Page 1

Operator Manual

RV Generator Set

HDKAH (Spec A−M)

HDKAJ (Spec A−M)

HDKAK (Spec A−M)

HDKAT (Spec A−M)

HDKAU (Spec A−M)

HDKAV (Spec A−M)

English − Original Instructions 5−2010 981−0161 (Issue 7)

Page 2

California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

diesel warnings

Page 3

Table of Contents

SAFETY PRECAUTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Identification 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Genset 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Recommendations 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Recommendations 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Batteries 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator’s Console 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control Panel 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conducting the Pre-Start Checks 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

priming the Fuel System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Genset 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Genset 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restarting the Genset 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the Genset 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting Circuit Breakers 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to Utility Power 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating in Cold Weather 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating in Hot Weather 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating at High Altitude 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating in Dusty Environments 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Breaking in a New Engine 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exercising the Genset 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing the Genset 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conducting General Inspections 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Engine Oil Level 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil and Oil Filter 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining the Battery and Battery Connections 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Air Filter Element 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Spark Arrestor 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Fuel Filter 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Coolant 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INFORMATION FOR CALIFORNIA GENSET USERS 33. . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO OBTAIN SERVICE 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE RECORD 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Page 5

1

Safety Precautions

Thoroughly read the OPERATOR’S MANUAL

before operating the genset. Safe operation and

top performance can only be obtained when

equipment is operated and maintained properly.

The following symbols in this manual alert you to potential hazards to the operator, service person and

equipment.

alerts you to an immediate hazard

that will result in severe personal injury or

death.

WARNING

alerts you to a hazard or unsafe

practice that can result in severe personal injury

or death.

CAUTION

alerts you to a hazard or unsafe

practice that can result in personal injury or

equipment damage.

When equipped with an integral or add−on Auto−

matic Generator Starting System (AGS) control,exhaust carbon monoxide (CO), electric shock, andmoving parts hazards are possible due to unex−

pected starting. Turn off AGS whenever performingmaintenance or service, when the vehicle is storedbetween uses, is awaiting service, or is parked in

agarage or other confined area.

Electricity, fuel, exhaust, moving parts and batteries

present hazards which can result in severe personal

injury or death.

ENGINE EXHAUST IS DEADLY

• Inspect for exhaust leaks at every startup and

after every eight hours of running.

• Learn the symptoms of carbon monoxide poisoning in the Operator’s Manual.

• Never sleep in the vehicle while the genset is

running unless the vehicle is equipped with a

working carbon monoxide detector.

• Do not operate the genset when the vehicle is

in a confined space, such as a garage.

• Disable the automatic genset starting feature of

an inverter-charger or other automatic starting

device before storing the vehicle or parking it in

a garage or other confined space.

• The exhaust system must be installed in accordance with the genset Installation Manual.

• Engine cooling air must not be used for heating

working or living spaces or compartments.

GENERATOR VOLTAGE IS DEADLY

• Disable the automatic genset starting feature(AGS) of an inverter−charger or other automatic starting device before servicing the genset to avoid electric shock from an unexpected

start.

• Generator electrical output connections must

be made by a trained and experienced electrician in accordance with applicable codes.

• The genset must not be connected to the public

utility or any other source of electrical power.

Back-feed could lead to electrocution of utility

personnel and damage to equipment. An approved switching device must be used to prevent interconnections.

• Use caution when working on live electrical

equipment. Remove jewelry, make sure clothing and shoes are dry, stand on a dry wooden

platform or rubber insulating mat and use tools

with insulated handles.

DIESEL FUEL IS COMBUSTIBLE

• Do not smoke or turn electrical switches ON or

OFF where fuel fumes are present or in areas

sharing ventilation with fuel tanks or equipment. Keep flames, sparks, pilot lights, arc-producing equipment and all other sources of ignition well away.

• Fuel lines must be secured, free of leaks and

separated or shielded from electrical wiring.

Page 6

2

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

• Disable the automatic genset starting feature(AGS) of an inverter−charger or other automatic starting device before servicing the genset to avoid unexpected starting.

• Do not wear loose clothing or jewelry near moving parts such as PTO shafts, fans, belts and

pulleys.

• Keep hands away from moving parts.

BATTERY GAS IS EXPLOSIVE

• Wear safety glasses.

• Do not smoke.

• To reduce arcing when disconnecting or recon-

necting battery cables, always disconnect the

negative (−) battery cable first and reconnect it

last.

FLAMMABLE VAPOR CAN CAUSE A

DIESEL ENGINE TO OVERSPEED

Flammable vapor can cause a diesel engine to

overspeed and become difficult to stop, resulting in

possible fire, explosion, severe personal injury and

death. Do not operate a diesel-powered genset

where a flammable vapor environment can be

created by fuel spill, leak, etc. The owners and op-

erators of the genset are solely responsible for operating the genset safely.

GENERAL PRECAUTIONS

• Keep children away from the genset.

• Do not use evaporative starting fluids. They are

highly explosive.

• To prevent accidental or remote starting while

working on the genset, disconnect the negative (−) battery cable at the battery.

• Let the engine cool down before removing the

coolant pressure cap or opening the coolant

drain. Hot coolant under pressure can spray

out and cause severe burns.

• Keep the genset and its compartment clean.

Excess oil and oily rags can catch fire. Dirt and

gear stowed in the compartment can restrict

cooling air.

• Make sure all fasteners are secure and torqued

properly.

• Do not work on the genset when mentally or

physically fatigued or after consuming alcohol

or drugs.

• You must be trained and experienced to make

adjustments while the genset is running—hot,

moving or electrically live parts can cause severe personal injury or death.

• Used engine oil has been identified by some

U. S. state and federal agencies as causing

cancer or reproductive toxicity. Do not ingest,

inhale, or contact used oil or its vapors.

• Ethylene glycol, used as engine antifreeze, is

toxic to humans and animals. Clean up spills

and dispose of used engine coolant in accordance with local environmental regulations.

• Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials such as wood and cloth; Class B fires,

combustible and flammable liquid fuels and

gaseous fuels; Class C fires, live electrical

equipment. (ref. NFPA No. 10)

• Genset installation and operation must comply

with all applicable local, state and federal codes

and regulations.

• Keep guards in place over fans, belts, pulleys,

and other moving parts.

Mobile-8

Page 7

3

Introduction

ABOUT THIS MANUAL

This manual covers the operation and maintenance

of the generator set (genset) models on the front

cover. Study this manual carefully and observe all of

its instructions and precautions. Keep this manual

and the genset Installation Manual with the other vehicle manuals.

Operation, Periodic Maintenance and Troubleshooting provide the instructions necessary for op-

erating the genset and maintaining it at top performance. The owner is responsible for performing

maintenance in accordance with the PERIODIC

MAINTENANCE SCHEDULE (Page 12). This

manual also includes genset specifications, information on how to obtain service and information for

California users.

WARNING

This genset is not a life support system. It can stop without warning. Children, persons with physical or mental limitations, and

pets could suffer personal injury or death. A personal attendant, redundant power or an alarm

system must be used if genset operation is critical.

