Page 1

OperatorOperator ManualManual

Generator Set with QSJ5.9G Engine and

PowerCommand® 1.1 Control

C45 N6 (Spec A)

C50 N6 (Spec A)

C60 N6 (Spec A)

C70 N6 (Spec A)

C80 N6 (Spec A)

C100 N6 (Spec A)

English

Original Instructions

8-2017 A051X877 (Issue 6)

Page 2

Page 3

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS ....................................................................................... 1

1.1 Warning, Caution, and Note Styles Used in This Manual ..................................................... 1

1.2 General Information ................................................................................................................ 1

1.3 Generator Set Safety Code .................................................................................................... 4

1.4 Moving Parts Can Cause Severe Personal Injury or Death ................................................... 4

1.5 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death.................. 5

1.6 Fuel and Fumes Are Flammable ............................................................................................ 5

1.7 Batteries Can Explode ............................................................................................................ 6

1.8 Exhaust Gases Are Deadly..................................................................................................... 7

1.9 The Hazards of Carbon Monoxide.......................................................................................... 9

1.10 Earth Ground Connection ..................................................................................................... 9

2. INTRODUCTION.......................................................................................................................... 11

2.1 Safety .................................................................................................................................... 11

2.2 About This Manual................................................................................................................ 11

2.3 Schedule of Abbreviations .................................................................................................... 12

2.4 Related Literature ................................................................................................................. 14

2.5 Model Specifications ............................................................................................................. 15

2.6 After Sales Services.............................................................................................................. 19

2.7 General Operating Conditions .............................................................................................. 20

2.8 Generator Set Nameplate .................................................................................................... 21

2.9 Manufacturing Facilities ........................................................................................................ 23

3. CONTROL SYSTEM .................................................................................................................... 25

3.1 Control System Description .................................................................................................. 25

3.2 Display Text or Symbolic Version ......................................................................................... 29

3.3 Exercise Settings ................................................................................................................. 30

3.4 Brightness and Contrast ....................................................................................................... 38

3.5 History and About Menu ....................................................................................................... 40

3.6 Fault Log ............................................................................................................................... 42

3.7 Selecting Operating Modes................................................................................................... 44

3.8 Operating Modes .................................................................................................................. 49

4. OPERATION - POWERCOMMAND 1.1 ...................................................................................... 51

4.1 Introduction ........................................................................................................................... 51

4.2 General Operating Conditions .............................................................................................. 51

4.3 Generator Set Operation....................................................................................................... 51

5. MAINTENANCE ........................................................................................................................... 63

5.1 Maintenance Safety .............................................................................................................. 63

5.2 Periodic Maintenance ........................................................................................................... 66

5.3 Exercising the Generator Set ............................................................................................... 71

5.4 Engine Oil ............................................................................................................................. 71

iA051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 4

Table of Contents 8-2017

5.5 Air Intake System.................................................................................................................. 77

5.6 Batteries ................................................................................................................................ 79

5.7 Spark Plugs .......................................................................................................................... 83

6. TROUBLESHOOTING ................................................................................................................. 85

6.1 Avoiding Generator Set Shutdowns ..................................................................................... 85

6.2 Fault Code Introduction......................................................................................................... 85

6.3 Engine Is Difficult to Start or Does Not Start ........................................................................ 85

6.4 Code 143 - Engine Oil Pressure Low (Warning) .................................................................. 86

6.5 Codes 146 and 151 - Engine Coolant Temperature High (Warning or Shutdown) .............. 86

6.6 Code 155 - Intake Manifold Temperature High (Shutdown) ................................................. 87

6.7 Code 197 - Coolant Level Low (Warning) ............................................................................ 87

6.8 Code 415 - Engine Oil Pressure Low (Shutdown)................................................................ 88

6.9 Code 441 - Battery Voltage Low (Warning).......................................................................... 88

6.10 Code 488 - Intake Manifold Temperature High (Warning).................................................. 89

6.11 Code 1438 - Fail to Crank (Shutdown) ............................................................................... 90

6.12 Code 1472 - High AC Current (Shutdown) ......................................................................... 90

6.13 Code 5134 - Unknown Shutdown at Idle ............................................................................ 90

ii A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS. This manual contains important instructions that

should be followed during installation and maintenance of the generator set and

batteries.

Safe and efficient operation can be achieved only if the equipment is properly

operated and maintained. Many accidents are caused by failure to follow

fundamental rules and precautions.

1.1 Warning, Caution, and Note Styles Used in This Manual

The following safety styles and symbols found throughout this manual indicate

potentially hazardous conditions to the operator, service personnel, or equipment.

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

Indicates information considered important, but not hazard-related (e.g.,

messages relating to property damage).

1.2 General Information

This manual should form part of the documentation package supplied by Cummins

Inc. with specific generator sets. If this manual has been supplied in isolation,

please contact your authorized dealer.

It is in the operator's interest to read and understand all warnings and

cautions contained in the documentation relevant to the generator set

operation and daily maintenance.

CAUTION

NOTICE

NOTICE

1A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 6

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

General Safety Precautions

WARNING

Hot Pressurized Liquid

Contact with hot liquid can cause severe burns.

Do not open the pressure cap while the engine is running. Let the engine

cool down before removing the cap. Turn the cap slowly and do not open it

fully until the pressure has been relieved.

WARNING

Moving Parts

Moving parts can cause severe personal injury.

Use extreme caution around moving parts. All guards must be properly

fastened to prevent unintended contact.

WARNING

Toxic Hazard

Used engine oils have been identified by some state and federal agencies to

cause cancer or reproductive toxicity.

Do not ingest, breathe the fumes, or contact used oil when checking or

changing engine oil. Wear protective gloves and face guard.

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or

death.

Do not operate equipment when fatigued, or after consuming any alcohol or

drug.

Make sure that only suitably trained and experienced service personnel

perform electrical and/or mechanical service.

WARNING

Toxic Gases

Substances in exhaust gases have been identified by some state and federal

agencies to cause cancer or reproductive toxicity.

Do not breathe in or come into contact with exhaust gases.

WARNING

High Noise Level

Generator sets in operation emit noise, which can cause hearing damage.

Wear appropriate ear protection at all times.

2 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 7

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is

minimized. Wear appropriate PPE when working on hot equipment and avoid

contact with hot surfaces.

WARNING

Toxic Hazard

Ethylene glycol, used as an engine coolant, is toxic to humans and animals.

Wear appropriate PPE. Clean up coolant spills and dispose of used coolant

in accordance with local environmental regulations.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause

severe burns or death.

Do not store fuel, cleaners, oil, etc., near the generator set. Do not use

combustible liquids like ether.

WARNING

Combustible Gases

Generator sets in operation have combustible gases under pressure, which

if ignited can cause eye and ear damage.

Wear appropriate eye and ear protection at all times.

WARNING

Combustible Gases

Generator sets in operation have combustible gases under pressure, which

if ignited can cause severe injury.

Do not operate the generator set with any doors open.

WARNING

Fire Hazard

Materials drawn into the generator set, as well as accumulated grease and

oil, are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from

obstructions. Make sure the generator set is mounted in a manner to prevent

combustible materials from accumulating under the unit.

3A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 8

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal

injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the

starting battery cables (negative [–] first).

NOTICE

Keep multi-type ABC fire extinguishers close by. Class A fires involve

ordinary combustible materials such as wood and cloth. Class B fires

involve combustible and flammable liquid fuels and gaseous fuels. Class C

fires involve live electrical equipment. (Refer to NFPA No. 10 in the

applicable region.)

NOTICE

Before performing maintenance and service procedures on enclosed

generator sets, make sure the service access doors are secured open.

NOTICE

Stepping on the generator set can cause parts to bend or break, leading to

electrical shorts, or to fuel, coolant, or exhaust leaks. Do not step on the

generator set when entering or leaving the generator set room.

1.3 Generator Set Safety Code

Before operating the generator set, read the manuals and become familiar with

them and the equipment. Safe and efficient operation can be achieved only if

the equipment is properly operated and maintained. Many accidents are caused

by failure to follow fundamental rules and precautions.

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or

death.

Read and follow all Safety Precautions, Warnings, and Cautions throughout

this manual and the documentation supplied with the generator set.

1.4 Moving Parts Can Cause Severe Personal Injury or Death

• Keep hands, clothing, and jewelry away from moving parts.

4 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 9

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

• Before starting work on the generator set, disconnect the battery charger from

its AC source, then disconnect the starting batteries using an insulated wrench,

negative (–) cable first. This will prevent accidental starting.

• Make sure that fasteners on the generator set are secure. Tighten supports and

clamps; keep guards in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of moving parts or while

working on electrical equipment. Loose clothing and jewelry can become

caught in moving parts.

• If any adjustments must be made while the unit is running, use extreme caution

around hot manifolds, moving parts, etc.

1.5 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death

• Only qualified service personnel certified and authorized to work on power

circuits should work on exposed energized power circuits.

• All relevant service material must be available for any electrical work performed

by certified service personnel.

• Exposure to energized power circuits with potentials of 50 VAC or 75 VDC or

higher poses a significant risk of electrical shock and electrical arc flash.

• Refer to standard NFPA 70E, or equivalent safety standards in corresponding

regions, for details of the dangers involved and for safety requirements.

1.6 Fuel and Fumes Are Flammable

Fire, explosion, and personal injury or death can result from improper practices.

• Do not fill fuel tanks while the engine is running unless the tanks are outside

the engine compartment. Fuel contact with hot engine or exhaust is a potential

fire hazard.

• Do not permit any flame, cigarette, pilot light, spark, arcing equipment, or other

ignition source near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of leaks. Fuel connection at the

engine should be made with an approved flexible line. Do not use copper piping

on flexible lines as copper will become brittle if continuously vibrated or

repeatedly bent.

• Make sure all fuel supplies have a positive shutoff valve.

• Make sure the battery area has been well-ventilated prior to servicing near it.

Lead-acid batteries emit a highly explosive hydrogen gas that can be ignited by

arcing, sparking, smoking, etc.

5A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 10

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

Do Not Operate in Flammable and Explosive Environments

Flammable vapor can cause an engine to over speed and become difficult to stop,

resulting in possible fire, explosion, severe personal injury, and death. Do not

operate a generator set where a flammable vapor environment can be created,

unless the generator set is equipped with an automatic safety device to block the air

intake and stop the engine. The owners and operators of the generator set are

solely responsible for operating the generator set safely. Contact your authorized

Cummins distributor for more information.

Spillage

Any spillage that occurs during fueling, oil top-off, or oil change must be cleaned up

before starting the generator set.

Fluid Containment

NOTICE

Where spillage containment is not part of a Cummins supply, it is the

responsibility of the installer to provide the necessary containment to

prevent contamination of the environment, especially water courses and

sources.

If fluid containment is incorporated into the bedframe, it must be inspected at

regular intervals. Any liquid present should be drained out and disposed of in line

with local health and safety regulations. Failure to perform this action may result in

spillage of liquids which could contaminate the surrounding area.

Any other fluid containment area must also be checked and emptied, as described

above.

1.7 Batteries Can Explode

Batteries can explode, causing severe skin and eye burns and can release toxic

electrolytes.

Combustible Gases

Batteries can explode, causing severe skin and eye burns, and can release

toxic electrolytes.

Do not dispose of the battery in a fire, because it is capable of exploding. Do

not open or mutilate the battery. Do not charge frozen batteries.

WARNING

6 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 11

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

WARNING

Electric Shock Hazard

Batteries present the risk of high short circuit current.

When servicing the generator set:

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

NOTICE

Servicing of batteries must be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized

personnel away from batteries.

• Wear safety glasses.

• Do not smoke.

• Do not charge frozen batteries.

• To prevent arcing when disconnecting the battery:

1. Press the Off switch from the display and then press the E-Stop button.

2. Disconnect AC power from any battery chargers.

3. Remove the negative (-) battery cable to prevent starting.

• To prevent arcing when reconnecting the battery:

1. Reconnect the positive (+) cable.

2. Reconnect the negative (-) cable.

3. Reconnect the battery charger to AC power supply.

• When replacing the generator set battery, always replace it with a battery as

specified in this manual.

1.8 Exhaust Gases Are Deadly

• Provide an adequate exhaust system to properly expel discharged gases away

from enclosed or sheltered areas, and areas where individuals are likely to

congregate. Visually and audibly inspect the exhaust system daily for leaks per

the maintenance schedule. Make sure that exhaust manifolds are secured and

not warped. Do not use exhaust gases to heat a compartment.

