Page 1

Models

GGHB

GGHC

GGHD

Detector™/Sentinel™ Controls

GENERATOR SETS

Printed in U.S.A. 928-0133B 11-98

Page 2

Safety Precautions

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal injury or death.

WARNING

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

•

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not warped. Do not use exhaust gases to

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

• DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use

copper piping on flexible lines as copper will become brittle if continuously vibrated or repeatedly

bent.

• Natural gas is lighter than air, and will tend to gather

under hoods. Propane is heavier than air, and will

tend to gather in sumps or low areas. NFPA code requires all persons handling propane to be trained

and qualified.

• Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, discon-

nect battery charger from its AC source, then disconnect starting batteries, negative (-) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts. Jewelry can short out electrical contacts and cause shock or burning.

• If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

MS-1

iii

Page 3

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH

•

Remove electric power before removing protective

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DI-

RECTLY TO ANY BUILDING ELECTRICAL SYS-

TEM. Hazardous voltages can flow from the gen-

erator set into the utility line. This creates a potential

for electrocution or property damage. Connect only

through an approved isolation switch or an ap-

proved paralleling device.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

•

than water. DO NOT open a radiator or heat ex-

changer pressure cap while the engine is running.

Allow the generator set to cool and bleed the system

pressure first.

• Benzene and lead, found in some gasoline, have

been identified by some state and federal agencies

as causing cancer or reproductive toxicity. When

checking, draining or adding gasoline, take care not

to ingest, breathe the fumes, or contact gasoline.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproductive toxicity. When checking or changing engine oil,

take care not to ingest, breathe the fumes, or con-

tact used oil.

• Provide appropriate fire extinguishers and install

them in convenient locations. Consult the local fire

department for the correct type of extinguisher to

use. Do not use foam on electrical fires. Use extin-

guishers rated ABC by NFPA.

• Make sure that rags are not left on or near the en-

gine.

• Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause over-

heating and engine damage which present a poten-

tial fire hazard.

• Keep the generator set and the surrounding area

clean and free from obstructions. Remove any de-

bris from the set and keep the floor clean and dry.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment un-

safe.

• Substances in exhaust gases have been identified

by some state or federal agencies as causing can-

cer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

iv

Page 4

Table of Contents

SECTION TITLE PAGE

SAFETY PRECAUTIONS iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 INTRODUCTION

General 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Obtain Service 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 SPECIFICATIONS 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 OPERATION (DETECTOR CONTROL)

General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prestart Checks 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator AC Voltage Regulator 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Control Module 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 TROUBLESHOOTING (DETECTOR CONTROL)

Safety Considerations 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Charts 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 OPERATION (SENTINEL CONTROL)

General 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prestart Checks 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator AC Voltage Regulator 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Monitoring 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 TROUBLESHOOTING (SENTINEL CONTROL)

Safety Considerations 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Charts 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

!!

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

i

Page 5

SECTION TITLE PAGE

7 MAINTENANCE

General 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedule 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Inspection 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication System 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling System 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Filter 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Belt 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Out-of-Service Protection 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 ADJUSTMENTS

Output Voltage Adjustment 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System Adjustments 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 OPERATING RECOMMENDATIONS

Break-In 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No-Load Operation 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exercise Period 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Operating Temperatures 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Rating Factors 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 6

1. Introduction

GENERAL

Each operator should read this manual before oper-

ating the set for the first time. A generator set (gen-

set) must be operated and maintained properly if

you are to expect safe, reliable and quiet operation.

The manual includes a troubleshooting guide and a

maintenance schedule.

The engine manual is included with the set. Where

there is conflicting information, this manual takes

precedence over the engine manual.

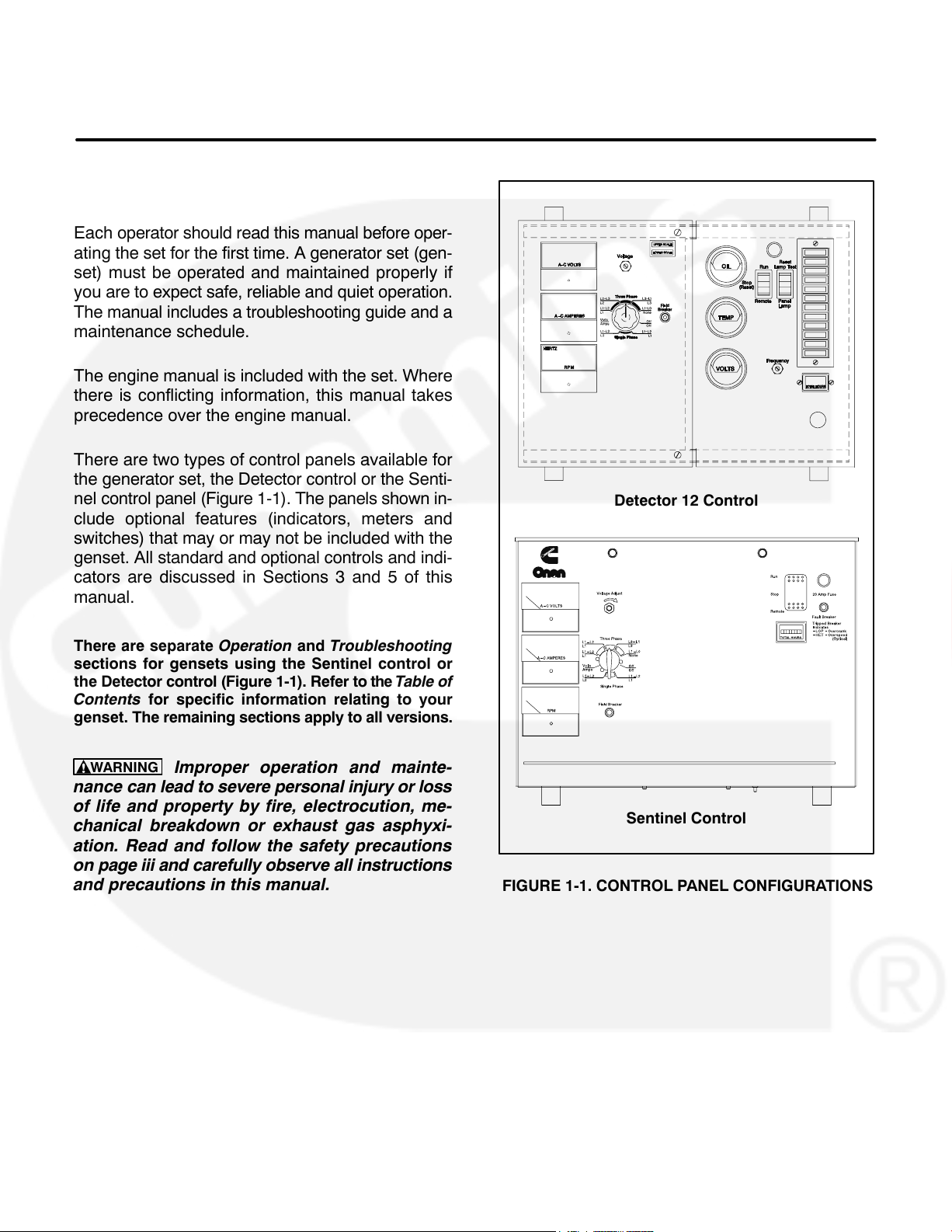

There are two types of control panels available for

the generator set, the Detector control or the Senti-

nel control panel (Figure 1-1). The panels shown in-

clude optional features (indicators, meters and

switches) that may or may not be included with the

genset. All standard and optional controls and indi-

cators are discussed in Sections 3 and 5 of this

manual.

Detector 12 Control

There are separate Operation and Troubleshooting

sections for gensets using the Sentinel control or

the Detector control (Figure 1-1). Refer to the Table of

Contents for specific information relating to your

genset. The remaining sections apply to all versions.

WARNING

nance can lead to severe personal injury or loss

of life and property by fire, electrocution, me-

chanical breakdown or exhaust gas asphyxi-

ation. Read and follow the safety precautions

on page iii and carefully observe all instructions

and precautions in this manual.

Improper operation and mainte-

Sentinel Control

FIGURE 1-1. CONTROL PANEL CONFIGURATIONS

1-1

Page 7

HOW TO OBTAIN SERVICE

When the generator set requires servicing, contact

your nearest Cummins

tor. Factory-trained Parts and Service representatives are ready to handle all your service needs.

®

/Onan® dealer or distribu-

1-800-888-ONAN (this automated service utilizes

touch-tone phones only). By entering your area

code and the first three digits of your local telephone

number, you will receive the name and telephone

number of the distributor nearest you.

If you are unable to locate a dealer or distributor,

consult the Yellow Pages. Typically, our distributors

are listed under:

For outside North America, call Onan Corporation,

1-612-574-5000, 7:30 AM to 4:00 PM, Central Stan-

dard Time, Monday through Friday. Or, send a fax to

Onan using the fax number 1-612-574-8087.

GENERATORS-ELECTRIC or

ELECTRICAL PRODUCTS

When contacting your distributor, always supply the

For the name of your local Cummins/Onan or Onan-

only distributor in the United States or Canada, call

complete Model, Specification, and Serial Number

as shown on the generator set nameplate.

