Page 1

Service Manual

Controller

PowerCommand 3201

Page 2

Table of Contents

SECTION TITLE PAGE

1. Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABOUT THIS MANUAL 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST EQUIPMENT 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO OBTAIN SERVICE 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Control Operation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEQUENCE OF OPERATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL POWER ON/OFF MODES 2-1. . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL ASSEMBLY 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

READING FAULT CODES 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MENU DISPLAY AND SWITCHES 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LANGUAGE/UNITS SELECTION MENU 2-8. . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN MENU 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SUBMENUS 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALTERNATOR SUBMENUS 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL SUBMENU 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HISTORY/ABOUT SUBMENUS 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HISTORY/ABOUT SUBMENUS (CONT.) 2-15. . . . . . . . . . . . . . . . . . . . . . . . .

PARALLEL DATA SUBMENU 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER TRANSFER MAIN/SUBMENUS 2-17. . . . . . . . . . . . . . . . . . . . . . . . .

UTILITY (PWR TRAN) SUBMENUS 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATUS (PWR TRAN) SUBMENUS 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFER CONTROL (PWR TRAN) SUBMENU 2-21. . . . . . . . . . . . . . . . .

GENSET (PWR TRAN) SUBMENUS 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Control Calibration and Adjustment 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARALLELING and NON−PARALLELING 3-1. . . . . . . . . . . . . . . . . . . . . . . . .

SOFTWARE CALIBRATIONS 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODIFYING SETUP/ADJUST SUBMENUS 3-1. . . . . . . . . . . . . . . . . . . . . . . .

SETUP MENUS 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GOVERNING/VOLT REG SUBMENU 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CUSTOMER FAULTS SUBMENUS 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALIBRATION SUBMENUS 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ISOLATED BUS SUBMENUS 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UTILITY SUBMENUS 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER TRANSFER CONTROL MAIN MENUS 3-19. . . . . . . . . . . . . . . . . . .

UTILITY SENSORS SUBMENUS 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENSET SENSORS SUBMENUS 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIMERS SUBMENU 3-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TEST/EXERCISE SUBMENU 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUST SUBMENU 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CALIBRATION PROCEDURE 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

SECTION TITLE PAGE

CONTROL BOX WIRING 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RUN RELAYS (K11, K12, K13) 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALARM RELAY (K16) 3-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAGNETIC SPEED PICKUP UNIT (MPU) INSTALLATION 3-35. . . . . . . . .

ii

Page 4

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS − This manual contains

important instructions that should be followed during

installation and maintenance of the generator set and

batteries.

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the oper-

ator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal in-

jury or death.

WARNING

This symbol refers to a hazard or un-

safe practice which can result in severe person-

al injury or death.

CAUTION

This symbol refers to a hazard or un-

safe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use zinc

coated or copper fuel lines with diesel fuel.

Be sure all fuel supplies have a positive shutoff

valve.

Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are se-

cured and not warped. Do not use exhaust gases to

heat a compartment.

Be sure the unit is well ventilated.

Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Keep your hands, clothing, and jewelry away from

moving parts.

Before starting work on the generator set, discon-

nect battery charger from its AC source, then dis-

connect starting batteries, negative (−) cable first.

This will prevent accidental starting.

Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equip-

ment. Loose clothing and jewelry can become

caught in moving parts.

If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor can cause an engine to overspeed and

become difficult to stop, resulting in possible fire, explo-

sion, severe personal injury and death. Do not operate a

genset where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset is

equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of

the genset are solely responsible for operating the genset safely. Contact your authorized Cummins Power

Generation distributor for more information.

v

Page 5

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH

Remove electric power before removing protective

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical con-

tacts and cause shock or burning.

Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

DO NOT CONNECT GENERATOR SET DIRECT-

LY TO ANY BUILDING ELECTRICAL SYSTEM.

Hazardous voltages can flow from the generator set

into the utility line. This creates a potential for elec-

trocution or property damage. Connect only

through an approved isolation switch or an ap-

proved paralleling device.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

than water. DO NOT open a radiator or heat ex-

changer pressure cap while the engine is running.

To prevent severe scalding, let engine cool down

before removing coolant pressure cap. Turn cap

slowly, and do not open it fully until the pressure has

been relieved.

Used engine oils have been identified by some state

or federal agencies as causing cancer or reproduc-

tive toxicity. When checking or changing engine oil,

take care not to ingest, breathe the fumes, or con-

tact used oil.

Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and cloth; Class B fires, combustible

and flammable liquid fuels and gaseous fuels; Class

C fires, live electrical equipment. (ref. NFPA No. 10).

Make sure that rags or combustible material are not

left on or near the generator set.

Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under or near the unit.

Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause over-

heating and engine damage which present a poten-

tial fire hazard.

Keep the generator set and the surrounding area

clean and free from obstructions. Remove any de-

bris from the set and keep the floor clean and dry.

Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment un-

safe.

Substances in exhaust gases have been identified

by some state or federal agencies as causing can-

cer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

Do not store any flammable liquids, such as fuel,

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

Wear hearing protection when near an operating

generator set.

To prevent serious burns, avoid contact with hot

metal parts such as radiator system, turbo charger

system and exhaust system.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

vi

Page 6

1. Introduction

ABOUT THIS MANUAL

This manual provides PowerCommand Control

3201 (PCC) calibration and adjustment proce-

dures, control operation, alternator test and repair

procedures.

Operating and maintenance instructions are in the

applicable Operator’s Manual.

Read Important Safety Instructions and carefully

observe all instructions and precautions in this

manual.

TEST EQUIPMENT

To perform the test procedures in this manual, the

following test equipment must be available

True RMS meter for accurate measurement of

small AC and DC voltages.

Battery Hydrometer

Jumper Leads

Tachometer or Frequency Meter

Wheatstone Bridge or Digital Ohmmeter

Variac

Load Test Panel

Megger or Insulation Resistance Meter

InPower Service Tool (PC based genset ser-

vice tool)

HOW TO OBTAIN SERVICE

Always give the complete Model, Specification and

Serial number of the generator set as shown on the

nameplate when seeking additional service infor-

mation or replacement parts. The nameplate is lo-

cated on the side of the generator output box.

WARNING

parts can result in severe personal injury or

death, and/or equipment damage. Service per-

sonnel must be trained and experienced to per-

form electrical and mechanical service. Read

and follow Important Safety Instructions, on

pages iii and iv.

Incorrect service or replacement of

1-1

Page 7

THIS PAGE LEFT INTENTIONALLY BLANK

1-2

Page 8

2. Control Operation

GENERAL

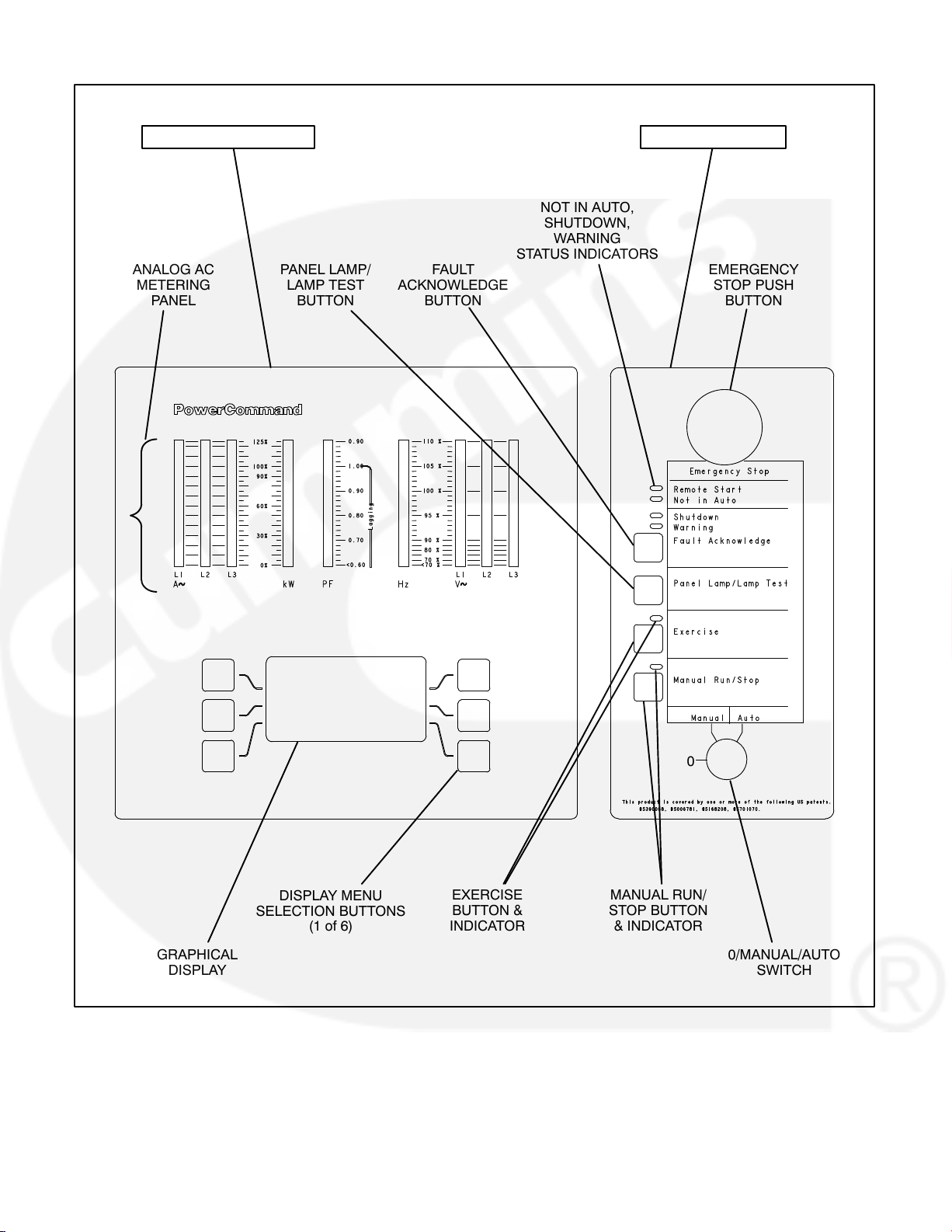

The following describes the function and operation

of the PowerCommand

dicators, control switches/buttons and graphical

display are located on the face of the control panel

as illustrated in Figure 2-1.

Normally, generator set configuration options are

set at the factory. When a new control is installed on

a generator set or when parts are replaced, the con-

trol must be configured for that generator set. Setup

and calibration procedures are described in Sec-

tion 3.

Control 3200 (PCC). All in-

SEQUENCE OF OPERATION

When the PowerCommand control is in the AUTO

mode, it will cause the generator set to start on re-

ceiving a signal from a remote device. The control

will initiate a starter cranking signal and verify that

the engine is rotating. The control will provide suffi-

cient fuel to the engine to accelerate to start discon-

nect speed. On reaching that speed, the control will

ramp the generator set to idle (warm-up) or rated

speed and voltage.

On reaching rated speed and voltage, the control

checks the system bus voltage. If no bus voltage is

present, it will wait for a pulse from a remote Master

First Start Sensor. On receiving that pulse, the control will signal the paralleling breaker to close.