• Make sure the unit is well ventilated.

7A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 12

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

Exhaust Precautions

WARNING

Hot Exhaust Gases

Contact with hot exhaust gases can cause severe burns.

Wear personal protective equipment when working on equipment.

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is

minimized. Wear appropriate PPE when working on hot equipment and avoid

contact with hot surfaces.

WARNING

Toxic Gases

Inhalation of exhaust gases can cause asphyxiation and death.

Pipe exhaust gas outside and away from windows, doors, or other inlets to

buildings. Do not allow exhaust gas to accumulate in habitable areas.

WARNING

Fire Hazard

Contaminated insulation is a fire hazard. Fire can cause severe burns or

death.

Remove any contaminated insulation and dispose of it in accordance with

local regulations.

The exhaust outlet may be sited at the top or bottom of the generator set. Make

sure that the exhaust outlet is not obstructed. Personnel using this equipment must

be made aware of the exhaust position. Position the exhaust away from flammable

materials - in the case of exhaust outlets at the bottom, make sure that vegetation is

removed from the vicinity of the exhaust.

The exhaust pipes may have some insulating covers fitted. If these covers become

contaminated they must be replaced before the generator set is run.

To minimize the risk of fire, make sure the following steps are observed:

• Make sure that the engine is allowed to cool thoroughly before performing

maintenance or operation tasks.

• Clean the exhaust pipe thoroughly.

8 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 13

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

1.9 The Hazards of Carbon Monoxide

Carbon monoxide (CO) is an odorless, colorless, tasteless and non-irritating gas.

You cannot see it or smell it. Red blood cells, however, have a greater affinity for

CO than for oxygen. Therefore, exposure even to low levels of CO for a prolonged

period can lead to asphyxiation (lack of oxygen) resulting in death. Mild effects of

CO poisoning include eye irritation, dizziness, headaches, fatigue and the inability to

think clearly. More extreme symptoms include vomiting, seizures and collapse.

Engine-driven generator sets produce harmful levels of carbon monoxide that can

injure or kill you.

Special Risks of CO near the Home

WARNING

Toxic Gases

Carbon monoxide (CO) gas can cause nausea, fainting, or death. Residents

can be exposed to lethal levels of CO when the generator set is running.

Depending on air temperature and wind, CO can accumulate in or near the

home.

To protect yourself and others from the dangers of CO poisoning, it is

recommended that reliable, approved, and operable CO detector alarms are

installed in proper locations in the home as specified by their manufacturer.

Protecting Yourself from CO Poisoning

• Locate the generator set in an area where there are no windows, doors, or

other access points into the home.

• Make sure all CO detectors are installed and working properly.

• Pay attention for signs of CO poisoning.

• Check the exhaust system for corrosion, obstruction, and leaks every time you

start the generator set and every eight hours when you run it continuously.

1.10 Earth Ground Connection

The neutral of the generator set may be required to be bonded to earth ground at

the generator set location, or at a remote location, depending on system design

requirements. Consult the engineering drawings for the facility or a qualified

electrical design engineer for proper installation.

NOTICE

The end user is responsible to make sure that the ground connection point

surface area is clean and free of rust before making a connection.

9A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 14

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

NOTICE

The end user is responsible for making sure that an earthing arrangement

that is compliant with local conditions is established and tested before the

equipment is used.

10 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 15

2 Introduction

2.1 Safety

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or

death.

Make sure that only a trained and experienced electrician makes generator

set electrical output connections, in accordance with the installation

instructions and all applicable codes.

Electrical Generating Equipment

Faulty electrical generating equipment can cause severe personal injury or

death.

Generator sets must be installed, certified, and operated by trained and

experienced person in accordance with the installation instructions and all

applicable codes.

WARNING

WARNING

2.2 About This Manual

The purpose of this manual is to provide the users with sound, general information.

It is for guidance and assistance with recommendations for correct and safe

procedures. Cummins Inc. cannot accept any liability whatsoever for problems

arising as a result of following recommendations in this manual.

The information contained within the manual is based on information available at the

time of going to print. In line with Cummins Inc. policy of continuous development

and improvement, information may change at any time without notice. The users

should therefore make sure that they have the latest information available before

starting any work. The latest version of this manual is available on QuickServe

Online (https://quickserve.cummins.com).

Users are respectfully advised that, in the interests of good practice and safety, it is

their responsibility to employ competent people to carry out any installation work.

Consult your authorized dealer for further installation information. It is essential that

the utmost care is taken with the application, installation, and operation of any

generator set due to their potentially hazardous nature. Careful reference should

also be made to other Cummins Inc. literature. You must operate and maintain your

generator set properly if you are to expect safe and reliable operation.

For further assistance, contact your authorized Cummins dealer.

11A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 16

2. Introduction 8-2017

NOTICE

This device complies with part 15 of the FCC rules. Operation is subject to

the following two conditions:

• This device may not cause harmful interferences.

• This device must accept any interference received, including

interference that may cause undesired operation.

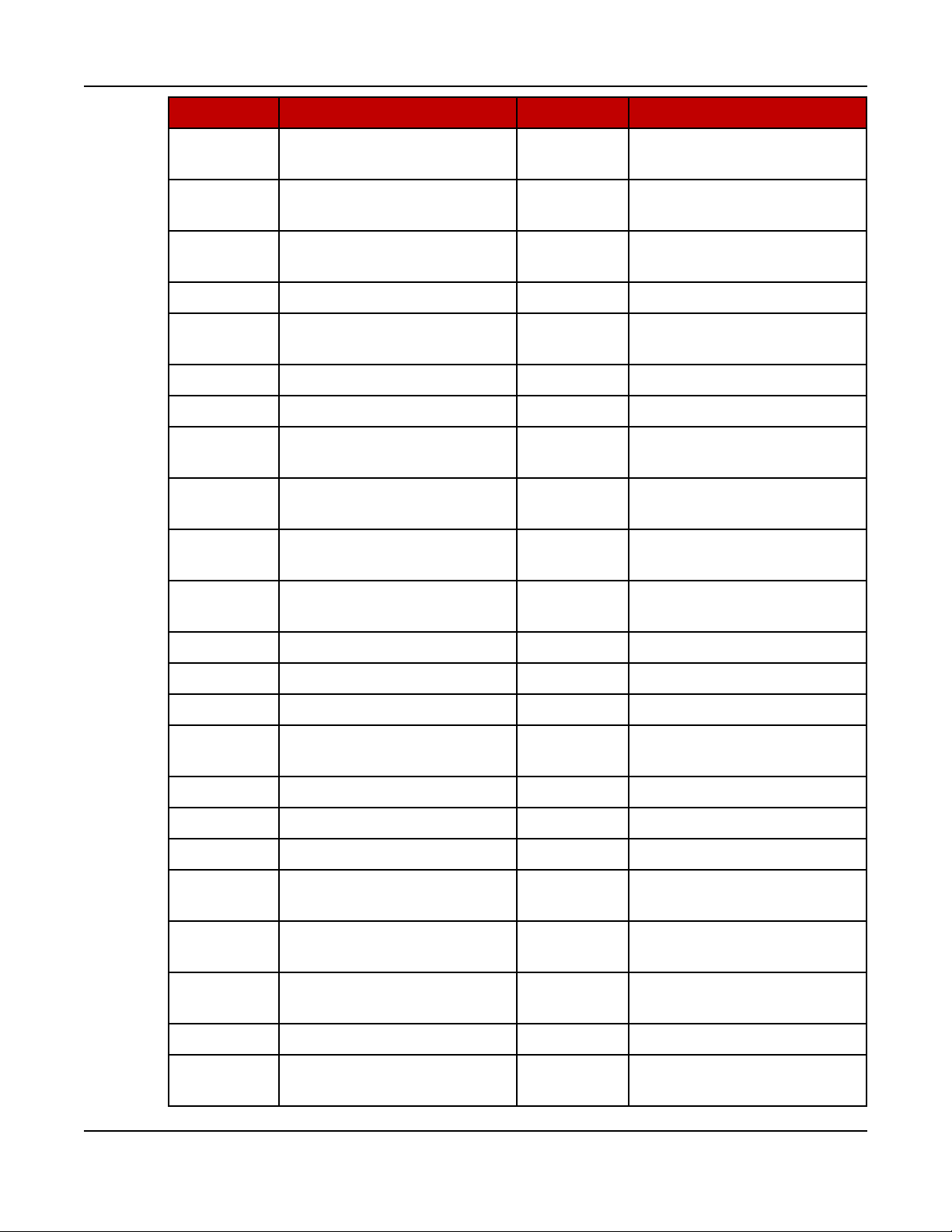

2.3 Schedule of Abbreviations

This list is not exhaustive. For example, it does not identify units of measure or

acronyms that appear only in parameters, event/fault names, or part/accessory

names.

AmpSentry, INSITE, and InPower are trademarks of Cummins Inc. PowerCommand

is a registered trademark of Cummins Inc.

ABBR. DESCRIPTION ABBR. DESCRIPTION

AC Alternating Current LED Light-emitting Diode

AMP AMP, Inc., part of Tyco

Electronics

ANSI American National

Standards Institute

ASOV Automatic Shut Off Valve MFM Multifunction Monitor

ASTM American Society for

Testing and Materials

(ASTM International)

ATS Automatic Transfer Switch MLD Masterless Load Demand

AVR Automatic Voltage

Regulator

AWG American Wire Gauge NC Not Connected

CAN Controlled Area Network NFPA National Fire Protection

CB Circuit Breaker NO Normally Open

CE Conformité Européenne NWF Network Failure

LTS Long Term Storage

LVRT Low Voltage Ride Through

Mil Std Military Standard

NC Normally Closed

Agency

CFM Cubic Feet per Minute OEM Original Equipment

Manufacturer

CGT Cummins Generator

Technologies

12 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

OOR Out of Range

Page 17

2. Introduction8-2017

ABBR. DESCRIPTION ABBR. DESCRIPTION

CMM Cubic Meters per Minute OORH /

Out of Range High

ORH

CT Current Transformer OORL /

Out of Range Low

ORL

D-AVR Digital Automatic Voltage

PB Push Button

Regulator

DC Direct Current PCC PowerCommand®Control

DEF Diesel Exhaust Fluid PGI Power Generation

Interface

DPF Diesel Particulate Filter PGN Parameter Group Number

ECM Engine Control Module PI Proportional/Integral

ECS Engine Control System PID Proportional / Integral /

Derivative

EMI Electromagnetic

interference

PLC Programmable Logic

Controller

EN European Standard PMG Permanent Magnet

Generator

EPS Engine Protection System PPE Personal Protective

Equipment

E-Stop Emergency Stop PT Potential Transformer

FAE Full Authority Electronic PTC Power Transfer Control

FMI Failure Mode Identifier PWM Pulse-width Modulation

FRT Fault Ride Through RFI Radio Frequency

Interference

FSO Fuel Shutoff RH Relative Humidity

Genset Generator Set RMS Root Mean Square

GCP Generator Control Panel RTU Remote Terminal Unit

GND Ground SAE Society of Automotive

Engineers

LCT Low Coolant Temperature SCR Selective Catalytic

Reduction

HMI Human-machine Interface SPN Suspect Parameter

Number

IC Integrated Circuit SWL Safe Working Load

ISO International Organization

for Standardization

13A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

SW_B+ Switched B+

Page 18

2. Introduction 8-2017

ABBR. DESCRIPTION ABBR. DESCRIPTION

LBNG Lean-burn Natural Gas UL Underwriters Laboratories

LCD Liquid Crystal Display UPS Uninterruptible Power

Supply

2.4 Related Literature

Before any attempt is made to operate the generator set, the operator should take

time to read all of the manuals supplied with the generator set, and to familiarize

themselves with the warnings and operating procedures.

The literature provided with the generator set is as follows:

• Operator Manual (A051X877)

• Installation Manual (A051X873)

NOTICE

A generator set must be operated and maintained properly if you are to

expect safe and reliable operation. The Operator manual includes a

maintenance schedule and a troubleshooting guide.

