Page 1

PowerCommand

Network Installation and Operation Manual

FT−10

English

Original Instructions 5-2017 0900−0529 (Issue 3)

Page 2

Page 3

Table of Contents

SECTION TITLE PAGE

Safety Precautions xi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Background 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Installation Tools 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New and Old Versions of LonMaker 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Obtain Service 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Network Hardware and Wiring 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Configuration 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Description 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Protocol 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Neuron Chip 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PowerCommand Controls 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Modules 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset Communications Module (GCM) 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset LonWorks Card (GLC) 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset Network Communications Module (NCM) − PCC 2100 Control 2-4 . . . . .

Network Communications Module (NCM) − PowerCommand ATS 2-4 . . . . . . . . .

Digital I/O Module (DIM) 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLTA-10 Gateway 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction Box/Terminator 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonWorks System Annunciator (LSA) 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls Communications Module

for Generator Set and Transfer Switch Monitoring 2-5 . . . . . . . . . . . . . . . . . . . . . . .

Network Router 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Etherlon Router 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ModLon II Gateway 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transmission Media 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectors and Wire Color Codes 2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Guidelines 2-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Power 2-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Network Power Configuration and Wire Size 2-12 . . . . . . . . . . . . . . . . . . . .

3. Self-Installation 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation Guidelines 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Annunciation and Custom Relay Events − PowerCommand Controls 3-1

Self-Installation 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Using LonMaker for Windows 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPG Network Support Files 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Support Files Installation Instructions 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Copyright 2017 Cummins Inc.

Page 4

Configuration Plug-In Installation Instructions 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using LonMaker 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting LonMaker 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding the CPG Device Stencil 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding a Device to the Network 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding Bindings 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the Drawing and Commissioning Devices 4-10 . . . . . . . . . . . . . . . . . . . . . . . .

Registering Plug-Ins 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the LonMaker Browser 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Software Upgrades to an Existing Network 4-14 . . . . . . . . . . . . . . . . . . . . . .

If Both the .nxe and .xif Files Have Changed: 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . .

If Only the .nxe File Has Changed: 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing FT-10 Networks for Both Local and Remote Monitoring 4-15 . . . . . . . . . . .

5. Device Configuration Using LonMaker Plug-Ins 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Plug-Ins 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonWorks System Annunciator (LSA) 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Control Communications Module (CCM-G) 5-2 . . . . . . . . . . . . . . . . .

CCM − Volts 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Amps 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Relays 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Out 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Analog Inputs 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Temperature 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Oil Pressure 5-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Spare 1, Spare 2, Spare 3 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Discrete Inputs 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 3100 Genset Communications Module (GCM) 5-7 . . . . . . . . . . . . . . . . . . . . . . .

Using the Plug-In on a Self-Installed GCM 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Out 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Codes 5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 3200 Genset LonWorks Card (GLC), PCC 2100 Network Communications Module

(NCM), and PowerCommand ATS NCM 5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dial Out 5-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Device Configuration Using InPower 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Configuration 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 3200 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Annunciation 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Outputs 6-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device 6-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialout 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Settings 6-6 .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 3200 Events Configuration 6-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 2100 6-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Annunciation 6-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Relay Events 6-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device 6-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialout 6-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Settings 6-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 2100 Events and Faults Configuration 6-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2017 Cummins Inc.

ii

Page 5

PC ATS 6-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC ATS Event Configuration 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Connection Setup 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gateway Driver Installation and Setup 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gateway Settings 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Settings 6-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing the Network Site Database 6-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Network Site Setup 6-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Network Site Setup 6-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

InPower Communications Setup 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Connection Example 6-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Dialout 6-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Device Monitoring Using PowerCommand for Windows II 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LNS Server Installation 7-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gateway Driver Installation and Setup 7-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gateway Module Settings 7-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Settings 7-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialing Configuration for Alarms 7-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling the Monitoring PC to Receive Remote Alarms 7-6 . . . . . . . . . . . . . . . . . .

Importing the Network Site Database 7-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare the Network Site Database File for PCW II 7-7 . . . . . . . . . . . . . . . . . . . . . .

Local Network Site Setup Example 7-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Setup 7-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create Site 7-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Network Site Setup Example 7-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Setup 7-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create Site 7-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Setup Network Site Example 7-10 . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Genset Communications Module used with PCC 3100 Controls 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 8-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 8-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Required 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Handling Precautions 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 8-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 8-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 8-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 8-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 8-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 8-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 8-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 8-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the GCM 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GCM Connections 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology, Data Media, and Network Power 8-7 . . . . . . . . . . . . . . . . . . . . . .

Network Data Media and Power Wiring 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TB1 Connections 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conduit 8-7 .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Copyright 2017 Cummins Inc.

Page 6

Switches and LEDs 8-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 8-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 8-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Genset LonWorks Card used with PCC 3200 Controls 9-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 9-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 9-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 9-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Handling Precautions 9-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 9-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Voltage Setting 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address (Self-Installation Only) 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 9-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 9-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 9-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Network Communications Module used with PCC 2100 Controls 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Precautions 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Removal Safety Precautions 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 10-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Module Installation 10-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 10-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 10-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 10-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 10-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 10-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 10-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 10-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 10-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. Network Communications Module used with PowerCommand Automatic Transfer Switches 11-1 . .

About This Section 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Module Installation 11-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2017 Cummins Inc.

iv

Page 7

DIN Rail Installation 11-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 11-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 11-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 11-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 11-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 11-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 11-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 11-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 11-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 11-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 11-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 11-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 11-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. Digital I/O Module 12-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 12-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Digital I/O Module 12-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital I/O Expansion Module 12-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 12-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 12-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 12-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 12-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination 12-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 12-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs 12-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outputs 12-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 12-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 12-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 12-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 12-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Autobinding Configurations 12-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 2100 Custom Relay Autobinding Configurations 12-8 . . . . . . . . . . . . . . . . . . . .

Logical Installation 12-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 12-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 12-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 12-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 12-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 12-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology, Data Media, and Network Power 12-11 . . . . . . . . . . . . . . . . . . . . . .

