Page 1

View Related Topic

screw

and position washer.

Page

1

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Table of Contents

Summary

General Information

Preparatory Steps

Remove

Front Gear Train

Rear Gear Train

Fuel Injection Pump, Rotary

(005-014)

Install

Front Gear Train

Rear Gear Train

Time

Finishing Steps

Summary

Stepblock Stepblock

Stepblock

Stepblock

Front Gear Train: Remove access cap,

gear retaining nut and washer.

Disengage pin after locating top dead

center.

Prepare engine for removal of rotary

fuel injection pump.

Stepblock

Locate top dead center for cylinder

Number 1.

Stepblock

Stepblock

Stepblock

Loosen CAV fuel injection pump lock

Tighten lock screw against drive shaft. Torque: 7 N•m [62 in-lb]

Loosen injection pump lock screw and

position washer.

Stepblock

Tighten lock screw until contact made

with shaft.

Torque: 12 N•m [106 in-lb]

Page 2

Stepblock

completion.

and

bolts.

Remove pump.

washer.

Page

2

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Tighten screw against shaft. Torque: 30 N•m [22 ft-lb]

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Pull drive gear loose from drive shaft.

Remove mounting nuts and pump.

Remove gasket and clean surface.

Rear Gear Train: Permanently mark

pump flange to match mark on fuel pump

mounting plate.

DO NOT

remove timing pin until repair

Special washer on Bosch® VE pump

be removed and lock screw

must

tightened.

Remove fuel pump mounting plate nuts

Remove pump, mounting plate and gear

pump as assembly.

Remove gasket and clean surface.

Torque: 40 N•m [29 ft-lb]

Gear

must not

rotate during removal.

Stepblock

Mark a tooth on fuel gear pump relative

to fuel pump mounting plate.

Stepblock

Remove retaining nut and washer.

Remove gear.

Stepblock

Stepblock

Loosen fuel pump to mounting plate nuts.

Remove gasket material and clean

surface.

Stepblock

Front Gear Train: Verify cylinder Number

1 at top dead center.

Stepblock

Stepblock Stepblock

Stepblock

Stepblock

Install new gasket.

Install pump drive shaft nut and spring

If installing original pump, rotate to align

with scribe marks.

Install pump. Tighten mounting nuts.

Torque: 15 to 20 N•m [133 to 177 in-lb]

Torque: 24 N•m [18 ft-lb]

Finger tight. Pump

move in slots.

must

be free to

Stepblock

Stepblock

Stepblock

If no scribe marks, rotate pump against

direction of drive rotation. Tighten nuts.

Torque: 24 N•m [18 ft-lb]

Mark injection pump flange. Mark on housing.

Loosen CAV pump lock screw and

position washer.

Torque: 20 N•m [177 in-lb]

Page 3

Stepblock

crankshaft.

1

is at top dead center.

plate.

washer.

Page

3

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Stepblock

Stanadyne DB4 Pump: Loosen pump

lock screw and position washer. Tighten

lock screw.

Loosen Bosch® pump lock timing screw

and install special washer. Tighten lock

timing screw.

Torque: 13 N•m [115 in-lb]

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Disengage timing pin before rotating

Tighten pump retaining nut. See detail.

Install access cap.

Disengage timing pin.

Tighten pump retaining nut. See detail.

Install access cap.

Rear Gear Train: Verify cylinder number

Install new pump gasket on mounting

Install pump to mounting plate. Torque: 18 N•m [159 in-lb]

If installing original pump, rotate pump to

align scribe marks.

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Stepblock

Install pump gear on pump shaft, align

mark on gear with mark on mounting

plate.

Install drive shaft nut and spring washer.

Tighten retaining nut.

Install new pump cover plate gasket,

pump, mounting plate and gear to rear

gear housing. Install cover plate gasket.

On Bosch® fuel pumps, install special

washer, that is wired to pump, under

lockscrew.

Disengage timing pin.

Tier 2/Stage II Timing Adjustment

Disengage timing pin. Remove special

washer on Bosch® VE pumps and

tighten lockscrew against drive shaft.

Remove access cap, retaining nut and

Torque: 98 N•m [72 ft-lb]

Torque: M8 = 18 N•m [159 in-lb]; M10 =

30 N•m [22 ft-lb]

See detail.

Stepblock

Remove fuel pump gear. See detail.

Page 4

Stepblock

rotate.

is removed.

check

for leaks.

Page

4

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Thoroughly clean and dry drive shaft

taper and drive gear bore.

Use residue-free cleaner and

compressed air.

Stepblock

Ensure engine is locked and can

Install pump gear onto shaft, with washer

Stepblock

and retaining nut. Remove top dead

center timing pin from camshaft and

timing pin on damper, if used.

Stepblock

Stepblock Stepblock

Stepblock

Stepblock

Tighten gear pump retaining nut. See detail.

Install access cap and check barring tool

Recheck timing. If timing within tolerance,

remove gauge and replace plug.

Stepblock

Stepblock

Tighten pump retaining nut. See detail.