If bus voltage is present, the control will check for

proper phase rotation, adjust the generator set to

the bus voltage and frequency level, and then syn-

chronize the generator set to the system bus. When

a synchronous condition is achieved, the control will

send a signal to close the paralleling breaker.

When the paralleling breaker is closed, the genera-

tor set will assume it’s proportional share of the total

load on the system bus.

CONTROL PANEL POWER ON/OFF

MODES

The power on/off modes of the control panel and op-

erating software are Power On, Screen Saver and

Sleep/Awake.

Power On Mode: In this mode, power is continu-

ously supplied to the control panel. The control’s

operating software and control panel LEDs/graphi-

cal display will remain active until the Screen Saver

mode is activated.

2-1

Page 9

Screen Saver Mode: Power to the graphical dis-

play will be removed after 10 minutes (generator set

not running or running). The 10 minute timer resets

and begins after each control panel action (any button or switch selection) or signal received by the operating software. The bottom LEDs of the Analog

AC Metering Panel (bar graphs) may remain on dur-

ing Screen Saver mode, indicating that the operat-

ing software is active (Awake mode).

If these conditions are not met, Sleep mode is disabled in Auto mode.

The graphical display can enter Screen Saver mode

even if Sleep mode is disabled.

If Sleep mode is enabled in Auto mode, Sleep mode

is activated when there are no unacknowledged

faults and Screen Saver mode is active.

When a “Warning” signal is sensed by the PCC (for

example, low coolant temp), the control will display

the warning message. The control will remain active

until the Fault Acknowledge button is pressed to

clear the warning message and start the 10 minute

timer.

Sleep/Awake Mode: In the Sleep mode, the con-

trol’s operating software is inactive and the LEDs

and the graphical display on the control panel are all

off. Sleep mode is a feature that is used to reduce

battery power consumption when the control is not

being used.

In Off mode, Sleep mode is activated when there

are no unacknowledged faults and Screen Saver

mode is active.

In Auto mode, Sleep mode can be enabled or dis-

abled. When shipped from the factory, it is disabled.

You can enable Sleep mode by making these

changes:

Use InPower service tool to set Auto Sleep En-

able to Sleep in Auto.

Set switch S1 on the Genset/Paralleling Card

to Sleep/Off. This switch is located next to con-

nector J8 and relay K9.

The operating software is initialized and the control

panel LEDs and graphical display are turned on in

response to one of the following:

Moving/pressing any control panel switch/but-

ton. (If Sleep mode is enabled in Auto mode,

the control will remain asleep if Sleep mode

was previously active in Off mode.)

Receiving a remote start input signal (genera-

tor set in Auto mode)

Receiving an active DCD signal on the RS-232

port.

Modem RI latch becoming active.

Digital display waking up.

Lonworks (backplane) wakeup becoming ac-

tive.

Customer fault 2 or 3 only (shutdown or warn-

ing indicator is on).

Dial Out process becoming active.

To activate the control and view the menu display

without starting the generator set, press any button

on the control panel.

2-2

Page 10

OPERATOR PANEL SWITCH PANEL

REMOTE START,

NOT IN AUTO,

SHUTDOWN,

WARNING

STATUS INDICATORS

ANALOG AC

METERING

PANEL

PANEL LAMP/

LAMP TEST

BUTTON

FAULT

ACKNOWLEDGE

BUTTON

EMERGENCY

STOP PUSH

BUTTON

GRAPHICAL

DISPLAY

0

DISPLAY MENU

SELECTION BUTTONS

(1 of 6)

EXERCISE

BUTTON &

INDICATOR

MANUAL RUN/

STOP BUTTON

& INDICATOR

FIGURE 2-1. CONTROL PANEL ASSEMBLY (FULL-FEATURED)

2-3

0/MANUAL/AUTO

SWITCH

Page 11

CONTROL PANEL ASSEMBLY

The control panel assembly (Figure 2-1) consist of

two panels, the Operator Panel and the Switch Pan-

el.

Dependent on site requirements, the Operator Pan-

el is either mounted on the control panel assembly

(full-featured) as shown in Figure 2-1 or contained

in a separate enclosure and mounted remotely of

the control panel assembly.

The function of several buttons on the control panel

will vary dependent on the location of the control

panel (remote or local of the control panel assem-

bly). If the function differs, it is noted as either “re-

mote” or “local operator panel” in the button de-

scription.

Operator Panel

The operator panel contains the following compo-

nents:

Analog AC Metering Panel: This panel simulta-

neously displays 3-phase line to line AC volts and

current, kW, power factor and frequency.

The meter panel is composed of a series of LEDs,

that are configured in bar graphs for each function.

The LEDs are color coded, with green indicating

normal range values, amber for warning levels and

red for shutdown conditions.

Scales for each function are in % of nominal values.

Resolution is 1% for values close to nominal, and increases at values further from nominal.

Graphical Display: The graphical display is capable of displaying up to 9-lines of data with approximately 27 characters per line. The display is used to

view the menus of the menu-driven operating sys-

tem.

The top three lines of the graphical display contain

the following control information in the order de-

scribed:

State Line − modes of operation, such as

Stopped, Time Delay To Start, Warm Up At

Idle, etc. (see Figure 2-2), and paralleling op-

erations, such as Standby, Dead BUS Close,

Synchronize, Load Share and Load Govern.

Action Line − system actions, such as Warning,

Derate, Shutdown Cool-down and Shutdown,

and fault codes.

Description Line − Fault code messages.

Display Menu Selection Buttons: Six momentary

buttons—three on each side of the graphical dis-

play window—are used to navigate through the sys-

tem control menus and to adjust generator set pa-

rameters. The button is active when the message

adjacent to the button is highlighted (displayed in in-

verse video).

2-4

Page 12

Switch Panel

The switch panel contains the following components:

Emergency Stop Button: Push the button in for

emergency shutdown of the engine. If the engine is

not running, pushing the button in will prevent the

starting of the engine, regardless of the start signal

source (local or remote).

Fault Acknowledge: Press this button to acknowledge warning and shutdown messages after the

fault has been corrected.

To acknowledge a Warning message, the 0/Manual/Auto switch can be in any position. (It is not nec-

essary to stop the generator set to acknowledge an

inactive Warning condition.) To acknowledge a

shutdown message with this button, the 0/Manual/

Auto switch must be in the 0 (Off) position.

To reset:

1. Pull the button out.

2. Move the 0/Manual/Auto switch to 0.

3. Press the front panel Fault Acknowledge

button.

4. Select Manual or Auto, as required.

Remote Start Indicator: This green lamp is lit

whenever the control is receiving a remote run sig-

nal. When flashing, it indicates a load demand stop

mode.

Not in Auto Indicator: This red lamp flashes con-

tinuously when the 0/Manual/Auto switch is not in

the Auto position. (If in Auto position and lamp is

flashing, service is required.)

Shutdown Status Indicator: This red lamp is lit

whenever the control detects a shutdown condition.

The generator set can not be started when this lamp

is on. After the condition is corrected, shutdown in-

dicators can be reset by turning the 0/Manual/Auto

switch to the 0 position, and pressing the Fault Ac-

knowledge button.

Dependent upon the specific fault that occurs, the

engine may or may not shut down immediately. A

fault that could cause engine damage, causes an

immediate engine shutdown (bypasses engine

cool-down sequence). All other faults would allow

the engine to run during the cool-down sequence

before engine shutdown. In this case, the Shutdown

Status Indicator blinks during the cooldown period.

This button is also used to blink a fault code if the

Shutdown or Warning Status Indicator is lit. (This

function is used when the control does not contain a

graphical display.) Refer to Reading Fault Codes in

this section, which describes how to use this button

for interpreting fault codes.

Panel Lamp/Lamp Test Button: Press this button

to turn on or off the panel lamp. Press and hold

down this button for three seconds or more to turn

all control panel LEDs on to make sure all lamps illu-

minate. The illumination will shut off after releasing

the button.

Exercise Button: Press this button to initiate a pre-

programmed exercise sequence. To start the exer-

cise sequence, press and hold down the Exercise

button and move the O/Manual/Auto switch from

Auto to Manual and back to Auto or from Manual to

Auto.

Manual Run/Stop Button: This button starts and

stops the set locally and will bypass Time Delay to

Start and Stop sequences. The 0/Manual/Auto

switch must be in the Manual position to enable this

button.

0/Manual/Auto Switch: Manual position enables

the use of the switch panel Manual Run/Stop but-

ton.

Auto position enables start/stop control of the en-

gine from a remote location. (Disables the use of the

switch panel Manual Run/Stop button.)

Warning Status Indicator: This yellow lamp is lit

whenever the control detects a warning condition.

After the condition is corrected, warning indicators

can be reset by pressing the Fault Acknowledge

button. (It is not necessary to stop the generator set

if the fault becomes inactive during genset opera-

tion.)

0 (Off) position prevents the starting of the set (local

or remote). If moved to 0 during set operation, will

cause an immediate engine shutdown (bypasses

cool-down timers). This hot shutdown should be

avoided, if possible, to help prolong the life of the

engine. Hot shutdowns are logged by the system

software.

2-5

Page 13

READING FAULT CODES

If the genset contains the optional graphical display

and a fault occurs, the fault code/message will be

displayed in the display Description Line (Figure

2-2). If the control does not contain the graphical

display, the fault code is read from the Warning and

Shutdown status indicators.

A three digit fault code is indicated by three sets of

blinks separated by a two second pause. The first

set corresponds to the hundreds position, the second to the tens position and the third to the ones digit. Example for Code No. 213:

Shutdown LED:

blink-blink-pause-blink-pause-blink-blink-blink

Reading Fault codes Using Warning/Shutdown

Indicators: If the Warning or Shutdown status indi-

cator is lit, press and hold the Fault Acknowledge

button and release after one second or more. After

one second, the Shutdown lamp will begin to blink

the active fault code(s) as follows.

The Warning lamp is used to indicate the start of a

new code. The Warning lamp will remain on for 2

seconds, followed by the Shutdown lamp blinking

the fault code. This sequence occurs three times for

each code. The fourth flash of the Warning lamp in-

dicates the beginning of the second fault code.

There are distinct pauses between repetitions of the

code blink transmissions of the Shutdown lamp.

Warning LED:

blink (2 seconds)

The light will display the fault codes (active or inac-

tive) in succession, starting with the most recent. Up

to 32 (unacknowledged) fault codes can be stored

in control panel memory.

To return the control to the most recent fault code,

press and release the Fault Acknowledge button

(less than one second) and repeat procedure.

When the fault code is acknowledged and cor-

rected, the recorded fault will be deleted from the

LED fault log, but will remain in a data log that main-

tains a fault code history. (The InPower service tool

is required to view this data log.)

