Page 1

Caution: This document contains mixed page sizes (8.5 x 11 or 11 x

17), which may affect printing. Please adjust your printer settings

according to the size of each page you wish to print.

Page 2

Service Manual

Redistribution or publication of this document,

by any means, is strictly prohibited.

PowerCommand Control

2100 Series

Generator Sets

Printed in U.S.A.

Models

DFAB, DFAC, DFBF, DFCB, DFCC, DFCE

DFGB, DFGE, DFLB, DFLC, DFLE

960-0519C 02-2004

Page 3

Table of Contents

Redistribution or publication of this document,

by any means, is strictly prohibited.

SECTION TITLE PAGE

IMPORTANT SAFETY INSTRUCTIONS iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 INTRODUCTION

About this Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How To Obtain Service 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 CONTROL OPERATION

General 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Power On/Off Modes 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Display and Buttons 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menus 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Configuration Menu 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Menu 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator Menu 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Menu 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faults Menu 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Menu 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

History Menu 2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Menu 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Transfer Menu 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 CIRCUIT BOARDS AND MODULES

General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Board 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 TROUBLESHOOTING

General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

InPower Service Tool 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Application and Customer Inputs 4-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Considerations 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedure 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 POWER TRANSFER CONTROL (PTC) TROUBLESHOOTING

General 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTC Module 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence of Events 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting using Fault Codes 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTC Fault Code Troubleshooting Procedure 5-3. . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting with Symptoms 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Source 1 Power Fails, But Genset Does Not Start 5-9. . . . . . . . . . . . . . . . . . .

i

Page 4

SECTION TITLE PAGE

Redistribution or publication of this document,

by any means, is strictly prohibited.

5 POWER TRANSFER CONTROL (PTC) TROUBLESHOOTING (CONT.)

Genset Starts, But Does Not Assume Load 5-11. . . . . . . . . . . . . . . . . . . . . . . .

PTC Module Does Not Retransfer When Source 1 Utility Power

Is Restored After A Power Failure Or On Initial Installation 5-13. . . . . . . .

Genset Continues To Run After Retransfer Of Load To S1 Utility 5-15. . . . . .

Genset Starts During Normal Power Service 5-15. . . . . . . . . . . . . . . . . . . . . . .

Generator Test Runs But Genset Does Not Assume Load 5-15. . . . . . . . . . . .

6 CONTROL ADJUSTMENT AND SERVICE

General 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Removal/Replacement 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying Setup Submenus 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Submenu 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank/Idle Setup Menu 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor/Regulator Setup Menu 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Transfer Setup Menu 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC Control Panel Box Components (Standard/Optional) 6-12. . . . . . . . . . .

Engine Sensors 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetic Speed Pickup Unit (MPU) 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Transformer (CT) Installation 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 SERVICING THE GENERATOR

Testing the Generator 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator/Base Board Isolation Procedure 7-2. . . . . . . . . . . . . . . . . . . . . . . . .

Testing the PMG 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Disassembly 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Reassembly 7-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 FUEL TRANSFER PUMP AND CONTROL

General 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Transfer Pump Motor Connections 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Float Switch Assembly 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 OPTIONAL ENCLOSURE FUEL TANK SYSTEM

General 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Transfer Pump 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Fuel Fill Box 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Alarm Panel 9-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rupture Basin Leak Detect Switch Test 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 WIRING DIAGRAMS

General 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

SAVE THESE INSTRUCTIONS − This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal injury or death.

WARNING

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

• DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use zinc

coated or copper fuel lines with diesel fuel.

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

•

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not warped. Do not use exhaust gases to

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

•

Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, discon-

nect battery charger from its AC source, then disconnect starting batteries, negative (−) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor can cause an engine to overspeed and

become difficult to stop, resulting in possible fire, explosion, severe personal injury and death. Do not operate a

genset where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset is

equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of

the genset are solely responsible for operating the genset safely. Contact your authorized Cummins Power

Generation distributor for more information.

LS-14L

iii

Page 6

ELECTRICAL SHOCK CAN CAUSE

Redistribution or publication of this document,

by any means, is strictly prohibited.

SEVERE PERSONAL INJURY OR DEATH

Remove electric power before removing protective

•

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical contacts and cause shock or burning.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DIRECT-

LY TO ANY BUILDING ELECTRICAL SYSTEM.

Hazardous voltages can flow from the generator set

into the utility line. This creates a potential for electrocution or property damage. Connect only

through an approved isolation switch or an approved paralleling device.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

•

than water. DO NOT open a radiator or heat exchanger pressure cap while the engine is running.

Allow the generator set to cool and bleed the system

pressure first.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproductive toxicity . When checking or changing engine oil,

take care not to ingest, breathe the fumes, or contact used oil.

• Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and cloth; Class B fires, combustible

and flammable liquid fuels and gaseous fuels; Class

C fires, live electrical equipment. (ref. NFP A No. 10).

• Make sure that rags are not left on or near the en-

gine.

• Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under the unit.

• Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause overheating and engine damage which present a potential fire hazard.

• Keep the generator set and the surrounding area

clean and free from obstructions. Remove any debris from the set and keep the floor clean and dry.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment unsafe.

• Substances in exhaust gases have been identified

by some state or federal agencies as causing cancer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

• Do not store any flammable liquids, such as fuel,

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

• Wear hearing protection when going near an oper-

ating generator set.

• To prevent serious burns, avoid contact with hot

metal parts such as radiator, turbo charger and exhaust system.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

iv

Page 7

1. Introduction

Redistribution or publication of this document,

by any means, is strictly prohibited.

ABOUT THIS MANUAL

This manual provides troubleshooting and repair

information regarding the PowerCommand

Control (PCC) and generators for the gensets listed

on the front cover. Engine service instructions are in

the applicable engine service manual. Operating

and maintenance instructions are in the applicable

Operator’s Manual.

This manual does not have instructions for

servicing printed circuit board assemblies. After

determining that a printed circuit board assembly is

faulty, replace it. Do not repair it. Attempts to repair a

printed circuit board can lead to costly damage to

the equipment.

This manual contains basic (generic) wiring

diagrams and schematics that are included to help

in troubleshooting. Service personnel must use the

actual wiring diagram and schematic shipped with

each unit. The wiring diagrams and schematics that

are maintained with the unit should be updated

when modifications are made to the unit.

Read

Safety Precautions

and carefully observe all

instructions and precautions in this manual.

2100

TEST EQUIPMENT

To perform the test procedures in this manual, the

following test equipment must be available

• True RMS meter for accurate measurement of

small AC and DC voltages. Fluke models 87 or

8060A are good choices.

• Grounding wrist strap to prevent circuit board

damage due to electrostatic discharge (ESD).

• Battery Hydrometer

• Jumper Leads

• Tachometer or Frequency Meter

• Wheatstone Bridge or Digital Ohmmeter

• Variac

• Load Test Panel

• Megger or Insulation Resistance Meter

• PCC Service Tool Kit (Harness Tool and Sen-

sor Tool)

• InPower Service Tool (PC based genset ser-

vice tool)

SYSTEM OVERVIEW

The PCC is a microprocessor-based control for

Cummins Power Generation generator sets. All

generator set control functions are contained on

one circuit board (Base board). The Base board

provides engine speed governing, main alternator

voltage output regulation, and complete generator

set control and monitoring.

The operating software provides control of the generator set and its performance characteristics, and

displays performance information on a digital display panel. It accepts menu-driven control and setup input from the push button switches on the front

panel.

Copyright2003 Cummins Power Generation. All rights reserved.

Cummins and PowerCommand are registered trademarks of Cummins Inc.

HOW TO OBTAIN SERVICE

Always give the complete Model, Specification and

Serial number of the generator set as shown on the

nameplate when seeking additional service

information or replacement parts. The nameplate is

located on the side of the generator output box.

WARNING

parts can result in severe personal injury or

death, and/or equipment damage. Service personnel must be qualified to perform electrical

and mechanical service. Read and follow Safety

Precautions, on pages iii and iv.

Incorrect service or replacement of

1-1

Page 8

THIS PAGE LEFT INTENTIONALLY BLANK

Redistribution or publication of this document,

by any means, is strictly prohibited.

1-2

Page 9

2. Control Operation

Redistribution or publication of this document,

by any means, is strictly prohibited.

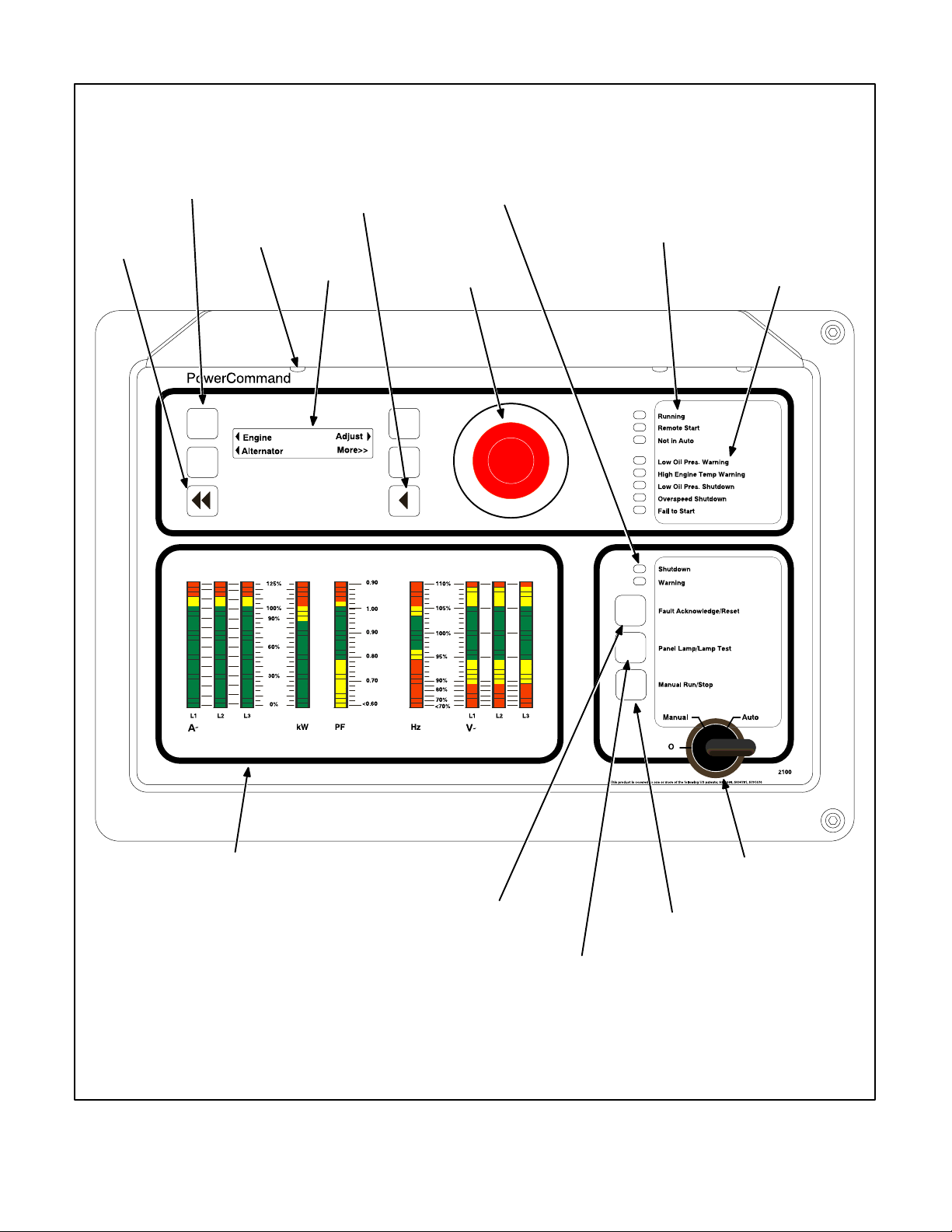

GENERAL

The following describes the function and operation

of the PowerCommand 2100 Control (PCC). All

indicators, control switches/buttons and digital display are located on the face of the control panel as

illustrated in Figure 2-1.

