Page 1

InstallationInstallation ManualManual

Generator Set

QSJ2.4 Engine with PowerCommand® 1.1 Control

C20 N6 (Spec A), C22 N6 (Spec A)

C25 N6 (Spec A), C30 N6 (Spec A)

C36 N6 (Spec A), C40 N6 (Spec A)

C30 N6H (Spec A), C36 N6H (Spec A)

C40 N6H (Spec A), C45 N6H (Spec A)

C50 N6H (Spec A), C60 N6H (Spec A)

English

Original Instructions

8-2017 A045R241 (Issue 10)

Page 2

Page 3

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS....................................................................................... 1

1.1 Warning, Caution, and Note Styles Used in This Manual ..................................................... 1

1.2 Save These Instructions ........................................................................................................ 1

1.3 General Information ................................................................................................................ 2

1.4 General Precautions .............................................................................................................. 2

1.5 Generator Set Voltage Is Deadly ........................................................................................... 6

1.6 Fuel and Fumes Are Flammable ............................................................................................ 6

1.7 Starting Batteries .................................................................................................................... 7

1.8 Batteries Can Explode............................................................................................................ 7

1.9 Vented Batteries ..................................................................................................................... 8

1.10 Moving Parts Can Cause Severe Personal Injury or Death ................................................ 9

1.11 Exhaust Gases Are Deadly................................................................................................... 9

1.12 The Hazards of Carbon Monoxide...................................................................................... 10

2. INTRODUCTION.......................................................................................................................... 11

2.1 About This Manual................................................................................................................ 11

2.2 Schedule of Abbreviations.................................................................................................... 11

2.3 Related Literature ................................................................................................................. 13

2.4 Before Installation ................................................................................................................. 14

2.5 Model Specifications............................................................................................................. 15

3. PRE-INSTALLATION CONSIDERATIONS.................................................................................. 21

3.2 Installation Codes and Standards for Safety ........................................................................ 22

3.3 Required Items for Installation.............................................................................................. 24

4. INSTALLATION............................................................................................................................ 29

4.1 Site Assessment and Preparation ........................................................................................ 29

4.2 Fuel Selection and Fuel System Connection........................................................................ 32

4.3 Engine Exhaust..................................................................................................................... 43

4.4 Electrical Connections .......................................................................................................... 43

5. STARTUP AND CONFIGURATION............................................................................................. 55

5.1 Time Setup (1-Phase ATS)................................................................................................... 55

5.2 Exercise Settings ................................................................................................................. 58

5.3 Brightness and Contrast ....................................................................................................... 62

5.4 History and About Menu....................................................................................................... 64

5.5 InPower Service Tool............................................................................................................ 66

5.6 Installation Checklist ............................................................................................................. 67

5.7 Startup ................................................................................................................................. 68

APPENDIX A. FUEL LINE SELECTION........................................................................................... 71

A.0 Fuel System Pipe Sizing Introduction................................................................................... 72

A.1 Gas Pipe Sizing.................................................................................................................... 73

iA045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 4

Table of Contents 8-2017

APPENDIX B. OUTLINE AND SYSTEM DRAWINGS...................................................................... 85

APPENDIX C. WIRING DIAGRAMS................................................................................................. 99

APPENDIX D. SEISMIC REQUIREMENTS.................................................................................... 109

D.1 Seismic Installation Instructions......................................................................................... 111

ii A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS. This manual contains important instructions that

should be followed during installation and maintenance of the generator set and

batteries.

Safe and efficient operation can be achieved only if the equipment is properly

operated and maintained. Many accidents are caused by failure to follow

fundamental rules and precautions.