Install access cap.

not

Loosen Bosch® pump lock timing

screw and install special washer.

Tighten lock timing screw.

Torque: 10 N•m [89 in-lb]

Torque: 13 N•m [115 in-lb]

Stepblock

Stepblock

Install remaining components. See detail.

Connect batteries, operate engine and

General Information

Fuel System Identification

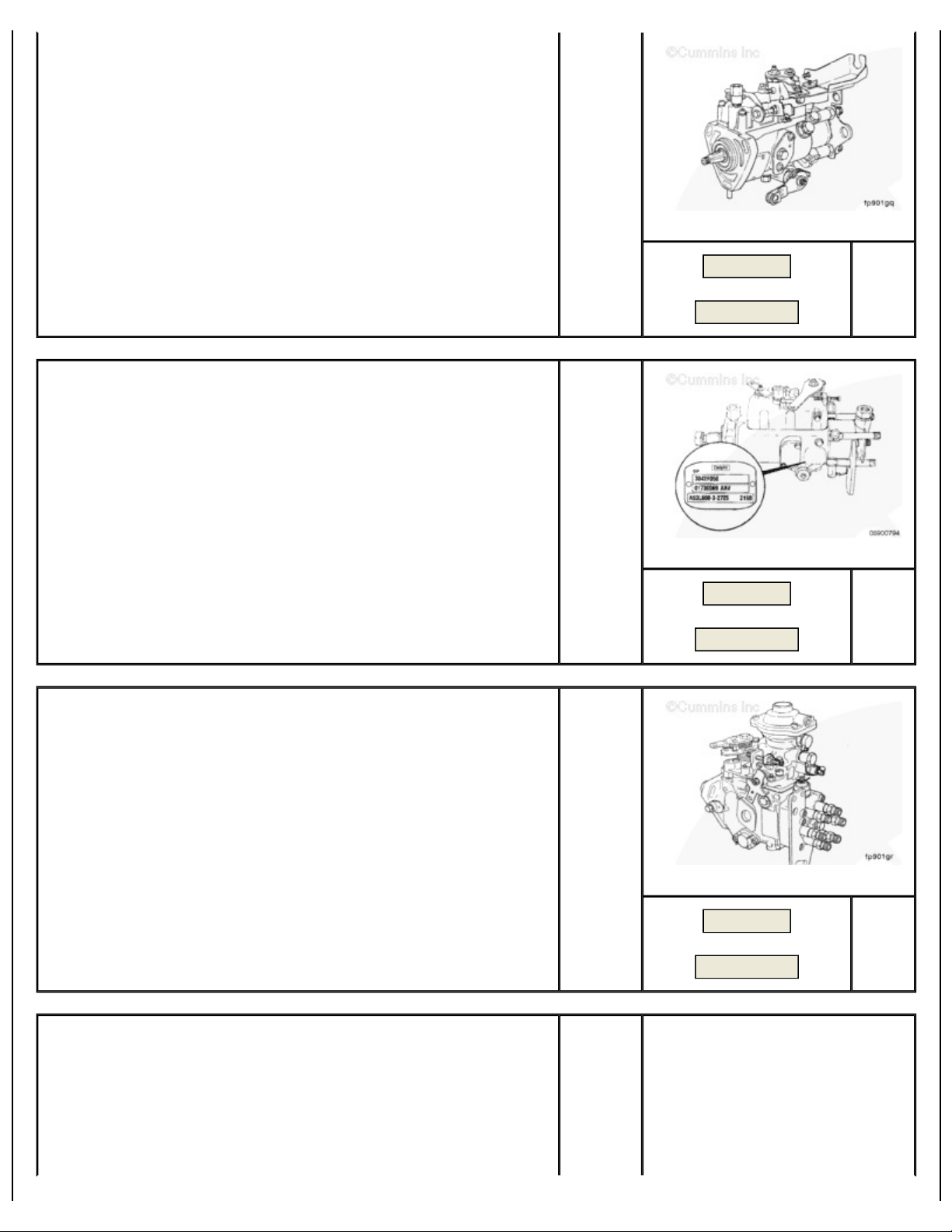

The B Series engine uses many different fuel injection

pumps, depending on the horsepower rating and

application.

The Lucas CAV DPA distributor-type fuel injection pump

can be found on the following engine applications:

Marine

Industrial.

TOC

SMALL | MEDIUM | LARGE

Next

The Lucas CAV DPS distributor-type fuel injection pump

can be found on the following engine application:

European and U.K. automotive ratings.

Page 5

SMALL | MEDIUM | LARGE

Page

5

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

The Delphi DP210 distributor-type fuel injection pump can

be found on the following applications:

Industrial (Tier 2/Stage II Certified).

The Bosch® VE distributor-type fuel injection pump can be

found on the following engine applications:

Previous

Next

SMALL | MEDIUM | LARGE

Previous

Next

Industrial

1991 low-horsepower automotive ratings.