2-6

Page 14

MENU DISPLAY AND SWITCHES

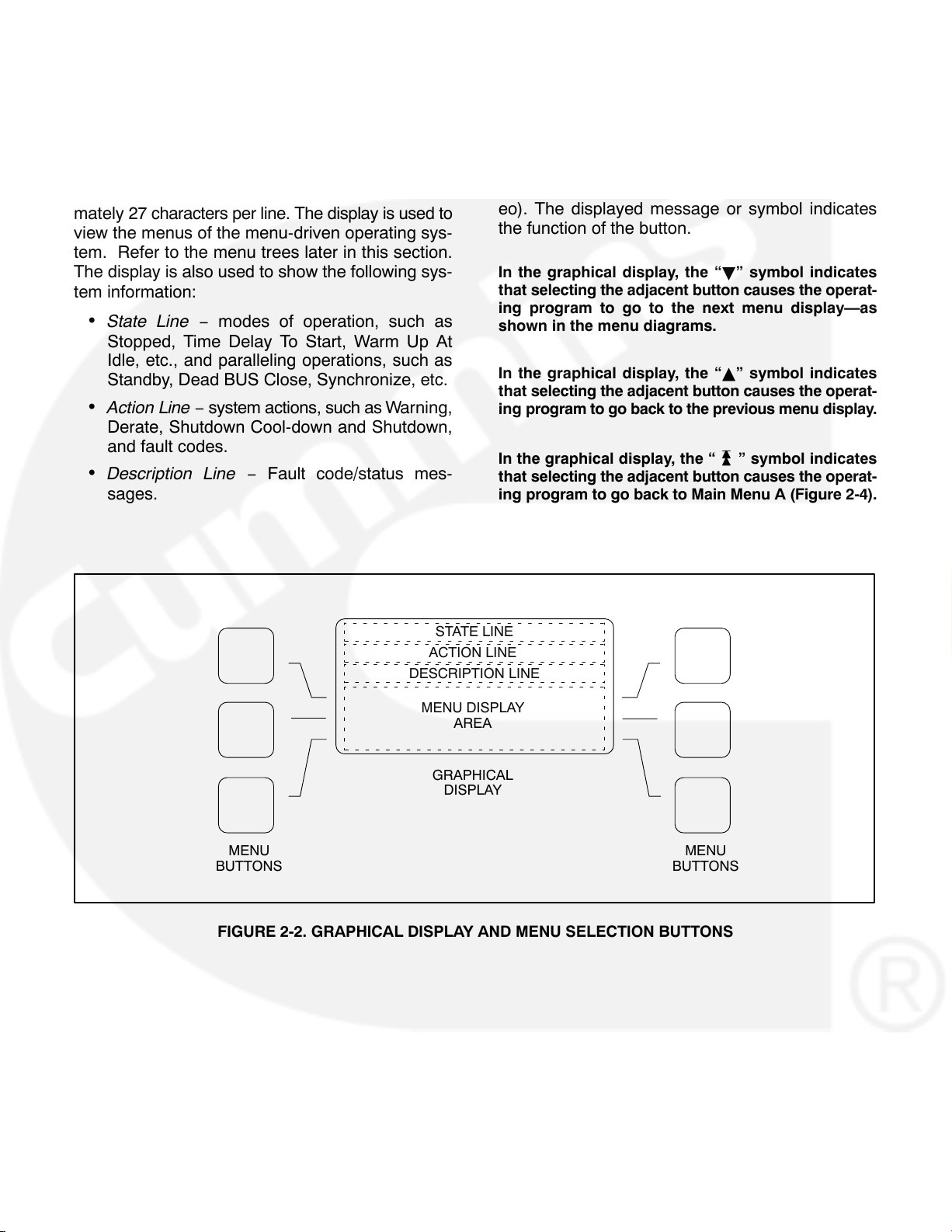

Figure 2-2 shows the graphical display and the

menu selection buttons.

Graphical Display: The graphical display is capable of displaying up to 9-lines of data with approximately 27 characters per line. The display is used to

view the menus of the menu-driven operating sys-

tem. Refer to the menu trees later in this section.

The display is also used to show the following sys-

tem information:

State Line − modes of operation, such as

Stopped, Time Delay To Start, Warm Up At

Idle, etc., and paralleling operations, such as

Standby, Dead BUS Close, Synchronize, etc.

Action Line − system actions, such as Warning,

Derate, Shutdown Cool-down and Shutdown,

and fault codes.

Description Line − Fault code/status mes-

sages.

Menu Buttons: Six momentary buttons—three on

each side of the graphical display window—are

used to navigate through the system control menus

and to adjust generator set parameters. The button

is active when the message or symbol adjacent to

the switch is highlighted (displayed in inverse video). The displayed message or symbol indicates

the function of the button.

In the graphical display, the “B” symbol indicates

that selecting the adjacent button causes the operat-

ing program to go to the next menu display—as

shown in the menu diagrams.

In the graphical display, the “Y” symbol indicates

that selecting the adjacent button causes the operat-

ing program to go back to the previous menu display.

In the graphical display, the “

that selecting the adjacent button causes the operat-

ing program to go back to Main Menu A (Figure 2-4).

” symbol indicates

STATE LINE

ACTION LINE

DESCRIPTION LINE

MENU DISPLAY

AREA

GRAPHICAL

DISPLAY

MENU

BUTTONS

FIGURE 2-2. GRAPHICAL DISPLAY AND MENU SELECTION BUTTONS

MENU

BUTTONS

2-7

Page 15

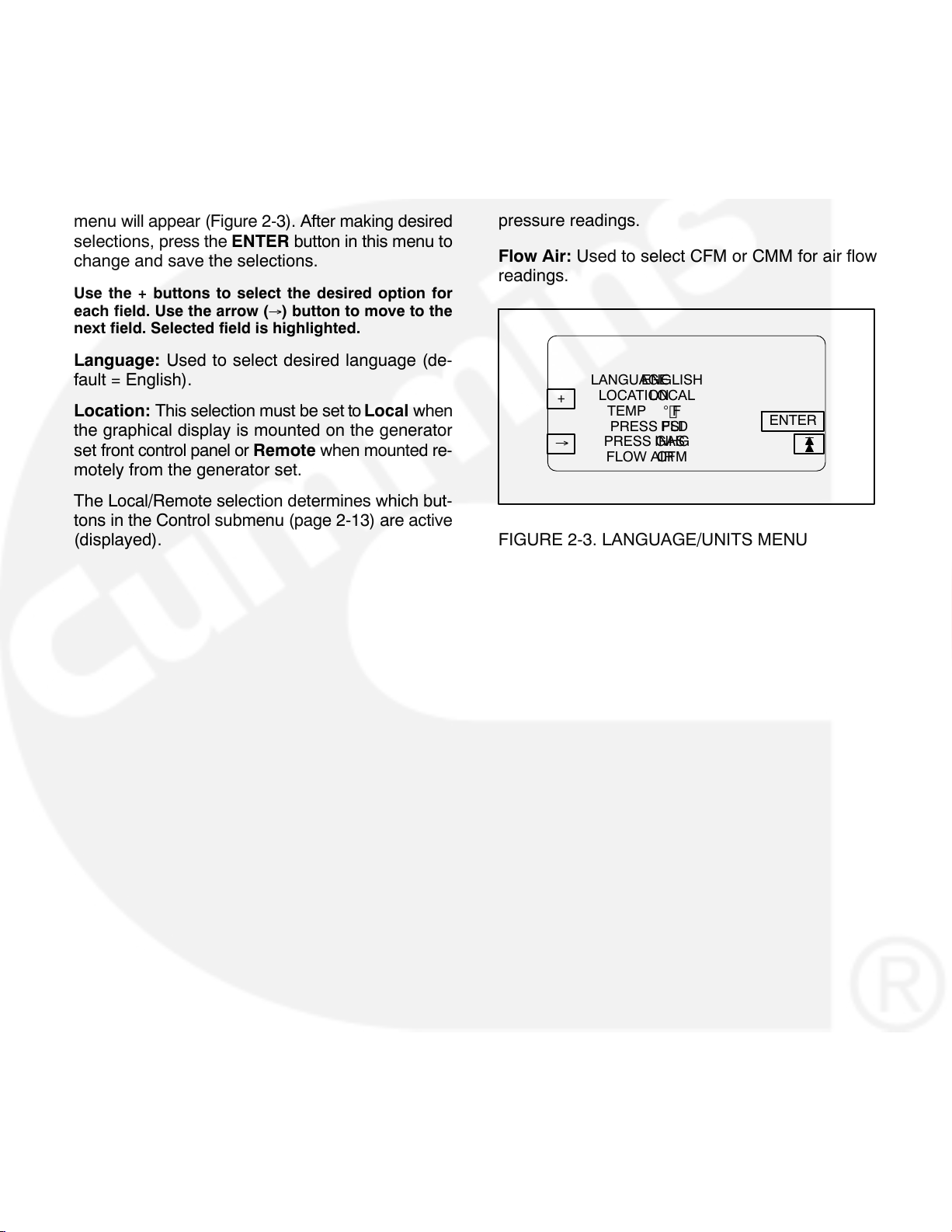

LANGUAGE/UNITS SELECTION MENU

During any control panel operation, you can select

one of three languages and change how units are

displayed by pressing the two lower menu buttons

(one on each side of display). When pressing these

two buttons simultaneously, the language/units

menu will appear (Figure 2-3). After making desired

selections, press the ENTER button in this menu to

change and save the selections.

Use the + buttons to select the desired option for

each field. Use the arrow (

next field. Selected field is highlighted.

Language: Used to select desired language (de-

fault = English).

Location: This selection must be set to Local when

the graphical display is mounted on the generator

set front control panel or Remote when mounted re-

motely from the generator set.

The Local/Remote selection determines which but-

tons in the Control submenu (page 2-13) are active

(displayed).

) button to move to the

Temp: Used to select F or C for temperature read-

ings.

Pressure Fluid: Used to select PSI, KPA, BAR or

IN for pressure readings.

Pressure Gas: Used to select INHG or MMHG for

pressure readings.

Flow Air: Used to select CFM or CMM for air flow

readings.

