CUMMINS DGBA, DGBB, DGCB, DGDA, DGDB Service Manual

...

Caution: This document contains mixed page sizes (8.5 x 11 or 11 x

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

17), which may affect printing. Please adjust your printer settings

according to the size of each page you wish to print.

Service Manual

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Detector Control

Generator Sets

Printed in U.S.A.

Models

DGBA, DGBB, DGBC, DGCA, DGCB, DGDA, DGDB

DGEA, DGFA, DGFB

QSGBA, QSGCA, QSGCB, QSDA, QSDB, QSEA, QSFA

4B3.9, 4BT3.9, 6BT5.9, 6CT8.3, 6CTA8.3

960-0505 4-2001

Table of Contents

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

SECTION TITLE PAGE

SAFETY PRECAUTIONS iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 INTRODUCTION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 AC CONTROL 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Control Panel Components 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Control Panel Components 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Voltage Regulator (AVR) Adjustments 2-2. . . . . . . . . . . . . . . . . . . . .

Principle Of Generator Operation 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 ENGINE CONTROL 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Control Panel Components 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Control Panel Components 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Box Interior 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Control Monitor (A11) 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Sensors 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Control Components 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence Of Operation 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 TROUBLESHOOTING 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Engine Does Not Crank 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Engine Cranks But Does Not Start 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Engine Runs Until Fault Shutdown (Red Shutdown Lamp On) 4-6. . . . .

The Engine Lacks Power Or Stable Speed 4-8. . . . . . . . . . . . . . . . . . . . . . . . .

Amber Warning Lamp On 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Green Run Lamps Stay Off But The Set Runs Normally 4-11. . . . . . . . .

There Is No Output Voltage (Engine Speed Is Stable) 4-12. . . . . . . . . . . . . . .

Output Voltage Is Too High Or Too Low 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Voltage Is Unstable 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Field Circuit Breaker Keeps Tripping 4-18. . . . . . . . . . . . . . . . . . . . . . . . . .

The Phase Currents Are Unbalanced 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

5 SERVICING THE GENERATOR 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Testing The Generator 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing And Disassembling The Generator 5-8. . . . . . . . . . . . . . . . . . . . . . .

Reassembling The Generator 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing The PMG 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 GOVERNORS 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Governor 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Governor 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 DAY TANK FUEL PUMP AND CONTROL 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Transfer Pump Motor Connections 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing The Float Switch Assembly 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 QS- AND QSG-SERIES GENERATOR SETS 8-1. . . . . . . . . . . . . . . . . . . . . . . . .

Optional Power Distribution Panel for QSG-Series 8-1. . . . . . . . . . . . . . . . . . .

Optional Trailer Package for QS- and QSG-Series 8-3. . . . . . . . . . . . . . . . . . .

Fan Belt Replacement Procedure for QSG-Series 8-5. . . . . . . . . . . . . . . . . . .

Blower Replacement Procedure for QS-Series 8-6. . . . . . . . . . . . . . . . . . . . . .

9 WIRING DIAGRAMS 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

IMPORTANT SAFETY INSTRUCTIONS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

SAVE THESE INSTRUCTIONS − This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal injury or death.

WARNING

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

• DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use zinc

coated or copper fuel lines with diesel fuel.

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

•

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not warped. Do not use exhaust gases to

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

•

Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, discon-

nect battery charger from its AC source, then disconnect starting batteries, negative (−) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor can cause an engine to overspeed and

become difficult to stop, resulting in possible fire, explosion, severe personal injury and death. Do not operate a

genset where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset is

equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of

the genset are solely responsible for operating the genset safely. Contact your authorized Onan/Cummins dealer or distributor for more information.

LS-13M

iii

ELECTRICAL SHOCK CAN CAUSE

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

SEVERE PERSONAL INJURY OR DEATH

•

Remove electric power before removing protective

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical contacts and cause shock or burning.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DIRECT-

LY TO ANY BUILDING ELECTRICAL SYSTEM.

Hazardous voltages can flow from the generator set

into the utility line. This creates a potential for electrocution or property damage. Connect only

through an approved isolation switch or an approved paralleling device.

MEDIUM VOLTAGE GENERATOR SETS

(601V to 15kV)

Medium voltage acts differently than low voltage.

•

Special equipment and training is required to work

on or around medium voltage equipment. Operation

and maintenance must be done only by persons

trained and qualified to work on such devices. Improper use or procedures will result in severe personal injury or death.

• Do not work on energized equipment. Unauthorized

personnel must not be permitted near energized

equipment. Due to the nature of medium voltage

electrical equipment, induced voltage remains even

after the equipment is disconnected from the power

source. Plan the time for maintenance with authorized personnel so that the equipment can be de-energized and safely grounded.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

•

than water. DO NOT open a radiator or heat exchanger pressure cap while the engine is running.

Allow the generator set to cool and bleed the system

pressure first.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproductive toxicity . When checking or changing engine oil,

take care not to ingest, breathe the fumes, or contact used oil.

• Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and cloth; Class B fires, combustible

and flammable liquid fuels and gaseous fuels; Class

C fires, live electrical equipment. (ref. NFP A No. 10).

• Make sure that rags are not left on or near the en-

gine.

• Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under the unit.

• Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause overheating and engine damage which present a potential fire hazard.

• Keep the generator set and the surrounding area

clean and free from obstructions. Remove any debris from the set and keep the floor clean and dry.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment unsafe.

• Substances in exhaust gases have been identified

by some state or federal agencies as causing cancer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

• Do not store any flammable liquids, such as fuel,

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

• Wear hearing protection when going near an oper-

ating generator set.

• To prevent serious burns, avoid contact with hot

metal parts such as radiator, turbo charger and exhaust system.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

iv

1. Introduction

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

GENERAL

This manual covers models produced under the

Cummins

tion brand names.

Each operator should read this manual before operating the set for the first time. A generator set (genset) must be operated and maintained properly if

you are to expect safe, reliable and quiet operation.

The manual includes a troubleshooting guide and a

maintenance schedule.

The engine manual is included with the set. Where

there is conflicting information, this manual takes

precedence over the engine manual.

WARNING

nance can lead to severe personal injury or loss

of life and property by fire, electrocution, mechanical breakdown or exhaust gas asphyxiation. Read and follow the safety precautions

on page iii and carefully observe all instructions

and precautions in this manual.

/Onan and Cummins Power Genera-

Improper operation and mainte-

tor. Factory-trained Parts and Service representatives are ready to handle all your service needs.

To contact your local Cummins Power Generation

distributor in the United States or Canada, call

1-800-888-6626 (this automated service utilizes

touch-tone phones only). By selecting Option 1

(press 1), you will be automatically connected to the

distributor nearest you.

If you are unable to contact a distributor using the

automated service, consult the Yellow Pages. Typically, our distributors are listed under:

GENERATORS-ELECTRIC or

ELECTRICAL PRODUCTS

For outside North America, call Cummins Power

Generation, 1-763-574-5000, 7:30 AM to 4:00 PM,

Central Standard Time, Monday through Friday. O r,

send a fax to Cummins Power Generation using the

fax number 1-763-574-8087.

HOW TO OBTAIN SERVICE

When contacting your distributor, always supply the

When the generator set requires servicing, contact

your nearest Cummins Power Generation distribu-

complete Model, Specification, and Serial Number

as shown on the generator set nameplate.

WARNING

INCORRECT SERVICE OR PARTS REPLACEMENT CAN RESULT IN SEVERE PERSONAL INJURY, DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST BE TRAINED

AND EXPERIENCED TO PERFORM ELECTRICAL AND/OR MECHANICAL SERVICE.

Copyright2001 Cummins Power Generation. All rights reserved.

Cummins and Onan are registered trademarks of Cummins Inc.

Detector is a trademark of Cummins Inc.

1-1

THIS PAGE LEFT INTENTIONALLY BLANK

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

1-2

2. AC Control

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

GENERAL

The control box is mounted on top of the generator,

facing the rear. Figure 2-1 points out the components on the AC control panel. Pages 9-3 through

9-6 show the wiring connections.

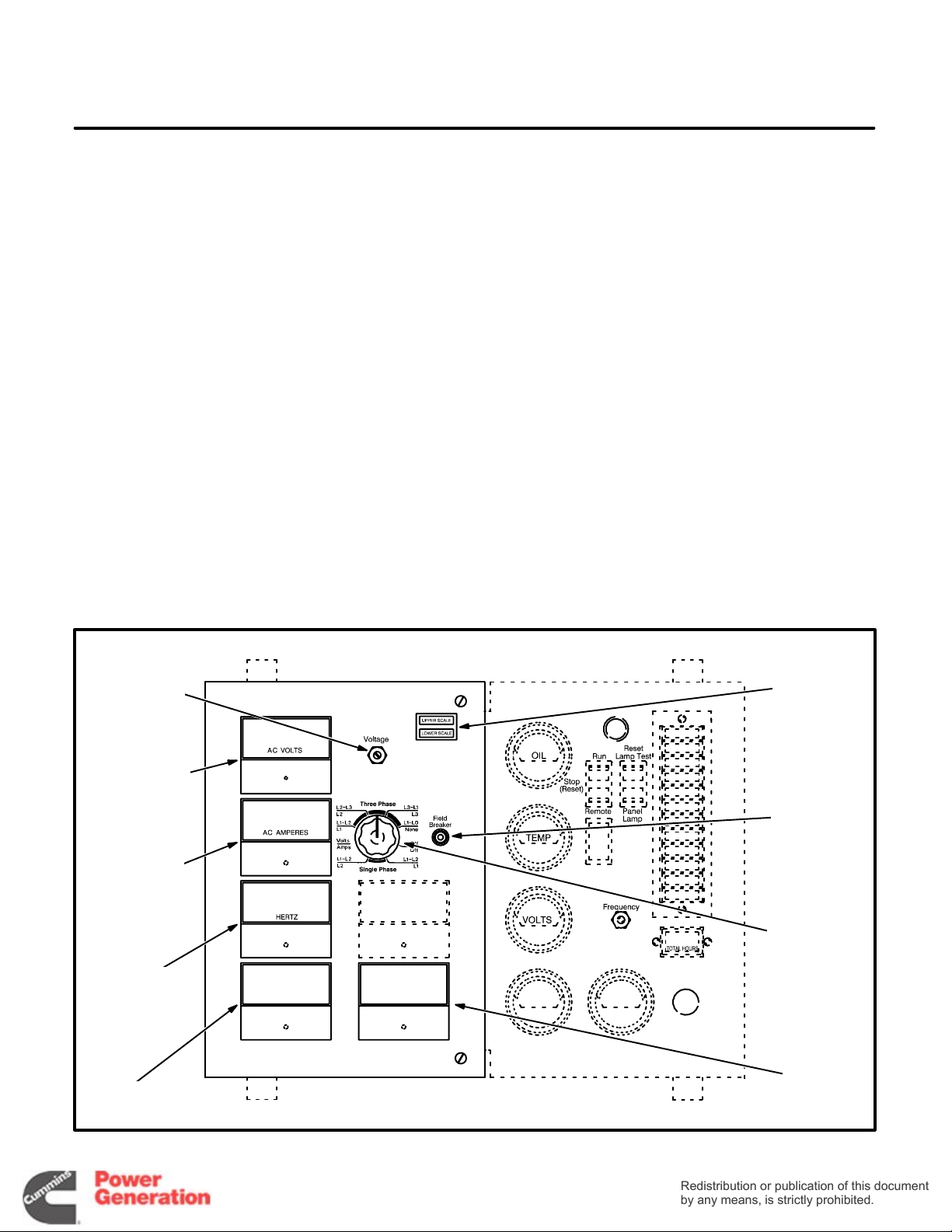

STANDARD CONTROL PANEL

COMPONENTS

Field Circuit Breaker (CB21) The field circuit

breaker protects the generator from over-excitation.

OPTIONAL CONTROL PANEL

COMPONENTS

AC V oltmeter (M21) The voltmeter indicates output

voltage for the phase selected.

AC Ammeter (M22) The ammeter indicates output

amperage for the phase selected. Input to the am-

meter is from current transformers CT21, CT22 and

CT23.

Phase Selector Switch (S21) The selector switch

is used to select the phase for voltage and amper-

age readings.

Scale Indicator Lamps (DS21 and DS22) The

scale indicator lamps indicate whether to read the

upper or lower scales of the voltmeter and ammeter .

Frequency Meter (M23) The frequency meter indi-

cates output frequency in Hertz (Hz) and engine

speed in RPM.

Wattmeter (M24) The wattmeter indicates output

power in kilowatts (kW).

Powerfactor Meter (M25)

The powerfactor meter

indicates output powerfactor as a percentage of

unity powerfactor.

Output V oltage T rimmer (R21) The output voltage

trimmer can be used to adjust output voltage plus or

minus five percent of nominal voltage.

OUTPUT

VOLTAGE

TRIMMER

AC

VOLTMETER

AC

AMMETER

FREQUENCY

METER

WATTMETER

SCALE

INDICATOR

LAMPS

FIELD

CIRCUIT

BREAKER

PHASE

SELECTOR

SWITCH

POWER

FACTOR

METER

FIGURE 2-1. AC CONTROL PANEL

2-1

AUTOMATIC VOLTAGE REGULATOR

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

(AVR) ADJUSTMENTS

Check and readjust the VOLTS pot, if necessary,

each time the STABILITY pot is readjusted.

The automatic voltage regulator is mounted on the

back wall of the control cabinet. It can be adjusted

by means of the potentiometers (pots) shown in Figure 2-2 or 2-3. Figures 2-4 and 2-5 show typical voltage regulating circuits.

These measurements and adjustments are done

while the set is running and require access to uninsulated high voltage parts in the control and power

output boxes.

HIGH VOLTAGE. Touching uninsulated high voltage parts inside the control and

power output boxes can result in severe personal injury or death. Measurements and adjustments must be done with care to avoid

touching high voltage parts.

For your protection, stand on a dry wooden platform or rubber insulating mat, make sure your

clothing and shoes are dry , remove jewelry from

your hands and wear elbow length insulating

gloves.

