Page 1

OperatorOperator ManualManual

Generator Set

40-4000 Amps

OTPCA (Spec A)

OTPCB (Spec A)

OTPCC (Spec A)

OTPCD (Spec A)

OTPCE (Spec A-C)

OTPCF (Spec A-B)

OTPCG (Spec A-B)

OTPCH (Spec A-B)

OTPCJ (Spec A)

English

Original Instructions 5-2013 962-0132 (Issue 6)

Page 2

Page 3

Table of Contents

1. SAFETY PRECAUTIONS .............................................................................................................. 1

1.1 Electrical Shock and Arc Flash Can Cause Severe Personal Injury or Death ....................... 1

1.2 General Precautions ............................................................................................................... 1

2. INTRODUCTION............................................................................................................................ 3

2.1 Operator Manual..................................................................................................................... 3

2.2 How to Obtain Service............................................................................................................ 3

2.3 Model Identification................................................................................................................. 4

2.4 Transfer Switch Application .................................................................................................... 4

2.5 Specifications .......................................................................................................................... 5

2.5.1 Model OTPC ................................................................................................................ 5

2.6 Automatic Transfer Switch Typical Function........................................................................... 6

2.6.1 Open Transition with Sync Check................................................................................ 6

2.6.2 Programmed Transition................................................................................................ 6

2.6.3 Closed Transition ......................................................................................................... 6

2.7 Utility-to-Generator Set Operation .......................................................................................... 6

2.8 Utility-to-Utility Operation ........................................................................................................ 6

2.9 Generator-to-Generator Operation ......................................................................................... 7

2.9.1 Prime Power (Plant-to-Plant) Operation ...................................................................... 8

2.9.2 Dual Stand-By Operation ............................................................................................. 9

2.10 Control Level 1 and Level 2................................................................................................ 10

3. DESCRIPTION............................................................................................................................. 11

3.1 Cabinet.................................................................................................................................. 11

3.2 Protective Relay.................................................................................................................... 11

3.3 Transfer Switch Components................................................................................................ 14

3.3.1 Contact Assemblies ................................................................................................... 14

3.3.2 Linear Actuator........................................................................................................... 14

3.3.3 Motor Disconnect Switch (150-1000 Amp Switches)................................................. 15

3.3.4 Motor Disconnect Switch (1200-4000 Amp Switches)............................................... 15

3.3.5 Auxiliary Contacts ...................................................................................................... 15

3.4 Electronic Control System..................................................................................................... 15

3.4.1 Time Delays ............................................................................................................... 16

3.4.2 System Sensors......................................................................................................... 18

3.4.3 Transfer Modes.......................................................................................................... 24

3.4.4 Front Panel Test - Sequence of Events..................................................................... 29

3.5 Options.................................................................................................................................. 39

3.5.1 Battery Charger Options ............................................................................................ 39

3.5.2 PowerCommand Network Interface Option ............................................................... 47

3.5.3 Load Sequencing Option ........................................................................................... 51

3.5.4 Load Current and Power Sensor Option.................................................................... 51

3.5.5 Source 1 and Source 2 Connected Relays................................................................ 52

962-0132 (Issue 6) i

Page 4

Table of Contents 5-2013

3.5.6 Source 1 and Source 2 Available Relays .................................................................. 52

3.5.7 Test or Exercise Active Relay .................................................................................... 52

3.5.8 Load Shed Relay ....................................................................................................... 52

3.5.9 Fail to Transfer/Retransfer Relay............................................................................... 52

3.5.10 Fail to Synchronize Relay ........................................................................................ 52

3.5.11 Fail to Disconnect Relay .......................................................................................... 52

3.5.12 Elevator Pre-Transfer Delay Relay .......................................................................... 53

3.5.13 Not-in-Auto Relay..................................................................................................... 53

3.6 Control Panel (PowerCommand Control) ............................................................................. 53

3.6.1 Bar Graph Meter Panel.............................................................................................. 53

3.6.2 Switch Panel .............................................................................................................. 54

3.6.3 Digital Display ............................................................................................................ 55

3.6.4 Time Delay Glossary.................................................................................................. 56

4. OPERATION ................................................................................................................................ 59

4.1 Manual Operation ................................................................................................................. 59

4.1.1 Manual Operation - 40 to 1000 Amp Switches .......................................................... 59

4.1.2 Manual Operation - 1200 to 4000 Amp Switches ...................................................... 59

4.2 Automatic Operation ............................................................................................................. 61

4.2.1 Motor Disconnect Switch ........................................................................................... 61

4.3 System Testing ..................................................................................................................... 62

4.3.1 Generator Set Manual Start Test ............................................................................... 62

4.3.2 With-Load Standby System Test ............................................................................... 62

4.4 Generator Set Exercise......................................................................................................... 62

4.5 Planned Maintenance ........................................................................................................... 63

5. DIGITAL DISPLAY MENU SYSTEM............................................................................................ 65

5.1 Main Menus .......................................................................................................................... 65

5.2 Password and Setup Menus................................................................................................. 65

5.3 Navigation ............................................................................................................................. 65

5.4 Main Menu Descriptions ....................................................................................................... 66

5.4.1 First Main Menu ......................................................................................................... 66

5.4.2 Second Main Menu .................................................................................................... 68

5.4.3 Third Main Menu ........................................................................................................ 69

5.4.4 Setup Menu Navigation and Description ................................................................... 72

6. WIRING CONSIDERATIONS FOR CLOSED TRANSITION SWITCHES ................................... 85

6.1 Wiring Considerations for Closed Transition Transfer Switches .......................................... 85

6.2 Re-transfer and transfer inhibit functions.............................................................................. 85

6.3 Fail to disconnect .................................................................................................................. 87

7. TROUBLESHOOTING ................................................................................................................. 89

7.1 Control Module LED Indicators and Switch .......................................................................... 89

7.2 Fault Flash-Out ..................................................................................................................... 90

7.3 Exerciser Enable/Disable Switch .......................................................................................... 90

7.4 Troubleshooting Transfer Switch With the Digital Display .................................................... 90

7.4.1 Fault Events ............................................................................................................... 91

ii 962-0132 (Issue 6)

Page 5

5-2013 Table of Contents

7.5 Fault Event Definitions .......................................................................................................... 92

7.5.1 Controller Checksum Error ........................................................................................ 92

7.5.2 Low Controller Battery ............................................................................................... 92

7.5.3 ATS Fail to Close: Transfer ....................................................................................... 92

7.5.4 ATS Fail to Close: Re-Transfer.................................................................................. 92

7.5.5 Battery Charger Malfunction ...................................................................................... 92

7.5.6 Network Battery Low .................................................................................................. 92

7.5.7 Network Communications Error ................................................................................. 93

7.6 15/12-Amp Battery Charger Troubleshooting and Faults ..................................................... 93

7.6.1 Clearing Faults........................................................................................................... 93

7.6.2 Fault Alarm Output Connector ................................................................................... 93

7.7 Code 101 – Source 1 Connected (Event)............................................................................. 94

7.8 Code 102 – Source 1 Available (Event) ............................................................................... 94

7.9 Code 103 – Source 2 Connected (Event)............................................................................. 94

7.10 Code 104 – Source 2 Available (Event) ............................................................................. 95

7.11 Code 105 – Emergency Start A (Event) ............................................................................. 95

7.12 Code 106 – Test Start A (Event) ........................................................................................ 96

7.13 Code 107 – Emergency Start B (Event) ............................................................................. 96

7.14 Code 108 – Test Start B (Event) ........................................................................................ 97

7.15 Code 109 – Time Delay Engine Start A (Event) ................................................................. 97

7.16 Code 111 – Time Delay Engine Start B (Event) ................................................................. 98

7.17 Code 112 – Time Delay Transfer (Event) ........................................................................... 98

7.18 Code 113 – Time Delay Retransfer (Event) ....................................................................... 99

7.19 Code 114 – Engine Cool-Down A (Event) ........................................................................ 100

7.20 Code 115 – Program Transition (Event)........................................................................... 100

7.21 Code 116 – Transfer Pending (Event).............................................................................. 100

7.22 Code 117 – Test in Progress (Event) ............................................................................... 101

7.23 Code 118 – Exercise Active (Event)................................................................................. 101

7.24 Code 119 – Sync Check (Event) ...................................................................................... 102

7.25 Code 121 – S1 Under Voltage (Event) ............................................................................. 102

7.26 Code 122 – S1 Over Voltage (Event) ............................................................................... 103

7.27 Code 123 – S1 Frequency Fail (Event) ............................................................................ 103

7.28 Code 124 – S1 Loss Phase (Event) ................................................................................. 103

7.29 Code 125 – S1 Imbalance Fail (Event)............................................................................. 104

7.30 Code 126 – S2 Under Voltage (Event) ............................................................................. 104

7.31 Code 127 – S2 Over Voltage (Event) ............................................................................... 105

7.32 Code 128 – S2 Frequency Fail (Event) ............................................................................ 105

7.33 Code 129 – S2 Loss Phase (Event) ................................................................................. 106

7.34 Code 131 – S2 Imbalance Fail (Event)............................................................................. 106

7.35 Code 132 – Phase Rotation Failure (Event) ..................................................................... 107

7.36 Code 133 – Motor Disconnect (Event) ............................................................................. 107

7.37 Code 134 – Load Shed (Event) ........................................................................................ 107

7.38 Code 135 – Transfer Inhibit (Event) ................................................................................. 108

7.39 Code 136 – Retransfer Inhibit (Event) .............................................................................. 108

7.40 Code 137 – Bypassed to S1 (Event) ................................................................................ 109

7.41 Code 138 – Bypassed to S2 (Event) ................................................................................ 109

962-0132 (Issue 6) iii

Page 6

Table of Contents 5-2013

7.42 Code 139 – Not in Auto (Fault) ......................................................................................... 110

7.43 Code 141 – Service Tool (Event) ..................................................................................... 110

7.44 Code 143 – Sync Enable (Event) ..................................................................................... 111

7.45 Code 144 – Speed Adjust (Event) .................................................................................... 111

7.46 Code 145 – Fail to Sync (Event)....................................................................................... 111

7.47 Code 146 – Sequencer Output 1-8 (Event) ...................................................................... 112

7.48 Code 155 – Network Wink (Event) ................................................................................... 112

7.49 Code 156 – Common Alarm A (Event) ............................................................................. 113

7.50 Code 157 – Common Alarm B (Event) ............................................................................. 113

7.51 Code 158 – Loss of Power (Event)................................................................................... 114

7.52 Code 159 – TD Stop B (Event) ......................................................................................... 114

7.53 Code 161 – High Neutral Amps (Event) ........................................................................... 115

7.54 Code 162 –Preferred Source 1 (Event) ............................................................................ 115

7.55 Code 163 –Preferred Source 2 (Event) ............................................................................ 115

7.56 Code 164 – Source 1 Stopped (Event)............................................................................. 116

7.57 Code 165 – Source 2 Stopped (Event)............................................................................. 116

7.58 Code 167 – Control Lockout (Event) ................................................................................ 116

7.59 Code 168 – Panel Lock (Event)........................................................................................ 117

7.60 Code 169 – Max Parallel Time Exceeded (Event)............................................................ 117

7.61 Code 441 – Low Controller Battery (Event) ...................................................................... 118

7.62 Code 597 –Battery Charger Malfunction (Fault)............................................................... 118

7.63 Code 1113 – ATS Fail to Close: Transfer (Fault) ............................................................. 119

7.64 Code 1114 – ATS Fail to Close: RE-Transfer (Fault) ....................................................... 119

7.65 Code 1121 – ATS Fail to Disconnect (Fault).................................................................... 120

7.66 Code 1452 – Fail to Close S2 (Fault) ............................................................................... 121

7.67 Code 1453 – Failed to Open S2 (Fault)............................................................................ 121

7.68 Code 1468 – Network Communications Error (Fault)....................................................... 122

7.69 Code 2396 – Failed to Close S1 (Fault) ........................................................................... 122

7.70 Code 2397 – Fail to Open S1 (Fault)................................................................................ 123

iv 962-0132 (Issue 6)

Page 7

1 Safety Precautions

This manual includes the following symbols to indicate potentially dangerous conditions. Read

the manual carefully and know when these conditions exist. Then, take the necessary steps to

protect personnel and the equipment.

DANGER

This symbol warns of immediate hazards that will result in severe personal

injury or death.

WARNING

This symbol refers to a hazard or unsafe practice that can result in severe personal

injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice that can result in personal injury or

product or property damage.

1.1 Electrical Shock and Arc Flash Can Cause Severe Personal Injury or Death

High voltage in transfer switch components presents serious shock hazards that can result in

severe personal injury or death. Read and follow these suggestions:

• The Operator must always keep the transfer switch cabinet closed and locked.

• Make sure only authorized personnel have the cabinet keys.

• All service and adjustments to the transfer switch must be performed only by an electrician

or authorized service representative.

Whenever closed transition is used, approval to parallel with the local electric utility

must be obtained.

1.2 General Precautions

Refer to NFPA 70E Standard for Electrical Safety in the Workplace to be sure the proper

personal protective equipment (PPE) is worn around this product.

Follow these guidelines while working on or around electrical equipment.

• Place rubber insulated mats on dry wood platforms over metal or concrete floors when

working on any electrical equipment.

NOTICE

• Do not wear damp clothing (particularly wet shoes) or allow skin surfaces to be damp when

handling any electrical equipment.

