Page 1

Installation Manual

Commercial Mobile Generator Set

HDKBB (Spec A−J)

HDKBC (Spec D−J)

English

Original Instructions 10-2016 981−0650 (Issue 9)

Page 2

California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 3

Table of Contents

TABLE OF CONTENTS II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About this Manual 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outline Drawings 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Codes and Standards for Safety 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electromagnetic compatibility 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOUNTING, LOCATION AND VENTILATION 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXHAUST CONNECTIONS 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Muffler 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailpipe 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL CONNECTIONS 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bio−diesel Fuels B5 − B20 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CONNECTIONS 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Connections 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Connections 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Connections 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION REVIEW AND STARTUP 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hot Air Recirculation Test 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Review 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 15. Outline Drawing—Sheet 1 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16. Outline Drawing—Sheet 2 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 17. Wiring Diagram—Sheet 1 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 18. Wiring Diagram—Sheet 2 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2016 Cummins Inc.

i

Page 4

This Page Intentionally Left Blank.

ii

Copyright 2016 Cummins Inc.

Page 5

SAFETY PRECAUTIONS

Thoroughly read the OPERAT OR’S MANUAL before operating the genset. Safe operation and top

performance can only be obtained when equipment is properly operated and maintained.

Only trained and experienced service personnel

with knowledge of fuels, electricity , and machinery hazards shall remove dismantle and dispose

of the generator set. See service manual.

Some generator set installation procedures

present hazards that can result in severe personal injury or death. Only trained and experienced

personnel with knowledge of fuels, electricity,

and machinery hazards should perform generator set installation procedures.

The following symbols in this manual alert you to potential hazards to the operator, service person and

equipment.

Used to alert you to a lethal hazard

against which you must take steps to prevent severe personal injury or death, as when you are in

the vicinity of High Voltage equipment.

WARNING

safe practice that can result in severe personal

injury or death.

CAUTION

safe practice that can result in personal injury or

equipment damage.

Electricity, fuel, exhaust, moving parts and batteries

present hazards which can result in severe personal

injury or death.

Used to alert you to a hazard or un-

Used to alert you to a hazard or un-

ENGINE EXHAUST IS DEADLY

Inspect for exhaust leaks at every startup and af-

ter every eight hours of running.

Prior to every startup and after every eight hours

of running, all carbon monoxide detectors must

be tested and confirmed to be working in accordance with the manufacturer’s instructions or

owners manual.

Learn the symptoms of carbon monoxide poi-

soning in the genset Operator’s Manual.

Never occupy the vehicle while the genset is

running unless the vehicle is equipped with a

working carbon monoxide detector.

Do not operate the genset when the vehicle is

parked in a confined space, such as a garage.

Disable the automatic genset starting feature

(AGS) of an inverter-charger or other automatic

starting device before storing the vehicle or

parking it in a garage or other confined space.

The exhaust system must be installed in accor-

dance with the genset Installation Manual.

Engine cooling air must not be used for heating

the vehicle.

GENERATOR VOLTAGE IS DEADLY

Disable the automatic genset starting feature

(AGS) of an inverter-charger or other automatic

starting device before servicing the genset.

Generator electrical output connections must be

made by a trained and experienced electrician

in accordance with applicable codes.

WARNING

and shore power can lead to electrocution of utility line workers, equipment damage and fire. Use

an approved switching device to prevent interconnections.

Use caution when working on live electrical

equipment. Remove jewelry, make sure clothing

and shoes are dry, stand on a dry wooden platform or rubber insulating mat and use tools with

insulated handles.

Interconnecting the generator set

DIESEL FUEL IS COMBUSTIBLE

Do not smoke or turn electrical switches ON or

OFF where fuel fumes are present or in areas

sharing ventilation with fuel tanks or equipment.

Keep flames, sparks, pilot lights, arc-producing

equipment and all other sources of ignition well

away.

Fuel lines must be secured, free of leaks and

separated or shielded from electrical wiring.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Disable the automatic genset starting feature

(AGS) of an inverter-charger or other automatic

starting device before servicing the genset.

Copyright 2016 Cummins Inc.

1

Page 6

Do not wear loose clothing or jewelry near mov-

ing parts such as PTO shafts, fans, belts and

pulleys.

Do not work on the genset when mentally or

physically fatigued or after consuming alcohol or

drugs.

Keep hands away from moving parts.

Keep guards in place over fans, belts, pulleys,

and other moving parts.

BATTERY GAS IS EXPLOSIVE

Wear splash−proof safety glasses.

Do not smoke or permit flames or sparks to oc-

cur near the battery at any time.

To reduce arcing when disconnecting or recon-

necting battery cables, always disconnect the

negative (−) battery cable first and reconnect it

last.

FLAMMABLE VAPOR CAN CAUSE A

DIESEL ENGINE TO OVERSPEED

WARNING

genset where a flammable vapor environment

can be created by fuel spill, leak, etc.

Flammable vapor can cause a diesel engine to overspeed and become difficult to stop, resulting in possible fire, explosion, severe personal injury and

death. The owners and operators of the genset are

solely responsible for operating the genset safely.

Do not operate a diesel-powered

GENERAL PRECAUTIONS

Keep children away from the genset.

Do not use evaporative starting fluids. They are

highly explosive.

To prevent accidental or remote starting while

working on the genset, disconnect the negative (−) battery cable at the battery.

Let the engine cool down before removing the

coolant pressure cap or opening the coolant

drain. Hot coolant under pressure can spray out

and cause severe burns.

Used engine oil has been identified by some

U. S. state and federal agencies as causing cancer or reproductive toxicity. Do not ingest, inhale, or contact used oil or its vapors.

Ethylene glycol, used as engine antifreeze, is

toxic to humans and animals. Clean up spills

and dispose of used engine coolant in accordance with local environmental regulations.

Keep multi-purpose fire extinguishers handy.

Multi−purpose fire extinguishers are used for

fires that involve ordinary combustible materials

such as wood and cloth; combustible and flammable liquid fuels and gaseous fuels; live electrical equipment. (North America or US: ref. NFPA

No. 10)

Genset installation and operation must comply

with all applicable local, state and federal codes

and regulations.

Generator sets with a sound shield shall not be

run with the service doors remove/missing.

Engine components can be hot and cause se-

vere burns. Hot coolant under pressure can

spray and cause severe burns.

Use personal protective equipment when main-

taining or installing the generator set such as

gloves, safety glasses, etc.

THE HAZARDS OF CARBON MONOXIDE

WARNING

duce harmful level of carbon monoxide that can

injure or kill you.

Engine−driven generators can pro-

ONLY YOU CAN PROTECT YOURSELF

FROM CO POISONING!

Watch constantly for people near the exhaust of

the generator set while it is running.

Use personal protective equipment when instal-

ling generator set (gloves, safety glasses, etc).

Keep the genset and its compartment clean. Ex-

cess oil and oily rags can catch fire. Dirt and gear

stowed in the compartment can restrict cooling

air.

Make sure all fasteners are secure and torqued

properly.

Make sure exhaust cannot enter the living quar-

ters through a window, vent or door.

Make sure all CO detectors and audible alarms

are working properly.

Pay attention to the signs of CO poisoning.

Check the exhaust system for corrosion, ob-

struction and leaks each time you start the gen-

2

Copyright 2016 Cummins Inc.

Page 7

erator set and every eight hours if you run it continuously.

SUBSTANCE HAZARDOUS TO HEALTH

Generator sets use substances, and emit and create

wastes that can cause health risks. Generator set

operators must use appropriate personal protective

equipment (such as clothing, gloves, protective

glasses/goggles, and respiration equipment) when

exposed to fuel, oil, coolant, wet batteries, grease,

cleaning agents, or other substances exposed to

lungs, eyes, or skin. use appropriate containers for

transport, storage, and disposal of waste substances. Follow local regulations for disposal and recycling.

