Page 1

PowerCommandr 500/550

Quick Setup Guide

Remote Monitoring

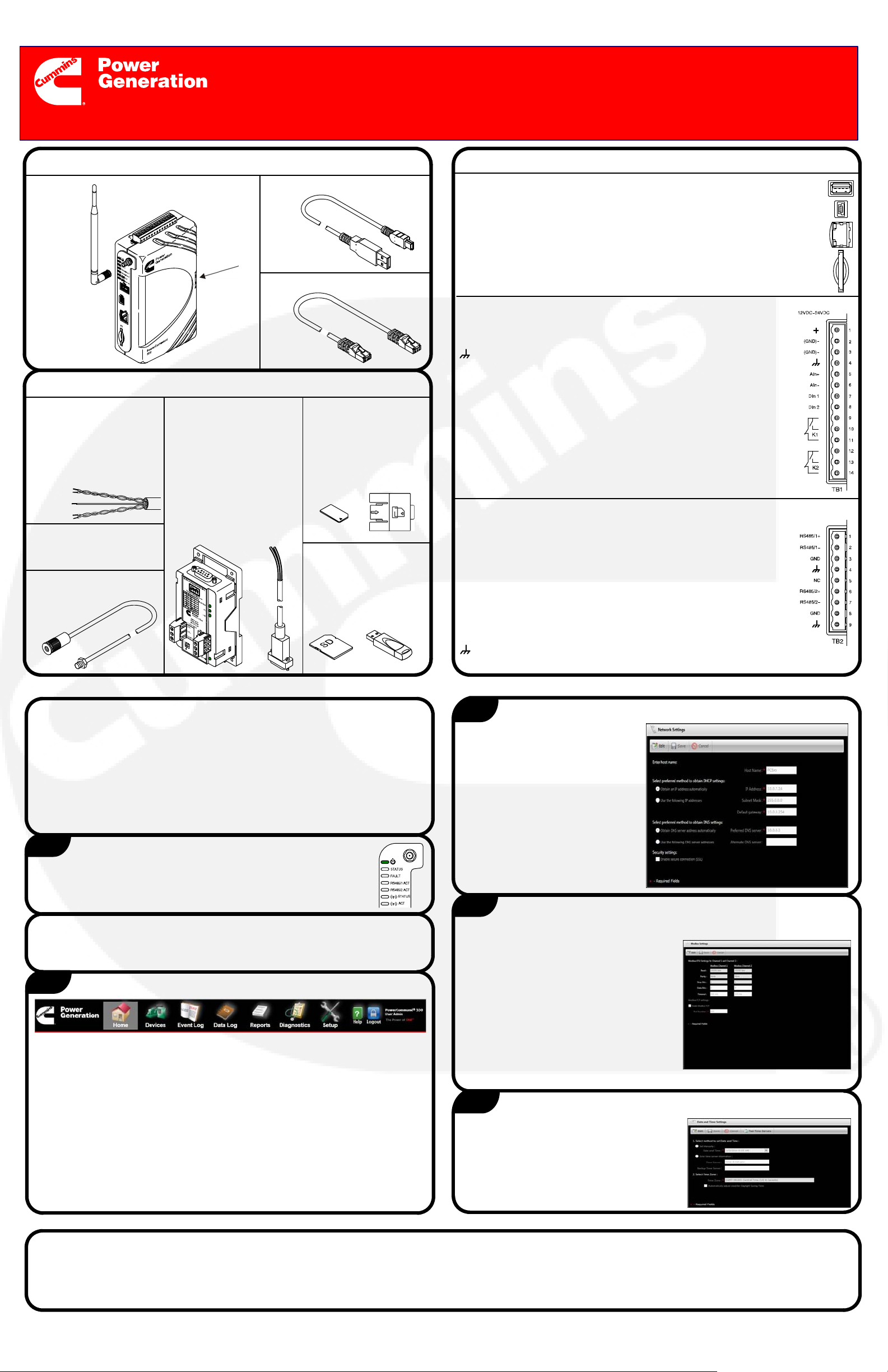

Verify Hardware Contents

Antenna

(CDMA

and GSM

only)

PowerCommand 550

Verify Additional Hardware Needed

Modbus Cable − Re-

quired shielded twisted

pair cable, 24 AWG or

larger, used to connect

PowerCommand

500/550 to monitored

device.

