CUMMINS Detector DFBF Series, Detector DFCB Series, Detector DFCC Series, Detector 275 DFBF, Detector 350 DFCC Installation Manual

...Page 1

Installation Manual

Detector Control

Generator Sets

Printed in U.S.A.

Models

DFBF, DFCB, DFCC

960-0606 1-2003

Page 2

Table of Contents

SECTION TITLE PAGE

1 INTRODUCTION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About this Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 SPECIFICATIONS 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 MOUNTING THE GENERATOR SET 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Access to Set 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration Isolators 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 MECHANICAL CONNECTIONS 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation and Cooling 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 ELECTRICAL CONNECTIONS 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Switch 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Wiring 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Wiring 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 PRESTART PREPARATION 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Checks 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical System 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coolant 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 INITIAL START AND CHECKS 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Gauges 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Meters 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Monitor Indicator Lamps 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Electrical System 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling System 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Adjustments 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 WIRING DIAGRAMS 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 3

ii

Page 4

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Before operating the generator set (genset), read the

Operator’s Manual and become familiar with it and the

equipment. Safe and efficient operation can be

achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure

to follow fundamental rules and precautions.

The following symbols, found throughout this manual,

alert you to potentially dangerous conditions to the operator, service personnel, or the equipment.

This symbol warns of immediate

hazards which will result in severe personal injury or death.

WARNING

This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe practice which can result in personal injury

or product or property damage.

FUEL AND FUMES ARE FLAMMABLE

Fire, explosion, and personal injury or death can result

from improper practices.

• DO NOT fill fuel tanks while engine is running, un-

less tanks are outside the engine compartment.

Fuel contact with hot engine or exhaust is a potential

fire hazard.

• DO NOT permit any flame, cigarette, pilot light,

spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of

leaks. Fuel connection at the engine should be

made with an approved flexible line. Do not use zinc

coated or copper fuel lines with diesel fuel.

• Be sure all fuel supplies have a positive shutoff

valve.

• Be sure battery area has been well-ventilated prior

to servicing near it. Lead-acid batteries emit a highly

explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

EXHAUST GASES ARE DEADLY

Provide an adequate exhaust system to properly

•

expel discharged gases away from enclosed or

sheltered areas and areas where individuals are

likely to congregate. Visually and audibly inspect

the exhaust daily for leaks per the maintenance

schedule. Make sure that exhaust manifolds are secured and not warped. Do not use exhaust gases to

heat a compartment.

• Be sure the unit is well ventilated.

• Engine exhaust and some of its constituents are

known to the state of California to cause cancer,

birth defects, and other reproductive harm.

MOVING PARTS CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

•

Keep your hands, clothing, and jewelry away from

moving parts.

• Before starting work on the generator set, discon-

nect battery charger from its AC source, then disconnect starting batteries, negative (–) cable first.

This will prevent accidental starting.

• Make sure that fasteners on the generator set are

secure. Tighten supports and clamps, keep guards

in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of

moving parts, or while working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If adjustment must be made while the unit is run-

ning, use extreme caution around hot manifolds,

moving parts, etc.

DO NOT OPERATE IN FLAMMABLE AND

EXPLOSIVE ENVIRONMENTS

Flammable vapor can cause an engine to overspeed and

become difficult to stop, resulting in possible fire, explosion, severe personal injury and death. Do not operate a

genset where a flammable vapor environment can be

created by fuel spill, leak, etc., unless the genset is

equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of

the genset are solely responsible for operating the genset safely. Contact your authorized Cummins Power

Generation distributor for more information.

LS-14M

iii

Page 5

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH

Remove electric power before removing protective

•

shields or touching electrical equipment. Use rubber insulative mats placed on dry wood platforms

over floors that are metal or concrete when around

electrical equipment. Do not wear damp clothing

(particularly wet shoes) or allow skin surface to be

damp when handling electrical equipment. Do not

wear jewelry. Jewelry can short out electrical contacts and cause shock or burning.

• Use extreme caution when working on electrical

components. High voltages can cause injury or

death. DO NOT tamper with interlocks.

• Follow all applicable state and local electrical

codes. Have all electrical installations performed by

a qualified licensed electrician. Tag and lock open

switches to avoid accidental closure.

• DO NOT CONNECT GENERATOR SET DIRECT-

LY TO ANY BUILDING ELECTRICAL SYSTEM.

Hazardous voltages can flow from the generator set

into the utility line. This creates a potential for electrocution or property damage. Connect only

through an approved isolation switch or an approved paralleling device.

MEDIUM VOLTAGE GENERATOR SETS

(601V to 15kV)

Medium voltage acts differently than low voltage.

•

Special equipment and training is required to work

on or around medium voltage equipment. Operation

and maintenance must be done only by persons

trained and qualified to work on such devices. Improper use or procedures will result in severe personal injury or death.

• Do not work on energized equipment. Unauthorized

personnel must not be permitted near energized

equipment. Due to the nature of medium voltage

electrical equipment, induced voltage remains even

after the equipment is disconnected from the power

source. Plan the time for maintenance with authorized personnel so that the equipment can be de-energized and safely grounded.

GENERAL SAFETY PRECAUTIONS

Coolants under pressure have a higher boiling point

•

than water. DO NOT open a radiator or heat exchanger pressure cap while the engine is running.

Allow the generator set to cool and bleed the system

pressure first.

• Used engine oils have been identified by some state

or federal agencies as causing cancer or reproductive toxicity . When checking or changing engine oil,

take care not to ingest, breathe the fumes, or contact used oil.

• Keep multi-class ABC fire extinguishers handy.

Class A fires involve ordinary combustible materials

such as wood and cloth; Class B fires, combustible

and flammable liquid fuels and gaseous fuels; Class

C fires, live electrical equipment. (ref. NFP A No. 10).

• Make sure that rags are not left on or near the en-

gine.

• Make sure generator set is mounted in a manner to

prevent combustible materials from accumulating

under the unit.

• Remove all unnecessary grease and oil from the

unit. Accumulated grease and oil can cause overheating and engine damage which present a potential fire hazard.

• Keep the generator set and the surrounding area

clean and free from obstructions. Remove any debris from the set and keep the floor clean and dry.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol

or drug that makes the operation of equipment unsafe.

• Substances in exhaust gases have been identified

by some state or federal agencies as causing cancer or reproductive toxicity. Take care not to breath

or ingest or come into contact with exhaust gases.

• Do not store any flammable liquids, such as fuel,

cleaners, oil, etc., near the generator set. A fire or

explosion could result.

• Wear hearing protection when going near an oper-

ating generator set.

• To prevent serious burns, avoid contact with hot

metal parts such as radiator, turbo charger and exhaust system.

KEEP THIS MANUAL NEAR THE GENSET FOR EASY REFERENCE

iv

Page 6

1. Introduction

ABOUT THIS MANUAL

This manual provides installation instructions for

the DF Series generator sets. This includes the following information:

Mounting Recommendations - for fastening

generator set to base and space requirements

for normal operation and service.