ANTIFREEZE (FLEETGUARD − ES

COMPLEAT/EG PREMIX)

This antifreeze is also know as an ethylene glycol

based coolant; summer coolant; coolant additive. It

is purple coloured, viscous liquid, with a mild chemical odour, is soluble in water and harmful. It contains

ethylene glycol, and diethylene glycol. Ethylene glycol is a potentially hazardous constituent.

The substance has a boiling point of 107 C, and a

flash point of 121 C.

It is used as an engine coolant additive, and can be

found in engine cooling systems, and head exchangers. Installers, operators and maintainers are likely to

encounter this substance.

HAZARDOUS REACTIONS

Ethylene glycol is combustible when exposed to heat

or flame and can react vigorously with oxidants.

Moderate explosive hazard in form of vapour when

exposed to heat or flame. Hazardous products resulting from combustion or decomposition include

carbon monoxide, carbon dioxide and acrid smoke.

Self−contained breathing apparatus must be worn in

the event of fume build up.

Avoid strong oxidizing agents − incompatible with

sulfuric acid, nitric acid, caustics and aliphatic

amines.

It may cause neurological signs and symptoms, and

kidney damage. It is also a skin and eye irritant.

Very toxic in particulate form upon inhalation. Harmful if swallowed, lethal dose for humans reported to

be 100ml.

PROTECTIVE MEASURES

Refrain from eating, drinking or smoking when using

the product. Adopt a high standard of personal hygiene. In ca s e o f s k i n c o n t a c t , w a s h i m m edia t e l y w i t h

soap and water.

Ensure good ventilation and avoid heat sources.

Avoid breathing mist, if there is a risk of vapour, or

particulate, use a suitable organic vapour mask.

Eye protection, gloves, overalls, impervious apron

should be used. Avoid contamination inside the

gloves. If overalls become contaminated, discontinue use and clean thoroughly.

STORAGE/TRANSPORT

Store and transport only in correctly marked containers. Keep containers closed when not in use. Keep

cool, out of sunlight, away for naked flames and

strong acids, do not freeze. Store well away from

food−stuffs and drinking water. Take special care to

avoid discharge into drains, sewers and water−

courses.

Contain leak/spill with sand, earth or non−combus-

tible, absorbent material to prevent entry of substance into drainage/sewerage system, water−

courses and land. Eliminate all ignition sources, use

plastic shovel to transfer to suitable container and

dispose of unwanted or absorbed substance through

and authorized contractor to a licensed site.

EMERGENCY ACTION

Fire

Extinguishing media: CO

foam, dry powder, or water spray.

Fire fighters to use self contained breathing apparatus. Keep fire exposed containers cool.

Prevent run−off from entering waterways,

drains and drinking water supplies.

Ingestion

Toxic by ingestion. If swallowed induce vomiting

only

under the advice of a Doctor or poison control centre. Delayed treatment may result in fatality.

Inhalation (of vapour)

Remove from further exposure. In case of irritation to lungs or throat, seek medical advice.

Aspiration (inhalation of liquid)

Obtain immediate medical assistance.

alcohol resistant

2,

Copyright 2016 Cummins Inc.

3

Page 8

Eyes

Flush copiously with water or preferably eye−

wash solution for at least five minutes. Seek

medical advice.

Skin

Wash thoroughly with soap and water, and seek

medical attention if irritation develops. Change

clothing if necessary and wash before re−use.

Spillage

Soak−up using an absorbent material and dispose of this as directed under Storage/Transport (Section 5.1.3)

GAS OIL

This product is also known as Red Diesel, Fuel Oil,

and type A1 or A2. It can be pale red or a clear liquid

with a characteristic mild odour. It contains catalytically cracked oil, petroleum distillates, quinizarin,

and gas oil maker dye red. The catalytically cracked

oil and petroleum distillates are potentially hazardous constituents.

The substance has an initial boiling point of 180C, a

flash point greater than 56C, and a vapour pressure

less than 0.7mm Hg at 2 0C and has negligible solubility in water.

Gas oil is slightly irritating to the skin and has a de−

fatting action. Toxicity following single exposure to

high level of gas oil is of low order. Prolonged, repeated skin contact may de−fat the skin resulting in

possible skin irritation and dermatitis. In some cases

warty, cancerous growths have occurred.

PROTECTIVE MEASURES

Ensure good ventilation and avoid heat sources. Observance of good housekeeping rules will ensure

general safety. Do not smoke. Avoid breathing mist.

When working on, or testing, injection equipment,

special care is required to avoid perforation of skin by

high pressure fuel. Use eye protection in the event of

suspected high pressure leak.

Adopt a high standard of personal hygiene. In the

case of skin contact, wash well with soap and water.

Use glove and overalls, and eye protection goggles if

there is a risk of splashing. Use oil impervious gloves

and avoid contamination inside the gloves. If overalls become contaminated, discontinue use and

clean thoroughly. Contaminated clothing should be

removed, soaked with water, and laundered before

re−use.

It is used as a fuel for off−road diesel powered vehicles and stationary engines, and can be found in

fuel tanks, pipes and injection systems. The substance should not be used for any other purpose

without contacting the manufacturer or supplier. Installers, operators and maintainers are likely to encounter this substance.

HAZARDOUS REACTIONS

This liquid is flammable. Avoid smoking, heat

sources, such as welding and naked flames, sparks

and static electricity build−up. Thermal decomposi-

tion products are hazardous, containing CO

and SOX compounds.

The vapour is explosive. High vapour concentrations

can cause respiratory irritation, dizziness, nausea,

and loss of consciousness. Excessive and prolonged exposure to the mist can cause chronic inflammatory reaction of the lungs and form of pulmonary fibrosis.

Avoid strong oxidizing agents, e.g. chlorates which

may be use in agriculture.

, NO

X

No special respiratory precautions are necessary in

normal use.

DO NOT use as a solvent for removing dirt/grease

etc, from skin.

STORAGE/TRANSPORT

Store and transport only in correctly marked containers. Keep containers closed when not in use. Keep

cool, out of sunlight and away from naked flames.

Electrical continuity is required between the transport and storage vessels during product transfer.

X

Contain leak/spill with sand, earth or other suitable

material, and prevent entry of substance into drainage/sewerage system, water−courses and land.

Dispose of unwanted or absorbed substance

through an authorized contractor to a licensed site.

Inform local and fire authorities should the product

reach waterways, drains etc.

4

Copyright 2016 Cummins Inc.

Page 9

EMERGENCY ACTION

Fire

Extinguishing media:

Large fire − Foam/water fog. Never use water

jet.

Small fire − foam/dry powder, AAAF, CO

earth.

Avoid making sparks. Fire fighters to use self−

contained breathing apparatus. Keep fire exposed containers cool, using water fog/spray.

Prevent run−off from entering waterway, drains

and drinking water supplies.

Ingestion

Do not induce vomiting. Wash the mouth out

with water, and send to hospital immediately.

Inhalation (of vapour)

Remove from further exposure. Obtain medical

assistance immediately.

2

, sand,

It has a boiling point greater than 150C, a flash point

Open Cup of 220C (Cleveland), and is insoluble in

cold water.

It is used in engine lubricant oil systems, sump pan

and filters, make−up tanks and piping systems as a

lubrication oil for use in wide range of diesel engines

operating under severe conditions. Installers, operators and maintainers are likely to encounter this product.

HAZARDOUS REACTIONS

This product is stable although slightly re−active with

oxidizing agents. Results of decomposition are carbon oxides (CO, CO

Although harmful if swallowed or aspirated (breathed

in), repeated or prolonged exposure is not known to

aggravate medical conditions.

