Page 1

Caution: This document contains mixed page sizes (8.5 x 11 or 11 x

17), which may affect printing. Please adjust your printer settings

according to the size of each page you wish to print.

Page 2

Installation Manual

Redistribution or publication of this document,

by any means, is strictly prohibited.

PowerCommand Control

2100 Series

Generator Sets

Printed in U.S.A.

Models

DFAB, DFAC, DFBF, DFCB, DFCC, DFCE

960-0634C 02-2004

Page 3

Table of Contents

Redistribution or publication of this document,

by any means, is strictly prohibited.

SECTION TITLE PAGE

IMPORTANT SAFETY INSTRUCTIONS iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 INTRODUCTION

About this Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 SPECIFICATIONS 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 MOUNTING THE GENERATOR SET

General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access to Set 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration Isolators 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning Generator with Engine (750 kW Gensets and Larger) 3-5. . . . . . . . .

4 MECHANICAL CONNECTIONS

General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation and Cooling 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 DC CONTROL WIRING

Control Wiring 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TB1 Remote Monitor/Control Connections 5-2. . . . . . . . . . . . . . . . . . . . . . . . . .

TB2 Power Transfer Control (PTC) Connections (Optional) 5-2. . . . . . . . . . . .

Control Relays (K11, K12, K13) 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

California

Proposition 65 Warning

i

Page 4

SECTION TITLE PAGE

Redistribution or publication of this document,

by any means, is strictly prohibited.

6 AC ELECTRICAL CONNECTIONS

General 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Switch 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Wiring 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Heater (Optional) 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coolant Heater (Optional) 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Heater (Optional) 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Transfer Pump (Optional) 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground Fault Alarm Relay (Optional) 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 ENCLOSURE ELECTRICAL CONNECTIONS

General 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional AC Distribution Panel 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Motorized Inlet/Outlet Louvers 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Transfer Fuel Pump 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 PRESTART PREPARATION

General 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical System 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCC Options Prestart Checks 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 INSTALLATION CHECKLIST

General 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Support 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Air Flow 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diesel Fuel System 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC and DC Wiring 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generator Set Prestart 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 WIRING DIAGRAMS

General 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

SAVE THESE INSTRUCTIONS − This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal injury or death.

WARNING

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

• DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use zinc

coated or copper fuel lines with diesel fuel.

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

•

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not warped. Do not use exhaust gases to

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

•

Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, discon-

nect battery charger from its AC source, then disconnect starting batteries, negative (−) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor can cause an engine to overspeed and

become difficult to stop, resulting in possible fire, explosion, severe personal injury and death. Do not operate a

genset where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset is

equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of

the genset are solely responsible for operating the genset safely. Contact your authorized Cummins Power

Generation distributor for more information.

LS-14L

iii

Page 6

ELECTRICAL SHOCK CAN CAUSE

Redistribution or publication of this document,

by any means, is strictly prohibited.

SEVERE PERSONAL INJURY OR DEATH

Remove electric power before removing protective

•

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical contacts and cause shock or burning.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DIRECT-

LY TO ANY BUILDING ELECTRICAL SYSTEM.

Hazardous voltages can flow from the generator set

into the utility line. This creates a potential for electrocution or property damage. Connect only

through an approved isolation switch or an approved paralleling device.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

•

than water. DO NOT open a radiator or heat exchanger pressure cap while the engine is running.

Allow the generator set to cool and bleed the system

pressure first.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproductive toxicity . When checking or changing engine oil,

take care not to ingest, breathe the fumes, or contact used oil.

• Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and cloth; Class B fires, combustible

and flammable liquid fuels and gaseous fuels; Class

C fires, live electrical equipment. (ref. NFP A No. 10).

• Make sure that rags are not left on or near the en-

gine.

• Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under the unit.

• Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause overheating and engine damage which present a potential fire hazard.

• Keep the generator set and the surrounding area

clean and free from obstructions. Remove any debris from the set and keep the floor clean and dry.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment unsafe.

• Substances in exhaust gases have been identified

by some state or federal agencies as causing cancer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

• Do not store any flammable liquids, such as fuel,

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

• Wear hearing protection when going near an oper-

ating generator set.

• To prevent serious burns, avoid contact with hot

metal parts such as radiator, turbo charger and exhaust system.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

iv

Page 7

1. Introduction

Redistribution or publication of this document,

by any means, is strictly prohibited.

ABOUT THIS MANUAL

This manual provides installation instructions for

the generator set models listed on the front cover.

This includes the following information:

Mounting Recommendations - for fastening

generator set to base and space requirements

for normal operation and service.

Mechanical and Electrical Connections covers most aspects of the generator set installation.

Prestart − checklist of items or procedures

needed to prepare generator set for operation.

Initial Startup − test complete system to ensure proper installation, satisfactory perfor-

mance, and safe operation. Refer to Operators

Manual for troubleshooting information.

Installation Checklist − reference checks

upon completion of installation.

This manual DOES NOT provide application information for selecting a generator set or designing the

complete installation. If it is necessary to design the

various integrated systems (fuel, exhaust, cooling,

etc.), additional information is required. Review

standard installation practices. For engineering

data specific to the generator set, refer to the

fication

tion, refer to Application Manual T-030, “Liquid

Cooled Generator Sets”.

and

Data Sheets

. For application informa-

Speci-

1-1

Page 8

INSTALLATION OVERVIEW

Redistribution or publication of this document,

by any means, is strictly prohibited.

These installation recommendations apply to typical installations with standard model generator

sets. Whenever possible, these recommendations

also cover factory designed options or modifications. However, because of the many variables in

any installation, it is not possible to provide specific

recommendations for every situation. If there are

any questions not answered by this manual, contact

your nearest Cummins Power Generation distributor for assistance.

Application and Installation

installed, maintained, and operated. However, the

overall safety and reliability of the complete system

is dependent on many factors outside the control of

the generator set manufacturer. To avoid possible

safety hazards, make all mechanical and electrical

connections to the generator set exactly as specified in this manual. All systems external to the generator (fuel, exhaust, electrical, etc.) must comply

with all applicable codes. Make certain all required

inspections and tests have been completed and all

code requirements have been satisfied before certifying the installation is complete and ready for service.

A standby power system must be carefully planned

and correctly installed for proper operation. This involves two essential elements: application and

installation.

Application (as it applies to generator set installations) refers to the design of the complete standby

power system that usually includes power distribution equipment, transfer switches, ventilation equipment, mounting pads, and cooling, exhaust, and

fuel systems. Each component must be correctly

designed so the complete system will function as intended. Application and design is an engineering

function generally done by specifying engineers or

other trained specialists. Specifying engineers or

other trained specialists are responsible for the design of the complete standby system and for selecting the materials and products required.

Installation refers to the actual set-up and assembly of the standby power system. The installers set

up and connect the various components of the system as specified in the system design plan. The

complexity of the standby system normally requires

the special skills of qualified electricians, plumbers,

sheetmetal workers, etc. to complete the various

segments of the installation. This is necessary so all

components are assembled using standard methods and practices.

Safety Considerations

The generator set has been carefully designed to

provide safe and efficient service when properly

Standby Heating Devices

In accordance with NFPA 110, Cummins Power

Generation recommends installing diesel standby

generator sets (life safety systems) equipped with

engine jacket water coolant heaters in locations

where the minimum ambient temperature is above

40

°F (4°C). NFPA also requires that the engine

jacket water coolant be maintained at a minimum of

°F (32°C) and, for most applications, accept the

90

emergency load in 10 seconds or less. Although

most Cummins Power Generation generator sets

will start in temperatures down to −25

when equipped with engine jacket water coolant

heaters, it might take more than 10 seconds to

warm the engine up before a load can be applied

when ambient temperatures are below 40

The Engine Cold (Code 1435) message, in con-

junction with illumination of the Warning LED, is provided to meet the requirements of NFPA 110. The

engine cold sensing logic initiates a warning when

the engine jacket water coolant temperature falls

below 70

ent temperature falls below 40

°F (21°C). In applications where the ambi-

°F (4°C), a cold en-

gine may be indicated even though the coolant

heaters are connected. Under these conditions, although the generator set may start, it may not be

able to accept load within 10 seconds. When this

condition occurs, check the coolant heaters for

proper operation. If the coolant heaters are operating properly, other precautions may be necessary to

warm the engine before applying a load.

°F (−32°C)

°F (4°C).

Copyright2003 Cummins Power Generation. All rights reserved.

Cummins and PowerCommand are registered trademarks of Cummins Inc.

1-2

Page 9

2. Specifications

Redistribution or publication of this document,

by any means, is strictly prohibited.