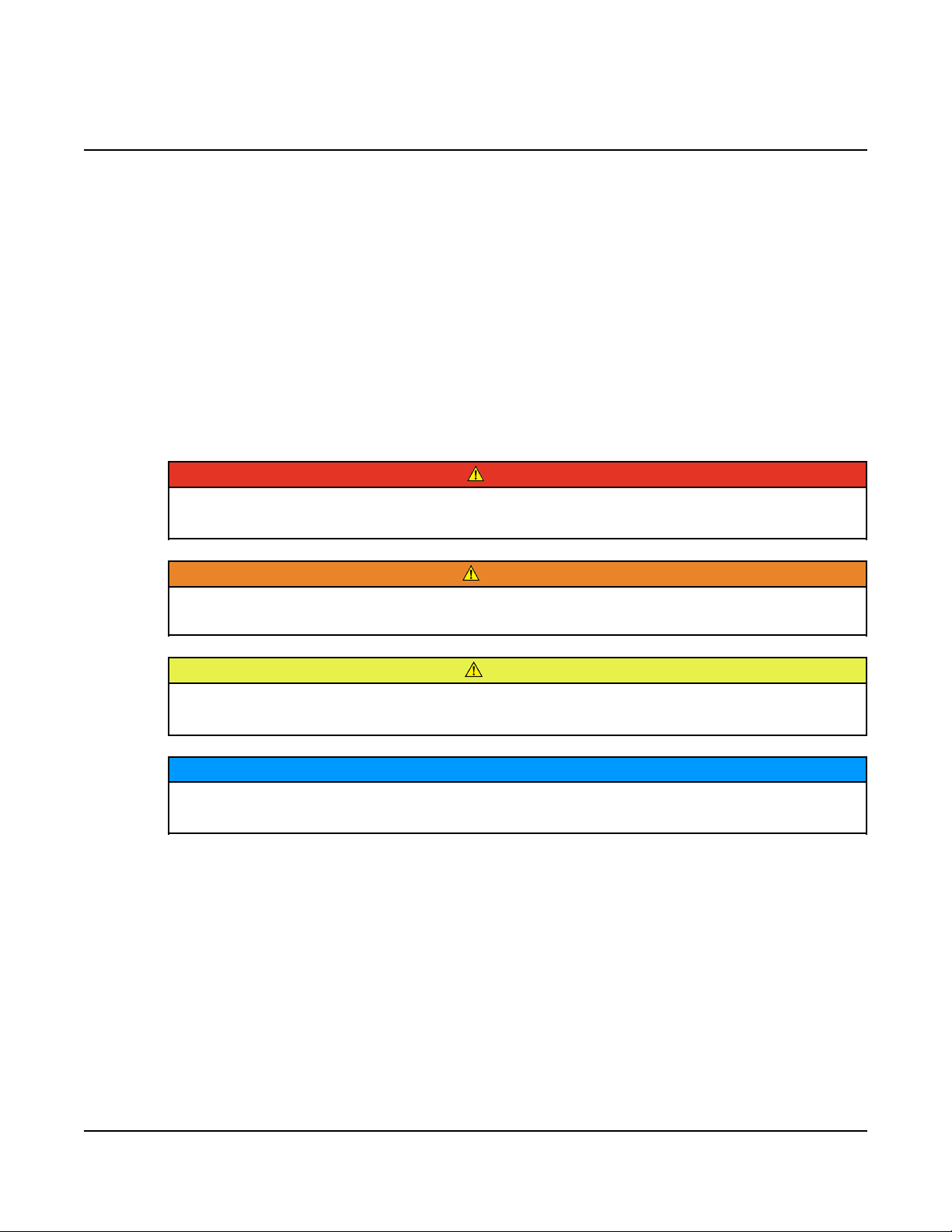

1.1 Warning, Caution, and Note Styles Used in This Manual

The following safety styles and symbols found throughout this manual indicate

potentially hazardous conditions to the operator, service personnel, or equipment.

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor or

moderate injury.

NOTICE

Indicates information considered important, but not hazard-related (e.g.,

messages relating to property damage).

1.2 Save These Instructions

This manual contains important instructions for the generator set that should be

followed during installation, operation and maintenance of the generator set and

batteries.

Thoroughly read the operator manual before operating the generator set. Safe

operation and top performance can only be obtained when equipment is properly

operated and maintained.

The following symbols in this manual alert you to potential hazards to the operator,

service person and equipment.

1A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 6

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

DANGER

Alerts you to an immediate hazard that will result in severe personal injury or

death.

WARNING

Alerts you to a hazard or unsafe practice that can result in severe personal

injury or death.

CAUTION

Alerts you to a hazard or unsafe practice that can result in personal injury or

equipment damage.

1.3 General Information

This manual should form part of the documentation package supplied by Cummins

Inc. with specific generator sets. If this manual has been supplied in isolation,

please contact your authorized dealer.

