Page 1

Operator Manual

Commercial Mobile Generator Set

HDKAL (Spec B−J)

HDKAS (Spec B−F)

English

Original Instructions 10-2016 981−0104 (Issue 9)

Page 2

California

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 3

Table of Contents

SAFETY PRECAUTIONS 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABOUT THIS MANUAL 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MODEL IDENTIFICATION 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL RECOMMENDATIONS 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BIO−DIESEL FUELS B5 − B20 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL RECOMMENDATIONS 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BATTERIES 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENSET-MOUNTED CONTROL PANEL 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE CONTROL PANELS 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRE-START CHECKS 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWERING APPLIANCES 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTIONS to UTILITY POWER 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RESETTING LINE CIRCUIT BREAKERS 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE BREAK-IN 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO-LOAD OPERATION 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENSET EXERCISE 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENSET STORAGE 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RETURNING GENSET to SERVICE 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE SCHEDULE 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE PROCEDURES 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INSPECTION 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHANGING OIL AND OIL FILTER 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR CLEANER MAINTENANCE 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPARK ARRESTOR CLEANING 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BATTERIES 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE COOLING SYSTEM 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL SYSTEM 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Copyright 2016 Cummins Inc.

Page 4

Table of Contents

TROUBLESHOOTING 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAULT CODE BLINKING 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RESTORING FAULT CODE BLINKING 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE DOES NOT CRANK 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE CRANKS BUT DOES NOT START 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE LACKS POWER OR UNSTABLE 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO OUTPUT VOLTAGE 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INFORMATION FOR CALIFORNIA GENSET USERS 27 . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO OBTAIN SERVICE 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE RECORD 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 2016 Cummins Inc.

iii

Page 5

Safety Precautions

Thoroughly read the OPERAT OR’S MANUAL before operating the genset. Safe operation and top

performance can be obtained only by proper operation and maintenance.

The following symbols in this Manual alert you to potential hazards to the operator, service personnel

and equipment.

alerts you to an immediate hazard

which will result in severe personal injury or

death.

WARNING

tice which can result in severe personal injury or

death.

CAUTION

tice which can result in personal injury or equipment damage.

Electricity, fuel, exhaust, moving parts and batteries

present hazards which can result in severe personal

injury or death.

alerts you to a hazard or unsafe prac-

alerts you to a hazard or unsafe prac-

GENERAL PRECAUTIONS

Use caution when making adjustments while the

genset is running—hot, moving or electrically

live parts can cause severe personal injury or

death.

Used engine oil has been identified by some

state and federal agencies as causing cancer or

reproductive toxicity. Do not ingest, inhale, or

contact used oil or its vapors.

Do not work on the genset when mentally or

physically fatigued or after consuming alcohol or

drugs.

Carefully follow all applicable local, state and

federal codes.

GENERATOR VOLTAGE IS DEADLY!

Generator output connections must be made by

a qualified electrician in accordance with applicable codes.

The genset must not be connected to the public

utility or any other source of electrical power.

Connection could lead to electrocution of utility

workers, damage to equipment and fire. An approved switching device must be used to prevent interconnections.

Keep ABC fire extinguishers handy.

Make sure all fasteners are secure and torqued

properly.

Keep the genset and its compartment clean. Ex-

cess oil and oily rags can catch fire. Dirt and gear

stowed in the compartment can restrict cooling

air.

Let the engine cool down before removing the

coolant pressure cap or opening the coolant

drain. Hot coolant under pressure can spray out

and cause severe burns.

Before working on the genset, disconnect the

negative (−) battery cable at the battery to pre-

vent starting.

Use caution when working on live electrical

equipment. Remove jewelry, make sure clothing

and shoes are dry and stand on a dry wooden

platform on the ground or floor.

FUEL IS FLAMMABLE AND EXPLOSIVE

Keep flames, cigarettes, sparks, pilot lights,

electrical arc-producing equipment and

switches and all other sources of ignition well

away from areas where fuel fumes are present

and areas sharing ventilation.

Fuel lines must be secured, free of leaks and

separated or shielded from electrical wiring.

Use approved non-conductive flexible fuel hose

for fuel connections at the genset.

Copyright 2016 Cummins Inc.

1

Page 6

ENGINE EXHAUST IS DEADLY!

Learn the symptoms of carbon monoxide poi-

soning in this manual.

Prior to every startup and after every eight hours

of running, all carbon monoxide detectors must

be tested and confirmed to be working in accordance with the manufacturer’s instructions or

owners manual.

Never occupy in the vehicle while the genset is

running unless the vehicle has a working carbon

monoxide detector.

The exhaust system must be installed in accor-

dance with the genset Installation Manual.

Keep guards in place over fans, belts, pulleys,

etc.

BATTERY GAS IS EXPLOSIVE

Wear safety glasses and do not smoke while

servicing batteries.

When disconnecting or reconnecting battery

cables, always disconnect the negative (−) bat-

tery cable first and reconnect it last to reduce

arcing.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Do not use engine cooling air to heat the vehicle

interior.

Make sure there is ample fresh air when operat-

ing the genset in a confined area.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Do not wear loose clothing or jewelry near mov-

ing parts such as PTO shafts, fans, belts and

pulleys.

Keep hands away from moving parts.

Flammable vapor can cause a diesel engine to overspeed and become difficult to stop, resulting in possible fire, explosion, severe personal injury and

death. Do not operate a diesel-powered genset

where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset

is equipped with an automatic safety device to

block the air intake and stop the engine. The own-

ers and operators of the genset are solely responsible for operating the genset safely. Contact your authorized Cummins Onan dealer or distributor for

more information.

2

Copyright 2016 Cummins Inc.

Page 7

Introduction

ABOUT THIS MANUAL

This manual covers operation and maintenance of

the model HDKAL and HDKAS generator sets (gensets). Study this manual carefully and observe all of

its instructions and precautions. Using the genset

properly and maintaining it regularly will promote longer genset life, better performance, and safer operation. Each operator should become thoroughly familiar with this manual. Keep this manual in a

convenient location for quick reference.