CONTROL PANEL POWER ON/OFF

MODES

The power on/off modes of the control panel and operating software are Power On, Screen Saver and

Sleep/Awake.

Power On Mode: In this mode, power is continuously supplied to the control panel. The control’s

operating software and control panel LEDs/digital

display will remain active until the Screen Saver

mode is activated.

Screen Saver Mode: Power to the digital display is

removed after 30 minutes (generator set not running or running). The 30 minute timer resets and begins after each control panel action (any button or

switch selection) or signal received by the operating

software. All LEDs on the control panel operate normally during Screen Saver mode, indicating that the

operating software is active (Awake mode).

When a “Warning” signal is sensed by the PCC (for

example, low coolant temp), the control displays the

warning message.

Sleep/Awake Mode: In the Sleep mode, the control’s operating software is inactive and the LEDs

and the digital display on the control panel are all off.

Sleep mode is a feature used to reduce battery

power consumption when the control is not being

used and the O/Manual/Auto switch is in the O position.

When all conditions are met (i.e., no unacknowledged faults and O/Manual/Auto switch is in the O

position) the Sleep mode is activated.

The operating software is initialized and the digital

display and control panel LEDs are turned on in response to moving/pressing the following control

panel switch/buttons:

• OManual/Auto switch

• Emergency Stop button

• Fault Acknowledge/Reset button

• Panel Lamp/Lamp Test button

To activate the control and view the menu display

without starting the generator set, press Fault Acknowledge or Panel Lamp button or move mode

switch from O to Manual.

The InPower service tool is required to enable or

disable the Sleep mode. When shipped from the

factory, the Sleep mode is disabled. When disabled,

the operating software will always remain active

(Awake mode). (If network and/or power transfer

control feature is installed, the sleep mode is not

available and should not be enabled − will cause error condition.)

2-1

Page 10

HOME

Redistribution or publication of this document,

by any means, is strictly prohibited.

BUTTON

MENU

SELECTION

BUTTON

(1 of 4)

PANEL

LAMP

(1 of 3)

PREVIOUS

MAIN MENU

BUTTON

DIGITAL

DISPLAY

SHUTDOWN

AND WARNING

STATUS

INDICATORS

EMERGENCY

STOP PUSH

BUTTON

(Pull to reset)

RUNNING/REMOTE

START/NOT IN AUTO

INDICATORS

CONFIGURABLE

INDICATORS

ANALOG AC

METERING

PANEL

(OPTIONAL)

FAULT

ACKNOWLEDGEMENT/

RESET BUTTON

PANEL LAMP

AND LAMP

TEST

BUTTON

FIGURE 2-1. FRONT PANEL

2-2

OFF/MANUAL/

AUTO SWITCH

MANUAL

RUN/STOP

BUTTON

Page 11

FRONT PANEL

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-1 shows the features of the front panel.

Remote Start Indicator:

This green lamp is lit

whenever the control is receiving a remote start signal.

Digital Display:

This two-line, 20-characters per

line alphanumeric display is used to view menus of

the menu-driven operating system. Refer to the

menu trees later in this section. The display is also

used to show warning and shutdown messages.

Display Menu Selection Buttons:

Four momentary buttons—two on each side of the digital display

window—are used to step through the various

menu options and to adjust generator set parame-

ters. A green triangle (

or ), arrow ( , , , or ),

>>, or plus/minus sign (+ or −) in the digital display

adjacent to the button is shown when the button can

be used (button is “active”). Refer to

And Buttons

Home Button:

later in this section.

Press this button ( ) to view the

Menu Display

Home Menu. Refer to the menu trees later in this

section.

Previous Main Menu Button:

Press this button ( )

to view the previous Main Menu. All main menus include both types of green triangles (

and ). Refer

to the menu trees later in this section.

NOTE: The up and down arrows (

and ) are used

to navigate between submenus.

Emergency Stop Button:

Push this button in for

emergency shutdown of the generator set. This will

stop the generator set immediately and prevent

starting of the set from any location (local and remote).

To reset:

1. Pull the button and allow it to pop out.

2. Turn the O/Manual/Auto switch to O (Off).

3. Press the front panel Fault Acknowledge/Reset button.

4. Select Manual or Auto, as required.

Emergency Stop shutdown can be reset only at the

PCC front panel.

Running Indicator:

This green lamp is lit whenever

the generator (local or remote) is running.

Not in Auto Indicator:

This red lamp flashes continuously when the O/Manual/Auto switch is not in

the Auto position.

Analog AC Metering Panel (Optional):

This panel

simultaneously displays (in percent of genset rated

output):

• 3-phase line-to-line AC current (A~)

• Kilowatts (kW)

• Generator output frequency in hertz (Hz)

• 3-phase line-to-line AC volts (V~)

• Power Factor (PF) (shown in 0.2 increments)

Shutdown Status Indicator:

This red lamp is lit

whenever the control detects a shutdown condition.

The generator set cannot be started when this lamp

is on. After the condition is corrected, shutdown indicators can be reset by turning the O/Manual/Auto

switch to the O position and pressing the Fault Acknowledge/Reset button.

Warning Status Indicator:

This yellow lamp is lit

whenever the control detects a warning condition.

After the condition is corrected, warning indicators

can be reset by pressing the Fault Acknowledge/

Reset button. (It is not necessary to stop the generator set.) In auto mode, warning indicators can also

be reset by cycling the remote reset input after the

condition is corrected.

Some warnings remain active after the condition is

corrected and the control reset button is pressed.

This will require the genset to be shutdown to reset

the warning indicator.

Fault Acknowledge/Reset Button:

Press this button to acknowledge warning and shutdown messages after the fault has been corrected. Pressing

this button clears the fault from the current fault list.

To acknowledge a Warning message, the O/Manual/Auto switch can be in any position. (It is not necessary to stop the generator set to acknowledge an

inactive Warning condition.) To acknowledge a

shutdown message with this button, the O/Manual/

Auto switch must be in the O position.

2-3

Page 12

Panel Lamp and Lamp Test Button:

Redistribution or publication of this document,

by any means, is strictly prohibited.

Press this

button to turn the control panel lamps on or off. The

lights will shut of f after about ten minutes. Press and

hold this button to test all front panel LEDs and meters. The meters will light one bar at a time.

Manual Run/Stop Button:

This button starts and

stops the set locally and will bypass Time Delay to

Start and Stop sequences. The O/Manual/Auto

switch must be in the Manual position to enable this

button.

O/Manual/Auto Switch:

The Manual position en-

ables the use of the Manual Run/Stop button.

The Auto position enables start/stop control of the

engine from a remote location. (It disables the use

of the Manual Run/Stop button.)

The O (Off) position prevents the starting of the set

(local or remote). If the switch is set to O during set

operation, the engine will immediately shut down

(cool-down timers are bypassed). This hot shutdown should be avoided, if possible, to help prolong

the life of the engine.

Configurable Indicators

The following configurable indicators (default values shown) can be changed with the InPower service tool. The configurable items are: change generator event and LED color (green, yellow or red),

and enable/disable indicator.

Low Oil Pressure Warning Indicator:

lamp indicates the oil pressure is lower than the normal range of operation.

High Engine Temperature Warning Indicator:

This yellow lamp indicates the engine temperature

is higher than the normal range of operation.

Low Oil Pressure Shutdown Indicator:

lamp indicates the engine has shut down because

of low oil pressure.

Overspeed Shutdown Indicator:

dicates

speed.

Fail to Start Indicator:

the engine has shut down because of excessive

This red lamp indicates the

engine failed to start.

This yellow

This red

This red lamp in-

2-4

Page 13

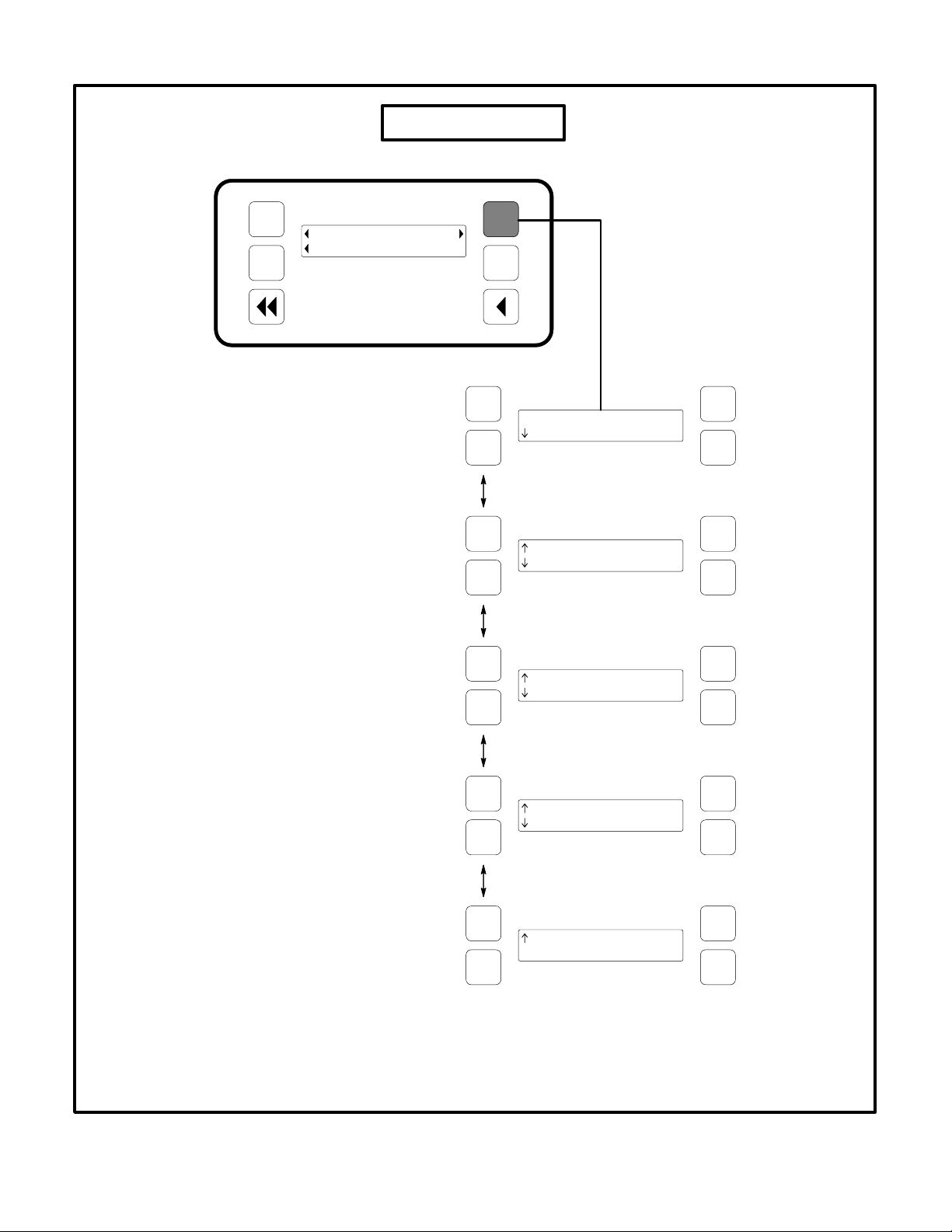

MENU DISPLAY AND BUTTONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-2 shows the digital display and the menu

selection buttons.