Mechanical Connections - Location of connection points for fuel, exhaust, ventilation, and

cooling.

Electrical Connections – Location of electrical connection points for the control, generator,

and starting system.

Prestart – Checklist of items or procedures

needed to prepare generator set for operation.

Initial Startup – Test complete system to ensure proper installation, satisfactory performance, and safe operation. Refer to Operators

Manual for troubleshooting information.

This manual DOES NOT provide application information for selecting a generator set or designing the

complete installation. If it is necessary to design the

various integrated systems (fuel, exhaust, cooling,

etc.), review standard installation practices, or

specify system materials, additional information is

required. For engineering data specific to the generator set, refer to the specification and product

data sheets. For application information, refer to

Application Manual T-030, ”Liquid Cooled Generator Sets”, available from Onan.

INSTALLATION OVERVIEW

These installation recommendations apply to typical installations with standard model generator

sets. Whenever possible, these recommendations

also cover factory designed options or modifications. However, because of the many variables in

any installation, it is not possible to provide specific

recommendations for every situation. If there are

any questions not answered by this manual, contact

an Onan distributor for assistance.

Application and Installation

A standby power system must be carefully planned

and correctly installed for proper operation. This involves two essential elements: application and

installation.

Application (as it applies to generator set installations) refers to the design of the complete standby

power system that usually includes power distribution equipment, transfer switches, ventilation

equipment, mounting pads, and cooling, exhaust,

and fuel systems. Each component must be correctly designed so the complete system will function

as intended. Application and design is an engineering function generally done by specifying engineers

or other trained specialists. Specifying engineers

are responsible for the design of the complete

standby system and for selecting the materials and

products required.

Installation refers to the actual set-up and assembly of the standby power system. The installers set

up and connect the various components of the system as specified in the system design plan. The

complexity of the standby system normally requires

the special skills of qualified electricians, plumbers,

sheet metal workers, etc. to complete the various

segments of the installation. This is necessary so

all components are assembled using standard

methods and practices.

Safety Considerations

The generator set has been carefully designed to

provide safe and efficient service when properly

installed and operated. However, the overall safety

and reliability of the complete system is dependent

on many factors outside the control of the generator

set manufacturer. To avoid possible safety hazards, make all mechanical and electrical connections to the generator set exactly as specified in this

manual. All systems external to the generator (fuel,

exhaust, electrical, etc.) must comply with all applicable codes. Make certain all required inspections

and tests have been completed and all code requirements have been satisfied before certifying

the installation is complete and ready for service.

1-1

Page 7

1-2

Page 8

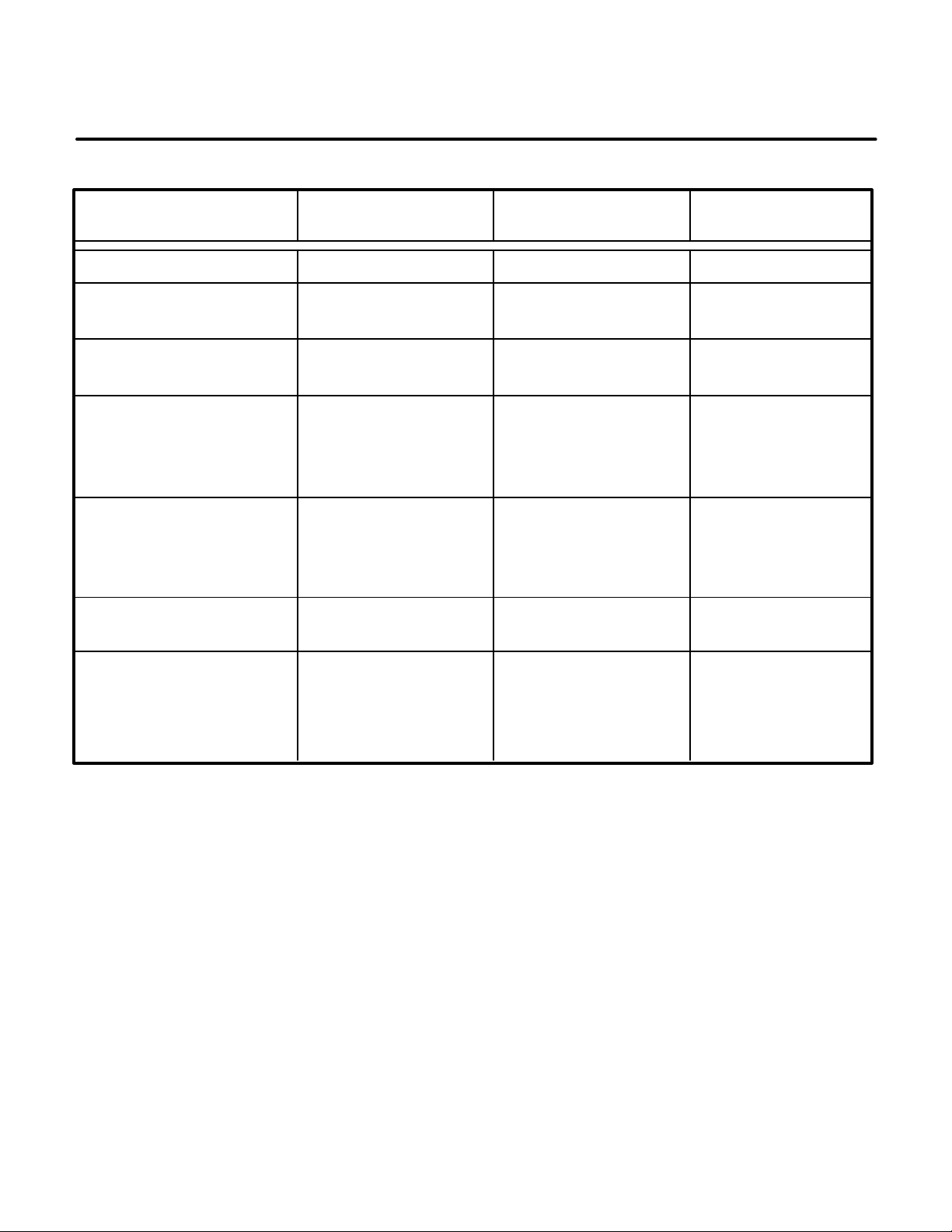

2. Specifications

Systems 275 DFBF 300 DFCB 350 DFCC

Cummins Model Engine NT855-G6 NTA855-G2 NTA855-G3

Coolant Capacity 66 Qt. 68 Qt. 68 QT.

Engine and Radiator (62.5L) (64.4L) (64.4L)

Oil Capacity 42 QT. 42 Qt. 42 Qt.

