Current Tools RotaBoom 77-22, RotaBoom 77SE-22, RotaBoom 77SR-22, RotaBoom 700SP, RotaBoom 700SI Operating, Maintenance, Safety And Parts Manual

Page 1

Current Tools™ 77 Series Electric Bender – 220 Volt

with Single Shoe Groups

for bending 1/2" thru 2" RIGID - EMT - IMC

and 40 mil PVC coated RIGID Conduit

50

130

140

Operating, Maintenance, Safety

This manual is free of charge. All personnel who operate this Bender

should have a copy of this manual and read and understand its

contents. To request a copy, call or write to the address below.

CURRENT TOOLS • P. O. BOX 17026 GREENVILLE, SC 29606

800.230.5421 or 864.721.4230 • FAX 864.721.4232

and Parts Manual

06/17

Read and understand this material before

operating or servicing this Bender. Failure to

understand how to safely operate and service

this unit may result in serious injury or death.

www.currenttools.com

Page 2

TABLE OF CONTENTS

Safety Alerts ....................................................................................3

Important Safety Information ....................................................4, 5

Specifications – 77 Series Electric Bender – 220 Volt ................. 6

Model Descriptions ........................................................................ 6

Features ........................................................................................6, 7

Shoe Groups ................................................................................... 8

Conduit Centerline Bending Radii ................................................ 8

Grounding Instructions .................................................................. 9

Mounting Bending Shoes .............................................................10

Mounting Roller Supports ............................................................ 11

General Bending Instructions ................................................12, 13

Bending Instructions for

1

1

⁄2" and 2" EMT & IMC Conduit ......................................... 14-16

Squeeze Adjustment Procedure for

1

1

⁄2" and 2" EMT & IMC Roller Supports ..................................17

Maintenance ............................................................................18, 19

Stub-Up Bending Information and Charts ............................20, 21

Offset Bending Information and Charts ................................22, 23

Troubleshooting ........................................................................... 24

Exploded Views .......................................................................25, 26

Parts List ..................................................................................27, 28

Electrical System Diagram ...........................................................29

Parts List – Bending Shoes & Roller Supports .................... 30-35

2

Page 3

jury

.

G

jury

.

ON

jury

.

G

R

SAFETY ALERTS

THIS SAFETY SYMBOL is used to call your attention to instructions

that concern your personal safety. It means: ATTENTION! BE AWARE!

THIS IS AN IMPORTANT SAFETY INSTRUCTION!

Read, understand, and follow these safety instructions. Failure to follow

these safety instructions may result in injury or death.

Safety Alert

Symbol

DAN

Immediate hazards which, if not avoided, WILL result in serious personal

or death

in

E

ARNIN

Hazards or unsafe practices which, if not avoided, COULD result in serious

personal in

or death

UTI

Hazards or unsafe practices which, if not avoided, COULD result in minor

personal in

or property damage

3

Page 4

RETAIN SAFETY INFORMATION

DANGER

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

This manual should be read and understood by all personnel who operate

or service this bender. Failure to understand how to safely operate and

service this unit could result in injury or death. This unit should only be

operated and serviced by qualified personnel.

IMPORTANT SAFETY INFORMATION

NEVER operate the bender in an explosive atmosphere.

NEVER operate the bender in wet or damp locations.

DO NOT expose the bender to rain.

ALWAYS connect to a power supply that is properly installed and

meets all applicable electrical codes. See grounding instructions

on page 9.

ALWAYS inspect power cord before using bender.

Replace damaged or worn cords.

DO NOT modify the plug provided with the bender.

ALWAYS disconnect power to the bender before servicing.

ALWAYS make sure the circuit breaker switch is in the OFF

position before plugging in. This will reduce the risk of

unintentional starting.

ALWAYS use three-wire, 12 AWG extension cords that have

three-prong grounding type plugs and three hole receptacles

that accept the bender's plug.

NEVER use an extension cord longer than 100 feet.

ALWAYS replace damaged extension cords.

ALWAYS disconnect power to the bender before servicing or

changing shoes, attachments or roller supports, and when not in

use.

ALWAYS inspect the bender before operating. Replace any

damaged, missing or worn parts.

NEVER alter this equipment. Doing so will void the warranty.

NEVER remove guards, they are installed for your protection.

ALWAYS check for damaged or worn parts. Check for alignment

of moving parts, binding of moving parts, breakage of parts,

mounting and any other conditions that may affect its

operation. A guard or other part that is damaged should be

properly repaired or replaced.

4

4

Page 5

IMPORTANT SAFETY INFORMATION — continued

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

WARNING

DANGER

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

ALWAYS use recommended accessories. Consult this manual for

recommended accessories. The use of improper accessories may

cause risk of injury.

ALWAYS keep hands and feet away from pinch points such as

bending shoes, roller supports and conduit when bender is in use.

Operator must ALWAYS face the front of the bender with the

bending degree scale visible and maintain a minimum of 3 feet

distance from the bender while the conduit is being bent. All

other personnel must remain out of the area while the bender is

in operation.

ALWAYS use appropriate shoe groove and roller support for

the type and size conduit to be bent.

If bending shoe will not turn, STOP unit and unplug before

checking for any obstructions.

DO NOT use bender or attachments to do a job for which

it was not designed.

ALWAYS keep conduit under control when unloading.

ALWAYS keep the path of the bending conduit clear of

obstructions. Make sure all obstacles are clear of the bending

path BEFORE you bend the conduit.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

Be sure handle is bolted securely to the bender frame before

moving or lifting the bender.

NEVER stand on bender. Serious injury could occur if the bender

is tipped or if the bending shoe is unintentionally contacted.

ALWAYS wear approved safety glasses when the bender is

in operation.

ALWAYS wear proper apparel. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which may

get caught in moving parts. Non-slip footwear is recommended.

Wear protective hair covering to contain long hair.

ALWAYS keep children away. All visitors should be kept a safe

distance from work area.

ALWAYS make bender childproof with lockouts, master switches

or by unplugging unit.

The bender and some accessories exceed 50 lbs. and will

require more than one person to lift, transport and assemble.

Only use the bender for its intended purpose as specified

in this manual.

ALWAYS use this bender in a dry, well lighted area.

CAUTION

ALWAYS maintain bender with care. Keep bender clean for

best and safest performance.

5

Page 6

SPECIFICATIONS – 77 SERIES ELECTRIC BENDER

SPECIFICATIONS - 77 SERIES ELECTRIC BENDER WITH SINGLE SHOE GROUPS

1/2" thru 2" RIGID conduit

1/2" thru 2" EMT conduit

1/2" thru 2" IMC conduit

1/2" thru 2" 40 mil PVC coated RIGID conduit

1/2" thru 2" schedule 40 steel pipe

No modification to the

77-22 POWER UNIT is required

to accommodate these shoes

or roller supports.