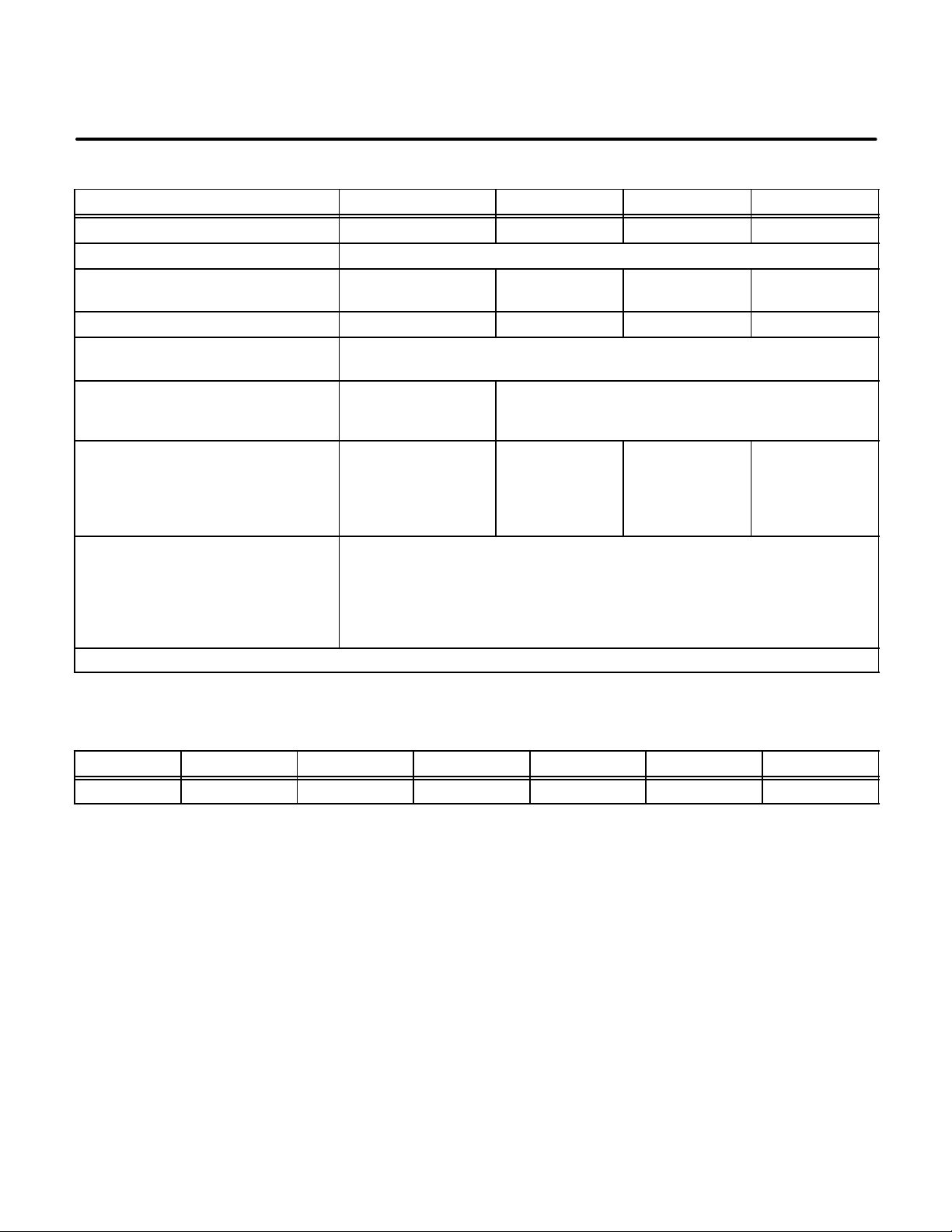

MODEL DFAB/DFAC DFBF DFCB/DFCC DFCE

Cummins Diesel Series LTA10 NT855 NTA855 NTA855

Generator kW Rating See Genset Nameplate for rating information.

Cooling System

Capacity with Standard Radiator 13 Gal (49 L) 13.5 Gal (51 L) 13.5 Gal (51 L) 15 Gal (57 L)

Oil Capacity* 9.5 Gal (36 L) 10.5 Gal (40 L) 10.5 Gal (40 L) 10 Gal (38 L)

Engine Fuel Connection

Inlet/Oultet Thread Size

Fuel Flow

Max. Fuel Inlet Restriction

Max. Fuel Return Restriction

Exhaust

Outlet Size

Max. Allowable Back Pressure

H20

kPa

Electrical System

Starting Voltage

Battery

Group number

CCA (minimum)

Cold Soak @ 0° F (-18° C)

* Refer to Cummins engine

Operation and Maintenance Manual

4 in. Hg. (13.5 kPa)

6.5 in. Hg. (22 kPa)

4 in. NPT

41

10.2

for lubricating oil recommendations/specifications.

Refer to Generator Outline Drawing

4 in. Hg. (13.5 kPa)

6 in. Hg. (20.3 kPa)

5 in. NPT

41

10.2

24 Volts DC

Two, 12 Volt

8D

1400

6 in. NPT

41

10.2

6 in. NPT

41

10.2

FUEL CONSUMPTION (STANDBY/FULL LOAD/60HZ)

MODEL DFAB DFAC DFBF DFCB DFCC DFCE

US gph (L/hr) 15.6 (59) 16.8 (63.7) 20.4 (77.3) 22.5 (85.3) 24.4 (92.5) 29.1 (110.3)

2-1

Page 10

THIS PAGE LEFT INTENTIONALLY BLANK

Redistribution or publication of this document,

by any means, is strictly prohibited.

2-2

Page 11

3. Mounting the Generator Set

Redistribution or publication of this document,

by any means, is strictly prohibited.

GENERAL

• Discharge of exhaust gases

• Electrical connections

Generator set installations must be engineered so

the generator set will function properly under the expected load conditions. Use these instructions as a

general guide only. Follow the instructions of the

consulting engineer when locating or installing any

components. The complete installation must comply with all local and state building codes, fire ordinances, and other applicable regulations.

Requirements to be considered prior to installation:

• Level mounting surface

• Adequate cooling air

• Adequate fresh induction air

• Discharge of generator set air

• Non-combustible mounting surface.

• Accessibility for operation and servicing

• Noise levels

• Vibration isolation

LOCATION

Generator set location is decided mainly by related

systems such as ventilation, wiring, fuel, and exhaust. The set should be located as near as possible to the main power service entrance. Exhaust

must not be able to enter or accumulate around inhabited areas.

Provide a location away from extreme ambient temperatures and protect the generator set from adverse weather conditions. An optional housing is

available for outside operation.

WARNING

INCORRECT INSTALLATION, SERVICE OR PARTS REPLACEMENT CAN RESULT IN SEVERE

PERSONAL INJURY, DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST

BE TRAINED AND EXPERIENCED TO PERFORM ELECTRICAL AND MECHANICAL COMPONENT INSTALLATION.

DEPENDING ON Y O U R L O C ATION AND INTENDED USE, FEDERAL, STATE OR LOCAL LA WS

AND REGULATIONS MAY REQUIRE YOU TO OBTAIN AN AIR QUALITY EMISSIONS PERMIT

BEFORE BEGINNING INSTALLATION OF YOUR GENSET. BE SURE TO CONSULT LOCAL

POLLUTION CONTROL OR AIR QUALITY AUTHORITIES BEFORE COMPLETING YOUR

CONSTRUCTION PLANS.

IMPORTANT

3-1

Page 12

MOUNTING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Generator sets are mounted on a steel skid or fuel

tank that provides proper support. The engine-generator assembly is isolated from the skid frame by

rubber mounts that provide adequate vibration

isolation for normal installations. Where required by

building codes or special isolation needs, generator

sets may be mounted on rubber pads or mechanical

spring isolators. The use of unapproved isolators

may result in harmful resonances and may void the

genset warranty.

For fuel tank mounted generator sets, it is required

that the tank be mounted such that an air space is

provided between the bottom of the tank and the

floor underneath to reduce corrosion and permit

visual inspections for leaks.

Mount the generator set on a substantial and level

base such as a concrete pad. A non-combustible

material must be used for the pad.