) and water.

2

Aspiration (inhalation of liquid)

If, following ingestion of gas oil, vomiting occurs,

there is danger of aspiration into the lungs. This

would cause intense local irritation and chemical pneumonitis that can be fatal. Obtain immediate medical assistance.

Eyes

Irrigate copiously with water or preferably eye−

wash solution for at least five minutes. If irritation

persists seek medical advice.

Skin

Wash thoroughly with soap and water. Change

clothing if necessary.

If high pressure injection has occurred prompt

surgical attention is required.

Spillage

Absorb using sand, earth or other suitable material. Dispose of unwanted or absorbed flammable material as directed under Storage/

Transport (Section 5.7.3).

LUBRICATION OIL − PREMIUM BLUE E

15W40

Used oil may contain harmful combustion by−prod-

ucts and unburnt fuel that will cause skin reactions as

detailed for fuel. Particular care must be taken if oil

form a severely overheated engine is handled − use

impervious gloves, lab coat and safety glasses.

Do not breathe vapour/spray.

PROTECTIVE MEASURES

Ensure good ventilation and avoid heat sources.

Adopt a high standard of personal hygiene. In case of

skin contact, wash thoroughly with soap and water.

Use safety glasses, impervious gloves and lab coat.

Avoid contamination inside the gloves. If overalls become contaminated, discontinue use and clean thoroughly.

No special respiratory precautions are necessary n

normal use. Do no breathe vapour/spray when handling hot materials.

STORAGE/TRANSPORT

Also known as oil, lube oil, sump oil, new oil is dark,

viscous liquid with a slight, characteristic odour. T he

base oil contains: distillates (petroleum), solvent−

dewaxed heavy paraffinic. It is not classified as dangerous according to Directive 1999/45/EC and its

amendments, and is not classified according to the

EU regulations.

Copyright 2016 Cummins Inc.

Store and transport only in correctly marked containers. Keep containers tightly sealed when not in use.

Keep in a cool, well ventilated area, out of sunlight

and away from naked flames. Store well away from

food−stuffs and drinking water.

5

Page 10

Wear splash goggles, full suit, boots and gloves. Absorb leak/spill with an inert material and dispose of

unwanted or absorbed substance through an authorized contractor to a licensed site. Finish cleaning by

spreading water on the contaminated surface and allow to evacuate through the sanitary system.

EMERGENCY ACTION

Fire

Extinguishing media:

Large fire − Use water spray, fog or foam. Do not

use water jet.

Small fire − Use dry chemical powder or CO

Fire−fighters to use self contained breathing apparatus and full turnout gear. Keep fire exposed

containers cool.

Ingestion

Do not induce vomiting, Obtain medical advice

immediately.

Inhalation (of vapour)

Remove from further exposure. Obtain medical

attention.

2

6

Copyright 2016 Cummins Inc.

Page 11

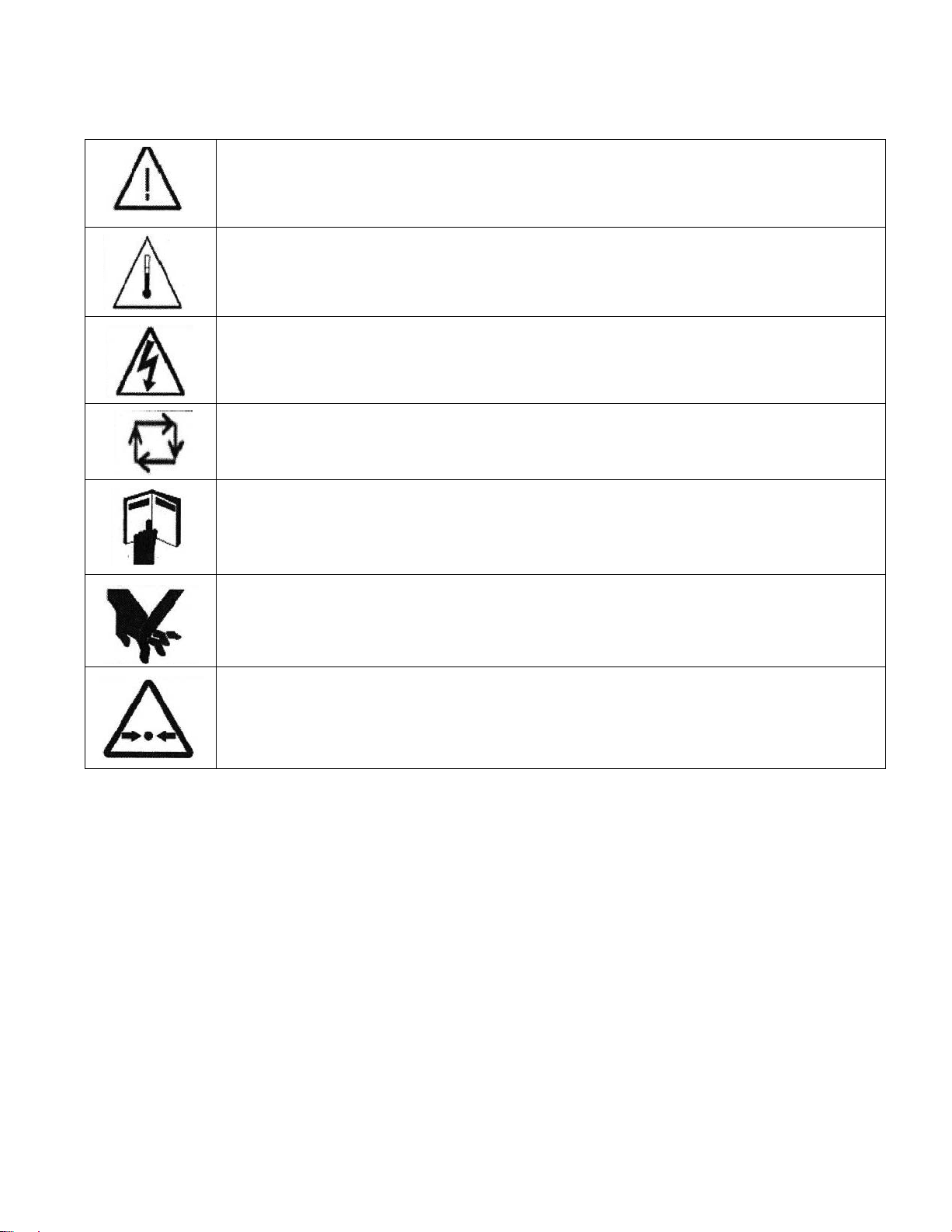

Generator Set Warning Labels

Warning signs are provided on the generator set at or near the point of risk. To avoid injury,

always take the necessary precautions – as indicated on the sample signs shown below:

Caution / Warning.

Indicates a risk of personal injury.

Caution / Warning of Temperature Hazard.

Indicates a risk of personal injury from high temperature.

Caution / Warning of High Voltage Hazard.

Indicates a risk of personal injury from electric shock/electrocution.

Caution / Warning.

Indicates a risk of personal injury from equipment that may be subject to

automatic starting or remote starting.

Caution / Warning.

Indicates to read Operator manual for additional information.

Caution / Warning of Belt and Rotating Part Hazard.

Indicates a risk of personal injury from entanglement in moving parts.

Caution / Warning of Pressure Hazard.

Indicates a risk of personal injury from pressurized fluids.

Copyright 2016 Cummins Inc.

7

Page 12

THIS PAGE IS INTENDED TO BE BLANK

8

Copyright 2016 Cummins Inc.

Page 13

Introduction

ABOUT THIS MANUAL

WARNING

severe personal injury, death and equipment

damage. The installer must be qualified to perform the installation of electrical and mechanical

equipment.