The Health and Safety manual must be read in conjunction with this manual

for the safe operation of the generator set:

• Health and Safety Manual (0908-0110)

• Warranty Statement (A028U870)

• C45 N6, C50 N6 and C60 N6 models only: Emissions Component Defect

Warranty Statement (A028X278)

• C70 N6, C80 N6 and C100 N6 models only: Emissions Component Defect

Warranty Statement (A028X279)

The relevant manuals appropriate to your generator set are also available. The

documents below are in English:

• Service Manual (A051X880)

• Parts Manual (A051X891)

• EControls, Inc., Global Control Platform (GCP) Software Service Manual

(A035C596)

• EControls, Inc., 4G Software Service Manual (A052G032)

• EControls, Inc., GCP Engine Display Interface Software (EDIS) Training

Manual (A035C608)

• EControls, Inc., 4G Software Operator Manual (A052G024)

• Engine Operation & Maintenance Manual for QSJ5.9G (4388606)

• RA Series Transfer Switch Owner Manual (A046S594) - if applicable

14 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 19

• PowerCommand® 1302 Controller Owner's Manual (900-0661)

• Service Tool Manual (A043D529)

• Standard Repair Times - HL Family (A053K365)

• T-030: Liquid Cooled Generator Set Application Manual (A040S369) - for

application information

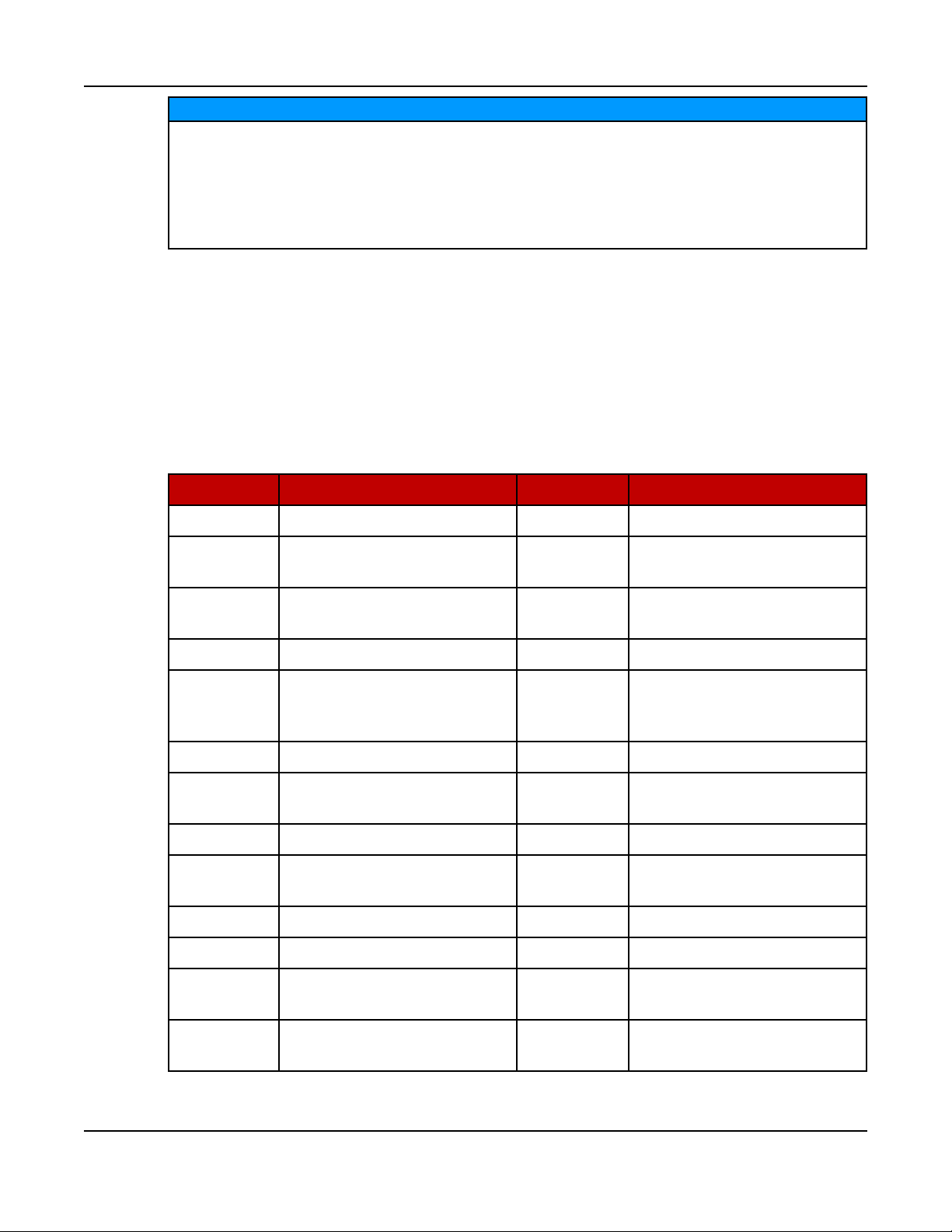

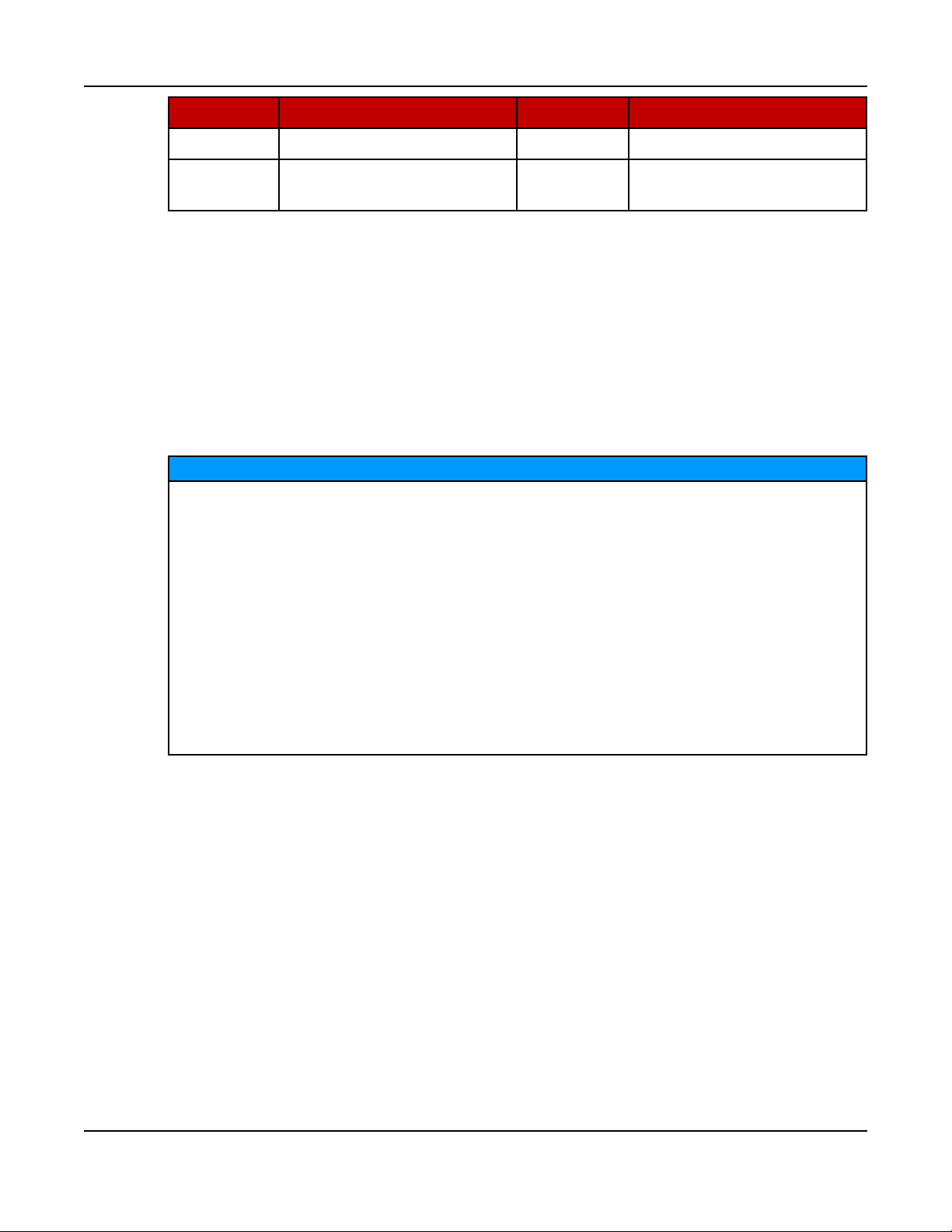

2.5 Model Specifications

Damage caused by failure to follow the manufacturer's recommendation will

not be covered by the warranty. Please contact your authorized distributor.

