CUMMINS Fire Pump Drive Engines, CFP9E SERIES Operation & Maintenance Manual

CFP9E SERIES

Operation & Maintenance Manual

Fire Pump Drive Engines

www.cumminsfirepower.com

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-i

Table of Contents

Warranty Information

Section 1 - Safety

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Advisory and Cautionary Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Section 2 - Description

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Fire Pump Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Operator Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 Overspeed Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.2 Operating Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Fire Pump Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Air Intake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.6 Raw Water Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.7 Fuel Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.7.1 Fuel Supply and Drain Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8 High Pressure Common Rail (HPCR) Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.9 Engine Oil System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.10 Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Section 3 - Installation

3.1 Receiving and Handling Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Damage During Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Claim Filing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Site Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Fuel Supply Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Fuel System Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Fuel Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Raw Water Supply Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4.1 Install Raw Water Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Battery Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.1 Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.5.2 Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5.3 Auxiliary Battery Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6 Signal and Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.7 Coolant System Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8 Charge Air Cooler System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.9 Engine Oil System Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.10 Pre-Start Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.11 Engine Start Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.11.1 Engine Will Not Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.11.2 Engine Starts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-ii

Table of Contents

Section 4 - Controls

4.1 Operator Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Coolant Temperature Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Engine Oil Pressure Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.3 Tachometer and Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.4 Battery A and B Voltmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.5 Circuit Breaker Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.6 AUTO/MANUAL Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.7 Overspeed Warning Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.8 Engine Overspeed Warning Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.9 Overspeed RESET/STOP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.10 High Coolant Temperature Warning Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.11 Low Oil Pressure Warning Lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.12 CRANK BATT A/B Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.13 ECM Fault Code Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.14 ECM A/B Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2 Electronic Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.1 ECM Data Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Overspeed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 Raw Water Flow Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5 Engine Protection System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.1 Engine Protection Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Section 5 - Operation

5.1 Start-up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 General Operating Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Remote Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 Local Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.5 Emergency Starting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.6 Engine Operating Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.7 Overspeed Set Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.8 Crank Terminate Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.9 ECM Fault Code Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.10 Isolated Acceptance Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.10.1 Integrated Acceptance Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Section 6 - Maintenance

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Engine Operation Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Weekly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.1 General Walk Around Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.2 Air Filter and Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.3 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.4 Engine Oil System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.5 Fuel System Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.6 Engine Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.7 Electrical Supply and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.8 Crankcase Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.9 Clean Raw Water Strainers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.10 Check Battery Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3.11 Engine Run Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.12 Engine Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Table of Contents

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-iii

6.3.13 Check Antifreeze. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.3.14 Air Cleaner Service Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4 Annual Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4.1 Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.4.2 Turbocharger Mounting Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.4.3 Engine Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.4.4 Inspect Fuel Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4.5 Engine Oil and Oil Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4.6 Change Fuel Filter of Filter/Separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4.7 Output Shaft Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4.8 Engine Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.8.1 Crank Termination Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.8.2 Engine Speed Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.8.3 Overspeed Set Point Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.9 Coolant Pump/Alternator Belt Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.10 Coolant Pump/Alternator Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.11 Heat Exchanger Pressure Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.12 Turbocharger Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.5 Every 2 Years or 2000 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5.1 Water Pump Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5.2 Drain and Flush Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.6 Every 4 Years or 5000 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.6.1 Coolant Thermostat Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.6.2 Coolant Pump/Alternator Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.6.3 Charge Air Cooler (CAC) Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.6.3.1 Charge Air Heat Exchanger Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Section 7 - Troubleshooting

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 Alternator Overcharging with the Engine Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.1.2 Neither Battery is Charging with the Engine Running. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.1.3 Only One Battery is Charging with the Engine Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.1.4 Voltage Indications Differ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.1.5 Coolant Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.1.6 Excessive Coolant Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.1.7 Coolant Temperature Above Normal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.1.8 Coolant Temperature Below Normal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.1.9 Raw Water Drain Steaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.1.10 Raw Water Solenoid Valve fails to Operate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.1.11 Auto Start failure - Does not Crank on BATT A or B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.1.12 Auto Start failure - Cranks but does not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.1.13 Auto Start failure - Engine Starts but Crank Terminate Does Not Occur . . . . . . . . . . . . . . . . . . 7-19

7.1.14 Manual Start Failure from Solenoid Lever - Does not Crank on A or B . . . . . . . . . . . . . . . . . . . 7-20

7.1.15 Manual Start Failure from Control Panel - Does not Crank on A or B . . . . . . . . . . . . . . . . . . . . 7-20

7.1.16 Engine Cranks Normally But Will Not Start (No Exhaust Smoke). . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.1.17 Engine Cranks Slowly But Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.1.18 Engine Stops During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.1.19 Engine Will Not Reach Rated Speed (RPM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.1.20 Engine Will Not Shut Off Remotely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.1.21 Engine Will Not Shut Off Locally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.1.22 Fuel Consumption is Excessive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.1.23 Fuel or Engine Oil Leaking From Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.1.24 Engine Oil is Contaminated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-iv

Table of Contents

7.1.25 Engine Oil Consumption is Excessive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

7.1.26 Engine Oil in the Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

7.1.27 Engine Overspeed Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.1.28 Tachometer Does not Indicate Engine Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Section 8 - Component Parts and Assemblies

8.1 Part Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Routine Service and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.3 Emergency Repairs and Technical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.4 Recommended Spares Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Index

Table of Contents

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-v

List of Figures

Figure 2-1 Heat Exchanger Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2 Raw Water Cooling Loop Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-3 Engine Components - Instrument Panel Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-4 Engine Components - Turbocharger Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-5 Engine Overspeed Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6 Turbocharger and Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-7 Engine Air Intake and Charge Air Cooling Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-8 Engine Cooling System Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-9 Fuel System Components - High Pressure Common Rail (HPCR) . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-10 Flow Diagram - Engine Lubricating Oil System (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-11 Flow Diagram - Exhaust System (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-12 Turbocharger Exhaust Flow Diagram (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

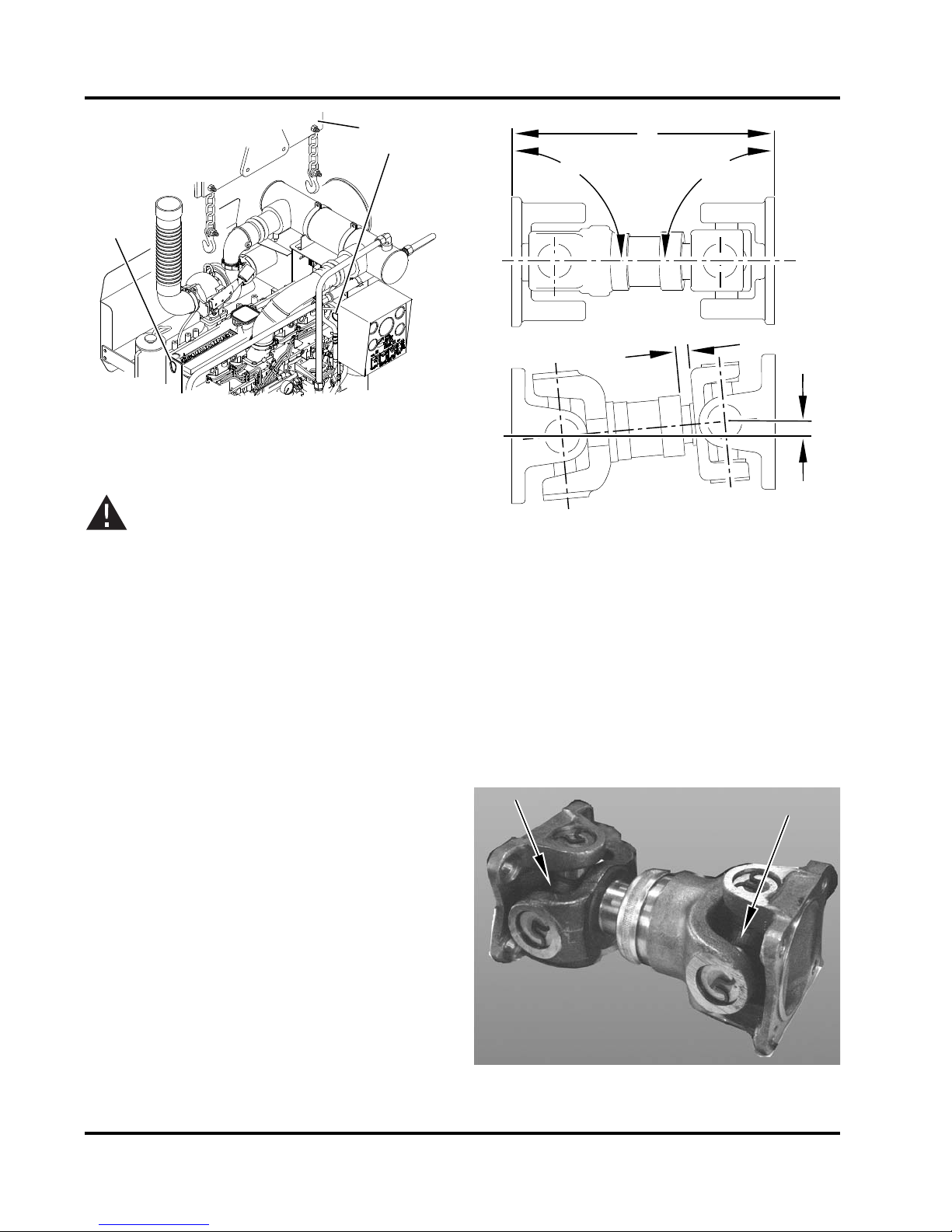

Figure 3-1 Engine Lifting lugs (Engine Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 Drive Coupling Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-3 Drive Coupling Grease Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-4 Fuel Line Supply and Return Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-5 Engine Fuel System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-6 Raw Water Cooling Loop Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-7 Cooling Loop Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-8 Series Battery Connection - 24 VDC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