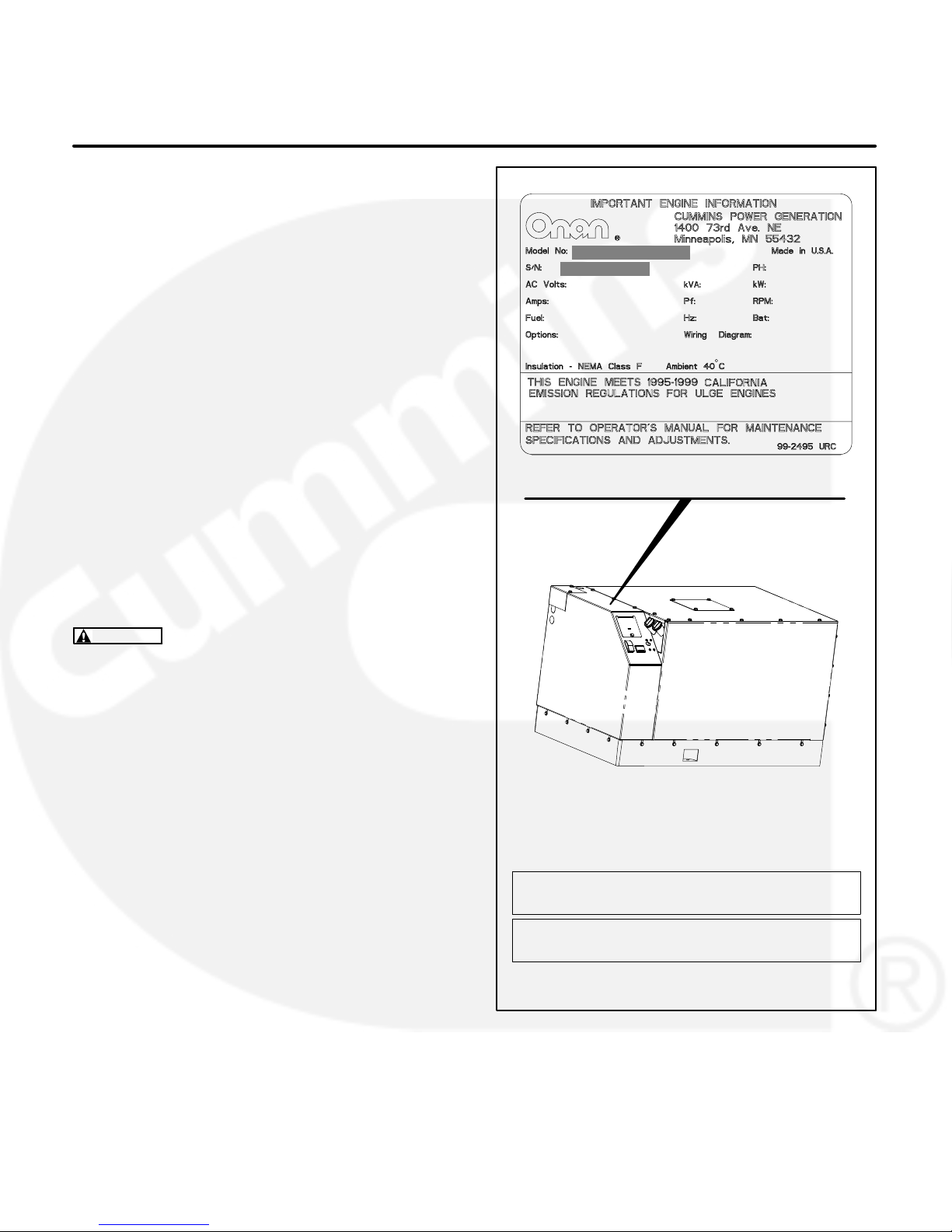

MODEL IDENTIFICATION

When contacting an Onan dealer for parts, service

or product information, be ready to provide the model and serial numbers on the genset nameplate. Figure 1 illustrates the nameplate and its location. The

numbers in the gray boxes are typical model and serial numbers. Every character in these numbers is

significant. (The last character of the model number

is the specification letter, which is important for obtaining the right parts.) Record the model and serial

numbers in the boxes in Figure 1 so that they are

easy to find when you need them.

RECORD NUMBERS HERE

MODEL NUMBER:

SERIAL NUMBER:

SKB719U6D2RA 719 cc

80HDKAK11454J

F990 123456

FIGURE 1. TYPICAL NAMEPLATE

Page 8

4

TYPICAL GENSET

The operator’s console, the components requiring

attention during periodic maintenance and other

features of a typical genset are shown in Figure 2.

See the PERIODIC MAINTENANCE SCHEDULE

(Page 12).

OPERATOR’S

CONSOLE

AC TERMINAL

BOX COVER

LIFTING EYE

ACCESS COVER

ACCESS TO

AIR FILTER

COOLING

AIR INLET

GRILLE

OIL DRAIN

PLUG

ACCESS DOOR FOR

OIL AND FUEL FILTERS

FUEL

CONNECTIONS

BATTERY

CONNECTIONS

COOLANT

DRAIN CAP

WARM AIR DISCHARGE

OPENING

EXHAUST TAILPIPE

FLANGE

(NOT VISIBLE)

FIGURE 2. TYPICAL GENSET

Page 9

5

FUEL RECOMMENDATIONS

WARNING

Diesel fuel is combustible and can

cause severe personal injury or death. Do not

smoke near diesel fuel tanks or equipment.

Keep flames, sparks, pilot lights, electrical arcs,

switches and arc-producing equipment and all

other sources of ignition well away. Keep a type

ABC fire extinguisher in the vehicle.

Use clean, fresh No. 2 diesel fuel (ASTM 2-D) when

the outdoor ambient temperature is above freezing,

and No. 1 diesel fuel (ASTM 1-D) when below freezing. The fuel should have a Cetane number of at

least 45 for reliable starting.

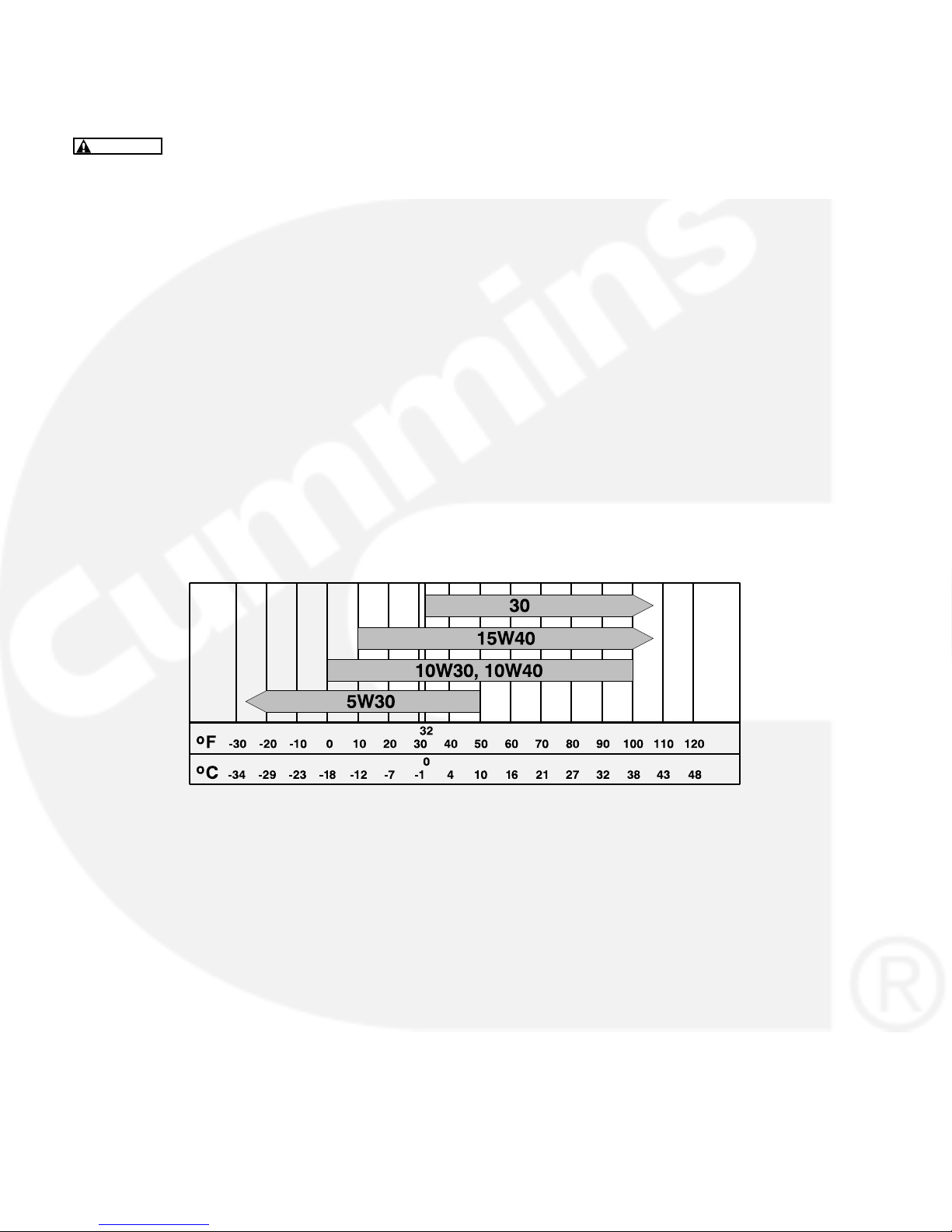

ENGINE OIL RECOMMENDATIONS

Use API (American Petroleum Institute) performance Class CH-4, CG-4 or CF-4 engine oil, which

may be in combination with performance Class SJ,

SH or SG (for example: CH-4/SJ). Also look for the

SAE (Society of Automotive Engineers) viscosity

grade. Referring to Chart 1, choose the viscosity

grade appropriate for the outdoor ambient temperatures expected until the next scheduled oil change.

STARTING BATTERIES

These gensets have a 12 volt, direct current (DC)

starting and control system. See Specifications

(Page 30) for minimum battery requirements (cold

cranking amperes) for genset starting.

Regular, monthly maintenance of batteries may be

required. See MAINTAINING THE BATTERY AND

BATTERY CONNECTIONS (Page 16) and any instructions available from the vehicle manufacturer

or battery manufacturer. Either the vehicle or the

genset will be equipped with a battery charger.

Reliable genset starting and starter service life depend upon adequate battery system capacity and

proper maintenance.