Jumper Reconnections

Jumpers provide for reconnections to adapt the

voltage regulator to the application. See Figure 2-2.

Reconnect the response jumper, if necessary, so

that terminal A connects to terminal C if generator

output is 90 kW o r less, B to C if generator output is

greater than 90 kW but less than 550 kW and A to B

if output is greater than 550kW. Reconnect the frequency jumper, if necessary, to correspond to the

application frequency.

Voltage and Voltage Stability Adjustments

Use the control panel mounted voltage trimmer, if

provided, for small voltage adjustments. Measure

generator output voltage while the set is running

without load at the nominal frequency. If the trimmer

does not provide enough adjustment, lock it at its

midpoint. Then turn the VOLTS pot fully counter-

clockwise and the STABILITY pot to its midpoint. If

the red LED (light emitting diode) on the board

lights, refer to Jumper Reconnections and to UFRO

Adjustments. Then turn the VOLTS pot clockwise

until rated voltage is obtained. If voltage becomes

unstable when a large load is connected, turn the

STABILITY pot clockwise until voltage is stable.

UFRO Adjustments

The voltage regulator has an under-frequency

protection circuit having a threshold frequency that

can be preset (typically at 59 Hz for 60 Hz applications and 49 Hz for 50 Hz applications). The red

LED on the board lights when frequency dips below

the threshold. The threshold frequency is preset by

turning the UFRO (under frequency roll off) pot

clockwise to raise it and counterclockwise to lower

it. Determine threshold frequency by lowering generator frequency until the LED lights. Note that Dip

and Dwell adjustments, below, are related.

Dip Adjustments

The DIP pot adjusts the voltage vs. frequency slope

of the generator for frequencies below the threshold

preset by the UFRO pot. Turning the DIP pot clockwise increases the slope (for greater voltage roll off

as frequency drops), making it easier for the engine

to pick up a large load, but also increasing the voltage dip. The generator voltage vs. frequency slope

is the same above and below the threshold frequency when the pot is turned fully counterclockwise.

Dwell Adjustments

The DWELL pot times voltage recovery when frequency dips below the preset threshold. Clockwise

adjustment increases dwell time. Full counterclockwise adjustment eliminates dwell, in which case,

voltage recovery follows engine speed recovery.

Droop Adjustments

The DROOP pot is for adjusting the input signal

from the droop compensating CT in paralleling applications. DROOP is preset at the factory for five

percent droop at full load and zero power factor.

V / Trim Adjustments

The V / Trim pot is for adjusting the input signal from

a VAR / PF controller in utility paralleling applications. Full clockwise adjustment is normal, resulting

in maximum sensitivity . The auxiliary controller has

no effect when the pot is turned fully counterclockwise.

EXC, OVER V, I / LIMIT, STAB/1and RMS

These pots are factory preset and do not require adjustment.

2-2

PMG-EXCITED GENERATORS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

I/LIMIT

VOLTS

LED

1

2

3

UFRO

MX321

DIP

V/TRIM

DROOP

STABILITY

DWELL

EXC

OVER V

VOLTAGE REGULATOR

(VR21)

FREQUENCY JUMPER:

50 HZ—3-2

60 HZ—3-1

A

B

C

RESPONSE JUMPER:

A TO C—UNDER 90 KW

B TO C—90-550 KW

A TO B—OVER 550 KW

SELF-EXCITED GENERATORS

ABC

60C 50

UFRO

LED

STABILITY

RESPONSE JUMPER:

A TO C—UNDER 90 KW

B TO C—90-550 KW

A TO B—OVER 550 KW

FREQUENCY JUMPER:

50 HZ—C-50

60 HZ—C-60

THESE JUMPERS

MUST BE:

2-3, 4-5 AND 6-7

FIGURE 2-2. VOLTAGE REGULATOR ADJUSTMENT POTS AND SELECTION JUMPERS

(BEGINNING JANUARY 1990)

2-3

8

7

6

5

4

3

2

1

SX440

VOLTS

DROOP

V/TRIM

PMG-EXCITED GENERATORS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

I/LIMIT

VOLTS

UFRO

DIP

LED

STABILITY

STAB/1

RMS

V/TRIM

DROOP

EXC

OVER V

VOLTAGE REGULATOR

(VR21)

SELF-EXCITED GENERATORS

60C 50

UFRO

LED

FREQUENCY JUMPER:

50 HZ—C-50

60 HZ—C-60

THESE JUMPERS

MUST BE:

2-3, 4-5 AND 6-7

FIGURE 2-3. VOLTAGE REGULATOR ADJUSTMENT POTS AND SELECTION JUMPERS

(PRIOR TO JANUARY 1990)

2-4

8

7

6

5

4

3

2

1

STABILITY

VOLTS

DROOP

V/TRIM

PMG

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

ROTOR

N

S

PMG

STATOR

EXCITER

ROTOR

EXCITER

STATOR

ROTATING

RECTIFIERS

MAIN

ROTOR

MAIN

STATOR

8

7

6

OUTPUT

VOLTAGE

SENSING

LEADS

(NOTE 2)

TB21

32

6

25

24

7

23

8

22

21

VOLTAGE

TRIMMER R21

(NOTE 4)

FIELD CIRCUIT

BREAKER

CB21

ISOLATION TRANSFORMER

(NOTE 3)

INPUT OUTPUT

786− 786−

2

1

8

7

6

X

VOLTAGE

XX

REGULATOR

P4

P3

P2

K1

K2

MX321

(VR21)

K1K2 P2 P3 P4 S2 S1 A2 A1XXXX 8 7 6 3 2 1

X

AUXILIARY TERMINAL BOARD

A2

A1

S2

S1

E1

E0

WHEN PARALLELING WITH

A GENERATOR SET OR

UTILITY, TERMINALS S1

AND S2 ARE FOR

CONNECTING A DROOP

COMPENSATING CT

WHEN PARALLELING WITH

A UTILITY, TERMINALS A1

AND A2 ARE FOR

CONNECTING A

VAR / POWER FACTOR

CONTROLLER

1. Connect like numbered terminals on auxiliary

terminal board and voltage regulator.

2. See the appropriate reconnection diagram for

connecting sensing leads 6, 7 and 8.

3. When the generator is connected for singlephase output, voltage regulator terminal 6 is

FIGURE 2-4. TYPICAL VOLTAGE REGULATING CIRCUITS FOR PMG-EXCITED GENERATORS

— NOTES —

not connected to the isolation transformer but

is jumpered to voltage regulator terminal 8.

4. There must be a jumper between voltage regulator terminals 1 and 2 when voltage trimmer

R21 is not used.

2-5

EXCITER

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

ROTOR

ROTATING

RECTIFIERS

MAIN

ROTOR

6

7

8

EXCITER

STATOR

TB21

32

25

24

23

22

21

SX440

VOLTAGE

REGULATOR

S2

S1

A2

A1

(VR21)

21 P4 P2P3

3

MAIN

STATOR

OUTPUT

8

VOLTAGE

7

SENSING

LEADS

6

(NOTE 2)

K1K2 P2 P3 P4 S2 S1 A2 A1XXXX 8 7 6 3 2 1

X

AUXILIARY TERMINAL BOARD

WHEN PARALLELING WITH

A GENERATOR SET OR

UTILITY, TERMINALS S1

K1K2XXX

AND S2 ARE FOR

CONNECTING A DROOP

COMPENSATING CT

VOLTAGE

TRIMMER R21

(NOTE 3)

1. Connect like numbered terminals on auxiliary

terminal board and voltage regulator.

2. See the appropriate reconnection diagram for

connecting sensing leads 6, 7 and 8.

FIGURE 2-5. TYPICAL VOLTAGE REGULATING CIRCUITS FOR SELF-EXCITED GENERATORS

— NOTES —

3. There must be a jumper between voltage regu-

2-6

WHEN PARALLELING WITH

A UTILITY, TERMINALS A1

AND A2 ARE FOR

FIELD CIRCUIT

BREAKER

CB21

CONNECTING A

VAR / POWER FACTOR

CONTROLLER

lator terminals 1 and 2 when voltage trimmer

R21 is not used.

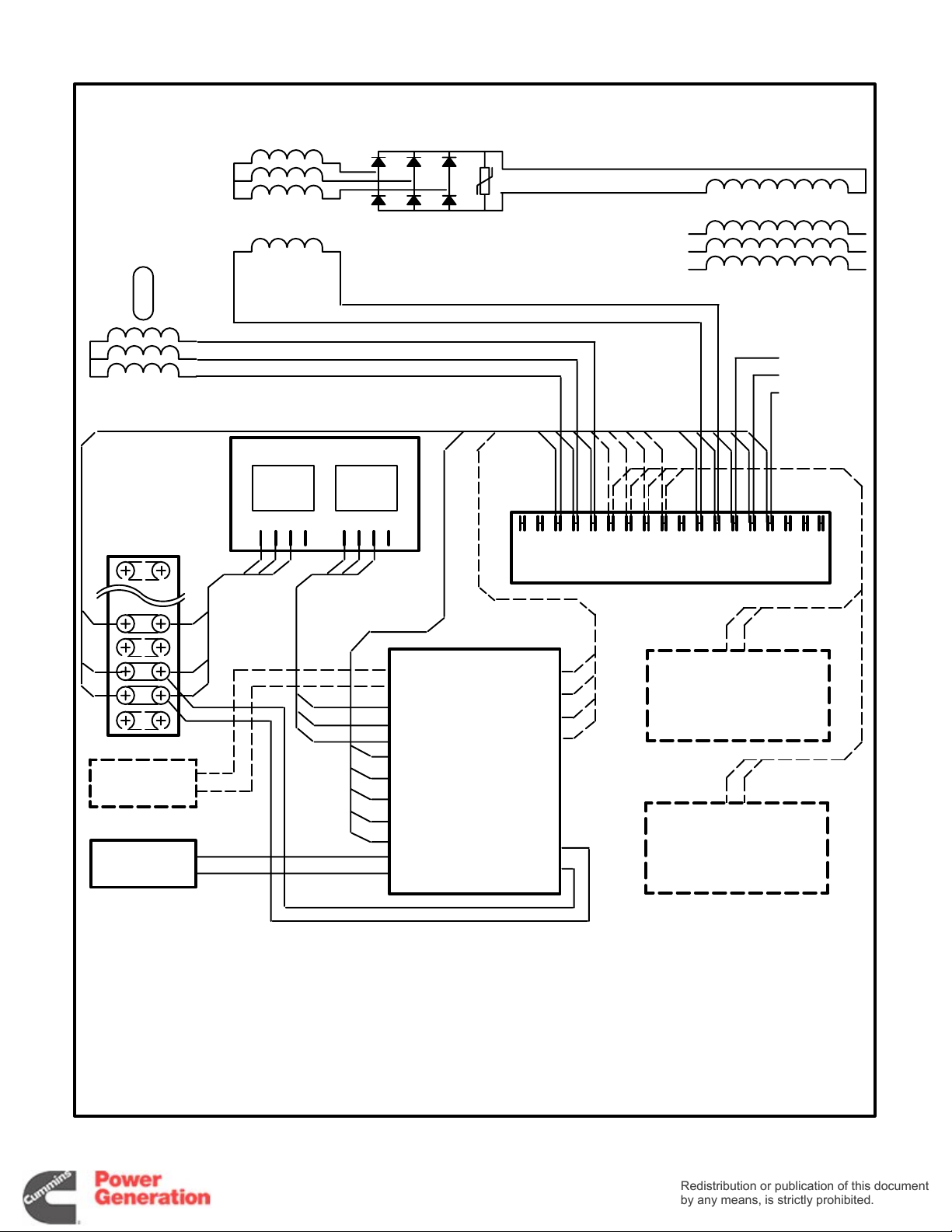

PRINCIPLE OF GENERATOR OPERATION

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

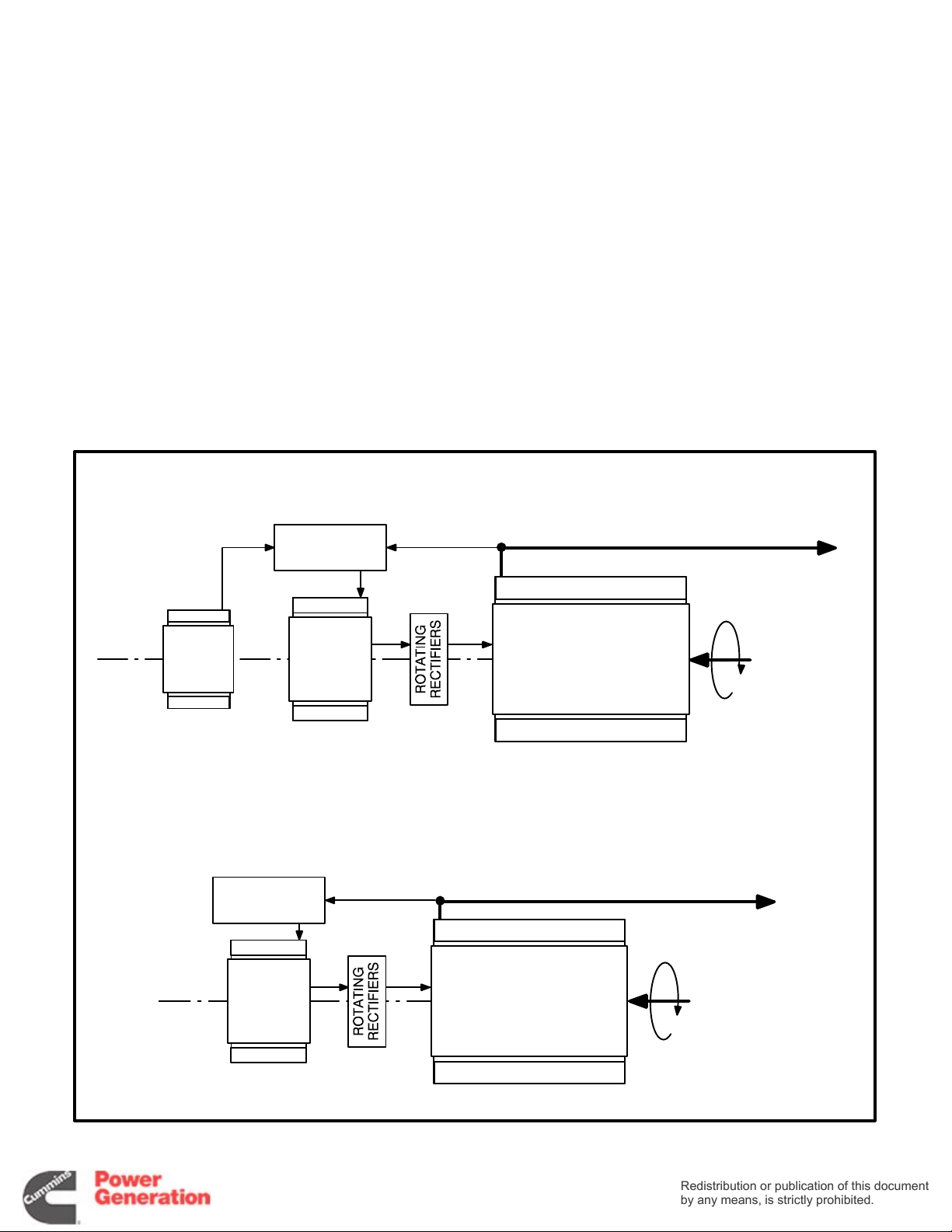

1. The generator field (main rotor) is rotated by

the engine to induce output current (AC) in the

main stator windings.