The Stanadyne DB4 distributor-type fuel injection pump can

be found on the following engine application:

Gen Sets

SMALL | MEDIUM | LARGE

Previous

Next

Page 6

SMALL | MEDIUM | LARGE

Page

6

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

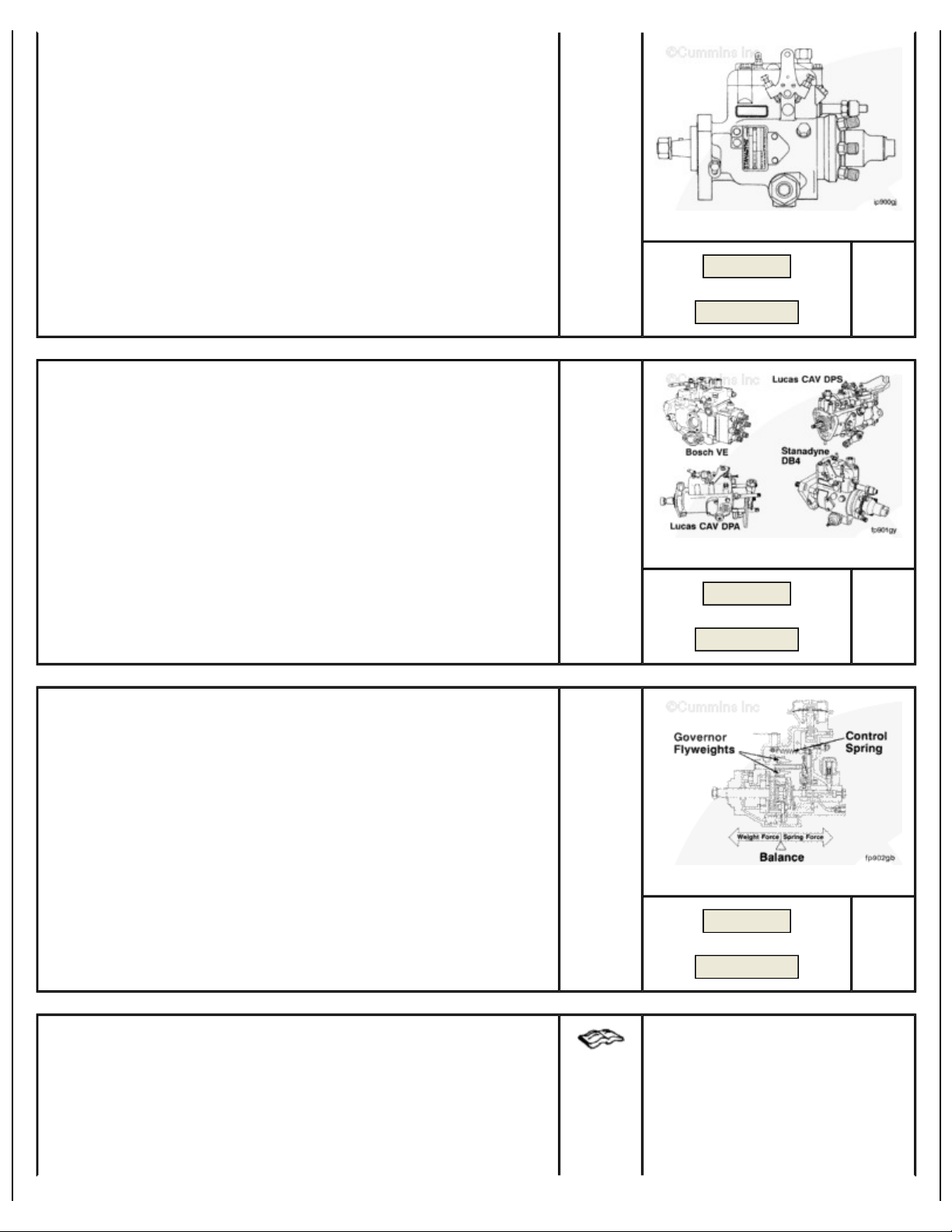

Fuel Injection Pump (Distributor Type)

The fuel injection pumps, Bosch® VE, Lucas CAV DPA,

Stanadyne DB4, Lucas CAV DPS, and Delphi DP210, are

rotary distributor pumps. These pumps perform the four

basic functions of:

1. Producing the high fuel pressure required for injection

2. Metering the exact amount of fuel for each injection

cycle

3. Distributing the high-pressure, metered fuel to each

cylinder at the precise time

4. Varying the timing relative to engine speed.

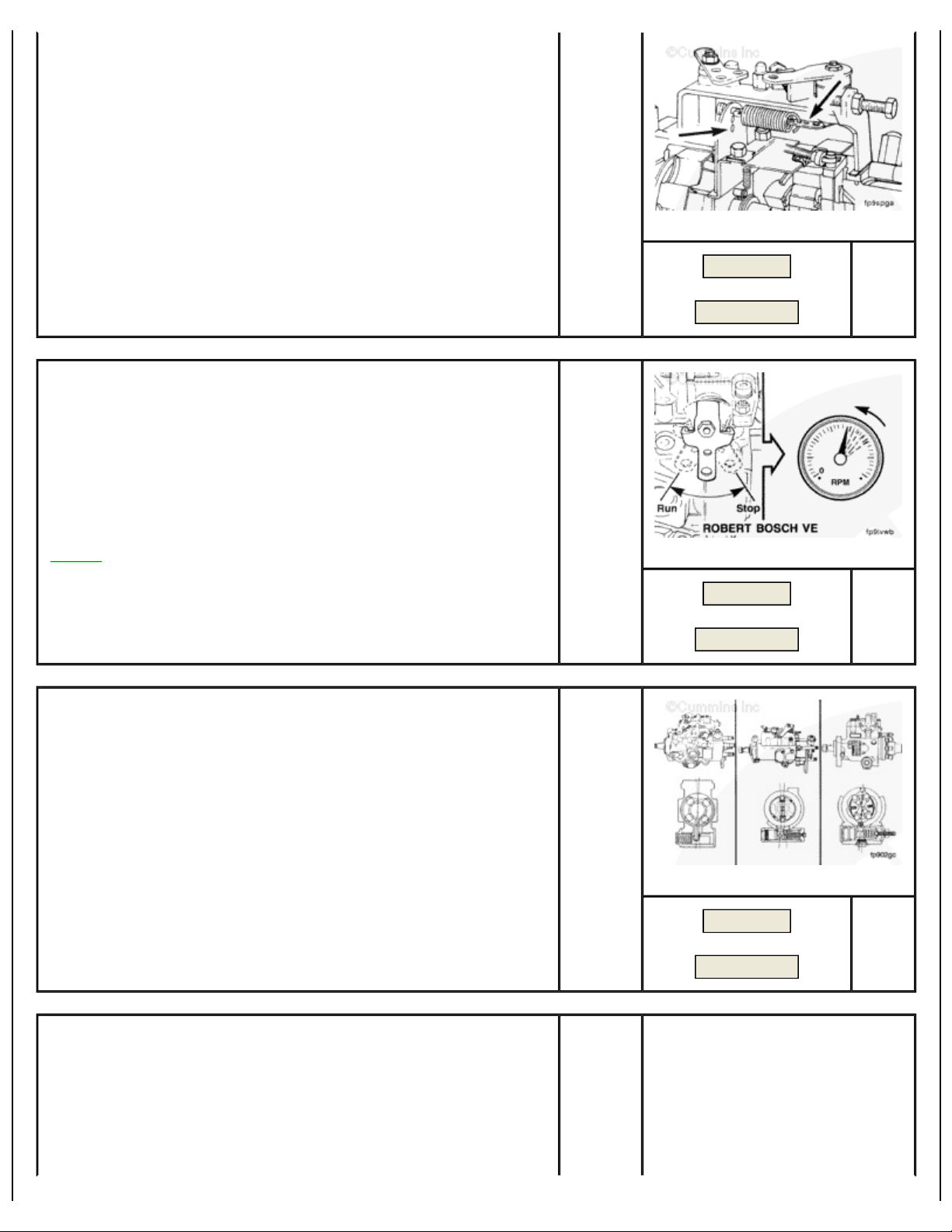

Distributor-Type Pump Governor

Previous

Next

SMALL | MEDIUM | LARGE

Previous

Next

Balance between the governor flyweights and control lever

position controls the metering of the amount of fuel to be

injected.

The fuel injection pump governor performance and setting

can affect engine power. Special equipment and qualified

personnel are required to verify governor performance. If

the seals are broken on the external Bosch® VE adjustment

screw, the fuel rate can, perhaps, be out of adjustment.

The Lucas CAV DPA/DPS fuel injection pump uses a coded

spring connection to change the governor setting. Incorrect

connection of the governor spring can affect performance.

Adjustments and rating changes are described in the

Master Repair Manual, Injector Pumps and Injectors,

SMALL | MEDIUM | LARGE

Previous

Next

Page 7

Bulletin 3666037.

Page

7

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

SMALL | MEDIUM | LARGE

Manual Shutdown Levers

Both fuel injection pumps are equipped with mechanical

shutdown levers. These levers are spring-loaded in the run

position.

all applications will use these manual

Not

shutdown controls and there will be no cable or rod

connected to the lever.

NOTE: Partial actuation of the mechanical shutdown

levers will affect fuel flow and engine power.

Advance Timing Mechanism

Previous

Next

SMALL | MEDIUM | LARGE

Previous

Next

Regulated pressure produced by a vane supply pump in

both fuel injection pumps is used to advance the timing as

the engine speed increases. A return spring is used to

retard the timing as the engine speed is reduced. If a spring

breaks, the timing will go to the advance position, resulting

in torque loss, fuel knock, and possible engine overheating.

Retarded (late) timing will result in torque loss, high fuel

consumption, and white to black smoke.

The Lucas CAV DPA/DPS advance timing mechanism uses

a check ball in the circuit which, if omitted during assembly,

will result in no timing advance. If the fuel injection pump

has been replaced or the mechanism has been removed to

fix a leak, the problem can be that the check ball is missing.