CHART 1. OIL VISCOSITY VS. TEMPERATURE

Anticipated Ambient Temperature

Page 10

6

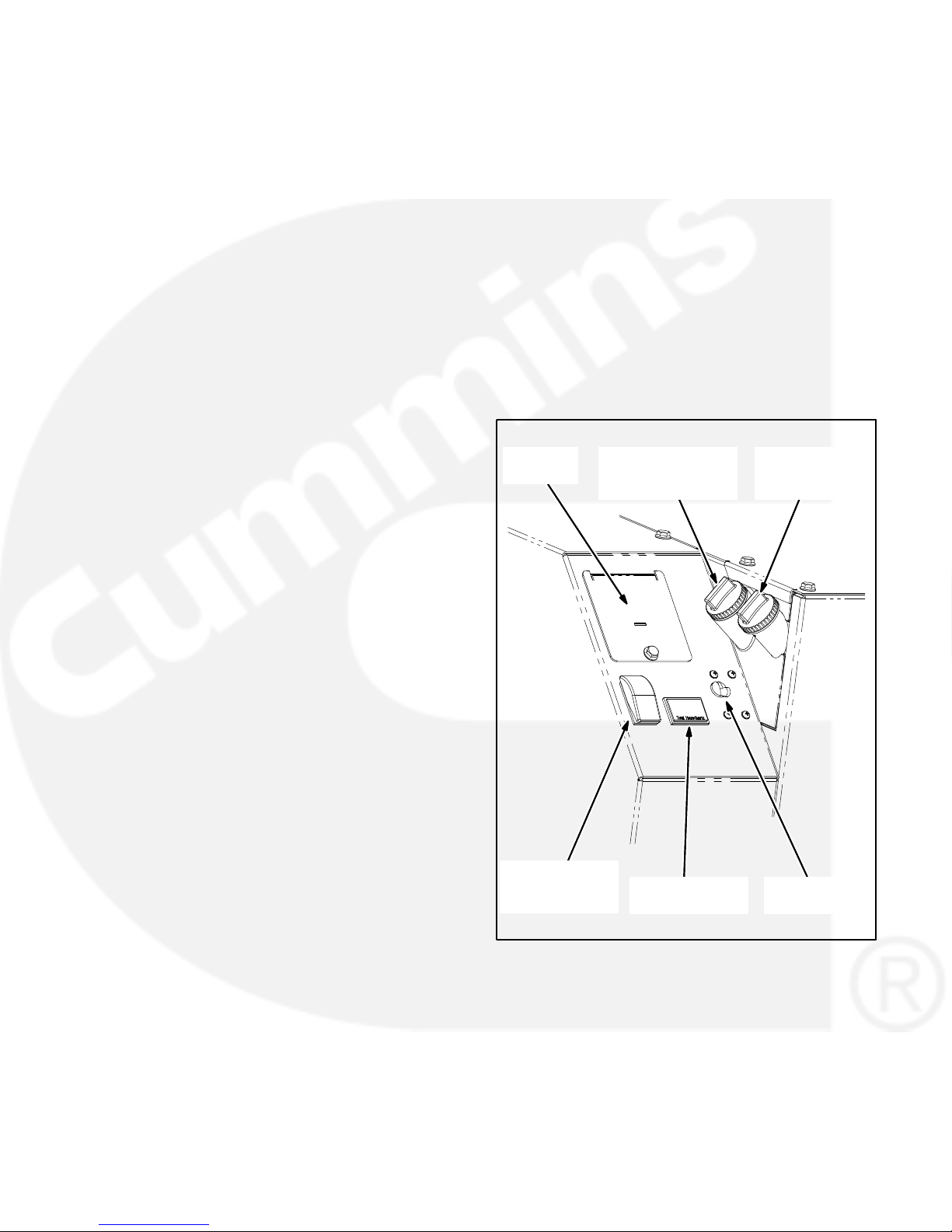

OPERATOR’S CONSOLE

The operator’s console (Figure 3) has the following

features:

Control Switch − This switch is used to start and

stop the genset, prime the engine fuel system and

restore the fault code (blinking status light).

Status Light − This is an LED (light emitting diode)

in the control switch which blinks rapidly during preheat and cranking. (Preheat is the period of time

prior to engine cranking when the glow plugs preheat the combustion chambers. The time is automatically varied by the genset controller on the basis of engine temperature.) After the genset starts

up, this light stays on continuously, indicating that

the genset is running and that the starter has disconnected. Also, if the genset shuts down, this light

blinks in a coded fashion to indicate the nature of the

shutdown (see Troubleshooting, Page 21).

Line Circuit Breaker(s) − The line circuit break-

er(s) protect the AC power leads connected to the

genset.

Engine Oil Fill Cap/Dipstick − The oil dipstick is at-

tached to the fill cap and is marked ADD and FULL.

Coolant Recovery Tank Fill Cap − The recovery

tank provides for coolant expansion. Replenish the

normal loss of coolant by filling here.

Coolant Pressure Cap − The coolant pressure cap

is accessible by removing the access plate on the

control console. It provides for a pressurized engine

cooling system. Fill coolant here when refilling the

system.

Fuses F1, F2 and F3 − These fuses are accessible

by removing the access plate on the control console. They protect the control circuits of the genset.

Hour Meter (Optional)− The hour meter records

the total running time of the genset. It cannot be reset.

REMOTE CONTROL PANEL

The vehicle may be equipped with a remote control

panel having a Control Switch and Preheat/Diag-

nostics Light. In addition, it may have an hour meter and the following engine gauges:

Oil Pressure Gauge − The oil pressure gauge indi-

cates the presence of engine oil pressure.

Water Temperature Gauge − The water tempera-

ture gauge indicates engine coolant temperature.

Voltmeter − The voltmeter indicates battery volt-

age.

ACCESS

PLATE

COOLANT

RECOVERY TANK

FILL CAP (BLUE)

OIL FILL CAP

AND DIP STICK

(YELLOW)

LINE CIRCUIT

BREAKER

HOUR METER

(OPTIONAL)

CONTROL

SWITCH AND

STATUS LIGHT

FIGURE 3. OPERATOR’S CONSOLE

Page 11

7

Operation

WARNING

EXHAUST GAS IS DEADLY!

Exhaust gases contain carbon monoxide, an odorless, colorless gas. Carbon monoxide is poisonous

and can cause unconsciousness and death. Symptoms of carbon monoxide poisoning include:

• Dizziness • Throbbing in Temples • Nausea

• Muscular Twitching • Headache • Vomiting

• Weakness and Sleepiness • Inability to Think Clearly

IF YOU OR ANYONE ELSE EXPERIENCES ANY OF THESE SYMPTOMS, GET OUT INTO THE FRESH

AIR IMMEDIATELY. If symptoms persist, seek medical attention. Shut down the genset and do not operate it until it has been inspected and repaired.

Never sleep in the vehicle with the genset running unless the vehicle is equipped with a working carbon monoxide detector. Primary protection against poisoning due to inhaling carbon monoxide, however, consists of proper installation of the exhaust system and inspections every day (every eight

hours of operation) for visible and audible exhaust system leaks.

CONDUCTING THE PRE-START CHECKS

Before the first start of the day and after every eight

hours of operation, inspect the genset as instructed

under CONDUCTING GENERAL INSPECTIONS

(Page 13). Keep a log of maintenance and the hours

run and perform any maintenance that may be due.

See Returning the Genset to Service (Page 11) if

the vehicle has been in storage.

Before each start:

1. Make sure all vehicle CO detectors are working.

2. Check for signs of fuel and exhaust leaks and

for damage to the exhaust system.

3. Turn off the air conditioner and other large appliances.

PRIMING THE FUEL SYSTEM

The fuel system should be primed after replacing

the fuel filter or running the genset out of fuel. To

prime the fuel system hold the control switch down

in its Stop position for at least 1 minute.

STARTING THE GENSET

Start the genset from the genset control panel or remote control panel inside the vehicle.

1. Push and hold the switch at START until the

genset starts. The status indicator light on the

switch flashes during preheat and cranking. It

will come on solid when the starter disconnects,

indicating that the genset is running. (Depending on how cold it is, preheat can take up to 15

seconds, extending the time that the light

blinks.)

CAUTION

Excessive cranking can overheat and damage the starter motor. Do not

crank for more than 20 seconds at a time.

Wait at least 2 minutes before trying again.

2. See Troubleshooting (Page 21) if the genset

does not start after three tries.

3. For top performance and engine life, especially

in colder weather, let the engine warm up for

two minutes before connecting appliances.

4. Monitor the engine gauges if the remote panel

is so equipped. Normal readings during operation are as follows:

Oil Pressure: Approximate center of scale

Temperature: 160

°-220° F (71°-104° C)

DC Voltage: 14-15 volts.

5. Check for fuel, exhaust and coolant leaks. Stop

the genset immediately if there is a fuel, exhaust or coolant leak and have it repaired.

Page 12

8

STOPPING THE GENSET

Turn off the air conditioner and other large appliances and let the genset run for two minutes to

cool down. Then press the switch to STOP to stop

the genset.

RESTARTING THE GENSET

See Troubleshooting (Page 21) if the genset shuts

down abnormally.

LOADING THE GENSET

The genset can power AC motors, air conditioners,

AC/DC converters, battery chargers and other appliances. How much appliance load* can be powered depends upon the genset power rating. The

genset will shut down or its circuit breakers will trip if

the sum of the loads exceeds genset power. (If the

genset shuts down, the status light will probably display Fault Code No. 11, 13, 22 or 38. See Trouble-

shooting, Page 21.)

To avoid overloading the genset and causing shutdowns, compare the sum of the loads of the appliances that are likely to be used at the same time to

the power rating of the genset. Use Table 1 or the

ratings on the appliances themselves (if so marked)

to obtain the individual appliance loads. It may be

necessary to run fewer appliances at the same

time—the sum of the loads must not be greater

than genset rating.

The genset may shut down due to overload when a

large motor or air conditioner is started or cycles off

and then on again, even though the sum of the loads

is less than genset rating. The reason for this is that

a motor’s startup load is much larger than its running

load. It may be necessary to run fewer ap-

pliances when large motors and air conditioners are cycling on and off.

Maximum power decreases as altitude increases

because air density decreases. For every 1000-foot

(305 m) increase in elevation you can expect power

to decrease approximately 3 percent. Table 2

shows the results of typical calculations. It may be

necessary to run fewer appliances at higher altitudes.