2. Generator output current is proportional to field

strength, which is varied to match the load.

Output voltage and frequency are held

constant by the voltage regulator and engine

governor, respectively.

3. Generator field strength is proportional to field

current, which is supplied by the exciter.

4. The exciter field (stator) induces current in the

exciter rotor windings. A full wave rectifier

bridge (rotating rectifiers) mounted on the exciter rotor converts exciter output (3-phase AC)

to DC. The exciter rotor is mounted on the main

rotor shaft.

PMG-EXCITED GENERATORS

5. Exciter output current is proportional to exciter

field current.

6. The automatic voltage regulator (AVR) regulates exciter field current by comparing generator output voltage and frequency with reference values.

7. PMG-Excited Generators. Exciter field current is supplied by a PMG (permanent magnet)

exciter through the voltage regulator . The PMG

consists of a stator and a permanent magnet

rotor mounted on the end of the main rotor

shaft.

8. Self-Excited Generators. Exciter field current

is supplied by the generator stator through the

voltage regulator. Residual field magnetism initiates “self-excitation” during startups.

PMG

ROTOR

AND

STATOR

AVR

EXCITER

ROTOR

AND

STATOR

AVR

EXCITER

ROTOR

AND

STATOR

ELECTRICAL POWER OUTPUT

MAIN STATOR

MAIN ROTOR

SELF-EXCITED GENERATORS

ELECTRICAL POWER OUTPUT

MAIN STATOR

MAIN ROTOR

ROTATING

MECHANICAL

POWER

INPUT

ROTATING

MECHANICAL

POWER

INPUT

FIGURE 2-6. SCHEMATIC OF GENERATOR OPERATION

2-7

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

2-8

3. Engine Control

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

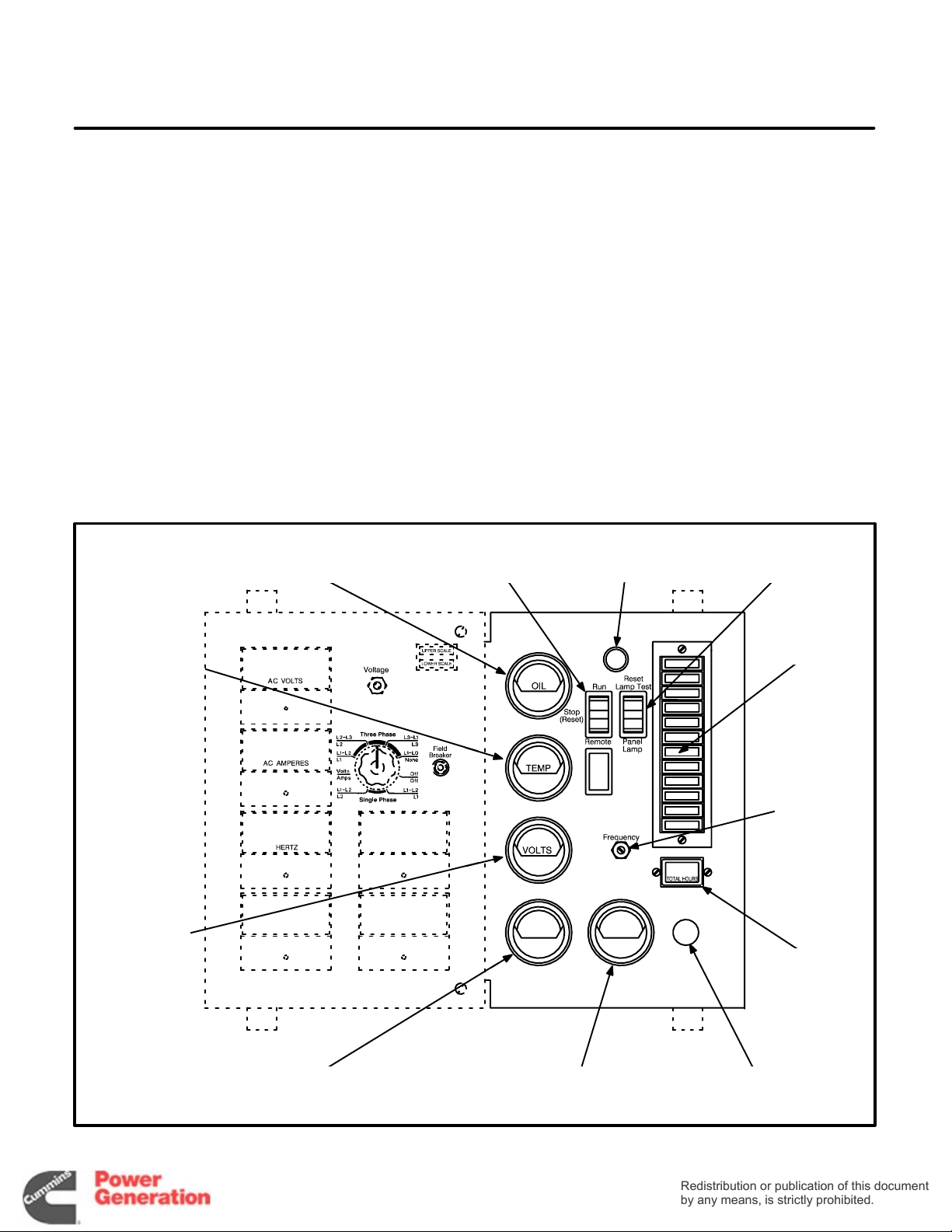

CONTROL PANEL

The control box is mounted on top of the generator,

facing the rear. Figure 3-1 shows the components

on the engine control panel.

STANDARD CONTROL PANEL

COMPONENTS

Run / Stop / Remote Switch (S12) The switch is

pushed to t h e Run position to start and run the generator set and the Stop position to stop the set. The

Remote position allows a remote controller to automatically run the set. The switch must be in the Stop

position when the reset switch (described next) is

used to restore generator set operation following a

fault shutdown.

OIL PRESSURE

GAUGE

COOLANT

TEMPERATURE

GAUGE

RUN/STOP/REMOTE

Reset / Lamp Test / Panel Lamp Switch (S11)

switch is pushed to the Reset position (momentary

contact) to reset the engine control to restore operation following a fault shutdown. The Run / Stop / Re-

mote switch must be in the Stop position for reset to

occur. The Lamp Test position (momentary con-

tact) lights all the fault indicator lamps. Replace

lamps that do not light. The Panel Lamp position

lights the panel illumination lamp.

Oil Pressure Gauge (M11)

The oil pressure gauge

indicates engine oil pressure.

Coolant Temperature Gauge (M12)

The coolant

temperature gauge indicates engine coolant temperature.

RESET/LAMP TEST/

PANEL LIGHT SWITCH

INDICATOR

SWITCH

PANEL

LIGHT

LAMPS

The

DC

VOLTMETER

OIL TEMPERATURE

GAUGE

SPEED

ADJUSTING

RHEOSTAT

HOUR

METER

TACHOMETER EMERGENCY STOP

BUTTON

FIGURE 3-1. ENGINE CONTROL PANEL

3-1

DC Voltmeter (M13) The DC voltmeter indicates

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

voltage across the battery terminals during operation.

Hour Meter (M14)

The hour meter indicates the accumulated number of hours the set has run. It cannot be reset.

Panel Lamp (DS1 1) The panel lamp illuminates the

control panel.

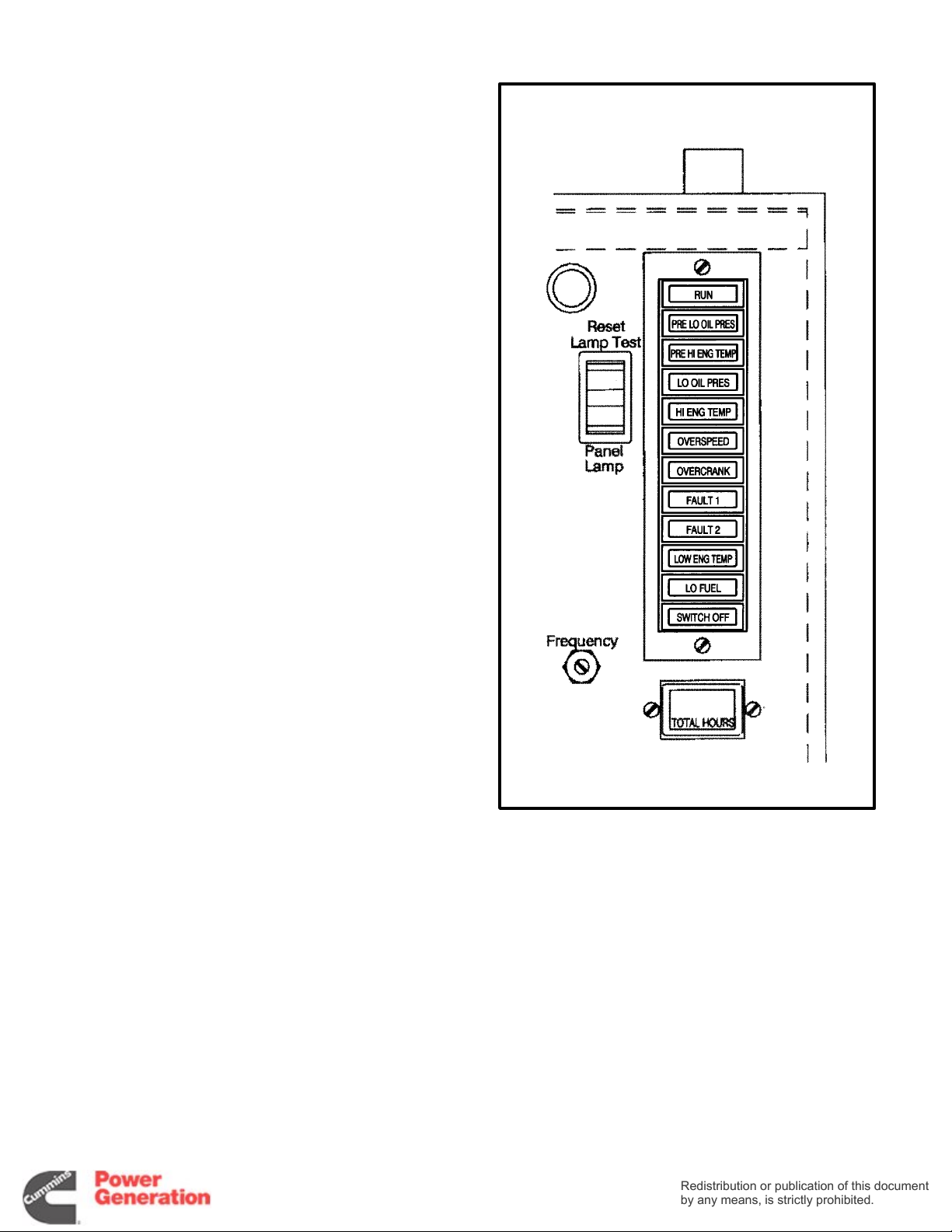

Detector-7 Fault and Status Indicator Lamps

(A12)

• Run (Green) This lamp indicates that the gen-

erator set is running and that the starter has

been disconnected.

• Pre Low Oil Pressure (Yellow) This lamp indi-

cates that engine oil pressure is abnormally low

(less than 20 psi).

• Low Oil Pressure (Red) This lamp indicates

that the engine shut down because of excessively low engine oil pressure (less than

14 psi).

• Pre High Engine Temperature (Yellow) This

lamp indicates that engine coolant temperature is abnormally high (greater than 220

° F).

• High Engine Temperature (Red) This lamp

indicates that the engine shut down because of

excessively high engine coolant temperature

(greater than 230

° F).

• Overcrank (Red) This lamp indicates that the

engine shut down because it did not start during the timed cranking period (approximately

75 seconds, including two rest periods).

• Overspeed (Red) This lamp indicates that the

engine shut down because of overspeed.

539−0741c2

OPTIONAL CONTROL PANEL

COMPONENTS

Oil Temperature Gauge (M15) The oil temperature

gauge indicates engine oil temperature.

Tachometer (M16) The tachometer indicates en-

gine speed in RPM.

Speed Adjusting Rheostat The speed adjusting

rheostat is used to adjust engine speed from the

control panel (an option with the optional electric

governor).

FIGURE 3-2. DETECTOR-12 INDICATOR LAMPS

3-2

Emergency Stop Button (S14) The emergency

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

stop button is a red, push-in switch used to stop the

engine. The button lights up when it is pushed in.

The button has to be pulled out and the engine control reset to restore operation.