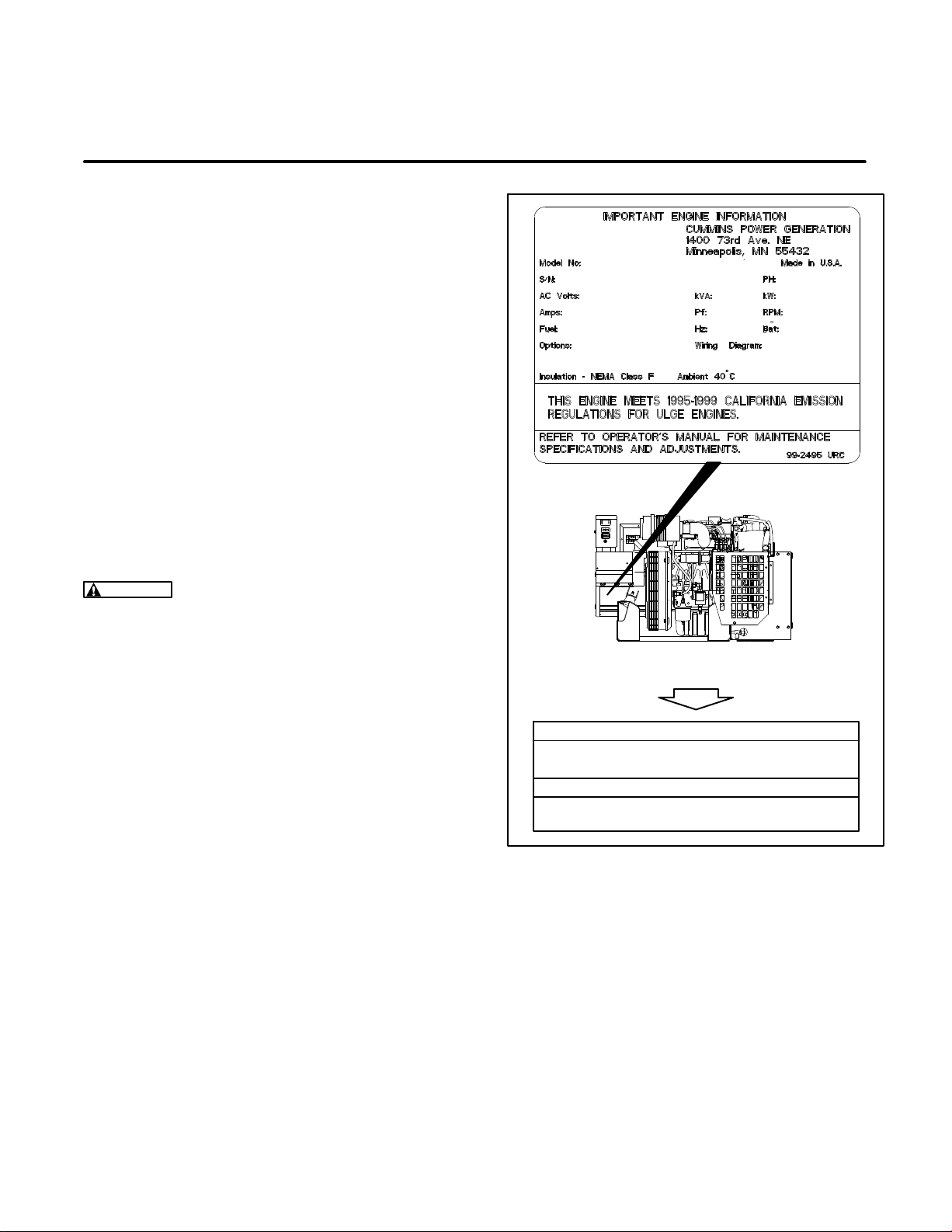

MODEL IDENTIFICATION

When you call for service or parts have the genset

model number and serial number ready (Figure 1).

For ready reference, record these numbers in the

boxes shown.

FUEL RECOMMENDATIONS

WARNING

Diesel fuel is combustible and can

cause severe personal injury or death. Do not

smoke near fuel tanks or fuel-burning equipment

or in areas sharing ventilation with such equipment. Keep flames, sparks, pilot flames, electrical arcs and switches and all other sources of

ignition well away. Keep a type ABC fire extinguisher handy.

Use clean, fresh No. 2 diesel fuel (ASTM 2-D) when

the outdoor ambient temperature is above freezing,

and No. 1 diesel fuel (ASTM 1-D) when below freezing. The fuel should have a Cetane number of at least

45 for reliable starting.

Note: Only low sulfer diesel or Ultra Low Sulfur Diesel

(ULSD) fuel that meets the ASTM D975 or EN 590 standard for lubricity may be used with this engine. The 1

to 2 percent less energy content of the fuel can have a

slight effect on maximum engine power.

Note: B5 Bio-Diesel fuel that meets industry specifications and quality is suitable for use with this engine.

RECORD MODEL AND SERIAL NUMBERS HERE

MODEL NUMBER

SERIAL NUMBER

FIGURE 1. TYPICAL NAMEPLATE

Copyright 2016 Cummins Inc.

3

Page 8

BIO−DIESEL FUELS B5 − B20

B5 bio−diesel fuel that meets industry specifications

and quality is suitable for use with this generator set.

Bio−Diesel Above B5 and up to B20

Bio−Diesel Blends

The following must be verified before using bio−die-

sel blends up to B20:

For model HDKAL, the generator set is at Spec

G or higher.

The vehicle propulsion engine is capable of us-

ing B20 when sharing the same fuel tank.

The OEM has installed B20 compatible fuel line

from fuel tank to generator set.

The OEM has installed a water separator in the

fuel line just before the generator set.

Approved Bio−Diesel Fuel:

For bio−diesel blends above B5 and up to B20,

Cummins Onan requires that the fuel meet the

specifications outlined in ASTM D7467.

The bio−diesel component of this fuel blend

must meet ASTM D6751 or EN14214 and the

petroleum−diesel component must meet ASTM

D975.

Blended bio−diesels fuels should be bought

pre−blended and not made by customers.

generator with bio−diesel blends in low ambient

temperatures, such as a fuel heater, hose insulation, or additional anti−gel fuel additives.

Bio−diesel fuel blends are an excellent medium

for microbial growth. Microbes cause fuel system corrosion and premature filter plugging. The

effectiveness of all commercially available conventional anti−microbial additives, when used in

bio−diesel, is not known. Consult your fuel and

additive supplier for assistance.

WARNING

It is highly recommended that specific

market applications are avoided or excercised with

extra care due to some of the properties of bio−diesel fuel blends such as cold weather operation, long

term storage, material incompatibilities and other effects on engine operating characteristics. Such applications that should use standard fuels include applications that will experience seasonal usage,

storage for periods exceeding 90 days, and extreme

temperatures or humidity.

Storage Requirements:

If using bio−diesel for seasonal applications

(stored more than 90 days), the generator must

be purged before storage by running the engine

on pure diesel fuel meeting ASTM D975 for a mininmum of 30 minutes.

Warranty Coverage:

Bio−Diesel Properties:

Bio−diesel has poor oxidation stability which

can accelerate fuel oxidation. Fuel oxidation will

reduce generator performance. This effect is ac-

celerated at increased ambient temperatures.

Bio−diesel properties change at low ambient

temperatures (below 23

F/−5C). Necessary

precautions must be taken when operating the

Cummins Onan Warranty covers failures that are a

direct result of defects in material or factory workmanship. Generator damage, service issues and/or

performance issues determined by Cummins Onan

to be caused by bio−diesel fuel blends not meeting

the specifications outlined in the applicable Installation, Operator, and Service Manuals are not considered to be defects in material or workmanship and

may affect your generator’s warranty.

4

Copyright 2016 Cummins Inc.

