CUMMINS Power Generation DQFAA, Power Generation DQFAC, Power Generation DQFAB, Power Generation DQFAD Installation Manual

InstallationInstallation ManualManual

Generator Set

QST30-G5 Engine with PowerCommand®3.3 Control

DQFAA (Spec G-K)

DQFAB (Spec G-K)

DQFAC (Spec G-K)

DQFAD (Spec G-K)

English

Original Instructions 6-2019 A053U867 (Issue 5)

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS ....................................................................................... 1

1.1 Warning, Caution, and Note Styles Used in This Manual ..................................................... 1

1.2 General Information ................................................................................................................ 1

1.2.1 General Safety Precautions ......................................................................................... 2

1.3 Generator Set Safety Code .................................................................................................... 5

1.3.1 Generator Set Operating Areas ................................................................................... 5

1.3.2 Moving Parts Can Cause Severe Personal Injury or Death ........................................ 5

1.3.3 Positioning of Generator Set....................................................................................... 6

1.4 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death.................. 6

1.4.1 Locking the Generator Set Out of Service ................................................................... 7

1.4.2 AC Supply and Isolation............................................................................................... 8

1.4.3 AC Disconnect Sources ............................................................................................... 8

1.5 Fuel and Fumes Are Flammable ............................................................................................ 8

1.5.1 Spillage ....................................................................................................................... 9

1.5.2 Fluid Containment....................................................................................................... 9

1.5.3 Do Not Operate in Flammable and Explosive Environments ...................................... 9

1.6 Exhaust Gases Are Deadly..................................................................................................... 9

1.6.1 Exhaust Precautions ................................................................................................... 9

1.7 Earth Ground Connection ..................................................................................................... 10

1.8 Decommissioning and Disassembly ..................................................................................... 11

2. INTRODUCTION.......................................................................................................................... 13

2.1 About This Manual................................................................................................................ 13

2.1.1 Additional Installation Manual Information ................................................................. 13

2.2 Schedule of Abbreviations .................................................................................................... 14

2.3 Related Literature ................................................................................................................. 15

2.3.1 Further Information - Literature .................................................................................. 16

2.4 After Sales Services.............................................................................................................. 16

2.4.1 Maintenance.............................................................................................................. 16

2.4.2 Warranty..................................................................................................................... 16

3. SYSTEM OVERVIEW .................................................................................................................. 19

3.1 Generator Set Identification .................................................................................................. 19

3.1.1 Nameplate.................................................................................................................. 19

3.1.2 Generator Set Components ....................................................................................... 19

3.2 Generator Set Rating ............................................................................................................ 20

3.3 Derating Factors ................................................................................................................... 20

3.4 Engine Components ............................................................................................................. 21

3.5 System Options..................................................................................................................... 22

3.5.1 Introduction ................................................................................................................ 22

3.5.2 Battery Charger.......................................................................................................... 22

3.5.3 Day Tank.................................................................................................................... 23

iA053U867 (Issue 5) Copyright © 2019 Cummins Inc.

Table of Contents 6-2019

3.5.4 Enclosures ................................................................................................................. 23

3.5.5 Fuel Transfer Pump ................................................................................................... 24

3.5.6 Heaters....................................................................................................................... 25

3.5.7 Remote Radiator Installation ..................................................................................... 26

3.5.8 Relays ........................................................................................................................ 26

3.5.9 Seismic Installation Requirements............................................................................. 26

3.5.10 Sensors.................................................................................................................... 26

4. INSTALLATION OVERVIEW ....................................................................................................... 29

4.1 Application and Installation ................................................................................................... 29

4.2 Safety Considerations........................................................................................................... 29

4.3 Standby Heating Devices...................................................................................................... 29

4.4 Product Modifications............................................................................................................ 30

4.5 De-Rating Factors................................................................................................................ 30

5. SPECIFICATIONS ....................................................................................................................... 31

5.1 Generator Set Specifications ................................................................................................ 31

5.2 Engine Fuel Consumption..................................................................................................... 32

6. INSTALLING THE GENERATOR SET ........................................................................................ 33

6.1 Transportation ....................................................................................................................... 33

6.2 Location ................................................................................................................................ 34

6.3 Moving the Generator Set..................................................................................................... 35

6.3.1 Rigging Instructions.................................................................................................... 36

6.4 Mounting ............................................................................................................................... 37

6.5 Access to Generator Set....................................................................................................... 38

6.6 Seismic Installation Notes..................................................................................................... 38

7. MECHANICAL CONNECTIONS .................................................................................................. 41

7.1 Fuel System .......................................................................................................................... 41

7.1.1 Fuel Return Restrictions (or Pressure) Limit.............................................................. 42

7.1.2 Fuel Line Connections ............................................................................................... 42

7.1.3 Engine Fuel Connections........................................................................................... 43

7.1.4 Supply Tank ............................................................................................................... 44

7.1.5 Fuel Inlet Pressure/Restriction Limit .......................................................................... 45

7.1.6 Day Tank.................................................................................................................... 45

7.1.7 Fuel Transfer Pump ................................................................................................... 46

7.1.8 Fuel Additives............................................................................................................. 46

7.2 Exhaust System .................................................................................................................... 47

7.3 Ventilation and Cooling......................................................................................................... 51

7.4 Vents and Ducts.................................................................................................................... 51

7.5 Dampers ............................................................................................................................... 52

7.6 Air Inlet and Outlet Openings................................................................................................ 52

7.7 Remote Radiator Cooling .................................................................................................... 54

7.7.1 Remote Radiator Installation...................................................................................... 54

7.8 Breakerless Conductor Connections .................................................................................... 55

7.8.1 Overload and Short Circuit Protection of Generator .................................................. 55

ii A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

Table of Contents6-2019

7.8.2 AmpSentry Protective Relay Time-Over Current Characteristic Curve ..................... 57

7.8.3 Coordination of Protective Devices............................................................................ 59

7.8.4 Additional AmpSentry Protective Relay Information .................................................. 59

8. DC CONTROL WIRING ............................................................................................................... 61

8.1 Guidelines for Customer Connections to the Control System .............................................. 61

8.1.1 Digital Connections .................................................................................................... 62

8.1.2 Relay Connections..................................................................................................... 62

8.2 PowerCommand 3.3 Customer Connections ....................................................................... 62

8.2.1 Configurable Outputs ................................................................................................. 62

8.2.2 Remote Start.............................................................................................................. 62

8.2.3 Configurable Inputs.................................................................................................... 63

8.2.4 Remote Emergency Stop........................................................................................... 63

8.3 Customer Relays .................................................................................................................. 63

8.3.1 Location of Customer Relays..................................................................................... 63

9. AC ELECTRICAL CONNECTIONS ............................................................................................. 65

9.1 AC Distribution Panel Connections....................................................................................... 66

9.1.1 AC Distribution Panel................................................................................................. 67

9.2 Transfer Switch ..................................................................................................................... 68

9.3 Alternator Voltage Connections ............................................................................................ 69

9.4 Load Connections ................................................................................................................. 70

9.4.1 Generator Set Load Cable Installation....................................................................... 70

9.4.2 Cabling through Non-Ferrous Gland Plates............................................................... 70

9.4.3 Cabling through Ferrous Gland Plates ...................................................................... 70

9.4.4 Distribution Cables..................................................................................................... 70

9.5 Installation of s-CAN Network Cable .................................................................................... 71

9.6 Load Balancing ..................................................................................................................... 73

9.7 Fuel Transfer Pump Installation............................................................................................ 73

9.7.1 Fuel Transfer Pump Control AC Connections ........................................................... 73

9.8 Current Transformers............................................................................................................ 75

9.9 Coolant Heater...................................................................................................................... 75

9.10 Alternator Heaters............................................................................................................... 75

9.10.1 Alternator Heater Connection .................................................................................. 75

9.11 Control Box Heater ............................................................................................................. 75

9.11.1 Control Box Heater Installation ................................................................................ 75

9.12 Battery Commissioning ....................................................................................................... 76

9.12.1 Safety Precautions................................................................................................... 77

9.12.2 Pre-Commissioning Procedure ................................................................................ 78

9.12.3 Filling the Battery with Electrolyte............................................................................ 78

9.12.4 Charging - Commissioning ...................................................................................... 78

9.12.5 Connecting the Battery to the Generator Set........................................................... 79

9.12.6 Electrolyte - Specific Gravity and Temperature ....................................................... 79

9.13 Battery Charger................................................................................................................... 81

9.13.1 PowerCommand Battery Charger - 15 Amp at 12 Volt and 12 Amp at 24 Volt....... 81

9.14 Grounding ........................................................................................................................... 82

iiiA053U867 (Issue 5) Copyright © 2019 Cummins Inc.