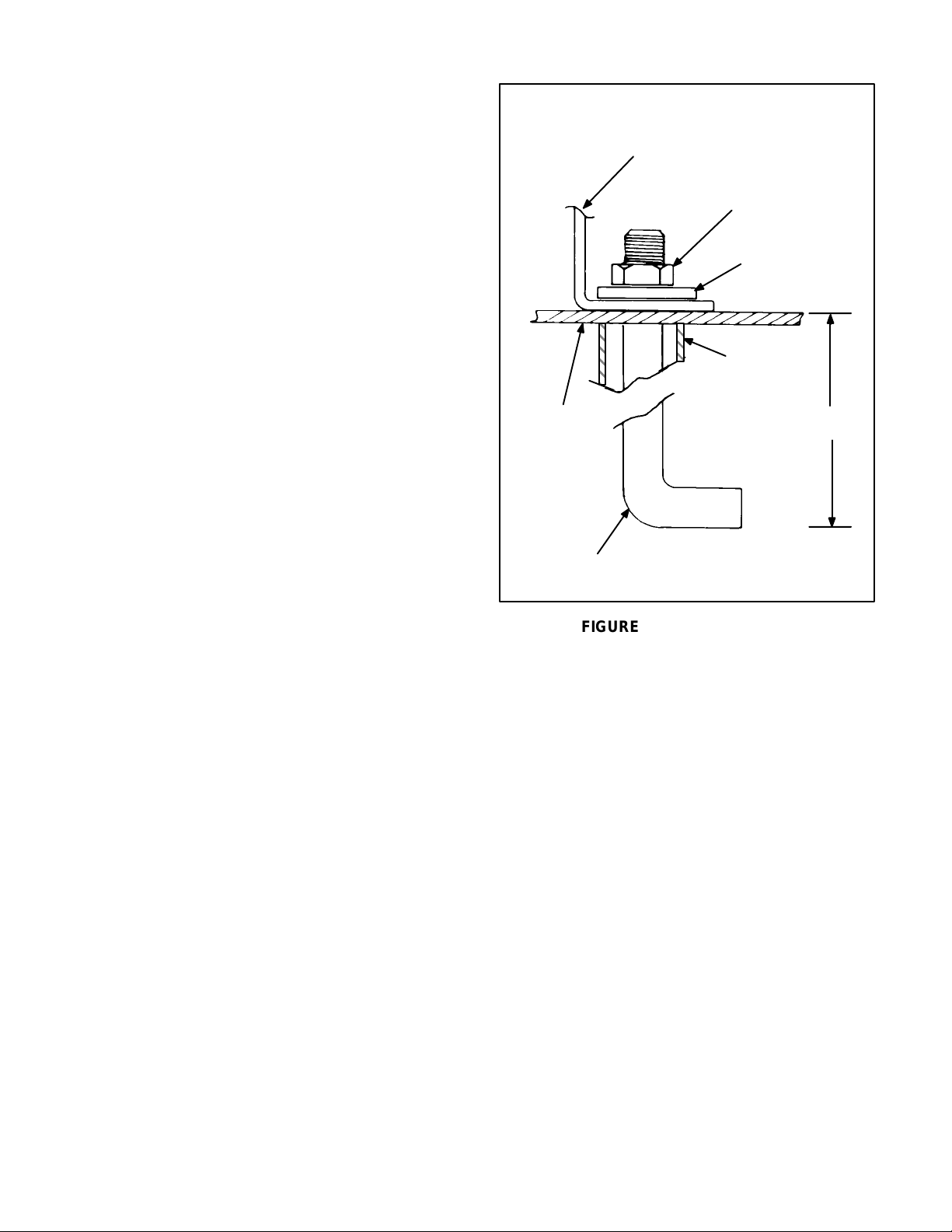

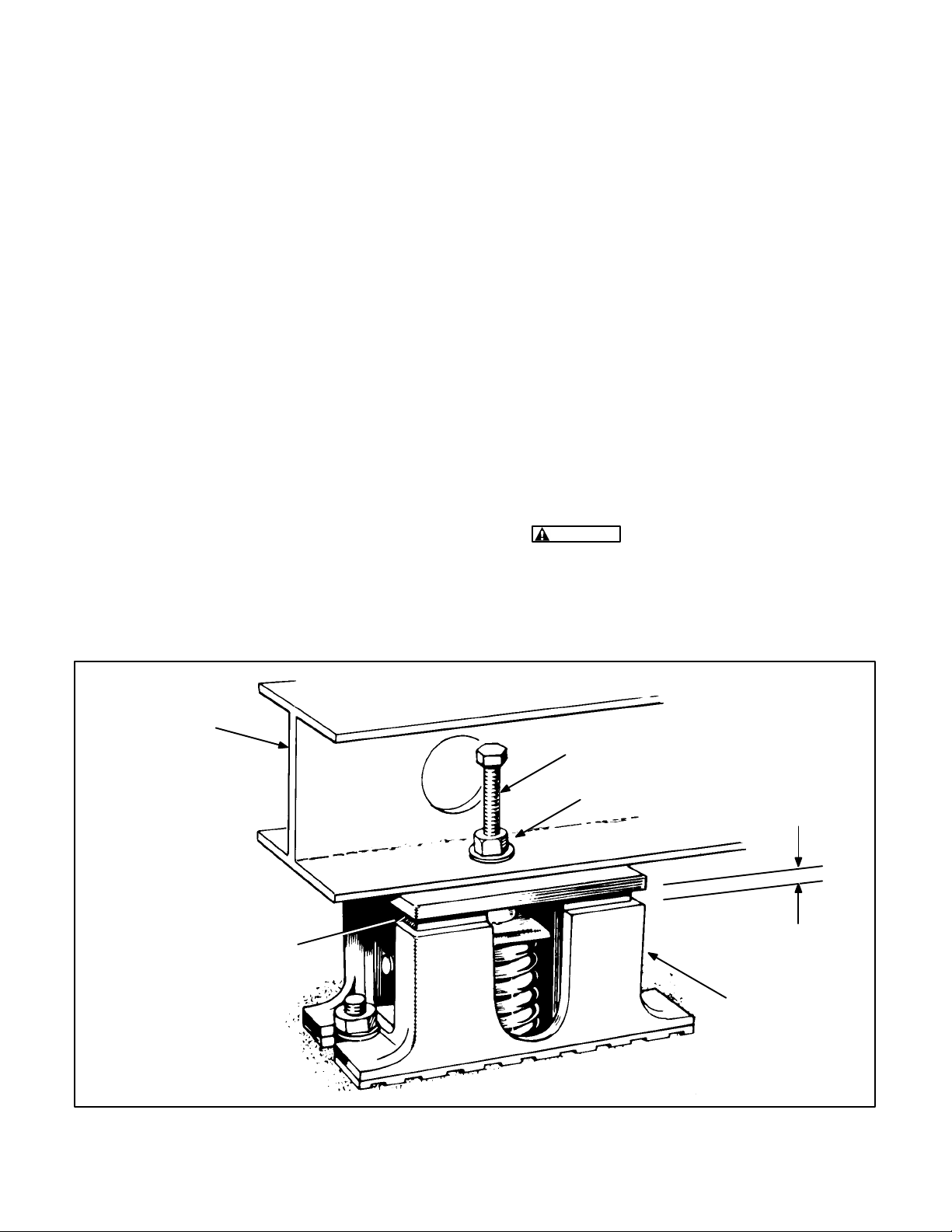

Use 5/8 inch or 16 mm anchored mounting bolts to

secure the vibration isolators to the base. Secure

the vibration isolators using flat or bevel washer and

hexagonal nut for each bolt (see Figure 3-1). The

1-1/2 x 6 inch pipe inserted over the mounting bolts

allows minor adjustment of the bolts to align them to

the holes in the subbase or vibration isolator.

Locate the isolators as shown on the generator set

Outline Drawing

referenced in the

Data Sheet

.

MOUNTING

BASE

MOUNTING

BOLT

SUBBASE OR

VIBRATION

ISOLATOR

FLANGE

HEX NUT

FLAT OR BEVEL

WASHER

1-1/2 x 6 INCH

PIPE

12 IN.

(305 mm)

CONCRETE

FIGURE 3-1. BOLT DIAGRAM

ACCESS TO SET

Generally, at least 1 meter (3 feet) of clearance

should be provided on all sides of the generator set

for maintenance and service access. (Increase

clearance by width of door if optional housing is

used.) A raised foundation or slab of 150 mm (6

inches) or more above floor level will make servicing easier.

Lighting should be adequate for operation, maintenance and service operations and should be connected on the load side of the transfer switch so that

it is available at all times.