LANGUAGEENGLISH

LOCATIONLOCAL

+

TEMP F

PRESS FLDPSI

PRESS GASINHG

FLOW AIRCFM

ENTER

FIGURE 2-3. LANGUAGE/UNITS MENU

2-8

Page 16

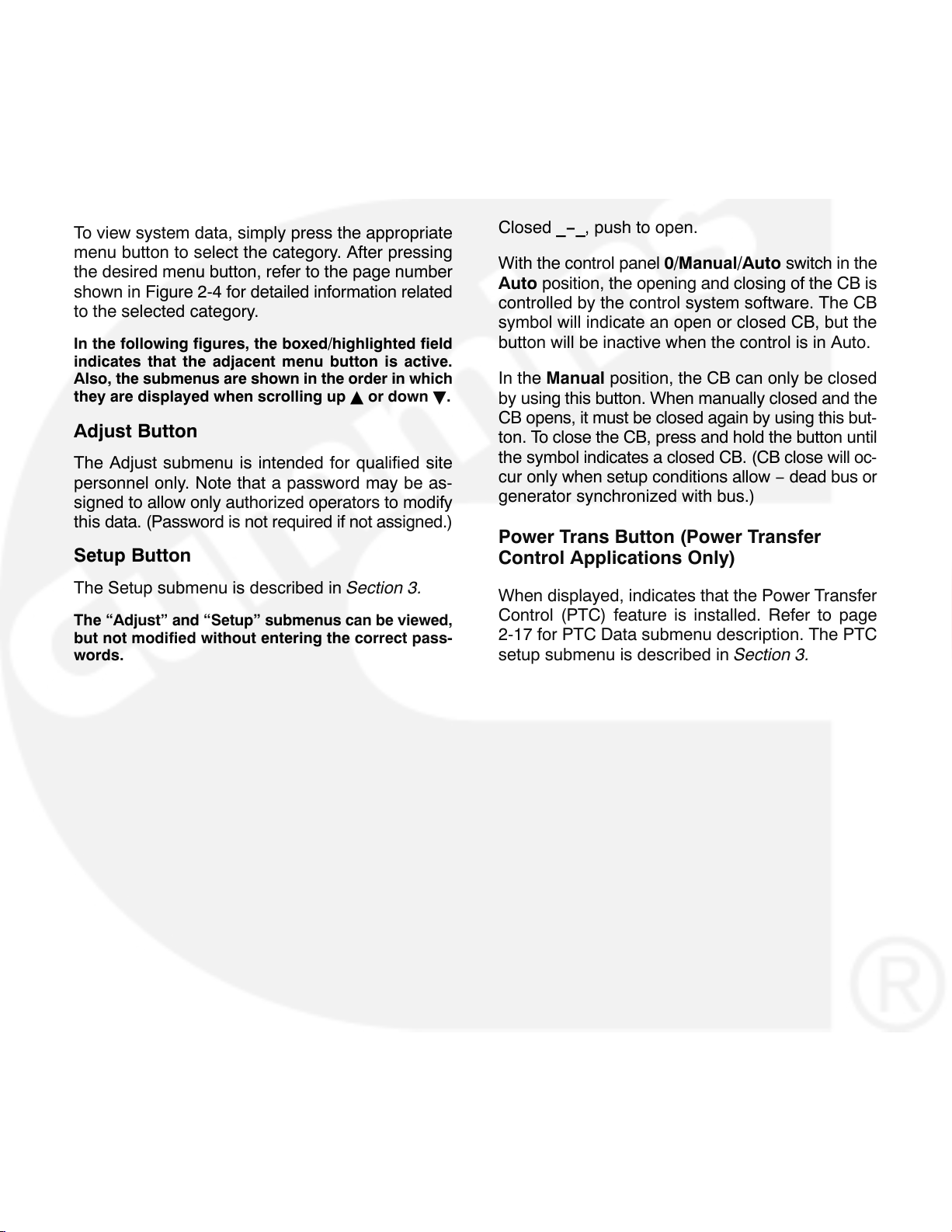

MAIN MENU

_\_ Button (Paralleling Applications Only)

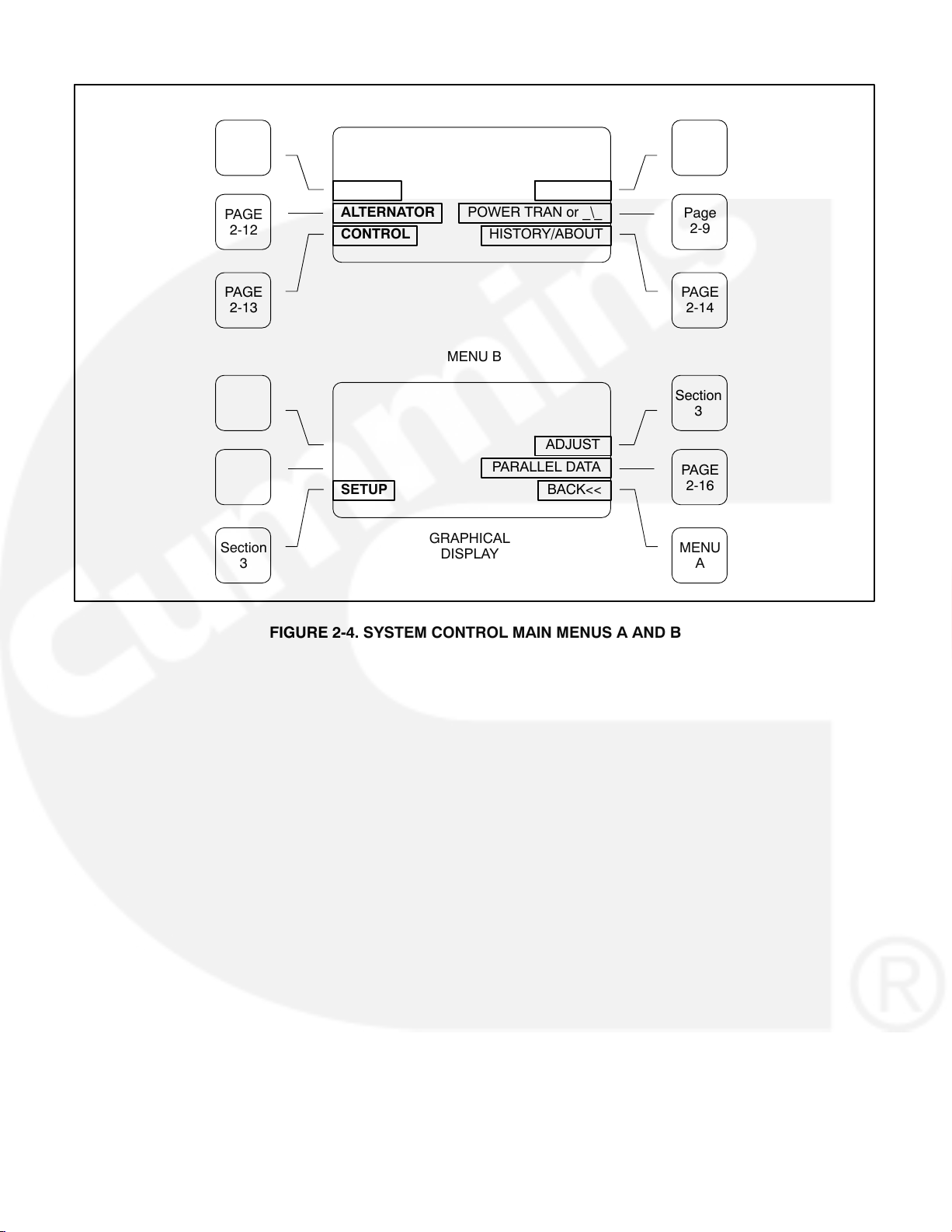

Figure 2-4 shows the main menus (Menu A and

Menu B) of the system control. The two main menus

are used to divide the system submenus into major

categories, such as, Engine Data, Alternator Data,

Control, etc.

To view system data, simply press the appropriate

menu button to select the category. After pressing

the desired menu button, refer to the page number

shown in Figure 2-4 for detailed information related

to the selected category.

In the following figures, the boxed/highlighted field

indicates that the adjacent menu button is active.

Also, the submenus are shown in the order in which

they are displayed when scrolling up

Y or down B.

Adjust Button

The Adjust submenu is intended for qualified site

personnel only. Note that a password may be as-

signed to allow only authorized operators to modify

this data. (Password is not required if not assigned.)

Setup Button

When displayed, indicates that the feature for generator set paralleling applications is installed. This

button is used to open and close the generator set

circuit breaker (CB). The symbol indicates if the CB

is opened or closed. Opened _\_, push to close.

Closed _−_, push to open.

With the control panel 0/Manual/Auto switch in the

Auto position, the opening and closing of the CB is

controlled by the control system software. The CB

symbol will indicate an open or closed CB, but the

button will be inactive when the control is in Auto.

In the Manual position, the CB can only be closed

by using this button. When manually closed and the

CB opens, it must be closed again by using this but-

ton. To close the CB, press and hold the button until

the symbol indicates a closed CB. (CB close will oc-

cur only when setup conditions allow − dead bus or

generator synchronized with bus.)

Power Trans Button (Power Transfer

Control Applications Only)

The Setup submenu is described in Section 3.

The “Adjust” and “Setup” submenus can be viewed,

but not modified without entering the correct pass-

words.

When displayed, indicates that the Power Transfer

Control (PTC) feature is installed. Refer to page

2-17 for PTC Data submenu description. The PTC

setup submenu is described in Section 3.

2-9

Page 17

MENU

BUTTONS

PAGE

2-11

MENU A

MENU

B

MENU

BUTTONS

PAGE

2-12

PAGE

2-13

Section

3

ENGINE

ALTERNATOR

CONTROL

SETUP

POWER TRAN or _\_

HISTORY/ABOUT

MENU B

PARALLEL DATA

GRAPHICAL

DISPLAY

MORE>>

ADJUST

BACK<<

FIGURE 2-4. SYSTEM CONTROL MAIN MENUS A AND B

Page

2-9

PAGE

2-14

Section

3

PAGE

2-16

MENU

A

2-10

Page 18

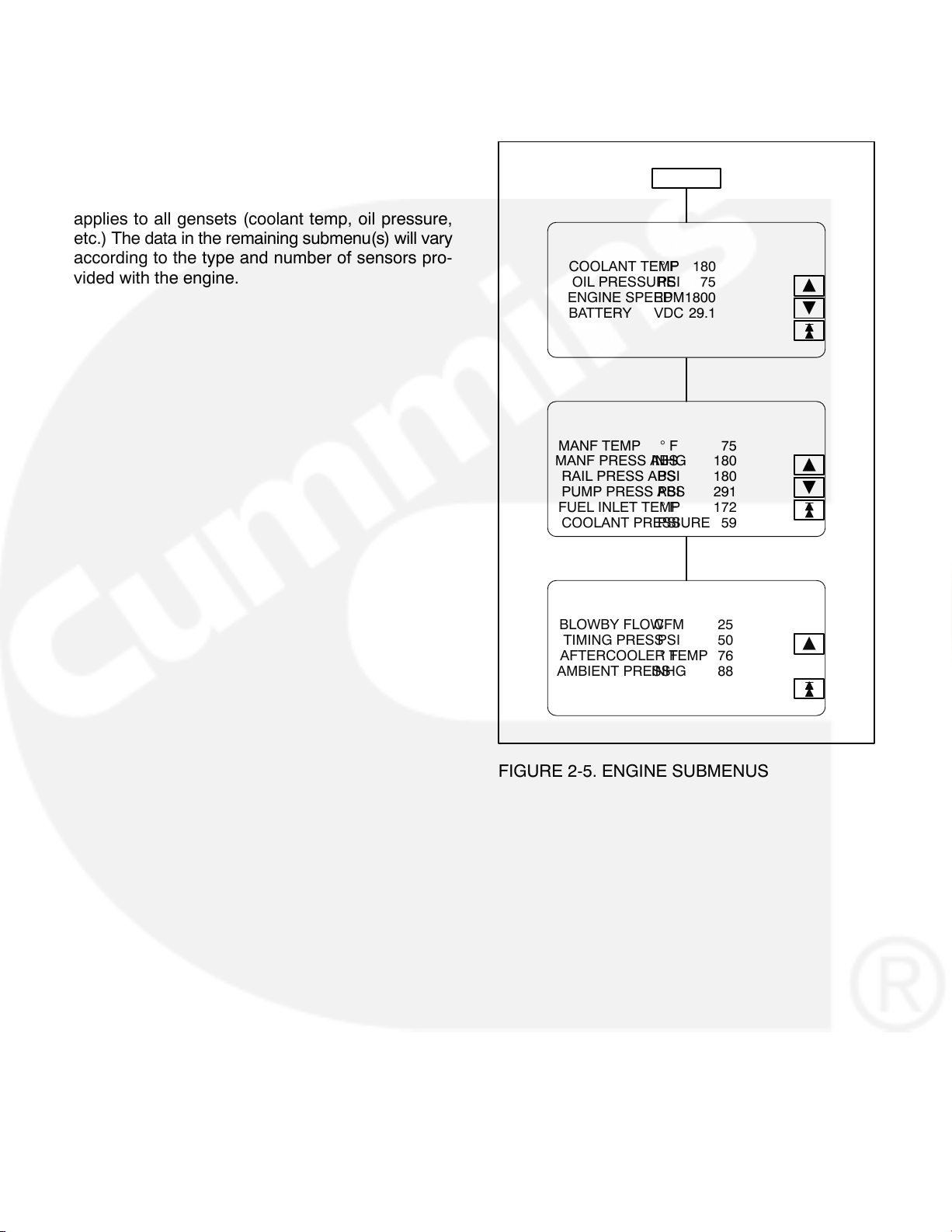

ENGINE SUBMENUS

If you press the “ENGINE” button in Menu A, the Engine submenus will appear (Figure 2-5).