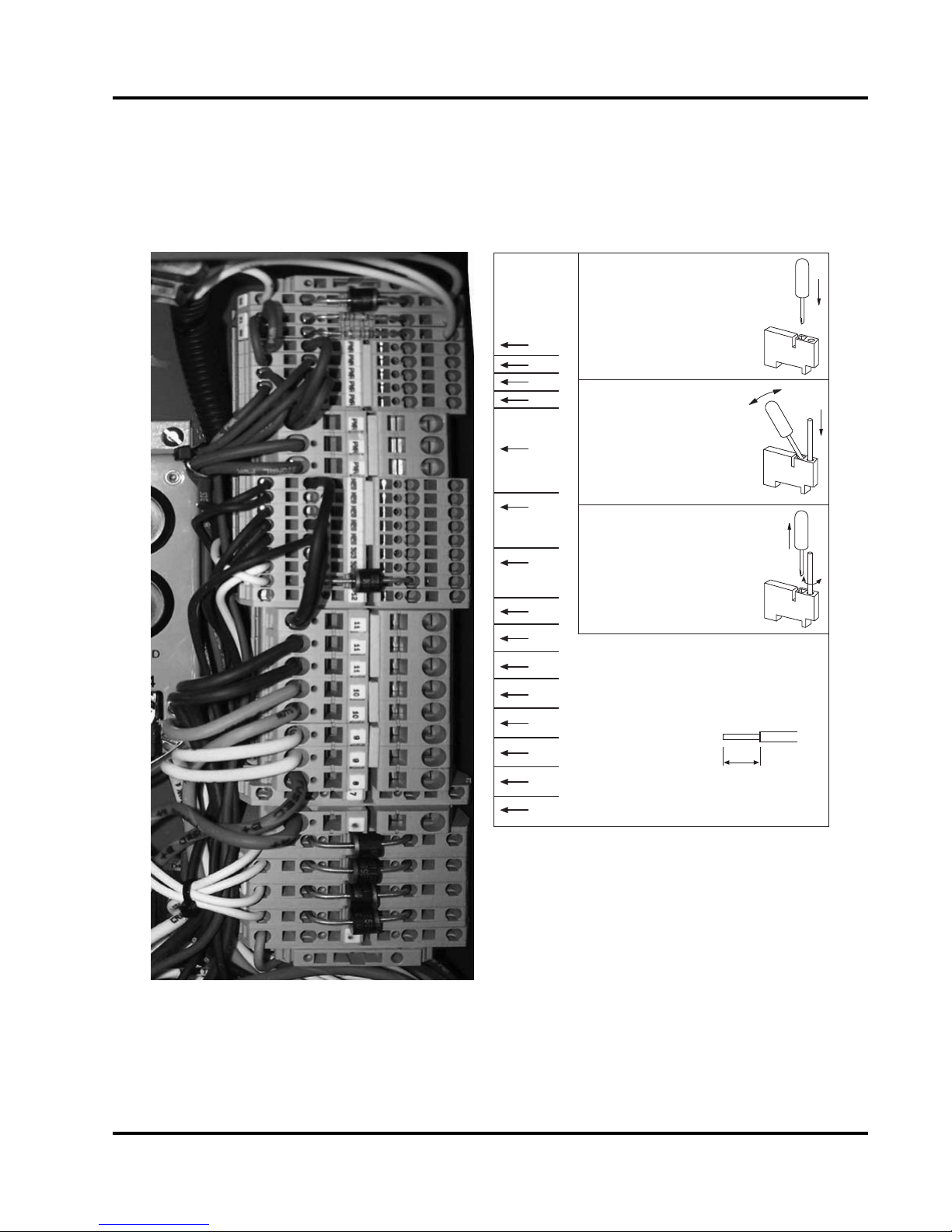

Figure 3-9 Termination Blocks and Wiring Decal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-10 Coolant Hoses and Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-11 Coolant Circulation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-12 Engine Coolant Expansion Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-13 Charge Air Cooler Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-14 Turbocharger and CAC Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-15 Oil Filter and Oil Level Dipstick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-16 Turbocharger Oil Line Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-17 Turbocharger Turbine Wheel (typical). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-18 Operator’s Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-19 Operator’s Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-20 Manual Starter Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 4-1 Instrument Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-2 Operator Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-3 Engine Settings Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-4 ECM Selector Panel and Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-5 Electronic Control module (ECM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-6 Engine Overspeed Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . 4-5

Figure 4-7 Raw Water Flow Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 5-1 Instrument Panel Switch Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Figure 5-2 ECM Selector Panel and Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-3 Raw Water Manual Valves (open) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 5-4 Manual Starter Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-5 ECM Diagnostic Reader Plug-ins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Figure 5-6 Instrument Panel Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Figure 6-1 Air Intake Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

TOC-vi

Table of Contents

Figure 6-2 Heat Exchanger Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Figure 6-3 Oil Level Dipstick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-4 Engine Fuel Filter/Water Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-5 Crankcase Breather. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Figure 6-6 Raw Water Wye Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Figure 6-7 Optional 24 VDC Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Figure 6-8 Engine Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-9 Air Cleaner Service Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Figure 6-10 Electrical Control Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-11 Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-12 Engine Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-13 Fuel Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-14 Oil Pan Drain Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Figure 6-15 Oil Filter and Oil Level Dipstick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Figure 6-16 Fuel Filter or Filter/Separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Figure 6-17 Drive Coupling Grease Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Figure 6-18 Engine Overspeed Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Figure 6-19 Coolant Pump/Alternator Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Figure 6-20 Turbocharger Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-21 Turbocharger Turbine Wheel (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-22 Engine Coolant Drains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Figure 6-23 Filter Housing Gasket Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Figure 6-24 Thermostat Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Figure 6-25 Coolant Pump/Alternator Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Figure 6-26 Coolant Filter & Shut-off Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Figure 6-27 Cooling Loop and Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Figure 6-28 Charge Air Tubing Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

This manual contains proprietary information to equipment produced by Cummins Fire

Power or Cummins, Inc. and is being supplied solely for the purpose of operating,

maintaining and servicing the fire pump engine purchased from Cummins Fire Power.

© Copyright 2008, Cummins Fire Power

Warranty Information

LIMITED WARRANTY

EXCLUSIVE EXPRESS LIMITED WARRANTY: Cummins Fire Power (CFP), division of Cummins NPower,

LLC expressly warrants to the original end consumer only that, for a period not to exceed the earlier of two (2)

years or 2000 hours of use from the start-up date (or, if the original end consumer fails to register as purchaser

with CFP, six (6) months from CFP shipment date), the diesel fire pump drivers, manufactured and sold by

CFP, shall be free from defects in material and workmanship when used and serviced in accordance with the

Operations and Maintenance manual for the applicable Cummins Fire Pump engine model (the “Exclusive

Warranty”). The Exclusive Warranty is nontransferable and shall immediately terminate and be of no further

force or effect upon the sale, lease, assignment, transfer or other disposition by an original end consumer of a

Cummins Fire Pump engine that contains a diesel fire pump driver covered by this Exclusive Warranty.

Nothing contained herein shall be construed to extend the Exclusive Warranty, and the Exclusive Warranty

shall not be extended, to:

• Maintenance, adjustment, installation or start-up costs;

• Diesel fire pump driver failure due to normal wear, accident, misuse, abuse, neglect, improper installation

or a defect attributable to a Cummins Fire Pump engine;

• Alterations or modifications not authorized in writing by CFP;

• Additional components added to a diesel fire pump driver package subsequent to shipment of the

engine; or

• Starting batteries

• Coolant heaters are covered for 12 months.

DISCLAIMER OF WARRANTIES: Except for the Exclusive Warranty provided above, which is in lieu of all

other express and implied warranties, CFP EXPRESSLY DISCLAIMS ALL EXPRESS AND IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION AND EXCLUSION OF REMEDIES: All claims under this Exclusive Warranty shall be deemed

waived by the original end consumer if not submitted to CFP or an authorized distributor within thirty (30) days

of initial discovery that a diesel fire pump driver is not conforming to the Express Warranty. The original end

consumer’s remedy under this Exclusive Warranty is limited, in CFP’s reasonable discretion, to repair, replacement or other appropriate adjustment of a nonconforming diesel fire pump driver determined, upon CFP’s

inspection, to have been properly installed, maintained and operated in accordance with the Operations and

Maintenance manual furnished by CFP. IN ANY EVENT, CFP SHALL NOT BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES.

The Cummins Industrial Warranty covers the base engine for a period of time not to exceed the earlier of two

(2) years or 2000 hours of operation from the date of delivery and start-up of the engine. Reference bulletin

numbers 3381321 US/Canada & 3381322 Outside US/Canada. Cummins Fire Power components are warranted for a period of time not to exceed the earlier of two (2) years or 2000 hours of operation from the startup date of the fire pump system, and the coverage includes travel time and mileage for the first year of the

Limited Warranty, and repair or replacement of parts and reasonable cost of labor. The Cummins Fire Power

Limited Warranty does not cover failures or damage due to abuse or neglect and including, but not limited to:

shipping damage, improper storage, improper installation, unauthorized modification or lack of maintenance.

Cummins Fire Power is not responsible for incidental or consequential damages.

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

1-1

Section 1 - Safety

1.1 Introduction

Cummin’s Fire Power and Engine Manuals should be

considered part of the equipment. Keep the manuals

with the equipment. If the equipment is traded or sold,

give the manuals to the new owner.

All personnel responsible for operation and maintenance of the equipment should read and thoroughly

understand this manual.

1.2 Advisory and Cautionary Statements

Advisory and Cautionary Statements are used

throughout this manual to call attention to special

information, correct operating procedures and to

safety precautions.

NOTE: A general advisory statement relating to

equipment operation and maintenance procedures

IMPORTANT: A specific advisory statement intended

to prevent damage to the equipment or associated

components.

Cautionary Statements consist of two levels:

WARNING

Indicates the presence of a hazard which CAN

cause severe personal injury.

CAUTION

Indicates the presence of a hazard which CAN

cause personal injury, or cause equipment

damage.

1.3 Safety Precautions

Warning: Read and understand all of the safety pre-

cautions and warnings before performing any repair.

This manual contains the general safety precautions

that must be followed to provide personal safety.

When they apply, special safety precautions are

included with operating procedures.

Warning: Perform a walk around inspection and alert

all area personnel that the equipment will be starting

before manual operation.

Warning: Do not operate faulty or damaged equipment. Ensure that all hoses, pipe connections,

clamps and guards are in place and securely fastened. Electrical components should be kept in good

working condition and repaired immediately by qualified personnel.

Warning: After performing maintenance, remove all

tools and foreign materials, reinstall and securely

fasten ALL guards, covers and protective devices.

Warning: Exposed in-running belt nips can cause

severe personal injury or dismemberment. Ensure

that guards are in place and securely fastened before

operation.

Warning: Rotating drive shafts can lacerate, dismember or cause strangulation. Keep hands, body

parts, long hair, or loose-fitting clothing clear at all

times.

Warning: Never attempt to manually clean a

machine while it is operating or in standby mode.

Warning: Never open ports on tanks or piping while

the engine is operating. Contact with pressurized

agents can cause severe personal injury.

Warning: Relieve all pressure in the air, oil, and the

cooling systems before any lines, fittings, or related

items are removed or disconnected.

Caution: Engine fuel is flammable when in contact

with electrical spark or flame sources. Remove all

sources of spark or flame from the work area.

Caution: Always use the same fastener part number

(or equivalent) when replacing fasteners.

Caution: Some state and federal agencies in the

USA have determined that used engine oil can be

carcinogenic and can cause reproductive toxicity.

Dispose of waste oil in accordance with applicable

requirements.

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

1-2

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-1

Section 2 - Description

2.1 Introduction

This manual contains information for the correct operation and maintenance of a Cummins Fire Pump

Engine. Read and follow all safety instructions. Refer

to the General Safety Instructions in Section 1 -

Safety.

Keep this manual with the equipment. If the equipment is traded or sold, give the manual to the new

owner.

Cummins Fire Power, Cummins NPower and Cummins, Inc. reserve the right to make changes at any

time without obligation. If any differences are found

between an engine and the information in this

manual, contact the local Cummins Authorized

Repair Location.

1. Coolant Fill Cap

2. Coolant Expansion Tank

3. Coolant Heat Exchanger

4. Heat Exchanger Discharge

5. Charge Air Cooler (CAC) Heat Exchanger

Figure 2-1 Heat Exchanger Tanks

The latest technology and the highest quality components were used to produce this engine. When

replacement parts are needed, we recommend using

only genuine Cummins or ReCon® exchange parts.

