Current Tools 8845, 88 Series, Mantis 8885 Series, 8085, Mantis 8890 Series Operating, Maintenance, Safety And Parts Manual

...Page 1

Model 88 Series Cable Puller

8,000 lb. Maximum Pulling Force

and

Model 8845 Cable Pulling Package

Operating, Maintenance, Safety

and Parts Manual

10/14 REV. 5

ead and understand this material before operating or

R

servicing the Cable Puller or any of component Cable Pulling

Package. Failure to understand how to safely operate and

service these units may result in serious injury or death.

his manual is free of charge. All personnel who operate the Cable Puller or any component of the

T

Cable Pulling Package should have a copy of this manual and read and understand its contents. To

request a copy of this manual or replacement safety decals, or for technical assistance, call or

write to the address below. All information, specifications and product designs may change due to

design improvements or updates and are subject to change without notice. Current Tools does not

assume any liability for damages resulting from misuse or incorrect application of its products.

CURRENT TOOLS • P. O. BOX 17026 GREENVILLE, SC 29606

800.230.5421 or 864.721.4230 • FAX 864.721.4232

www.currenttools.com

Page 2

TABLE OF CONTENTS

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 8

Components Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cable Pulling Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

Model 88 Cable Puller and Accessories

Power Requirements

Force Gauge

Mounting Chain Installation

Floor Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14, 15

Safety Information

Installation Instructions

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-19

Rope Set-Up

Pulling Operation

Common Set-Ups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tandem Pulling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lubrication

Inspection

Exploded View – Model 88 Cable Puller . . . . . . . . . . . . . . . . . . 22

Parts List – Model 88 Cable Puller . . . . . . . . . . . . . . . . . . . . . . . 23

Exploded View – Model 88 Cable Puller Motor . . . . . . . . . . . . 24

Parts List – Part #88-44 Cable Puller Motor . . . . . . . . . . . . . . . 25

Wiring Schematic – Model 88 Cable Puller . . . . . . . . . . . . . . . 26

Wiring Drawing – Model 88 Cable Puller . . . . . . . . . . . . . . . . . 26

2

Page 3

jury

.

W

G

jury

.

ON

jury

.

G

R

SAFETY ALERTS

3

THIS SAFETY SYMBOL is used to call your attention to instructions

that concern your personal safety. It means: ATTENTION! BE AWARE!

THIS IS AN IMPORTANT SAFETY INSTRUCTION!

Read, understand, and follow these safety instructions. Failure to follow

these safety instructions may result in injury or death.

Safety Alert

Symbol

DAN

Immediate hazards which, if not avoided, WILL result in serious personal

in

or death

E

ARNIN

Hazards or unsafe practices which, if not avoided, COULD result in serious

personal in

or death

UTI

Hazards or unsafe practices which, if not avoided, COULD result in minor

personal in

or property damage

Page 4

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

DANGER

DANGER

RETAIN SAFETY INFORMATION

4

Do NOT operate cable puller in wet or damp locations.

Do NOT expose to rain.

Do NOT operate in an explosive atmosphere.

Do NOT use cable puller as a hoist or for lifting, supporting

or transporting people or loads. Use only for its intended

purpose as a cable puller.

Do NOT wrap rope around any body parts. Do NOT wrap

rope around wrists.

ALWAYS keep rope away from operator’s feet.

Do NOT exceed load rating of cable puller, rope, or accessories.

ALWAYS inspect rope before each use.

ALWAYS disconnect cable puller before servicing.

ALWAYS plug the Model 88 Cable Puller into a grounded

receptacle with a 15 amp GFCI protected circuit. Do NOT

modify the plug provided with the Model 88 Cable Puller.

ALWAYS inspect the structural integrity of any supports,

conduit, anchoring system etc. that will hold the cable puller

during the pull. These supports should be able to withstand

the maximum pulling force of the cable puller plus a safety

factor of 3:1.

Example: 8,00 0 lb. puller should be anchored

to a support that can withstand 24,000 lbs. of pull

.

IMPORTANT SAFETY INFORMATION

G

pp

.

p

.

OK

E

This manual should be read and understood by all personnel who operate or service

this Cable Puller or any component of the Cable Pulling Package. Failure to understand

how to operate and service this equipment could result in serious injury or death. This

equipment should only be operated and serviced by qualified personnel.

ARNIN

ALWAYS insure cable puller is properly secured before operating.

ALWAYS attach to su

See mounting chain installation section of this manual for proper mounting

of cable

uller and tie-down chain installation

orts that are at least 2" and not more than the 10" wide

TOO WID

Page 5

5

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Pulling Rope should be the only thing to contact the capstan.

NEVER let swivels, grips, etc. come in contact with the capstan.

Keep as much rope confined in conduit as possible. This will

help prevent injury should the rope break and whip violently.

Rope must ALWAYS be pulled over a r

otating sheave. If

a sheave does not rotate, turn cable puller off immediately

and determine problem before continuing the pull.

This cable puller is equipped with an anti-reversing pawl.

The pawl will make a clicking sound when the capstan is

rotating. If you can not hear the clicking sound as the capstan

rotates, immediately turn the cable puller off and do not

use until repaired.

ONL

Y use 3/4” or larger double-braided composite pulling

rope with an average breaking strength of 26,000 lbs.

NEVER allow the rope to slip on a rotating capstan for more

than a couple of seconds. The rope will wear in that spot and

the rope could break under pressure. If you need to stop the

pull, turn the cable puller off and tie the rope off to hold it

in place until you restart your pull.

Keep all body parts, hair, loose clothing, etc. away from rotating

parts and pinch points. Keep hands away from capstan.

NEVER allow the rope to overlap on the capstan. If this condition

begins to occur, immediately release the tailing force on the rope

so that the rope can feed back toward the conduit or cable tray.

If this does not remedy the overlap, turn off the cable puller

immediately.

There is

no known solution for

rope overlap.

Rope should approach

capstan as shown in

Figure 1.

Figure 1

IMPORTANT SAFETY INFORMATION continued . . .

MAXIMUM

10

˚

PULL

DIRECTION

MAXIMUM

10

˚

Page 6

Some components of the cable pulling package exceed 50 lbs.

and will require more than one person to lift, transport, and

assemble.

ALWAYS inspect pins to be sure they are fully inserted through

holes and have spring clips properly attached.Do NOT substitute

any other object for factory supplied pins.