The first submenu displays general information that

applies to all gensets (coolant temp, oil pressure,

etc.) The data in the remaining submenu(s) will vary

according to the type and number of sensors pro-

vided with the engine.

ENGINE

COOLANT TEMP 180 F

OIL PRESSURE 75PSI

ENGINE SPEED 1800RPM

BATTERY 29.1VDC

MANF TEMP 75 F

MANF PRESS ABS 180INHG

RAIL PRESS ABS 180PSI

PUMP PRESS ABS 291PSI

FUEL INLET TEMP 172 F

COOLANT PRESSURE 59PSI

Y

B

Y

B

BLOWBY FLOW 25CFM

TIMING PRESS 50PSI

AFTERCOOLER TEMP 76 F

AMBIENT PRESS 88INHG

FIGURE 2-5. ENGINE SUBMENUS

Y

2-11

Page 19

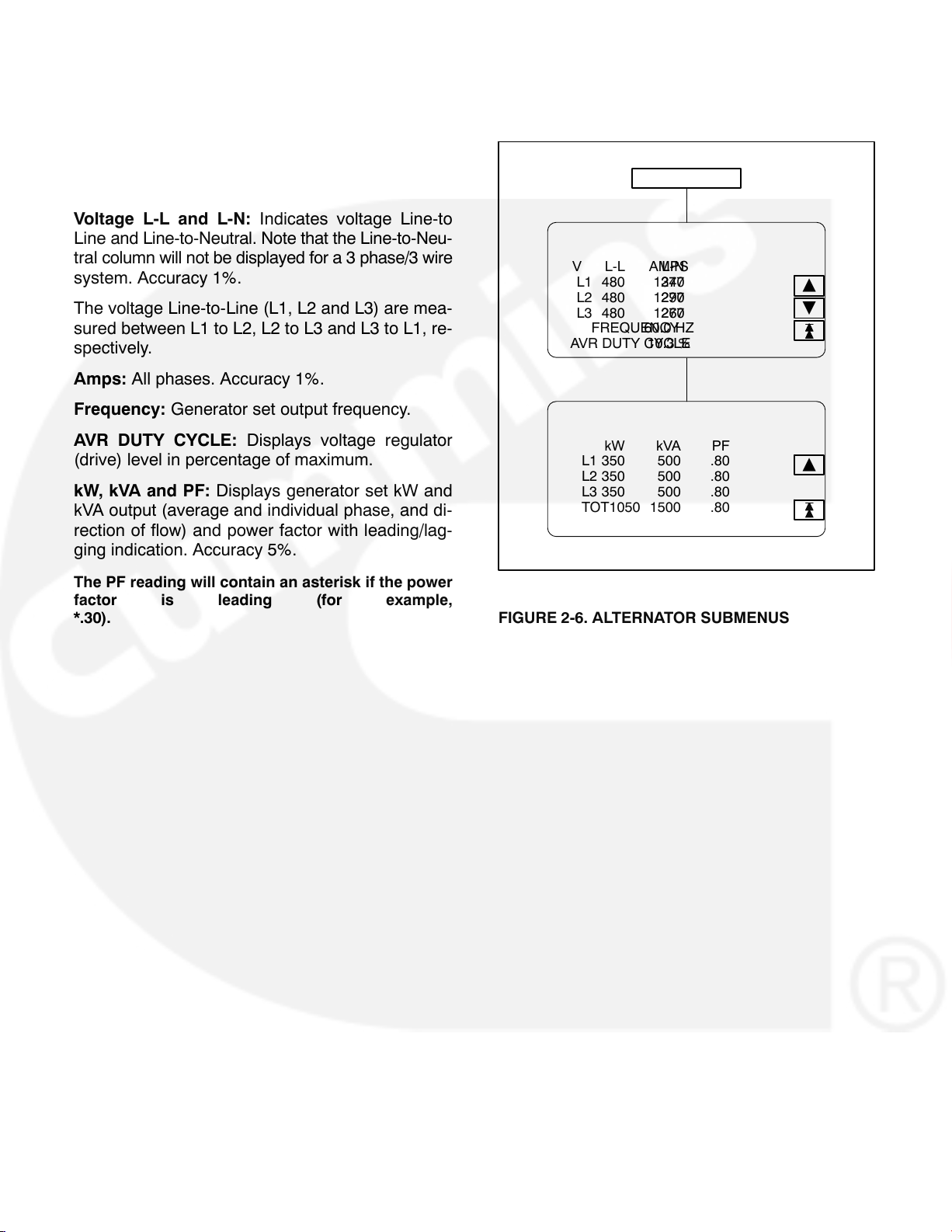

ALTERNATOR SUBMENUS

If you press the “ALTERNATOR” button in Menu A,

the Alternator Data submenus will appear (Figure

2-6).

Voltage L-L and L-N: Indicates voltage Line-to

Line and Line-to-Neutral. Note that the Line-to-Neu-

tral column will not be displayed for a 3 phase/3 wire

system. Accuracy 1%.

The voltage Line-to-Line (L1, L2 and L3) are mea-

sured between L1 to L2, L2 to L3 and L3 to L1, re-

spectively.

Amps: All phases. Accuracy 1%.

Frequency: Generator set output frequency.

ALTERNATOR

V L-L L-NAMPS

L1 480 2771340

L2 480 2771290

L3 480 2771260

FREQUENCY60.0 HZ

AVR DUTY CYCLE10.3 %

Y

B

AVR DUTY CYCLE: Displays voltage regulator

(drive) level in percentage of maximum.

kW, kVA and PF: Displays generator set kW and

kVA output (average and individual phase, and di-

rection of flow) and power factor with leading/lag-

ging indication. Accuracy 5%.

The PF reading will contain an asterisk if the power

factor is leading (for example,

*.30).

kW kVA PF

L1 350 500 .80

L2 350 500 .80

L3 350 500 .80

TOT1050 1500 .80

FIGURE 2-6. ALTERNATOR SUBMENUS

Y

2-12

Page 20

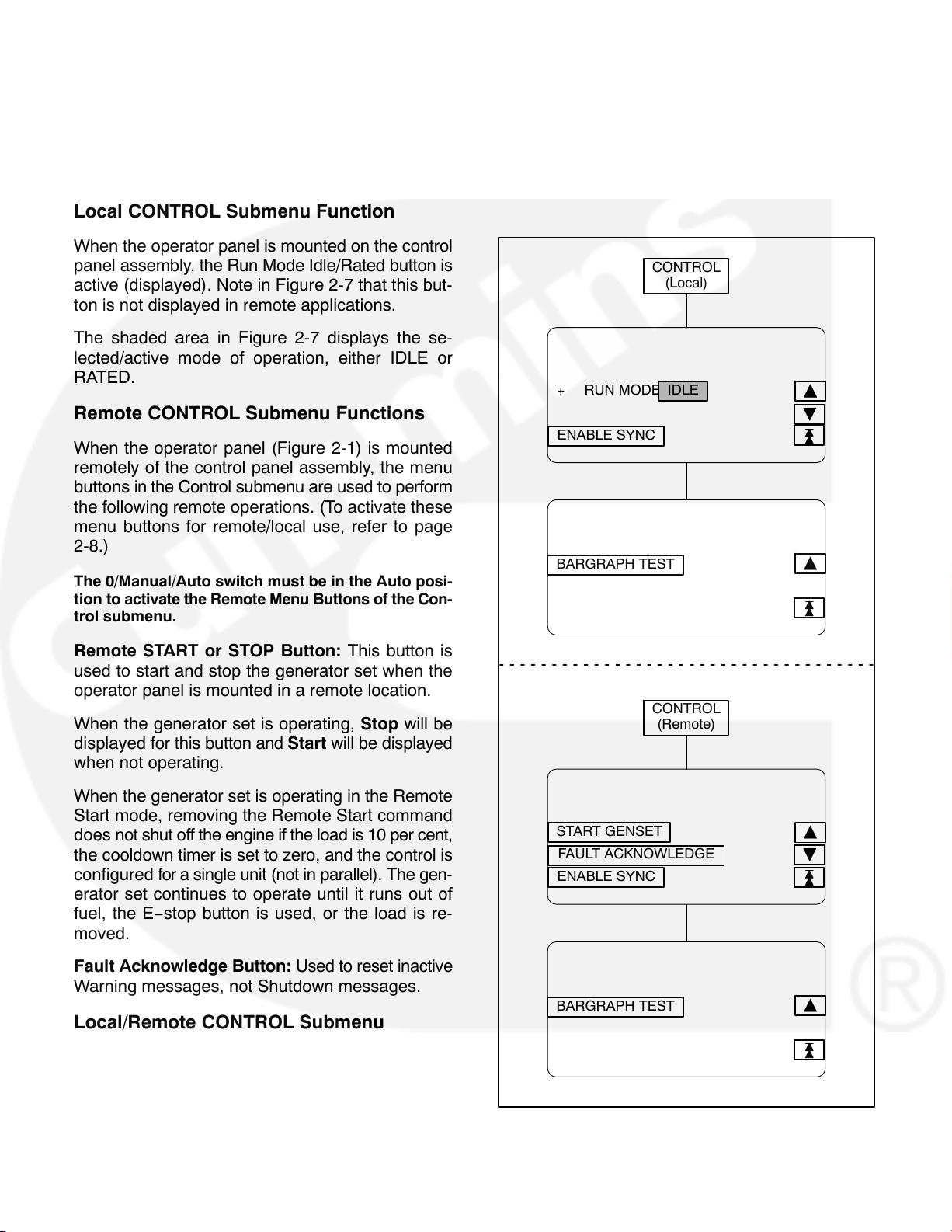

CONTROL SUBMENU

If you press the “CONTROL” button in Menu A, the

Control submenu will appear (Figure 2-7).

Local CONTROL Submenu Function

When the operator panel is mounted on the control

panel assembly, the Run Mode Idle/Rated button is

active (displayed). Note in Figure 2-7 that this but-

ton is not displayed in remote applications.

The shaded area in Figure 2-7 displays the se-

lected/active mode of operation, either IDLE or

RATED.

Remote CONTROL Submenu Functions

When the operator panel (Figure 2-1) is mounted

remotely of the control panel assembly, the menu

buttons in the Control submenu are used to perform

the following remote operations. (To activate these

menu buttons for remote/local use, refer to page

2-8.)

The 0/Manual/Auto switch must be in the Auto posi-

tion to activate the Remote Menu Buttons of the Con-

trol submenu.

Enable Sync: Displayed in paralleling applications

only. Intended for service personnel to turn off the

synchronizer for troubleshooting/testing purposes.