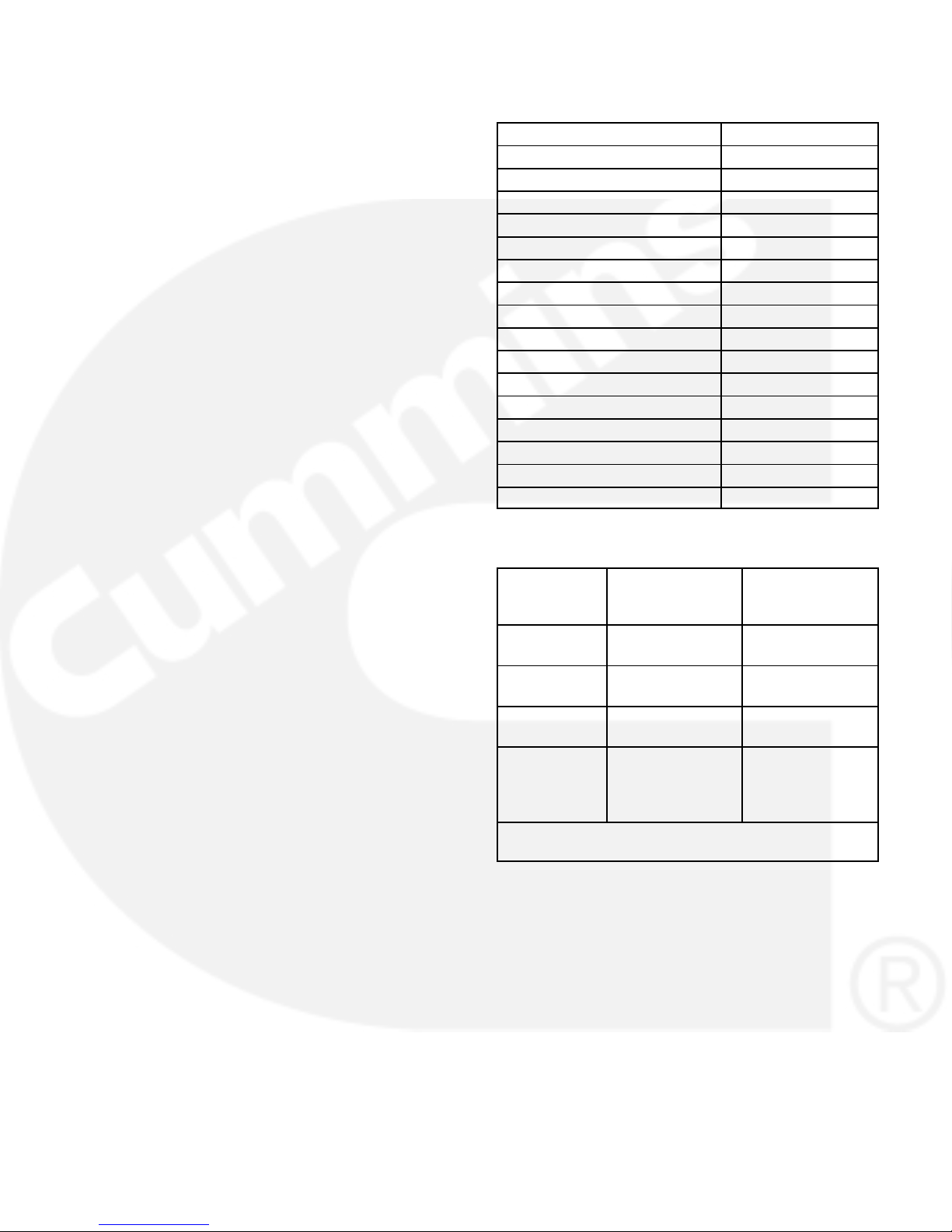

TABLE 1. TYPICAL APPLIANCE LOADS

Appliance Load (watts)

Air Conditioner 1400-2000

Battery Charger Up to 2000

DC Converter 300-1200

Refrigerator 600-1000

Microwave Oven 1000-1500

Electric Frying Pan or Wok 1000-1500

Electric Stove Element 350-1000

Electric Water Heater 1000-1500

Electric Iron 500-1200

Electric Hair Dryer 800-1500

Coffee Percolator 550-750

Television 200-600

Radio 50-200

Electric Drill 250-750

Electric Broom 200-500

Electric Blanket 50-200

TABLE 2. POWER VS. ALTITUDE

Elevation

above Mean

Sea Level

Max Genset

Power*

Max Genset

Power*

up to 500 ft

(152 m)

7500 watts

(rated)

8000 watts

(rated)

2500 ft

(762 m)

7050 watts 7520 watts

5500 ft

(1676 m)

6375watts 6800watts

above

5500 ft

(1676 m)

6375watts minus

225 watts ev-

ery1000 ft

(305 m)

6800watts minus

240 watts ev-

ery1000 ft

(305 m)

* This table does not take into account the effect cir-

cuit breakers may have in limiting maximum power.

Commercial Genset Applications

Maximum genset power (nameplate rating) is

7500 watts in an ambient of 85° F (29° C), but only

6000 watts in an ambient of 120° F (50° C)—the

maximum operating temperature. Also, continuous

operation at up to 80 percent of maximum power

(6000 watts) is acceptable.

* Appliance load and genset power are measured in terms of watts (W) or kilowatts (kW), where 1 kilowatt (kW) = 1000 watts (W).

Page 13

9

RESETTING CIRCUIT BREAKERS

If a circuit breaker in the main power distribution

panel of the vehicle or on the genset (Figure 4) trips,

either a circuit shorted or too many appliances were

running. Note that the genset will continue to run after a circuit breaker trips.

If a circuit breaker trips, disconnect or turn off as

many loads as possible and reset the circuit breaker. (Push the circuit breaker to OFF to reset it and

then to ON to reconnect the circuit.) If the circuit

breaker trips right away, either the electrical distribution system has a short or the circuit breaker is

faulty. Call a qualified electrician.

If the circuit breaker does not trip, reconnect the appliances, one by one, up to a total load that does not

overload the genset or cause the circuit breaker to

trip. If a circuit breaker trips right away when an appliance is connected, the appliance probably has a

short.

Electrical appliances and tools must be used and

maintained properly and be properly grounded to

cause the line circuit breakers to trip when short circuits occur.

WARNING

Short circuits in electrical appliances and tools can cause fire and electrical

shock leading to severe personal injury or

death. Read and follow the equipment and tool

manufacturer’s instructions and warnings regarding use, maintenance and proper grounding.

CONNECTING TO UTILITY POWER

When the vehicle has provisions for connecting to

utility power, such as a cord for plugging into a power outlet receptacle, it must also have an approved

device to keep the genset and utility from being interconnected. See the genset Installation Manual

for more information.

WARNING

Interconnecting the genset and the

public utility (or any other power source) can

lead to the electrocution of personnel working

on the utility lines, damage to equipment and

fire. An approved switching device must be

used to prevent interconnections.

LINE CIRCUIT

BREAKER

FIGURE 4. LINE CIRCUIT BREAKER

Page 14

10

OPERATING IN COLD WEATHER

Make sure the engine oil viscosity is appropriate for

the cold weather temperatures. See ENGINE OIL

RECOMMENDATIONS (Page 5). Be sure to

change the oil if a sudden drop in temperature occurs.

OPERATING IN HOT WEATHER

Pay particular attention to the following items when

operating the genset in hot weather:

1. Make sure nothing blocks airflow to and from

the genset.

2. Make sure engine oil viscosity is appropriate for

the ambient temperatures. See ENGINE OIL

RECOMMENDATIONS (Page 5).

3. Keep the genset clean.

4. Perform maintenance due. See PERIODIC

MAINTENANCE SCHEDULE (Page 12).

OPERATING AT HIGH ALTITUDE

For the effect of altitude on maximum power, see

LOADING THE GENSET (Page 8).

OPERATING IN DUSTY ENVIRONMENTS

Pay particular attention to the following items when

operating the genset in dusty environments:

1. Do not let dirt and debris accumulate inside the

genset compartment. Keep the genset clean.

2. Perform air cleaner maintenance more often.

See PERIODIC MAINTENANCE SCHEDULE

(Page 12).

3. Change engine oil more often. See PERIODIC

MAINTENANCE SCHEDULE (Page 12).

4. Keep containers of engine oil that have been

opened tightly closed to keep out dust.

BREAKING IN A NEW ENGINE

Proper engine break-in on a new genset or on one

with a rebuilt engine is essential for top engine performance and acceptable oil consumption. Run the

genset at approximately 1/2 rated power for the first

2 hours and then at 3/4 rated power for 2 more

hours. See LOADING THE GENSET (Page 8).

Proper engine oil and oil level are especially critical

during break-in because of the higher engine temperatures that can be expected. Change the oil if not

appropriate for the ambient temperatures during

break-in. See ENGINE OIL RECOMMENDATIONS

(Page 5). Check oil level twice a day or every

4 hours during the first 24 hours of operation and

change the oil and oil filter after the first 50 hours of

operation.

EXERCISING THE GENSET

Exercise the genset at least 2 hours each month if

use is infrequent. Run the genset at approximately

1/2 rated power. See LOADING THE GENSET

(Page 8). A single two hour exercise period is better than several shorter periods.

Exercising a genset drives off moisture, re-lubricates the engine, replaces stale fuel and removes

oxides from electrical contacts. The result is better

starting, more reliable operation and longer engine

life.

Page 15

11

STORING THE GENSET

Proper storage is essential for preserving top genset performance and reliability when the genset

cannot be exercised regularly and will be idle for

more than 120 days.

Storing the Genset

1. Push the genset line circuit breaker OFF

(Page 9).

2. Change the engine oil and attach a tag indicating oil viscosity. See ENGINE OIL RECOMMENDATIONS (Page 5).

3. Disconnect the battery cables (negative [−]

cable first) from the starting battery and store

the battery according to the battery manufacturer’s recommendations. See MAINTAINING

THE BATTERY AND BATTERY CONNECTIONS (Page 16).

