Page 1

OT III

Redistribution or publication of this document

by any means, is strictly prohibited.

Transfer Switch

40 to 1000 Amperes

Nonautomatic/Remote

;HFGIED @%>%.%

-+)J'((, +J-*

Page 2

9< =E@ GA /GFK@FKJ

Redistribution or publication of this document

by any means, is strictly prohibited.

SECTION TITLE PAGE

1INTRODUCTION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator’s Manual1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Switch Application 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Identification 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Obtain Service1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2DESCRIPTION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Switch 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3OPERATION 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Operation 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4TROUBLESHOOTING 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Switch Does Not Transfer to the Standby Source4-1. . . . . . . . . . . . . . . . . . . . .

Transfer Switch Does Not Retransfer to the Normal Source4-1. . . . . . . . . . . . . . . . . . . .

INCORRECT SERVICE OR REPLACEMENT OF PARTS CAN RESULT IN

DEATH, SEVERE PERSONAL INJURY, AND/OR EQUIPMENT DAMAGE.

SERVICE PERSONNEL MUST BE QUALIFIED TO PERFORM ELECTRICAL

AND/OR MECHANICAL SERVICE.

i

Page 3

8<A@KM 6I@><LKDGFJ

Redistribution or publication of this document

by any means, is strictly prohibited.

This manual includes the following symbols to indi-

cate potentially dangerous conditions. Read the

manual carefully and know when these conditions

exist. Then take the necessary steps to protect per-

sonnel and the equipment.

This symbol warns of immediate

hazards that will result in severe personal injury

or death.

;.74241

unsafe practice that can result in severe per-

sonal injury or death.

/.:9254

safe practice that can result in personal injury

or product or property damage.

High voltage in OT transfer switch components pre-

sents serious shock hazards that can result in se-

vere personal injury or death. Read and follow

these suggestions.

Keep the transfer switch cabinet closed and locked.

Make sure only authorized personnel have the cabi-

net and operational keys.

This symbol refers to a hazard or

This symbol refers to a hazard or un-

Due to the serious shock hazard from high voltages

within the cabinet, all service and adjustments to

the transfer switch must be performed only by an

electrician or authorized service representative.

If the cabinet must be opened for any reason:

1. Move the operation selector switch on the gen-

erator set to Stop.

2.Disconnect the starting batteries of the generator set (remove the ground [–] lead first).

3.Remove AC power to the transfer switch. If the

instructions require otherwise, use extreme

caution due to the danger of shock hazard.

Place rubber insulative mats on dry wood platforms

over metal or concrete floors when working on any

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surfaces to be

damp when handling any electrical equipment.

Jewelry is a good conductor of electricity and

should be removed when working on the electrical

equipment.

Do not work on this equipment when mentally or

physically fatigued, or after consuming alcohol or

any drug that makes the operation of equipment un-

safe.

OT3-N-2

ii

Page 4

&$ 2FKIG?L>KDGF

Redistribution or publication of this document

by any means, is strictly prohibited.

OPERATOR’S MANUAL

This operator’s manual provides information necessary for operation of an OT III transfer switch with

a nonautomatic/remote control.

TRANSFER SWITCH APPLICATION

Transfer switches are an essential part of a build-

ing’s standby (or emergency) power system. The

Normal power source, commonly the utility line, is

backed up by a Standby power source, often an

electric generating set. A transfer switch supplies

the electrical load with power from one of these two

power sources.

