Page 1

Installation Manual

Home Standby Generator Set

GSAA (Spec A & C)

English−Orignal Instructions 6−2012 983−0603 (Issue 10)

Page 2

!!

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Page 3

Table of Contents

SECTION PAGE

IMPORTANT SAFETY INSTRUCTIONS iv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. INTRODUCTION 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About this Manual 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Installation Considerations 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

specifications 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Codes and Standards for Safety 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. STEP-BY-STEP OUTLINE OF INSTALLATION 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locating the Site 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Clearances 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Site 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting and Moving Generator Set 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Staking Generator Set In Place 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Wiring connections 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Line Connections 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. MECHANICAL 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location and Access 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Exhaust 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Natural Gas Fuel System 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propane Fuel System 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. ELECTRICAL CONNECTIONS 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC POwer Supply Connections 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessory Supply Connections 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Panel 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Connections (Optional) 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. STARTUP AND CONFIGURATION 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Review 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Configuration 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Adjustments 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

SECTION PAGE

APPENDIX A. OPERATION A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In-Home Operator Panel A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Operation A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Enable / Disable Standby A-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Manually Start / Stop Generator Set A-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault, Maintenance and New Event Screens A-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Genset Status A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Setup and Software Info A-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Log A-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Log A-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Settings A-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exercise Settings A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Setup A-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Management A-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX B. INTERNET / EMAIL INTERFACE B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Home Page B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Time and Date B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Exercise Schedule B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Control (Management) B-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Log B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Log B-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Setup B-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C. Cummins Onan Model RS12000 Generator Set Network Setup Guide . . .

C-1

Setting up In-Home Network Access to the Generator Set C-2 . . . . . . . . . . . . . . . . . .

Setting up Console Internet Access to the Generator Set C-3 . . . . . . . . . . . . . . . . . .

Setting up Email Alerts from the Generator Set C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help Hotline C-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequently Asked Questions C-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D. Communication Troubleshooting D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In-Home Network Access to Generator Set Troubleshooting D-1 . . . . . . . . . . . . . . . .

Remote Internet Access to Generator Set Troubleshooting D-2 . . . . . . . . . . . . . . . . .

Email Alert Troubleshooting D-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E. Specifications E-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G. Outline

and System Drawings F-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS − This manual

contains important instructions that should be followed during installation and maintenance of the

generator and batteries.

Before operating the generator set (genset),

read the Operator Manual (983−0104) and become

familiar with it and the equipment.

Note: Safe and efficient operation can be achieved

only if the equipment is properly operated and main-

tained. Many accidents are caused by failure to fol-

low fundamental rules and precautions.

The following symbols, found throughout this

manual, alert you to potentially dangerous condi-

tions to the operator, service personnel, or the

equipment.

DANGER

hazards which will result in severe personal in

jury or death.

WARNING

unsafe practice which can result in severe per-

sonal injury or death.

This symbol warns of immediate

This symbol refers to a hazard or

Lead-acid batteries emit a highly explosive

hydrogen gas that can be ignited by arcing,

sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

WARNING

constituents are known to the state of California

to cause cancer, birth defects, and other repro-

ductive harm.

Be sure the unit is well ventilated.

Provide an adequate exhaust system to

Exhaust height should be tall enough to

Do not use exhaust gases to heat a compart-

ment.

Visually and audibly inspect the exhaust daily

for leaks per the maintenance schedule.

Make sure that exhaust manifolds are se-

Engine exhaust and some of its

properly expel discharged gases away from

enclosed or sheltered areas and areas

where individuals are likely to congregate.

help clear gases, avoid accumulation of

snow or in accordance with local mechani-

cal code.

cured and not warped.

CAUTION

unsafe practice which can result in personal in-

jury or product or property damage.

This symbol refers to a hazard or

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can re-

sult from improper practices.

All persons handling propane are required to

be trained and qualified, according to NFPA

code.

Natural gas is lighter than air, and will tend

to gather under hoods. Propane is heavier

than air, and will tend to gather in sumps or

low areas.

Be sure all fuel supplies have a positive shutoff

valve.

Be sure battery area has been well-ventilated

prior to servicing near it.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Do not wear loose clothing or jewelery and

keep your hands away from all moving parts.

Loose clothing and jewelry can become

caught in moving parts.

If adjustment must be made while the unit is

running, use extreme caution around hot

manifolds, moving parts, etc.

Before starting work on the generator set, dis-

connect battery charger from its AC source,

then disconnect starting batteries, negative (-)

cable first. This will prevent accidental starting.

To prevent accidental air starting, make sure

the air supply line is connected until the generator set is ready to start.

Make sure that fasteners on the generator set

are secure. Tighten supports and clamps,

keep guards in position over fans, drive belts,

etc.

iii

Page 6

BATTERIES CAN EXPLODE CAUSING

SEVERE SKIN AND EYE BURNS AND

RELEASE TOXIC ELECTROLYTES

Wear safety glasses.

Do not smoke.

Do not dispose of the battery in a fire.

The battery is capable of exploding.

Do not open or mutilate the battery.

Released electrolytes has been known to

be harmful to the skin and eyes, and be

toxic.

Remove watches, rings and other metal ob-

jects, and use tools with insulated handles.

Batteries present the risk of high short cir-

cuit current.

To prevent arcing when disconnecting the bat-

tery, first disconnect the battery charger, then

the negative (−) battery cable and finally the

positive (+) cable.

To prevent arcing when reconnecting the bat-

tery, first reconnect the positive (+) cable, then

the negative (−) cable, and finally, reconnect

the battery charger.

When replacing the generator set battery, al-

ways use a 26 R, maintenance free, 12 volt

battery with a minimum battery CCA of 530.

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH

DANGER

on electrical components. High voltages can

cause injury or death. DO NOT tamper with in-

terlocks.

Follow all applicable state and local electrical

codes. Have all electrical installations per-

formed by a qualified licensed electrician. Tag

and lock open switches to avoid accidental clo-

sure.

Use extreme caution when working

isolation switch or an approved paralleling device.

Remove electric power before removing pro-

tective shields or touching electrical equipment.

Use rubber insulative mats placed on dry wood

platforms over floors that are metal or concrete

when around electrical equipment.

Do not wear damp clothing (particularly wet

shoes) or allow skin surface to be damp when

handling electrical equipment.

Do not wear jewelry.

Jewelry can short out electrical contacts

and cause shock or burning.

MEDIUM VOLTAGE GENERATOR SETS

(601V to 15kV)

DANGER

sult in severe personal injury or death.

Special equipment and training is required to

work on or around medium voltage equipment.

Operation and maintenance must be done

only by persons trained and qualified to work

on such devices.

WARNING

ment, as this can cause severe personal injury

or death.

Plan the time for maintenance with authorized

personnel so that the equipment can be de-en-

ergized and safely grounded.

Due to the nature of medium voltage electri-

Unauthorized personnel must not be permitted

near energized equipment.

Improper use or procedures will re-

Do not work on energized equip-

cal equipment, induced voltage remains

even after the equipment is disconnected

from the power source.

Do not connect the generator set directly to

any building electrical system.

CAUTION

the generator set into the utility line. This

creates a potential for electrocution or property

damage. Connect only through an approved

Hazardous voltages can flow from

iv

Page 7

GENERAL SAFETY PRECAUTIONS

WARNING

changer pressure cap while the engine is running.

DO NOT open a radiator or heat ex-

Make sure generator set is mounted in a man-

ner to prevent combustible materials from accumulating under the unit.

Remove all unnecessary grease and oil from

the unit.

Allow the generator set to cool and bleed the

system pressure first.

Coolants under pressure have a higher boil-

ing point than water.

WARNING

Used engine oils have been identi-

fied by some state or federal agencies as caus-

ing cancer or reproductive toxicity.

When checking or changing engine oil, take

care not to ingest, breathe the fumes, or con-

tact used oil.

Keep multi-class ABC fire extinguishers

handy.

Class A fires involve ordinary combustible

materials such as wood and cloth

(ref. NFPA No. 10)

Class B fires, combustible and flammable

liquid fuels and gaseous fuels

(ref. NFPA No. 10)

Class C fires, live electrical equipment.

(ref. NFPA No. 10)

Make sure that rags are not left on or near the

engine.

Accumulated grease and oil can cause

overheating and engine damage which

present a potential fire hazard.

Keep the generator set and the surrounding

area clean and free from obstructions. Re-

move any debris from the set and keep the

floor clean and dry.

Do not work on this equipment when mentally

or physically fatigued, or after consuming any

alcohol or drug that makes the operation of

equipment unsafe.

WARNING

Substances in exhaust gases have

been identified by some state or federal agen-

cies as causing cancer or reproductive toxicity.

Take care not to breathe or ingest or come into

contact with exhaust gases.

Do not store any flammable liquids, such as

fuel, cleaners, oil, etc., near the generator set.

A fire or explosion could result.

Wear hearing protection when going near an

operating generator set.

WARNING

Avoid contact with hot metal parts

such as the radiator, turbo charger and exhaust

system to prevent serious burns.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

v

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

vi

Page 9

1. Introduction

ABOUT THIS MANUAL

This manual is a guide for the installation of the gen-

erator set(s) listed on the front cover. Proper instal-

lation is essential for top performance, reliable op-

eration and safety. The installation must comply

with all applicable building codes. Read through this

manual before starting the installation.

Information For After Installation

WARNING

severe personal injury, death and damage to

equipment. The installation must comply with

all applicable building codes. It is strongly rec-

ommended that the installer be properly trained

and licensed to perform electrical and mechani-

cal equipment installations, however a person

with the proper knowledge and experience in

installing electrical and mechanical equipment

installations may also install this genset.

Refer to Appendix E. Specifications for specific in-

formation about the system and its components.

Refer to Appendix F. Outline and System Drawings

for specific information about the installation and the

wiring connections.

See the Operator Manual for operation and mainte-

nance instructions.

Improper installation can result in

PRE-INSTALLATION CONSIDERATIONS

The location of the generator set affects all other as-

pects of the installation, such as the lengths of elec-

tric wiring and gas lines, and is one of the first deci-

sions to be made. The installation cannot be com-

pleted without connections to an automatic transfer

switch and a source of fuel, Natural Gas or Propane,

which must be inspected by the gas and electric uti-

lities.

Decide where to locate the generator set and auto-

matic transfer switch, how fuel supply will be pro-

vided, what materials are required (wiring, fuel lines,

etc.), and what site preparations are necessary (ac-

cess to and preparation of the site, trenches, etc.).

Prior co-ordination will reduce delays and the

amount of time power has to be interrupted.

IMPORTANT NOTICE: Depending on the locality

and use of the generator set, it may be necessary to

obtain an air quality emissions permit before instal-

lation begins. Check with the local pollution control

or air quality authority.

Automatic Transfer Switch

The Model GSAA generator set is for installation

only with Cummins Onan Model RSS automatic

transfer switches. Use of other makes and models

of transfer switches voids the Model GSAA genera-

tor set Warranty.

Note: Manuals are updated from time to time to re-

flect changes in the equipment and its specifica-

tions. See an authorized Cummins Onan representa-

tive for current manuals.

Install the transfer switch in accordance with its

Installation Manual and make connections to the

generator set in accordance with Section 4. Electri-

cal Connections.

