CUMMINS PS0500, PowerStart0500 Technical Training Participant’s Manual

Technical Training Participant’s Guide

- 1 -

PowerStart0500 Module

Table Of contents

Introduction.…………….……………………………………………..3

Overview………………...……………………………………………. 5

How to operate me……...……..…………………………………….7

PS0500 control features..…………………..……………………...25

Mounting Guidelines…….…………….………………………… . 28

Control outputs/inputs………………………………………..…...29

Control systems………….………………..…………………….….34

Setup Trims and adjustments……………………………............40

Meter Calibrations……………….…………………………….……44

Wiring diagram…….…………….…………………………….…….51

Environmental capability…………………………………….…….52

Faultcode list……………………………………………………..….53

Troubleshooting………………………………………………….…54

- 2 -

Introduction

Welcome! Welcome to the training module for the PowerStart 0500. This module was

written by the Cummins Sales and Service India Limited-Electronic Cell department for your use

and reference. We suggest you read through the entire Introduction to become familiar with the

module’s structure. Then, just follow along in the module during your training session.

Module Purpose

The purpose of the Power Start 0500 training module is to help you to understand the

Power Start 0500 which is going to be used on Low Horse Power (LHP) genset.

With this information, you will be better prepared to meet your customers’ varying needs.

Module Audience

This module was written for dealer service technicians who have previous experience with or

knowledge of electrical engine, and generator basics.

Module Structure

This module contains lessons on related topics. Each lesson follows a carefully designed training

format, including a warm up, presentation, and activity (or exercise).

Module Assessment

After completing all the lessons in the module, you will complete a module assessment. The

module assessment lets us evaluate the level of knowledge you have on the topic after

completing the module.

Module Comment Form

You will also complete a module comment form. This form gives you the chance to comment on

the usefulness and effectiveness of the training module and make suggestions for improvements.

We will use the results from the module assessment and module comment form to help us

determine if there is a need to modify the module.

- 3 -

Overview

The PS0500 controller is a microprocessor-based generator set monitoring, metering,

and control system. The control provides a simple operator interface to the Genset and engine

parameters, remote start / stop control and generator set protective functions. The control does

not have in-built speed governing and voltage regulation features. It does not support magnetic

pickup connectivity.

The PS0500 series controllers are designed for use on engines from 10 to 100 KW

range, it means it is genset controller without AVR controller in the range of 12.5KVA to 125KVA

for non-paralleling applications. The control can also be configured for various frequency (50 Hz /

60 Hz operation), voltage configuration up to 600 Vrms L-L. The control is designed for mounting

on the generator set.