WARNING

INCORRECT SERVICE OR PARTS REPLACEMENT CAN RESULT IN SEVERE PERSONAL IN-

JURY, DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST BE QUALIFIED

TO PERFORM ELECTRICAL AND/OR MECHANICAL SERVICE.

Onan is a registered trademark of Onan Corporation.

Cummins is a registered trademark of Cummins Engine Company, Inc.

1-2

Page 8

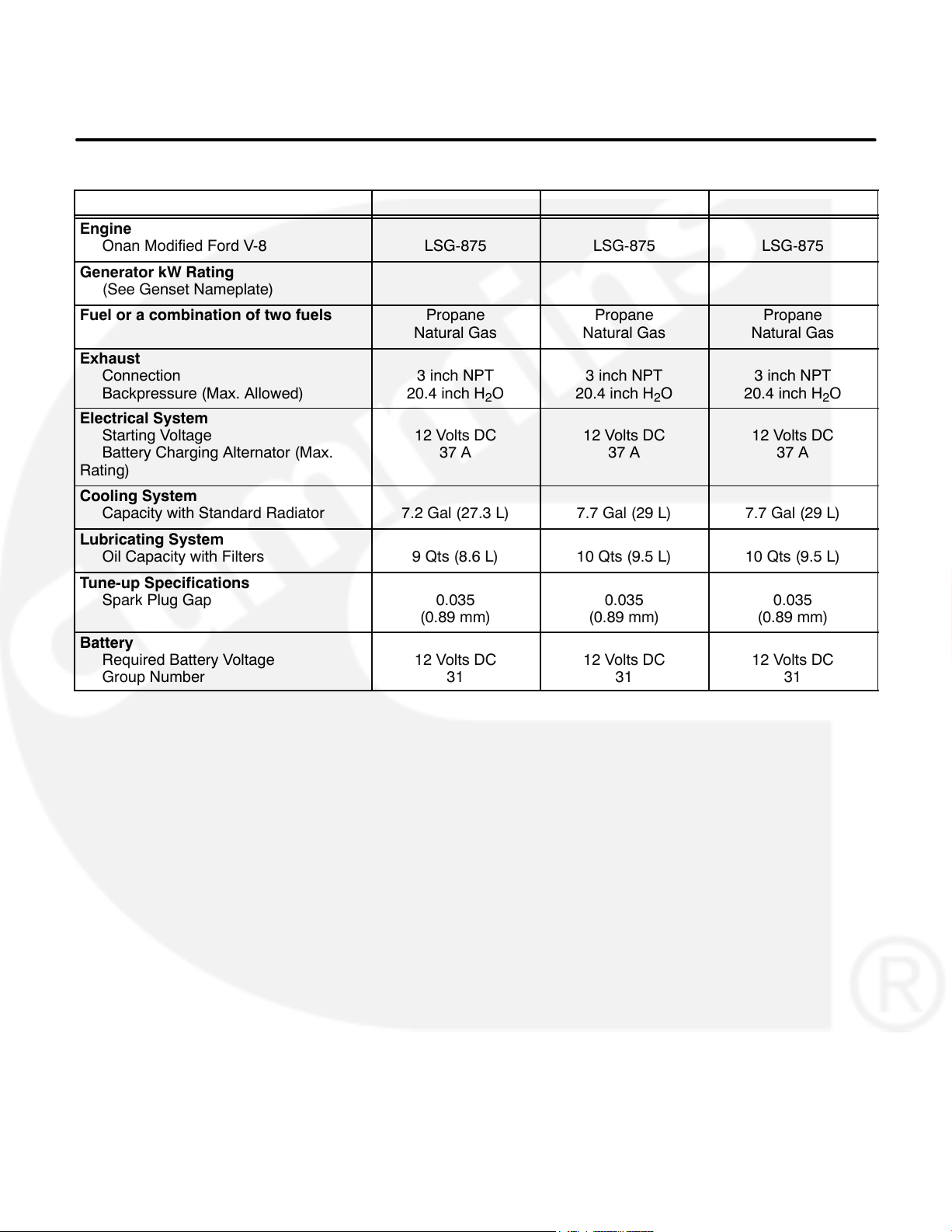

2. Specifications

MODEL GGHB GGHC GGHD

Engine

Onan Modified Ford V-8

Generator kW Rating

(See Genset Nameplate)

Fuel or a combination of two fuels Propane

Exhaust

Connection

Backpressure (Max. Allowed)

Electrical System

Starting Voltage

Battery Charging Alternator (Max.

Rating)

Cooling System

Capacity with Standard Radiator

Lubricating System

Oil Capacity with Filters

Tune-up Specifications

Spark Plug Gap

Battery

Required Battery Voltage

Group Number

LSG-875 LSG-875 LSG-875

Natural Gas

3 inch NPT

20.4 inch H

12 Volts DC

37 A

7.2 Gal (27.3 L) 7.7 Gal (29 L) 7.7 Gal (29 L)

9 Qts (8.6 L) 10 Qts (9.5 L) 10 Qts (9.5 L)

0.035

(0.89 mm)

12 Volts DC

31

Propane

Natural Gas

3 inch NPT

O

2

20.4 inch H

12 Volts DC

37 A

0.035

(0.89 mm)

12 Volts DC

31

O

2

Propane

Natural Gas

3 inch NPT

20.4 inch H

12 Volts DC

37 A

0.035

(0.89 mm)

12 Volts DC

31

O

2

2-1

Page 9

2-2

Page 10

3. Operation (Detector Control)

GENERAL

This section covers prestart checks, starting and

stopping and operating the generator set. Each op-

erator should read through this entire section before

attempting to start the set. It is essential that the op-

erator be completely familiar with the set for safe

operation. Refer to Section 9 for operating recom-

mendations.

PRESTART CHECKS

Before starting, be sure the following checks have

been made and the unit is ready for operation. Refer

to the Maintenance section for the recommended

procedures.

Lubrication

Check the engine oil level. Keep the oil level as

close as possible to the dipstick high mark without

overfilling.

Coolant

Check the engine coolant level. The cold coolant

level should be about 3/4 inch (18 mm) below the ra-

diator cap lower sealing surface. Do not check while

the engine is hot.

WARNING

severe burns. Do not bleed hot, pressurized coolant

from a closed cooling system.

Contact with hot coolant can result in

Fuel

Open all manual shutoff valves in the fuel supply

system.

Exhaust

Check to make sure entire exhaust system is tight,

that no combustible materials are near system, and

gases are discharged away from building openings.

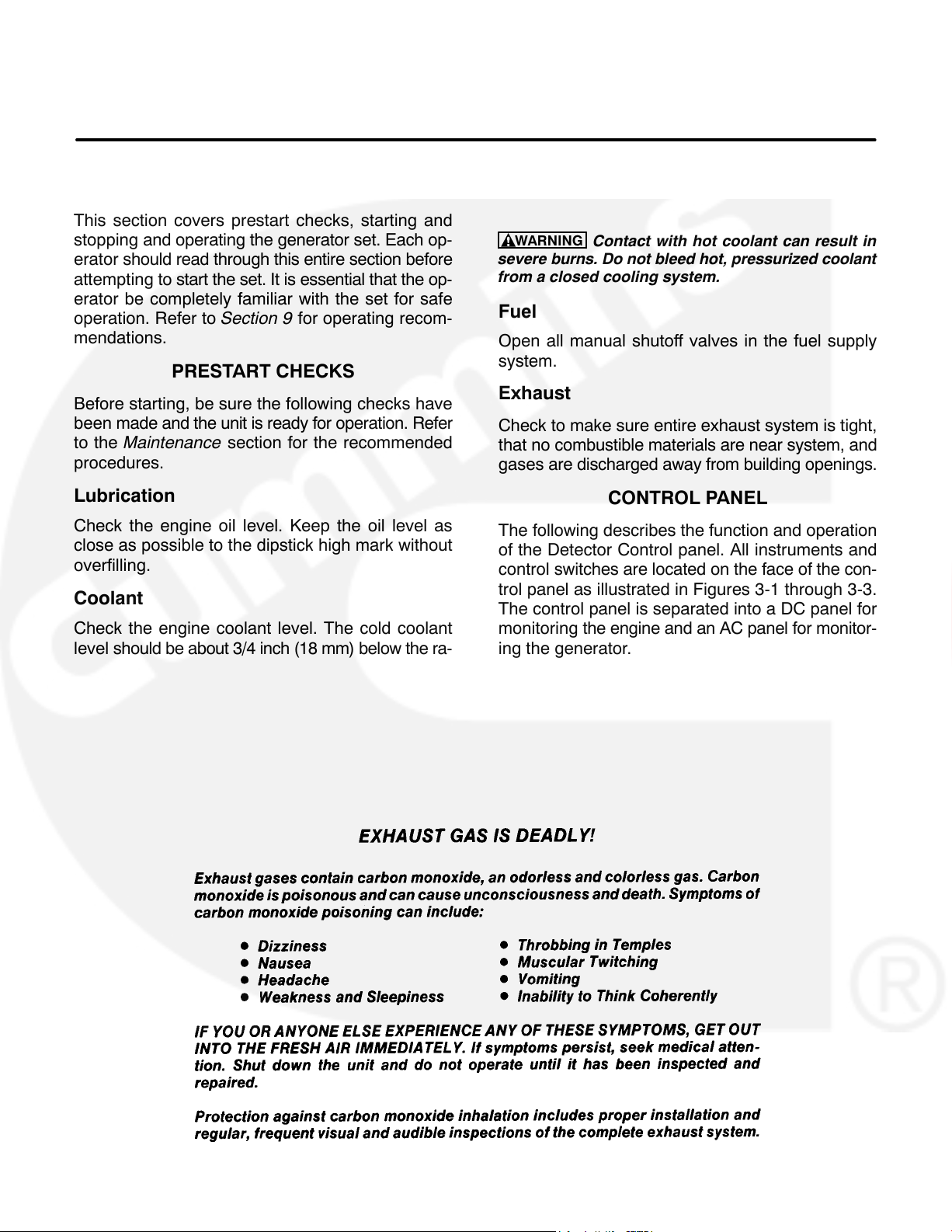

CONTROL PANEL

The following describes the function and operation

of the Detector Control panel. All instruments and

control switches are located on the face of the con-

trol panel as illustrated in Figures 3-1 through 3-3.