Low Coolant Level Cutout Switch (S7) When

coolant level in the radiator top tank falls below the

switch sensor, the switch closes the circuit to

ground. This switch may be connected in parallel

with the high engine temperature cutout switch to

shut down the engine and light the High Engine

Temperature lamp or in parallel with the pre-high

engine temperature switch to light the Pre High En-

gine Temperature light only.

Detector-12 Fault and Status Indicator Lamps

(A12) The Detector-12 control panel has the five fol-

lowing indicator lamps in addition to the standard

seven.

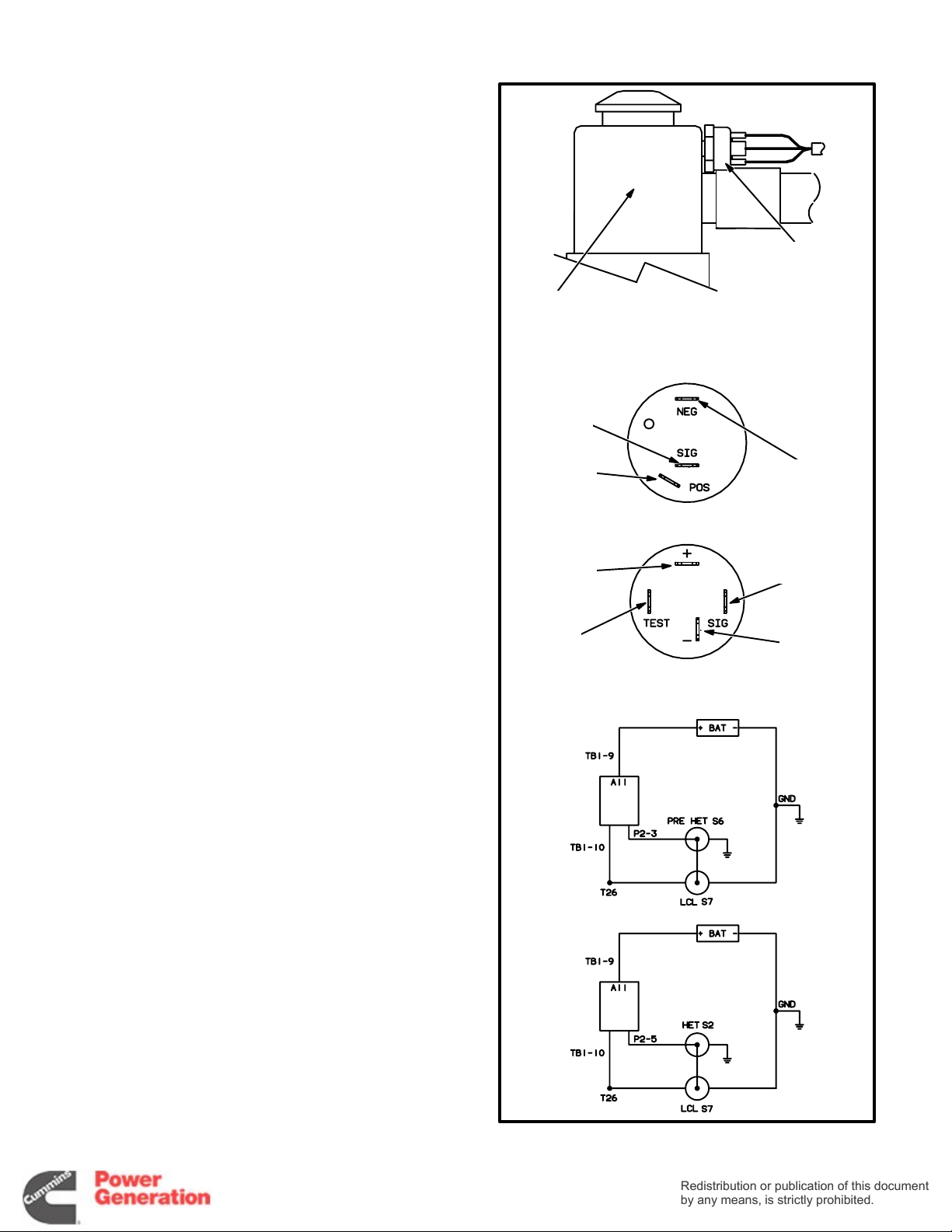

RADIATOR

TOP TANK

——— SWITCH TERMINALS ——-

SWITCH

S2 OR S6

SWITCHED

B+

(T26)

LOW

COOLANT

LEVEL

SWITCH

(S7)

ENGINE

GROUND

• Low Engine Temperature (Yellow) This lamp

indicates that engine temperature is less than

° F, and the possibility that the engine might

70

not start.

• Low Fuel (Yellow) This lamp indicates that the

fuel level in the supply tank has dropped to less

than the reserve necessary to run the set at full

load for the prescribed number of hours. The

customer has to make connections to use this

lamp.

• Fault 1 (Red) This lamp indicates that the en-

gine shut down because of a system fault. The

customer has to make connections to use this

lamp. The lamp is a part of a 10 second time

delay shutdown circuit. The customer can

make reconnections for non-timed shutdown.

See Engine Control Monitor (ECM).

• Fault 2 (Red) This lamp indicates that the en-

gine shut down because of a system fault. The

customer has to make connections to use this

lamp. The lamp is part of a non-time delay shutdown circuit. The customer can make reconnections for 10 second time delay shutdown.

See Engine Control Monitor (ECM).

SWITCHED

B+

(T26)

NOT

USED

———— SCHEMATICS ————

—— OR ——

ECM

ECM

SWITCH

S2 OR S6

ENGINE

GROUND

WARNING

ONLY

SHUTDOWN

• Switch-off (Flashing Red) This lamp indi-

cates that the Run / Stop / Remote switch is in

the Stop position, which prevents remote, automatic operation.

FIGURE 3-3. LOW COOLANT LEVEL SWITCH

3-3

VOLTAGE

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

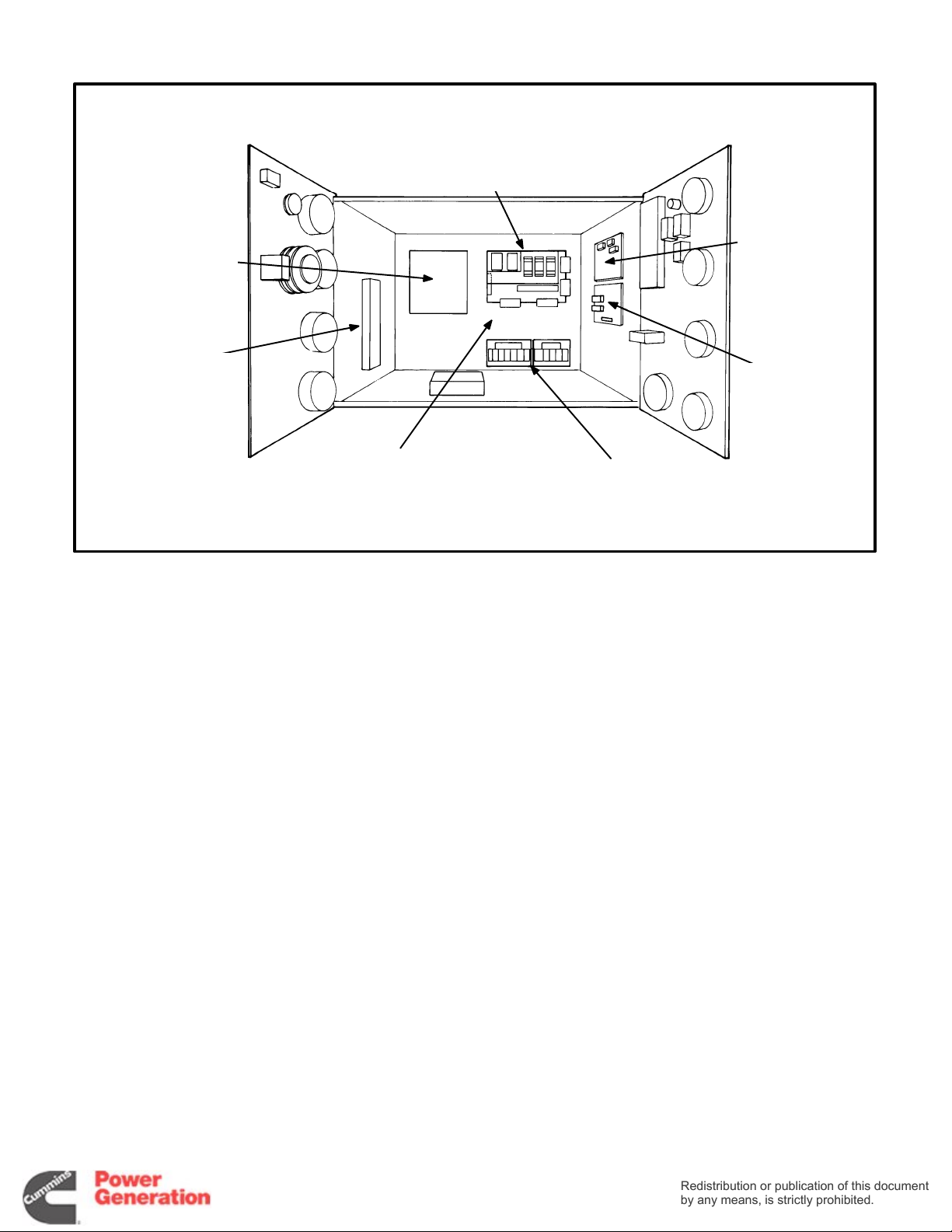

REGULATOR

VR21

ENGINE

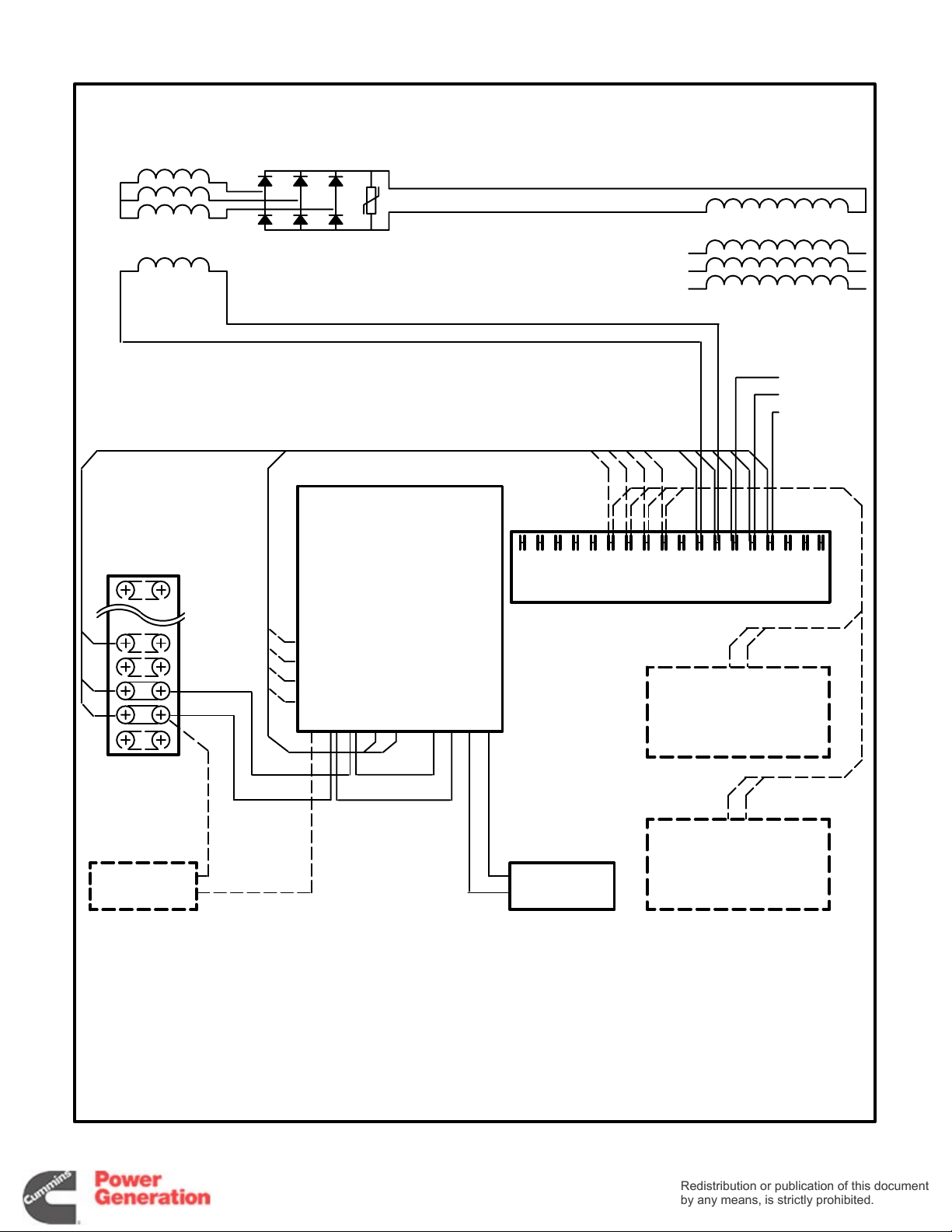

CONTROL

MONITOR A11

TIME DELAY

START/STOP

MODULE A15

TERMINAL BOARD

TB21

RUN RELAYS K11

(NOT SHOWN − MOUNTED ON

A BRACKET IN FRONT OF A11)