(40L) (40L) (40L)

Fuel Pump

Inlet Thread Size 7/8-14 UNF 7/8-14 UNF 7/8-UNF

Outlet Thread Size 3/4-16 UNF 3/4-16 UNF 3/4-16 UNF

Maximum Lift 5 ft (1.5m) 5 ft (1.5m) 5 ft (1.5m)

Exhaust

Outlet Size 5 in NPT 6 in NPT 6 in NPT

Maximum Allowable 40.8 in H

Exhaust Back Pressure (10.2 kPa) (10.2 kPa) (10.2 kPa)

0 40.8 in H20 40.8 in H20

2

Starting System

Voltage DC 24 24 24

Battery Requirements

Battery Two, 12V Two, 12V Two, 12V

Group 8D Group 8D Group 8D

Cold Cranking Amps 975 975 975

IMPORTANT

DEPENDING ON Y O U R L O C ATION AND INTENDED USE, FEDERAL, STATE OR LOCAL LAWS

AND REGULATIONS MAY REQUIRE YOU TO OBTAIN AN AIR QUALITY EMISSIONS PERMIT

BEFORE BEGINNING INSTALLATION OF YOUR GENSET. BE SURE TO CONSULT LOCAL

POLLUTION CONTROL OR AIR QUALITY AUTHORITIES BEFORE COMPLETING YOUR

CONSTRUCTION PLANS.

2-1

Page 9

2-2

Page 10

3. Mounting the Generator Set

GENERAL

Most generator set installations must be designed

so the generator set will function properly under all

anticipated operating conditions. Use these instructions as a general guide only. Follow the instructions of the consulting engineer when locating or

installing any components. The complete installation must comply with all local and state building

codes, fire ordinances, and other applicable regulations.

Requirements to be considered prior to installation

(refer to Figure 3-2):

• Level mounting surface

• Adequate cooling air supply

• Adequate fresh induction air

• Discharge of cooling air

• Discharge of exhaust gases

• Fuel system installation

• Electrical connections

• Accessibility for operation and servicing

• Noise levels

• Vibration isolation

LOCATION

Optimum generator set location is determined by

related systems such as ventilation, wiring, fuel,

and exhaust. The set should be located as near as

possible to the main power fuse box.

Wood floors should be covered with sheet metal extending 12 inches (305 mm) beyond the extremities

of the set.

Provide a location away from extreme ambient temperatures. Protect the generator set from adverse

weather conditions, and unauthorized personnel.

3-1

Page 11

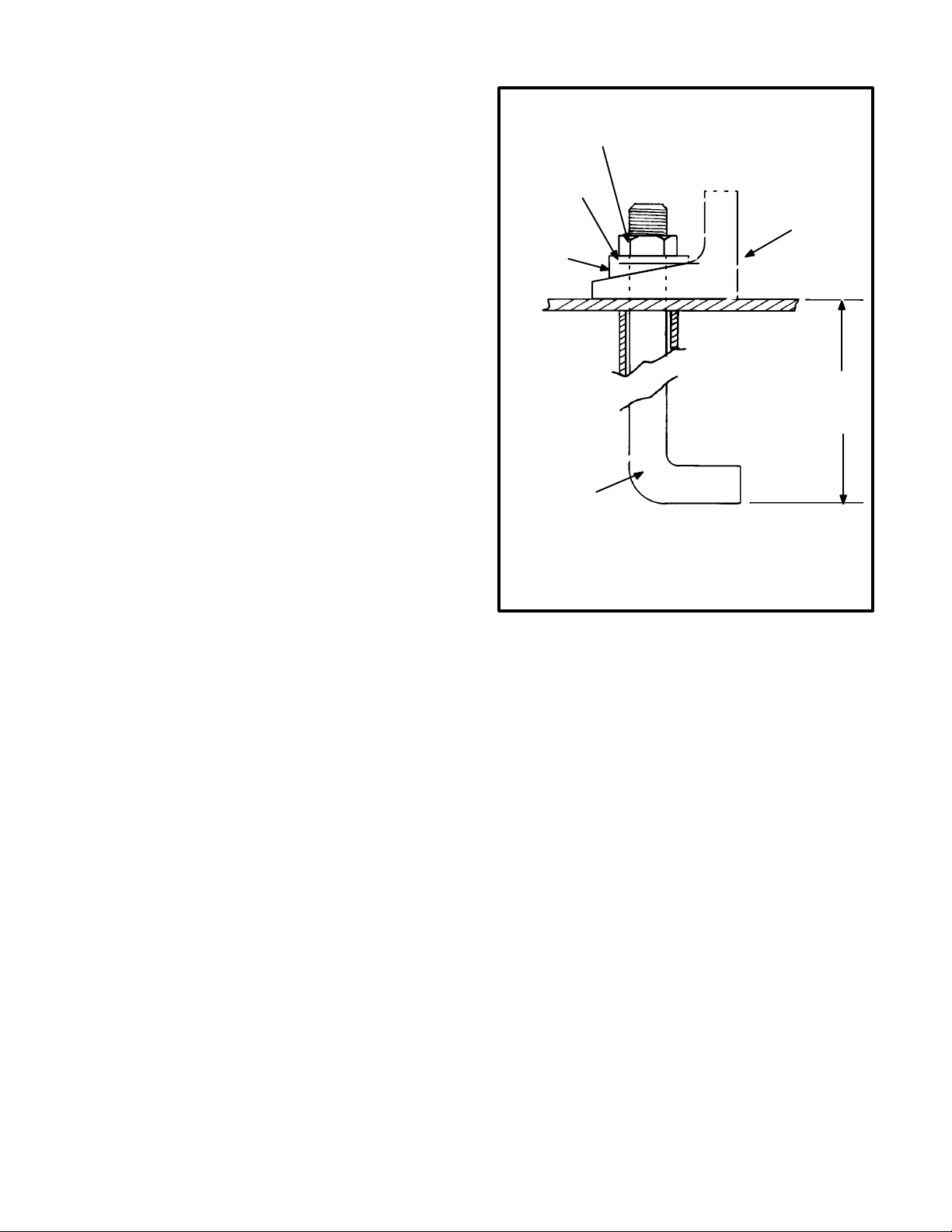

MOUNTING

Generator sets are mounted on a steel subbase

that provides proper support. For critical installations, install vibration isolators between the subbase and the foundation.

Mount the generator set on a substantial and level

base such as a concrete pad. For typical installations, use 3/4 inch anchored mounting bolts to secure the generator set subbase to the floor to prevent movement. Secure the subbase/vibration isolators using flat or bevel washer and hexagonal nut

for each bolt (see Figure 3-1). For proper spacing of

mounting bolts and set mounting dimensions, see

your generator set outline drawing.

ACCESS TO SET

Plan for access to the generator set for servicing

and provide adequate lighting around the set. For

convenience in general servicing such as the radiator, fan belt, and changing the crankcase oil, the

surface of the mounting base should be at least 6

inches (152 mm) above the floor.