It is in the operator's interest to read and understand all warnings and

cautions contained in the documentation relevant to the generator set

operation and daily maintenance.

1.4 General Precautions

• Keep multi-type ABC fire extinguishers accessible.

• Make sure that all fasteners are secure and torqued properly.

• Keep the generator set and its compartment clean. Do not store any items in

the generator set compartment.

• Before working on the generator set, make sure the generator set is shut down

and disabled.

1. Press the generator set's "O" (Off) button or the red STOP button on the

local display (whichever is applicable) to stop the generator set. Allow the

generator set to thoroughly cool to the touch.

2. If applicable, turn off and disconnect the battery charger from the AC

source before disconnecting the battery cables.

NOTICE

3. Disconnect the negative (–) cable from the battery and secure it from

contacting the battery terminals to prevent accidental starting.

2 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 7

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

• Use caution when making adjustments when the generator set is running, hot,

or when parts are electrically live, as all situations may cause personal injury or

death.

• Used engine oil has been identified by some state and federal agencies as

causing cancer or reproductive toxicity. Do not ingest, inhale, or come into

contact with used oil or its vapors.

• Do not work on the generator set when mentally or physically fatigued or after

consuming alcohol or drugs.

NOTICE

Only trained and authorized personnel shall maintain or service the

generator set.

NOTICE

The installation of the generator set shall provide enough ventilation to

ensure that gases generated by vented batteries during charging, or caused

by equipment malfunction, are removed.

General Safety Precautions

WARNING

Hot Pressurized Liquid

Contact with hot liquid can cause severe burns.

Do not open the pressure cap while the engine is running. Let the engine

cool down before removing the cap. Turn the cap slowly and do not open it

fully until the pressure has been relieved.

WARNING

Moving Parts

Moving parts can cause severe personal injury.

Use extreme caution around moving parts. All guards must be properly

fastened to prevent unintended contact.

WARNING

Toxic Hazard

Used engine oils have been identified by some state and federal agencies to

cause cancer or reproductive toxicity.

Do not ingest, breathe the fumes, or contact used oil when checking or

changing engine oil. Wear protective gloves and face guard.

3A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 8

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or

death.

Do not operate equipment when fatigued, or after consuming any alcohol or

drug.

Make sure that only suitably trained and experienced service personnel

perform electrical and/or mechanical service.

WARNING

Toxic Gases

Substances in exhaust gases have been identified by some state and federal

agencies to cause cancer or reproductive toxicity.

Do not breathe in or come into contact with exhaust gases.

WARNING

High Noise Level

Generator sets in operation emit noise, which can cause hearing damage.

Wear appropriate ear protection at all times.

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is

minimized. Wear appropriate PPE when working on hot equipment and avoid

contact with hot surfaces.

WARNING

Toxic Hazard

Ethylene glycol, used as an engine coolant, is toxic to humans and animals.

Wear appropriate PPE. Clean up coolant spills and dispose of used coolant

in accordance with local environmental regulations.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause

severe burns or death.

Do not store fuel, cleaners, oil, etc., near the generator set. Do not use

combustible liquids like ether.

4 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 9

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

WARNING

Combustible Gases

Generator sets in operation have combustible gases under pressure, which

if ignited can cause eye and ear damage.

Wear appropriate eye and ear protection at all times.

WARNING

Combustible Gases

Generator sets in operation have combustible gases under pressure, which

if ignited can cause severe injury.

Do not operate the generator set with any doors open.

WARNING

Fire Hazard

Materials drawn into the generator set, as well as accumulated grease and

oil, are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from

obstructions. Make sure the generator set is mounted in a manner to prevent

combustible materials from accumulating under the unit.

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal

injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the

starting battery cables (negative [–] first).

NOTICE

Keep multi-type ABC fire extinguishers close by. Class A fires involve

ordinary combustible materials such as wood and cloth. Class B fires

involve combustible and flammable liquid fuels and gaseous fuels. Class C

fires involve live electrical equipment. (Refer to NFPA No. 10 in the

applicable region.)

NOTICE

Before performing maintenance and service procedures on enclosed

generator sets, make sure the service access doors are secured open.