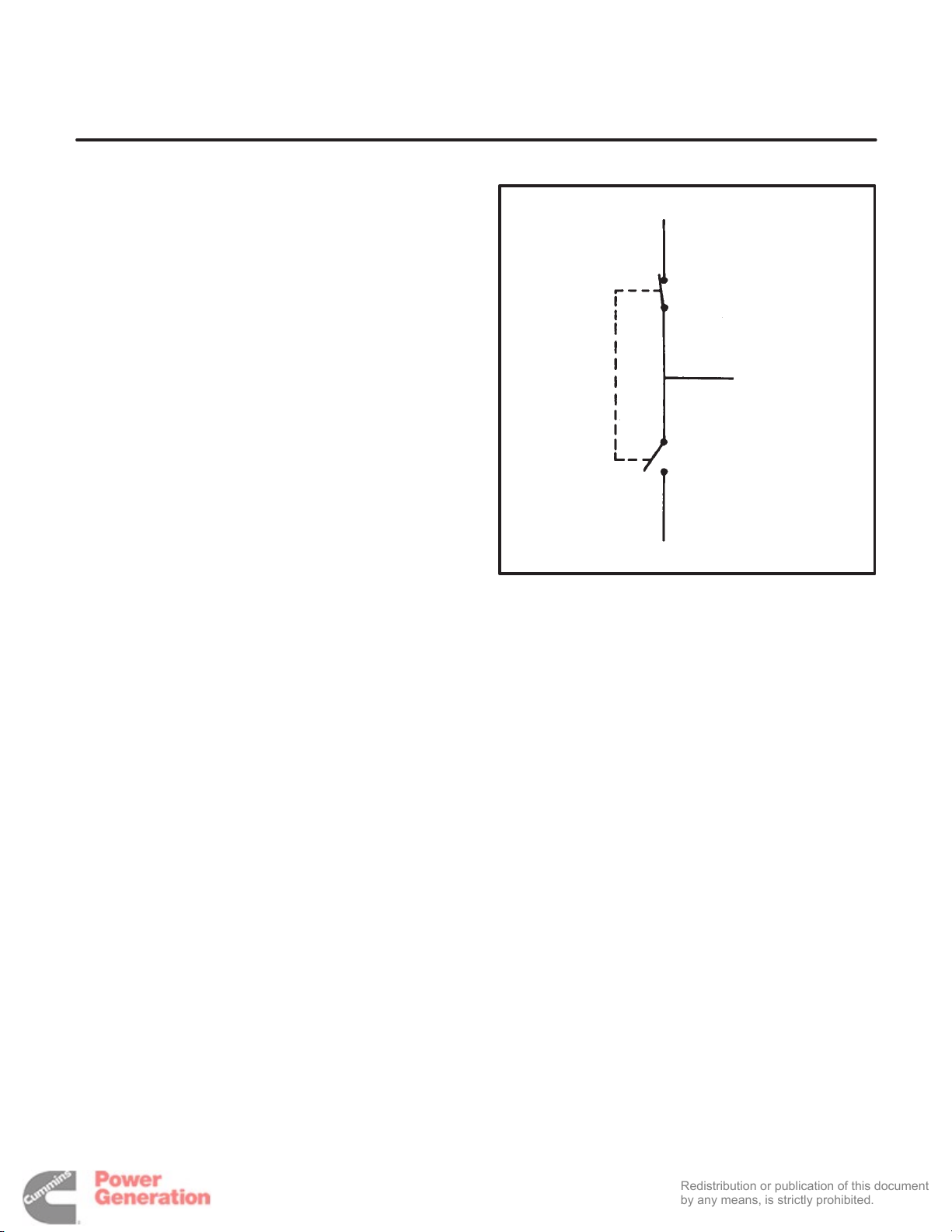

The load is connected to the common of the transfer

switch (Figure 1-1). Under normal conditions, the

load is supplied with power from the Normal source

(as illustrated). If the Normal power source must be

interrupted, the load is transferred to the Standby

power source. When Normal power returns, the

load should be retransferred to the Normal power

source. The transfer and retransfer of the load are

the two most basic functions of a transfer switch.

9:=8.7

7:.1

>?.91/C

FIGURE 1-1. LOAD TRANSFER SWITCH

(TYPICAL FUNCTION)

SC1101

Operation of a nonautomatic/remote transfer

switch is initiated either by an operator at the trans-

fer switch or by an external signal from a remote

source.

MODEL IDENTIFICATION

Identify your model by referring to the Model and

Specification number as shown on the nameplate.

Electrical characteristics are shown on the lower

portion of the nameplate, which is located on the

cabinet door.

If it is necessary to contact a dealer or distributor re-

garding the transfer switch, always give the com-

plete Model, Specification, and Serial number. This

information is necessary to properly identify your

unit among the many types manufactured.

