CUMMINS PowerCommand 3100 Series, DQAD, DQAF, DQAE Installation Manual

Power

Generation

Installation Manual

PowerCommand® Control

3100

Series

Generator

Sets

Printed in U.S.A.

DQAD.

Models

DQAE. DQAF

960-0624 5-2001

Table of Contents

SECTION

2

3

TITLE

IMPORTANT SAFETY INSTRUCTIONS iii

INTRODUCTION

SPECIFICATIONS

MOUNTING

MECHANICAL

DC

PAGE

About this Manual 1-1

Installation Overview 1-2

2-1

THE

GENERATOR

General 3-1

Location 3-1

Mounting 3-2

Access to Set 3-2

Vibration Isolators 3-4

CONNECTIONS

General 4-1

Fuel System 4-1

Exhaust System 4-4

Ventilation and Cooling 4-6

CONTROL

Control Wiring .* 5-1

TB1 Remote Monitor/Control Connections 5-1

Run Relays (K11,K12, Kl

Alarm Relay (K14) 5-4

WIRING

SET

3)

5-3

California

Proposition 65

Diesel engine exhaust

to the State of California to cause cancer, birth defects, and

other reproductive harm.

and

some of its constituents are known

Warning

6 AC

7

PRESTART

8

INSTALLATION

ELECTRICAL

General 6-1

Transfer Switch 6-2

AC Wiring 6-3

Control Heater (Optional) 6-5

Coolant Heater 6-6

Generator Heater 6-7

Fuel Transfer Pump 6-8

Ground Fault Alarm Relay (Optional) 6-9

PREPARATION

General 7-1

PCC Power On/Standby Mode 7-1

Electrical System 7-2

PCC Options Prestart Checks 7-3

Starting 7-5

General ..8-1

Generator Set Support 8-1

Cooling Air Flow 8-1

Diesel Fuel System 8-1

Exhaust System 8-2

AC and DC Wiring 8-2

Genset Prestart 8-2

CONNECTIONS

CHECKLIST

9

WIRING

General .• 9-1

DIAGRAMS

IMPORTANT

SAFETY

INSTRUCTIONS

SAVE THESE INSTRUCTIONS important instructions that should be followed during

installation and maintenance of the generator

ies.

Before operating the generator set (genset), read the

Operator's Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

ri^ij'isMazd This symbol warns of immediate

hazards which will result in severe personal in-

jury or death.

IAWARNINGI This symbol refers to a hazard or un-

safe practice which can result in severe personal injury or death.

IACAUTIONI This symbol refers to a hazard or un-

safe practice which can result in personal injury

or product or property damage.

This

manual contains

and

batter-

FUEL AND FUMES ARE FLAMMABLE

Fire,

explosion, and personal injury or death can result

from improper practices.

• DO NOT fill fuel tanks while engine is running, unless tanks are outside the engine compartment.

Fuel contact

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks.

made with an approved flexible

coated or copper fuel lines with diesel

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to sen/icing near

explosive hydrogen gas that can be ignited by arcing,

sparking, smoking, etc.

with

hot engine or exhaust is a potential

Fuel connection at the engine should be

line.

Do not

it.

Lead-acid batteries emit a highly

fuel.

use

zinc

EXHAUST

• Provide an adequate exhaust system to properly

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

GASES

warped.

ARE

DEADLY

Do not use exhaust gases to

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

• Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, disconnect battery charger from its AC source, then dis-

connect starting batteries, negative (-) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over

• Do not wear loose clothing or jewelry

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If adjustment must be made while the unit is

ning,

use extreme caution around hot manifolds,

moving parts, etc.

fans,

drive belts, etc.

in

the vidnity of

run-

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor

become difficult to stop, resulting in possible fire, explosion,

severe personal injury and

genset where a flammable vapor environment can be

created by fuel

equipped with an automatic safety device to block the air

intake and stop the

the genset are solely responsible for operating the

set safely. Contact your authorized Onan/Cummins

er or distributor for more information.

can

cause an engine to overspeed and

death.

spill,

leak, etc., unless the genset is

engine.

The owners and operators of

Do not operate a

gen-

deal-

in

LS-13L

ELECTRICAL

SEVERE

• Remove electric power before removing protective

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical

tacts and cause shock or burning.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DIRECTLY TO ANY BUILDING ELECTRICAL SYS-

TEM.

Hazardous voltages can flow from the

erator set into the utility

for electrocution or property

through an approved isolation switch or an approved paralleling device.

GENERAL

• Coolants under pressure have a higher boiling point

than

water.

changer pressure cap while the engine is running.

Allow the generator

pressure first.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproduc-

tive toxicity. When checking or changing engine oil,

take care not to ingest, breathe the fumes, or

tact used oil.

SHOCK

PERSONAL

DO NOT tamper with interlocks.

SAFETY

DO NOT open a radiator or heat ex-

CAN

INJURY

line.

CAUSE

OR

DEATH

This creates a potential

damage.

Connect only

PRECAUTIONS

set

to cool and bleed the system

con-

gen-

con-

Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and

and flammable liquid fuels and gaseous

C

fires,

live electrical equipment, (ref. NFPA

Make sure that rags are not left on or near the engine.

Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under the unit.