The control panel is separated into a DC panel for

monitoring the engine and an AC panel for monitor-

ing the generator.

3-1

Page 11

OIL PRESSURE

GAUGE

PANEL LAMP

RUN/STOP/REMOTE

SWITCH

COOLANT

TEMPERATURE

GAUGE

DC VOLTMETER

FIGURE 3-1. DC CONTROL PANEL (DETECTOR 12 SHOWN)

DC Panel

Panel Lamp: Illuminates control panel.

RESET/LAMP

TEST/ PANEL

LAMP SWITCH

INDICATOR

LAMPS

RUNNING

TIME METER

EMERGENCY STOP

PUSHBUTTON

Run/Stop/Remote Switch: Starts and stops the

set locally, or from a remote location wired to the

control engine monitor board.

Oil Pressure Gauge: Indicates pressure of lubri-

cating oil in engine (wired to a sensor located on the

engine). Normal oil pressure is 40 to 65 psi (276 to

449 kPa) at normal operating temperature.

Coolant Temperature Gauge: Indicates tempera-

ture of circulating coolant in engine (wired to a sen-

sor located on engine). Engine coolant temperature

is typically between 165

° to 195° F(74° to 91° C).

DC Voltmeter: Indicates the battery charging sys-

tem voltage. Normal charging voltage is 12 to 14

volts.

Running Time Meter: Registers the total number

of hours the unit has run. Use it to keep a record of

periodic servicing. Time is cumulative; meter can-

not be reset.

Reset/Lamp Test/Panel Lamp Switch: Resets

the fault circuit only when the Run/Stop/Remote

switch is in the Stop (Reset) position. Tests fault

lamps and turns on the control panel lamp.

Emergency Stop Button (Optional): Push-in

switch for emergency shutdown of the engine. To

reset, pull switch out and move Run/Stop/Remote

switch to Stop position. Then push test switch to Re-

set/Lamp Test position.

3-2

Page 12

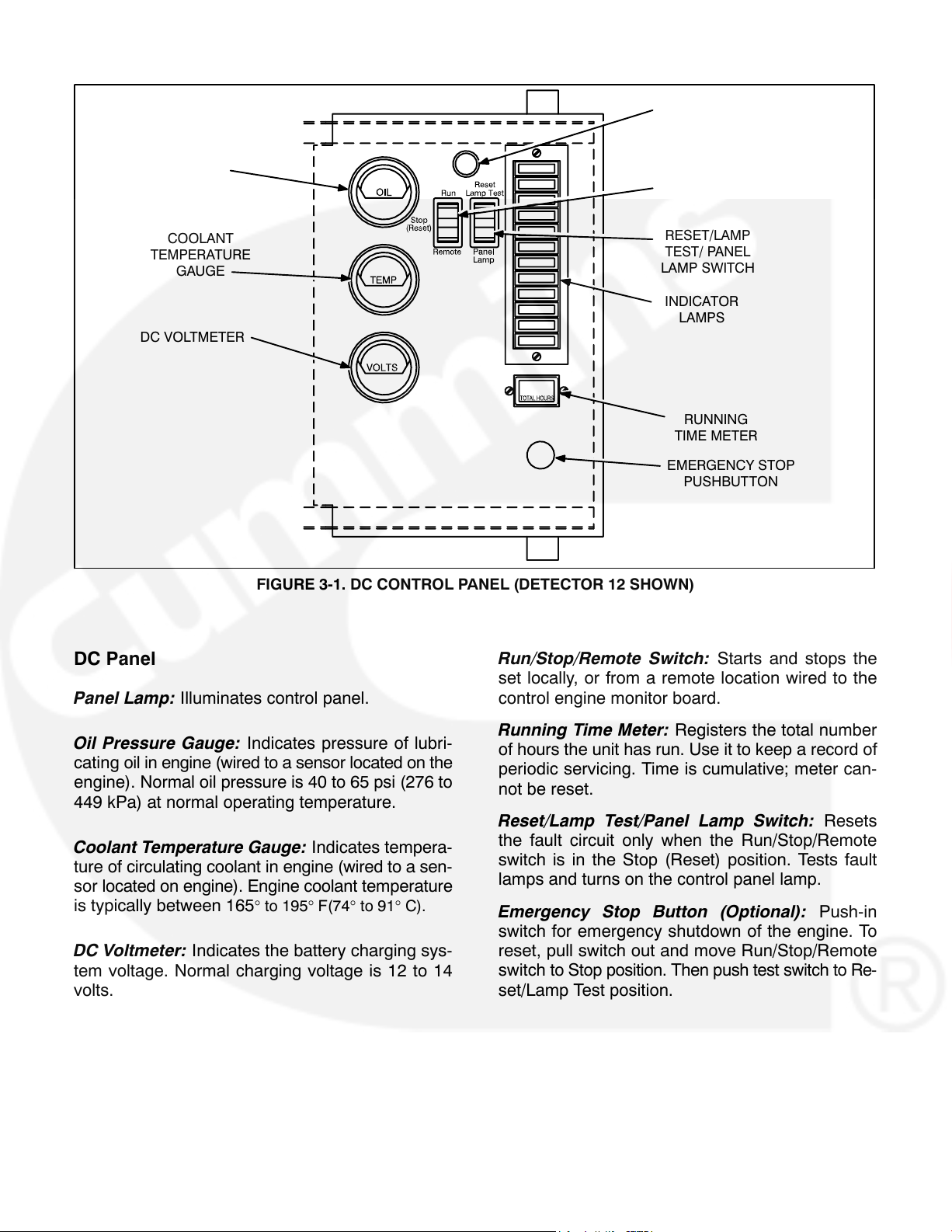

Indicator Lamps: The control panel has twelve indicator lamps which are described as follows:

• RUN (green) lamp comes on when starter cir-

cuit opens after set starting.

• PRE LO OIL PRES (yellow) indicates engine

oil pressure is marginally low.

• PRE HI ENG TEMP (yellow) indicates engine

temperature is marginally high.

• LO OIL PRES (red) indicates engine has shut

down because of critically low oil pressure.

• HI ENG TEMP (red) indicates engine has shut

down because of critically high engine tem-

perature.

• OVERSPEED (red) indicates engine has shut

down because of excessive speed.

• OVERCRANK (red) indicates engine has failed

to start during the cranking period.

• FAULT 1 (red) lamp indicates an undedicated

fault. May be field programmed as a shutdown

or non-shutdown, and as a timed or non-timed

fault. (Normally set for timed shutdown).

• FAULT 2 (red) lamp indicates same features as

Fault 1 (normally set for non-timed shutdown).

• LOW ENG TEMP (yellow) lamp lights if engine

temperature is marginally low for starting. It

may indicate an inoperative coolant heater.

• LO FUEL (yellow) (optional) indicates fuel sup-

ply pressure is marginally low (5 inches [127

mm] WC or less).

• SWITCH OFF (flashing red) indicates genera-

tor set is not in automatic start mode.