3-2

Page 13

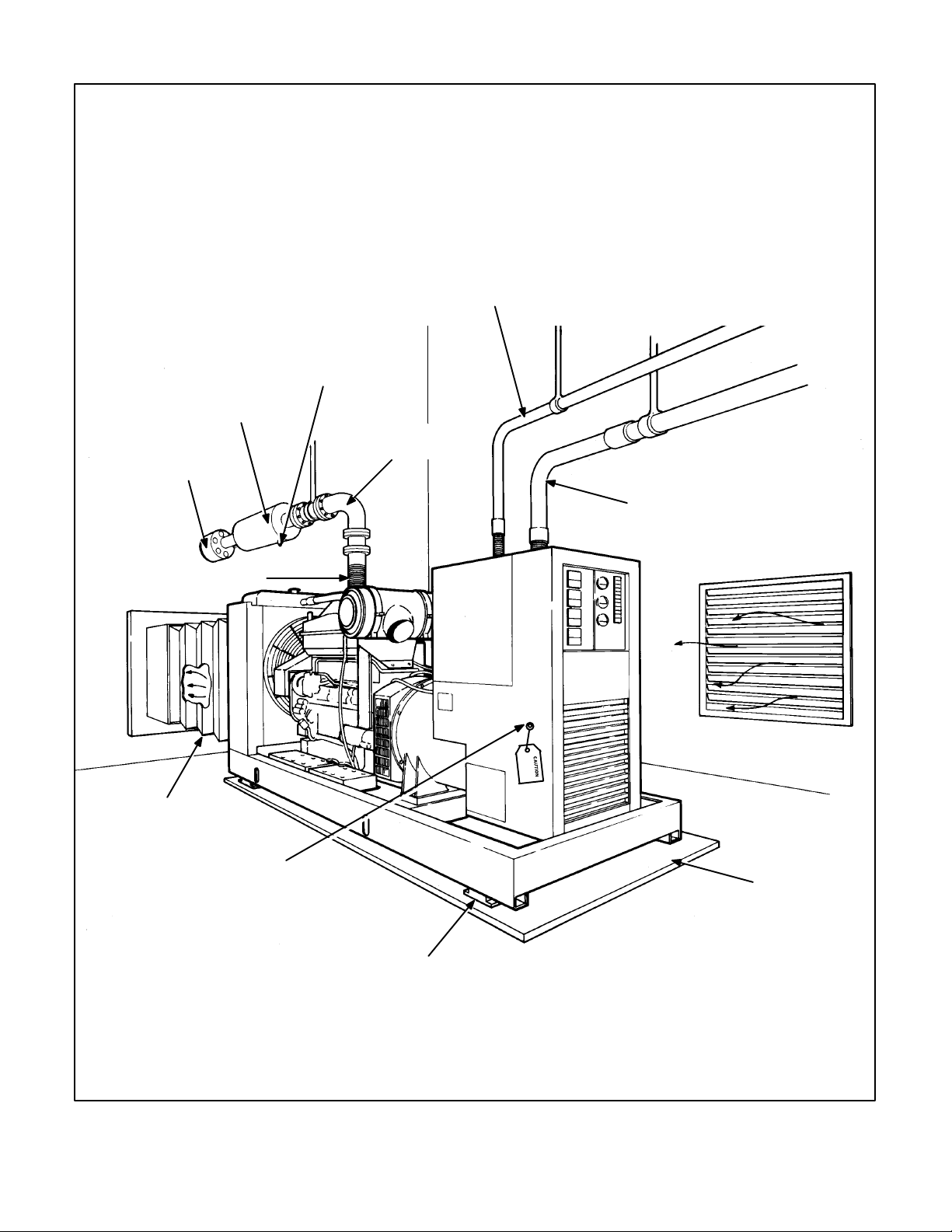

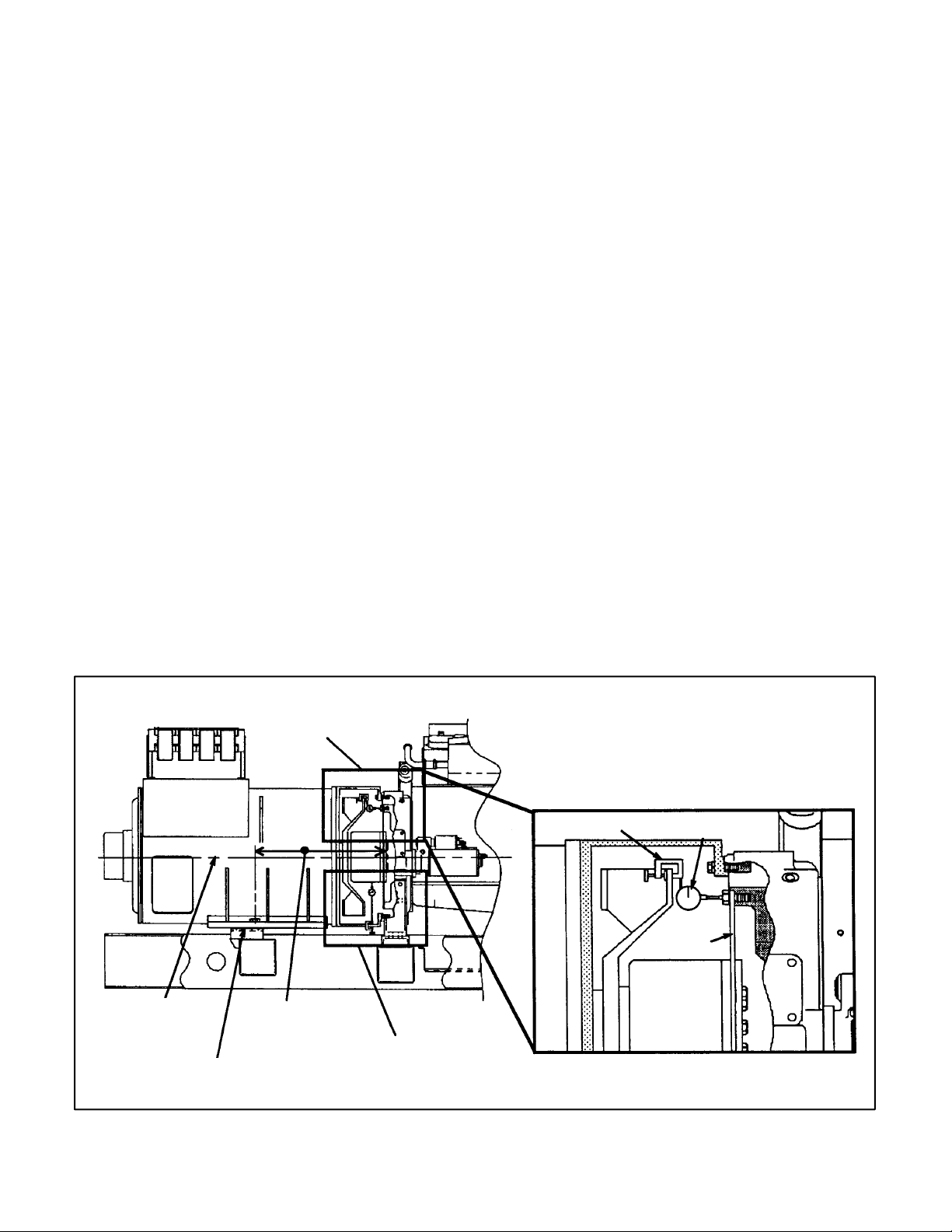

MUFFLER

Redistribution or publication of this document,

by any means, is strictly prohibited.

THIMBLE

FLEXIBLE SECTION

DC CONTROL

WIRING

CONDENSATION

DRAIN TRAP

SWEEPING

ELBOW

AC POWER

WIRING

AIR

IN

AIR OUTLET

DUCT

SHIPPING SCREW

(DFCE ONLY) EACH SIDE

VIBRATION

ISOLATORS

COOLING AIR INLET MUST BE AT LEAST 1-1/2

TIMES LARGER THAN RADIATOR DUCT OUTLET

AREA ON RADIATOR COOLED MODELS

FLOW OR COOLING AIR AND HEATED AIR CAN

BE CONTROLLED BY AUTOMATICALLY

FIGURE 3-2. TYPICAL INSTALLATION

3-3

CONCRETE

BASE

IMPORTANT!

OPERATED LOUVRES

Page 14

VIBRATION ISOLATORS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Installation and Adjustment Procedure

1. Place the vibration isolators (Figure 3-3) on the

genset support structure. The isolators should

be shimmed or grouted to ensure that all of the

isolator bases are within 0.25 inch (6 mm)

elevation of each other. The surface that the

isolator bases rest on must also be flat and level.

2. Loosen the side snubber lock nuts so that the

top plate of the isolator is free to move vertically

and horizontally. Be sure that the top plate is

correctly aligned with the base and springs.

3. Place the genset onto the isolators while aligning the skid’s mounting with the threaded isolator hole. The top plates will move down and approach the base of the isolator as load is applied.

4. Once the genset is in position, the isolators

may require adjusting so that the set is level.

The isolators are adjusted by inserting the leveling bolt through the skid and into the isolator

(the leveling bolt’s locking nut should be

threaded up towards the bolt head).

The leveling bolt will adjust the clearance between the top plate and the isolator base. A

nominal clearance of 0.25 inch (6 mm) or greater is desired. This will provide sufficient clearance for the rocking that occurs during startup

and shutdown. If the 0.25 inch (6 mm) clearance is not present, turn the leveling bolt until

the desired clearance is achieved.

5. The genset may not be level yet; therefore, adjust the leveling bolts until the set is level and

sufficient clearance still remains. (Clearance

on all isolators should be roughly equal). Once

all isolators have been set, lock the leveling bolt

in place with the lock nut.

6. The snubber nuts may remain loose and therefore provide better isolation between the genset and support structure.

7. Model DFCE only: With the genset in position

and secured to the isolators, remove the two

controller cabinet shipping screws (see Figure

3-2).

CAUTION

Remove shipping screws (two)

prior to genset operation. Genset operation

with shipping screws in place will damage

control components.

GENSET SKID

LEVELING BOLT

LOCK NUT

CLEARANCE

SNUBBER

BASE

FIGURE 3-3. VIBRATION ISOLATORS

3-4

Page 15

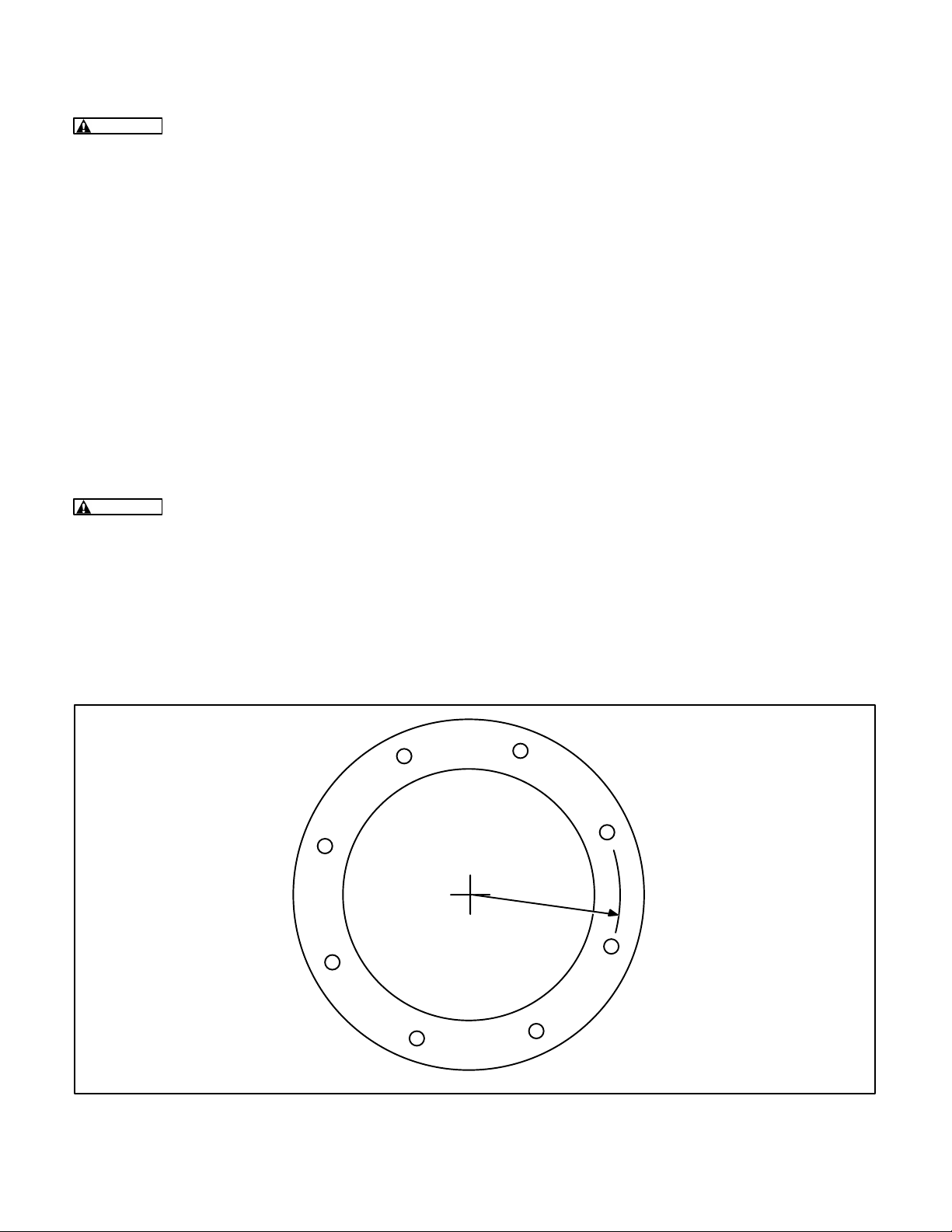

ALIGNING GENERATOR WITH ENGINE

Redistribution or publication of this document,

by any means, is strictly prohibited.

(750 kW GENSETS AND LARGER)

Proper alignment of the generator and engine assemblies is necessary to avoid premature wear and

improper operation of the genset. Review the following alignment conditions and procedures for

aligning the generator assembly to engine flywheel

housing.

Angular Misalignment

Angular misalignment is the result of the generator

bearing center axis not aligning with axis of the engine crankshaft. This condition creates an angle

between the generator shaft axis and the crankshaft axis . The cause of this type of misalignment is

usually shimming error.

Axial Misalignment

Axial misalignment is the result of the generator

shaft axis not aligning with engine crankshaft axis.

The tolerances in the bolted flywheel and drive disc

connection may add up to displace the generator

axially relative to the crankshaft axis.

Misalignment Symptoms

If the assembly is allowed to run under these conditions, the discs must flex in alternate directions

twice for each engine revolution. It is important to

minimize the amount of disc flexing since, if it is excessive, the drive disc will crack. Although perfect

bearing alignment is desirable, it is more important

to keep disc deflection to the very minimum possible. This procedure assumes that the pilot bore of

the drive discs are in the exact center and the flywheel counterbore (pilot) has no practical runout.

Under these conditions, perfect Angular alignment

will be attained when no deflection of the discs is

measured.

Excessive Axial alignment will cause more generator vibration than Angular misalignment.

Axial misalignment needs to be checked only when

an objectionable vibration is present.

Either type off misalignment may be present in a

generator set assembly , with angular misalignment

being the most common problem. Angular alignment may also be effected by set installation conditions and/or mishandling during shipping of the genset.

GENERATOR

AND ENGINE

CRANKSHAFT

CENTERLINE

SHIMS

SEE DETAIL A

CLAMP

MOUNTING BOLT

TO DISC

MEASUREMENT

FIGURE 3-4. ANGULAR ALIGNMENT MEASUREMENT

AXIAL

ALIGNMENT

DIAL INDICATOR

FLEX

DISCS

DETAIL A

3-5

Page 16

Angular Alignment Procedure

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

set during this procedure presents the hazard

of severe personal injury or death. Make sure to

disconnect the negative (-) battery cable(s) before beginning.