Do NOT mount the Model 88 Cable Puller to square columns

or I-beams. The mounting chains will not tighten properly on

these structures.

The ONLY approved method to secure the Model 88 Cable Puller

is with the 2 mounting chains provided. Do NOT attempt to use

any other object to secure the cable puller.

Inspect mounting chains for wear before each installation.

NEVER alter the mounting chains or handle.

When making a vertical cable pull, keep the area underneath

the cable pull clear of all personnel.

Do NOT alter this cable puller. Doing so will void the warranty.

Guards and safety features are provided for you r pr otection.

Do NOT use an extension cord longer than 100 ft. Extension

cord should be a minimum of 12 gauge wire with ground.

6

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

IMPORTANT SAFETY INFORMATION continued . . .

A

B

O

OK

g

y

g

g

G

Figure 2BFigure 2A

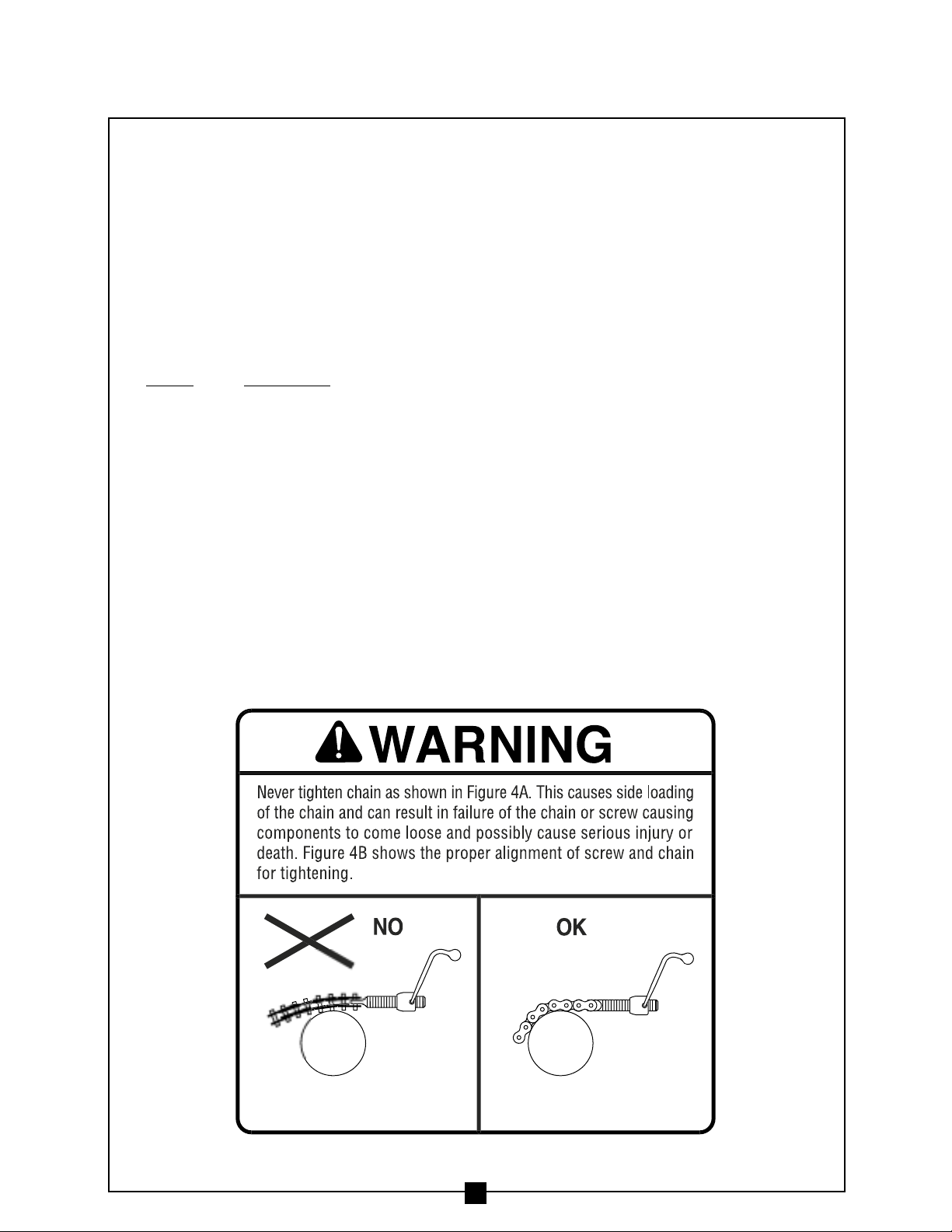

ARNIN

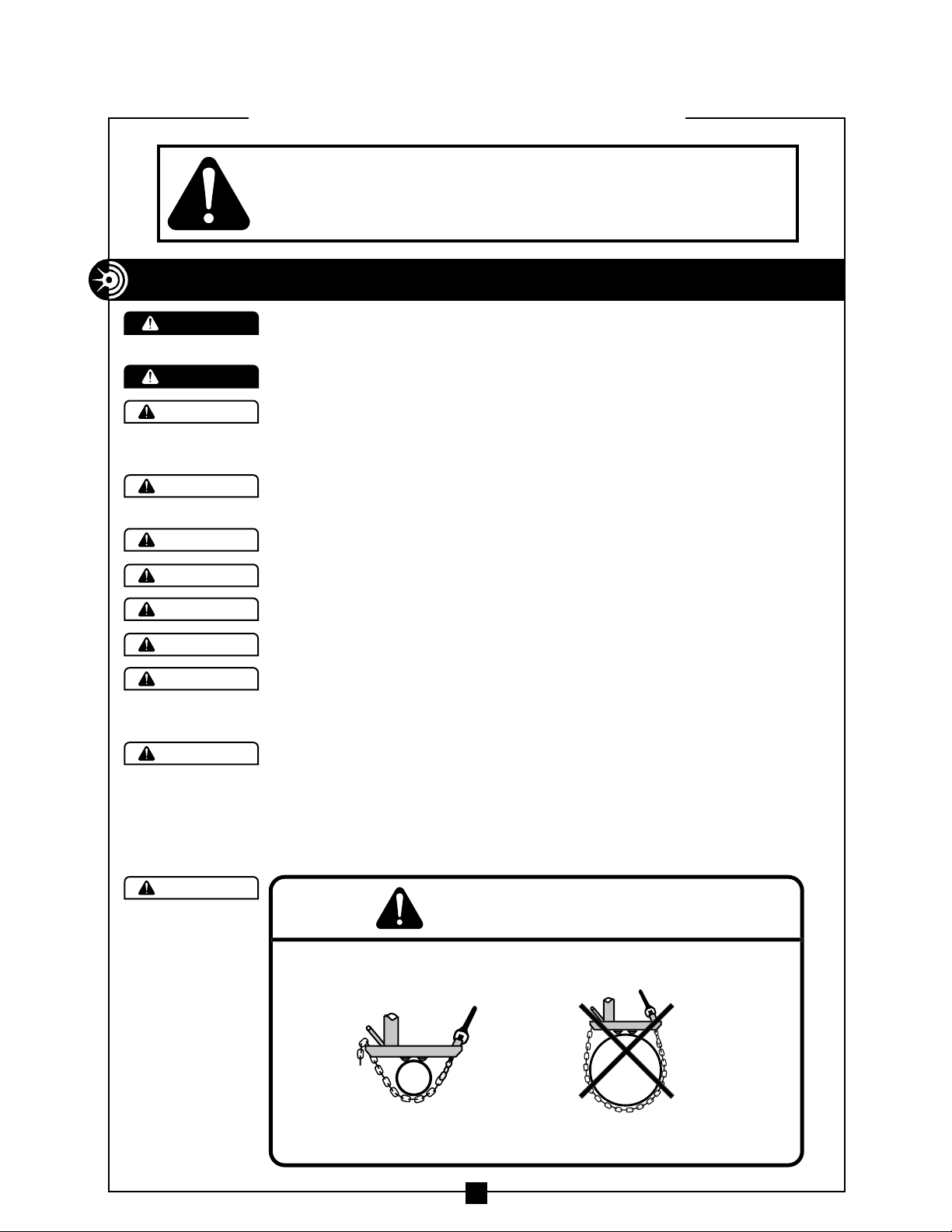

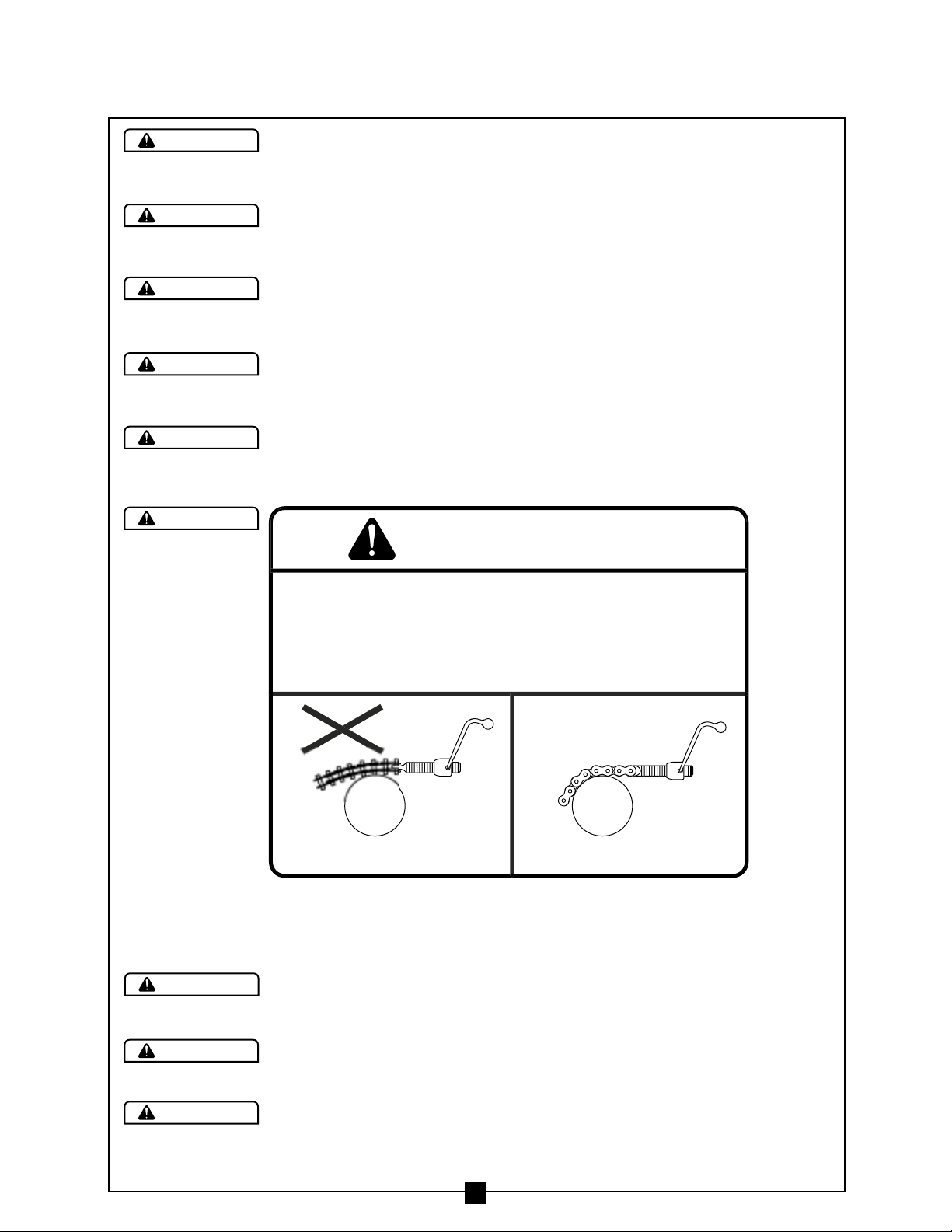

Never tighten chain as shown in Figure 2A. This causes side loadin

of the chain and can result in failure of the chain or screw causing

components to come loose and possibl

death. Fi

for ti

ure 2B shows the proper alignment of screw and chain

htening.

cause serious injury or

N

FIGURE 2

FIGURE 2

Page 7

CAUTION

CAUTION

CAUTION

Wear eye protection when operating cable puller.

Inspect all components of the pulling system before begin-

ning any cable pull. This includes the cable puller and any

accessories ( sheaves, swivels. etc. ) Replace any worn or

defective components.