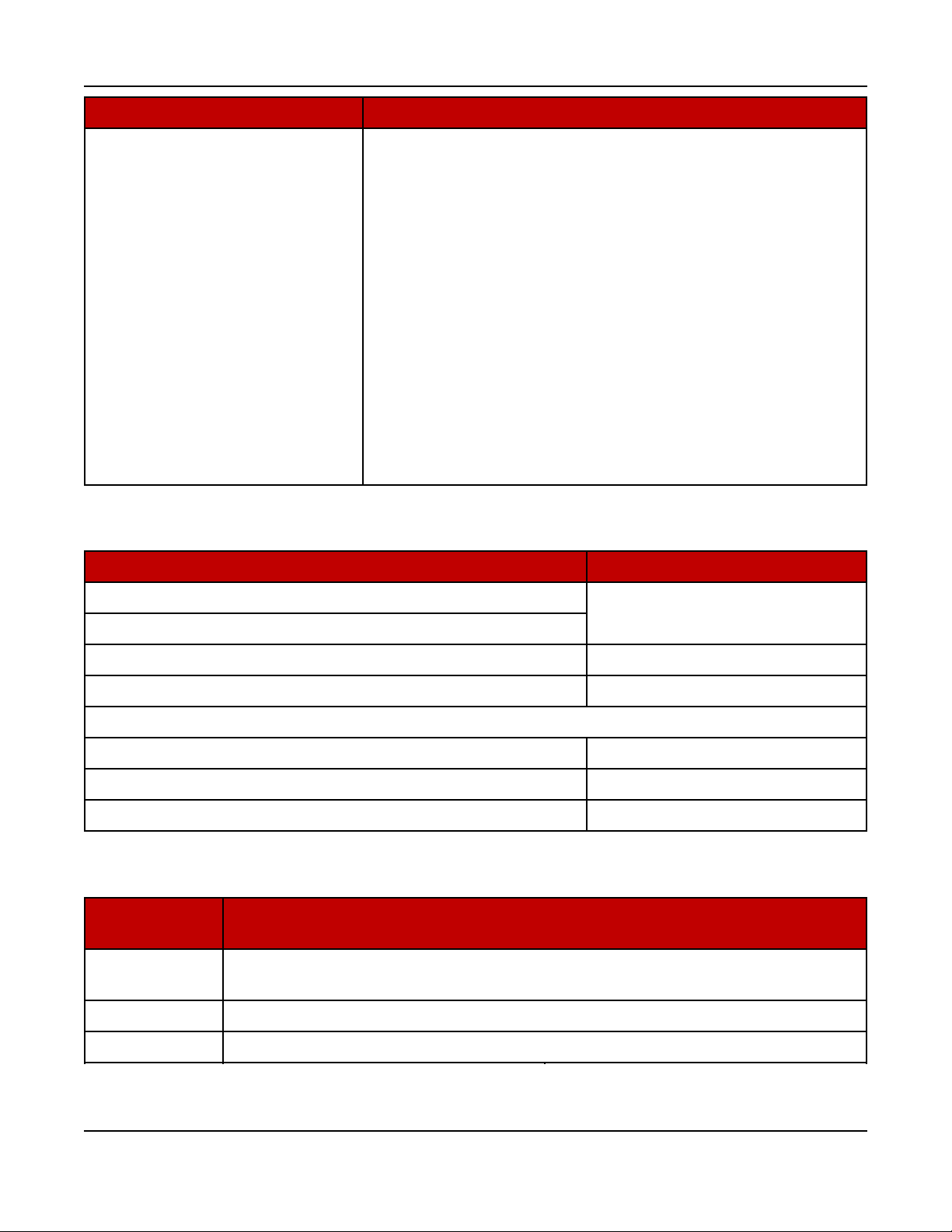

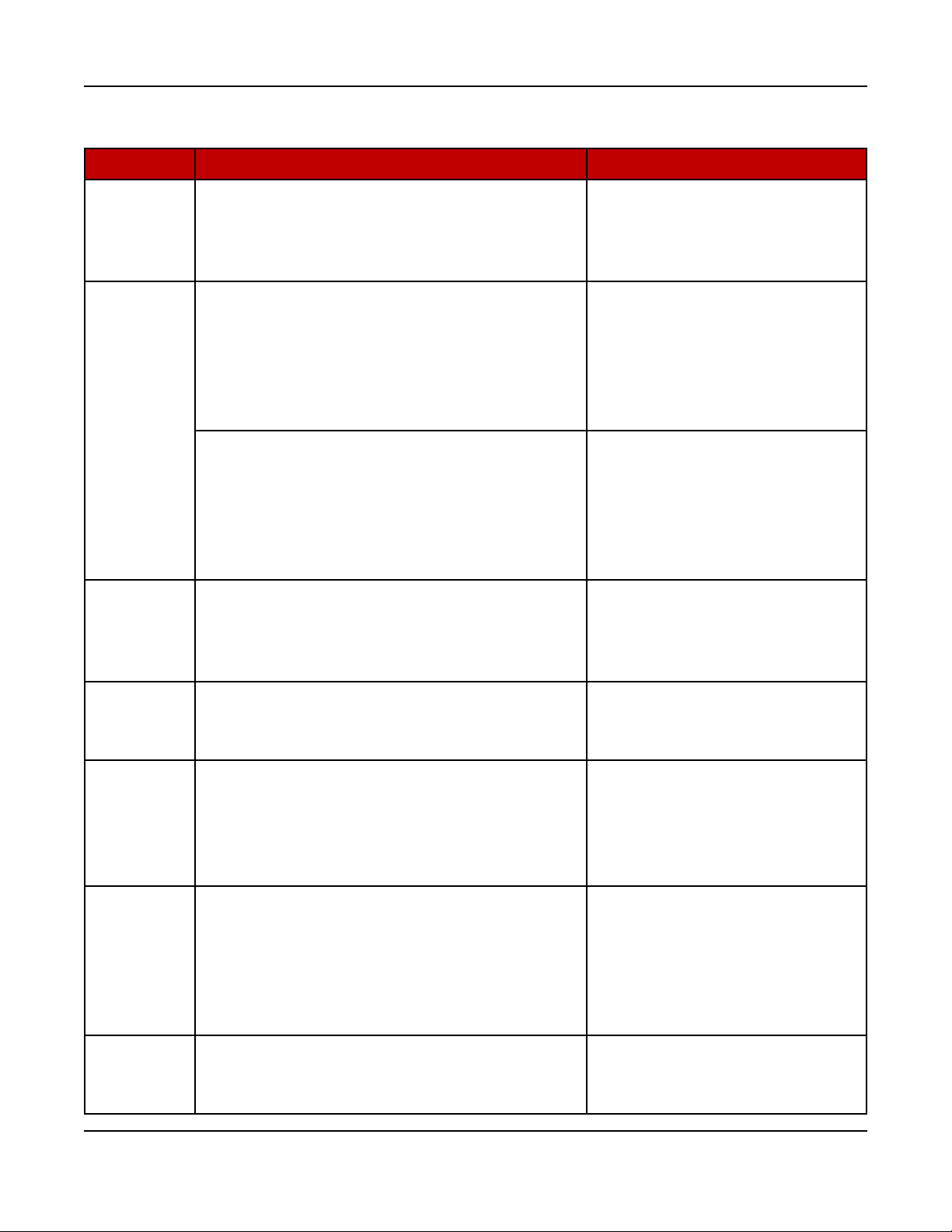

TABLE 1. 5.9L MODEL VARIATIONS

Models Description

2. Introduction8-2017

NOTICE

C45 N6, C50 N6, C60 N6, C70 N6, C80 N6, C100 N6 60 Hz, 1800 RPM

TABLE 2. COLD WEATHER SPECIFICATIONS (ALL MODELS)

Temperature Description

Battery

Type

Group

Above 4 °C (40 °F) Battery charger Standard 34

-17 to 4 °C (0 to 40 °F)

Battery charger, coolant heater (1000W),

CCV heater

1

Standard 34

Battery charger, coolant heater (1500W),

Below -17 °C (0 °F)

1

CCV heaters are provided as part of the cold and extreme cold coolant heater packages.

2

The cold weather starter is provided as part of the extreme cold coolant heater package.

oil heater, battery heater, CCV heater1,

cold weather starter

2

NOTICE

Larger 4D

For NFPA 110 applications, a coolant heater is required. A factory option is

available.