Accidental starting of the generator

-.015”.) The indicator is closer to the top and further

away at the bottom. This example indicates that the

generator bearing is high. Since the side readings

are equal, the generator is centered side to side. T o

lower the generator, remove equal shims from under both generator mounting feet. To approximate

the amount of shims to remove or add:

Fasten a dial indicator to either the generator shaft

or the cooling fan with the sensing point resting on

the capscrew head or the flat surface of the drive

disc at the bolt circle diameter, see Figure 3-4. Bar

the engine over in a clockwise rotation as viewed

from engine flywheel. Do not allow it to roll back on

compression at the end of the travel of each reading. It is unnecessary to zero the indicator since the

total indicator reading (T.I.R.) of the deflection measurement to the bolt heads is what is required. T.I.R.

will be the sum of the maximum positive and negative dial indicator readings as the engine completes

one revolution.

CAUTION

Do not bar engine over by prying on

fan blade. This may damage the blade and result

in premature, sudden blade failure.

Sample Generator Runout Readings: When taking

the deflection readings described, make a diagram

similar to the example shown in Figure 3-5, with a

total indicator reading of .025”. (The highest positive value of +.010” and the largest negative value of

1. Measure the distance between the center of

the generator shaft to the point the indicator is

measuring at. (For example; a SAE 18 Disc

coupling distance is 10.7”).

2. Measure the distance from the generator side

of the flex discs to the center of the generator

mounting bolt, refer to Figure 3-4. (For example; a HC6 Frame’s distance is 28.4”.)

3. Compare the distance measured in steps 1 and

2. (28.4” vs 10.7” or a 2.65 to 1 ratio.) Multiply

this ratio times one half the T.I.R. (In our example, .025” divided by 2 is .0125”. This, times

2.65 equals .033”. Therefore, remove .033” of

shims from under both mounting feet.)

In general, the T.I.R. should not be more than .001”

for each inch of radius (center of shaft to indicator

axis). If w e use our example of 10.7 inches, then the

maximum T.I.R. would be .011”. This would only require a correction of .014” from the T.I.R. of .025”. (A

reading of +.002 at the top and −.009 at the bottom

would fall within the satisfactory range.)

FIGURE 3-5. ANGULAR ALIGNMENT MEASUREMENT READINGS (EXAMPLE)

−.004

−.010

+.010

MEASURED AT

BOLT CIRCLE

DIAMETER

−.015

−.015

3-6

+.010

−.002

10.7 IN.

−.010

Page 17

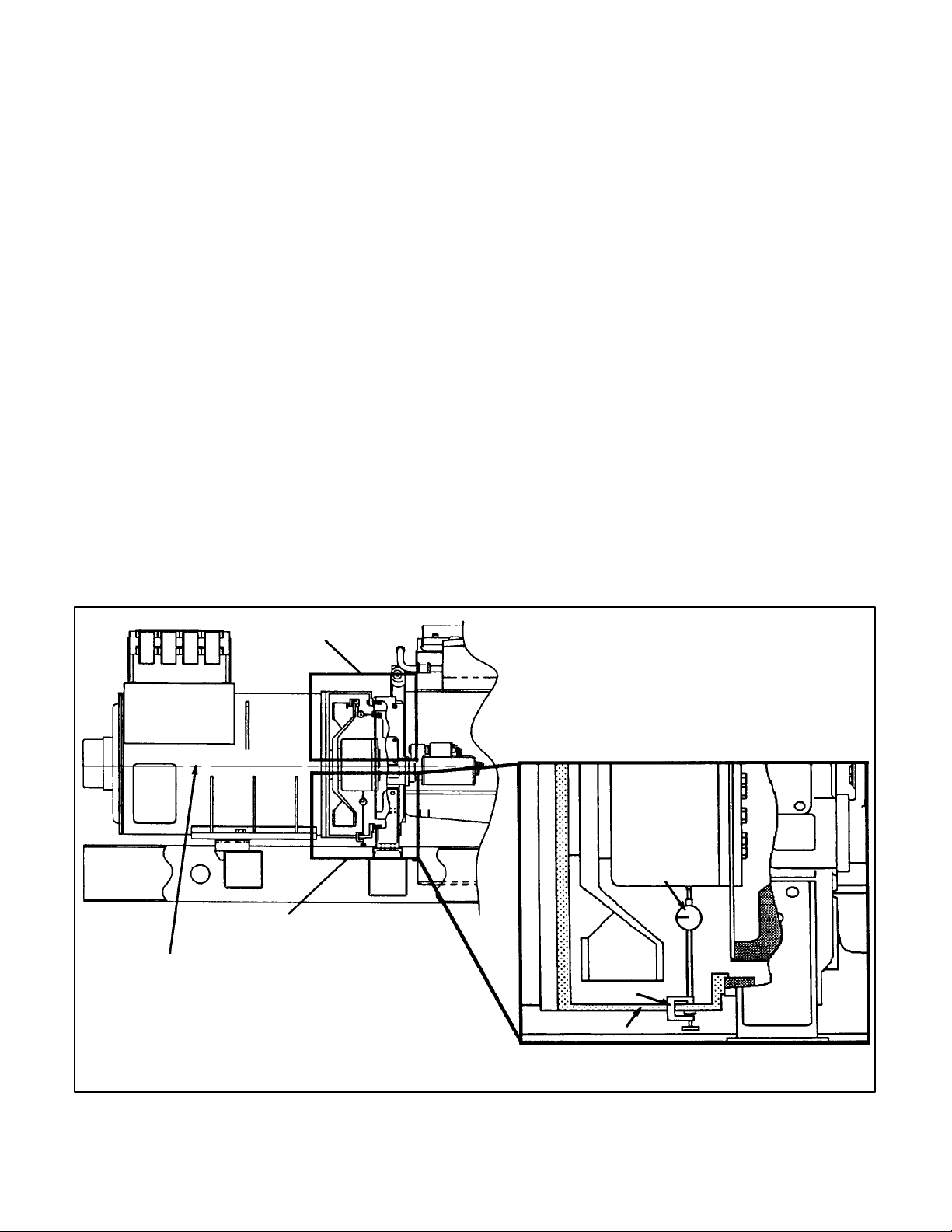

Axial Alignment Procedure

Redistribution or publication of this document,

by any means, is strictly prohibited.

Axial misalignment needs to be checked only when

an objectionable vibration is present.

If excessive vibration remains after the angular

alignment, check for concentric alignment of the

generator shaft/engine crankshaft axis.

to the varying surface quality of the generator

shaft’s drive disc mounting hub.

The goal of the Axial alignment is to reduce the

vibration level of the genset while it is operating. A

small improvement in the T.I.R. runout may have

dramatic effects in the mechanically measured or

physically observed vibration levels.

Fasten dial indicator holding device to skid base,

engine block, or generator shell with a magnetic

base or clamp and position so the sensor point of in dicator rests on the generator shaft hub, see Figure

3-6. Bar the engine over in a clockwise rotation as

viewed from engine flywheel, through a couple of

rotations. Record indicator readings in eight equally spaced points around the shaft diameter. This will

provide a T.I.R. for Axial shaft misalignment.

The maximum allowable T.I.R. runout is subjective,

the optimal T.I.R. for runout would be .000 inches,

however that may not be attainable. The recommendation of this procedure will be to reduce the

measured T.I.R. runout by one half. Specific out-oftolerance runout levels are difficult to establish due

ANGULAR ALIGNMENT

To correct for an out-of-tolerance T.I.R. indication,

remove the capscrews connecting drive discs and

flywheel. Mark the drive discs and flywheel with respect to each other. Rotate either the engine or generator so that drive discs holes are repositioned 180

degrees from their original location. Put the drive

discs capscrews back in and retorque. Recheck

shaft alignment as before. If shaft T.I.R. runout remains unchanged then discs should be rotated to

either 30, 60 or 90 degrees from original location to

correct the out-of-tolerance condition. If the T.I.R.

does not improve after repositioning, a closer inspection of the flywheel pilot and drive disc runouts

is required. This will help determine the cause of the

Axial misalignment.

SEE DETAIL A

GENERATOR

AND ENGINE

CRANKSHAFT

CENTERLINE

GENERATOR

SHAFT

HUB

DIAL

INDICATOR

CLAMP

FAN HOUSING

DETAIL A

FIGURE 3-6. AXIAL ALIGNMENT MEASUREMENT

3-7

Page 18

THIS PAGE LEFT INTENTIONALLY BLANK

Redistribution or publication of this document,

by any means, is strictly prohibited.

3-8

Page 19

4. Mechanical Connections

Redistribution or publication of this document,

by any means, is strictly prohibited.

GENERAL

The generator set mechanical system installation

includes connecting the fuel, exhaust, ventilation

and cooling systems. Before starting any type of

fuel installation, all pertinent state and local codes

must be complied with and the installation must be

inspected before the unit is put in service.

FUEL SYSTEM

Cummins engines normally use ASTM No. 2 diesel

fuel. They will, however , operate on alternate diesel

fuels within the specifications shown in the Cummins engine

In all fuel system installations, cleanliness is of the

upmost importance. Make every effort to prevent

entrance of moisture, dirt or contaminants of any

kind into the fuel system. Clean all fuel system components before installing.

A fuel filter/strainer/water separator of 100-120 mesh

or equivalent (approximately 150 microns nominal)

must be fitted between either the main tank and day

tank or between the main tank and the engine.

Use only compatible metal fuel lines to avoid electrolysis when fuel lines must be buried. Buried fuel

lines must be protected from corrosion.

Operation and Maintenance Manual.

CAUTION

Never use galvanized or copper fuel

lines, fittings or fuel tanks. Condensation in the

tank and lines combines with the sulfur in diesel

fuel to produce sulfuric acid. The molecular

structure of the copper or galvanized lines or

tanks reacts with the acid and contaminates the

fuel.

An electric solenoid valve in the supply line is recommended for all installations and required for indoor automatic or remote starting installations.

Connect the solenoid wires to the genset “Switched

B+” circuit to open the valve during generator set

operation.