1-1

Page 5

HOW TO OBTAIN SERVICE

Redistribution or publication of this document

by any means, is strictly prohibited.

When the transfer switch requires servicing, con-

tact your nearest dealer or distributor. Factory-

trained Parts and Service representatives are

ready to handle all your service needs.

If unable to locate a dealer or distributor, consult the

Yellow Pages. Typically, our distributors are listed

under:

GENERATORS-ELECTRIC,

ENGINES-GASOLINE OR DIESEL, OR

RECREATIONAL VEHICLES-EQUIPMENT,

PARTS AND SERVICE.

For the name of your local Cummins /Onan or

Onan-only distributor in the United States or Canada, call 1-800-888-ONAN. (This automated serv-

ice utilizes touch-tone phones only.) By entering

your area code and the first three digits of your local

telephone number, you will receive the name and

telephone number of the distributor nearest you.

For the name of your local Cummins-only distributor, or if you need more assistance, please call

Onan Corporation, 1-612-574-5000, 7:30 AM to

4:00 PM, Central Standard Time, Monday through

Friday.

When contacting your distributor, always supply the

complete Model Number and Serial Number as

shown on the nameplate.

Cummins is a registered trademark of Cummins Engine Company.

Onan is a registered trademark of Onan Corporation.

1-2

Page 6

'$ 0@J>IDHKDGF

Redistribution or publication of this document

by any means, is strictly prohibited.

CABINET

The standard cabinet (Figure 2-1) meets the re-

quirements for a UL Type 1 cabinet. This type is

designated as a general-purpose, indoor cabinet.

Indicator Lamps

There are four indicator lamps on the cabinet door.

The Normal Available and Standby Available lamps

are lit whenever their corresponding power sources

are producing power. These two lamps can be lit simultaneously.

The Normal Connected lamp is lit when the Normal

source is connected to the load.

The Standby Connected lamp is lit when the

Standby source is connected to the load.

9:=8.7

0:9920?21 7.8;

Normal/Standby Switch

This three-position (spring return to center) switch

is used to electrically select which source is con-

nected to the load. The Normal position causes the

Normal source to be connected. The Standby posi-

tion causes the Standby source to be connected.

Under electrical control, the transfer switch will con-

nect to a source only if voltage is present at that

source.

The Normal/Standby switch controls transfer

switch position only when the Local/Remote switch

is in the Local position.

>?.91/C

0:9920?21 7.8;

9:=8.7

.A.67./72 7.8;

;5.>2 >2720?:=

>B6?05 #3:=

:;?6:9.7 82?2=>$

7:0.7&=28:?2

>B6?05

>?.91/C

.A.67./72 7.8;

:;?6:9.7 .0

A:7?82?2=

:;?6:9.7 .0

.882?2=

:;?6:9.7 3=2<@290C

82?2=

9:=8.7&>?.91/C

>B6?05

3&+-)#-J

FIGURE 2-1. OT III CABINET WITH OPTIONS

2-1

Page 7

Local/Remote Switch

Redistribution or publication of this document

by any means, is strictly prohibited.

The Local/Remote switch is used to enable the Normal/Standby switch (Local position) or the remote

control inputs at TB2 (Remote position).

make and break the current flow. When closed to

either the Normal or the Standby power source, the

contacts are mechanically held. A mechanical in-

terlock prevents them from closing to both power

sources at the same time.

Optional Meter Package

The optional meter package includes an AC amme-

ter, an AC voltmeter, a frequency meter, and a

phase selector switch.

AC Voltmeter: The voltmeter measures line-to-line

voltage of the selected power source.

AC Ammeter: The ammeter measures the line cur-

rents of the load.

Frequency Meter: This meter measures the out-

put frequency of the selected power source in hertz.

Phase Selector Switch: This switch is used to se-

lect the source and phase to be measured.

TRANSFER SWITCH

The transfer switch (Figure 2-2) opens and closes

the contacts that transfer the load between Normal

and Standby power. The transfer switch is mechani-

cally interlocked to prevent simultaneous closing to

both power sources. The main parts of the transfer

switch discussed here are the contact assemblies,

linear actuator, Motor Disconnect switch, and auxil-

iary contacts.

