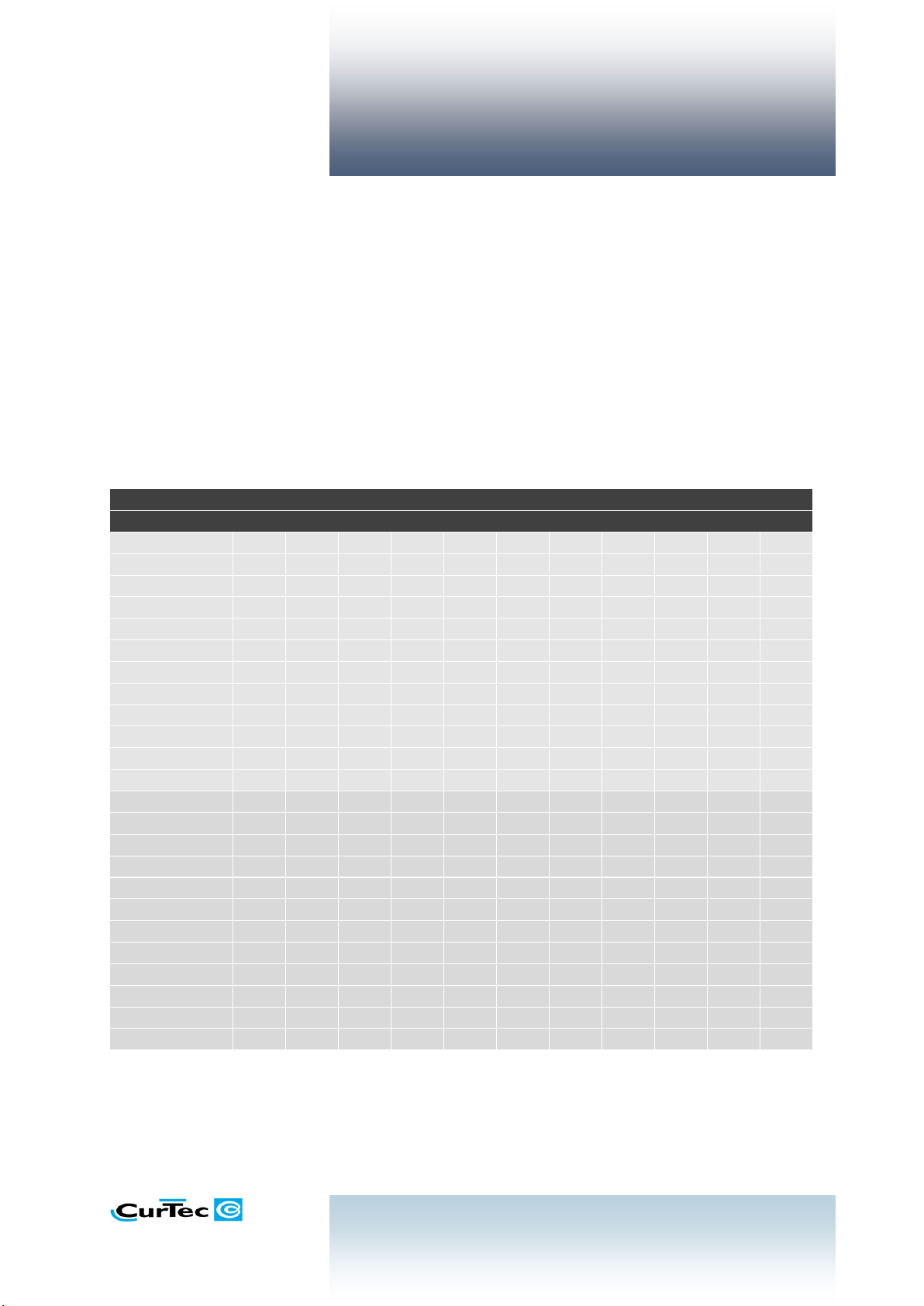

04 Static load

Max. temp °C

0 0 0

15

15

15

25

25

25

35

35

Months

1 4 12 1 4

12 1 4

12

0,5

6

6940

320

270

235

205

165

145

145

125

110

130

90

6941

320

270

235

205

165

145

145

125

110

130

90

6942

320

270

235

205

165

145

145

125

110

130

90

6943

320

270

235

205

165

145

145

125

110

130

90

6944

320

270

235

205

165

145

145

125

110

130

90

6945

290

230

200

180

150

130

130

110

95

105

75

6947

290

230

200

180

150

130

130

110

95

105

75

6948

290

230

200

180

150

130

130

110

95

105

75

6949

290

230

200

180

150

130

130

110

95

105

75

6950

290

230

200

180

150

130

130

110

95

105

75

6990

440

380

325

285

240

210

210

185

155

175

125

6994

440

380

325

285

240

210

210

185

155

175

125

7003

110

92

80

72

60

52

52

44

38

42

30

7004

110

92

80

72

60

52

52

44

38

42

30

7006

110

92

80

72

60

52

52

44

38

42

30

7010

150

125

110

98

80

70

70

60

52

58

42

7011

150

125

110

98

80

70

70

60

52

58

42

7015

150

125

110

98

80

70

70

60

52

58

42

7019

300

250

220

210

180

160

150

125

110

120

90

7020

150

125

110

98

80

70

70

60

52

58

42

7026

180

150

130

115

95

85

85

72

62

68

50

7042

320

270

235

220

180

160

160

135

115

135

95

7055

320

270

235

220

180

160

160

135

115

135

95

7068

320

270

235

220

180

160

160

135

115

135

95

When stacking drums for storage in e.g. a warehouse or cold

store, it is important to know what the maximum load on the

lowest drum in a stack can be.

The stacking load depends strongly on: the weight of a drum, the

number of drums to be stacked, the weight of interlayers and

pallets, the ambient temperature, the duration of the load and