Separate fuel return lines to the day tank or supply

tank must be provided for each generator set in a

multiple-set installation to prevent the return lines of

idle sets from being pressurized. Fuel return lines

must not contain a shutoff device. Engine damage

will occur if the engine is run with the return fuel lines

blocked or restricted.

CAUTION

Never install shutoff device in fuel

return line(s). If fuel return line(s) is blocked or

exceeds fuel restriction limit, engine damage

will occur.

Fuel Return Restriction (or Pressure) Limit: Fuel

return drain restriction (consisting of friction head

and static head) between the engine injector return

line connection and the fuel tank must not exceed

the limit stated in the

Specification

section.

4-1

Page 20

Fuel Lines − Routing

Redistribution or publication of this document,

by any means, is strictly prohibited.

A flexible fuel hose(s) or section of flexible fuel

hose(s) must be used between the engine’s fuel

system and fuel supply and return line(s) to protect

the fuel system from damage caused by vibration,

expansion and contraction. Flexible lines for connecting between the engine and the stationary fuel

lines are supplied as standard equipment.

Installation of the fuel hose must be done according

to all applicable codes and standards, and installation recommendations provided by the manufacturer. The supplied flexible hose is approved by the

hose manufacture for use with the genset fuel type

and product application.

Support fuel lines to restrain movement and prevent

chaffing or contact with sharp edges, electrical wiring and hot exhaust parts.

WARNING

Sparks and hot surfaces can ignite

fuel, leading to severe personal injury or death.

Do not route fuel lines near electrical wiring or

hot exhaust parts.

Fuel lines must be routed and secured to maintain a

1/2 inch (12.7 mm) minimum clearance from electrical wiring and a 2 inch (51 mm) minimum clearance

from hot exhaust parts.

Engine Fuel Connections

Identification tags are attached to the fuel supply

line and fuel return line connections.

Supply Tank

Locate the f uel tank as close as possible to the generator set and within the restriction limitations of the

fuel pump.

Install a fuel tank that has sufficient capacity to supply the genset operating continuously at full rated

load for the planned period of operation or power

outage. Refer to

Data Sheet

for fuel consumption

data.

WARNING

Fuel leaks create fire and explosion

hazards which can result in severe personal injury or death. Always use flexible tubing between engine and fuel supply and return to

avoid line failure and leaks due to vibration. The

fuel system must meet applicable codes.

If the fuel inlet restriction exceeds the defined limit

due to the distance/customer-supplied plumbing

between the genset and the main fuel tank, a transfer tank (referred to as a day tank) and auxiliary

pump will also be required. If an overhead main fuel

tank is installed, a transfer tank and float valve will

be required to prevent fuel head pressures from being placed on the fuel system components.

For critical start applications, where generator sets

are paralleled or must satisfy emergency start-time

requirements, it is recommended that a fuel tank or

reservoir be located such that the lowest possible

fuel level is not less than 6 inches (150 mm) above

the fuel pump inlet. This will prevent air from accumulating in the fuel line while the set is in standby,

eliminating the period during startup when it has to

be purged.

Fuel Inlet Pressure/Restriction Limit:: Engine

performance and fuel system durability will be compromised if the fuel inlet pressure or restriction limits

are not adhered to. Fuel inlet pressure or restriction

must not exceed the limits stated in the

tion

section.

Specifica-

4-2

Page 21

Day Tank (If Used)

Redistribution or publication of this document,

by any means, is strictly prohibited.

Fuel day tanks are used when fuel inlet restriction

limits can not be met, or the supply tank is overhead

and presents problems of high fuel head pressure

for the fuel inlet and return lines.

Supply T ank Lower Than Engine:

lation, the day tank is installed near the generator

set, below the fuel injection system and within the

fuel inlet restriction limit. Install an auxiliary fuel

pump, to pump fuel from the supply tank to the day

tank. A float switch in the day tank controls operation of the auxiliary fuel pump.

The supply tank top must be below the day tank top

to prevent siphoning from the fuel supply to the day

tank.

Provide a return line from the engine injection system return connection to the day tank. Plumb the re-

With this instal-

turn line to the bottom of day tank as shown in Figure 4-1. Provide a day tank overflow line to the supply tank in case the float switch fails to shut off the

fuel transfer pump. Also, the overflow line should be

one pipe diameter larger than the supply line.

WARNING

Spilled fuel presents the hazard of

fire or explosion which can result in severe personal injury or death. Provide an overflow line

to the supply tank from the day tank.

Supply Tank Higher Than Engine:

Install the day

tank near the generator set, but below the fuel injection system. Use fuel line at least as large as the fuel

pump inlet. The engine fuel return line must enter

the day tank.

Include a shutoff valve in the fuel line between the

fuel supply tank and the day tank to stop fuel flow

when the generator set is off.

WARNING

Spilled fuel can create environmental hazards. Check local requirements for containment

and prevention of draining to sewer and ground water.

ENGINE

FUEL

PUMP

DAY TANK

FUEL TRANSFER

PUMP ELECTRIC

MOTOR DRIVEN

VENTED

FILL CAP

SHUTOFF

VALVE

1 INCH

BAFFLE

FLOAT

SWITCH

INJECTOR FUEL

RETURN LINE

CONNECT TO

AC OUTPUT

SUPPLY

LINE

All models require a fuel return

line from injectors to tank.

VENT LINE

FILL PIPE

120 MESH FUEL

STRAINER

LARGER OVER-

FLOW LINE

FIGURE 4-1. TYPICAL FUEL SUPPLY INSTALLATION

FUEL TANK

4-3

Page 22

EXHAUST SYSTEM

Redistribution or publication of this document,

by any means, is strictly prohibited.

Pipe exhaust gases to the outside of any enclosure.

Locate the exhaust outlets away from any air inlets

to avoid gases re-entering the enclosure. Exhaust

installations are subject to various detrimental conditions such as extreme heat, infrequent operation

and light loads. Regularly inspect the exhaust system both visually and audibly to see that the entire

system remains fume tight and safe for operation.

WARNING

sult in severe personal injury or death. Use extreme care during installation to provide a tight

exhaust system. Terminate exhaust pipe away

from enclosed or sheltered areas, windows,

doors and vents.

For indoor installation, the exhaust system must

use sealed joint type fittings, (for example NPT fittings) to provide a tighter exhaust system. Use of

slip type fittings (secured with a muffler clamp) may

allow leakage of exhaust gases into the building.

WARNING

sult in severe personal injury or death. Use extreme care during installation to provide a tight

exhaust system. Use NPT or equivalent type fittings for all indoor installations.

Use an approved thimble (Figure 4-2) where exhaust pipes pass through wall or partitions. Insulated wall/roof thimbles are used where exhaust

pipes pass through a combustible roof or wall. This

includes structures, such as wood framing or insulated steel decking, etc. Uninsulated wall/roof

thimbles are used where exhaust pipes pass

through a non-combustible wall or roof, such as

concrete. Refer to NFPA 37, Section 6-3. “Stationary Combustion Engines and Gas Turbines” for ac-

Inhalation of exhaust gases can re-

Inhalation of exhaust gases can re-

cepted design practices. Build according to the

code requirements in effect at the installation site.

WARNING

Hot exhaust pipes can start a fire

and cause severe injury or death if improperly

routed through walls. Use an approved thimble

where exhaust pipes pass through walls or

partitions.

WARNING

Inhalation of exhaust gases can result in severe personal injury or death. Do not

use exhaust heat to warm a room, compartment

or storage area.

Rain caps are available for the discharge end of vertical exhaust pipes. The rain cap clamps onto the

end of the pipe and opens due to exhaust discharge

force from the generator set. When the generator

set is stopped, the rain cap automatically closes,

protecting the exhaust system from rain, snow, etc.

Use a section of flexible exhaust pipe between the

engine and remainder of exhaust system. Support

exhaust system to prevent weight from being applied to engine exhaust outlet elbow/turbocharger

connection.

CAUTION

Weight applied to the engine manifold can result in turbocharger damage. Support the muffler and exhaust piping so no

weight or stress is applied to engine exhaust el bow.

The exhaust system design should meet local code

requirements.

Liability for injury, death, damage, and warranty expense due to use of unapproved mufflers or modifications becomes the responsibility of the person

installing the unapproved muffler or performing the

modification. Contact a Cummins Power Generation

distributor for approved exhaust system parts.

4-4

Page 23

Avoid sharp bends by using sweeping, long radius

Redistribution or publication of this document,

by any means, is strictly prohibited.

elbows and provide adequate support for muffler

and tailpipe. Pitch a horizontal run of exhaust pipe

DOWNWARD (away from engine) to allow any

moisture condensation to drain away from the engine. If an exhaust pipe must be turned upward,

install a condensation trap at the point where the

rise begins (Figure 4-3).

Shield or insulate exhaust lines if there is danger of

personal contact. Allow at least 12 inches (305 mm)

of clearance if the pipes pass close to a combustible

wall or partition. Before installing insulation on exhaust system components, check the exhaust system for leaks while operating the genset under full

load and correct all leaks.

RAIN CAP

9 INCH

(230 mm)

VERTICAL

DRIP CAP

HOLES IN

END OF INNER

SLEEVE

ROOF

9 INCH

(230 mm)

WARNING

Exhaust pipes are very hot and they

can cause severe personal injury or death from

direct contact or from fire hazard. Shield or insulate exhaust pipes if there is danger of personal contact or when routed through walls or

near other combustible materials.

HORIZONTAL

WALL OR PARTITION

FIGURE 4-2. MOUNTING EXHAUST THIMBLE

IF EXHAUST LINE MUST BE

PITCHED UPWARD, CONSTRUCT

A TRAP AT POINT OF RISE

AVOID

SHARP

BENDS

DRAIN CONDENSATION

TRAP PERIODICALLY

FIGURE 4-3. CONDENSATION TRAP

4-5

Page 24

VENTILATION AND COOLING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Generator sets dissipate heat and fumes that must

be removed by proper cooling and ventilation.

Generator sets in factory-mounted housings for

outdoor installation are designed for proper cooling

and ventilation.

Indoor installations require careful design with respect to cooling and ventilation. In an indoor installation, all radiator cooling air must be discharged to

the out-of-doors. Duct adapter kits are available.

See Figure 4-5 for a typical indoor installation.