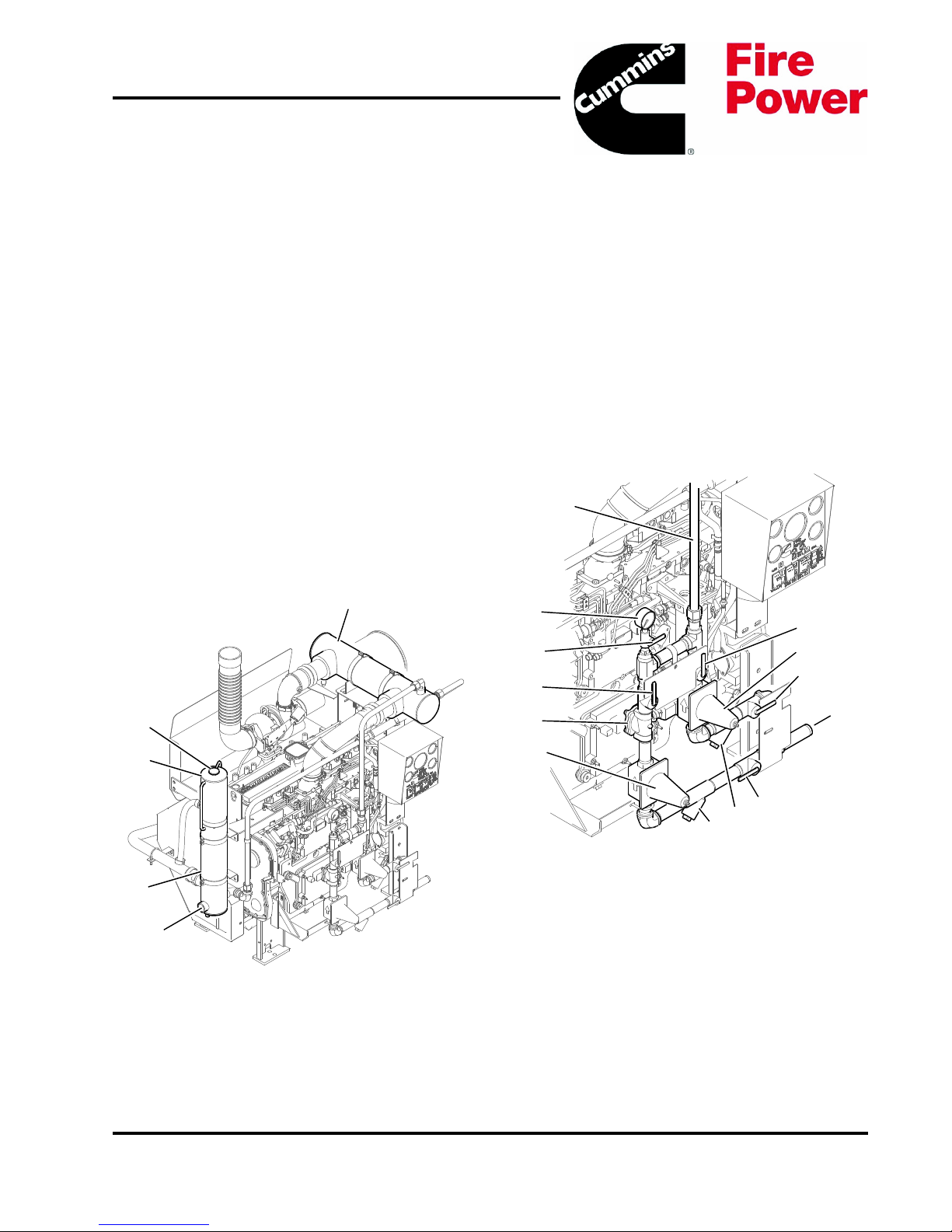

2.2 Fire Pump Engines

Cummins complete line of fire pump engines have

been approved as packaged units (engine and all

accessories) by Factory Mutual Approvals and listed

by Underwriter’s Laboratories, Inc. and Underwriter’s

Laboratories of Canada.