15A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 20

2. Introduction 8-2017

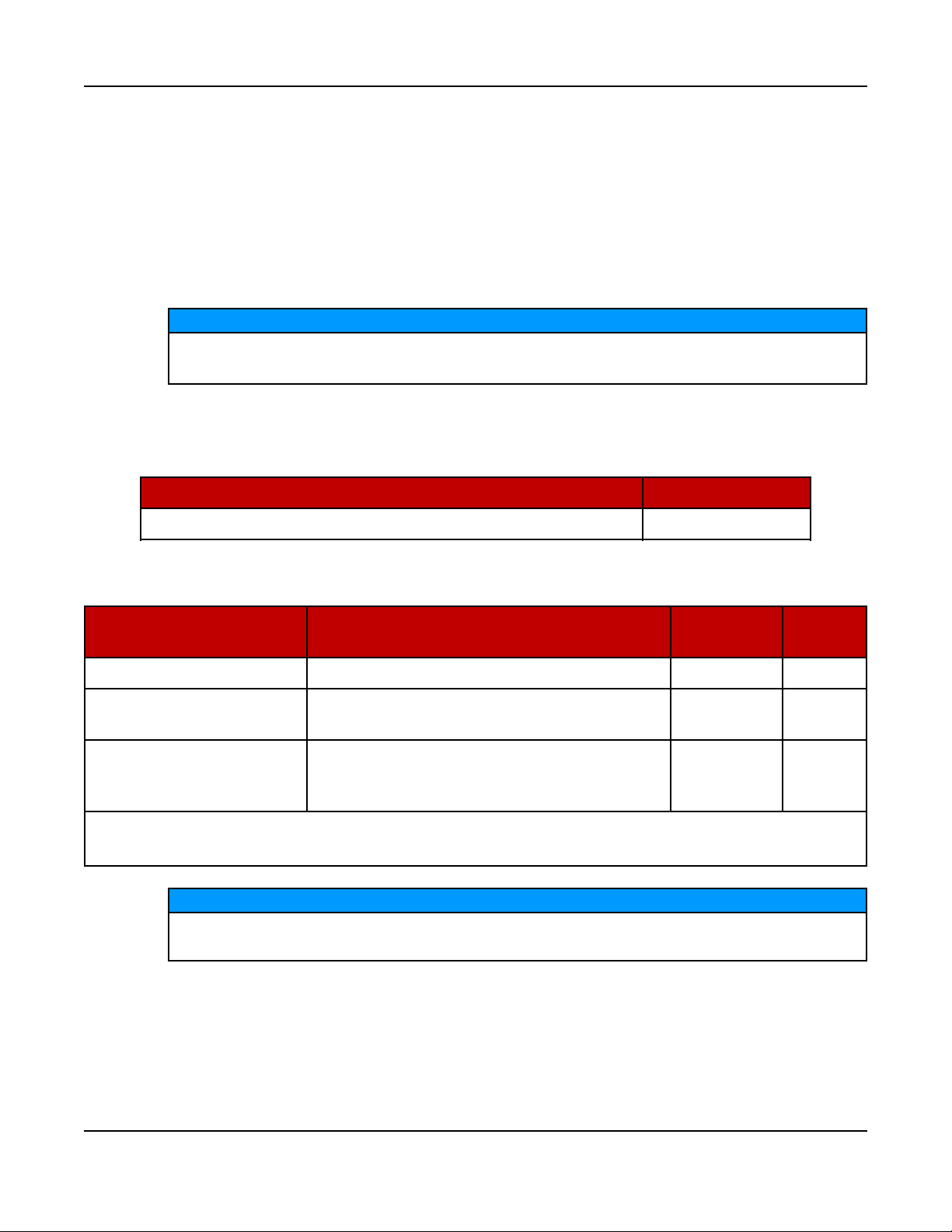

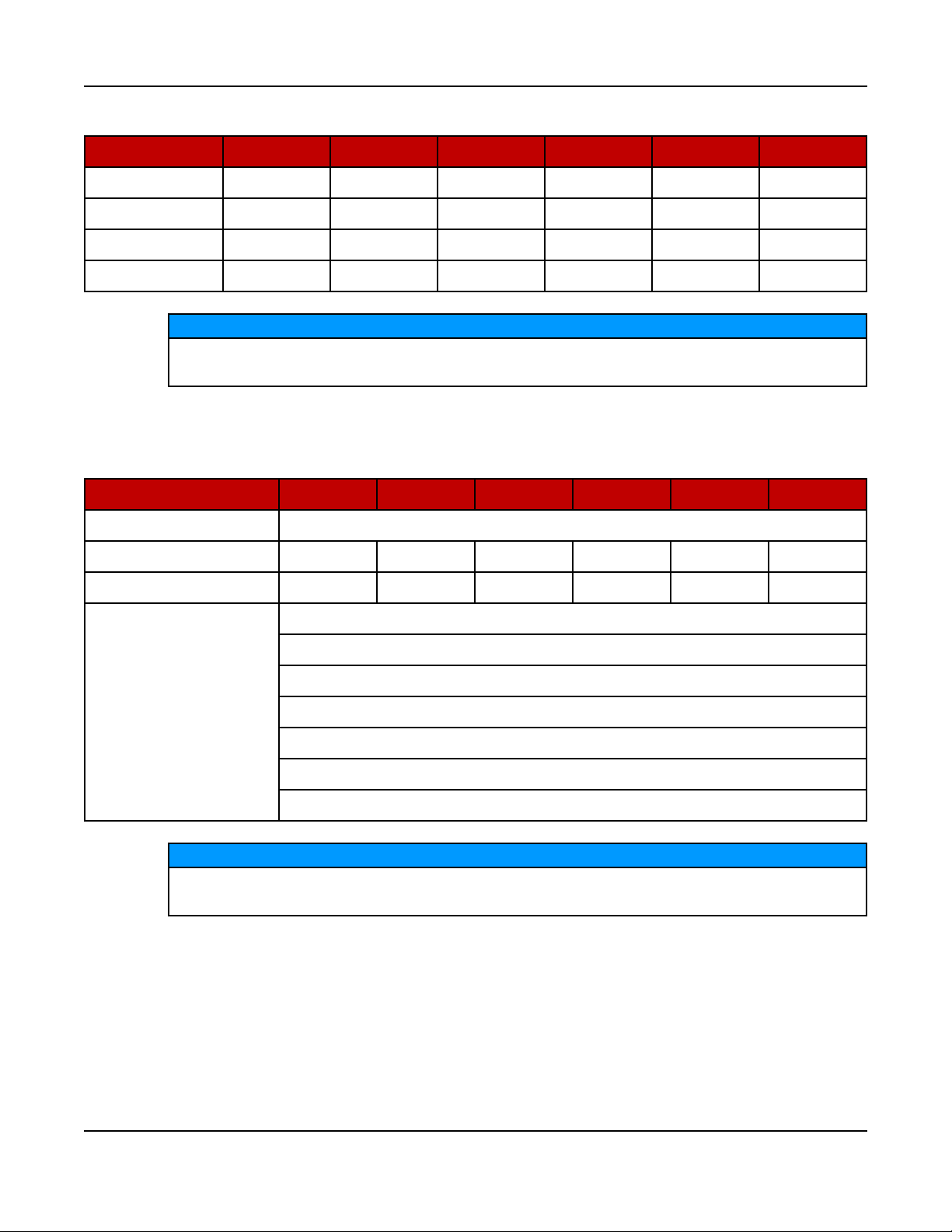

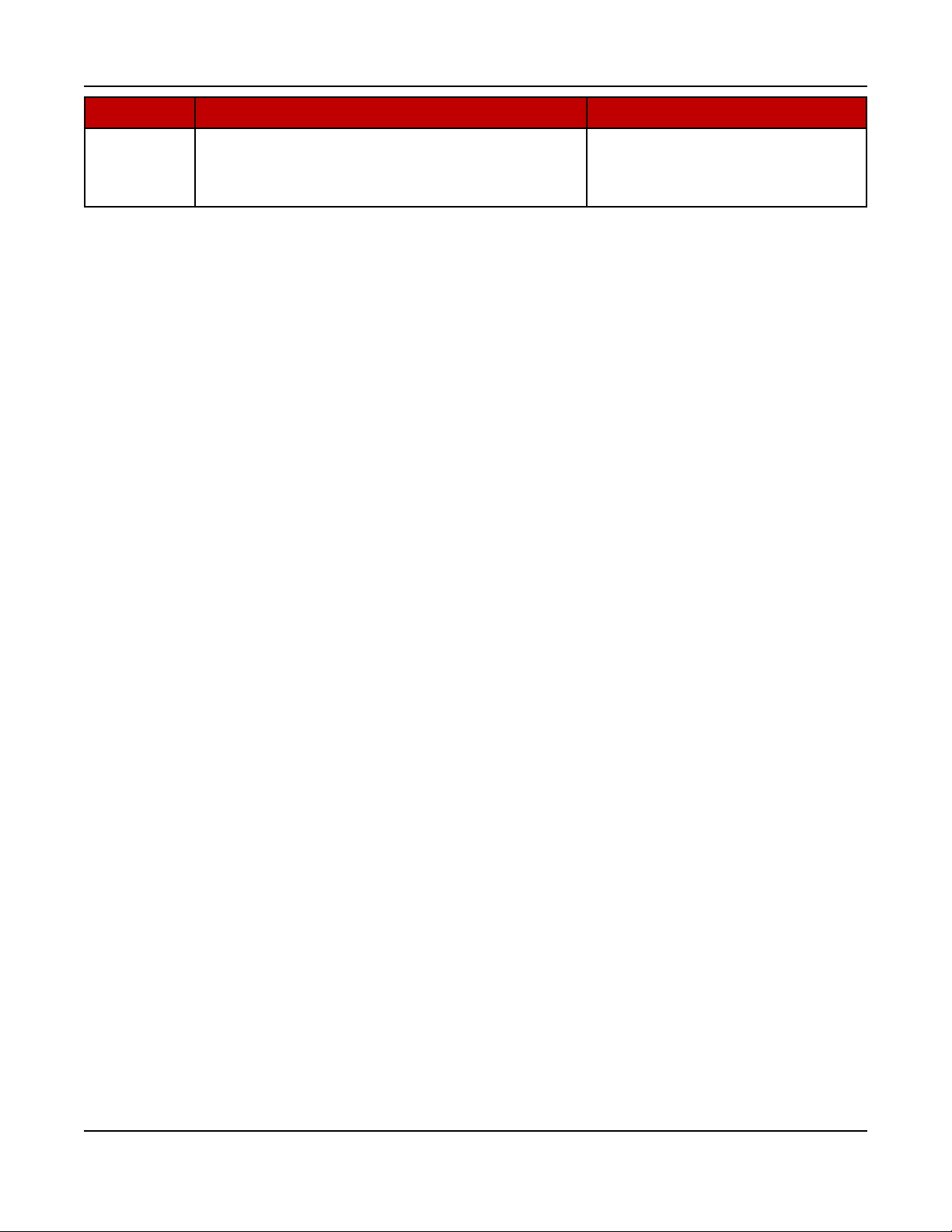

TABLE 3. FUEL SPECIFICATIONS 60 HZ, 1800 RPM

Type Unit C45 N6 C50 N6 C60 N6 C70 N6 C80 N6 C100 N6

Liquid

Propane

scfh 289.6 321.6 370.2 384.2 420.8 518.7

BTU/hr 651,600 723,600 832,950 864,450 946,800 1,167,075

Full Load

Natural

Gas

scfh 711.2 806.3 933.8 988.4 1,083.5 1,317.7

BTU/hr 721,868 818,395 947,807 1,003,226 1,099,753 1,337,466

Full Load

Fuel

6-13 inches of water column (1.5 - 3.2 kPa) under any condition

Pressure

TABLE 4. ENGINE SPECIFICATIONS (ALL MODELS)

Type Specification

Engine

6 cylinder-in-line, single-cam, liquid-cooled, 4-stroke, spark

ignited

Bore 102 mm 94.02 in)

Stroke 120 mm (4.72 in)

Displacement 5.88 L (359 in3)

Compression Ratio (Natural

Gas & LPG)

8.5:1

Firing Order 1-5-3-6-2-4

Spark Plug Gap 45, 50, 60 kW) 0.508 mm (0.020 in)

Spark Plug Gap (70, 80, 100

kW)

0.40 mm (016 in)

Spark Plug Torque 38 Nm (8 ft-lb)

Crankshaft Rotation (Viewed

from the Front of the Engine)

Engine Weight (Dry, Long Block

Only)

Clockwise

413 kg (911 lb)

Valve Clearance (Intake) 0.305 mm (0.012 in)

Valve Clearance (Exhaust) 0.610 mm (0.024 in)

• 50/50 coolant solution (50% pure water and 50% anti-

Coolant

freeze)

• 16 L (4.23 gal) capacity

Oil Capacity 15 L (4 gal)

16 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 21

Oil Standards

2. Introduction8-2017

Type Specification

• Must adhere to Cummins®Engineering Standard

(CES) 20085

• Use of improper oils can result in engine damage. Use

only the required oils:

◦ 5W-40 (all ambient temperatures)

◦ 15W-40 (above 4 °C [40 °F] ambient temperature)

(use of GEO 15W-40 oil in ambient temperatures

below 4 °C (40 °F] could result in engine

turbocharger damage)

• A sulfated ash limit of 0.6% mass has been placed on

all engine lubricating oils recommended for use in

Cummins® B, natural gas engines. Higher ash oils can

cause valve and/or piston damage, cause spark plug

fouling, and lead to excessive oil consumption and

degradation of the catalyst.

TABLE 5. LUBRICATING OIL SYSTEM SPECIFICATIONS

Type Specification

Lubricating Oil Pressure at Idle (Minimum) 104 kPa (15 psi)

Lubricating Oil Pressure at Rated Speed (Minimum)

Filter Bypass Valve-Opening Pressure 311 kPa (45 psi)

Pressure Regulator Valve-Opening Pressure 449 kPa (65 psi)

Lubricating Oil Capacity (Standard Sump):

--High 14.2 L (15 qt)

--Low 12.4 L (13 qt)

--Total System 15.1 L (16 qt)

TABLE 6. GENERATOR SET SIZE SPECIFICATIONS

Enclosure

Type

Open/Weather

2489 x 1016 x 1473 mm (98 x 40 x 58 in); does not include exhaust

Size (L x W x H)

discharge elbow

Sound Level 1 3023 x 1016 x 1473 mm (119 x 40 x 58 in)

Sound Level 2 3454 x 1016 x 1473 mm (136 x 40 x 58 in)

17A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 22

2. Introduction 8-2017

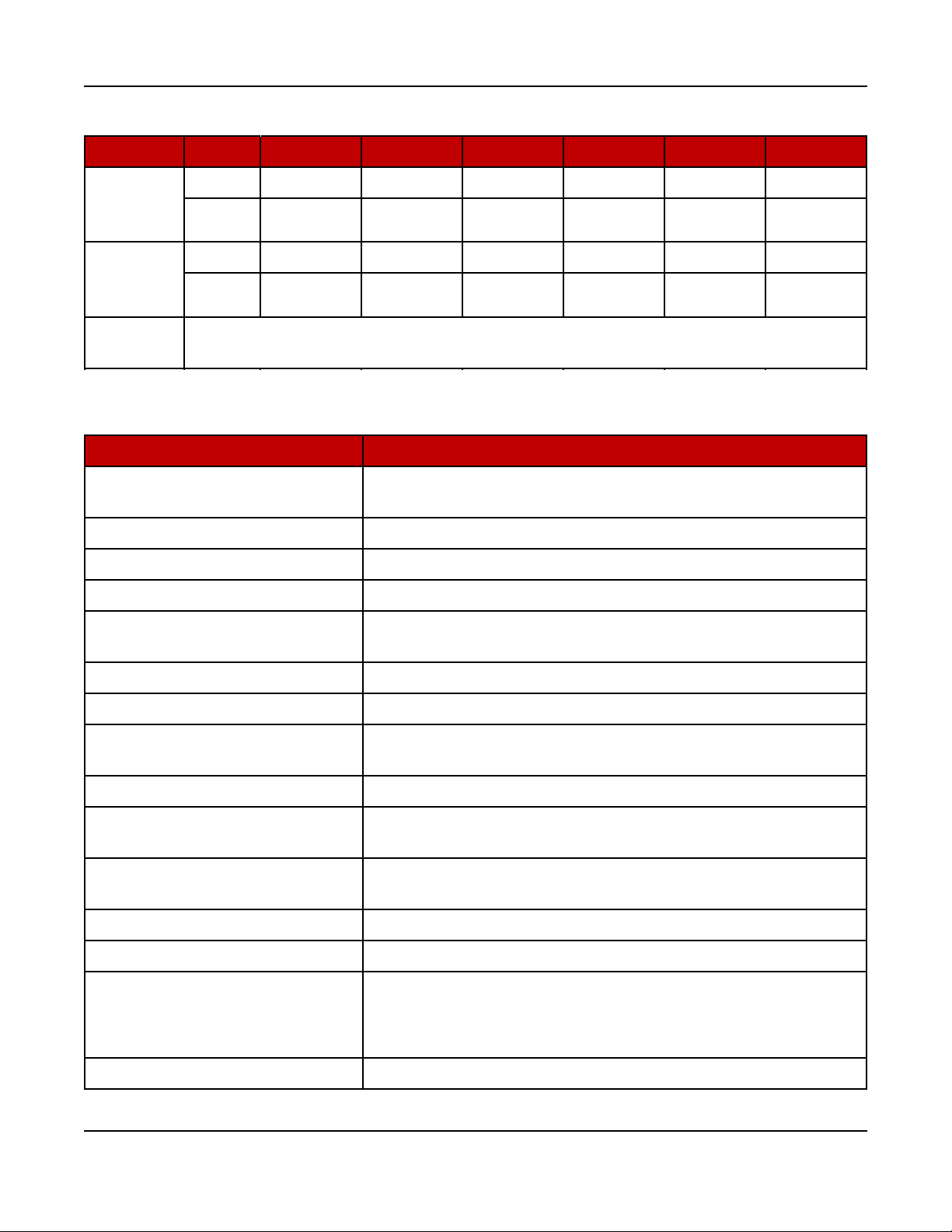

TABLE 7. GENERATOR SET WET WEIGHT (POUNDS) (60 HZ, 1800 RPM)

Configuration C45 N6 C50 N6 C60 N6 C70 N6 C80 N6 C100 N6

Open 2180 2180 2431 2449 2587 2719

Weather 2359 2359 2610 2628 2766 2898

Sound Level 1 2455 2455 2706 2724 2862 2994

Sound Level 2 2485 2485 2736 2754 2892 3024

NOTICE

Weights are approximate and can be affected by selected options. Refer to

outline drawings for specific weight information.

TABLE 8. ALTERNATOR SPECIFICATIONS 60 HZ, 1800 RPM

Type C45 N6 C50 N6 C60 N6 C70 N6 C80 N6 C100 N6

Generator Brushless, 4-pole rotating field, single bearing

Power (kVA) 1 Phase 45 50 60 70 80 100

Power (kVA) 3 Phase 56.3 62.5 75 87.5 100 125

120/240, 1 Ph

227/480, 3 Ph

347/600, 3 Ph

Rated Voltages (V)

120/240, 3 Ph

120/208, 3 Ph

127/220, 3 Ph

F1PO (Reconnectable, Full Single Phase Output)

NOTICE

Maximum I2= 8%. Generator set load unbalance must not exceed 25%

between any phases.