Remove all unnecessary grease and oil from the

* unit. Accumulated grease and oil can cause

heating and engine damage which present a poten-

tial fire hazard.

Keep the generator set and the surrounding area

clean and free from obstructions. Remove any debris from the set and keep the floor clean and dry.

Do not work on this equipment when mentally or

physically

or drug that makes the operation of equipment unsafe.

Substances in exhaust gases have been identified

by some state or federal agencies as causing

cer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases

Do not store any flammable liquids, such as

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

Wear hearing protection when going near an

ating generator set.

To prevent serious burns, avoid contact with hot

metal parts such as radiator, turbo charger and exhaust system.

fatigued,

cloth;

Class B

or after consuming any alcohol

fires,

combustibli

fuels;

Clas

No.

10).

over-

can-

fuel,

oper-

KEEP

THIS

MANUAL

NEAR

THE

IV

GENSET

FOR

EASY

REFERENCE

1.

Introduction

ABOUT

This manual covers models produced under the

Cummins®/Onan® and Cummins Power Genera-

tion brand names.

This manual provides installation instructions for

the generator set models listed on the front cover.

This includes the following information:

Mounting Recommendations - for fastening

generator set to base and space requirements

for normal operation and service.

Mechanical Connections and Electrical

connections - covers most aspects of

erator set installation.

THIS

MANUAL

the

gen-

Prestart - Checklist of items or procedures

needed to prepare generator set for operation.

Initial Startup - Test complete system to ensure proper installation, satisfactory performance,

and safe operation. Refer to Operators

Manual for troubleshooting information.

This manual DOES NOT provide application infor-

mation for selecting a generator set or designing the

complete installation. If it is necessary to design the

various integrated systems (fuel, exhaust, cooling,

etc.),

additional information is required. Review

standard installation practices. For engineering

data specific to the generator

ator set Specifications

cation information, refer to Application Manual

T-030, "Liquid Cooled Generator Sets".

and

set,

refer

to

the gener-

Data sheets. For appli-

1-1

INSTALLATION

These installation recommendations apply to

OVERVIEW

typical installations with standard model generator

sets.

Whenever possible, these recommendations

also cover factory designed options or modifica-

tions.

However, because of the many variables in

any installation, it is not possible to provide specific

recommendations for every situation. If there are

any questions not answered by this manual, contact

your nearest Cummins Power Generation distributor for assistance.

Application and Installation

A standby power system must be carefully planned

and correctly installed for proper

operation.

This involves two essential elements: application and installation.

Application (as it applies to generator set installations) refers to the design of the complete standby

power system that usually includes power distribu-

tion equipment, transfer

switches,

ventilation equip-

ment, mounting pads, and cooling, exhaust, and

fuel systems. Each component must be correctly

designed so the complete system will function as intended.

Application and design is an engineering

function generally done by specifying engineers or

other trained specialists. Specifying engineers are

responsible for the design of the complete standby

system and for selecting the materials and products

required.

Installation refers to the actual set-up and assembly of the standby power

system.

The installers set

up and connect the various components of the system as specified in the system design plan. The

complexity of

the

standby system normally requires

the special skills of qualified electricians, plumbers,

sheetmetal workers, etc. to complete the various

segments of the installation. This is necessary so

all components are assembled using standard

methods and practices.

Safety

Considerations

The generator set has been carefully designed to

provide safe and efficient service when properly installed,

maintained, and operated. However, the

overall safety and reliability of the complete system

is dependent on many factors outside the control of

the generator set manufacturer. To avoid possible

safety hazards, make all mechanical and electrical

connections to the generator set exactly as specified in this

manual.

All systems external to the

generator (fuel, exhaust, electrical, etc.) must comply

with all applicable codes. Make certain all required

inspections

code requirements have been satisfied before

and

tests have been completed and all

certifying the installation is complete and ready for service.

Copyright®

Cummins, Onan and PowerCommand are registered trademarks of Cummins Inc.

2001

Cummins Power

Generation.

All rights reserved.