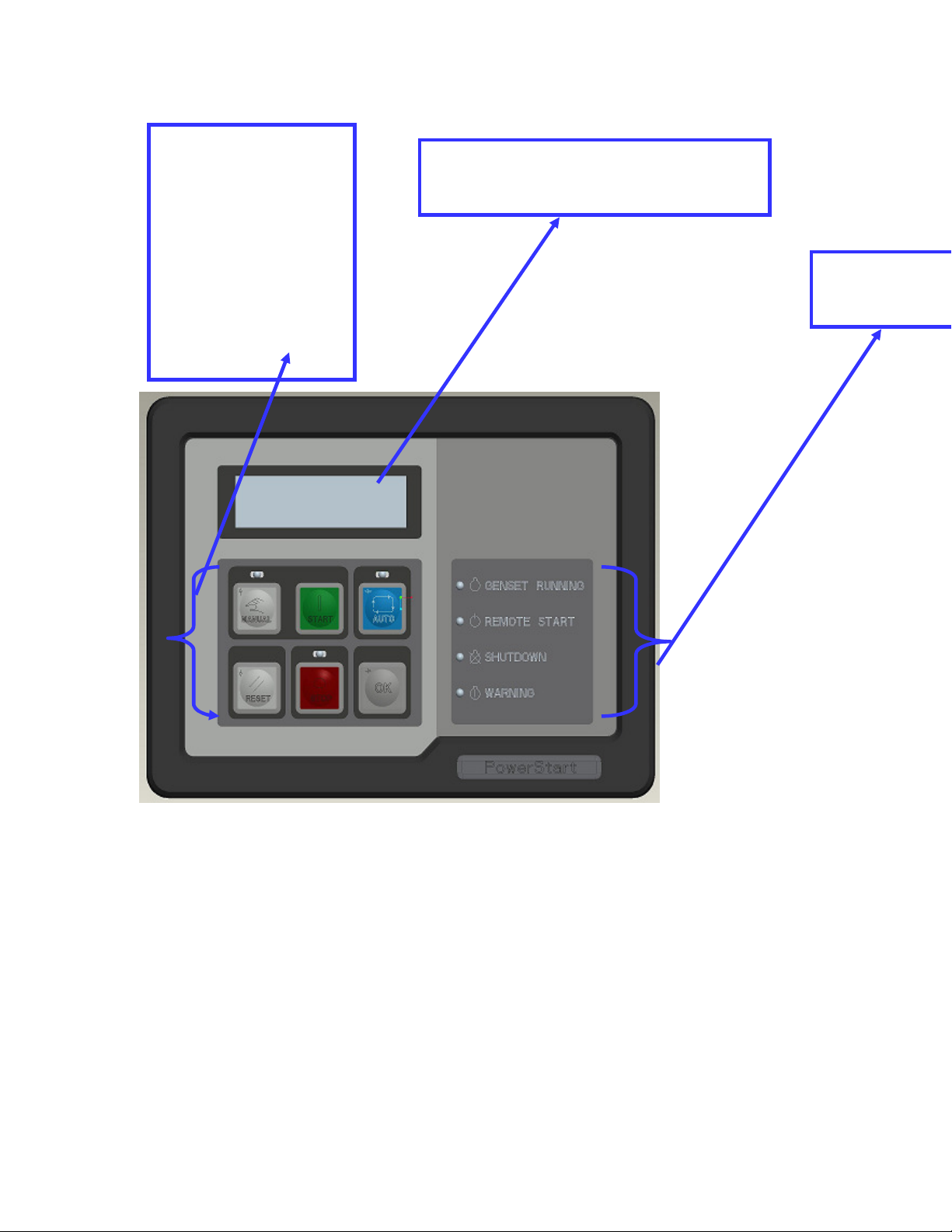

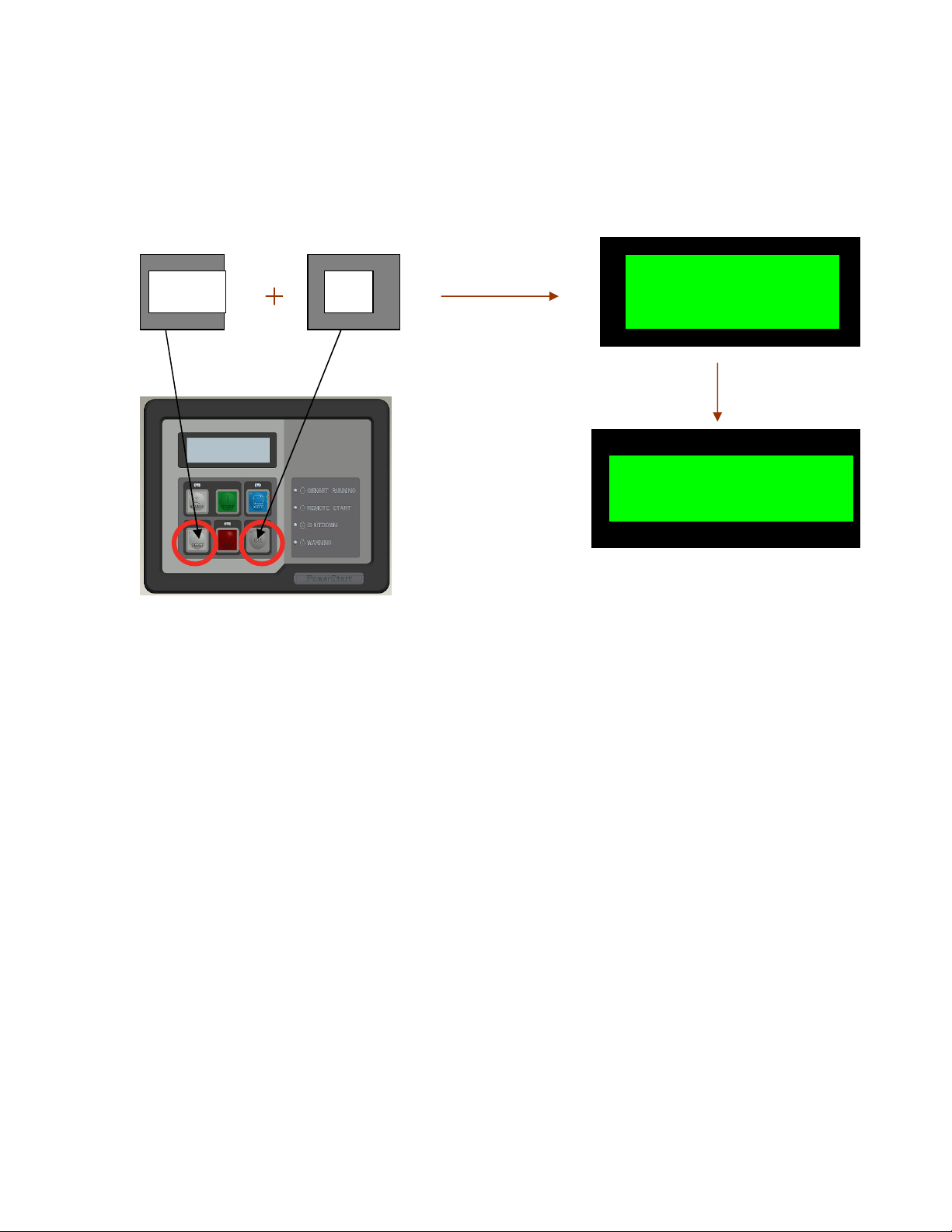

The control also has a 16X2 LCD module with seven indicator LEDs and six tactile feel

pushbuttons, which can be used for navigation.

- 4 -

Tactile Push

Genset status

Buttons

•Manual

•Auto

•Start

16 X 2 Alphanumeric

display

•Stop

•Reset

•Ok

LEDs

- 5 -

Module assessment :

1) What is operating range of engine KVA rating for PS0500?

2) What are the functions of PS0500 controller?

3) Will PS0500 support voltage regulation?

4) What is maximum line to line RMS voltage reading configured in PS0500?

5) Can we get MPU support for PS000?

6) Can we start engine remotely by PS0500?

7) Will PS0500 support paralleling operation?

8) How many push buttons are uses in PS0500?

9) How many indicator LEDs are use in PS0500?

- 6 -

How to operate PS0500

The reason to include this module,is to make everyone aware of the product and its

operations.

One who will go through this will be very well educated about PS0500,its

operations,applications.