18 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 23

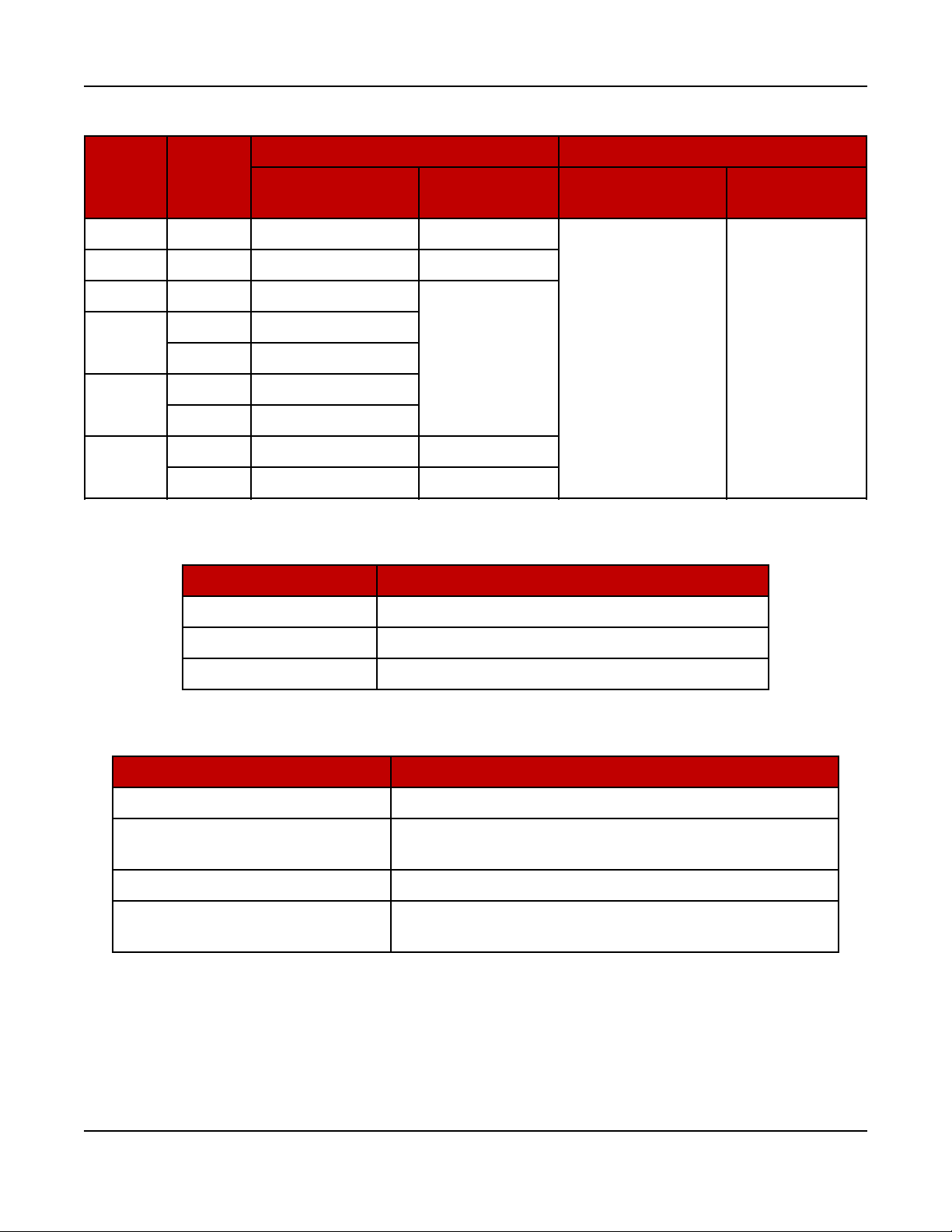

TABLE 9. GENERATOR SET DERATING GUIDELINES

Engine Power Available Up To... Derate At…

Model Phase

Elevation

C45 N6 Both 675 m (2200 ft) 40 °C (104 °F)

C50 N6 Both 150 m (490 ft) 25 °C (77 °F)

C60 N6 Both 1000 m (3280 ft)

Ambient

Temperature

2. Introduction8-2017

Elevation Temperature

C70 N6

C80 N6

C100 N6

1 2575 m (8450 ft)

3 3048 m (10000 ft)

1 1825 m (5985 ft)

3 2500 m (8200 ft)

1 700 m (1560 ft) 25 °C (77 °F)

3 1000 m (3280 ft) 40 °C (104 °F)

TABLE 10. CONTROL SPECIFICATIONS (ALL MODELS)

Control Purpose

PC 1.1 Generator Set

Enovations I28 EPR Engine (45, 50, 60 kW Generator Sets)

Enovations 4G LDI Engine (70, 80, 100 kW Generator Sets)

TABLE 11. DC SYSTEM SPECIFICATIONS (ALL MODELS)

Type Specification

40 °C (104 °F)

per 300 m (985 ft)

4%

2%

per 10 °C (18

°F)

Nominal Battery Voltage 12 VDC

Battery Group

Battery Type Maintenance-free

Minimum Cold Crank Amps

34 standard, 4D high capacity (requires large battery

tray)

850 standard, 1080 high capacity (requires large

battery tray)

2.6 After Sales Services

Cummins offers a full range of maintenance and warranty services.

19A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 24

2. Introduction 8-2017

Maintenance

WARNING

Electrical Generating Equipment

Incorrect service or parts replacement can result in severe personal injury,

death, and/or equipment damage.

Make sure service personnel are qualified to perform electrical and

mechanical service.

For expert generator set service at regular intervals, contact your Cummins Inc.

service provider. See power.cummins.com/sales-service-locator for service

locations that service this application. Maintenance tasks should only be undertaken

by trained and experienced technicians provided by your Cummins Inc. service

provider.

Warranty

For details of the warranty coverage for your generator set, refer to the Warranty

Statement listed in the Related Literature section.

Extended warranty coverage is also available. In the event of a breakdown, prompt

assistance can normally be given by factory trained service technicians with

facilities to undertake all minor and many major repairs to equipment on site.

For further warranty details, contact your authorized dealer.

NOTICE

Damage caused by failure to follow the manufacturer's recommendations

will not be covered by the warranty. Please contact your authorized dealer.

Warranty Limitations

For details of the warranty limitations for your generator set, refer to the

warranty statement applicable to the generator set.

How to Obtain Service

For parts, service, and product information, contact the nearest authorized Cummins

Inc. dealer. To easily locate the nearest certified distributor/dealer for Cummins

generator sets in your area, or for more information, contact us at 1-800CUMMINSTM(1-800-286-6467) or visit http://www.cummins.com/support.

2.7 General Operating Conditions

The area surrounding the generator set is critical for safety and its performance.

Follow the guidelines below.

• Do not stack anything on top of the generator set.

20 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 25

2. Introduction8-2017

• Do not store anything inside of the generator set.

• Keep areas clear in front of the cool air in and hot air out (free of obstructions,

debris, plants, etc.).

NOTICE

All maintenance procedures must be performed or supervised by authorized

and trained service personnel only.

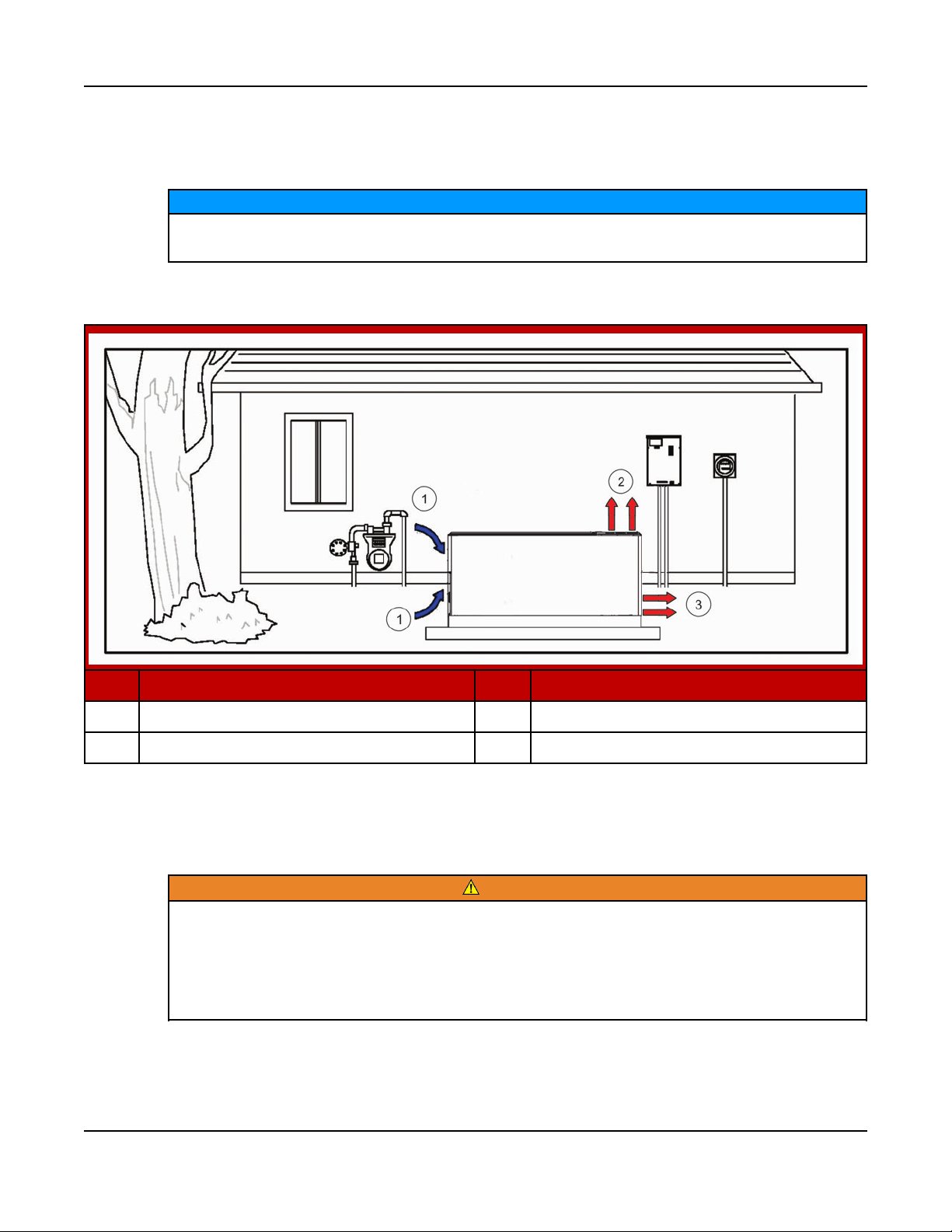

No. Description No. Description

1 Cool Air In 3 Hot Air Out (Weather Enclosure)

2 Hot Air Out (Sound Level Enclosure)

FIGURE 1. EXAMPLE OF GENERATOR SET LOCATION

2.8 Generator Set Nameplate

WARNING

Electrical Generating Equipment

Improper service or replacement of parts can lead to severe personal injury

or death and to damage to equipment and property.

Make sure service personnel are qualified to perform electrical and

mechanical service.

21A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 26

2. Introduction 8-2017

NOTICE

Unauthorized modifications or replacement of fuel, exhaust, air intake or

speed control system components that affect engine emissions are

prohibited by law in the State of California.

Model, Spec, and Serial Numbers: Be ready to provide the model, spec, and

serial numbers on the generator set nameplate when contacting Cummins Inc. for

information, parts, and service. The nameplate is located on the inside of the control

access door on enclosed products or on the side of the radiator for open products.

Record these numbers so that they are easy to find when needed. Each character

in these numbers is significant for obtaining the right parts listed in the Parts

Catalog. Genuine Cummins Inc. replacement parts are recommended for best

results.

My Generator Set Information

Model

Spec

Serial

Number

22 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 27

2.9 Manufacturing Facilities

Facility Address Phone Numbers

U.S. and

CANADA

Cummins Inc.

1400 73rd Ave. NE

Minneapolis, MN 55432 USA

Toll Free 1-800-CUMMINS

(1-800-286-6467)

Phone +1 763-574-5000

Fax +1 763-574-5298

2. Introduction8-2017

TM

EMEA, CIS Cummins Inc.

Columbus Avenue

Manston Park

Manston, Ramsgate

Kent CT12 5BF

United Kingdom

Cummins Inc.

Royal Oak Way South

Daventry

Northamptonshire

NN11 8NU

United Kingdom

ASIA

PACIFIC

Cummins Inc.

10 Toh Guan Road #07-01

TT International Tradepark

Singapore 608838

BRAZIL Rua Jati, 310, Cumbica

Guarulhos, SP 07180-900

Brazil

Phone +44 1843 255000

Fax +44 1843 255902

Phone +44 1843 255000

Fax +44 1843 255902

Phone +65 6417 2388

Fax +65 6417 2399

Phone +55 11 2186 4195

Fax +55 11 2186 4729

CHINA Cummins Inc.

2 Rongchang East Street,

Beijing Economic – Technological

Development Area

Beijing 100176, P.R. China

INDIA Cummins Inc.