WARNING

tem. It can stop without warning. Children, persons with physical or mental limitations, and

pets could suffer personal injury or death. A personal attendant, redundant power or an alarm

system must be used if genset operation is critical.

WARNING

tected” and shall not be used in a flammable vapor environment.

CAUTION

placement of fuel, exhaust, air intake or speed

control system components that affect engine

emissions are prohibited by law in the State of

California.

This manual is a guide for the installation of the generator sets listed on the front cover. Proper installation is essential for top performance. Read through

this manual before starting the installation.

Improper installation can result in

This genset is not a life support sys-

This generator is not “ignition pro-

Unauthorized modifications or re-

This manual addresses the following aspects of the

installation:

Location and Mounting

Exhaust Connections

Fuel Connections

Electrical Connections

Startup

See the Operator’s Manual for operation and maintenance and the Service Manual for service.

Manuals are updated from time to time to reflect

changes in the equipment and its specifications. For

this reason, only the copy of the installation manual

supplied with the genset should be used as a guide for

the installation.

OUTLINE DRAWINGS

See the Outline Drawings (Pages 31 and 32) for

installation details: mounting bolt hole locations, connection points (fuel, battery, exhaust, remote control,

AC output), sizes and types of fittings, cooling air

openings, weight, and overall dimensions. See your

Cummins Onan dealer for a large-scale Outline

Drawing and full-size floor cutout template.

Copyright 2016 Cummins Inc.

9

Page 14

INSTALLATION CODES AND STANDARDS

FOR SAFETY

CAUTION

applies only when the genset is installed in a

Commercial or Recreational Vehicle.

The genset installer bears sole responsibility for the

selection of the appropriate genset, for its proper

installation and for obtaining approvals from the authorities (if any) having jurisdiction over the installation.

Federal, State and local codes, such as the California Administrative Code—Title 25 (RV installation),

might also be applicable. Installation codes and recommendations can change from time-to-time and

are different in different countries, states and municipalities. It is recommended that the standards in

Table 1 be obtained for reference.

TABLE 1. REFERENCE CODES AND STANDARDS

Code of Federal

Regulations:

Title 49: Chapter III,

Chapter V

National Electrical

NFPA No 70, 1192

ANSI/RVIA-EGS-1

California

Administrative Code:

Title 25, Chapter 3

CAN/CSA-Z240:

Recreational Vehicles

Bulletin 946

IEC 60364-7-708:

Electrical Installations

in Caravan Parks &

Caravans

The Commercial Genset Warranty

Superintendent of Documents

P. O. Box 371954

Pittsburgh, PA 15250-7954

Code:

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02210

Recreational Vehicle Industry Association

14650 Lee Road

Chantily, VA 22021

State of California Documents Section

P.O. Box 1015

North Highlands, CA 95660

Canadian Standards Association

Housing & Construction Materials

178 Rexdale Blvd.

Rexdale, Ontario, Canada M9W 1R3

International Electrotechnical Commission

3, Rue de Varembé

Geneva, Switzerland

NOISE

Generator sets emit noise. As noise level and time of

exposure increase, risk of hearing damage increases. The Specifications page n the Operator

manual states noise level for this generator set. Select and use personal hearing protection appropriate

for your exposure to generator set noise.

Note for use in countries where compliance to the EU

Noise directive is required: This generator set has

not been evaluated and is not marked for use in open

air. Install the generator set in accordance with the

Installation manual. Obey local noise restrictions

when you operate the generator set.

ELECTROMAGNETIC COMPATIBILITY

Generator sets emit and receive electromagnetic

(radio frequency) energy . If the generator set affects

operation of nearby devices, or nearby devices affect

generator set operation, increase the distance between them.

Note for use in countries where compliance to the

EMC directive is required: This generator set has

been evaluated for use in residential, commercial,

and light industrial environments.

10

Copyright 2016 Cummins Inc.

Page 15

Mounting, Location and Ventilation

MOUNTING

Installation of the generator set requires lifting apparatus. Ensure that correctly rated

lifting slings with suitable attachments are

available prior to commencing work. Lifting

and lowering operations should only be carried out by properly trained personnel. Do

not exceed the rating of any lifting component. Wear head, eye, hand and foot protection during lifting operations.

The generator set has a 2 point lifting system, which

is accessible through an access cover. Refer to outline drawing (p 24 and p 25) for the location of the access cover and weight of the generator set. Make

provisions accordingly for safe handling.

Support the genset on a structure able to resist the

dynamic weight of the genset:

3 g-force vertical and

1 g-force horizontal. See Specifications for the

weight of the genset. Use four Grade 5 screws

(3/8-16 UNC) to secure the genset to the floor or

frame. The screws must protrude at least 1/2 inch

(13 mm) but not more than 1 inch (25 mm) into the

base, as measured from the bottom surface of the

base. Torque the screws to 35 lb-ft (41 N-m).

WARNING

be designed and installed to support the dynamic weight of the genset. Failure to do so can result

in the genset dropping onto the roadway causing

property damage, severe personal injury and

death.

The genset support structure must

LOCATION

Typical genset locations on a vehicle are illustrated in

Figure 1.

Provide access to the operator’s console to start and

stop the genset and to check for and add engine

oil and coolant.

Provide access for connecting and disconnecting

fuel lines, battery cables, remote control wiring

and AC wiring.

Provide access for removing the front and bottom ac-

cess covers to perform periodic maintenance in

accordance with the Operator Manual. If the

genset compartment has a floor, use the floor

cutout template that is available from your Cummins Onan dealer. The crosshatched areas on

Page 16 indicate the areas that must be open in

the floor. These areas must not be obstructed by

frame members, exhaust tail pipes or other

equipment.

Make sure the genset clears the ground by at least

12 inches (305 mm) to provide adequate ventilation and reduce the amount of dust pulled in

by the cooling fan.

A genset compartment must be large enough to pro-

vide at least 1/2 inch (12.7 mm) clearance at the

top of the genset, 1/4 inch (6.4 mm) at the back

and left side, 2 inches (51 mm) at the front for air

intake and 4 inches (102 mm) at the right side for

air discharge (Figure 2). These minimum clear-

ances apply to any thermal or acoustic insulation with which the compartment may be lined.

Acoustic/thermal insulation and adhesive must be

Classified as “Self-Extinguishing” at not less

than 200

compartment with insulation, which absorbs

spilled fuel and oil.

Provide a vapor-tight, fire-resistive barrier between

the genset and the interior of the vehicle. Use

approved materials (26 gauge galvanized steel

or equivalent). See NFPA 1192 for details.

EXHAUST GAS IS DEADLY. Construct a suitable vapor barrier of approved materials between the genset and vehicle interior to keep

out exhaust gas.

Provide protection from rain and snow when the gen-

set is not mounted in a compartment. The genset housing is not water tight. Protection must

extend over the entire top of the genset, including the operator control panel.

F (90C). Do not line the bottom of the

Copyright 2016 Cummins Inc.

11

Page 16

Provide protection from direct road splash if the gen-

set is located behind a road wheel or the front

grille of the vehicle.

FIGURE 1. TYPICAL GENSET LOCATIONS

VENTILATION

Unrestricted air flow for cooling, ventilation and combustion (Figure 2) is essential for proper genset performance and service life. See HOT AIR RECIRCULATION TEST (Page 27).

The crosshatched areas on Page 16 must be open

for unobstructed air flow into and out of the genset for cooling, ventilation and combustion.

When the genset is installed in a compartment that

surrounds the top and sides (Figure 2), provide

non-flammable baffles (UL 94 HBF foam or better) to prevent hot side-discharge air from recirculating back into the front air inlet grille. The

baffles must extend all the way across the top,

down the front and half way back below the side

air discharge grille. They must close off the gap

between the genset and enclosure.