1-1

Page 10

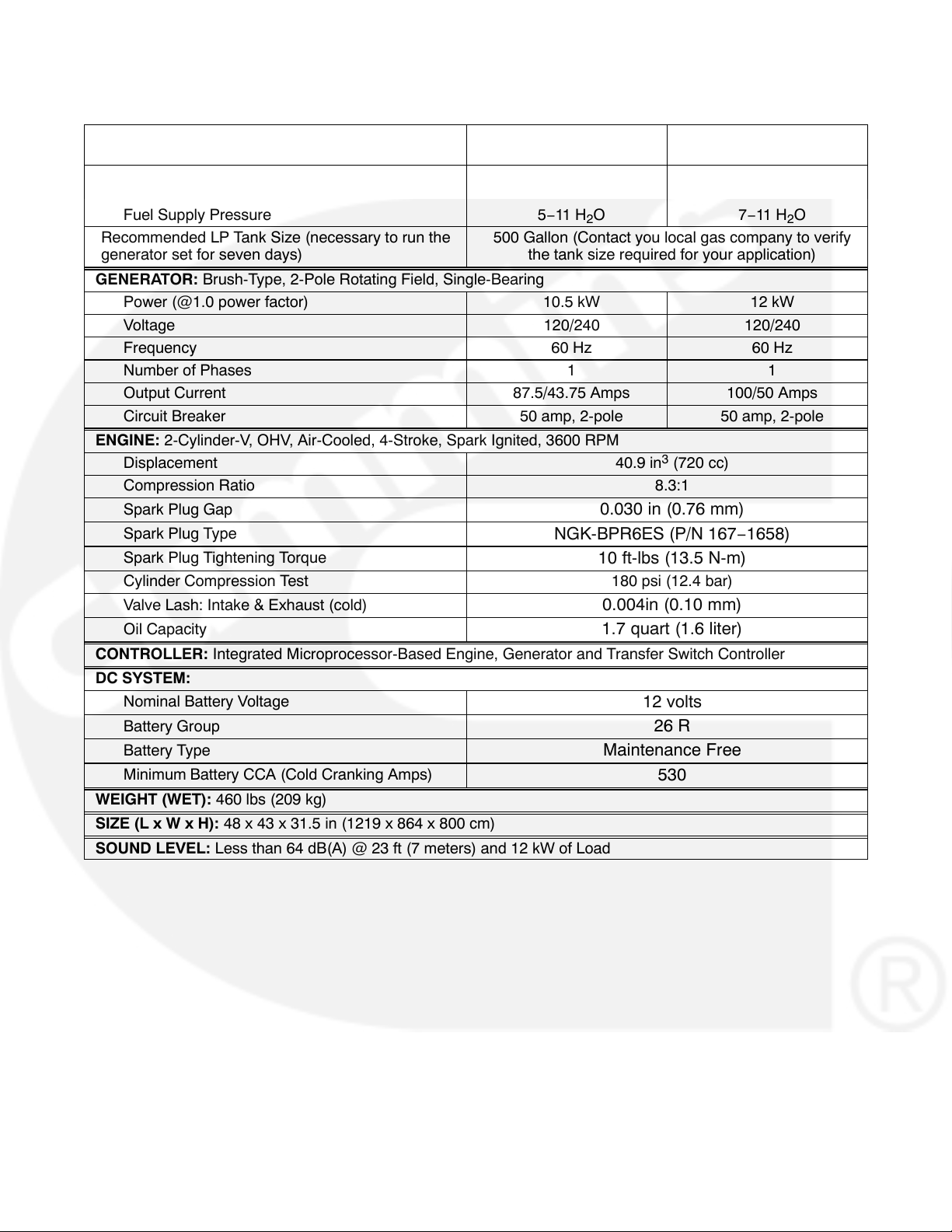

SPECIFICATIONS

FUEL CONSUMPTION:

@ 1/2 Load

@ Full Load

Fuel Supply Pressure

Recommended LP Tank Size (necessary to run the

generator set for seven days)

GENERATOR: Brush-Type, 2-Pole Rotating Field, Single-Bearing

Power (@1.0 power factor) 10.5 kW 12 kW

Voltage 120/240 120/240

Frequency 60 Hz 60 Hz

Number of Phases 1 1

Output Current 87.5/43.75 Amps 100/50 Amps

Circuit Breaker 50 amp, 2-pole 50 amp, 2-pole

ENGINE: 2-Cylinder-V, OHV, Air-Cooled, 4-Stroke, Spark Ignited, 3600 RPM

Displacement 40.9 in3 (720 cc)

Compression Ratio 8.3:1

Spark Plug Gap

Spark Plug Type

Spark Plug Tightening Torque

Cylinder Compression Test 180 psi (12.4 bar)

Valve Lash: Intake & Exhaust (cold)

Oil Capacity

CONTROLLER: Integrated Microprocessor-Based Engine, Generator and Transfer Switch Controller

DC SYSTEM:

Nominal Battery Voltage

Battery Group

Battery Type

Minimum Battery CCA (Cold Cranking Amps)

WEIGHT (WET): 460 lbs (209 kg)

SIZE (L x W x H): 48 x 43 x 31.5 in (1219 x 864 x 800 cm)

SOUND LEVEL: Less than 64 dB(A) @ 23 ft (7 meters) and 12 kW of Load

Natural Gas Installation

(1000 BTU/ft3)

122 ft3/hr (3.5 m3/hr)

191 ft3/hr (5.4 m3/hr)

5−11 H2O

500 Gallon (Contact you local gas company to verify

the tank size required for your application)

0.030 in (0.76 mm)

NGK-BPR6ES (P/N 167−1658)

10 ft-lbs (13.5 N-m)

0.004in (0.10 mm)

1.7 quart (1.6 liter)

12 volts

26 R

Maintenance Free

Propane Installation

(2500 BTU/ft3)

53 ft3/hr (1.5 m3/hr)

88 ft3/hr (2.5 m3/hr)

7−11 H2O

530

1-2

Page 11

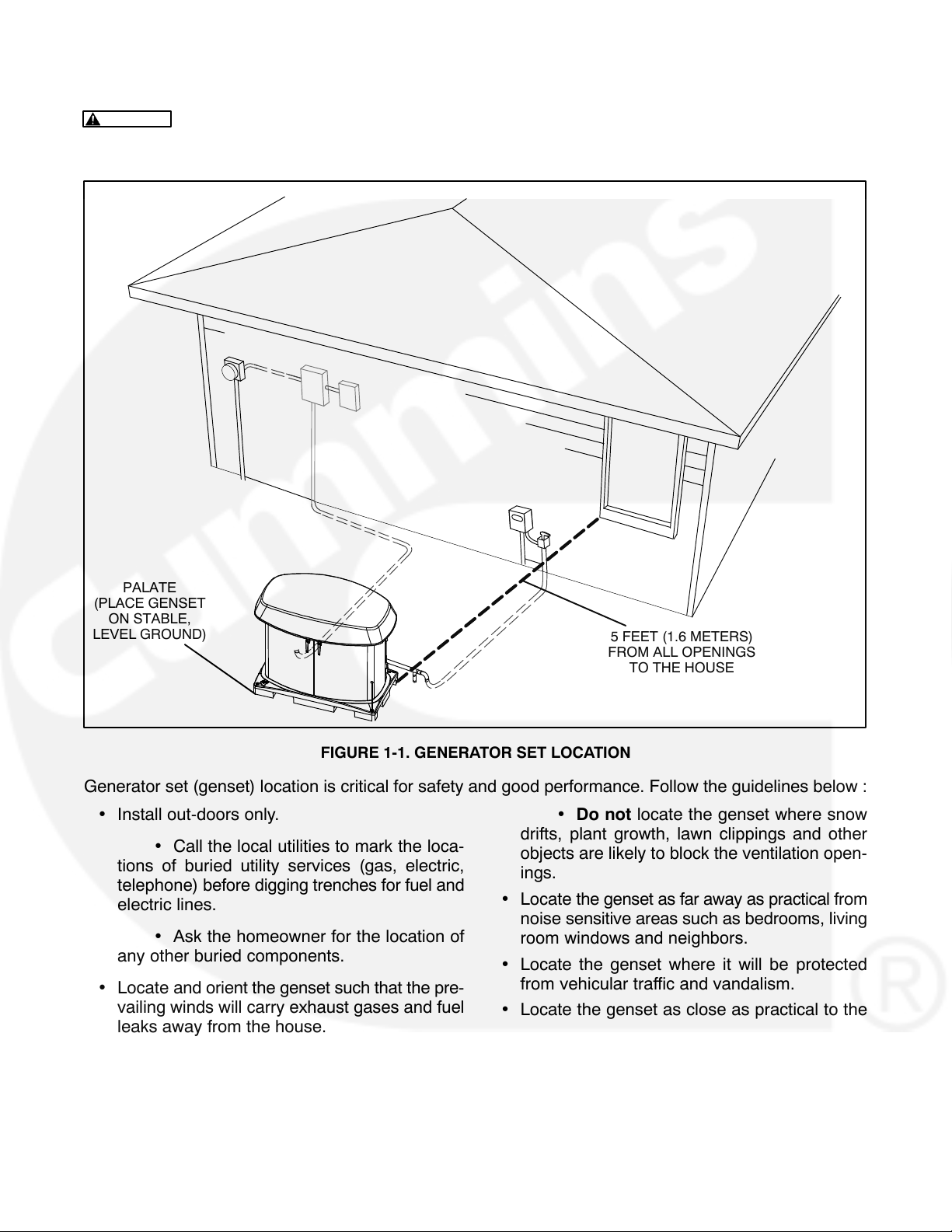

Generator Set Location

WARNING

doors, windows and other openings into the house and where the exhaust gases will disperse away

from the house.

EXHAUST GAS IS DEADLY! Install the generator set out-of-doors only, away from

PALATE

(PLACE GENSET

ON STABLE,

LEVEL GROUND)

FIGURE 1-1. GENERATOR SET LOCATION

5 FEET (1.6 METERS)

FROM ALL OPENINGS

TO THE HOUSE

Generator set (genset) location is critical for safety and good performance. Follow the guidelines below :

Install out-doors only.

Call the local utilities to mark the loca-

tions of buried utility services (gas, electric,

telephone) before digging trenches for fuel and

electric lines.

Locate the genset as far away as practical from

Do not locate the genset where snow

drifts, plant growth, lawn clippings and other

objects are likely to block the ventilation open-

ings.

noise sensitive areas such as bedrooms, living

Ask the homeowner for the location of

any other buried components.

Locate and orient the genset such that the pre-

vailing winds will carry exhaust gases and fuel

leaks away from the house.

Genset must be at least 5 feet (1.6 me-

ters) away from all openings to the house.

Do not locate the genset in a three-

sided niche of the house, under an overhang or

in a low-lying area or next to a basement.

room windows and neighbors.

Locate the genset where it will be protected

from vehicular traffic and vandalism.

Locate the genset as close as practical to the

house to reduce the lengths electric wiring and

fuel lines.

Place the genset on stable ground, not subject

to flooding.

Note: The area should be leveled and compacted with

sand or pea gravel.

1-3

Page 12

Natural Gas Supply

The Natural Gas supply meter may need to be exchanged for a higher capacity meter to supply the

additional gas consumed by the generator set. At

full load, the generator set alone requires 191,000

BTU/hr. To determine the required meter capacity,

generator set consumption must be added to the

gas consumed for heating, cooking, clothes drying,

etc. A typical installation might require a

400,000 BTU meter.

Consideration should also be given to utilizing high

pressure gas supply (2 psi), if available, to reduce

the required size, and therefore cost, of gas piping,

especially if the location of the generator set re-

quires a long supply line.

Note: The wire size varies, depending on distance (see Table 4-1).

10. Communications Wiring Connectors: Up to

twelve UL listed 18 AWG fork terminals for Item

9 wires (Cummins Part Number 0332−2527).

11. DC Conduit for Item 9 wires.

12. One or two 12 volt relays for load management

(optional)

Note: It is recommended that the two 18AWG wires

from Generator set terminals TB1-7 and TB1-8 for

load management be pulled along with the other con-

trol/communications wires at the time of installation

so that they are available if it is determined later that

load management is necessary.

Tools Required

Note: An older site might require upgrading and re-

pair of the gas supply system, which should be

scheduled to minimize power and gas supply inter-

ruptions.

Materials Required

The installer must provide the following materials to

complete the installation:

1. Gas line and step down regulators (as re-

quired) for gas connections:

A. Natural Gas at 191,000 BTU/hour

B. Propane at 220,000 BTU/ hr or 2.4 gallons/

hour

C. Gas pressure at generator set: 5−11 inch

WC

2. UL listed pipe dope

3. Electrical Conduit sealing putty

4. Cat 5 Ethernet cable (optional)

5. Four wall anchors and 4 No. 6 black screws for

mounting the Operator Panel.

6. AC Power Output Wiring: Four 8 AWG 90C

wires for runs up to 125 feet. (L1, L2, N and

GND)

7. AC Accessory Supply Wiring: Two 12 AWG

90C wires for runs up to 125 feet. (Hot and

Neutral)

8. AC Conduit for Items 6 and 7, which may be run

in the same conduit.

9. Control/Communications Wiring: Up to twelve

18 AWG wires, depending on Transfer Switch.

(Generator set TB1-1 through TB1-12)

Use a forklift to move the generator set and set it in

place. Alternatively, a one-man hand dolly designed

to fit the generator set base is available to move the

generator set and set it in place (P/N 0541-1624).

Hand tools required include the following:

1. Wire stripper and lug crimper for terminating

the twelve communications wires.

2. Rachet set with 10 mm socket and extension.

3. Two pipe wrenches for gas connections.

4. Phillips-head and flat-blade screwdrivers.

Loose Parts Shipped With the Generator

The following loose parts are shipped with the

GSAA generator set.

Oil Drain Hose (P/N 0503−2151)

Flexible Fuel Hose Assembly

(P/N 0501−0776−06)

Four Base Spikes (Ground Stakes)

(P/N 0403−4365)

Snap Bushing (P/N 0508−0208−05)

In-Home Display (P/N 0300−6385)

Pigtail Harness for In-Home Display

(P/N 0338−5023)

LP Orifice for LP Fuel Changeover (Wire tied to

the engine lifting bracket) (P/N 0148−1385)

Two Keys (P/N A026G567)

Quick Connect Guide (located in the battery

box)

Literature − Operator Manual, Installation

Manual, Setup Guide, and Warranty Statement

1-4

Page 13

INSTALLATION CODES AND STANDARDS

FOR SAFETY

WARNING

sole responsibility for following all applicable

local codes and regulations.