4. Plug the exhaust tail pipe to keep out dirt, moisture, bugs, etc.

5. Close the fuel supply valve (if so equipped).

Returning the Genset to Service

1. Check the oil tag on the genset and change the

oil if the viscosity indicated is not appropriate for

the temperatures expected. See ENGINE OIL

RECOMMENDATIONS (Page 5).

2. Reconnect the starting battery (negative [−]

cable last). See MAINTAINING THE BATTERY

AND BATTERY CONNECTIONS (Page 16).

3. Remove the plug from the exhaust tailpipe.

4. Change the air filter element if it is dirty

(Page 16).

5. Open the fuel supply valve (if so equipped).

6. Inspect the genset. See CONDUCTING GENERAL INSPECTIONS (Page 13).

7. Push the genset line circuit breaker ON

(Page 9) when the genset is ready to power

appliances.

Page 16

12

Periodic Maintenance

Periodic maintenance is essential for top performance and long genset life. Use Table 3 as a guide

for normal periodic maintenance. In hot and dusty

environments some maintenance procedures

should be performed more frequently, as indicated

by the footnotes in the table. Keeping a log of maintenance performed and hours run (Page 34) will

help you keep genset maintenance regular and provide a basis for supporting warranty claims.

Maintenance, replacement or repair of emission

control devices and systems may be performed by

any engine repair establishment or individual. However, warranty work must be completed by an authorized Onan dealer.

TABLE 3. PERIODIC MAINTENANCE SCHEDULE

MAINTENANCE PROCEDURE

MAINTENANCE FREQUENCY

Every

Day

After First

50 Hours

Every

Month

Every

150

Hours

Every

500

Hours

Every

1000

Hours

P

a

g

e

General Inspection X 13

Check Engine Oil Level X 14

Check Engine Coolant Level X 19

Clean and Check Battery X

3

16

Change Engine Oil and Filter X

1

X

2, 3, 4

15

Clean Spark Arrestor X

4

17

Replace Engine Air Filter X

2, 4

16

Replace Fuel Filter X 18

Check Coolant Anti-freeze Protection X 19

Flush Coolant System X

5

19

Replace Coolant Pressure Cap X

5

19

Replace Engine V-belt X

6,7

−

Clean Crankcase Breather X

6,7

−

Replace Coolant Hoses and Thermostat X

6, 7

−

1 − As a part of engine break-in, change the engine oil after the first 50 hours of operation.

2 − Perform more often when operating in dusty conditions.

3 − Perform more often when operating in hot weather.

4 − Perform at least once a year.

5 − Perform at least once every two years.

6 − Perform at least once every five years.

7 − Must be performed by a qualified mechanic (authorized Onan dealer).

Page 17

13

CONDUCTING GENERAL INSPECTIONS

Inspect the genset before the first start of the day

and after every eight hours of operation.

Oil Level

Check engine oil level (Page 14).

Engine Coolant System

CAUTION

Operating the genset when coolant

level is low can cause serious engine damage.

Check the coolant level and look for coolant leaks

around the bottom of the genset and on the ground

below. Minor leaks that can be replenished by daily

additions of coolant to the recovery tank should be

repaired by a qualified service technician as soon as

possible. Larger leaks are cause for shutting down

the genset until it can be repaired.

Exhaust System

WARNING

EXHAUST GAS IS DEADLY! Do not

operate the genset if there is an exhaust leak or

any danger of exhaust gases entering or being

drawn into the vehicle.

Look and listen for exhaust system leaks while the

genset is running. Shut down the genset if a leak is

found and have it repaired before operating the genset again.

Look for openings or holes between the genset

compartment and vehicle cab or living space if the

genset engine sounds louder than usual. Have all

such openings or holes closed off or sealed to prevent exhaust gases from entering the vehicle.

Replace dented, bent or severely rusted sections of

the tailpipe and make sure the tailpipe extends at

least 1 inch (25.4 mm) beyond the perimeter of the

vehicle.

WARNING

Do not park the vehicle in high grass

or brush. Contact with the exhaust system can

cause a fire.

Park the vehicle so that the genset exhaust gases

can disperse away from the vehicle. Barriers such

as walls, snow banks, high grass and brush and other vehicles can cause exhaust gases to accumulate

in and around the vehicle.

Do not operate power ventilators or exhaust fans

while the vehicle is standing with the genset running. The ventilator or fan can draw exhaust gases

into the vehicle.

Fuel System

Check for leaks at hose, tube and pipe fittings in the

fuel supply system while the genset is running and

while it is stopped. Check flexible fuel hose sections

for cuts, cracks, and abrasions. Make sure the fuel

line is not rubbing against other parts. Replace worn

or damaged fuel line parts before leaks occur.

WARNING

Diesel fuel leaks can lead to fire. Do

not operate the genset if operation causes fuel

to leak.

Battery Connections

Check the battery terminals for clean, tight connections. Loose or corroded connections have high

electrical resistance which makes starting harder.

See MAINTAINING THE BATTERY AND BATTERY

CONNECTIONS (Page 16).

WARNING

Arcing at battery terminals or in

light switches or other equipment, and flames or

sparks, can ignite battery gas causing severe

personal injury.

Ventilate battery area before working on or near

battery—Wear safety glasses—Do not smoke—

Switch trouble light ON or OFF away from battery—Stop genset and disconnect charger before disconnecting battery cables—Disconnect

negative (−) cable first and reconnect last.

Mechanical

Look for mechanical damage. Start the genset and

look and listen for any unusual noises and vibrations.

Check the genset mounting bolts to make sure they

are secure.

Check to see that the genset air inlet and outlet

openings are not clogged with debris or blocked.

Check the engine gauges from time to time while the

genset is running (if so equipped).

Page 18

14

CHECKING ENGINE OIL LEVEL

WARNING

State and federal agencies have determined that contact with used engine oil can

cause cancer or reproductive toxicity. Try to

avoid skin contact and breathing of vapors. Use

rubber gloves and wash exposed skin.

Park the vehicle on level ground and shut off the

genset before checking the engine oil level.

1. Unscrew the oil fill cap, pull out the dipstick and

wipe off the oil (Figure 5). Reinsert the dipstick,

screw the cap back on, remove the dipstick

again and check the oil level on the dip stick.

2. Add or drain oil as necessary. See ENGINE OIL

RECOMMENDATIONS (Page 5). Keep the

oil level between the FULL and ADD marks.

CAUTION

Too much oil can cause high oil

consumption. Too little oil can cause severe

engine damage. Keep the oil level between

the FULL and ADD marks.

3. Reinsert the dipstick and screw the oil fill cap

back on securely.

FIGURE 5. CHECKING ENGINE OIL LEVEL

Page 19

15

CHANGING ENGINE OIL AND OIL FILTER

WARNING

State and federal agencies have determined that contact with used engine oil can

cause cancer or reproductive toxicity. Avoid

skin contact and breathing of vapors. Use rubber gloves and wash exposed skin.

Refer to Table 3 for scheduled engine oil change.

Change oil more often in hot and dusty environments.

1. Run the engine until warm, stop it and remove

the oil fill cap and dipstick (Figure 5).

2. Place a pan underneath the genset and unscrew the oil drain plug (Figure 6). Let all oil

drain from the engine.

3. Reinstall the oil drain plug and tighten it securely to prevent oil leakage.

4. Squeeze the access door latches together and

let the door swing down (Figure 6).

5. Spin off the oil filter canister. Thoroughly wipe

off the filter mounting surface and remove the

old gasket if it does not come off with the filter

canister.

6. Make sure the new gasket is in place on the

new filter canister and apply a thin film of oil to

the gasket. (The replacement filter canister has

a larger diameter than the original filter cannister, but will fit.)

7. Spin on the new filter canister by hand until the

gasket just touches the mounting pad and then

turn it an additional 1/2 to 3/4 turn. Do not overtighten. Close the access door, making sure it

latches securely.

8. Refill with 3 quarts (2.6 l) of oil. See ENGINE

OIL RECOMMENDATIONS (Page 5). Check

the oil level and add or drain oil as necessary.

CAUTION

Too much oil can cause high oil

consumption. Too little oil can cause severe

engine damage. Keep the oil level between

the FULL and ADD marks.

9. Reinsert the dipstick and screw the oil fill cap

back on securely.

10. Dispose of the used oil and oil filter in accordance with local environmental regulations.

OIL DRAIN PLUG

OIL FILTERACCESS DOOR

FIGURE 6. OIL DRAIN PLUG AND OIL FILTER

Page 20

16

MAINTAINING THE BATTERY AND

BATTERY CONNECTIONS

WARNING

Arcing at battery terminals or in

light switches or other equipment, and flames or

sparks, can ignite battery gas causing severe

personal injury.

Ventilate battery area before working on or near

battery—Wear safety glasses—Do not smoke—

Switch trouble light ON or OFF away from battery—Stop genset and disconnect charger before disconnecting battery cables—Disconnect

negative (−) cable first and reconnect last.

Refer to Table 3 for scheduled battery maintenance,

and follow the battery manufacturer’s instructions.

Have the battery charging system serviced if DC

system voltage is consistently low or high. Always:

1. Keep the battery case and terminals clean and

dry and the terminals tight.

2. Remove battery cables with a battery terminal

puller.

3. Make sure which terminal is positive (+) and

which is negative (−) before making battery

connections, always removing the negative (−)

cable first and reconnecting it last to reduce

arcing.