Digital Display:

line, digital display is used to view the menus of the

menu-driven operating system. Refer to the menu

trees later in this section. The display is also used to

show fault messages.

Display Menu Selection Buttons:

tary buttons—two on each side of the digital display

window—are used to step through the various

menu options and to adjust generator set parameters. The button is active when a symbol adjacent to

the button is displayed. The displayed symbol indicates the function of the button.

• In the digital display for main menus (Figure

2-3), the

the adjacent button causes the operating pro-

gram to go to the selected submenu (e.g., Engine Menu in Figure 2-5).

The two-line, 20 characters per

Four momen-

and symbols indicate that pressing

• In the digital display, the plus or minus symbols

(+ or −) indicate that pressing the adjacent button can be used to change a parameter or value shown on the display.

When there is a choice of two parameters, one

parameter is associated with the + symbol and

the other is associated with the − symbol.

When changing values, pressing the button a d jacent to the + symbol increase the value and

pressing the button adjacent to the − symbol

decreases the value. Only one numeric character of a field can be changed at a time.

• In the digital display, the

or symbol indicates

that pressing the adjacent button causes the

operating program to move the cursor to the

next numeric character. The selected numeric

character can then be changed by pressing the

buttons adjacent to the + and − symbols. Only

symbol is displayed when the cursor is on

the

the first character of a field that can be

changed. Only the

is displayed when the cursor is on the last character. Both symbols are

displayed when the cursor is on any other character.

• In the digital display, the More>> symbol indicates that pressing the adjacent button causes

the operating program to go to the next main

menu, as shown in Figure 2-3.

• In the digital display, the

or symbols indicate that pressing the adjacent button causes

the operating program to go to the next or previous submenu, as shown in the menu diagrams. Only the

first submenu. Only the

symbol is displayed in the

is displayed in the

last submenu. Both symbols are displayed in

the rest of the submenus.

• After adjusting values/parameters, pressing

the

symbol results in the changes being

saved. If the Home button or Previous Main

Menu button is pressed before pressing the

symbol, the changes are not saved.

Home Button:

Pressing this button causes the operating system to show Main Menu 1 (Figure 2-3) in

the digital display.

Previous Main Menu Button:

Pressing this button

causes the operating system to show the previous

Main Menu in the digital display . All main menus in-

clude both types of green triangles (

and ).

2-5

Page 14

2 LINE, 20 CHARACTERS PER LINE

Redistribution or publication of this document,

by any means, is strictly prohibited.