FIGURE 3-4. ARRANGEMENT OF COMPONENTS INSIDE THE CONTROL BOX

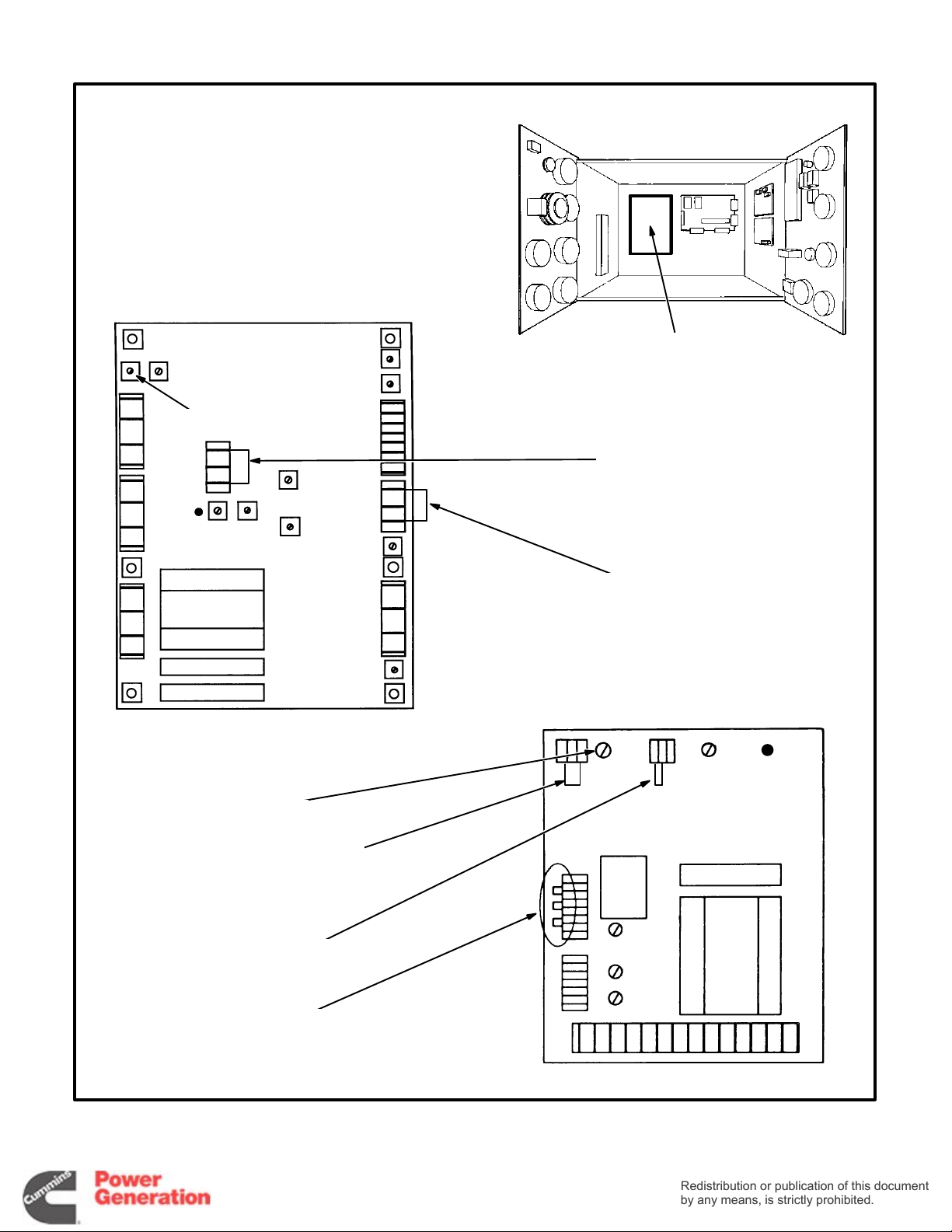

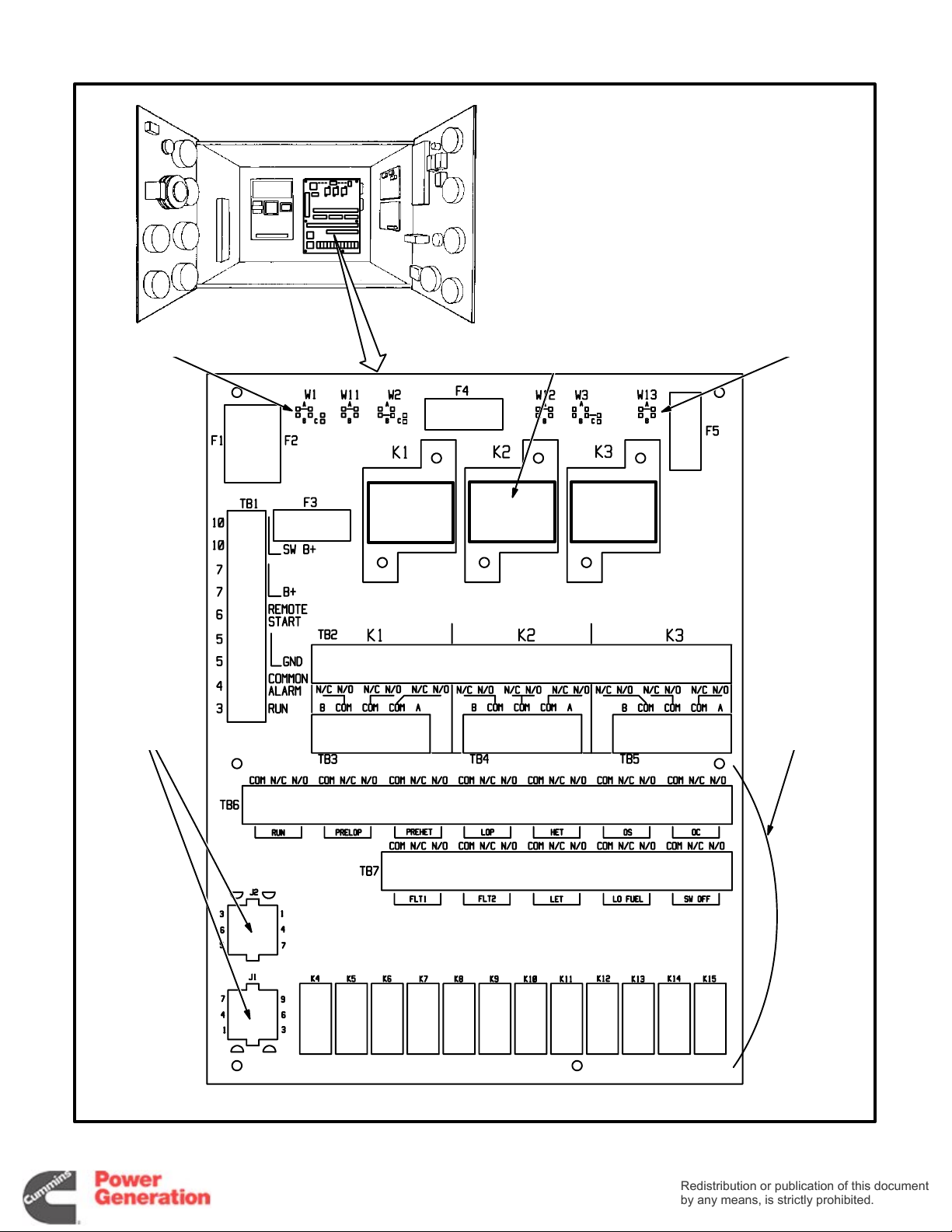

CONTROL BOX INTERIOR

Figure 3-4 shows the arrangement of components

inside the control box, including the engine control

monitor and some of the auxiliary components under following headings.

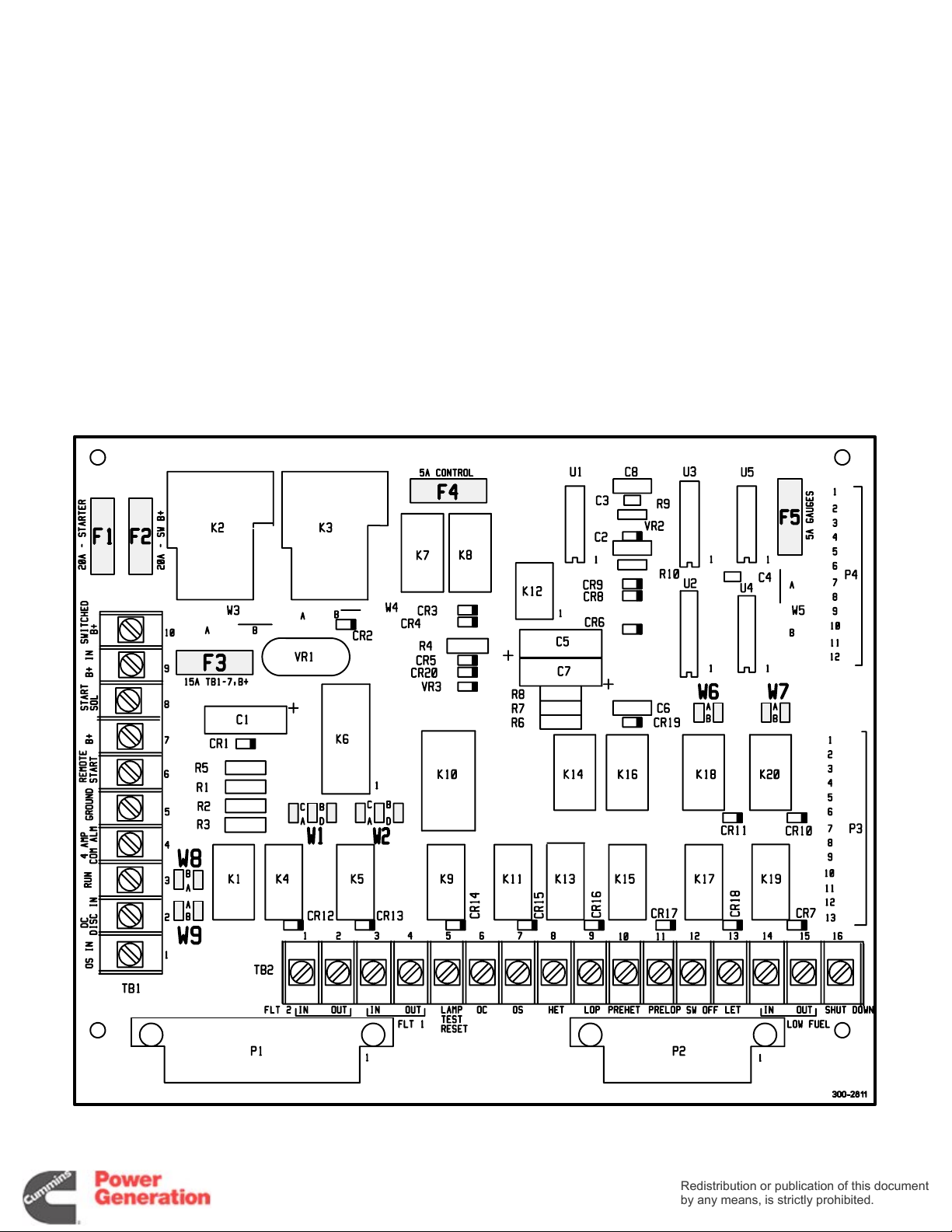

ENGINE CONTROL MONITOR (A11)

The heart of the engine control system is the engine

control monitor (ECM). It is a printed circuit board

assembly mounted on the back wall of the control

box. It starts and stops the engine in response to the

control panel switches, engine sensors and remote

control signals. Figure 3-5 shows the newer ECM

board used in current production and as a direct replacement for older boards. The boards are distinquishable from each other in that the newer boards

have automotive-type fuses and the older boards

have cartridge-type fuses.

Terminals and Connectors

See Pages 9-7 through 9-10 for the appropriate

connection and schematic drawings for the DC control system. See Page 9-16 for typical customer

connections at terminal boards TB1 and TB2 on the

ECM and page 9-17 if the set is also equipped with

the auxiliary relay board.

OVERSPEED

MODULE

ALARM RELAY MODULES

A13 AND A14

ES1561s−

1

Fuses

The ECM has five replaceable fuses to protect it

from overloads and groundfaults. They are:

F1 Starter solenoid circuit, 20 amps

F2 Fuel solenoid (switched B+) circuits, 20 amps

F3 Continuous B+ out to remote circuits, 15 amps

F4 ECM circuits, 5 amps

F5 Engine gauge circuits, 5 amps.

Function Selection Jumpers

Newer ECM boards have six selection jumpers that

can be repositioned to provide the following timed

or non-timed warnings or timed or non-timed shutdowns with warnings:

W1 Jumper Position (jumper W8 must be in the B

position):

A Non-timed warning under FLT 2 condi-

tions.

B Non-timed shutdown and warning under

FLT 2 conditions.

C Timed warning under FLT 2 conditions.

D Timed shutdown and warning under FLT 2

conditions.

3-4

W2 Jumper Position (jumper W9 must be in the B

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

position):

A Non-timed warning under FLT 1 condi-

tions.

B Non-timed shutdown and warning under

FLT 1 conditions.

C Timed warning under FLT 1 conditions.

D Timed shutdown and warning under FLT 1

conditions.

W6 Jumper Position:

A Warning under Pre-High Engine Tem-

perature conditions.

B Shutdown and warning under Pre-High

Engine Temperature conditions.

W7 Jumper Position:

A Warning under Pre-Low Oil Pressure

conditions.

B Shutdown and warning under Pre-Low

Oil Pressure conditions.

W8 Jumper Position:

A Warning while running or during standby

under FLT 2 conditions.

B Allows selection of functions with W1

jumper.

W9 Jumper Position:

A Warning while running or during standby

under FLT 1 conditions.

B Allows selection of functions with W2

jumper.