SMALL | MEDIUM | LARGE

Previous

Next

Page 8

SMALL | MEDIUM | LARGE

Page

8

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Electrical Shutoff Valves

The fuel injection pumps are equipped with electrical shutoff

valves. These solenoid-operated valves block the supply of

fuel to the high-pressure pumping and distribution

components.

The Bosch® VE shutoff valve is located at the top rear of

the pump.

The Lucas CAV DPA/DPS shutoff valve is located at the

bottom rear of the pump.

Previous

Next

SMALL | MEDIUM | LARGE

Previous

Next

Both 12- and 24-VDC activate-to-run and activate-to-stop

solenoids are available.

The Stanadyne DB4 shutdown solenoid is located under the

governor cover.

Both 12-VDC and 24-VDC activate-to-run and activate-tostop solenoids are available.

SMALL | MEDIUM | LARGE

Previous

Next

Page 9

SMALL | MEDIUM | LARGE

indexed to the shaft

Page

9

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Preparatory Steps

Batteries can emit explosive gases. To reduce the

possibility of personal injury, always ventilate the

compartment before servicing the batteries. To reduce

the possibility of arcing, remove the negative (-) battery

cable first and attach the negative (-) battery cable last.

WARNING

Previous

Next

TOC

SMALL | MEDIUM | LARGE

Disconnect the batteries.

CAUTION

Do not remove the control lever. The fuel control lever on

the Bosch® VE fuel injection pump is

during pump calibration. If the lever has been removed

and reinstalled incorrectly, engine speed and power will

be affected.

Rotary Distributor Type Fuel Injection Pumps

Bosch® VE, Lucas CAV DPA, Stanadyne DB4, and Delphi

DP210

Previous

Next

SMALL | MEDIUM | LARGE

Page 10

Page

10

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Disconnect the fuel drain manifold. Refer to

Previous

Summary 1

Procedure 006-021.

Remove the injection pump supply line. Refer to

Next

Procedure 006-024.

Remove the high-pressure lines. Refer to Procedure

006-051.

Disconnect the electrical wire to the fuel shutoff valve.

Refer to Procedure 005-043.

Remove the fuel air control tube, if used. Refer to

Procedure 006-001.

Disconnect all control linkage. Refer to the OEM

service manual

Remove the pump support bracket. Refer to

Procedure 005-033.

Remove

Front Gear Train

Remove the access cap, gear retaining nut, and washer.

TOC

SMALL | MEDIUM | LARGE

Previous

Next

Summary 2

NOTE: Be sure to disengage the pin after locating top

dead center.

Locate top dead center for cylinder Number 1 by barring the

engine slowly, while pushing in on the top dead center pin.

SMALL | MEDIUM | LARGE

Page 11

Previous

Page

11

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Lucas CAV DPA Pump and Delphi DP210

Loosen the CAV fuel injection pump lock screw and position

the special washer; then tighten the lock screw against the

pump drive shaft.

Torque

Value:

7

n.m

[62 inlb ]

Next

Summary 3

Summary 4

SMALL | MEDIUM | LARGE

Previous

Next

Summary 5

Stanadyne DB4 Pump

Loosen the Stanadyne DB4 fuel injection pump lock screw

and position the special washer. Tighten the lock screw

until contact is made with the fuel injection pump drive

shaft.

Torque

Value:

12

n.m

[106 inlb ]

Summary 6

SMALL | MEDIUM | LARGE

Previous

Next

Summary 7

Summary 8

Bosch® VE

The special washer on the Bosch® VE injection pump

must

be removed so the lock screw can be tightened against the

Page 12

drive shaft.

Page

12

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Torque

Value:

30

n.m

[22 ftlb ]

NOTE: Wire the washer to the pump.

SMALL | MEDIUM | LARGE

Pull the fuel injection pump drive gear loose from the pump

drive shaft.

Use fuel pump gear puller, Part Number 3163381 or Part

Number 3824469, with M8-1.25 x 50 capscrews, Grade

8.8 or equivalent.

Previous

Next

Summary 9

SMALL | MEDIUM | LARGE

Previous

Next

Summary 10

CAUTION

Do not drop drive gear key when removing the pump.

Failure to do so can result in severe engine damage.

Remove the three mounting nuts and take off the fuel

injection pump.

NOTE: Fuel pumps on engines designed to meet Tier

2/Stage II Industrial emissions levels have straight

holes ( not kidney slots) and do not use a timing key.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 11

Page 13

Remove the gasket and clean the surface.

Page

13

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

SMALL | MEDIUM | LARGE

Rear Gear Train

Permanently mark the injection pump flange to match the

mark on the fuel pump mounting plate.

Previous

Next

Summary 12

SMALL | MEDIUM | LARGE

Previous

Unlike the front gear train engine, do

remove the

NOT

timing pin until completion of the repair. Failure to do so

can result in difficult reassembly and incorrect timing of the

fuel pump.

Next

Summary 13

SMALL | MEDIUM | LARGE

Previous

Next

Summary 14

Page 14

CAUTION

Page

14

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Failure to properly torque the lock screw will result in

improper timing of the pump during reassembly.