NOTICE

Stepping on the generator set can cause parts to bend or break, leading to

electrical shorts, or to fuel, coolant, or exhaust leaks. Do not step on the

generator set when entering or leaving the generator set room.

5A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 10

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

1.5 Generator Set Voltage Is Deadly

• Generator set output connections must be made by a trained and experienced

electrician in accordance with all applicable codes.

• This generator set and the public utility may only be connected to house circuits

by means of the automatic transfer switch.

CAUTION

Improper connections can lead to electrocution of utility workers and

damage to equipment. Make sure that the connections are installed

properly by a trained technician.

• Use caution when working on live electrical equipment. Remove jewelry, and

make sure clothing and shoes are dry. Stand on a dry wooden platform.

1.6 Fuel and Fumes Are Flammable

Fire, explosion, and personal injury or death can result from improper practices.

• DO NOT permit any flame, cigarette, pilot light, spark, arcing equipment, or

other ignition source near the generator set or fuel system.

• Fuel lines must be adequately secured and free of leaks. Fuel connection at the

engine should be made with an approved flexible line. Do not use copper piping

on flexible lines because copper will become brittle if continuously vibrated or

repeatedly bent.

• Be sure all fuel supplies have a positive shutoff valve.

• Be sure the battery area has been well-ventilated prior to servicing near it.

Lead-acid batteries emit a highly explosive hydrogen gas that can be ignited by

arcing, sparking, smoking, etc.

6 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 11

1.7 Starting Batteries

Toxic Hazard

The electrolyte in starting batteries is a dilute sulfuric acid that is harmful to

the skin and eyes. It is also electrically conductive and corrosive.

Always:

1. Wear full eye protection and protective clothing;

2. If the electrolyte contacts the skin, wash it off immediately with water;

3. If the electrolyte contacts the eyes, flush them thoroughly and

immediately with water and seek medical attention; and

4. Wash spilled electrolyte down with an acid neutralizing agent. A

common practice is to use a solution of one pound (500 grams)

bicarbonate of soda (also known as baking soda or sodium bicarbonate)

to one gallon (4 liters) of water.

5. Continue to add the bicarbonate of soda solution until the evidence of

reaction (that is, foaming) has stopped.

6. Flush the resulting liquid with water and dry the area.

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

WARNING

1.8 Batteries Can Explode

Batteries can explode, causing severe skin and eye burns and can release toxic

electrolytes.

Combustible Gases

Batteries can explode, causing severe skin and eye burns, and can release

toxic electrolytes.

Do not dispose of the battery in a fire, because it is capable of exploding. Do

not open or mutilate the battery. Do not charge frozen batteries.

Electric Shock Hazard

Batteries present the risk of high short circuit current.

When servicing the generator set:

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

WARNING

WARNING

7A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 12

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

NOTICE

Servicing of batteries must be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized

personnel away from batteries.

• Wear safety glasses.

• Do not smoke.

• Do not charge frozen batteries.

• To prevent arcing when disconnecting the battery:

1. Press the Off switch from the display and then press the E-Stop button.

2. Disconnect AC power from any battery chargers.

3. Remove the negative (-) battery cable to prevent starting.

• To prevent arcing when reconnecting the battery:

1. Reconnect the positive (+) cable.

2. Reconnect the negative (-) cable.

3. Reconnect the battery charger to AC power supply.

• When replacing the generator set battery, always replace it with a battery as

specified in this manual.

1.9 Vented Batteries

Toxic Hazard

The electrolyte in vented batteries is a dilute sulfuric acid that is harmful to

the skin and eyes. It is also electrically conductive and corrosive.

Always:

1. Wear full eye protection and protective clothing;

2. If the electrolyte contacts the skin, wash it off immediately with water;

3. If the electrolyte contacts the eyes, flush them thoroughly and

immediately with water and seek medical attention; and

4. Wash spilled electrolyte down with an acid neutralizing agent. A

common practice is to use a solution of one pound (500 grams)

bicarbonate of soda (also known as baking soda or sodium bicarbonate)

to one gallon (4 liters) of water.

5. Continue to add the bicarbonate of soda solution until the evidence of

reaction (that is, foaming) has stopped.

6. Flush the resulting liquid with water and dry the area.

WARNING

8 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 13

1. IMPORTANT SAFETY INSTRUCTIONS8-2017

1.10 Moving Parts Can Cause Severe Personal Injury or Death

• Do not wear loose clothing or jewelry near moving parts, such as cooling fans.