Network Data Media and Power Wiring 12-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 12-11

Conduit 12-11

Customer Input and Relay Output Connections 12-11 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 12-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 12-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 12-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variable Outputs 12-13

Network Variable Inputs 12-13

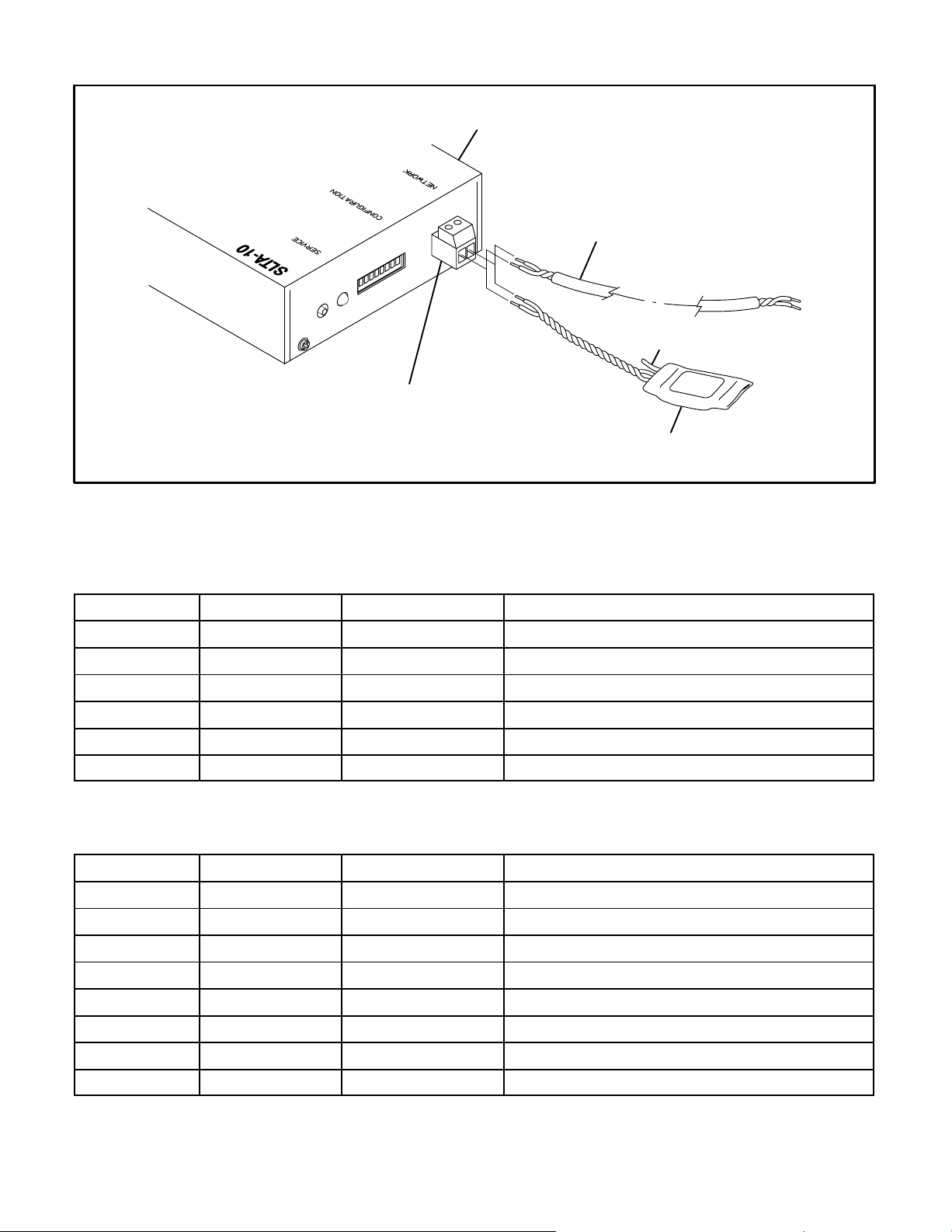

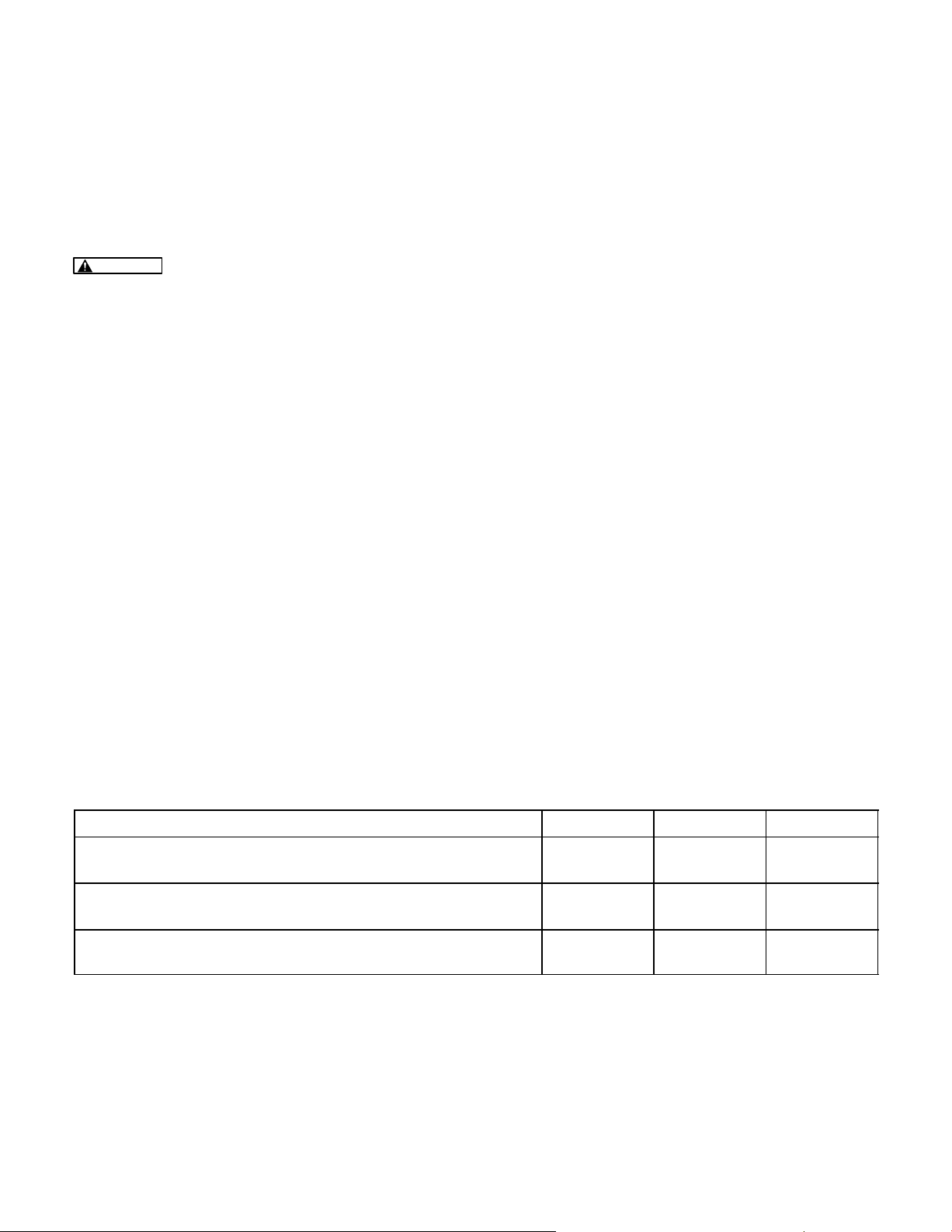

13. SLTA-10 Gateway 13-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 13-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 13-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 13-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Copyright 2017 Cummins Inc.

Page 8

Configuration 13-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Connection 13-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PC Connection 13-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 13-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Cables 13-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. Junction Box / Terminator 14-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 14-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 14-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 14-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 14-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 14-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology, Data Media, and Network Power 14-3 . . . . . . . . . . . . . . . . . . . . . .