No tools are required to

install or remove these

shoes and roller supports.

The 77 Series Electric Bender is NOT to be

used for bending any conduit or pipe wall thickness above schedule 40 pipe.

width 29 1/2"

length 24 3/4"

height 39"

weight 256 lbs. Power Unit Only - without shoes and roller supports

MODEL DESCRIPTIONS

Bender Power Unit and Bender Power Unit with Shoe Group

77-22 Electric Bender Power Unit only, without shoes and roller supports

77SR-22 Electric Bender with shoe and roller support for 1/2" thru 2" RIGID conduit

and schedule 40 pipe and 1/2" thru 1 1/4" IMC conduit

77SE-22 Electric Bender with shoe and roller support for 1/2" thru 2" EMT conduit

Shoe Group ONLY for use with 77-22 Power Unit

700SI 1/2" thru 2" IMC single shoe group for 77-22 power unit

700SP 1/2" thru 2" 40 MIL PVC Coated RIGID single shoe group for 77-22 power unit

FEATURES

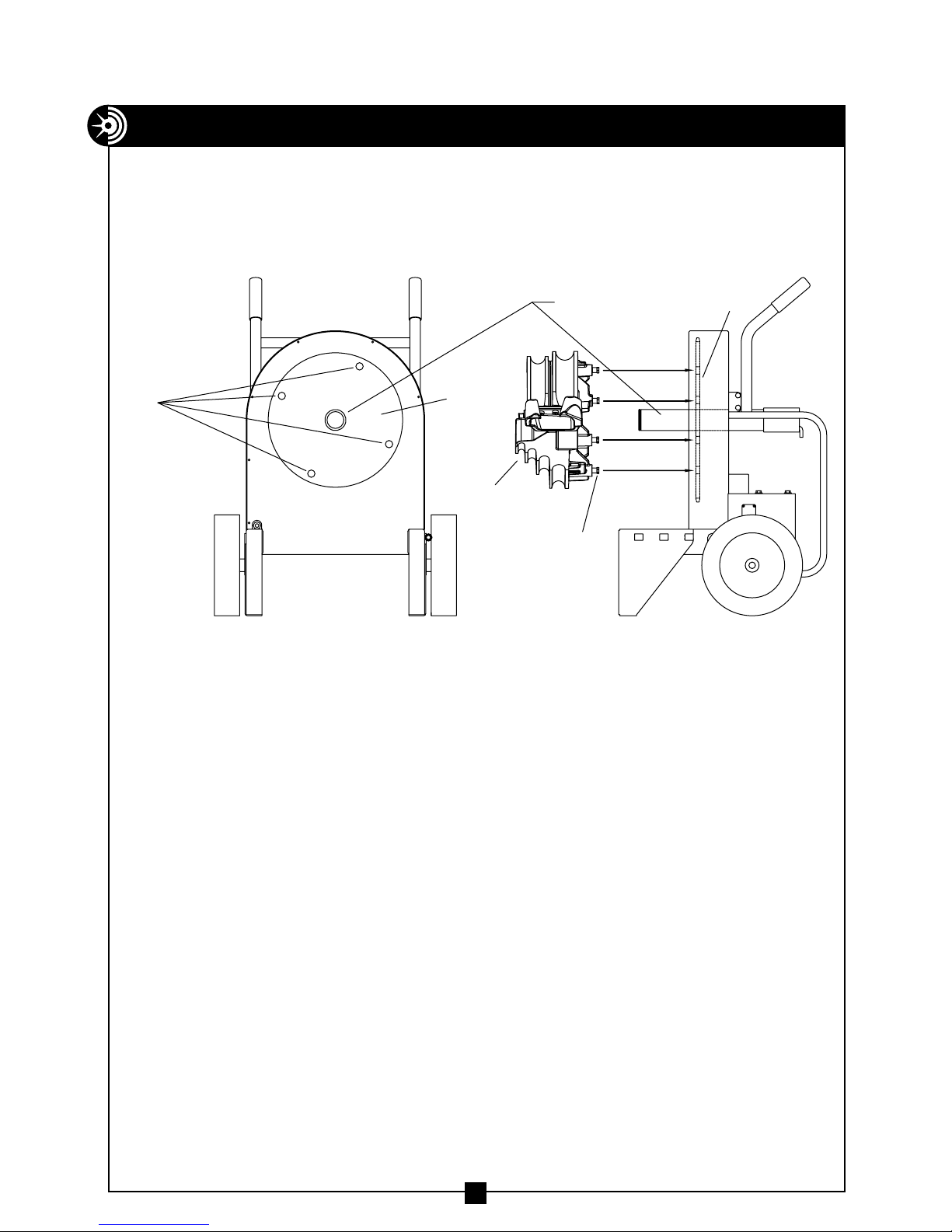

1. Bending Degree Scale - easy to read for exact bends.

2. Roller Supports - for supporting the conduit during bending.

3. Hinge Pin - for securing the roller supports.

4. 12 inch Wheels - for easy mobility.

5. D.C. Motor - quiet and strong.

6. Bending Instructions Decal -

easy to read for quick reference.

7. Remote Pendant - with 6 foot cord.

( Bend and unload from pendant. )

8. Removable Handle - may be

removed for dog-leg bends

9. Back Rails - Protect the back

of bender and enable the

bender to be used horizontally

1

50

2

8

6

9

130

140

5

4

7

3

6

Page 7

FEATURES — continued

y

.

G

REMOVE BOTH SCREWS

AND NUTS ON EACH SIDE

TO REMOVE HANDLE

Special Features

The 77 Series Electric Benders have a unique

feature to remove the handles during a

“Dog-Leg Bend." See Figure 7a below.

Figure 7a

ARNIN

When replacing handle, be sure to replace screws and nuts and also to tighten

securel

The 77 Series Electric Benders may also be used in a horizontal position

The bender can operate in this position as efficiently as it does in the upright

position. See Figure 7b below.

before moving or transporting

Figure 7b

7

Page 8

SINGLE SHOE GROUPS

RIGID

1

2

700SR - for bending 1/2" thru 2" RIGID conduit, 1/2" thru

1 1/4" IMC conduit and 1/2" thru 2" schedule 40 pipe

includes the following items.

Key Catalog# Description

1 2-3000 1/2" thru 2" bending shoe

2 2-4000 1/2" thru 2" roller support

3 8-0501 Storage box (not shown)

IMC

EMT

1

2

700SE - for bending 1/2" thru 2" EMT ( Thinwall )

includes the following items.