FIGURE 3-2. INDICATOR LAMPS

3-3

Page 13

AC VOLTMETER

AC AMMETER

FREQUENCY/

RPM METER

UPPER AND LOWER

SCALE INDICATOR

A−C VOLTS

VOLTAGE

ADJUST

A−C AMPERES

EXCITATION

FIELD BREAKER

RPM

HERTZ

FIGURE 3-3. AC CONTROL PANEL

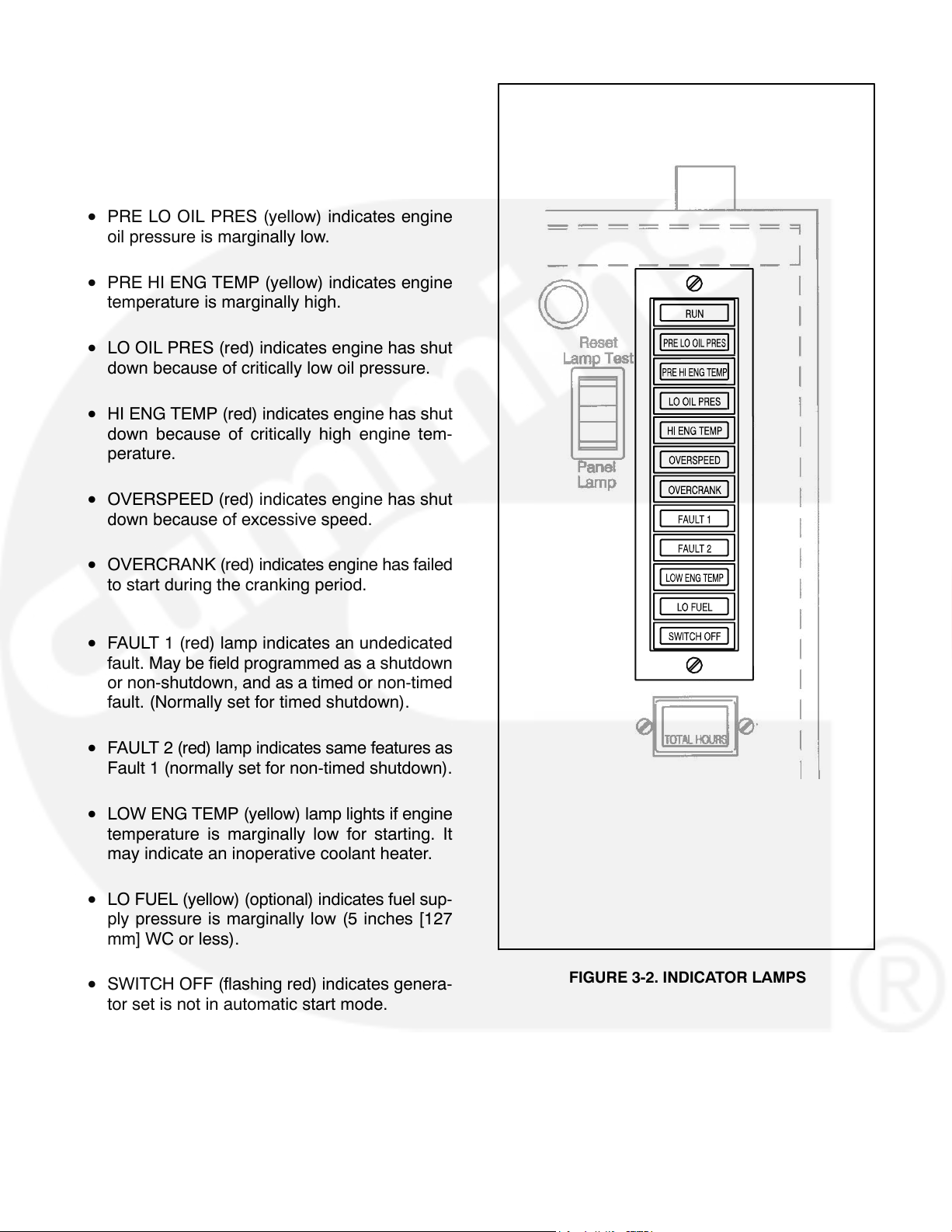

AC Panel

AC Voltmeter: Dual range instrument indicating

AC voltage. Measurement range in use shown on

indicator lamp.

AC Ammeter: Dual range instrument indicates AC

generator line current.

Frequency/RPM Meter: Indicates generator out-

put frequency in hertz and engine speed in revolu-

tions-per-minute (RPM).

Voltage Adjusting Rheostat: Provides approxi-

mately plus or minus five percent adjustment of the

rated output voltage.

PHASE

SELECTOR

SWITCH

Upper and Lower Scale Indicator Lamps: Indi-

cates which scale to use on the AC voltmeter and

ammeter.

Phase Selector Switch: Selects phases of gen-

erator output to be measured by AC voltmeter and

ammeter.

Field Breaker: Provides generator exciter and

regulator protection from overheating in the event of

certain failure modes of generator, exciter and volt-

age regulator.

3-4

Page 14

GENERATOR AC VOLTAGE REGULATOR

The solid-state regulator controls AC output voltage

from the generator at a predetermined level regardless of load. Refer to the GG Series Specification

Sheet for the voltage regulation and random voltage variation specifications.

ENGINE CONTROL MODULE

Electronic and relay components of the engine

monitoring circuit are on a circuit board assembly.

Sensor inputs are connected by the wiring harness

to plug connectors on the board. The control mod-

ule provides the following functions of unit protec-

tion.

• Overcrank - The standard cycle cranking fea-

ture allows three 15-second cranking cycles

with two 15-second rest periods. If engine fails

to start, the module lights a fault lamp and

opens the cranking circuit.

The overcrank option limits engine cranking to

75 seconds. If engine fails to start, the module

lights a fault lamp and opens the cranking cir-

cuit.

• Overspeed - Shuts down the engine immedi-

ately if overspeed occurs and lights a fault

lamp.

For non-PMG generator sets, the sensor

switch is mounted in the end bell on the genera-

tor shaft. It is factory adjusted to shut down 60

hertz units at 2100

1850+

PMG generator sets, a frequency detection

module, located inside the control box, moni-

tors PMG frequency and shuts down 60 hertz

units at 2100

1850+

50 r/min.

50 r/min.

±90 r/min, 50 hertz units at

±90 r/min, 50 hertz units at

• Low Oil Pressure - Shuts down the engine im-

mediately and lights a fault lamp if oil pressure

drops below:

GGHB − 14 psi (97 kPA)

GGHC, GGHD − 25 psi (195 kPA)

The fault is time-delayed about 10 seconds following starter disconnect and inhibited during

cranking. The delay allows oil pressure to rise

to normal before the electronic control module

monitors this system.

A pre-low oil pressure sensor and lamp pro-

vides an alarm that oil pressure is marginally

low or less than:

GGHB − 20 psi (137 kPA)

GGHC, GGHD − 30 psi (207 kPA)

The cause should be found and corrected as

soon as possible.

• High Engine Temperature - shuts down the en-

gine immediately if coolant temperature rises

above 230° F (110° C) and lights a fault lamp.

The fault is time-delayed about 10 seconds fol-

lowing starter disconnect and inhibited during

cranking. This delay allows coolant in a hot en-

gine time to circulate and return the water

jacket to normal before the electronic control

module monitors this system.

A pre-high engine temperature sensor and

lamp provides an alarm that engine tempera-

ture is marginally high, 220° F (104° C)

cause should be found and corrected as soon

as possible.

CAUTION

shutdown system may not operate if the

coolant level is too low. The high engine

temperature sensor monitors coolant tem-

perature. Loss of coolant will prevent sen-

sor operation and allow the engine to over-

heat causing severe damage to the engine.

Therefore, maintain adequate coolant level

for proper operation of the high engine tem-

perature shutdown system.

The high engine temperature

. The

• Low Coolant Level Alarm/Shutdown (Optional)

- An electronic switch that provides engine

alarm or shutdown if coolant level falls too low.

It also turns on the fault lamp.

3-5

Page 15

STARTING

The following sections cover the three systems

used to start the generator set.

Before starting the generator set, make sure that

exhaust and fuel fittings are tight and properly positioned and that proper maintenance has been per-

formed. See Prestart Checks in this section.

Starting at Control Panel

where the minimum ambient temperature is above

40

°F (4°C). NFPA also requires that the engine

coolant be maintained at a minimum of 90

and for most applications, accept the emergency

load in 10 seconds or less. Although most Onan

generator sets will start in temperatures below 40

°C) when equipped with coolant heaters, it might

(4

take some running time to warm the engine up be-

fore a load can be applied when ambient tempera-

tures are below 40

°F (4°C).

°F (32°C)

°F

Move the Run-Stop-Remote switch on the DC pan-

el to the RUN position. This will activate the engine

control system and the starting system. The starter

will begin cranking and after a few seconds the en-

gine should start. The starter will disconnect when

the engine reaches a speed of 450 to 570 RPM.

If the engine does not start, the starter will disen-

gage after a specified period of time and the control

will indicate an overcrank fault. Generator sets with

the optional overcrank control will crank continu-

ously for up to 75 seconds before disengaging the

starter. Generator sets with the standard cycle

cranking feature will crank for 15 seconds in each

cycle until 3 cycles have been completed. To clear

an overcrank fault, place the Run-Stop-Remote

switch in the STOP position and momentarily press

the Reset switch. Wait two minutes for the starter

motor to cool and then repeat the starting proce-

dure. If the engine does not run after a second at-

tempt at starting, refer to the Troubleshooting sec-

tion.

Starting From Remote Location

Move the Run/Stop/Remote switch on the genera-

tor set DC panel to the REMOTE position. This al-

lows the generator set to be started from a remote

switch. Closing the remote switch initiates the start-

ing sequence described in the previous section.

Automatic Starting

Place the Run/Stop/Remote switch on the genera-

tor set DC panel in the REMOTE position if an auto-

matic transfer switch is used. This allows the trans-

fer switch to start the generator set if a power outage

occurs and stop it when the power returns.

Cold Starting With Loads

In accordance with NFPA 110, Onan recommends

installing standby generator sets (life safety systems) equipped with coolant heaters in locations

The Low Engine Temperature (LET) lamp on the

Onan Detector 12 control is provided to meet the re-

quirements of NFPA 110. The LET sensor signals

an alarm when the engine coolant temperature falls

below 70

ent temperature falls below 40

may be lit even though the coolant heaters are con-

nected and operable. Under these conditions, al-

though the generator set may start, it may not be

able to accept load within 10 seconds. When this

condition occurs, check the coolant heaters for

proper operation. If the coolant heaters are operat-

ing properly, other precautions might be necessary

to warm the engine before applying a load.

