1

Cuppone Pizzaform

User and Installation Manual

Note: Pizza Equipment Professionals has provided this

manual as an English only copy of the Cuppone F. LLI SRL

Manual provided by the manufacturer. Words and

Descriptions may have been altered. If you have questions

please reference the Manufacturer’s Manual you have

received with your purchase.

www.PizzaEquipmentPros.com 800.655.1831 17981 S. Ideal Parkway. Manteca, CA. 95336. U.S.A. info@PizzaEquipmentPros.com

2

INDEX

Introduction

Initial Instructions

Explanation of Symbols

Risk Analysis

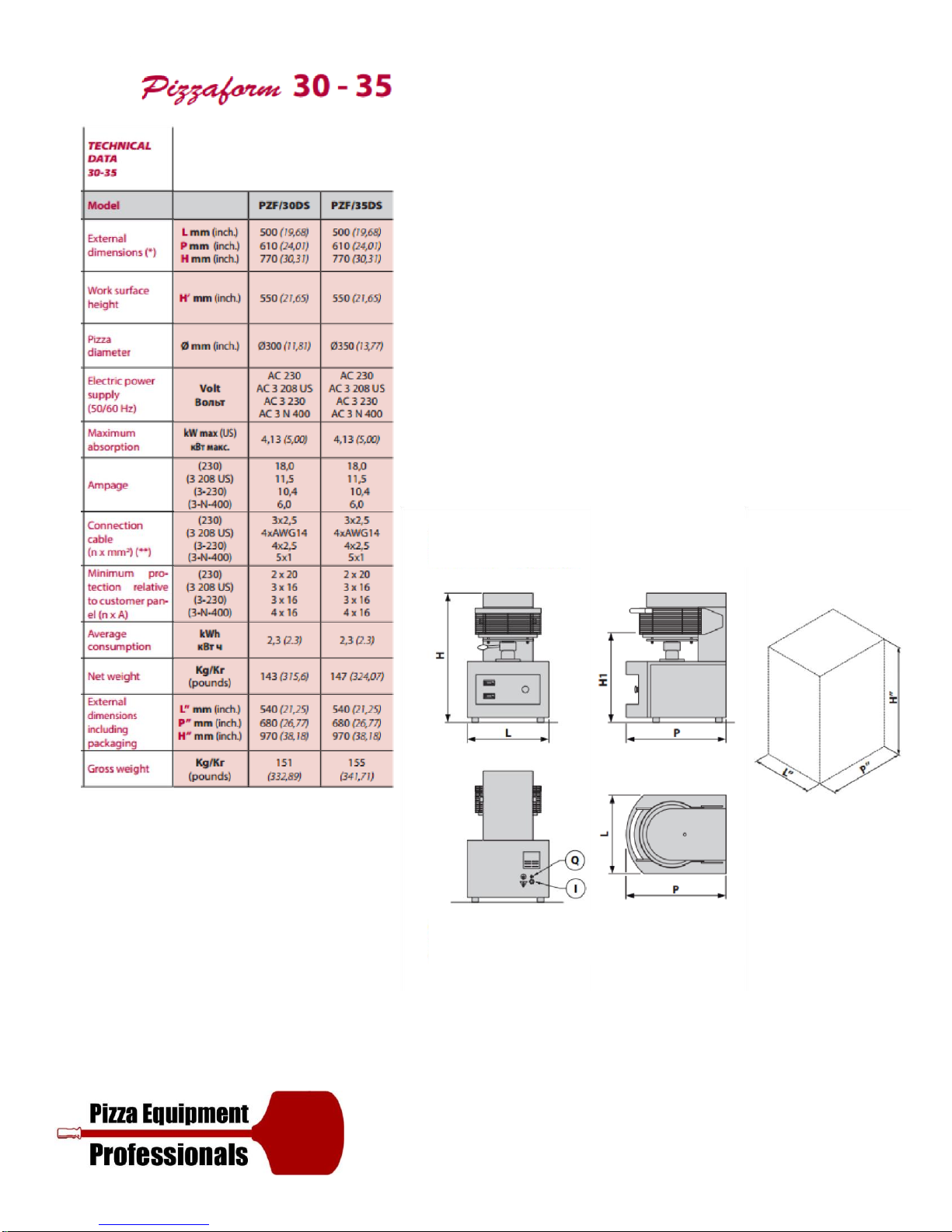

Technical Data (Pizzaform 30, 35)