1. 1” NPT Raw Water Inlet

2. Bypass Water Inlet Valve

3. Bypass Water Pressure Regulator

4. Bypass Water Outlet Valve

5. Pipe To Heat Exchanger

6. Water Supply Pressure Gauge

7. Pressure Gauge Isolation Valve

8. Normal Water Outlet Valve

9. Normal Water Solenoid Valve

10. Normal Water Pressure Regulator

11. Normal Water Wye Strainer

12. Bypass Water Wye Strainer

13. Normal Water Inlet Valve

Figure 2-2 Raw Water Cooling Loop Manifold

1

2

3

4

5

CFP9-001

1

2

3

4

6

5

7

8

9

10

11

12

13

CFP9-002

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-2

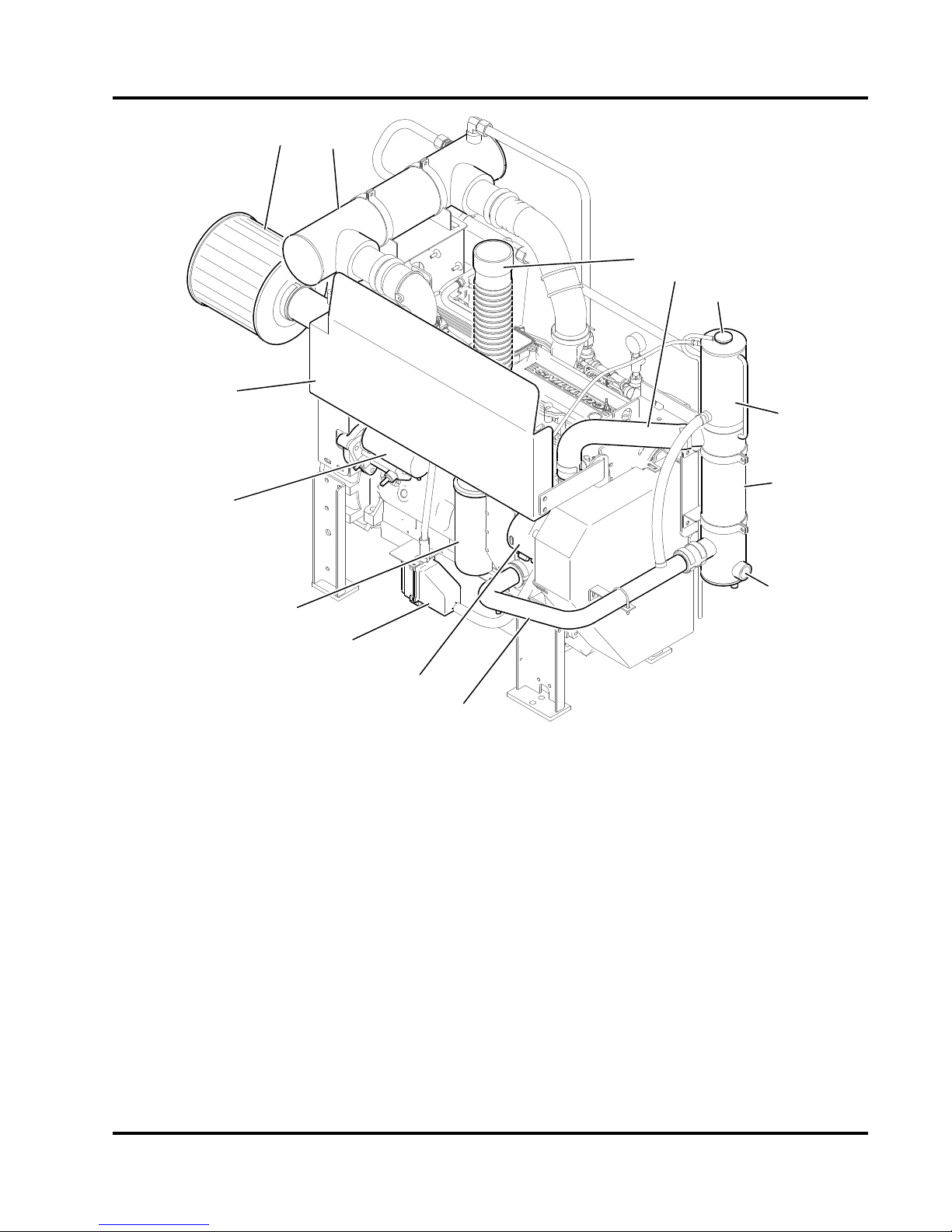

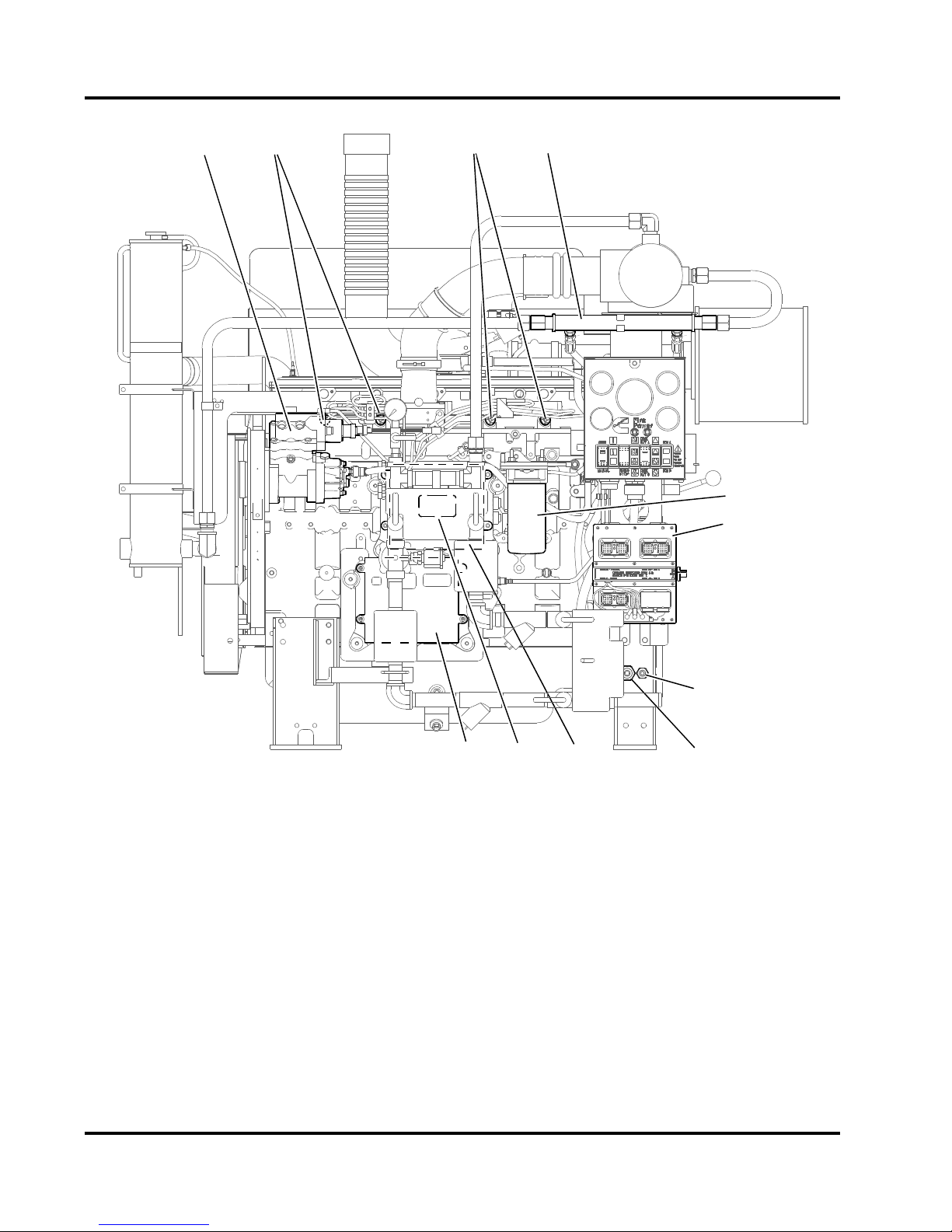

1. Coolant Fill Cap

2. Coolant Expansion Tank

3. Exhaust Flex Connection

4. Charge Air Cooler Hose

5. Terminal Box

6. Charge Air Cooler (CAC) Heat Exchanger

7. Air Cleaner Element

8. Engine Speed Setting Plates

9. Battery Starter Contactors

10. Manual Start Instruction Decal

11. Engine Supports

12. Flywheel Housing

13. Fuel Return Outlet

14. Raw Water Inlet

15. Fuel Inlet

16. Oil Pan and Drain

17. Operator Control Panel

18. Fuel Filter or Filter/Separator

19. Cooling Loop Manifold Piping

20. Electronic Control Modules (ECMs)

Figure 2-3 Engine Components - Instrument Panel Side

19

17

16

1

23

4

6

5

7

8

9

10

11

12

20

11

14

15

13

18

CFP9-003

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-3

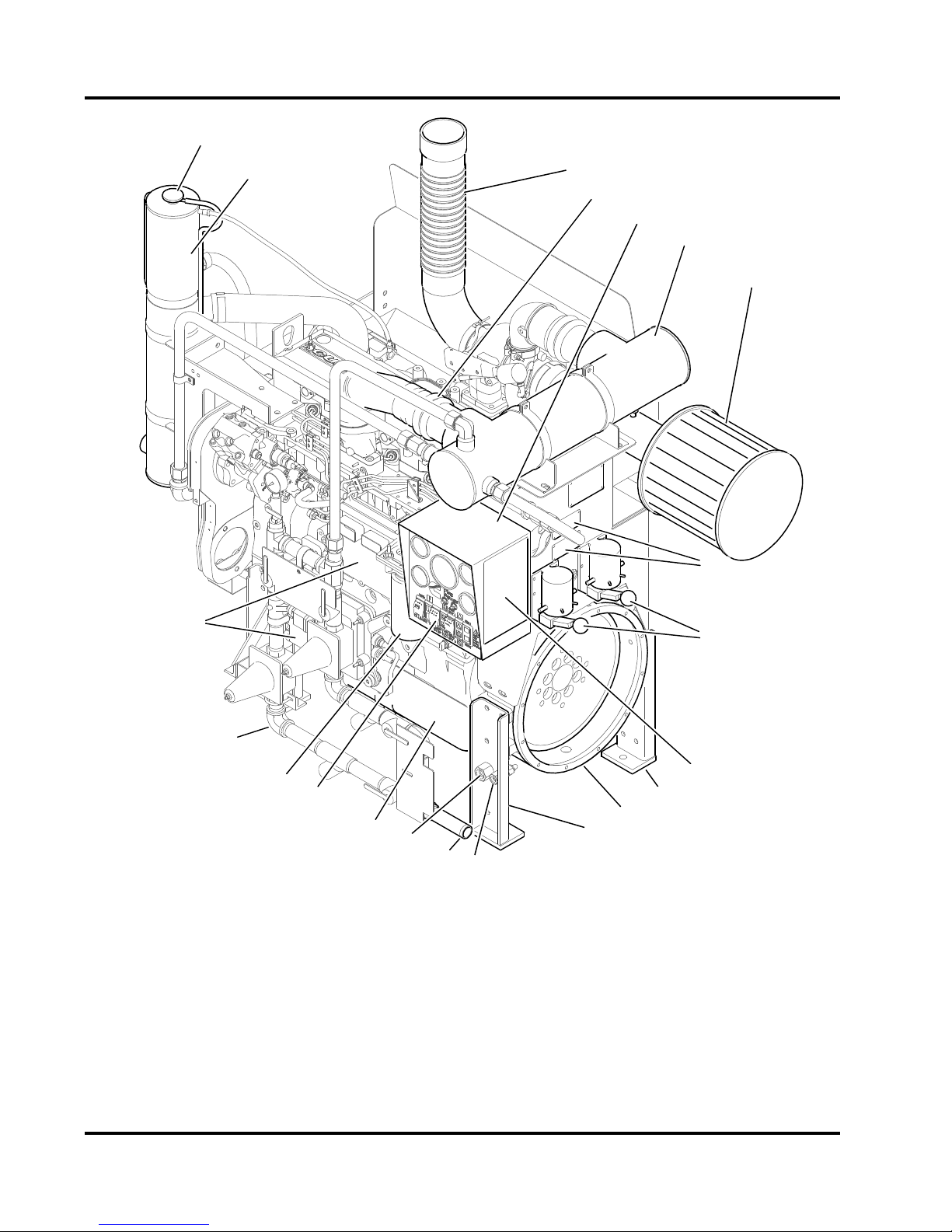

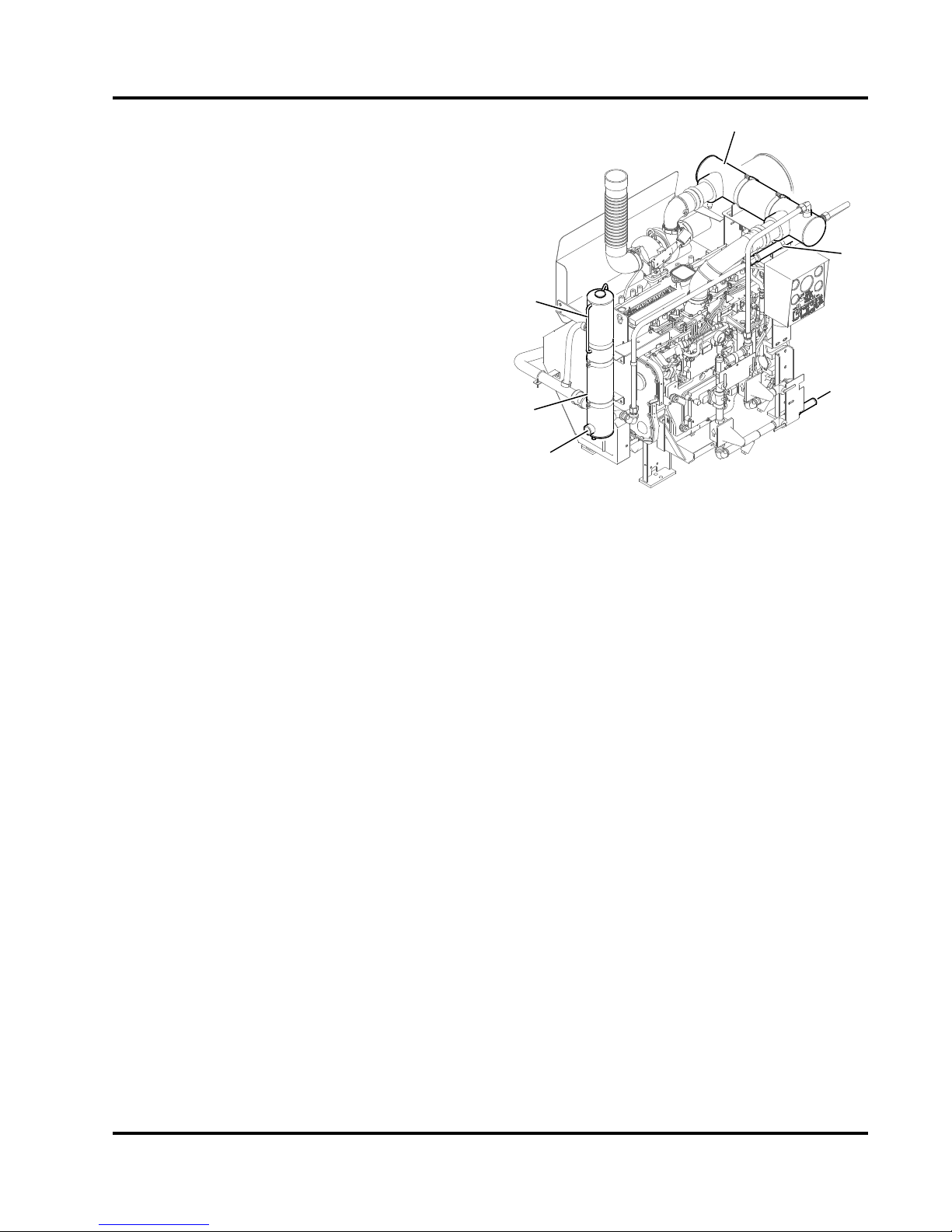

1. Air Cleaner Element

2. Charge Air Cooler (CAC) Heat Exchanger

3. Exhaust Flex Connection

4. Upper Coolant Hose

5. Coolant Fill Cap

6. Coolant Expansion Tank

7. Coolant Heat Exchanger

8. Heat Exchanger Raw Water Discharge

9. Lower Coolant Hose/Tube

10. Alternator

11. Engine Heater

12. Engine Oil Filter

13. Starter Motor

14. Manifold Heat Shield

Figure 2-4 Engine Components - Turbocharger Side

This product meets Tier 3 emission levels. This turbocharged engine requires charge air cooling (CAC)

and fuel cooling.

No deviations are permitted without prior written

approval. These engines are to be used only for fire

protection applications. Refer to Figure 2-1, Figure

2-2, Figure 2-3 and Figure 2-4.

2.3 Operator Control Panel

The operator control panel is mounted on the flywheel end on the left (fuel pump) side of the engine.

Refer to Section 4 - Controls for additional information.

The operator control panel contains controls for starting, monitoring engine performance and controlling

fire pump engine operation.

1

2

3

4

6

5

7

8

9

10

11

12

14

13

CFP9-004

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-4

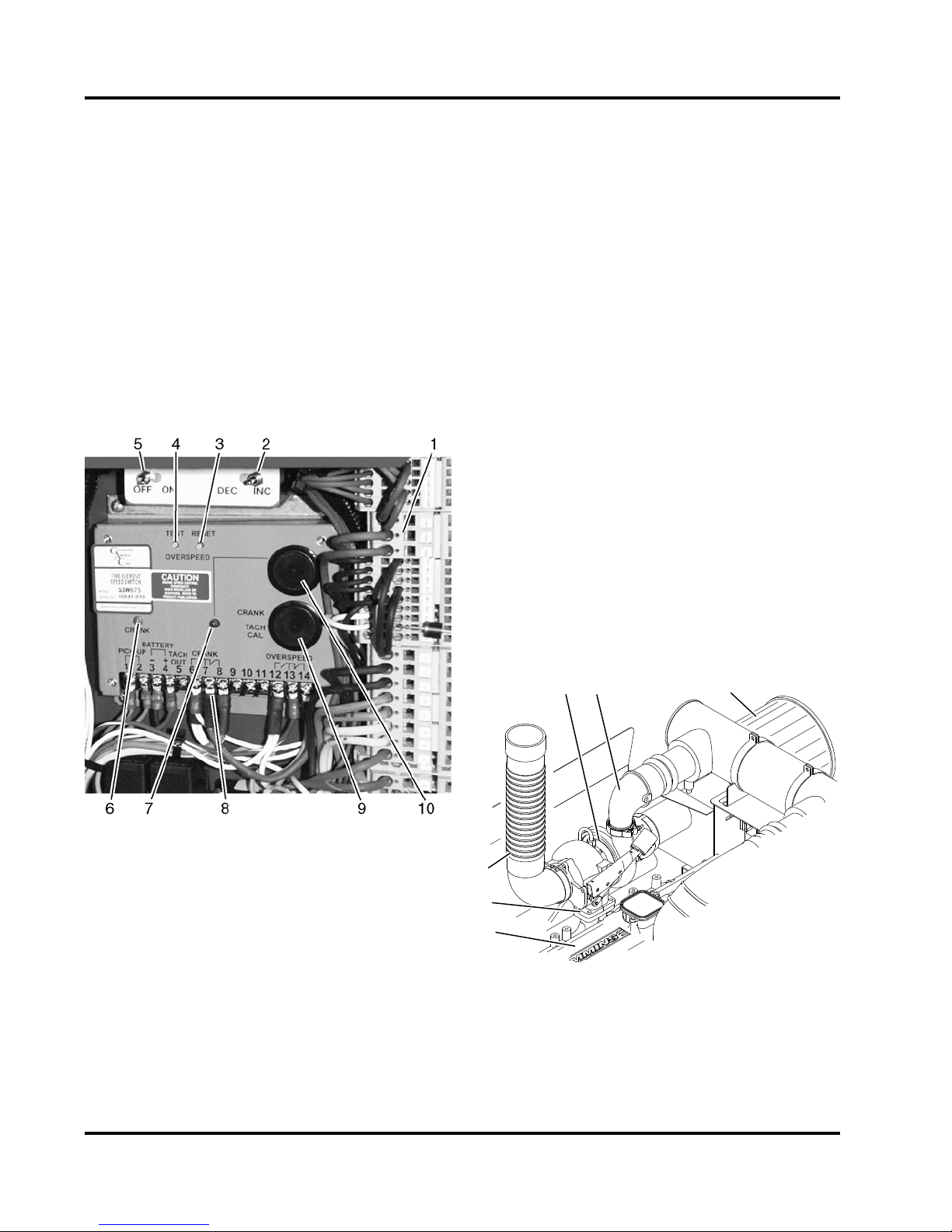

2.3.1 Overspeed Switches

Each engine is equipped with an electronic overspeed module which activates the fuel pump solenoid