CONTROL

(Local)

+ RUN MODE IDLE

ENABLE SYNC

BARGRAPH TEST

YYY

B

Y

Remote START or STOP Button: This button is

used to start and stop the generator set when the

operator panel is mounted in a remote location.

When the generator set is operating, Stop will be

displayed for this button and Start will be displayed

when not operating.

When the generator set is operating in the Remote

Start mode, removing the Remote Start command

does not shut off the engine if the load is 10 per cent,

the cooldown timer is set to zero, and the control is

configured for a single unit (not in parallel). The gen-

erator set continues to operate until it runs out of

fuel, the E−stop button is used, or the load is re-

moved.

Fault Acknowledge Button: Used to reset inactive

Warning messages, not Shutdown messages.

Local/Remote CONTROL Submenu

Function

Bargraph Test: The function of this button remains

the same and is not dependent on operator panel

location. This button sequentially lights the LEDs to

test the bar graph display.

CONTROL

(Remote)

START GENSET

FAULT ACKNOWLEDGE

ENABLE SYNC

BARGRAPH TEST

FIGURE 2-7. CONTROL SUBMENU

B

Y

2-13

Page 21

HISTORY/ABOUT SUBMENUS

If you press the “HISTORY/ABOUT” button in Menu

A, the History/About submenus will appear (Figure

2-8).

HISTORY: The control maintains a data log of the

number of engine starts and number of operating

hours for the engine and control, and the megawatt

and maximum torque hours of the generator set.

This information is stored in non-volatile memory

and will not be deleted due to loss of battery power.

ABOUT: The About submenus provide the follow-

ing generator set information.

Genset model and wattage (kW/MW)

Output voltage and WYE, DELTA or SINGLE

Frequency 50 or 60 Hz

Rating: Standby, Prime or Base

Version level of the controller and panel operat-

ing software.

HISTORY/ABOUT

STARTS 533

ENGINE HOURS1236

CONTROL HOURS7879

KWHRS 890

HISTORY-HRS@ %MAX TORQUE

12345@0-923455@50-59

12345@10-1912345@60-69

12345@20-2912345@70-79

12345@30-3912345@80-89

Y

B

Y

B

MODEL 1750DQKB

VOLTAGE416 WYE

FREQUENCY60

RATINGSTANDBY

CONTROLLER VERSION

RTOPDN30008.DFA

BATSAPR 23 1999

OP PANEL VERSION

RTOP1.09 AUG 17 1999

BATS1.02 MAY 6 1999

CONTINUED TO NEXT PAGE

Y

B

Y

B

FIGURE 2-8. HISTORY/ABOUT SUBMENUS

2-14

Page 22

HISTORY/ABOUT SUBMENUS (CONT.)

FAULT HISTORY: The control maintains a data log

of all fault conditions as they occur, and time stamps

them with the control and engine operating hours.

Up to 32 (unacknowledged) fault codes can be

stored in control panel memory. After the fault is ac-

knowledged and corrected, the recorded fault will

be deleted from the control panel memory, but will

remain in a data log that maintains a fault code his-

tory. (The InPower service tool is required to view

this data log.)

The Fault History display line: 1 of 24 indicates that

24 faults are recorded and that the most recent fault

(1) detected by the controller is displayed.

The Occurrences display line: In this example, 5 in-

dicates that this is the fifth occurrence of this fault.

(The InPower service tool is required to review the

last four faults of this code.)

The Occurrences number is incremented for each

new occurrence of the same fault. The controller

must detect that the original sensed fault is cor-

rected before it will increment the occurrence num-

ber for that fault.

HISTORY/ABOUT (CONT.)

FAULT HISTORY: 1 OF 24

CNTL HOURS459

+

OCCURRENCES5

ENGINE HOURS334

FAULT CODE1437

(FAULT DESCRIPTION)

FIGURE 2-8. HISTORY/ABOUT SUBMENUS (CONT.)

Y

For example, when a Low Oil Pressure fault is de-

tected, the controller will increment the Occurrences

number by 1. This fault will remain active until the

fault is acknowledged and the controller detects that

the fault is corrected. An active fault will prevent the

controller from incrementing the Occurrences num-

ber each time the engine is started. When the con-

troller detects that the oil pressure is normal the fault

will become inactive, allowing the occurrences num-

ber to be incremented for the next detected Low Oil

Pressure

fault.

2-15

Page 23

PARALLEL DATA SUBMENU

If you press the “PARALLEL DATA” button in Menu

B, the Parallel Data submenu will appear (Figure

2-9). This menu is displayed in paralleling applications only.

_\_ Button: Used to open and close the generator

set circuit breaker (CB). The symbol indicates if the

CB is opened or closed. Opened _\_, push to close.

Closed _−_, push to open.

PARALLEL DATA STATUS LINE: The top line of

the graphical display is used to indicate the follow-

ing PARALLEL DATA status:

− STANDBY: Indicates no paralleling activity is

occurring at present.

− DEAD BUS CLOSE: Indicates first genset in

system to close to bus.

− SYNCHRONIZE: Genset is synchronizing to

bus.

− LOAD SHARE: Genset has closed to bus and

is sharing load with other gensets in system.

− LOAD GOVERN: Genset closed to bus in par-

allel with utility (mains).

BUS Voltage L-L: The BUS voltage Line-to-Line

(L1, L2 and L3) are measured between L1 to L2, L2

to L3 and L3 to L1, respectively.

BUS/GEN HZ: BUS/GEN hertz.

BUS/GEN SYNC STATUS: The bottom line of the

graphical display is used to indicate the following

BUS/GEN Sync status:

− NOT SYNCHRONIZING: Genset is in service

mode that does not allow auto sync feature.

(Selected via InPower service tool − deactivate

to allow synchronization.)

− SYNCHRONIZING: Genset is synchronizing to

bus.

− READY TO CLOSE: In manual mode, push cir-

cuit breaker close button to close breaker.

With the control panel 0/Manual/Auto switch in the

Auto position, the opening and closing of the CB is

controlled by the control system software. The CB

symbol will indicate an open or closed CB, but the

button will be inactive when the control is in Auto.

In the Manual position, the CB must be closed by

this button. When manually closed and the CB

opens, it must be closed again by using this button.

To close the CB, press and hold the button until the

symbol indicates a closed CB. (CB close will occur

only when setup conditions allow − dead bus or

generator synchronized with bus.)

PARALLEL DATA

LOAD GOVERN

V BUS GEN

L1 480 480

L2 480 480

L3 480 480

HZ60.1 60.1

DEG −122 NOT SYNCHRONIZING

Y

_\_

FIGURE 2-9. BUS DATA SUBMENU

2-16

Page 24

POWER TRANSFER MAIN/SUBMENUS

If you press the “POWER TRANS” button in Menu

A, the Power Transfer main menu will appear (Figure 2-10). The Power Transfer Control (PTC) feature must be installed to display this menu.

The PTC feature enables the PCC to monitor the

utility voltage (mains) and frequency for failure and

control the opening and closing of the contacts (cir-

cuit breakers) for the utility (S1) and the genset

(S2).

If utility fails, the control will initiate the genset start-

ing sequence, open S1 and close S2 to the load.

When utility returns, the load is retransferred to the

utility (S1 closes/S2 opens) and the control initiates

the genset shutdown sequence.

The

er Transfer main menu indicates which breaker

(utility or genset) is closed/opened to the load. The

symbol presently shown indicates that the utility

breaker is closed and supplying power to the load.

The Power Transfer main menu also indicates if the

utility and the generator set are available to accept

load. When the control detects that either source is

ready to accept load, UTILITY and/or GENSET will

be displayed in inverse video.

The Power Transfer main menu has four submenu

groups. Refer to the page numbers shown in Figure

2-10 for the Power Transfer submenu descriptions.

symbol displayed in the middle of the Pow-

2-17

Page 25

PTC Status Line

The top line of the graphical display is used to indicate the following PTC status:

− NOT ENABLED: PTC is not enabled. Control

panel switch in O (Off) position.

− MANUAL: Control panel switch is in Manual

position. All PTC actions or genset start/stop

actions are manually controlled.

− NORMAL UTIL: Load is connected to the util-

ity.

− RETRAN: Retransfer of load to utility.

− RETRAN OVRD: Immediate retransfer of load

to utility due to genset fault (e.g., warning, der-

ate, or shutdown w/cooldown fault). The re-

transfer timer is ignored as is the retransfer in-

hibit.

− EMERG TEST: Emergency Test sequence ini-

tiated through Remote Start switch with emer-

gency start sequence enabled (TB8-3 terminal

opened). Emergency test mode means that

the genset will continue to run even if a genset

warning or derate fault occurs. This test can be

performed with or without load (refer to TEST/

EXERCISE submenu in Section 3).

− TEST: Test sequence initiated through Remote

Start switch with emergency start sequence

disabled (TB8-3 terminal closed). Test mode is

non-emergency, which means that a retransfer

to utility will occur if any problems occur with

the genset while testing with load. This test can

be performed with or without load (refer to

TEST/EXERCISE submenu in Section 3).

− EXERCISE: Exercise sequence initiated

through control panel. This test can be per-

formed with or without load (refer to TEST/EX-

ERCISE submenu in Section 3). A retransfer to

utility will occur if any problems occur with the

genset during the exercise sequence.

− UTILITY FAIL: Utility has failed. (Initiates

transfer of load to genset if O/MANUAL/AUTO

switch is in AUTO.)

MENU

BUTTONS

PAGE

2-19

PAGE

2-20

PAGE

2-21

PTC STATUS LINE

B UTILITY

STATUS

TRANSFER CONTROL

DEG −123 SYNCHRONIZING

FIGURE 2-10. POWER TRANSFER MAIN MENU

GENSET B

PAGE

2-22

MENU

A

MENU

BUTTONS

2-18

Page 26

UTILITY (PWR TRAN) SUBMENUS

If you press the “Utility” button in the Power Transfer

Main menu, the Utility submenus will appear (Figure 2-11).

Voltage L-L and L-N: Indicates utility voltage Line-

to Line and Line-to-Neutral. Note that the Line-to-

Neutral column will not be displayed for a 3 phase/3

wire system. Accuracy 1%.

The voltage Line-to-Line (L1, L2 and L3) are mea-

sured between L1 to L2, L2 to L3 and L3 to L1, re-

spectively.

Amps: L2 only. Accuracy 1%.

UTILITY

UTILITY:

V L-L L-NAMPS

L1480 277

L2 480 2771320

L3480 277

FREQUENCY60.0 HZ

Y

B

Frequency: Utility frequency.

kW, kVA and PF: Displays (L2 only) utility kW and

kVA output (average and direction of flow) and pow-

er factor with leading/lagging indication. Accuracy

5%.

The PF reading will contain an asterisk if the power

factor is leading (for example, *.30).

UTILITY:

kW kVA PF

L1

L2 125 175 .96

L3

TOT

FIGURE 2-11. UTILITY SUBMENUS

Y

2-19

Page 27

STATUS (PWR TRAN) SUBMENUS

If you press the “Status” button in the Power Transfer Main menu, the Status submenus will appear

(Figure 2-12).

Connected: Indicates which source(s) is con-

nected to the load.

Available: Indicates when the corresponding

sources have acceptable output voltage and fre-

quency. Both can be available simultaneously.

Volt L12: Indicates utility and generator set Line 1 to

Line 2 voltage.

HZ: Utility and generator set output frequency.

KW L2: Utility and generator set Phase B (L2) kW

output.