FLAT

WASHER

BEVEL

WASHER

MOUNTING

BOLT

HEX NUT

SKID

12 INCH

(305 mm)

M-1627

FIGURE 3-1. TYPICAL ANCHOR BOLT DIAGRAM

3-2

Page 12

CONDENSATION

DRAIN TAP

DC

CONTROL

WIRING

MUFFLER

THIMBLE

FLEXIBLE SEC-

TION

AIR

OUTLET

DUCT

SWEEPING

ELBOW

AC POWER WIRING

AIR

IN

M-1808

VIBRATION

ISOLATORS

CONCRETE

BASE

IMPORTANT!

COOLING AIR INLET MUST BE AT

LEAST 1-1/2 TIMES LARGER THAN

RADIATOR DUCT OUTLET AREA

ON RADIATOR COOLED MODELS

FLOW OF COOLING AIR AND

HEATED AIR CAN BE CONTROLLED

BY AUTOMATICALLY OPERATED

LOUVRES

FIGURE 3-2. TYPICAL INSTALLATION

3-3

Page 13

VIBRATION ISOLATORS

Installation and Adjustment Procedure

1. Place the isolators (Figure 3-3) on the genset

support structure. The isolators should be

shimmed or grouted to ensure that all of the isolator bases are within 0.25 inch (6 mm) elevation of each other. The surface on which the

isolator bases rest on must also be flat.

2. Loosen the side snubber lock nuts so that the

top plate of the isolator is free to move vertically

and horizontally. Be sure that the top plate is

correctly aligned with the base and springs.

3. Place the genset onto the isolators while aligning the skid’s mounting with the threaded isolator hole. The top plates will move down and approach the base of the isolator as load is applied.

4. Once the genset is in position, the isolators

may require adjusting so that the set is level.

The isolators are adjusted by inserting the leveling bolt through the skid and into the isolator

(the leveling bolt’s locking nut should be

threaded up towards the bolt head).

The leveling bolt will adjust the clearance between the top plate and the isolator base. A

nominal clearance of 0.25 inch (6 mm) or greater is desired. This will provide sufficient clearance for the rocking that occurs during startup

and shutdown. If the 0.25 inch (6 mm) clearance is not present, turn the leveling bolt until

the desired clearance is achieved.

5. The genset may not be level yet, therefore adjust the leveling bolts until the set is level and

sufficient clearance still remains. Once all isolators have been set, then lock the leveling bolt

in place with the lock nut.

6. The snubber nuts may remain loose and therefore provide better isolation between the genset and support structure.

GENSET SKID

SNUBBER

LEVELING BOLT

LOCK NUT

CLEARANCE

BASE

M1828–1s

FIGURE 3-3. VIBRATION ISOLATORS

3-4

Page 14

4. Mechanical Connections

GENERAL

The generator set mechanical system installation

includes connecting the fuel, exhaust, ventilation

and cooling systems (Figure 3-2). Before starting

any type of fuel installation, all pertinent state and

local codes must be complied with and the installation must be inspected before the unit is put in service.

FUEL SYSTEM

Cummins engines used on DF series generator

sets normally use ASTM No. 2 Diesel fuel. They will,

however, operate on alternate diesel fuels within

the specifications shown in engine manual.

In all fuel system installations, cleanliness is of the

upmost importance. Make every effort to prevent

entrance of moisture, dirt or contaminants of any

kind. Clean all fuel system components before

installing.

Use only compatible metal fuel lines to avoid electrolysis when fuel lines must be buried. Use a flexible section of tubing between the engine and fuel

supply line to provide vibration isolation. Refer to

your generator set outline drawing for sizes and

locations.

CAUTION

Never use galvanized or copper fuel

lines, fittings or fuel tanks. Condensation in the

tank and lines combines with the sulfur in diesel

fuel to produce sulfuric acid. The molecular

structure of the copper or galvanized lines or

tanks reacts with the acid and contaminates the

fuel.

An electric solenoid shutoff valve in the supply line

is recommended for all installations and required for

indoor automatic or remote starting installations.

Connect the so l enoid wires to the battery run circuit

to open the valve during genset operation.

Supply Tank

Locate the f uel t ank as close as possible to the genset and within the 5 foot (1.5 m) lift capacity of the

fuel pump. Install a fuel tank that has sufficient capacity to keep the genset operating continuously at

full load for at least 36 hours. Refer to product Specification sheet for fuel consumption data.

FUEL PUMP

WATER/SEDIMENT

SEPARATOR

INJECTOR FUEL

RETURN LINE

VENTED

FILL CAP

DAY TANK

FUEL TRANSFER

PUMP - ELECTRIC

MOTOR DRIVEN

FIGURE 4-1. TYPICAL FUEL SUPPLY INSTALLATION

FLOAT

SWITCH

LARGER

OVERFLOW

LINE

CONNECT TO

AC OUTPUT

SUPPLY

LINE

FUEL TANK

All models require a fuel return

line from injectors to tank.

VENT LINE

FILL PIPE

ES-1214-2

4-1

Page 15

WARNING

Fuel leaks create fire and explosion

hazards which can result in severe personal injury or death. Always use flexible tubing between engine and fuel supply to avoid line failure and leaks due to vibration. The fuel system

must meet applicable codes.

If the main fuel tank is installed below the lift capabilities of the standard fuel transfer pump, a transfer

tank (referred to as a day tank) and auxiliary pump

will also be required. If an overhead main fuel tank is

installed, a transfer tank and float valve will be required to prevent fuel head pressures from being

placed on the fuel system components. See Day

Tank and Figure 4-1.

Day Tank (If Used)

Fuel day tanks are used when the standard engine

fuel pump does not have the capacity to draw the

fuel from the supply tank; or the supply tank is overhead and presents problems of high fuel head pressure for the fuel return.

Supply T ank Lower Than Engine:

lation, the day tank is installed near the generator

set and within the engine fuel pump lift capability,

but below the fuel injection system. Install an auxiliary fuel pump as close as possible to the supply

tank to pump fuel from the supply tank to the day

tank. A float switch in the day tank controls operation of the auxiliary fuel pump.

With this instal-

The supply tank top must be below the day tank top

to prevent siphoning from the fuel supply to the day

tank.

Provide a return line from the engine injection system return connection to the day tank (near the top).

Provide a day tank overflow line to the supply tank in

case the float switch fails to shut off the fuel transfer

pump.

WARNING

Spilled fuel presents the hazard of

fire or explosion which can result in severe personal injury or death. Provide an overflow line

to the supply tank from the day tank.

Supply Tank Higher Than Engine:

tank near the generator set, but below the fuel injection system. Use fuel line at least as large as the fuel

pump inlet. The engine fuel return line must enter

the day tank.

Include a shutoff valve in the fuel line between the

fuel supply tank and the day tank to stop fuel flow

when the generator set is off.

Install the day

Engine Fuel Connections

Identification tags are attached to the fuel supply

line and fuel return line connections by the factory.

Flexible lines for connecting between the engine

and the stationary fuel line are supplied as standard

equipment.