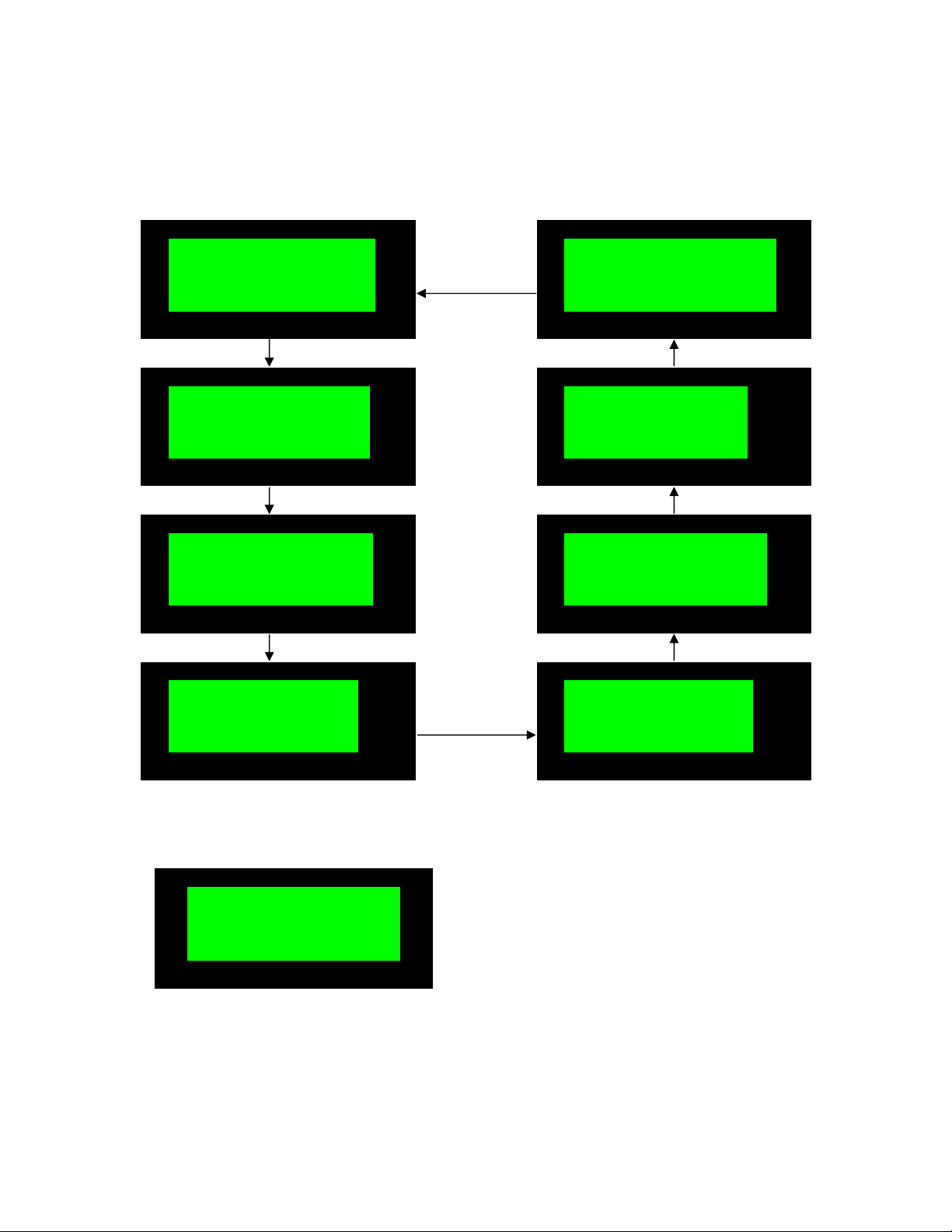

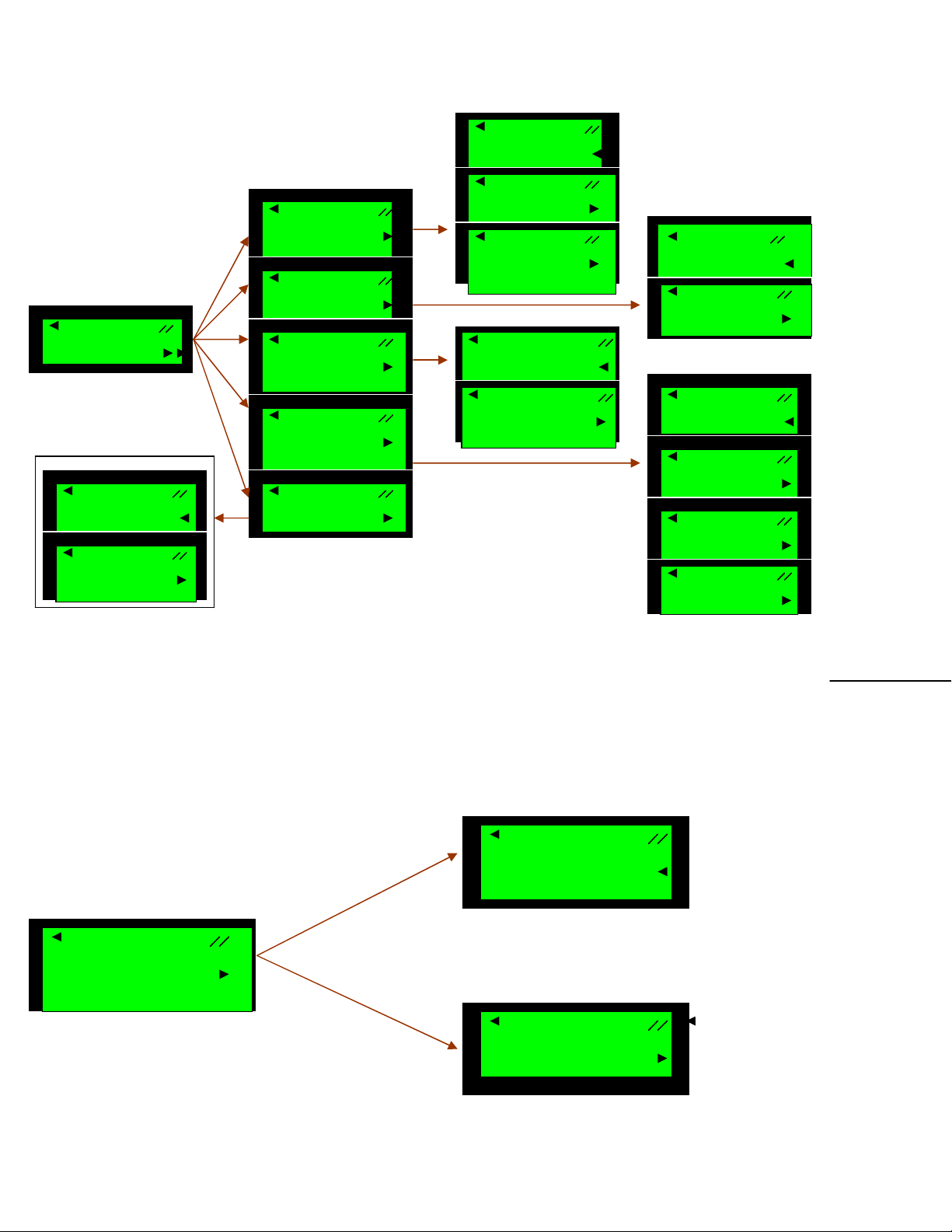

This is basic block diagram for PS0500,which will be refer throughout this module for

your reference.

PS0500

(16*2)

Manual

Reset Stop

LCD Display

Start Auto

OK

- 7 -

Lets first know how to start PS0500 after connecting it to 12V battery supply.

PS0500

BattVolts =------GensetHrs=------

Press this button

Once you press this push buttons all LED’s will glow for 1 second. And LED above

STOP button will start bblinking continuosly.While as on display show message shown

as in above picture.