962-0132 (Issue 6) 1

Page 8

1. Safety Precautions 5-2013

• Remove all jewelry when working on electrical equipment.

• Wear safety glasses whenever servicing the transfer switch.

• Do not smoke near the batteries.

• Do not work on this equipment when mentally or physically fatigued, or after consuming

alcohol or any drug that makes the operation of equipment unsafe.

WARNING

Incorrect service or replacement of parts can result in death, severe personal injury,

and/or equipment damage. Service personnel must be qualified to perform electrical

and/or mechanical service.

2 962-0132 (Issue 6)

Page 9

2 Introduction

2.1 Operator Manual

This manual covers models produced under the Cummins®and Cummins Power Generation

(CPG) brand names.

The information contained within the manual is based on information available at the time of

going to print. In line with Cummins Power Generation policy of continuous development and

improvement, information may change at any time without notice. The users should therefore

make sure that before commencing any work, they have the latest information available. The

latest version of this manual is available on QuickServe Online

(https://qsol.cummins.com/info/index.html).

This Operator Manual provides information necessary for the operation of the transfer switch(es)

identified on the cover of this manual. The transition capabilities of the transfer switch(es) are

identified in the following sections.

2.2 How to Obtain Service

When the transfer switch requires servicing, contact your nearest Cummins Power Generation

distributor. Factory-trained Parts and Service representatives are ready to handle all of your

service needs.

To contact your local Cummins Power Generation distributor in the United States or

Canada:

• Call 1-800-888-6626 (this automated service utilizes touch-tone phones only).

• Select Option 1 (press 1) and you will be automatically connected to the distributor nearest

you.

If you are unable to contact a distributor using the automated service, consult the Yellow

Pages. Typically, distributors are listed under one of the following:

• Generators-Electric

• Engines-Gasoline

• Engines-Diesel

• Recreational Vehicles-Equipment

• Parts and Service

For outside North America:

• Call Cummins Power Generation at 1-763-574-5000, 7:30 AM to 4:00 PM Central Standard

Time, Monday through Friday.

OR

• Send a fax to Cummins Power Generation using the fax number, 1-763-574-5298.

When contacting your distributor, always supply the complete model, specification and serial

number as shown on the generator set nameplate.

962-0132 (Issue 6) 3

Page 10

2. Introduction 5-2013

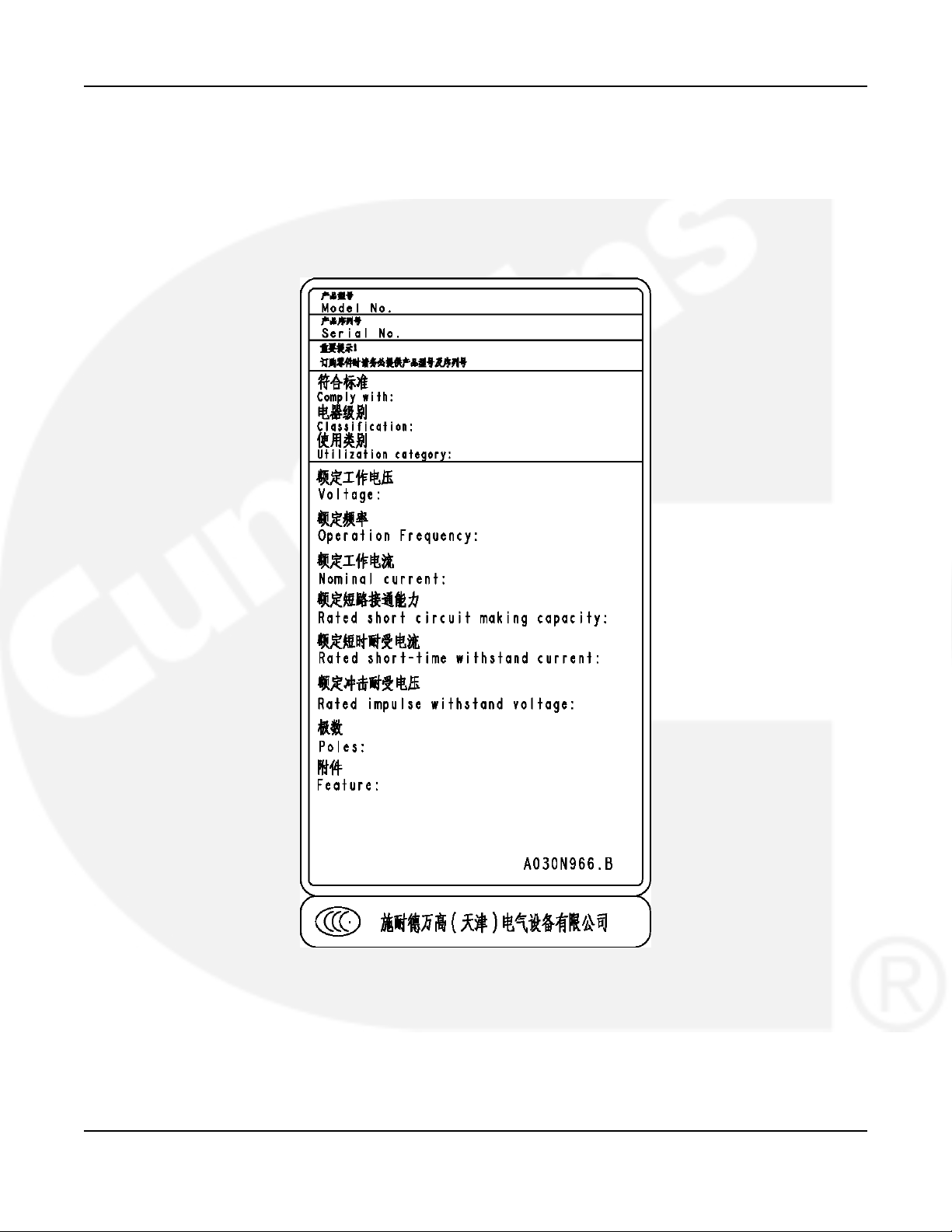

2.3 Model Identification

If the transfer switch ever needs to be serviced, the distributor will need this information in order

to properly identify your unit from the many types manufactured:

• Model No. (Product Model)

• Serial No. (Product Serial Number)

• Spec. (Product Specification Letter)

FIGURE 1. CONTROL NAMEPLATE

2.4 Transfer Switch Application

Transfer switches are an essential part of a building's standby or emergency power system. The

utility line (normal power), is backed up by a generator set (emergency power). The transfer

switch automatically switches the electrical load from one source to the other.

4 962-0132 (Issue 6)

Page 11

5-2013 2. Introduction

If utility power is interrupted, the load is transferred to the generator set (genset). When utility

power returns, the load is retransferred to the utility. The transfer and retransfer of the load are

the two most basic functions of a transfer switch.

2.5 Specifications

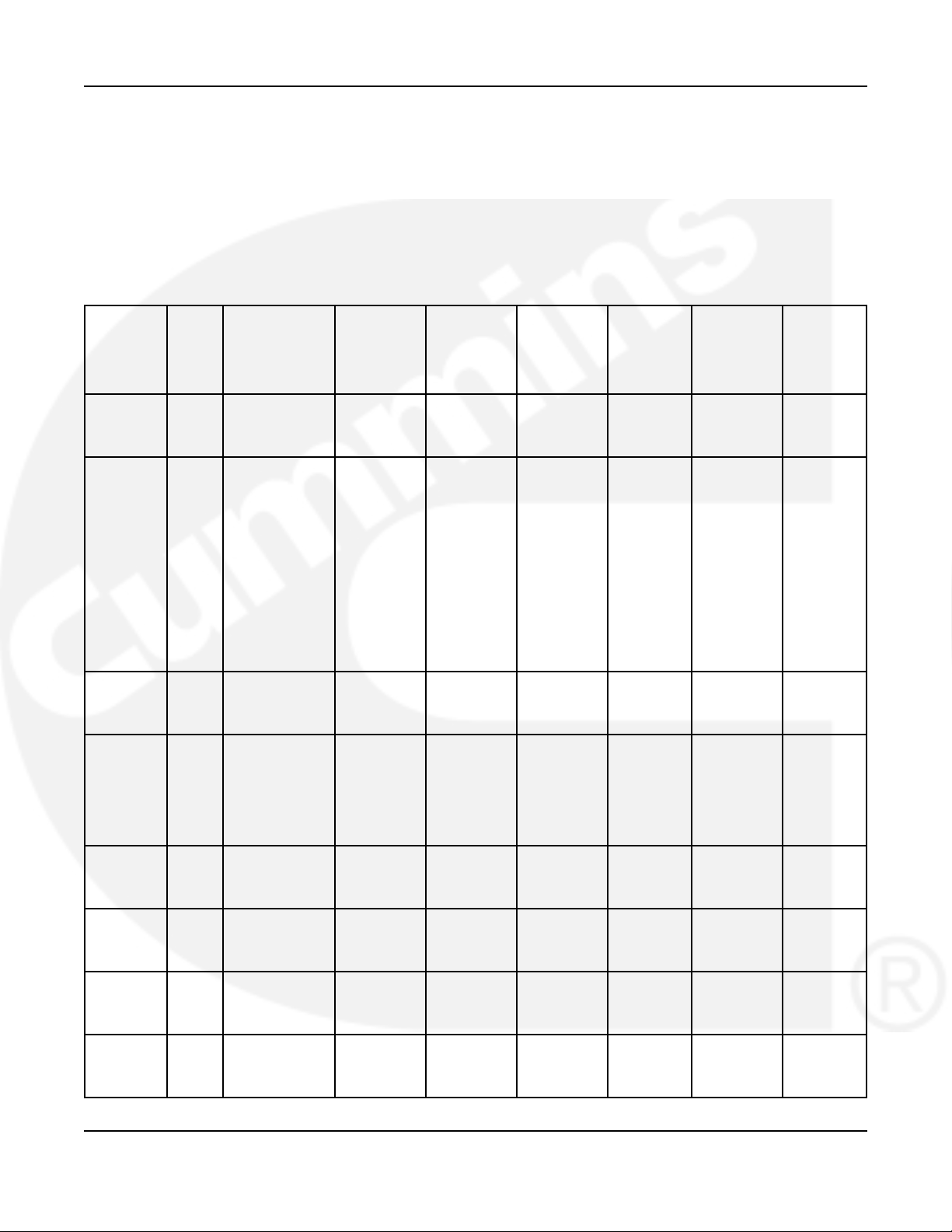

2.5.1 Model OTPC

Transfer Switch Model OTPC Specifications:

Model Amps Cabinet Types Util-to-Gen Gen-to-Gen Util-to-Gen Dual Plant-to- Transfer

(Level 1 & (Level 2)

2) (Prime

OTPCA 40 All Amps: OT

70 4, 3R, 1, 12, 4x X X X X PT

125

OTPCB 150 150-225 Amp OT

OTPCC 300 All Amps: OT

OTPCD 800 All Amps (3 & OT

1000 PT

OTPCE 1000 All Amps: OT

1200 1, 3R, 12, 4, 4x X X X X X PT

OTPCF 1600 1, 3R, 12, 4 OT

OTPCG 2000 1, 3R, 12, 4 OT

OTPCH 3000 1, 3R OT

(3 & 4-Pole):

225 PT

1, 3R, 12, 4x

260

150-225 Amp

(3 pole):

4

260 Amp (3 &

4-Pole):

1, 3R, 12, 4x

260 Amp (3

pole):

4

400 1, 3R, 12, 4, 4x X X X X PT

600

4-Pole):

1, 3R, 12, 4x

All Amps (3Pole):

4

X X X X

X X X X

X X X X X PT

X X X X X PT

X X X X X PT

& Util-to- Standby Plant Modes

Util

(Level 1 & Power)

2)

CT

CT

CT

CT

962-0132 (Issue 6) 5

Page 12

2. Introduction 5-2013

OTPCJ 4000 1, 3R OT

X X X X X PT

CT

2.6 Automatic Transfer Switch Typical Function

Automatic transfer switches perform the basic function of transferring the load to the available

power source. The controller monitors each source for allowable voltage and frequency range.

The transfer switch(es) identified on the cover of this manual are designed for each, all or a

combination of the following applications (If you are unsure which of these your transfer switch

uses, refer to the Specifications section of this manual):

2.6.1 Open Transition with Sync Check

Open transition with sync check executes an open transition (OT) transfer when both sources of

power are within specified tolerances of frequency, voltage and relative phase difference. If both

sources meet the tolerances, a fast transfer occurs.

2.6.2 Programmed Transition

Programmed transition executes a programmed transition (PT) transfer by disconnecting the

load from the source of power, pausing in the neutral position of the transfer switch (between

switched positions) to allow transient voltages from the load to diminish, and then the load is

switched to the other source.

2.6.3 Closed Transition

Closed transition executes a load transfer by momentarily paralleling both sources (a maximum

of 100ms) before switching sources.

2.7 Utility-to-Generator Set Operation

In utility-to-generator set applications, the transfer switch performs the following functions:

1. Senses the interruption of the Source 1 power (Utility).

2. Sends a start signal to the generator set (Source 2).

3. Transfers the load to the Source 2 power.

4. Senses the return of Source 1 (Utility).

5. Retransfers the load to Source 1.

6. Sends a stop signal to the generator set.

2.8 Utility-to-Utility Operation

In utility-to-utility applications, the transfer switch performs the following functions:

1. Senses the interruption of the Source 1 power (Utility).

2. Transfers the load to the Source 2.

3. Senses the return of Source 1 (Utility).

6 962-0132 (Issue 6)

Page 13

5-2013 2. Introduction

4. Retransfers the load to Source 1.

2.9 Generator-to-Generator Operation

In generator-to-generator applications, there are two possible configurations.