REPLACING THE AIR FILTER ELEMENT

Refer to Table 3 for scheduled air filter element replacement. In dusty environments the filter element

should be inspected and changed more frequently.

To change the filter element (Figure 7), remove the

outer and inner cover and reassemble with a new air

filter element. Turn the inner cover wingnut three to

four clicks past seating. Make sure the outer cover is

seated before tightening its wingnut. Check for

noise when the genset is running, and retighten

if necessary.

OUTER COVER INNER COVER FILTER ELEMENT SPACER SEAL HOUSING

FIGURE 7. REPLACING THE AIR FILTER ELEMENT

Page 21

17

CLEANING THE SPARK ARRESTOR

Refer to Table 3 for scheduled cleaning of the spark

arrestor muffler (which meets U.S. Forest Service

requirements). Cleaning is required for maximum

genset performance.

WARNING

A hot muffler can cause severe

burns. Let the muffler cool down before removing or installing the cleanout plug.

The muffler is mounted inside the genset housing.

The cleanout plug is located on the side of the muf-

fler, accessible through the air outlet opening in the

bottom of the genset. Clean out the spark arrestor

muffler as follows:

1. Remove the cleanout plug from the muffler

(Figure 8).

2. Restart the genset and load it nearly to full power. See LOADING THE GENSET (Page 8).

Let the genset run for about five minutes to expel the soot in the muffler.

3. Stop the genset, allow the muffler to cool down

and then reinstall the plug.

CLEANOUT PLUG

FIGURE 8. SPARK ARRESTOR CLEANOUT PLUG

Page 22

18

REPLACING THE FUEL FILTER

Refer to Table 3 for scheduled replacement of the

fuel filter (Figure 9). A dirty fuel filter may be the

cause if the engine fails to start. The fuel filter is accessible through the maintenance access door in

the skid-base. Squeeze the latches together to

open the door.

CAUTION

Wipe dirt off the fuel hose connections at the fuel filter before disconnecting the

hoses so as to keep dirt out of the fuel system.

WARNING

Diesel fuel is combustible and can

cause severe personal injury or death. Do not

smoke. Keep flames, sparks, pilot lights, electrical arcs, switches and arc-producing equipment and all other sources of ignition well away.

Keep a type ABC fire extinguisher handy.

Removing the Fuel Filter: To remove the filter, dis-

connect the two fittings at the filter and remove the

mounting nut. Apply a wrench on the filter fitting as

well as on the flare nut so as not to stress the fitting.

Flare nut wrenches should be used on the flare nuts

so as not to round the corners on the nuts. Dispose

of the fuel filter according to local regulations.

Installing the Fuel Filter: Rotate the filter half a

turn around its mounting stud if the fittings interfere

with the bracket. It only fits properly one way.

Connect the fuel fittings before tightening the filter

mounting nut. Take care not to crossthread the fuel

fittings. Thread them in by hand and tighten one flat

past seating.

Close the access door and prime the fuel system by

holding the control switch down in its Stop position

for at least 1 minute. Priming is necessary to displace the air in the new filter with fuel.

FILTER

MOUNTING

NUT

TUBING FROM

FUEL PUMP

FUEL HOSE

TO ENGINE

FUEL

FILTER

FIGURE 9. FUEL FILTER

Page 23

19

CHANGING COOLANT

Refer to Table 3 for scheduled maintenance. The

engine cooling system is filled with a 50/50 mixture

of ethylene glycol anti-freeze and water when the

genset leaves the factory, which is suitable for temperatures down to -34

° F (-37° C).

Replace the coolant every two years. Use ethylene

or propylene glycol anti-freeze solution that contains a rust and corrosion inhibitor. The anti-freeze

should not contain a stop-leak additive.

The water used for engine coolant should be clean,

low in minerals, and free of corrosive chemicals.

Use distilled water if available. The cooling system

has a 4.2 quart (4 l) capacity.

Pressure Cap

Replace the pressure cap (Figure 10) every two

years because its seals can deteriorate and begin to

leak. Proper cooling system pressure is essential

for optimal engine cooling and minimal coolant loss.

Draining the Cooling System

WARNING

Hot coolant spray can cause severe

burns. Let the engine cool before releasing the

pressure cap or removing the drain cap.

Allow the engine to cool before removing the pressure cap. Then relieve any remaining pressure by

turning the pressure cap slowly, without pushing

down on it, until it catches. When the pressure has

been relieved, remove the pressure cap by pushing

down and turning it until it can be withdrawn. Then

get a suitable container and drain the coolant by removing the system drain cap (Figure 10).

WARNING

Ethylene glycol antifreeze is considered toxic. Dispose of it according to local

regulations for hazardous substances.

It is recommended that the system be cleaned and

flushed before refilling. Radiator cleaning chemicals

are available at local auto parts stores. Follow the

instructions for cleaning and flushing that come with

the cleaning solution.

Refilling the Cooling System

Fill the recovery tank with coolant mixture to the

COLD mark.

Secure the system drain cap. Fill the cooling system

with coolant mixture through the pressure cap/fill

opening. Pull the hose connected to the pressure

cap assembly out as far as it will go. When coolant

fills up to the fill opening, start and operate the genset for a few minutes and shut it down. (It is recommended that the air conditioners or other large loads

be turned on so that the genset will operate under

load, causing the engine to run faster and expel

trapped air.) Add more coolant if necessary and secure the pressure cap.

Coolant Level Check

Check coolant level in the recovery tank (Figure 10)

before the first startup of each day and fill to the

COLD mark if necessary.

Page 24

20

PRESSURE CAP AND

SYSTEM FILL OPENING

COOLING SYSTEM

DRAIN CAP

COOLANT RECOVERY

TANK FILL CAP (BLUE)

FIGURE 10. ENGINE COOLING SYSTEM FILL AND DRAIN CAPS

Page 25

21

Troubleshooting

WARNING

Hot engine parts can cause severe

burns. Always allow the engine time to cool before performing any maintenance or service.

TABLE 4. TROUBLESHOOTING lists the Fault

Codes in numerical order along with step-by-step

instructions for corrective action. If you fail to resolve the problem after taking the corrective actions

suggested, contact an authorized Onan dealer. See

How to Obtain Service (Page 33).

First note the following:

• Maintaining engine oil level, keeping battery

connections clean and tight, watching the fuel

gauge, not overloading the genset, etc. will

prevent most shutdowns.

• When the genset and vehicle engine share a

common fuel tank the fuel dip tubes are usually arranged so that the genset will run out of

fuel first. Marking the genset empty point on

the fuel gauge will make it easier to tell when

to stop the genset before running it out of fuel.

First-Level Fault Codes: The genset controller

provides extensive diagnostics by causing the status indicator light on the Control Switch to blink in a

coded fashion. Following a fault shutdown, the indicator light will repeatedly blink 1, 2 or 3 blinks at a

time.

• One blink indicates shut down due to high tem-

perature

• Two blinks indicates shutdown due to a loss of

engine oil pressure

• Three blinks indicates shutdown due to some

other abnormal condition.

Second-Level Fault Codes: For a 1-blink or 3-blink

first-level fault code, one touch to Stop brings up a

second-level fault code. This code consists of 1, 2, 3

or 4 blinks, a brief pause, and then 1 to 9 blinks. The

first set of blinks represents the tens digit and the

second set of blinks the units digit of the fault code

number. For example, Fault Code No. 23 would appear as:

blink-blink—pause—blink-blink-blink—...

NOTE: Fault Code Nos. 1, 2 and 3 are first-level faults.

Avoid interpreting them as second-level Fault Codes

11, 22 and 33. The pauses between repetitions of the

fault code are longer than the pauses between the

tens and units digits of the the code. For example,

Fault Code 33 would appear as:

blink-blink-blink—pause—blink-blink-blink

—longer pause—

blink-blink-blink—pause—blink-blink-blink—...

Restoring Fault Code Blinking: The fault code

stops blinking after five minutes. Press Stop three

times within five seconds to restore blinking. Note

that the last fault logged will blink, even after the

condition that caused the shutdown has been corrected.

Page 26

22

TABLE 4. TROUBLESHOOTING

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

GENSET WON’T STOP RUNNING—STATUS INDICATOR LIGHT ON

(Faulty Stop Switch or grounded wiring)

Removing genset panels or disconnecting fuel lines to stop a genset that won’t stop

can lead to severe personal injury or death from electrocution, contact with moving parts or fire.

Try the genset Stop Switch if the remote Stop Switch does not work, and vice versa. Otherwise, let

the genset run out of fuel.

WARNING

GENSET WON’T STOP RUNNING—STATUS INDICATOR LIGHT OFF

(Binding governor mechanism, misadjusted speed stop)

Removing genset panels or disconnecting fuel lines to stop a genset that won’t stop

can lead to severe personal injury or death from electrocution, contact with moving parts or fire.

Let the genset run out of fuel.

WARNING

STATUS INDICATOR LIGHT STAYS ON

(Reversed battery connections)

Corrective Action: Reconnect the battery correctly (Page 16).

ENGINE CRANKS WHEN BATTERY CONNECTED

(Faulty Start Switch or grounded wiring)

Corrective Action: See an authorized Onan dealer.

ENGINE WON’T CRANK—FUEL PUMP WON’T STOP

(Faulty Stop Switch or grounded wiring)

Corrective Action: See an authorized Onan dealer.