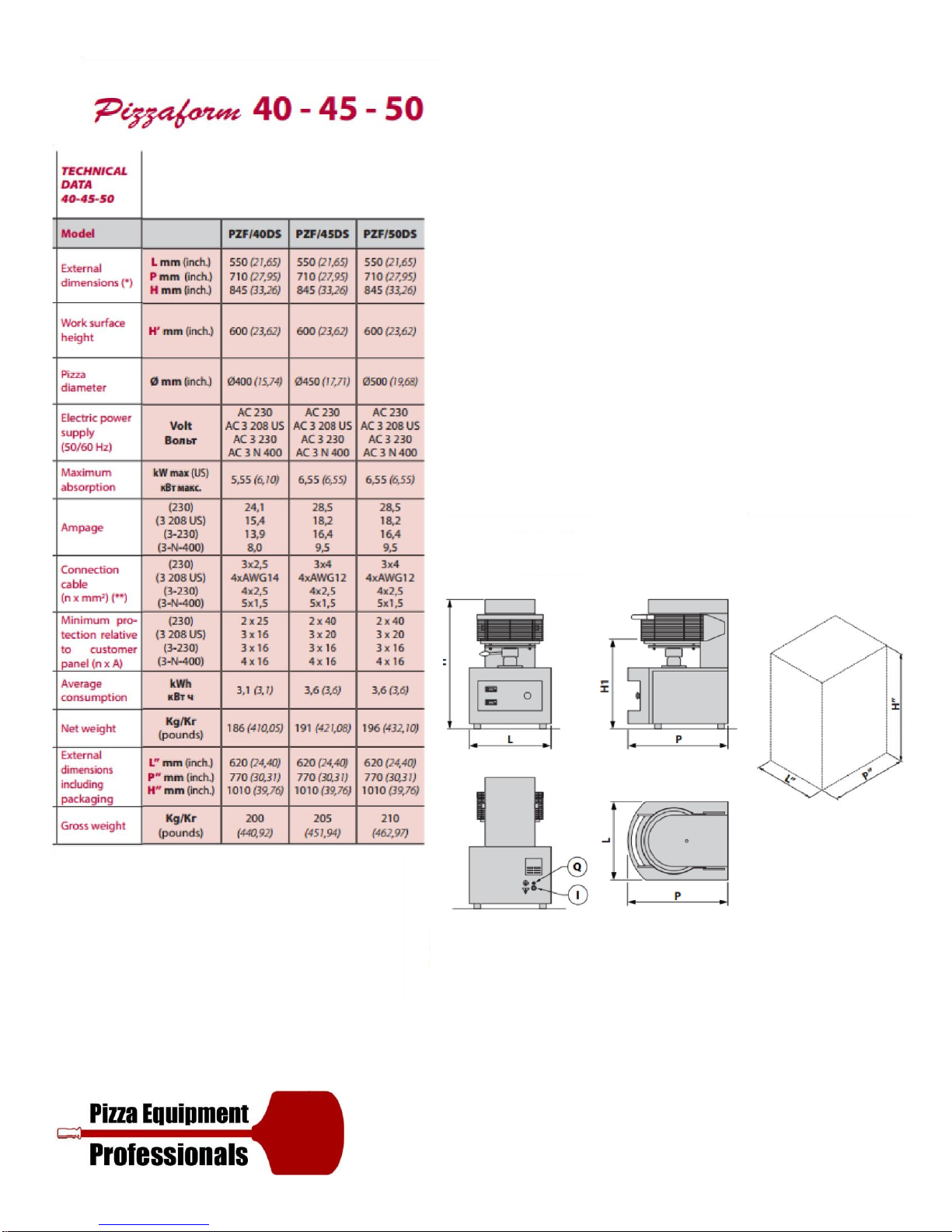

Technical Data (Pizzaform 40, 45, 50)

General Specifications

Installation Requirements

Safety Distances

Instructions for the Installer

Uploading & Transport

Preparations and Checks

Positioning

Electrical Connections

Power Supply, Activation, Operation Verification

Pre-test

Control Panel Description

Instructions for the User

Turning On

Setting the Plate Temperature

Setting the Plate Contact Time (Dwell Setting)

Use

Shutting OFF

Countdown Function

Strike Counting Function

Troubleshooting

Recommendations Governing Use

Maintenance Instructions

Maintenance

Positioning of Main Controls

Wiring Diagram

Warranty Conditions

Limits

Exclusions

3

INTRODUCTION

The present manual refers to various electronic control PIZZAFORM pizza hot forming machine models.