If the air inlet is in the compartment door, it must allow

the air to flow straight into each opening of the

inlet air grille without obstruction (Figure 2).

If the air inlet is in the compartment floor in front of the

genset, the opening must be at least 2 inches

(51 mm) wide and extend across the entire front

of the genset (crosshatched area, Page 16).

COMPARTMENT WITH BAFFLES

AND AIR OPENINGS ON SIDES OF GENSET

AIR OUTLET IN BOTTOM OF GENSET

FIGURE 2. GENSET COMPARTMENT WITH

BAFFLES TO PREVENT HOT AIR RECIRCULATION

The compartment outlet for side-discharge air must

be at least 4 inches (102 mm) wide and extend

across the back half of the floor (Figure 2).

12

Copyright 2016 Cummins Inc.

Page 17

Exhaust Connections

The exhaust system must be gas-tight and designed

to limit entry of exhaust gases into the vehicle.

WARNING

EXHAUST GAS IS DEADLY! To keep

exhaust gases from entering the vehicle do not

terminate the exhaust tailpipe underneath the

vehicle or closer than specified to openings into

the vehicle (Figure 6) or route it such that it is

likely to be damaged (Figure 7). Use approved

materials and parts only.

CAUTION

Unauthorized modifications or replacement of fuel, exhaust, air intake or speed

control system components that affect engine

emissions are prohibited by law in the State of

California.

MUFFLER

The muffler is mounted inside the genset housing

and has a flanged outlet opening (Figure 3). It has a

USDA (Forest Service) spark arrestor and meets

RVIA EGS-1 construction requirements. The Outline

Drawing (Page 16) shows the dimensions of the exhaust flange and the locations of the tailpipe clearance holes.

A genset without a properly installed and maintained

spark arresting exhaust system can cause a brush or

forest fire, and is illegal on federal lands. Liability for

damage, injury and warranty expense due to the

modification of the exhaust system or to use of unapproved parts is the responsibility of the person performing the modification or installing the unapproved

parts. Contact a Cummins Onan distributor for approved exhaust system parts.

SIDE AND BACK TAILPIPE

EXIT HOLES

MUFFLER OUTLET FLANGE

Copyright 2016 Cummins Inc.

FIGURE 3. EXHAUST CONNECTIONS AT GENSET

13

Page 18

TAILPIPE

The tailpipe of the generator set will be hot during operation and can cause severe burns. To reduce the risk of contact, consideration must be

taken on where the tailpipe will be located and

routed.

Tailpipe adapter kits are separately available. Use a

straight adapter for a tailpipe routed through the bottom. Use an elbow adapter for a tailpipe routed

through the side or back exit holes. When connecting

and routing the tailpipe:

Use 1-3/8 inch ID 18-gauge aluminized steel tubing

or equivalent (minimum 35 mm ID with minimum 0.012 mm wall thickness). Do not use flexible tubing, which is not gas tight or durable.

Secure the tailpipe or adapter flange to the muffler

flange with the gasket and two stainless steel

bolts supplied in the kit.

Use U-bolt muffler clamps to connect sections of tail-

pipe. It is recommended that the overlapping

pipe be slotted as shown in Figure 4.

3/4 INCH (19 MM)

MAXIMUM SLOT

(BOTH SIDES)

FIGURE 4. EXHAUST TAILPIPE CONNECTIONS

Use flexible automotive-type tailpipe hangers every

2 to 3 feet (0.6 to 0.9 m). Attach the hangers to

steel framework, not to wood or other combustible material.

Do not terminate the tailpipe underneath the vehicle.

Extend it a minimum of 1 inch (25 mm) beyond

the perimeter of the vehicle (Figure 5). Support

the end of the tailpipe such that it cannot be

pushed inward and up under the skirt of the vehicle.

Do not route the tailpipe such that it will interfere with

removing the service access cover and performing periodic maintenance. See the Operator

Manual.

Do not route the tailpipe closer than 3 inches

(76 mm) to combustible material (wood, felt,

cotton, organic fibers, etc.) unless it is insulated

or shielded. The temperature rise (above ambient) on adjacent combustible material must not

exceed 117

F (65C).

Do not route the tail pipe near fuel lines or fuel tanks.

1 INCH (25 mm)

MINIMUM

LAST TAILPIPE HANGER AS

CLOSE TO END AS

PRACTICAL

FIGURE 5. TERMINATING THE EXHAUST TAILPIPE

NO OPENING INTO THE VEHICLE INTERIOR MAY

BE CLOSER THAN 6 INCHES (153 mm) TO THE

END OF THE TAIL PIPE (WITHIN SHADED AREA)

6 in

153 mm

Do not terminate the tailpipe such that it is closer than

6 inches (153 mm) to any opening into the vehicle interior (door, window, vent). See Figure 6.

TAILPIPE

FIGURE 6. MINIMUM DISTANCES TO OPENINGS

Route the tailpipe such that it is not likely to be struck

when the vehicle is moving. Keep it out of the ap-

14

Copyright 2016 Cummins Inc.

Page 19

proach and departure angles of the vehicle and

above the axle clearance line (Figure 7).

Excessive back pressure can cause loss of

performance and engine damage.

Interconnecting the engine exhaust systems

will allow exhaust condensates and soot to

migrate into the engine that is idle, causing

engine damage.

Do not connect the genset to the vehicle engine ex-

haust system.

DEPARTURE

ANGLE

Exhaust back pressure under full load must not ex-

ceed 2 inches (51 mm) water column (WC) as

measured within 6 inches (154 mm) of the muffler outlet flange.

APPROACH

ANGLE

AXLE CLEARANCE LINE

FIGURE 7. APPROACH AND DEPARTURE ANGLES AND AXLE CLEARANCE LINE

Copyright 2016 Cummins Inc.

15

Page 20

THIS PAGE IS INTENDED TO BE BLANK

16

Copyright 2016 Cummins Inc.

Page 21

Fuel Connections

WARNING

Diesel fuel is a combustible and can

cause severe personal injury or death. Do not

smoke or allow any flame, spark, pilot light, arcproducing equipment, electrical switch or other

ignition source around fuel or fuel components,

or in areas sharing ventilation. Keep a type multi−class fire extinguisher handy.

Do not interconnect genset and vehicle engine fuel

lines. Follow the vehicle chassis manufacturer’s instructions when making connections to the vehicle

engine fuel tank.

CAUTION

Either or both engines could starve

for fuel if the genset and vehicle engine fuel lines

are interconnected. Always use separate fuel

lines or a separate fuel tank for the genset.

To prevent the genset from running the vehicle out of

fuel, do not extend the genset fuel pickup tube down

into the fuel tank as far as the pickup tube for the vehicle engine.

Fuel lines (supply and return) must have at least a

1/4 inch (6.4 mm) ID See Figure 8 for connections at

the genset.

Run the fuel line at or above the top of the fuel tank to

reduce the risk of siphoning fuel out of the tank if the

line should break. The maximum fuel pump lift is

36 inches (1 meter).

Route fuel lines away from electrical wiring and hot

engine exhaust components. Fuel lines should be

accessible for inspection and replacement, protected from damage and secured to prevent kinking,

contact with sharp edges and chafing due to vibration.

FUEL SUPPLY

(1/8 INCH NPT)

FUEL RETURN

(1/8 INCH NPT)

FIGURE 8. FUEL CONNECTIONS

Copyright 2016 Cummins Inc.

17

Page 22

BIO−DIESEL FUELS B5 − B20

Approved Bio−Diesel Fuel:

Bio−diesel meeting either ASTM D6751 or

EN14214.

Place the fuel water separator in a location that

is accessible for service by as close the generator set as possible. Locating the separator

ahead of the generator set fuel pump is acceptable.