°F (21°C). In applications where the ambi-

°F (4°C), the LET

STOPPING

Before Stopping

Run the generator set at no load for three to five

minutes before stopping. This allows the lubricating

oil and engine coolant to carry heat away from the

combustion chamber and bearings.

To Stop

If the set was started at the set control panel or at a

remote control panel, move the Run/Stop/Remote

switch or remote starting switch to the STOP posi-

tion. If the set was started by an automatic transfer

switch, the transfer switch will send a remote (timed

delay) stop signal after the normal power source re-

turns.

Emergency Stop

An optional emergency stop button is located on the

right side of control panel (Figure 3-1). Push button

in for emergency stop. To reset, pull switch out and

move Run/Stop/Remote switch to Stop position.

Then push test switch to Reset/Lamp Test position.

Onan automatic transfer switches have as an op-

tion an exerciser that can be preset to provide regu-

lar exercise periods. Typically the exerciser can be

set for time of start, length of run, and day of week.

3-6

Page 16

4. Troubleshooting (Detector Control)

The generator set has sensors that continuously

monitor the engine for abnormal conditions, such as

low oil pressure or high coolant temperature. If

these conditions occur, the engine monitor acti-

vates a fault lamp, and may also stop the engine

(depending on the condition). If the generator set is

stopped for this reason, the operator may be able to

restart the set after making adjustments or correc-

tions. This section describes the fault condition sys-

tem, and suggests troubleshooting procedures.

The control has a single green light to indicate RUN,

four amber lights and seven red fault lights. The

control also has a terminal connection for an audi-

ble alarm, that sounds when a fault occurs.

SAFETY CONSIDERATIONS

High voltages are present inside the control box and

generator output box when the set is running. Do

not open the control box or generator output box

while the set is running.

WARNING

nents can cause electrocution, resulting in se-

vere personal injury or death. Keep control and

output box covers in place during troubleshoot-

ing.

When troubleshooting a set that is shut down, make

certain the generator set cannot be accidentally re-

started. Place the Run/Stop/Remote switch in the

STOP position and remove the negative battery ca-

ble from the set starting battery.

CAUTION

charger from its AC source before disconnect-

ing the battery cables. Otherwise, disconnect-

ing the cables can result in voltage spikes high

enough to damage the DC control circuits of the

set.

Contacting high voltage compo-

Always disconnect a battery

WARNING

set while working on it can cause severe per-

sonal injury or death. Prevent accidental start-

ing by disconnecting the starting battery cables

(negative [−] first).

Make certain battery area has been well venti-

lated before servicing battery, especially if a

battery charger has been connected. Arcing

can ignite explosive hydrogen gas given off by

batteries, causing severe personal injury. Arc-

ing can occur when cable is removed or re-at-

tached, or when negative (−) battery cable is

connected and a tool used to connect or discon-

nect positive (+) battery cable touches frame or

other grounded metal part of the set.

When a fault lamp turns on during operation, follow

the procedures listed below to locate and correct

the problem. For any symptom not listed, contact an

authorized service center for assistance.

Accidental starting of the generator

Resetting the Control

The external alarm and fault lamp may be deacti-

vated by moving the Run/Stop/Remote switch to

the Stop position and pressing the Reset/Lamp

Test/Panel Lamp switch. Locate the problem and

correct it before restarting the set. While pressing

the Reset/Lamp Test/Panel Lamp switch, make cer-

tain that all lamps light.

Line Circuit Breaker (Optional)

The optional line circuit breaker mounts on the gen-

erator output box. If the load exceeds the generator

current rating, the line circuit breaker will open, pre-

venting the generator from being overloaded. If the

circuit breaker trips, locate the source of the over-

load and correct as necessary. Manually reset the

breaker to reconnect the load to the generator.

4-1

Page 17

TABLE 4-1. TROUBLESHOOTING

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM CORRECTIVE ACTION

1. Green RUN lamp lights following engine

startup.

2. PRE HI ENGINE TEMP lamp lights. En-

gine continues to operate.

3. HI ENG TEMP lamp lights. Engine shuts

down.

1. Indicates all engine systems are normal. No correc-

tive action required.

2. Indicates engine has begun to overheat and engine

temperature has risen to approximately 220

C). If generator is powering non-critical and critical

loads and cannot be shut down, use the following:

a. Reduce load if possible by turning off non-critical

loads.

b. Check air inlets and outlets and remove any ob-

structions to airflow.

If engine can be stopped, follow procedure in

step 3.

3. Indicates engine has overheated (engine tempera-

ture has risen above 230

low (sets with coolant level sensor). Allow engine to

cool down completely before proceeding with the fol-

lowing checks:

a. Check coolant level and replenish if low. Look for

possible coolant leakage points and repair if

necessary.

°F/110°C) or coolant level is

°F (104°

4. PRE LO OIL PRES lamp lights. Engine

continues to operate.

b. Check for obstructions to cooling airflow and

correct as necessary.

c. Check for a slipping fan belt and tighten if loose.

d. Reset control and restart after locating and cor-

recting problem. Contact an authorized service

center for service if none of the above.

4. Indicates engine oil pressure has dropped to:

GGHB − 20 psi (137 kPA)

GGHC, GGHD − 30 psi (207 kPA)

If generator is powering critical loads and cannot be

shut down, wait until next shutdown period and then

follow step 5 procedure. If engine can be stopped, fol-

low procedures in step 5.

4-2

Page 18

TABLE 4-1. TROUBLESHOOTING (continued)

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM CORRECTIVE ACTION

5. LO OIL PRES lamp lights. Engine shuts

down. NOTE: See also step 6.

6. OVERCRANK lamp lights and engine

stops cranking.

or

Engine runs, shuts down, and LO OIL

PRES lamp lights..

7. OVERSPEED lamp lights and the en-

gine shuts down.

5. Indicates engine oil pressure has dropped to:

GGHB − 14 psi (97 kPA)

GGHC, GGHD − 25 psi (195 kPA)

Check oil level, lines and filters. If oil system is OK but

oil level is low, replenish. Reset control and restart.

Contact an authorized service center if oil pressure is

not in the range of 40 to 65 psi (276 to 449 kPa).

6. Indicates possible fuel system problem.

a. Open any closed fuel shutoff valve.

b. Check for dirty or plugged air filter and replace if

necessary (see Maintenance section).

c. Gaseous fuel delivery to the set is inadequate.

Contact an authorized service center for service.

d. Reset the control and restart after correcting the

problem. Contact an authorized service center

for service if none of the above.

7. Indicates engine has exceeded normal operating

speed. Contact an authorized service center for serv-

ice.

8. SWITCH OFF lamp flashes. 8. Indicates Run/Stop/Remote switch is in the Stop po-

sition which will prevent automatic starting if an auto-

matic transfer switch is used. Move the Run/Stop/Re-

mote switch to the Remote position for automatic

starting.

9. LO ENG TEMP lamp lights. Set is in

standby mode but is not operating.

(Lamp lights when engine coolant tem-

perature is 70

the lamp goes out after the engine

warms up, there should be no cause for

alarm even during initial generator set

operation.)

° F (21° C) or lower. Since

9. Indicates engine coolant heater is not operating, not

circulating coolant or ambient temperature too cold

for heater to keep up with demand. Check for the fol-

lowing conditions:

a. Coolant heater not connected to power supply.

Check for blown fuse or disconnected heater

cord and correct as required.

b. Check for low coolant level and replenish if re-

quired. Look for possible coolant leakage points

and repair as required.

c. Contact an authorized service center for service

if none of the above.

4-3

Page 19

TABLE 4-1. TROUBLESHOOTING (continued)

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM

10. The FAULT 1 or FAULT 2 fault lamp

lights. Engine shuts down immediately,

engine runs for several seconds and

then shuts down, or engine continues to

run.

11. The LOW FUEL fault lamp lights. En-

gine continues to run or is in standby

mode.

12. Fault lamp lights but no fault exists. En-

gine gauges show oil pressure, engine

temperature, and frequency (speed) are

within normal limits.

13. Engine starts from generator control

panel but will not start automatically or

from a remote panel. (Note: The Run/

Stop/Remote switch must be in the Re-

mote position for automatic or remote

starting).

CORRECTIVE ACTION

10. The standard undesignated fault functions are pro-

grammed to shut down the set when a fault is sensed.

Fault 1 is time delayed while Fault 2 is immediate.

The nature of the fault is an optional selection that is

determined when the set installation is designed.

The undesignated fault functions may also be pro-

grammed for non-shutdown or non-time delay.

11. Indicates fuel supply pressure is marginally low (5

inches [127 mm] WC or less). Check for partially

closed shutoff valve, empty propane supply tank. For

natural gas fueled sets, check with the gas utility.

12. The monitor board or a sensor may be at fault. Con-

tact an authorized service center for service.

13. Remote circuit breaker is tripped. Reset breaker and

restart. Contact an authorized service center if

breaker trips after resetting.

14. Engine will not crank.

14. Indicates possible fault with control or starting sys-

tem. Check for the following conditions:

a. Fault lamp on. Correct fault and reset control.

b. Poor battery cable connections. Clean the bat-

tery cable terminals and tighten all connections.

c. Discharged or defective battery. Recharge or re-

place the battery.

d. Emergency stop button (if equipped) pushed in.

To reset, pull switch out and move Run/Stop/Re-

mote switch to Stop position. Then push test

switch to Reset/ Lamp position.

e. Contact an authorized service center if none of

the above.