Page 9

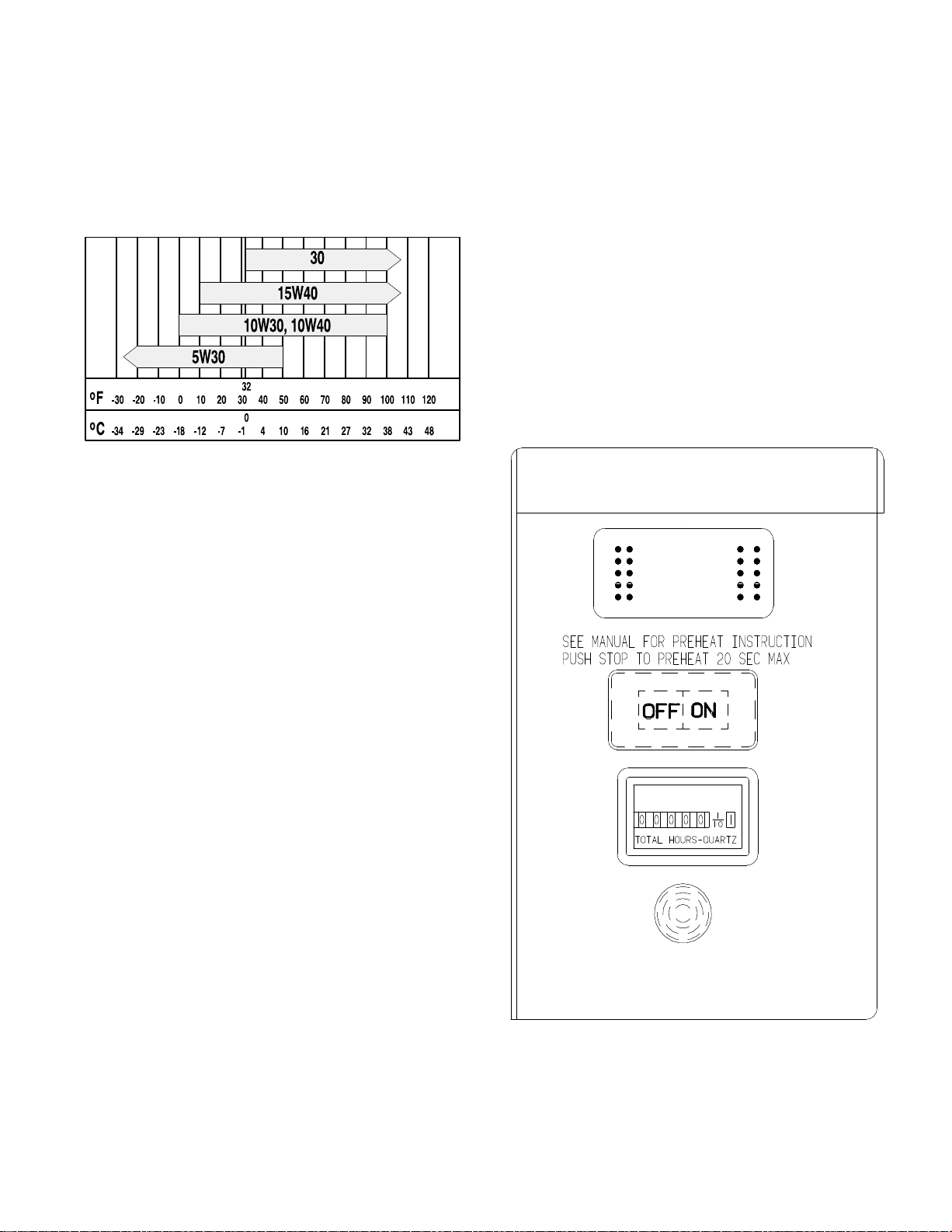

ENGINE OIL RECOMMENDATIONS

Use premium quality motor oil. Look for the API

(American Petroleum Institute) classification and

use Class CF-4 or CF or better oil. Also look for the

SAE (Society of Automotive Engineers) viscosity

FIGURE 2. SAE VISCOSITY GRADE vs. AMBIENT

TEMPERATURE

BATTERIES

The genset requires a 12 volt battery to power its

control and starting circuits. Reliable genset starting

and starter service life depend upon adequate battery system capacity and maintenance. See Specifi-

cations for battery requirements and Periodic Main-

tenance for battery care.

grade. Referring to Figure 2, choose the viscosity

grade appropriate for the range of ambient temperatures expected before the next scheduled oil change.

Multi-grade oils such as SAE 15W-40 are recommended for year-round use.

S

t

o

p

S

t

a

r

t

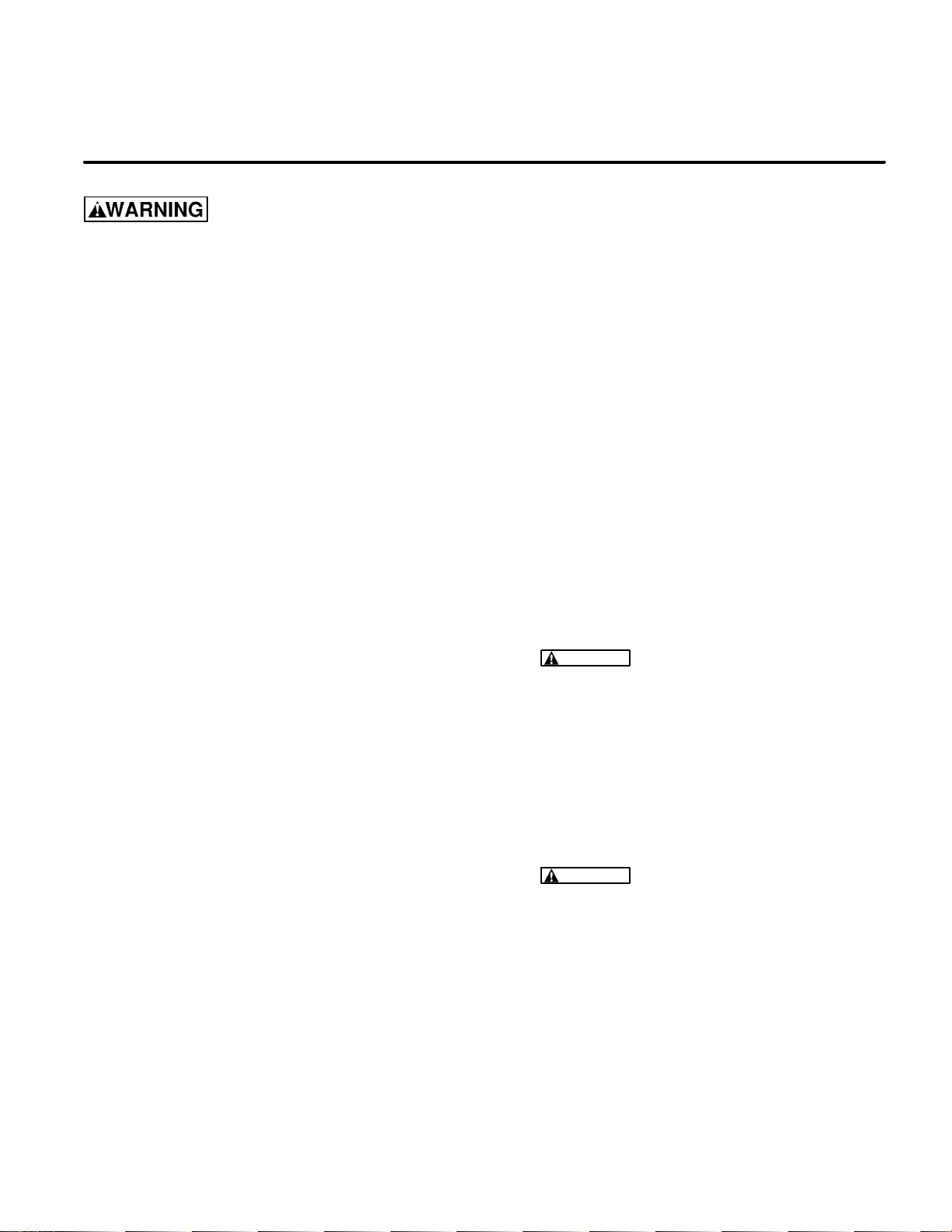

GENSET-MOUNTED CONTROL PANEL

Figure 3 illustrates the genset control panel.

Start-Stop-Preheat Switch (S1): Starts the genset

when held at Start and stops the genset when mo-

mentarily touched to Stop. Holding the switch at

Stop causes the glow plugs to preheat the combustions chambers.

DC Control Breaker: Protects the control circuits

from shorts to ground. Can be used as an emergency

stop switch. Reset with handle.

Hour Meter: Indicates the number of hours the genset has run. It cannot be reset.

Fault Reset Breaker: T rips and shuts down the genset when there is a low oil pressure or high coolant

temperature fault condition. Reset by pushing in the

red button.

REMOTE CONTROL PANELS

Remote control panels with a control switch and engine gauges are available.

DC

Control

Brkr

Fault

Brkr

FIGURE 3. GENSET CONTROL PANEL

Copyright 2016 Cummins Inc.

5

Page 10

THIS PAGE IS INTENDED TO BE BLANK

6

Copyright 2016 Cummins Inc.

Page 11

Operation

EXHAUST GAS IS DEADLY!

Engine exhaust contains carbon monoxide, a poisonous, odorless and colorless gas that can

cause unconsciousness and death. Symptoms of carbon monoxide poisoning include:

Dizziness Throbbing in Temples Nausea

Muscular Twitching Headache Vomiting

Weakness Trouble Thinking Clearly Sleepiness

GET EVERYONE OUT INTO FRESH AIR IMMEDIATELY IF ANYONE EXPERIENCES ANY OF

THESE SYMPTOMS. Seek medical attention if symptoms persist.