Be careful during assembly and disassembly of the pulling

system components. Have control of components before

removing any pins.

7

IMPORTANT SAFETY INFORMATION continued . . .

SPECIFICATIONS — Model 88 Cable Puller

Model No. 88 Cable Puller

width – 20 1/2”

length – 24 3/4”

height – 16”

weight – 101 lbs. (includes two mounting chains)

maximum pulling force – 8,000 lbs.

speeds (approx.) no load – 16 ft/min.

4,000 lbs. – 9 ft/min.

6,000 lbs. – 7 ft/min.

motor – 120 volts AC, 60 hertz, 15 amps

FEATURES

• Heavy duty all welded unitized steel frame

• Permanently mounted force gauge allows operator to monitor the pulling force

• Circuit breaker on/off switch — helps protect motor

• Safety pawl on capstan sprocket to prevent reverse rotation

• Tapered capstan to help avoid rope overlap

• Simple design provides for easy maintenance — only one guard covers all

sprockets and chains

• Tailing rope safety roller for operator safety — lets operator stand out of the

direct line of tight pulling rope

• Three handles for carrying or positioning puller

• Simple electrical system for easy maintenance

Page 8

CAPSTAN

C

N

D

E

CE

E

T

CH

OR

R

CORD

E

G

S

Y

R

FEATURES continued . . .

8

Figure 3

HAI

GUAR

AFET

ROLLE

HANDL

FOR

GAUG

OFF/ON CIRCUI

BREAKER SWIT

MOT

MOUNTIN

HAIN

POWE

T-HANDL

Page 9

CAT. NO. KEY DESCRIPTION

PULLER

PULLER WITH FLOOR MOUNT WT.

ONLY

88 8845

88 A Cable puller with chains 1 1 101

8045

B floor mount 116

COMPONENTS LISTING

9

Cable Puller Package

A

B

Page 10

CABLE PULLING BASICS

Model 88 Cable Puller and Accessories

The Model 88 Cable Puller has a maximum pulling force of 8,000 lbs.

Therefore, all of the accessories used to make a cable pull with this unit

must

be rated to meet or exceed the forces generated. This includes, but

is not limited to pulling rope, sheaves, swivels, grips, etc. Be aware that

the pulling force on a sheave and its anchoring system can be as great as

twice the pulling force generated by the cable puller.

Power Requirements

The Model 88 Cable Puller motor is rated at 120 volt – 60 hz – 15 amps.

10

p

.

,

.

G

.

ON

G

y

)

.

ON

ARNIN

Do NOT exceed load rating of cable puller, rope, or accessories.

UTI

Inspect all components of the pulling system before beginning any cable pulling.

This includes the cable puller and an

Replace any worn or defective components

accessories sheaves, swivels. etc.

ARNIN

ALWAYS plug the Model 88 Cable Puller into a grounded receptacle with

a 15 am

DO NOT modify the plug provided with the Model 88 Cable Puller. If needed

have a 15 amp GFCI receptacle installed by a qualified electrician

GFCI protected circuit

UTI

If an extension cord is used, it should be a minimum of 12 gauge wire with

round and a maximum length of 100 ft

Page 11

11

CABLE PULLING BASICS continued . . .

Force Gauge

The Model 88 Cable Puller is equipped with an integral force gauge.

To calibrate the force gauge, run the puller for 1 minute with no load.

While the puller is running (with no load), use adjustment screw on face

of force gauge to set needle to zero pounds of force.

The operator should always monitor the force gauge throughout the entire

cable pull. The force gauge has 3 color sections to help you identify operating

conditions. These sections are:

Color

Condition

Green Puller can be run continuously

Yellow 50% duty cycle; 15 minutes on / 15 minutes off

Red Overload Condition – Do NOT operate puller

Correct overload condition or set up a tandem pull

(See page 21. )

Mounting Chain Installation

The Model 88 Cable Puller is designed to be mounted using the two mounting

chains provided. The handles on the chains should provide sufficient leverage

to tighten the chains securely. No other tools are needed. Be sure to check the

mounting chains for kinks and twists before you tighten them. See Warning

below for proper mounting chain installation.

Figure 4BFigure 4A

Page 12

pp

.

E

G

12

Figure 5

A– Loosen the mounting chain

handle so that only 3 or 4 threads

remain engaged.

B– Wrap the chain around the

floor mount, conduit or structural

support sufficient to handle

the pulling forces.

C– Pull the loose end of the mounting

chain tight and hook the closest

chain link into the recessed area.

D– Tighten the chain handle.

Repeat this process for second

mounting chain.

G

CABLE PULLING BASICS continued . . .

ARNIN

Be sure threads do not bottom out before chain becomes tight.

DAN

ALWAYS insure cable puller is properly secured before operating.

ALWAYS attach to su

orts that are at least 2" and not more than the 10" wide

ER

TOO WID

Page 13

13

CABLE PULLING BASICS continued . . .

y

g

y

f

.

G

y

.

G

g

y

.

.

.

G

ARNIN

The only approved method to secure the Model 88 cable puller is with

the 2 mountin

attempt to use an

Inspect mounting chains for wear before each installation

. NEVER alter the mounting chains or handle

chains provided with the Model 88 cable Puller. Do NOT

other object to secure the puller

ARNIN

ALWAYS inspect the structural integrity of any supports, conduit, anchoring

s

stem etc. that will hold the cable puller during the pull. These supports

should be able to withstand the maximum pullin

plus a safet

a support that can withstand 24,000 lbs. o

factor of 3:1. Example: 8,000 lb. puller should be anchored to

force of the cable puller

pull

ARNIN

Do NOT mount the Model 88 Cable Puller to square columns or I-Beams.

The mounting chains will not tighten properl

on these structures

Page 14

FLOOR MOUNT

The Model 8045 Floor Mount is made to fit the Current Tools Model 88

Cable Puller. The floor mount is to be mounted only to a concrete floor

using the method described below.

Safety Information

1. ALWAYS mount to a smooth, flat

concrete floor with a minimum

3000 psi rating.

2. Mount only to a concrete floor.

NEVER

mount to cinder blocks, brick, etc.