Table of Contents 6-2019

10. PRE-START PREPARATION..................................................................................................... 85

10.1 Initial Pre-start Checks........................................................................................................ 85

10.2 Electrical System ................................................................................................................ 86

10.3 Battery Connections............................................................................................................ 86

10.4 Site-Specific Configuration.................................................................................................. 87

10.5 Starting................................................................................................................................ 87

11. INSTALLATION CHECKLIST ..................................................................................................... 89

11.1 Checklist ............................................................................................................................. 89

12. MANUFACTURING FACILITIES ................................................................................................ 93

12.1 How to Obtain Service ....................................................................................................... 93

12.1.1 Locating a Distributor ............................................................................................... 93

APPENDIX A. ALTERNATOR RECONNECT DRAWING ................................................................ 95

A.1 Alternator Reconnect Drawing.............................................................................................. 97

A.2 Alternator Reconnect Drawing.............................................................................................. 99

APPENDIX B. CUSTOMER CONNECTIONS ................................................................................ 107

B.1 Control Wiring Diagrams (0630-3440)................................................................................ 109

APPENDIX C. OUTLINE DRAWINGS ............................................................................................ 121

C.1 Generator Set Outline Drawing (A053G789) - Set Mounted Radiator............................... 123

C.2 Generator Set Outline Drawing (A049K674) - Set Mounted Radiator ............................... 127

C.3 Generator Set Outline Drawing (A062H932) - Set Mounted Radiator ............................... 131

C.4 Generator Set Outline Drawing (A053G787) - Remote Radiator....................................... 135

C.5 Generator Set Outline Drawing (A062M281) - Remote Radiator....................................... 140

APPENDIX D. WIRING DIAGRAMS............................................................................................... 145

D.1 PCC3300 Wiring Diagram (A053C830) ............................................................................. 147

D.2 Outline Drawing and Schematic - Heater........................................................................... 154

D.3 Wiring of Optional Equipment ............................................................................................ 155

APPENDIX E. SEISMIC REQUIREMENTS.................................................................................... 157

E.1 Seismic Installation Instructions (A045K403) ..................................................................... 159

iv A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS. This manual contains important instructions that should be followed

during installation and maintenance of the generator set and batteries.

Safe and efficient operation can be achieved only if the equipment is properly operated and maintained.

Many accidents are caused by failure to follow fundamental rules and precautions.

1.1 Warning, Caution, and Note Styles Used in This Manual

The following safety styles and symbols found throughout this manual indicate potentially hazardous

conditions to the operator, service personnel, or equipment.

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

Indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

1.2 General Information

This manual should form part of the documentation package supplied by Cummins with specific generator

sets. In the event that this manual has been supplied in isolation, please contact your authorized

distributor.

It is in the operator’s interest to read and understand all warnings and cautions contained within

the documentation relevant to the generator set, its operation and daily maintenance.

NOTICE

NOTICE

1A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

1.2.1 General Safety Precautions

WARNING

Hot Pressurized Liquid

Contact with hot liquid can cause severe burns.

Do not open the pressure cap while the engine is running. Let the engine cool down before

removing the cap. Turn the cap slowly and do not open it fully until the pressure has been

relieved.

WARNING

Moving Parts

Moving parts can cause severe personal injury.

Use extreme caution around moving parts. All guards must be properly fastened to prevent

unintended contact.

WARNING

Toxic Hazard

Used engine oils have been identified by some state and federal agencies to cause cancer or

reproductive toxicity.

Do not ingest, breathe the fumes, or contact used oil when checking or changing engine oil.

Wear protective gloves and face guard.

WARNING

Electrical Generating Equipment

Incorrect operation can cause severe personal injury or death.

Do not operate equipment when fatigued, or after consuming any alcohol or drug.

WARNING

Toxic Gases

Substances in exhaust gases have been identified by some state and federal agencies to cause

cancer or reproductive toxicity.

Do not breathe in or come into contact with exhaust gases.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause severe burns or

death.

Do not store fuel, cleaners, oil, etc., near the generator set.

WARNING

High Noise Level

Generator sets in operation emit noise, which can cause hearing damage.

Wear appropriate ear protection at all times.

2 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS6-2019

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is minimized. Wear

appropriate PPE when working on hot equipment and avoid contact with hot surfaces.

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death.

Make sure that only suitably trained and experienced service personnel perform electrical and/or

mechanical service.

WARNING

Toxic Hazard

Ethylene glycol, used as an engine coolant, is toxic to humans and animals.

Wear appropriate PPE. Clean up coolant spills and dispose of used coolant in accordance with

local environmental regulations.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause severe burns or

death.

Do not use combustible liquids like ether.

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the starting battery

cables (negative [–] first).

WARNING

Fire Hazard

Materials drawn into the generator set are a fire hazard. Fire can cause severe burns or death.

Make sure the generator set is mounted in a manner to prevent combustible materials from

accumulating under the unit.

WARNING

Fire Hazard

Accumulated grease and oil are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from obstructions. Repair oil

leaks promptly.

3A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

WARNING

Fall Hazard

Falls can result in severe personal injury or death.

Make sure that suitable equipment for performing tasks at height are used in accordance with

local guidelines and legislation.

WARNING

Fire Hazard

Materials drawn into the generator set are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from obstructions.

WARNING

Pressurized System

Pressurized systems can rupture/leak which can result in severe personal injury or death.

Use appropriate lock out/tag out safety procedures to isolate from all energy sources before

performing any service tasks. Use PPE.

WARNING

Confined Areas

Confined spaces or areas with restricted access or potential to entrap can cause severe personal

injury or death.

Use appropriate lock out/tag out safety procedures to isolate from all energy sources. Use PPE.

Follow site specific lone worker protocols/permits to work.

CAUTION

Manual Handling Heavy Objects

Handling heavy objects can cause severe personal injury.

Use appropriate lifting equipment and perform tasks with two people where doing so would make

completion of the task safe.

CAUTION

Power Tools and Hand Tools

Tools can cause cuts, abrasions, bruising, puncture injuries.

Only trained and experienced personnel should use power tools and hand tools. Use PPE.

CAUTION

Sharp Edges and Sharp Points

Projecting corners/parts may cause cuts, abrasions and other personal injury.

Use PPE. Be aware of sharp edges and corners/sharp points. Cover/protect them.

NOTICE

Keep multi-type ABC fire extinguishers close by. Class A fires involve ordinary combustible

materials such as wood and cloth. Class B fires involve combustible and flammable liquid fuels

and gaseous fuels. Class C fires involve live electrical equipment. (Refer to NFPA No. 10 in the

applicable region.)

4 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

NOTICE

Before performing maintenance and service procedures on enclosed generator sets, make sure

the service access doors are secured open.

NOTICE

Stepping on the generator set can cause parts to bend or break, leading to electrical shorts, or to

fuel leaks, coolant leaks, or exhaust leaks. Do not step on the generator set when entering or

leaving the generator set room.

NOTICE

Remove fuel from subbase fuel tank before conducting any hot work.