MENU DISPLAY

DIGITAL DISPLAY

HOME

BUTTON

FIGURE 2-2. DIGITAL DISPLAY AND MENU SELECTION BUTTONS

PREVIOUS MAIN

MENU BUTTON

2-6

Page 15

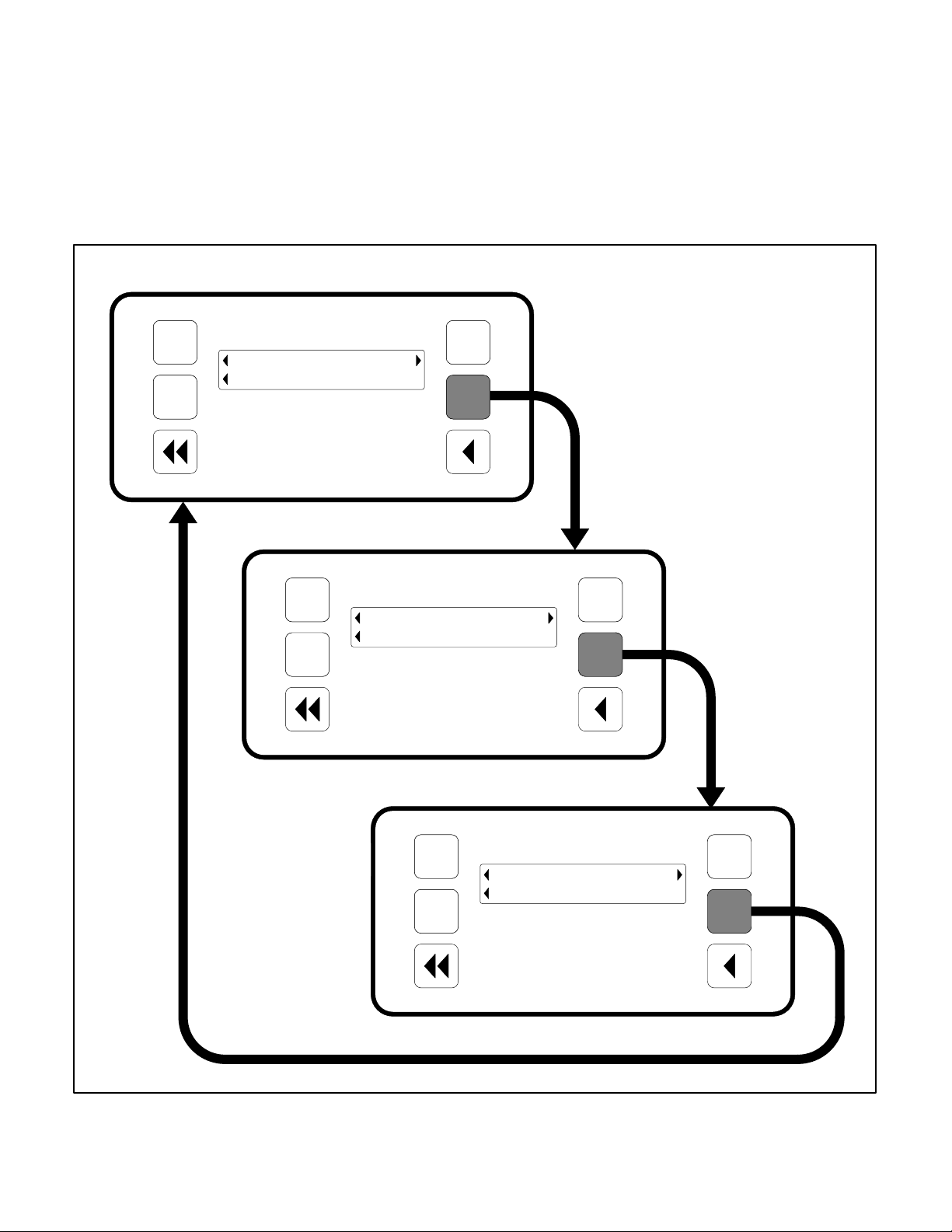

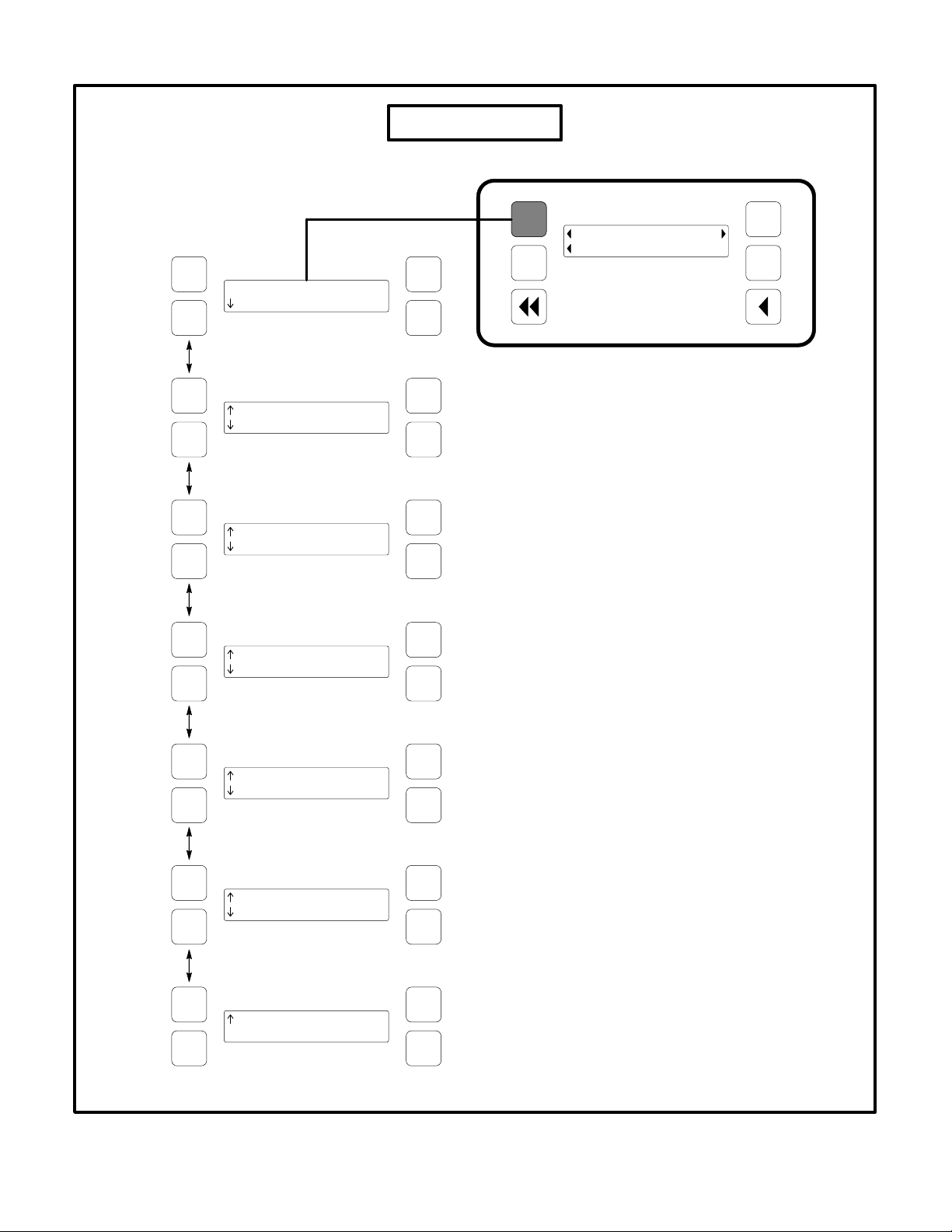

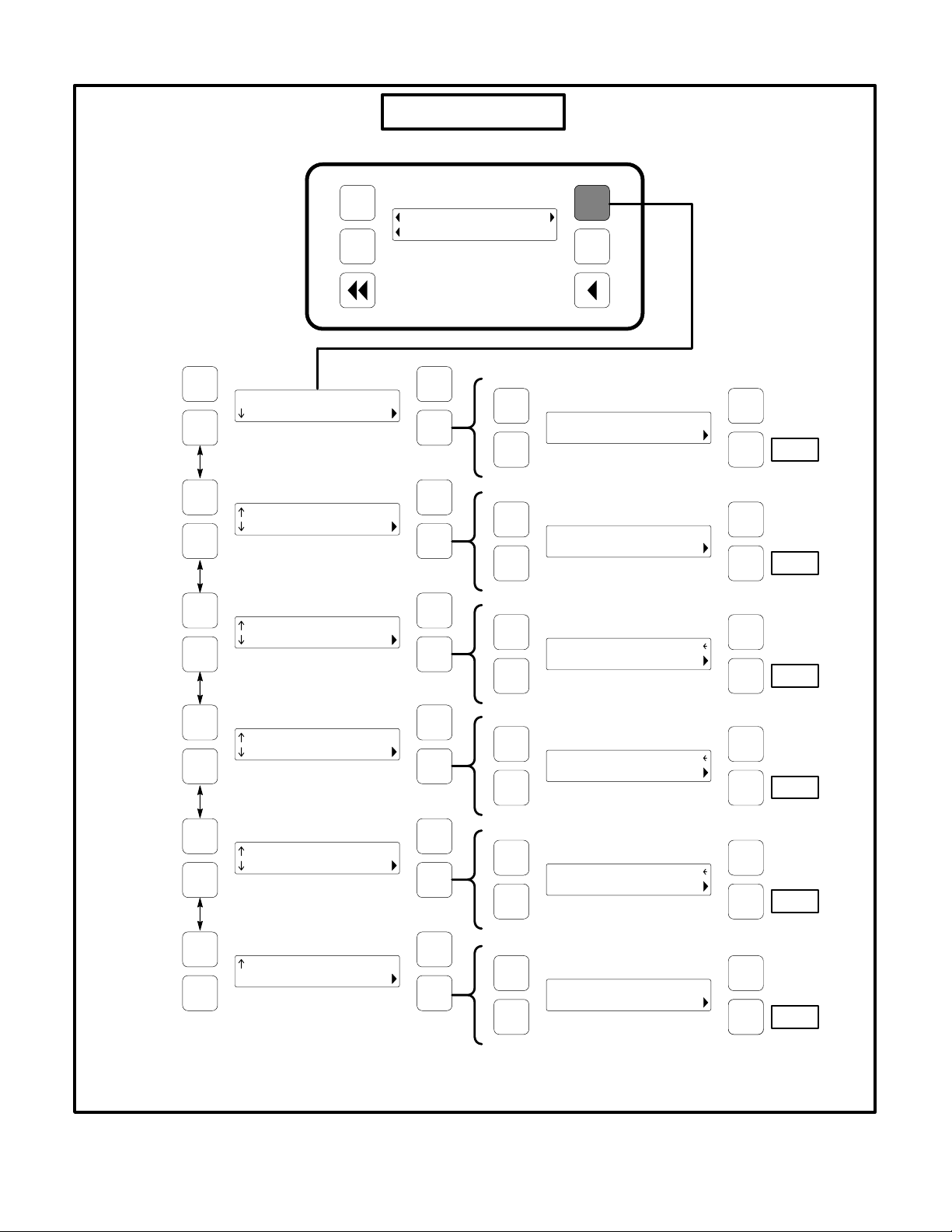

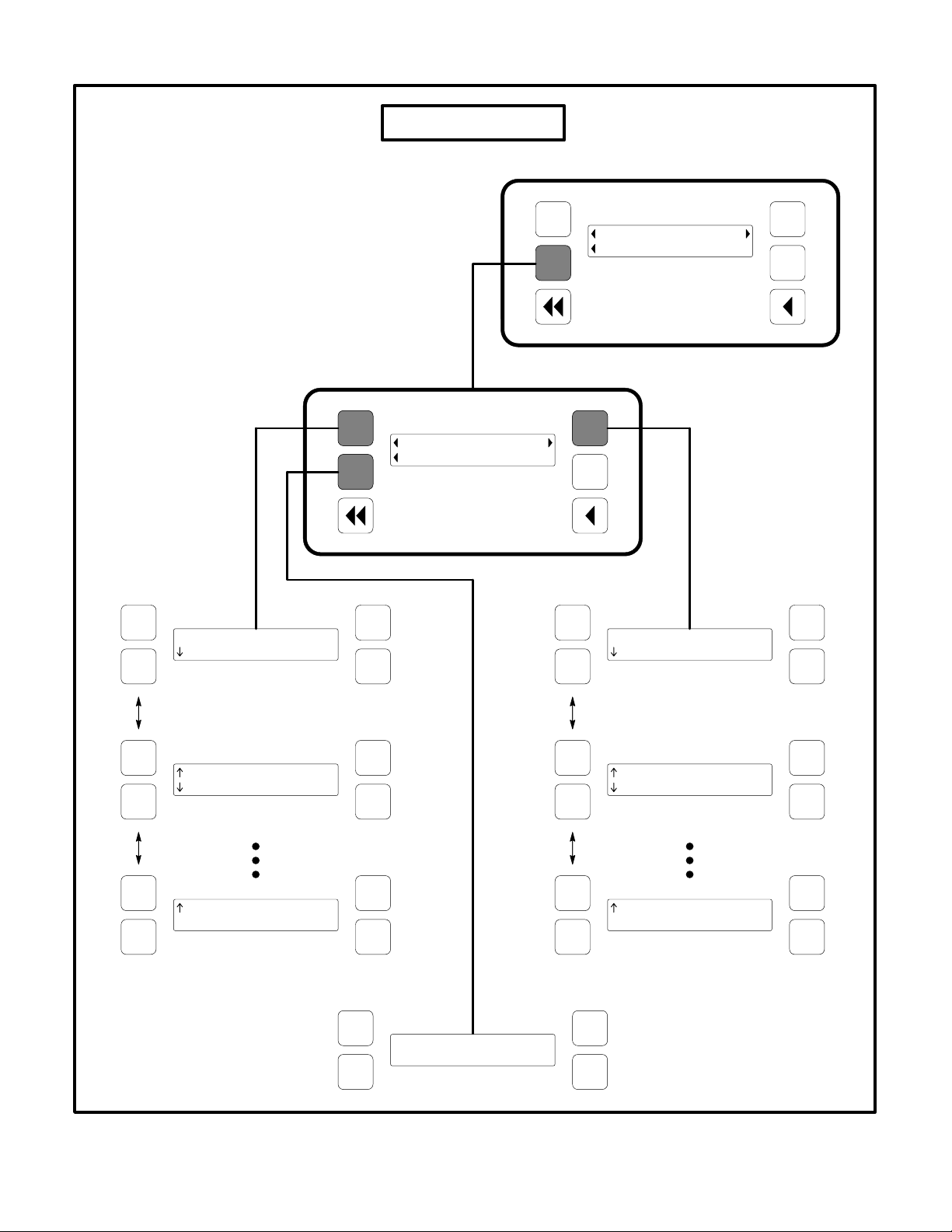

MAIN MENUS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-3 shows the three major main menus available to t h e user . Figure 2-3 also includes references

to pages in this section where you can find additional information on submenus. When viewing a submenu, you can press the previous main menu button at any time to view its main menu.

Main Menu 1

As shown in the illustration, each main menu can

branch into one of four directions. Press the button

next to “More>>” in the display to view the next Main

menu. Main Menu 1 is redisplayed when you press

the button next to “More>>” in the Main Menu 3 display.

PAGE

2-11

PAGE

2-13

Engine

Alternator

PAGE

2-17

PAGE

2-19

Adjust

More>>

Main Menu 2

Faults

System

PAGE

NO TAG

History

More>>

PAGE

2-21

Main Menu 3

PAGE

2-23

PAGE

2-25

FIGURE 2-3. MAIN MENUS

About

Pwr Tran

2-7

Setup

More>>

PAGE

5-5

Page 16

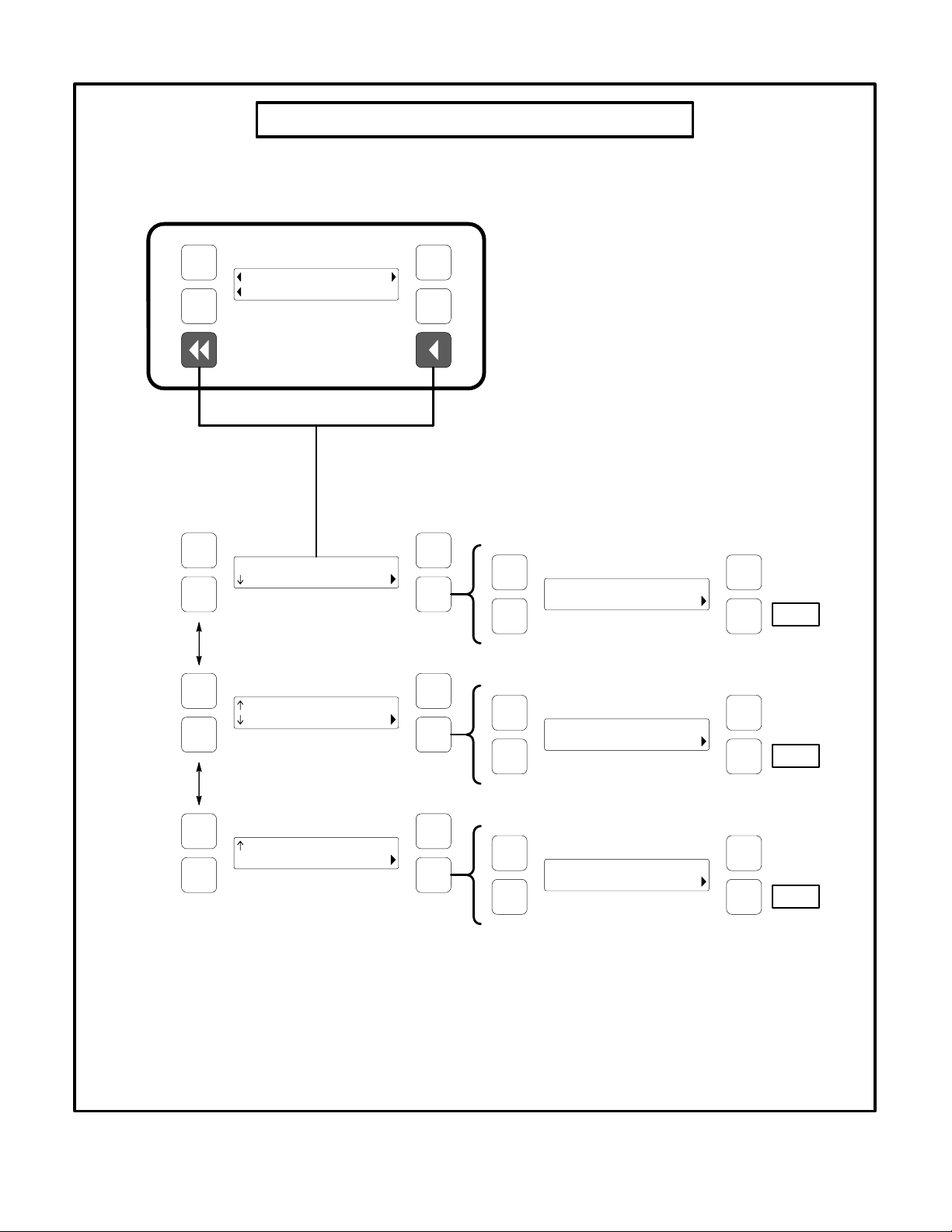

CONTROLLER CONFIGURATION MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-4 shows a block representation of the Controller Configuration menus. These menus are used

to change the default language, temperature units,

and pressure units to be displayed in menus.

To view the first Controller Configuration menu,

make sure Main Menu 1 is displayed and simultaneously press the Home Menu and Previous Main

Menu buttons.

As shown in the diagram, the Controller Configuration menu has three submenus.

Press the button next to the symbol in the display

until the + and − symbols are displayed.

Press the button next to the + or − symbol to select

the desired option.

After selecting option, pressing the

symbol results

in the changes being saved. If the Home button or

Previous Main Menu button is pressed before

pressing the

Language Selected submenu:

symbol, the changes are not saved.

Used to select de-

sired language (default = English).