Bosch® VE

The special washer on the Bosch® VE injection pump

be removed so the lock screw can be tightened

must

against the drive shaft.

SMALL | MEDIUM | LARGE

Torque

Value:

40

n.m

[22 ftlb ]

NOTE: Wire the washer to the pump.

NOTE: The torque specification for the rear gear train

engine is higher than the front gear train engine, to

prevent rotation of the pump shaft during installation

of the fuel pump gear retaining nut.

Remove the mounting nuts and bolts affixing the fuel pump

mounting plate to the rear gear housing.

Take off the fuel injection pump, fuel pump mounting plate,

and fuel pump gear as an assembly.

NOTE: Make sure the gear does not rotate during

removal; failure to do so can result in incorrect timing

of the pump during installation.

Previous

Next

Summary 15

SMALL | MEDIUM | LARGE

Remove the gasket and clean the surface.

Previous

Next

Summary 16

Summary 17

Page 15

SMALL | MEDIUM | LARGE

Page

15

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Mark a tooth on the fuel gear pump relative to the fuel

pump mounting plate.

Previous

Next

Summary 18

SMALL | MEDIUM | LARGE

Previous

Next

Summary 19

Remove the fuel pump retaining nut and washer.

Remove the fuel pump gear.

Loosen the three mounting nuts attaching the fuel pump to

the fuel pump mounting plate.

Remove the fuel pump from the fuel pump mounting plate.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 20

Summary 21

Remove the gasket material and clean the surface.

Page 16

SMALL | MEDIUM | LARGE

Page

16

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Install

Front Gear Train

Verify cylinder Number 1 is at top dead center by barring

the engine slowly while pushing in on the top dead center

pin.

Previous

Next

Summary 22

TOC

Install a new gasket.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 23

Page 17

SMALL | MEDIUM | LARGE

Page

17

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

CAUTION

The drive shaft must be clean and free of all oil before

installation. Failure to make certain the drive shaft is free

of oil can result in the drive gear slipping on the shaft.

NOTE: The shaft of a new or reconditioned pump is

locked so the key aligns with the drive gear keyway

when cylinder Number 1 is at top dead center on the

compression stroke.

Install the pump. Make sure the key does

gear housing.

fall into the

not

Previous

Next

Summary 24

SMALL | MEDIUM | LARGE

Previous

NOTE: Fuel pumps on engines designed to meet Tier

2/Stage II Industrial emission levels do not use a timing

key.

Hand tighten the three mounting nuts. The pump

must

be

free to move in the slots.

NOTE: Fuel pumps on engines designed to meet Tier

2/Stage II Industrial emissions levels have straight

holes ( not kidney slots) and do not use a timing key.

Next

SMALL | MEDIUM | LARGE

Previous

Next

Summary 25

CAUTION

Page 18

Page

18

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Be sure the timing pin is disengaged before the final

torque step to avoid damage to the timing pin.

Install the pump drive shaft nut and spring washer. The

pump will rotate slightly because of gear helix and

clearance. This is acceptable, provided the pump is free to

move on the flange slots and the crankshaft does

not

move.

SMALL | MEDIUM | LARGE

Previous

Torque

Value:

15 to 20

n.m

[132 to 177

in-lb ]

If installing the original pump, rotate the pump to align the

scribe marks.

Torque

Value:

24

n.m

[18 ftlb ]

Next

Summary 26

SMALL | MEDIUM | LARGE

Previous

Next

Summary 27

If installing a new or rebuilt pump without scribe marks,

take up gear lash by rotating the pump against the

direction of drive rotation. Tighten the flange mounting

nuts.

Torque

Value:

24

n.m

[18 ftlb ]

SMALL | MEDIUM | LARGE

Previous

Next

Summary 28

Page 19

Permanently mark the injection pump flange to match the

Page

19

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

mark on the gear housing.

SMALL | MEDIUM | LARGE

Lucas CAV DPA Pump and Delphi DP210

For CAV fuel injection pumps, loosen the lockscrew and

position the special washer behind the lockscrew head.

Torque

Value:

20

n.m

[177 inlb ]

Previous

Next

Summary 29

SMALL | MEDIUM | LARGE

Previous

Next

Summary 30

Stanadyne DB4 Pump

For Stanadyne DB4 fuel injection pumps, loosen the lock

screw and position the special washer behind the lock

screw head.

Tighten the lock screw.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 31

Page 20

Bosch® VE

Page

20

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Loosen the Bosch® fuel pump lock timing screw and install

the special washer that is wired to the fuel pump.

Tighten the Bosch® fuel pump lock timing screw.

Torque

Value:

13

n.m

[115 inlb ]

Disengage the timing pin before rotating the crankshaft.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 32

Tighten the pump retaining nut.