1-2

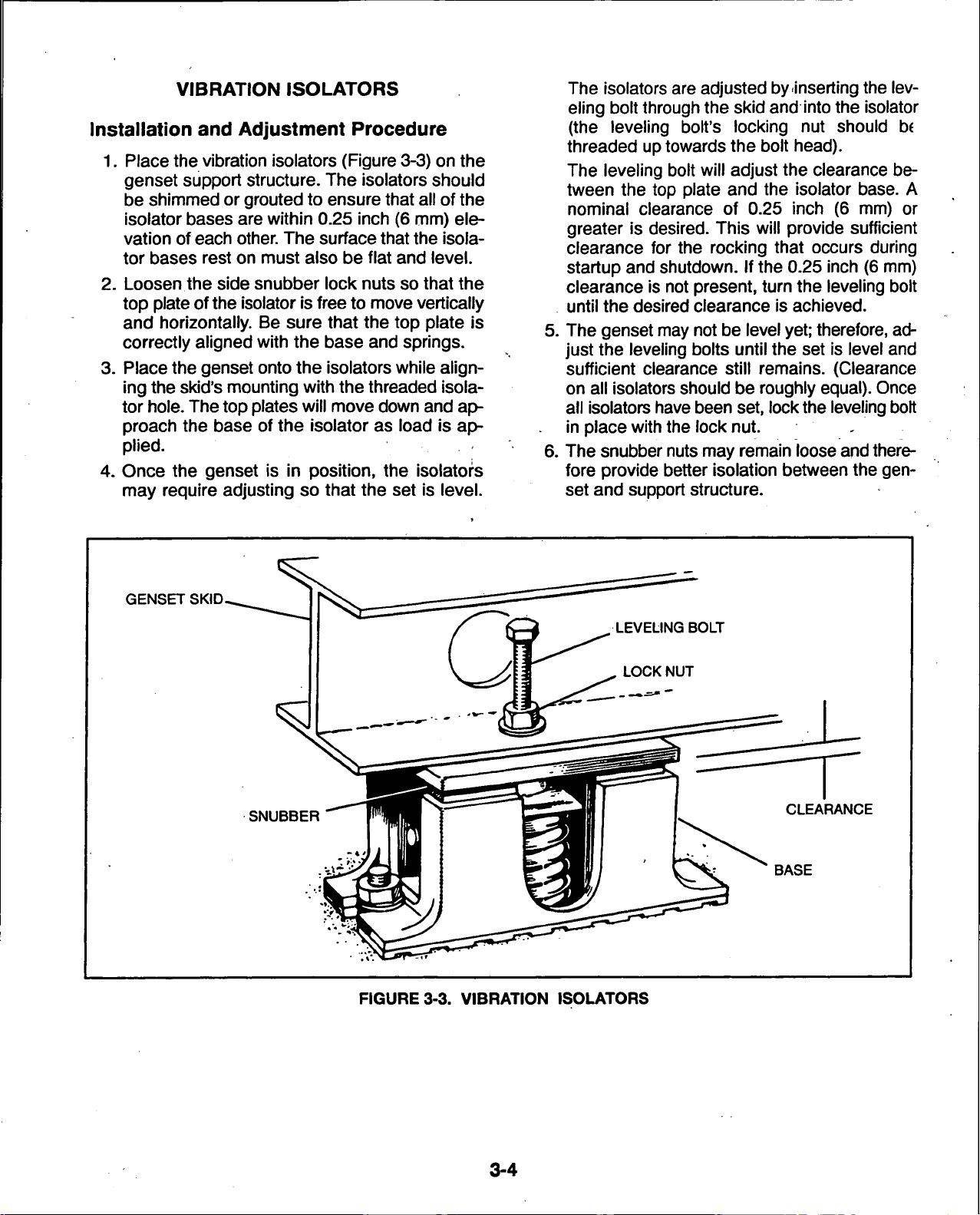

2.

Specifications

MODEL

Cummins

Generator kW Rating See Genset Nameplate for rating information.

Cooling

Capacity with Standard Radiator

Oil

Capacity*

Engine

Inlet/Outlet Thread Size

Fuel

Max. Fuel Inlet Pressure

Max. Fuel Inlet Restriction

Max. Fuel Return Restriction

Exhaust

Outlet Size

Maximum Allowable Back Pres.

Electrical

Starting Voltage

Battery

* Referto Cummins engine Operation and Maintenance Manual for lubricating oil recommendations/specifications.

Diesel

System

Fuel

Flow

System

Group Number

Cold Cranking Amps (minimum)

Cold Soak@0oF(-18o C)

Series

Connection

Refer to Generator Outline Drawing

DQAD/DQAE/DQAF

QSM11

10.5 Gal (40 L)

9.7 Gal (36.7 L)

10PSI(69kPa)

4 in. Hg. (13.5 kPa)

2.5 in. Hg. (8.5 kPa)

5 in. NPT

41 in. H20(10.2kPa)

24 Volts DC

Two,

12 Volt

8D

900

MODEL

US gph (L/hr)

FUEL

CONSUMPTION

DQAD

17.3 (65.5)

(STANDBY/FULL

DQAE

19.4 (73.4)

LOAD/60Hz)

DQAF

21.4(81.0)

2-1

3.

Mounting

the Generator Set

GENERAL

Generator set installations must be engineered so

the generator set will function properly under

pected load

general guide only. Follow the instructions of the

consulting engineer when locating or installing any

components. The complete installation must comply with all local and state building codes, fire ordinances, and other applicable regulations. Consider

these requirements before installation:

Requirements to be considered prior to installation:

• Level mounting surface

• Adequate cooling air

• Adequate fresh induction air

• Discharge of generator set air

• Non-combustible mounting surface.

INCORRECT

PERSONAL

BE

TRAINED AND

PONENT

conditions.

INSTALLATION,

INJURY,

INSTALLATION.

Use these instructions as a

DEATH,

EXPERIENCED

SERVICE

AND/OR EQUIPMENT DAMAGE.

the

ex-

IAWARNING

OR

PARTS

TO

PERFORM

• Discharge of exhaust gases

• Electrical connections

• Accessibility for operation and servicing

• Noise levels

• Vibration isolation

LOCATION

Generator set location is decided mainly by related

systems such as ventilation, wiring, fuel, and exhaust. The set should be located as near as possible to the main power service entrance. Exhaust

must not be able to enter or accumulate around inhabited areas.