Temperature Units submenu:

Used to select

Fahrenheit or Centigrade for temperature readings.

Press the buttons next to the

and symbols in the

digital display to navigate between the menus.

Fluid Pressure Units submenu:

PSI or kPA for pressure readings.

Used to select

2-8

Page 17

CONTROLLER CONFIGURATION MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 1

Engine

Alternator

Language Selected

English

Temperature Units

Deg F

Adjust

More>>

+Language Selected

− English

Back

+Temperature Units

− Deg C

Back

Fluid Pressure Units

PSI

+Fluid Pressure Units

− kPa

FIGURE 2-4. CONTROLLER CONFIGURATION MENU

2-9

Back

Page 18

ENGINE MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-5 shows a block representation of the Engine menu. If you press the button next to the word

“Engine” in the display, the first Engine submenu is

displayed.

As shown in the diagram, the Engine menu has

seven submenus. The data in the submenus will

vary according to the type and number of sensors

provided with the engine.

Press the buttons next to the

digital display to navigate between the menus.

Press the Home button or the Previous Main Menu

button to return to Main Menu 1.

and symbols in the

Coolant Temperature submenu:

This submenu

displays the engine coolant temperature which can

be viewed in degrees Fahrenheit or Centigrade

(see

Controller Configuration Menu

Oil Pressure submenu:

This submenu displays

in this section).

the engine oil pressure which can be viewed in PSI

or kPA (see

Controller Configuration Menu Menu

in

this section).

Oil Temperature submenu:

This submenu displays the engine oil temperature which can be

viewed in degrees Fahrenheit or Centigrade (see

Controller Configuration Menu

Engine Speed submenu:

in this section).

This submenu displays

the engine RPM.

Battery Voltage submenu:

This submenu dis-

plays the engine battery voltage.

Governor Duty Cycle submenu:

This submenu

displays the governor duty cycle (drive) levels in

percentage of maximum.

Active Time Delay submenu:

This submenu displays the time delay that is currently active: warm−

up, cool down, start or stop delays.

2-10

Page 19

ENGINE MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 1

Coolant Temperature

nnn Deg F

Oil Pressure

nnn PSI

Oil Temperature

nn Deg F

Engine Speed

nnnn RPM

Engine

Alternator

Adjust

More>>

Battery Voltage

nn.n VDC

Governor Duty Cycle

nnn %

Active Time Delay

None nnnn Sec

FIGURE 2-5. ENGINE MENU

2-11

Page 20

ALTERNATOR MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-6 shows a block representation of the Alternator menu. If you press the button next to the

word “Alternator” in the display, the first Alternator

submenu is displayed.

As shown in the diagram, the Alternator menu has

eleven submenus.

Press the buttons next to the

digital display to navigate between the menus.

Press the Home button or the Previous Main Menu

button to return to Main Menu 1.

and symbols in the

Line-to-Line V oltage submenu:

The voltage Lineto-Line (L1, L2 and L3) are measured between L1 to

L2, L2 to L3 and L3 to L1, respectively. (Single

phase − L1 to L2 only.)

Line-to-Neutral Voltage submenu:

Note that the

Line-to -Neutral column will not be displayed for a 3

phase/3 wire system. Single phase − L1 to N and L2

to N.

Amps submenu:

All phases. (Single phase − L1

and L2 only.)

Frequency submenu:

Generator set output fre-

quency.

Total Real Power submenu:

This submenu displays the total amount of real power output, in kilowatts (kW).

Real Power submenu:

This submenu displays the

amount of real power output for L1, L2, and L3, in

kilowatts (kW). (Single phase − L1 and L2 only.)

Total Apparent Power submenu:

This submenu

displays the total amount of apparent power output,

in kilovolt amps (kVA).

Apparent Power submenu:

This submenu displays the amount of apparent power output for L1,

L2, and L3, in kilovolt amps (kVA). (Single phase −

L1 and L2 only.)

Total Power Factor submenu:

This submenu displays the power factor with leading/lagging indication.

The PF reading will contain an asterisk if the power

factor is leading (for example, Total PF 0.9 * ).

Power Factor submenu:

This submenu displays a

power factor value for L1, L2, and L3. (Single

phase − L1 and L2 only.)

The PF reading will contain an asterisk if the power

factor is leading (for example, PF L1 0.9*).

AVR Duty Cycle submenu:

This submenu displays the voltage regulator (drive) level in percentage of maximum. (Where maximum is 100% Duty

Cycle, software clamps Duty Cycle maximum to

60% for PMG and 90% for shunt.)

2-12

Page 21

ALTERNATOR MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 1

Volts L12 L23 L31

V nnn nnn nnn

Volts L1N L2N

V nnn nnn

Amps L1 L2 L3

nnn nnn nnn

Engine

Alternator

Total Power

nn.n kVA

Power L1 L2 L3

kVA nn.n nn.n nn.n

Adjust

More>>

Frequency

nn.n Hz

Total Power

nnn kW

Power L1 L2 L3

kW nn.n nn.n nn.n

Total PF

n.nn*

PF L1 L2 L3

*n.nn *n.nn *n.nn

AVR Duty Cycle

nnn %

FIGURE 2-6. ALTERNATOR MENU

2-13

Page 22

ADJUST MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-7 shows a block representation of the Adjust menu. If you press the button next to the word

“Adjust” in the display, the first Adjust submenu is

displayed.

As shown in the diagram, the Adjust menu has five

submenus. Each submenu includes a parameter or

value that can be changed.

Press the buttons next to the

digital display to navigate between the menus.

Press the Home button or the Previous Main Menu

button to return to Main Menu 1.

Adjusting Values/Parameters:

and symbols in the

Voltage Adjust submenu:

Voltage can be adjusted to 5 percent of the nominal voltage. For ex-

ample, if genset output voltage is 208 volts, the voltage can be adjusted from 198 to 218 volts.

If the displayed value is greater or less than the allowed (5%) range, the control will not except the

entry and will return to the previous setting. Retry by

entering a smaller change in one volt increments.

Frequency Adjust submenu:

Frequency can be

adjusted to 5 percent of the nominal frequency.

For example, if the genset frequency is 60.0 Hz, the

frequency can be adjusted from 57.0 to 63.0 Hz.

Start Delay submenu:

Start Delay can be set from

0 to 300 seconds (default = 0). This function is bypassed during a manual start/stop sequence.

Stop Delay submenu:

Stop Delay can be set from

0 to 600 seconds (default = 0). This function is bypassed during a manual start/stop sequence and

engine shutdown faults.

1.. Press the button next to the symbol in the display until the + and − symbols are displayed.

2.. If necessary , press the button next to the

or

symbols to move to the numeric character you

wish to change.

3.. Press the button next to the + symbol to increase the value or select parameter; press the

button next to the − symbol to decrease the value or select parameter.

4.. After adjusting values/selecting parameters,

pressing the

symbol results in the changes

being saved. (When adjusting values, make

sure the cursor is on the last numeric character

before pressing the

symbol).

If the Home button or Previous Main Menu button is pressed before pressing the

symbol,

the changes are not saved.

Rated To Idle (Beginning Version 2.303):

Rated

To Idle delay can be set from 0 to 10 seconds (default = 0). (Enter 1 or more to enable.) Entering a

non-zero delay will cause the genset to delay the

transition to Cooldown At Idle.

Idle Start submenu (Not available on all mod-

Idle Start can be enabled or disabled (default =

els):

Disable). This function is only enabled when the

genset is started in manual mode. Idle Start can

also be enabled while the set is running in manual

mode.

Enabling Idle Start will cause the genset to run in

idle mode until Idle Start is disabled. A warning is

displayed if genset is left in idle more than 10 minutes. Long periods of engine idling can eventually

affect engine performance and may void engine

warranty.

The idle speed can be adjusted from 700 to 1100

RPM (default of 800 RPM). Refer to

up Menu

in Section 5. A countdown timer is used to

Crank/Idle Set-

limit engine idle time. With InPower , idle time can be

adjusted from 0 to 60 minutes in 1 minute increments.

2-14

Page 23

ADJUST MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 1

Voltage Adjust

nnn V

Frequency Adjust

nn.n Hz

Start Delay

nnn Sec

Engine

Alternator

Adjust

More>>

+Voltage Adjust

− nnn V

Back

+Frequency Adjust

− nn.n Hz

Back

+Start Delay

− nnn Sec

Back

Stop Delay

nnn Sec

Rated To Idle Delay

nn Sec

Idle Start

Disable

+Stop Delay

− nnn Sec

Back

+Rated To Idle Delay

− nn Sec

Back

+Idle Start

− Enable

Back

FIGURE 2-7. ADJUST MENU

2-15

Page 24

FAULTS MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

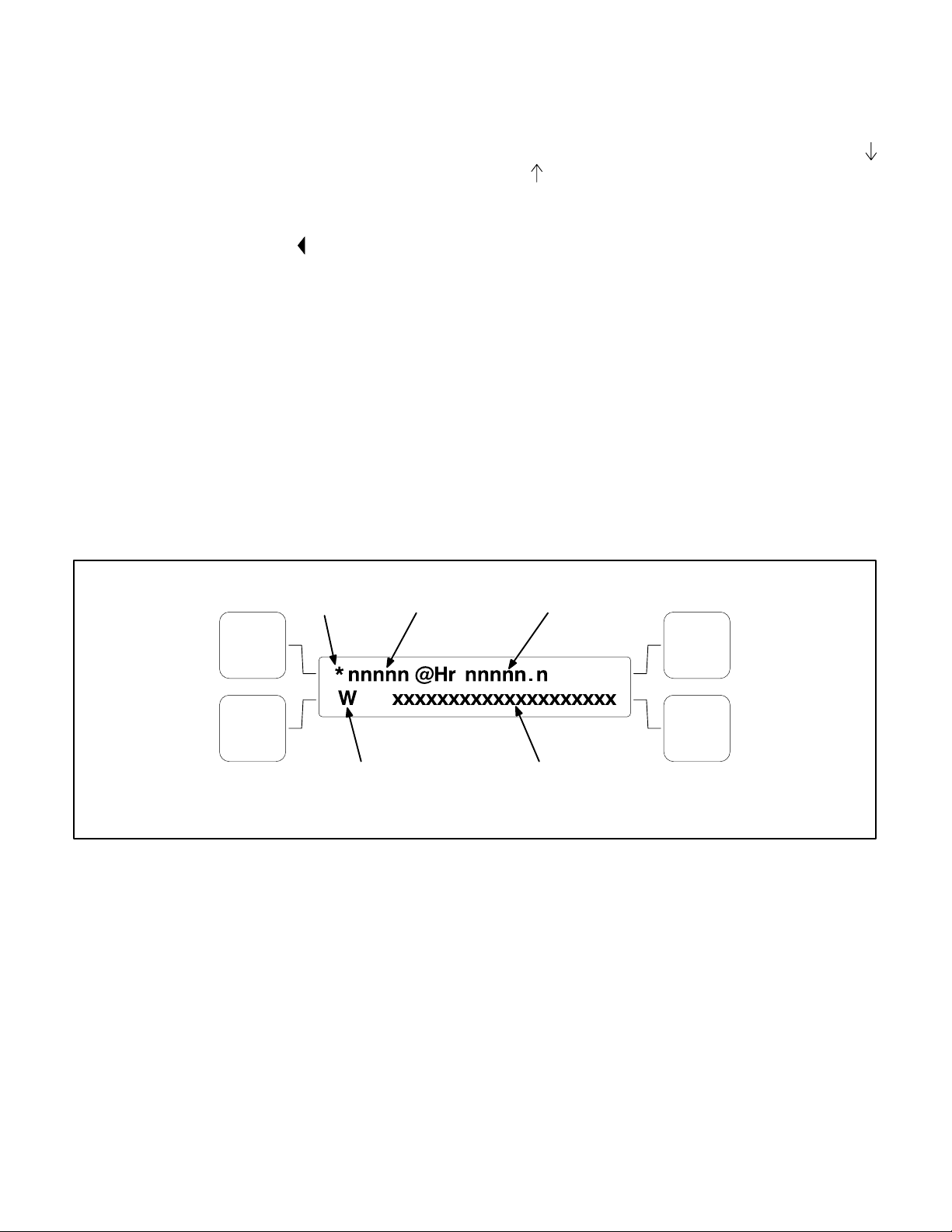

Figure 2-9 shows a block representation of the

Faults menu. Up to 20 of the most recent faults can

be viewed. An example of how a fault code is displayed is shown in Figure 2-8.