valve and ECM ignition to shut off the engine when

the RPM exceeds a preset limit. The overspeed

switch senses engine speed during the start cycle

and stops the starting motor cranking cycle. Refer to

Figure 2-5.

2.3.2 Operating Speed

All Cummins fire pump engines are shipped from the

factory adjusted to the requested operating speed

(RPM). Final operating speed adjustment must be

made during the in-service inspection to obtain the

required operating speed specified by the pump manufacturer.

1. Spring Clamp Terminal Blocks

2. Speed Increase/Decrease Toggle Switch

3. RESET Button

4. TEST Button

5. Diagnostic ON/OFF Toggle Switch

6. CRANK Termination or RUN Signal Indicator

LED (Factory Use Only)

7. Overspeed Indicator LED

8. Pre-wired Terminals

9. Crank Terminate Potentiometer Cover

10. Overspeed Potentiometer Cover

Figure 2-5 Engine Overspeed Control Module

2.4 Fire Pump Controller

Fire pump controller is not supplied by Cummins Fire

Power, or Cummins, Inc. The fire pump controller

starts the engine automatically when a remote fire

demand signal is initiated and automatically shuts

down the engine when the fire demand signal is discontinued.

The engine may be started locally in the Manual

Mode and shut down using the operator control panel

Stop Switch or by returning the switch back to automatic mode.

NOTE: Pressure recorders are available to provide a

permanent record of water pressure fluctuations and

engine starts. Sequential starting is available for

multiple-pump installations to prevent all pumps from

starting simultaneously.

2.5 Air Intake System

The Air Intake System supplies combustion air to the

fire pump engine cylinders. The air filter prevents particulate matter from entering the air intake. Combustion air drawn into the system by the turbocharger is

directed through the charge air cooler (CAC) heat

exchanger for cooling before entering the intake manifold where the charge air is mixed with fuel. Refer to

Figure 2-6 and Figure 2-7.

1. Turbocharger

2. Turbo Connection to Charge Air Cooler

3. Intake Air Cleaner

4. Valve Cover

5. Exhaust Manifold

6. Exhaust Flex Connection

Figure 2-6 Turbocharger and Exhaust Manifold

CFP9-040

1

2

3

4

6

5

CFP9-005

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-5

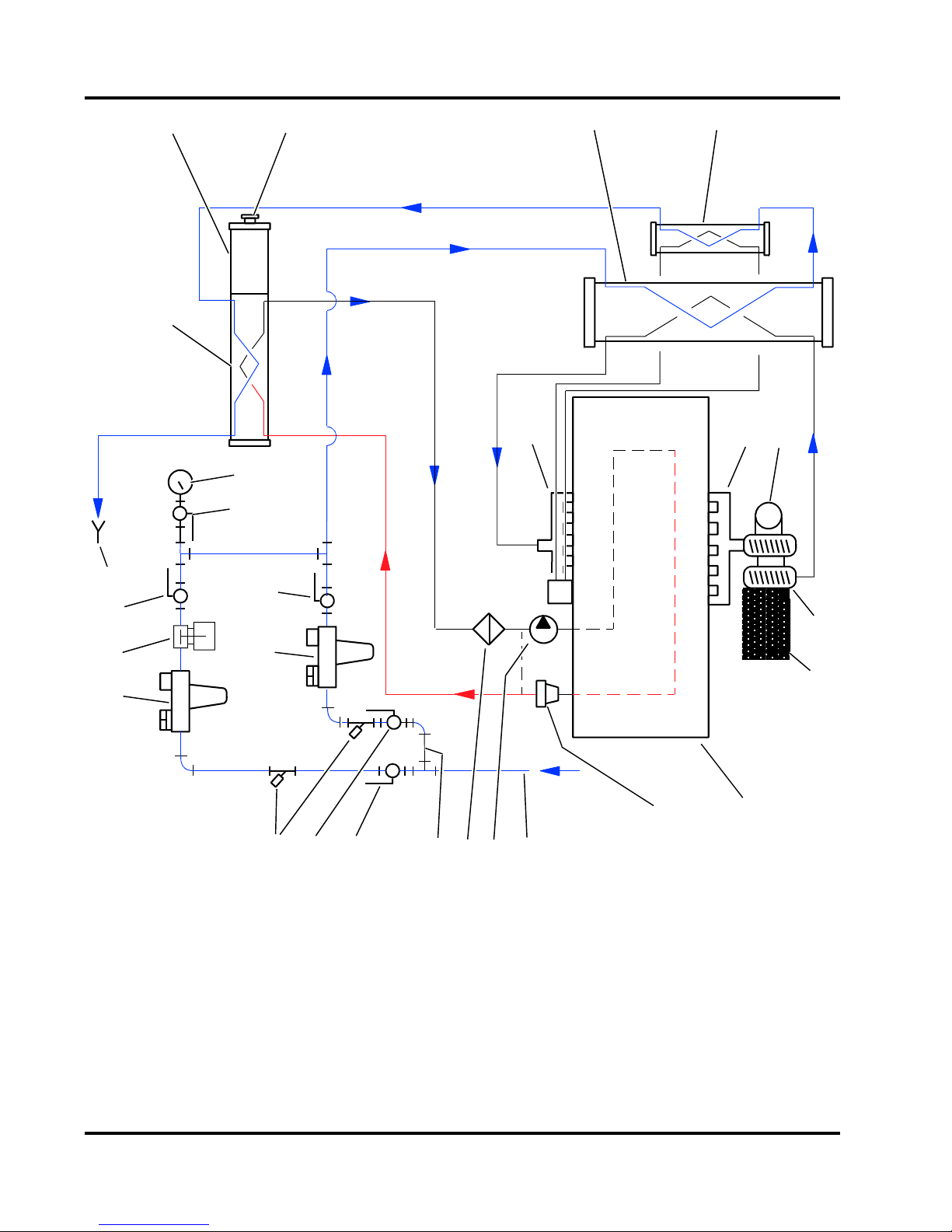

1. Turbocharger

2. Air Hose To Charge Air Cooler

3. Intake Air Cleaner

4. Charge Air Cooler (CAC) Heat Exchanger

5. Charge Air Cooler Hose

6. Combustion Air Intake Manifold

Figure 2-7 Engine Air Intake and Charge Air Cooling Flow Diagram

2.6 Raw Water Cooling System

The fire pump raw water supply provides cooling

water for the engine heat exchanger system. A waterto-air Charge Air Cooler (CAC) Heat Exchanger,

reduces the combustion air temperature at the intake

manifold. A low charge air temperature (requirement

of 60° C (140° F) (with 25° C (77° F) ambient) meets

emission levels, while improving engine performance

and efficiency.

1

2

3

4

6

5

CFP9-006

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-6

1. Coolant Heat Exchanger

2. Coolant Expansion Tank

3. Coolant Fill Cap

4. Charge Air Cooler

5. Fuel Cooling Heat Exchanger

6. Exhaust Manifold

7. Exhaust Flex Connection

8. Turbocharger

9. Air Filter

10. Engine Block

11. 185° F. Thermostat

12. Raw Water Inlet Pipe

13. Coolant Pump

14. Coolant Filter

15. Bypass Piping

16. Manual Shut-off Valve

17. Raw Water Wye Strainer

18. Raw Water Pressure Regulator

19. Raw Water Solenoid Valve

20. Raw Water Pressure Gauge

21. Raw Water Drain Line

22. Combustion Air Intake Manifold

Figure 2-8 Engine Cooling System Flow Diagram

2

3

4

22

8

6

9

10

11

13

14

1616

18

16

18

19

16

21

16

20

7

12

15

1

5

17

CFP9-007

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-7

Water entering the cooling system through the 1”

NPT raw water inlet, first circulates through the

charge air cooler heat exchanger, cooling the compressed air from the turbocharger outlet ducting. The

cooled combustion air exits the CAC outlet duct to the

engine air intake manifold. Refer to Figure 2-1, Figure

2-2 and Figure 2-7.

NOTE: The raw water supply must be immediately

available when the engine is started.

The raw water from the CAC heat exchanger then

passes through the Fuel Cooling Heat Exchanger

and the Engine Coolant Heat Exchanger. The raw

water exits the Coolant Heat Exchanger through a

1-1/4” NPT discharge connection.

IMPORTANT: If the piping will be supplied by the

customer, provide raw water supply piping and components equivalent to components supplied by

Cummins Fire Power and as shown in Assembly Diagram, Raw Water Piping. Refer to National Fire Protection Association NFPA20 Chapter 11 for US

installation requirements. When choosing components for the raw water supply and bypass, ensure

that the internal cross sectional area of the component is at least as large as the recommended pipe

size.

When the raw water piping is installed, adjust both

pressure regulator set points before operating the

pump.

1. The upper line is the bypass line. The bypass

line outlet valve should be closed.

2. The lower line with the solenoid valve is the

normal inlet line. The pressure gauge isolation

valve must be open. The normal water inlet line

valve should be open.

IMPORTANT: Monitor the oil pressure and coolant

temperature gauges frequently. Refer to Lubricating

Oil System Specifications or Cooling System Specifications in the Engine Data Sheets for recommended

operating pressures and temperatures. Shut off the

engine if any pressure or temperature does not meet

the specifications.

Maximum engine coolant temperature should not

exceed 107° C (225° F). The coolant expansion pressure/fill cap must meet the minimum pressure of 10

kPa (15 psi).

The engine coolant system contains a mixture of at

least 50 percent antifreeze and 50 percent water. The

coolant level should be maintained just below the fill

neck of the coolant supply tank.

CAUTION

Continuous operation with low coolant temperature (below 70° C (158° F)) or high coolant temperature (above 107° C (225° F)) can damage the

engine. Verify raw water pressure and flow.

2.7 Fuel Cooling System

A fuel cooling heat exchanger maintains fuel temperature to meet the maximum allowable fuel inlet temperature (71° C (160° F)). Performance of the fuel

cooling system is critical to engine durability, performance and emissions compliance.