PREVAILING WINDS PREVAILING WINDS

WARNING

Engine or radiator cooling air may

carry deadly carbon monoxide gas which can

cause asphyxiation and death. All engine or radiator cooling air must be discharged to the outof-doors. Do not use it for heating a room or

compartment.

Vents and Ducts

For indoor installations, locate vents so incoming air

passes through the immediate area of the installation before exhausting. Install the air outlet higher

than the air inlet to allow for convection air movement.

Size the vents and ducts so they are large enough to

allow the required flow rate of air . The ”free area” of

ducts must be as large as the exposed area of the

radiator. Refer to the genset

flow requirements and allowed airflow restriction.

Wind will restrict free airflow if it blows directly into

the air outlet vent. Locate the outlet vent so the effects of wind are eliminated. See Figure 4-4.

Data Sheet

for the air-

FIGURE 4-4. WIND BARRIER

4-6

Page 25

Dampers

Redistribution or publication of this document,

by any means, is strictly prohibited.

Dampers or louvres protect the genset and equipment room from the outside environment. Their operation of opening and closing should be controlled

by operation of the genset.

In cooler climates movable or discharge dampers

are used. These dampers allow the air to be recirculated back to the equipment room. This enables the

equipment room to be heated while the genset engine is still cold, increasing the engine efficiency.

Radiator Set Requirements

Radiator set cooling air is drawn past the control

end of the set by a pusher fan that blows air through

the radiator (Figure 4-5). Locate the air inlet to the

rear of the set. Make the inlet vent opening 1-1/2 to 2

times larger than the radiator area.

Louvers and screens over air inlet and outlet openings restrict air flow and vary widely in performance.

A louver assembly with narrow vanes, for example,

tends to be more restrictive than one with wide

vanes. The effective open area specified by the louver or screen manufacturer should be used.

Locate the cooling air outlet directly in front of the radiator and as close as possible. The outlet opening

must be at least as large as the radiator area.

Length and shape of the air outlet duct should offer

minimum restriction to airflow.

Attach a canvas or sheet metal duct to the flange

and the air outlet opening using screws and nuts so

duct can be removed for maintenance purposes.

The duct prevents circulation of heated air. Before

installing the duct, remove the radiator core guard.

Standard Radiator Cooling uses a set mounted

radiator and engine pusher fan to cool engine water

jacket. Air travels from the generator end of the set,

across the engine and out through the radiator. An

integral discharge duct adapter flange surrounds

the radiator grille.]

INLET AIR

DAMPER

COOL AIR

* Louvers should close when room

ambient is above 60

° F (16° C)

FIGURE 4-5. TYPICAL RADIATOR SET INSTALLATION

THERMOSTATIC AIR RE-

CIRCULATING DAMPER

*

RADIATOR FLEXIBLE DUCT

CONNECTOR

WIND/NOISE

BARRIER

HOT AIR

D

DISTANCE SHOULD NOT

BE LESS THAN HEIGHT

OF RADIATOR

4-7

Page 26

Remote Radiator Cooling (Optional) substitutes

Redistribution or publication of this document,

by any means, is strictly prohibited.

a remote mounted radiator and an electrically driven fan in place of mounted components. Removal

of the radiator and the fan from the set reduces

noise levels without forcing dependence on a continuous cooling water supply (necessary with heat

exchanger cooling). The remote radiator installation must be completely protected against freezing.

Remote radiator plumbing will vary with installation.

Follow recommendations given in Application

Manual T-030. See product

Data Sheet

for friction

head and static head limits.

Before filling cooling system, check all hardware for

security. This includes hose clamps, capscrews, fittings and connections. Use flexible coolant lines

with heat exchanger or remote mounted radiator.

Engine Coolant Heater (Optional)

An optional coolant heater is available to keep the

engine warm for improved starting and code compliance. Connect the heater to a power source that

will be energized when the engine is NOT running.

Heat Exchanger (Optional)

The optional heat exchanger (Figure 4-6) uses a

shell and tube type heat exchanger instead of the

standard radiator and fan. Engine jacket coolant circulates through the shell side of the heat exchanger

while the cooling water is pumped through the

tubes. Engine coolant and raw water do not mix.

This system may reduce set enclosure airflow requirements and noise levels. Proper operation depends on a constant supply of raw water for heat removal. Adjust the flow to maintain engine coolant

temperature between165

° C) while viewing the water temperature gauge.

91

The engine coolant side of the system can be protected from freezing; the raw water side cannot be

protected.

° F and 195° F (74° C and

COOL AIR

WATER

SOLENOID

VALVE

VENTILATING

FAN

WARM

AIR

FLEXIBLE WA-

TER

CONNECTIONS

MOUNTED HEAT

EXCHANGER

RAW WATER

SUPPLY

RAW WATER

DISCHARGE

FIGURE 4-6. TYPICAL HEAT EXCHANGER INSTALLATION

4-8

Page 27

5. DC Control Wiring

Redistribution or publication of this document,

by any means, is strictly prohibited.

CONTROL WIRING

The generator set control panel box contains connection points for remote control and monitor options.

CAUTION

for all customer connections to the control panel. Solid copper wire may break due to genset

vibration.

Use flexible conduit for all wiring connections to the

generator set. All conduit used for control wiring is

attached to the control housing.

Stranded copper wire must be used

NETWORK COMMUNICATION

MODULE

Route the control wiring through the control housing

and into the access holes on the bottom of the control panel box. Figure 5-1 also shows the access

holes that should be used according to where the

wires are terminated inside the control box.

A compression type strain-relief connector should

be used to prevent dust, insects, etc. from entering

control box.

Use cable ties to keep control wiring away from

sharp edg e s a n d A C power cables within the control

housing.

CONTROL RELAYS

(K10, K1 1, K12) &

CONTROL BOX

HEATER

FIGURE 5-1. SUGGESTED CUSTOMER WIRE ROUTING

TB2

5-1

TB1

STRAIN-RELIEF

CONNECTOR

Page 28

TB1 REMOTE MONITOR/CONTROL

Redistribution or publication of this document,

by any means, is strictly prohibited.

CONNECTIONS

Customer monitor/control connections are attached to terminal block TB1 (Figure 5-2). Optional

equipment such as a remote annunciator panel,

sensing devices used to monitor genset operation,

remote start/stop switches, battery charger, etc. ar e

attached to TB1. Refer to Customer Connections

diagram in Section 9.

TB1 Wiring

CAUTION

a separate metal conduit from AC power cables

to avoid inducing currents that could cause

problems within the control.

Always run control circuit wiring in

Relay Connections: Due to the wide variety of de-

vices that can be attached to the relay outputs of

TB1, the electrical contractor must determine the

gauge of the stranded copper wire that is used at

this installation site. Refer to PCC Customer Connections diagram in Section 9 for the relay specifications.

Network Connections: Refer to 900-0366

Power-

Command Network Installation and Operation

manual for the type/gauge wire to use for these connections.

Switched B+: (Fused at 5 amps.) Same as Relay

Connection description.

B+: (Fused at 10 amps.) Same as Relay Connection description.

Digital Connections: Connection points, other

than relayed outputs, network, switched B+ and B+

are considered digital connections to terminal strip

TB1. The type/gauge wire to use for these connections are:

• Less than 1000 feet (305m), use 20 gauge

stranded copper wire.

• 1000 to 2000 feet (305 to 610m), use 18 gauge

stranded copper wire.

TB2 POWER TRANSFER CONTROL (PTC)

CONNECTIONS (OPTIONAL)

TB2 is used to connect the optional PTC module to

the control. With this option installed, the control will

monitor the utility voltage (mains) and frequency for

failure. If power fails, the PTC control will start the

generator, open the mains circuit breakers and

close the generator circuit breakers. Refer to Customer Connections diagram in Section 9 and installation instructions sent with the PTC Module Kit.

5-2

Page 29

BASE

Redistribution or publication of this document,

by any means, is strictly prohibited.

BOARD

VOLTAGE

SUPPRESSOR

TB2

TERMINAL

END BRACKET

CONTROL

RELAYS

TB1

MACHINE

FIGURE 5-2. CONTROL PANEL BOX

SCREW

TERMINAL

DIN RAIL

TERMINAL

END BRACKET

5-3

Page 30

CONTROL RELAYS (K11, K12, K13)

Redistribution or publication of this document,

by any means, is strictly prohibited.

4-pole relay with 2 poles normally open and two

poles normally closed.

CAUTION

Damage to the Base board can occur if the voltage suppressors (Figures 5-2 and

5-3) are not installed accross relay coils (A1/A2)

of control relays K11, K12 and K13 before connecting genset battery cables.

The three optional control relays are rail mounted

inside the control panel housing. Each relay is a

VOLTAGE

SUPPRESSOR

These relays (Figure 5-3) are used to control auxiliary equipment, such as fans, pumps and motorized

air dampers. Energizing of the relays is user definable.

The contacts are rated at 10 amps at 600 VAC.

Refer to Customer Connections diagram in Sec-

tion 9.

20 AWG Wire, UL Rated for 600 VAC

FIGURE 5-3. OPTIONAL CONTROL RELAYS (K10, K11, K12)

5-4

Page 31

6. AC Electrical Connections

Redistribution or publication of this document,

by any means, is strictly prohibited.

GENERAL

This section provides the procedure that is used to

connect the AC electrical system of the genset.

Before making any AC electrical connections, make

certain the generator set cannot be accidentally

started. Place the control panel run switch in the

OFF position. Turn off or remove AC power from the

battery charger and then remove the negative (−)

battery cable from the set starting battery.

WARNING

can cause severe personal injury or death. Arcing at battery terminals, light switch or other

equipment, flame, pilot lights and sparks can ignite battery gas. Do not smoke, or switch

trouble light ON or OFF near battery. Discharge

static electricity from body before touching batteries by first touching a grounded metal surface.

Ventilate battery area before working on or near

battery—Wear goggles—Stop genset and disconnect charger before disconnecting battery

cables—Disconnect negative (−) cable first and

reconnect last.

CAUTION

source before disconnecting battery cables.

Otherwise, disconnecting cables can result in

voltage spikes damaging to DC control circuits

of the set.

WARNING

set can cause severe personal injury or death.

Prevent accidental starting by disconnecting

the negative (−) cable from the battery terminal.