• Prime Power (Plant-to-Plant) Operation - Two generator sets provide all of the power

(utility power is not available).

• Dual Standby - Two generator sets are used to back up utility power.

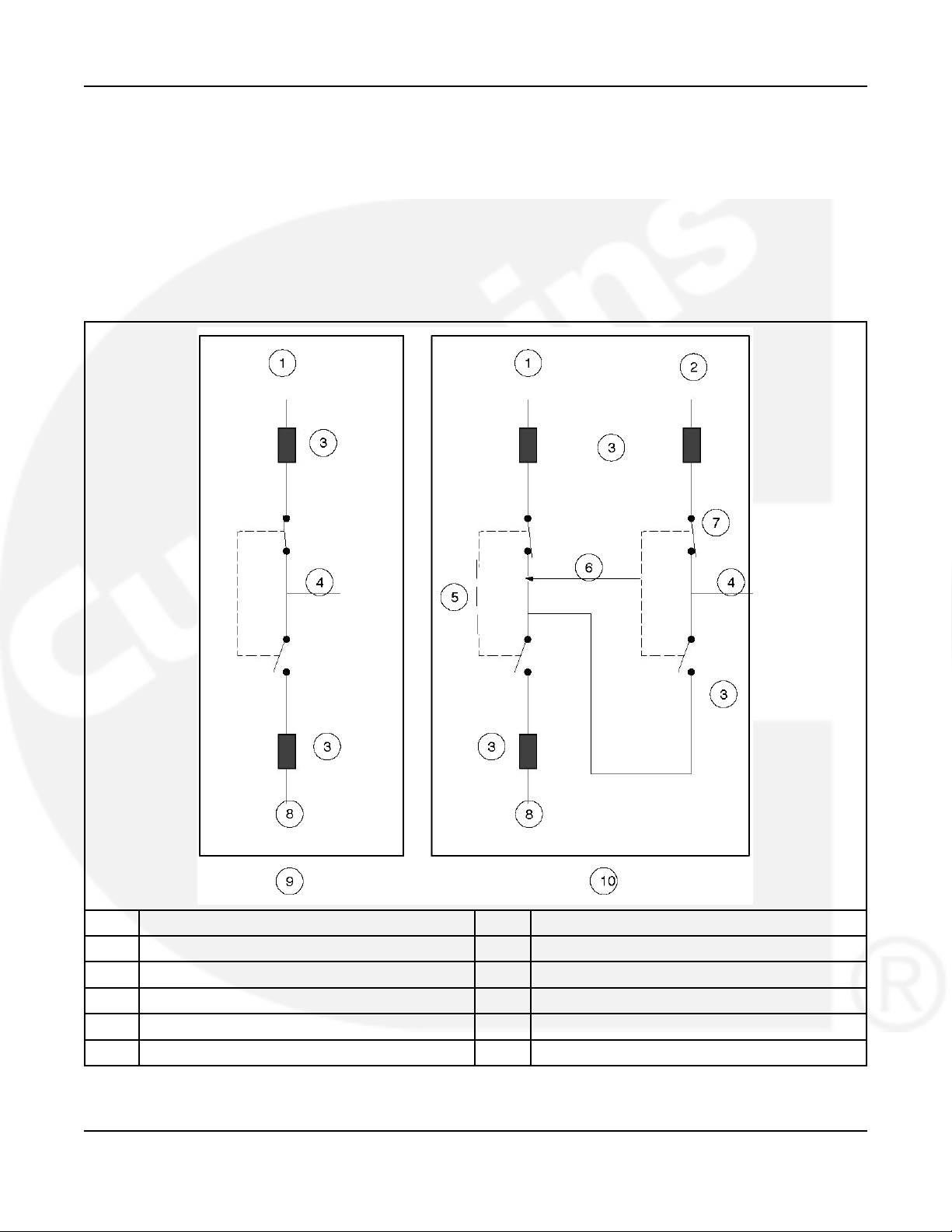

No. Description No. Description

1 Generator set B 6 Standby start signal

2 Utility 7 Utility-to-Gen ATS

3 Over current protective device 8 Generator set A

4 Load 9 Gen-to-Gen configuration in Prime Power mode

5 Gen-to-Gen ATS 10 Gen-to-Gen configuration in Dual Standby mode

FIGURE 2. GENERATOR-TO-GENERATOR CONFIGURATION IN PRIME POWER AND DUAL

STANDBY MODES

962-0132 (Issue 6) 7

Page 14

2. Introduction 5-2013

2.9.1 Prime Power (Plant-to-Plant) Operation

In prime power applications, utility power is not available. The system includes one transfer

switch and two generator sets. One generator set is always running and supplying power to the

load while the other generator set is the backup generator set. An external power supply is not

needed in this application.

2.9.1.1 Preferred Source Selection

Under normal operation, one genset is designated as the preferred source and supplies power

to the load. The second genset is the backup power source. If the preferred genset fails, the

backup genset starts and the transfer switch transfers the load to the backup genset.

At any time, the PC service tool or the Test sub-menu can be used to designate either genset

(Source 1 or Source 2) as the preferred genset. The Preferred Source menu is included in the

Test submenus.

If the preferred genset is changed and the backup genset becomes the preferred genset, the

transfer switch transfers the load to the new preferred genset when it becomes available. The

unit that is carrying the load is always considered the preferred source.

FIGURE 3. PREFERRED SOURCE SUBMENU

2.9.1.2 Automatic Changeover

The transfer switch can be set up to change the preferred source automatically by enabling the

changeover timer. The Time Delay submenus under Setup or the PC service tool can be used

to enable the changeover timer and specify a changeover delay time period. The Changeover

menus are included in the Time Delay submenus.

The automatic changeover timer automatically changes the preferred source and transfers the

load to the new preferred genset after a TDEN time delay. After the transfer is complete, the

control initiates a cool-down period (TDEC) on the old preferred genset before shutting it down.

The old preferred genset is now the new backup genset. The changeover timer is now timing for

the next changeover and the cycle continues as long as the changeover timer is enabled.

8 962-0132 (Issue 6)

Page 15

5-2013 2. Introduction

FIGURE 4. CHANGEOVER SUBMENUS

2.9.2 Dual Stand-By Operation

In dual stand-by applications, utility power is available. The system includes two transfer

switches (a Utility-to-Generator ATS and a Generator-to-Generator ATS) and two generator

sets. Utility power supplies power to the load and both generator sets are backup generator

sets.

Under normal operation, the utility is supplying power to the load through the lead transfer

switch. The lead transfer switch is a utility-to-generator set switch. The two generator sets are

connected to the generator set-to-generator set transfer switch. The load side of this switch is

connected to the generator set side of the lead transfer switch.

Upon loss of utility power to the lead transfer switch, a standby start signal is sent to the

generator set-to-generator set transfer switch to start the preferred generator set. When the lead

transfer switch senses generator voltage, it transfers the load to that generator set. If the

preferred generator set fails to start, a signal is sent to the backup generator set to start. The

PC Service tool or the Test sub-menu on the generator set-to-generator set transfer switch can

be used to set the preferred source.

If the Stand-By Start is inactive, upon initial power–up (or reset), or during software initialization,

the transfer switch control will not start either generator set. When a Stand-By Start command is

received by the Generator-to-Generator ATS from a Utility-to-Generator ATS (or other device),

the preferred generator set immediately starts. If the preferred generator set does not start, the

control starts the backup generator set. The load is connected to the generator set when it

becomes available.

If the preferred generator set becomes available while the backup generator set is active, a time

delay re-transfer (TDEN) period is initiated and the load is re-transferred back to the preferred

generator set. A time delay cool-down (TDEC) period is initiated before turning off the backup

generator set. When the Stand-By Start becomes deactivated, a TDEC period is initiated and

the active generator is turned off.

962-0132 (Issue 6) 9

Page 16

2. Introduction 5-2013

2.9.2.1 Preferred Source Selection

Under normal operation, one genset is designated as the preferred source and the second

genset is designated as the backup power source. If both the utility power and the preferred

genset fails, the backup genset starts and the genset-to-genset transfer switch transfers the

load to the backup genset.

At any time, the PC service tool or the Test sub-menu on the genset-to-genset transfer switch

can be used to designate either genset (Source 1 or Source 2) as the preferred genset. If the

preferred genset is changed and the backup genset becomes the preferred genset, the transfer

switch transfers the load to the new preferred genset if it is needed and when it becomes

available.

2.9.2.2 Alternating Preferred Source

In an attempt to keep the running time equally distributed between both generator sets, the

control can be set to alternate between the generator sets when utility power fails. The selected

preferred generator set starts with the first power outage. The second power outage starts the

backup generator set, which now becomes the preferred generator set. Upon subsequent

outages, the preferred generator set alternates.

Only utility outages and tests or exercises initiated at the lead transfer switch result in the

generator sets being alternated. The designated preferred generator set will not change if it fails

and the backup generator set takes over the load. This alternating preferred source can only be

enabled with the PC Service tool. When enabled, a generator set can be designated as the

preferred source for a maximum of two weeks. Time adjustments can be made in one-hour

increments with the Test submenu.

2.10 Control Level 1 and Level 2

Two controls are available. The type of power source switched and the desired features

determine the control levels available.

The control board level can be viewed, using the digital display. This menu is included in the

About submenus.

NOTICE

The digital display comes standard with level 2 controls and is optional with level 1

controls.

FIGURE 5. CONTROL LEVEL SUBMENU

10 962-0132 (Issue 6)

Page 17

3 Description

3.1 Cabinet

Cabinets are available in various configurations that meet UL and National Electrical

Manufacturer's Association (NEMA) requirements. Each cabinet includes an identification label.

The standard cabinet offerings are:

• Type 1 Indoor - general purpose

• Type 3R Outdoor - rainproof

• Type 4 Outdoor - watertight

• Type 4X Outdoor - watertight, stainless steel

• Type 12 Indoor - dust tight

3.2 Protective Relay

This section describes the solid state relays designed for use in single- or three-phase systems

to protect equipment against overpower and/or under-power conditions.

To increase the level of protection in our closed transition switches we have included a lock out

relay (86) that can trip from two different signals. It can trip from the K32R directional relay when

it senses reverse power is exported to utility or when the 62PL parallel timer has detected that

two sources have been connected for more than the predefined time (not the same as

“Maximum Parallel Timer" in the digital board).

The 86 lockout relay trips when the internal 24VDC relay coil is energized, and it is always

required to manual reset the relay. NC and NO dry contacts are provided for customer wiring

which are rated for 20A 600V. Factory settings for the 62PL are 1 and 3 closed (ON), 2 and 410 open (OFF), for 500mS delay.