2.7.1 Fuel Supply and Drain Location

The fuel supply and return connections are located

on the rear (flywheel end) left (injection pump side)

engine support. Refer to Figure 2-9.

2.8 High Pressure Common Rail (HPCR)

Fuel System

The fire pump engine is equipped with an electronic

fuel system that delivers precise fuel quantities with

precise injection timing at high injection pressures.

The system consists of a high pressure pump (up to

1100 BAR) that supplies a common fuel rail and

accumulator manifold feeding 6 high-pressure electronic controlled injectors to provide precise fuel

metering and timing. The system is controlled by the

Engine Control module CM850 for fueling and timing

based on temperature, altitude, boost pressure, and

throttle position. Refer to Figure 2-9.

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-8

1. High Pressure Fuel Pump

2. Injector (4)

3. Fuel Cooling Heat Exchanger

4. Fuel Filter or Filter/Separator

5. ECM Selector Panel and Switch

6. Fuel Return Connection

7. Fuel Supply Connection

8. ECM Module A

9. Lift Pump (behind ECM A)

10. ECM Module B

Figure 2-9 Fuel System Components - High Pressure Common Rail (HPCR)

With the High Pressure Common Rail (HPCR) fuel

system, fuel priming is required for conditions such

as: initial start-up, running out of fuel and maintenance of fuel system components (i.e., filter change).

A 12 VDC fuel lift pump is standard.

NOTE: The system will prime a totally dry fuel system

in 120 seconds or less. Applications with remote fuel

tank requires a fuel lift pump (supplied). Lift pump run

time is limited to two minutes.

CFP9-009

1

2

7

9

10

2

3

8

6

5

4

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-9

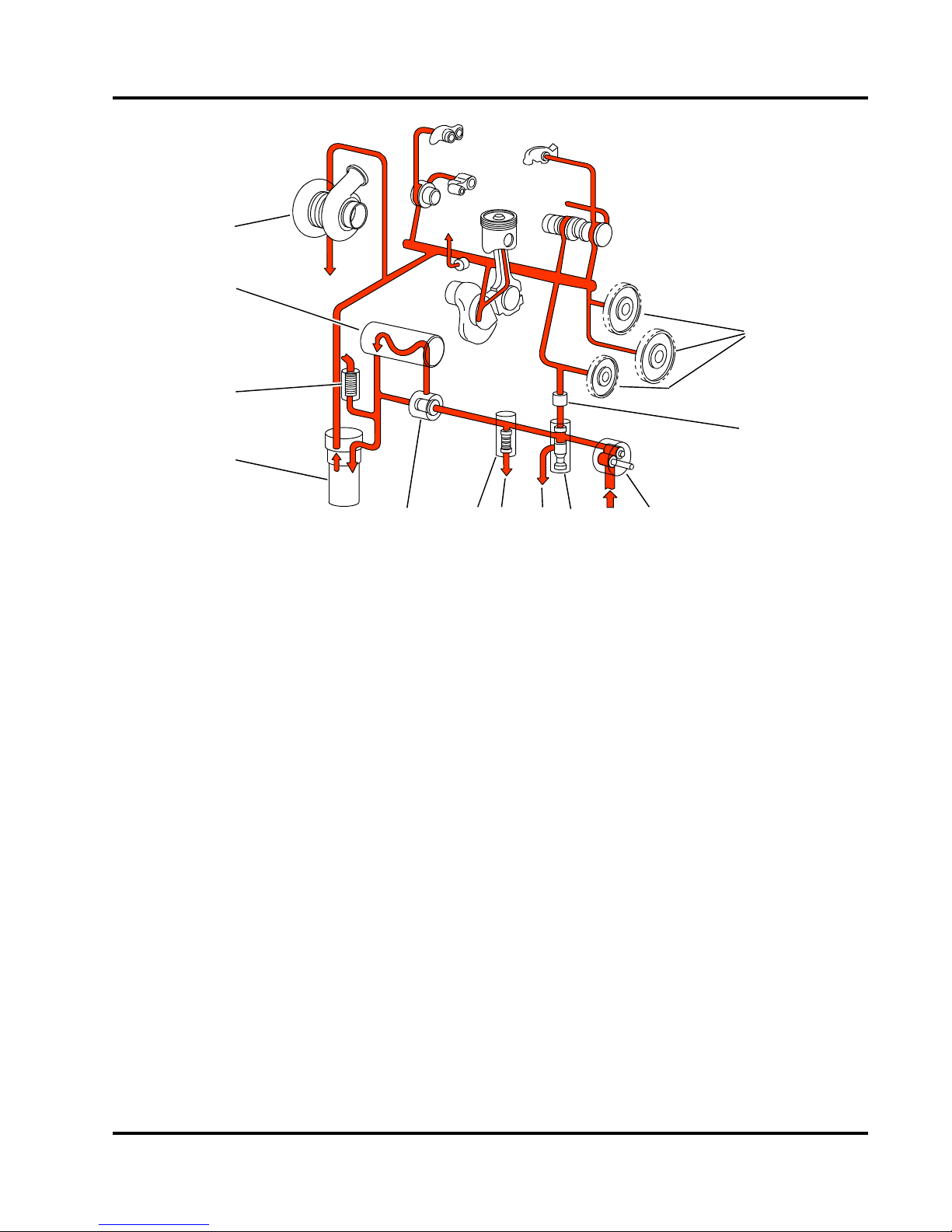

1. Oil Pump

2. Pressure Regulator Valve

3. Oil Return To Pan

4. High Pressure Relief Valve

5. Oil Return To Pan

6. Oil Thermostat

7. Oil Cooler

8. Combination Oil Filter

9. Filter Bypass Gears

10. Idler Gears

11. Viscosity Sensor

12. Turbocharger

Figure 2-10 Flow Diagram - Engine Lubricating Oil System (typical)

2.9 Engine Oil System

The Engine Oil System lubricates moving internal

engine parts (pistons, piston arms, valves, cam

shafts, drive shafts and bearings). The oil pump circulates oil from the oil pan, through the oil filter and into

engine areas where friction may develop. Refer to

Figure 2-10.

Typically engine oil has been added during manufacture and testing procedures, however, shipping

restrictions can affect whether the oil is maintained in

the engine or drained for shipment.

Check the oil level at the dipstick. Add oil as necessary to bring the oil level to the H (high) mark on the

dipstick.

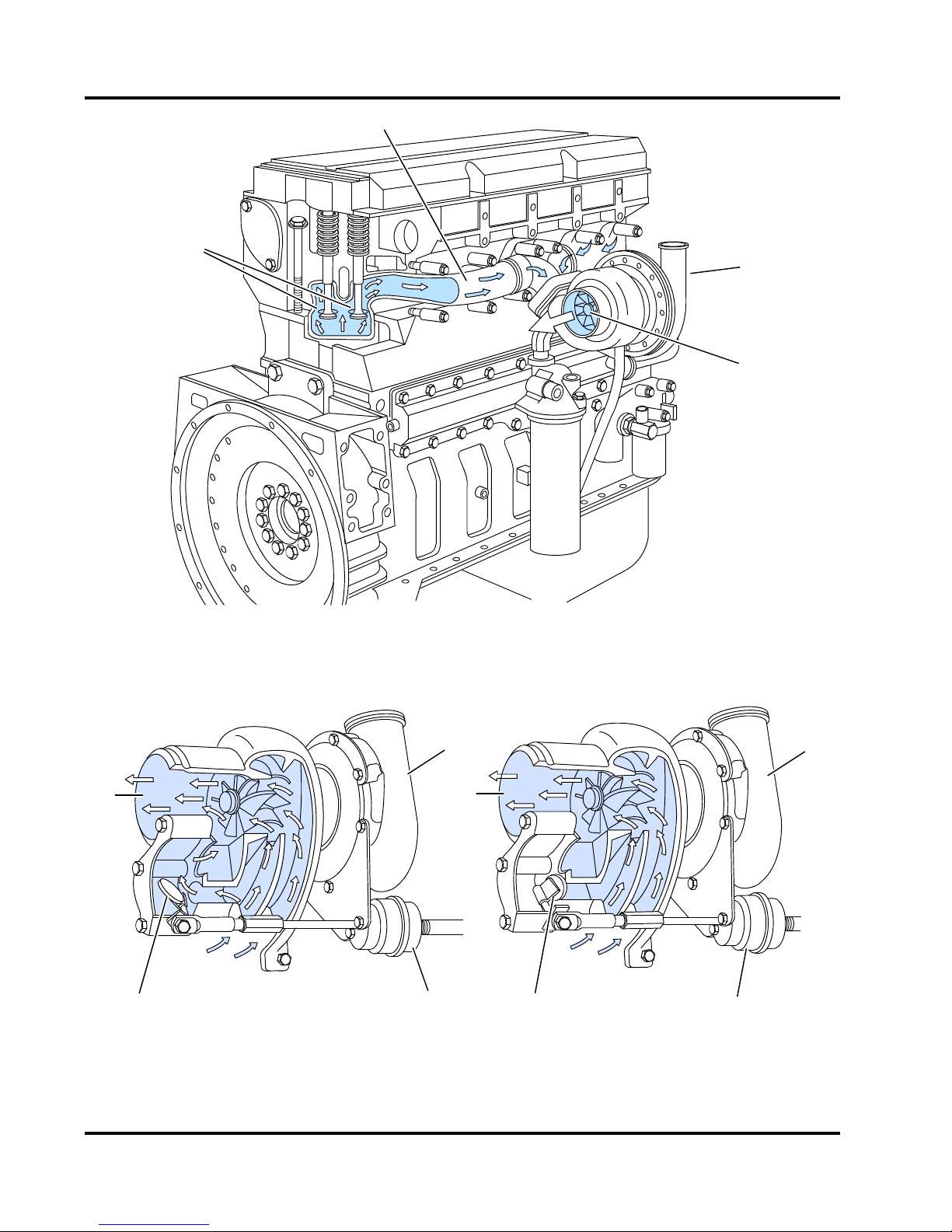

2.10 Exhaust System

The exhaust system removes engine exhaust from

the cylinders after the combustion process.The

exhaust discharges from the exhaust manifold,

passes through (drives) the turbocharger, and exits

through the exhaust flex-pipe. Refer to Figure 2-11,

and Figure 2-12.

CFP9-010

1

2

3

4

7

5

8

9

10

12

6

11

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

2-10

1. Exhaust Valve Ports

2. Engine Exhaust Manifold

3. Combustion Air To Charge Air Cooler

4. Turbocharger Turbine

Figure 2-11 Flow Diagram - Exhaust System (typical)

1. Wastegate Actuator Cylinder

2. Exhaust Flow to Flex Pipe

3. Combustion Air To Charge Air Cooler

4. Wastegate OPEN

5. Wastegate CLOSED

Figure 2-12 Turbocharger Exhaust Flow Diagram (typical)

1

2

3

4

CFP9-008

1

2

3

4

5

1

3

2

CFP9-011

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-1

Section 3 - Installation

3.1 Receiving and Handling Information

Cummins Fire Power Pump Engines are pre-assembled and tested before shipment. Parts not shipped

attached to the engine are sometimes shipped individually. The equipment was thoroughly inspected

and prepared for shipping before it was turned over to

the carrier.

1. Carefully remove the components from the shipping container. Remove crating, shipping tape,

braces and tie-downs.

2. Inspect the equipment for damage that may

have occurred in shipping.

3. Check each item carefully against the shipping

manifest or bill of lading.