Fuel meeting either ASTM D6751 or EN14214

fuel can be blended with an acceptable diesel

fuel meeting ASTM D975 meeting ASTMD975

up to 20 percent volume concentration (B20).

For bio−diesel blends above B5 and up to B20 the

following installation requirements must be met:

Supply and Return fuel lines and fittings must be

bio−diesel compatible. Not all fuel hoses and fittings are bio−diesel compatible. All fuel wetted

components must not contain the following materials: copper, brass, bronze, zinc, lead, tin,

natural rubber and nitrile rubber compounds.

Check with your manufacturer for bio−diesel

compatibility.

Fuel tanks must be made from the following ma-

terials: aluminum, steel, flourinated polyethylene, flourinated polypropylene or Teflon

(PTFE).

Verify the vehicle propulsion engine is capable

of using B20 when sharing the same fuel tank

with the generator set.

A bio−diesel compatible fuel water separator is

required. Cummins Onan strongly recommends

using Cummins Filtration filters equipped with

StrataPoret media. This filter media removes

water more efficiently than standard cellulosic

filter media, which will not provide adequate fuel

water separation capabilities. However, even

StrataPoret fuel filter media is not as effective

in removing water from bio−diesel as it is in re-

moving water from petro diesel. Therefore, preventing water from entering the fuel supply (vehicle or storage) remains very important.

Additional information:

Bio−diesel blends have higher pour and cloud

points than standard diesel fuels. Generator set

locations far from the fuel tank combined with

low fuel flow rates can make the generator set

fuel system very susceptible to fuel starvation

related to gelling in cold weather (below 23

C). In addition to electric or coolant tank

–5

F/

heaters, consideration to routing and possible

heating or insulation of the fuel lines to the generator set may be needed.

Bio−Diesel blends can oxidize more quickly

than standard diesel fuels; more frequent fuel filter service intervals may be required and shorter

fuel storage life in tanks is likely.

WARNING

It is highly recommended that specific

market applications are avoided or excercised with

extra care due to some of the properties of bio−diesel

fuel blends such as cold weather operation, long

term storage, material incompatibilities and other effects on engine operating characteristics. Such applications that should use standard fuels include applications that will experience seasonal usage,

storage for periods exceeding 60 days, and extreme

temperatures or humidity.

Storage requirements:

If using bio−diesel for seasonal applications

(stored more than 90 days), the generator set

must be purged before storage by running the

engine on pure diesel fuel meeting ASTM D975

for a minimum of 30 minutes.

18

Copyright 2016 Cummins Inc.

Page 23

TABLE 2. CUMMINS ONAN BIO−DIESEL RECOMMENDATIONS

APPLICATION

RECOMMENDATION FOR

BIO−DIESEL BLENDS

Emergency Standby

Not Recommended Use petroleum diesel only. Low fuel usage and critical

RV

Seasonal/Commercial with

low annual hour accumulation

Limited Time Prime Approved with

Recommendations

Unlimited Time Prime Approved with

Recommendations

Continuous Approved with

Recommendations

RECOMMENDATIONS COMMENTS

start nature of Emergency

Standby make bio−diesel

impractical.

Use fuel within 6 months of

manufacture. Flush fuel

system with petroleum diesel prior to storage.

Use fuel within 6 months of

manufacture. Fluh fuel system with petroleum diesel

Bio−diesel is suitable for

constant high load operation with proper precautions.

Bio−diesel is suitable for

variable load operation with

proper precautions.

prior to storage/transport.

Use fuel within 6 months of

manufacture.

Bio−diesel is suitable for

base load operation with

proper precautions.

Copyright 2016 Cummins Inc.

19

Page 24

THIS PAGE IS INTENDED TO BE BLANK

20

Copyright 2016 Cummins Inc.

Page 25

Electrical Connections

AC POWER CONNECTIONS

WARNING

uninsulated live parts inside the generator set

and connected equipment can result in severe

personal injury or death. For your protection,

stand on a dry wooden platform or rubber insulating mat, make sure your clothing, and shoes

are dry, remove jewelry from your hands and use

tools with insulated handles. Secure protective

covers when completing installation.

WARNING

electric shock resulting in severe personal injury

or death.

WARNING

cause severe personal injury or death. Do not

connect the starting battery until so instructed in

Installation Review and Startup.

HAZARDOUS VOLTAGE! Touching

IMPROPER WIRING can cause fire or

Accidental starting of the genset can

Wiring Methods

The genset is equipped with a terminal block and

conduit connector knockouts for AC power output

connections (Figure 9). See the generator connection diagrams on Page 34.

terminals must be re-torqued after a few minutes because the connection can loosen if the

individual strands spread out.

Use vibration-proof switches and controls to prevent

the opening and closing of circuits while the vehicle is in motion.

Use rain-tight conduit, conduit connectors and junc-

tion boxes for all exterior wiring.

Provide ground fault circuit interrupters (GFCIs) or

residual current devices (RCDs) for all convenience power receptacles.

Seal all conduit openings into the vehicle interior to

keep out exhaust gas. Apply silicone rubber or

equivalent sealant inside and outside each conduit connector. (Flexible conduit is not vaportight and will allow exhaust gas to enter along

the wires if not sealed.)

Route or protect AC wiring so that it will not be cut or

abraded, exposed to hot surfaces or damaged

by road debris. Keep AC wiring away from fuel

lines and control wiring (see Remote Control).

AC TERMINAL

ACCESS

AC wiring methods must be in accordance with the

National Electrical Code or IEC 60364-7-708, as appropriate. Note especially the following:

WARNING

EXHAUST GAS IS DEADLY! Seal all

wiring openings into the vehicle interior to keep

out exhaust gas.

WARNING

Routing AC wiring with fuel lines can

lead to fire and severe personal injury or death.

Keep AC wiring away from fuel lines.

Have a trained and experienced electrician super-

vise and inspect the installation of all AC wiring.

Secure only one lead at each AC output terminal.

The terminals are suitable for wire gauges up to

No. 6 AWG (16 mm

2

). Torque the terminals to

13 in-lbs (1.5 N-m). When stranded conductors

are used, it is recommended that copper ferrules, available for the various wire gauges, be

crimped on the stripped ends of the conductors

to facilitate terminal connections. Otherwise, the

CONTROL

KNOCKOUTS FOR 3/4

AND 1 INCH CONDUIT

FIGURE 9. ACCESS FOR AC OUTPUT AND

REMOTE CONTROL CONNECTIONS

WIRING

KNOCKOUTS

Copyright 2016 Cummins Inc.

21

Page 26

Grounding

WARNING

electrocution and severe personal injury or

death. Grounding must be in accordance with

applicable codes.

Faulty grounding can lead to fire or

screw on the red, hexagonal insulator. Cut the jumper as close to each terminal connector as possible to

avoid having to loosen the connections for the other

wires at the terminals.

Vehicle Connections to Utility Power

Connect grounding terminal TB1-5 (Page 34) in accordance with applicable codes.

50 Hz Model HDKBB Only − If the authority having

jurisdiction requires an ungrounded 230 VAC system, it will be necessary to cut the internal grounding

jumper (Figure 10). To do this, remove the side access cover (four screws) and cut the short jumper between the ground terminal screw and the terminal

WARNING

Interconnecting the genset and the

public utility (or any other power source) can

lead to electrocution of utility line workers,

equipment damage and fire. Use an approved

switching device to prevent interconnections.

A vehicle with provisions for connecting utility power

must have an approved device to keep the genset

and utility from being interconnected.

FOR UNGROUNDED 230 VAC, 50 HZ APPLICATIONS, CUT

THIS JUMPER FROM ITS TERMINAL CONNECTORS

DO NOT LOOSEN THE TERMINAL SCREWS

FIGURE 10. MODEL HDKBB GROUNDING JUMPER

22

Copyright 2016 Cummins Inc.