• Keep hands away from moving parts.

• Keep guards in place over fans.

1.11 Exhaust Gases Are Deadly

• Provide an adequate exhaust system to properly expel discharged gases away

from enclosed or sheltered areas, and areas where individuals are likely to

congregate. Visually and audibly inspect the exhaust system daily for leaks per

the maintenance schedule. Make sure that exhaust manifolds are secured and

not warped. Do not use exhaust gases to heat a compartment.

• Make sure the unit is well ventilated.

Exhaust Precautions

WARNING

Hot Exhaust Gases

Contact with hot exhaust gases can cause severe burns.

Wear personal protective equipment when working on equipment.

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

The unit is to be installed so that the risk of hot surface contact by people is

minimized. Wear appropriate PPE when working on hot equipment and avoid

contact with hot surfaces.

WARNING

Toxic Gases

Inhalation of exhaust gases can cause asphyxiation and death.

Pipe exhaust gas outside and away from windows, doors, or other inlets to

buildings. Do not allow exhaust gas to accumulate in habitable areas.

WARNING

Fire Hazard

Contaminated insulation is a fire hazard. Fire can cause severe burns or

death.

Remove any contaminated insulation and dispose of it in accordance with

local regulations.

9A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 14

1. IMPORTANT SAFETY INSTRUCTIONS 8-2017

The exhaust outlet may be sited at the top or bottom of the generator set. Make

sure that the exhaust outlet is not obstructed. Personnel using this equipment must

be made aware of the exhaust position. Position the exhaust away from flammable

materials - in the case of exhaust outlets at the bottom, make sure that vegetation is

removed from the vicinity of the exhaust.

The exhaust pipes may have some insulating covers fitted. If these covers become

contaminated they must be replaced before the generator set is run.

To minimize the risk of fire, make sure the following steps are observed:

• Make sure that the engine is allowed to cool thoroughly before performing

maintenance or operation tasks.

• Clean the exhaust pipe thoroughly.

1.12 The Hazards of Carbon Monoxide

Carbon monoxide (CO) is an odorless, colorless, tasteless and non-irritating gas.

You cannot see it or smell it. Red blood cells, however, have a greater affinity for

CO than for oxygen. Therefore, exposure even to low levels of CO for a prolonged

period can lead to asphyxiation (lack of oxygen) resulting in death. Mild effects of

CO poisoning include eye irritation, dizziness, headaches, fatigue and the inability to

think clearly. More extreme symptoms include vomiting, seizures and collapse.

Engine-driven generator sets produce harmful levels of carbon monoxide that can

injure or kill you.

Special Risks of CO near the Home

WARNING

Toxic Gases

Carbon monoxide (CO) gas can cause nausea, fainting, or death. Residents

can be exposed to lethal levels of CO when the generator set is running.

Depending on air temperature and wind, CO can accumulate in or near the

home.

To protect yourself and others from the dangers of CO poisoning, it is

recommended that reliable, approved, and operable CO detector alarms are

installed in proper locations in the home as specified by their manufacturer.

Protecting Yourself from CO Poisoning

• Locate the generator set in an area where there are no windows, doors, or

other access points into the home.

• Make sure all CO detectors are installed and working properly.

• Pay attention for signs of CO poisoning.

• Check the exhaust system for corrosion, obstruction, and leaks every time you

start the generator set and every eight hours when you run it continuously.

10 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 15

2 Introduction

2.1 About This Manual

Improper installation can result in severe personal injury, death and damage

to equipment. The installation must comply with all applicable building

codes (including project permits and inspections). The installer should be

properly trained and licensed to perform electrical and mechanical

equipment installations (including gaseous fuel installation).

Manuals are updated from time to time to reflect changes in the equipment

and its specifications. The most up-to-date version of this manual is found

on the QuickServe website

(https://quickserve.cummins.com/info/index.html).

This manual is a guide for the installation of the generator set models listed on the

front cover. Proper installation is essential for top performance, reliable operation,

and safety. Read through this manual before starting the installation. This manual

covers outdoor applications only; for other installations, refer to the T-030: Liquid-

Cooled Generator Set Application manual available from your Cummins distributor.