962-0132 (Issue 6) 11

Page 18

3. Description 5-2013

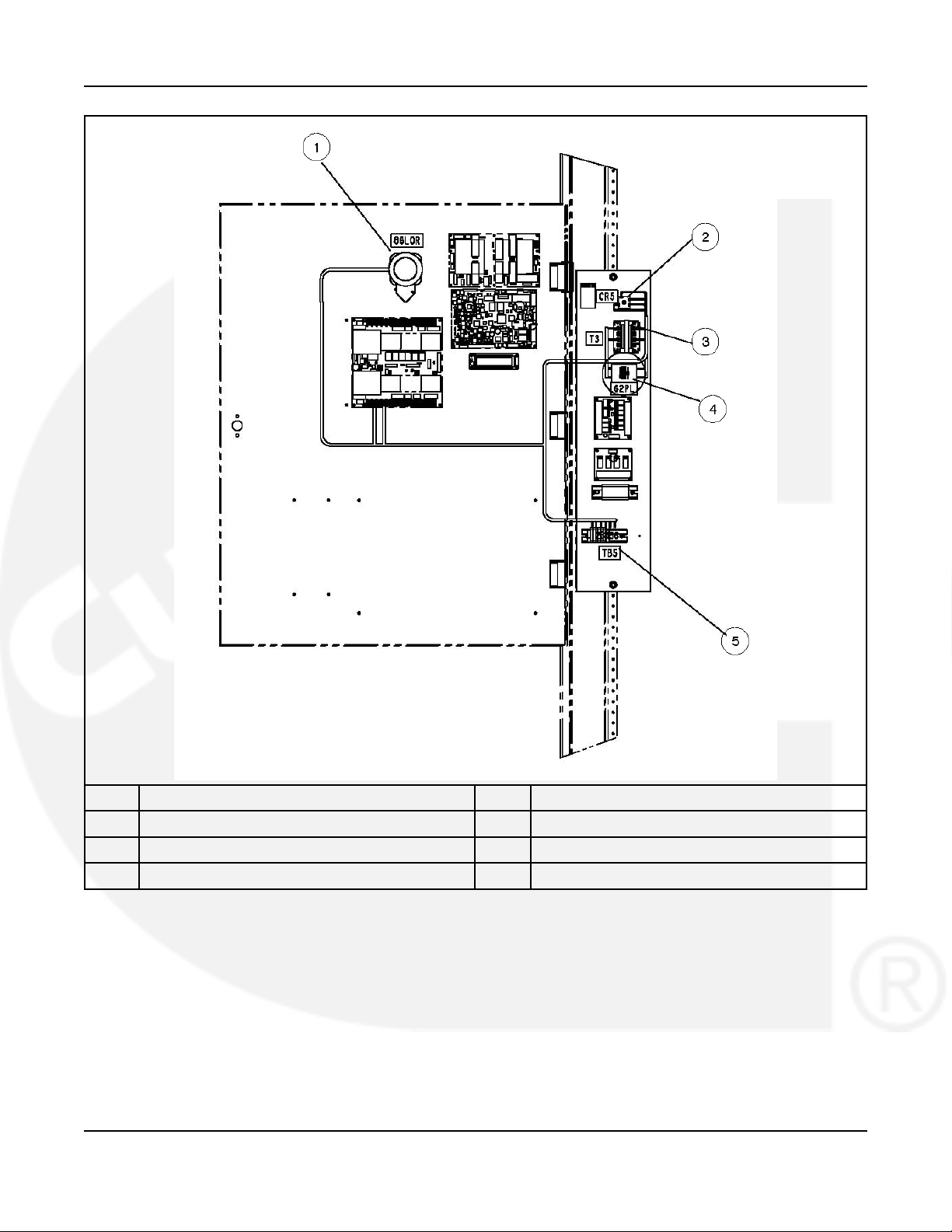

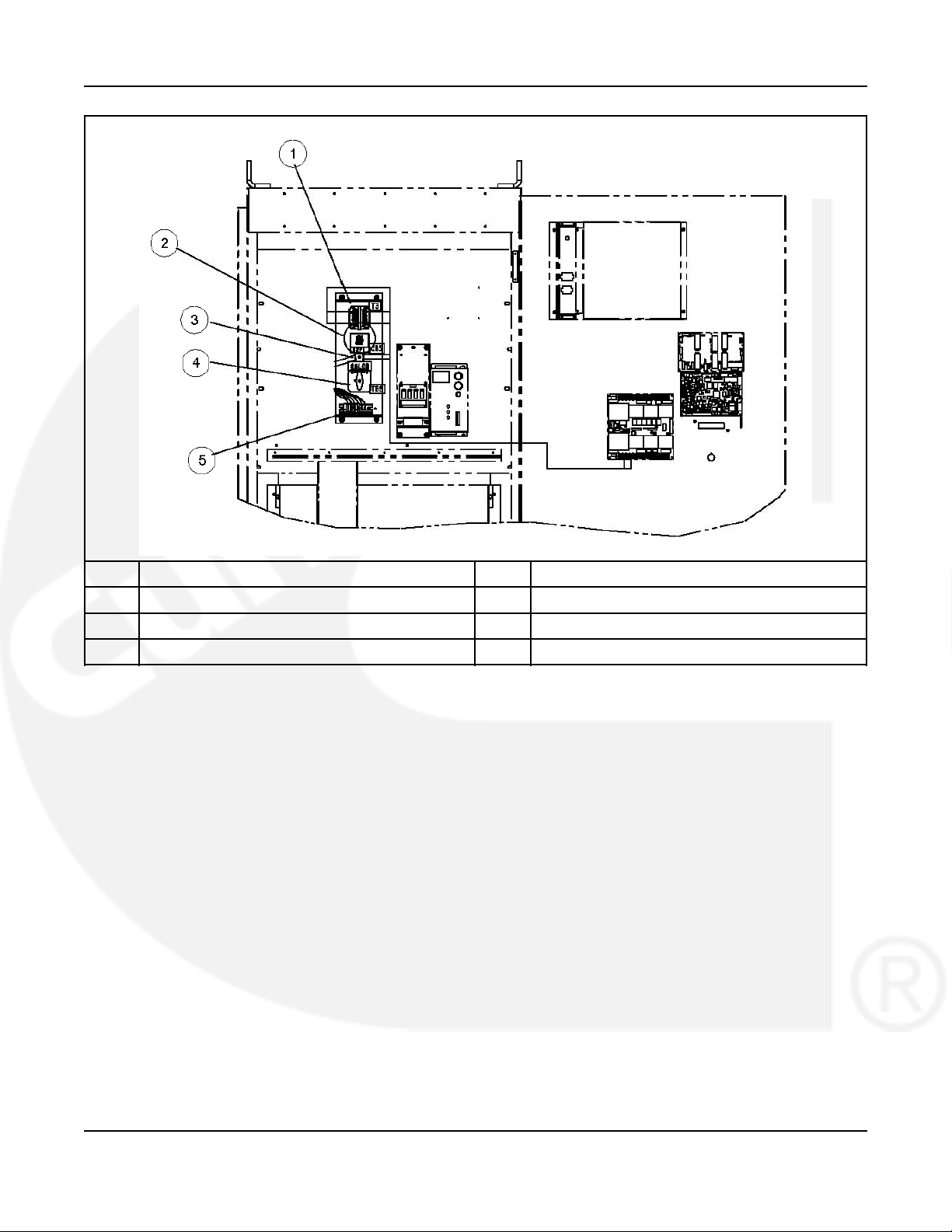

No. Description No. Description

1 Lockout relay 2 Rectifier

3 Transformer 4 Relay

5 Terminal blocks

FIGURE 6. RELAY INSTALLATION M036/M038

12 962-0132 (Issue 6)

Page 19

5-2013 3. Description

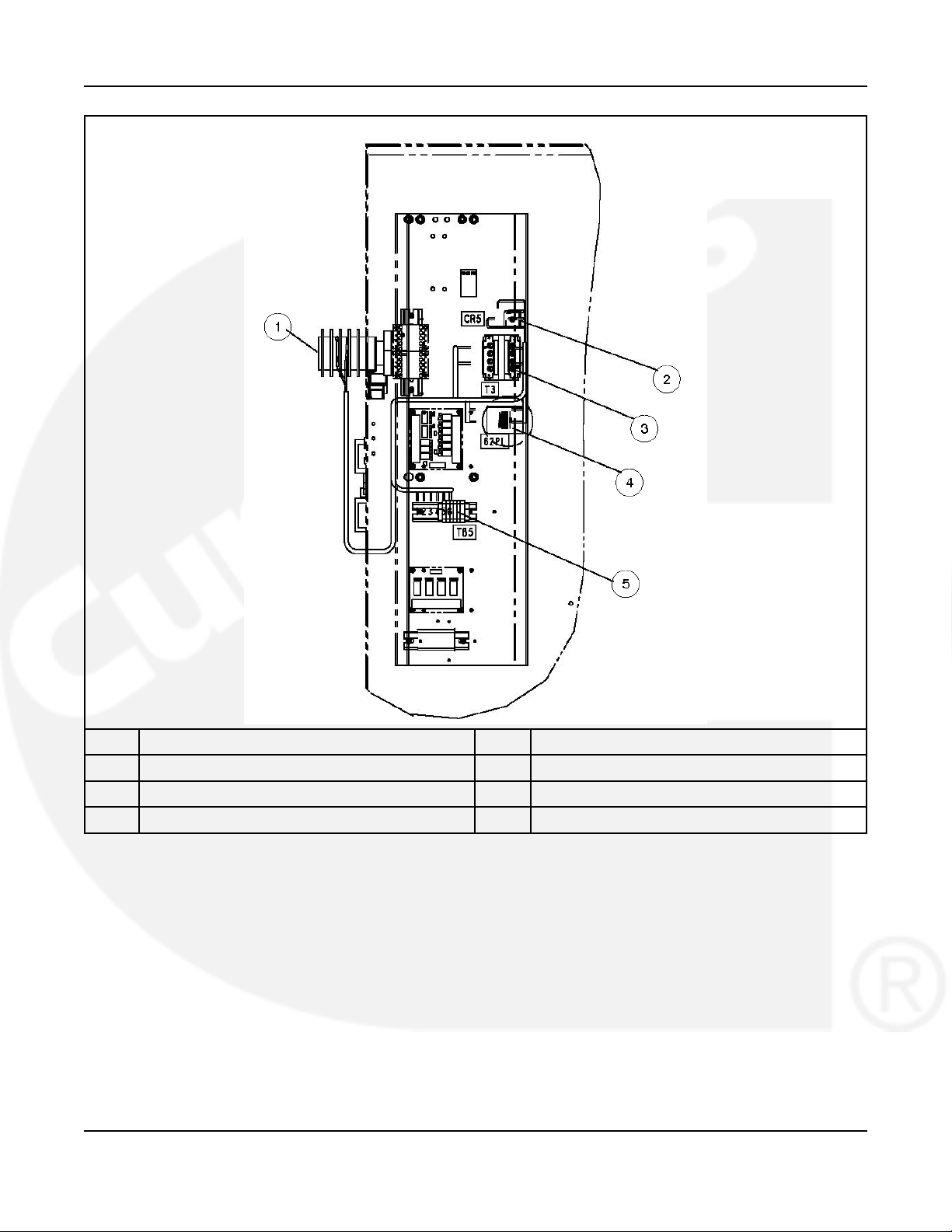

No. Description No. Description

1 Lockout relay 2 Rectifier

3 Transformer 4 Relay

5 Terminal Blocks

FIGURE 7. RELAY INSTALLATION M036/M038

962-0132 (Issue 6) 13

Page 20

3. Description 5-2013

No. Description No. Description

1 Transformer 2 Relay

3 Rectifier 4 Lockout relay

5 Terminal blocks

FIGURE 8. RELAY INSTALLATION M036/M038

3.3 Transfer Switch Components

The transfer switch opens and closes the contacts that transfer the load between the power

sources (Source 1 and Source 2). The switch is mechanically interlocked to prevent

simultaneous closing to both power sources (except in switches capable of closed transitions).

3.3.1 Contact Assemblies

The automatic transfer switch has either three or four poles. Three pole transfer switches are

provided with a neutral bar. The contact assemblies make and break the current flow. When

closed to either power source the contacts are mechanically held. A mechanical interlock

prevents them from closing to both power sources at the same time.

3.3.2 Linear Actuator

The linear actuator moves the contact assemblies between the contacts of both power sources.

Linear actuator operation is initiated automatically by the transfer switch control. Manual

operation of the switch is also possible.

14 962-0132 (Issue 6)

Page 21

5-2013 3. Description

3.3.3 Motor Disconnect Switch (150-1000 Amp Switches)

Moving the Draw out lever to the Release position disables the linear actuator. The Not In Auto

indicator on the front panel will light and the display indicates a motor disconnect event.

3.3.4 Motor Disconnect Switch (1200-4000 Amp Switches)

The Motor Disconnect toggle switch on the accessory control plate enables and disables the

linear actuator.

• Placing the switch in the AUTO position enables the linear actuator.

• Placing the switch in the OFF position disables the linear actuator. When placed in the

OFF position, the Not In Auto indicator on the front panel will light and the display indicates

a motor disconnect event.

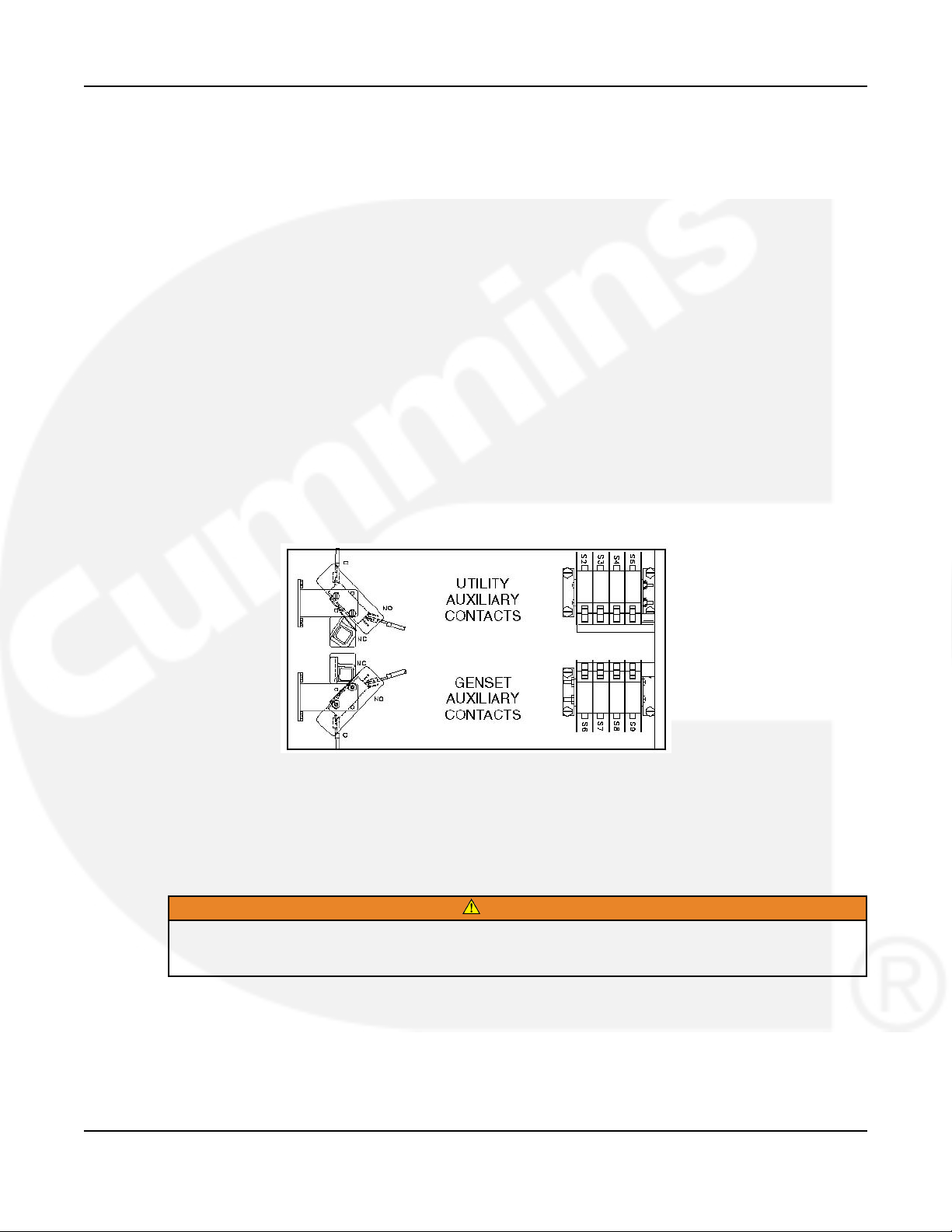

3.3.5 Auxiliary Contacts

Auxiliary contacts are provided on the utility and genset sides of the transfer switch. They are

actuated by operation of the transfer switch during transfer and retransfer. The utility auxiliary

contact switch is actuated when the transfer switch is connected to the utility. The genset

auxiliary contact switch is actuated when the transfer switch is connected to the genset. The

auxiliary contacts have current ratings of 10 amperes at 250 VAC. The contacts are wired to

terminal block TB1.