4-2

Page 16

EXHAUST SYSTEM

Pipe exhaust gases to the outside of any enclosure.

Locate the exhaust outlets away from any air inlets

to avoid gases re-entering the enclosure. Exhaust

installations are subject to various detrimental conditions such as extreme heat, infrequent operation

and light loads. Regularly inspect the exhaust system both visually and audibly to see that the entire

system remains fume tight and safe for operation.

WARNING

Inhalation of exhaust gases can result in severe personal injury or death. Use extreme care during installation to provide a tight

exhaust system. Terminate exhaust pipe away

from enclosed areas, windows, doors and

vents.

Use an approved thimble (Figure 4-2) where exhaust pipes pass through wall or partitions. Refer to

NFPA 37, Section 6-3. “Stationary Combustion Engines and Gas Turbines” for accepted design practices. Build according to the code requirements in

effect at the installation site.

WARNING

Inhalation of exhaust gases can result in severe personal injury or death. Do not

use exhaust heat to warm a room, compartment

or storage area.

Rain caps are available for the discharge end of vertical exhaust pipes. The rain cap clamps onto the

end of the pipe and opens due to exhaust discharge

force from the generator set. When the generator

set is stopped, the rain cap automatically closes,

protecting the exhaust system from rain, snow, etc.

RAIN CAP

9 INCH MIN

(230 mm)

VERTICAL

HORIZONTAL

WALL OR PARTITION

FIGURE 4-2. MOUNTING EXHAUST THIMBLE

DRIP CAP

HOLES IN

END OF

INNER SLEEVE

ROOF

9 INCH MIN

(230 mm)

EXS-1036

Use a section of flexible exhaust pipe between the

engine and remainder of exhaust system. Support

exhaust system to minimize weight applied to engine exhaust outlet elbow/turbocharger connection.

CAUTION

Weight applied to the engine manifold can result in turbocharger damage. Support the muffler and exhaust piping so no

weight or stress is applied to engine exhaust el bow.

4-3

Page 17

Avoid sharp bends by using sweeping, long radius

elbows and provide adequate support for muffler

and tailpipe. Pitch a horizontal run of exhaust pipe

DOWNWARD to allow any moisture condensation

to drain away from the engine. If an exhaust pipe

must be turned upward, install a condensation trap

at the point where the rise begins (Figure 4-3).

Shield or insulate exhaust lines if there is danger of

personal contact. Allow at least 12 inches (305 mm)

of clearance if the pipes pass close to a combustible

wall or partition.

IF EXHAUST LINE MUST BE

PITCHED UPWARD, CONSTRUCT

A TRAP AT POINT OF RISE

AVOID

SHARP

BENDS

WARNING

Exhaust pipes are very hot and they

can cause severe personal injury or death from

direct contact or from fire hazard. Shield or insulate exhaust pipes if there is danger of personal contact or when routed through walls or

near other combustible materials.

VENTILATION AND COOLING

Generator sets create considerable heat that must

be removed by proper ventilation. Outdoor installations rely on natural air circulation but indoor installations need properly sized and positioned vents for

required airflow.

Vents and Ducts

For indoor installations, locate vents so incoming air

passes through the immediate area of the installation before exhausting. Install the air outlet higher

than the air inlet to allow for convection air movement.

Size the vents and ducts so they are large enough to

allow the required flow rate of air . The “free area” of

ducts must be as large as the exposed area of the

radiator. Refer to the DF series Product Data

Sheets for the airflow requirements.

DRAIN CONDENSATION

TRAP PERIODICALLY

EXS-1046s

FIGURE 4-3. CONDENSATION TRAP

Wind will restrict free airflow if it blows directly into

the air outlet vent. Locate the outlet vent so the effects of wind are eliminated. See Figure 4-4.

For operation outside a building, a shelter housing

with electrically operated louvers is available as an

option. T ransformers connected across the generator output supply current to the motors.

CS-1366

FIGURE 4-4. WIND BARRIER

4-4

Page 18

Dampers

Dampers or louvers protect the genset and equipment room from the outside environment. Their operation of opening and closing should be controlled

by operation of the genset.

In cooler climates movable or discharge dampers

are used. These dampers allow the air to be recirculated back to the equipment room. This enables the

equipment room to be heated while the genset engine is still cold, increasing the engine efficiency.

Radiator Set Requirements

Radiator set cooling air is drawn past the rear of the

set by a pusher fan that blows air through the radiator (Figure 4-5). Locate the air inlet to the rear of the

set. Make the inlet vent opening 1-1/2 times larger

than the radiator area.

Locate the cooling air outlet directly in front of the radiator and as close as possible. The outlet opening

must be at least as large as the radiator area.

Length and shape of the air outlet duct should offer

minimum restriction to airflow.

The radiator has an air discharge duct adapter

flange. Attach a canvas or sheet metal duct to the

flange and the air outlet opening using screws and

nuts so duct can be removed for maintenance purposes. The duct prevents circulation of heated air.

Before installing the duct, remove the radiator core

guard.

Standard Radiator Cooling uses a set mounted

radiator and engine pusher fan to cool engine water

jacket. Air travels from the generator end of the set,

across the engine and out through the radiator. An

integral discharge duct adapter flange surrounds

the radiator grille.

Remote Radiator Cooling (Optional) substitutes

a remote mounted radiator and an electrically driven fan for the set mounted components. Removal of

the radiator and the fan from the set reduces noise

levels without forcing dependence on a continuous

cooling water supply. The remote radiator installation must be completely protected against freezing.

Remote radiator plumbing will vary with installation.

Follow recommendations given in Application

Manual T-030. See product data sheet for friction

head and static head limits.

Before filling cooling system, check all hardware for

security. This includes hose clamps, capscrews, fittings and connections. Use flexible coolant lines

with heat exchanger, standpipe or remote mounted

radiator.

INLET

AIR

DAMPER

COOL

AIR

* Louvers should close when

room ambient is above 60

° C)

(16

° F

FIGURE 4-5. TYPICAL RADIATOR SET INSTALLATION

THERMOSTATIC AIR

RECIRCULATING

DAMPER *

RADIATOR

FLEXIBLE DUCT

CONNECTOR

WIND/

NOISE

BARRIER

HOT

AIR

D

DISTANCE SHOULD NOT

BE LESS THAN HEIGHT

OF RADIATOR

CS-1382c

4-5

Page 19

Water Jacket Heater (Optional)

An optional water jacket heater can be installed to

keep the engine warm for starting under adverse

weather conditions. Connect the heater to a power

source that will be on when the engine is NOT running.

Heat Exchanger (Optional)

The optional heat exchanger (Figure 4-6) uses a

shell and tube type heat exchanger instead of the

standard radiator and fan. Engine jacket coolant circulates through the shell side of the heat exchanger

while the cooling water is pumped through the

tubes. Engine coolant and raw water do not mix.

This type of cooling separation is necessary when

the raw water contains scale forming lime or other

impurities.