WARNING

NOTICE

NOTICE

The installation must comply with all applicable building codes.

See the generator set's specific operator manual for operation and maintenance and

specific service manual for service.

Refer to the Model Specifications section for specific information about the system

and its components.

Refer to the Outline and System Drawings appendix and the Wiring Diagrams

appendix for specific information about installation and wiring connections.

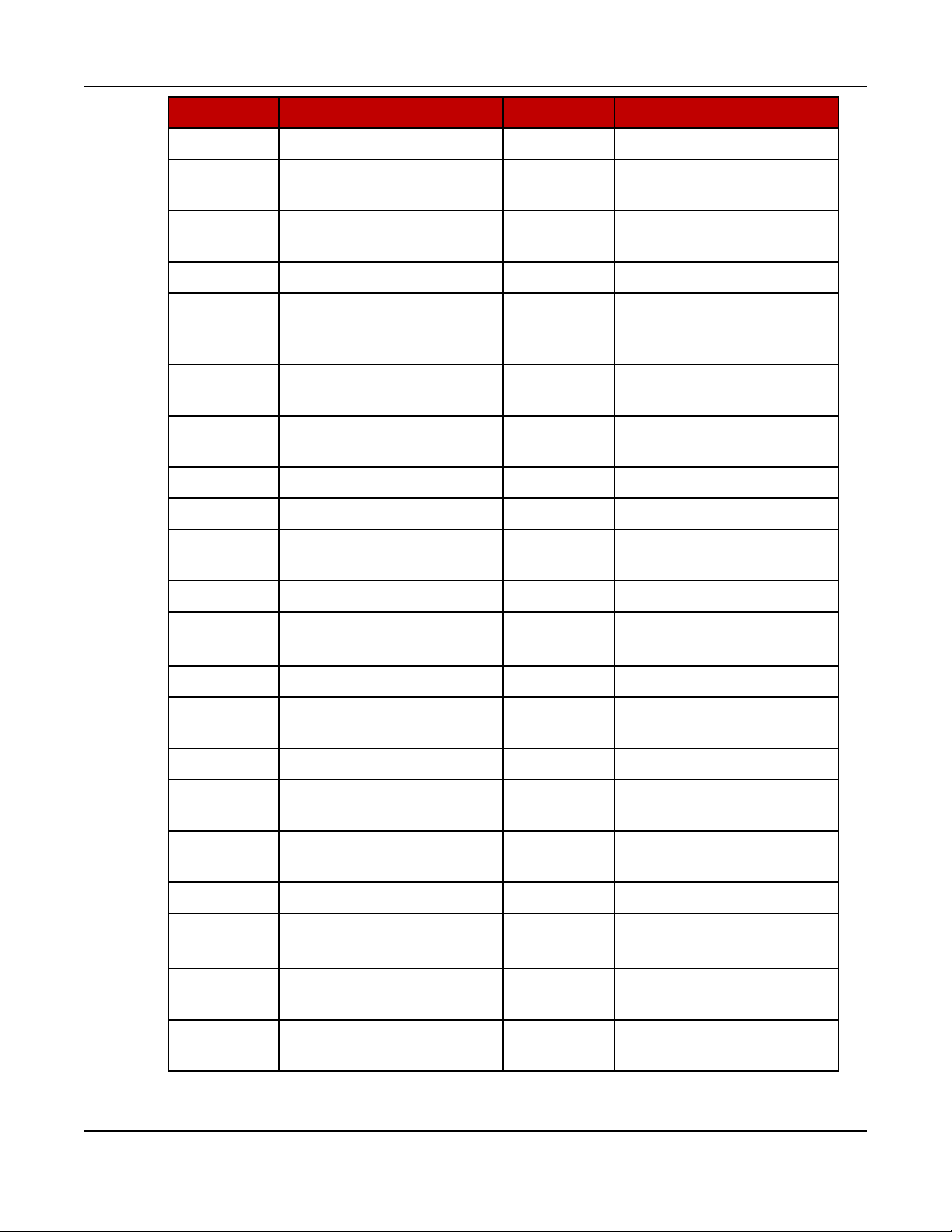

2.2 Schedule of Abbreviations

This list is not exhaustive. For example, it does not identify units of measure or

acronyms that appear only in parameters, event/fault names, or part/accessory

names.