4-4

Page 20

TABLE 4-1. TROUBLESHOOTING (continued)

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM

15. No AC output voltage.

16. RUN or fault lamp(s) does not light when

Lamp Test switch is engaged.

17. Green RUN lamp does not light follow-

ing engine startup.

CORRECTIVE ACTION

15. Field breaker is tripped. Reset breaker. Contact an

authorized service center if voltage buildup causes

breaker to trip.

16. Contact an authorized service center for assistance.

17. Indicates possible Start/Disconnect relay failure.

Contact an authorized service center for assistance.

4-5

Page 21

4-6

Page 22

5. Operation (Sentinel Control)

GENERAL

This section covers prestart checks, starting and

stopping and operating the generator set. Each op-

erator should read through this entire section before

attempting to start the set. It is essential that the op-

erator be completely familiar with the set for safe

operation. Refer to Section 9 for operating recom-

mendations.

PRESTART CHECKS

Before starting, be sure the following checks have

been made and the unit is ready for operation. Refer

to the Maintenance section for the recommended

procedures.

Lubrication

Check the engine oil level. Keep the oil level as

close as possible to the dipstick high mark without

overfilling.

Coolant

Check the engine coolant level. The cold coolant

level should be about 3/4 inch (18 mm) below the ra-

diator cap lower sealing surface. Do not check while

the engine is hot.

WARNING

in severe burns. Do not bleed hot, pressurized

coolant from a closed cooling system.

Contact with hot coolant can result

Fuel

Check the fuel supply and open all manual shutoff

valves in the fuel supply system.

Exhaust

Check to make sure entire exhaust system is tight,

that no combustible materials are near system, and

gases are discharged away from building openings.

CONTROL PANEL

The following describes the function and operation

of the Sentinel control. All instruments and control

switches are located on the face of the control panel

as illustrated in Figure 5-1.

5-1

Page 23

AC VOLTMETER

AC AMMETER

PHASE

SELECTOR

SWITCH

FREQUENCY/

RPM METER

FIELD BREAKER

(EXCITATION)

VOLTAGE

ADJUST

RUN/STOP/REMOTE

SWITCH

20A CONTROL

FUSE

COMMON FAULT

CIRCUIT BREAKER

RUNNING

TIME METER

AC CONTROL DC CONTROL

FIGURE 5-1. SENTINEL CONTROL PANEL

DC Control

Run/Stop/Remote Switch: Starts and stops the

set locally, or from a remote location wired to the

control.

Running Time Meter: Registers the total number

of hours the unit has run. Use it to keep a record of

periodic servicing. Time is cumulative; meter can-

not be reset.

20A Control Fuse: Protects control components

and wiring from current overload.

Common Fault Circuit Breaker: The common

fault circuit breaker shuts down the engine when

any fault shutdown sensor activates. Fault shut-

down is indicated when the breaker reset button ex-

tends out past normal. Push the button to restore

operation (after the engine has been properly serviced).

The standard fault shutdowns are low oil pressure,

high engine temperature or overcrank. Overspeed

is optional.

AC Control

AC Voltmeter (Optional): Dual range instrument

indicating AC voltage. Measurement range in use

shown on indicator lamp.

AC Ammeter (Optional): Dual range instrument

indicates AC generator line current.

Frequency/RPM Meter (Optional): Indicates gen-

erator output frequency in hertz and engine speed

in revolutions-per-minute (RPM).

Voltage Adjusting Rheostat (Optional): Provides

approximately plus or minus five percent adjust-

ment of the rated output voltage.

Phase Selector Switch (Optional): Selects

phases of generator output to be measured by AC

voltmeter and ammeter.

Field Breaker (Excitation): Provides generator

exciter and regulator protection from overheating in

the event of certain failure modes of generator, exciter and voltage regulator.

5-2

Page 24

GENERATOR AC VOLTAGE REGULATOR

The solid-state regulator controls AC output voltage

from the generator at a predetermined level regardless of load. Refer to the GG Series Specification

Sheet for the voltage regulation and random voltage variation specifications.

ENGINE MONITORING

Electronic and relay components of the engine

monitoring circuit are mounted inside the control

box. An optional Dry Contact Module (DCM) can

also be installed in the control box to enable remote

monitoring of these components. The components

provide the following functions of unit protection.

Note: Refer to the Installation Manual for a functional

description of the Dry Contact Module option.

• Overcrank - Limits engine cranking to 60 se-

conds. If engine fails to start, the Fault Breaker

trips and opens the cranking circuit.

• Low Coolant Level (optional w/DCM) - Shuts

down the engine immediately if coolant level

falls too low. Fault condition cannot be cleared

until sensor detects coolant in radiator.

• Low Fuel Pressure (optional w/DCM) - Indi-

cates fuel supply pressure is marginally low (5

inches [127 mm] WC or less). Used only in

single fuel systems. (Remote panel must be at-

tached to control to monitor this error.)

CAUTION

down system may not operate if the coolant

level is too low. The high engine temperature

sensor monitors coolant temperature. Loss of

coolant will prevent sensor operation and allow

the engine to overheat causing severe damage

to the engine. Therefore, maintain adequate

coolant level for proper operation of the high

engine temperature shutdown system.

The high engine temperature shut-

STARTING

• Overspeed (optional) - Shuts down the engine

immediately and trips the common fault circuit

breaker if overspeed occurs. The sensor

switch is mounted in the end bell on the genera-

tor shaft for non-PMG sets. PMG sets, a fre-

quency detection module, located inside the

control box, monitors PMG frequency. The shut

down limits are: 60 hertz units at 2100

min, 50 hertz units at 1850+

50 r/min.

±90 r/

• Low Oil Pressure - Shuts down the engine im-

mediately and trips the common fault circuit

breaker if oil pressure drops below:

GGHB − 14 psi (97 kPA)

GGHC, GGHD − 25 psi (195 kPA)

The fault is time-delayed about 10 seconds fol-

lowing starter disconnect and inhibited during

cranking. The delay allows oil pressure to rise

to normal before the electronic control module

monitors this system.

• High Engine Temperature - Shuts down the en-

gine immediately if coolant temperature rises

above 230° F (110° C) and trips the common

fault circuit breaker. Fault condition cannot be

cleared until sensor detects coolant tempera-

ture of lower than 220° F (104° C)

.

The following sections cover the three systems

used to start the generator set.

Before starting the generator set, make sure that

exhaust and fuel fittings are tight and properly posi-

tioned and that proper maintenance has been per-

formed. See Prestart Checks in this section.

Starting at Control Panel

Move the Run-Stop-Remote switch on the DC pan-

el to the RUN position. This will activate the engine

control system and the starting system. The starter

will begin cranking and after a few seconds the en-

gine should start. The starter will disconnect when

the engine reaches a speed of 450 to 570 RPM.

If the engine does not start, the starter will disen-

gage after 60 seconds and the control will indicate

an overcrank fault. To clear an overcrank fault,

place the Run-Stop-Remote switch in the STOP po-

sition and reset the common fault circuit breaker.

Wait two minutes for the starter motor to cool and

then repeat the starting procedure. If the engine

does not run after a second attempt at starting, refer

to the Troubleshooting (Sentinel Control) section.

5-3

Page 25

Starting From Remote Location

Move the Run/Stop/Remote switch on the generator set DC panel to the REMOTE position. This allows the generator set to be started from a remote

switch. Closing the remote switch initiates the starting sequence described in the previous section.

Automatic Starting

Engine coolant heaters are available for easier

starting in cold weather. Make sure the voltage of

the separate power source is correct for the coolant

heater element rating.

CAUTION

heater, make sure the cooling system is full be-

fore applying power to the heater.

To avoid damage to the coolant

STOPPING

Place the Run/Stop/Remote switch on the genera-

tor set DC panel in the REMOTE position if an auto-

matic transfer switch is used. This allows the trans-

fer switch to start the generator set if a power outage

occurs and stop it when the power returns.

Cold Starting With Loads

Change the engine oil if it is not of the viscosity rec-

ommended for the ambient temperature (Figure

7-1).

To prevent engine coolant from freezing, make sure

the coolant is a 50/50 mixture of anti-freeze and wa-

ter.

Before Stopping

Run the generator set at no load for three to five

minutes before stopping. This allows the lubricating

oil and engine coolant to carry heat away from the

combustion chamber and bearings.

To Stop

If the set was started at the set control panel or at a

remote control panel, move the Run/Stop/Remote

switch or remote starting switch to the STOP posi-

tion. If the set was started by an automatic transfer

switch, the transfer switch will send a remote (timed

delay) stop signal after the normal power source re-

turns.

5-4

Page 26

6. Troubleshooting (Sentinel Control)

The generator set has sensors that continuously

monitor the engine for abnormal conditions, such as

low oil pressure or high coolant temperature. If

these conditions occur, the common fault circuit

breaker trips, and the engine shuts down. After the

problem is corrected, reset the common fault circuit

breaker to restart the generator set. This section de-

scribes the fault condition system, and suggests

troubleshooting procedures.

SAFETY CONSIDERATIONS

High voltages are present inside the control box and

generator output box when the set is running. Do

not open the control box or generator output box

while the set is running.

WARNING

nents can cause electrocution, resulting in se-

vere personal injury or death. Keep control and

output box covers in place during troubleshoot-

ing.