3. Wedge anchors must be at least 12” away from edge of concrete.

4. ALWAYS use new anchors. NEVER REUSE ANCHORS.

5. Use only 5/8” x 6” wedge anchors or equivalent with a tension

and shear rating of 2,500 lbs. (Current Tools part #8045-3)

6. ALWAYS wear eye protection when installing anchors.

14

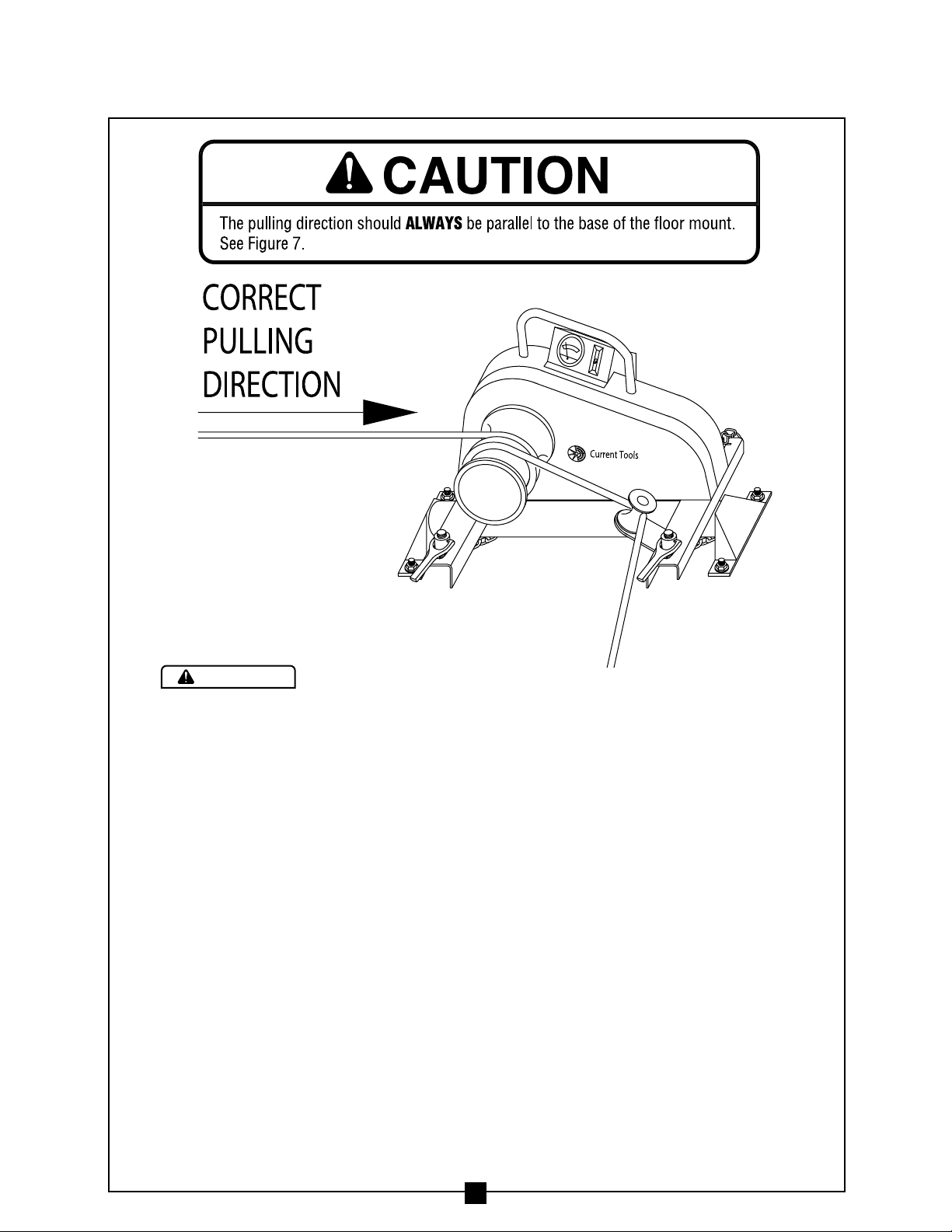

CAUTION

S

y

.

G

Figure 6A

Figure 6B

ALWAY

possibilit

place the floor mount close to the conduit. This will reduce the

of injury should the rope break. See Figure 6B

place close to conduit

ARNIN

Page 15

CAUTION

15

FLOOR MOUNT continued . . .

Installation Instructions

1. Wear safety glasses.

2. Follow the safety instructions provided by the drill manufacturer.

3. Use only 5/8” diameter solid carbide tipped bits that meet ANSI B94-12.

4. Using the floor mount as a template, drill four 5/8” holes a minimum

of 6” deep but not closer than 1 1/4” to the bottom (opposite surface) of

the concrete. Be sure to drill the holes perpendicular to the work surface

and do not ream the holes or let the drill bit wobble.

5. Clean the holes with compressed air and a wire brush. Clean holes are

necessary for proper performance.

6. Assemble the washer and nut on the anchor so the top of the nut is flush

with the top of the anchor.

7. Next, drive the 4 wedge anchors through the 4 floor mount holes and into

the concrete holes making sure the nut and washer rests solidly against

the floor mount.

8. Tighten the anchors with a torque wrench to 75–90 ft. lbs.

Note: If anchor spins, pull up on the anchor using the claw end of hammer

and then torque. If spinning still occurs, Do NOT use this location; reposition

the floor mount and repeat this installation procedure.

9. Place the Model 88 Cable Puller so that the “V” positioning units on the

bottom of the puller legs straddle the floor mount. Mount puller to the

floor mount using the mounting chain installation procedure found on

pages 11, 12, & 13 of this manual.