Provide a location away from extreme ambient temperatures and protect the generator set from ad-

verse weather conditions.

REPLACEMENT

ELECTRICAL

CAN

SERVICE

AND MECHANICAL COM-

RESULT

PERSONNEL

IN

SEVERE

MUST

DEPENDING

AND

REGULATIONS

BEFORE

POLLUTION

STRUCTION

BEGINNING INSTALLATION OF YOUR

ON YOUR

MAY

CONTROL

PLANS.

LOCATION

REQUIRE

OR AIR QUALITY

AND INTENDED

YOU TO OBTAIN AN AIR QUALITY EMISSIONS PERMIT

IMPORTANT

USE,

GENSET.

AUTHORITIES

3-1

FEDERAL,

BE

SURE

BEFORE

COMPLETING

STATE

TO

OR

LOCAL

CONSULT

YOUR

LAWS

LOCAL

CON-

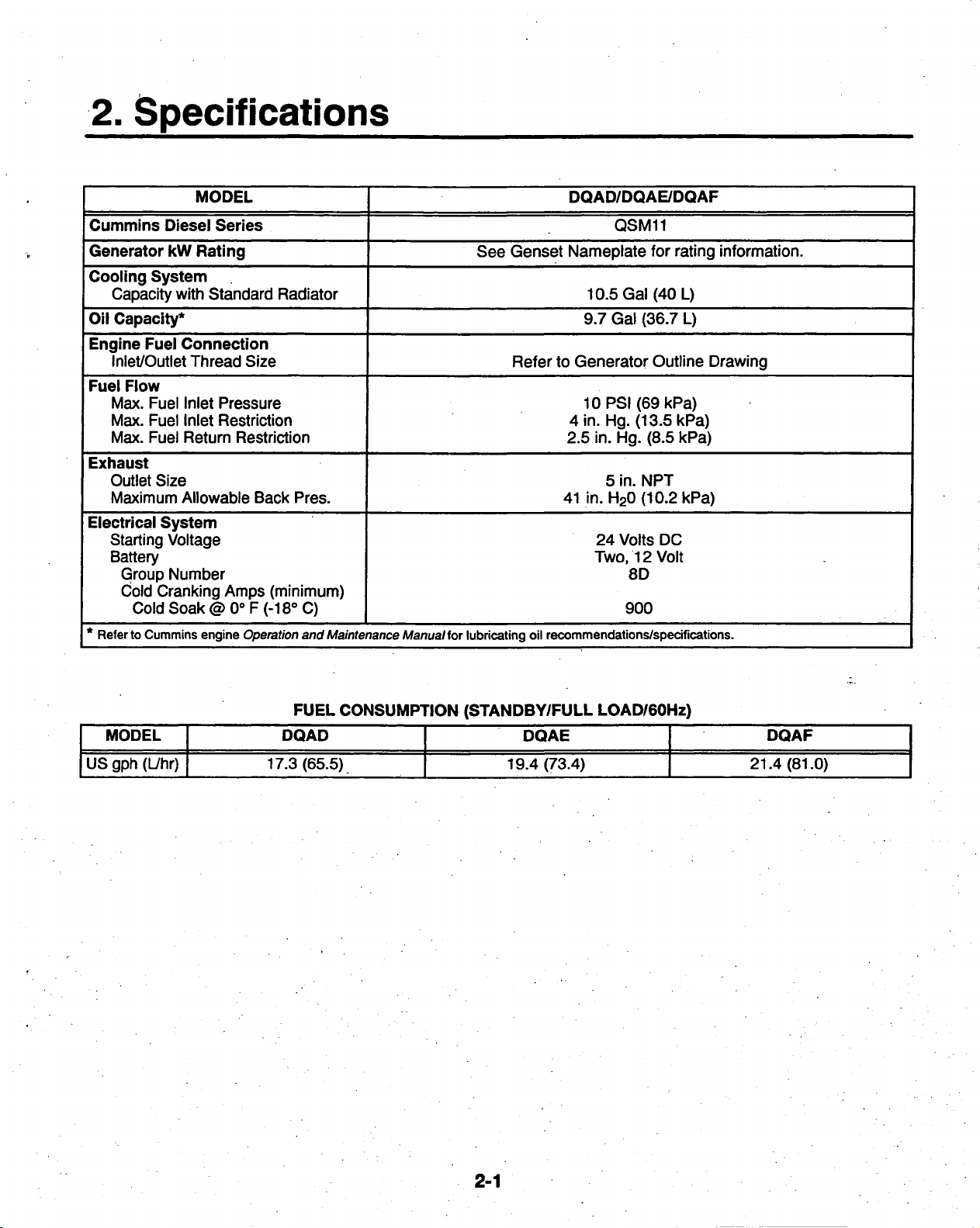

MOUNTING

Generator sets are mounted on a steel

skid

that provides proper support. The engine-generator assembly is isolated from the skid frame by rubber

mounts that provide adequate vibration isolation for

normal installations. Where required by building

codes or special isolation needs, generator sets

may be mounted on rubber pads or mechanical

spring isolators. The use of unapproved isolators

may result in harmful resonances and may void the

genset warranty.

Mount the generator set on a substantial and level

base such as a concrete pad. A non-combustible

material must be used for the pad.