The available menus are dependent on the number

of faults that have occurred.

• If there are

word “Faults” is not displayed and no Fault

menus are available.

• If

more than one fault

the button next to the word “Fault” in the

screen display to view the Faults Main Menu.

As shown in the diagram, the Faults Main

Menu has two submenus. Press the Previous

Main Menu button to return to the Faults

Main Menu. Press the Previous Main Menu

button a second time to return to Main

Menu 2.

Press the Home button at any time to return to Main

Menu 1.

no faults

, the symbol next to the

has occurred, press

History submenu:

From the Faults Main Menu,

press the button next to the word “History” in the display to view up to twenty of the most recent ac-

knowledged faults. Press the buttons next to the

and symbols in the digital display to navigate be-

tween the menus. Press the Previous Main Menu

button to return to the Faults Main Menu.

Current Fault submenu:

From the Faults Main

Menu, press the button next to the word “Current” in

the display to view up to twenty of the most recent

unacknowledged faults. Press the Previous Main

Menu button to return to the Faults Main Menu.

ASTERISK =

ACTIVE FAULT

W = WARNING

S = SHUTDOWN

FIGURE 2-8. HISTORY/CURRENT FAULT SUBMENU

FAULT

CODE

HOUR FAULT

OCCURRED

FAULT

DESCRIPTION

2-16

Page 25

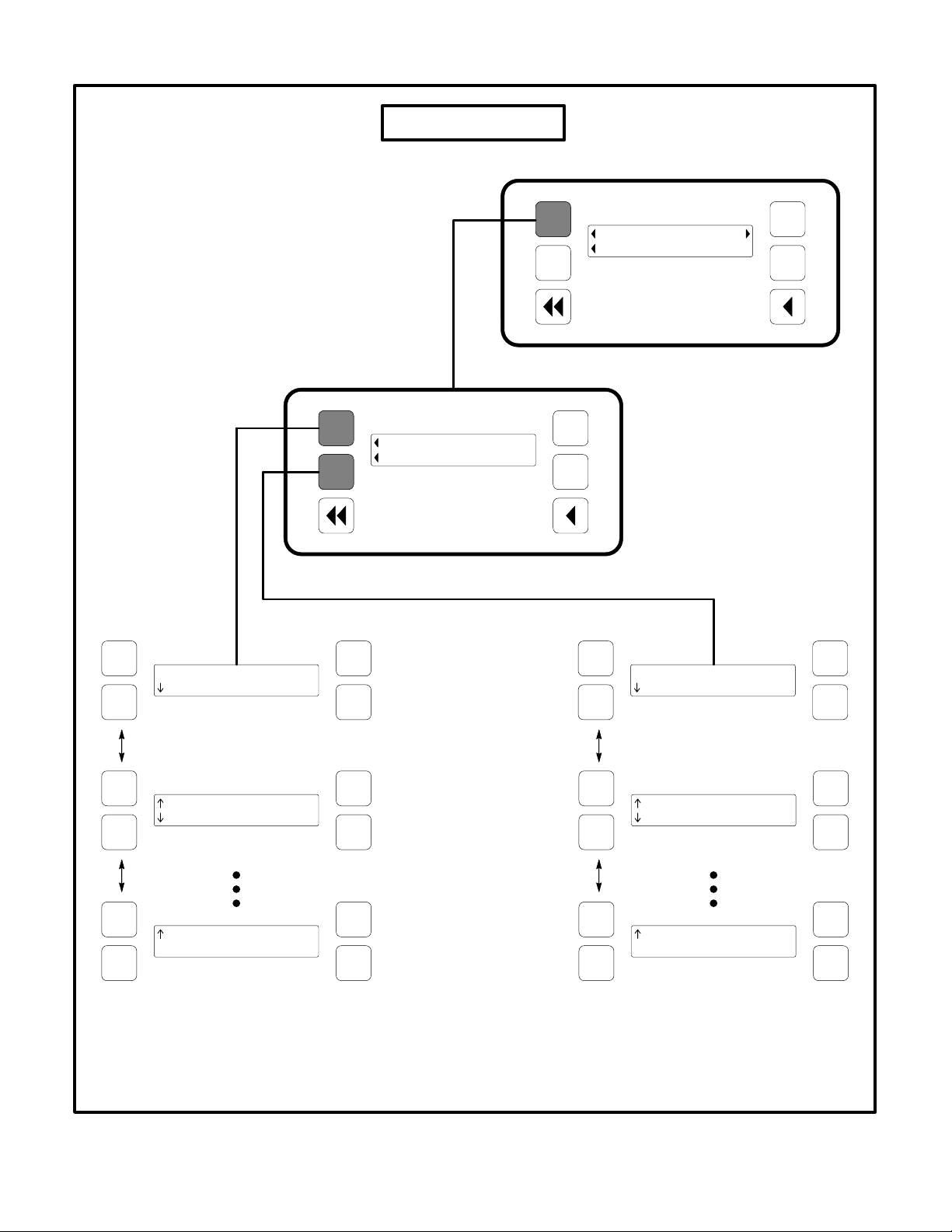

FAULTS MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 2

Faults Main Menu

nnnnn @Hr nnnnn.n

W xxxxxxxxxxxxxxxxxxxx

Fault 1

History

Current

Faults

System

nnnnn @Hr nnnnn.n

S xxxxxxxxxxxxxxxxxxxx

Fault 1

History

More>>

nnnnn @Hr nnnnn.n

S xxxxxxxxxxxxxxxxxxxx

Fault 2

nnnnn @Hr nnnnn.n

W xxxxxxxxxxxxxxxxxxxx

Fault 20

nnnnn @Hr nnnnn.n

W xxxxxxxxxxxxxxxxxxxx

Fault 2

nnnnn @Hr nnnnn.n

W xxxxxxxxxxxxxxxxxxxx

Fault 20

FIGURE 2-9. FAULTS MENU

2-17

Page 26

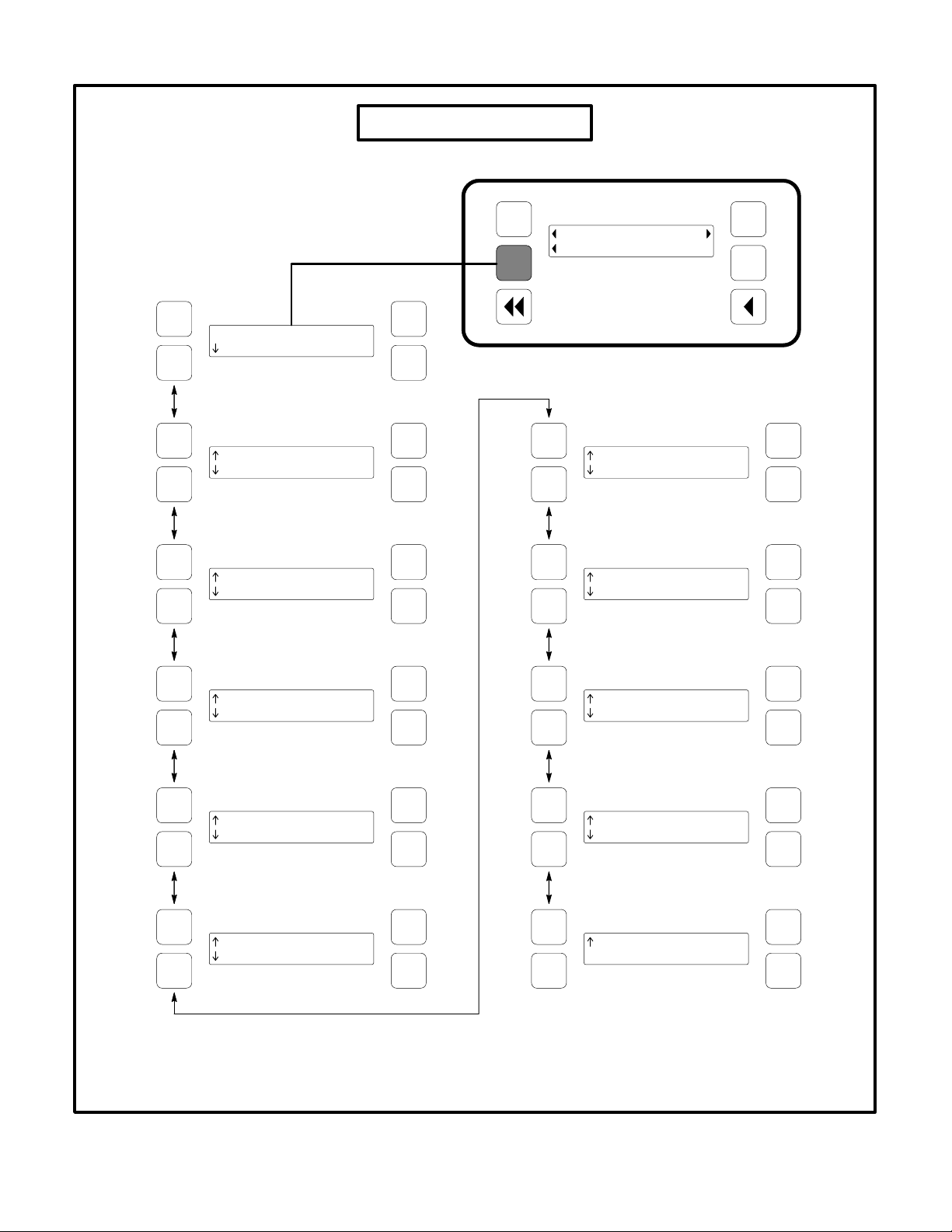

SYSTEM MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-10 shows a block representation of the

System menu. If you press the button next to the

word “System” in the display, the System Main

Menu is displayed. This menu is displayed only if

the network communications module (NCM) feature is installed. The System Main Menu allows you

to view the status and load of other PCC equipment

connected on a common network with the PCC

2100 control.

As shown in the diagram, the System Main Menu

has three submenus.

When viewing ATS and Genset System submenus,

press the buttons next to the

digital display to navigate between the menus.

Press the Previous Main Menu button to return to

the System Main Menu. Press the Previous Main

Menu button a second time to return to Main

Menu 2. Press the Home button to return to Main

Menu 1.

and symbols in the

ATS System submenus:

From the System Main

Menu, press the button next to the word “A TS” in the

display to view the first of up to 16 ATS System submenus. An ATS system must be available in the network to display this submenu.

The ATS submenu allows viewing of the transfer

switch name (configured with InPower), kW load (if

monitored by the ATS system), status (e.g., not in

auto), and source connected and availability (ON =

source connected, OK = source available, or NA =

source not available).

Master System submenu:

From the System Main

Menu, press the button next to the word “Master” in

the display to view the Master System submenu. A

master controller must be available in the network

to display this submenu.