This system can reduce set enclosure airflow requirements and noise levels. Proper operation depends on a constant supply of raw water for heat removal. Adjust the flow to maintain engine coolant

temperature between165

° C) while viewing the water temperature gauge.

91

° F and 195° F (74° C and

The engine coolant side of the system can be protected from freezing; the raw water side cannot be

protected.

VENTILATING

FAN

COOL AIR

WATER

SOLENOID

VALVE

FIGURE 4-6. TYPICAL HEAT EXCHANGER INSTALLATION

WARM

AIR

FLEXIBLE WA-

TER

CONNECTIONS

MOUNTED HEAT

EXCHANGER

RAW WATER

SUPPLY

RAW WATER

DISCHARGE

4-6

Page 20

Coolant Filter

One spin-on type corrosion filter (Figure 4-7) is

standard equipment. This precharge filter is compatible with plain water and all ethylene glycol base

permanent antifreeze coolants. Refer to engine

manufacturer’s manual for instructions if a methoxy

propanal base antifreeze is desired. Replace filter

periodically as recommended in the

Maintenance

section of the Operator’s manual.

Coolant Heater

A coolant heater is used to keep the engine coolant

warm when the engine is shut down. It heats and circulates the coolant within the engine. This reduces

startup time and lessens engine wear caused by

cold starts. It is electrically operated and thermostatically controlled.

COOLANT

FILTER

SHUTOFF

VALVES

FILTER

WARNING

The coolant heater must not be operated while the cooling system is empty or

when the engine is running or damage to the

heater will occur.

Figure 4-8 shows the heater line connections. Connect the heater to a source of power that will be on

during the time the engine is not running. Be sure

the voltage rating is correct for the heater element

rating.

NOTE: OPEN COOLANT FILTER SHUTOFF VALVES

BEFORE OPERATING GENERATOR SET.

CS-1198

FIGURE 4-7. TYPICAL COOLANT FILTER

THERMOSTAT

1/2 NPT

OUTLET

(FOR 1” ID HOSE)

DRAIN

4-7

INLET

(FOR 1” ID HOSE)

CS-1367

FIGURE 4-8. TYPICAL COOLANT HEATER

Page 21

4-8

Page 22

5. Electrical Connections

GENERAL

The genset electrical system includes connecting

the load, installing the control wiring and connecting

the batteries. Connect the batteries last to avoid accidental starting of the unit during installation.

WARNING

Accidental starting of the generator

set while working on it can cause severe personal injury or death. Prevent accidental starting by disconnecting the starting battery cables

(negative [–] first).

Arcing can ignite the explosive hydrogen gas

given off by batteries, causing severe personal

injury. Arcing can occur if the negative (–) battery cable is connected and a tool being used to

connect or disconnect the positive (+) battery

cable accidentally touches the frame or other

grounded metal part of the set. To prevent arcing, always remove the negative (–) cable first,

and reconnect it last.

CAUTION

To prevent arcing, always disconnect a battery charger from its AC source before

disconnecting the battery cables. Otherwise,

disconnecting the cables can result in voltage

spikes high enough to damage the DC control

circuits of the set.

LOAD

NORMAL

SOURCE

NOTE: SHOWN WITH LINE

CONNECTED TO LOAD

FIGURE 5-1. TYPICAL LOAD TRANSFER SWITCH

GENSET

SC-1101-1

Most local regulations require that wiring connections be made by a licensed electrician and the

installation be inspected and approved before operation. All connections, wire sizes, etc. must conform to the requirements of all electrical codes in effect at the installation site.

WARNING

Improper wiring can cause a fire or

electrocution, resulting in severe personal injury or death and/or property and equipment damage.

TRANSFER SWITCH

If the installation is for standby service, a transfer

switch is required for switching the load from the

normal power source to the generator set (Figure

5-1). Either a manual or automatic switch can be

used. Follow the installation instructions provided

with the transfer switch when connecting the load

and control wiring.

5-1

Page 23

AC WIRING

Generator Voltage Connections

The generator output voltage and maximum current

rating are specified on the generator set nameplate.

Line-to-neutral voltage is always the lower voltage

shown and line-to-line voltage is the higher rating.

These generators can be configured for the voltages shown in

these voltages must be reconnected by the installer

to give the voltage required by the installation. Before shipping, the factory tests the generator set

output by connecting the generator to produce a

particular test voltage. The generator may be connected at the factory to produce a specified voltage

per customer order. The installer must always

check the stator lead terminal block connections

and perform any necessary reconnect to obtain the

voltage desired.

Wiring Diagram

section. Most of

ers are labeled CT21, CT22 and CT23 on the wiring

diagram. Refer to

fy the output leads that must be routed through each

current transformer, and also appropriate transformer post selection for meter lead harness connection. Use cable ties to secure the loose transformers to the generator output leads.

Wiring Diagram

section to identi-

Load Balancing

When connecting loads to the generator set, balance the loads so the current flow from each line terminal (L1, L2 and L3) is about the same. This is especially important if both single phase and three

phase loads are connected. Any combination of

single phase and three phase loading can be used

as long as each line current is about the same, within 10 percent of median value and no line current

exceeds the nameplate rating of the generator.

Check the current flow from each line after connections by observing the control panel ammeter.

Refer to

the voltage connection information; and use the

electrical schematic supplied with your generator

set when actually performing load connections.

CAUTION

Wiring Diagram

section when reviewing

Reconnecting factory connected

generator sets to lower voltages can reduce se t

ratings, and also render line circuit breakers too

small. Consult with your distributor before performing reconnection for a different voltage.

Load Connections

Connecting the Load:

the generator by bolting the load wires to the appropriate terminals on the generator terminal block.

The terminals are stamped U, V, W and N to indicate

the line and neutral connections. (Reference: U, V,

and W correspond with L1, L2 and L3; and N with L0

respectively).

When installing sets with AC meters, the generator

output leads must be routed through current transformers for proper meter operation. The transform-

All loads are connected to

Grounding

Grounding involves making a conducting connection between the metal parts of the generator set or

one of its electrical circuits and the earth. The design and installation of a grounding system is affected by many factors such as the use of multiple

transformers, ground fault protection requirements

and physical location of the generator. Follow the

recommendations of the consulting engineer when

installing the grounding system.

WARNING

can result in severe personal injury or death. It

is extremely important that bonding and equipment grounding be properly done. All metallic

parts that could become energized under abnormal conditions must be properly grounded.

Typical requirements for bonding and grounding

are given in the National Electrical Code, Article

250. All connections, wire sizes, etc. must conform

to the requirements of the electrical codes in effect

at the installation site.

Contact with electrical equipment

5-2

Page 24

DC WIRING

Remote Control Connections

inducing currents that could cause problems within

the control.

Provisions are made inside the control box for adding optional remote starting stations and alarms.

Connections are made on the terminal block (TB1)

located on the engine monitor circuit board (A11).