Figure 7

Page 16

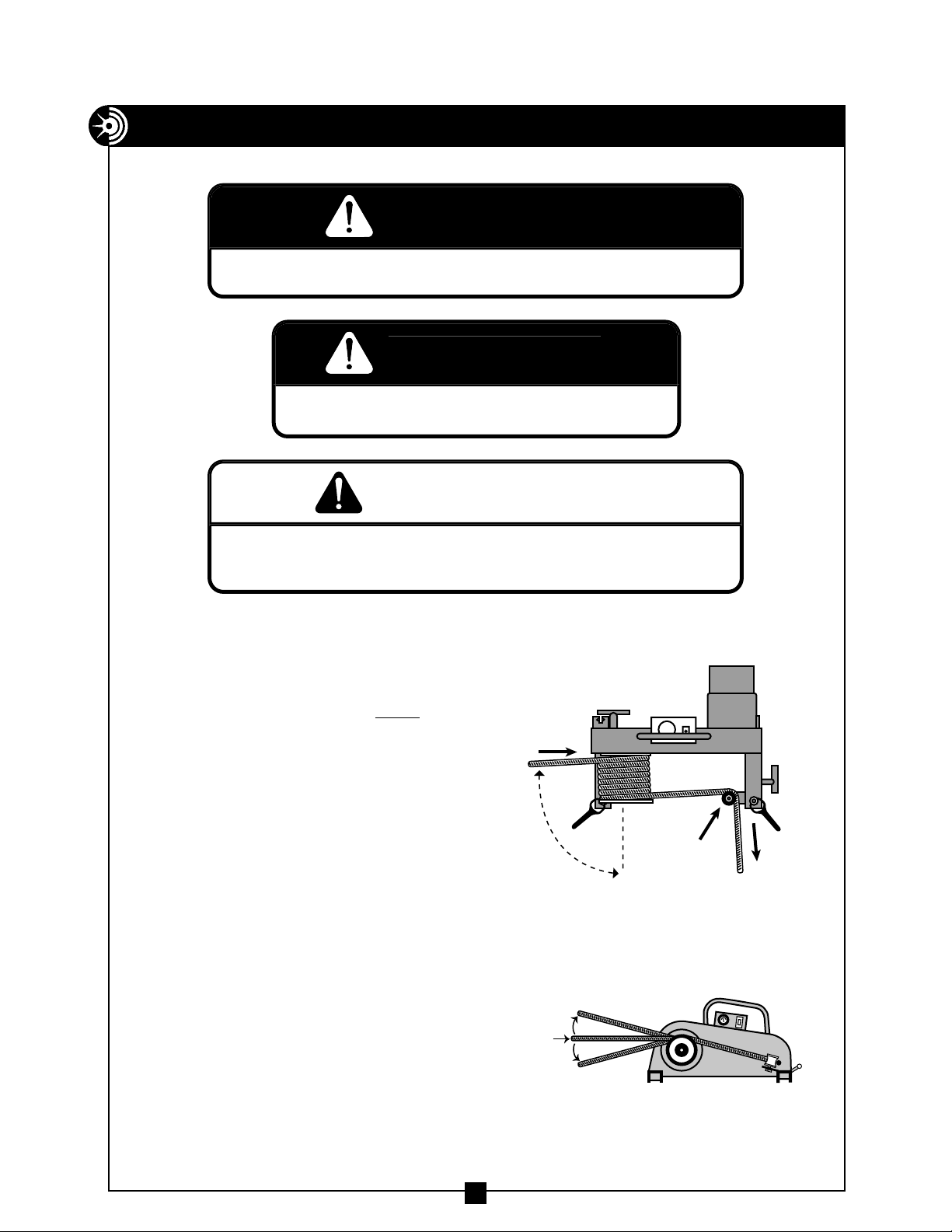

Rope Set-Up

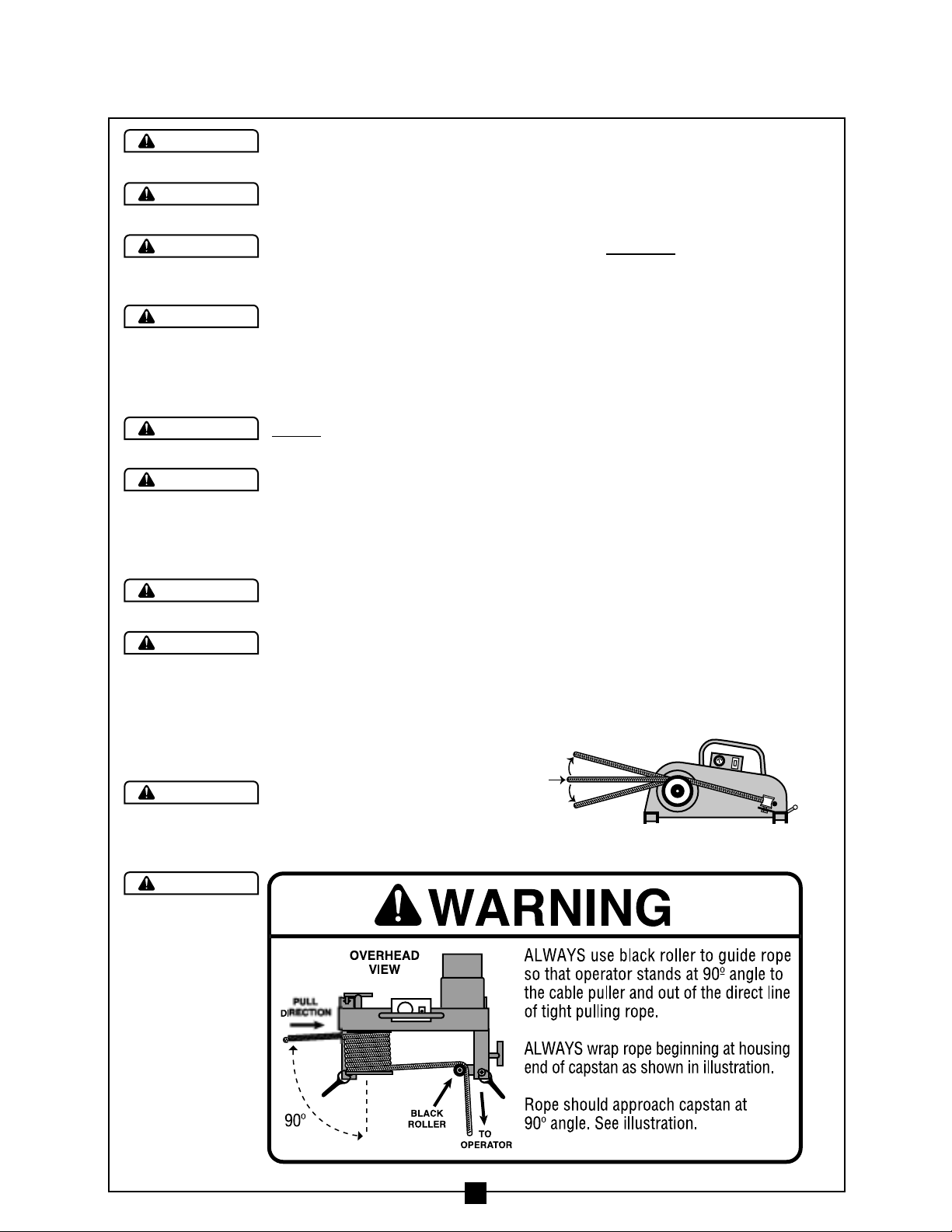

As shown in the overhead view,

Figure 8A, the pulling rope must

approach the capstan at a 90º angle.