Network Data Media and Power Wiring 14-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 14-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conduit 14-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches 14-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15. Network LonWorks System Annunciator 15-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 15-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 15-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 15-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Overview 15-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 15-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 15-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 15-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination 15-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power 15-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conduit 15-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserts 15-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 15-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 15-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 15-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Annunciation Set 15-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lamps 15-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn 15-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 15-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 15-10

Verify Binding 15-10

Removing Bindings 15-10

Re-Binding 15-10

LonMaker Installation 15-10

Network Variables 15-10

Configuration 15-12

Operation 15-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Lamps 15-13

Horn 15-13

Silence/Lamp Test 15-13

Network Status Lamp 15-13

Troubleshooting 15-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Pre-Checks 15-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting LSA Components 15-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 15-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2017 Cummins Inc.

vi

Page 9

Network Variables 15-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 15-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16. Controls Communications Module / Genset 16-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 16-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 16-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-G Inputs 16-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-G Outputs 16-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-G Power Supply 16-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Displays 16-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 16-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 16-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Mounting 16-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire and Conduit 16-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections 16-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 16-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 16-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 16-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 16-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 16-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 16-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 16-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 16-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LonMaker Installation 16-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology, Data Media, and Network Power 16-10 . . . . . . . . . . . . . . . . . . . . . .

Network Data Media and Power Wiring 16-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 16-10

Conduit 16-11

Network Installation 16-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 16-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 16-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17. Controls Communications Module / ATS 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Installation 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-T Inputs 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-T Outputs 17-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM-T Power Supply 17-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Displays 17-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Installation 17-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the CCM-T 17-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Mounting 17-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire and Conduit 17-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections 17-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Installation 17-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Requirements 17-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Address 17-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 17-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Binding Sequence 17-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Binding 17-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Bindings 17-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Binding 17-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Copyright 2017 Cummins Inc.

Page 10

LonMaker Installation 17-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology and Data Media 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Power 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Data Media and Power Wiring 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conduit 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 17-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and LEDs 17-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variables 17-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18. Network Router 18-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 18-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 18-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 18-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 18-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 18-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 18-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power 18-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Connection 18-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Stranded Twisted Pair Wiring 18-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery and Replacement 18-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Installation 18-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19. Etherlon Router 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site requirements 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Installation 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Settings 19-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 19-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Network 19-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PowerCommand Network 19-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power 19-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Connection 19-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Configuration 19-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IP Configuration 19-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PowerCommand Configuration 19-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channels 19-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Devices 19-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 19-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification 19-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20. ModLon II Gateway 20-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Section 20-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Software 20-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Software 20-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 20-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination Switch 20-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ModLon II Gateway Installation 20-3

Power

Supply 20-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Topology and Data Media 20-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 20-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Template Selection Dipswitch 20-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch and LEDs 20-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2017 Cummins Inc.

viii

Page 11

Service Pushbutton and Service LED 20-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Pushbutton 20-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status LEDs 20-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation 20-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ModLon Configuration 20-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FT-10 Networks 20-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Template 5 20-14

Using ModScan Software 20-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes 20-15

Genset Control 20-15

Miscellaneous 20-15

ModLon II Write Commands 20-19

ModLon II with LonWorks Troubleshooting Guide 20-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 20-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ModLon II with LonWorks 20-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 20-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ModLon II Write Commands 20-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Cables / DB9 Connection 20-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Communications 20-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-485 Communications 20-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A. Glossary of Network Terms A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B. Application Notes B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Sender Settings B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C. Network Troubleshooting C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using LonMaker for Windows Troubleshooting C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D. Wiring Diagrams D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E. Bindings E-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset Applications Control Communications Module (CCM-G) Bindings E-1 . . .

Automatic Transfer Switch Control Communications Module (CCM-T) Bindings E-3

Digital I/O Module (DIM) Bindings E-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset Communications Module (GCM) Bindings E-8 . . . . . . . . . . . . . . . . . . . . . . .

Genset LonWorks Card (GLC) Bindings E-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC 2100 Genset Network Communications Module (NCM) Bindings E-12 . . . . . .

PowerCommand ATS (OTPC/BTPC) Network Communications Module (NCM) Bind-

ings E-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix F. Network Variables F-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Variable Types F-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Tags F-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Inputs F-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable Inputs F-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variable Outputs F-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G. Using LonMaker for Windows Browser with TP/XF-78 Devices G-1 . . . . . . . . . . . . . . . . . . .

Basic Procedure G-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls Communications Module G-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − General G-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Voltage Scaling G-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Current Scaling G-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Relays G-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

− Dial Out G-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM

CCM − Analog Inputs G-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Copyright 2017 Cummins Inc.

Page 12

CCM − Temperature 1, Temperature 2, Temperature 3 G-11 . . . . . . . . . . . . . . . . . . .

CCM − Oil Pressure G-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Spare 1, Spare 2 G-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Spare 3 G-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CCM − Discrete Inputs G-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix H. Index H-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2017 Cummins Inc.

x

Page 13

Safety Precautions

The PowerCommand Network can be used to remotely operate power transfer equipment (e.g.,

transfer switches, paralleling systems) and start

and stop generator sets. All of the safety precautions for that equipment must be observed. Refer to

the Operator’s Manual for the equipment that is being monitored and controlled by the network for important safety precautions.

The following symbols, found throughout this

manual, alert you to potentially dangerous conditions to the operator, service personnel, or the

equipment.

DANGER

hazards which will result in severe personal injury or death.

WARNING

unsafe practice which can result in severe personal injury or death.

CAUTION

unsafe practice which can result in personal injury or product or property damage.

This symbol warns of immediate

This symbol refers to a hazard or

This symbol refers to a hazard or

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Keep your hands, clothing, and jewelry away

from moving parts.

Before starting work on the generator set, dis-

connect battery charger from its AC source,

then disconnect starting batteries, negative (-)

cable first. This will prevent accidental starting.

Make sure that fasteners on the generator set

are secure. Tighten supports and clamps, keep

guards in position over fans, drive belts, etc.

Do not wear loose clothing or jewelry in the vi-

cinity of moving parts, or while working on electrical equipment. Loose clothing and jewelry

can become caught in moving parts. Jewelry

can short out electrical contacts and cause

shock or burning.

If adjustment must be made while the unit is

running, use extreme caution around hot manifolds, moving parts, etc.

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH

Remove electric power before removing protective shields or touching electrical equipment. Use rubber insulative mats placed on dry

wood platforms over floors that are metal or

concrete when around electrical equipment.

Do not wear damp clothing (particularly wet

shoes) or allow skin surface to be damp when

handling electrical equipment.

Use extreme caution when working on electri-

cal components. High voltages can cause injury or death. DO NOT tamper with interlocks.

Follow all applicable state and local electrical

codes. Have all electrical installations performed by a qualified licensed electrician. Tag

and lock open switches to avoid accidental closure.