Power Generation Business Unit,

Plot No B-2, SEZ Industrial Area,

Village-Nandal & Surwadi, Taluka- Phaltan

Dist- Satara, Maharashtra 415523

India

LATIN

AMERICA

3350 Southwest 148th Ave.

Suite 205

Miramar, FL 33027 USA

Phone 86 10 59023001

Fax +86 10 5902 3199

Phone

+91 021 66305514

Phone +1 954 431 551

Fax +1 954 433 5797

23A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 28

2. Introduction 8-2017

Facility Address Phone Numbers

MEXICO Eje 122 No. 200 Zona Industrial

San Luis Potosi, S.L.P. 78395

Mexico

Phone +52 444 870 6700

Fax +52 444 824 0082

24 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 29

3 Control System

3.1 Control System Description

The control system is used to start and stop the generator set, and provides full

generator set monitoring capability and protection in a stand-alone situation (nonparalleling) from the display screen. It monitors the engine for temperature, as well

as oil pressure and speed. It also provides voltage and current metering. In the

event of a fault, the unit indicates the fault type and, on critical faults, automatically

shuts down the generator set.

All indicators, control buttons, and the display screen are on the face of the operator

panel, as illustrated in the figure below.

There are three fault level signals generated by the control system:

• Event: Signals that a temporary condition exists.

• Warning: Signals an imminent or non-critical fault for the engine. The control

provides an indication only for this condition.

• Shutdown: Signals a potentially critical fault for the engine. The control

immediately takes the engine off-load and automatically shuts it down.

The standard control system operates on 12 VDC (or 24 VDC if applicable) battery

power. History data is stored in non-volatile memory and is not deleted if battery

power is lost.

Standard Operator Panel

The operator panel includes indicator lights (LEDs), display buttons used to

navigate through the menus, control mode buttons, and an LCD display. The display

enables the operator to check the status, adjust the settings, and start and stop the

generator set. The standard operator panel (show below) is located on every

generator set. An optional in-home operator panel accessory is also available for

location inside the home.

25A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 30

3. Control System 8-2017

FIGURE 2. STANDARD OPERATOR PANEL (HMI211)

Standard Key Functions (HMI211)

The user interface includes two fixed action buttons and four soft key buttons.

The action of the soft key buttons changes to meet the requirements of each

screen.

TABLE 12. KEY FUNCTIONS

Key/Symbol Action

Switches to Off mode (fixed action button).

Switches to Auto mode.

Switches to Manual Run mode.

Navigates to the previous menu level (fixed action button).

(Up Arrow) Navigates to the previous screen/menu in a list.

(Down Arrow) Navigates to the next screen/menu in a list.

and Hold the up and down arrows simultaneously for two seconds from any

Info Menu to navigate to the Menu screen.

Save Saves changes and navigates to the associated screen.

Adjust Navigates to the Adjust Menu of a specific menu.

(Right Arrow) Advances the highlighted field to the next editable field.

26 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 31

Key/Symbol Action

- Decreases value of the highlighted editable field.

+ Increases value of highlighted editable field.

Standard LED Indicators (HMI211)

The operator panel has six LED indicators. Colors, flashing frequency, and

conditions to turn them on/off/blink are included in the table below.

TABLE 13. LED INDICATORS

LED Color Action

Not in Auto Red Indicates the generator set is in Manual or Off Mode.

Shutdown Red Indicates a Shutdown Fault has occurred.

Warning Yellow Indicates a Warning Fault has occurred.

3. Control System8-2017

Remote

Start

Auto Green Indicates that the generator set is in Auto Mode. The generator starts

Manual Run Green Indicates that the generator set has received a Manual Run

Green Indicates that the generator set has received a Remote Start

Command.

when it receives a Remote Start Command.

Command.

In-Home Operator Panel (Accessory)

The in-home operator panel is an optional display that may be purchased. This

panel is intended to serve as a convenience option to the standard operator panel

mounted on the generator set.

27A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 32

3. Control System 8-2017

FIGURE 3. IN-HOME OPERATOR PANEL

Key Functions (In-Home Operator Panel)

The user interface includes two fixed action buttons and four soft key buttons.

The action of the soft key buttons changes to meet the requirements of each

screen.

TABLE 14. KEY FUNCTIONS

Key/Symbol Action

Stop Switches to Off mode. This key works from any screen (fixed action

button).

(Up Arrow) Navigates to the previous screen/menu in a list.

(Down Arrow) Navigates to the next screen/menu in a list.

and Hold the up and down arrows simultaneously for two seconds from any Info

Menu to navigate to the Service Menu.

Back Navigates to the previous screen/menu in a list (fixed action button). In

Adjust screens, settings are not saved.

Save Saves changes and navigates to the associated screen.

Adjust Navigates to the Adjust Menu of a specific menu.

(Right Arrow) Advances the highlighted field to the next editable field.

- Decreases value of the highlighted editable field.

+ Increases value of highlighted editable field.

28 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 33

3. Control System8-2017

LED Indicators (In-Home Operator Panel)

The operator panel has five LED indicators. Colors, flashing frequency, and

conditions to turn them on/off/blink are included in the table below.

TABLE 15. LED INDICATORS

LED Color Action

Shutdown Red Indicates a Shutdown Fault has occurred.

Warning Yellow Indicates a Warning Fault has occurred.

Auto Start Green Indicates that the generator set has received a Remote Start

Command.

Auto Green Indicates that the generator set is in Auto Mode. The

generator starts when it receives a Remote Start Command.

Manual Run Green Indicates that the generator set has received a Manual Run

Command.

3.2 Display Text or Symbolic Version

The operator panel graphical display can be set to show text (English only) or

symbols for fault messages, operator menus, and the Mode Change Menu.

Descriptions of commonly used symbols are included in the following table.

Combinations of symbols are used to display some fault conditions.

When shipped from the factory, the display is set to display symbols. Qualified

service personnel are required to change the default setting.

TABLE 16. SYMBOLS

Symbol Text

Generator Warning Fault

Generator Shutdown Fault

Coolant Temperature

Oil Pressure

Voltage Alternating Current (VAC)

Voltage Direct Current (VDC)

AC Current

Hz Frequency

29A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 34

3. Control System 8-2017

Symbol Text

Battery

Out of Range

High or Pre-High

Low or Pre-Low

Annunciator

Over Speed

Crank Fail

Emergency Stop

3.3 Exercise Settings

When battery power is lost, these settings must be reset.

Not applicable without an RA series transfer switch.

To access the Clock/Exerciser Menu:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Navigate through the screens to find and select Clock/Excr in the Service

Menu.

The following screens represent the standard operator panel (that is,

HMI211). If using an in-home operator panel, which may be additionally

purchased as an option, the screens may look slightly different. This

procedure applies to both operator panels.

NOTICE

NOTICE

NOTICE

30 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 35

3. Control System8-2017

FIGURE 4. CLOCK/EXERCISER MENU NAVIGATION

31A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 36

3. Control System 8-2017

Updating Exercise Frequency (3-Phase ATS)

NOTICE

Not applicable without an RA series transfer switch.

To update the exercise frequency and dates on the Clock/Exerciser Menu:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Access the Time Setup screen by selecting Clock Exerciser on the Genset

Service Menu.

3. Press the down key on the Time Setup screen to access the Daylight Saving

Adjust screen.

4. Select Adjust.

5. Press the down key on the Daylight Saving Adjust Start screen.

6. Select Adjust.

7. Press Exercise Schdr on the Daylight Saving Adjust End screen.

8. Press Adjust.

When updating these settings, the functions of the keys are as follows:

• The horizontal right arrow key is used to select successive blocks for editing

settings on the screen.

• Use the + or - keys to edit the following settings:

◦ Schdr Enable: Enable or Disable

◦ Exercise Schedule: Semi-Annual (every six months), Quarterly, Monthly,

Bi-Weekly (every two weeks) , or Weekly

◦ Exercise Schedule: Day, Hours, Minutes, AM/PM

• Press Save to save any changes. After saving, the Save button changes to the

Adjust button.

32 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 37

FIGURE 5. EXERCISE FREQUENCY NAVIGATION

3. Control System8-2017

Updating Exercise Duration (3-Phase ATS)

NOTICE

Not applicable without an RA series transfer switch.

To update the exercise duration on the Clock/Exerciser Menu:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Access the Time Setup screen by selecting Clock Exerciser on the Genset

Service Menu.

3. Press the down key on the Time Setup screen to access the Daylight Saving

Adjust screen.

4. Select Adjust.

5. Press the down key on the Daylight Saving Adjust Start screen.

6. Select Adjust.

7. Press Exercise Schdr on the Daylight Saving Adjust End screen.

8. Press the down key on the Exercise Schdr Menu.

9. Press Adjust.

When updating these settings, the functions of the keys are as follows:

• The horizontal right arrow key is used to select the duration block for editing

exercise duration.

• Use the + or - keys to edit the exercise duration minutes.

33A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 38

3. Control System 8-2017

• Press Save to save any changes. After saving, the Save button changes to the

Adjust button.

FIGURE 6. EXERCISE DURATION NAVIGATION

Time Setup (3-Phase ATS)

NOTICE

When battery power is lost, these settings must be reset.

NOTICE

Not applicable without an RA series transfer switch.

To set up the generator set clock for the current date and time:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Access the Time Setup screen by selecting Clock Exerciser on the Genset

Service Menu.

3. Select Adjust.

When updating these settings, the functions of the keys are as follows:

• The horizontal right arrow key is used to select successive blocks for editing

settings on the screen.

• Select the left arrow to return to the previous screen.

• Adjust values by using the + or - keys on the Adjust Menu of the Time Setup

screen.

• Press Save to save any changes. After saving, the Save button changes to the

Adjust button.

34 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 39

FIGURE 7. TIME SETUP SCREEN

Updating Daylight Saving Adjust Screens

3. Control System8-2017

Update Values on the Daylight Saving Adjust Screen

1. From any Information Menu, hold down the up and down arrows

simultaneously for two seconds. The Service Menu appears.

2. Navigate to the Genset Service Menu.

3. Select Clock Exerciser to access the Time Setup screen.

4. Press the down key on the Time Setup screen to access the Daylight

Saving Adjust screen.

5. Select Adjust. When updating these settings, the functions of the keys

are as follows:

TABLE 17. KEY FUNCTIONS ON THE DAYLIGHT SAVING ADJUST SCREEN

Key/Button Function

Horizontal right arrow key Select successive blocks for editing settings on the screen

Left arrow key Return to the previous screen

+ or - keys Adjust values on the Adjust screen of the Daylight Saving Adjust

screen

Save button Save any changes; after saving, the Save button changes to the

Adjust button

35A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 40

3. Control System 8-2017

FIGURE 8. "DAYLIGHT SAVING ADJUST SAVING TIME" SCREEN NAVIGATION

Access and Update the Daylight Saving Adjust Start Screen

1. Press the down arrow key on the Daylight Saving Adjust screen.

2. Press Adjust. When updating these settings, the functions of the keys are

as follows:

TABLE 18. KEY FUNCTIONS ON THE DAYLIGHT SAVING ADJUST START SCREEN

Key/Button Function

Horizontal right arrow key Select successive blocks for editing settings on the screen

+ or - keys Adjust Month, Week, Day or Hour

Save button Save any changes; after saving, the Save button changes to the

Adjust button

36 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 41

FIGURE 9. DAYLIGHT SAVING ADJUST START SCREEN

3. Control System8-2017

Update the Daylight Saving Adjust End Screen

1. Press the down key on the Daylight Saving Adjust Start screen.

2. Press Adjust. When updating these settings, the functions of the keys are

as follows:

TABLE 19. KEY FUNCTIONS ON THE DAYLIGHT SAVING ADJUST END SCREEN

Key/Button Function

Horizontal right arrow key Select successive blocks for editing settings on the screen

+ or - keys Adjust Month, Week, Day or Hour

Save button Save any changes; after saving, the Save button changes to the

Adjust button

37A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 42

3. Control System 8-2017

FIGURE 10. DAYLIGHT SAVING ADJUST END SCREEN

3.4 Brightness and Contrast

The Screen Adjust screen allows the contrast, brightness, and units to be set. To

access the Screen Adjust screen:

1. From any Information screen, hold down the up and down arrows

simultaneously for two seconds to gain access to the Service Menu screen.

2. Select Screen Adjust.

To adjust the contrast, brightness, or units from the Screen Adjust screen:

1. From the Screen Adjust screen, select Adjust to access the screen variables.

2. Press the right arrow to move between the variables.

3. Adjust settings, and press Save to save any changes.

When updating these settings, the functions of the keys are as follows:

• The horizontal right arrow key is used to select successive blocks for editing

settings on the screen.

• Select the left arrow to return to the previous screen.

• Adjust values by using the + or - keys on the Adjust screen of the Display

Setup screen.