FIGURE 9. AUXILIARY CONTACTS

3.4 Electronic Control System

This section describes the standard and optional components of the electronic control system.

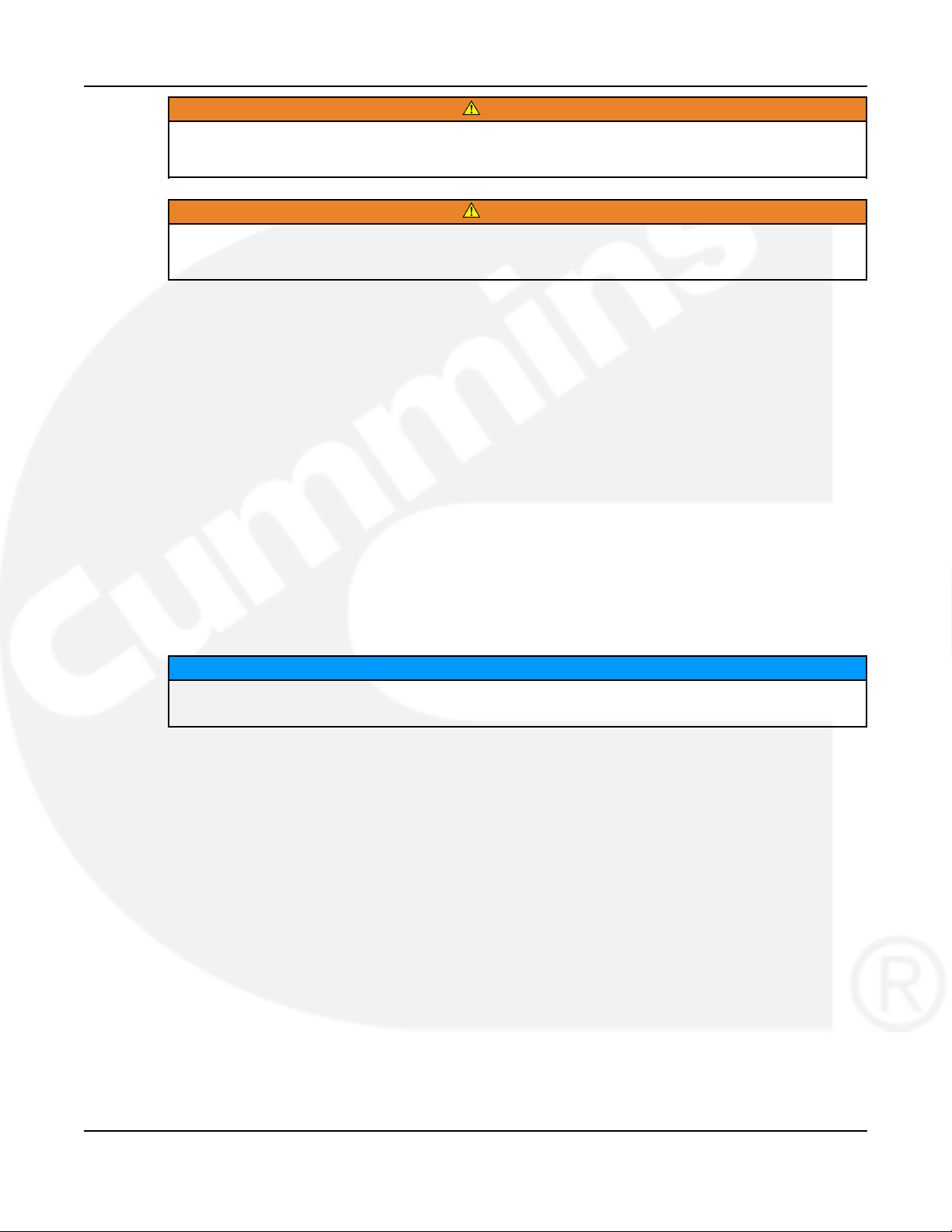

WARNING

Improper calibration or adjustment of electronic control modules can cause death, severe

personal injury, and equipment or property damage. Calibration and adjustment of these

components must be performed by technically qualified personnel only.

For further information regarding installation, calibration and adjustment of these components,

refer to the:

• Installation Manual (shipped with the product)

• Service Manual (available through your distributor)

962-0132 (Issue 6) 15

Page 22

3. Description 5-2013

WARNING

Accidental actuation of the linear motor could cause severe personal injury. Before making any

adjustments, place the Motor Disconnect Switch in the OFF position. Return the switch to the

Auto position after adjustments are completed.

WARNING

AC power within the cabinet and the rear side of the cabinet door presents a shock hazard that

can cause severe personal injury or death. When the cabinet door is open, use extreme caution

to avoid touching electrical contacts with body, tools, jewelry, clothes, hair, etc.

3.4.1 Time Delays

3.4.1.1 Time Delay Engine Start (TDES-A and TDES-B)

Time Delay Default: 3 seconds (for both TDES-A and TDES-B)

Adjustable: The value is set with the InPower service tool or the digital display.

• Adjustable from 0-15 seconds in 1 second increments on Level 1 controls.

• Adjustable from 0-120 seconds on Level 2 controls.

• Values up to 20 seconds are adjustable in 1 second increments.

• Values over 20 seconds are adjustable in 5 second increments.

Purpose: Prevents the generator set from starting during short power interruptions.

Sequence of Events: Timing begins at the Source 1 power interruption (or the preferred source

interruption on gen-to-gen units). If the duration of interruption exceeds the delay time, the

control system starts the generator.

NOTICE

For long engine start time delays (over 15 seconds) a remote battery source must be

used.

For Genset-to-Genset applications: TDES-A is the start time delay to start the Source 2 genset

and TDES-B is the start time delay to start the Source 1 genset.

For Utility-to-Utility applications: TDES-A and TDES-B are not available.

3.4.1.2 Time Delay Engine Cool-down (TDEC-A and TDEC-B)

Time Delay Default: 10 minutes

Adjustable: Adjustable from 0-30 minutes, in 1 minute increments. The value is set with the

InPower service tool or the digital display.

Purpose: Allows the generator set to cool without load before stopping.

Sequence of Events: Timing begins when the load is retransferred to Source 1 (or to the

preferred source on gen-to-gen units). At the end of the delay, the stop signal is sent to the

generator set. During this time delay, the generator set cools down without load before stopping.

For Genset-to-Genset applications: TDEC-A is the stop time delay to stop Source 2 genset and

TDEC-B is the stop time delay to stop Source 1 genset.

For Utility-to-Utility applications: TDEC-A and TDEC-B are not available.

16 962-0132 (Issue 6)

Page 23

5-2013 3. Description

3.4.1.3 Time Delay Normal to Emergency (TDNE)

Time Delay Default: 5 seconds

Adjustable: Adjustable from 0-120 seconds, in 1 second increments. The value is set with the

InPower service tool or the digital display.

Purpose: Allows the generator set to stabilize before the load is applied.

Sequence of Events: Timing begins when:

• Source 2 voltage and frequency reaches the settings of the control.

• Preferred source voltage (on gen-to-gen units) and frequency reaches the settings of the

control.

• Preferred utility becomes available (on utility-to-utility units).

After the delay, the transfer switch transfers the load to Source 2.

3.4.1.4 Time Delay Emergency to Normal (TDEN)

Time Delay Default: 10 minutes

Adjustable: Configurable for 0 (disabled), 0.1, 5, 10, 15, 20, 25 or 30 minutes.

Purpose: Allows utility power to stabilize before retransfer. This delay also allows the generator

to operate under load for a minimum amount of time before transferring back to utility power.

Sequence of Events: Timing begins with the transfer switch connected to the generator and

after the utility becomes available following an outage (the green Utility Power Available LED is

lit). This time delay also starts when an active test or exercise period has ended. After the delay,

the transfer switch can retransfer the load to the utility power source.

• If the utility fails any time during this time delay, the control resets the timer and restarts it

once utility power becomes available.

• If the generator fails at any time during this time delay, the timer expires and the normal

retransfer sequence takes place.

• If the Override pushbutton is pressed or the Override input is grounded while the TDEN

timer is active, the TDEN timer immediately expires.

• The TDEN timer will not begin if a Retransfer Inhibit input is active.

3.4.1.5 Time Delay Elevator (TDEL)

Time Delay Default:0 seconds

Adjustable: Adjustable from 0-60 seconds, in 1 second increments. The value is set with the

InPower service tool or the digital display.

Purpose: Allows an elevator to come to a complete stop before the switch transfers.

Sequence of Events: Timing begins after the transfer or retransfer timing ends. TDEL only

times when transferring between two live sources.

3.4.1.6 Time Delay Programmed Transition (TDPT)

Time Delay Default:0 seconds

Adjustable: Configurable for 0 (disabled), 0.5, 1, 2, 3, 4, 6 or 10 seconds.

962-0132 (Issue 6) 17

Page 24

3. Description 5-2013

Purpose: Allows the transfer switch to pause in the Neutral position for an adjustable period of

time whenever there is a transfer from one source to another.

• This intentional delay allows the residual voltage of an inductive load to sufficiently decay

before connecting it to another power source.

• This delay prevents potentially damaging voltage and current transients in the customer's

power system.

Sequence of Events: Timing begins whenever the transfer switch has disconnected from one

source and is in the Neutral position.

• If TDPT is set to zero, then the transfer switch transfers from one source to the other with

no neutral position delay.

• The control also detects if the transfer switch has disconnected from the first source before

connecting it to the second one.

• If there is a power source failure while the TDPT is active, the control only transfers to the

remaining active power source.

• The control does not terminate the TDPT timer if either source fails while the transfer

switch is in the Neutral position.

3.4.2 System Sensors

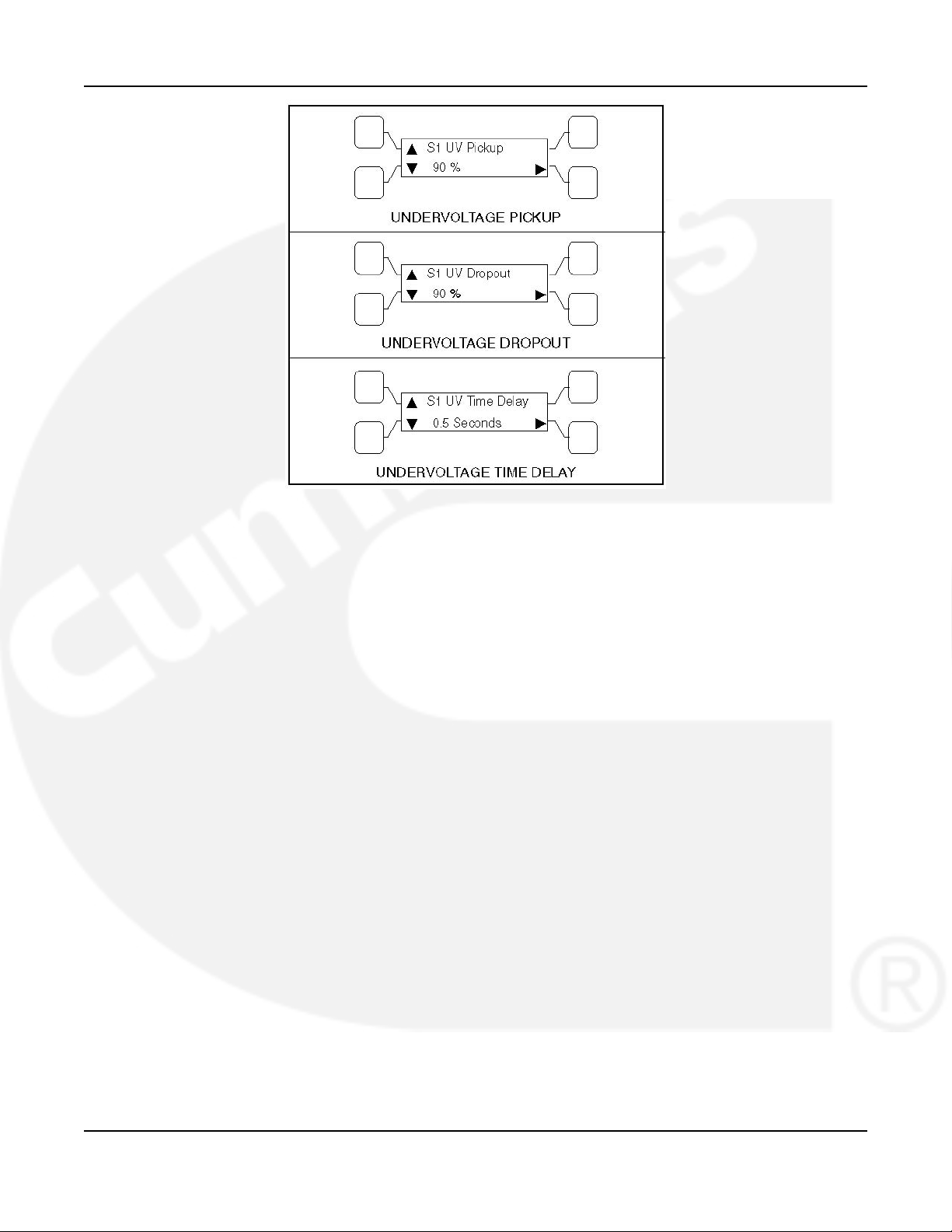

3.4.2.1 Under-Voltage Sensing

All controls include under-voltage sensors for Source 1 and Source 2.