Power Supply (12−24V,

2A) − Required for all

installations.

Antenna Extension −

Required for cabinet

installations.

USB−OTG CablePowerCommand 500 or

SIM Card

Door

Ethernet Cable

ModLon II Gateway Kit

and ModLon Connection Cable (A040T087) −

Required for legacy controls (PCC2100, 3100,

3200, and 3201 generator set controls and

OTPC, BTPC, OHPC,

and CHPC transfer

switch controls).

SIM Card −

Required for GSM

cellular modem

(needs to be

obtained from your

local service

provider).

Secure Digital (SD)

Memory Card or

USB Flash Drive

(Optional) − Used as

external memory for

data logs.

Connections

PORTS:

External USB Memory: Insert a USB flash drive as external

memory for data logs.

USB Mini: This direct connection to PC is used to access User

Interface during initial configuration.

Ethernet: Used to connect to the network; it supports both IEEE 10

BASE-T and 100 BASE-TX standards.

SD Card Slot: Insert an SD card as external memory for data logs.

TB1 − INPUT/OUTPUT CONNECTIONS:

Input +: 12−24 VDC power supply or B+ battery.

Negative Ground (GND)−: GND from power supply or B− battery.

Chassis Ground: Connect to an earth grounded metal surface.

Analog Resistive Input (AIn+ and AIn−): Connection for a

resistive sensor into the PowerCommand 500/550 (600−2500

ohms).

Discrete Inputs (DIn 1 and DIn 2): Two isolated ‘open-collector’

type discrete inputs. These inputs are activated when connected to

the PowerCommand 500/550 GND (B− or power supply ground).

Discrete Outputs: K1 and K2 from the PowerCommand 500/550.

Pins 9 and 12 are common. Pins 10 and pins 14 are normally open.

Pins 11 and 13 are normally closed. Each output is rated at 1A 30

VDC, 0.3A 125 VAC (resolve load).

TB2 − COMMUNICATIONS TERMINAL:

RS485/1+ and RS485/1−, RS485/2+ and RS485/2−: Two sets of

connections are used to support Modbus communications with

PowerCommand controls on generator sets, transfer switches, or

AUX 101/102. Both the control and the PowerCommand 500/550

must have the same Modbus configuration (baud rate, parity bit,

and stop bit). Connections are made using the Modbus

communication cable.

GND (Ground): Ground reference between PowerCommand

500/550 and controls, depending on power supply configuration

(see External Connectivity Diagrams).

Chassis Ground: Connect to shield of the Modbus cable.

NC: Not used

Verify System Requirements

PC or Macintosh computer with CD drive

Browser: Internet Explorer 8 or later is recommended

Operating System: Microsoft Windows, Mac OS X, or Linux

Microsoft Silverlight software, version 5.0 or later

Minimum Screen Resolution: 1024 x 768

Windows Mobile Device Center

1

1. Connect the PowerCommand 500/550 to a power supply. Refer

to the Connections topic.

2. Check the Power LED to confirm power is available.

Connect to Power Supply

Note to Installer/Customer

Software setup (steps 2 through 10) can be completed before arriving at

the site and prior to physical installation.

2

1. Turn on the computer.

2. Connect PC500/550 to the Internet using an Ethernet cable.

3. Connect the USB−OTG cable from the PowerCommand 500/550 to the

computer. The computer automatically installs a software driver. If not,

install “Windows Mobile Device Center” manually.

4. Open an Internet browser window and go to Tools > Internet Options >

Connections > LAN Settings. Under Proxy Server, uncheck the box for

Use a Proxy server for your LAN.

5. In Internet browser address bar, enter the following IP address:

169.254.0.1 to load PowerCommand 500/550 login screen.

NOTE: Use https when SSL is enabled or http when it is disabled.

6. Enter the user name (admin) and password (admin).

Access the Home Page

3

1. Once the Home page

appears, select Setup on the

menu bar.

2. Select Network Settings in

the Setup menu.