1.3 Generator Set Safety Code

Before operating the generator set, read the manuals and become familiar with them and the equipment.

Safe and efficient operation can be achieved only if the equipment is properly operated and maintained.

Many accidents are caused by failure to follow fundamental rules and precautions.

1. IMPORTANT SAFETY INSTRUCTIONS6-2019

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death.

Read and follow all Safety Precautions, Warnings, and Cautions throughout this manual and the

documentation supplied with the generator set.

1.3.1 Generator Set Operating Areas

WARNING

Ejected Debris

Debris ejected during destructive failure can cause serious injury or death by impact, severing or

stabbing.

Do not to stand alongside the engine or alternator while the generator set is running.

• Operators must not stand alongside the engine or alternator while the generator set is running,

unless the risks of doing so have been assessed and adequate mitigation steps have been taken.

• If there are operation/maintenance procedures that require spending time alongside the generator

set when it is running, take every precaution to perform these tasks safely. Keep time spent

performing these tasks to a minimum.

• Be aware of the product environment. Other equipment may be in operation or energized in the

surrounding area.

1.3.2 Moving Parts Can Cause Severe Personal Injury or Death

• Keep hands, clothing, and jewelry away from moving parts.

5A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

• Before starting work on the generator set, disconnect the battery charger from its AC source, then

disconnect the starting batteries using an insulated wrench, negative (–) cable first. This will prevent

accidental starting.

• Make sure that fasteners on the generator set are secure. Tighten supports and clamps; keep

guards in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of moving parts or while working on electrical

equipment. Loose clothing and jewelry can become caught in moving parts.

• If any adjustments must be made while the unit is running, use extreme caution around hot

manifolds, moving parts, etc.

1.3.3 Positioning of Generator Set

The generator set should be placed on level ground with adequate open space around it. The immediate

area around the generator set should be free of any flammable material.

NOTICE

Access or service doors must be closed and locked before repositioning, and they must remain

locked during transportation and siting.

NOTICE

The generator set is capable of operating at inclines of up to +/– 2.5 degrees.

1.4 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death

WARNING

Electric Shock Hazard

Voltages and currents present an electrical shock hazard that can cause severe burns or death.

Contact with exposed energized circuits with potentials of 50 Volts AC or 75 Volts DC or higher

can cause electrical shock and electrical arc flash. Refer to standard NFPA 70E or equivalent

safety standards in corresponding regions for details of the dangers involved and for the safety

requirements.

Guidelines to follow when working on de-energized electrical systems:

• Use proper PPE. Do not wear jewelry and make sure that any conductive items are removed from

pockets as these items can fall into equipment and the resulting short circuit can cause shock or

burning. Refer to standard NFPA 70E for PPE standards.

• De-energize and lockout/tagout electrical systems prior to working on them. Lockout/Tagout is

intended to prevent injury due to unexpected start-up of equipment or the release of stored energy.

Please refer to Locking the Generator Set Out of Service section for more information.

• De-energize and lockout/tagout all circuits and devices before removing any protective shields or

making any measurements on electrical equipment.

• Follow all applicable regional electrical and safety codes.

Guidelines to follow when working on energized electrical systems:

6 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS6-2019

NOTICE

It is the policy of Cummins Inc. to perform all electrical work in a de-energized state. However,

employees or suppliers may be permitted to occasionally perform work on energized electrical

equipment only when qualified and authorized to do so and when troubleshooting, or if deenergizing the equipment would create a greater risk or make the task impossible and all other

alternatives have been exhausted.

NOTICE

Exposed energized electrical work is only allowed as per the relevant procedures and must be

undertaken by a Cummins authorized person with any appropriate energized work permit for the

work to be performed while using proper PPE, tools and equipment.

In summary:

• Do not tamper with or bypass interlocks unless you are authorized to do so.

• Understand and assess the risks - use proper PPE. Do not wear jewelry and make sure that any

conductive items are removed from pockets as these items can fall into equipment and the resulting

short circuit can cause shock or burning. Refer to standard NFPA 70E for PPE standards.

• Make sure that an accompanying person who can undertake a rescue is nearby.

1.4.1 Locking the Generator Set Out of Service

Before any work is carried out for maintenance, etc., the generator set must be immobilized. Even if the

generator set is put out of service by pressing the Off switch on the operator panel, the generator set

cannot be considered safe to work on until the engine is properly immobilized, as detailed in the following

procedures.

NOTICE

Refer also to the engine specific Operator Manual. This manual contains specific equipment

instructions that may differ from the standard generator set.

1.4.1.1 Immobilizing for Safe Working

To immobilize the generator set:

1. Press the Off mode switch on the operator panel to shut down the generator set.

2. Press the Emergency Stop button. This prevents the generator set starting, regardless of the Start

signal source and provides an additional safety step for immobilizing the generator set.

NOTICE

When the Emergency Stop button is pressed, the operator panel indicates a Shutdown

condition. The red Shutdown status LED illuminates and a message is displayed.

NOTICE

This condition is stored in the Fault History.

3. As an additional precaution, thoroughly ventilate the plant room before disconnecting any leads.

4. Isolate and lock off the supply to the heater, where fitted.

7A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

5. Isolate and lock off the supply to the battery charger, where fitted.

6. Isolate the fuel supply to the engine.

7. Using an insulated wrench, disconnect the negative (–) cable first on the starting batteries and

control system batteries (if separate).

8. Fit warning notices at each of the above points to indicate Maintenance in Progress – Plant

Immobilized for Safe Working.

1.4.2 AC Supply and Isolation

NOTICE

Local electrical codes and regulations (for example, BS EN 12601:2010 Reciprocating internal

combustion engine driven generating sets) may require the installation of a disconnect means

for the generator set, either on the generator set or where the generator set conductors enter a

facility.

NOTICE

The AC supply must have the correct over current and earth fault protection according to local

electrical codes and regulations. This equipment must be earthed (grounded).

It is the sole responsibility of the customer to provide AC power conductors for connection to load devices

and the means to isolate the AC input to the terminal box; these must comply with local electrical codes

and regulations. Refer to the wiring diagram supplied with the generator set.

The disconnecting device is not provided as part of the generator set, and Cummins accepts no

responsibility for providing the means of isolation.

1.4.2.1 AmpSentry

Generator sets with PC 3.3 control utilize AmpSentry™ protective relay which includes integral AC

protective functions for the alternator and conductors, if conductors are rated for operation at a minimum

of 100% of the generator nameplate rating.

1.4.3 AC Disconnect Sources

WARNING

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or death.

The equipment may have more than one source of electrical energy. Disconnecting one source

without disconnecting the others presents a shock hazard. Before starting work, disconnect the

equipment, and verify that all sources of electrical energy have been removed.

1.5 Fuel and Fumes Are Flammable

Fire, explosion, and personal injury or death can result from improper practices.

• Do not fill fuel tanks while the engine is running unless the tanks are outside the engine

compartment. Fuel contact with hot engine or exhaust is a potential fire hazard.

• Do not permit any flame, cigarette, pilot light, spark, arcing equipment, or other ignition source near

the generator set or fuel tank.

8 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

• Fuel lines must be adequately secured and free of leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use copper piping on flexible lines as copper will

become brittle if continuously vibrated or repeatedly bent.

• Make sure all fuel supplies have a positive shutoff valve.

• Make sure the battery area has been well-ventilated prior to servicing near it. Lead-acid batteries

emit a highly explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

1.5.1 Spillage

Any spillage that occurs during fueling, oil top-off, or oil change must be cleaned up before starting the

generator set.

1.5.2 Fluid Containment

Where spillage containment is not part of a Cummins supply, it is the responsibility of the

installer to provide the necessary containment to prevent contamination of the environment,

especially water courses and sources.