Bosch® VE (M14-1.5 nut) 98 n.m [72 ft-lb ]

Bosch® VE (M12 nut) 65 n.m [48 ft-lb ]

Lucas CAV/DPA 81 n.m [60 ft-lb ]

Stanadyne 65 n.m [48 ft-lb ]

Delphi DP21 93 n.m [68 ft-lb ]

SMALL | MEDIUM | LARGE

Previous

Next

Summary 33

Summary 36

SMALL | MEDIUM | LARGE

Previous

Next

Summary 37

Page 21

Page

21

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Install the access cap.

SMALL | MEDIUM | LARGE

Rear Gear Train

Verify cylinder number 1 is at top dead center by barring

the engine slowly while pushing in on the top dead center

pin.

Previous

Next

Summary 38

SMALL | MEDIUM | LARGE

Previous

Install a new fuel pump gasket on the fuel pump mounting

plate.

Next

Summary 39

SMALL | MEDIUM | LARGE

Previous

Next

Summary 40

Page 22

the drive shaft is free

Page

22

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Install the fuel pump to the fuel pump mounting plate.

Torque

Value:

18

n.m

[159 inlb ]

SMALL | MEDIUM | LARGE

If installing the original fuel pump, rotate the pump to align

the scribe marks on the fuel pump mounting plate.

Torque

Value:

18

n.m

[159 inlb ]

Previous

Next

Summary 41

SMALL | MEDIUM | LARGE

Previous

Next

Summary 42

CAUTION

The drive shaft must be clean and free from oil before

installation. Failure to make certain

of oil can result in the drive gear slipping on the shaft.

Install the fuel pump gear on the fuel pump shaft.

Align the mark on the fuel pump gear with the mark on the

fuel pump mounting plate.

Install the fuel pump drive shaft nut and spring washer.

Tighten the pump retaining nut.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 43

Summary 44

Page 23

Torque

Page

23

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Value:

98

n.m

[72 ftlb ]

With a new fuel pump cover plate gasket, install the fuel

pump, fuel pump mounting plate, and fuel pump gear

assembly onto the rear gear housing.

M8 18 n.m [159 in-lb ]

M10 30 n.m [266 in-lb ]

Loosen the Bosch® fuel pump lock timing screw and install

the special washer that is wired to the pump.

Tighten the Bosch® fuel pump lock timing screw.

Torque

Value:

13

n.m

[115 inlb ]

SMALL | MEDIUM | LARGE

Previous

Next

Summary 45

SMALL | MEDIUM | LARGE

Disengage the timing pin before rotating the crankshaft.

Previous

Next

Previous

SMALL | MEDIUM | LARGE

Summary 46

Summary 47

Page 24

Next

Page

24

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Time

Tier 2/Stage II Timing Adjustment

If the pump timing is out by more than the specified

tolerance as determined in Procedure 005-037 it is

possible on Tier 2/Stage II engines, which no longer use

the keyway in the fuel pump shaft, that the fuel pump gear

has slipped on the fuel pump shaft. The fuel pump gear to

pump shaft taper will need to be broken so the pump timing

can be reset.

NOTE: This procedure applies to front gear train Tier

2/Stage II engines only. Refer to Procedure directions

in 005-037, when adjusting the fuel pump timing of

engines equipped with kidney slots.

The top dead center timing pin

the engine in the

clockwise

direction, when viewed from

the front of the engine, until the dial indicator reading

reflects the plunger travel specified on the engine

dataplate. This point will be beyond top dead center. Lock

the pump drive shaft at this position. Refer to Procedure

100-001 Engine Identification in Section E, for the engine

dataplate location.

NOTE: If barring the engine past the specified timing

plunger travel value, turn the engine in an

counterclockwise direction, when viewed from the

front of the engine, past top dead center at least one

quarter turn, then bring the engine back toward top

dead center in a clockwise direction when viewed from

the front of the engine, until the desired timing value is

achieved.

The special washer on the Bosch® VE injection pump

be removed so the lock screw can be tightened

must

against the drive shaft.

Torque

Value:

30

n.m

be disengaged. Bar

must

[22 ftlb ]

TOC

SMALL | MEDIUM | LARGE

Previous

Next

Summary 48

SMALL | MEDIUM | LARGE

Previous

Next

Summary 49

Page 25

NOTE: Wire the washer to the fuel pump.

recommendations for

Page

25

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Remove the access cap.

Remove the fuel pump gear retaining nut and washer.

SMALL | MEDIUM | LARGE

To remove the fuel pump gear, use gear puller, Part

Number ST647 or 3163381, to separate the fuel pump

gear from the shaft.

With the gear loose from the fuel pump drive shaft, bar the

engine in the opposite direction of rotation, when viewed

from the front of the engine, past top dead center at least

one quarter turn. Then bar engine in the direction of

rotation to top dead center until the timing pin engages the

camshaft.

Previous

Next

Summary 50

SMALL | MEDIUM | LARGE

Previous

Next

Summary 51

WARNING

When using solvents, acids, or alkaline materials for

cleaning, follow the manufacturer's

use. Wear goggles and protective clothing to reduce the

possibility of personal injury.