Connect one or more remote switches across remote terminal and B+ terminal. Refer to Figure 5-2.

If the distance between the generator set and remote stations is less than 1000 feet (305 m), use 18

gauge stranded copper wire. If the distance is 1000

to 2000 feet (305 to 610 m), use 16 gauge stranded

copper wire. Always run control circuit wiring in a

separate conduit from the AC power cables to avoid

TB1

7

B+ (DC POWER)

6

RMT (REMOTE START)

5

GND (GROUND)

4

ALM (COMMON ALARM)

CONTROL

PANEL BOX

TB1

Remote Monitor Connections

Provisions are made inside the control box for adding optional remote monitoring on these gensets

employing optional Detector 12 (12 lamp panel).

Connections are made on the terminal block (TB2)

located on the engine monitor circuit board A11. Refer to Figure 5-2.

CAUTION

the same conduit as the AC power. AC voltage

induced currents can create operational problems with electronic solid-state devices.

ENGINE

CONTROL

MONITOR

A11

Do not install DC control wiring in

TB2

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

FAULT 2 - INPUT

FAULT 2 - OUTPUT

FAULT 1 - INPUT

FAULT 1 - OUTPUT

LAMP TEST/RESET

OVERCRANK

OVERSPEED

HIGH ENGINE TEMPERATURE

LOW OIL PRESSURE

PRE-HIGH ENGINE TEMPERATURE

PRE-LOW OIL PRESSURE

SWITCH OFF

LOW ENGINE TEMPERATURE

LOW FUEL - INPUT

LOW FUEL - OUTPUT

SHUTDOWN

NON-TIMED

SHUTDOWN

TIMED

SHUTDOWN

GROUND STUD

(USE GROUND

STUD OR A11-TB1-5

FOR CONTROL

GROUND WIRES)

FIGURE 5-2. REMOTE CONTROL AND REMOTE MONITOR CONNECTION POINTS

A13 A14

INTERFACE

RELAY MODULES

5-3

TB2

ES-1561

Page 25

Battery Connections

Starting the unit requires 24 volt battery current.

Use two, 12 volt (Type 8D) batteries for a normal

installation (Figure 5-3). Connect the batteries in

series (negative post of first battery to the positive

post of the second battery) as shown in Figure 5-3.

Necessary battery cables and rack are on the unit.

Service batteries as necessary. Infrequent use (as

in emergency standby service), may allow battery

to self-discharge to the point where it cannot start

the unit. If installing an automatic transfer switch

that has no built-in charge circuit, connect a separate trickle charger. Onan automatic transfer

switches include such a battery charging circuit.

WARNING

Ignition of explosive battery gases

can cause severe personal injury. Always connect battery negative last to prevent arcing.

WARNING

Do not smoke while servicing the

batteries. Explosive gases are emitted from batteries in operation. Ignition of these gases can

cause severe personal injury.

Control Heater (Optional)

A control heater provides a means of humidity/temperature control of the control box interior. It protects the components and ensures their effectiveness when the generator set is subjected to varying

ambient air conditions during extended periods of

non-use. The element is controlled by an adjustable

thermostat (Figure 5-4).

POSITIVE

NEGATIVE

TWO, 12 VOLT

BATTERIES

ES-1865–1s

FIGURE 5-3. BATTERY CONNECTIONS

THERMOSTAT

TO 120 VAC

SUPPLY

5-4

HEATER

ELEMENT

ES-1563s–3

FIGURE 5-4. OPTIONAL CONTROL HEATER

Page 26

6. Prestart Preparation

GENERAL

Before attempting the initial starting of the generator set, be sure it is serviced and ready for operation

(Figure 6-1). Perform the following:

• Check ventilation and exhaust systems

• Check all mechanical connections

• Fill the coolant, lubrication and fuel systems

• Prime the lubrication and fuel systems

• Check the fuel system for leaks

• Check the lubrication system for leaks

VENTILATION

Verify all air vents and ducts are open and free from

any obstructions. Verify dampers, if used, operate

properly.

EXHAUST SYSTEM

Check the exhaust system for proper installation.

Verify there is at least 12 inches (305 mm) clearance between exhaust pipes and combustible materials, and all connections are tight.

MECHANICAL CHECKS

Check the generator set for loose or damaged components and repair or replace as required.

ELECTRICAL SYSTEM

Verify all electrical connections are secure and all

wiring is complete and inspected. Replace and secure any access panels that may have been removed during installation.

Load Connections

Check that load cables from generator set are properly connected to either a transfer switch or circuit

breaker panel.

EXHAUST

SYSTEM

AIR OUTLET

• FILL COOLANT SYSTEM

• FILL AND PRIME LUBRICATION SYSTEM

• FILL AND PRIME FUEL SYSTEM

FIGURE 6-1. TYPICAL INSTALLATION

AIR INLET

CHECK THAT ALL ASPECTS

OF INSTALLATION ARE

READY FOR OPERATION

M-1808

6-1

Page 27

Battery Connections

4

Use two 12 volt batteries for a normal installation.

Connect the negative (-) battery cable last to reduce

the risk of arcing.

Service the batteries as necessary. If an automatic

transfer switch is not used or installed without a

built-in charge circuit, connect a separate float charger to the battery.

OIL SUPPLY INLET

LINE. DISCONNECT AT

THIS POINT TO PRIME

COOLANT

Engine coolant is drained prior to shipment. Before

starting, fill the cooling system with the recommended coolant. See Operator’s manual

nance

section for more information.

Mainte-

LUBRICATION

Engine oil is drained prior to shipment. Before starting, fill and prime the lubrication system as follows:

1. Remove oil inlet line from turbocharger housing (Figure 6-2), fill bearing housing with clean

engine lubricating oil; replace line and secure.

2. Fill crankcase to “L” (low) mark on dipstick (Figure 6-3) and refer to

Operator’s manual for oil recommendations.

3. Remove plug from head of oil filter housing.

Connect a hand or motor driven priming pump,

equipped with pressure gauge, from a source

of clean lubricating oil to the plug boss in the filter housing.

4. Prime until a 30 psi (207 kPa) pressure is obtained.

5. Disconnect wire from fuel solenoid valve (Figure 6-4).

6. On the engine control panel, depress the RUN

switch to crank the engine, while maintaining

an oil priming pressure of 15 psi (103 kPa) for

15 seconds, at filter head priming port.

7. Stop engine cranking, remove external priming

equipment, reinstall plug in filter housing and

torque to 15 to 20 ft lb (20 to 27 N

8. Reconnect wire to fuel solenoid valve.

9. Complete oil fill to “H” (high) mark on dipstick.

Maintenance

section in

•m).

TURBOCHARGER

HOUSING

PRIMING

PLUG

OIL

FILTER

B-342-3s

FIGURE 6-2. PRIMING TURBOCHARGER

OIL

DIPSTICK

STARTER

B342–7s

FIGURE 6-3. OIL DIPSTICK LOCATION

B3

6-2

Page 28

FUEL

Fill the fuel tanks with the recommended fuel. Engine fuel may not be primed at the fuel filters after

shipment. To verify and reprime the fuel system perform the following procedure:

1. Remove each fuel filter and fill with clean fuel

(Figure 6-5).