Page 27

REMOTE CONTROL CONNECTIONS

Leads for connection to a remote control panel are

terminated in a 10-pin sealed connector and are

stowed inside the AC terminal enclosure when the

genset leaves the factory. Details of the connector

and its mate are provided on the Outline Drawing

(Figure 15). Refer to the Wiring Schematic (Figure 17) for pin connections.

Remote Control Panels

Onan offers harnesses of various lengths with mating receptacles and three remote control kits as follows:

Remote switch / status lamp.

Remote switch / status lamp and hour meter.

Remote switch / status lamp and DC voltmeter.

If another source is used for the remote panel:

The control switch should be a two-pole, momentary-

contact, center-return/center-off type of switch

with an indicator light.

nect to the wiring from the remote panel. Use insulated 18 AWG ( 1 mm

2

) copper conductors for

the wiring from the remote panel.

Keep control leads away from AC power leads to re-

duce the possibility of erratic operation due to induced signals.

Seal the hole where the leads enter the interior of the

vehicle to keep out exhaust gas. Use silicone

rubber or an equivalent type of sealant.

BATTERY CONNECTIONS

WARNING

cause severe personal injury or death. Do not

connect the starting battery until so instructed in

Installation Review and Startup. Make sure an

automatic genset starting system is disabled.

Accidental starting of the genset can

Battery Capacity

The genset has a 12 VDC, negative-ground control

and starting system. See Specifications for the re-

quirements for cranking batteries.

The total load connected to P2-E (Switched B+)

should not exceed 2 amp.

The total load connected to P2-F (Status Light)

should not exceed 2 amp.

Wiring Methods

WARNING

wiring openings into the vehicle interior to keep

out exhaust gas.

Remove the AC terminal access cover and remove

one of the control wiring knockouts.

Pull out the remote control connector plug, fit the

bushing around the connector leads into the

knockout slot and secure the access cover.

Snap the connector plug and harness receptacle to-

gether.

If the harness does not have a plug for connections

at the control panel, use solder-type butt connectors and heat-shrink insulation tubing to con-

EXHAUST GAS IS DEADLY! Seal all

Battery Recharging

The genset is equipped with a 10-amp, regulatedvoltage battery charger.

Battery Compartment

Batteries must be mounted in a separate compartment from that of the genset and away from sparkproducing equipment. An enclosed compartment

must have openings of at least 1.7 square inches

(11 square centimeters) at the top and bottom for

ventilation of battery gasses. Batteries should be

mounted such that spills and leaks will not drip acid

on fuel lines, wiring and other equipment that could

be damaged.

WARNING

drogen gas given off by the battery, causing severe personal injury. The battery compartment

must be ventilated and must isolate the battery

from spark-producing equipment.

Arcing can ignite the explosive hy-

Copyright 2016 Cummins Inc.

23

Page 28

Battery Cables

Battery wiring methods must be in accordance with

the National Electrical Code or IEC 60364-7-708, as

appropriate.

Size battery cables according to Table 3. The current

path between the genset and the negative (−) battery

terminal must also be able to carry full cranking current without causing excessive voltage drop. It is

highly recommended that a full-length cable be used

to connect the genset to the negative (−) battery ter-

minal (Figure 1 1). Note also that codes may require a

bonding conductor between the genset and vehicle

frame and between the battery and vehicle frame.

If the vehicle frame is used as the path between the

negative (−) battery terminal and the genset (Figure 12), all frame members in the path of battery

cranking currents must have substantial cross sections. The electrical resistance of riveted or bolted

frame joints must also be carefully considered, especially if the joints will be exposed to corrosive conditions. A cable sized according to Table 3 must be

used to connect the frame to the designated negative

(−) terminal on the genset (Figure 12). The genset

mounting bolts are not considered adequate

means for bonding the genset to the vehicle

frame, either for the purpose of carrying cranking currents or for complying with requirements

for genset/system grounding.

WARNING

lines can lead to fire and severe personal injury

or death. Keep battery cables away from fuel

lines.

Routing battery cables with fuel

TABLE 3. BATTERY CABLE SIZES FOR AMBIENT

TEMPERATURES DOWN TO −20 F (−29 C)

TOTAL CABLE LENGTH,

FEET (METERS)

0 to 15 (0 to 4.5) 0* (50)

16 to 20 (4.5 to 6) 000 (95)

* − A total length of up to 25 feet (7.6 meters) may be

used in warmer climates or when battery capacity totals

at least 1200 CCA (Cold Cranking Amps).

SIZE PER TABLE 3

GENSET

+

−

VEHICLE FRAME

FIGURE 11. FULL-LENGTH CABLE FROM

BATTERY NEGATIVE (−) TERMINAL

GENSET

+

−

VEHICLE FRAME

FIGURE 12. VEHICLE FRAME AS PATH FROM

BATTERY NEGATIVE (−) TERMINAL

8 AWG

2

(10mm

MINIMUM

SIZE PER TABLE 3

)

CABLE SIZE,

AWG (mm

− +

BAT

− +

BAT

2

)

Route battery cables away from fuel lines and hot engine exhaust components. Battery cables should be

accessible for inspection and replacement, protected from damage and secured to prevent chafing

due to vibration.

24

Copyright 2016 Cummins Inc.

Page 29

Genset Bonding Terminal

The negative (−) battery cable terminal shown in Fig-

ure 13 is also the bonding terminal for grounding the

genset to the vehicle chassis. If the grounding cable

is also going to carry starter motor current, it must be

sized the same as the battery cables.

Connecting Battery and Bonding Cables

Terminate the battery cables with ring terminals

sized for the 5/16 inch genset terminal screws (Figure 13). Permanently mark each end of each cable

as to its polarity, positive (+) or negative (−). After

making sure the battery cables are not connected at

the battery and that an automatic genset starting system is disabled, connect the battery and grounding

cables to the genset. Torque the terminals to 7.5 lb-ft

(10 N−m).

POSITIVE (+)

NEGATIVE (−)

FIGURE 13. BATTERY CABLE TERMINALS

Copyright 2016 Cummins Inc.

25

Page 30

THIS PAGE IS INTENDED TO BE BLANK

26

Copyright 2016 Cummins Inc.

Page 31

Installation Review and Startup

LOCATION

HOT AIR RECIRCULATION TEST

A representative installation of the genset must be

tested to determine that the genset will not overheat

due to recirculation of hot air back into the genset.

Test Method

Complete a representative installation.

Conduct the test in a well ventilated space in which

carbon monoxide cannot accumulate, but that is

protected from cross drafts that could affect temperature measurements.

Connect a large, constant load to the genset. If a load

bank is available, connect at least 3/4 full load.

If not, connect and run the largest combination

of constant loads that can be kept on during the

test without tripping the genset circuit breaker.

For example, run a combination of air conditioners and lights. Make sure air conditioners stay

on and do not cycle during the test.

Measure temperatures with thermocouples not

heavier than No. 24 AWG (0.21 mm

Measure genset inlet air temperature with one ther-

mocouple tied in the middle of the inlet air grille

(Figure 14).

Measure ambient air temperature with a shielded

thermocouple within 4 feet (1.2 meters) of the

genset and at approximately the same height.

Make sure the thermocouple will not b e a ffected

2

).

by warm air discharged from the genset or by

sunlight. Use 2 inch diameter white PVC piping

at least 6 inches long as a thermocouple shield.

Close all genset compartment doors and run the

genset for at least 90 minutes. Record temperatures at 15 minute intervals. See Table 4 for an

example of how the data can be arranged for recording and analysis.