STATUS INDICATOR LIGHT DEAD

(Faulty connections, no battery voltage)

Corrective Action:

1. Try the genset Start Switch if the remote Start Switch does not work, and vice versa.

2. Replace Fuse F1 (B+) if blown (Page 6).

3. Clean and tighten the positive (+) and negative (−) battery cable connections at the battery, vehicle

frame and genset (Page 16).

4. Recharge or replace the battery. Refer to the battery manufacturer’s recommendations.

Page 27

23

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

STARTING BATTERIES RUN DOWN

(Marginal battery, battery connections, or charging system; or parasitic loads)

Corrective Action:

1. Clean and tighten the positive (+) and negative (−) battery cable connections at the battery, vehicle

frame and genset (Page 16).

2. Recharge or replace the battery. Refer to the battery manufacturer’s recommendations.

ENGINE CRANKS BUT DOES NOT START

(Fuel delivery, glow plugs or engine are marginal)

Corrective Action:

1. Check fuel level. (Note: The genset fuel pickup is probably higher than the vehicle engine pickup.)

2. Prime the engine fuel system by holding the control switch down in its Stop position for at least 1 minute.

3. Check the engine air filter and remove any blockage (Page 16).

4. Replace Fuse F3 (glow plugs) if blown (Page 6).

STARTER ENGAGES-DISENGAGES

(Cranking voltage dips below 6 volts—low battery charge, poor connections, long cables)

Corrective Action:

1. Have the vehicle propulsion engine running while trying to start the genset—the battery charging

alternator may be able to maintain starting voltage high enough to get the genset started.

2. Clean and tighten the positive (+) and negative (−) battery cable connections at the battery, vehicle

frame and genset (Page 16).

3. Recharge or replace the battery. Refer to the battery manufacturer’s recommendations.

4. Increase battery cable size or run parallel cables.

NO POWER—GENSET RUNNING, RUN LIGHT ON

(Line circuit breaker OFF or tripped or faulty wiring)

Corrective Action: Reset or turn “On” the line circuit breaker on the genset operator’s console.

GENSET HUNTS UNDER FULL LOAD

(Fuel delivery marginal, governor misadjusted)

Corrective Action: Prime the engine fuel system by holding the control switch down in its Stop position for at least 1 minute.

Page 28

24

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

HIGH TEMPERATURE—FAULT CODE NO. 1

(Engine coolant or inverter heat sink temperature exceeded design limit)

Corrective Action: Check the second-level fault code by touching Stop. The second-level fault will be

either No. 33 or No. 34.

LOW OIL PRESSURE—FAULT CODE NO. 2

(Low oil pressure cutoff switch did not open)

Corrective Action:

1. Check engine oil level and add oil as necessary (Page 14).

2. Drain excess oil (above dipstick Full mark).

SERVICE CHECK FAULT—CODE NO. 3

(A second-level fault occurred)

Corrective Action: Check the second-level fault code by touching Stop. The second-level fault will be

one of the following in this table.

OVERLOAD—CODE NO. 8

(Models HDKAH & HDKAV only: Load exceeded110 percent of genset rating for 2 minutes)

Corrective Action: Reduce load and restart

OVERCURRENT FAULT—CODE NO. 11

(AC output short)

Corrective Action:

1. Turn off the genset line circuit breaker. If the genset no longer shuts down, the genset is probably

okay—check for and repair a short circuit in the vehicle appliances, wiring or shorted battery charger

transformer.

2. Check whether the vehicle engine and genset share the same starting battery. If so, and this fault

occurs when cranking the vehicle engine, low battery voltage may be causing this shutdown. Increase battery capacity or install a separate battery and battery charging system for the genset.

Page 29

25

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

INVERTER OVERVOLTAGE FAULT—CODE NO. 12

(Controller not able to regulate to rated voltage)

Corrective Action: Check whether the vehicle engine and genset share the same starting battery. If

so, and this fault occurs when cranking the vehicle engine, low battery voltage may be causing this

shutdown. Increase battery capacity or install a separate battery and battery charging system for the

genset.

INVERTER UNDERVOLTAGE FAULT—CODE NO. 13

(Controller not able to regulate to rated voltage)

Corrective Action: Check whether the vehicle engine and genset share the same starting battery. If

so, and this fault occurs when cranking the vehicle engine, low battery voltage may be causing this

shutdown. Increase battery capacity or install a separate battery and battery charging system for the

genset.

INVERTER OVERFREQUENCY FAULT—CODE NO. 14

(Controller not able to regulate to rated frequency)

Corrective Action: Reduce the number of connected appliances, especially when air conditioners and

battery chargers are running.

INVERTER UNDERFREQUENCY FAULT—CODE NO. 15

(Controller not able to regulate to rated frequency)

Corrective Action:

1. Reduce the number of connected appliances, especially when air conditioners and battery chargers

are running.

2. Have air conditioners and other appliances checked for proper operation. (A locked compressor rotor can cause very low power factor.)

GOVERNOR ACTUATOR FAULT—CODE NO. 19

(Controller sensed open or short circuit)

Corrective Action: See an authorized Onan dealer.

GOVERNOR ACTUATOR OVERLOAD FAULT—CODE NO. 22

(Duration of operation at or near full-duty cycle beyond design limit)

Corrective Action: Reduce the number of connected appliances, especially when air conditioners and

battery chargers are running.

Page 30

26

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

LOW OIL PRESSURE CUTOFF SWITCH FAULT—CODE NO. 23

(Controller sensed switch still open during start—not a running fault)

Corrective Action: See an authorized Onan dealer.

COOLANT TEMPERATURE SENDER FAULT—CODE NO. 24

(Controller did not sense temperature change during first 5 minutes of operation)

Corrective Action: See an authorized Onan dealer.

ENGINE ABOVE SPEED TARGET FAULT—CODE NO. 25

(Governor unable to regulate to target speed)

Corrective Action: See an authorized Onan dealer.

ENGINE BELOW SPEED TARGET FAULT—CODE NO. 26

(Governor unable to regulate to target speed)

Corrective Action:

1. Reduce the number of connected appliances, especially when air conditioners and battery chargers

are running.

2. Prime the engine fuel system by holding the control switch down in its Stop position for at least 1 minute.

PMA SENSE LOST FAULT—CODE NO. 27

(Controller unable to sense PMA frequency)

Corrective Action: See an authorized Onan dealer.

DC SENSE LOST FAULT—CODE NO. 28

(Controller unable to sense DC bus voltage)

Corrective Action: Open the circuit breaker. If the fault does not persist, check for and disconnect excessive loads from the genset before starting.

Page 31

27

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

HIGH BATTERY VOLTAGE FAULT—CODE NO. 29

(Voltage across battery system greater than 17.5 volts)

Corrective Action:

1. Check battery bank connections and reconnect if necessary so that the 12 volt batteries serving the

genset are connected in parallel (12 volt) rather than in series (24 volt).

2. Select a lower battery booster charge rate.

OVERSPEED FAULT—CODE NO. 31

(Engine speed greater than 3600 rpm)

Corrective Action: See an authorized Onan dealer.

LOW CRANKING SPEED FAULT—CODE NO. 32

(Cranking speed less than 180 rpm for more than 2 seconds)

Corrective Action:

1. Replace Fuse F2 (starter solenoid) if blown (Page 6).

2. Clean and tighten the positive (+) and negative (−) battery cable connections at the battery and at

the genset (Page 16).

3. Recharge or replace the battery. Refer to the battery manufacturer’s recommendations.

4. Replace the engine oil with oil of proper viscosity for the ambient temperature (Page 15). (High oil

viscosity can slow cranking speed.)

HIGH ENGINE COOLANT TEMPERATURE FAULT—CODE NO. 33

(Engine coolant temperature exceeded design limit)

Corrective Action:

1. Check the engine coolant level and add coolant and repair leaks as necessary (Page 19).

2. Check for and remove any objects blocking the air inlet or outlet openings in the bottom of the genset.

3. Reduce the number of appliances connected at the same time. (Note that high altitude and high ambient temperature decrease engine cooling capacity.)

4. Clean and flush the cooling system to remove coolant passage fouling.

5. If the genset overheats only underway, see the coach manufacture regarding air baffles or other

means to direct cooling air into the genset.

Page 32

28

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

HIGH INVERTER TEMPERATURE FAULT—CODE NO. 34

(Inverter heat sink temperature exceeded design limit*)

Corrective Action:

1. Check for and remove any objects blocking the air inlet or outlet openings in the bottom of the genset.

2. Reduce the number of appliances connected at the same time. (Note that high altitude and high ambient temperature decrease cooling capacity.)

CONTROL CARD FAILURE FAULT—CODE NO. 35

(Microprocessor EEPROM error during self-test)

Corrective Action: See an authorized Onan dealer.

ENGINE STOPPED FAULT—CODE NO. 36

(Engine stopped without command by controller)

Corrective Action:

1. Check fuel level. (Note: The genset fuel pickup is probably higher than the vehicle engine pickup.)

2. Prime the engine fuel system by holding the control switch down in its Stop position for at least 1 minute.

3. Check the engine air filter and remove any blockage (Page 16).

4. Check for mechanical damage.

INVALID GENSET CONFIGURATION FAULT—CODE NO. 37

(Genset configuration is preprogrammed at the factory)

Corrective Action: See an authorized Onan dealer.

OVERCURRENT FAULT—CODE NO. 38

(Too many loads connected)

Corrective Action: Reduce the number of appliances running at the same time, especially those with

high motor starting loads such as air conditioners. Start up with no load and let the genset run for five

minutes to cool down the inverter.