3.1.1 Damage During Shipping

File a Claim For Damages with the carrier, if your

equipment was received damaged or not received at

all. Notify Cummins Fire Power, or Cummins Inc. as

soon as possible to determine if a replacement item

or repair is required.

3.1.2 Claim Filing Procedure

The following information is required if a claim is filed:

1. A Claim Statement describing the damaged or

lost merchandise and how the claim was determined.

2. A Bill of Lading or Freight Bill is required as proof

of who transported the freight.

3. A noted Freight Bill or Inspection Report Copy,

as evidence of loss or damage.

4. Invoice Copy or other documents establishing

the cost to you of the freight lost or damaged, or

an Invoice for Repairs.

3.2 Site Preparation

This section provides instructions for the initial installation, adjustment, and testing of the Cummins Fire

Pump Engine. Appropriate portions of this section

should be used when returning the engine to operation after overhaul or major maintenance.

The site should be clean and relatively level. Clear

the proposed equipment area of overhanging

obstructions and obstacles protruding from the floor.

Raw water piping should be installed by trained technicians, familiar with local, state and federal codes

and regulations, per the equipment layouts supplied

by Cummins Fire Power, or Cummins Inc.

3.2.1 Site Considerations

Refer to the general fire pump and engine layout

drawings for installation dimensions supplied with this

manual.

CAUTION

Avoid installation in a dusty or dirty environment.

Provide adequate physical protection from other

physical damage as may be present in the specific location.

Refer to National Fire Protection Association NFPA

20, Chapter 11 for US installation and applicable local

code requirements.

1. Lay out a designated center line on the site floor.

Find the center line of the engine drive shaft. Lay

out a center line on the cross frame members.

IMPORTANT: Ensure that the lifting device or forklift

is capable of handling the package weight and size

requirements.

2. If the engine is lifted separately, use the lifting

hooks (supplied with the engine) and a spreader

bar to position the engine. Refer to Figure 3-1.

If the engine is assembled with the drive line,

pump and mounting base, use the lifting points

provided on the mounting base or lift the entire

skid using an approved fork lift. Refer to the layout drawings supplied with this manual for lifting

points.

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-2

1. Lifting Lug

2. Lifting Spreader Bar

Figure 3-1 Engine Lifting lugs (Engine Only)

CAUTION

Ensure that the lifting device is capable of safely

lifting the weight of the engine or the combined

weight of the assembled pump base, drive line

and pump. Refer to the Bill of Lading for combined shipping weights.

3. Position the engine as required for the interface

with the fire pump, water piping, fuel piping,

exhaust and air system connections.

4. Position the engine center line to align the

engine drive shaft with the fire pump drive.

Ensure that the engine and pump are correctly

aligned.

a. Ensure engine position is centered on frame

side to side within ± .03 inch, by measuring

outside of frame side to engine support leg

mounting pad. (Compare two front engine

supports and two back engine supports).

b. Align engine center line to pump center line

within ± .03 inch. Refer to Figure 3-2.

c. The pump center line to the engine crank-

shaft center line (in vertical plane) is to be .25

inch: +0, -.25 inch offset.

d. Drive shaft mounting flanges must be

parallel.

1. Planes Must Be Parallel

2. Align Both Mounting Center lines to

± .03”

3. Distance to Equal Half of Total Travel

4. .25”: +0, -.25” Offset

Figure 3-2 Drive Coupling Alignment

5. Check that the fire pump is properly installed per

the pump manufacturer’s specifications.

6. Connect the exhaust piping to a safe location,

away from building air intake sources (air conditioners, windows, fresh air intake pipes, etc.).

Figure 3-3 Drive Coupling Grease Fittings

2

1

1

CFP9-012

2

4

1

3

90

°

90

°

TOP

SIDE

CFP9-013

CFP9-015

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-3

7. Check that the alternator/coolant pump drive belt

is properly installed.

8. Check that all hoses and tubes are properly

installed and all clamps secure.

9. Lubricate grease fittings on the drive shaft universal joint. Refer to Figure 3-3.

a. Wipe the grease fittings and grease gun noz-

zle with a clean cloth.

b. Add grease to the universal joint grease fit-

tings.

c. Wipe excess grease from the grease fittings.

NOTE: Cummins Fire Power, or Cummins Inc. recommends using a good quality semi-synthetic,

molybdenum-fortified NLGI #2 lithium complex

grease which protects from -54° to 400° F such as

Valvoline Durablend®.

NOTE: Some lubrication loss may occur during transport and storage. It is recommended that the drive

shaft be re-lubricated upon installation.

3.3 Fuel Supply Installation

1. Install an elevated no. 2 diesel fuel tank or other

fuel supply arrangement which is compatible

with ASTM no. 2 diesel fuel specifications.

1. Engine Pedestal Leg

2. 1/2” Fuel Return Connection

3. 5/8” Fuel Supply Connection

Figure 3-4 Fuel Line Supply and Return Hoses

NOTE: The fuel supply line at the fuel tank must be

higher than the fuel intake port on the engine fuel

filter or filter/separator. Ensure that the fuel system is

installed in a safe and effective manner.

2. Size the fuel tank for the maximum expected fullload engine operation period with the initial fuel

level at the minimum level for refueling.

3. Install a 1/2“NPT (minimum) fuel return line.

Route this line to the bottom of the fuel tank in

order to minimize the return head. Refer to

Figure 3-4.

4. Install a 5/8” NPT (minimum) fuel supply line to

the fire pump engine.

NOTE: DO NOT use copper or galvanized pipe for

the fuel return or supply lines.

3.3.1 Fuel System Preparation

The fire pump engine fuel system has been primed

during manufacturing and test procedures. The

engine is equipped with an electric lift pump which

primes the fuel filter or filter/separator and high pressure fuel pump when the engine is cranked. Refer to

Figure 3-5.

A Water Separator must be integrated into the fuel

delivery system of the fire pump engine. A Fuel Filter/

Water Separator may be installed directly on the unit

in the primary fuel filter location, or a separate filter/

separator may be installed in the fuel delivery system

near the fire pump engine assembly.

1. Ensure that the filter/separator is free of water by

opening the fuel filter/water separator drain at

the bottom of the filter. Refer to 6.3.5 Fuel Sys-

tem Inspections for additional information.

2. Drain the fuel into a container until no water is

present. Dispose of the contaminated fuel in

accordance with local environmental regulations.

CAUTION

Due to the precise tolerances of diesel injection

systems, it is extremely important that the fuel be

kept clean and free of dirt or water. Dirt or water

in the system can cause severe damage to both

the fuel pump and the fuel injectors.

3

2

1

CFP9-041

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-4

1. High Pressure Fuel Pump

2. Fuel Filter or Filter/Separator

3. Fuel Return Connection

4. Fuel Supply Connection

5. Lift Pump (behind ECM A)

Figure 3-5 Engine Fuel System Components

3.3.2 Fuel Recommendations

WARNING

Do not mix gasoline, alcohol, gasohol, ethanol or

methanol with diesel fuel. This mixture will cause

severe engine damage or explosion.

CAUTION

Use ONLY no. 2 diesel (ASTM no. 2D) fuel. Any

adjustment to compensate for reduced performance with a fuel system using alternate fuel is

not warrantable.

3.4 Raw Water Supply Installation

Raw water circulated through the system cools the

charge air cooler (CAC) heat exchanger, the fuel

cooling heat exchanger, and the engine coolant heat

exchanger fluid. Raw water supplied from the fire

pump water source prior to the pump discharge

flange, is forced through the cooling system to the

various heat exchangers. Refer to Figure 3-6 and

Figure 3-7.

IMPORTANT: The raw water supply must be immediately available when the engine is started. Ensure

that the supply line valves are in the OPEN position.

CAUTION

When the raw water piping is installed, adjust

both pressure regulator set points before operating the pump. Damage to the heat exchanger may

occur from improperly regulated raw water

supply pressure.

3.4.1 Install Raw Water Piping

NOTE: The velocity of the raw water should be as

great as possible without exceeding the maximum

allowable pressure shown in the appropriate engine

data sheet.

1. Provide 1-1/4” NPT raw water discharge line at

the outlet of the engine coolant heat exchanger.

Refer to Figure 3-7.

1. 1” NPT Raw Water Inlet

2. Bypass Water Inlet Valve

3. Bypass Pressure Regulator/Strainer

4. Bypass Water Outlet Valve

5. Pipe To Heat Exchanger

6. Water Supply Pressure Gauge

7. Pressure Gauge Isolation Valve

8. Normal Water Outlet Valve

9. Solenoid Valve

10. Normal Pressure Regulator/Strainer

11. Normal Water Wye Strainer

12. Bypass Water Wye Strainer

13. Normal Water Inlet Valve

Figure 3-6 Raw Water Cooling Loop Manifold

CFP9-043

3

2

4

1

5

1

2

3

4

6

5

7

8

9

10

11

12

13

CFP9-002

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-5

NOTE: Raw water outlet piping from the heat

exchanger should be one pipe size larger than the

supply piping.

2. Provide a raw water supply line to the 1” NPT

raw water inlet.

NOTE: The water supply set points have been set by

the manufacturer during engine assembly and

testing.

3. Check the pressure regulator setting with water

flowing through the heat exchanger. If supplied

as an option from CFP, both water pressure regulators have been set at 207 kPa (30 psig) or

slightly less water pressure, during manufacture

and testing. The raw water should be adjusted

based on water flow rather than water pressure.

The flow is dependent on the raw water temperature. Refer to the engine curve and data sheets

for details.

4. Use a 5 gallon container to measure and time

the flow from discharge pipe.

Flow rate = time to fill container/container size.

Example: Time to fill 5 gallon container = 15 seconds.

Divide 15 by 5 = 3 (seconds per gallon).

Divide 60 seconds by 3 = 20 gallons per minute.

5. Adjust both pressure regulators to a pressure

that will provide a flow rate at or above the specifications.

The minimum raw water flow rate is 20 GPM @

50F, 30 GPM @ 70F, and 40 GPM @ 90F.

IMPORTANT: The manual water valves for the Automatic Loop should remain OPEN at ALL times. The

manual valves for the Bypass Loop should be

CLOSED during Automatic (pump controller) operation.

NOTE: When running, the engine should stabilize

between 180° F and 185° F. The flow rate may need

to be increased if the temperature stabilizes above

this range. Do not exceed 60 psi.

NOTE: Excess cold (40° F to 75° F) raw water flow

can cause condensation inside the charge air cooler.

1. Charge Air Cooler (CAC) Heat Exchanger

2. Fuel Cooling Heat Exchanger

3. 1” NPT Raw Water Inlet

4. 1-1/4” NPT Raw Water Discharge

5. Coolant Heat Exchanger

6. Coolant Expansion Tank

Figure 3-7 Cooling Loop Heat Exchangers

IMPORTANT: Continuous operation with low coolant

temperature (below 70° C (158° F)) or high coolant

temperature (above 107° C (225° F)) can damage the

engine.