Contact Assemblies

Linear Actuator

The linear actuator is a linear induction motor that

moves the contact assemblies between the Normal

power source and the Standby power source. Nor-

mally, linear actuator operation is initiated electrically. Manual operation of the transfer switch is also

possible. Refer to Manual Operation in the Opera-

tion section.

Motor Disconnect Switch

The Motor Disconnect toggle switch, on the acces-

sory control panel, enables and disables the linear

actuator. Place the switch in the Off position for

manual operation and in the Auto position for elec-

trical (local/remote) operation.

Auxiliary Contacts

Auxiliary contacts are provided on the Normal and

Emergency (Standby) sides of the transfer switch.

They are actuated by operation of the transfer

switch during transfer and retransfer.

The Normal side auxiliary contact switch is actuated

when the transfer switch is in the Normal position.

The Emergency side auxiliary contact switch is ac-

tuated when the transfer switch is in the Emergency

position.

The automatic transfer switch has either three or

four poles. Three pole transfer switches are pro-

vided with a neutral bar. The contact assemblies

The auxiliary contacts have current ratings of 10

amperes at 250 VAC. The contacts are wired to ter-

minal block TB1.

2-2

Page 8

69160.?:=

Redistribution or publication of this document

by any means, is strictly prohibited.

7.8;>

:;?6:9.7

82?2=>

>B6?052>

:;?6:9.7

;=:4=.8821

?=.9>6?6:9

.002>>:=C

0:9?=:7

;.927

8:?:=

16>0:9920?

>B6?05

FIGURE 2-2. INTERIOR/COMPONENTS

?=.9>32=

>B6?05

.>>28/7C

8/&*,&#&J

2-3

Page 9

Programmed Transition Option

Redistribution or publication of this document

by any means, is strictly prohibited.

The optional Program Transition module (Figures

2-2 and 2-3) is used to introduce a pause during

transition. Programmed transition is the capability

of the transfer switch to assume a mid-transition po-

sition, for an adjustable interval of time, when the

load is neither connected to the Normal power

source nor to the Standby power source.

This feature allows residual voltage from motor

loads to decay to an acceptable level before trans-

fer is completed. The length of time that the transfer

switch is in the midposition can be adjusted from 0

to 7.5 seconds or 0 to 60 seconds, depending on the

timer option. The proper adjustment is a function of

the motor and its connected load.

To set the time delay, align the slot on the potenti-

ometer with the desired marking on the faceplate

(Figure 2-3).

If a time delay is desired, make sure that the Delay/

No Delay switch is in the Delay position.

SC1583

FIGURE 2-3. PROGRAM TRANSITION MODULE

Load Shed

The Load Shed function is used to disconnect the

load from an available Standby source in order to

reduce the power consumed from that source.

When the load shed function is initiated, the switch

is moved to the neutral position.

The load shed function is initiated by a customer-

supplied signal.

Auxiliary Relays Option

Optional auxiliary relays provide contacts for ener-

gizing external alarms, remote indicators, and control equipment such as louver motors and water

pumps.

Alarm Module Option

The optional alarm module (Figure 2-4) provides an

audible indication that the transfer switch has trans-

ferred to the Standby power source.

A push button on the alarm module provides a

means to silence the horn.

The Alarm lamp indicates that the transfer switch is

in the Standby Connected position. If the horn is si-

lenced, the Horn Silenced lamp will also light. Both

lamps will stay lit until the transfer switch is moved

from the Standby Connected position to the discon-

nected (neutral) or Normal Connected position.

(%%#(--,

FIGURE 2-4. ALARM MODULE

2-4

Page 10

($ 5H@I<KDGF

Redistribution or publication of this document

by any means, is strictly prohibited.

LOCAL OPERATION

;.74241

rapid movement of the manual operator han-

dles and presents a hazard of serious personal

injury. Keep the cabinet door closed.

To set the transfer switch for local operation:

1. Place the Local/Remote switch in the Local po-

sition.