The master submenu allows viewing of the master

controller name (configured with InPower), kW load

and operational state.

Genset System submenus:

From the System

Main Menu, press the button next to the word “Genset” in the display to view the first of up to 16 Genset

System submenus. One genset must be available

in the network to display this submenu.

The genset submenu allows viewing of the genset

name (configured with InPower), kW load and operational state.

If a PCC 2100 control genset, in the network, contains the Power Transfer Control (PTC) feature, a

genset system submenu will be displayed for the

genset and the ATS System submenu will be displayed for the PTC feature.

2-18

Page 27

SYSTEM MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 2

System Main Menu

ATSnameTag01>nnnnkW

Non Auto S1=On, S2=On

ATS Menu 1

ATS

Master

Genset

Faults

System

GensetName01>nnnnkW

Warning Fail2Start

History

More>>

Genset Menu 1

ATSnameTag02>nnnnkW

NonAut o S1=Ok, S2=NA

ATS Menu 2

ATSnameTag16>nnnnkW

NonAuto S1=Ok, S2=NA

ATS Menu 16

GensetName02>nnnnkW

NonAuto Alarm

Genset Menu 2

GensetName16>nnnnkW

NonAuto Alarm

Genset Menu 16

Master>nnnn kW

Shutdwn N=On,E=NA

FIGURE 2-10. SYSTEM MENU

2-19

Page 28

HISTORY MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-11 shows a block representation of the

History menu. If you press the button next to the

word “History” in the display, the first History submenu is displayed.

Number of Starts submenu:

This submenu shows

the number of engine starts.

Engine Hours submenu:

This submenu shows

the number of operating hours for the engine.

As shown in the diagram, the History menu has five

submenus. This information is stored in non-volatile

memory and will not be deleted due to loss of battery power.

Press the buttons next to the

and symbols in the

digital display to navigate between the menus.

Press the the Previous Main Menu button to return

to Main Menu 2. Press the Home button to return to

Main Menu 1.

Control Hours submenu:

This submenu shows

the number of operating hours for the control.

Kilowatt Hours submenu:

This submenu shows

the number of kilowatt (kW) or megawatt (MW)

hours.

Genset Duty Cycle submenu:

This submenu

shows the percent of genset operating hours that

are less than 30 percent of rated load and percent of

hours that are greater than 90 percent.

2-20

Page 29

HISTORY MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 2

Faults

System

History

More>>

Number Starts

nnnnn

Engine Hours

nnnnn Hours

Control Hours

nnnnn Hours

kW Hours

nnnnn kW Hrs

Genset Duty Cycle

Hr <30:nn% >90:nn%

FIGURE 2-11. HISTORY MENU

2-21

Page 30

ABOUT MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-12 shows a block representation of the

About menu. If you press the button next to the word

“About” in the display, the first About submenu is

displayed.

As shown in the diagram, the About menu has three

submenus.

Model submenu:

This submenu shows the genset

model.

Rating submenu:

This submenu shows the rating

(Standby or Prime) and number of kilowatts (kW)).

Press the buttons next to the

and symbols in the

digital display to navigate between the menus.

Press the the Previous Main Menu button to return

to Main Menu 3. Press the Home button to return to

Main Menu 1.

Software Version submenu:

This submenu

shows the software version level. This information

is required to service the generator set.

2-22

Page 31

ABOUT MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 3

Model

xxxxxxxxxxxxxxx

Rating

Standby nn.n kW

Software Version

nn.nnn

About

Pwr Tran

Setup

More>>

FIGURE 2-12. ABOUT MENU

2-23

Page 32

POWER TRANSFER MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Figure 2-13 shows a block representation of the

Power Transfer menu. If you press the button next

to the word “Pwr Tran” in the display, the first Power

Transfer submenu is displayed. (The Power Transfer Control feature must be installed to display this

submenu.)

With this option installed, the control will monitor the

utility voltage (mains) and frequency for failure. If

power fails, the PTC control will start the generator,

open the mains circuit breakers and close the generator circuit breakers.

S1 (Source 1) submenu:

This submenu shows

power transfer source voltage. The voltages Lineto-Line (L1, L2 and L3) are measured between L1 to

L2, L2 to L3 and L3 to L1, respectively. (Single

phase − L1 to L2 only.)

S1 (L-N Source) submenu:

This submenu is displayed only if the control system is configured for

line−to−neutral voltage sensing of source 1. Single

phase only − L1 to N and L2 to N.

Frequency submenu:

This menu shows power

transfer frequency.

As shown in the diagram, the Power Transfer menu

has five submenus.

Press the buttons next to the

and symbols in the

digital display to navigate between the menus.

Press the the Previous Main Menu button to return

to Main Menu 3. Press the Home button to return to

Main Menu 1.

Source 1 submenu:

This submenu shows utility

status (On, Ok, or NA). “On” means Source 1 is connected and available. “Ok” means Source 1 i s available but not connected. “NA” means Source 1 is not

available.

Genset submenu:

This submenu shows generator

status (On, Ok, or NA). “On” means the genset is

connected and available. “Ok” means the genset is

available but not connected. “NA” means the genset is not available.

Active Transfer Timer submenu:

This submenu

shows the time delay, in seconds.

2-24

Page 33

POWER TRANSFER MENU

Redistribution or publication of this document,

by any means, is strictly prohibited.

Main Menu 3

S1 L12 L23 L31

V nnn nnn nnn

S1 L1N L2N

V nnn nnn

Frequency

nn.n Hz

About

Pwr Tran

Setup

More>>

S1

On

Genset

On

Active Tran Timer

TD Re-Trans nnn Sec

FIGURE 2-13. POWER TRANSFER MENU

2-25

Page 34

THIS PAGE LEFT INTENTIONALLY BLANK

Redistribution or publication of this document,

by any means, is strictly prohibited.

2-26

Page 35

3. Circuit Boards

Redistribution or publication of this document,

by any means, is strictly prohibited.

GENERAL

WARNING

uninsulated parts inside the control panel box

can result in severe personal injury or death.

Measurements and adjustments must be done

with care to avoid touching hazardous voltage

parts.

Stand on a dry wooden platform or rubber insulating mat, make sure your clothing and shoes

are dry, remove jewelry and use tools with insulated handles.

HAZARDOUS VOLTAGE. Touching

INDICATOR

BOARD

DISPLAY

BOARD

This section describes the function of the Power-

Command

2100 Control (PCC) base circuit board

that is contained in the control panel box (Figure

3-1). The block diagram in Figure 3-2, shows the external connections of the PCC system. The system

schematics are provided in

Section 10

of this manu-

al.

CAUTION

Electrostatic discharge will damage

circuit boards. Always wear a grounding wrist

strap when touching or handling circuit boards.

CONTROL

PANEL BOX

BASE

BOARD

FRONT CONTROL

PANEL ASSEMBLY

(MEMBRANE BUTTONS)

BARGRAPH BOARD

(OPTIONAL)

FIGURE 3-1. CIRCUIT BOARD LOCATIONS

3-1

Page 36

Redistribution or publication of this document,

by any means, is strictly prohibited.

FIGURE 3-2. BLOCK DIAGRAM

3-2

Page 37

BASE BOARD

Redistribution or publication of this document,

by any means, is strictly prohibited.

The base circuit board (Figure 3-3) contains all of

the electronic circuitry required to operate the generator set. The Base board provides fuel control

and engine speed governing, main alternator volt-

J6

NCM

J4

DIGITAL DISPLAY

J1

HARNESS

S12, S13

XX = F5 (PCB P/N 300-5381)

RS1 (PCB P/N 327-1379)

age output regulation, and complete generator set

control and monitoring.

The following paragraphs describe each of the connectors (J), fuses (F) and terminal boards (TB)

shown in Figure 3-3.

J2

LED BOARD &

BARGRAPH

J9

InPOWER

J3

MEMBRANE

TB2

PTC

F1 F2 F3

TB1

CUSTOMER CONNECTIONS

FIGURE 3-3. BASE BOARD

XX

F4

F4

J7

ENGINE

J8 − AC

GENERATOR

3-3

Page 38

Connector J1

Redistribution or publication of this document,

by any means, is strictly prohibited.

J1 connects to the Emergency Stop switch (S13)

and the O/Manual/Auto control panel switch (S12).

J1

S13

14

WIRE TABULATION

SIGNAL FROM TO

GND S12-4 J1-8

OFF (O) S12-1 J1-7

MANUAL S12-3 J1-6

AUTO S12-5 J1-5

ESTOP-NC1 S13-1 J1-2

ESTOP-NC2 S13-2 J1-1

ESTOP-NO1 S13-3 J1-3

ESTOP-NO2 S13-4 J1-4

S12

PIN 1

PIN 2

BASE

BOARD

32

EMERGENCY STOP

SWITCH

15

3

4

O/MANUAL/AUTO

SWITCH

FIGURE 3-4. CONNECTOR J1 (CONTROL HARNESS)

3-4

Page 39

Connector J2

Redistribution or publication of this document,

by any means, is strictly prohibited.

J2 connects to LED (indicator) board and bargraph

board of front control panel assembly.

CONNECTOR J2

PIN SIGNAL

1 MOSI

PIN 1

BASE

BOARD

J2

PIN 15

FIGURE 3-5. J2 LED/BARGRAPH CONNECTOR

Connector J3

J3 connects to membrane buttons of front control

panel assembly.

2, 4, 6, 16 GND

3 SCK

5 SEL_A

7 SEL_B

10, 14, 15 VCC

9 SEL_C

11 SEL_D

13 BAR_ENABLE

CONNECTOR J3

PIN SIGNAL

1 HOME MENU <<

2 PREVIOUS MENU <

BASE

BOARD

J3

PIN 10

FIGURE 3-6. J3 MEMBRANE CONNECTOR

3 UPPER LEFT

4 LOWER LEFT

5 UPPER RIGHT

6 LOWER RIGHT

7 FAULT ACK/RESET

8 PANEL LAMP

9 MANUAL RUN/STOP

10 COMMON (GND)

3-5

Page 40

Connector J4

Redistribution or publication of this document,

by any means, is strictly prohibited.

J4 connects to display menu of front control panel

assembly.

PIN 1

BASE

BOARD

J4

PIN 13

FIGURE 3-7. J4 DISPLAY MENU CONNECTOR

CONNECTOR J4

PIN SIGNAL

1 GND

2 VCC

3 N.U.

4 RS

5 R/W

6 ENABLE DISPLAY

7 D[0]

8 D[1]

9 D[2]

10 D[3]

11 D[4]

12 D[5]

13 D[6]

14 D[7]

3-6

Page 41

Connector J7

Redistribution or publication of this document,

by any means, is strictly prohibited.

J7 connects to the engine sensors, battery, starter,

governor actuator and magnetic pickup.

PIN 36

J7

PIN 1

PIN 4

FIGURE 3-8. J7 ENGINE HARNESS CONNECTOR

BASE

BOARD

CONNECTOR J7

PIN SIGNAL

5, 6, 7, 8 GND

1, 2, 3, 4 B+ IN

9

10

11

12

13

17

21

15

16

GEN SW B+

FUEL SOL B−

CT1

CT1−COM

OIL PRE OUT

OIL PRE COM

OIL PRE 5V

CT2

CT2−COM

18 ALT FLASHOUT

19

20

22

26

23

27

24

28

25

29

33

30

34

31

32

35

COOLANT SNDER

COOLANT SNDER COM

CT3

CT3−COM

OIL TEMP

OIL TEMP COM

GEN SW B+

START SOL B−

ACTUATOR +

ACTUATOR −

MAG PICKUP+

MAG PICKUP−

GND

COOL LVL B+

COOL LVL RTN

COOL LVL GND

3-7

Page 42

Connector J8

Redistribution or publication of this document,

by any means, is strictly prohibited.