This will help avoid rope overlap.

Make several wraps of the pulling

rope around the capstan, beginning

at the housing end of the capstan.

See Figure 8A.

Next, guide the pulling rope around

the black safety roller as shown in

Figure 8A. This will enable the operator

to stand at a 90º angle to the cable

puller and out of the direct line of

tight pulling rope.

Also note the pulling rope should

approach the capstan as indicated

in

Figure 8B.

16

Figure 8B

Figure 8A

OPERATING INSTRUCTIONS — Model 88 Cable Puller

G

.

G

y

G

DAN

Do NOT operate cable puller in wet or damp locations. Do NOT expose to rain.

DAN

Do NOT operate in an explosive atmosphere

ARNIN

Do NOT use cable puller as a hoist or for lifting, supporting or transporting

people or loads. Use onl

for its intended purpose as a cable puller.

ER

ER

90º

MAXIMUM

10

˚

PULL

DIRECTION

MAXIMUM

10

˚

BLACK

ROLLER

TO

OPERATOR

Page 17

17

Pulling Operation

1. Be sure the cable puller power switch is in the off position.

2. Operator should monitor the force gauge throughout the entire cable pull.

3. Hold the tailing end of the pulling rope and pull slightly. Turn the cable

puller

on.

Note: The tailing rope is that portion of the pulling rope that has

passed the capstan and is now excess to the pull. By pulling on the

tailing rope the operator can control and vary the pulling force. It

should require no more than 10 lbs. of tailing force by the operator

to engage the pulling rope on the capstan. If the rope slips on the

capstan, turn the puller off and add an additional wrap of rope

around the capstan. Also note that with the tailing force at a constant pull, each additional wrap of rope around the capstan will

approximately double the pulling force of the cable puller.

g

.

.

.

.

G

th

.

.

G

.

ON

OPERATING INSTRUCTIONS continued . . .

ARNIN

ALWAYS use black roller to guide rope so that operator stands at 90

cable puller and out of the direct line of ti

ALWAYS wrap rope beginning at housing end of capstan as shown in Figure 8A

Rope must approach capstan at a 90o angle. See Figure 8A

Rope should approach capstan as shown in Figure 8B

ht pulling rope. See Figure 8A

angle to the

ARNIN

Rope Requirements: Use only 3/4" or larger double braided composite pulling rope

wi

an average breaking strength of 26,000 lbs

Be sure to inspect rope for damage before each cable pull

UTI

Wear eye protection when operating cable puller

Page 18

18

4. As the rope is tailed it should mound on the floor between the

operator and the cable puller.

5. Turn the cable puller switch to the

off position when the pull is completed.

Note: The Model 88 Cable Puller is equipped with a circuit breaker

switch. If the amperage rating of the breaker is exceeded the puller

will stop. Before restarting the pull, allow the motor to cool and

determine the cause for the overload condition. Correct before

restarting the pull.

g

y

.

G

,

y

G

.

p

.

G

y

y

.

.

G

OPERATING INSTRUCTIONS continued . . .

ARNIN

NEVER allow the rope to slip on a rotating capstan for more than a couple of seconds

The rope will wear in that spot and the rope could break under pressure. If you need

to sto

the pull, turn the cable puller off and tie the rope off to hold it in place until

ou restart your pull

ARNIN

This cable puller is equipped with an anti-reversing pawl. The pawl will make a clickin

sound when the capstan is rotating. if you can not hear the clicking sound as the

capstan rotates, immediatel

turn the cable puller off and do not use until repaired

ARNIN

NEVER allow the rope to overlap on the capstan. If this condition begins to occur

immediately release the tailing force on the rope so that the rope can feed back toward

he conduit or cable tray. If this does not remedy the overlap, turn off the cable puller

immediatel

. There is no known solution for rope overlap.

ARNIN

Keep all body parts, hair, loose clothing, etc. away from rotating parts and pinch

points. Keep hands awa

Do NOT wrap rope around an

ALWAYS keep the tailing rope away from the operator

from capstan.

body parts. Do NOT wrap rope around wrists

feet

Page 19

19

G

y

G

y

G

p

G

y

y

y

p.

G

OPERATING INSTRUCTIONS continued . . .

ARNIN

Rope must ALWAYS be pulled over a rotating sheave. If a sheave does not rotate, turn

cable puller off immediatel

and determine the problem before continuing the pull.

ARNIN

Pulling Rope should be the only thing to contact the capstan. NEVER let swivels, grips,

tc. come in contact with the capstan.

ARNIN

NEVER allow the rope to overlap on the capstan. If this condition begins to occur,

immediatel

toward the conduit or cable tra

cable puller immediatel

release the tailing force on the rope so that the rope can feed back

. If this does not remedy the overlap, turn off the

. There is no known solution for rope overla

ARNIN

Keep as much rope confined in the conduit as possible. This will help prevent injur

should the rope break and whip violently.

ARNIN

When making a vertical cable pull, keep the area underneath the cable pull clear

of all

ersonnel.

Page 20

COMMON SET-UPS

NOTE: When using Manhole Sheave,

always refer to Model 308/310/312 Manhole

Sheave instruction sheet. For a FREE copy

of this instruction sheet, call Current Tools

at 800-230-5421 or write to Current Tools;

PO Box 17026; Greenville, SC 29606

20

Page 21

TANDEM PULLING

If the amount of pulling force required to make a pull exceeds the load rating

for a single cable puller, two cable pullers may be used in tandem to make the

pull. See Figure 9 below. Be sure to use a separate rope and set of accessories

for each cable puller. Each set of rope and accessories should meet or exceed

each cable pullers maximum pulling force.

21

Figure 9

MAINTENANCE

Capstan

Replace the capstan if it is grooved more than 1/16” deep.

Lubrication

Front and Rear Drive Chains — Lubricate the inside of both drive chains every

20 hours of operation with 90 wt. gear oil.