Use 5/8 inch or 16 mm anchored mounting bolts to

secure the vibration isolators to the base. Secure

the vibration isolators to the skid using flat or bevel

washer and hexagonal nut for each bolt (see Figure

3-1). The 1-1/2 x 6 inch pipe inserted over the

mounting bolts allows minor adjustment of the bolts

to align them to the holes

in

the subbase or vibration

isolator.

Locate

Outline Drawing

the

isolators

as

shown

referenced

on the

generator set

in the Data Sheet

MOUNTING

BASE

MOUNTING

BOLT

SUBBASE OR

VIBRATION

ISOLATOR

FLANGE

CONCRETE

HEX NUT

FLAT OR BEVEL

WASHER

1-1/2x6

INCH

PIPE

12 IN.

(305 mm)

ACCESS

TO SET

Generally, at least 1 meter (3 feet) of clearance

should be provided on all sides of the generator set

for maintenance and service access. A raised

foundation or slab of 150 mm (6 inches) or more

above floor level will make servicing easier.

Lighting should be adequate for

nance and service operations and should be

nected on the load side of

the

operation,

mainte-

con-

transfer switch so that

it is available at all times.

FIGURE

3-1.

BOLT DIAGRAM

3-2

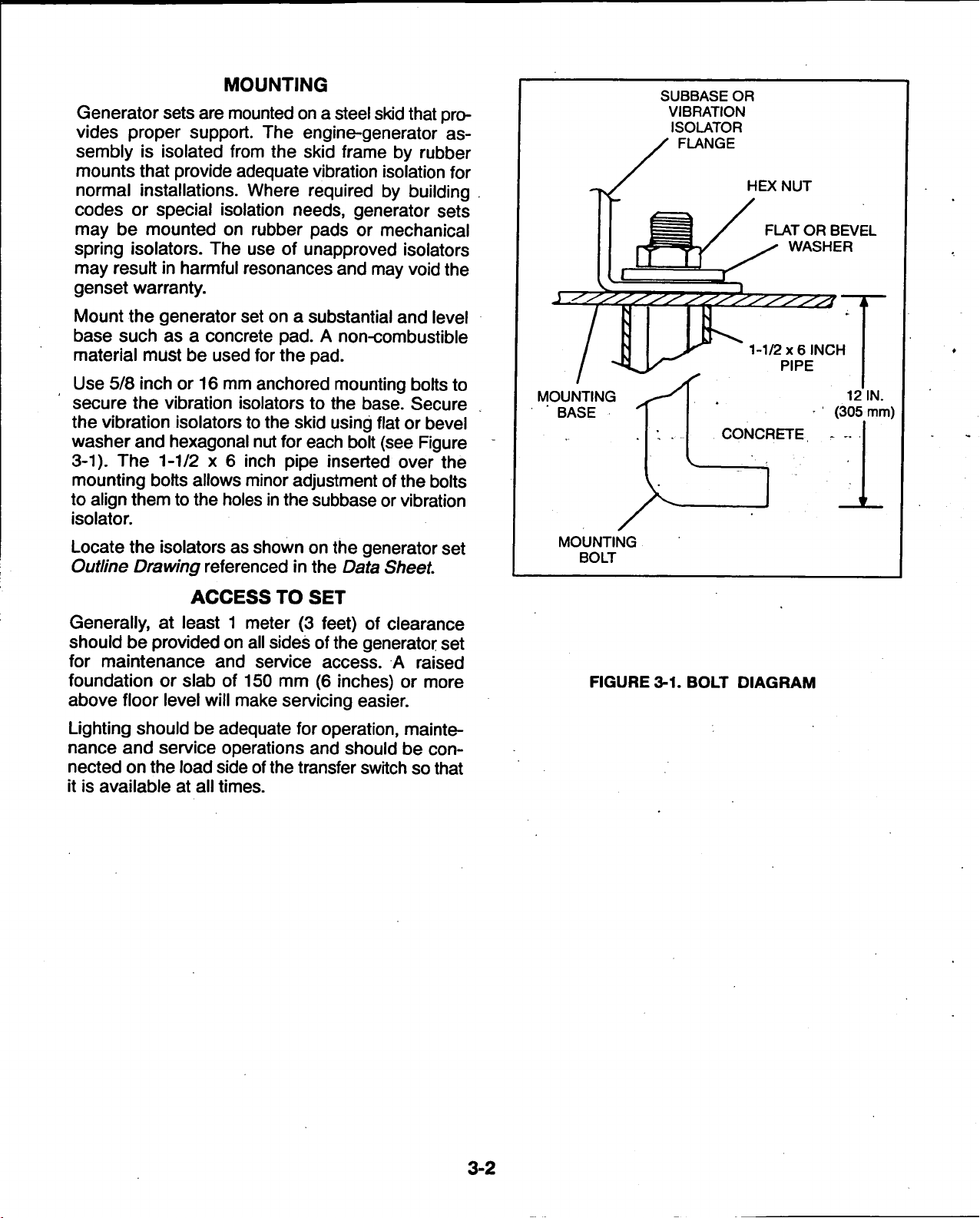

MUFFLER

THIMBLE

FLEXIBLE

SECTION

CONDENSATION

DRAIN TRAP

DC CONTROL

WIRING

AC POWER

WIRING

AIR OUTLET

DUCT (FLEXIBLE

BELLOWS)

LEVEL

CONCRETE

BASE

FIGURE

3-2.