Jewelry is a good conductor of electricity and

should be removed before working on electrical equipment.

xi

Copyright 2017 Cummins Inc.

Page 14

MEDIUM VOLTAGE GENERATOR SETS

(601V to 15kV)

Medium voltage acts differently than low volt-

age. Special equipment and training is required

to work on or around medium voltage equipment. Operation and maintenance must be

done only by persons trained and qualified to

work on such devices. Improper use or procedures will result in severe personal injury or

death.

Do not work on energized equipment. Unau-

thorized personnel must not be permitted near

energized equipment. Due to the nature of medium voltage electrical equipment, induced

voltage can remain even after the equipment is

disconnected from the power source. Plan the

time for maintenance with authorized personnel so that the equipment can be de-energized

and safely grounded.

TRANSFER SWITCHES

AC and DC voltages in the transfer switch com-

ponents present serious shock hazards that

can result in severe personal injury or death.

Read and follow these instructions.

Keep the transfer switch cabinet closed and

locked. Make sure only authorized personnel

have cabinet and operational keys.

Due to the serious shock hazard from medium

voltages within the cabinet, all service and adjustments to the transfer switch must be performed only by an electrician or authorized service representative.

If the cabinet must be opened for any reason:

1. Move the operation selector switch on the

generator set to Stop.

2. Disconnect battery charger from its AC

source. Disconnect the starting batteries

of the generator set. (Remove the negative [−] lead first to prevent arcing from igniting explosive battery gas.)

3. Remove AC power to the automatic transfer switch. If the instructions require otherwise, use extreme caution due to the danger of shock hazard.

GENERAL SAFETY PRECAUTIONS

The PowerCommand Network allows remote

operation of equipment. PowerCommand Software for Windows can remotely start and stop a

genset or exercise a transfer switch. Network

modules can independently control other network modules and operate other electrical devices such as fans or pumps etc. Make certain

that all appropriate personnel are notified before remotely operating equipment and make

them aware of any equipment that can be energized automatically.

Do not work on this equipment when mentally

or physically fatigued, or after consuming any

alcohol or drug that makes the operation of

equipment unsafe.

Use only the latest physical and logical connec-

tion diagrams for installing and maintaining the

PowerCommand Network. If changes are

made to the physical or logical network connections, make sure the site connection diagrams are updated. Create a new CSV file if the

number or type of modules changes or if the

bindings change.

Copyright 2017 Cummins Inc.

xii

Page 15

1. Introduction

ABOUT THIS MANUAL

This manual covers the PowerCommandR FT-10

Network installation, setup, and service information. The PowerCommand FT-10 Network is an

Echelon

trol network. This manual is intended for use by

trained network installers and operators.

Sections 1 and 2 provide an overview of this manual, the expected technical background of the installer/operator, the required hardware and software

tools, installation guidelines, and some basic network concepts.

Section 3 describes creating a self-installed network using auto-binding of devices. It includes

guidelines for a self-installed network. If these

guidelines cannot be met, the network must be

installed using LonMakert software.

Section 4 describes the logical installation and con-

nection of the various modules on the network using

LonMaker software. This section also describes

network testing and service procedures using LonMaker.

Much of the material in Section 4 is derived from the

Echelon LonMaker Installation Tool Users Guide.

The Echelon manual is included with the LonMaker

software, and should be considered a reference

companion to this manual.

Section 5 describes using Plug-Ins with LonMaker

software to configure devices. This program is used

to complete the network installation by performing

R

LONWORKSR based local operating con-

several functions including setting network settings

for each device.

Section 6 describes using InPowert to configure

devices. This program is used to complete the network installation by performing several functions including setting device network settings.

Section 7 describes monitoring network devices

using PowerCommand for Windows

R

II (PCW II)

software.

Sections 8 thru 20 describe individual modules,

routers, the SLTA-10 Gateway, the ModLon Gateway, and the Junction Box/Terminator on the PowerCommand Network and provide procedures for

locating, mounting, and wiring these devices

(physical installation). As new devices are made

available, they will be added to this manual.

A glossary of network terms, troubleshooting information, and installation aids (application notes, wiring diagrams, bindings, and network variables), are

included in the Appendices at the back of this manual.

Use normal and necessary safety precautions before starting any service procedures. Identify all

hazards by referring to the Safety Precautions section and observing all warnings and cautions within

the manual. When troubleshooting, remember that

the PowerCommand Network, generator set, transfer switch, and utility power source are all interdependent.

Keep this manual where it will be readily available to

the network installer and operator.

WARNING

THE GENSET, TRANSFER SWITCH, AND OTHER EQUIPMENT ASSOCIATED WITH THE POWERCOM-

MAND NETWORK WILL NOT FUNCTION PROPERLY, OR WILL NOT BE SUBJECT TO PROPER MONITORING AND SERVICE, UNLESS THE INSTRUCTIONS IN THIS MANUAL ARE FOLLOWED IN DETAIL.

IMPROPER FUNCTIONING CAN RESULT IN SEVERE PERSONAL INJURY, DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST HAVE THE REQUIRED INSTALLATION TOOLS AND

BE TRAINED AND EXPERIENCED TO PERFORM NETWORK INSTALLATIONS, INCLUDING USE OF

INSTALLATION SOFTWARE, AND BE ABLE TO PERFORM ELECTRICAL AND MECHANICAL SERVICE. READ THIS ENTIRE MANUAL BEFORE STARTING.

Cummins and PowerCommand are registered trademarks of Cummins Inc.

Echelon and L

LonMaker is a trademark of Echelon Corporation.

InPower is a trademark of Onan Corporation.

Windows is a registered trademark of Microsoft Corporation.

PartitionMagic is a registered trademark of PowerQuest Corporation.

ONWORKS are registered trademarks of Echelon Corporation.

1-1

Copyright 2017 Cummins Inc.

Page 16

REQUIRED BACKGROUND

To use this manual, you need:

Experience and familiarity with generator set

installation and service.

A basic understanding of control networks.

Experience and familiarity with personal com-

puters and using a mouse.

Experience and familiarity with DOS, and Win-

dows-type graphical user interfaces.

Experience and familiarity with the organiza-

tion of disk drives, directories, subdirectories,

files, and path names.

REQUIRED INSTALLATION TOOLS

In additional to conventional tools and all system

components and cabling, you need the following

tools and manuals to install a PowerCommand

work:

PowerCommand Network Support CD (part

number 326−5706) − includes the following:

− Cummins Inc. Device Stencil

− Resource Files

− .XIF Files

− .NXE Files

− Plug-Ins

Echelon

LonMaker for Windows, version 3.1

software

InPower, version 3.0

PC with Pentium II 350 or better

VGA monitor (color or gray scale) and video

card

Windows 2000 or Windows NT 4.0 with Service

Pack 3

64 MB of conventional RAM

225 MB of available hard disk storage

CD ROM drive

Serial port, Network Gateway, cable, and driver

software or PCC-10 network interface card,

cables, connectors, PCMCIA-II Slot, and driver

software

Microsoft-compatible mouse and mouse driver

software

Net-

The LonMaker Installation Tool Users Guide

(provided with LonMaker)

To test the PowerCommand Network before leaving

the site, the following tools will be needed:

A Network Gateway Module or a PCC-10 card,

cables, and PCMCIA-II Slot

InPower version 3.0

LonMaker for Windows, version 3.1

New and Old Versions of LonMaker

IMPORTANT! Installing LonMaker 3.1 for Windows

on the same computer as LonMaker 2.02 for DOS

can cause software problems.