3. Select Edit.

4. Enter network setting

information obtained from

your IT network administrator

or local service provider.

5. Select Save.

4

1. Navigate to Modbus Settings in the Setup menu. Default information is

displayed.

2. If any information needs to be changed,

select Edit.

3. Enter the Modbus Channel−1 and

Channel−2 information. Obtain from

service tool or applicable control HMI.

Also, enter the port number for Modbus

TCP.

4. Select Save.

5. All devices connected to same Modbus

channel must have same Modbus

Configuration (baud rate, parity, stop bits).

5

1. Navigate to Date and Time Settings

in the Setup menu.

2. Select Edit.

3. Select time method and enter any

required information.

4. Select Save.

Enter Network Settings

Modify Modbus Settings

Enter Date and Time Settings

Additional Information

If you have any questions regarding the installation, contact your nearest authorized Cummins distributor or dealer.

For additional information, refer to the PowerCommand 500/550 Owner Manual available on the Technical Publications CD.

For more information on Cummins products and services, go to www.power.cummins.com.

E 2014 Cummins Power Generation Inc. All rights reserved.

Cummins Power Generation and Cummins are registered trademarks of Cummins Inc. PowerCommand is a registered trademark of Cummins Power Generation

Printed in USA 1/2014 A040G393

English − Original Instructions

Page 2

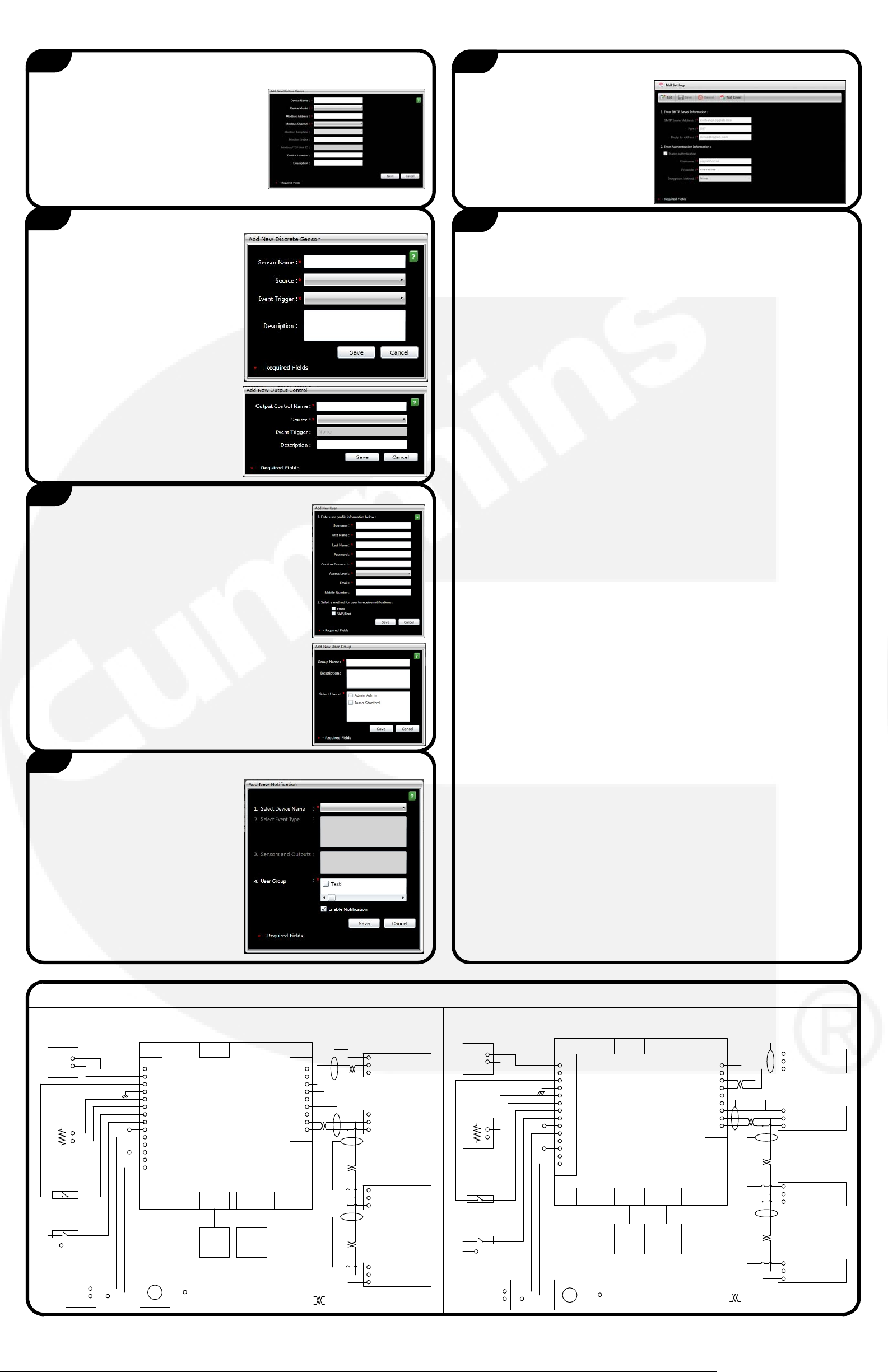

6

Add Devices

1. Navigate to Device Configuration in the Setup menu.

2. Select Add New Device.

3. Select the device type (Genset, ATS, I/O

Device) and enter the required

information for setting up the device.

4. Select Save.

5. Repeat steps 2 through 4 for each

additional Modbus device.

6. To view the devices, select Home on the menu bar.

10

Enter Mail Settings Information

1. Navigate to Mail Settings in the

Setup menu.

2. Select Edit.

3. Enter the SMTP server information.

4. Select Save.

7

Add Sensors and Outputs

1. Navigate to Sensors and Outputs in

the Setup menu.

2. To add a sensor, from the Inputs

tab, select Add New Sensor.

a. Select the sensor type

(Discrete or Analog) and enter

sensor information.

b. Select Save.

3. Repeat step 2 to add additional

sensors.

4. To add an output, from the

Outputs tab, select Add New

Output.

a. Enter output information.