Never ocupy in the vehicle when the genset is running unless the vehicle has an operating carbon monoxide detector.

Look and listen for leaks along the entire run of the exhaust system every time you start up the

genset and every eight hours if the genset is being run continuously. Shut down the genset

immediately if there is a leak and do not run it until the leak has been repaired.

The installation of the exhaust system must be in accordance with the genset Installation

Manual.

PRE-START CHECKS

Perform General Inspection (p. 13). Check for fuel,

exhaust, oil and coolant leaks every eight hours

if the genset is being run continuously.

Check the Maintenance Record and perform any

maintenance due (Periodic Maintenance Schedule).

Also see GENSET BREAK-IN if the genset is new

and RETURNING THE GENSET TO SERVICE if the

vehicle has been in storage.

STARTING

Disconnect all loads from the genset.

Preheat − Hold the control switch in the PREHEAT

position for the following number of seconds depending on ambient temperature:

a. 10 seconds—above 50

b. 15 seconds—0

c. 20 seconds—below 0

F to 50F (−17to 10C)

F (10C)

F (−17C)

CAUTION

seconds can damage the glow plugs.

Start − Immediately after PREHEAT push the control

switch to START and hold it there until the en-

gine starts. The starter will automatically disconnect as the engine starts up.

Do not crank for more than 15 seconds at a time.

Wait two minutes before trying again. See Trou-

bleshooting if the engine does not start on the

second try.

CAUTION

heat and damage the starter. Do not crank for

more than 15 seconds at a time and wait two

minutes before trying again.

Connect the electrical loads after the genset has

warmed up for a few minutes.

Check for fuel, exhaust, oil and coolant leaks and

complete General Inspection (p. 13). Check the

engine gauges regularly (if provided) while the

genset is running.

Oil Pressure Gauge: Normal engine oil pres-

sure is 28 − 64 psi (194 − 442 kPa) at normal operating temperature.

Preheat times longer than 20

Excessive cranking can over-

Copyright 2016 Cummins Inc.

7

Page 12

DC Voltmeter: Normal DC system voltage is

12.5 − 15 volts depending on battery condition and state-of-charge.

Coolant Temperature Gauge: Normal engine

coolant temperature is 160 −195

(71 − 91

C) depending on load and ambi-

F

ent temperature.

STOPPING

Before stopping let the genset cool down by running at no-load for three to five minutes. Then touch

the control switch momentarily to STOP.

CAUTION

Failure to let the engine cool down

before stopping can lead to engine damage. Let

the genset run three to five minutes at no-load

before stopping.

POWERING APPLIANCES

The genset can power AC motors, air conditioners,

AC/DC converters and other appliances. How much

appliance load* can be serviced depends upon the

genset power rating. The genset will shut down or its

circuit breakers will trip if the sum of the loads exceeds genset rating.

To avoid overloading the genset and causing shutdowns, compare the sum of the loads of the appliances that are likely to be used at the same time to

the power rating of the genset. Use Table 1 or the ratings on the appliances themselves (if so marked) to

obtain the individual appliance loads. It may be nec-

essary to run fewer appliances at the same time

so that the sum of the loads is not greater than

genset rating.

Note that air density decreases as altitude increases,

decreasing engine power . Power decreases approximately 3 percent of rated power every 1000 feet

(305 m) that elevation increases above sea level.

See Table 2 for typical calculations. It may be nec-

essary to operate fewer appliances at higher altitudes.

TABLE 1. TYPICAL APPLIANCE LOADS

Appliance Load (watt)

Air Conditioner 1400-2000

Battery Charger Up to 800

DC Converter 300-1500

Refrigerator 600-1000

Microwave Oven 1000-1500

Electric Frying Pan/Wok 1000-1500

Electric Stove Element 350-1000

Electric Water Heater 1000-1500

Electric Iron 500-1200

Electric Hair Dryer 800-1500

Coffee Percolator 550-750

Television 200-600

Radio 50-200

Electric Drill 250-750

Electric Broom 200-500

Electric Blanket 50-200

TABLE 2. MAXIMUM POWER VS. ALTITUDE

Note that the genset may shut down due to overload,

even though the sum of the loads is less than genset

rating, when a large motor or air conditioner is started

last or cycles off and then on again. The reason for

Elevation above Sea

Level

at/below 500 ft (152 m) 7500 W (rated)

at 2500 ft (762 m) 7050 W

Maximum Power

this is that motor startup load is much larger than running load. It may be necessary to run fewer ap-

pliances when large motors and air conditioners

are cycling on and off.

* Appliance load and genset power are measured in terms of watt (W) or kilowatt (kW), where 1 kilowatt (kW) = 1000 watt (W).

at 5500 ft (1676 m) 6375 W

above 5500 ft (1676 m)

8

6375 W minus 225 W

every 1000 ft (305 m)

Copyright 2016 Cummins Inc.

Page 13

CONNECTIONS TO UTILITY POWER

A vehicle that has provisions for connection to utility

power must be equipped with an approved transfer

switch to keep the genset and utility power from being interconnected.

WARNING

Backfeed to utility power can cause

electrocution and damage to equipment. Use an

approved device to prevent the genset from being interconnected with utility power.

RESETTING LINE CIRCUIT BREAKERS

If a circuit breaker in the main power distribution panel in the vehicle or on the genset (Figure 4) trips,

there is either a short circuit or too much load. Note

that the genset will continue to run after a circuit

breaker trips.

If a circuit breaker trips, disconnect or turn off as

many appliances as possible and reset the circuit

breaker. (Push the circuit breaker OFF to reset it and

then ON to reconnect the circuit.) If the circuit break-

er trips right away, either the electrical distribution

system has a short or the circuit breaker is faulty. Call

a qualified electrician.

WARNING

Electrical shock can cause severe

personal injury or death. Read and follow the appliance manufacturer’s instructions and warnings.

ENGINE BREAK-IN

Change the oil and oil filter after the first 50 hours of

operation. See Maintenance Procedures.

NO-LOAD OPERATION

Keep no-load operation to a minimum. During no-

load operation combustion chamber temperatures

drop to the point where fuel does not burn completely, causing slobbering and white smoke. Always

have some load connected when the genset is run

for long periods.

If the circuit breaker does not trip, reconnect a combination of appliances that does not overload the

genset or cause the circuit breaker to trip. An appliance that causes a circuit breaker to trip right away

probably has a short.

Electrical appliances must be properly grounded and

in good working condition.

LINE CIRCUIT

BREAKER RESET HANDLES

FIGURE 4. GENSET MOUNTED LINE CIRCUIT

BREAKERS

Copyright 2016 Cummins Inc.

9

Page 14

GENSET EXERCISE

If use is infrequent, run the genset at approximately

1/2 rated power for an hour every week. Exercising

the genset results in better starting, longer engine life

and increased genset reliability by driving off moisture, re-lubricating the engine, using up fuel before it

becomes stale and removing oxides from electrical

contacts. One longer period during which the engine

and generator warm up thoroughly is better than several shorter periods.

GENSET STORAGE

If the genset will be inactive for more than 30 days

and it is impractical to have someone exercise it, prepare it for storage as follows:

Run the genset until it has thoroughly warmed up and

shut it down.

necting battery cables—Disconnect the negative (−) cable first and reconnect it last—

Wear safety glasses—Do not

smoke—Switch lights ON and Off away from

the battery.

Disconnect the battery cables (negative [−] cables

first) and store the battery(ies) in accordance

with the manufacturer’s recommendations.

WARNING

Hot coolant is under pressure

and can cause severe burns when loosening

the pressure cap. Let the engine cool before

loosening the pressure cap.

Check the coolant level and add coolant as neces-

sary . Test the coolant mixture if freezing temperatures are possible and change if necessary.