PROCESSOR FAULT—CODE NO. 42

(Microprocessor ROM error during self-test)

Corrective Action: See an authorized Onan dealer.

Page 33

29

TABLE 4. TROUBLESHOOTING (CONT.)

Some genset service procedures present hazards that can result in severe personal injury or death. Only qualified service personnel with knowledge of fuels, electricity, and

machinery hazards should perform genset service. See Safety Precautions.

WARNING

PROCESSOR FAULT—CODE NO. 43

((Microprocessor RAM error during self-test)

Corrective Action: See an authorized Onan dealer.

INVERTER POWER SUPPLY FAULT—CODE NO. 46

(Low battery voltage or power supply device failure)

Corrective Action:

1. Avoid running the genset while cranking the vehicle engine in installations where the genset batteries

are used to supplement the vehicle engine batteries.

2. Clean and tighten the positive (+) and negative (−) battery cable connections at the battery, vehicle

frame and genset (Page 16).

3. Recharge or replace the battery. Refer to the battery manufacturer’s recommendations.

4. Install or service a battery charging system in the vehicle if the genset is not so equipped.

Page 34

30

Specifications

HDKAH HDKAJ HDKAK

GENSET CONTROLLER: Integrated Microprocessor Based Engine and Generator Controller

GENERATOR: Brushless, Exciterless, Bearingless, Permanent Magnet Alternator

AC OUTPUT RATINGS:

Power (@1.0 power factor) 6000 W 7500 W 8000 W

Voltage 120 volts 120 volts 120 volts

Frequency 60 Hz 60 Hz 60 Hz

Number of Phases 1 1 1

Current 50.0 ampere 62.5 ampere 66.7 ampere

Line Circuit Breaker(s) 2-pole, 30 amp 2-pole, 30 or 35 amp 2-pole, 30 or 35 amp

ENGINE: 3-Cylinder In-Line, Water-Cooled, Indirect-Injection, 4-Stroke Cycle Diesel

Bore 2.64 inch (67 mm)

Stroke 2.68 inch (68 mm)

Displacement 44 inch3 (719 cc)

Compression Ratio 23 : 1

Oil Capacity (with filter)*

3 quart (2.6 l)

Cooling System Capacity**

4.2 quart (4 l)

Intake and Exhaust Valve Lash (Cold)

0.0065 inch (0.165 mm)

OPERATING SPEED RANGE:

1600 to 2900 RPM 1600 to 3200 RPM 1600 to 3300 RPM

FUEL CONSUMPTION:

No-load

Half-load (4000 W)

Full-load

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

.80 gph (3.03 l/h)

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

.96 gph (3.63 l/h)

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

1.02 gph (3.86 l/h)

DC SYSTEM:

Nominal Battery Voltage

12 volts

Minimum Battery Capacity

450 CCA*** down to 0° F (−17° C)

650 CCA*** down to −20° F (−29° C)

Maximum Regulated-Voltage Battery

Charging Current (Optional)

10 ampere

Fuse F1 (control circuit)

10 ampere mini-bayonet

Fuse F2 (starter solenoid circuit)

10 ampere mini-bayonet

Fuse F3 (glow plug circuit)

25 ampere

WEIGHT AND SIZE:

Weight (wet)

Length x Width x Height

420 lbs (191 kg)

36.3 x 23.6 x 22.3 inch (922 x 599 x 566 mm)

* See oil filling instructions.

** Includes coolant recovery tank.

*** Cold Cranking Amps @ 0° F (−17° C)

Page 35

31

HDKAV HDKAT HDKAU

GENSET CONTROLLER: Integrated Microprocessor Based Engine and Generator Controller

GENERATOR: Brushless, Exciterless, Bearingless, Permanent Magnet Alternator

AC OUTPUT RATINGS:

Power (@1.0 power factor) 6000 W 7500 W 8000 W

Voltage 120 volts 120 volts 120 volts

Frequency 60 Hz 60 Hz 60 Hz

Number of Phases 1 1 1

Current 50.0 ampere 62.5 ampere 66.7 ampere

Line Circuit Breaker(s) 2-pole, 30 amp 2-pole, 30 or 35 amp 2-pole, 30 or 35 amp

ENGINE: 3-Cylinder In-Line, Water-Cooled, Indirect-Injection, 4-Stroke Cycle Diesel

Bore 2.64 inch (67 mm)

Stroke 2.68 inch (68 mm)

Displacement 44 inch3 (719 cc)

Compression Ratio 23 : 1

Oil Capacity (with filter)*

3 quart (2.6 l)

Cooling System Capacity**

4.2 quart (4 l)

Intake and Exhaust Valve Lash (Cold)

0.0065 inch (0.165 mm)

OPERATING SPEED RANGE:

1600 to 2900 RPM 1600 to 3200 RPM 1600 to 3300 RPM

FUEL CONSUMPTION:

No-load

Half-load (4000 W)

Full-load

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

.80 gph (3.03 l/h)

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

.96 gph (3.63 l/h)

.13 gph (.49 l/h)

.49 gph (1.85 l/h)

1.02 gph (3.86 l/h)

DC SYSTEM:

Nominal Battery Voltage

12 volts

Minimum Battery Capacity

450 CCA*** down to 0° F (−17° C)

650 CCA*** down to −20° F (−29° C)

Maximum Regulated-Voltage Battery

Charging Current (Optional)

10 ampere

Fuse F1 (control circuit)

10 ampere mini-bayonet

Fuse F2 (starter solenoid circuit)

10 ampere mini-bayonet

Fuse F3 (glow plug circuit)

25 ampere

WEIGHT AND SIZE:

Weight (wet)

Length x Width x Height

420 lbs (191 kg)

36.3 x 23.6 x 22.3 inch (922 x 599 x 566 mm)

* See oil filling instructions.

** Includes coolant recovery tank.

*** Cold Cranking Amps @ 0° F (−17° C)

Page 36

32

Information for California Genset Users

These gensets meet the requirements of California’s Exhaust Emissions Standards as stated on the

nameplate (Page 3).

As a California user of these gensets, please be

aware that unauthorized modifications or replacement of fuel, exhaust, air intake, or speed control

system components that affect engine emissions

are prohibited. Unauthorized modification, removal

or replacement of the genset label is prohibited.

You should carefully review Operator (Owner),

Installation and other manuals and information you

receive with your genset. If you are unsure that the

installation, use, maintenance or service of your

genset is authorized, you should seek assistance

from an approved Onan dealer.

California genset users may use Table 5 as an aid in

locating information related to the California Air Resources Board requirements for emissions control.

TABLE 5. EMISSIONS CONTROL INFORMATION

Genset Warranty Information

The California emissions control warranty statement is located in

the same packet of information as this manual when the genset is

shipped from the factory.

Engine Valve Clearance (Lash) See Specifications (Page 30).

Engine Fuel Requirements

The engine is certified to operate on diesel fuel. See FUEL RECOMMENDATIONS (Page 5).

Engine Lubricating Oil Requirements See ENGINE OIL RECOMMENDATIONS (Page 5).

Engine Adjustments

High Idle Speed. This is a service procedure requiring trained

personnel and proper tools. See the Service Manual.

Engine Emission Control System

The engine emission control system consists of engine design

and precision manufacture. (IFI)

Page 37

33

How to Obtain Service

When you need parts or service for your genset contact the nearest authorized dealer or distributor.

Onan has factory-trained representatives to handle

your needs for genset parts and service. To locate

the nearest authorized distributor:

1. Check the North American Sales and Service

Directory (F-118) and the International Sales

and Service Directory (IN-1013) supplied with

your Onan genset. These directories list authorized distributors who will assist you in locating

the nearest authorized dealer.

2. Consult the Yellow Pages. Typically, our distributors are listed under:

GENERATORS − ELECTRIC,

ENGINES − GASOLINE OR DIESEL, or

RECREATIONAL VEHICLES − EQUIPMENT,

PARTS AND SERVICE.

3. Call 1-800-888-ONAN for the name and telephone number of the nearest Onan dealer in

the United States or Canada. (This automated

service utilizes touch-tone phones only). By

calling this number you can also request a di-

rectory of authorized RV servicing dealers: RV

Sales and Service Directory F-919.

To get service, contact the authorized dealer or distributor nearest you, explain the problem and make

an appointment. If you have difficulty in arranging

for service or resolving a problem, please contact

the dealer coordinator or service manager at the

nearest Onan dealer for assistance.

Before calling for service, have the following information available:

1. The complete genset model number and serial

number. See Model Identification (Page 4).

2. The date of purchase

3. The nature of the problem. See Troubleshoot-

ing (Page 21).

WARNING

Improper service or replacement of

parts can result in severe personal injury, death,

and/or equipment damage. Service personnel

must be qualified to perform electrical and/or

mechanical service.

Page 38

34

Maintenance Record

Record all periodic and unscheduled maintenance and service. See Periodic Maintenance (Page 12).

DATE

HOUR

METER

READING

MAINTENANCE OR SERVICE PERFORMED

Record the name, address, and phone number of your authorized Onan service center.

Page 39

Page 40

Cummins Power Generation

1400 73rd Ave. NE

Minneapolis, MN 55432 USA

Phone 1 763 574 5000

Toll-free 1 800 888 6626

Fax 1 763 574 5298

Email www.cumminsonan.com/contact

www.cumminsonan.com

CumminsR, OnanR, the “C” logo, and “Performance you rely on.”

are trademarks of Cummins Inc.

E2010 Cummins Power Generation, Inc. All rights reserved.

Loading...

Loading...