b. Select Save.

5. Repeat step 4 to add additional

outputs.

8

Enter User/User Group Information

1. Navigate to User Profile Settings in the Setup

menu.

2. From the Users tab, select Add New User.

3. Enter the appropriate user information.

4. If the user is to receive notifications, select the

appropriate methods.

5. Select Save.

6. Repeat steps 2 through 5 to add additional users.

7. To create a group (for notifications), select the User

Groups tab.

8. Select Add New User Group.

9. Enter the user group name and select the users to

be included.

10.Select Save.

11. Repeat steps 7 through 10 to add additional user

groups.

11

Complete the Installation

1. After all configurations are complete, unplug the USB−OTG cable from the

PowerCommand 500/550. Then move PowerCommand 500/550 to the

installation site.

2. Connect the Ethernet cable from the PowerCommand 500/550 to the site’s

network (Ethernet hub/switch).

3. For the wireless option only (GSM or CDMA cell modems),

Open Installations − Attach antenna to the SMA connector on the

PowerCommand 500/550.

Metal Cabinet Installations − Choose a location for the antenna,

preferably near the top of the cabinet. Create a 9/32-inch (7mm) hole

and install the bulkhead end of the antenna extension cable. Connect

the other end to the SMA connector on the PowerCommand 500/550.

Attach the antenna to the connector on the outside of the cabinet.

Activate the modem. Refer to the Owner Manual for the appropriate

Modem Activation Process.

4. For installations that use legacy controls, install a ModLon II Gateway for

interfacing LonWorks to Modbus RTU communications. (See instructions

in Instruction Sheet C673.)

5. For wiring up the Modbus communication over RS-485, use 24 AWG or

larger, shielded, twisted pair cable. Both Modbus channels are located on

the TB2 connector.

Using a twisted pair of the Modbus cable, connect the RS-485 signal wires

from the generator set, ATS, or AUX101 control to the corresponding points

on the PowerCommand 500/550 terminal block. Either channel is acceptable,

provided it is consistent with information from step 7 (Add Devices).

Note: All devices wired to the same Modbus channel must have the same

Modbus configuration (baud rate, parity, stop bits). Multiple devices can be

wired over daisy chain before connecting to Channel−1 or Channel−2).