Key Catalog# Description

1 2-3100 1/2" thru 2" bending shoe

2 2-4200 1/2" thru 2" roller support

3 8-0501 storage box (not shown)

PVC COATED RIGID

1

1

2

700SP - for bending 1/2" thru 2" 40 mil PVC coated RIGID

700SI - for bending 1/2" thru 2" IMC conduit

includes the following items.

Key Catalog# Description

1 2-3000 1/2" thru 2" bending shoe

2 2-4100 1/2" thru 2" roller support

3 8-0501 storage box (not shown)

includes the following items.

Key Catalog Description

1 2-3200 1/2" thru 2" bending shoe

2 2-4300 1/2" thru 2" roller support

3 8-0501 storage box (not shown)

CONDUIT CENTERLINE BENDING RADII

size 1/2" 3/4" 1" 1 1/4" 1 1/2" 2"

EMT 4-5/16 5-1/2 7 8-13/16 8-3/8 9-1/4

IMC 4-1/4 5-7/16 6-15/16 8-3/4 8-1/4 9

RIGID 4-1/4 5-7/16 6-15/16 8-3/4 8-1/4 9

PVC COATED RIGID 4-1/4 5-7/16 6-15/16 8-3/4 8-1/4 9

2

8

Page 9

GROUNDING INSTRUCTIONS

RECEPTACLE PLUG

NEMA 6-15

WARNING

ELECTRIC SHOCK HAZARD! Only connect the bender to a 15 AMP GFCI

protected circuit. DO NOT modify the plug which is provided with the unit.

Failure to follow these warnings can result in serious injury or death.

Figure 9a Figure 9b

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. The bender is

equipped with an electric cord having an equipment grounding conductor and a

grounding plug. Only connect the bender to a 15 AMP GFCI protected receptacle

which is properly installed and grounded to meet all applicable electrical codes.

Do NOT use an adapter.

Do NOT modify the plug provided. If it will not fit the receptacle, have the

proper receptacle installed by a qualified electrician.

Improper connection of the equipment grounding conductor can result in risk

of electric shock. The conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipment grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect

the equipment grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether

the bender is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and

3-pole receptacles that accept the bender’s plug.

Repair or replace damaged or worn cord immediately.

This bender is intended for use on a circuit that has a receptacle that looks

like the one illustrated in Figure 9a above. The bender has a grounding plug

that looks like the plug illustrated in Figure 9b above.

9

Page 10

MOUNTING BENDING SHOE

MAIN

DRIVE

HOLES

Choose the desired shoe (RIGID, IMC, EMT, or 40 mil PVC coated RIGID) and

slide shoe onto the main drive sprocket shaft. See Figure 10a below.

Note: Rigid and IMC conduit are bent on the same shoe. However, the roller

supports are specific for Rigid or IMC.

SPROCKET SHAFT

MAIN

DRIVE

SPROCKET

BENDING

SHOE

DRIVE

STUDS

Figure 10a Figure 10b

DRIVE

SPROCKET

Next, align the four drive studs on the back of the shoe with the four drive

holes in the main drive sprocket.

Push the shoe onto the main drive sprocket shaft. See Figure 10b.

10

Page 11

MOUNTING ROLLER SUPPORT

Choose the correct roller support for the

corresponding shoe and type conduit ( RIGID,

IMC, EMT, or 40 mil PVC coated RIGID ). The

appropriate size and type

of roller support MUST be used with the

corresponding shoe size and type.

Mount the roller support on the bender.

Secure the roller support with the quick

release hinge pin. See Figures 11a and 11b.

Figure 11a

Bender shown with

1/2" to 2" Rigid roller support

Figure 11b

Bender shown with

1/2" to 2" EMT roller support

MOUNTING INSTRUCTIONS FOR

GREENLEE® SHOES AND ATTACHMENTS

Most bending shoes and attachments for the Greenlee® 555® and 555 Classic® will

fit the Model #77-22 Bender. In addition, most bending shoes and attachments for

the Model #77-22 Bender will fit the Greenlee® 555® and 555 Classic® bender.

Contact Current Tools for specific applications and compatibility.

* Greenlee® 555® and 555 Classic® are registered trademarks of Greenlee/Textron.

11

Page 12

GENERAL BENDING INSTRUCTIONS

G

Bending instructions for:

1/2" thru 2" RIGID conduit

1/2" thru 1 1/4" EMT conduit

1/2" thru 1 1/4" IMC conduit

1/2" thru 2" 40 mil PVC coated RIGID conduit

1/2" thru 2" schedule 40 pipe

See pages 10 and 11 for mounting shoe and roller support.

Be sure to match the appropriate shoe with its corresponding roller support.

1. Mark pipe/conduit to the desired length. Note that a 2" minimum distance

from the end of the conduit to the bending mark is required to eliminate

flattening the end of the pipe/conduit. See Figure 12.

NOTE: Stub-up and Offset dimensions can be found on the bending charts

on pages 20 thru 23 of this manual or on the bending instruction decal on

top of each bender.

2. Rotate the bending shoe to 10 degrees below the 0 ( zero ) degree setting,

as shown in Figure 12 below.

DAN

operate this bender in an explosive atmosphere. Injury or Death may occur.

0°

-10°

BENDING

MARK

ER

Figure 12

MINIMUM

HOOK

2"

12

Page 13

GENERAL BENDING INSTRUCTIONS — continued

y

.

G

3. After marking the pipe/conduit, place it into the bender. See Figure 12.

The pipe/conduit should slide over the correct size roller support, through

the shoe groove and into the hook. The bending mark should be at the

front ( OUTSIDE ) edge of the hook. See Figure 12.

4. Using the remote pendant, place the “Bend/Unload" switch in the “bend"

position. Press the “Jog" button and advance the bender shoe. Be sure to

check the alignment of the bending mark as the rotating shoe locks the

pipe/conduit into position. Advance the bender shoe to the desired degree

of bend. When the arrow on the shoe reaches the desired degree of bend,

release the “Jog" button and the bender will stop.

NOTE: Due to springback in pipe/conduit, some over bending is

necessary to achieve the desired degree of bend. See page 21 or

the bending instruction decal on top of each bender for approximate

springback compensation figures.

5. To release the pipe/conduit, place the “Bend/Unload" switch in the

“Unload" position. Press the “Jog" button and reverse the shoe far

enough to release the conduit. Then, rotate the roller support out of

the way. See Figure 13a & 13b. The pipe/conduit can now be removed.

ARNIN

The pipe/conduit should be under control when unloading.

Failure to do this ma

result in injury or death

Figure 13a

Bender shown with

1/2" to 2" Rigid roller support

Figure 13b

Bender shown with

1/2" to 2" EMT roller support

13

Page 14

BENDING INSTRUCTIONS FOR

1 1/2" AND 2" EMT & IMC CONDUIT

1. See pages 10 and 11 for mounting shoe and roller support.

Be sure to match the appropriate shoe with its corresponding roller support.