87654321 654321

FIGURE 3-5. ENGINE CONTROL MONITOR FUSES AND FUNCTION SELECTION JUMPERS

3-5

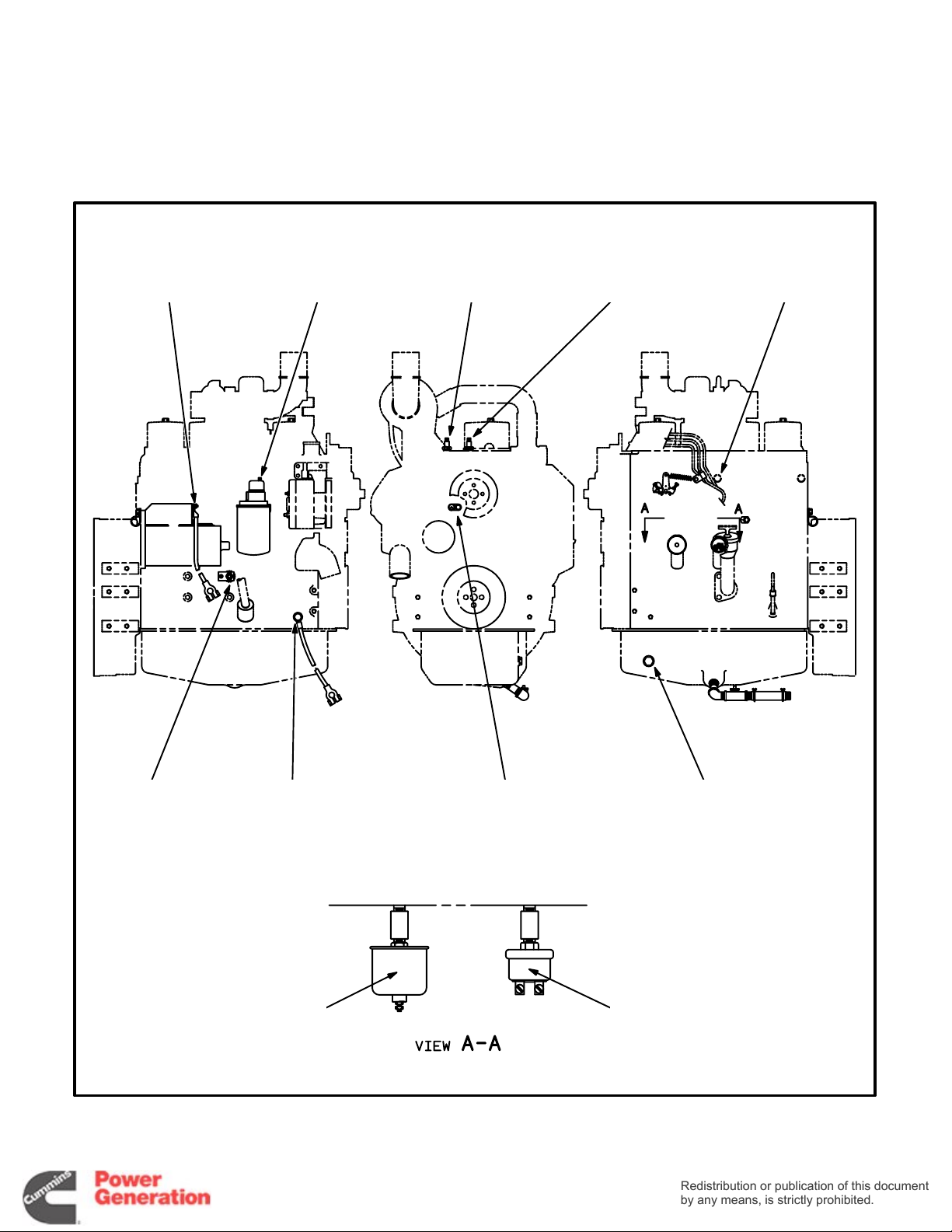

ENGINE SENSORS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

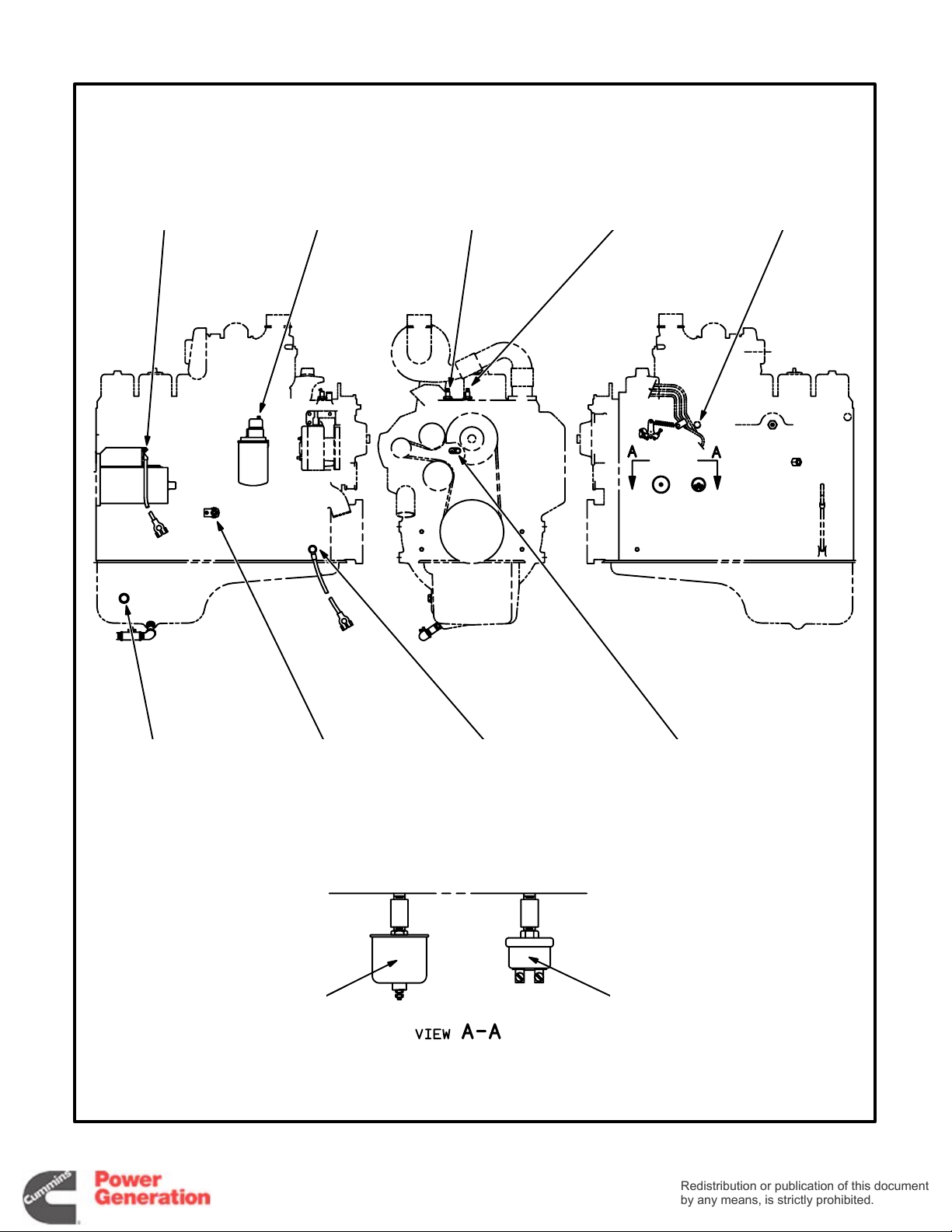

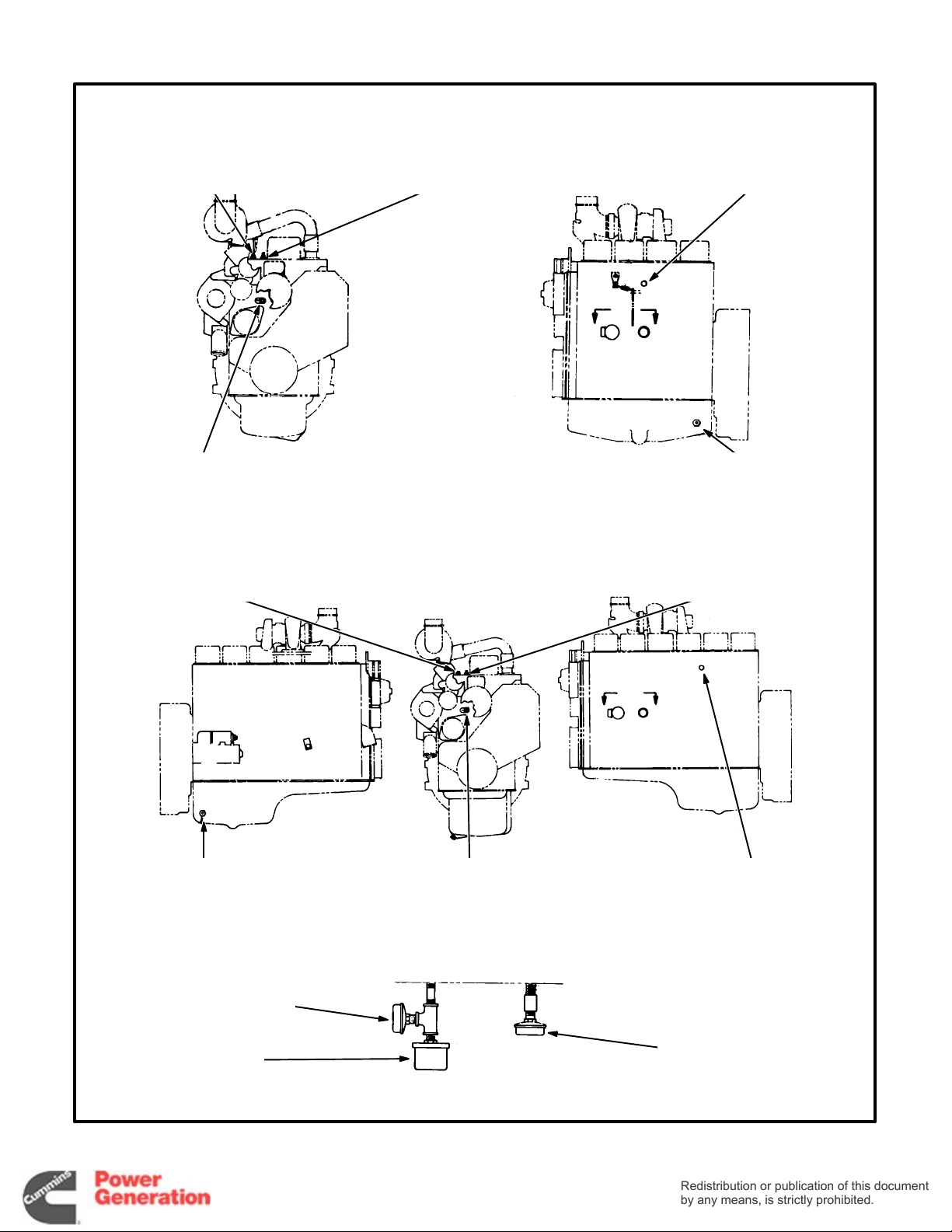

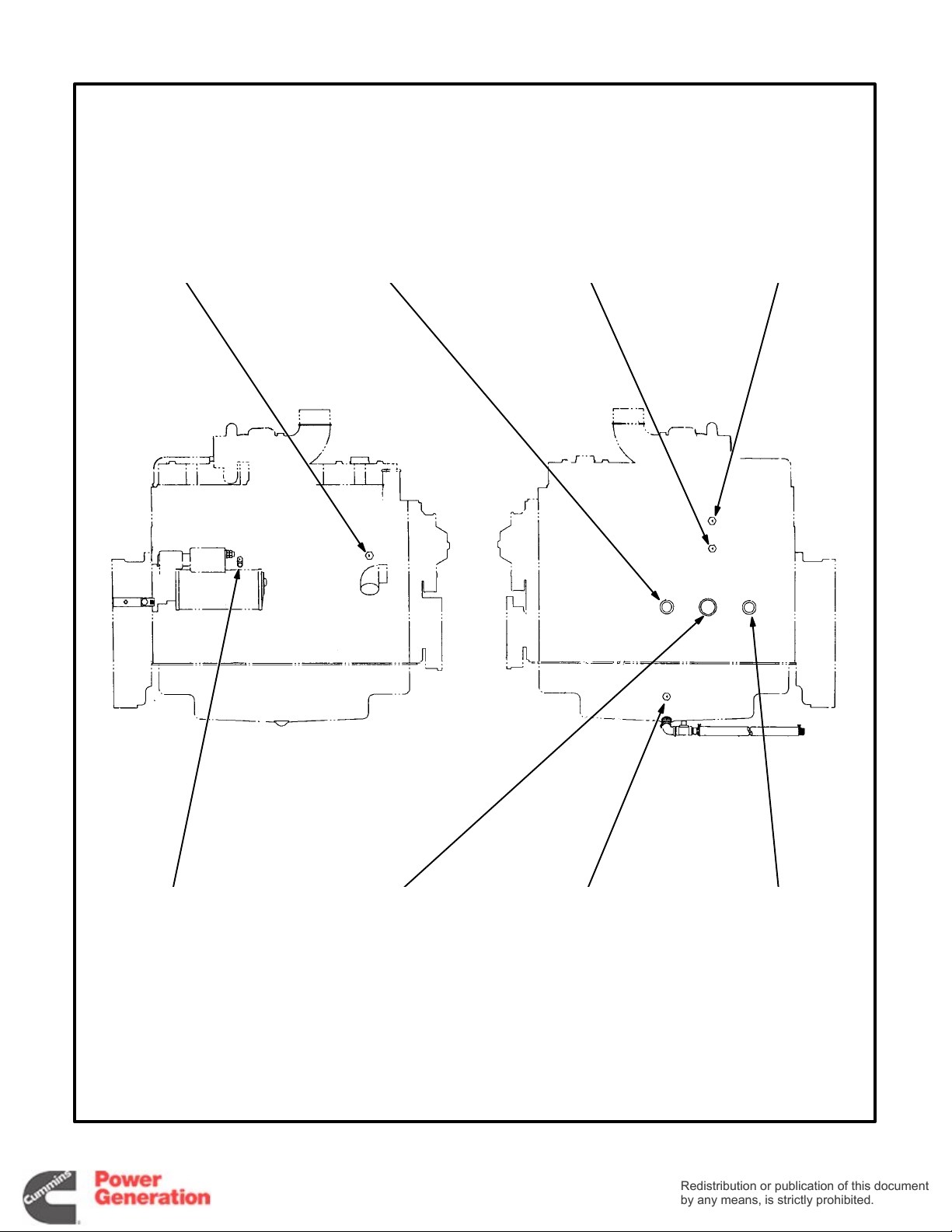

Figures 3-6, 3-7, 3-8 and 3-9 show the locations of

the gauge senders and the coolant temperature

and oil pressure sensing switches to which the ECM

responds. The switches function by closing the fault

or warning circuit to the engine chassis ground (battery negative [-]).