2.Place the Motor Disconnect switch (on the Ac-

cessory Control Panel) in the Auto position.

To transfer the load to the Standby source:

1. Check that the Standby Available lamp is lit.

(The transfer switch will only permit transfer to

the Standby source if the Standby source volt-

age is available.)

2.Move the Normal/Standby switch to the

Standby position and hold it there until the

Standby Connected lamp is lit.

To transfer the load to the Normal source:

1. Check that the Normal Available lamp is lit.

(The transfer switch will only permit transfer to

the Normal source if the Normal source voltage

is available.)

2.Move the Normal/Standby switch to the Normal position and hold it there until the Normal

Connected lamp is lit.

Transfer switch operation results in

REMOTE OPERATION

;.74241

rapid movement of the manual operator han-

dles and presents a hazard of serious personal

injury. Keep the cabinet door closed.

To set the transfer switch for remote operation:

1. Place the Local/Remote switch in the Remote

position.

2.Place the Motor Disconnect switch (on the Ac-

cessory Control Panel) in the Auto position.

Remotely controlled transfer to the Standby source

is accomplished by closing a set of normally open

contacts that are connected across terminals 1 and

3 of TB2.

The contacts must be held closed until transfer is

complete.

Remotely controlled retransfer to the Normal

source is accomplished by closing a set of normally

open contacts that are connected across terminals

1 and 2 of TB2.

The contacts must be held closed until transfer is

complete.

As with local operation, the transfer switch permits

transfer and retransfer only when the selected

source voltage is present.

Transfer switch operation results in

3-1

Page 11

MANUAL OPERATION

Redistribution or publication of this document

by any means, is strictly prohibited.

The transfer switch has operator handles for manu-

ally transferring the load. Use the following proce-

dure:

;.74241

rear side of the cabinet door presents a shock

hazard that can cause severe personal injury or

death. Use extreme caution to avoid touching

electrical contacts whenever the cabinet door is

open.

If possible, remove all AC power to the transfer

switch before manually operating the switch. If

it is necessary to perform manual operation

with AC power connected, follow the “Safety

Related Work Practices” listed in NFPA 70E.

1. Place the Local/Remote switch in the Local po-

sition.

2.Open the cabinet door of the transfer switch.

3.Move the Motor Disconnect switch to the Off

position.

AC power within the cabinet and the

4. Transfer from the Normal to the Standby

power source:

A.Pull the upper manual operator handle

down.

B.Push the lower manual operator handle

down.

Retransfer from the Standby to the Normal

power source:

C.Pull the lower manual operator handle up.

D.Push the upper manual operator handle

up.

;.74241

Transfer switch operation re-

sults in rapid movement of the manual op-

erator handles and presents a hazard of se-

rious personal injury. Keep hands clear of

handles when switching back to Auto.

5. To return to electrical operation, move the Mo-

tor Disconnect switch to the Auto position.

6.Close the cabinet door.

7.If remote control operation is being used, place

the Local/Remote switch in the Remote position.

3-2

Page 12

PREVENTIVE MAINTENANCE

Redistribution or publication of this document

by any means, is strictly prohibited.

Performing the yearly preventive maintenance procedures in Ta ble 3-1 will result in operational reliability of the

transfer switch.

The following procedures must only be performed by technically qualified personnel, following the procedures

provided in the Service manual (962-0512). If repair or replacement of components is necessary, call

your dealer or distributor.

;.74241

that can cause severe personal injury or death. In addition, incorrect installation, service, or parts re-

placement can result in severe personal injury, death, and/or equipment damage. Therefore, all cor-

rective service procedures must only be performed by technically qualified personnel, following the

procedures provided in the Service manual (962-0512).

;.74241

death unless all AC power is removed. Be sure to move the generator set operation selector switch to

Stop, disconnect AC line power, disconnect the battery charger from its AC power source, and disconnect the starting battery (negative [–] lead first) before servicing.

;.74241

cause any spark, arc, or flame while servicing batteries.