If fluid containment is incorporated into the bedframe, it must be inspected at regular intervals. Any liquid

present should be drained out and disposed of in line with local health and safety regulations. Failure to

perform this action may result in spillage of liquids which could contaminate the surrounding area.

1. IMPORTANT SAFETY INSTRUCTIONS6-2019

NOTICE

Any other fluid containment area must also be checked and emptied, as described above.

1.5.3 Do Not Operate in Flammable and Explosive Environments

Flammable vapor can cause an engine to over speed and become difficult to stop, resulting in possible

fire, explosion, severe personal injury, and death. Do not operate a generator set where a flammable

vapor environment can be created, unless the generator set is equipped with an automatic safety device

to block the air intake and stop the engine. The owners and operators of the generator set are solely

responsible for operating the generator set safely. Contact your authorized Cummins distributor for more

information.

1.6 Exhaust Gases Are Deadly

• Provide an adequate exhaust system to properly expel discharged gases away from enclosed or

sheltered areas, and areas where individuals are likely to congregate. Visually and audibly inspect

the exhaust system daily for leaks per the maintenance schedule. Make sure that exhaust manifolds

are secured and not warped. Do not use exhaust gases to heat a compartment.

• Make sure the unit is well ventilated.

1.6.1 Exhaust Precautions

WARNING

Hot Exhaust Gases

Contact with hot exhaust gases can cause severe burns.

Wear personal protective equipment when working on equipment.

9A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is minimized. Wear

appropriate PPE when working on hot equipment and avoid contact with hot surfaces.

WARNING

Toxic Gases

Inhalation of exhaust gases can cause asphyxiation and death.

Pipe exhaust gas outside and away from windows, doors, or other inlets to buildings. Do not

allow exhaust gas to accumulate in habitable areas.

WARNING

Fire Hazard

Contaminated insulation is a fire hazard. Fire can cause severe burns or death.

Remove any contaminated insulation and dispose of it in accordance with local regulations.

The exhaust outlet may be sited at the top or bottom of the generator set. Make sure that the exhaust

outlet is not obstructed. Personnel using this equipment must be made aware of the exhaust position.

Position the exhaust away from flammable materials - in the case of exhaust outlets at the bottom, make

sure that vegetation is removed from the vicinity of the exhaust.

The exhaust pipes may have some insulating covers fitted. If these covers become contaminated they

must be replaced before the generator set is run.

To minimize the risk of fire, make sure the following steps are observed:

• Make sure that the engine is allowed to cool thoroughly before performing maintenance or operation

tasks.

• Clean the exhaust pipe thoroughly.

1.7 Earth Ground Connection

The neutral of the generator set may be required to be bonded to earth ground at the generator set

location, or at a remote location, depending on system design requirements. Consult the engineering

drawings for the facility or a qualified electrical design engineer for proper installation.

NOTICE

The end user is responsible to make sure that the ground connection point surface area is clean

and free of rust before making a connection.

NOTICE

The end user is responsible for making sure that an earthing arrangement that is compliant with

local conditions is established and tested before the equipment is used.

10 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS6-2019

1.8 Decommissioning and Disassembly

NOTICE

Decommissioning and disassembly of the generator set at the end of its working life must

comply with local guidelines and legislation for disposal/recycling of components and

contaminated fluids. This procedure must only be carried out by suitably trained and

experienced service personnel. For more information contact your authorized distributor.

11A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

1. IMPORTANT SAFETY INSTRUCTIONS 6-2019

This page is intentionally blank.

12 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

2 Introduction

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or death.

Make sure that only a trained and experienced electrician makes generator set electrical output

connections, in accordance with the installation instructions and all applicable codes.

Electrical Generating Equipment

Faulty electrical generating equipment can cause severe personal injury or death.

Generator sets must be installed, certified, and operated by trained and experienced persons in

accordance with the installation instructions and all applicable codes.

2.1 About This Manual

The purpose of this manual is to provide the users with sound, general information. It is for guidance and

assistance with recommendations for correct and safe procedures. Cummins Inc. cannot accept any

liability whatsoever for problems arising as a result of following recommendations in this manual.

The information contained within the manual is based on information available at the time of going to print.

In line with Cummins Inc. policy of continuous development and improvement, information may change at

any time without notice. The users should therefore make sure that before commencing any work, they

have the latest information available. The latest version of this manual is available on QuickServe Online

(https://quickserve.cummins.com).

WARNING

WARNING

Users are respectfully advised that, in the interests of good practice and safety, it is their responsibility to

employ competent persons to carry out any installation work. Consult your authorized distributor for further

installation information. It is essential that the utmost care is taken with the application, installation, and

operation of any engine due to their potentially hazardous nature. Careful reference should also be made

to other Cummins Inc. literature. A generator set must be operated and maintained properly for safe and

reliable operation.

For further assistance, contact your authorized distributor.

2.1.1 Additional Installation Manual Information

The purpose of this manual is to provide the Installation Engineer with sound, general information for the

installation of the generator set. Refer to the Generator Set Operator Manual for additional information

which must also be read before operating the set.

This manual provides installation instructions for the generator set models listed on the front cover. This

includes the following information:

• Mounting Recommendations - for fastening the generator set to a base and space requirements

for normal operation and service.

• Mechanical and Electrical Connections - covers most aspects of the generator set installation.

• Prestart - checklist of items or procedures needed to prepare the generator set for operation.

• Installation Checklist - reference checks upon completion of the installation.

13A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

2. Introduction 6-2019

This manual DOES NOT provide application information for selecting a generator set or designing the

complete installation. If it is necessary to design the various integrated systems (fuel, exhaust, cooling,

etc.), additional information is required. Review standard installation practices. For engineering data

specific to the generator set, refer to the Specification and Data Sheets. For application information, refer

to Application Manual T-030, "Liquid Cooled Generator Sets." To find this manual online:

1. Go to powersuite.cummins.com

2. Click on "Login" on the Home page.

3. Click on "Library".

4. Click on "Technical Documents".

5. Click on "Technical information".

6. Click on "Liquid Cooled Genset Application Manual".

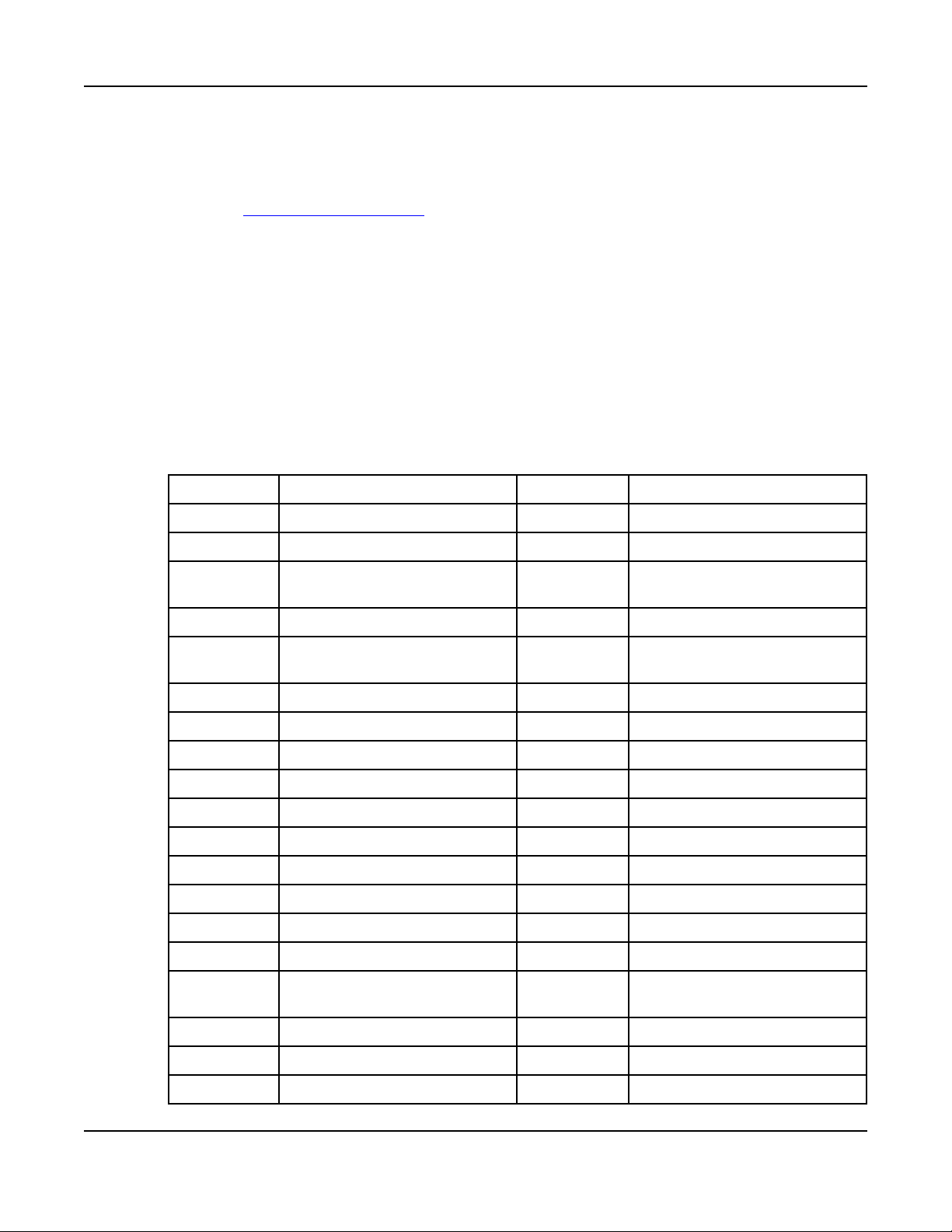

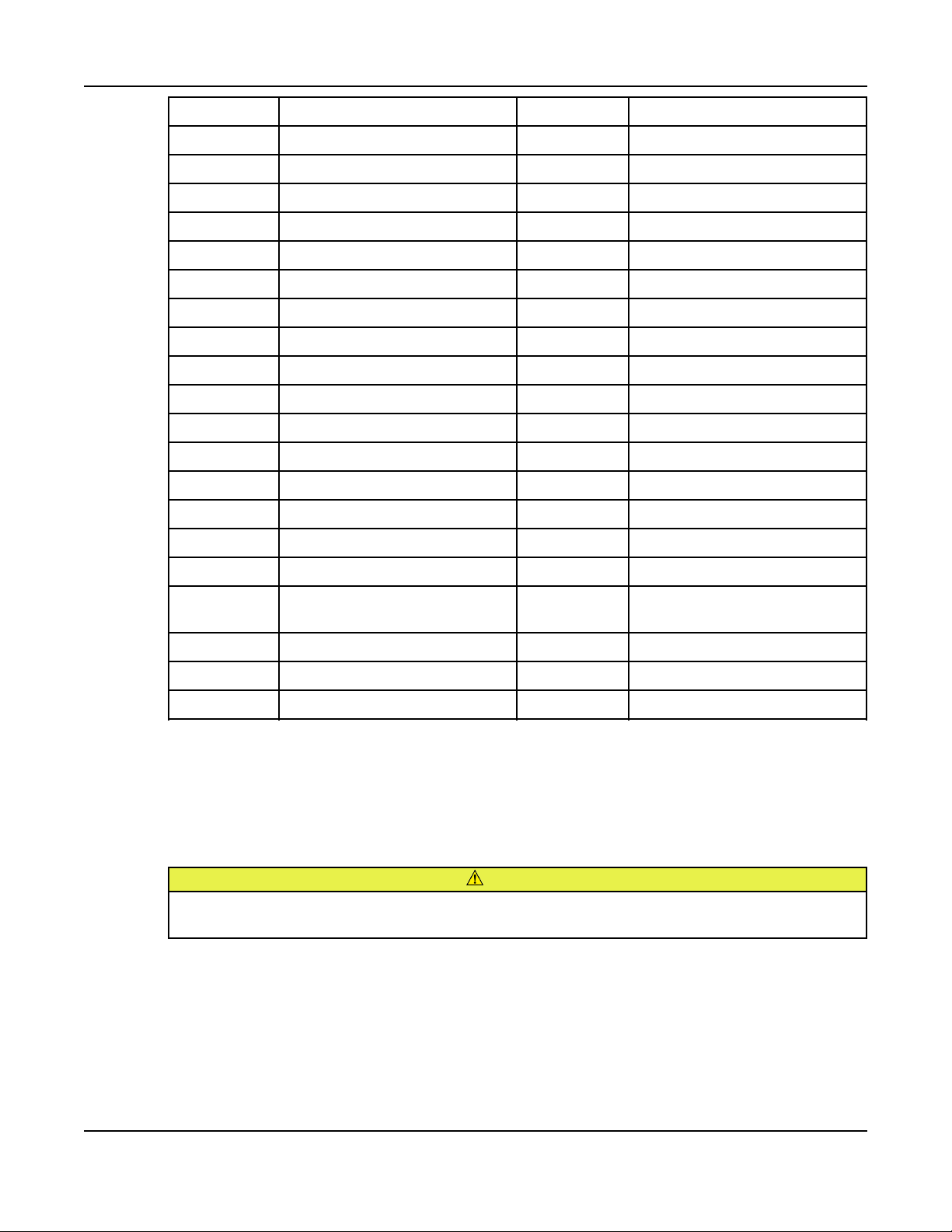

2.2 Schedule of Abbreviations

This list is not exhaustive. For example, it does not identify units of measure or acronyms that appear only

in parameters, event/fault names, or part/accessory names.

ABBR. DESCRIPTION ABBR. DESCRIPTION

AC Alternating Current LED Light-emitting Diode

AMP AMP, Inc., part of Tyco Electronics LTS Long Term Storage

ANSI American National Standards

Institute

ASOV Automatic Shut Off Valve MFM Multifunction Monitor

ASTM American Society for Testing and

Materials (ASTM International)

ATS Automatic Transfer Switch MLD Masterless Load Demand

AVR Automatic Voltage Regulator NC Normally Closed

AWG American Wire Gauge NC Not Connected

CAN Controlled Area Network NFPA National Fire Protection Agency

CB Circuit Breaker NO Normally Open

CE Conformité Européenne NWF Network Failure

CFM Cubic Feet per Minute OEM Original Equipment Manufacturer

CGT Cummins Generator Technologies OOR Out of Range

CMM Cubic Meters per Minute OORH / ORH Out of Range High

CT Current Transformer OORL / ORL Out of Range Low

LVRT Low Voltage Ride Through

Mil Std Military Standard

D-AVR Digital Automatic Voltage

Regulator

DC Direct Current PCC PowerCommand®Control

DEF Diesel Exhaust Fluid PGI Power Generation Interface

DPF Diesel Particulate Filter PGN Parameter Group Number

PB Push Button

14 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

2. Introduction6-2019

ABBR. DESCRIPTION ABBR. DESCRIPTION

ECM Engine Control Module PI Proportional/Integral

ECS Engine Control System PID Proportional / Integral / Derivative

EMI Electromagnetic interference PLC Programmable Logic Controller

EN European Standard PMG Permanent Magnet Generator

EPS Engine Protection System PPE Personal Protective Equipment

E-Stop Emergency Stop PT Potential Transformer

FAE Full Authority Electronic PTC Power Transfer Control

FMI Failure Mode Identifier PWM Pulse-width Modulation

FRT Fault Ride Through RFI Radio Frequency Interference

FSO Fuel Shutoff RH Relative Humidity

Genset Generator Set RMS Root Mean Square

GCP Generator Control Panel RTU Remote Terminal Unit

GND Ground SAE Society of Automotive Engineers

LCT Low Coolant Temperature SCR Selective Catalytic Reduction

HMI Human-machine Interface SPN Suspect Parameter Number

IC Integrated Circuit SWL Safe Working Load

ISO International Organization for

Standardization

LBNG Lean-burn Natural Gas UL Underwriters Laboratories

LCD Liquid Crystal Display UPS Uninterruptible Power Supply

2.3 Related Literature

Before any attempt is made to operate the generator set, the operator should take time to read all of the

manuals supplied with the generator set, and to familiarize themselves with the warnings and operating

procedures.