When troubleshooting a set that is shut down, make

certain the generator set cannot be accidentally re-

started. Place the Run/Stop/Remote switch in the

STOP position and remove the negative battery ca-

ble from the set starting battery.

Contacting high voltage compo-

CAUTION

charger from its AC source before disconnect-

ing the battery cables. Otherwise, disconnect-

ing the cables can result in voltage spikes high

enough to damage the DC control circuits of the

set.

WARNING

set while working on it can cause severe per-

sonal injury or death. Prevent accidental start-

ing by disconnecting the starting battery cables

(negative [−] first).

Make certain battery area has been well venti-

lated before servicing battery, especially if a

battery charger has been connected. Arcing

can ignite explosive hydrogen gas given off by

batteries, causing severe personal injury. Arc-

ing can occur when cable is removed or re-at-

tached, or when negative (−) battery cable is

connected and a tool used to connect or discon-

nect positive (+) battery cable touches frame or

other grounded metal part of the set.

When a fault condition occurs during operation, fol-

low the procedures in Table 6-1 to locate and cor-

rect the problem. For any symptom not listed, con-

tact an authorized service center for assistance.

Always disconnect a battery

Accidental starting of the generator

6-1

Page 27

TABLE 6-1. TROUBLESHOOTING

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM CORRECTIVE ACTION

1. Engine will not crank. 1. Indicates possible fault with control or starting system.

Check for the following conditions:

a. Correct fault and reset common fault circuit break-

er.

b. Poor battery cable connections. Clean the battery

cable terminals and tighten all connections.

c. Discharged or defective battery. Recharge or re-

place the battery.

d. Replace the control circuit fuse (located inside the

control panel) if it has blown.

2. The engine cranks, but does not start.

3. The engine shuts down due to high en-

gine temperature or low coolant level.

The Fault Shutdown is being indicated

by the fault circuit breaker reset button

(extended out).

2. Indicates possible fuel system problem.

a. Check for empty fuel tank, fuel leaks, or plugged

fuel lines and correct as required.

b. Check for dirty or plugged air filter and replace if

necessary (see Maintenance section).

c. Reset the tripped common fault circuit breaker and

restart after correcting the problem. Contact an

authorized service center for service if none of the

above.

3. Indicates engine has overheated (engine temperature

has risen above 230

down completely before proceeding with the following

checks:

a. Check coolant level and replenish if low. Look for

possible coolant leakage points and repair if neces-

sary.

b. Check for obstructions to cooling airflow and cor-

rect as necessary.

° F/110° C). Allow engine to cool

c. Check for a slipping fan belt and tighten if loose.

d. Reset the tripped common fault circuit breaker.

Contact an authorized service center for service if

none of the above.

6-2

Page 28

TABLE 6-1. TROUBLESHOOTING (continued)

Many troubleshooting procedures present hazards which can result in severe personal

injury or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery

hazards should perform service procedures. Review safety precautions on pages iii and iv.

SYMPTOM

4. Engine shuts down due to low oil pres-

sure. The Fault Shutdown is being indi-

cated by the fault circuit breaker reset

button (extended out).

5. The engine shuts down due to over-

speed. The Fault Shutdown is being in-

dicated by the fault circuit breaker reset

button (extended out).

6. The engine shuts down due to low cool-

ant level. The Fault Shutdown is being

indicated by the fault circuit breaker re-

set button (extended out).

7. The engine shuts down due any of five

faults but remote monitor device does

not detect fault.

CORRECTIVE ACTION

4. Indicates engine oil pressure has dropped to:

GGHB − 14 psi (97 kPA)

GGHC, GGHD − 25 psi (195 kPA)

Check oil level, lines and filters. If oil system is OK but

oil level is low, replenish. Reset the tripped common

fault circuit breaker. Contact an authorized service

center if oil pressure is not in the range of 40 to 65 psi

(276 to 449 kPa).

5. Indicates engine has exceeded normal operating

speed. Contact an authorized service center for service.

6. Indicates low coolant level. Replenish coolant and

look for possible coolant leakage points and repair as

required.

7. Indicates possible fault with control or external wiring.

8. Engine starts from generator control

panel but will not start automatically or

from a remote panel. (Note: The Run/

Stop/Remote switch must be in the Re-

mote position for automatic or remote

starting).

8. Remote circuit breaker is tripped. Reset breaker and

restart. Contact an authorized service center if

breaker trips after resetting.

6-3

Page 29

6-4

Page 30

7. Maintenance

GENERAL

Establish and adhere to a definite schedule for

maintenance and service based on the application

and severity of the environment. The table below

covers the recommended service intervals for a

generator set on STANDBY service. If the set will

be subjected to extreme operating conditions, the

service intervals should be reduced accordingly.

Some of the factors that can affect the maintenance

schedule are the following:

• Use for continuous duty (prime power)

• Extremes in ambient temperature

• Exposure to elements

• Exposure to salt water

• Exposure to windblown dust or sand.

Consult with an authorized Onan Distributor if the

generator set will be subjected to any extreme operating conditions and determine a suitable schedule

of maintenance. Use the running time meter to

keep an accurate log of all service performed for

warranty support. Perform all service at the time

period indicated or after the number of operating

hours indicted, whichever comes first. Use Table

7-1 to determine the maintenance required and

then refer to the sections that follow for the correct

service procedures.

WARNING

performing maintenance procedures can cause

serious personal injury or death. Place the Run-

Stop-Remote switch in the Stop position,dis-

connect battery charger from its AC source and

disconnect the negative(-) battery cable from

the battery terminal before beginning mainte-

nance procedures.

Accidental starting of the set while

7-1

Page 31

TABLE 7-1. PERIODIC MAINTENANCE SCHEDULE

OPERATIONAL FREQUENCY - HOURS

MAINTENANCE ITEMS 10 100 200 Yearly

General Set Inspection.

Check engine oil level

Check radiator coolant level

Check air cleaner (clean or replace as necessary)

Check battery electrolyte level

Check governor linkage

Change engine oil and filter

Check all hardware (fittings, clamps, fasteners, etc.)

Drain exhaust condensate trap

Adjust drive belt tension

Inspect or replace spark plugs x

Inspect coolant hoses and clamps

Inspect coolant heater hoses

Check coolant anti-freeze protection

Check AC generator and controls

Clean cooling system

1

x

1

x

1

x

2

x

3

x

2

x

2

x

4

x

x

5

x

6

x

6

x

x

x

x

x1- As noted or after every run.

2

- Perform more often in extremely dusty conditions

x

3

- Or every two weeks.

x

4

- Or every three months.

x

5

- Adjust to 1/2-inch (12.5 mm) depression between pulleys.

x

6

Replace if hard or brittle.

x

7-2

Page 32

GENERATOR SET INSPECTION

During operation, be alert for mechanical problems

that could create unsafe or hazardous conditions.

The following sections cover several areas that

should be frequently inspected for continued safe

operation.

Exhaust System

WARNING

personal injury or death by fire or explosion. Do

not permit any flame, cigarette, pilot light, arcing switch or equipment, or other ignition

source near the fuel system.

Ignition of fuel can cause severe

AC Electric System

Check the following while the generator set is oper-

ating; otherwise measure load lines L1, L2 and L3

using the appropriate AC meter.

With the generator set operating, inspect the entire

exhaust system visually and audibly, including the

exhaust manifold, muffler, and exhaust pipe. Check

for leaks at all connections, welds, gaskets, and

joints and also make sure that exhaust pipes are not

heating surrounding areas excessively. If any leaks

are detected, shut down the generator set and have

leaks corrected immediately.

WARNING

sult in serious personal injury or death. Be sure

deadly exhaust gas is piped outside and away

from windows, doors or other inlets to building.

Inhalation of exhaust gases can re-

Fuel System

With the generator set operating, inspect the fuel

supply lines, filters, and fittings for leaks. Check any

flexible sections for cuts, cracks and abrasions and

make sure they are not rubbing against anything

that could cause breakage. If any leaks are de-

tected, shut off fuel supply valves, shut down gener-

ator set and have them corrected immediately.

Frequency Meter: The generator frequency

should be stable and the reading should be the

same as the nameplate rating.

AC Voltmeter: Turn the phase selector switch to

each line-to-line phase selection shown on the volts

scale (L1-L2, L2-L3, and L3-L1). Read the AC volt-

meter using the upper or lower scale as indicated by

the scale indicator light. At no load, the line-to-line

voltage(s) should be the same as the set nameplate

rating.

AC Ammeter: Turn the phase selector switch to

each phase selection shown on the amps scale (L1,

L2 and L3). Read the ammeter using the upper or

lower scale as indicated by the scale indicator light.

At no load, the current readings should be zero.

With a load applied, each line current should be

about the same.

Fault Lamps: Push the Reset/Lamp switch on the

control panel. All indicator lamps should light. Con-

firm that all of the bulbs are on, then release the

switch. Have any bulbs that are burned out re-

placed.

7-3

Page 33

DC Electrical System

Check the terminals on the battery for clean and

tight connections. Loose or corroded connections

create resistance which can hinder starting. Clean

and reconnect the battery cables if loose. Always

disconnect both ends of the negative battery cable.

Reconnect one end of the cable to the negative bat-

tery terminal and the other end to ground. Following

this sequence will help to reduce arcing at the bat-

tery.