the surface beneath the lowest drum.

The following table shows the maximum stacking load (in kg) at a

given ambient temperature, during a certain period of time, for a

drum placed on a flat, closed surface or pallet.

Attention! The weights mentioned in the table have been

established after simulation and can only serve as indications.

CurTec recommends users to perform tests at all times.

Drums manual 2020-7

The table allows you to calculate the number of drums that can be

stacked: Reduce the stacking weight mentioned with the relevant

share of the weight of intermediate layers and divide by the

weight of the drum with content. This number, with a figure after

the decimal point lower than 8, rounded down is the total amount

of drums that can be stacked on the lowest drum of a stack.

Example

How many 15 liter drums (art. no. 7015) with a content weighing

15 kg can be stacked on a pallet at 15°C during 1 month?

The relevant weight share of intermediate layers is 5 kg, so

(98-5)/15 = 6.2. The number of drums that can be stacked on the

lowest drum is 6.

In case of a different duration or temperature, please choose the

next appropriate column. For shorter stacking durations, the table

of instruction 5 (Dynamic load) can be of service.

Attention points

Before stacking the drums, the temperature of the contents must

be equal or lower than the ambient temperature.

The maximum stacking time is reduced considerably at

temperatures above 35°C. The stacking load in the table is at 50°C

only 75% of the last mentioned value and at 60°C only 50%.

When a stack is higher than 2.5 meters, the floor angle cannot

exceed 0.5%.

CurTec strongly discommends stacking drums horizontally, lying

on the side.

When changing transport mode, from storage to shipping or vice

versa, the lowest drums of a stack must always be placed highest

in a new stack.