Default Value:

• Pick-up: 90%

• Drop-out: 90% of the pick-up setting

Range:

• The pick-up range for a rising voltage is 85 to 100% of the nominal voltage set point.

• The under-voltage sensing range for a falling voltage (drop-out) is 75 to 98% of the pick-up

voltage setting.

Default Delay Time: 0.5 second

Adjustable: The adjustable range for the time delay period is 0.1 to 1.0 seconds in 0.1 second

increments. These values are set with the PC service tool or the digital display.

Sequence of Events:

• When a sensor detects a voltage below the set drop-out voltage for a period longer than

the time delay, it deems the voltage as unacceptable.

• When the sensor detects a voltage at or above the set pick-up point, it deems the voltage

as acceptable.

18 962-0132 (Issue 6)

Page 25

5-2013 3. Description

FIGURE 10. UNDER-VOLTAGE SENSING SUBMENUS

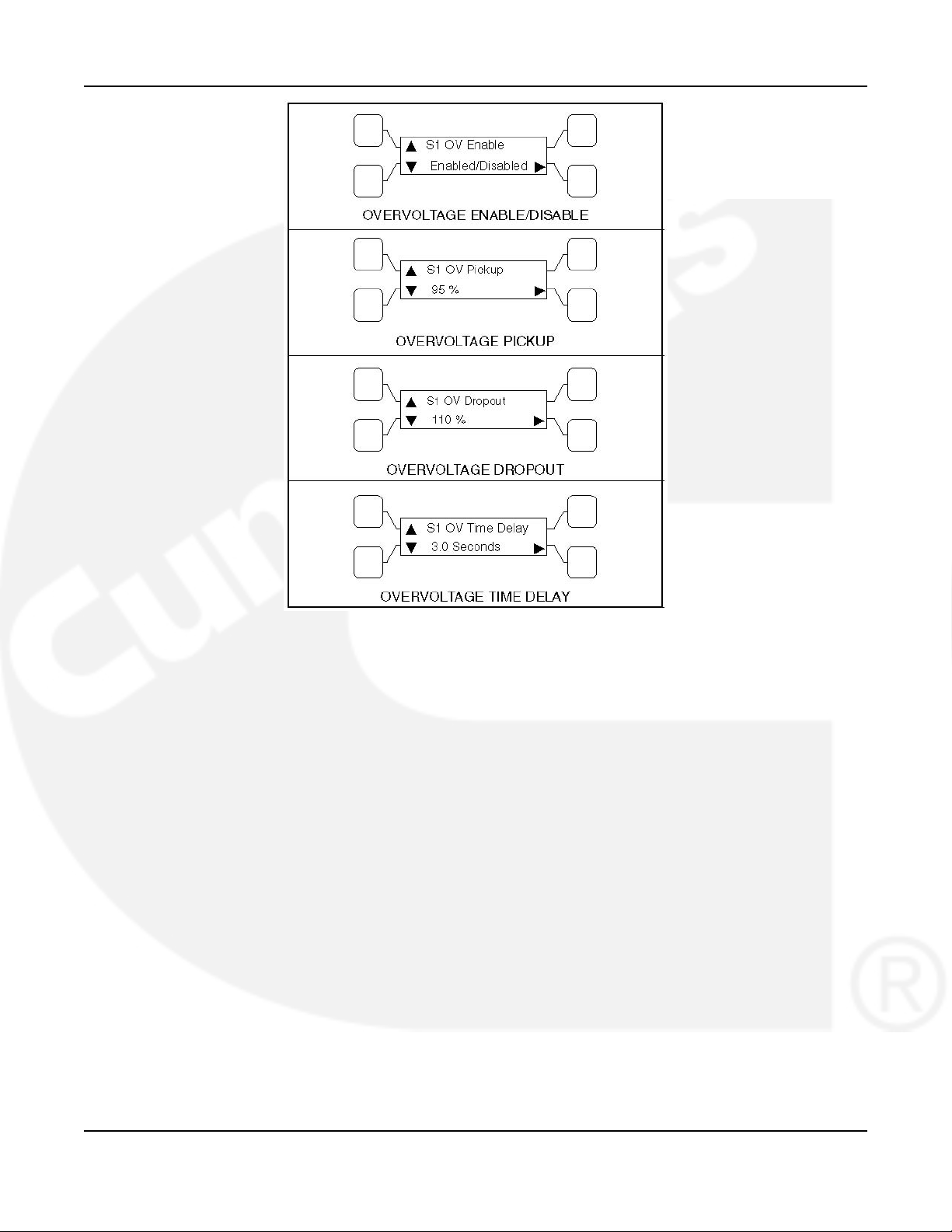

3.4.2.2 Over-Voltage Sensing

All controls include over-voltage sensors for Source 1 and Source 2 that can be disabled and

not used. The over-voltage sensing feature is enabled by default.

Default Value:

• Over-voltage (drop-out) sensing range: 110%

• Pick-up range: 95%

Range:

• The over-voltage sensing range (drop-out) for a rising voltage is 105 to 135% of the

nominal voltage set point.

• The pick-up range for a falling voltage is 95 to 99% of the drop-out setting.

Default Delay Time: 3.0 seconds

Adjustable: The adjustable range for the delay time period is 0.5 to 120.0 seconds in 1 second

intervals. These values are set with the PC service tool or the digital display.

Sequence of Events:

• When a sensor detects a voltage above the set dropout voltage for a period longer than

the time delay, it deems the voltage as unacceptable.

• When the sensor detects a voltage at or below the set pickup point, it deems the voltage

as acceptable.

962-0132 (Issue 6) 19

Page 26

3. Description 5-2013

FIGURE 11. OVER-VOLTAGE SENSING SUBMENUS

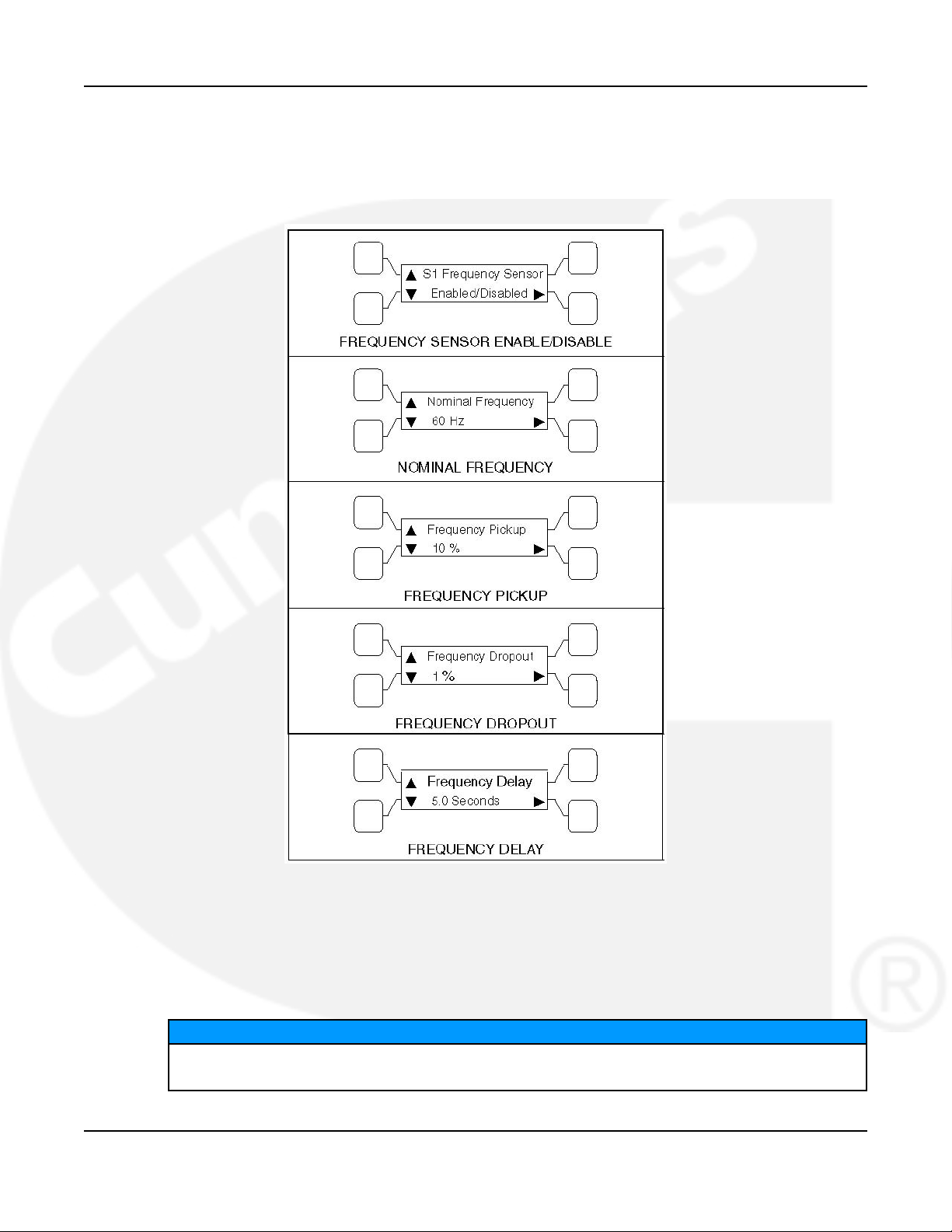

3.4.2.3 Frequency Sensing

All controls include frequency sensors for Source 1 and Source 2 that can be disabled and not

used.

Default Value:

• Nominal frequency: 60 Hz

• Frequency pick-up bandwidth: ±10%

• Frequency drop-out: 1% beyond pick-up bandwidth setting

Range:

• The nominal frequency can be set between 45.0 and 60.0 Hz in 0.1 Hz increments.

• The acceptable frequency bandwidth (pick-up) is ±5 to ±20% of the nominal frequency set

point.

• The drop-out frequency is 1 to 5% beyond the pick-up.

The frequency sensing feature is enabled by default.

Default Delay Time: 1.0 second

Adjustable: The adjustable range for the time delay period is 0.1 to 15 seconds.

20 962-0132 (Issue 6)

Page 27

5-2013 3. Description

Sequence of Events:

• When a sensor detects a frequency outside the dropout bandwidth for a period longer than

the time delay, it deems the frequency as unacceptable.

• When the sensor detects a frequency within the pickup bandwidth, it deems the frequency

as acceptable.