See ENGINE COOLING SYSTEM in Mainte-

nance Procedures.

Clean the genset and lightly oil parts that can rust.

WARNING

Crankcase pressure can blow

out hot oil and cause severe burns. Stop the

engine before checking the oil level or opening the fill cap.

Change the oil and oil filter while still warm and attach

a tag to the dip stick indicating the oil viscosity

grade. See CHANGING OIL AND OIL FILTER in

Maintenance Procedures.

WARNING

Arcing at battery terminals or in a

light switch or other equipment, flames and

sparks can ignite battery gas causing severe

personal injury. Ventilate the battery

compartment before connecting or discon-

RETURNING GENSET TO SERVICE

Check the tag on the dipstick and change the oil if the

viscosity is not suitable for present and anticipated ambient temperatures.

Reconnect the battery(ies) (negative [−] cables last)

and service as necessary in accordance with the

manufacturer’s instructions.

Prime the fuel system (p. 20).

Perform PRE-START CHECKS and start and run the

genset according to STARTING. Perform main-

tenance or service as required before placing

the genset in service.

10

Copyright 2016 Cummins Inc.

Page 15

Periodic Maintenance Schedule

Periodic maintenance is essential for top genset performance and long service life. Use Table 3 as a

guide, follow Maintenance Procedures and record

maintenance performed in Maintenance Record.

WARNING

Accidental starting can cause severe personal injury or death. Disconnect the

negative (−) cable(s) at the battery(ies) to prevent

starting while working on the genset.

TABLE 3. PERIODIC MAINTENANCE SCHEDULE

FREQUENCY

After

first

PROCEDURE

50 Hrs

Inspect Genset x

Every

Day/

8 Hrs

1

Every

50 Hrs

Every

Month/

100 Hrs

Every 6

Month/

250 Hrs

Every

Year/

500 Hrs

Every 2

Years

Every

5 years

Check Oil Level x 13

Check Coolant Level x 13

Check Fuel Level x 13

Clean Spark Arrestor x 16

Clean Air Cleaner

Dust Boot

Check Battery x

Check V-Belt Tension x

Drain Water in Fuel x

5

x

2

3

4

P

g

13

16

16

17

19

Change Engine Oil

and Oil Filter

x x

Change Fuel Filter x

Change Air Cleaner

Element

5

7

5

x

15

19

16

Change Coolant x 17

Adjust Valve Lash x

Replace Pressure

Cap

Replace Generator

Bearing

1 − Check for oil, fuel, coolant and exhaust system leaks.

2 − See battery manufacturer’s recommendations.

3 − Check for slippage.

4 − Drain about one cup to remove water and sediment.

5 − Perform more often in dusty conditions.

6 − Must be performed by an authorized Cummins Onan dealer.

7 − Perform every 250 hours when using B20 Bio−diesel fuel.

6

−

x 17

6

x

−

Copyright 2016 Cummins Inc.

11

Page 16

THIS PAGE IS INTENDED TO BE BLANK

12

Copyright 2016 Cummins Inc.

Page 17

Maintenance Procedures

GENERAL INSPECTION

Perform these checks and inspections every time the

genset is started or every eight hours if the genset is

being run continuously.

Oil Level Check

WARNING

hot oil and cause severe burns. Stop the engine

before checking the oil level or opening the fill

cap.

Shut down the genset to check engine oil level and

wait a few minutes for the oil to drain down to the

crankcase to get an accurate indication of oil level.

Keep the oil level between FULL and ADD on the dipstick (Figure 5). See ENGINE OIL RECOMMENDATIONS (page 5) for the oil to use.

CAUTION

gine damage and too much oil to high oil consumption and foaming, which can cause engine

shutdown. Keep the oil level between FULL and

ADD.

Crankcase pressure can blow out

Too little oil can lead to severe en-

Replace dented, bent or severely rusted sections of

the tailpipe and make sure the tailpipe extends at

least 1 inch (25.4 mm) beyond the perimeter of the

vehicle.

Park the vehicle so that the genset exhaust gases

can disperse away from the vehicle. Barriers such as

walls, snow banks, high grass, brush and other vehicles can cause exhaust gases to accumulate in

and around the vehicle.

To avoid drawing exhaust gases into the vehicle, do

not turn on power ventilators or exhaust fans when

the genset is running and the vehicle is standing still.

WARNING

operate the genset if there is an exhaust leak or

any danger of exhaust gases entering or being

drawn into the vehicle.

WARNING

or brush. Contact with the exhaust system can

cause a fire.

EXHAUST GAS IS DEADLY! Do not

Do not park the vehicle in high grass

Fuel System Inspection

Coolant Level Check

Replenish the normal loss of coolant by keeping the

level in the coolant recovery tank between COLD

and HOT. See COOLING SYSTEM (page 17) for the

recommended mixture of antifreeze and if it is necessary to refill the system.

Exhaust Leaks

Look and listen for exhaust system leaks while the

genset is running. Shut down the genset if a leak is

found and have it repaired before operating the genset.

Look for openings or holes between the genset

compartment and vehicle cab or living space if the

genset engine sounds louder than usual. Have all

such openings or holes closed off or sealed to prevent exhaust gases from entering the vehicle.

Copyright 2016 Cummins Inc.

Check for leaks at all fuel line fittings and gaskets.

Replace fuel hose that has been abraded or cut and

install new hose in such a way that it will not become

kinked, rub against other parts or come in contact

with sharp edges, hot surfaces or wiring.

WARNING

leaks immediately. Do not run the genset if it

causes fuel to leak.

Prime the fuel system if the genset ran out of fuel or a

fuel filter was replaced. See FUEL SYSTEM (page

19).

Fuel leaks can lead to fire. Repair

Battery Inspection

Check for clean, tight battery connections. Loose

and corroded connections make for hard starting because of high electrical resistance. See BATTERIES

(page 16).

13

Page 18

WARNING

Arcing at battery terminals or in a

light switch or other equipment, flames and

sparks can ignite battery gas causing severe personal injury. Ventilate the battery compartment

before connecting or disconnecting battery

cables—Disconnect the negative (−) cable first

and reconnect it last—Wear safety glasses—Do

not smoke—Switch lights ON and Off away from

the battery.

Mechanical Inspection

WARNING

Crankcase pressure can blow out

hot oil and cause severe burns. Stop the engine

before checking the oil level or opening the fill

cap.

Draining Engine Oil: To drain the engine oil, run the

engine until thoroughly warm and stop it. Open either

the side or bottom service access door to get at the

oil drain valve and oil filter (Figure 5). Drain the oil

into a suitable container and close the valve when

the oil has completely drained.

Check for unusual noises and vibrations, loose genset mounts and signs of mechanical damage. Check

the engine gauges regularly (if provided) while the

genset is running. See Operation for normal gauge

readings.

Keep the genset clean. Do not clean the genset while

it is running. Protect the generator, control panel, and

electrical connections from cleaning solvents. Remove the generator endbell cover and use compressed air to blow dust out of the generator and radiator core.

WARNING

Wear safety glasses when using

compressed air to prevent eye injury.

CHANGING OIL AND OIL FILTER

WARNING

termined that contact with used engine oil can

cause cancer or reproductive toxicity. Take care

to limit skin contact and breathing of vapors. Use

protective gloves and wash exposed skin.

See Table 3 for frequency of maintenance.

State and federal agencies have de-

Changing Oil Filter: To change the oil filter, place a

container under the oil filter (Figure 5) to catch oil that

drips out and then spin off the oil filter. Clean the filter

mounting surface (making sure to remove the old

gasket), apply oil to the new filter gasket and spin the

filter on until the gasket just touches the mounting

pad. Then tighten an additional 3/4 turn.

Refilling Engine Oil: See ENGINE OIL RECOMMENDATIONS (page 5) for the oil to use and

Specifications for the amount. Refill with the proper

amount of oil, start the engine and check for leakage

around the filter gasket. Tighten the filter only

enough to stop leakage. Shut off the genset, recheck the oil level and add oil as necessary. Secure

the access door.