A generator set must be operated and maintained properly if you are to expect safe and reliable

operation. The Operator manual includes a maintenance schedule and a troubleshooting guide.

SW_B+ Switched B+

VPS Valve Proving System

CAUTION

The relevant manuals appropriate to your generator set are also available:

• Operator Manual for DQFAA, DQFAB, DQFAC, and DQFAD Generator Sets with PowerCommand

3.3 Controller (A053U864)

• Installation Manual for DQFAA, DQFAB, DQFAC, and DQFAD Generator Sets with

PowerCommand®3.3 Controller (A053U867)

• Service Manual for DQFAA, DQFAB, DQFAC, and DQFAD Generator Sets with PowerCommand

3.3 Controller (A053U869)

15A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

®

®

2. Introduction 6-2019

• Parts Manual for DQFAA, DQFAB, DQFAC, and DQFAD Generator Sets with PowerCommand®3.3

Controller (961-0211)

• Service Manual for PowerCommand®3.3 Controller (960-0670)

• Alternator Service Manual for HC Alternator (A040J849)

• Alternator Service Manual for P7 Alternator (A040J850)

• Common Manual for Preventative Maintenance Requirements for High Range Standby Diesel

Generator Sets (A035G976)

• Engine Operator and Maintenance Manual for QST30-G5 Engine (3666134)

• Specification and Data Sheets

• Application Manual T-030: Liquid Cooled Generator Sets (A040S369)

• Parts Manual for HC Alternator (0900-9914)

• Parts Manual for P7 Alternator (0900-9912)

• Standard Repair Times - CJ Family (A029C347)

• Fuels for Cummins Engines Service Bulletin (3379001)

• Emissions Warranty Statement (A043G561)

• Warranty Manual (A040W374)

• Global Commercial Warranty Statement (A028U870)

2.3.1 Further Information - Literature

Contact your authorized distributor for more information regarding related literature for this product.

2.4 After Sales Services

Cummins offers a full range of maintenance and warranty services.

2.4.1 Maintenance

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death.

Make sure that only suitably trained and experienced service personnel perform electrical and/or

mechanical service.

For expert generator set service at regular intervals, contact your local distributor. Each local distributor

offers a complete maintenance contract package covering all items subject to routine maintenance,

including a detailed report on the condition of the generator set. In addition, this can be linked to a 24-hour

call-out arrangement, providing year-round assistance if necessary. Specialist engineers are available to

maintain optimum performance levels from generator sets. Maintenance tasks should only be undertaken

by trained and experienced technicians provided by your authorized distributor.

2.4.2 Warranty

For details of the warranty coverage for your generator set, refer to the Global Commercial Warranty

Statement listed in the Related Literature section.

16 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

In the event of a breakdown, prompt assistance can normally be given by factory trained service

technicians with facilities to undertake all minor and many major repairs to equipment on site.

Extended warranty coverage is also available.

For further warranty details, contact your authorized service provider.

Damage caused by failure to follow the manufacturer's recommendations will not be covered by

the warranty. Please contact your authorized service provider.

2.4.2.1 Warranty Limitations

For details of the warranty limitations for your generator set, refer to the warranty statement applicable to

the generator set.

2. Introduction6-2019

NOTICE

17A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

2. Introduction 6-2019

This page is intentionally blank.

18 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

3 System Overview

This section provides an overview of the generator set.

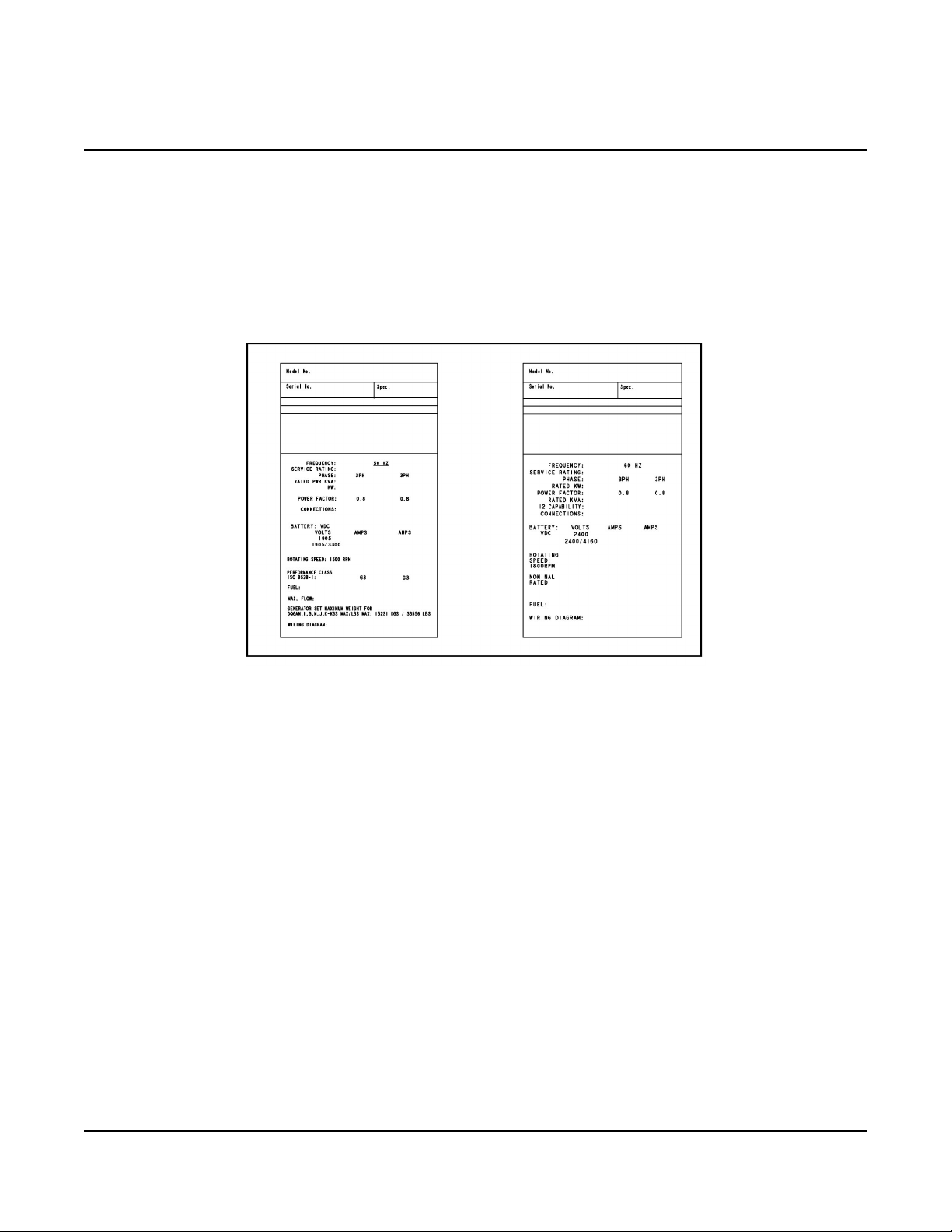

3.1 Generator Set Identification

Each generator set is provided with a nameplate similar to that shown below. The nameplate provides

information unique to the generator set.