FIGURE 12. FREQUENCY SUBMENUS

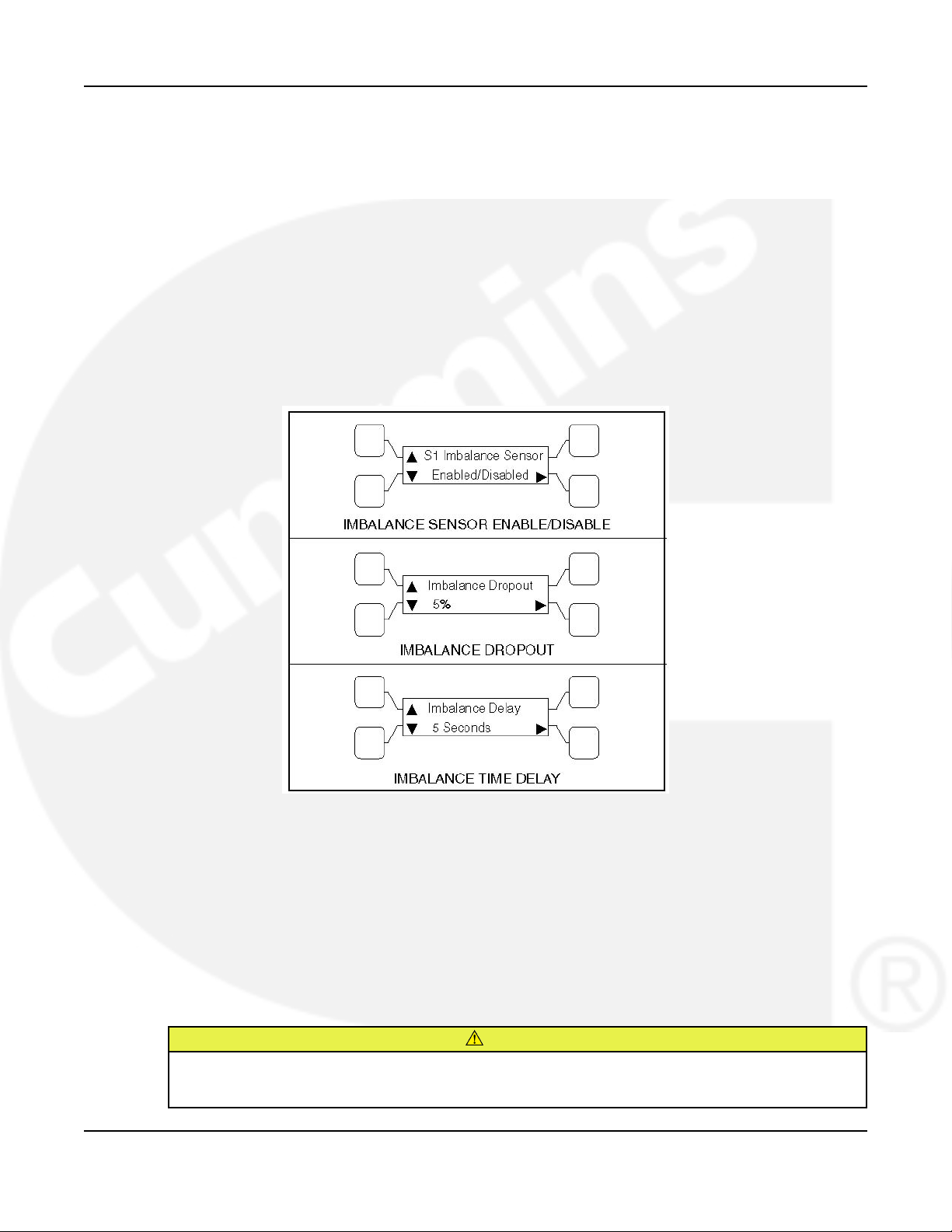

3.4.2.4 Voltage Imbalance Sensing

Three phase Level 2 controllers include a voltage imbalance sensor for both Source 1 and

Source 2. This feature informs the operator when there is significant voltage imbalance between

the phases of Source 1 or Source 2. This feature is used for equipment protection.

NOTICE

This sensor is inactive for single phase systems and indicates no failures. To prevent

nuisance faults, the setting can be increased up to 10% of the nominal voltage.

962-0132 (Issue 6) 21

Page 28

3. Description 5-2013

This sensor can be enabled using the PC service tool or the digital display Setup submenus.

Default Value: 10%

Range:

• The maximum deviation from the average voltage is greater than a user-specified value

between 2 and 10% (dropout) of the average voltage in 1% increments.

• The pickup value is fixed at 10% of the dropout.

Default Delay Time: 10 seconds

Adjustable: The adjustable range for the time delay period for the imbalance sensor drop-out is

2 to 20 seconds.

Sequence of Events: A voltage imbalance is typically caused by severe single phase loading.

The sensor indicates a failure when the maximum deviation from the average voltage is greater

than a user-specified value (dropout) of the average voltage.

FIGURE 13. VOLTANGE IMBALANCE SENSOR SUBMENUS

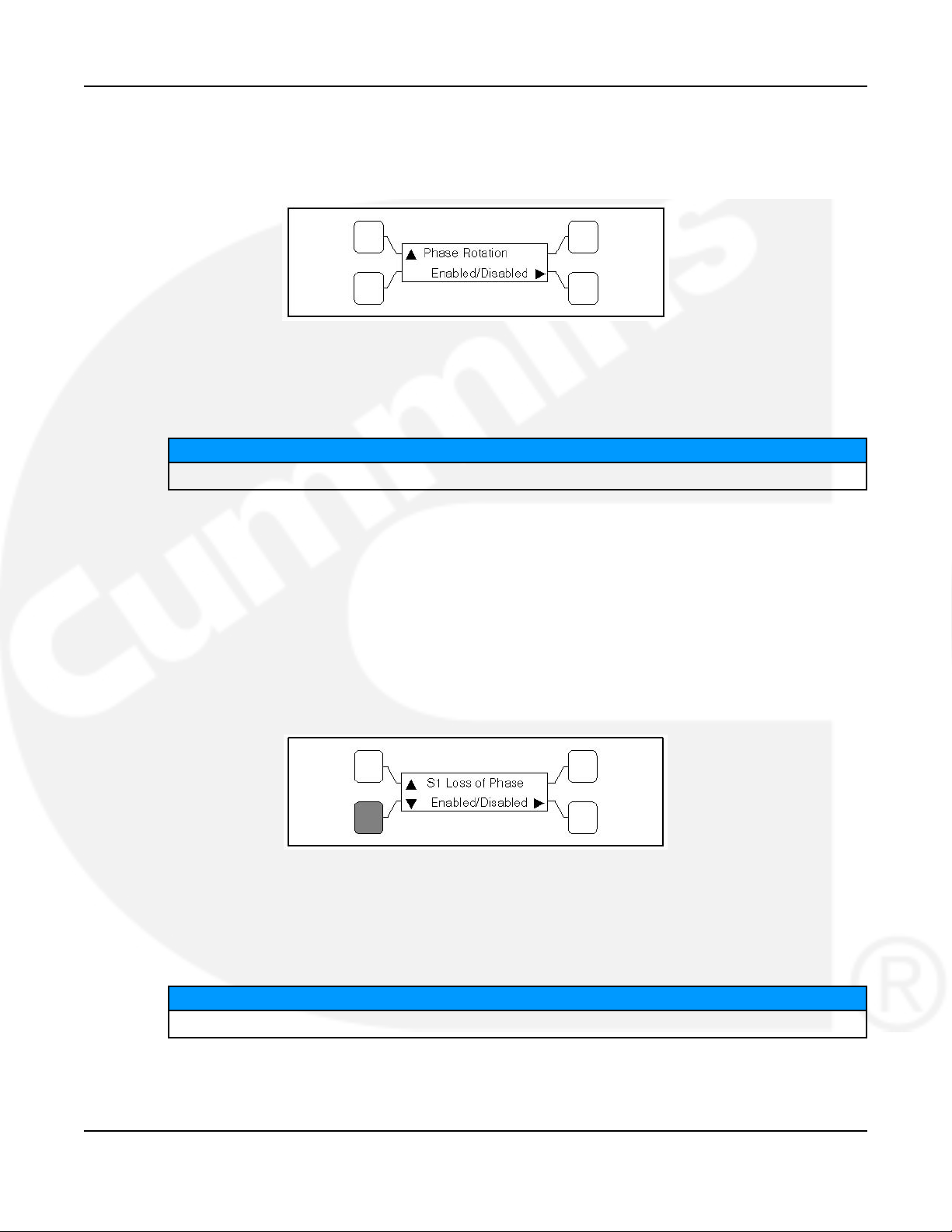

3.4.2.5 Phase Rotation Sensing

Three phase Level 2 controllers include a phase rotation sensor.

This feature monitors the phase rotation of the source opposite from the connected source. Both

voltage sources must be applied in order to check phase rotation.

This feature protects against equipment damage by preventing transfer to a source that is out of

phase. This generally occurs on new installations or after storm damage or generator rewiring.

This feature is required in fire pump applications.

CAUTION

Level 1 controls do not support three-phase sensing on Source 2. Do not select the three-phase

option for the Source 2 Sensing adjustment with Level 1 controls, even if the system is three

phase. This setting will prevent Source 2 from becoming available.

22 962-0132 (Issue 6)

Page 29

5-2013 3. Description

Default Value: Disabled

Adjustable: The adjustable range for phase rotation sensing is Enabled or Disabled (On or Off).

Sequence of Events: When the alternate source is out of phase rotation with the connected

source, transfer is inhibited.

FIGURE 14. PHASE ROTATION SENSING SUBMENU

3.4.2.6 Loss of Single Phase Sensing

Three phase Level 2 controllers include a loss of single phase sensor.

NOTICE

This sensor is inactive for single phase systems and indicates no failures.

This feature initiates a transfer from a source that has lost a single phase and prevents a

transfer to a source that has lost a single phase. This is generally caused by a single phase to

line ground or open.

This feature is mainly used to protect three phase devices, such as motors.

Default Value: Disabled

Adjustable: The adjustable range for loss of single phase sensing is Enabled or Disabled (On

or Off).

Sequence of Events: The controller indicates a fault when the relative phase angle between

any line-to-line phase angle drops to less than 90 degrees.

FIGURE 15. LOSS OF PHASE SENSING SUBMENU

3.4.2.7 Transfer Times

The controller senses and records the time it takes for the transfer switch to break from one

source and reconnect to the other source.

NOTICE

Transfer times are not recorded if Programmed Transition delay is in use.

962-0132 (Issue 6) 23

Page 30

3. Description 5-2013

3.4.3 Transfer Modes

A transfer mode can be selected from the front panel digital display.

Since not all automatic transfer switches are configured the same, some may not have access

to all transition mode types. The transfer modes available on your transfer switch are identified

in the following section.

The transfer switch mode setting can be changed with the PC service tool or with the digital

display.

FIGURE 16. TRANSFER MODE SUBMENU

3.4.3.1 Available Transfer Modes

• Open Transition (OT) with Sync Check

• Programmed Transition (PT)

• Closed Transition (CT)

3.4.3.2 Open Transition with Sync Check

Open transition with sync check executes an open transition (OT) transfer when both sources of

power are within specified tolerances of frequency, voltage and relative phase difference. If both

sources meet the tolerances, a fast transfer occurs.

3.4.3.2.1 Transfer from Source 1 to Source 2 (OT)

This sequence begins with Source 1 supplying power to the load. The Source 1 Available and

Source 1 Connected indicators are lit. The sequence ends with Source 2 (generator) assuming

the load.

1. When Source 1 goes “out of spec," the control starts a Time Delay to Engine Start (TDES)

timer and the Source 1 Available indicator goes out.

2. If the TDES expires without a return to acceptable Source 1 power, the genset receives a

remote start signal. The engine starts and accelerates to rated speed.

3. When the alternator output reaches the “pickup" level, the Source 2 Available indicator is

lit. The control starts the Time Delay Normal to Emergency (TDNE) timer.

3.4.3.2.2 Transfer from Source 2 to Source 1 (OT)

This sequence begins with Source 2 supplying power to the load. The Source 2 Available and

Source 2 Connected indicators are lit. The sequence ends with Source 1 (utility) assuming the

load.

1. When Source 1 returns to “in spec," the Source 1 Available indicator is lit and the control

starts the Time Delay Emergency to Normal (TDEN) timer. When this time is complete, the

controller starts monitoring both live sources looking for when they are in sync

24 962-0132 (Issue 6)

Page 31

5-2013 3. Description

2. When both sources are in sync, the switch transfers the load to Source 1. However, if the

two sources fail to synchronize and the “Return PT Enabled" feature is active, the switch

executes a programmed transition by stopping in the Neutral position and transferring the

load to Source 1. If Source 2 goes offline while the controller is trying to synchronize the

two sources, the controller executes a Programmed Transition and transfers the load to

Source 1.

3. A Time Delay Engine Cool-down (TDEC) for the genset is activated. When the engine cooldown delay expires, the genset shuts down and the Source 2 Available indicator goes out.

3.4.3.2.3 Return PT Enable

A feature included with controls that have a Sync Check sensor is Return to Programmed

Transition.

Adjustable: This feature can be enabled and disabled with the PC service tool or with the digital

display, if available.

Sequence of Events: If the two sources fail to synchronize within two minutes, a Failed to

Synchronize event occurs. If the Return to Programmed Transition feature is enabled, the

control reverts to transferring the transfer switch to the programmed transition mode.

FIGURE 17. RETURN TO PROGRAMMED TRANSITION SUBMENU

3.4.3.2.4 Sync Check Sensor

Sync Check is used to determine when both sources of power are within specified tolerances of

frequency, voltage, and relative phase difference. If both sources are within this range, a fast or

synchronized transfer occurs.

The transfer switch controller measures non-programmed transition transfer times from one

source to another. It takes into account relay coils and solenoids energizing.

Default Value:

• Frequency bandwidth: 1.0 Hz

• Voltage: 10 V

• Offset: 0 milliseconds

Range:

• The frequency bandwidth range is from 0.1 and 1.0 Hz.

• The frequency difference between the sources must be equal to or less than the set

value in order for transfer to occur.

• The voltage window is from 5 and 25 volts.

• The average voltage difference between the two sources must be equal to or less

than the set value in order for transfer to occur.

• The manual offset range is from -25 to +25 milliseconds.

962-0132 (Issue 6) 25

Page 32

3. Description 5-2013

Adjustable: Synchronicity parameters are adjustable. The transfer switch mode setting can be

changed with the PC service tool or with the digital display, if available.

Sequence of Events: If enabled, the Sync Check sensor overrides programmed transition

whenever transferring between two live sources. If only one power source is available,

programmed transition overrides the Sync Check sensor.

FIGURE 18. SYNCHRONICITY PARAMETER SUBMENUS

3.4.3.2.5 Active Sync Feature

When the transfer switch is configured to transfer in closed transition mode it is recommended

to use the active sync feature. When the active sync feature is enabled,

the transfer switch control can send a Sync Enable command to the genset to synchronize with

the utility. This command is activated just before the Sync Check sensor is activated.