The following list of Installation Codes and Stan-

The generator set installer bears

TABLE 1-1. INSTALLATION CODES AND SAFETY RECOMMENDATIONS

dards for Safety applies to the installation and operation of standby generator sets. This list is for reference only and not intended to be inclusive of all

applicable codes and standards. The address of

each agency is listed so that copies of the codes

may be obtained for reference. Installation codes

and recommendations are subject to change, and

may vary by location or over time.

NFPA 70 National Electric Code

NFPA 37 Installation and Use of Stationary Combus-

tion Engines and Gas Turbines

NFPA 54 National Fuel Gas Code

NFPA 58 Storage and Handling of Liquefied Petro-

leum Gases

CSA Electrical Bulletin

CSA C22.2 No. 100

CSA C22.2 No. 14

California Administrative Code - Title 25 Chapter 3 State of California

Underwriters Laboratories

UL2200 Stationary Engine Generator Assemblies

National Fire Protection Association,

470 Atlantic Avenue

Boston, MA 02210

Canadian Standards Association,

Housing and Construction Materials Section

178 Rexdale Blvd.

Rexdale, Ontario, Canada M9W 1R3

Documents Section

P.O. Box 1015

North Highlands, CA 95660

Underwriters Laboratories, Inc.

333 Pfingsten Road

Northbrook, IL 60062-2096

1-5

Page 14

2. Step-by-Step Outline of Installation

INTRODUCTION

WARNING

plying with all applicable installation codes and

safety requirements.

This section is a step-by-step overview of a typical

installation. This section includes:

Locating the site

Generator set Clearances

Preparing the site

Moving the generator set

Placing the generator set

The installer is responsible for com-

Connecting the generator set

Review this section, then refer to the detailed in-

structions that are given in the following sections for

specific procedures and important safety precau-

tions before starting the installation.

LOCATING THE SITE

These generator sets are housed in a weather-pro-

tective enclosure for installation out-of-doors on a

non-combustible base.

Choose a site close to the electric service and Natu-

ral Gas meter or Propane tank. The main distribu-

tion, transfer switch, and sub-panels are usually in-

side the house.

ELECTRIC

METER

GENERATOR

UNDERGROUND

ELECTRIC

SERVICE

SET

TRANSFER

SWITCH

DISTRIBUTION

PANEL

GAS

METER

GAS

SHUTOFF

VALVE

UNDERGROUND

GAS SERVICE

FIGURE 2-1. TYPICAL GENERATOR SET SITE

2-1

Page 15

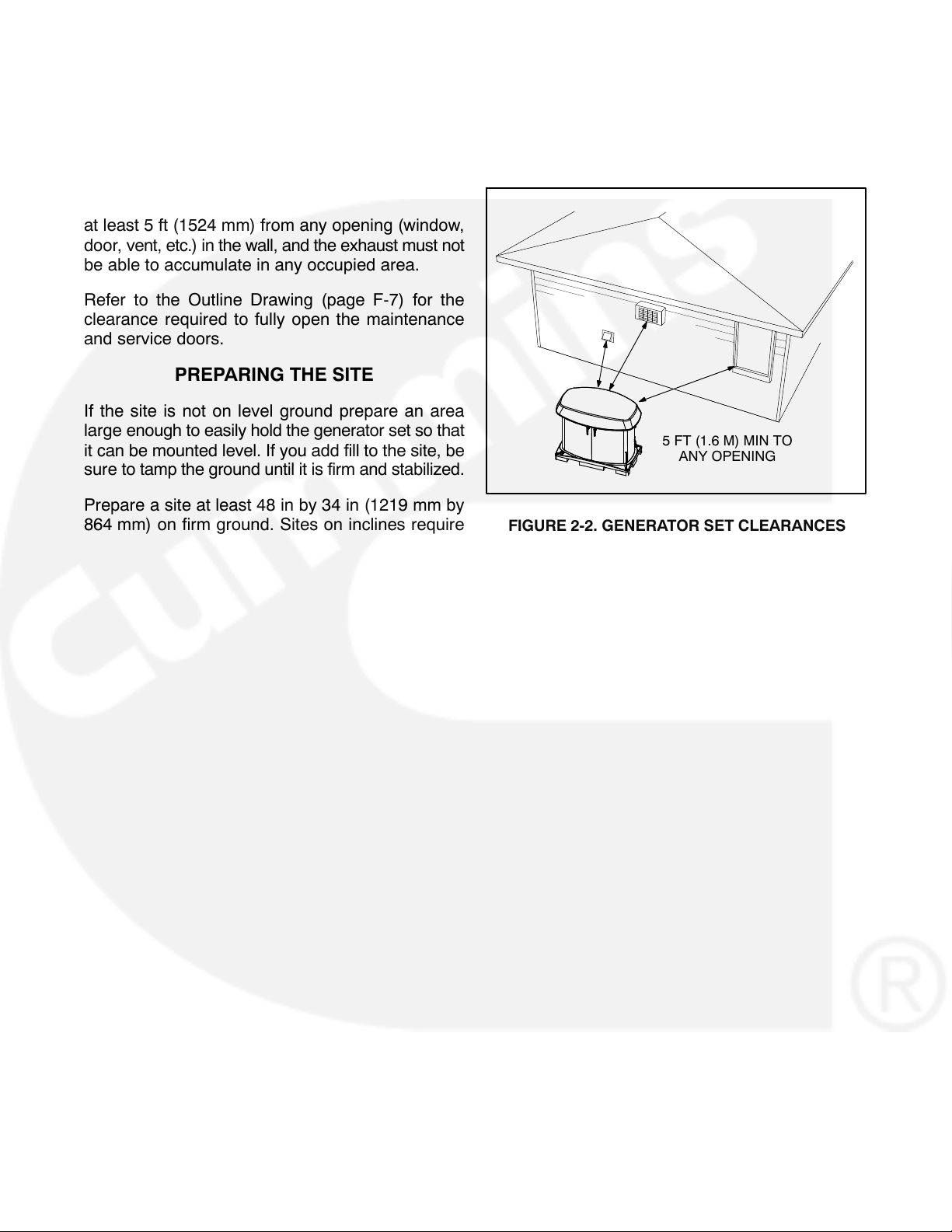

GENERATOR SET CLEARANCES

The generator set must be a minimum of 3 ft

(915 mm) from combustible material (NFPA 37).

Leave at least 3 ft (915 mm) all around the generator set enclosure for access to the inside (NEC Art.

110-26a, Art. 110-26b). The generator set must be

at least 5 ft (1524 mm) from any opening (window,

door, vent, etc.) in the wall, and the exhaust must not

be able to accumulate in any occupied area.

Refer to the Outline Drawing (page F-7) for the

clearance required to fully open the maintenance

and service doors.

PREPARING THE SITE

If the site is not on level ground prepare an area

large enough to easily hold the generator set so that

it can be mounted level. If you add fill to the site, be

sure to tamp the ground until it is firm and stabilized.

Prepare a site at least 48 in by 34 in (1219 mm by

864 mm) on firm ground. Sites on inclines require

more area. Add a layer of sand or pea gravel deep

enough so that you can level the generator set. Remove any combustible material that would be under

and around the generator set.

5 FT (1.6 M) MIN TO

ANY OPENING

FIGURE 2-2. GENERATOR SET CLEARANCES

2-2

Page 16

LIFTING AND MOVING GENERATOR SET

WARNING

ping the generator set can cause severe personal injury or death. Keep feet and hands clear

when lifting the generator set.

CAUTION

in the crankcase. Keep it upright.

The generator set is heavy and must be handled

with care. Use a forklift to move the generator set

and set it in place. Alternatively, a one-man hand

dolly designed to fit the generator set base is avail-

able to move the generator set and set it in place.

The generator set is heavy. Drop-

The generator set is shipped with oil

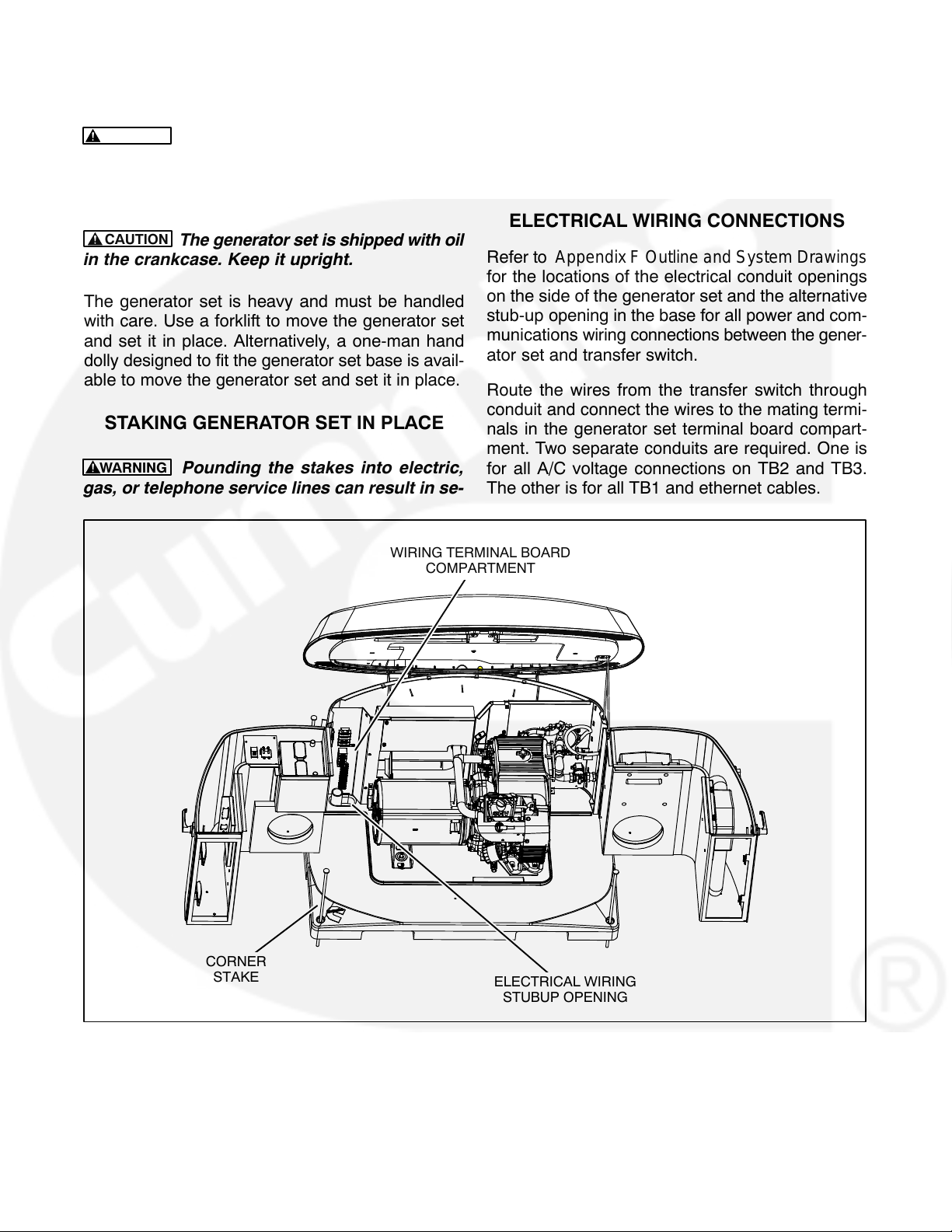

STAKING GENERATOR SET IN PLACE

WARNING

gas, or telephone service lines can result in se-

Pounding the stakes into electric,

vere personal injury or death. Observe the utility

company markings.

Set the generator set in place and pound the four

corner stakes into the ground to secure the generator set in place.

ELECTRICAL WIRING CONNECTIONS

Refer to Appendix F Outline and System Drawings

for the locations of the electrical conduit openings

on the side of the generator set and the alternative

stub-up opening in the base for all power and com-

munications wiring connections between the gener-

ator set and transfer switch.

Route the wires from the transfer switch through

conduit and connect the wires to the mating termi-

nals in the generator set terminal board compart-

ment. Two separate conduits are required. One is

for all A/C voltage connections on TB2 and TB3.

The other is for all TB1 and ethernet cables.