NOTE: The frame color of the EMT roller support is silver (see Figure 14a).

The frame color of the IMC roller support is yellow (see Figure 14b).

SILVER YELLOW

EMT ROLLER SUPPORT IMC ROLLER SUPPORT

Figure 14a Figure 14b

2. Mark pipe/conduit to the desired length. Note that a 2" minimum distance

from the end of the conduit to the bending mark is required to eliminate

flattening the end of the pipe/conduit. See Figure 14c.

BENDING

MARK

HOOK

2"

MINIMUM

Figure 14c

NOTE: Stub-up and Offset dimensions can be found on the bending

charts on pages 20 thru 23 of this manual or on the bending instruction

decal located on the top of each bender.

14

Page 15

BENDING INSTRUCTIONS FOR

1 1/2" AND 2" EMT & IMC CONDUIT — continued

3. Rotate the bending shoe to 10 degrees below the 0 (zero) degree setting.

See Figure 12.

4. After marking the pipe/conduit, place it into the bender. The pipe/conduit

should slide over the roller support and through the shoe groove and into

the hook. The bending mark should be at the front ( OUTSIDE ) edge of

the hook. See Figure 14c.

NOTE: The appropriate size and type of roller support MUST be used

with the corresponding shoe size and type.

5. Step on the “Engaging Pedal" which will raise the rollers to come in

contact with the conduit. See Figure 15. Be sure the correct rollers for

the size conduit being bent are in position to engage the conduit.

NOTE: See SQUEEZE ADJUSTMENT PROCEDURE on page 17.

STOP

ENGAGING

PEDAL

ROLLERS SHOWN

IN RAISED (BENDING)

POSITION

Figure 15

15

Page 16

BENDING INSTRUCTIONS FOR

y

.

G

1 1/2" AND 2" EMT & IMC CONDUIT — continued

6. Keep foot pressure on the engaging pedal and push the “Bend/Unload”

switch to the “Bend” position. Then press the “Jog” button. The conduit

will pull the roller support against the stop. Foot pressure can then be

removed from the engaging pedal. Be sure to check the alignment of

the bending mark as the rotating shoe locks the conduit into position.

NOTE: If the roller support will not pull against the stop, the squeeze

adjustment is too tight and will need to be adjusted. See squeeze

adjustment procedure on page 17.

Advance the bender shoe to the desired degree of bend. When the pointer

on the shoe reaches the desired degree of bend, release the “Jog” button

and the bender will stop.

NOTE: Due to springback in pipe/conduit, some over bending is necessary

to achieve the desired degree of bend. See page 21 or the bending

instructions decal located on the top of each bender for approximate

springback compensation figures.

NOTE: DO NOT allow the rollers to come in contact with the bending

shoe. The shoe and rollers squeeze the conduit but they should never

touch each other.

7. To release the pipe/conduit, place the “Bend/Unload” switch in the “Unload”

position. Press the “Jog” button and reverse the shoe. The roller support

will then drop, allowing removal of the conduit.

ARNIN

The pipe/conduit should be under control when unloading.

Failure to do this ma

8. After removal of the conduit, inspect it for wrinkling or excessive side marks.

If these conditions occur, refer to the SQUEEZE ADJUSTMENT PROCEDURE.

See page 17.

result in injury or death

16

Page 17

SQUEEZE ADJUSTMENT PROCEDURE FOR

BO

MUST C

1 1/2" AND 2" EMT & IMC ROLLER SUPPORTS

The 1 1/2" and 2" rollers on the single shoe EMT Roller Support and the 1 1/2"

and 2" rollers on the single shoe IMC Roller Support on the 77 bender have a

Squeeze Adjustment feature if wrinkling or side marking becomes a problem

during the bending process. This feature allows you to increase or decrease

the amount of pressure applied to the conduit during bending, thereby eliminating these problems. Begin with the 7/8" starting location of the adjusting

bolts as shown in Figure 17a.

1. If wrinkling occurs, pressure against the conduit during the bending process

must increase. To increase the squeeze ( pressure ), loosen both set screws

and turn both adjusting bolts one-half turn clockwise. Bend one piece of

conduit to test the adjustment, and if wrinkling still occurs, repeat the

procedure. Once you have achieved a good bend, tighten both set screws.

NOTE: Both adjusting bolts MUST be in contact with the bender leg.

See Figure 17a.

STARTING LOCATION

OF ADJUSTING BOLT

7/8"

BENDER LEG

SET SCREW

ADJUSTING BOLT

Figure 17a

STOP

TH ADJUSTING BOLTS

ONTACT BENDER LEG

Figure 17b

2. If side marking occurs, pressure against the conduit during the bending

process must be decreased. To decrease the squeeze ( pressure ), loosen

both set screws and turn both adjusting bolts one-half turn counter-clock

wise. Bend one piece of conduit to test the adjustment, if side marking

still occurs, repeat the procedure. Once you have achieved a good bend,

tighten both set screws.

NOTE: Both adjusting bolts MUST be in contact with the bender leg. See

Figure 17a.

17

Page 18

MAINTENANCE

ALWAYS disconnect power supply before removing any guards or covers and

before servicing this bender. Failure to do so ma

y

result in serious injury or deat

h

ARNIN

G

1. The Gear Box is filled with oil at the factory and should not require periodic

flushing. If the Gear Box is opened for repair, flush by filling the unit with

an AGMA #7 oil. Next, run the unit with no load for 3 minutes. Then, drain

and refill the unit with 28 fluid ounces of an AGMA #7 oil such as the ones

listed below.

Amoco – Amoco Worm Gear Oil

Chevron – Cylinder Oil 460X

Exxon – CYLESSTIC TK460

Mobil – 600 W Cylinder Oil

Shell – Sun Gear Oil 7C

2. To inspect FRONT #60 chain tension:

• Remove front cover plate.

• To adjust, loosen hex bolt with 3/4 wrench and rotate chain tensioner

toward chain as shown until chain moves no more than a total of 1/4".

See Figure 18 below.

• Grease chain periodically with a good quality MP grease.

Figure 18

18

Page 19

WS

X SPROCKET

MAINTENANCE — continued

3. To inspect REAR #40 chain tension:

• Check chain tension after an initial break-in period of 2 - 3 hours of

use and tighten per the instructions below. See Figure 19.

Thereafter, inspect monthly.

• Remove the chain guard by taking out the 2 mounting screws.

• Loosen 8 bolts ( 4 on top and 4 on bottom ) that hold the gear box

in position.