Transfer Inhibit: This feature is used to control

load transfer to the genset. When activated, load

transfer to the genset will not take place if the utility

fails.

Transfer inhibit is controlled by connecting a remote

contact between TB3-57 and TB3-58. Closing the

contact enables the feature and opening the con-

tact disables it. When enabled, the event is dis-

played on the graphical display.

Retransfer inhibit is controlled by connecting a remote contact between TB3-64 and TB3-65. Closing

the contact enables the feature and opening the

contact disables it. When enabled, the event is displayed on the graphical display.

STATUS

CONNECTEDYESNO

AVAILABLEYESNO

VOLT L12 4800

HZ 60.00.0

KW L2 4560

TRAN INHOFF

RETRAN INHON

UTILGEN

Y

B

Y

Retransfer Inhibit: This feature is used to prevent

the PTC from automatically transferring the load

back to the utility. When activated, load transfer will

not take place unless the genset fails (Retransfer

Inhibit is ignored if the genset fails).

FIGURE 2-12. STATUS SUBMENUS

2-20

Page 28

TRANSFER CONTROL (PWR TRAN) SUBMENU

If you press the “TRANSFER CONTROL” button in

the Power Transfer Main menu, the Transfer Control submenu will appear (Figure 2-13).

TRANSFER CONTROL

The

symbol displayed in the middle of the

TRANSFER CONTROL submenu indicates which

breaker (utility or genset) is closed/opened to the

load. The symbol presently shown indicates that the

utility breaker is closed and supplying power to the

load.

During genset operation in the manual mode, you

can manually transfer/retransfer load between the

utility and the genset. To transfer load, press the ap-

propriate CB ENABLE button (Utility or Genset).

Example (Figure 2-13)

In the example in Figure 2-13, the CB ENABLE but-

ton for “Utility” was pressed. (If the CB ENABLE

button for the “Genset” was pressed, ENABLE

GEN CB would be displayed in the second subme-

nu, allowing you to open or close the genset circuit

breaker.)

After pressing the “utility” CB ENABLE button, the

second submenu will be displayed allowing you to

either CANCEL or ENABLE the entered selection.

Pressing the CANCEL button will return the display

to the previous menu.

UTILITY GENSET

CB ENABLE CB ENABLE

<< BACK

ENABLE UTIL CB

CANCEL

UTILITY GENSET

OPEN UTIL CB ENABLE

<< BACK

Pressing the ENABLE button will display the third

submenu. With this submenu displayed you can re-

turn to the second submenu without opening the

utility circuit breaker (press <<BACK) or you can

press the OPEN UTIL button.

Pressing the OPEN UTIL button will display the

fourth submenu, indicating that the utility circuit

breaker is now opened.

Note that the fourth submenu displays CLOSE

UTIL. Pressing this button will close the utility circuit

breaker and redisplay the third subme-

nu.

UTILITY GENSET

CLOSE UTIL CB ENABLE

<< BACK

FIGURE 2-13. TRANSFER CONTROL SUBME-

NUS

2-21

Page 29

GENSET (PWR TRAN) SUBMENUS

If you press the “Genset” button in the Power Transfer Main menu, the Genset submenus will appear

(Figure 2-14).

Voltage L-L and L-N: Indicates voltage Line-to

Line and Line-to-Neutral. Note that the Line-to-Neu-

tral column will not be displayed for a 3 phase/3 wire

system. Accuracy 1%.

The voltage Line-to-Line (L1, L2 and L3) are mea-

sured between L1 to L2, L2 to L3 and L3 to L1, re-

spectively.

Amps: All phases. Accuracy 1%.

GENSET

GENSET:

V L-L L-NAMPS

L1 480 2771320

L2 480 2771320

L3 480 2771320

FREQUENCY60.0 HZ

Y

B

Frequency: Generator set output frequency.

kW, kVA and PF: Displays generator set kW and

kVA output (average and individual phase, and di-

rection of flow) and power factor with leading/lag-

ging indication. Accuracy 5%.

The PF reading will contain an asterisk if the power

factor is leading (for example,

*.30).

GENSET:

kW kVA PF

L1 100 150 .97

L2 125 175 .96

L3 150 200 .95

TOT375 525 .96

FIGURE 2-14. GENSET SUBMENUS

Y

2-22

Page 30

3. Control Calibration and Adjustment

GENERAL

This section contains calibration and adjustment

procedures for the generator set control.

PARALLELING AND NON−PARALLELING

If the generator set was purchased for a paralling

application but will be used for a non−paralling ap-

plication, entering the checksum data into the Data-

plate Checksum dialog in InPowert is not re-

quired. However, the Adjustments Paralleling −

Paralleling Level must be set to Basic.

SOFTWARE CALIBRATIONS

If the base card has software assembly A026 F566

v1.0 on the U33 flash memory chip, you must use

the latest software calibration for the control. If you

load an earlier software calibration onto a base card

with software assembly A026 F566 v1.0, the soft-

ware calibration will fail, and the board will lock up

permanent-

ly.

CAUTION

sembly A026 F566 v1.0 on the U33 flash memory

chip, you must use the latest software calibra-

tion for the control, or the board will lock up per-

manently.

If the base card has software as-

MODIFYING SETUP/ADJUST SUBMENUS

The Setup and Adjust submenus allow you to cali-

brate the graphical display meters and to adjust

system parameters, customer defined faults, gen-

erator set voltage/frequency and paralleling ap-

plications.

CAUTION

of the control can cause equipment malfunction

or damage. Calibration and adjustment must be

performed by technically qualified personnel

only.

The Setup submenus are intended for qualified ser-

vice personnel only. The Adjust submenu is in-

tended for qualified service and site personnel only.

For this reason, a password must be entered before

this data can be modified. The Setup and Adjust

submenus can be viewed, but not modified without

entering the correct password.

Improper calibration or adjustment

FIGURE 3-1. U33 FLASH MEMORY CHIP

Saving Menu Changes

Changes are automatically saved when the menu is

exited.

3-1

Page 31

PASSWORD Menu

To allow the site personnel to modify only the Adjust

submenu and not the Setup submenus, two passwords are assigned within the system software. An

Application password is used for the Setup submenus and a User password is used for the Adjust

submenu.

unauthorized adjustment, the entered password is

valid for 10 minutes after the last button is pressed

(i.e., the password will need to be reentered after

the ten minute time−out.

Entering Password

To enter the password:

The two passwords are assigned during the initial

installation of the generator set (via InPower) and

will vary between sites. The installer must make

sure that the passwords are available to the ap-

propriate personnel.

When the generator set is first installed, the Applica-

tion and User password are both set to GENSET to

allow initial modification of the Setup and Adjust

submenus. Assign new passwords when site instal-

lation is complete.

When viewing the Adjust menu, pressing the + or −

button will display the User Password menu.

When viewing a Setup menu, pressing the + or −

button will always display the Application Password

menu.

After entering the correct password, the system will

allow you to modify the submenus. To help prevent

+ OR − BUTTON

1. Display submenu to modify.

2. Press either the + or − button within the dis-

played submenu. The Password menu ap-

pears.

3. Press the + and − button to select the first char-

acter of the password (A−Z or 0−9). (Enter Ap-

plication password for Setup submenus; En-

ter User password for Adjust submenu.)

4. Press the

button to select the next character

field. Selected character field is highlighted.

5. Repeat steps 3 and 4 to enter remaining pass-

word characters.

6. Press the Enter button after entering the pass-

word. The submenu selected in step 1 will re-

appear.

7. After making desired changes to submenu, exit

submenu to save changes.

+ OR − BUTTON

ENTER APPLICATION PASSWORD

+

−

SETUP SUBMENU PASSWORD MENU

XXXXXXXX

ENTER

FIGURE 3-2. PASSWORD MENUS

3-2

ENTER USER PASSWORD

+

−

ADJUST SUBMENU PASSWORD MENU

XXXXXXXX

ENTER

Page 32

SETUP MENUS

Figure 3-3 shows the main menus (Menu A and

Menu B) of the system control and the two Setup

menus.

The Setup procedure is intended for qualified ser-

vice personnel only. The APPLICATION password

must be entered to modify the Setup submenu

fields. Refer to PASSWORD Menu in this section to

enter password and to save menu changes.

To display the two Setup menus, press the

MENU A MENU B

MORE>> button in Menu A and then the SETUP

button in Menu B.

To view system data or to adjust system parameters, press the appropriate Setup menu button to

display the desired Setup submenu(s). Refer to the

page number shown in Figure 3-3 for detailed information related to the selected submenu(s).

CAUTION

Improper calibration or adjustment

of the control can cause equipment malfunction

or damage. Calibration and adjustment must be

performed by technically qualified personnel

only.

ENGINE

ALTERNATOR

CONTROL

MORE>>

POWER TRAN or _\_

HISTORY/ABOUT SETUP

PAGE

3-4

GOVERNING/VOLT REG

PAGE

3-5

PAGE

3-6

PAGE

3-12

PAGE

3-7

CUSTOMER FAULTS

CALIBRATION

POWER TRANSFER SETUP

ISOLATED BUS

UTILITY

MENU

B

SETUP MENU 1

SETUP MENU 2

Y

Y

B

ADJUST

PARALLEL DATA

BACK<<

MENU

B

NEXT

MENU

MENU

A

ABOVE

MENU

MENU

A

PAGE

3-11

MENU

A

FIGURE 3-3. SETUP SUBMENUS

3-3

Page 33

GOVERNING/VOLT REG SUBMENU

If you press the “GOVERNING/VOLT REG” button

in the Setup menu, the Governing/Volt Regulator

submenu will appear (Figure 3-4).

Use the + and − buttons to increase or decrease the

values in the following fields. Use the arrow (

ton to move the cursor within a field or to the next

field. Exit menu to safe changes.

) but-

GOV GAIN: If the gain adjustment is set too high,

engine speed will “hunt” or oscillate. If gain is set too

low, the engine will respond too slowly to changes in

load and overspeed may result. (Gain should be reduced to 80% for paralleling installations.)

AVR GAIN: If the gain adjustment is set too high,

output voltage will be unstable. If gain is set too low,

the output voltage will respond sluggishly to

changes in load and overshoot may result.

3-4

Page 34

GOVERNING/VOLT REG

+

−

GOV GAIN80%

AVR GAIN100%

Y

FIGURE 3-4. GOVERNING/VOLT REG SUBMENU

3-5

Page 35

CUSTOMER FAULTS SUBMENUS

If you press the “CUSTOMER FAULTS” button in

the Setup menu, the Customer Faults submenus

will appear (Figure 3-5).

There are a total of four customer fault inputs.

(Faults 3 and 4 paralleling only.) The message dis-

played at the bottom of the menu can be modified

for each of these faults in addition to selecting the

following operating parameters for each fault.

Enable − On or Off

Active − Closed or Open

Response − Shutdown, Cooldown, Derate or

Warning

Shutdown: Genset will immediately shut

down. Normally used for engine faults.

Cooldown: Cooldown sequence will be initi-

ated before shutdown. Should not be used for

engine faults.

Derate: Used to lower kW output of genset for

warnings such as pre-high coolant tempera-

ture, etc. Paralleling application − controller will

reduce precentage of kW load sharing on the

set. Non-paralleling application − controller will

lower percentage of kW load by operating load

shed relay contacts.

Warning: Display message, genset continues

to operate.