The display of PS0500 has three display mode-

1)Monitor

2)Set Up

3)Calibration

Monitor mode allows user to monitor the Genset parameters

Monitor mode has 2 modes of operations

Scroll - The display will scroll the screen one by

one

Scroll Stop – User can monitor a desired screen

continuously

Manual

Reset Stop

Start Auto

OK

- 8 -

2 sec

2 sec delay

2 sec

2 sec

2 sec delay

2 sec

2 sec delay

Current Flt=212

L1N=000 L2

N=000

L12=000 L23=000

E Stop=Inactive

I1=00.0 KVA=00.0

Batt Volts=11.7

KVA1 KVA2 KVA3

Oil Press=003PSI

L1N=000 L2 N=000

In scroll mode one will observe following screens,the screens will scroll in the time span

of 2 sec.

L3N=000 HZ=00.0

L13=000 HZ=00.0

delay

I2=00.0 I3=00.0

00.0 00.0 00.0

delay

Clnt TempOOR Wrn

Cust In=Inactive

delay

Genset Hrs=00000

delay

Clnt Temp=342F

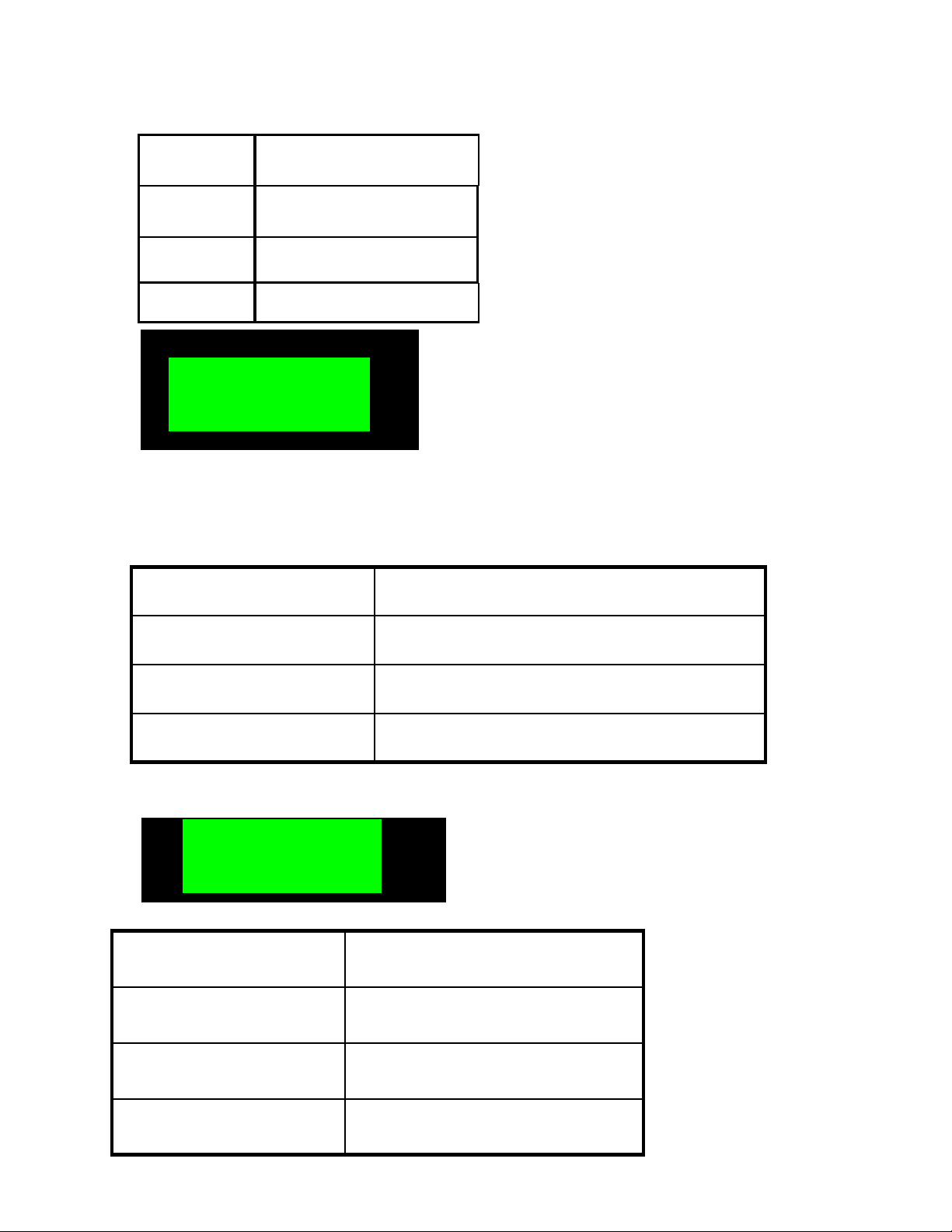

Following is the explanation for all above screens.

Table

- 9 -

L3N=000 HZ=00.0

Table

L12=000 L23=000

Frequency

HZ

Line 2 to Line

3 Voltage

L23

Line 1 to Line 2 Voltage

L12

I1=0.0 KVA=00.0

Line 3 current

I3

Line 2 current

I2

Total power

KVA

Line 1 current

I1

L1N Line1 to Neutral Voltage

L2N Line2 to Neutral Voltage

L3N Line3 to Neutral Voltage

HZ Frequency

L13=000 HZ=00.0

L13

Line 1 to Line 3 Voltage

- 10 -

I2=00.0 I3=00.0

Table

KVA1 KVA2 KVA3

Line3 P

ower

KVA3

Line2 Power

KVA2

Line1 Power

KVA1

Table

Oil Press=003PSI

Coolant Temperature

Clnt Temp

Oil Pressure

Oil Press

00.0 00.0 00.0

Clnt Temp=342F

- 11 -

Table

Batt Volts=11.7

Genset Hours

Genset Hrs

Battery Voltage

Batt Volts

Table

E Stop=Inactive

Customer Input

Cust In

Emergency Stop

E Stop

Cust In=Inactive

Genset Hrs=00000

NOTE: E Stop and Cust In shows the status of the

input that whether it is active or inactive

- 12 -

Table

Current Flt=212

Coolant Temperature Out Of Range

Warning

Clnt Temp OOR Wrn

Current Fault

Current Flt

How to

enter

the Scroll Stop Monitor m

ode ?