If enough space is available on the hard drive,

R

PartitionMagic

can be used to separate the

two versions of software.

If not enough space is available on the hard

drive, install LonMaker for Windows and its operating software companions on a separate

hard drive.

HOW TO OBTAIN SERVICE

When the equipment requires service, contact the

nearest dealer or distributor. Factory-trained Parts

and Service representatives are ready to handle all

your service needs.

To contact your local Cummins Inc. distributor in the

United States or Canada, call 1-800-CUMMINS

(1−800−286−6467).

If you are unable to contact a distributor using the

automated service, consult the Yellow Pages. Typically, our distributors are listed under:

Generators-Electric,

Engines-Gasoline or Engines-Diesel, or

Recreational Vehicles-Equipment,

Parts and Service.

For outside North America, call Cummins Inc.,

1-763-574-5000, 7:30 AM to 4:00 PM, Central Standard Time, Monday through Friday. Or, send a fax to

Cummins Inc. using fax number 1-763-528-7229.

TM

WARNING

INCORRECT SERVICE OR PARTS REPLACEMENT CAN RESULT IN SEVERE PERSONAL INJURY,

DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST BE TRAINED AND EXPERIENCED TO PERFORM ELECTRICAL AND/OR MECHANICAL SERVICE ON HIGH VOLTAGE EQUIPMENT.

Copyright 2017 Cummins Inc.