CAUTION

Due to the precise tolerances of

diesel injection systems, it is extremely important the fuel be kept clean and free of

water. Dirt or water in the system can cause

severe damage to both the injection pump

and the injection nozzles.

2. Put a light coat of fuel on the sealing gasket.

3. Install and tighten by hand until the gasket just

touches the filter head.

4. Tighten the filter an additional one-half to threefourths turn.

FUEL SOLENOID

FS1692s

FIGURE 6-4. FUEL SOLENOID VALVE LOCATION

FUEL SUPPLY

INLET

FIGURE 6-5. FUEL FILTERS

SUPPLY LINE,

FILTER TO

INJECTION

PUMP

FUEL FILTERS

FS1803s

6-3

Page 29

6-4

Page 30

7. Initial Start and Checks

Before putting the generator set under load conditions, verify the set will perform correctly by checking the following areas.

STARTING

Move the Run/Stop/Remote switch on the engine

control panel to the Run position. The starter should

crank the engine and the engine should start within

a few seconds. If after a few seconds of cranking the

engine fails to start or starts, runs and then stops,

refer to Troubleshooting charts in the Operator’s

Manual.

ENGINE GAUGES

Check the following while the genset is operating:

Oil Pressure Gauge

The oil pressure should be in the range of 40 to 60

psi (275 to 414 kPa) when the engine is at operating

temperature.

Water Temperature Gauge

Frequency Meter

The generator frequency should be stable and the

reading should be the same as the nameplate rating

(50 or 60 hertz).

AC Voltmeter

Turn the phase selector switch to each line-to-line

phase selection shown on the volts scale (L1-L2 on

single phase sets; L1-L2, L2-L3 and L3-L1 on three

phase sets). Read the AC voltmeter using the upper

or lower scale as indicated by the scale indicator

light. At no load, the line-to-line voltage should be

the same as the set nameplate rating.

AC Ammeter

Turn the phase selector switch to each phase selection shown on the amperes scale (L1and L2 on

single phase sets; L1, L2 and L3 on three phase

sets). Read the ammeter using the upper or lower

scale as indicated by the scale indicator light. At no

load, the current readings should be zero. With a

load applied, each line current should be approximately the same and no line current should exceed

the set nameplate reading.

ENGINE MONITOR INDICATOR LAMPS

The water temperature should be in the range of

° to 195°F (74° to 91°C) depending on the load

165

and ambient temperature.

DC Voltmeter

This is a voltage reference gauge, indicating condition of the batteries and also of the battery charging

circuit. Gauge should read approximately 24 to 28

volts while set is running. If reading is high or low,

check batteries and the battery charging circuit.

AC METERS (IF EQUIPPED)

Note the AC instruments on the control panel. The

frequency meter and voltmeter should indicate

rated nameplate frequency and voltage. Turn the

control panel Voltage Adjust control (if equipped) for

nameplate voltage. Use the Phase Selector Switch

to read each of the line-to-line voltages.

Move the Run/Stop/Remote switch on the engine

panel to the Stop position. Hold the Reset/Lamp

Test switch in the Test position. All indicator lamps

should light. Verify all the lamps are on and then release the switch. Contact your authorized service

center if any lamps require replacement.

EXHAUST SYSTEM

With the genset operating, inspect the entire exhaust system including the exhaust manifold, muffler, turbocharger and exhaust pipe. Visually and

audibly check for leaks at all connections, welds,

gaskets and joints. Make sure exhaust pipes are not

heating surrounding areas excessively . If any leaks

are detected, have them corrected immediately.

WARNING

sult in severe injury or death. Inspect exhaust

system visually and audibly for leaks daily. Repair any leaks immediately.

Inhalation of exhaust gases can re-

7-1

Page 31

FUEL SYSTEM

With the genset operating, inspect the fuel supply

lines, filters and fittings for leaks. Check any flexible

sections for cuts, cracks and abrasions and make

sure they are not rubbing against anything that

could cause breakage.

WARNING

that can result in severe personal injury or

death if ignited by a spark. If any leaks are detected, have them corrected immediately.

Leaking fuel will create a fire hazard

WARNING

Ignition of explosive gases can

cause explosion and fire, resulting in severe

personal injury or death. Do not smoke while

servicing the batteries.

COOLING SYSTEM

When the engine is first started, remove the radiator

pressure cap and monitor the coolant level. As

trapped air is expelled from the system, the coolant

level will drop and additional coolant must be added. Replace the pressure cap when the coolant level is stable.

MECHANICAL ADJUSTMENTS

DC ELECTRICAL SYSTEM

With the generator set off, check the terminals on

the battery for clean and tight connections. Loose or

corroded connections create resistance that can

hinder starting. Clean and reconnect the battery

cables if loose. Always connect the negative battery

cable last.

EXCITATION

AC VOLTMETER

AC AMMETER

FIELD

BREAKER

VOLTAGE

ADJUST

UPPER AND

LOWER SCALE

INDICATOR LAMPS

With the generator stopped, check for loose belts

and fittings, leaking gaskets and hoses, or any

signs of mechanical damage. If any problems are

found, have them corrected immediately.

With the set running, listen for any unusual noises

that can indicate mechanical problems. Check the

oil pressure frequently. Refer to Operator’s or Service Manual for required adjustments.

OIL PRESSURE

GAUGE

RUN-STOP-REMOTE

SWITCH

PANEL LAMP

RESET, LAMP TEST,

PANEL LAMP SWITCH

INDICATOR

LAMPS

COOLANT

TEMPERATURE

GAUGE

PHASE SELECTOR

SWITCH

FREQUENCY METER

WATTMETER

OTHER

OPTIONAL

METERS

FIGURE 7-1. CONTROL PANEL WITH OPTIONS

OIL TEMP

GAUGE

7-2

TACHOMETER

DC VOLTMETER

FREQUENCY

ADJUST

RUNNING TIME

METER

EMERGENCY STOP

PUSHBUTTON

Page 32

8. Wiring Diagrams

Reconnectible Voltages 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-reconnectible Voltages 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1

Page 33

8-2

Page 34

RECONNECIBLE VOLTAGES

8-3

No. 625-2165 Sh 1 of 2

Rev. J Sys: Revisio

Modified 2/1994

Page 35

NON-RECONNECIBLE VOLTAGES

8-4

No. 625-2165 Sh 2 of 2

Rev. J Sys: Revisio

Modified 2/1994

Page 36

Cummins Power Generation

1400 73rd Avenue N.E.

Minneapolis, MN 55432

1-800-888-6626

763-574-5000 International Use

Fax: 763-528-7229

Cummins is a registered trademark of Cummins Inc.

Loading...

Loading...