To use the Active Sync feature, it must first be enabled. The Active Sync feature can be

enabled with the PC service tool or the digital display, if available.

The active sync feature may be used with a non-paralleling genset control as well as a paralleling

control. A non-paralleling genset control will not synchronize the genset to the utility but

enabling the active sync feature will impose the active sync time delay so that the two source

must remain synchronized for the set time period maximizing the reliability of the transfer. When

using a non-paralleling genset with this feature it is recommended to set the generator set

frequency to 0.1 Hz higher than the utility to make sure that the generator set will come into sync

with the utility.

Default Value: 0.5 seconds

Range: The Active Sync Time Delay is adjustable from 0 to 5 seconds in 0.1 second

increments.

NOTICE

Default Delay Time:

26 962-0132 (Issue 6)

Page 33

5-2013 3. Description

Adjustable: The Active Sync Delay timer can be set with the PC service tool or the digital

display.

Sequence of Events: When the Active Sync feature is enabled, the control runs an Active Sync

Time Delay (if greater than 0) and sends the Sync Enable command to the genset. The Active

Sync Time Delay is used to check the stability of the system before transferring to the other

source. The two sources must remain synchronized for this period of time period before a

transfer command is given.

When a paralleling genset control receives a Sync Enable command and detects the Source 1

bus voltages, the genset control automatically synchronizes its speed and phase to match the

Source 1 bus. The Sync Check sensor monitors both sources. When they are synchronized, a

transfer or retransfer command is initiated.

FIGURE 19. ACTIVE SYNC SUBMENUS

3.4.3.2.6 Speed Adjust

If a PowerCommand transfer switch and a non-paralleling genset are networked together, the

transfer switch control can send a Speed Adjust command to the genset to increase its speed

just enough to increase its frequency by 0.5 Hz.

The genset must be capable of reacting to a Speed Adjust command. This feature is

only available if a PowerCommand network is installed.

Default Value: Speed Adjust is always enabled unless Active Sync is enabled.

Sequence of Events: The command is activated just before the Sync Check sensor is

activated. It is used when the genset takes a long time to drift in sync with the utility. This

increases the number of “in-phase" opportunities to satisfy the Sync Check sensor.

3.4.3.3 Programmed Transition

Programmed transition executes a programmed transition (PT) transfer by disconnecting the

load from the source of power, pausing in the neutral position of the transfer switch (between

switched positions) to allow transient voltages from the load to diminish, and then the load is

switched to the other source.

NOTICE

962-0132 (Issue 6) 27

Page 34

3. Description 5-2013

3.4.3.3.1 Transfer from Source 1 to Source 2 (PT)

This sequence includes a programmed transition and begins with Source 1 supplying power to

the load. The Source 1 Available and Source 1 Connected indicators are lit. The sequence ends

with Source 2 (generator) assuming the load.

1. When source 1 goes “out of spec," the control starts a Time Delay Engine Start (TDES)

timer and the Source 1 Available indicator goes out.

2. If the TDES expires without a return to acceptable Source 1 power, the genset receives a

remote start signal. The engine starts and accelerates to rated speed.

3. When the alternator output reaches the “pickup" level, the Source 2 Available indicator

lights. The transfer switch starts the Time Delay Normal to Emergency (TDNE) timer. When

this time is complete, the switch moves to the Neutral position. The Source 1 Connected

indicator goes out.

4. The transfer switch stops in the Neutral position for the Time Delay Programmed Transition

(TDPT) and then completes its transition to the Source 2 position. The Source 2 Connected

indicator lights.

3.4.3.3.2 Transfer from Source 2 to Source 1 (PT)

This sequence begins with Source 2 supplying power to the load. The Source 2 Available and

Source 2 Connected indicators are lit. The sequence ends with Source 1 (utility) assuming the

load.

1. When Source 1 returns to “in spec," the Source 1 Available indicator lights and the digital

board starts the Time Delay Emergency to Normal (TDEN) timer. When this time is

complete, the switch moves to the neutral position (the Source 2 indicator goes out).

2. If there is a programmed transition delay, the transfer switch stops in the Neutral position

for the Time Delay Programmed Transition (TDPT) and then completes its transition to the

Source 1 position. The Source 1 Connected indicator lights and the Time Delay Engine

Cooldown (TDEC) timer starts.

3. When the engine cool-down delay expires, the genset shuts down and the Source 2

Available indicator goes out.

3.4.3.4 Closed Transition

Closed transition executes a load transfer by momentarily paralleling both sources (a maximum

of 100ms) before switching sources.

3.4.3.4.1 Transfer from Source 1 to Source 2 (CT)

This sequence begins with Source 1 supplying power to the load. The Source 1 Available and

Source 1 Connected indicators are lit. The sequence ends with Source 2 (generator) assuming

the load.

1. When Source 1 goes “out of spec," the digital board starts a Time Delay to Engine Start

(TDES) timer and the Source 1 Available indicator goes out.

2. If the TDES expires without a return to acceptable Source 1 power, the genset receives a

remote start signal, the engine starts and accelerates to rated speed.

3. When the alternator output reaches the “pickup" level, the Source 2 Available indicator is

lit. The transfer switch starts the Time Delay Normal to Emergency (TDNE) timer. When

this time is complete, the switch moves to the Neutral position. The Source 1 Connected

indicator goes out.

28 962-0132 (Issue 6)

Page 35

5-2013 3. Description

4. If there is a programmed transition delay, the transfer switch stops in the Neutral position

for the Time Delay Programmed Transition (TDPT) and then completes its transition to the

Source 2 position. The Source 2 Connected indicator is lit.

3.4.3.4.2 Transfer from Source 2 to Source 1 (CT)

This sequence begins with Source 2 supplying power to the load. The Source 2 Available and

Source 2 Connected indicators are lit. The sequence ends with Source 1 (utility) assuming the

load.

1. When Source 1 returns to “in spec," the Source 1 Available indicator is lit and the digital

board starts the Time Delay Emergency to Normal (TDEN) timer. When this time is

complete, the controller starts monitoring both live sources until they are in phase.

2. When they are in phase, the controller closes the Source 1 contact and allows Source 1

and Source 2 to simultaneously feed the load for a maximum of 100ms.

3. After the 100ms timer expires, the controller opens the Source 2 contacts.

4. A Time Delay Engine Cool-down (TDEC) for the genset is activated. When the engine cooldown delay expires, the genset shuts down and the Source 2 Available indicator goes out.

3.4.4 Front Panel Test - Sequence of Events

If the test button is pushed on the Front Panel, then the controller simulates a Source 1 or Utility

failure and proceeds to transfer the load to the generator.

FIGURE 20. FRONT PANEL TEST SEQUENCE OF OPERATION

962-0132 (Issue 6) 29

Page 36

3. Description 5-2013

3.4.4.1 Transfer from Source 1 to Source 2 (Front Panel Test)

This sequence begins with Source 1 supplying power to the load continuously. The Source 1

Available and Source 1 Connected indicators are lit. The sequence ends with Source 2

(generator) assuming the load.

1. When the operator holds the Test button on the front panel for at least two seconds, the

digital board starts a Time Delay to Engine Start (TDES) timer.

2. When the TDES timer expires, the genset receives a remote start signal. The engine starts

and accelerates to rated speed.

3. When the alternator output reaches the "pickup" level, the Source 2 Available indicator

lights. The transfer switch starts the Time Delay Normal to Emergency (TDNE) timer. When

this time is complete, the controller proceeds to transfer the load in accordance with how it

is configured.

• If the controller is configured for OT with Sync Check, it monitors the two sources until

they are in phase and transfers the load to Source 2. The Source 2 Connected

indicator lights.

• If the controller is configured for Programmed Transition and there is a programmed

transition delay, the transfer switch stops in the Neutral position for the Time Delay

Programmed Transition (TDPT) and then completes its transition to the Source 2

position. The Source 2 Connected indicator lights.

• If the controller is configured for Closed Transition, it monitors the two sources until

they are in phase, close Source 2 for a maximum of 100ms, and open Source 1. The

Source 2 Connected indicator lights.

3.4.4.2 Transfer from Source 2 to Source 1 (Front Panel Test)

This sequence begins with Source 2 supplying power to the load. The Source 2 Available and

Source 2 Connected indicators are lit. The sequence ends with Source 1 (utility) assuming the

load.

1. When the operator pushes the Test button on the Front Panel, the digital board starts the

Time Delay Emergency to Normal (TDEN) timer.

2. When the TDEN is complete, the controller proceeds to transfer the load in accordance

with how it is configured.

• If the controller is configured for OT with Sync check, it monitors the two sources until

they are in phase and transfers the load to Source 1. The Source 1 Connected

indicator lights.

• If the controller is configured for Programmed Transition and there is a programmed

transition delay, the transfer switch stops in the Neutral position for the Time Delay

Programmed Transition (TDPT) and then completes its transition to the Source 1

position. The Source 1 Connected indicator lights.

• If the controller is configured for Closed Transition, it monitors the two sources until

they are in phase, closes Source 1 for a maximum of 100ms, and opens Source 2.

The Source 1 Connected indicator lights.

3. A Time Delay Engine Cool-down (TDEC) for the genset is activated. When the engine cooldown delay expires, the genset shuts down and the Source 2 Available indicator goes out.

30 962-0132 (Issue 6)

Page 37

5-2013 3. Description

3.4.4.3 Test With or Without Load

The operator can test the transfer switch, generator, and power system locally. The operator

can choose to transfer the load during the test or only test the generator. A test sequence can

be activated either through the switch panel push button or through the PowerCommand

network.

NOTICE

The Test button does not function unless the Front Panel Security Switch is in the

Program position.

FIGURE 21. TEST WITH OR WITHOUT LOAD SUBMENU

3.4.4.4 Programmable Generator Exerciser

Programmable generator exercises and exercise exceptions are generally programmed to be

recurring. They can be programmed from the PC service tool or the digital display, if available.

Level 1 controllers include two programmable generator exercises and two programmable

exercise exceptions. All events can be set using the PC service tool or the digital display.

NOTICE

Early versions of software on Level 1 controllers allow for setting only one exercise period and

one exercise exception using the digital display.

Level 2 controllers include eight programmable generator exercises and eight programmable

exercise exceptions. All events can be set using the PC service tool or the digital display.

NOTICE

Early versions of software on Level 2 controllers allow for setting only two exercise periods and

two exercise exceptions using the digital display.

All controllers have a push-button switch on the digital module that enables and disables the

exerciser clock. The Real-Time clock must be set before exercise programs are entered.

For utility-to-genset configurations: the exerciser clock initiates genset start and run cycles at

specified intervals for specified durations.

NOTICE

The exerciser is not used in utility-to-utility or genset-to-genset configurations.

962-0132 (Issue 6) 31

Page 38

3. Description 5-2013

FIGURE 22. EXERCISE SUBMENUS

32 962-0132 (Issue 6)

Page 39

5-2013 3. Description

FIGURE 23. EXERCISE EXCEPTIONS SUBMENUS

962-0132 (Issue 6) 33

Page 40

3. Description 5-2013

3.4.4.5 Real-Time Clock

All controllers have a real-time clock that keeps track of the time and date. The controller uses

the real-time clock to time and date stamp all events.

NOTICE

The clock is not set at the factory. To set the clock, use the PC service tool or the

digital display.

FIGURE 24. CLOCK SUBMENUS

3.4.4.6 Sleep Mode

After a period of screen inactivity (35 minutes), the digital display goes blank. Screen inactivity is

when there is no user interaction with the menu system and when there are no events. The

digital display is reactivated when an event occurs or when an operator touches one of the

menu buttons.

In order to conserve controller battery power, the loss of utility power also causes the digital

display to go blank. The digital display is reactivated when a second power source becomes

available.

The status of the controller batteries can be viewed using the digital display.

FIGURE 25. CONTROLLER BATTERIES STATUS SUBMENU

3.4.4.7 Remote Test Switch

The transfer switch can be wired with a remote test switch.

34 962-0132 (Issue 6)

Page 41

5-2013 3. Description

For utility-to-genset applications, closure of a set of contacts across the remote test transfer

input (TB2-5 and TB2-8) causes the transfer switch to sense a simulated utility power failure

and sends a start/run signal to the generator set and transfers the load to the genset when it

becomes available.

For utility-to-utility applications, closure of a set of contacts across the remote test transfer

input causes the transfer switch to sense a simulated power failure of the primary source and

transfers the load to the backup source.

Opening a set of contacts across the remote test transfer input causes the transfer switch to

sense that the primary source has been restored and transfers the load back to the primary

source (Source 1).

No. Description No. Description

1 GND 2 2

3 B+ 4 RMT

5 Remote Test 6 Transfer Inhibit

7 Load Shed (Optional) 8 Common

FIGURE 26. TB2 CONNECTIONS FOR REMOTE TEST TRANSFER

3.4.4.8 Remote Test Input

The transfer switch may be wired for a remote test input. The switch is used to start and stop

manually initiated system tests. As with the control panel Test pushbutton, the remote test input

can be configured to test with or without load.

A remote test input is set up by connecting a dry (voltage free) contact between TB2-5 and TB2-

8. Closing the contact starts a test and opening the contact cancels the test. The Test LED

flashes to signify the start of a test and stays on during the test.

Closing the contact causes the transfer switch to sense a (simulated) utility power failure and