Make certain battery area has been well ventilated before servicing battery, especially if a

battery charger has been connected. Arcing

can ignite explosive hydrogen gas given off by

batteries, causing severe personal injury. Arcing can occur when cable is removed or re-attached, or when negative (−) battery cable is

connected and a tool used to connect or discon-

nect positive (+) battery cable touches frame or

other grounded metal part of the set.

CAUTION

Always disconnect a battery

charger from its AC source before disconnect-

ing the battery cables. Otherwise, disconnect-

ing the cables can result in voltage spikes high

enough to damage the DC control circuits of the

set.

WARNING

Accidental starting of the generator

set while working on it can cause severe per-

sonal injury or death. Prevent accidental start-

ing by disconnecting the starting battery cables

(negative [−] first).

Mechanical

With the generator set stopped, check for loose

belts and fittings, leaking gaskets and hoses, or any

signs of mechanical damage. If any problems are

found, have them corrected immediately. With the

set running, listen for any unusual noises that may

indicate mechanical problems and check the oil

pressure frequently. Investigate anything that indi-

cates possible mechanical problems.

7-4

Page 34

LUBRICATION SYSTEM

MODELS GGHC / GGHD

Before the initial start, check dipstick to be sure

crankcase is filled with oil. See Specifications sec-

tion for lubricating oil capacity.

Generator sets are shipped with oil and coolant add-

ed. Be sure to check these systems to make sure

they are at proper operating levels before starting.

Oil Recommendations

Refer to Figure 5-1 for the recommended oil viscos-

ity grades at various ambient temperatures. Oils

must conform to the American Petroleum Institute

(API) classification SH or SH/CD. When selecting

the oil viscosity, pick the grade that is right for the

lowest temperature expected. Oil that is too thick

can result in a lack of lubrication when the engine is

started. If the ambient temperature is consistently

below -13

°F (-25°C), use a SAE5W synthetic oil.

SAE 40

10W, 5W30

MODEL GGHB

SAE 30, 40

15W30

10W30, 10W40

5W30

FIGURE 5-1. OIL VISCOSITY

7-5

Page 35

Engine Oil Level

Check the engine oil level during engine shutdown

periods at the intervals specified in the Maintenance Table. The dipstick is stamped with FULL

and ADD to indicate the level of oil in the crankcase.

For accurate readings, shut off the engine and wait

approximately 10 minutes before checking the en-

gine oil level. This allows oil in the upper portion of

the engine to drain back into the crankcase.

Keep the oil level as near as possible to the FULL

mark on the dipstick. Remove the oil fill cap and add

oil of the same quality and brand when necessary.

ENGINE OIL

LEVEL DIPSTICK

CAUTION

Do not operate the engine with the

oil level below the ADD mark or above the FULL

mark. Overfilling can cause foaming or aeration

of the oil. Operation below the ADD mark can

cause loss of oil pressure.

Engine Oil Change

WARNING

termined that contact with used engine oil can

cause cancer or reproductive toxicity. Take care

to limit skin contact and the breathing of its va-

pors. Use rubber gloves and wash exposed

skin.

Run engine until thoroughly warm before draining

oil. Stop the set, place a pan under the drain outlet

and remove the oil drain plug or open the drain

valve. After the oil is completely drained, replace

the drain plug or close the drain valve. Refill with oil

of the correct API viscosity grade for the tempera-

ture conditions.

WARNING

it is spilled or splashed on skin. Keep fingers

and hands clear when removing the oil drain

plug and wear protective clothing.

State or federal agencies have de-

Hot crankcase oil can cause burns if

Oil Filter Change

FIGURE 7-2. OIL LEVEL DIPSTICK

FILTER

GASKET

FIGURE 7-3. ENGINE OIL FILTER

Spin off oil filter and discard it in accordance with lo-

cal environmental regulations. Thoroughly clean fil-

ter mounting surface. Apply a thin film of oil to filter

gasket and install new element. Spin element on by

hand until gasket just touches mounting pad and

then turn an additional 1/2 to 3/4 turn. Do not over-

tighten (Figure 7-3).

With oil in crankcase, start engine and check for

leaks around filter element. Retighten only as much

as necessary to eliminate leaks but do not overtighten.

7-6

Page 36

COOLING SYSTEM

The cooling system capacity of a standard unit with

set mounted radiator is shown in Specifications

section.

CAUTION

Never pour hot water into a cold engine or cold water into a hot engine. Doing so

can crack a head or cylinder block. Do not operate the generator set without water for even a

few minutes.

Generator sets are shipped with oil and coolant add-

ed. Be sure to check these systems to make sure

they are at proper operating levels before starting.

Coolant Requirements

Satisfactory engine coolant inhibits corrosion and if

necessary protects against freezing. Use a 50/50

coolant solution (50% pure water and 50% anti-

freeze). If temperatures below -37

° F (-38° C) are

possible, use a mixture of 65% antifreeze and 35%

water. Do not use an antifreeze that contains anti-

leak additives.

The water used for engine coolant should be clean,

low in mineral content and free of any corrosive

chemicals such as chloride, sulfate or acid. Use soft

water. Well water often contains lime and other ma-

terials which eventually can clog the radiator core

and reduce the cooling efficiency and can also

cause heater element failure.

Filling the Cooling System

Check to make sure that all drain cocks are closed

and all hose clamps secure. Remove the radiator

pressure cap and slowly fill the cooling system with

the recommended coolant.

When the engine is first started, remove the pressure cap and monitor the coolant level. As trapped

air is expelled from the system, the coolant level

may drop and additional coolant must be added.

Replace the pressure cap when the coolant level is

stable.

Coolant Level

Check the coolant level during shutdown periods at

the intervals shown in Table 7-1. Remove the radia-

tor cap after allowing the engine to cool and if nec-

essary, add coolant until the level is near the top of

the radiator.

WARNING

in severe burns. Allow cooling system to cool

before releasing pressure and removing radia-

tor cap.

CAUTION

will shut down engine in an overheat condition

only if coolant is sufficiently high to physically

contact shutdown switch. Loss of coolant will

allow engine to overheat without protection of

shutdown device and cause severe damage to

the engine. It is therefore imperative that ade-

quate engine levels be maintained to provide

operational integrity of the cooling system and

for engine coolant overheat shutdown protec-

tion.

Contact with hot coolant can result

High Engine Temperature Cutoff

7-7

Page 37

Draining and Flushing

WARNING

Some coolant is toxic. Keep away

from children and animals. Follow local environmental regulations for disposal.

To maintain adequate corrosion protection and remove rust and scale deposits, drain and flush radiator at the recommended interval.

CAUTION

The heater element will burn out if

engine coolant is removed with heater con-

nected to power source.

Disconnect engine coolant heater from power

source (if equipped).

Allow the engine to cool and then remove radiator

pressure cap. Open the radiator drain cock and re-

move the water drain plugs (one on each side of en-

gine). When the coolant is drained, place the end of

a water hose into the radiator filler and turn on water

supply. Regulate the flow of water into the radiator

until it is equal to the outflow from drain openings.

Continue flushing until outflow from drains is clear

of rust sediment.

If engine is equipped with engine coolant heater,

drain coolant by removing hose and clamp from bot-

tom of heater.

Replace the water drain plugs and close the radia-

tor drain cock when flushing is complete. Refill the

cooling system with the recommended coolant (re-

fer to Filling the Cooling System).

With cooling system properly filled and the engine

has been run, connect heater plug to receptacle.

DRAIN

DRAIN PLUG

(FAR SIDE)

FIGURE 7-4. DRAIN PLUG LOCATIONS

PLUG

7-8

Page 38

AIR FILTER

Remove wing nut in center of filter cover. Remove

cover and filter. Tap filter on a flat surface to remove

dirt. Place a light source inside filter and inspect for

air passage. If necessary, apply a low pressure air

source (30 psi) to the inside of filter to remove as

much dirt as possible. Inspect interior housing. Vac-

uum clean if dirty or remove housing and wipe

clean.

WING NUT

& PLASTIC

WASHER

COVER

CAUTION

Do not clean filter housing while still

installed. Loose dirt entering intake could dam-

age carburetor or engine.

Clean air filter every 100 hours of operational time,

more often in extremely dusty conditions. Replace

air filter after 500 hours of operational time.

FILTER

ELEMENT

FIGURE 7-5. AIR CLEANER (NATURALLY

ASPIRATED FUEL SYSTEM)

WING NUT

& PLASTIC

WASHER

7-9

COVER

FILTER

ELEMENT

FIGURE 7-5. AIR CLEANER (TURBOCHARGED

FUEL SYSTEM)

Page 39

DRIVE BELT

A worn or improperly adjusted drive belt can cause

engine overheating and insufficient battery charging. Before inspecting or adjusting the drive belt,

disconnect the battery (negative [−] cable first) to

prevent accidental starting.

Check the drive belt at the recommended interval.

Remove the belt guard and inspect the belt for

cracks, fraying, or glazing. Replace when neces-

sary.

ALTERNATOR

PULLEY

WATER PUMP

PULLEY

WARNING

Accidental starting can cause se-

vere personal injury or death. To prevent acci-

dental starting, place the Run/Stop/Remote

switch in the Stop position and disconnect the

negative (−) battery cable from the battery be-

fore working on the generator set.

Arcing can ignite battery gases and cause se-

vere personal injury and can cause voltage

spikes that can damage generator set control

circuits. to reduce arcing:

Never disconnect the battery cables while the