3.1.1 Nameplate

FIGURE 1. TYPICAL GENERATOR SET NAMEPLATE

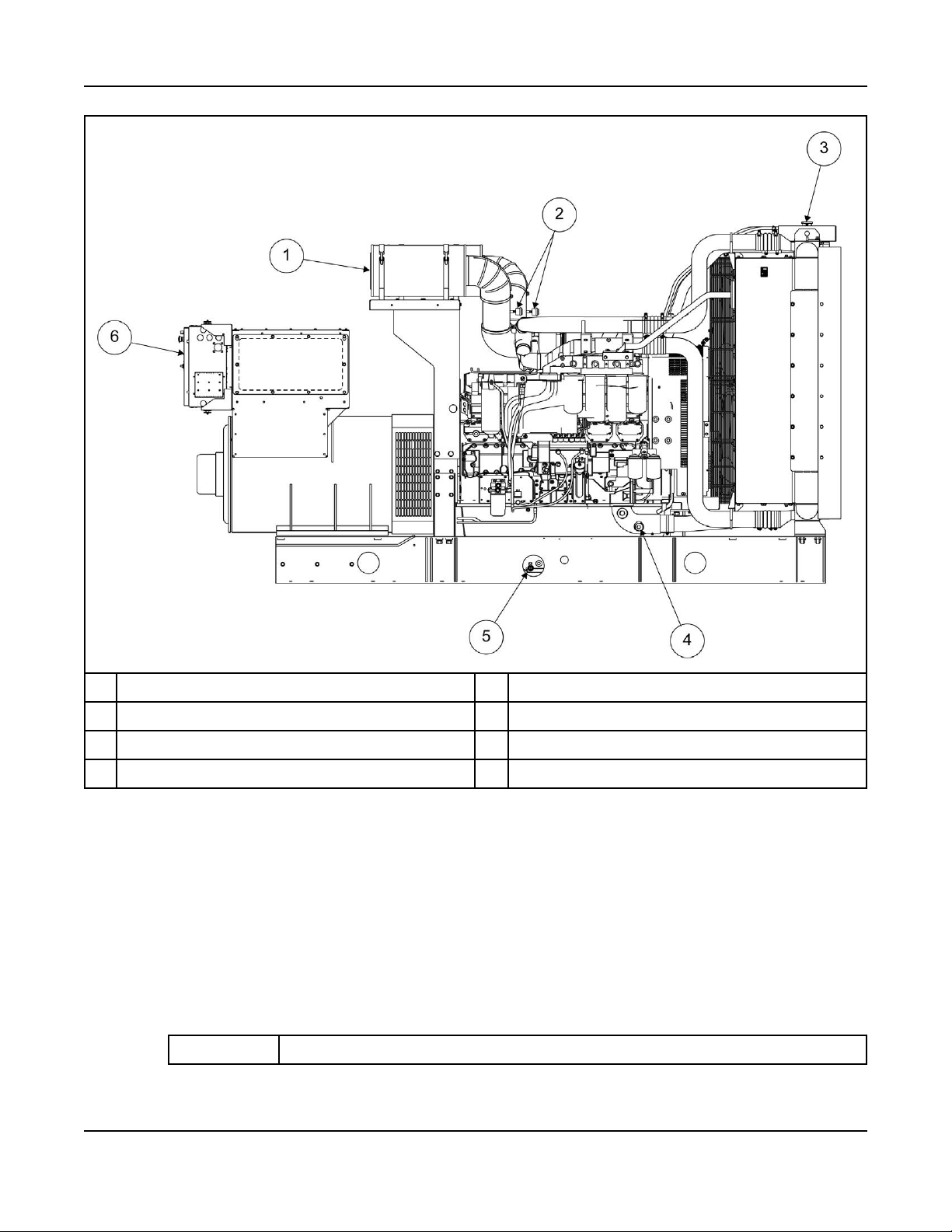

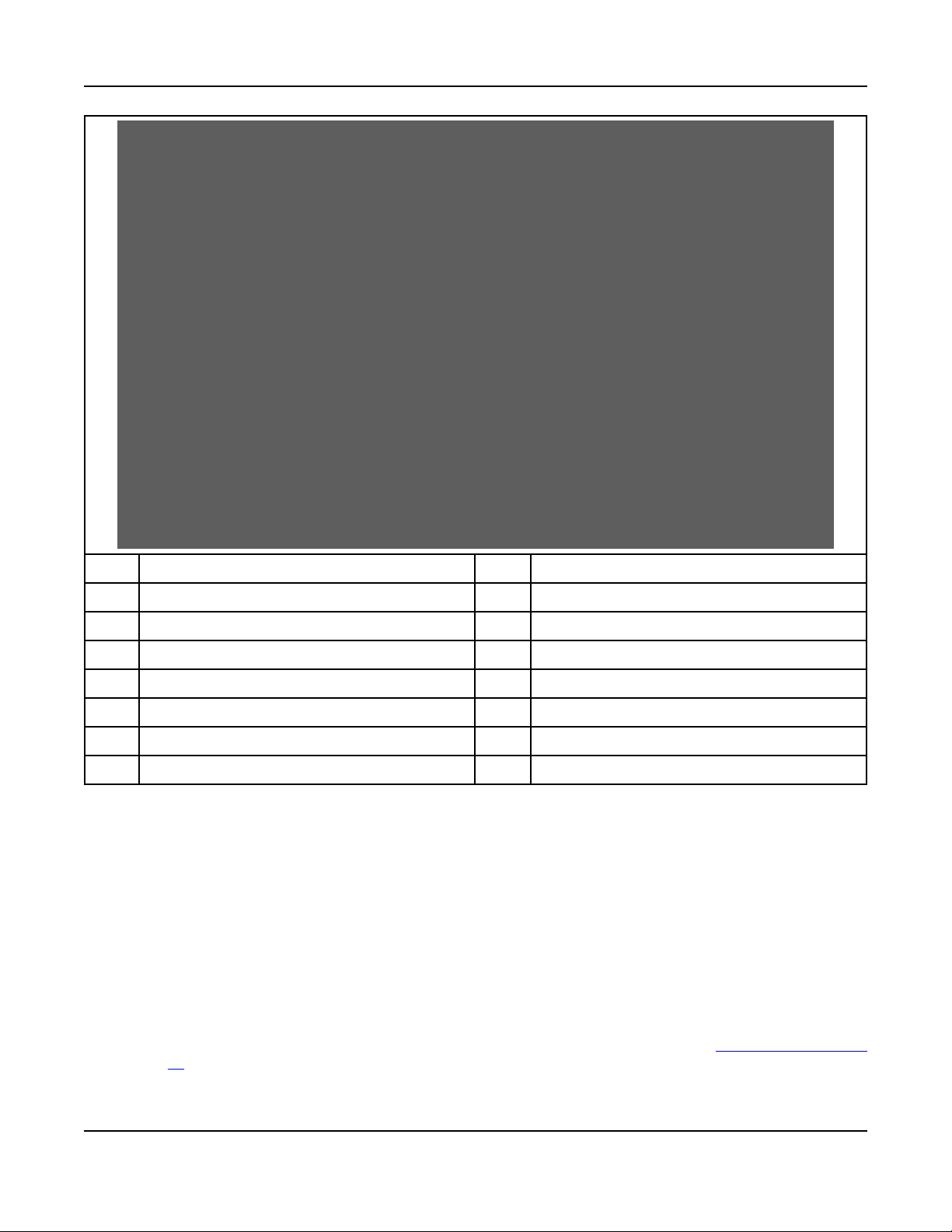

3.1.2 Generator Set Components

The main components of a QST30-G5 engine generator set are shown below, and referred to within this

section.

There are various options listed although they may not be available for all models.

19A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

3. System Overview 6-2019

No Description No Description

1 Air Cleaners 4 Coolant Drain

2 Air Cleaner Service Indicators 5 Oil Drain

3 Radiator Cap 6 Control Panel

FIGURE 2. GENERATOR SET COMPONENTS

3.2 Generator Set Rating

For details of the generator set rating, refer to the generator set nameplate. For operation at temperatures

or altitudes above those stated on the nameplate, a derate may be necessary.