Clnt Temp OOR Wrn

L1N=000 L2N=000

L3N=000 HZ=00.0

NOTE: It displays the type of the warning for

the fault condition

- 13 -

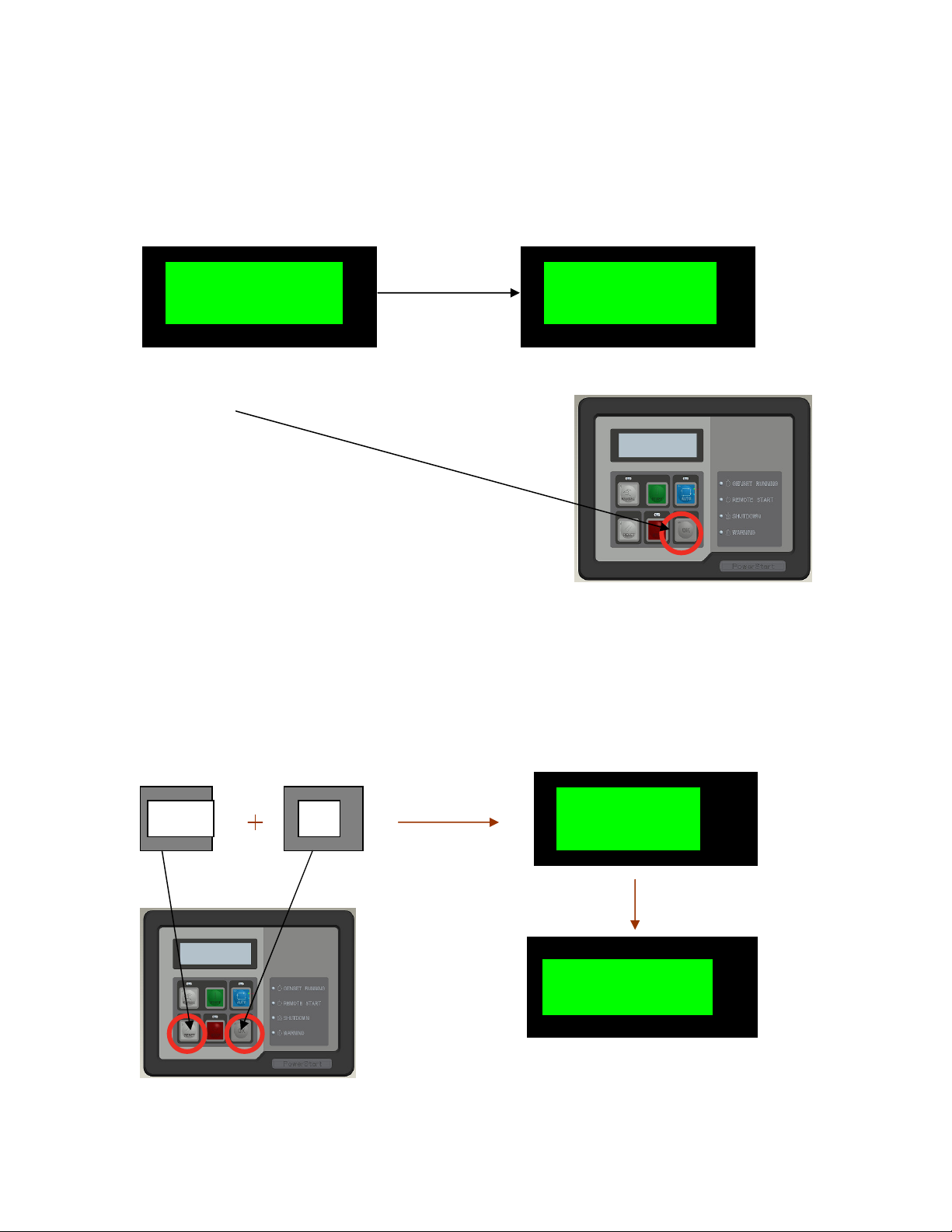

Press

Ok

button on front

How to

exit

from the Scroll Stop Monitor mode ?