1-2

Page 17

SYSTEM OVERVIEW

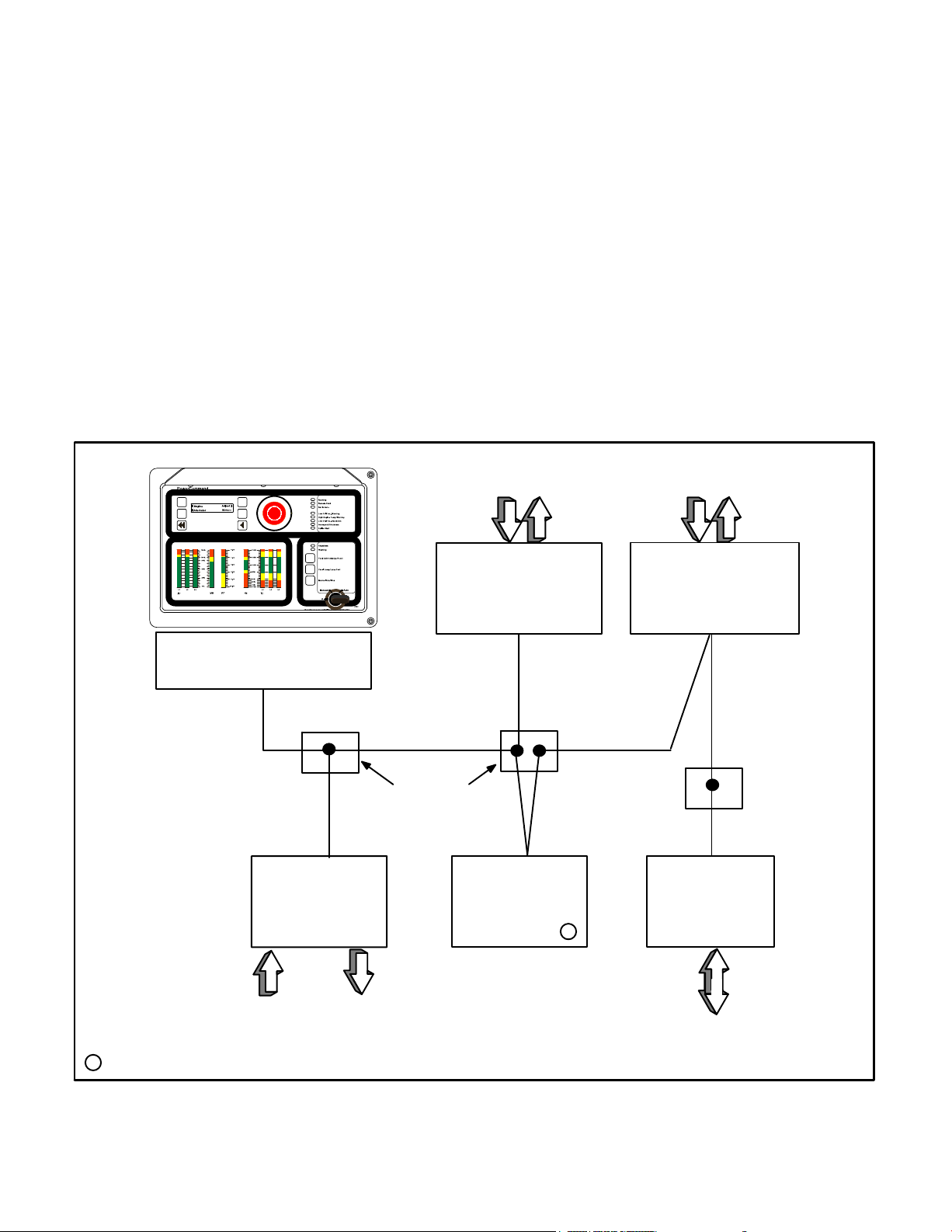

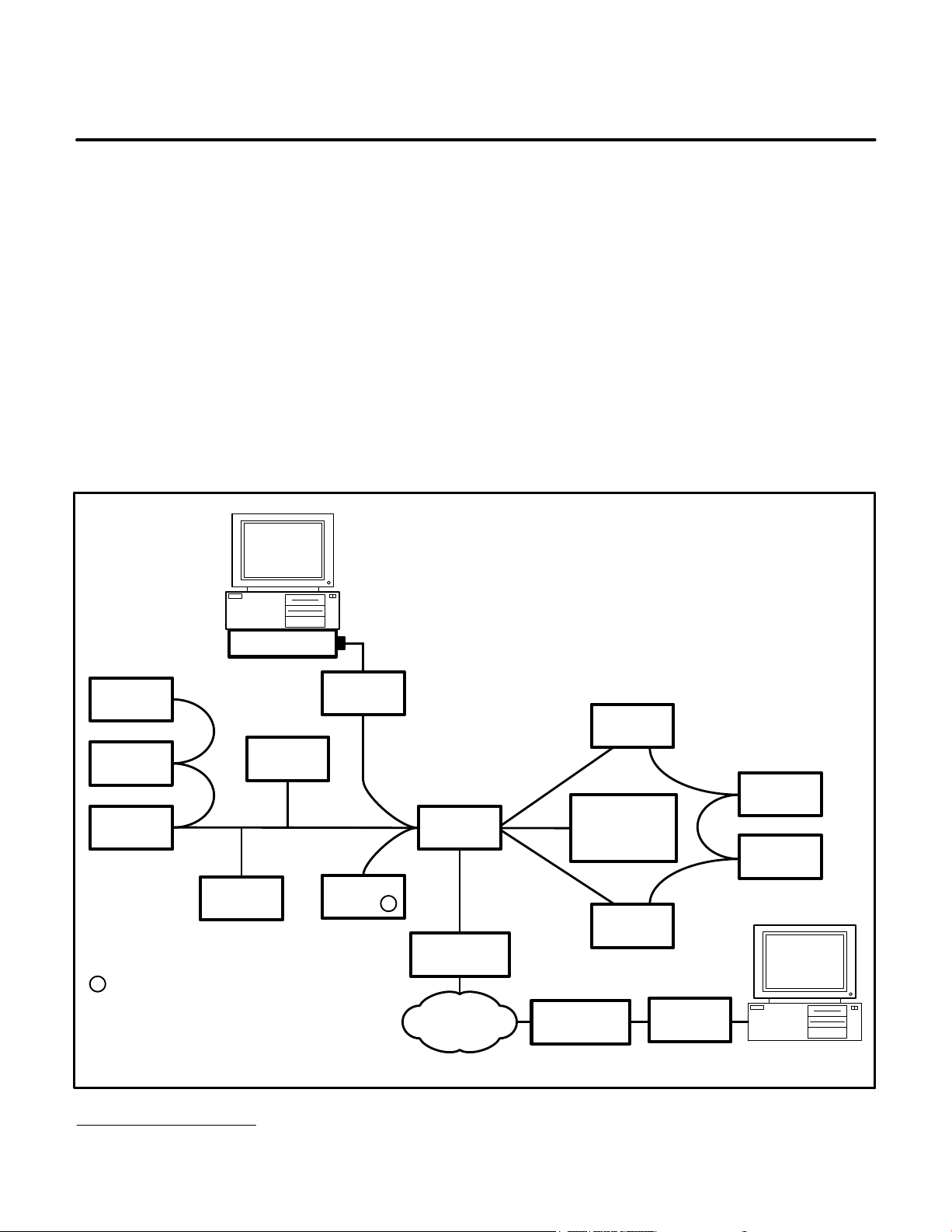

Figure 1-1 shows a block diagram using some of the

network modules described in this manual. The network and network modules are covered in detail in

the following sections.

The PowerCommand Control (PCC) communi-

cates through the Genset Communications Module

with other modules, such as a Digital I/O Module, or

Network Communications Module.

The Genset Communications Module (GCM) is

mounted in the PCC 3100 and is required for connecting the PCC to the network.

The Genset L

the PCC 3200 and is required for connecting the

PCC to the network.

ONWORKS Card (GLC) is mounted in

The Genset Network Communications Module

(NCM) is mounted in the PCC 2100 and is required

for connecting the PCC to the network.

The ATS Network Communications Module

(NCM) is mounted in the PowerCommand automatic transfer switch (OTPC, BTPC, OHPC, or CHPC)

and is required for connecting the transfer switch to

the network.

The Digital I/O Module (DIM) provides a group of

relay contact outputs and discrete inputs for interfacing the PowerCommand system to alarm or status outputs and to equipment that does not have

compatible communications capability.

PCC 2100 NETWORK

COMMUNICATIONS MODULE

(NCM)

DIGITAL I/O

MODULE (DIM)

NON-OTPC/BTPC

TRANSFER SWITCH

CONTROLS

COMMUNICATIONS

POWERCOMMAND

FT-10 NETWORK

JUNCTION

BOX

ANNUNCIATOR

MODULE

(CCM-T)

LONWORKS

SYSTEM

(LSA)

NON-PCC

GENERATOR SET

CONTROLS

COMMUNICATIONS

MODULE

(CCM-G)

JUNCTION

BOX

SLTA-10

T

CUSTOMER

= NETWORK TERMINATOR

T

RELAY

INPUTS

OUTPUTS

FIGURE 1-1. BLOCK DIAGRAM OF NETWORK MODULES

1-3

MODEM OR

LOCAL PC

Copyright 2017 Cummins Inc.

Page 18

The LONWORKSR System Annunciator (LSA) al-

1

1

lows remote annunciation via the PowerCommand

Network of a genset or transfer switch etc. The annunciator shows an operator what is happening in

the network.

FT-10 NETWORK

CHANNEL

The SLTA-10 Gateway provides a network inter-

face to a PC or modem.

The Junction Box/Terminator provides connec-

tion points for network power and data wires.

The Controls Communications Module (CCM)

allows interfacing the network to a non−PCC generator set (CCM-G) or transfer switch (CCM-T).