TABLE 4. TEMPERATURE DATA

TEMPERATURE C (F)

THERMOCOUPLE

AMBIENT AIR

INLET AIR

Time Of Reading

Test Requirement

The rise in inlet air temperature over ambient air temperature must not exceed 15F (8C). A rise in inlet

air temperature indicates hot air recirculation. If the

rise exceeds the requirement, steps must be taken to

reduce recirculation to an acceptable level. Review

Mounting, Location and Venting (Page 11).

CAUTION

tures can reduce maximum genset power if the

air temperature rise in this test is on the high end

of the acceptable range.

High ambient operating tempera-

Copyright 2016 Cummins Inc.

AMBIENT AIR

INLET AIR

FIGURE 14. THERMOCOUPLE LOCATIONS

27

Page 32

INSTALLATION REVIEW

Before starting the genset inspect the installation

and check off (

can be answered “YES”. If a question cannot be

checked off, review the appropriate section in the

manual.

[ ] Is the operator’s console easily accessible for

starting and stopping the genset, resetting circuit breakers and checking and adding engine

coolant?

[ ] Is the genset securely bolted in place?

[ ] Is there clearance all around the genset?

[ ] Are the cooling and combustion air inlet and out-

let openings free of obstructions?

[ ] Is there easy access for draining the engine oil?

[ ] Is there easy access for draining the engine

coolant?

[ ] Is there easy access for changing the air filter,

checking oil level and adding oil?

[ ] Is there easy access for cleaning out the spark-

arrest muffler?

[ ] Are all tailpipe connections tight and all hangers

and support straps secure?

[ ] Does the tailpipe terminate at least 1 inch

(25 mm) beyond the perimeter of the vehicle

and at least 6 inches (153 mm) away from any

opening into the vehicle?

[ ] Is the tailpipe routed such that it is not likely to be

struck while the vehicle is moving?

[ ] Is the genset located outside the interior space

of the vehicle and separated by approved vapor-

tight and fire-resistive materials?

[ ] Are all wiring holes into the vehicle interior (in-

side and outside conduit connectors) sealed to

keep out exhaust gas?

[ ] Have the AC output connections been made

properly.

[ ] Have properly sized batteries and battery

cables been installed?

[ ] Have the battery cables been secured at suffi-

cient intervals to prevent chaffing and contact

with sharp edges, fuel lines and hot exhaust

parts?

[ ] Is the genset bonding terminal (negative [−] bat-

tery cable terminal) properly grounded to the ve-

hicle chassis?

[ ] Are all fuel connections tight?

[ ] Have the fuel lines been secured at sufficient in-

tervals to prevent chaffing and contact with

) each of the following questions if it

sharp edges, electrical wiring and hot exhaust

parts?

[ ] Is the genset protected from direct road splash,

rain and snow?

[ ] Does the genset clear the ground by at least

12 inches (305 mm)?

[ ] Has the HOT AIR RECIRCULATION TEST

been conducted? Are the results acceptable?

STARTUP

When all installation requirements have been met,

connect the battery cables to the battery, positive (+)

cable first.

WARNING

switches or other equipment, and flames or

sparks, can ignite battery gas causing severe

personal injury. To prevent injury:

fore working on or near

OFF away from battery

nect charger before

cables

Disconnect negative (−) cable first and

Read through the Operator Manual and perform the

maintenance and pre-start checks instructed. The

genset is shipped from the factory with proper levels

of engine oil and coolant, which should nevertheless

be checked before the genset is started. Start and

operate the genset, following all the instructions and

precautions in the Operator Manual.

WARNING

operate the genset when the vehicle is indoors

unless there is ample fresh air ventilation.

Check for fuel, coolant and exhaust leaks and unusual noises while the genset is running under full and

intermediate loads. To calculate electrical loads see

POWERING EQUIPMENT in the Operator Manual.

Do not place the genset in service until all leaks have

been fixed and operation is satisfactory.

Arcing at battery terminals or in light

Ventilate battery area be-

battery

Wear safety glasses

Do not smoke

Switch work light ON or

Stop genset and discon-

disconnecting battery

reconnect it last.

EXHAUST GAS IS DEADLY! Do not

28

Copyright 2016 Cummins Inc.

Page 33

Specifications

HDKBB HDKBC

GENSET CONTROLLER: Integrated Microprocessor Based Engine and Generator Controller

GENERATOR: Two-Bearing, Two-Pole Rotating Field, “Poly-Vee” Belt Drive

Power (@1.0 PF) 4800 W 5000 W

RPM 3000 3600

Frequency 50 Hz 60 Hz

Voltage 230V 1-Ph 120V 1-Ph, 120/240V 1-Ph, or 120/240V 3-Ph

Current 21 A 41.7/20.8 A or 12 A (3-Ph)

Circuit Breakers 2-pole 25 A (1 pole used) 2-pole 25 A (1-Ph) or 3-pole 15 A (3-Ph)

FUEL CONSUMPTION:

No-load

Half-load

Full-load

ENGINE: 2-Cylinder In-Line, Water-Cooled, Indirect-Injection, 4-Stroke Cycle Diesel

RPM 2880 2880

Bore 2.64 in (67 mm) 2.64 in (67 mm)

Stroke 2.68 in (68 mm) 2.68 in (68 mm)

Displacement 29.23 in3 (479 cc) 29.23 in3 (479 cc)

Compression Ratio 23 : 1 23 : 1

Injection Order 1−2 1−2

Engine Timing 18.25 to 19.75 BTDC 18.25 to 19.75 BTDC

Fuel Nozzle Injection

Pressure

Valve Lash: Intake & Ex-

haust (cold)

Oil Capacity

(with filter)

Cooling System

Capacity

0.0057 − 0.0073 inch (0.145 − 0.185 mm) 0.0057 − 0.0073 inch (0.145 − 0.185 mm)

DC SYSTEM:

Nominal Battery

Voltage

Minimum Battery

Capacity CCA

(Cold Cranking Amps)

Fuse F1 (control, start

and glow plug circuits)

650 amps down to −20F (−29C)

WEIGHT: 400 lbs (181 kg)

SIZE (L x W x H): 34.5 x 22.9 x 20.3 in (876 x 581.2 x 514.4 mm)

SOUND LEVEL: 68 dB(A) @ 10 ft (3m) before installation and @ 1/2-load

0.20 gph (0.74 lph)

0.32 gph (1.23 lph)

0.54 gph (2.04 lph)

1991 psi (13.73 mPa) 1991 psi (13.73 mPa)

2 quart (1.9 liter) 2 quart (1.9 liter)

3.0 quart (2.8 liter) 3.0 quart (2.8 liter)

12 volts 12 volts

475 amps down to 0F (−17C)

650 amps down to −20F (−29C)

30 amp mini-bayonet 30 amp mini-bayonet

0.25 gph (0.95 lph)

0.39 gph (1.47 lph)

0.60 gph (2.27 lph)

475 amps down to 0F (−17C)

Copyright 2016 Cummins Inc.

29

Page 34

THIS PAGE IS INTENDED TO BE BLANK

30

Copyright 2016 Cummins Inc.

Page 35

FIGURE 15. OUTLINE DRAWING—SHEET 1

Copyright 2016 Cummins Inc.

31

Page 36

FIGURE 16. OUTLINE DRAWING—SHEET 2

32

Copyright 2016 Cummins Inc.

Page 37

FIGURE 17. WIRING DIAGRAM—SHEET 1

Copyright 2016 Cummins Inc.

33

Page 38

FIGURE 18. WIRING DIAGRAM—SHEET 2

34

Copyright 2016 Cummins Inc.

Page 39

Page 40

power.cummins.com

Copyright E 2016 Cummins Inc. All rights reserved.

Cummins, Onan, the “C” logo, and “Performance you rely on.” are trademarks of Cummins Inc.

Other company, product, or service names may be trademarks or service marks of others.

Specifications are subject to change without notice.

Loading...

Loading...