The present manual was originally written in Italian. All other languages are translations.

Congratulations on selecting a product that was designed and constructed with advanced technology.

We recommend that you read through this manual fully before using this equipment. It contains very

important information and instructions regarding installation, use and maintenance.

The equipment you have purchased was carefully designed and constructed and has been subjected to strict

inspection tests in our laboratories, therefore we can guarantee its absolute safety and functionality.

Installation must be done according to the instructions by professionally qualified personnel who are able to

take on the responsibility for the installation and guarantee the best conditions for operation and safety.

TECHNICAL SUPPORT

The manufacturer is able to solve any technical problem concerning use and maintenance. In the remote

possibility of poor operation or a repair, only use qualified personnel or contact our authorized service

centers.

INITIAL INSTRUCTIONS

ATTENTION! Failure to comply with what is described in this handbook could jeopardize safety.

The manual must be kept carefully in an accessible location, it must also always accompany the product

during its life.

Before installing and using the equipment, this manual must be read carefully and the instructions it contains

must be followed scrupulously.

The manufacturer declines all civil and criminal liability for damage to people, property or animals deriving

from the failure to observe current safety regulations, failure to respect the contents of this manual and

from any printing or transcription errors.

It also declares that it reserves the right to make any changes to the product that it considers appropriate

without the obligation to provide notice.

Before handling, installing, or using the product, verify the suitability of the room where it will be located.

Make sure that all safety measures have been taken in order to avoid any accidents.