CAUTION

Too little oil can lead to severe engine damage and too much oil to high oil consumption and foaming, which can cause engine

shutdown. Keep the oil level between FULL and

ADD.

Disposing of Used Oil and Oil Filter: Dispose of

the used oil and oil filter according to local environmental regulations.

14

Copyright 2016 Cummins Inc.

Page 19

OIL FILTER

OIL DIPSTICK

(BOTH SIDES)

OIL DRAIN VALVE

OIL FILL

SERVICE AC-

CESS DOORS

FIGURE 5. OIL CHECK, FILL, DRAIN AND FILTER

Copyright 2016 Cummins Inc.

15

Page 20

AIR CLEANER MAINTENANCE

See Table 3 for frequency of maintenance. The air

cleaner element must be handled carefully and must

never have oil applied to it. Before changing the filter

element, squeeze the dust boot to release any

trapped dust. Install the new filter element as follows:

1. Unclip the cover (Figure 6) and pull the filter element out gently to reduce the amount of dust dislodged. Gently twist or move the element side to

side to disengage the seal and pull it out.

2. Clean the sealing surface and inside of the outlet

tube to keep dust and dirt from entering the engine.

3. Examine the old filter element for dust on the

clean-air side of the element. This could indicate

leakage on the sealing surface. Correct as necessary.

4. Inspect the new element for damage. Do not

install a damaged element. Insert the new element into the housing, applying pressure at the

outer rim of the element and not on its flexible

center, and secure the cover.

SPARK ARRESTOR CLEANING

DUST BOOT

FIGURE 6. AIR CLEANER ASSEMBLY

See Table 3 for frequency of maintenance. Cleaning

is necessary to maintain good performance and

meet Forest Service requirements. To clean the

spark arrestor, remove the 1/8 inch pipe plug in the

bottom of the muf fler and run the genset for five minutes at full load. Replace the plug when the muffler

has cooled down. See Figure 7.

BATTERIES

See Table 3 for frequency of maintenance. Sealed,

maintenance-free batteries are recommended. Follow the manufacturer’s instructions for battery care.

Keep the terminals clean and tight.

WARNING

light switch or other equipment, flames and

sparks can ignite battery gas causing severe personal injury. Ventilate the battery compartment

before connecting or disconnecting battery

cables—Disconnect the negative (−) cable first

and reconnect it last—Wear safety glasses—Do

not smoke—Switch lights ON and Off away from

the battery.

Arcing at battery terminals or in a

FIGURE 7. SPARK ARRESTOR WITH CLEANOUT

PLUG

16

Copyright 2016 Cummins Inc.

Page 21

ENGINE COOLING SYSTEM

See Table 3 for frequency of maintenance.

Cooling System Overview

The engine is cooled by a pressurized, closed-loop

liquid cooling system. Coolant is pumped through

passages in the engine block and head and is cooled

in a genset-mounted radiator. The radiator fan is arranged to either pull or push air through the radiator.

ADJUSTING BRACK-

ET BOLT

Recommended Coolant Mixture

Use the best quality ethylene or propylene glycol antifreeze solution available. It should be fully formulated with rust inhibitors and coolant stabilizers but

not with stop-leak additives. Use fresh water that

is low in minerals and corrosive chemicals. Distilled

water is best. Unless prohibited by shipping regulations, gensets are shipped with the recommended

50/50 mixture of water and ethylene glycol, which is

good for -34

F (-37C).

Adjusting V-Belt Tension

See Table 3 for frequency of maintenance. The Vbelt (Figure 8) drives the coolant pump and battery

charging alternator. (The radiator fan is mounted on

the crankshaft pulley and therefore is not driven by

the belt.)

WARNING

vere personal injury or death. Disconnect the

negative (−) cable(s) at the battery(ies) to prevent

the engine from starting.

Disconnect the negative (−) cable(s) at the bat-

tery(ies) to prevent the engine from starting and

remove the top belt guard.

Loosen the alternator pivot bolt first and then the ad-

justing bracket bolt on top.

Tighten belt tension by pivoting the alternator out-

wards. Hold tension by tightening the adjusting

bracket bolt. Apply 20 pounds (10 kg) as shown

to the middle of the pulley span and measure

belt deflection, which should be 0.4 inch

(10 mm). Tighten the alternator bolts when tension is correct.

Secure the belt guard and reconnect the battery

cables (negative [−] last).

Accidental starting can cause se-

0.4 INCH

(10 MM)

DEFLECTION

A T 20 LBS

(10 KG)

FIGURE 8. ADJUSTING V-BELT TENSION

PIVOT

BOLT

Copyright 2016 Cummins Inc.

17

Page 22

Pressure Cap

See Table 3 for frequency of replacement. Replace

the pressure cap as recommended to maintain optimal engine cooling and minimal coolant loss.

Coolant Recovery Tank

tem pressure cap and open the block and radiator

drain valves (Figure 9). Collect used coolant in containers for proper disposal.

WARNING

Ethylene glycol antifreeze is considered toxic. Dispose of it according to local regulations for hazardous substances.

Replenish the normal loss of coolant by keeping the

level in the recovery tank between COLD and HOT.

Use the recommended mixture of antifreeze. See

Changing Coolant if it is necessary to fill the system.

Changing Coolant

WARNING

can cause severe burns when loosening the

pressure cap. Let the engine cool before loosening the pressure cap.

WARNING

vere personal injury or death. Disconnect the

negative (−) cable(s) from the battery(ies) to pre-

vent the engine from starting.

Draining the System: Let the engine cool down, dis-

connect the negative (−) cable(s) at the battery(ies)

to prevent the engine from starting, remove the sys-

Hot coolant is under pressure and

Accidental starting can cause se-

Cleaning and Flushing the System: Use radiator

cleaning chemicals to clean and flush the cooling

system before new coolant is added. Follow the

manufacturer’s instructions.

CAUTION

Filling a hot engine with cold water

can cause cracks in the manifold, head and

block. Follow the manufacturer’s instructions

for cleaning and flushing.

Filling the System: Close all drain valves and se-

cure all hose clamps and fill the system through the

fill opening, holding the fill hose vertical. The system

will fill only as fast as the air can escape. Start and run

the engine for a minute to dislodge air pockets and

shut it down. Add as much coolant as necessary to fill

up the tube and secure the pressure cap.

CAUTION

Low coolant level can cause severe

engine damage. Make sure the system is full.

RAISE HOSE VERTICAL

AND REMOVE CAP TO

CHECK COOLANT LEV-

EL

CYLINDER

BLOCK COOLANT

DRAIN VALVE

RADIATOR COOLANT DRAIN

VALVE LOCATED UNDER

THIS CORNER OF RADIA-

TOR

FIGURE 9. COOLING SYSTEM

18

RECOVERY

TANK LOCATED

NEAR GENSET

Copyright 2016 Cummins Inc.

Page 23

FUEL SYSTEM

Fuel Handling Precautions

Keep dirt, water and other contaminants from entering the fuel system and damaging, corroding or clogging fuel injection components. The genset has a

water-separator type of fuel filter.

drain the filter, remove the plug (Figure 10), collect

the water and sediment (about 1/2 cup [120 ml]) in a

suitable container and dispose of properly. Reinstall

the plug securely.

Replacing the Filter Element: See Table 3 for fre-

quency of maintenance. Replace the filter sooner if

the engine lacks power or surges.

A primary source of water in fuel, which can clog fuel

passages by freezing and cause corrosion by forming sulfuric acid with the sulfur in the fuel, is the condensation of humid air on the walls of the fuel tank.

Keeping fuel tanks as full as possible reduces condensation by reducing the area on which condensation can take place.