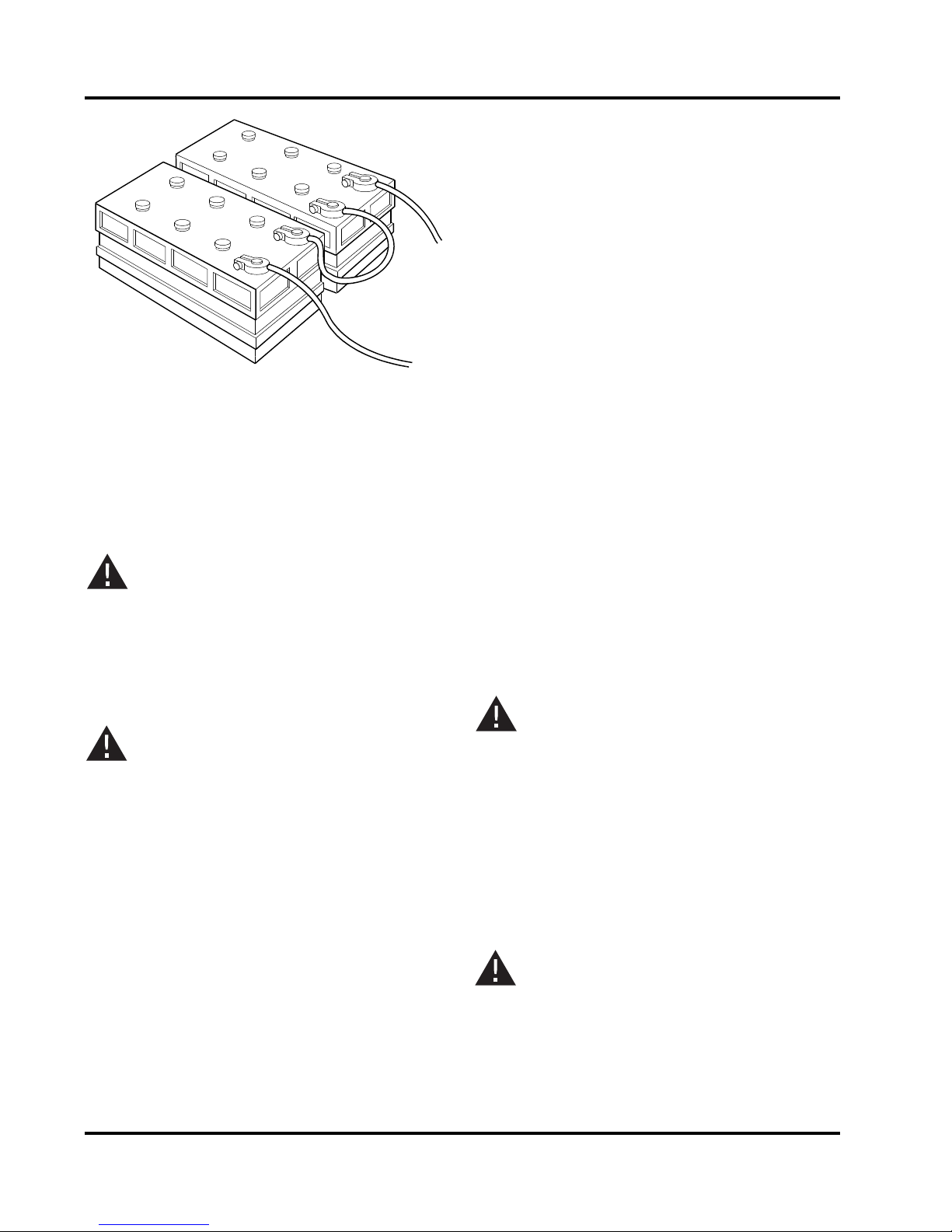

3.5 Battery Selection

The minimum recommended reserve capacity (SAE

RC) and cold cranking ampere (SAE CCA) values for

a particular engine can be found on the engine curve

and data sheets. RC and CCA definitions can be

found in SAE standard J537. All battery information is

for lead/acid batteries.

3.5.1 Battery Requirements

One set of batteries must be supplied for the standard 12VDC operating voltage. Two redundant sets

of batteries must be supplied for the optional 24 VDC

operating voltage. Refer to National Fire Protection

Association, NFPA 20, Chapter 11 and Section 1 Safety of this manual for additional battery installation

information.

6

5

4

1

3

2

CFP9-042

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-6

Figure 3-8 Series Battery Connection - 24 VDC

IMPORTANT: Batteries must meet the requirement

listed in Electrical System Specifications. Batteries

may be supplied by Cummins Fire Power, or

Cummins Inc. as an option or may be supplied by the

customer.

WARNING

Battery electrolyte (sulfuric acid) is highly caustic

and can burn clothing, and skin. Wear impervious

neoprene gloves, and safety goggles or full face

shield, when working with the batteries. Always

disconnect the negative battery cable first and

reconnect it last.

CAUTION

Do not connect battery charging cables to any

electronic control system component. This can

damage the electronic control system.

NOTE: Use the inductive charging-cranking systems

analyzer, Cummins Part Number 3377193, to test the

output amperage of either maintenance-free or conventional vent cap batteries. Follow the instructions

provided with the test equipment.

3.5.2 Battery Installation

Install the Loose Wire Kit per instructions on

Cummins Drawing 9768. If purchased, install the

optional Battery Cable Kit (Cummins Fire Power Part

No. 9614). Otherwise, install equivalent customer

supplied wiring. Install battery sets in a well ventilated

or otherwise protected location.

NOTE: There are two possible heavy-duty battery

connections: Battery terminal and clamp or threaded

battery terminal and nut.

1. Provide adequate room for servicing or replacing

the batteries. Provide protection from extremes

of temperature and weather.

2. Locate the batteries near the engine or increase

the size of the conductors as required by applicable codes. Ensure that the batteries are configured properly for standard 12 VDC operations

or optional 24 VDC operations. Refer to Figure

3-8.

3. Check the battery cables and connections.

NOTE: Coat the terminals with petroleum jelly to

prevent corrosion. Install the cables and tighten the

battery connections.

3.5.3 Auxiliary Battery Starting

If a battery charging system is not provided, the

engine can be started using charged batteries.

NOTE: For maintainable lead acid batteries supplied

by Cummins Fire Power, or Cummins Inc., check the

state of charge by measuring battery cell specific

gravity. Refer to Battery Testing in Section 6 - Mainte-

nance for additional information.

WARNING

Batteries can emit explosive gases during charging. Always ventilate the compartment before servicing the batteries. Remove sources of spark or

open flame. To avoid arcing, remove the negative

(-) battery cable first and attach the negative (-)

battery cable last.

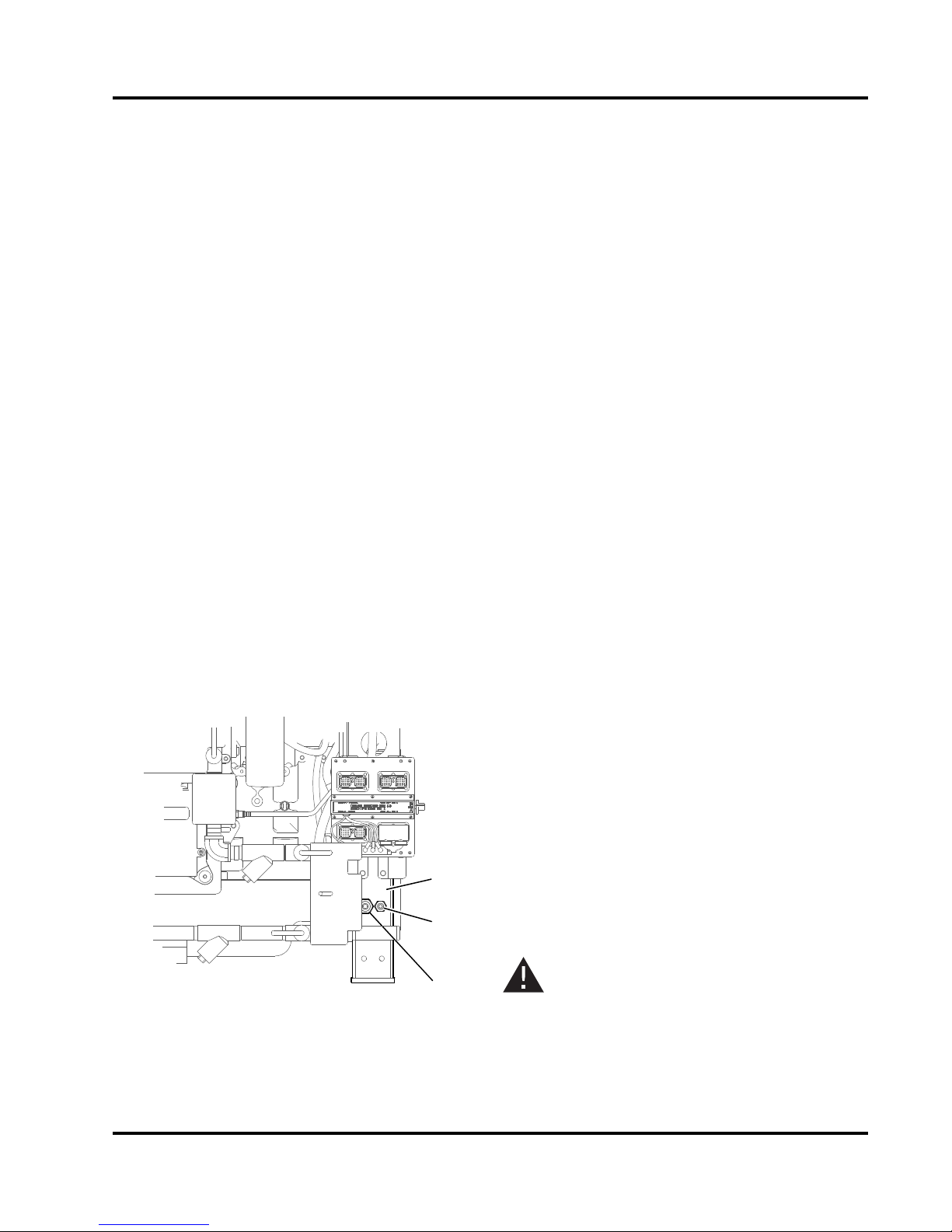

3.6 Signal and Control Installation

This section explains how to connect the controller

wires to the terminal block.

CAUTION

If the batteries have been installed prior to the

control wiring, disconnect the negative cable first

and then disconnect the positive battery lead.

Install the cables with the positive cable first and

the negative cable last before testing.

CFP9-014

Fire Power Pump Engine CFP9E

Doc. 9778, Rev. 10-08

3-7

NOTE: Install signal and control wiring at Terminal

Board TB. Refer to the terminal wiring schematic

decal on the inside of the instrument enclosure.

1. Ensure that the fire control system is properly

installed and configured per the manufacturer’s

instructions. Refer to the Wiring Schematic

Drawings provided with the pump manual.

2. Complete the fire pump controller wiring (customer supplied) per the manufacturer’s instructions.

Figure 3-9 Termination Blocks and Wiring Decal

3. Connect the following wires to the Fire Pump

Engine Instrument Panel per the engine electrical diagrams. Refer to Figure 3-9.

a. TB-1: Connect the Control Power from the

Fire Pump Controller. This power source is

necessary for fire pump operations while in

the AUTO Mode.

INSERT FLAT SCREW DRIVER

INTO THE SQUARE HOLE

PRY OPEN THE SPRING

CLAMP WITH THE

SCREW DRIVER

INSERT THE STRIPPED

LEAD WIRE INTO THE

ROUND HOLE.

RELEASE THE SCREW DRIVER.

VERIFY THAT THE

STRIPPED PORTION OF

THE LEAD WIRE (AND

NOT THE INSULATION)

IS CLAMPED BY LIGHTLY

TUGGING ON THE WIRE.

STRIP LENGTH

1/2 INCH

303

302

301

12

11

10

9

8

7

6

5

4

3

2

1

CFP9-044

Loading...

Loading...