CORNER

STAKE

WIRING TERMINAL BOARD

COMPARTMENT

ELECTRICAL WIRING

STUBUP OPENING

FIGURE 2-3. ELECTRICAL WIRING TERMINAL BOARDS AND STUBUP OPENING

2-3

Page 17

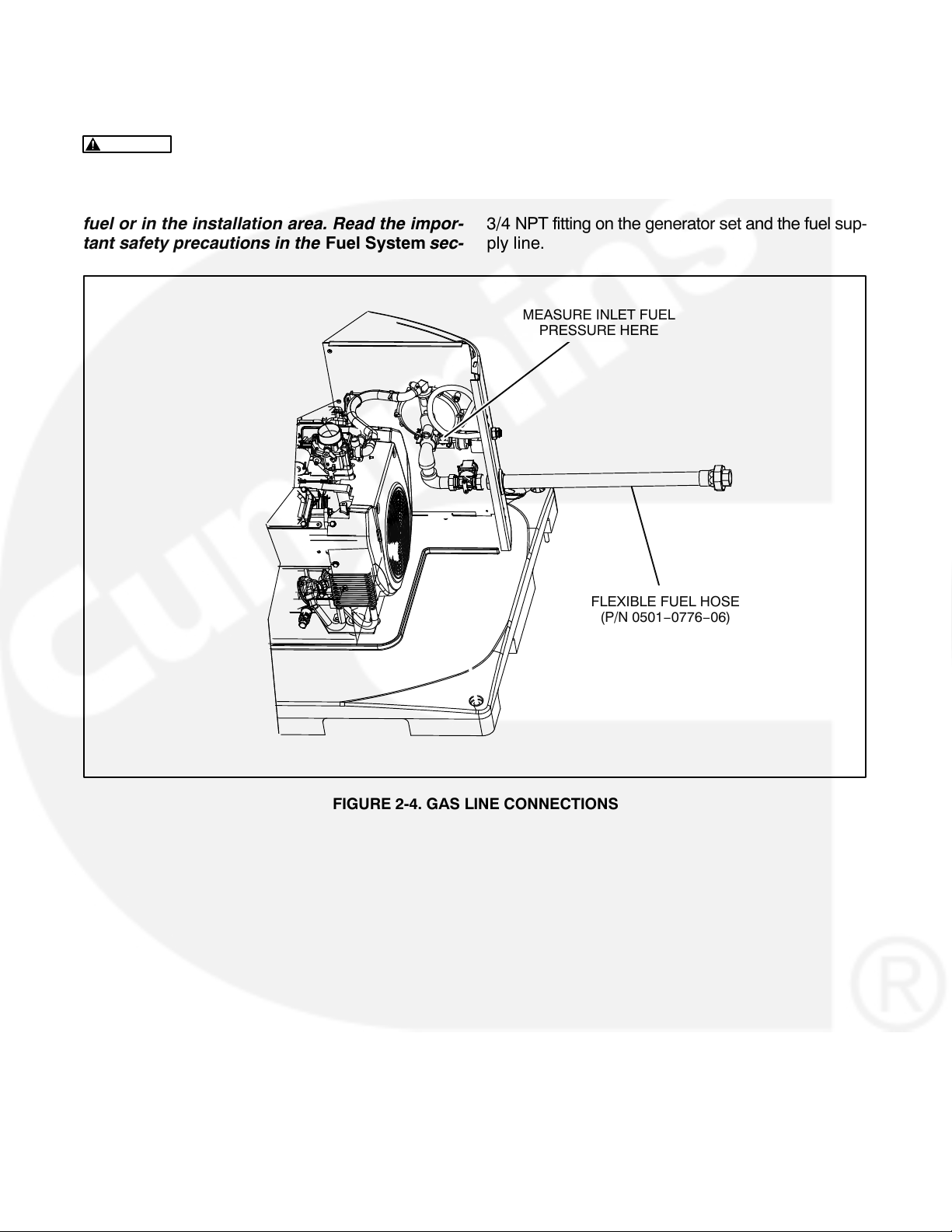

GAS LINE CONNECTIONS

WARNING

explosion that can result in severe personal injury or death. Do not smoke or allow any flame,

spark, pilot light, or other ignition sources near

fuel or in the installation area. Read the impor-

tant safety precautions in the Fuel System sec-

Fuel presents the hazard of fire or

tion.

Refer to Appendix F Outline and System Drawings

for the location of the fuel supply connection through

the side of the generator set. A flexible fuel hose is

packaged inside the generator set (Assembly part

number: 0501−0776−06). Connect it between the

3/4 NPT fitting on the generator set and the fuel sup-

ply line.

MEASURE INLET FUEL

PRESSURE HERE

FLEXIBLE FUEL HOSE

(P/N 0501−0776−06)

FIGURE 2-4. GAS LINE CONNECTIONS

2-4

Page 18

3. Mechanical

LOCATION AND ACCESS

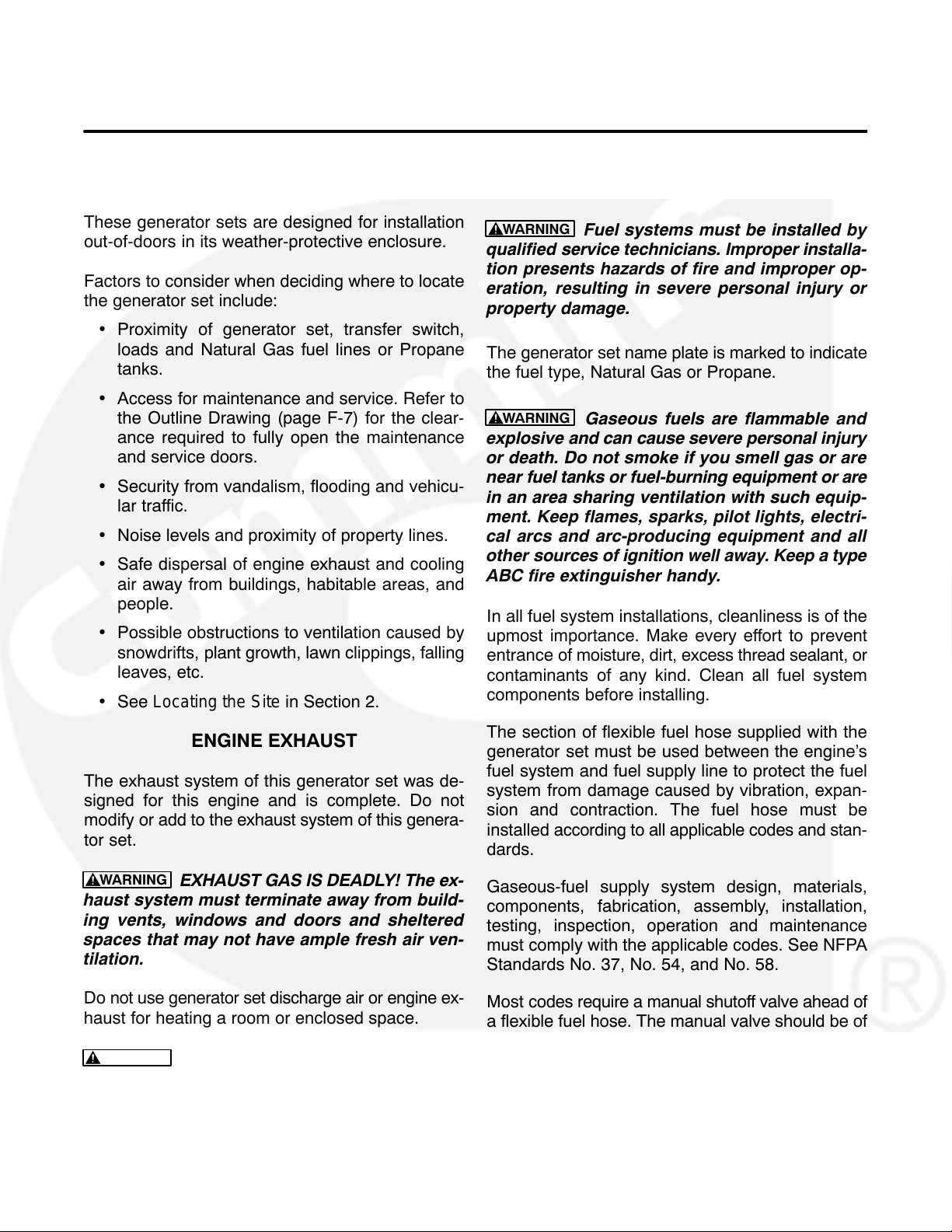

These generator sets are designed for installation

out-of-doors in its weather-protective enclosure.

Factors to consider when deciding where to locate

the generator set include:

Proximity of generator set, transfer switch,

loads and Natural Gas fuel lines or Propane

tanks.

Access for maintenance and service. Refer to

the Outline Drawing (page F-7) for the clear-

ance required to fully open the maintenance

and service doors.

Security from vandalism, flooding and vehicu-

lar traffic.

Noise levels and proximity of property lines.

Safe dispersal of engine exhaust and cooling

air away from buildings, habitable areas, and

people.

Possible obstructions to ventilation caused by

snowdrifts, plant growth, lawn clippings, falling

leaves, etc.

See Locating the Site in Section 2.

FUEL SYSTEM

WARNING

qualified service technicians. Improper installa-

tion presents hazards of fire and improper op-

eration, resulting in severe personal injury or

property damage.

The generator set name plate is marked to indicate

the fuel type, Natural Gas or Propane.

WARNING

explosive and can cause severe personal injury

or death. Do not smoke if you smell gas or are

near fuel tanks or fuel-burning equipment or are

in an area sharing ventilation with such equip-

ment. Keep flames, sparks, pilot lights, electri-

cal arcs and arc-producing equipment and all

other sources of ignition well away. Keep a type

ABC fire extinguisher handy.

In all fuel system installations, cleanliness is of the

upmost importance. Make every effort to prevent

entrance of moisture, dirt, excess thread sealant, or

contaminants of any kind. Clean all fuel system

components before installing.

Fuel systems must be installed by

Gaseous fuels are flammable and

ENGINE EXHAUST

The exhaust system of this generator set was de-

signed for this engine and is complete. Do not

modify or add to the exhaust system of this genera-

tor set.

WARNING

haust system must terminate away from build-

ing vents, windows and doors and sheltered

spaces that may not have ample fresh air ven-

tilation.

Do not use generator set discharge air or engine ex-

haust for heating a room or enclosed space.

WARNING

carry carbon monoxide gas (odorless and invisible) which can cause asphyxiation and death.

Never use engine discharge air or exhaust for

heating a room or enclosed space.

EXHAUST GAS IS DEADLY! The ex-

Engine discharge air and exhaust

The section of flexible fuel hose supplied with the

generator set must be used between the engine’s

fuel system and fuel supply line to protect the fuel

system from damage caused by vibration, expan-

sion and contraction. The fuel hose must be

installed according to all applicable codes and stan-

dards.

Gaseous-fuel supply system design, materials,

components, fabrication, assembly, installation,

testing, inspection, operation and maintenance

must comply with the applicable codes. See NFPA

Standards No. 37, No. 54, and No. 58.

Most codes require a manual shutoff valve ahead of

a flexible fuel hose. The manual valve should be of

the indicating type. The generator set has an electric (battery-powered) shutoff valve included between the fuel supply and the carburetor.

Until the generator set is connected, cap the fuel line

stub-up at the generator set to prevent dirt from en-

3-1

Page 19

tering and gas discharging if the gas supply shutoff

valve is opened inadvertently.

Refer to Appendix E. Specifications for the fuel inlet

size.