• To tighten chain, move the gear box to the left and re-tighten bolts.

• For correct tension, chain should deflect approximately 1/8".

NOTE: Be sure to keep the gear box and motor in line with the bender.

• Grease chain periodically with a good quality MP grease.

4 BOLTS ON TOP

4 BOLTS ON BOTTOM

Figure 19

• Access to the gearbox sprocket

is possible by removing access

door as shown.

CHAIN GUARD

MOUNTING SCREWS

THIS COVER ALLO

ACCESS TO THE

GEARBO

IF ADJUSTMENT IS

NEEDED

19

Page 20

UB

H

G

UCT

H

GTH

UB

H

STUB-UP BENDING INFORMATION AND CHARTS — continued

PLA

IN LINE

EDGE OF SHOE HOOK

To locate bending marks and springback of 15, 30, 45, 60, and 90 degree

bends for a desired stub:

1. Check Chart A, B, C or C1 on Page 21 for deduct length. Note that minimum

stub length is deduct length plus 2".

2. Measure and mark desired stub length on conduit ( stub length mark ).

Subtract “Deduct Length" from this mark and make a second mark

( bending mark ). See Fig 20a and 20b. Place bending mark at front edge

of shoe hook. See Figure 20c. Check Chart A, B, C or C1 on Page 21 for

springback of desired degree of bend. Bender should be advanced to this

degree to obtain desired degree of bend.

Figure 20a

T

LENGT

Figure 20b

Figure 20c

BENDIN

LEN

TUB

DED

LENGT

T

LENGT

CE BENDING MARK

WITH FRONT

20

Page 21

STUB-UP BENDING INFORMATION AND CHARTS — continued

Chart A – RIGID Conduit/Schedule 40 Pipe

Conduit

Size

1/2" 7-1/2 17 33 49 64 96

3/4" 9 17 33 48 64 95

1" 11 17 32 48 63 94

1 1/4" 13-5/8 17 32 48 63 94

1 1/2" 14-7/8 17 32 48 63 94

2" 16-1/8 17 32 48 63 94

Deduct

Length

————— Springback —————

15° 30° 45° 60° 90°

Chart B – EMT Conduit

Conduit

Size

1/2" 7-1/2 16 32 48 63 95

3/4" 9 17 33 48 64 95

1" 11 17 32 48 63 94

1 1/4" 13-5/8 17 32 48 63 94

1 1/2" 14-7/8 19 35 50 66 97

2" 16-3/8 19 34 50 65 96

Deduct

Length

————— Springback —————

15° 30° 45° 60° 90°

Chart C – IMC Conduit

Conduit

Size

1/2" 7-1/2 20 36 51 67 98

3/4" 9 19 35 50 66 97

1" 11 19 35 50 66 97

1 1/4" 13-5/8 19 35 50 66 97

1 1/2" 14-7/8 17 33 49 64 96

2" 16-1/8 19 34 50 65 96

Deduct

Length

————— Springback —————

15° 30° 45° 60° 90°

Chart C1 – PVC Coated Rigid Conduit

Conduit

Size

1/2" 7-1/2 16 31 47 62 93

3/4" 9 15 31 46 62 93

1" 11 16 32 47 63 94

1 1/4" 13-5/8 15 30 46 61 92

1 1/2" 14-7/8 18 33 49 64 95

2" 16-1/8 19 34 50 65 96

NOTE: Springback figures are approximate.

Deduct

Length

————— Springback —————

15° 30° 45° 60° 90°

Minimum Stub Length = Deduct Length plus 2"

21

Page 22

END OF CONDUIT

TO START OF

BEND

ANGLE

OFFSET

HEIGHT

DEDUCT

LENGTH

MARK NO. 1

MARK NO. 3

CENTER TO CENTER

LENGTH

MARK NO. 2

OFFSET BENDING INFORMATION AND CHARTS

PLA

IN LINE

EDGE OF SHOE HOOK

To locate bending marks for a desired offset:

1. Measure distance from end of conduit to start of bend and mark conduit.

( Mark 1 ) See Figure 22a and 22b.

2. Refer to chart E for measurement “X" (see page 23) and deduct this

distance from Mark 1 and place Mark 2 on conduit. (See Figure 22b).

3. Refer to chart D (see page 23) for center-to-center distance between marks.

Measure this distance from Mark 2 and place Mark 3 on conduit.

4. Layout of bends is now complete. Next, place Mark 2 in line with front

edge of shoe hook and make first bend. (See Figure 22c).

5. Rotate conduit 180 degrees. Place Mark 3 in line with front edge of

shoe hook and complete second bend.

Figure 22a

Figure 22b

Figure 22c

CE BENDING MARK

WITH FRONT

22

Page 23

OFFSET BENDING INFORMATION AND CHARTS — continued

To locate center-to-center distance of offset bending marks other than those

listed in Chart D, use the following multipliers. Multiply the height of offset

desired by 3.86 on 15 degree bends, 2 on 30 degree bends, and 1.4 on 45

degree bends.

Chart E

Conduit Size

Figures are approximate.

1/2 3/4 1 1 1/4 1 1/2 2

“x” 3 1/16" 3 1/16" 3 3/16" 4" 4 1/4" 4 1/2"

23

Page 24

TROUBLESHOOTING

ALWAYS disconnect power supply before removing any guards or covers and

before servicing this bender. Failure to do so ma

y

result in serious injury or death

.

ARNIN

G

Problem Cause Diagnosis Cure

1. Bender will not operate Power source Check for voltage If power is on,

at power source go to ( #3 )

2. No power at bender Bad power cord Ohm cord for Replace cord

broken wire

3. Power to bender but Circuit breaker / Check power on Turn circuit

will not operate power switch in load side of breaker breaker on.

the off position to neutral with If on, go to

volt meter next step.