4

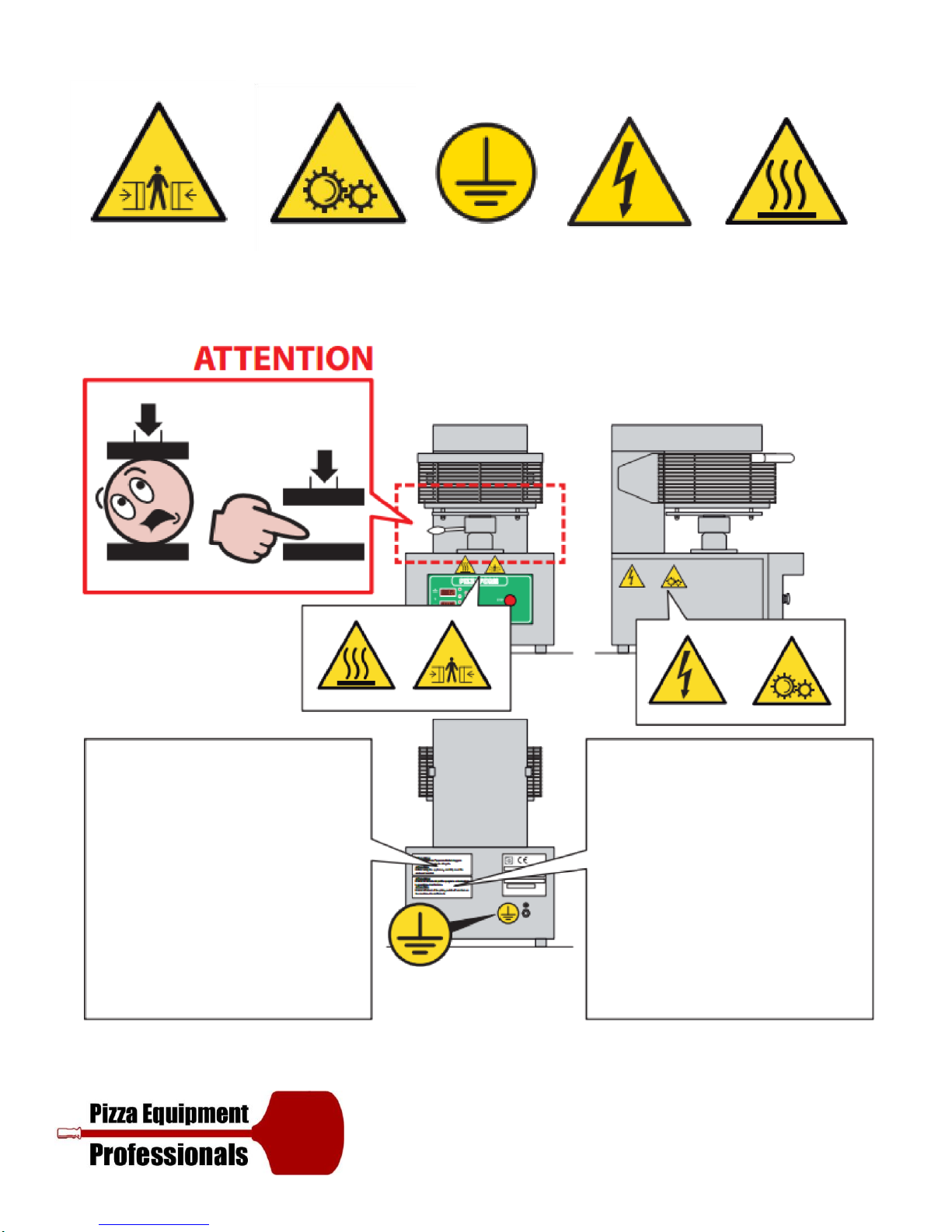

EXPLANATION OF SYMBOLS

Risk of Crushing Fingers

Equipotential

Risk of Electric

Shock

Risk of Blistering

Surface

Warning: Before using

the equipment

carefully read the

enclosed booklet.

Warning Gear

Wheels

Warning: In case of

arrest of the plate,

switch off and turn on

the machine. Do not

force it.

5

RISK ANALYSIS

The machine was designed in compliance with the Machinery Directive 2006/42/EC and Legislative Decree

no. 17 of the 27 January 2010.

In compliance with these standards an assessment of the possible damage resulting from risks to health and

the safety of operators of the machines in question, should a hazed come to light, was carried out.

According to the analysis there are outstanding risks associated with the use of the machine which cannot be

eliminated without loss of machine functionality and without increased cost.

These outstanding risks include:

The operators head may get crushed by the plates upon opening. The outstanding

risk is signaled by the pictogram on the machine.

Risk of breakage and projection of objects during insertion of the blade into the

protections during closure. Do not insert any objects into the protection grille when the machine is

moving, not even to unblock the plates.

In the case where the machine is blocked, switch it off and then on again.

Risk of crushing fingers at the plate piston base. The piston base is flared to enable

sliding of the fingers and to prevent catching; an outstanding risk of crushing of the

fingers where forced into position, remains.

Do not attempt to access or intervene at the piston base where the machine is moving.

The outstanding risk is signaled by the pictogram on the machine.

Risk of burns when touching the plates: during use, the surfaces of plates become hot,

we recommend taking extra caution. The outstanding risk is signaled by this pictogram.

6

Ensure that you keep a distance of at least 500 mm

(20

inches) between the equipment and other

equipment of inflammable materials.

We advise that you leave an unrestricted space of

at least 500 mm to the right side to allow for easy

access to the electrical system.

Leave the space above the equipment free: do not

place anything on it.

L: width P: depth H: height

Front View

Side View

Packaging

Dimensions

These cables can only be used provided

that their length does not exceed 2 m

between the point where the cable or

relative protection enters the equipment

and the plug input.

Plain View

Rear View

7

Front View

Side View

Packaging

Dimensions

Ensure that you keep a distance of at least 500 mm

(20

inches) between the equipment and other

equipment of inflammable materials.

We advise that you leave an unrestricted space of

at least 500 mm to the right side to allow for easy

access to the electrical system.

Leave the space above the equipment free: do not

place anything on it.

L: width P: depth H: height

These cables can only be used provided

that their length does not exceed 2 m

between the point where the cable or

relative protection enters the equipment

and the plug input.