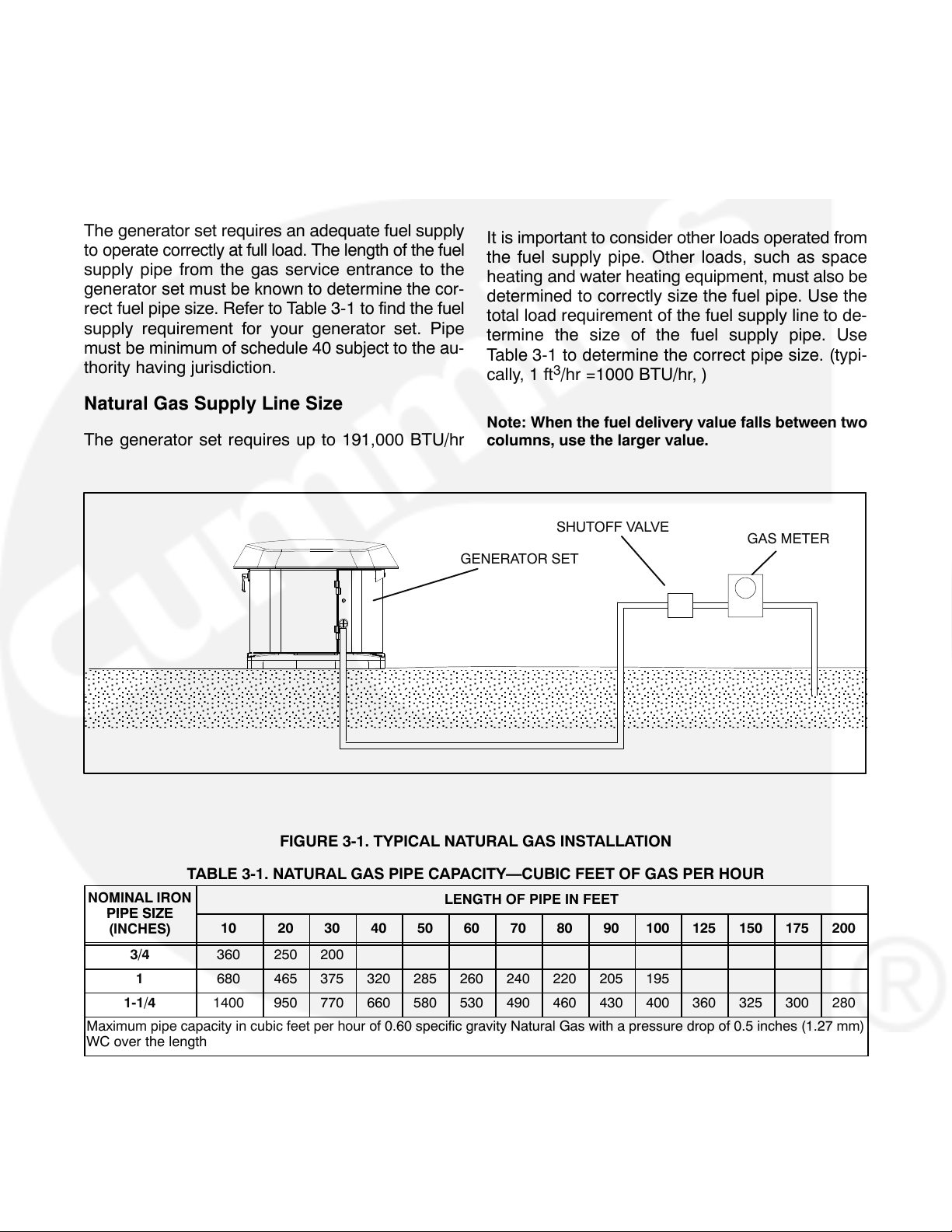

NATURAL GAS FUEL SYSTEM

(191 cubic feet/hr) delivered to the generator set inlet at 5−11 inches (28 mm) WC (Water Column). If

the meter serves other gas appliances such as a furnace, water heater, or stove, you must consult with

the local Natural Gas utility to determine whether

the Natural Gas meter is adequate.

The generator set requires an adequate fuel supply

to operate correctly at full load. The length of the fuel

supply pipe from the gas service entrance to the

generator set must be known to determine the cor-

rect fuel pipe size. Refer to Table 3-1 to find the fuel

supply requirement for your generator set. Pipe

must be minimum of schedule 40 subject to the au-

thority having jurisdiction.

Natural Gas Supply Line Size

The generator set requires up to 191,000 BTU/hr

It is important to consider other loads operated from

the fuel supply pipe. Other loads, such as space

heating and water heating equipment, must also be

determined to correctly size the fuel pipe. Use the

total load requirement of the fuel supply line to de-

termine the size of the fuel supply pipe. Use

Table 3-1 to determine the correct pipe size. (typi-

cally, 1 ft

Note: When the fuel delivery value falls between two

columns, use the larger value.

GENERATOR SET

3

/hr =1000 BTU/hr, )

SHUTOFF VALVE

GAS METER

FIGURE 3-1. TYPICAL NATURAL GAS INSTALLATION

TABLE 3-1. NATURAL GAS PIPE CAPACITY—CUBIC FEET OF GAS PER HOUR

NOMINAL IRON

PIPE SIZE

(INCHES)

3/4 360 250 200

1 680 465 375 320 285 260 240 220 205 195

1-1/4 1400 950 770 660 580 530 490 460 430 400 360 325 300 280

Maximum pipe capacity in cubic feet per hour of 0.60 specific gravity Natural Gas with a pressure drop of 0.5 inches (1.27 mm)

WC over the length

10 20 30 40 50 60 70 80 90 100 125 150 175 200

LENGTH OF PIPE IN FEET

3-2

Page 20

PROPANE FUEL SYSTEM

WARNING

NFPA Standard No. 58 requires all

persons handling and operating Propane to be

trained in proper handling and operating procedures.

WARNING

Fuel leaks can lead to explosive ac-

cumulations of gas. Propane sinks in air and

can accumulate inside housings, basements

and other below-grade spaces. Prevent gas

leaks and the accumulation of gaseous fuel in

the event of a leak.

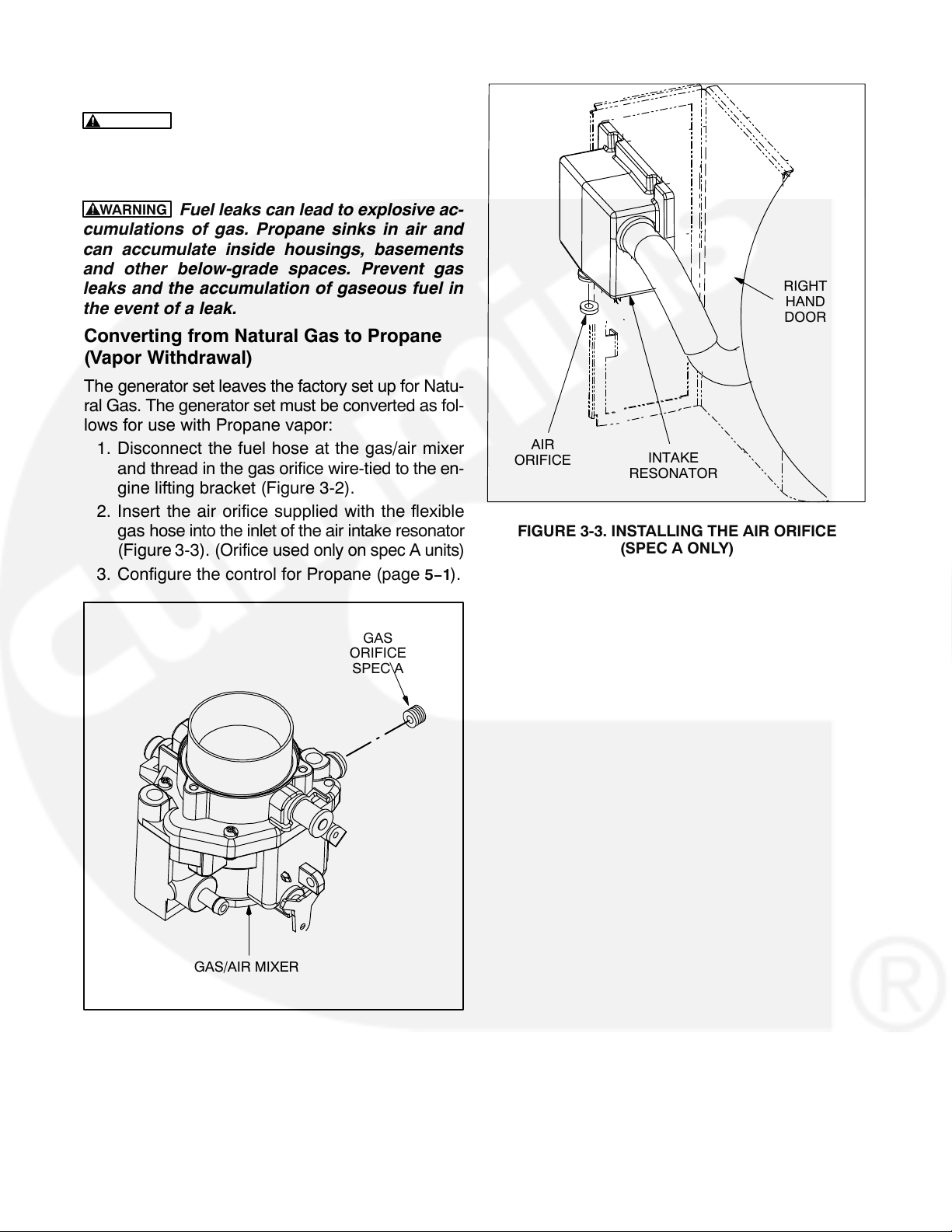

Converting from Natural Gas to Propane

(Vapor Withdrawal)

The generator set leaves the factory set up for Natu-

ral Gas. The generator set must be converted as fol-

lows for use with Propane vapor:

1. Disconnect the fuel hose at the gas/air mixer

and thread in the gas orifice wire-tied to the en-

gine lifting bracket (Figure 3-2).

2. Insert the air orifice supplied with the flexible

gas hose into the inlet of the air intake resonator

(Figure 3-3). (Orifice used only on spec A units)

3. Configure the control for Propane (page

5−1).

RIGHT

HAND

DOOR

AIR

ORIFICE

FIGURE 3-3. INSTALLING THE AIR ORIFICE

INTAKE

RESONATOR

(SPEC A ONLY)

GAS

ORIFICE

SPEC A

GAS/AIR MIXER

FIGURE 3-2. INSTALLING THE PROPANE GAS

ORIFICE

3-3

Page 21

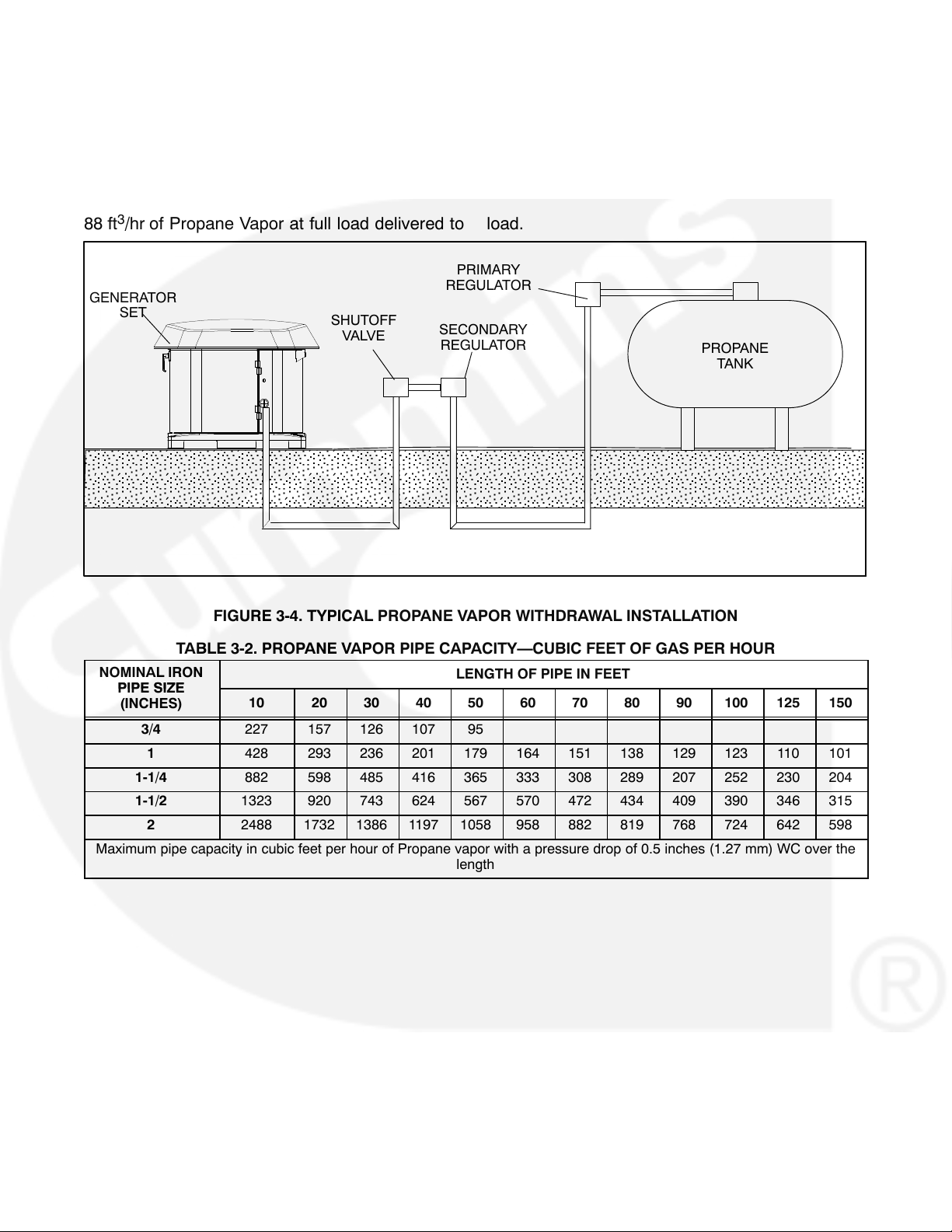

Propane Vapor Fuel Supply Line Size and

Pressure

Fuel line size depends on the amount of fuel needed

to run the generator set at full load at the distance

the fuel must be moved. The generator set requires

3

88 ft

/hr of Propane Vapor at full load delivered to

GENERATOR

SET

SHUTOFF

VALVE

REGULATOR

SECONDARY

REGULATOR

the generator set inlet at 7−11 inches WC (Water

Column) gas pressure. Figure 3-4 shows a typical

Propane Vapor installation and Table 3-2 lists fuel

capacity for given distances and pipe size.