Fuse #1 blown Ohm circuit for short Replace

Control Transformer Check voltage in and out, Replace

bad if input but no output

Contactor bad Check contacts and ohm Replace

coil for open circuit

Bridge rectifier bad Check with Replace

ohm meter

Switch bad Check with ohm meter Replace

Motor bad Check brushes and ohm Replace

for open or short

armature

4. Motor runs but Chain from gear box Remove cover and Replace

will not bend to jack shaft broken visually check for

broken parts

Bad gear box Motor running but no Replace

output through gear box

Chain from jack shaft Remove cover and Replace

to shoe sprocket broken visually check for

broken parts

Key between motor and Remove motor from Replace key

gear box missing gear box

5. Bender operates in Bad FWD / REV switch Ohm switch for open Replace

one direction only contact or shorted

contacts

Bad pendant cord Ohm for broken wire Replace

Bad contactor Check contacts and Replace

ohm coil for open circuit

6. Contactors chatter Low power to bender Check with amp meter Do not use

long drop cords

24

Page 25

EXPLODED VIEWS

35

39

40

GEARBOX

MOUNT (REF)

41

37

42

WITH

SUPPLIED

GEARBOX

refer to PARTS LIST on page 27

190

3

130

120

40

110

100

90

16

12

7

17

180

170

160

150

140

73

80

70

60

50

40

30

20

10

10

0

11

10

34

27

SEE SEPARATE

BREAKDOWN

38

WITH GEARBOX

SCREWS INCLUDED

(4) 3/8-16 HEX

15

47

21

45

13

76

5

71

25

14

1

68

,75

29

24

8

23

20

73

6

9

47

2

46

32

,75

26

28

25

43

15

9

31

8

16

19

19

67

30

17

18

33

25

Page 26

BREAKER

SWITCH

CIRCUIT

62

44 (7)

ELECTRICAL

PLATE

22

53

55

56

66

57

61

63

MOUNTING HOLES-BENDER FRAME

54

AC

+

AC

27

54

60

58

76(7),80

59

72

74

4

PENDANT

REMOTE

53

28

48

77

78

49

50

51

64

65

52

36

53

80

81

79

EXPLODED VIEWS — continued

26

Page 27

PARTS LIST — 77-22 SERIES ELECTRIC BENDER

ITEM # PART # QTY DESCRIPTION

1 ........... 77-375..........1 ..................FRAME

2 ........... 77-346..........1 ................. HANDLE

3 ...........77-004D .........1 ..................COVER

4 ........... 77-004 ..........12 ......SCREW - #8-32 X 1/2" THD CUTTER

5 ........... 77-343 ..........1 ............. SPROCKET SHAFT

6 ...........77-006A .........2 .......KEY - SQUARE, 1/4" X 3/4" LONG

7 ........... 77-007 ..........1 ........ RETAINING RING - EXT, 2 1/2"

8 ........... 77-008 ..........2 ......WASHER - PHENOLIC (JACKSHAFT)

9 ........... 77-009..........2 ............. SLEEVE BEARING

10........... 77-010..........1 ............. #60 MASTER LINK

11........... 77-011..........1 ................ #60 CHAIN

12........... 77-394..........1 ........ SPROCKET - MAIN DRIVE #60

13...........77-013B .........1 .........SLEEVE - PHENOLIC (LONG)

14........... 77-014..........1 .........WASHER - PHENOLIC (MAIN)

15........... 77-015..........2 .................. WHEEL

16........... 77-016..........2 .........PIN - COTTER, 3/16" X 1 1/4"

17........... 77-017..........2 .............WASHER - 3/4" USS

18........... 77-429..........1 ...................AXLE

19...........77-033A .........9 .......SCREW - HEX, 10 X 1/2, #2 TEKS

20........... 77-413..........1 .............CHAIN TENSIONER

21...........77-013A .........1 ........ SLEEVE - PHENOLIC (SHORT)

22...........453-16A .........2 ............. NUT - HEX #8 - 32

23........... 8092-2..........1 ..........SCREW - HEX 1/2 - 13 X 1"

24...........2-1301-4 .........4 ......NUT - HEX, 5/16 - 18 (NYLON INS.)

25..........77-002D1 ........4 .........SCREW - HEX 5/16 - 18 X 3/4

26........... 77-026..........1 ............COVER - ELECTRICAL

27........... 77-339..........1 ............ PLATE - ELECTRICAL

28...........77-028A .........2 ......... STRAIN RELIEF - PENDANT

29........... 77-028..........1 ........STRAIN RELIEF - POWER CORD

30........... 77-288..........1 ............SPROCKET - #40 B48

31........... 77-031..........1 ................CHAIN - #40

32........... 77-032..........1 .............MASTER LINK - #40

33........... 77-468..........1 ............COVER - REAR CHAIN

34..........9518SR-12 ........4 ..........NUT - HEX, 1/4-20 (LOCK)

35........... 77-237..........1 ............SPROCKET - #40 B13

36...........77-3-1A .........1 ..............PLUG - PLASTIC

37........... 77-037..........1 ................ GEAR BOX

38............504-1 ..........2 ...................GRIP

39.........77-039-220V .......1 .............MOTOR – 220 VOLT

40........... 77-040..........8 ......BOLT - FLANGE LOCK, 3/8 - 16 X 3/4

27

Page 28

PARTS LIST — continued

ITEM # PART # QTY DESCRIPTION

41........... 77-041..........2 ...........FITTING - 90° LIQUITITE

42...........77-042A .........1 .............. FLEX CONDUIT

43..........77-043-22 ........1 ....... DECAL - SAFETY INFORMATION

44...........77-004B .........7 ..... SCREW - #8 - 32 X 5/8" THD CUTTER

45..........77-22SNP ........1 .......... SERIAL NUMBER PLATE

46........... 77-046..........1 ......DECAL - BENDING INSTRUCTIONS

47........... 77-047..........2 ...........PIN - ROLLER SUPPORT

48........... 77-048..........1 ..............CONDULET - 1/2"

49........... 77-451..........1 ................. GASKET

50........... 77-128..........1 .........GUARD - PENDANT SWITCH

51........... 77-051..........1 ....... SWITCH - FORWARD / REVERSE

52........... 77-052..........1 ...............SWITCH - JOG

53........... 77-053..........3 ... SCREW - #8 - 32 X 3/8" PAN HEAD MACH.

54........... 77-054..........2 ...............CONTACTORS

55.........77-055-220V .......1 ......... TRANSFORMER - 24 VOLT

56.........77-056-220V .......1 ...................FUSE

57........... 77-057..........1 ............. TERMINAL BLOCK

58.........77-058-220V .......1 .................RESISTOR

59.........77-059-220V .......1 ...........VARISTOR WITH WIRES

60........... 77-060..........1 .............BRIDGE RECTIFIER

61........... 77-061..........2 ....SCREW - RD. HEAD MACH., #6 -32 X 3/8"

62.........77-062-220V .......1 .............CIRCUIT BREAKER

63........... 77-063..........1 ......... COVER - CIRCUIT BREAKER

64........... 77-064..........1 .............DECAL - PENDANT

65........... 77-065..........1 ..........FISH PAPER - INSULATING

66........... 77-066..........1 ...............FUSE HOLDER

67........... 77-067..........1 ..............RETAINING RING

68........... 450-20..........4 ..................SPACER

69.........77-068-220V .......1 .........CORD - POWER (not shown)

70...........77-048A .........1 ........CORD - PENDANT (not shown)

71........... 77-714..........1 .............. ACCESS COVER

72...........77-058A .........2 ...... BRACKET - RESISTOR (not shown)