POSITIVE BATTERY

CABLE CONNECTION

POINT (B1)

PRE-LOW OIL

PRESSURE

SENSOR S5

PRE-HIGH ENGINE

TEMPERATURE

SENSOR S6

HIGH ENGINE

TEMPERATURE

SENSOR S2

COOLANT

TEMPERATURE

SENDER E2

GND

AND T26

(SWITCHED B+)

CONNECTION POINT

FIGURE 3-6. ENGINE SENSOR LOCATIONS (FOUR CYLINDER B-SERIES ENGINES)—BEGINNING SPEC H

NEGATIVE

BATTERY CABLE

OIL

PRESSURE

SENDER E1

LOW ENGINE

TEMPERATURE

SENSOR S4

3-6

TEMPERATURE

SENDER E4

LOW OIL

PRESSURE

SENSOR S1

OIL

100-3148, REV

C

POSITIVE BATTERY

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

CABLE CONNECTION

POINT (B1)

PRE-LOW OIL

PRESSURE

SENSOR S5

PRE-HIGH ENGINE

TEMPERATURE

SENSOR S6

HIGH ENGINE

TEMPERATURE

SENSOR S2

COOLANT

TEMPERATURE

SENDER E2

OIL

TEMPERATURE

SENDER E4

FIGURE 3-7. ENGINE SENSOR LOCATIONS (SIX CYLINDER B-SERIES ENGINES)—BEGINNING SPEC H

(SWITCHED B+)

OIL

PRESSURE

SENDER E1

GND

AND T26

NEGATIVE

BATTERY CABLE

CONNECTION POINT

3-7

LOW ENGINE

TEMPERATURE

SENSOR S4

LOW OIL

PRESSURE

SENSOR S1

100-3141, REV

D

— FOUR CYLINDER ENGINES —

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

HIGH ENGINE TEMPERATURE

SENSOR (S2)

LOW ENGINE TEMPERATURE

SENSOR (S4)

HIGH ENGINE TEMPERATURE

SENSOR (S2)

PRE-HIGH ENGINE

TEMPERATURE SENSOR (S6)

— SIX CYLINDER ENGINES —

COOLANT TEMPERATURE

SENDER (E2)

AA

OIL TEMPERATURE

SENDER (E4)

PRE-HIGH ENGINE

TEMPERATURE SENSOR (S6)

OIL TEMPERATURE

SENDER (E4)

LOW OIL PRESSURE

SENSOR (S1)

OIL PRESSURE

SENDER (E1)

LOW ENGINE TEMPERATURE

SENSOR (S4)

— VIEW A-A —

AA

COOLANT TEMPERATURE

PRE-LOW OIL PRESSURE

SENDER (E2)

SENSOR (S5)

M1695

M1695−1

FIGURE 3-8. ENGINE SENSOR LOCATIONS (B-SERIES ENGINES)—PRIOR TO SPEC H

3-8

HIGH ENGINE

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

TEMPERATURE

SENSOR (S2)

PRE-LOW OIL

PRESSURE

SENSOR (S5)

PRE-HIGH ENGINE

TEMPERATURE

SENSOR (S6)

COOLANT

TEMPERATURE

SENDER (E2)

LOW ENGINE

TEMPERATURE

SENSOR (S4)

FIGURE 3-9. ENGINE SENSOR LOCATIONS (C-SERIES ENGINES)

OIL

PRESSURE

SENDER (E1)

3-9

OIL

TEMPERATURE

SENDER (E4)

LOW OIL

PRESSURE

SENSOR (S1)

M1720

AUXILIARY CONTROL COMPONENTS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

The set might be equipped with one or more of the

following components.

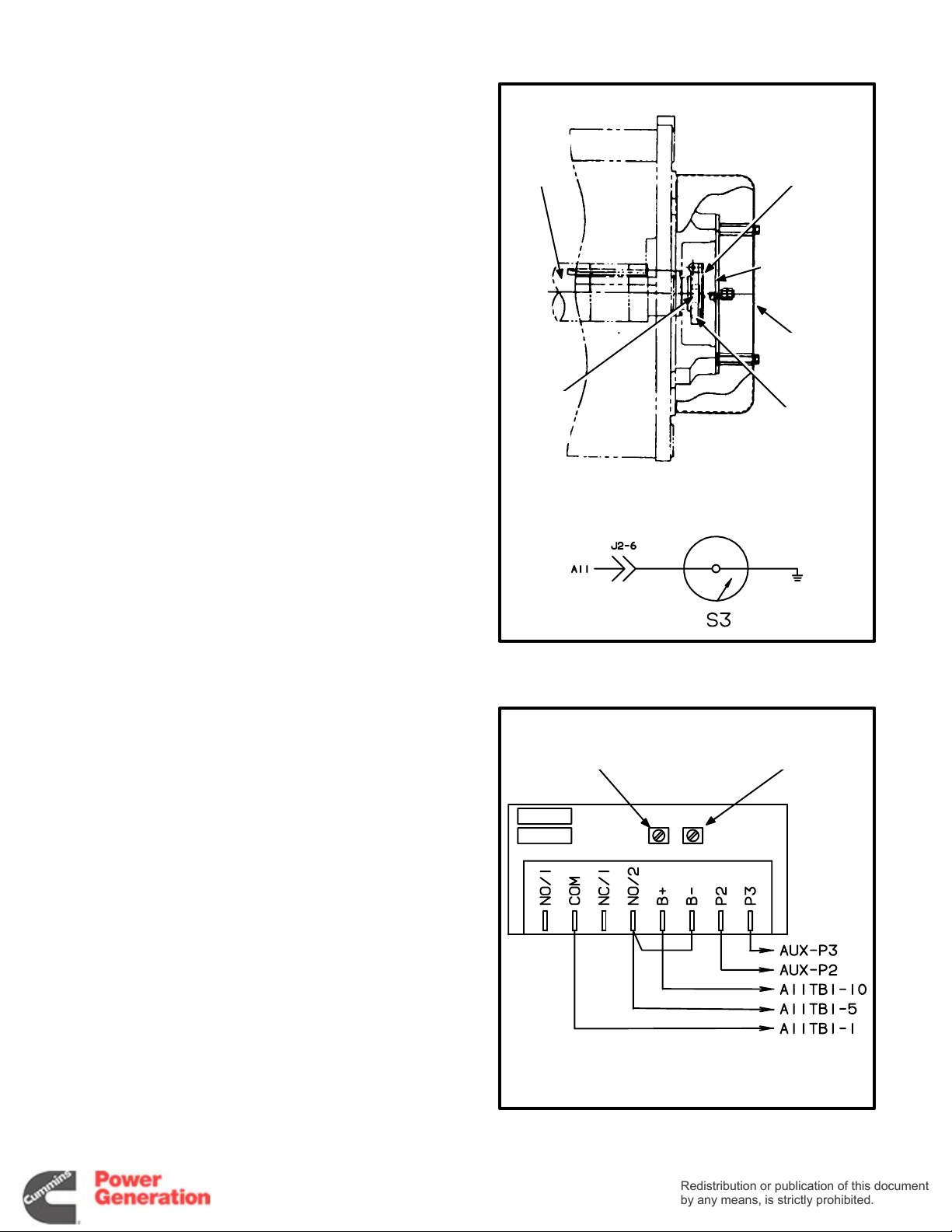

Mechanical Overspeed Switch (Standard)

The mechanical overspeed switch is bolted to the

end of the generator rotor shaft.

1. Check overspeed cutout RPM and turn the adjustment screw, i f necessary, so that shutdown

occurs within the following RPM ranges:

60 Hz Sets 2000 to 2200 RPM. . . . . . . .

50 Hz Sets 1800 to 2100 RPM. . . . . . . .

2. Replace the switch if the cutout speed adjustment results in an air gap between the magnet

and the fly arm of less than 0.005 inches (0.13

mm).

3. Torque the center rotor bolt to 40 ft-lbs (54 Nm)

when replacing the switch.

MAIN

ROTOR

SHAFT

ROTOR

CENTER

BOLT

CUTOUT

SWITCH

ASSEMBLY

SWITCH

CONTACT

BRACKET

SWITCH

COVER

CUTOUT RPM

ADJUSTMENT

SCREW

Es1860s

—SCHEMATIC—

Electronic Overspeed Module (Optional)

PMG-excited generators are equipped with an electronic overspeed module in the control box. The

module senses PMG output frequency to determine

generator speed (frequency). Adjust the overspeed

pot to cut out at 1800 to 1900 RPM for 50 Hz sets

and 2100 to 2200 RPM for 60 Hz sets. Do not adjust

the cranking pot.

FIGURE 3-10. MECHANICAL OVERSPEED SWITCH

FOR FACTORY

ADJUSTMENTS

ONLY

* − AUXILIARY TERMINAL BLOCK

OVERSPEED

ADJUSTMENT

POT

*

*

612-6488

FIGURE 3-11. ELECTRONIC OVERSPEED MODULE

3-10

Run Relays (K11)

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

The set can be equipped with one to three 3-pole,

double-throw relays to control auxiliary equipment

such as fans, pumps, and motorized air dampers.

The relays are mounted on a standoff bracket in

front of the ECM.

A11

TB1

TB1

10

K11

B

A

5

The contacts are rated:

• 10 amps at 28 VDC or 120 VAC, 80% PF

• 6 amps at 240 VAC, 80% PF

• 3 amps at 480 VAC, 80% PF

The set might instead be equipped with an auxiliary

relay board. If so, see Auxiliary Relay Board (ARB).

Alarm Relay Modules (A13 and A14)

The set can be equipped with relay modules to interface with a remote annunciator that is powered

independently of the control circuit of the set. Sets

with Detector-7 need module A13 and sets with Detector-12, modules A13 and A14.

These are all normally open contacts and they are

rated:

• 15 amps at 250 VAC

• 15 amps at 30 VDC

K11

K11

K11

FIGURE 3-12. RUN RELAYS

A14

TB1

FAULT#1

FAULT#2

LET

LOW FUEL

SWITCH

OFF

1

7

4

5

3

9

2

8

6

CUSTOMER

CONNECTIONS

TB2

A11-TB2-4

A11-TB2-2

A11-TB2-13

A11-TB2-15

A11-TB2-12

A13-TB2-8

The set might instead be equipped with an auxiliary

relay board. If so, see Auxiliary Relay Board (ARB).

3-11

A13

TB1

RUN

PRE -LOP

PRE-HET

LOP

HET

OS

OC

TB2

A11-TB1-3

A11-TB2-11

A11-TB2-10

A11-TB2-9

A11-TB2-8

A11-TB2-7

A11-TB2-6

A11-TB1-7

A14-TB2-6

(12 LIGHT)