Capstan Shaft, Rear Drive Shaft and Ratchet Pawl — Grease every 10 hours with a

good quality multi-purpose (M.P.) grease. These grease fittings are located on the

side of the cable puller.

See item #39 on Model 88 Cable Puller exploded view.

Inspection

Important: After the first 5 hours of operation remove the cover and

inspect both chain tensioners. Adjust as needed.

Front and Rear Chain Inspection — Every 40 hours of operation the front and rear

drive chains should be removed and inspected for excessive wear or binding.

Motor Brushes – Inspect the two motor brushes every 30 hours. Replace

if less than 3/8” long. Always replace both brushes at the same time.

g.

G

y

ON

ARNIN

Unplug the cable puller before servicin

UTI

Do NOT alter this cable puller. Doing so will void the warranty. Guards and

safet

features are provided for your protection.

Page 22

EXPLODED VIEW – MODEL 88 CABLE PULLER

52

44

38

34

21

28

54

28

31

29

9

30

29

27

51

32

27

49

50

INCLUDED

WITH ITEM 45

35

39

40

41

38

46

47

48

39

45

2

39

1

37

53

5

33

22

42

24

23

25

19

52

20

6

4

7

3

26

18

53

10

8

12

13

11

51

15

17

16

16

17

14

51

32

51

32

22

Page 23

PARTS LIST – MODEL 88 CABLE PULLER

ITEM # PARTS DESCRIPTION QTY PART #

1 PULLER HOUSING 1 88-53

2 CHAIN GUARD 1 88-32

3 FLAT HEAD SOCKET CAP SCREW 5 88-1

4 #60 SPROCKET 1 88-54

5 CAPSTAN SPROCKET BOLT 4 88-55

6 STAR LOCK WASHER 4 88-56

7 CAPSTAN 1 88-33

8 CAPSTAN BUSHING 1 88-57

9 SPACER – JACKSHAFT 1 88-58

10 CAPSTAN WASHER – STEEL 1 88-59

11 CAPSTAN BOLT 1 88-60

12 #60 CHAIN MASTER LINK 1 77-010

13 #60 CHAIN 1 88-61

14 #60 IDLER SPROCKET 1 88-62

15 #60 IDLER SPROCKET BUSHING 1 88-63

16 CHAIN TENSIONER ARM 2 88-64

17 TENSIONER ARM COTTER PIN 2 88-2

18 #40 CHAIN 1 88-65

19 #40 IDLER SPROCKET BUSHING 1 88-66

20 #40 IDLER SPROCKET 1 88-67

21 KEP NUT 4 88-68

22 MOUNTING CHAIN ASSEMBLY 2 88-21 L

23 #40 CHAIN MASTER LINK 1 77-032

24 #40 SPROCKET – MOTOR 1 88-69

25 MOTOR SHAFT RETAINING RING 1 88-25

26 JACKSHAFT & SPROCKET WELDMENT 1 88-19

27 JACKSHAFT PHENOLIC WASHER 2 88-70

28 ROLLER BEARING – JACKSHAFT 2 88-35

29 INNER RACE – JACKSHAFT 2 88-36

30 PAWL 1 88-27

31 PAWL SPRING 1 88-26

32 HEX NUT 3 88-71

33 SAFETY ROLLER 1 88-18

34 SOCKET HEAD SHOULDER BOLT 1 280-2D

35 POWER CORD 1 450-4

37 WASHER – PHENOLIC 1 88-37

38 BOLT 2 88-38

39 GREASE FITTING 3 88-39

40 HEAVY DUTY RETAINING RING 1 88-40

41 JACKSHAFT WASHER – STEEL 1 88-41

42 MOUNTING CHAIN HANDLE ASSEMBLY 2 88-42

44 PULLER MOTOR 1 88-44

45 PULLER FORCE GAUGE 1 88-17

46 COVER 1 88-46

47 CIRCUIT BREAKER SWITCH 1 88-47

48 SLOTTED PAN HEAD MACH. SCREW 2 88-31

49 COVER SCREW 4 77-004

50 GAUGE ASSEMBLY SCREW 3 88-50

51 STAR LOCK WASHER 4 88-51

52 FLAT WASHER 2 88-52

53 CAPSTAN SHAFT WASHER – PHENOLIC 2 88-48

54 BEARING SPACER 1 88-74

23

Page 24

EXPLODED VIEW – MODEL 88 CABLE PULLER MOTOR

120

117

119

118

116

115

114

111

123

113

112

103

101

102

100

110

109

108

103

122

103

107

121

106

105

104

24

Page 25

PARTS LIST – PART #88-44 CABLE PULLER MOTOR

ITEM # PARTS DESCRIPTION QTY PART #

100 ARMATURE BEARING – FRONT 1 88-44A

101 ARMATURE 1 88-44B

102 ARMATURE BEARING – REAR 1 88-44C

103 BELLEVILLE WASHER 8 88-44D

104 NUT 4 88-44E

105 LOCK WASHER 4 88-44F

106 MOTOR END PLATE 1 88-44G

107 GEAR BOX HOUSING 1 88-44H

108 FAN SCREEN 1 88-44I

109 THREADED STUD 4 88-44J

110 MIDDLE MOTOR HOUSING 1 88-44K

111 FIELD 1 88-44L

112 SCREW 2 88-44O

113 LOCK WASHER 2 88-44N

114 END CAP HOUSING 1 88-44P

115 BRUSH 2 88-44Q

116 BRUSH CAP 2 88-44R

117 SCREW 4 88-44S

118 SET SCREW 2 88-44T

119 BRUSH HOLDER 2 88-44U

120 MOTOR CORD 1 450-4

121 OUTPUT SHAFT GEAR ASSEMBLY 1 88-44W

122 2ND GEAR ASSEMBLY 1 88-44X

123 1ST GEAR ASSEMBLY 1 88-44Y

25

Page 26

BLACK

MOTOR

ON/OFF

POWER

GAUGE

FORCE

120V AC

GREEN

WHITE

BLACK

SWITCH

BLACK

K

FORCE GAUGE

WIRING SCHEMATIC – MODEL 88 CABLE PULLER

WHITE

GREEN

120V AC

POWER

ON/OFF

FORCE

GAUGE

MOTOR

WIRING DRAWING – MODEL 88 CABLE PULLER

WHITE

BLAC

BLACK

TO MOTOR

GREEN GREEN

TO PLUG

26

Loading...

Loading...