73...........452-6A .........9 .........SCREW #8 X ½” SELF DRILL

74........... 77-387..........1 .........BRACKET – TRANSFORMER

75...........77-041A .........2 ..............NUT – 1/2" LOCK

76...........77-004A .........11 .....SCREW – #8 – 32 X 3/8" THD CUTTER

77........... 747-19..........1 .................MAGNET

78........... 451-22..........1 .....SCREW 10-32 X 3/8" RD HD SLOTTED

79........... 451-21..........1 ...... NUT HEX 10 - 32 (NYLON INSERT)

80........... 747-39..........1 .......WASHER, LOCK – #8 EXT. TOOTH

81........... 747-40..........2 ..... WASHER, LOCK – 15/32" INT. TOOTH

28

Page 29

ELECTRICAL SYSTEM DIAGRAM

29

Page 30

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-3000 & 2-4000 Bending Shoe & Roller Support —

1/2" to 2" RIGID Conduit AND Schedule 40 pipe

1/2" to 1 1/4" IMC conduit

10

ITEM # PART # QTY DESCRIPTION

1 ..................2-1304 .................4 .................................................... DRIVE STUD

2 ................ 2-2301-2 ................3 .......................... SCREW, SHOULDER SOCKET – 3/4" × 1 1/2"

3 ..................2-2302 .................1 ........................................ HOOK, 1 1/2"–2" RIGID/IMC

4 .............. 2-3000-101 ..............1 ......................................... SHOE – 1/2"–2" RIGID/IMC

5 .............. 2-3000-102 .............2 ................................... POINTER — DEGREE INDICATOR

6 ..................2-3002 .................1 .......................................HOOK, 1/2"–1 1/4" RIGID/IMC

7 ....................99-8 ...................2 ............................... SCREW, SKT. HD. CAP — 1/4-20 × 1/2"

8 ...................99-59 ..................4 ............................. SCREW, SKT. HD. CAP — 3/8-16 × 1 1/4"

9 ................ 450-14G ................2 .............................................. WASHER, LOCK 1/4"

10 .................2-4000 .................1 ........... ROLLER SUPPORT – 1/2" TO 2" RIGID AND 1/2" TO 1 1/4" IMC

11 ............2-4000-107A ............1 ........................ROLLER SUPPORT ASSEMBLY – 1/2" TO 1 1/4"

12 ............. 2-4000-122 ..............1 ...................................................... HINGE PIN

13 ............. 2-4000-123 ..............1 .......................................... RETAINING RING – 7/16"

14 ............. 2-4000-125 ..............1 ......................... ROLLER SUPPORT ASSEMBLY – 1 1/2" TO 2"

15 ............. 2-4000-001 ..............4 ............................... COLLAR, 3/4" I.D. — 1 1/2"–2" ROLLER

16 ............2-4000-106A ............1 ........................... WELDMENT – 1 1/2"–2" ROLLER SUPPORT

17 ............. 2-4000-128 ..............1 ................................. PIN – 3/4" DIA. FOR 1 1/2" ROLLER

18 ............. 2-4000-126 ..............1 ........................................... ROLLER — 1 1/2" RIGID

19 ............. 2-4000-127 ..............1 .............................................. ROLLER — 2" RIGID

20 ............. 2-4000-115 ..............2 .................................... PIN — 3/4" DIA. FOR 2" ROLLER

30

Page 31

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-3200 & 2-4300

Bending Shoe & Roller Support —

1/2" to 2" PVC Coated RIGID Conduit

10

ITEM # PART # QTY DESCRIPTION

1.......................2-1304 ..................... 4 ................................................ DRIVE STUD

2..................... 2-2301-2 .................... 3 ...................... SCREW, SHOULDER SOCKET — 3/4 × 1 1/2"

3.......................2-3203 ..................... 1 ............................ HOOK, 1 1/2"–2" PVC COATED RIGID

4................... 2-3200-101 .................. 1 ............................ SHOE — 1/2"–2" PVC COATED RIGID

5................... 2-3000-102 .................. 2 ............................... POINTER — DEGREE INDICATOR

6.......................2-3202 ..................... 1 ........................... HOOK, 1/2"–1 1/4" PVC COATED RIGID

7.........................99-8 ....................... 2 ...........................SCREW, SKT. HD. SKT. — 1/4-20 × 1/2"

8........................99-59 ...................... 4 ......................... SCREW, SKT. HD. CAP — 3/8-16 × 1 1/4"

9..................... 450-14G .................... 2 .......................................... WASHER, LOCK 1/4"

10......................2-4300 ..................... 1 ...............ROLLER SUPPORT — 1/2" TO 2" PVC COATED RIGID

11.................2-4000-107B................. 1 ....................ROLLER SUPPORT ASSEMBLY – 1/2" TO 1 1/4"

12.................. 2-4000-122 .................. 1 .................................................. HINGE PIN

13.................. 2-4000-123 .................. 1 ..................................... RETAINING RING — 7/16"

14.................. 2-4300-103 .................. 1 ..................... ROLLER SUPPORT ASSEMBLY – 1 1/2" TO 2"

15.................. 2-4000-001 .................. 4 ........................... COLLAR, 3/4" I.D. — 1 1/2"–2" ROLLER

16.................2-4000-106B................. 1 ...................... WELDMENT — 1 1/2"–2" ROLLER SUPPORT

17.................. 2-4000-128 .................. 1 .............................. PIN – 3/4" DIA. FOR 1 1/2" ROLLER

18.................... 2-1005A ....................1 ........................... ROLLER — 1 1/2" PVC COATED RIGID

19.................... 2-1005B ....................1 .............................. ROLLER — 2" PVC COATED RIGID

20.................. 2-4000-115 .................. 2 ................................ PIN — 3/4" DIA. FOR 2" ROLLER

31

Page 32

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-3100

6 1

Bending Shoe

1/2" to 2" EMT Conduit

8

5

4

9

7

2

2

2

3

1

9

4

1

1

7

ITEM # PART # QTY DESCRIPTION

1 ................ 2-1304 ........................ 4 ................................... DRIVE STUD

2 ...............2-2301-2 ...................... 3 ....... SCREW, SHOULDER SOCKET — 3/4" × 1 1/2"

3 ................ 2-2303 ........................ 1 ............................ HOOK, 1 1/2"–2 EMT

4 .............2-3000-102 .................... 2 ................. POINTER — DEGREE INDICATOR

5 .............2-3100-101 .................... 1 ........................... SHOE — 1/2"–2" EMT

6 ................ 2-3102 ........................ 1 .......................... HOOK, 1/2"–1 1/4" EMT

7 .................. 99-8 .......................... 2 ............. SCREW, SKT. HD. CAP — 1/4-20 × 1/2"