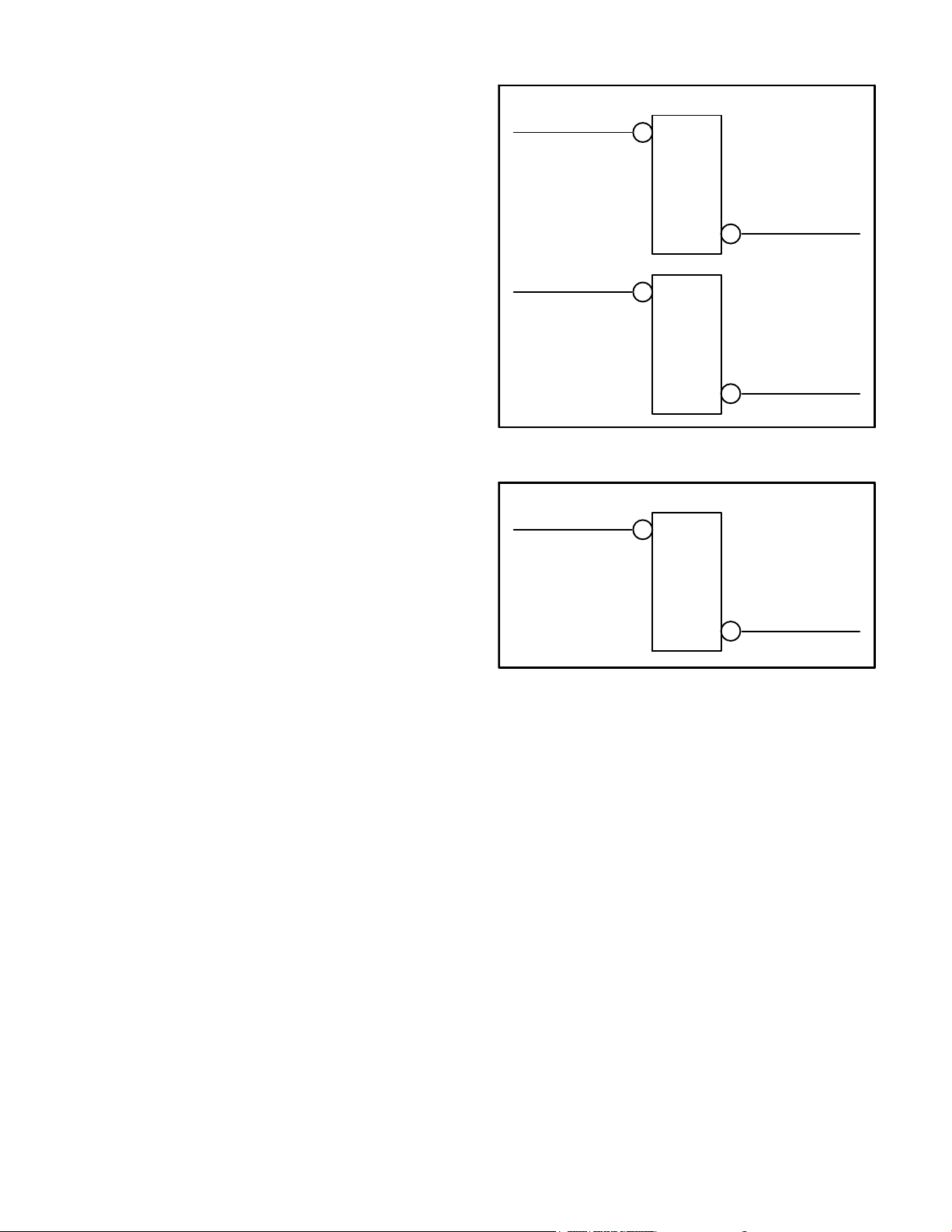

The PowerCommand L

ONWORKS Network Router

connects two communications channels (for example, FT-10 to FT-10) and routes messages between

them (see Figure 1-2).

The PowerCommand Etherlon Router connects

one FT-10 Network LonWorks channel to one

Ethernet channel (see Figure 1-3).

ROUTER

NETWORK

FT-10 NETWORK

CHANNEL

ROUTER

NETWORK

FIGURE 1-2. NETWORK ROUTERS

FT-10 NETWORK

CHANNEL

ROUTER

EITHERLON

FT-10 NETWORK

CHANNEL

TP-78 NETWORK

CHANNEL

EITHERNET

CHANNEL

FIGURE 1-3. ETHERLON ROUTER

Copyright 2017 Cummins Inc.

1-4

Page 19

2. Network Hardware and Wiring

OVERVIEW

This section describes the free topology (FT) network communications protocol and the individual

R

modules used in the PowerCommand

FT-10 network. This section also describes network media,

network power supply, and physical connection requirements. For a definition of the terms used in a

PowerCommand network, refer to the Glossary in

Appendix A.

NETWORK CONFIGURATION

The PowerCommand network uses a free topology

(Figure 2-1). The network is made up of individual

devices that are connected by stranded twisted-pair

MODEM

communications cable for the transmission of network data. Network power is transmitted over wires

in the DC conduit.

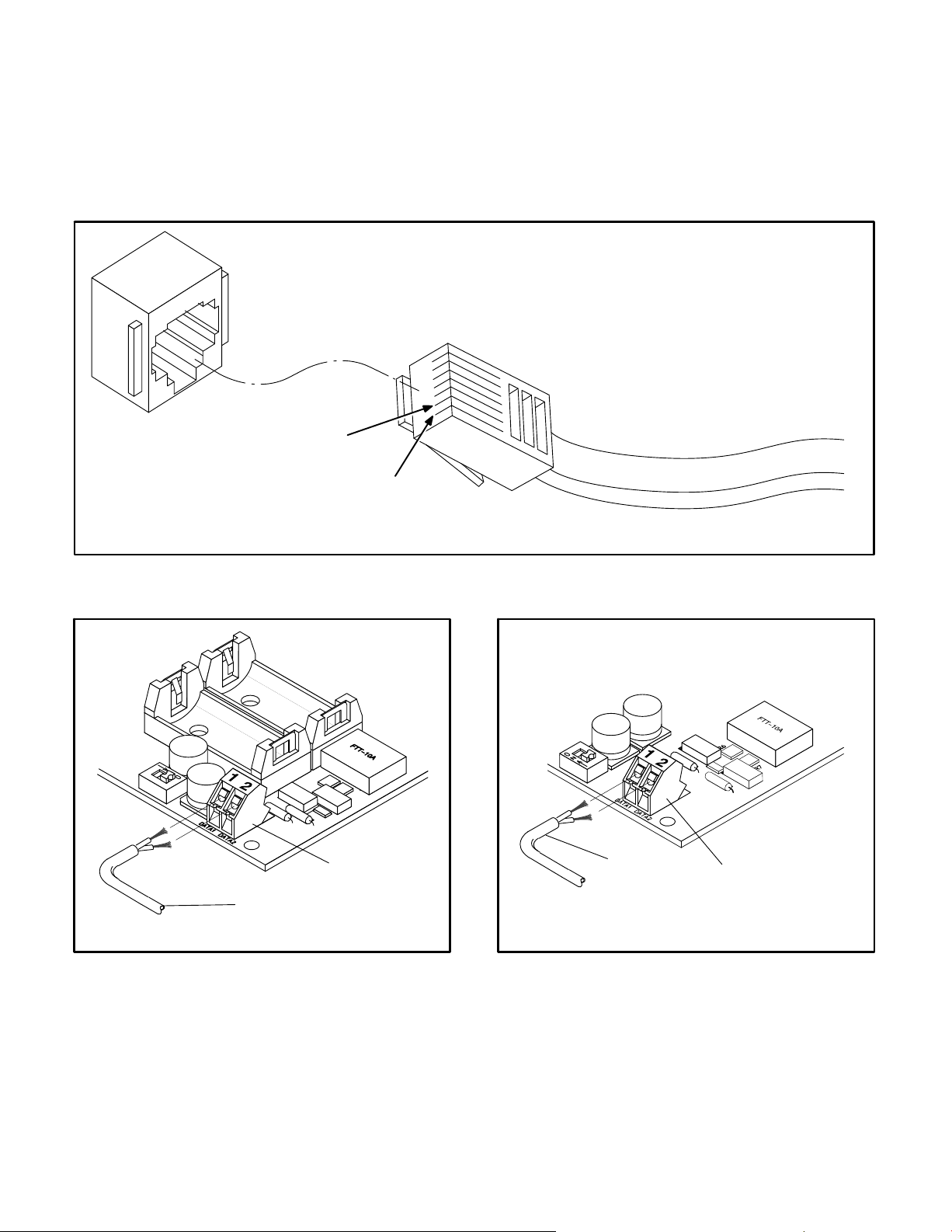

The devices used in this network include a free topology transceiver (FTT-10). FTT-10 devices are

transformer isolated, have a 78 kbps bit rate, and

are polarity insensitive. External power must be

provided for FTT-10 devices (LSA, DIM, CCM-T,

CCM-G, GLC, NCM, and GCM).

A router can be configured as a repeater to extend a

segment into a channel. Repeaters transmit every

network variable signal they receive, no matter

where it originates.