WARNING

Wear appropriate eye and face protection when using

compressed air. Flying debris and dirt can cause

SMALL | MEDIUM | LARGE

Page 26

personal injury.

Page

26

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Previous

Clean the fuel injection pump drive shaft taper and drive

gear bore with a residue-free cleaner. Dry both surfaces

with compressed air.

Failure to clean and dry the shaft thoroughly can result in

further timing slip after the engine is run.

CAUTION

Prior to torquing the fuel pump gear nut, make sure the

engine is locked and can not rotate during final torquing

of the fuel pump nut.

This can be achieved by using the engine barring tool to

prevent the engine from rotating. Make sure the fuel pump

is locked at this stage.

Next

Summary 52

SMALL | MEDIUM | LARGE

Previous

Next

Summary 53

Push the fuel pump gear onto the shaft and assemble the

washer and nut.

Remove the top dead center timing pin from the camshaft

and the timing pin on the damper, if used.

Tighten the fuel pump retaining nut.

Bosch® VE (M14-1.5 nut) 98 n.m [72 ft-lb ]

Bosch® VE (M12 nut) 65 n.m [48 ft-lb ]

Lucas CAV/DPA 81 n.m [60 ft-lb ]

Stanadyne 65 n.m [48 ft-lb ]

Delphi DP21 93 n.m [68 ft-lb ]

SMALL | MEDIUM | LARGE

Previous

Next

Summary 54

Summary 55

Bosch® VE

Loosen the Bosch® fuel pump lock timing screw and install

the special washer that is wired to the fuel pump.

Page 27

Tighten the Bosch® fuel pump lock timing screw.

Page

27

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Torque

Value:

13

n.m

[115 inlb ]

SMALL | MEDIUM | LARGE

CAUTION

To reduce the possibility of engine or timing pin damage,

you must disengage the timing pin before attempting to

bar or crank the engine.

Disengage the timing pin before rotating the crankshaft.

Install the access cap and check to make sure the engine

barring tool is removed, then recheck the timing as

described in the previous steps.

Previous

Next

SMALL | MEDIUM | LARGE

Previous

Next

Summary 56

If the timing is within tolerance, remove the timing gauge

from the fuel pump and replace the plug.

Torque

Value:

10

n.m

[89 inlb ]

Tighten the gear pump retaining nut.

Bosch® VE (M14-1.5 nut) 98 n.m [72 ft-lb ]

SMALL | MEDIUM | LARGE

Previous

Next

Summary 57

Summary 58

Page 28

Bosch® VE (M12 nut) 65 n.m [48 ft-lb ]

Page

28

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Lucas CAV/DPA 81 n.m [60 ft-lb ]

Stanadyne 65 n.m [48 ft-lb ]

Delphi DP21 93 n.m [68 ft-lb ]

SMALL | MEDIUM | LARGE

Install the access cap.

Previous

Next

Summary 34

Summary 59

SMALL | MEDIUM | LARGE

Previous

Finishing Steps

Rotary Distributor Type Fuel Injection Pumps

Bosch® VE, Lucas CAV DPA, Stanadyne DB4, and Delphi

DP210

Install the injection pump support bracket. Refer to

Procedure 005-033

Next

Summary 35

Summary 60

TOC

Page 29

Feedback / Help

Page

29

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Install all high-pressure fuel lines. Refer to Procedure

006-051

Install the injection pump supply line. Refer to

Procedure 006-024

Connect the fuel drain manifold. Refer to Procedure

006-021

Connect the electrical wire to the fuel shutoff valve.

Refer to Procedure 005-043

If required, install the air-to-fuel control valve. Refer

to Procedure 006-001

Disconnect all control linkage. Refer to OEM service

manual.

NOTE: When connecting the cable and rod to the

control lever, adjust the length so the lever has stopto-stop movement. Adjust the length of the cable or

rod to the mechanical shutdown lever so there is stopto-stop movement.

Replacing the fuel supply lines, fuel filters, fuel injection

pump, high-pressure fuel lines, and injectors will let air

enter the fuel system. Follow the specified procedure to

bleed the air from the system.

SMALL | MEDIUM | LARGE

Previous

Next

Summary 61

Refer to Procedure 006-015, Fuel Filter, Spin-On, for

proper venting of the low pressure side of the fuel

system

Refer to Procedure 006-051, Injector Supply Lines

(High Pressure), for venting of the high-pressure side

of the fuel system.

WARNING

Batteries can emit explosive gases. To reduce the

possibility of personal injury, always ventilate the

compartment before servicing the batteries. To reduce

the possibility of arcing, remove the negative (-) battery

cable first and attach the negative (-) battery cable last.

Connect the batteries

Operate the engine and check for leaks.

SMALL | MEDIUM | LARGE

Previous

Summary 62

Last Modified: 05-Dec-2006

Page 30

Copyright © 2006 Cummins Inc. All rights reserved

Page

30

of 30Fuel Injection Pump, Rotary

10/31/2008

https://quickserve.cummins.com/qs2/pubsys2/xml/en/procedures/40/40

-

005-014-tr.html

Loading...

Loading...