Size the fuel line so that the Propane vapor pressure

drops no more than 2 inches WC from no load to full

load.

PRIMARY

PROPANE

TANK

FIGURE 3-4. TYPICAL PROPANE VAPOR WITHDRAWAL INSTALLATION

TABLE 3-2. PROPANE VAPOR PIPE CAPACITY—CUBIC FEET OF GAS PER HOUR

NOMINAL IRON

PIPE SIZE

(INCHES)

3/4 227 157 126 107 95

1 428 293 236 201 179 164 151 138 129 123 110 101

1-1/4 882 598 485 416 365 333 308 289 207 252 230 204

1-1/2 1323 920 743 624 567 570 472 434 409 390 346 315

2 2488 1732 1386 1197 1058 958 882 819 768 724 642 598

Maximum pipe capacity in cubic feet per hour of Propane vapor with a pressure drop of 0.5 inches (1.27 mm) WC over the

10 20 30 40 50 60 70 80 90 100 125 150

LENGTH OF PIPE IN FEET

length

3-4

Page 22

Fuel Pressure

WARNING

cause gas leaks which can lead to fire and severe personal injury or death. Gas supply pressure must be adjusted to Specifications by

trained and experienced personnel.

Satisfactory performance requires that the Propane

Vapor be supplied at a pressure within the range of

7-11 inches WC (water column).

When measuring supply pressure, the most accu-

rate reading would be on the input side of the sole-

noid valve.

High gas supply pressure can

Recommended Fuel

Use clean, fresh HD-5 grade Propane or equivalent

product consisting of at least 90 percent Propane.

Commercial Propane may contain more than 2.5

percent butane which can result in poor fuel vapor-

ization and low tank pressure resulting in poor en-

gine starting in low ambient temperatures (below

32F (0C).

WARNING

or explosion that can cause severe personal in-

jury or death. Do not permit any flame, spark,

Propane presents the hazard of fire

arc-producing equipment, switch, pilot light,

cigarette, or other ignition source near the fuel

system. Keep an ABC type fire extinguisher

nearby.

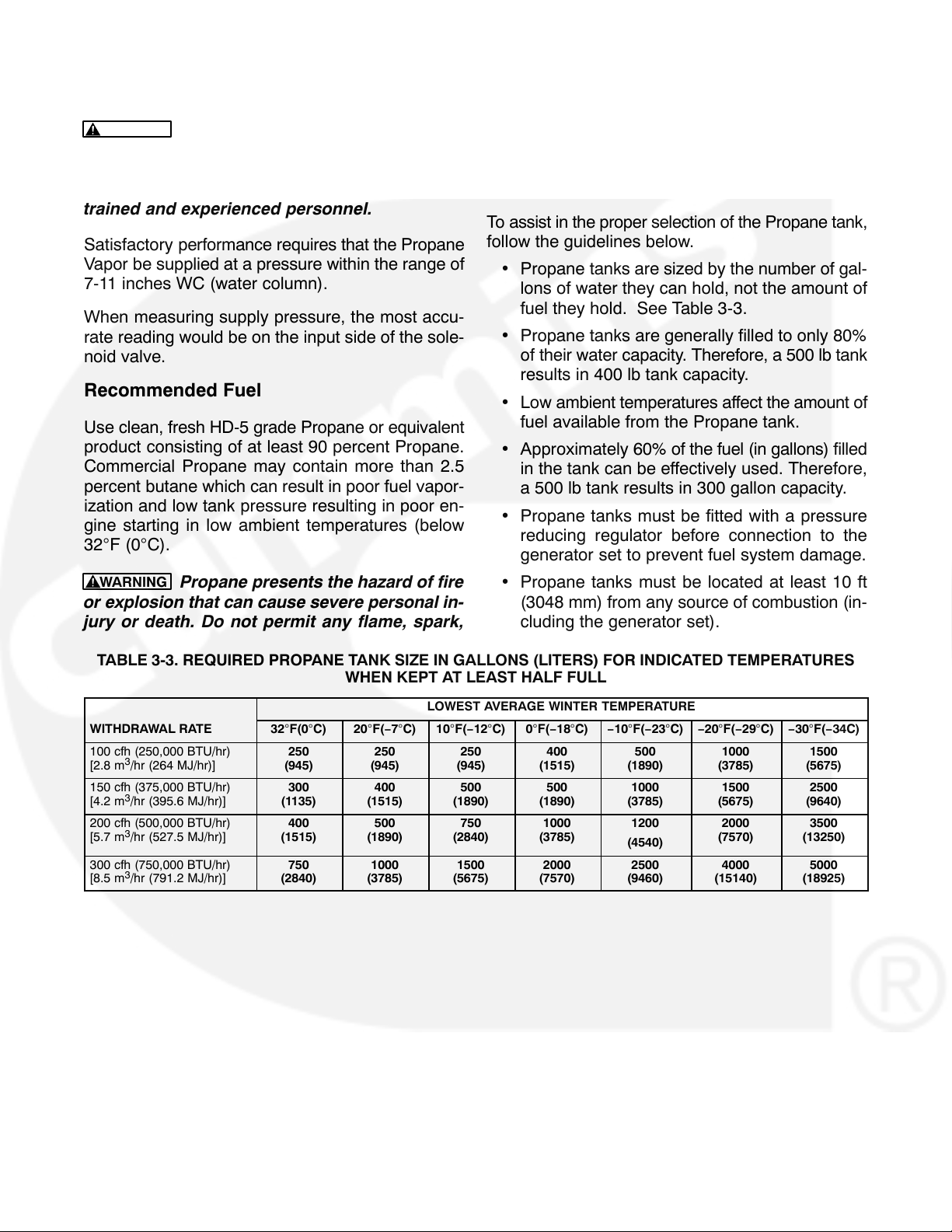

Propane Tank Size

To assist in the proper selection of the Propane tank,

follow the guidelines below.

Propane tanks are sized by the number of gal-

lons of water they can hold, not the amount of

fuel they hold. See Table 3-3.

Propane tanks are generally filled to only 80%

of their water capacity. Therefore, a 500 lb tank

results in 400 lb tank capacity.

Low ambient temperatures affect the amount of

fuel available from the Propane tank.

Approximately 60% of the fuel (in gallons) filled

in the tank can be effectively used. Therefore,

a 500 lb tank results in 300 gallon capacity.

Propane tanks must be fitted with a pressure

reducing regulator before connection to the

generator set to prevent fuel system damage.

Propane tanks must be located at least 10 ft

(3048 mm) from any source of combustion (in-

cluding the generator set).

TABLE 3-3. REQUIRED PROPANE TANK SIZE IN GALLONS (LITERS) FOR INDICATED TEMPERATURES

WHEN KEPT AT LEAST HALF FULL

LOWEST AVERAGE WINTER TEMPERATURE

WITHDRAWAL RATE 32F(0C) 20F(−7C) 10F(−12C) 0F(−18C) −10F(−23C) −20F(−29C) −30F(−34C)

100 cfh (250,000 BTU/hr)

[2.8 m3/hr (264 MJ/hr)]

150 cfh (375,000 BTU/hr)

[4.2 m3/hr (395.6 MJ/hr)]

200 cfh (500,000 BTU/hr)

[5.7 m3/hr (527.5 MJ/hr)]

300 cfh (750,000 BTU/hr)

[8.5 m3/hr (791.2 MJ/hr)]

250

(945)

300

(1135)

400

(1515)

750

(2840)

250

(945)

400

(1515)

500

(1890)

1000

(3785)

250

(945)

500

(1890)

750

(2840)

1500

(5675)

400

(1515)

500

(1890)

1000

(3785)

2000

(7570)

500

(1890)

1000

(3785)

1200

(4540)

2500

(9460)

1000

(3785)

1500

(5675)

2000

(7570)

4000

(15140)

1500

(5675)

2500

(9640)

3500

(13250)

5000

(18925)

3-5

Page 23

Testing Fuel System for Leaks

Before operating the set, test the Propane fuel system for leaks. Energize the fuel solenoid from a separate 12-volt DC source before testing the fuel system. Testing must conform to procedures listed in

NFPA-58, or to the UL recommended test procedure, as follows:

After assembly and before initial operation, all fuel

system connections, hose valves, regulators, and

fittings must be tested and proven free of leaks us-

ing a soap-and-water (or equivalent) solution while

the system is under gas or air pressure of at least

1.5 times the supply pressure or 3 psi (20.7 kPa)

minimum.

Other approved methods of detecting leaks can be

used if appropriate. DO NOT use a flame to test for

gas leaks.

WARNING

plosion or fire which can result in severe per-

sonal injury or death. Do not smoke or allow any

flame, spark, pilot light, arc-producing equip-

ment, switch, or other ignition sources around

fuel or fuel components.

Propane presents the hazard of ex-

3-6

Page 24

4. Electrical Connections

AC POWER SUPPLY CONNECTIONS

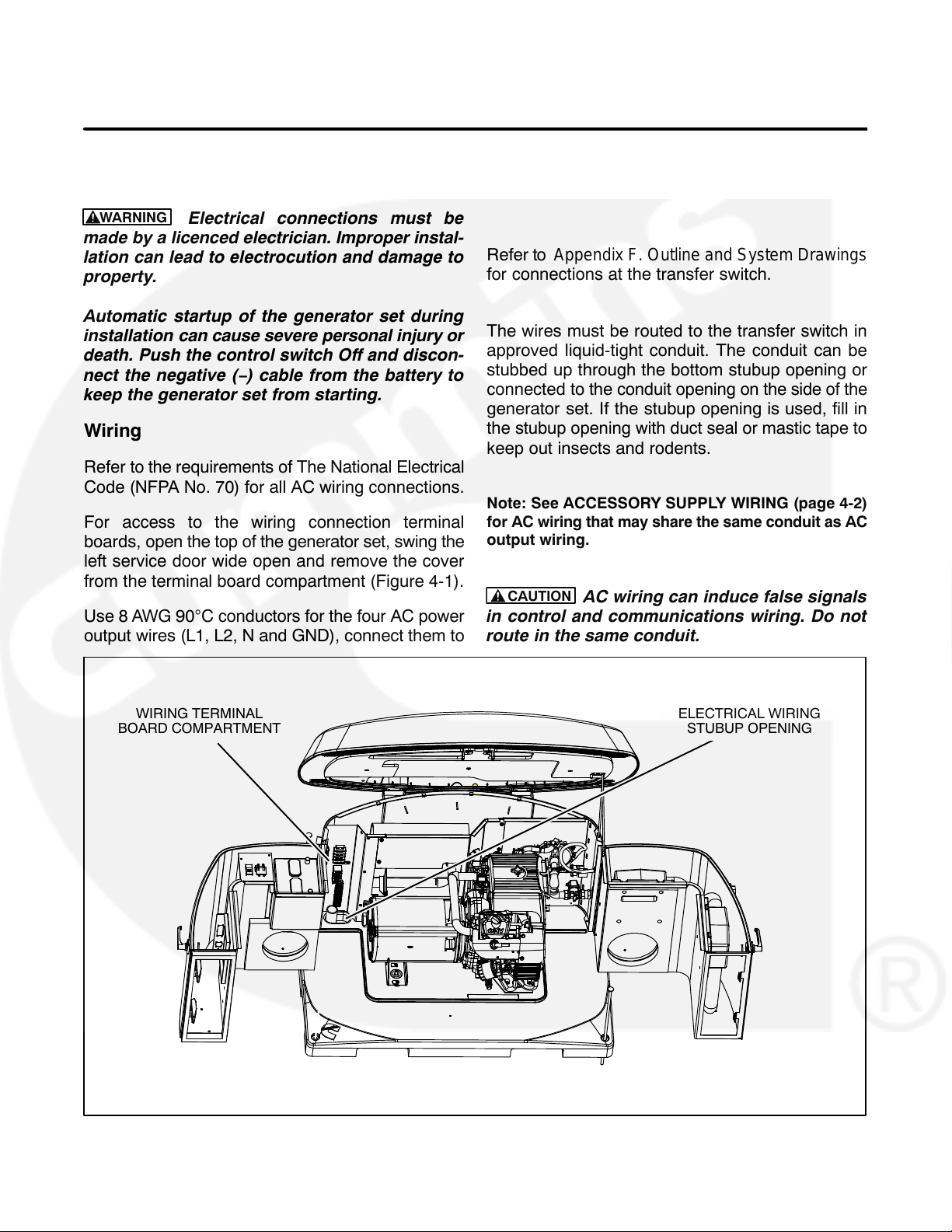

WARNING

made by a licenced electrician. Improper instal-

lation can lead to electrocution and damage to

property.