Ignition of explosive battery gases

Disconnect battery charger from AC

Accidental starting of the generator

Connecting the genset AC electrical system involves:

• Generator insulation check

• Installation of transfer switch

• Generator output voltage selection

• Load cable connection

• Standard and optional AC equipment connec-

tions (e.g., control box heater, coolant heater,

etc.

• Optional enclosure electrical connections (re-

fer to

Section 7

Local regulations often require that wiring connections be made by a licensed electrician, and that the

installation be inspected and approved before operation. All connections, wire sizes, materials used,

etc. must conform to the requirements of electrical

codes in effect at the installation site.

WARNING

Improper wiring can cause a fire or

electrocution, resulting in severe personal injury or death and/or property and equipment damage.

Before starting the genset, check to make sure that

all electrical connections are secure, and that all

wiring is complete. Replace and secure any access

panels that have been removed during installation.

Check that the load cables from the genset are

properly connected.

).

WARNING

Each of the operations described in

this section should be done only by persons

trained and experienced in electrical maintenance. Improper procedures may result in property damage, bodily injury or death.

WARNING

Backfeed to utility system can

cause electrocution or property damage. Do

not connect to any building electrical system

except through an approved device and after

building main switch is opened.

6-1

Page 32

TRANSFER SWITCH

Redistribution or publication of this document,

by any means, is strictly prohibited.

If the installation is for standby service, a transfer

switch must be used for switching the load from the

normal power source to the genset (see Figure 6-1).

Follow the installation instructions provided with the

transfer switch when connecting the load and control wiring.

LOAD

NORMAL

SOURCE

FIGURE 6-1. TYPICAL LOAD TRANSFER

FUNCTION

GENSET

6-2

Page 33

AC WIRING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Generator Voltage Connections

The available generator output voltages and maximum current ratings are specified on the generator

set nameplate. Line-to-neutral voltage is always the

lower voltage shown and line-to-line voltage is the

higher rating.

All loads are connected to the generator by bolting

stranded load wires to the appropriate terminals on

the generator reconnection terminal block or circuit

breaker lugs. The terminals are stamped U, V, W

and N to indicate the line and neutral connections.

(Reference: U, V, and W correspond with L1, L2 and

L3; and N with L0 respectively).

Load Balancing

These generators can be configured to the nameplate voltages as shown on the Reconnection Diagram located on the side access cover of the control

housing. Many of the voltages listed will require reconfiguration of the generator output leads on the

connection terminal block. This reconfiguration

must only be done by service personnel that are

trained and experienced to perform electrical installation. The generator set was adjusted to produce a

specified voltage during production verification testing prior to shipment. The installer must always

check the stator lead terminal block connections

and perform any necessary reconnect to obtain the

voltage required.

Some generator sets are capable of producing a

wide range of voltages and connection configurations, others have specific limited capabilities. Refer to wiring diagram and generator voltages (from

the nameplate) when reviewing the voltage connection information and use the wiring diagram supplied with your generator set when actually performing load connections.

CAUTION

Reconfiguring generator sets to

higher voltages can exceed the voltage capability of the specific generator windings and damage the generator and also decrease line current, rendering line circuit breakers too large.

Consult with your distributor before performing

reconnection for a different voltage.

CAUTION

Reconfiguring generator sets to

lower voltages can reduce generator set ratings, and also increase line current, rendering

line circuit breakers too small. Consult with

your distributor before performing reconnection for a different voltage.

Load Connections

Flexible conduit and stranded conductors must be

used for connections to take up movement of the

generator set.

When connecting loads to the generator set, balance the loads so the current flow from each line terminal (L1, L2 and L3) is about the same. This is especially important if both single phase and three

phase loads are connected. Any combination of

single phase and three phase loading can be used

as long as each line current is about the same, within 10 percent of median value and no line current exceeds the nameplate rating of the generator . Check

the current flow from each line after connections by

observing the control panel ammeter.

Current Transformers

Current transformers (CT’s) are required on gensets that contain AC meters. The CT’s must be

installed as noted in the following CT Installation

Requirements.

Refer to the Reconnection Diagram to identify the

output leads/phase that must be routed through

each CT, and also appropriate transformer post

selection for meter sensing leads. The transformers

are labeled CT1, CT2 and CT3 on the reconnection

wiring diagram. (The Reconnection Diagram is located on the upper side cover of the control housing.)

CT Installation Requirements:

A. The CT has a dot on one side. This dot must be

facing toward the generator (conventional current flowing into the dot). A dot is also used to

indicate pin 1 of the CT.

B. CT1 − U load leads (A phase),

CT2 − V load leads (B phase)

CT3 − W load leads (C phase)

C. Route the appropriate load wires through each

CT.

D. The CT’s have dual secondaries (3 pins). The

CT secondary wire marked 1 is connected to

pin 1 of the CT. CT secondary wire marked 2/3

is connected to pin 2 for high voltage gensets or

to pin 3 for low voltage gensets. (Refer to Reconnection Diagram.)

6-3

Page 34

Grounding

Redistribution or publication of this document,

by any means, is strictly prohibited.

The following is a brief description of system and

equipment grounding of permanently installed AC

generators within a facility wiring system. It is important to follow the requirements of the local electrical

code.

Figure 6-2 illustrates typical system grounding for a

3-pole and a 4-pole automatic transfer switch

(ATS). In the 3-pole ATS, note that the generator

neutral is connected to the ATS and is NOT bonded

to ground at the generator. In the 4-pole ATS system, a grounding electrode conductor and a bonding jumper are used to connect the generator neutral to ground.

Make sure the genset is grounded to earth in one

location only. On generators without a circuit breaker, ground to the point indicated on the top of the

generator. O n gensets with circuit breakers, use the

ground lug provided in the circuit breaker box.

WARNING

Electric current can cause severe

personal injury or death. Bonding and grounding must be done properly. All metallic parts

that could become energized under abnormal

conditions must be properly grounded.

Typical requirements for bonding and grounding

are given in the National Electrical Code, Article

250. All connections, wire sizes, etc. must conform

to the requirements of the electrical codes in effect

at the installation site.

SERVICE ENTRANCE

THREE-PHASE, FOUR-WIRE UTILITY, THREE-POLE ATS

SERVICE ENTRANCE

GENERATOR SET

3-POLE ATS

LOAD

GENERATOR SET

4-POLE ATS

FIGURE 6-2. TYPICAL SYSTEM GROUNDING ONE-LINE DIAGRAMS

LOAD

THREE-PHASE, FOUR-WIRE UTILITY, FOUR-POLE ATS

6-4

Page 35

CONTROL HEATER (OPTIONAL)

Redistribution or publication of this document,

by any means, is strictly prohibited.

A control heater (Figure 6-3) provides a means of

humidity/temperature control of the control box inte-

rior. I t protects the components when the generator

set is subjected to varying ambient air conditions

during extended periods of non-use.

THERMOSTAT

HEATER

240V PLUG

FIGURE 6-3. OPTIONAL CONTROL HEATER

120V PLUG

6-5

Page 36

COOLANT HEATER

Redistribution or publication of this document,

by any means, is strictly prohibited.

The coolant heater keeps engine coolant warm

when the engine is shut down. It heats and circulates the coolant within the engine. This reduces

startup time and lessens engine wear caused by

cold starts. It is electrically operated and thermostatically controlled.

CAUTION

erated while the cooling system is empty or

damage to the heater will occur.

Figure 6-4 shows a typical coolant heater. Connect

the heater to a source of power that will be on during

The coolant heater must not be op-

the time the engine is not running. Be sure the supply voltage and circuit amperage is correct for the

heater element rating.

A battery charger is required to prevent battery discharge. The heater control relay draws 83 mA of current when the heater(s) is off. The heater is off when

the engine has reached the proper temperature or

the engine is running.

CAUTION

Do not connect AC power to the

heater before connecting battery cables. Heater

will run continuously without DC power and

can overheat and damage heater.

THERMOSTAT

COOLANT

FLOW

AC ELECTRICAL CONNECTION

BOX (ELECTRICAL DIAGRAM

INSIDE COVER)

DC SUPPLY

LINE

COOLANT

FLOW

DC CONTROL

LINE

DRAIN

AC POWER

LINE

FIGURE 6-4. TYPICAL COOLANT HEATER

6-6

Page 37

GENERATOR HEATER

Redistribution or publication of this document,

by any means, is strictly prohibited.

A generator heater(s) is used to help keep the generator free of condensation when the generator set

is not running. During cool and humid conditions,

condensation can form within a generator, creating

flashing and a shock hazard.

WARNING

tor increases the possibility of flashing and

electrical shock, which can cause equipment

damage and severe personal injury or death. Do

not use a generator which is not dry inside and

out.

Water or moisture inside a genera-

HEATER LEADS

Figure 6-5 illustrates the installation of two heater

elements. Connect the heater(s) terminals to a

source of power that will be on during the time the

engine is not running. Be sure the supply voltage

and circuit amperage is correct for the heater element rating.

HEATER

HEATER LEADS

HEATERS

TERMINAL BOX

HEATER

VOLT/WATTS

LABEL

TERMINAL

BLOCK

FIGURE 6-5. TYPICAL GENERATOR HEATER INSTALLATION

6-7

Page 38

FUEL TRANSFER PUMP

Redistribution or publication of this document,

by any means, is strictly prohibited.

A fuel transfer pump and control are available when

a sub-base or in-skid day tank are provided. The automatic control operates the fuel pump to maintain a

reservoir of fuel in the day tank.

WARNING

Diesel fuel is highly combustible.

Improper installation of this kit can lead to spillage of large quantities of fuel and loss of life and

property if the fuel is accidentally ignited. Installation and service must be performed by trained

and experienced persons in accordance with

the applicable codes.

Do not smoke near fuel and keep flames,

sparks, pilot lights, arcing switches and equipment, and other sources of ignition well away.

CONTROL

FLEXIBLE FUEL

RETURN LINE

FLEXIBLE FUEL

SUPPLY LINE

FUEL PUMP

AND MOTOR

FLOAT SWITCH

ASSEMBLY

DAY

TANK

FUEL

GAUGE

FIGURE 6-6. TYPICAL IN-SKID DAY TANK INSTALLATION

6-8

FUEL FILL

CAP

Page 39

Fuel Pump Control AC Connections

Redistribution or publication of this document,

by any means, is strictly prohibited.

The control can be powered by 120 VAC or 240

VAC. The control is set up at the factory for connection to 240 VAC.

1. To convert the day tank controller from 240