3.3 Derating Factors

TABLE 1. DQFAA DERATING FACTOR

Application Derating Factor

20 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

3. System Overview6-2019

Prime Engine power available up to 3150 m (10335 ft) at ambient temperatures up to 40 °C

(104 °F) and 2630 m (8628 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F).

Standby Engine power available up to 3200 m (10500 ft) at ambient temperatures up to 40 °C

(104 °F) and 2200 m (7217 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F).

TABLE 2. DQFAB DERATING FACTOR

Application Derating Factor

Prime Engine power available up to 2660 m (8727 ft) at ambient temperatures up to 40 °C

(104 °F) and 2090 m (6856 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F)

Standby Engine power available up to 2700 m (8858 ft) at ambient temperatures up to 40 °C

(104 °F) and 1655 m (5429 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F)

TABLE 3. DQFAC DERATING FACTOR

Application Derating Factor

Prime Engine power available up to 1650 m (5413 ft) at ambient temperatures up to 40 °C

(104 °F) and 975 m (3198 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F).

Standby Engine power available up to 1720 m (5643 ft) at ambient temperatures up to 40 °C

(104 °F) and 595 m (1952 ft) at ambient temperatures up to 50 °C (122 °F). Above

these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18 °F)

TABLE 4. DQFAD DERATING FACTOR

Application Derating Factor

Prime Engine power available up to 727 m (2385 ft) at ambient temperatures up to 40 °C (104

°F). Above these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18

°F).

Standby Engine power available up to 701 m (2300 ft) at ambient temperatures up to 40 °C (104

°F). Above these elevations, derate at 3.5% per 305 m (1000 ft) and 7% per 10 °C (18

°F).

3.4 Engine Components

For additional engine specific information, refer to the relevant engine manual for the generator set.

21A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

3. System Overview 6-2019

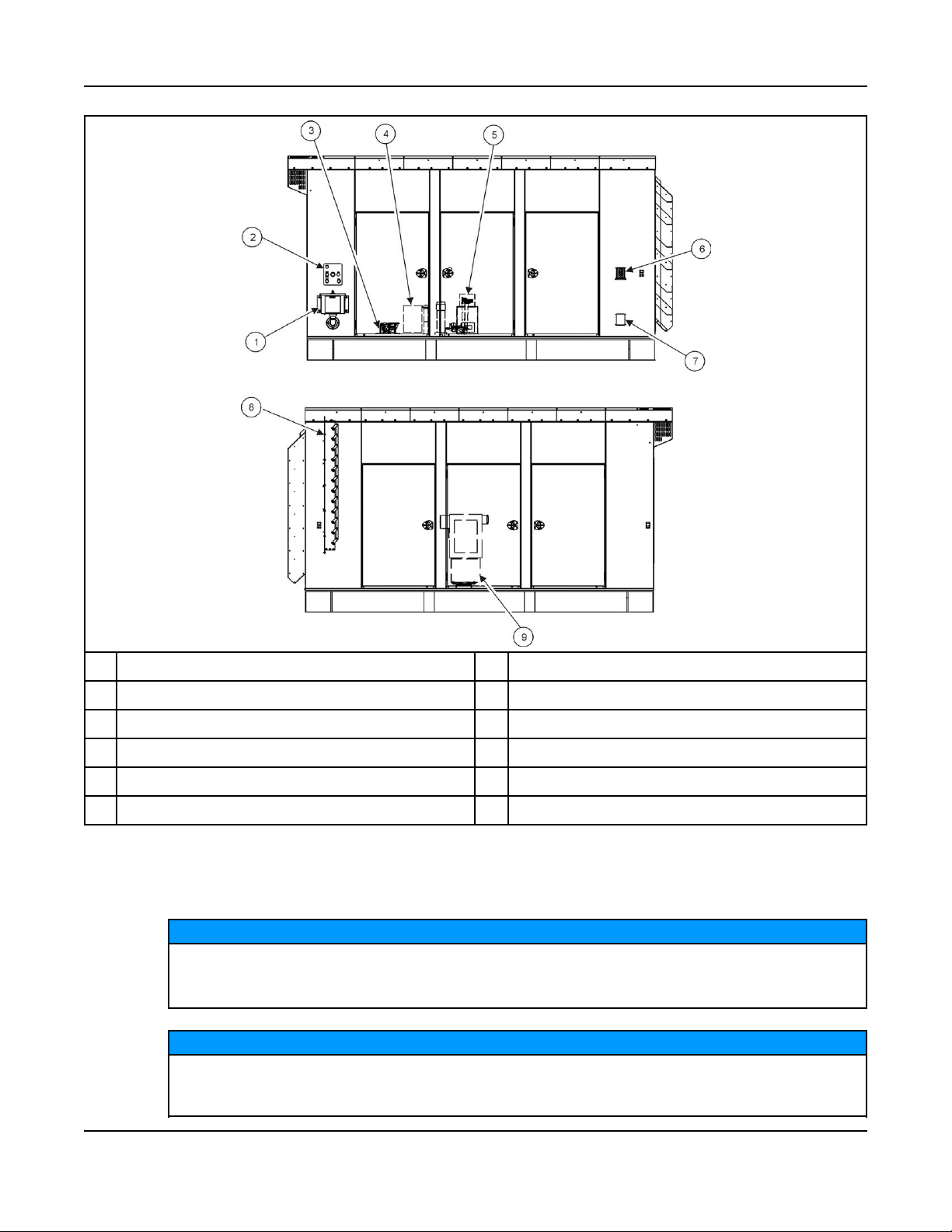

No. Description No. Description

1 Crankcase Breather Tube (each side) 8 Fuel system

2 Thermostat Housing 9 Fuel Outlet

3 Temperature Sender 10 Oil Pan

4 Water Outlet Connection 11 Oil Drain

5 Exhaust Outlet 12 Oil Fill

6 Magnetic Switch 13 Oil Check

7 Starting Motor 14 Water Inlet Connection

FIGURE 3. ENGINE COMPONENTS

3.5 System Options

3.5.1 Introduction

This section provides information for system options that require installation or customer connections

before commissioning the generator set. For more information regarding system options, refer to the

operator and service manual.

3.5.2 Battery Charger

Battery chargers can be wall, bench, or skid mounted. For more information, see Section 9.13 on page

81.

22 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

3.5.3 Day Tank

Some generator set installations include a fuel day tank. For more information, refer to Section 7.1.6 on

page 45.

3.5.4 Enclosures

Enclosed generator sets can require optional features to be electrically connected during installation.

Use flexible conduit and stranded conductors for connections. Solid copper wire may break

during generator set operation.

3. System Overview6-2019

NOTICE

23A053U867 (Issue 5) Copyright © 2019 Cummins Inc.

3. System Overview 6-2019

No. Description No. Description

1 External Fuel Fill Box 6 Emergency Stop Switch

2 Fuel Alarm Panel 7 120 VAC External Receptacle

3 Overfill Alarm Assembly 8 Motorized Inlet Louver

4 Fuel Fill 9 AC Distribution Panel

5 Fuel System Control

FIGURE 4. TYPICAL OPTIONAL ENCLOSURE FEATURES

3.5.5 Fuel Transfer Pump

NOTICE

Damage to the fuel transfer pump can occur if the pump operates with no fuel in the supply tank.

Do not connect AC power to the fuel transfer pump control without having fuel in the supply

tank.

NOTICE

Power to the fuel transfer pump must be fed from a transfer switch and step-down transformer to

maintain 120V power to the pump when utility power in interrupted. Power must be supplied to

the transfer pump during the time the generator set is running or not running.

24 A053U867 (Issue 5)Copyright © 2019 Cummins Inc.

Loading...

Loading...