11A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 16

2. Introduction 8-2017

Abbr. Description Abbr. Description

AC Alternating Current LED Light-Emitting Diode

AMP AMP, Inc. (part of Tyco

MFM Multifunction Monitor

Electronics)

ANSI American National

Mil Std Military Standard

Standards Institute

ASOV Automatic Shut Off Valve MPU Magnetic Pickup

ASTM American Society for

NC Normally Closed

Testing and Materials

(ASTM International)

ATS Automatic Transfer

NC Not Connected

Switch

AVR Automatic Voltage

Regulator

NFPA National Fire Protection

Agency

AWG American Wire Gauge NO Normally Open

CAN Controlled Area Network NWF Network Failure

CB Circuit Breaker OEM Original Equipment

Manufacturer

CE Conformité Européenne OOR Out Of Range

CCA Cold Cranking Ampere OORH/

Out Of Range High

ORH

CFM Cubic Feet per Minute OORL/ORL Out Of Range Low

CGT Cummins Generator

PB Push Button

Technologies

CMM Cubic Meters per Minute PCC PowerCommand®Control

CT Current Transformer PGI Power Generation

Interface

DC Direct Current PGN Parameter Group

Number

DEF Diesel Exhaust Fluid PI Proportional/Integral

DPF Diesel Particulate Filter PID Proportional/Integral/

Derivative

EBS Excitation Boost System PLC Programmable Logic

Controller

ECM Engine Control Module PMG Permanent Magnet

Generator

12 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 17

2. Introduction8-2017

Abbr. Description Abbr. Description

ECS Engine Control System PPE Personal Protective

Equipment

EMI Electromagnetic

Interference

EN European Standard PTC Power Transfer Control

EPS Engine Protection

System

E-Stop Emergency Stop RFI Radio Frequency

FAE Full Authority Electronic RH Relative Humidity

FMI Failure Mode Identifier RMS Remote Monitoring

FSO Fuel Shutoff RMS Root Mean Square

Genset Generator Set RTU Remote Terminal Unit

GCP Generator Control Panel SAE Society of Automotive

GND Ground scfh Standard Cubic Feet of

HMI Human-Machine

Interface

PT Potential Transformer

PWM Pulse-Width Modulation

Interference

System

Engineers

gas per Hour

SCR Selective Catalytic

Reduction

IC Integrated Circuit SPN Suspect Parameter

ISO International Organization

for Standardization

LBNG Lean-Burn Natural Gas UL Underwriters

LCD Liquid Crystal Display UPS Uninterruptible Power

LCT Low Coolant

Temperature

2.3 Related Literature

The literature provided with the generator set is as follows:

• Installation Manual (A045R241)

• Operator Manual (A045R242)

Number

SW_B+ Switched B+

Laboratories

Supply

13A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 18

2. Introduction 8-2017

CAUTION

A generator set must be operated and maintained properly if you are to

expect safe and reliable operation. The Operator Manual includes a

maintenance schedule and a troubleshooting guide.

The Health and Safety Manual must be read in conjunction with this manual

for the safe operation of the generator set:

• Health and Safety Manual (0908-0110)

• Warranty Statement (A040H442)

• Emissions Component Defect Warranty Statement (A028X278)

The relevant manuals appropriate to your generator set are also available. The

documents below are in English:

• Service Manual (A045R243)

• Parts Manual (A046Z094)

• EControls, Inc. Service Manual (A035C596)

• Global Control Platform (GCP) Engine Display Interface Software (EDIS)

Training Manual (A035C608)

• RA Series Transfer Switch Owner Manual (A046S594) (if applicable)

• PowerCommand® 1302 Controller Owner's Manual (900-0661)

• Standard Repair Times (SRT) Manual (A046Z674)

• Application Manual T-030 - for application information (A040S369)

• Service Tool Manual (A043D529)

2.4 Before Installation

Before beginning the installation of the generator set, verify that the unit was

correctly selected. Check the following features:

• Model

• Specifications

• Options

• Fuel Supply

◦ The gas supplied to the generator set must be of acceptable quality.