OK

L1N=000 L2N=000

L12=000 L23=000

Ok

Press

Entering into the

Reset

SW PART 3267727

No Navigation is needed

Press Ok button to stop the scrolling and enter scroll stop to

monitor the parameters on specific screen continuously

L3N=000 HZ=00.0

L13=000 HZ=00.0

panel

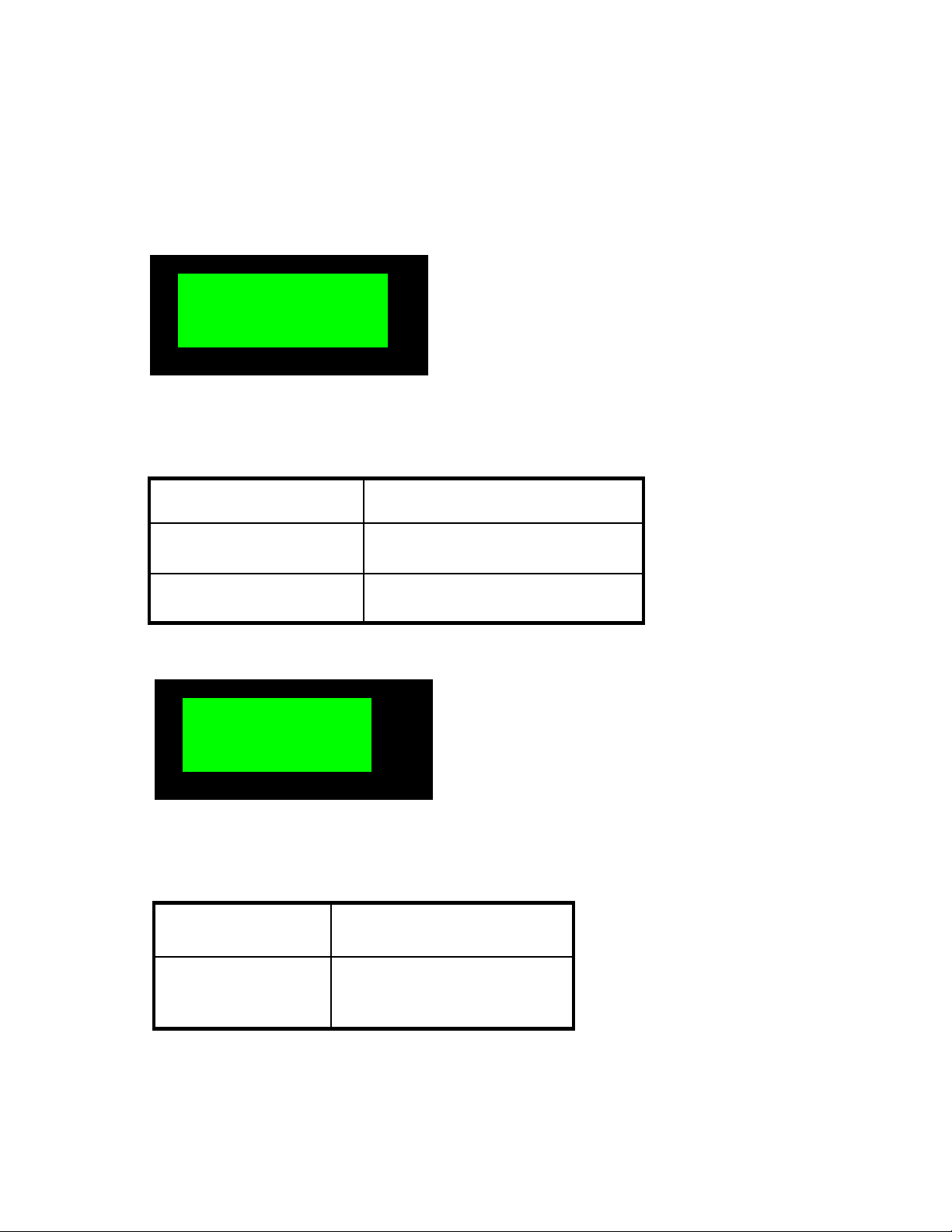

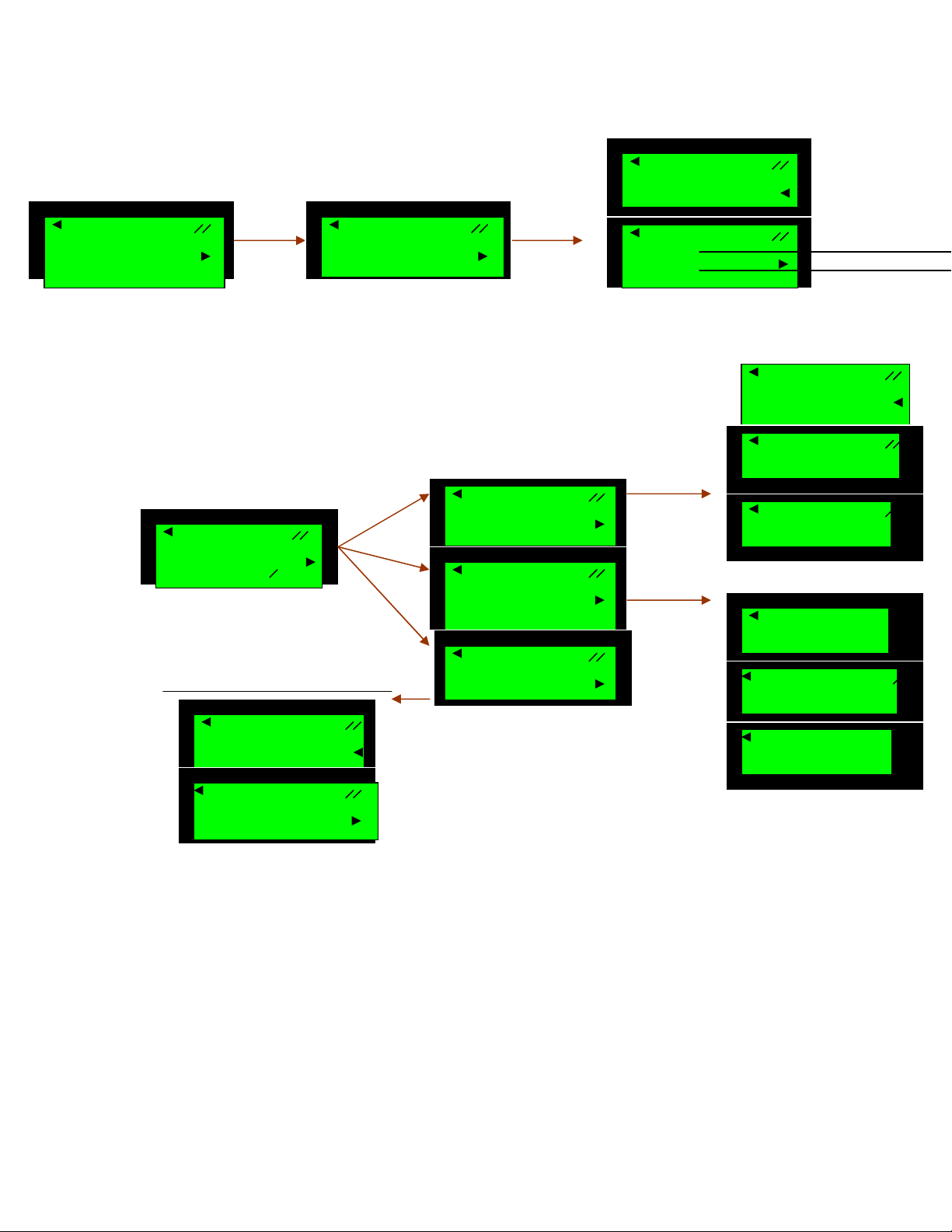

To enter into SETUP mode-

After going to stop mode only we can enter in to Setup mode.