1. DISCONNECT ALL SOURCES OF AC POWER:

Disconnect both AC power sources from the transfer switch before continuing. Turn the generator set

operation selector switch to Stop. (The selector switch is located on the generator set control panel.)

If there is an external battery charger, disconnect it from its AC power source. Then disconnect

the set starting battery (negative [–] lead first).

2.CLEAN

3.INSPECT

4. PERFORM ROUTINE MAINTENANCE

5. CONNECT AC POWER AND CHECK OPERATION

AC power within the cabinet and the rear side of the cabinet door presents a shock hazard

The transfer switch presents a shock hazard that can cause severe personal injury or

Ignition of explosive battery gases can cause severe personal injury. Do not smoke or

TABLE 3-1. ANNUAL PREVENTIVE MAINTENANCE

a.Thoroughly dust and vacuum all controls, meters, switching mechanism components, interior

buswork, and connecting lugs.

b.Close the cabinet door and wash exterior surfaces with a damp sponge (mild detergent and

water). Do not allow water to enter the cabinet, especially at meters, lamps, and switches.

a.Check buswork and supporting hardware for carbon tracking, cracks, corrosion, or any other

types of deterioration. If replacement is necessary, call your dealer or distributor.

b.Check stationary and movable contacts. If contact replacement is necessary, the procedures are

described in section 4 of the Service manual (962-0512).

c.Check system hardware for loose connections. Tighten as indicated in step 4.

d. Check all control wiring and power cables (especially wiring between or near hinged door) for

signs of wear or deterioration.

e. Check all control wiring and power cables for loose connections. Tighten as indicated in step 4.

f. Check the cabinet interior for loose hardware. Tighten as indicated in step 4.

a.Tighten buswork, control wiring, power cables, and system hardware, as necessary. Hardware

torque values are given in section 4 of the Service manual (962-0512). Retorque all cable lug

connections. Lug torque requirements are listed in section 1 of the Service manual.

b.Service or replace the batteries.

a.Connect the set starting battery (negative [–] lead last). Connect the normal AC power source,

enable the backup power source. If applicable, connect power to the battery charger.

b.Verify proper operation of the battery charger.

c.Test system operation as described in this section. Close and lock the cabinet door.

3-3

Page 13

Redistribution or publication of this document

by any means, is strictly prohibited.

3-4

Page 14

)$ 9IGL=E@JCGGKDFB

Redistribution or publication of this document

by any means, is strictly prohibited.

The following procedures describe preliminary

troubleshooting checks. If the trouble persists, call

your dealer or distributor.

;.74241

rear side of the cabinet door presents a shock

hazard that can cause severe personal injury or

death. Use extreme caution to avoid touching

electrical contacts whenever the cabinet door is

open.

AC power within the cabinet and the

TRANSFER SWITCH DOES NOT

TRANSFER TO THE STANDBY SOURCE

1. Check the Motor Disconnect switch. It should

be in the Auto position.

2.Are the Local/Remote and Normal/Standby

switches in the correct positions?

3.Has the programmed transition time delay (if

equipped) expired?

4. Is the Standby source voltage present? Check

the Standby Available lamp. Check the

Standby source voltage.

5. Manually transfer the switch (see Operation).

Call your dealer or distributor.

TRANSFER SWITCH DOES NOT

RETRANSFER TO THE NORMAL SOURCE

1. Check the Motor Disconnect switch. It should

be in the Auto position.

2.Are the Local/Remote and Normal/Standby

switches in the correct positions?

3.Has the programmed transition time delay (if

equipped) expired?

4. Is the Normal source voltage present? Check

the Normal Available lamp. Check the Normal

source voltage.

5. Manually retransfer the switch (see Opera-

tion). Call your dealer or distributor.

4-1

Page 15

Redistribution or publication of this document

by any means, is strictly prohibited.

4-2

Page 16

Cummins Power Generation

Redistribution or publication of this document

by any means, is strictly prohibited.

1400 73rd Avenue N.E.

Minneapolis, MN 55432

1-800-888-6626

763-574-5000 International Use

Fax: 763-528-7229

Cummins is a registered trademark of Cummins Inc.

Loading...

Loading...