• Press Save to save any changes. After saving, the Save button changes to the

Adjust button.

38 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 43

3. Control System8-2017

NOTICE

The following screens represent the standard operator panel (HMI211). If

using an in-home operator panel, which may be additionally purchased as an

option, the screens may look slightly different. This procedure applies to

both operator panels.

FIGURE 11. BRIGHTNESS AND CONTRAST SCREEN NAVIGATION

39A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 44

3. Control System 8-2017

NOTICE

Adjusting the brightness on the operator panel adjusts the brightness of

both the LCD backlight and the LEDs on the display. The contrast should

never be 0 or 100% on any of the screens. The default value for Brightness is

50%.

3.5 History and About Menu

To access the History/About screen:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Select History/About.

3. Advance through the screens to view information about the generator set,

control, and display.

NOTICE

The following screens represent the standard operator panel (HMI211). If

using an in-home operator panel, which may be additionally purchased as an

option, the screens may look slightly different. This procedure applies to

both operator panels.

40 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 45

3. Control System8-2017

FIGURE 12. HISTORY/ABOUT MENU

41A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 46

3. Control System 8-2017

3.6 Fault Log

To check the fault log:

1. From any Information Menu, hold down the up and down arrows simultaneously

for two seconds. The Service Menu appears.

2. Select Fault History.

NOTICE

The active faults are displayed first. If there are no active faults, this screen

is skipped. Following the Active Faults screen are the Fault History screens.

These screens display the faults in chronological order from newest to

oldest.

NOTICE

The following screens represent the standard operator panel (HMI211). If

using an in-home operator panel, which may be additionally purchased as an

option, the screens may look slightly different. This procedure applies to

both operator panels.

42 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 47

3. Control System8-2017

FIGURE 13. FAULT LOG SCREEN

43A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 48

3. Control System 8-2017

3.7 Selecting Operating Modes

Selecting Manual Run Mode

WARNING

Electrical Generating Equipment

When changing modes, the generator set can start or stop without warning

(for example, Auto Mode may have been selected with no mains (utility)

power available).

Make sure there is no danger to personnel or equipment, if the generator set

starts or stops when changing modes.

1. Before proceeding to change the mode, make sure that it is safe to do so.

2. Press the Manual Run button on any of the Operator menus or the

"Establishing/Re-establishing communication with control" menus.

3. If the Mode Change Access Code menu is enabled, the Mode Change Access

Code is displayed. Enter the Mode Change Access Code.

4. A menu with alternating arrows is displayed above a second symbol.

5. Press the second Manual Run button, and the generator set will now begin

the Manual start sequence. The Operator menu that was displayed before

Manual Run mode was selected is re-displayed, but with the symbol blacked

out.

NOTICE

To disable Manual Run mode, press the Off button.

NOTICE

Auto mode can also be selected while in Manual Run mode. Switching to

Auto mode may result in the generator set shutting down.

44 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 49

3. Control System8-2017

No. Description No. Description

1 Menu Displayed Only When the Mode

3 Manual Run Mode Selected

Change Access Code Feature Is

Enabled

2 Alternating Arrows Displayed

FIGURE 14. SELECTING MANUAL RUN MODE

45A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 50

3. Control System 8-2017

Selecting Auto Mode

WARNING

Electrical Generating Equipment

When changing modes, the generator set can start or stop without warning

(for example, Auto Mode may have been selected with no mains (utility)

power available).

Make sure there is no danger to personnel or equipment, if the generator set

starts or stops when changing modes.

To switch to Auto mode (see Figure 15 on page 47),

1. Ensure that it is safe to do so before proceeding to change the mode.

2. Press the Auto button on any of the Operator menus, or the

‘Establishing/Re-establishing communication with control’ menus.

3. If the mode change access code feature is enabled, the Mode Change Access

Code menu is displayed. Enter the Mode Change Access Code.

4. A menu with alternating arrows will then be displayed above a second

Auto symbol.

5. Press this second Auto button. The Operator menu that was displayed

before Auto mode was selected is re-displayed, but with the Auto symbols

blacked out and Manual Run symbols visible.

To disable Auto mode, press the Off button.

The generator set is now ready to receive a remote start signal that will initiate the

Auto run mode.

WARNING

Should a remote start signal be received, the generator set starts

automatically. Make sure there is no danger to personnel or equipment

should the generator set start without warning.

NOTICE

Manual Run mode can also be selected FROM Auto mode. Switching to

Manual Run mode results in the generator set starting up.

46 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 51

3. Control System8-2017

No. Description No. Description

1 This Menu Is Displayed Only if the

3 Auto Mode Selected

Mode Change Access Code Feature Is

Enabled

2 Alternating Arrows Are Displayed

FIGURE 15. SELECTING AUTO MODE

47A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 52

3. Control System 8-2017

Selecting Off Mode

WARNING

Electrical Generating Equipment

When changing modes, the generator set can start or stop without warning

(for example, Auto Mode may have been selected with no mains (utility)

power available).

Make sure there is no danger to personnel or equipment, if the generator set

starts or stops when changing modes.

To switch to Off mode (see the figure below),

1. Make sure that it is safe to do so before proceeding to stop the set.

2. Press the Off button on any of the Operator menus or the "Establishing/Reestablishing communication with control" menus.

3. If the Mode Change Access Code is enabled, the Mode Change Access Code

will be displayed. Enter the Mode Change Access Code.

4. On entering the last correct digit, the basic screen will re-appear, and the set

will stop without a Time Delay to Stop.

NOTICE

Make sure that there is no danger to personnel or equipment if the

generator set is stopped.

48 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 53

3. Control System8-2017

No. Description No. Description

1 Off Button 2 This Mode Is Displayed Only if the

Mode Change Access Code Feature Is

Enabled

FIGURE 16. SELECTING OFF MODE

3.8 Operating Modes

The generator set's PowerCommand®control has Manual Run, Off, and Auto

operating modes that are available from the operator panel.

49A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 54

3. Control System 8-2017

Off Mode

When in Off mode, the control does not allow the generator set to start. If the

generator set is already running and the control is set to Off, it initiates a normal

shutdown sequence.

Manual Run Mode

When in Manual Run mode, the generator set starts and continues to run until the

control is put into the Off mode. While in Manual Run mode, the remote start signal

is ignored.

Auto Mode

When in Auto mode, the control allows the generator set to be started with a remote

start signal only.

When in Auto mode, the generator set can start at any time. When a remote start

signal is received, the genset starts after a time delay preheat (if programmed) and

time delay start (if programmed) is completed.

If the generator set is running in Auto mode and the Off button is pressed, the

control immediately stops the genset and the control transitions to the Off mode.

When all remote start signals are removed, the control performs a normal shutdown

sequence which may include a time delay stop.

50 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 55

4 Operation - PowerCommand 1.1

4.1 Introduction

This section describes the operation of the generator set. The text should be read in

conjunction with the Control System section of this manual.

All indicators, control switches/buttons, and graphical display are located on the

face of the Operator Panel.

4.2 General Operating Conditions

The area surrounding the generator set is critical for safety and its performance.

Follow the guidelines below.

• Do not stack anything on top of the generator set.

• Do not store anything inside of the generator set.

• Keep areas clear in front of the cool air in and hot air out (free of obstructions,

debris, plants, etc.).

NOTICE

All maintenance procedures must be performed or supervised by authorized

and trained service personnel only.

4.3 Generator Set Operation

WARNING

Combustible Vapors

Do not operate an engine where there are or can be combustible vapors.

These vapors can be sucked through the air intake system and cause engine

acceleration and overspeeding, which can result in a fire, an explosion,

personal injury and extensive property damage.

Correct care of your engine will result in longer life, better performance, and more

economical operation.

Cummins Inc. does not know how you will use your generator set. The equipment

owner and operator, therefore, is responsible for safe operation in the installation

site environment. Consult your authorized Cummins dealer for further information.

51A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 56

4. Operation - PowerCommand 1.1 8-2017

NOTICE

Diesel engines only: Cummins Inc. recommends the installation of an air

intake shutoff device or a similar safety device to minimize the risk of

overspeeding where an engine will be operated in a combustible

environment.

NOTICE

Long periods of idling (more than ten minutes) can damage an engine. Do

not idle the engine for excessively long periods.

Sequence of Operation

NOTICE

The following sequences are based on an approximate time duration. Your

generator set may vary slightly from the timing diagrams in this manual. All

referenced times are based on default control settings. The following

sequences are applicable to generator sets connected to an RA series

transfer switch.

Power Outage Sequence

The sequence of operation after a power outage (when the generator set is in

Auto Mode) is as follows:

1. In normal operation, the utility power is running to the transfer switch and

then to the building load, and the generator set is off.

2. The utility power turns off (power outage).

3. One second after the power outage, the transfer switch sends the

command to the generator set to start.

4. If the ambient temperature is below 20 °F/-6.7 °C, the generator set will

idle at 800 rpm for up to 2 minutes to allow sufficient turbo lubrication.

• The set points are 20 °F/-6.7 °C and below, ramping linearly from 0

sec (20 °F/-6.7 °C) to 2 minutes (-40 ° F/-40 °C) and held constant at

2 minutes if below -40 °F/-40 °C.

FIGURE 17. COLD START IDLE ACTIVE

52 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 57

4. Operation - PowerCommand 1.18-2017

NOTICE

The control box area is equipped with an ambient temperature

sensor for controlling the idle feature. Do not install any heaters in

the control box area as this can influence the sensor and lead to

engine damage.

5. After the generator set ramps up to rated speed, the generator set

provides voltage to the transfer switch, but the transfer switch does not

switch (allowing the voltage to go to the building) until after a delay.

FIGURE 18. TIME REMAINING UNTIL TRANSFER SCREEN

6. Five seconds after starting, the generator set provides a signal to the

transfer switch to transfer the building load to the generator set.

FIGURE 19. BUILDING LOAD TRANSFER IN PROCESS

7. The transfer switch switches the generator set power to the building load.

The building is now running on generator power.

FIGURE 20. GENERATOR SET POWERING BUILDING LOAD

8. When the utility power is back and providing voltage to the transfer

switch, the transfer switch waits for utility power stability.

53A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 58

4. Operation - PowerCommand 1.1 8-2017

FIGURE 21. TIME REMAINING UNTIL RE-TRANSFER

9. When the utility power is stable for 5 minutes, the transfer switch

switches back to utility power.

FIGURE 22. BUILDING LOAD TRANSFER IN PROCESS

FIGURE 23. UTILITY POWERING BUILDING LOAD

10. The generator set runs for a 5-minute cooldown and shuts off.

FIGURE 24. TIME REMAINING UNTIL STOP

11. Normal operation resumes.

Exercise Sequence

The exercise sequence when the programmed exercise time is realized (the

generator set is in Auto Mode) is as follows:

1. The generator set starts and runs.

54 A051X877 (Issue 6)Copyright © 2017 Cummins Inc.

Page 59

4. Operation - PowerCommand 1.18-2017

2. If the ambient temperature is below 20 ° F (6.7 °C), the generator set will

idle at 800 rpm for up to 2 minutes to allow sufficient turbo lubrication.

• Idle time is linear from 2 minutes at -40 °F (4 °C), or below to off at

20 °F (6.7 °C) or above.

FIGURE 25. COLD START IDLE ACTIVE

3. The Exerciser Scheduler On screen displays every 3 seconds and toggles

between the existing Information screen that is displayed for 1 second.

FIGURE 26. EXERCISER SCHEDULER SCREEN AND INFORMATION SCREEN

TOGGLE - EXAMPLE

4. The transfer switch is not commanded to switch the building load to the

generator set.

NOTICE

The user may navigate to other screens from the Information

screens during this duration. No functional keys are active on the

Exerciser Scheduler On screen.

5. The generator set stops after programmed exercise run time.

Manually Starting the Generator Set Sequence

If the generator set is manually started with the standard operator panel,

HMI211 (the generator set is in Man Mode), the sequence is as follows:

55A051X877 (Issue 6) Copyright © 2017 Cummins Inc.

Page 60

4. Operation - PowerCommand 1.1 8-2017

NOTICE

Open the generator set main line circuit breaker to prevent the transfer

switch from transferring building load to the generator set. The

generator set display will still show the RA series ATS transfer;

however, the switch will not transfer if the generator set breaker is

open.

1. In normal operation, the utility power is running to the transfer switch and

then to the building load, and the generator set is off.

2. Manually start the generator set via the standard control (HMI211)

mounted on the generator set.