The Enable and the Active fields apply to the Fault 1

and 4 submenus only.

With the Active field selected, pressing the + or −

buttons will toggle the selection between CLOSED

and OPEN. Use same operation for remaining field

selections.

To enter the desired customer fault message, press

the

B or Y button to display the submenu that con-

tains the customer fault message (1 through 4) to be

changed. Use the

button to scroll down through

the menu selections to the editable fault message

(bottom menu line).

Use the

button to move to each character posi-

tion within the fault message line.

With the desired character position selected, use +

or − buttons to select the appropriate character.

If these messages are changed, you should note

these changes in the Troubleshooting section of the

Operator’s manual for this generator set.

3-6

Page 36

CUSTOMER FAULTS

+

−

***CUSTOMER FAULT1 ******************

+

−

***CUSTOMER FAULT2 ******************

CUSTOMER FAULT1:

ENABLE ON

ACTIVE CLOSED

RESPONSEWARNING

CUSTOMER FAULT2:

RESPONSEWARNING

CONTINUES THROUGH TWO

ADDITIONAL MENUS FOR A

TOTAL OF FOUR POSSIBLE

CUSTOMER FAULT MESSAGES

Y

B

Y

B

FIGURE 3-5. CUSTOMER FAULTS SUBMENUS

3-7

Page 37

CALIBRATION SUBMENUS

If you press the “CALIBRATION” button in the Setup

menu, the Calibration submenus will appear (Figure 3-6).

Use the + and − buttons to increase or decrease the

values in the following fields. Use the arrow (

ton to move the cursor within a field or to the next

field. Exit menu to safe changes.

) but-

The Calibration submenus allow you to calibrate the

control with the reading from a calibrated meter.

Calibration is accomplished by using this section of

the menu software to adjust the display so that it

matches the reading taken on an accurate, recently

calibrated meter.

Calibration is normally only required when replac-

ing certain circuit cards. Refer to the Calibration

Procedure in this section which contains a list of the

cards that require control calibration.

When performing Bus Voltage Calibration from the

graphical display, the genset must be off and the Bus

live. If the genset is running, it will synchronize to the

Bus.

3-8

Page 38

CALIBRATION

VOLTAGE CALIBRATION

+

−

+

−

+

−

L1 480-X.X%

L2 480-X.X%

L3 480-X.X%

CURRENT CALIBRATION

L1 234-X.X%

L2 123-X.X%

L3 562-X.X%

BUS VOLTAGE CALIBRATION

L1 480 -X.X%

L2 480 -X.X%

L3 480 -X.X%

Y

B

Y

B

Y

FIGURE 3-6. CALIBRATION SUBMENUS

3-9

Page 39

ISOLATED BUS / UTILITY Submenus

(Paralleling Application)

The Isolated BUS submenus (Figure 3-7) and the

Utility submenus (Figure 3-8) adjust the control parameters for generator set protection, synchronizing and load sharing for both isolated bus and utility

(mains) paralleling applications. Utility (mains) par-

allel applications may require adjustment of both

the Isolated BUS and Utility submenus.

Always perform ISO BUS calibration before Utility

BUS calibration.

The sync check (permissive) function is operational

in both automatic and manual (RUN) modes. The

control will make sure that the generator set is at

proper voltage, within the defined sync check win-

dow for the defined period of time and that phase

rotation is correct. When all criteria are met, the par-

alleling breaker is closed automatically by the con-

trol (auto mode), or by operation of the breaker

close switch by the operator (manual mode).

The synchronizing function of the control is enabled

when the control has brought the generator set to

90% of rated speed and voltage, and has sensed

that bus voltage is available. The control automati-

cally adjusts the generator set speed and voltage to

match the bus frequency and voltage. The control

can force the generator set to match bus voltage

and frequency in a range of minus 40% to plus 10%

of normal bus conditions. When the paralleling

breaker has closed, the control will bring the generator set back to normal voltage and frequency.

When the generator set is paralleled to another

generator set, the control provides automatic load

sharing functions for both real (kW) and reactive

(kVAR) loads. Load sharing is proportional between

generator sets based on their standby ratings. If two

generator sets of different sizes are paralleled, they

will assume the same percentage of the system

load automatically. This can easily be verified on the

kW Load LED bar graph on the front of the control

panel.

When the utility paralleling mode is enabled and the

generator set paralleling breaker is closed, the gen-

erator set will assume load based on external ana-

log input signal. The input signal must be calibrated

from 0−5 VDC. When the signal is at 0.5 to 1 VDC,

the control will operate the generator at no load in

parallel with the utility (mains) source. At 4.5 VDC

and greater, the control will operate the generator

set at 110% of the generator set base load setting.

When the load govern signal is between 1 VDC and

4.5 VDC the control will operate the generator set at

a load level which is determined by a linear relation-

ship between the kW reference and the load govern

signal.

3-10

Page 40

ISOLATED BUS SUBMENUS

If you press the “ISOLATED BUS” button in the Setup menu, the Isolated BUS submenus will appear

(Figure 3-7).

Use the + and − buttons to increase or decrease the

values in the following fields. Use the arrow (

ton to move the cursor within a field or to the next

field. Exit menu to safe changes.

) but-

SYNC TIME LIMIT: This parameter adjusts the time

delay in seconds before the Fail To Synchronize

alarm will operate.

REVERSE PWR LMT: Adjusts the reverse power

set point. For PowerCommand generator sets, a

typical set point is 10-15%.

REVERSE PWR TIME: Adjusts the reverse power

function time delay. A typical time delay which is

suitable for PowerCommand generator sets is 3

seconds.

Lower reverse power set points can result in nuisance reverse power shutdown faults.

PERM WIN-PHASE: Adjusts the width of the per-

missive (sync-check) acceptance window. The ad-

justment range is from five to twenty electrical de-

grees. Recommended set point is 20 degrees for

isolated bus applications, and 15 degrees for utility

(mains) paralleling applications.

PERM WIN-TIME: Adjusts the time period (in sec-

onds) for which the generator set must be synchro-

nized with the system bus, before a breaker close

signal is issued by the PowerCommand control.

Available range is 0.5 to 5 seconds. Recommended

value for PowerCommand generator sets is 0.5

seconds for isolated bus applications.

3-11

Page 41

ISOLATED BUS

+

−

SYNC TIME LIMIT 120SEC

REV PWR TIME 3SEC

PERM WIN-PH 20DEG

PERM WIN-TIME .5SEC

CONTINUED TO NEXT PAGE

ISOLATED BUS:

REV PWR LMT 10%

Y

B

FIGURE 3-7. ISO BUS SUBMENUS

3-12

Page 42

Adjusting the control for a smaller sync-check window or longer time delay will cause synchronizing

time to be extended.

SYNC GAIN: The sync gain adjustment controls

how quickly the governor will respond to try to minimize the bus/generator phase difference. Increasing the gain speeds up the response. If the gain is

too high instability can result.

KVAR BALANCE: This function adjusts the kVAR

load sharing function of the generator set. Before

adjusting this value, all generator set calibrations

should be performed. If the total load on the system

is not shared proportionately, the kVAR balance can

be used to adjust the generator set for more precise

load sharing. Increasing the kVAR balance value

will cause the generator set to reduce the percent-

age of the total kVAR load on that set.

KW Balance and KVAR Balance changes should be

equally shared among all generator sets.

KW BALANCE: This function adjusts the kW load

sharing function of the generator set. Before adjust-

ing this value, all generator set calibrations should

be performed. If the total load on the system is not

shared proportionately, the kW Balance can be

used to adjust the generator set for more precise

load sharing. Increasing the kW Balance value will

cause the generator set to reduce the percentage of

the total kW load on that set.

KW GAIN: Adjusts the rate of change of kW load on

the generator set. With a constant load on the sys-

tem, if the generator set load is constantly chang-

ing, reduce the gain adjustment on the generator

set. This also allows modification of the rate of load

assumption on transient load change.

KVAR GAIN: Adjusts the rate of change of kVAR

load on the generator set. With a constant load on

the system, if the generator set load is constantly

changing, reduce the gain adjustment on the gener-

ator set. This also allows modification of the rate of

load assumption on transient load change.

3-13

Page 43

ISOLATED BUS (CONT.)

ISOLATED BUS:

SYNC GAIN 1.0

+

KW BALANCE 0.3

−

KVAR BALANCE 1.2

KW GAIN 1.0

KVAR GAIN 1.0

CONTINUED TO NEXT PAGE

Y

B

FIGURE 3-7. ISO BUS SUBMENUS (CONT.)

3-14

Page 44

1ST FAIL TIME: Time delay in seconds after a sig-

nal from the first start master is not sensed by the

PCC that a FIRST START FAIL warning is displayed.

RAMP UNLOAD TIME: When a load demand stop

input is sensed the load is ramped down from the

present load level on the set to the ramp unload lev-

el in the time specified in seconds.

RAMP UNLOAD LEVEL: The load demand ramp

unload function will ramp the load down from the

present level on the set to this level before opening

the set circuit breaker. Value shown is in % of genset

standby rating.

RAMP LOAD TIME: When the load demand stop

signal is removed the load is ramped from 0kW to

the load share level in the specified time after the

circuit breaker closes.

LOSS FIELD TIME: Adjusts the loss of field func-

tion time delay. A typical delay which is suitable for

PowerCommand generator sets is 2 seconds.

3-15

Page 45

ISOLATED BUS (CONT.)

1ST FAIL TIME 12SEC

+

RAMP UNLD 20SEC

−

RAMP UNLD LEVEL 10%

RAMP LOAD TIME 3SEC

LOSS FIELD 20SEC

ISOLATED BUS:

Y

FIGURE 3-7. ISO BUS SUBMENUS (CONT.)

3-16

Page 46

UTILITY SUBMENUS

If you press the “UTILITY” button in the Setup

menu, the Utility submenus will appear (Figure 3-8).

Use the + and − buttons to increase or decrease the

values in the following fields. Use the arrow (

ton to move the cursor within a field or to the next

field. Exit menu to safe changes.

) but-

BASE LOAD (%): This controls the maximum kW

load level that the generator set will operate at when

paralleled with the utility (mains). The value shown

indicates the steady state load on the generator as

a percent of the generator set standby rating.

Check generator set ratings for maximum load level

at which the generator set should operate when

paralleled with the utility (mains). Extended opera-

tion at load levels in excess of the generator set rat-

ing can cause abnormal engine wear or premature

engine failure.

PF LEVEL: Adjusts the power factor that the gener-

ator set will run at when paralleled to the utility

(mains). Recommended setting is 1.0.

RAMP LOAD TIME: This is the ramp time from

present set load to level determined by the load set

analog input. This is active when the control first enters the load govern mode.

RAMP UNLOAD TIME: This is the ramp time from

present set load to 0 kW. This ramp is active when

the load set analog input is less than 0.5 volts.

MODE − MULTIPLE/SINGLE: This controls wheth-

er the set is to operate as part of a multiple set or

single set (PLTE or PLTF) system. (Refer to “LOAD

DEMAND SHUTDOWN” and “SINGLE MODE EN-

ABLE” function descriptions in wiring diagram,

page 5-8.)

KW GOVERN GAIN: This controls the rate that the

generator set kW load is increased after the genera-

tor set has closed to the system bus when utility

(mains) paralleled. Decreasing this value will result

in slower loading of the generator set.