Fuel Filter

Draining Water and Sediment: See Table 3 for frequency of maintenance. Drain more often if fuel quality is poor or condensation cannot be avoided. To

FUEL SO-

LENOID

Drain the filter as explained above and spin off the

element.

Clean the contact surface of the base.

Lubricate the new element and its gasket, and fill the

element with clean diesel fuel.

Spin the new element onto the base and hand tight-

en.

Start and run the genset and check for fuel leakage.

Tighten the filter only enough to stop leakage.

See Priming the Fuel System if the genset does

not start.

FUEL INJECTION

PUMP

FUEL RETURN CON-

NECTION

Copyright 2016 Cummins Inc.

FUEL

FILTER

FIGURE 10. FUEL SYSTEM

FUEL SUPPLY

CONNECTION

19

FUEL

PUMP

Page 24

Priming the Fuel System

Priming the High-Pressure Side: This procedure

should only be performed by a diesel mechanic.

Priming the Low-Pressure Side: The fuel lift pump

is usually able to prime the low-pressure side during

cranking. If the engine does not start after two tries

(15 second crankings with a two minute rest between

crankings), jumper the fuel lift pump directly to the 12

VDC cranking battery and let the pump run for a few

minutes to make sure the fuel lines, fuel filter and injection pump have been purged of all air . (The air and

fuel are returned to the fuel tank. There are no bleed

screws to open.)

Note: If the genset has been mounted at an elevated

location on the vehicle, the vehicle manufacture probably has provided an auxiliary fuel pump and solenoid

shutoff valve which must also be energized during

priming. Check with the vehicle manufacturer if it is

not clear as to how the auxiliary pump and solenoid

should be energized.

USE TWO FLARE-NUT WRENCHES TO LOOSEN THESE FIT-

TINGS TO BLEED HIGH PRESSURE INJECTOR LINES

WEAR SAFETY GLASSES AND KEEP FINGERS OUT OF SPRAY

WARNING

The high pressure oil spray from an

injector line fitting can penetrate the skin, leading to possible blood poisoning. Wear safety

glasses and keep your hands away from the

spray. Do not delay getting proper medical attention if oil spray penetrates your skin.

Loosen the high pressure fittings at the nozzles. Use

two wrenches to keep from twisting the return fittings. Use flare-nut wrenches to keep from

rounding the shoulders.

Crank the genset until fuel appears at the loosened

fittings and then snug up each fitting. The engine

should start and run when the first fitting is

snugged.

Shut down the engine and torque the fittings to

19 − 25 lb-ft (25 − 34 N-m).

DO NOT LOOSEN

THESE FITTINGS

FIGURE 11. PRIMING THE HIGH-PRESSURE FUEL INJECTION SYSTEM

20

Copyright 2016 Cummins Inc.

Page 25

Troubleshooting

The following troubleshooting tables are designed to

help you think through genset problems. The problem could be as simple as an empty fuel tank, closed

fuel shutoff valve or tripped circuit breaker. If you fail

to resolve the problem after taking the corrective actions suggested, see How to Obtain Service.

Troubleshooting time can be saved if abnormal engine gauge readings were noted before shutdown;

that is, whether shutdown was due to low oil pressure

or to high engine temperature. Note that shutdown

occurs when oil pressure falls below 14 psi (97 kPa)

or engine temperature reaches 222

F (106C).

FAULT CODE BLINKING

At fault shutdown, the status indicator light will repeatedly blink sets of 1, 2, 3 or 4 blinks.

One blink indicates shutdown due to high en-

gine coolant temperature.

Two blinks indicate shutdown due to a loss of

engine oil pressure.

Three blinks indicate a service fault. Press

Stop once to cause the two-digit, second-level

shutdown code to blink. (Pressing Stop again

will stop the blinking.) The two-digit code con-

sists of 1, 2, 3, 4 or 5 blinks, a brief pause, and

then 1 to 9 blinks. The first set of blinks represents the tens digit and the second set of blinks

the units digit of the shutdown code number. For

example, shutdown code No. 36 appears as:

blink-blink-blink—pause—blink-blink-blink-blink-blink-blink—long

pause—repeat

Four blinks indicate that cranking time exceed-

ed 35 seconds.

Fault Code Nos. 1, 2, 3, and 4 are first level faults.

Pay close attention to the pause sequence to avoid

interpreting first level faults as second-level Fault

Codes Nos. 11, 22, 33, or 44.

To avoid the possibility of anyone misinterpreting

Code Nos. 3 and 4 as Code Nos. 33 and 44, the latter

have not been assigned faults.

RESTORING FAULT CODE BLINKING

The fault code stops blinking after five minutes.

Press Stop three times within three seconds to restore fault code blinking.

Note: The last fault logged will blink even though the

condition that caused the shutdown may have been

corrected.

ENGINE DOES NOT CRANK

WARNING

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

There are hazards present in troubleshooting that can cause equipment

Possible Cause Corrective Action

Faulty remote circuit Try starting at the genset control panel. If the genset starts,

have the remote circuit repaired as necessary.

Fault shutdown Perform maintenance or have service performed as neces-

sary to clear the fault condition. Push the red button on the

fault reset breaker on the genset-mounted control panel to reset the control panel.

Copyright 2016 Cummins Inc.

21

Page 26

ENGINE DOES NOT CRANK

WARNING

There are hazards present in troubleshooting that can cause equipment

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

Possible Cause Corrective Action

Tripped DC control breaker Reset the control breaker handle. Have the genset serviced

if it keeps tripping.

Low cranking voltage 1. Clean and tighten or replace the positive (+) and negative (−)

battery cable connectors and cables at the battery and the

genset.

a. Recharge or replace the battery. Specific gravity for a fully

charged battery is approximately 1.260 at 80F (27C).

ENGINE CRANKS BUT DOES NOT START

WARNING

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

There are hazards present in troubleshooting that can cause equipment

Possible Cause Corrective Action

Engine not getting fuel 1. Open any closed shutoff valve.

a. Check fuel level and refill as necessary.

b. Prime the fuel system (p.11).

c. Check for fuel (air) leaks at all fittings and tighten as neces-

sary.

d. Replace the fuel filter (p. 19).

Low engine temperature e. Plug in, repair or install engine coolant and engine oil heaters.

f. Replace the engine oil if it is not of the recommended viscosity

for the ambient temperature.

Low cranking voltage g. Clean and tighten or replace the positive (+) and negative (−)

battery cable connectors and cables at the battery and the

genset.

h. Recharge or replace the battery. Specific gravity for a fully

charged battery is approximately 1.260 at 80 F (27 C).

Service as necessary.

22

Copyright 2016 Cummins Inc.

Page 27

FAULT SHUTDOWN

WARNING

There are hazards present in troubleshooting that can cause equipment

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

Possible Cause Corrective Action

Low engine oil pressure Check engine oil level, repair any leaks and fill to the proper

level (p. 15).

High engine temperature 1. Check engine coolant level, repair any leaks and fill to the

proper level (p. 17).

a. Check V-belt tension (p. 17).

b. Clean and service the cooling system as required to restore

full cooling capacity (p. 17).

ENGINE LACKS POWER OR UNSTABLE

WARNING

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

There are hazards present in troubleshooting that can cause equipment

Possible Cause Corrective Action

Inadequate fuel delivery 1. Check for fuel (air) leaks at all fittings and tighten as neces-

sary.

a. Replace the fuel filter (p. 19).

Contaminated fuel Connect the fuel lift pump to a container of fuel of known quali-

ty. Replace the contents of the fuel supply tank if there is a no-

ticeable difference in performance.

Copyright 2016 Cummins Inc.

23

Page 28

NO OUTPUT VOLTAGE

WARNING

There are hazards present in troubleshooting that can cause equipment

damage, severe personal injury or death. Troubleshooting must be performed by qualified persons who know about the hazards of fuel, electricity and machinery. Read Safety Precautions and

observe all instructions and precautions in this manual.