Plain View

Rear View

8

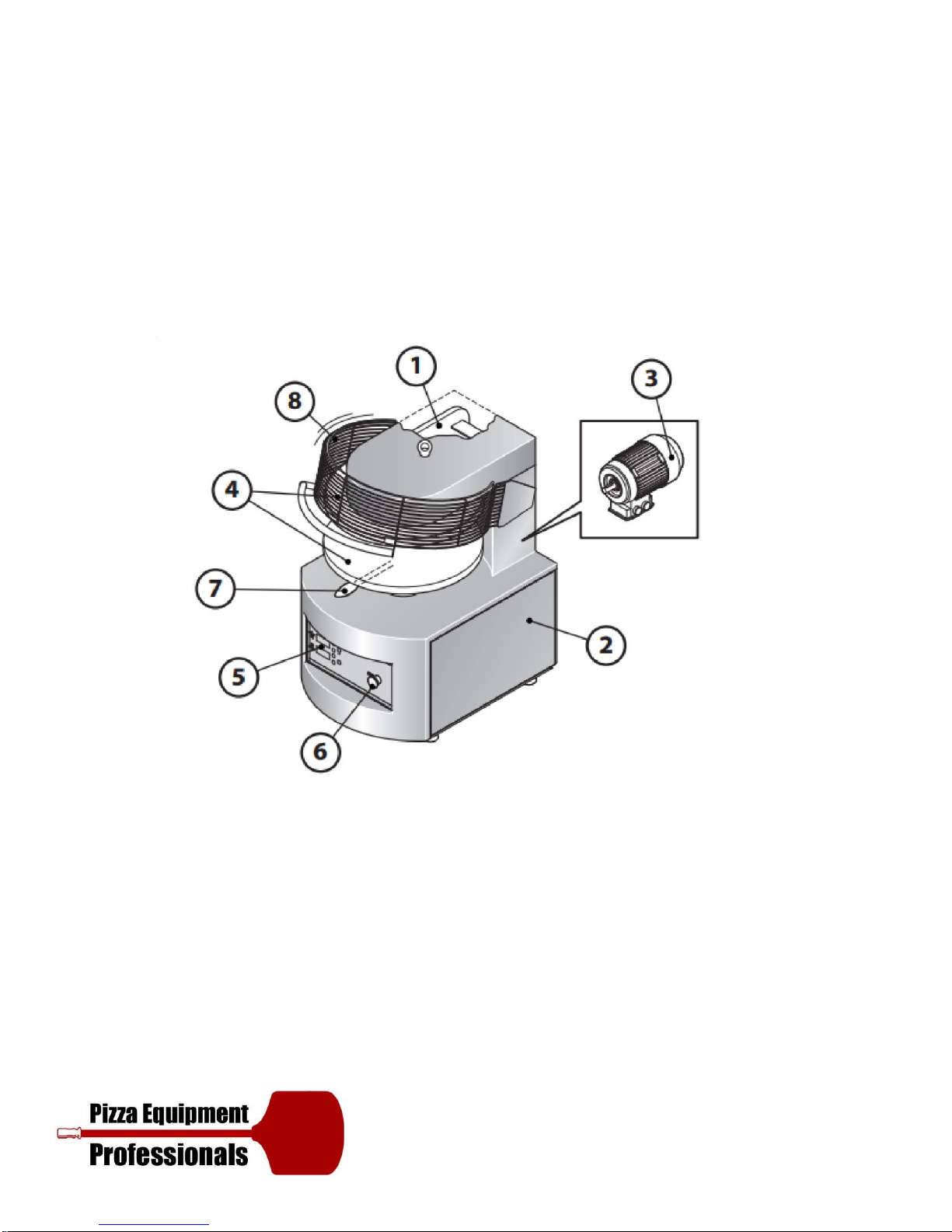

GENERAL SPECIFICATIONS

1 Iron supporting frame with thickness of 20 mm.

2 Stainless steel body

3 Self-braking motor (direct-current brake) with built-in thermal protection.

4 Thick chromed plates with flared perimeter.

5 Electronic control of temperature and plate contact time.

6 EC certified safety devices.

7 Lever to adjust the distance between plates.

8 Protection grille.

To access the specifications explicit to your model, consult the technical data table above.

9

INSTALLATION REQUIREMENTS

Before starting the installation, check the following conditions that are necessary for proper equipment

operation and maintenance:

1) Handling: Make sure that the floor is able to support the weight of the equipment. Handle the packaged

equipment using a forklift or a pallet truck.

2) Electrical connection: Provide a box for the connection to the mains power supply in the immediate

surroundings.