8 ................. 99-59 ......................... 4 ............SCREW, SKT. HD. CAP — 3/8-16 × 1 1/4"

9 ............... 450-14G ...................... 2 ............................ WASHER, LOCK 1/4"

32

Page 33

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-4200

Roller Support

1/2" to 2" EMT Conduit

1

20

7

19

11

4

6

21

13

14

17

2

15

17

12

ITEM # PART # QTY. DESCRIPTION

1 ..................2-1103 ................... 2 ................................ ROLLER - 1.5" EMT

2 ..................2-1108 ................... 1 .................................... SPACER TUBE

3 ..................2-1109 ................... 4 ............................... 3/4" RETAINER RING

4 ..................2-1111 ................... 1 .......................187" DIA. X 1.25 LG ROLL PIN

5 ..................2-1112 ................... 2 ............... 1/2-13 X .75 LG SET SCREW - CONE PT

6 ..................2-1116 ................... 2 .................................. ROLLER - 2" EMT

7 ..................2-1118 ................... 8 ............................ 7/16-14 X 1.00 LG FHCS

8 ............. 2-4000-107D .............. 1 ...................1/2" - 1.25" EMT ROLLER SUPPORT

9 .............. 2-4000-122 ............... 1 ................................ HINGE PIN, UPPER

10 ............. 2-4000-123 ............... 1 .............................. 7/16" RETAINER RING

11 ............ 2-4100-107D .............. 1 ..................... EMT ROLLER SUPPORT FRAME

12 ............. 2-4100-118 ............... 1 ........................... AXLE, ROLLER BRACKET

13 ............. 2-4100-119 ............... 2 ............................. BRACKET - 2" ROLLER

14 ............. 2-4100-121 ............... 1 ......................... SPRING CLIP, 2.00" ROLLER

15 ............. 2-4100-122 ............... 1 ......................... SPRING CLIP, 1.50" ROLLER

16 ............. 2-4100-123 ............... 2 ................... 3/4" DIA. PIN, 1.50" - 2.00" ROLLER

17 ............. 2-4100-124 ............... 2 ..........................................SPRING

18 ............... 2-4200-1 ................. 1 ............................. DECAL (NOT SHOWN)

19 ............. 2-4200-101 ............... 2 ....................... BRACKET, 1.50" EMT ROLLER

20 ................747-858 .................. 2 ................................. ROLLER PIN 1.50"

21 ................747-859 .................. 2 ................................. ROLLER PIN 2.00"

22 ................747-894 .................. 2 .............................. ROLLER - URETHANE

23 .................8092-2 ................... 2 ......... SCREW-HEX HEAD CAP GR5 ZINC (1/2-13 X 1)

33

Page 34

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-3000

Bending Shoe

1/2" to 2" IMC Conduit

2

6

4

5

9

7

2

2

3

1

1

8

8

1

7

9

5

1

ITEM # PART # QTY DESCRIPTION

1 ................ 2-1304 ........................ 4 ................................... DRIVE STUD

2 ...............2-2301-2 ...................... 3 ....... SCREW, SHOULDER SOCKET — 3/4" × 1 1/2"

3 ................ 2-2302 ........................ 1 ....................... HOOK, 1 1/2"–2 RIGID/IMC

4 .............2-3000-101 .................... 1 .......................SHOE — 1/2"–2" RIGID/IMC

5 .............2-3000-102 .................... 2 ................. POINTER — DEGREE INDICATOR

6 ................ 2-3002 ........................ 1 ..................... HOOK, 1/2"–1 1/4" RIGID/IMC

7 .................. 99-8 .......................... 2 ............. SCREW, SKT. HD. CAP — 1/4-20 × 1/2"

8 ................. 99-59 ......................... 4 ........... SCREW, SKT. HD. CAP — 3/8–16 × 1 1/4"

9 ............... 450-14G ...................... 2 ............................ WASHER, LOCK 1/4"

34

Page 35

PARTS LIST — SINGLE SHOES & ROLLER SUPPORTS

2-4100

Roller Support —

1/2" to 2" IMC Conduit

6

20

5

17

15

12

3

19

13

7

21

14

16

19

1

ITEM # PART # QTY. DESCRIPTION

1 .................2-1108 ........................... 1 ........................................ SPACER TUBE

2 .................2-1109 ........................... 4 ...................................3/4" RETAINER RING

3 .................2-1111 ........................... 1 .......................... .187" DIA. X 1.25 LG ROLL PIN

4 .................2-1112 ........................... 2 ...................1/2-13 X .75 LG SET SCREW - CONE PT

5 .................2-1118 ........................... 8 ................................ 7/16-14 X 1.00 LG FHCS

6 .................2-1204 ........................... 2 .....................................1.50" IMC ROLLER

7 .................2-1205 ........................... 2 .....................................2.00" IMC ROLLER

8 ............2-4000-107C ...................... 1 ....................... .50" - 1.25" IMC ROLLER SUPPORT

9 ............. 2-4000-122 ........................ 1 .................................... HINGE PIN, UPPER

10 ............ 2-4000-123 ........................ 1 .................................. 7/16" RETAINER RING

11 .............. 2-4100-1 .......................... 1 ................................. DECAL (NOT SHOWN)

12 ...........2-4100-107C ...................... 1 ..........................IMC ROLLER SUPPORT FRAME

13 ............ 2-4100-118 ........................ 1 ............................... AXLE, ROLLER BRACKET

14 ............ 2-4100-119 ........................ 2 ............................... BRACKET, 2.00" ROLLER

15 ............ 2-4100-120 ........................ 2 ............................BRACKET, 1.50" IMC ROLLER

16 ............ 2-4100-121 ........................ 1 ............................. SPRING CLIP, 2.00" ROLLER

17 ............ 2-4100-122 ........................ 1 ............................. SPRING CLIP, 1.50" ROLLER

18 ............ 2-4100-123 ........................ 2 ............................... .75" PIN, FOR 2" ROLLER

19 ............ 2-4100-124 ........................ 2 ..............................................SPRING

20 ...............747-858 .......................... 2 ..................................... ROLLER PIN 1.50"

21 ...............747-859 .......................... 2 ..................................... ROLLER PIN 2.00"

22 ...............747-894 .......................... 2 ..................................ROLLER - URETHANE

23 ................8092-2 ........................... 2 .............SCREW-HEX HEAD CAP GR5 ZINC (1/2-13 X 1)

24 ............ 2-4100-126 ........................ 1 ............................ .75" PIN FOR 1 1/2" ROLLER

25 ............ 2-4000-001 ........................ 1 ...................................... .75" I.D. COLLAR

35

Loading...

Loading...