Drums manual 2020-7

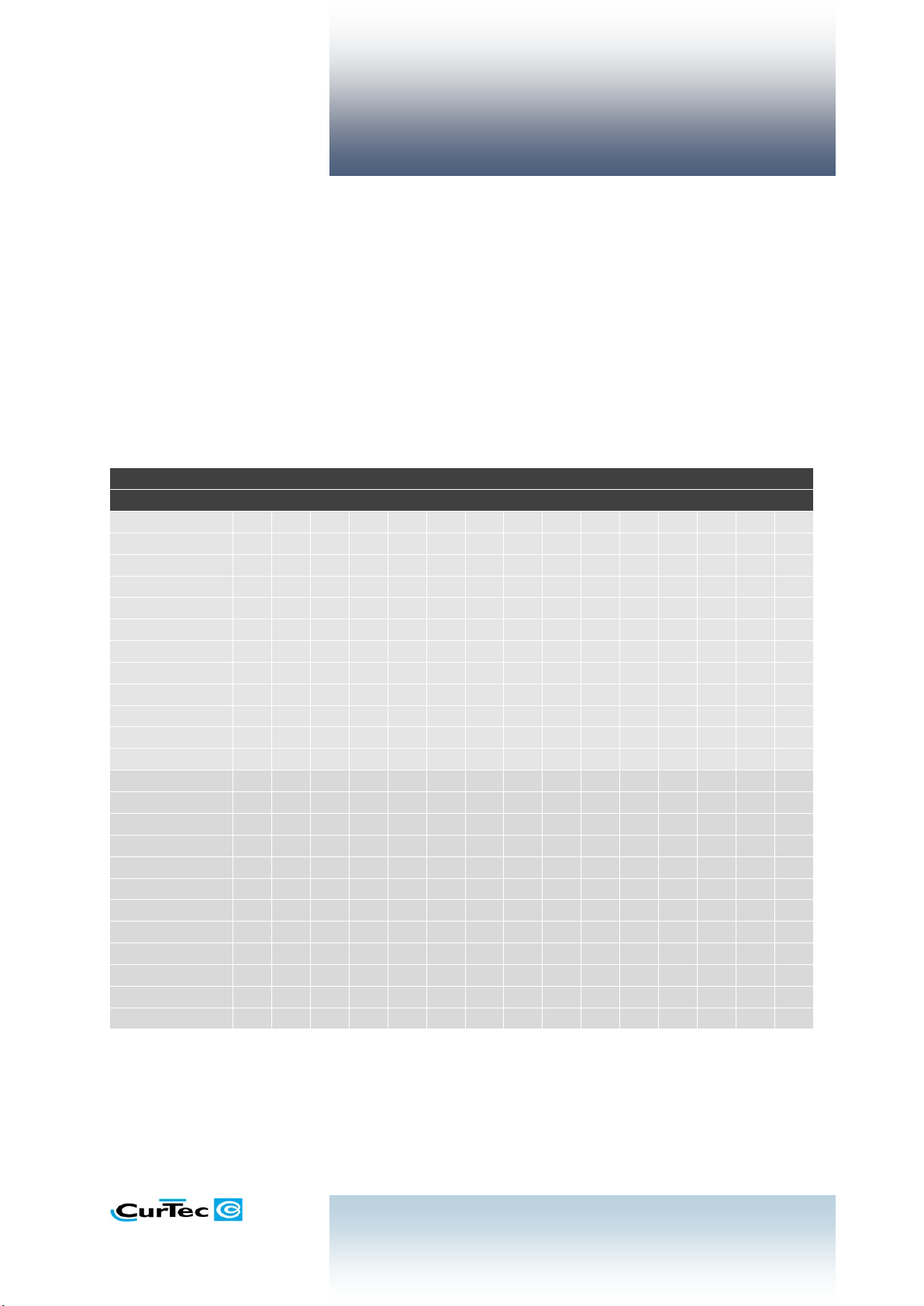

05 Dynamic load

Max. temp °C

5 5 5 5 5

30

30

30

30

30

40

40

40

40

40

Weeks

0,5 1 2 3 5

0,5 1 2 3 5

0,5 1 2 3 5

6940

360

330

300

285

250

175

160

150

140

135

135

120

112

105

100

6941

360

330

300

285

250

175

160

150

140

135

135

120

112

105

100

6942

360

330

300

285

250

175

160

150

140

135

135

120

112

105

100

6943

360

330

300

285

250

175

160

150

140

135

135

120

112

105

100

6944

360

330

300

285

250

175

160

150

140

135

135

120

112

105

100

6945

320

290

265

250

240

155

140

130

122

117

117

104

96

92

87

6947

320

290

265

250

240

155

140

130

122

117

117

104

96

92

87

6948

320

290

265

250

240

155

140

130

122

117

117

104

96

92

87

6949

320

290

265

250

240

155

140

130

122

117

117

104

96

92

87

6950

320

290

265

250

240

155

140

130

122

117

117

104

96

92

87

6990

500

460

420

395

375

235

215

200

190

180

180

165

150

140

130

6994

500

460

420

395

375

235

215

200

190

180

180

165

150

140

130

7003

126

115

106

100

95

62

56

52

49

46

46

42

38

36

34

7004

126

115

106

100

95

62

56

52

49

46

46

42

38

36

34

7006

126

115

106

100

95

62

56

52

49

46

46

42

38

36

34

7010

170

155

145

138

130

84

77

70

67

64

64

57

54

50

47

7011

170

155

145

138

130

84

77

70

67

64

64

57

54

50

47

7015

170

155

145

138

130

84

77

70

67

64

64

57

54

50

47

7019

320

300

280

250

240

170

155

140

130

120

120

110

105

100

95

7020

170

155

145

138

130

84

77

70

67

64

64

57

54

50

47

7026

200

180

165

155

150

95

90

83

78

74

74

66

60

57

54

7042

380

350

320

300

290

180

165

155

145

140

140

125

115

110

105

7055

380

350

320

300

290

180

165

155

145

140

140

125

115

110

105

7068

380

350

320

300

290

180

165

155

145

140

140

125

115

110

105

When stacking drums for transport, it is important to know what

the maximum load on the lowest drum in a stack can be.

For transport, this stacking load is called dynamic load and can be

found by dividing the admissible static load by a so-called safety

factor. These factors are:

3 for air transport

2 for road transport

1.8 for rail transport

1.3 for maritime transport

Attention! The weights mentioned in the table have been

established after simulation and can only serve as indications.