For 5

Sec

- 14 -

Config Mode…

SW VER 1.01

*

Will go to the next value

Will go to the Previous value

Will go down

One need to understand key to operate-

Keys Properties

It shows the default value. when we select the particular

value it will comes to that value

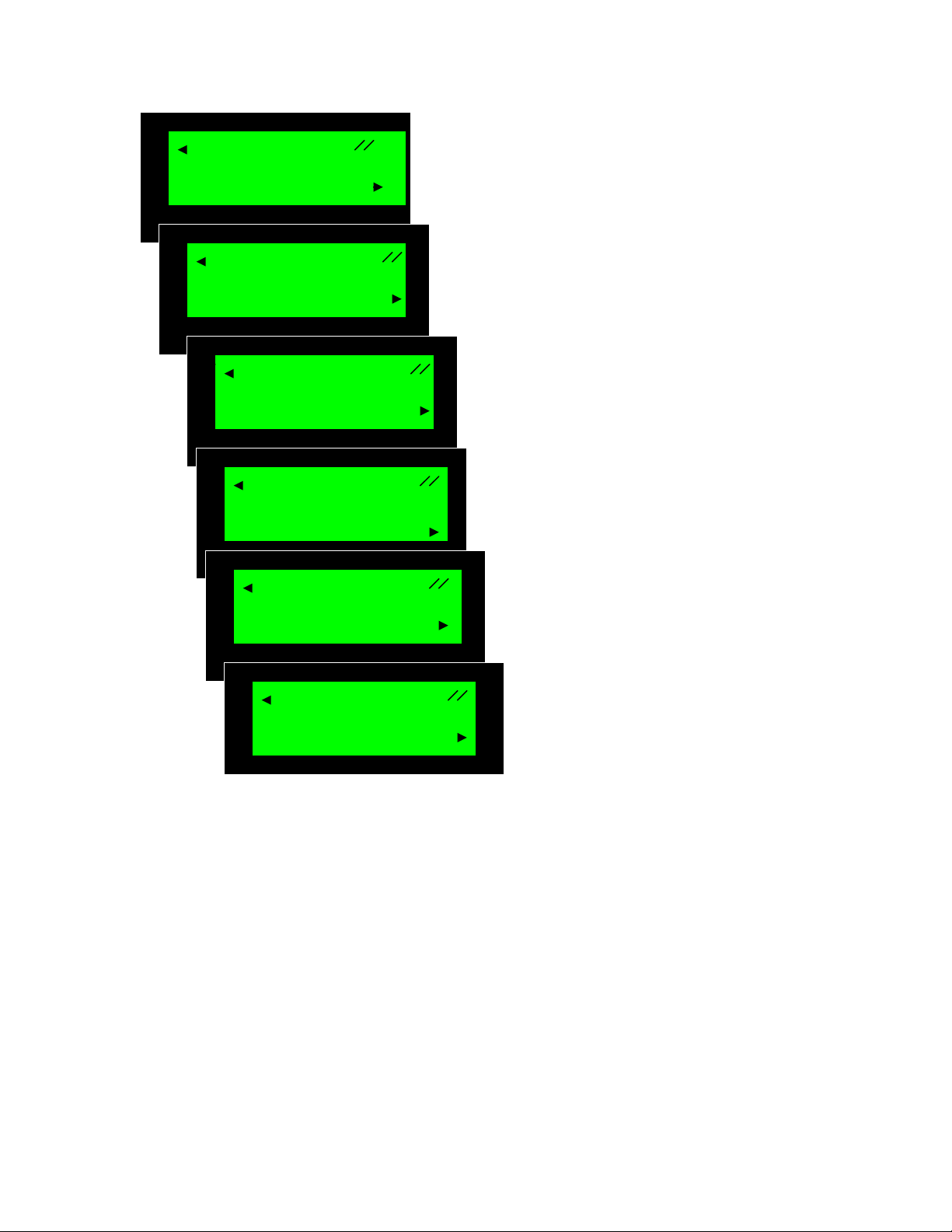

Following are the screens of the display when you will enter setup mode.Use

above explain keys to go through and to change the value.

Jus look down for more clear understanding.