Automatic startup of the generator set during

installation can cause severe personal injury or

death. Push the control switch Off and discon-

nect the negative (−) cable from the battery to

keep the generator set from starting.

Electrical connections must be

Wiring

Refer to the requirements of The National Electrical

Code (NFPA No. 70) for all AC wiring connections.

For access to the wiring connection terminal

boards, open the top of the generator set, swing the

left service door wide open and remove the cover

from the terminal board compartment (Figure 4-1).

Use 8 AWG 90C conductors for the four AC power

output wires (L1, L2, N and GND), connect them to

the AC output terminal board (TB-2). Torque the

termninals to 25 lb−inch (2.8 N−m).

Refer to Appendix F. Outline and System Drawings

for connections at the transfer switch.

The wires must be routed to the transfer switch in

approved liquid-tight conduit. The conduit can be

stubbed up through the bottom stubup opening or

connected to the conduit opening on the side of the

generator set. If the stubup opening is used, fill in

the stubup opening with duct seal or mastic tape to

keep out insects and rodents.

Note: See ACCESSORY SUPPLY WIRING (page 4-2)

for AC wiring that may share the same conduit as AC

output wiring.

CAUTION

in control and communications wiring. Do not

route in the same conduit.

AC wiring can induce false signals

WIRING TERMINAL

BOARD COMPARTMENT

ELECTRICAL WIRING

STUBUP OPENING

FIGURE 4-1. WIRING TERMINAL BOARDS

4-1

Page 25

ACCESSORY SUPPLY CONNECTIONS

To supply 120 VAC to power the GFCI outlet on the

side of the generator set, optional battery heater

(P/N 0333−0770) and optional engine oil and carburetor heater (P/N 0333-0771), connect two 12 AWG

90C wires to generator set terminal block TB3 (Hot

and Neutral) from a 15 amp protected circuit in the

main distribution panel in the house. The wires may

be run through the same conduit as the power sup-

ply wires.

Grounding

The generator set, transfer switch, power supply

wiring, and all connected electrical equipment must

be bonded to a common grounding point in accor-

dance with applicable codes or standards (Figure

4-2).

WARNING

The generator set grounding terminal (TB2-4) must be connected to the grounding

terminal in the transfer switch. Do not provide a

separate grounding rod for the generator set.

Note that generator neutral is not grounded at the

generator set, but at the common system grounding

point.

WARNING

Contact with electrical equipment

can result in severe personal injury or death. It is

extremely important that bonding and equip-

ment grounding be properly done. All metallic

parts that could become energized under ab-

normal conditions must be properly grounded.

4-2

Page 26

GROUNDING WITH MODEL RSS 100−6634 AND RSS 200−6635 TRANSFER SWITCHES

SERVICE ENTRANCE

2-POLE TRANSFER

SWITCH

L

TO UTILITY

SERVICE

GROUNDING WITH MODEL RSS 100−6868 AND RSS 200−6869 TRANSFER SWITCHES

N

LOADS

COMBINED SERVICE-ENTRANCE AND

2-POLE TRANSFER SWITCH

L

GENERATOR SET

GENERATOR SET

TO UTILITY

SERVICE

N

LOADS

FIGURE 4-2. TYPICAL SYSTEM GROUNDING ONE-LINE DIAGRAMS

4-3

Page 27

Transfer Switch

O

WARNING

and the public utility can lead to the electrocution of personnel working on the utility lines,

damage to equipment and fire. An approved

switching device must be used to prevent interconnections.

Interconnecting the generator set

TABLE 4-1. WIRE SIZE SPECIFICATIONS

Wire Size

(AWG)

16 90

14 150

12 225

Distance in Feet, One Way

(Multiply by 0.3 for Meters)

The Model GSAA generator set is designed to be

installed with Cummins Onan Model RSS automatic

transfer switches. Use of other makes and models

of transfer switches with the Model GSAA generator

will result in a reduced warranty. Reference the War-

ranty statement for further details.

Install the transfer switch in accordance with its

Installation Manual. Refer to Appendix F. Outline

and System Drawings for wiring connections be-

tween the generator set and transfer switch.

See Wiring (page 4-1) regarding wiring to use for

AC power output connections between the genera-

tor set and transfer switch.

Use 18 AWG conductors for the control/commu-

nications wires (generator set TB1 to transfer switch

terminal TB4). It is recommended that all twelve

conductors (nine conductors for RSS 100−6634

and RSS 200−6635) be pulled through the conduit

at the time of installation to be ready for functions

that might be activated later, such as load control.

Note: The wire used must be sized to accommodate

any specific voltage drop. Refer to Table 4-1 to deter-

mine the correct wire size.

10 350

8 600

6 1000

Block diagrams showing partial or full load coverage

are shown on the following pages. Figures 4-3 and

4-4 show installations without a controller (RSS

100-6634 and RSS 200−6635) and Figures 4-5 and

4-6 show installations with a controller (RSS

100−6868 and RSS 200−6869). The RSS100 trans-

fer switch models can be connected for full or partial

load coverage equal to the capacity of the generator

set. The RSS200 transfer switch models can be

connected for full load coverage greater than the ca-

pacity of the generator set. If the transfer switch is

connected for full load coverage which exceeds

generator set rating, it may be necessary to shed

large loads such as air conditioners. Refer to Ap-

pendix F. Outline and System Drawings for con-

necting load shed relays to generator set load con-

trol terminals TB1−1 and TB1-2.

TABLE 4-2. TITLE???

CONNECTION CAPABILITIES

TRANSFER SWITCH MODEL FULL LOAD

RSS 100−6634 X

RSS 200−6635 X

RSS 100−6868 X

RSS 200−6869 X

1. XXXXXXXXXXXXXXXXXXXXXXXXXXXX

Note: Model RSS100−6634 and RSS200−6635 Transfer Switches do not incorporate a utility circuit breaker and therefore must be connected through a Service Entrance Utility Panel incorporating the utility

(GREATER THAN

CAPACITY OF GENSET)

circuit breaker.

Perform GENERATOR SET CONFIGURATION

(page 5-1) when ready start up the generator set.

4-4

FULL OR PARTIAL LOAD

(EQUAL T

CAPACITY OF GENSET)

Page 28

UTILITY PANEL

UTILITY

SOURCE

LOADS

TRANSFER SWITCH

CIRCUIT

BREAKER

CIRCUIT

BREAKER

DISTRIBUTION PANEL

GENERATOR

SOURCE

LOADS

FIGURE 4-3. PARTIAL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITHOUT CONTROLLER)

TRANSFER SWITCH*

UTILITY

SOURCE

CIRCUIT

BREAKER

CIRCUIT

BREAKER

GENERATOR

SOURCE

MAIN

BREAKER

PANEL

ALL LOADS

FIGURE 4-4. FULL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITHOUT CONTROLLER,

ONE CIRCUIT BREAKER)

4-5

Page 29

UTILITY PANEL

UTILITY

SOURCE

LOADS

TRANSFER SWITCH

CIRCUIT

BREAKER

DISTRIBUTION PANEL

GENERATOR

SOURCE

LOADS

FIGURE 4-5. PARTIAL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITH CONTROLLER)

TRANSFER SWITCH

UTILITY

SOURCE

CIRCUIT

BREAKER

CIRCUIT

BREAKER

GENERATOR

SOURCE

MAIN

BREAKER

PANEL

ALL LOADS

FIGURE 4-6. FULL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITH CONTROLLER)

4-6

Page 30

OPERATOR PANEL

See the Operator Manual for operating and monitoring the generator set using the Operator Panel.

Mount the generator set Operator Panel on a wall at

a convenient location, such as next to the house

thermostat. To install the Operator Panel cut out an

opening in the wall as shown in Figure 4-7 and

mount it with four No. 6 wood screws or wall anchors.

Refer to Appendix F. Outline and System Drawings

for connecting the Operator Panel to the generator

set. Use the plug-in connection harness (shipped

loose with the generator set) to connect to the wiring

from the generator set. Use 18 AWG wires.

WALL CUTOUT

PLUG-IN CONNECTION HARNESS

FIGURE 4-7. CUTOUT FOR OPERATOR PANEL AND CONNECTION HARNESS

4-7

Page 31

ETHERNET CONNECTIONS (OPTIONAL)

The generator set control board has a connector for

Cat 5 Ethernet cable for connection to a remote mo-

dem/router. See Appendix B. Ethernet/Email Inter-

face for setup and operation.

along with other wiring from the control to the wiring

terminal board compartment and then into the conduit to the house.

Note: The Internet/Email interface requires “high

speed” or “broadband” cable or DSL service to the

house.

Use Cat 5 Ethernet cable and route it separately into

the house or along with the control/communications

wiring. At the generator set route the Cat 5 cable

ETHERNET

CONNECTOR ON

CONTROL BOARD

Wiring connections to the Ethernet RJ-45 plug are

shown in Figure 4-9. Utilize an appropriate Ethernet

stripping and crimping tool for these connections.

PIN 1

g = Green and White

G = Green

o = Orange and White

O = Orange

b = Blue and White

B = Blue

br = Brown and White

BR = Brown

FIGURE 4-8. ETHERNET CONNECTOR

FIGURE 4-9. ETHERNET RJ-45 CONNECTOR WIRING

4-8

Page 32

BATTERY

The generator set has a 12 VDC, negative-ground

control and engine cranking system. The engine

has a battery charger for recharging during generator set operation. A battery charger located in the

transfer switch keeps the battery charged during

generator set standby.

Install the heater in accordance with the kit instructions.

To prevent injury due to accidental start-up, do not

connect the battery cables to the battery until the

installation has been completed and it is time to start

the set. See Section 5. Installation Review and

Startup

Refer to Appendix E. Specifications regarding bat-

tery specifications.

An optional thermostatically controlled battery heat-

er is available for more reliable starting in ambient

temperatures down to −20 F (−28.8 C). The heat-

er wraps around the battery. The heater cord is con-

nected to the 120V, accessory connection block.

BATTERY

WARNING

Automatic startup of the generator

set while performing maintenance or service

can cause severe personal injury or death. Push

the control switch to Off and disconnect the

negative (−) battery cable from the battery to

keep the generator set from starting up while

working on it.

FIGURE 4-10. BATTERY INSTALLATION

4-9

Page 33

5. Startup and Configuration

INSTALLATION REVIEW

Before starting the genset inspect the installation

and check off () each of the following questions if it

can be answered “YES”. If a question cannot be

checked off, review the appropriate section in the

manual.

[ ] Can the top and the maintenance and service

access doors be swung fully open for opera-

tion, maintenance and service?

[ ] Are the cooling air inlet and outlet openings

free of obstructions?

[ ] Have the AC output connections been made

properly?

[ ] Has the transfer switch been installed properly

to prevent connecting the generator set to the

utility?

[ ] Has a properly sized battery been installed?

[ ] Are all fuel connections tight?

[ ] Is fuel supply pressure correct?

[ ] Are electrical and fuel lines properly sepa-

rated?

[ ] Does engine exhaust disperse away from

buildings?

STARTUP

genset, following all the instructions and precautions in the Operator Manual.

Perform GENERATOR SET CONFIGURATION

(page 5-1).

Note: Before leaving the site, if the genset is ready to

be placed in service, set the control switch to the

AUTO position to provide automatic standby power.

GENERATOR SET CONFIGURATION

The Operator Panel has a menu with four generator

set/transfer switch parameters that must be config-

ured for the installation.

Generator Configuration

To configure the generator set:

1. Press the MENU button on the home screen.

2. Press and hold the blank button on the menu

screen for at least 5 seconds to go to the Con-

fig Menu.

3. Press the up or down arrow button on the Con-

fig Menu screen to select Generator Config.

4. Press Enter on the Config Menu to go to the

Generator Config screen.

5. Press the NEXT button on the Generator Con-

fig Menu screen to select the Config, Frequen-

cy or Rating field.

When all installation requirements have been met,

connect the battery cables to the battery, positive

(+) cable first.

WARNING

set during installation can cause severe per-

sonal injury or death. Push the control switch

Off and disconnect the negative (−) cable from

the battery to keep the generator set from start-

ing.

Read through the Operator’s Manual and perform

the maintenance and pre-start checks instructed.

The genset is shipped from the factory with the

proper level of engine oil, but should be checked

before the genset is started. Start and operate the

Automatic startup of the generator

6. Press the up or down arrow button to increase

or decrease the configuration parameter.