TYPICAL

3-3

IMPORTANT!

COOLING AIR INLET MUST BE AT LEAST 1-1/2

TIMES LARGER THAN RADIATOR DUCT OUTLET

AREA ON RADIATOR COOLED MODELS

FLOW OF COOLING AIR AND HEATED AIR CAN

BE CONTROLLED BY AUTOMATICALLY

OPERATED LOUVRES

INSTALLATION

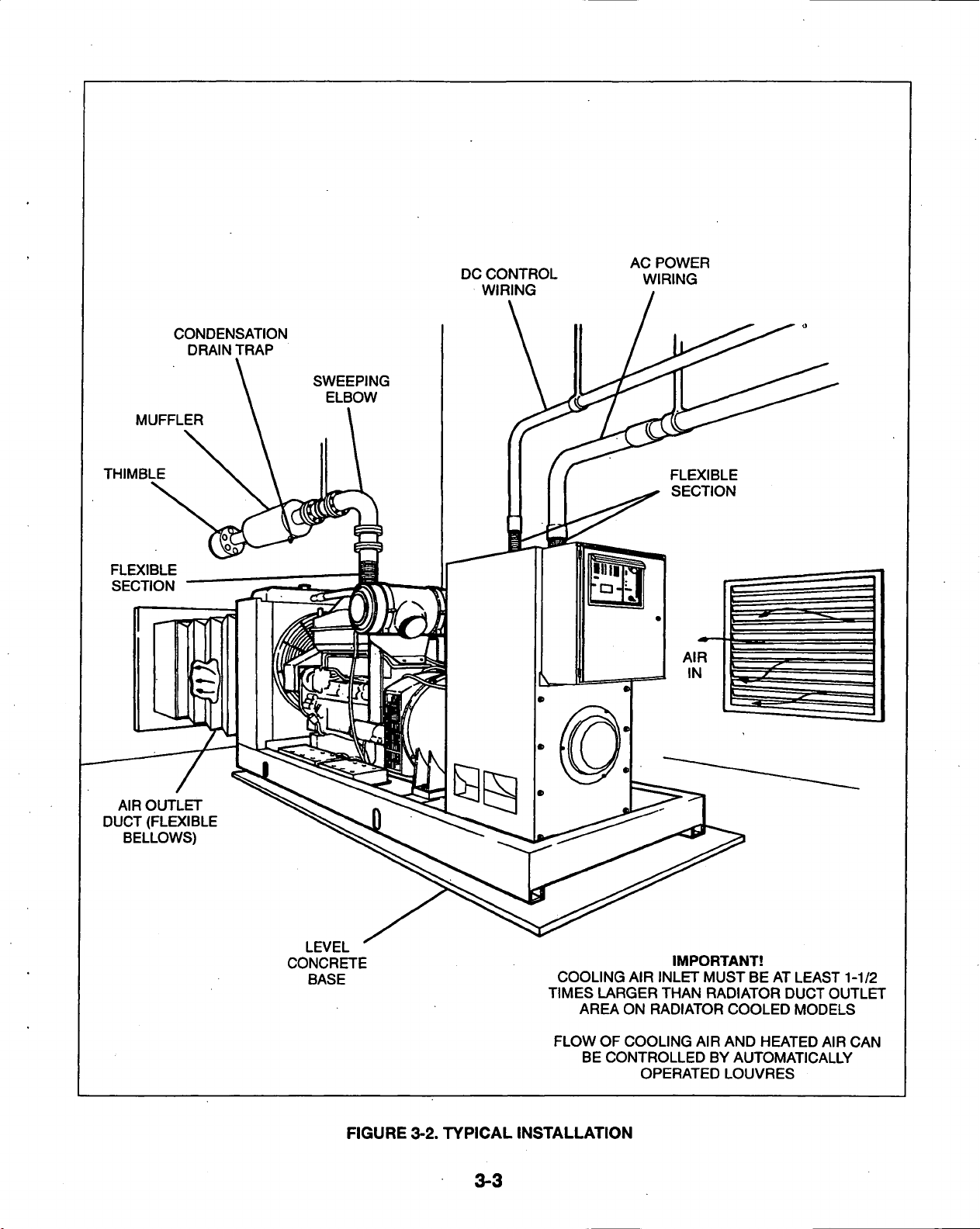

VIBRATION

ISOLATORS

Installation and Adjustment Procedure

1.

Place the vibration isolators (Figure 3-3) on the

genset support structure. The isolators should

be shimmed or grouted to ensure that all of the

isolator bases are within 0.25 inch (6 mm) ele-

vation of each

other.

The surface that the isola-

tor bases rest on must also be flat and level.

2.

Loosen the side snubber lock nuts so that the

top plate ofthe isolator is free to move vertically

and horizontally. Be sure that the top plate is

correctly aligned with the base and springs.

3. Place the genset onto the isolators while aligning the skid's mounting with the threaded isola-

tor

hole.

The top plates will move down and approach the base of the isolator as load is applied.

4.

Once the genset is in position, the isolators

may require adjusting so that the set is level.