CurTec recommends users to perform tests at all times.

Drums manual 2020-7

The stacking weights mentioned in the table above are indicative

and depend on temperature and time: 5°C is the temperature for

cooled transport, 30°C is the temperature for the average

transport by road or inland waterways and 40°C is the

temperature for transport in warmer surroundings. In case of a

different duration or temperature below 40°C, please choose the

next appropriate column. In case of even higher temperature,

please consider that the dynamic load is at 50°C only 75% of the

last mentioned value and at 60°C only 50%.

The table allows you to calculate the number of drums that can be

stacked: Reduce the stacking weight mentioned with the relevant

share of the weight of intermediate layers and divide by the

weight of the drum with content. This number, with a figure after

the decimal point lower than 8, rounded down is the total amount

of drums that can be stacked on the lowest drum of a stack.

Example

How many 15 liter drums (art. no. 7015) with a content weighing

13 kg can be transported by rail at 3°C during 1.5 weeks?

The relevant weight share of intermediate layers is 7 kg, so

(145-7)/(13x1.8) = 5.89. The number of drums that can be stacked

on the lowest drum is 6.

Attention points

When changing transport mode, from storage to shipping or vice

versa, the lowest drums of a stack must always be placed highest

in a new stack.

The drums must be stowed professionally and fixed in such a way

that makes moving impossible.

For the use of pallets, see instruction 6 (Palletization).

For stacking drums in a warehouse, see instruction 4 (Static load).

Drums manual 2020-7

06 Palletization

Palletization

Each pallet should be fitted with a solid, flat intermediate layer

prior to loading. A pallet should have an almost closed surface

fitted with planks that are no more than 5 cm/ 2 inches apart.

CurTec advises not to exceed a total stacking height of 2 meters.

In case a pallet is placed on top of another pallet, an intermediate

layer is required to enable an equal spread of the pressure. This

layer should also be solid and flat.

Filled drums are placed on a flat surface and stacked by placing

the base of the drum in the counter shape of the lid.

Packing

CurTec recommends the use of a heat shrink pallet cover, which

needs to be shrunk around the pallet as well. In addition, the base

of the pallet needs to be stretched with foil as well. The drums at

the base of a stack will carry most of the load and to avoid a

collapse they cannot be deformed by overstretching the foil or

over-heating the cover.

When positioning the drums on a pallet it is important to turn the

handgrips away from the pallet corners to avoid damaging the

heat shrink pallet cover or the stretch foil.

Attention! The total load on the bottom drum of a stack may

never exceed the maximum loads as indicated in the tables of

instructions 4 and 5.

Pallet handling

From a safety point of view, CurTec recommends to transport only

one pallet at a time with a fork lift truck. In order not to disturb

the stack, the forks of the truck need to be kept almost horizontal.

Pallet schemes

CurTec advises you to respect the following quantities per layer:

Drums manual 2020-7

Art. No. 7003 ▪ 7004 ▪ 7006

(24)

1200 x 800 mm

(30)

1200 x 1000 mm

48 x 40 inches

Art. No. 7010 ▪ 7011 ▪ 7015 ▪ 7020

(12)

1200 x 800 mm

(15)

1200 x 1000 mm

48 x 40 inches

Drums manual 2020-7

Art. No. 7026

(8)

1200 x 800 mm

(10)

1200 x 1000 mm

48 x 40 inches

Art. No. 6945 ▪ 6946 ▪ 6947 ▪ 6948 ▪ 6949 ▪ 6950

(7)

1200 x 800 mm

(9)

1200 x 1000 mm

48 x 40 inches

Drums manual 2020-7

Art. No. 6940 ▪ 6941 ▪ 6942 ▪ 6943 ▪ 6944 ▪ 7042 ▪ 7055 ▪ 7068

(5)

1200 x 800 mm

(6)

1200 x 1000 mm

48 x 40 inches

Art. No. 6990 ▪ 6994

(5)

1200 x 1000 mm

48 x 40 inches

Attention! Our ex-works palletization is different. Please check our

website for more info.

Drums manual 2020-7

Disclaimer

CurTec manufactures packaging material for a wide range of

purposes. This declaration is restricted to the packaging material

as it leaves the production facility. CurTec has neither control over

final end use of the product nor over processing conditions. It is

therefore the responsibility of the end user to check compliance

with the relevant regulations and to validate material

performance in the end application through proper end use

testing.

CurTec International

Spoorlaan Noord 92

5121 WX Rijen

The Netherlands

UK & Ireland: +44 20 3514 4624

North America: +1 908 450 98 16

All other countries: +31 88 808 2000

curtec.en@curtec.com

curtec.com

Loading...

Loading...