A. Config: Select “12” for Natural Gas or “13”

for Propane.

B. Frequency: “60” Hz cannot be changed at

this time.

C. Rating: Select “50” Amps for Propane or

“43” Amps for Natural Gas. Select lower

values if it is necessary to derate for high

altitude or hot climates. (Selecting the correct Amps value is necessary for displaying the correct genset load on the Operator Panel.

7. Press the BACK button to save the setting and

return to the home screen.

5-1

Page 34

Sun 10:35 AM

Battery 12.5

GENERATOR ADJUSTMENTS

Refer to Figure 5-2. To adjust the Operator Panel

voltage display and hour meter, access the Adjustment Menu Screen as follows:

1. Press the MENU button on the home screen.

Genset Load

L1 L2

EXCER

Genset Status

Display Setup

Event Log

Fault Log

Ethernet Setup

hold blank button

for 5 seconds

Config Menu

Generator Config

Generator Adjustments

TS Config

TS Adjustments

MENUCLOCK LOAD

ENTER

ENTER

2. Press and hold the blank button on the menu

screen for at least 5 seconds to go to the Con-

fig Menu.

3. Press the up or down arrow button on the Con-

fig Menu screen to select Generator Adjust-

ments.

4. Press Enter on the Config Menu to go to the

Adjustments screen.

Generator Config

Config: 12

Frequency: 60

Rating:

FIGURE 5-1. GENERATOR CONFIGURATION

50

Hz

Amps

NEXT

5-2

Page 35

Sun 10:35 AM

To Adjust the Output Voltage − Use the

following procedure:

1. Connect an accurate AC volt meter across L1

and L2 while the generator set is running.

Battery 12.5

Genset Load

L1 L2

EXCER

Genset Status

Display Setup

Event Log

Fault Log

Ethernet Setup

hold blank button

for 5 seconds

Config Menu

Generator Config

Generator Adjustments

TS Config

TS Adjustments

MENUCLOCK LOAD

ENTER

ENTER

2. With Output Volts selected on the Adjustments

Menu screen, press the up or down arrow button to adjust the voltage to the desired setting

(Figure 5-3).

3. The control allows an adjustment of 240 VAC

7% (17 VAC).

4. Press the BACK button to save the settings

and return to the home screen.

To Calibrate the Display Meter − Use the

following procedure:

1. Connect an accurate AC volt meter across L1

and L2 while the generator set is running.

2. Press the NEXT button to select the Display

Cal field (screen not shown).

3. Press the up or down arrow to adjust the volt-

age reading on the screen until it matches the

meter reading.

4. Press the BACK button to save the settings

and return to the home screen.

Adjustments

Use Meter to Set

FIGURE 5-2. GENERATOR ADJUSTMENTS

Output Volts

Hr Meter

FIGURE 5-3. ADJUSTMENT MENU SCREEN

5-3

0.4

240

NEXT

Page 36

Transfer Switch Configuration

To configure the generator set for the transfer

switch being used:

1. Press the MENU button on the home screen.

2. Press and hold the blank button on the menu

screen for at least 5 seconds to go to the Con-

fig Menu.

3. Press the up or down arrow button on the Con-

fig Menu screen to select TS Config.

4. Press Enter on the Config Menu to go to the

Transfer Switch screen.

5. Press the up or down arrow button to select be-

tween two choices: “RSS100−6868 and

RSS200−6869” or “RSS100−6634 and

RSS200−6635,” which must match the model

number of the transfer switch being used.

6. Press the BACK button to save the setting and

return to the home screen.

Sun 10:35 AM

Battery 12.5

Genset Load

L1 L2

EXCER

Genset Status

Display Setup

Event Log

Fault Log

Ethernet Setup

hold blank button

for 5 seconds

MENUCLOCK LOAD

ENTER

Config Menu

Generator Config

Generator Adjustments

TS Config

TS Adjustments

ENTER

Transfer Switch

Model:

RSS100−6868 or

RSS200−6869

FIGURE 5-4. TRANSFER SWITCH CONFIGURA-

TION

5-4

Page 37

Transfer Switch Parameter Adjustments

Model RSS100−6634 and RSS200−6635 Transfer Switches: Refer to Transfer Switch Installation

Manual 962−0620 to set the parameters inside the

transfer switch.

Model RSS100−6868 and RSS200−6869 Trans-

fer Switches: To make transfer switch parameter

adjustments:

1. Press the MENU button on the home screen.

2. Press and hold the blank button on the menu

screen for at least 5 seconds to go to the Con-

fig Menu.

3. Press the up or down arrow button on the Con-

fig Menu screen to select TS Adjustments.

4. Press Enter on the Config Menu to go to the

Transfer Switch screen.

5. Press the NEXT button on the Generator Con-

fig Menu screen to select the Pickup, Dropout

or Nominal field.

6. To set Nominal − Press the up or down

double-arrow button to increase or decrease

the nominal utility voltage parameter to match

actual (Present) utility voltage. The Pickup and

Dropout parameters are percentages of the

nominal voltage parameter.

Sun 10:35 AM

Battery 12.5

Genset Load

L1 L2

EXCER

Genset Status

Display Setup

Event Log

Fault Log

Ethernet Setup

hold blank button

for 5 seconds

Config Menu

Generator Config

Generator Adjustments

TS Config

TS Adjustments

MENUCLOCK LOAD

ENTER

ENTER

7. To set Pickup− Press the up or down double-

arrow button to increase or decrease the mini-

mum utility voltage to which the transfer switch

will connect. Default is 90% of nominal. It can

be increased to 95% of nominal.

8. To set Dropout− Press the up or down double-

arrow button to increase or decrease the mini-

mum utility voltage at which the transfer switch

will disconnect. Default is 85% of nominal. It

can be decreased to 80/75/70% of nominal.

9. Press the BACK button to save the setting and

return to the home screen.

Transfer Switch

Pickup:

Dropout:

90 %

85 %

Nominal: 240 VAC

Present: 240 VAC

NEXT

FIGURE 5-5. TRANSFER SWITCH ADJUSTMENTS

5-5

Page 38

Appendix A. Operation

IN-HOME OPERATOR PANEL

The in-home generator set Operator Panel (Figures A-1 and A-2) is intended for wall mounting at a

convenient location inside the house. The Operator

Panel must be hard-wired to the generator set for

the generator system to operate. Refer to Appendix

B. Internet / Email Interface for an alternative inter-

face to operate and monitor the generator set. The

in-home operator panel and Internet/Email inter-

face can be used simultaneously.

The Operator Panel has two UTILITY status lamps,

three GENERATOR status lamps, three action but-

tons (BACK, STANDBY ON/OFF and START/

STOP) and an LCD display screen with four naviga-

tion buttons.

BACK Button

When navigating through the LCD menus, press the

BACK button to return to the main operating screen.

UTILITY

PRESENT

CONNECTED

Sun 10:35 AM

Battery 12.5

Genset Stopped

EXCER

FIGURE A-1. UTILITY PRESENT AND

CONNECTED—STANDBY OFF LAMP ON

MENUCLOCK LOAD

GENERATOR

RUNNING

STANDBY OFF

ACTION REQUIRED

STANDBY

BACK

ON/OFF

START

STOP

STANDBY ON/OFF Button

See Page A-3 to enable / disable generator set

STANDBY.

START STOP Button

See Page A-3 to manually START / STOP the gen-

erator set.

TYPICAL OPERATION

Normal Operation—Utility Power Available

and Connected

As long as utility power is available and connected,

both of the green UTILITY lamps (PRESENT and

CONNECTED) will stay on and the LCD screen will

indicate “Genset Stopped”.

If the red GENERATOR STANDBY OFF light is on,

the generator set will not start up automatically if util-

ity power is interrupted. See Page A-3 to enable

STANDBY so that the generator set will automati-

cally supply power if utility power is interrupted.

A-1

Page 39

Emergency Operation—Utility Power

Interrupted

If utility power is interrupted,

1. The green UTILITY PRESENT lamp will go out

2. The generator set will start automatically and

the green GENERATOR RUNNING lamp will

come

3. The UTILITY CONNECTED light will go out

when the generator set is connected to supply

power.

The LCD screen will provide a visual indication of

“Genset Load” (bar graphs). The bar graphs indi-

cate how much of the available power is being used

in each supply line (L1 and L2).

If the red ACTION REQUIRED light comes on, ei-

ther the generator shut down or periodic mainte-

nance has come due. The LCD screen will indicate

what maintenance is due or which fault occured.

UTILITY

PRESENT

CONNECTED

Sun 10:35 AM

Battery 12.5

Genset Load

L1 L2

EXCER

MENUCLOCK LOAD

FIGURE A-2. GENERATOR SET RUNNING—ACTION

REQUIRED LAMP ON

GENERATOR

RUNNING

STANDBY OFF

ACTION REQUIRED

STANDBY

BACK

ON/OFF

START

STOP

A-2

Page 40

TO ENABLE / DISABLE STANDBY

You should normally not have occasion to disable

generator set STANDBY. STANDBY should always

be enabled (ON) except during maintenance/service.

STANDBY will have to be re-enabled (STANDBY

OFF light on) if the generator set is started or

stopped manually (normally a maintenance/service

function) or a fault shutdown has occurred.

CAUTION

generator set will NOT automatically start to

supply power if utility power is interrupted.

To enable or disable generator set standby:

1. Press the STANDBY ON/OFF button on the

Operator Panel (Figure A-1), which takes you

to the Standby ON/OFF screen (Figure A-3).

2. Press the up or down arrow button to select ON

or OFF.

3. To enable STANDBY select ON and press the

BACK button. The STANDBY OFF lamp will go

out and the display will state: “Standby ready

enabled by user.”

4. To disable STANDBY select OFF and press

the BACK button. The STANDBY OFF lamp will

come on and the display will state: “Standby

ready disabled by user.”

When STANDBY is disabled the

TO MANUALLY START / STOP

GENERATOR SET

Normally only the maintenance/service technician

has occasion to manually start and stop the generator set. Starting the generator set will result in the

generator powering the house loads.

CAUTION

generator set disables generator set STANDBY.

The generator set will not automatically start to

supply power if utility power is interrupted.

To manually start or stop the generator set:

1. Press the START STOP button on the Operator

Panel (Figure A-1), which takes you to the Gen-

set START/STOP screen (Figure A-4). The

screen will display “Genset Stopped” or “Gen-

set Running,” as appropriate.

2. Press START to manually start the generator

set and connect it to supply power to the house.

The STANDBY OFF lamp will come on and the

display will state: “Genset started manually

(Standby Ready Disabled).”

3. Press STOP to manually stop the generator set

and disconnect it. The STANDBY OFF lamp will

come on and the display will state: “Genset

stopped manually (Standby Ready Disabled).”

Note: To start the generator set without connecting

loads pick Exercise Now on the Exerciser Clock

screen (page A-10).

Manually starting or stopping the

Standby required

for automatic

start/stop

Standby: ON /OFF

FIGURE A-3. ENABLE/DISABLE STANDBY SCREEN

Manual Operation

Disables Standby

Genset Stopped

START STOP

FIGURE A-4. GENSET START/STOP SCREEN

A-3

Page 41

FAULT, MAINTENANCE AND NEW EVENT

SCREENS

Various warning and event screens may appear on

the Operator Panel during Normal or Emergency

Operation.

Fault Screen

If a generator set shutdown fault occurs, a FAULT

warning appears (Figure A-5) with the following in-

formation:

Brief description of the warning or fault

The two-digit Fault Code Number

The time of occurrence of the fault

Maintenance Due Screen

A maintenance due screen appears (Figure A-5)

when a scheduled maintenance operation is due.

Perform the maintenance due. The warning does

not time out.

Press the BACK button to return to the home

screen.

Fault

Starting Fault

Fault Number 32

Hour 10000.1

BACK

FIGURE A-5. TYPICAL FAULT SCREEN

INFO

HIST

Maintenance

Due

Air Filter

New Event Screen

A New Event screen appears (Figure A-5) whenev-

er system status changes, such as when there is an

interruption of utility power. The screen provides a

brief description of the event along with the time and

date of the event.

FIGURE A-6. TYPICAL MAINTENANCE DUE

SCREEN

New Event

Auto Start

Loss of Utility

07/10/2007 4:08PM

FIGURE A-7. TYPICAL NEW EVENT SCREEN

A-4

Page 42

GENSET STATUS

To check generator set output voltage and frequency and the total numbers of hours run:

1. Press the MENU button on the home screen.

2. Press the up or down arrow button on the menu

screen to select Genset Status.

3. Press the ENTER button on the menu screen

and note the values displayed on the Genset

Status screen.

4. Press the BACK button to return to the home

screen.

Sun 10:35 AM

Battery 12.5

Genset Load

L1 L2

EXCER

Genset Status