3) Safety distances: It is mandatory that the minimum safety distances between the equipment and the

other equipment or inflammable material are respected (see page 20).

It is also prohibited to use the equipment in areas at risk of explosion. The indicated distances must be

increased in the presence of heat sensitive material.

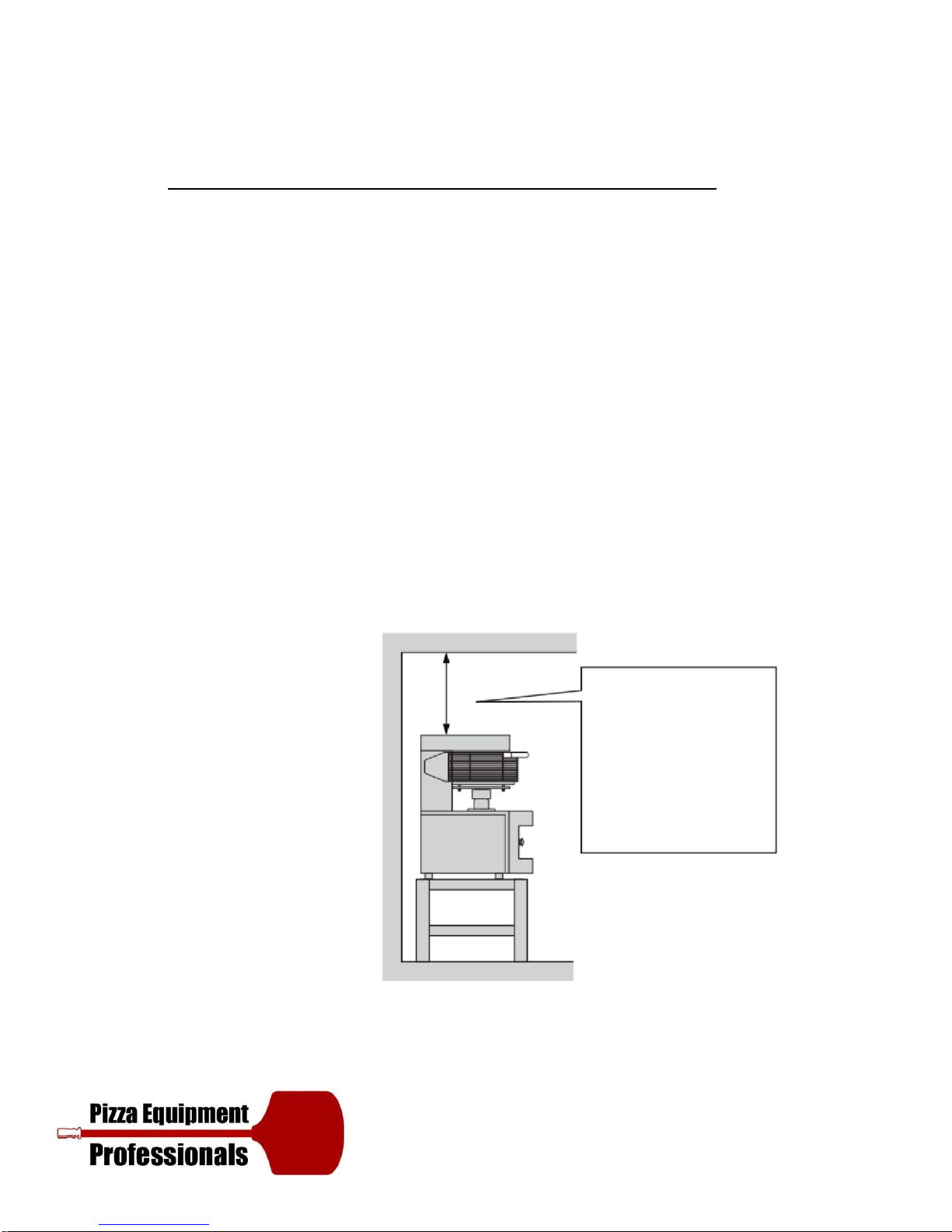

SAFETY DISTANCES

It is mandatory that the minimum safety distances between the equipment and the other equipment or

inflammable material are respected (see page 20).

It is also prohibited to use the equipment in areas at risk of explosion. The indicated distances must be

increased in the presence of heat sensitive material.

Leave this area

unobstructed

Loading...

Loading...