The isolators are adjusted by inserting the leveling bolt through the skid and into the isolator

(the leveling bolt's locking nut should be

threaded up towards the bolt head).

The leveling bolt will adjust the clearance be-

tween the top plate and the isolator base. A

nominal clearance of 0.25 inch (6 mm) or

greater is desired. This will provide sufficient

clearance for the rocking that occurs during

startup and shutdown. If the 0.25 inch (6 mm)

clearance is not present, turn the leveling bolt

until the desired clearance is achieved.

5. The genset may not be level

yet;

therefore, adjust the leveling bolts until the set is level and

sufficient clearance still remains. (Clearance

on all isolators should be roughly

all isolators have been set, lock

equal).

the

leveling bolt

in place with the lock nut. -

6. The snubber nuts may remain loose

and

fore provide better isolation between the

set and support structure.

Once

there-

gen-

GENSET SKID.

SNUBBER

FIGURE

3-3. VIBRATION

CLEARANCE

ISOLATORS

3-4

4. Mechanical

Connections

GENERAL

The generator set mechanical system installation

includes connecting the

and cooling systems. Before starting any type of

fuel installation, all pertinent state and local codes

must be complied with and the installation must be

inspected before the unit is put in service.

FUEL

Cummins engines normally use ASTM No. 2 diesel

fuel. They will, however, operate on alternate diesel

fuels within

mins engine Operation and Maintenance Manual.

In all fuel system installations, cleanliness is ofthe

upmost importance. Make every effort to prevent

entrance of moisture, dirt or contaminants of any

kind into the fuel

ponents before installing.

A

fuel filter/strainer/water separator of 100-120 mesh

or equivalent (approximately 150 microns nominal)

must

be

tank or between the main tank

Use only compatible metal fuel lines to avoid elec-

trolysis when fuel lines must be buried. Buried fuel

lines must be protected from corrosion.

IACAUTIONI

lines, fittings

tank and

fuel to produce sulfuric acid. The molecular

structure

tanks reacts with the

fuel.

An electric solenoid valve in the supply line is recommended for all installations and required for indoor automatic or remote starting installations.

Connect the solenoid wires to the genset "Switched

B+"

circuit to open the valve during generator set

operation.

the

specifications shown

system.

fitted between either the main tank and day

Never use galvanized

or

fuel tanks. Condensation

lines combines with the

of the copper or

fuel,

exhaust, ventilation

SYSTEM

in the Cum-

Clean all fuel system com-

and

the engine.

or

copper fuel

sulfur in

galvanized

acid

and contaminates

lines or

in the

diesel

the

must not contain a shutoff

will occur if

blocked or restricted.

IA

retum

exceeds fuel

will

Fuel Retum Restriction (or Pressure) Limit: Fuel

return drain restriction (consisting of friction head

and static head) between the engine injector return

line connection and the fuel tank must not exceed

the limit stated in the Specification section.

Fuel

A flexible fuel hose(s) or section of flexible fuel

hose(s) must be used between the engine's fuel

system and fuel supply and return line(s) to protect

the fuel system from damage caused by vibration,

expansion and contraction. Flexible lines for

necting between the engine and the stationary fuel

lines are supplied as standard equipment.

Installation of

to all applicable codes and standards, and installation recommendations provided by the manufacturer. The supplied flexible hose is approved by the

hose manufacture for use with the genset fuel type

and product application.

Support fuel lines to restrain movement

chaffing or contact with sharp edges, electrical

ing and hot exhaust parts.

IAWARNINGI

fuel,

Do not

hot exhaust parts.

Fuel lines must be routed and secured to maintain a

1/2 inch (12.7 mm) minimum clearance from electrical wiring and a 2 inch

from hot exhaust parts.

CAUTION I

line(s).

occur.

Lines

leading

route

device.

the

engine is

Never

If

fuel return

restriction

- Routing

the

fuel hose must be done according

Sparks

to

severe personal injury

fuel

install

and hot

lines

(51

run

with the return fuel lines

shutoff

limit, engine damage

near

mm) minimum clearance

Engine damage

device

linefs) is

surfaces can

electrical wiring

blocked

and

prevent

or

in fuel

or

con-

wir-

ignite

death.

or

Separate fuel return lines to the day tank or supply

ank must be provided for each generator set in a

multiple-set installation to prevent the return lines of

idle sets from being pressurized. Fuel return lines

Engine

Identification tags are attached to the fuel supply

line and fuel return line connections.

Fuel

Connections

4-1

ENGINE

FUEL

PUMP

DAY TANK

FUEL TRANSFER•

PUMP ELECTRIC '

MOTOR DRIVEN

VENTED

FILL CAP

120 MESH FUEL

STRAINER

LARGER OVER-

FLOW LINE

INJECTOR FUEL

RETURN LINE

CONNECT TO

AC OUTPUT

FUELTANK

All models require a fuel return

line from injectors to tank.