POWERCOMMAND NETWORK

22 AWG MAXIMUM LENGTH

1640 FEET (500 M) PER SEGMENT

NOTE: Although 128 devices can be added to a

channel, only 64 devices are allowed per segment.

Add a repeater between segments to extend the

reach and allow for a higher device count.

CCM-G

CCM-G

CCM-G

T

= Network Terminator

GLC

CCM-T

SLTA-10

Channel 1

PCC 2100

NCM

T

NOTE: One device on each

segment must be terminated.

* Do not use the JBT terminator in FT-10 networks.

FIGURE 2-1. FREE TOPOLOGY NETWORK EXAMPLE

PowerCommand is a registered trademark of Cummins Inc.

Echelon, LonW

ORKS, AND Neuron are registered trademarks of Echelon Corporation.

JBT*

ETHERLON

ETHERNET

CCM-T

OTPC/BTPC/

OHPC/CHPC

ATS NCM

ETHERLON

DIM

LSA

GCM

SLTA-10

2-1

Copyright 2017 Cummins Inc.

Page 20

A free topology architecture allows for wiring the

control devices without topology restrictions. It supports the use of star, loop, and/or bus wiring. Some

of the advantages of free topology include:

It allows for a method of wiring that best suits

the installation, thus reducing the need for advanced planning. It also allows for last minute

changes.

PowerCommand Network

(twisted pair)

Rewiring of existing installations is usually not

required.

The network can be expanded by tapping into

the existing wiring where it is most convenient

to do so.

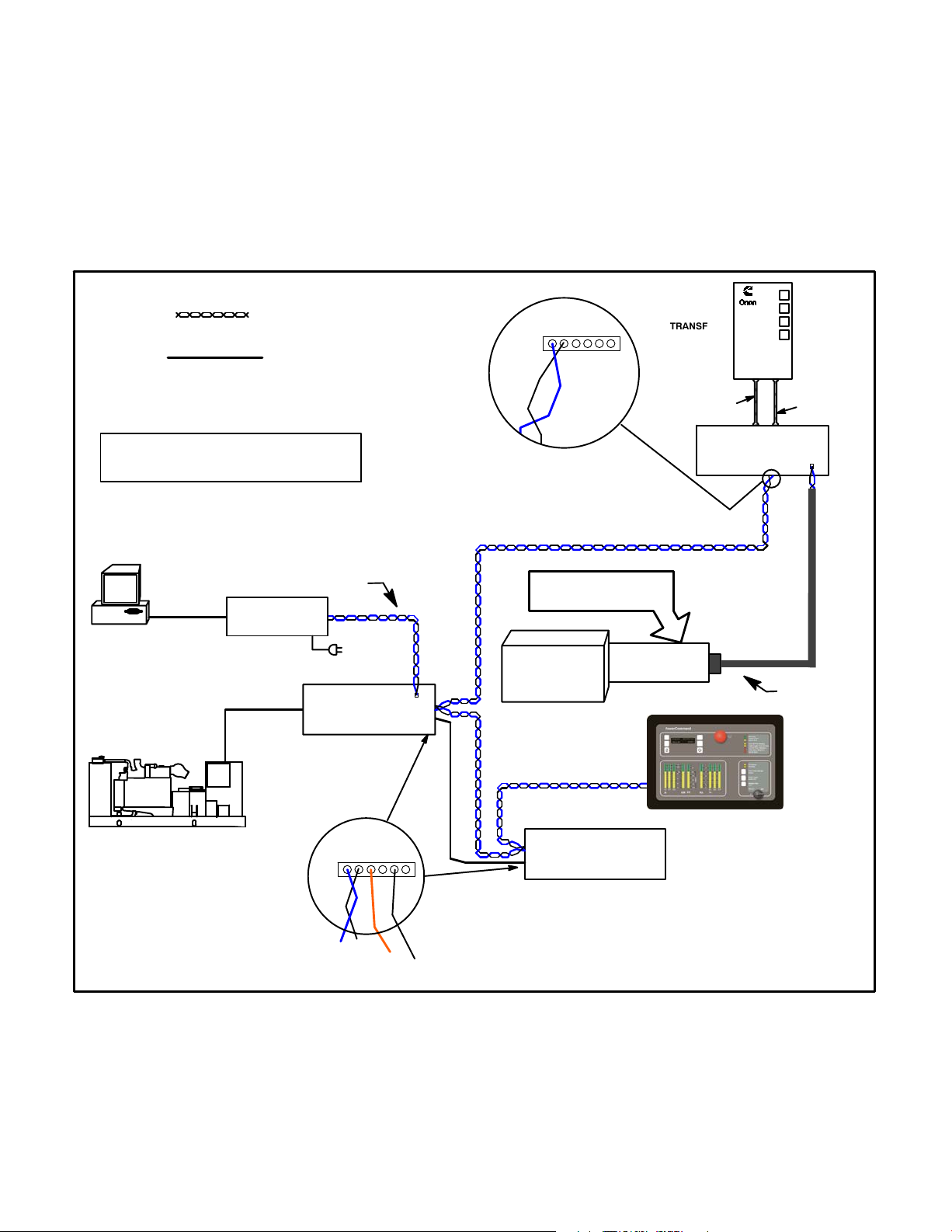

Figure 2-2 shows a typical network with several

modules. Refer to Figure E-1 in Appendix D for a

more detailed network example.

Data

on pins

+

+

1 & 2

−−

TRANSFER

SWITCH

Non-PowerCommand Network

NOTE: JBTs can be used as twisted pair or

power connection points only. Do not use

the JBT terminator for FT-10 networks.

Customer’s PC

COM1

Connect one

Power Wiring

(RS−232C)

SLTA-10 Cable

Network Patch Cable

FT-10 SLTA-10

Gateway Module

Site Gateway

Control Wiring

PowerCommand

CCM-G

(Terminated)

Blue

Network Data and Power Connector:

6-pin Black connector

Blue − White/Blue

For Installation

and Service only

Blue − White/BlueBlue − White/Blue

RJ45

Jack

Technician’s

Laptop PC

Echelon PCC-10

PowerCommand

Control 2100

Connect to NCM Terminal Block

PCMCIA card

AC WIRING

PowerCommand

Controls Communications

Module - ATS

DC WIRING

RJ45

Jack

Echelon FT-10 Cable

Copyright 2017 Cummins Inc.

Data

on pins

1 & 2

+

+

−−

PowerCommand

LonWorks System Annunciator

Blue

B+

Ground

FIGURE 2-2. TYPICAL NETWORK CONFIGURATION

2-2

Page 21

SYSTEM DESCRIPTION

The PowerCommand Network is a distributed control network. Echelon

vides the communications protocol via Echelon’s

Neuron

Chip and firmware. The network consists

of nodes (for example: PCCs with Genset Communications Modules, Digital I/O Modules, Controls

Communication Modules, and Network Gateway

Modules) wired together on a common network

data bus.

The control of the system does not reside in a central device, but rather is distributed at the system

component level. That is, each node has its own intelligenceintelligence needed at that location to

perform functions for that particular component.

The nodes communicate control and monitoring information to one another over the network data bus.