FIGURE 3-13. ALARM RELAY MODULES

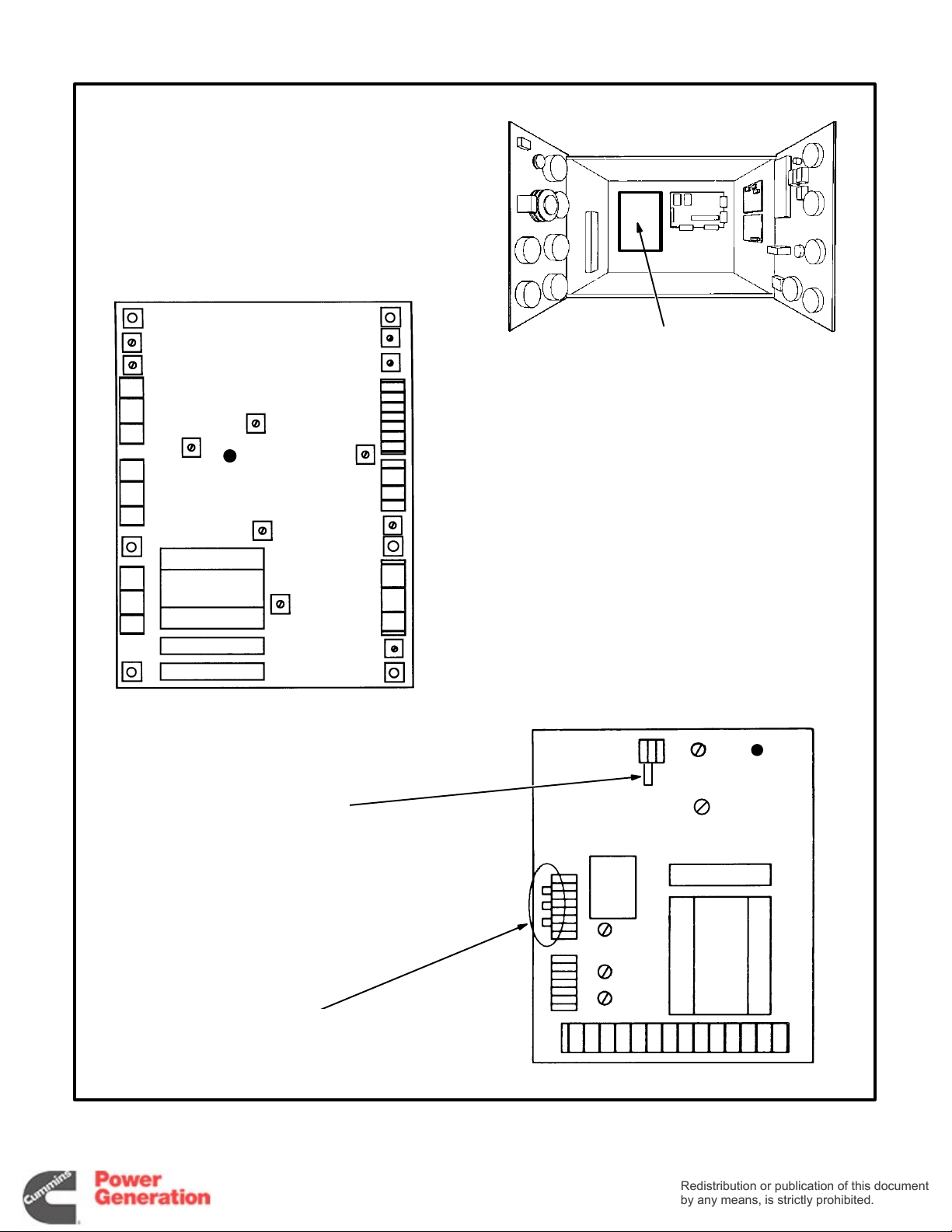

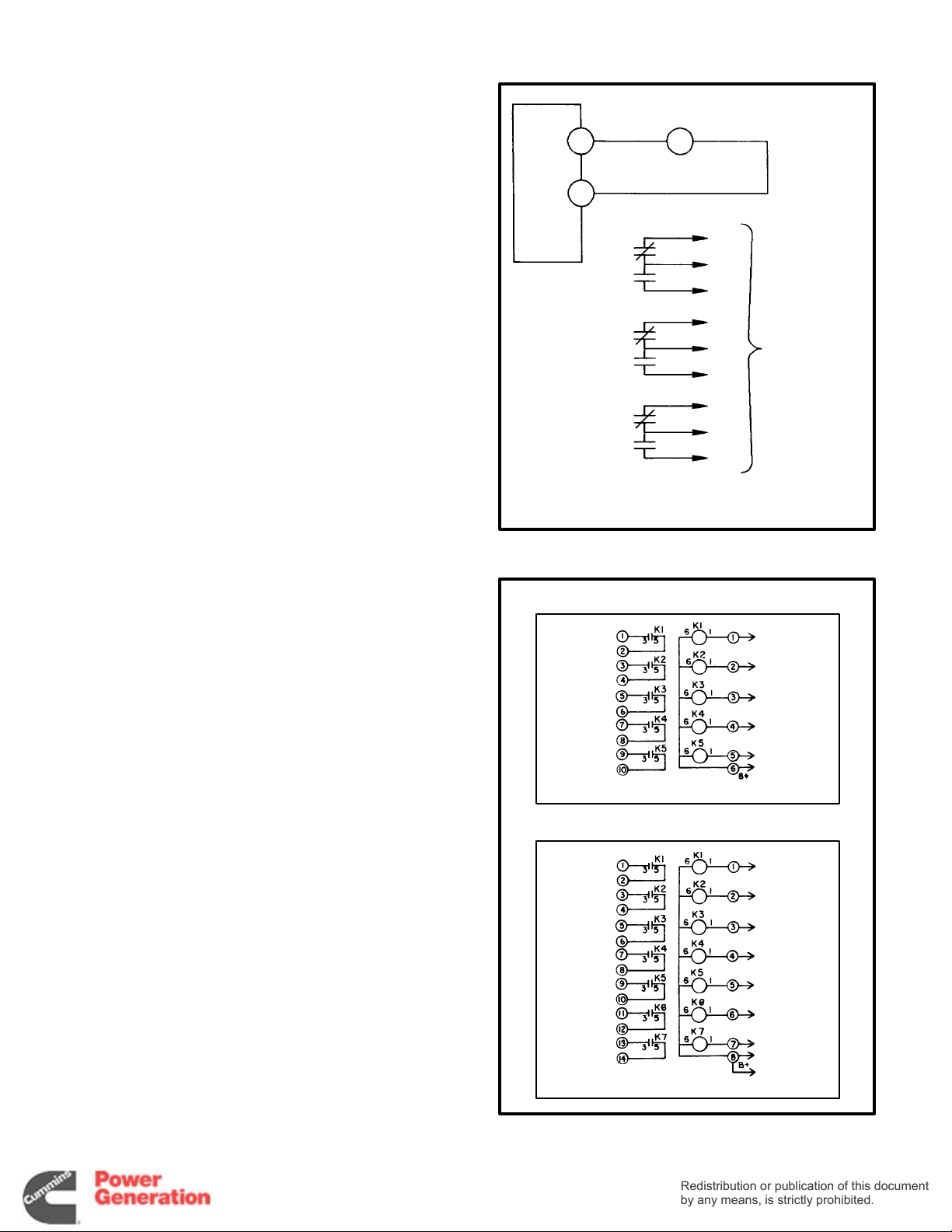

Auxiliary Relay Board (ARB)

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

The following describes the design/functional criteria for the auxiliary relay board (ARB) with a Detector-7 or -12 Genset control. The board is mounted

directly on top of the ECM using standoffs and has

access holes for the fuses located on the ECM.

There are two versions of the ARB; with and without

the set of 12 Fault relays (Figure 3-14). Page 9-17 is

a detailed connection diagram for the ARB.

The set might instead be equipped with separate

run and alarm relay modules. If so, see Run Relay

(K11) and Alarm Relay Modules (A13 and A14).

Terminal Blocks:

• TB1 − ARB TB1 and ECM TB1 are identically

numbered and provide the same remote control connection points. Note that additional terminals are provided for terminals 5, 7, and 10 of

ARB TB1.

• TB2 through TB5 − Connection points for re-

lays K1 through K3. TB2 provides the N/O and

N/C connections (three form ‘C’ contacts for

each relay). TB3 through TB5 provide the common connection points (TB3 for K1, TB4 for K2

and TB5 for K3).

• TB6 and TB7 − Connection points for fault re-

lays K4 through K15. Three terminals are provided for each relay, which are labeled COM,

N/C, N/O.

Plug-In Relays (K1, K2, K3):

equipped with one to three 3-pole, double-throw relays. These relays (K1, K2, K3) are field changeable

plug-in relays for easy field addition and replacement.

Each relay can be operated as a RUN, COMMON

ALARM, or ISOLATED COIL with the changing of a

jumper.

The relay contact ratings are:

The ARB can be

• 10 amps at 28 VDC or 120 VAC, 80% PF

• 6 amps at 240 VAC, 80% PF

• 3 amps at 480 VAC, 80% PF

Jumper Positions for Plug-In Relays:

W1, W2 and W3 perform the same functions for

Jumpers

their respective relays, W1 for relay K1, W2 for relay

K2, and W3 for relay K3. They can be located in any

of 3 positions (A, B, C) independently of each other.

• Jumper Position A (Run) − The relay oper-

ates as a Run relay, energizing when SW B+ is

applied from the ECM.

• Jumper Position B (Common Alarm) − The

relay operates as a Common Alarm relay. The

relay energizes any time there is an engine

shutdown. This signal is provided from the

ECM.

• Jumper Position C (Isolated) − The relay op-

erates as an Isolated relay. The relay coil is energized by a customer applied B+ signal

through the terminal block; TB3-1 for relay K1,

TB4-1 for relay K2, and TB5-1 for relay K3.

Jumpers W11, W12, and W13 perform the same

functions for their respective relays; W11 for relay

K1, W12 for relay K2, and W13 for relay K3. They

can be located in two different positions (A, B) independently of one another.

• Jumper Position A − The relay operates iso-

lated from the board. The customer provides

the circuit completion through terminal block;

TB3 for relay K1, TB4-5 for relay K2, and TB5-5

for relay K3. The customer can operate the

relay with switched ground logic or use this

relay in the middle of more complex logic circuits if needed.

• Jumper Position B − The relays operate with

the coils connected to ground through the

board connections. The coil will require a B+

signal to energize with the jumper in this position.

Fault Relays (K4 through K15):

relay modules are used to operate a remote alarm

annunciator that has an independent power source.

This allows the use of either AC or DC for alarm

drives. The relays are energized through the latching relays on the ECM and provided N/O and N/C

contacts for each external alarm connection.

The 12 relays with form ‘C’ contacts are rated:

These optional

• 10 Amp, 120 VAC

• 10 Amp. 30 VDC

3-12

JUMPERS JUMPERS

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

RUN RELAY

MODULE(S)

K1 K2 K3

J1, J2 WIRE

HARNESS PLUG

CONNECTIONS

FROM ECM

TB6, TB7 AND

RELAYS K4

THROUGH K15

ARE OPTIONAL

300−4111c

FIGURE 3-14. AUXILIARY RELAY BOARD (ARB)

3-13

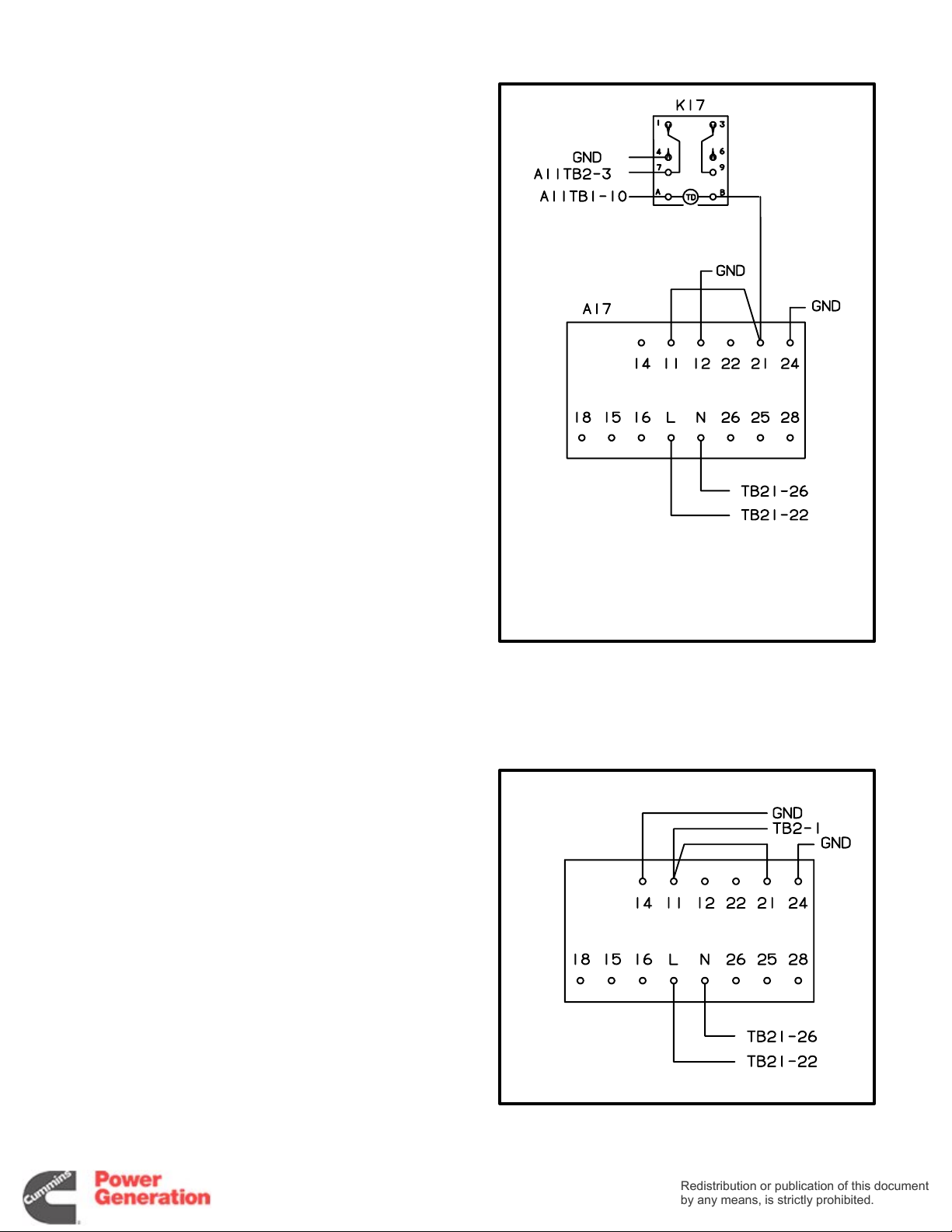

Over / Under Voltage Module (A17)

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

The set can be equipped with an adjustable voltage-sensitive relay usually connected into the Fault

1 circuit (Detector-12 controls only) to shut down

the set when the output voltage is over or under

nominal voltage by the preselected percentage

(typically 10 percent over and under).

With the module is an adjustable time delay relay

(K17) to prevent nuisance tripping. An adjustment

of 25 percent is equivalent to about 2.5 seconds

delay.

Recalibrate the module as follows before installing

it on 139/240 VAC or 277/480 VAC sets.

1. Remove the two screws that secure the top to

the case of the module and withdraw the top

assembly.

2. Adjust the SET pot for the UNDER setpoint on

the face of the top assembly to 75 percent.

3. Apply single-phase, 60 Hertz, 104.25 VAC

across terminals L and N.

4. Adjust pot R25 on the PC board until the relay

trips (de-energizes).

5. Adjust the SET pot for the OVER setpoint on

the face of the top assembly to 125 percent.

6. Apply single-phase, 60 Hertz, 173.75 VAC

across terminals L and N.

7. Adjust pot R26 on the PC board until the relay

trips (energizes).

8. Repeat the above steps until no adjustments

are necessary.

9. Reassemble the module.

10. On the module nameplate mark out the factory

calibration value for monitored voltage (120 V)

and write in 139 V.

*

*

**

* CONNECTED TO TB11-45 WHEN GENERA-

TOR IS PARALLELED.

** CONNECTED TO GENERATOR LEAD LO

WHEN THE GENERATOR IS CONNECTED

FOR SINGLE PHASE.

FIGURE 3-15. OVER / UNDER VOLTAGE

MODULE

Over / Under Frequency Module (A19)

The set can be equipped with an adjustable frequency-sensitive relay to shut down the set when

the output frequency (Hz) is over or under nominal

frequency by the preselected amount. It is usually

connected into the Fault 2 circuit (Detector-12 con-

trols only) if the over / under voltage module is also

provided. Set points are typically 5 Hertz over and

under nominal frequency (50 or 60 Hertz) and reset

points 3 Hertz over and under.

3-14

300-314

FIGURE 3-16. OVER / UNDER FREQUENCY

MODULE

1

Loading...

Loading...