VENT LINE

. FILL PIPE

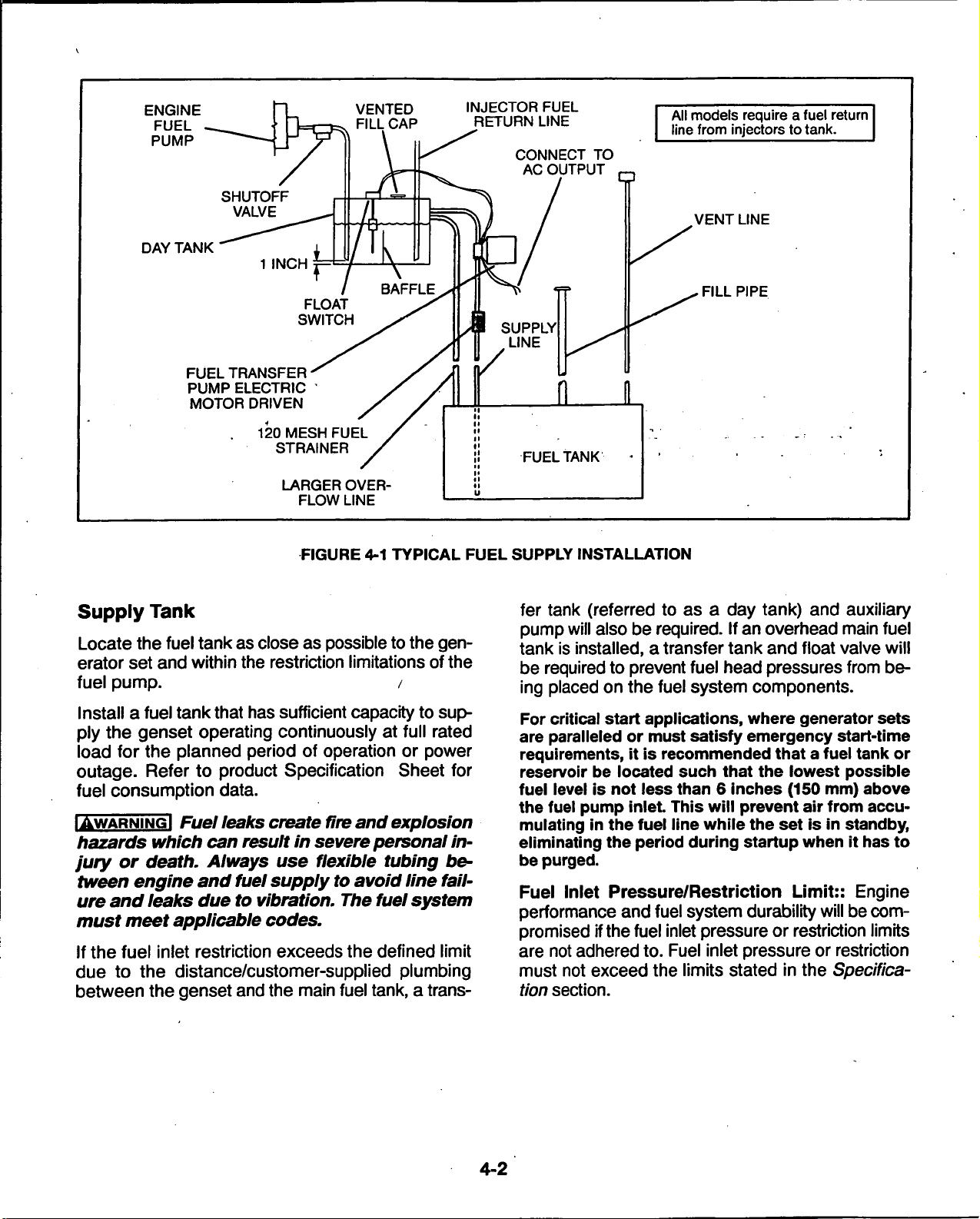

FIGURE 4-1 TYPICAL FUEL SUPPLY INSTALLATION

Supply

Tank

fer tank (referred to as a day tank) and auxiliary

pump will also be required. If an overhead main fuel

Locate the fuel tank as close as possible to the

erator set and within the restriction limitations of the

fuel pump. /

Install a fuel tank that has sufficient capacity to supply the genset operating continuously at full rated

load for the planned period of operation or power

outage. Refer to product Specification Sheet for

fuel consumption data.

gen-

tank is installed, a transfer tank and float valve will

be required to prevent fuel head pressures from be-

ing placed on the fuel system components.

For critical start applications, where generator sets

are paralleled or must satisfy emergency start-time

requirements, it is recommended that a fuel tank or

reservoir be located such that the lowest possible

fuel level is not less than 6 inches (150 mm) above

the fuel pump inlet This will prevent air from accu-

IAWARNINGI Fuel leaks create fire and explosion

hazards which can result in severe personal in-

jury or death. Always use flexible tubing be-

tween engine and fuel supply to avoid line failure and leaks due to vibration. The fuel system

must meet applicable codes.

If the fuel inlet restriction exceeds the defined limit

due to the distance/customer-supplied plumbing

between the genset and the main fuel tank, a trans-

mulating in the fuel line while the set is in standby,

eliminating the period during startup when it has to

be purged.

Fuel Inlet Pressure/Restriction Limit:: Engine

performance and fuel system durability will be compromised ifthe fuel inlet pressure or restriction limits

are not adhered to. Fuel inlet pressure or restriction

must not exceed the limits stated in the Specification section.

4-2

Loading...

Loading...