J8 connects directly to the generator to monitor and

control AC output of the genset.

BASE

BOARD

PIN 24

J8

CONNECTOR J8

PIN SIGNAL COMMENTS

4

12

20

7

13

5

21

22

23

U1 (T1)

V2 (T2)

W3 (T3)

N (T4)

FIELD +

FIELD −

AC2 (PMG2)

AC3 PMG3)

AC4 (PMG4)

Used for alternator

voltage sensing and

power factor angle

sensing

Excitation drive

output

Used for excitation

power (Shunt connection − pins 21 &

22 only)

PIN 1

FIGURE 3-9. J8 AC GENERATOR CONNECTOR

REFERENCE

DESIGNATION

F1 10A Customer B+ (to TB1 customer terminal block)

F2 5A Customer switched B+ (to TB1 customer terminal block)

F3 2A Customer switched B+ (to T26 engine terminal block)

F4 5A Base board power supply fuse

F5 2A B+ supply to Power Transfer Control (PTC) module (optional) (PCB P/N 300-5381)

RS1 (Fuse/Auto

Reset)

PIN 4

TABLE 3-1. BASE BOARD FUSES

RATING FUNCTION

0.9A B+ supply to Power Transfer Control (PTC) module (optional) (PCB P/N 327-1379)

TB1 Customer Connections

Customer monitor/control connections are attached to terminal board TB1. Optional equipment

such as sensing devices used to monitor genset operation, remote start/stop switches and etc. are attached to this terminal. Refer to Customer Connections diagram in

Section 10

for TB1 connections.

TB2 Power Transfer Control (PTC)

Connections

TB2 is used to connect the optional PTC module to

the control. With this option installed, the control will

monitor the utility voltage (mains) and frequency for

failure. If power fails, the PTC control will start the

generator, open the mains circuit breakers and

close the generator circuit breakers. Refer to Customer Connections diagram in

Section 10

connections.

3-8

for TB2

Page 43

4. Troubleshooting

Redistribution or publication of this document,

by any means, is strictly prohibited.

GENERAL

The PowerCommand 2100 Control (PCC) continuously monitors engine sensors for abnormal conditions, such as low oil pressure and high coolant

temperature. If any of these conditions occur, the

PCC will light a yellow Warning lamp or a red Shutdown lamp and display a message on the digital display panel.

INPOWER SERVICE TOOL

The InPower service tool can be used in troubleshooting to perform tests, verify control inputs and

outputs, and test protective functions. Refer to the

InPower User’s Guide, provided with the InPower

software for test procedures.

InPower, when used improperly, can cause symptoms like warnings and shutdowns that appear to be

a defective base board. When these problems occur, always verify that a self-test or fault simulation

(override) have not been left enabled with InPower.

If you do not have InPower, or the enabled fault simulation(s) can not be found using InPower, disconnect battery power to disable the test or override

condition.

Make sure that parameter adjustments and time delays, related to the fault condition, have been appro-

priately set for the application. It may be necessary

to write the initial capture file to the device or update

the calibration file.

Updating a calibration file requires the InPower Pro

version. Confirm that the installed calibration part

number matches the serial plate information.

CAUTION

Using the wrong calibration file can

result in equipment damage. Do not swap Base

boards from another genset model and only use

the calibration file shown on the nameplate.

Some features are not available until the hardware

for that feature is installed and InPower Pro is used

to update (enable) that feature. Confirm that the

feature is installed and enabled prior to troubleshooting the base board for symptoms related to a

feature.

NETWORK APPLICATIONS AND

CUSTOMER INPUTS

In applications with networks and remote customer

inputs, the genset may start unexpectedly or fail to

crank as a result of these inputs. These symptoms

may appear to be caused by the base board. Verify

that the remote input is not causing the symptom or

isolate the control from these inputs before troubleshooting the control.

4-1

Page 44

SAFETY CONSIDERATIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

nents can cause electrocution, resulting in severe personal injury or death. Keep the output

box covers in place during troubleshooting.

Contacting high voltage compo-

CAUTION

Disconnect battery charger from AC

source before disconnecting battery cables.

Otherwise, disconnecting cables can result in

voltage spikes damaging to DC control circuits

of the genset.

High voltages are present when the genset is running. Do not open the generator output box while

the genset is running.

WARNING

Ignition of explosive battery gases

can cause severe personal injury or death. Arcing at battery terminals, light switch or other

equipment, flame, pilot lights and sparks can ignite battery gas. Do not smoke, or switch

trouble light ON or OFF near battery. Discharge

static electricity from body before touching batteries by first touching a grounded metal surface.

Ventilate battery area before working on or near

battery—Wear goggles—Stop genset and disconnect charger before disconnecting battery

cables—Disconnect negative (−) cable first and

reconnect last.

WARNING

Accidental starting of the generator

set can cause severe personal injury or death.

Prevent accidental starting by disconnecting

the negative (−) cable from the battery terminal.

When troubleshooting a generator set that is shut

down, make certain the generator set cannot be accidentally restarted as follows:

1. Move the O/Manual/Auto switch on the control

panel to the O position.

2. Turn off or remove AC power from the battery

charger.

3. Remove the negative (−) battery cable from the

generator set starting battery.

4-2

Page 45

TROUBLESHOOTING PROCEDURE

Redistribution or publication of this document,

by any means, is strictly prohibited.

The following tables are a guide to help you evaluate problems with the generator set. You can save

time if you read through the manual ahead of time

and understand the system.

Try to think through the problem. Go over what was

done during the last service call. The problem could

be as simple as a loose wire, an opened fuse or a

tripped circuit breaker.

NOTE: Each fault code “warning” can be changed to

“shutdown” using InPower. Default settings are

used in this manual. It is recommended that all

changes to settings be recorded at each site to aid in

the troubleshooting of the genset.

This section contains the following information:

• Table 4-1 and 4-2: Describes how to trouble-

shoot a local/remote fail to crank problem when

control panel does not indicate fault condition.

• Table 4-3: Describes each status, warning and

shutdown code, warning and shutdown limits

where applicable, and basic corrective actions,

such as, checking fluid levels, control reset

functions, battery connections, etc.

• Fault Code Tables: Provide detailed trouble-

shooting procedures. In the following tables,

the fault codes are used as the table reference

number and are arranged in numeric order.

Figure 4-2 shows the location of the components

within the control panel that are referenced in the

following troubleshooting procedures. Connector

locations for each circuit board are provided in

tion 3

. The control wiring and circuit board connec-

tions are shown in

CAUTION

Always set the O/Manual/Auto

Section 10

.

switch to the O position before disconnecting

or connecting harness connectors. Otherwise,

disconnecting the harness connectors can result in voltage spikes high enough to damage

the DC control circuits of the set.

CAUTION

Electrostatic discharge will damage

circuit boards. Always wear a wrist strap when

handling circuit boards or when disconnecting

or connecting harness connectors. See Circuit

Board Removal/Replacement in Section 6.

Sec-

4-3

Page 46

EMERGENCY STOP

Redistribution or publication of this document,

by any means, is strictly prohibited.

INDICATOR

BOARD

O/MANUAL/AUTO

SWITCH (S12)

BUTTON

DISPLAY

BOARD

BASE

BOARD

CONTROL ALIVE

INDICATOR

FRONT CONTROL

PANEL ASSEMBLY

(MEMBRANE BUTTONS)

BARGRAPH BOARD

(OPTIONAL)

FIGURE 4-2. PCC CONTROL COMPONENTS

TB2 (1−6) TB1 (1−22)

CHASSIS GROUND

SCREW

AUX RELAYS

(OPTIONAL)

LOCATION

4-4

Page 47

WARNING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Hazards present in troubleshooting can cause equipment damage, severe personal injury

or death. Only trained and experienced service personnel with knowledge of fuels, electricity, and machinery hazards should perform service procedures. Read Safety Precautions page and observe all

instructions and precautions in this manual.

TABLE 4-1. ENGINE DOES NOT CRANK IN MANUAL MODE

(NO FAULT MESSAGE)

Reason: This indicates that the PCC has not received or recognized a manual start signal.

Effect: Engine will not start.

POSSIBLE CAUSE CORRECTIVE ACTION

1. No power supplied to control. (Control

Alive indicator on Base board is not

flashing.)

2. Base board not properly calibrated or

corrupt calibration. (Control Alive indicator flashes every 1/2 second.)

3. The Emergency Stop switch or wiring is

defective.

4. The Manual input is not getting from the

Manual select switch (S12) to the Base

board indicting that S12, Base board or

the harness is bad.

5. The Manual Run/Stop button, harness

or the Base board is bad.

1a. Poor battery cable connections. Clean the battery cable terminals

and tighten all connections.

1b. Remove F4 and check continuity. If open, replace the fuse with one

of the same type and amp rating (5 Amps).

If F4 is OK, remove connector P7 and check for B+ at P7-1 through

P7-4 and GND at P7-5 through P7-8. If B+ or ground missing,isolate to harness and TB BAT terminal mounted on engine block.

If B+ and ground check OK, Base board may be defective. Cycle

power to Base board by reconnecting P7. If Control Alive indicator

does not blink, replace Base board.

2. Confirm that the installed calibration part number matches the serial plate information. Re-enter calibration file if necessary. (When

properly installed, Control Alive indicator flashes every second.)

3. With Emergency Stop push button not activated, remove connector P1 and check for continuity between P1-1 (ESTOP-NC1) and

P1-2 (ESTOP-NC2). (If circuit is open, the control will detect a local

E-Stop condition but will not display the E-Stop condition.) If circuit

is open, isolate to Emergency Stop switch and wiring.

If there is continuity, go to next step.

4. With S12 in Manual, remove connector P1 from the Base board

and check for continuity from P1-6 (MAN) to P1-9 (GND). If no continuity, isolate to switch and wiring.

If there is continuity, go to next step.

5. Remove connector P3 from the Base board and check for continuity from P3-9 (MAN RUN/STOP) to P3-10 (GND). If no continuity

when pressing the Manual Run/Stop button, replace front membrane panel. If there is continuity, the Base board is bad.

4-5

Page 48

WARNING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Hazards present in troubleshooting can cause equipment damage, severe personal injury

or death. Only trained and experienced service personnel with knowledge of fuels, electricity, and machinery hazards should perform service procedures. Read Safety Precautions page and observe all

instructions and precautions in this manual.

TABLE 4-2. ENGINE DOES NOT CRANK IN REMOTE MODE

(NO FAULT MESSAGE)

Reason: This indicates that the PCC has not received or recognized a remote start signal.

Effect: Engine will not start in remote mode, but starts in manual mode.

POSSIBLE CAUSE CORRECTIVE ACTION

1. The remote start switch or customer wiring is faulty.

2. The Auto mode input is not getting from

the Auto select switch (S12) to the Base

board indicting that S12, Base board or

the harness is bad.

1. Reset the control. Attempt to start, and check for ground at TB1-1.

If ground level is not present, isolate to the remote switch or customer wiring. Repair as necessary.

If ground is present, go to next step.

2. With S12 in Auto, remove connector P1 from the Base board and

check for continuity from P1-5 (AUTO) to P1-9 (GND). If no continuity, isolate to switch or wiring harness. If there is continuity, the

Base board is bad.

4-6

Page 49

WARNING

Redistribution or publication of this document,