A ground reference wire may be necessary depending on the power supply

configuration. If the PowerCommand 500/550 is powered from the same

source as the connected PowerCommand Control, a ground wire is not needed. If the PowerCommand 500/550 uses a separate power supply, a ground

reference wire should be connected.

Connect the cable shield to either CGND on the PowerCommand 500/550, or

the ground pin on the generator set, ATS or AUX101 control, but not both.

Refer to the External Connectivity Diagrams for more information.

9

Enter Notification Information

1. Navigate to Notifications in the

Setup menu.

2. Select Add New Notification.

3. Select a Device Name and Event

Type.

4. To receive notifications, select a

user group and make sure

Enable Notifications is

checked.

5. Select Save.

6. Repeat steps 2 through 5 to add

6. If needed, use standard 24 AWG or larger wire to complete the following

PowerCommand 500/550 TB1 connections.

Wire the Analog Resistive Inputs to an appropriate sensor (for

example, a fuel sensor).

Wire Discrete Input(s) and Discrete Output(s) to the desired

device(s).

Refer to the External Connectivity Diagrams for common examples.

7. If needed, insert an SD card or USB flash drive as external memory for

data logs.

8. Connect the PowerCommand 500/550 to a 12/24VDC generator set

battery or an isolated DC power supply.

9. Mount the PowerCommand 500/550 on a DIN rail or place on flat surface

(rubber feet are provided underneath base).

additional notifications.

External Connectivity Diagrams

Common Power Supply: Separate Power Supply:

+

−

CGND to grounded

metal surface

Fuel

Direct

B−

Alarm

+

−

One of the

Generator

Set Batteries

B−

Shield

Shield Shield

Shield

Either type of shield

connection is acceptable.

Only one end is terminated.

The controls are powered

from the generator set

batteries with all B−

connections tied together.

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

TB1

B+

1

B−

B+

B+

B+

2

GND

3

GND

4

CGND

5

ANALOG IN+

6

ANALOG IN−

7

DIN 1

8

DIN 2

9

DOUT1 COMMON

10

DOUT1 NO

11

DOUT1 NC

12

DOUT2 COMMON

13

DOUT2 NO

14

DOUT2 NC

SIM

Card

RS-485 2 GND

RS-485 2 −

RS-485 2 +

RS-485 1 GND

RS-485 1 −

RS-485 1 +

CGND

NC

CGND

TB2

9

8

7

6

5

4

3

2

1

PowerCommand 550

Lamp

USB

Host

USB

Device

B−

PC

Ether-

net

Router/

Switch

SD

Card

= Twisted Pair

Battery

Level

Sensor

Resistive

Sensor Range

600 to 2500

Generic Switch

Grounding

Generic Switch

Remote

Grounding

Power

Supply

+

−

CGND to grounded

Fuel

Level

Sensor

Resistive

Sensor Range

600 to 2500

Generic Switch

Direct

Grounding

Generic Switch

PS−

Remote

Grounding

Alarm

+

−

metal surface

PS+

PS−

B+

PS+

PS−

TB1

B+

2

GND

3

GND

4

CGND

5

ANALOG IN+

6

ANALOG IN−

7

DIN 1

8

DIN 2

9

DOUT1 COMMON

10

DOUT1 NO

11

DOUT1 NC

12

DOUT2 COMMON

13

DOUT2 NO

14

DOUT2 NC

Lamp

USB

Host

SIM

Card

RS-485 2 GND

RS-485 2 −

RS-485 2 +

RS-485 1 GND

RS-485 1 −

RS-485 1 +

PowerCommand 550

USB

Device

B−

PC

Ether-

net

Router/

Switch

CGND

NC

CGND

SD

Card

TB2

91

8

7

6

5

4

3

2

1

Shield

Either type of shield

connection is acceptable.

Only one end is terminated.

Shield

The controls are powered

from the generator set

batteries with all B−

connections tied together.

Shield Shield

= Twisted Pair

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Control

1 RS-485 1 GND

4 RS-485 1 −

3 RS-485 1 +

Loading...

Loading...