- 15 -

Main Menu

Main Menu

Main Menu

Main Menu

Main Menu

Main Menu

Alt SetUp

Units

Sensor Config

Customer I/O

Battle Shot

Flt History

- 16 -

Connection type

NomVolt L

-L

*416 Volts

NomVolt L

-L

NomVolt L

-L

NomVolt L

-L

600 Volts

Freq

*50 Hz

Freq

Main Menu

Alt SetUp

Main Menu

Main Menu

Main Menu

Main Menu

Main Menu

Freq

Phase Type

Phase Type

Phase Type

CT Ratio

CT Ratio

Connection type

Units

Main Menu

Units

Phase Type

CT Ratio

Connect type

*3 Phase

Single2 wire

Single 3 wire

*Star Connect

*100:5

200:5

60 Hz

Setup screen

NomVolt L-L

Delta Connect

440 Volts

480 Volts

Units

*USA

Metric

- 17 -

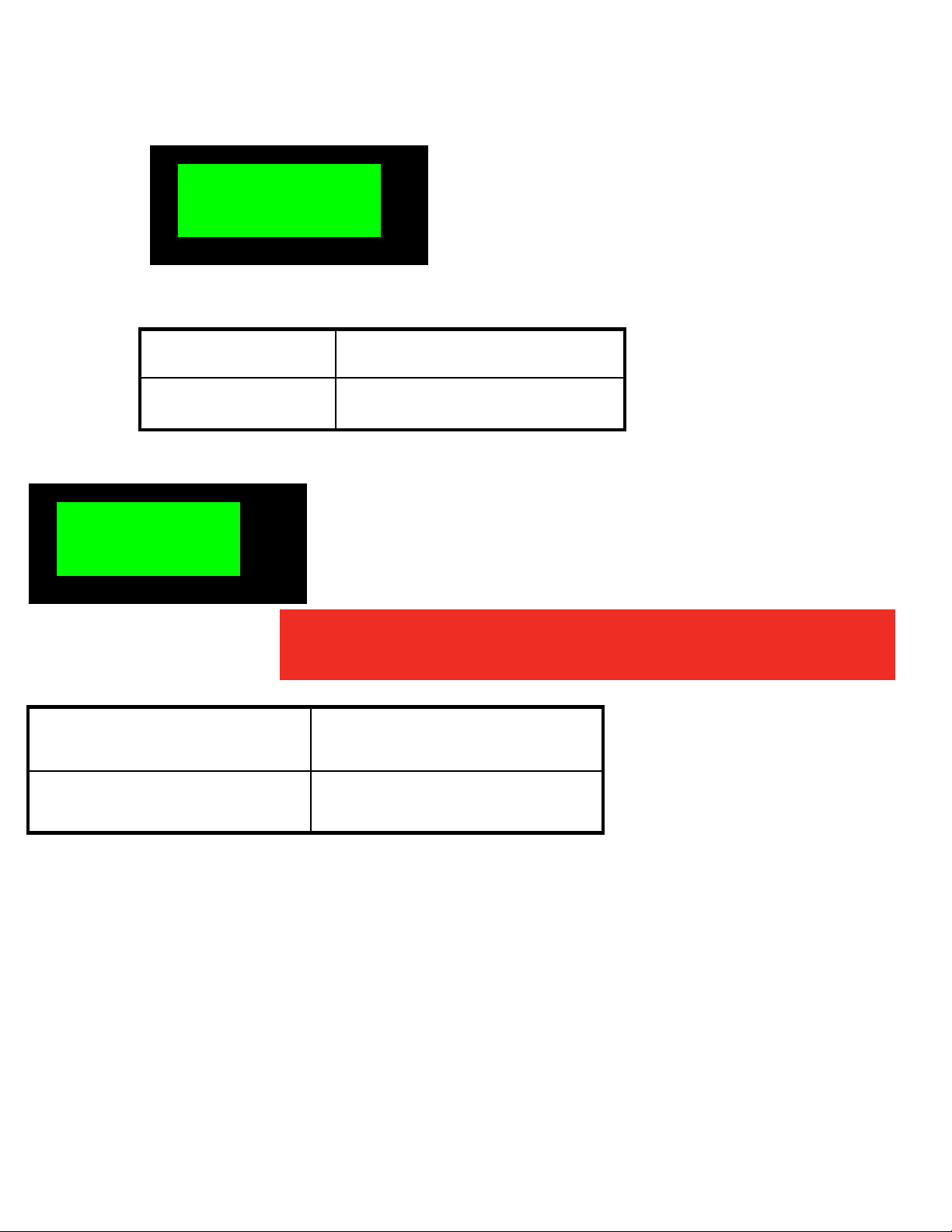

Oil Pr Input

Sensor config

Main Menu

Oil Pr Input

*Sensor

Main Menu

Customer I/O

Customer I/O

Customer

I/O

Customer O/P1

Customer O/P1

Customer O/P1

Customer O/P2

Customer O/p2

Customer O/P2

Cust I/P Flt1

Cust

I/P Flt1

Sensor Config

Setup screen

Customer I/O

Oil Pr Input

Switch

*Warning faults

Shutdown faults

Customer O/p1

Glow Plug

Customer O/P2

*Warning Faults

Cust I/P Flt 1

Shutdown Faults

*Warning Faults

Shutdown Faults

- 18 -

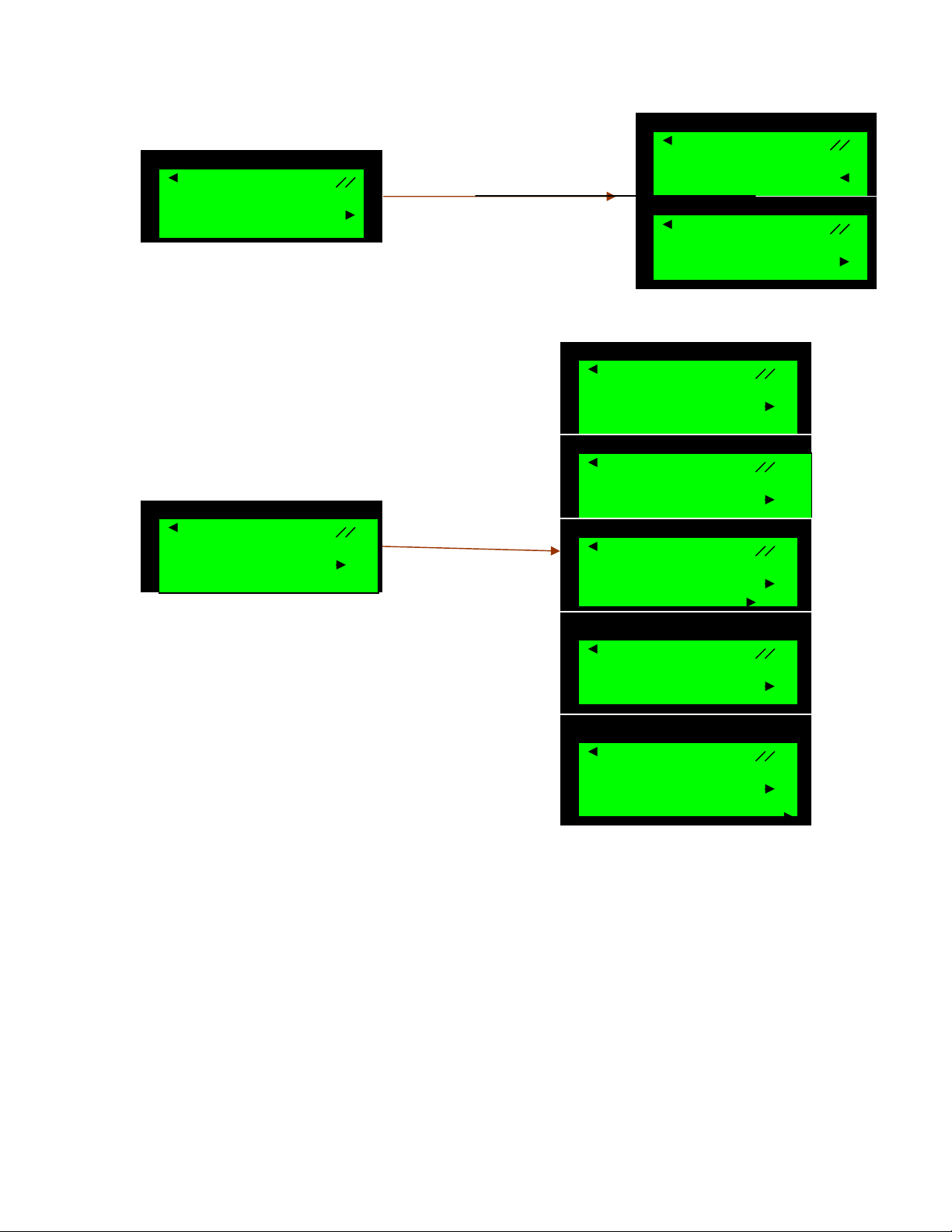

Genset Running

Battle Shot

Battle Shot

Main menu

Battle Shot

Main Menu

Hours Flt 1

Hours Flt 2

Hours Flt 3

Hours Flt 4

Hours Flt 5

Flt History

*Inactive

Active

0000.00 212

0002.10 002

0002.09 215

0002.00 074

0001.88 213

- 19 -

Ok

Reset

No Navigation is needed

To enter into CALIBRATION MODE-

Press

For 5 Sec

Entering into the

Config Mode…

SW PART 3267727

SW VER 1.01

Meter calibration screens

Keys Action

will increase the voltage value

will decrease the voltage value

will calibrate next value

will calibrate previous value

- 20 -

Loading...

Loading...