Possible Cause Corrective Action

Line circuit breaker Off. Find out why the circuit breaker was turned Off, make sure it

is safe to reconnect power, and then throw the circuit breaker

On.

Line circuit breaker Tripped. Shut do w n t h e g e nset and have service performed as neces-

sary to clear the short circuit or ground fault that caused tripping. Then Reset the circuit breaker and start the genset.

24

Copyright 2016 Cummins Inc.

Page 29

Specifications

Control

System

Engine

Detail

Unit Mounted, Drip-Proof, Vibration Isolated

Console

DC Controls - 12-Volt System

Start/Stop/Preheat Switch

Sealed Remote Connector for

Start/Stop/Preheat

Switch Gauge Package

Manual Reset Fault Relay Indicating

Engine Shutdown for High Coolant

Temperature, Low Oil Pressure

Design: 4-Cycle, Liquid-cooled Diesel Engine

Cylinders: Inline Vertical - 3

Bore:

HDKAL 3.07 in (78 mm)

HDKAS 2.83 IN (72 MM)

Stroke:

HDKAL 3.09 in 78.4 mm

HDKAS 2.90 in (73.6 mm)

Displacement

HDKAL 68.53 in

HDKAS 54.8 in

Compression Ratio: 24 to 1

Lube Oil Capacity: 5.39 qt (5.1 L)

Cooling System Capacity:1.25 gal (4.73 L)

Starting System: Remote, 12-volt

3

(1124 cm3)

3

(898 cm3)

AC Controls

Voltage Regulator (See Generator Detail)

One or Two Circuit Breakers

Fuel Injection Pump: Bosch K mini

Combustion Chamber: Spherical

Fuel Consumption: No. 2 Diesel Fuel, gph/lph

No Load Half Load Full Load

HDKAL 0.24 gph 0.49 gph 0.85 gph

0.90 lph 1.85 lph 3.2 lph

HDKAS 0.23 gph 0.46 gph 0.8 gph

0.87 lph 1.74 lph 3.03 lph

Generator

Detail

GenSet

Performance

Accessories

Design: Brush type, Drip-proof Construction.

Insulation System Rise: Class F per NEMA

MGI-1.65 and BS 2757 Insulating Varnish Conforms

to MIL-1-24092, Grade CB, Class 155 C.

Exciter System: Electronic Voltage Regulator

Regulation, No Load to Rated Load

Voltage:

Frequency:

Battery Charging: 12 Volt Battery Charging

DC Alternator (30 amp output)

Sound Level: 76 dB(a) @ 3 m rated load

Random Frequency Variation for Constant Loads

Required Accessory

2.5%

2.5%

(USDA Forest Service Approved Spark

Arrester Muffler .

Optional Accessories

Battery - 12 volt, 475 Cold Cranking Amps at

F (-17.8C)

0

Remote Gauge Package with Start/Stop/-

Preheat Switch, Voltage Meter, Water

Temperature Gauge, Oil Pressure Gauge,

Hour Meter (Standard on Comm

HDKAL/HDKAS)

Bearing: Double Sealed Prelubricated Ball Bearing

Cooling: Direct Drive Centrifugal Blower

Damper Bar: Improves Harmonics and Voltage

Waveforms (Comm HDKAL/HDKAS Only)

from No Load to Full Load is

Random Voltage Variation: Under These

Conditions is 1%

Maximum Operating Ambient Temperature:

Efficient Radiator Cooling System Permits Operation

at Ambient Temperatures up to 120

1%

F (49C).

Remote Circuit Breaker Kits

Remote Wiring Harness, 10 or 30 ft.

Engine Block Heater (Comm HDKAL/HDKAS

Only)

RACOR Fuel/Water/Separator

(Comm HDKAL/HDKAS Only)

Remote DC Gauge Kit (Comm

HDKAL/HDKAS Only)

Copyright 2016 Cummins Inc.

25

Page 30

THIS PAGE IS INTENDED TO BE BLANK

26

Copyright 2016 Cummins Inc.

Page 31

Information for California Genset Users

These gensets meet the requirements of California’s

Exhaust Emissions Standards for 1995 and later for

Utility and Lawn and Garden Equipment Engines.

As a California user of these gensets, please be

aware that unauthorized modifications or replacement of fuel, exhaust, air intake, or speed control

system components that affect engine emissions are

prohibited. Unauthorized modification, removal or

replacement of the genset label is prohibited.

TABLE 4. EMISSIONS CONTROL INFORMATION

The California emissions control warranty statement is located in

Genset Warranty Information

Engine Fuel Requirements

Engine Lubricating Oil Requirements See ENGINE OIL RECOMMENDATIONS.

Engine Adjustments

the same packet of information as this manual when the engine is

shipped from the factory.

The engine is certified to operate on diesel fuel. See FUEL RECOMMENDATIONS.

High Idle Speed. This is a service procedure requiring trained personnel and proper tools. See the Service Manual.

You should carefully review Operator (Owner),

Installation and other manuals and information you

receive with your genset. If you are unsure that the

installation, use, maintenance or service of your genset is authorized, you should seek assistance from

an authorized dealer.

California genset users may use Table 4 as an aid in

locating information related to the California Air Resources Board requirements for emissions control.

Engine Emission Control System

The engine emission control system consists of engine design

and precision manufacture. (IFI)

Copyright 2016 Cummins Inc.

27

Page 32

THIS PAGE IS INTENDED TO BE BLANK

28

Copyright 2016 Cummins Inc.

Page 33

How to Obtain Service

When you need parts or service for your genset con-

tact the nearest authorized Cummins Onan dealer or

distributor. Cummins Onan has factory-trained representatives to handle your needs for genset parts

and service. T o locate the nearest authorized distributor:

1. Check the North American Sales and Service

Directory (F-118) and the International Sales

and Service Directory (IN-1013) supplied with

your genset. These directories list authorized

distributors who will assist you in locating the

nearest authorized dealer.

2. Consult the Yellow Pages. Typically, our distributors are listed under:

GENERATORS − ELECTRIC,

ENGINES − GASOLINE OR DIESEL, or

RECREATIONAL VEHICLES − EQUIPMENT,

PARTS AND SERVICE.

3. Call 1-800-888-0626 for the name and telephone number of the nearest Cummins Onan

distributor in the United States or Canada. (This

automated service utilizes touch-tone phones

only). By calling this number you can also request a directory of authorized RV servicing

dealers: RV Sales and Service Directory F-919.

To get service, contact the authorized dealer or distributor nearest you, explain the problem and make

an appointment. If you have difficulty in arranging for

service or resolving a problem, please contact the

dealer coordinator or service manager at the nearest

Cummins Onan distributor for assistance.

Before calling for service, have the following information available:

1. Complete model number and serial number

2. Date of purchase

3. Nature of the problem.

WARNING

parts can result in severe personal injury, death,

and/or equipment damage. Service personnel

must be qualified to perform electrical and/or

mechanical service.

Improper service or replacement of

Copyright 2016 Cummins Inc.

29

Page 34

THIS PAGE IS INTENDED TO BE BLANK

30

Copyright 2016 Cummins Inc.

Page 35

Maintenance Record

Use the following table to keep a record of all periodic and unscheduled maintenance and service. See Periodic

Maintenance.

HOUR

DATE

METER

READING

MAINTENANCE OR SERVICE PERFORMED

Record the name, address, and phone number of your authorized Cummins Onan service center.

Copyright 2016 Cummins Inc.

31

Page 36

THIS PAGE IS INTENDED TO BE BLANK

32

Copyright 2016 Cummins Inc.

Page 37

Page 38

power.cummins.com

Copyright E 2016 Cummins Inc. All rights reserved.

Cummins, Onan, the “C” logo, and “Performance you rely on.” are trademarks of Cummins Inc.

Other company, product, or service names may be trademarks or service marks of others.

Specifications are subject to change without notice.

Loading...

Loading...