◦ The gas supply must have sufficient pressure. Care must be taken to be

sure that the gas supply at the generator set, not just at the source, is of

proper pressure for operation. The specified pressure must be available

while the generator set is starting and running at full load.

14 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 19

2. Introduction8-2017

◦ The gas must be supplied to the generator set in sufficient volume to

support operation of the generator set. This is normally a matter of

selecting fuel line size to be large enough to transport the volume of fuel

needed. For liquid propane vapor-withdrawal fuel systems the size and

temperature of the fuel tank also affects this requirement.

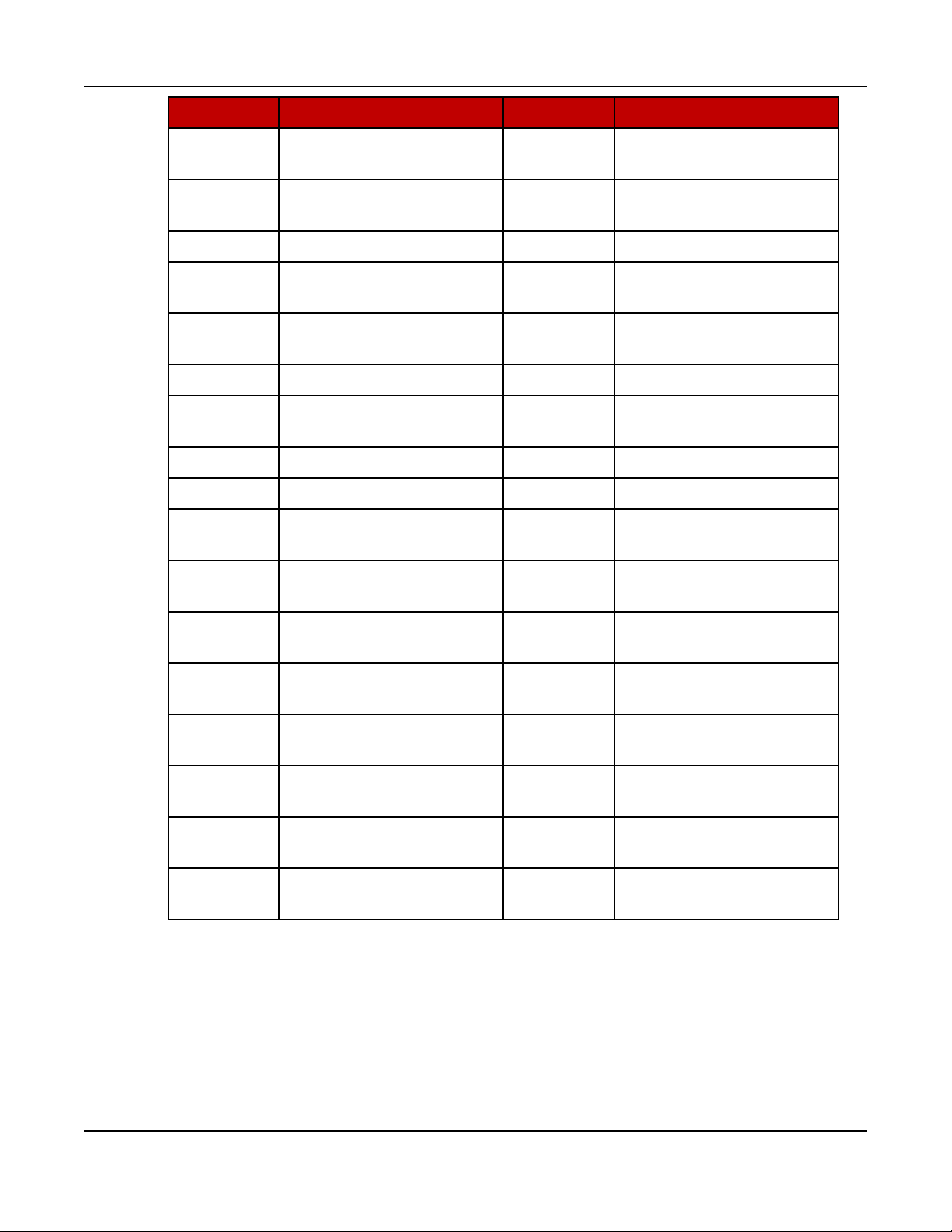

2.5 Model Specifications

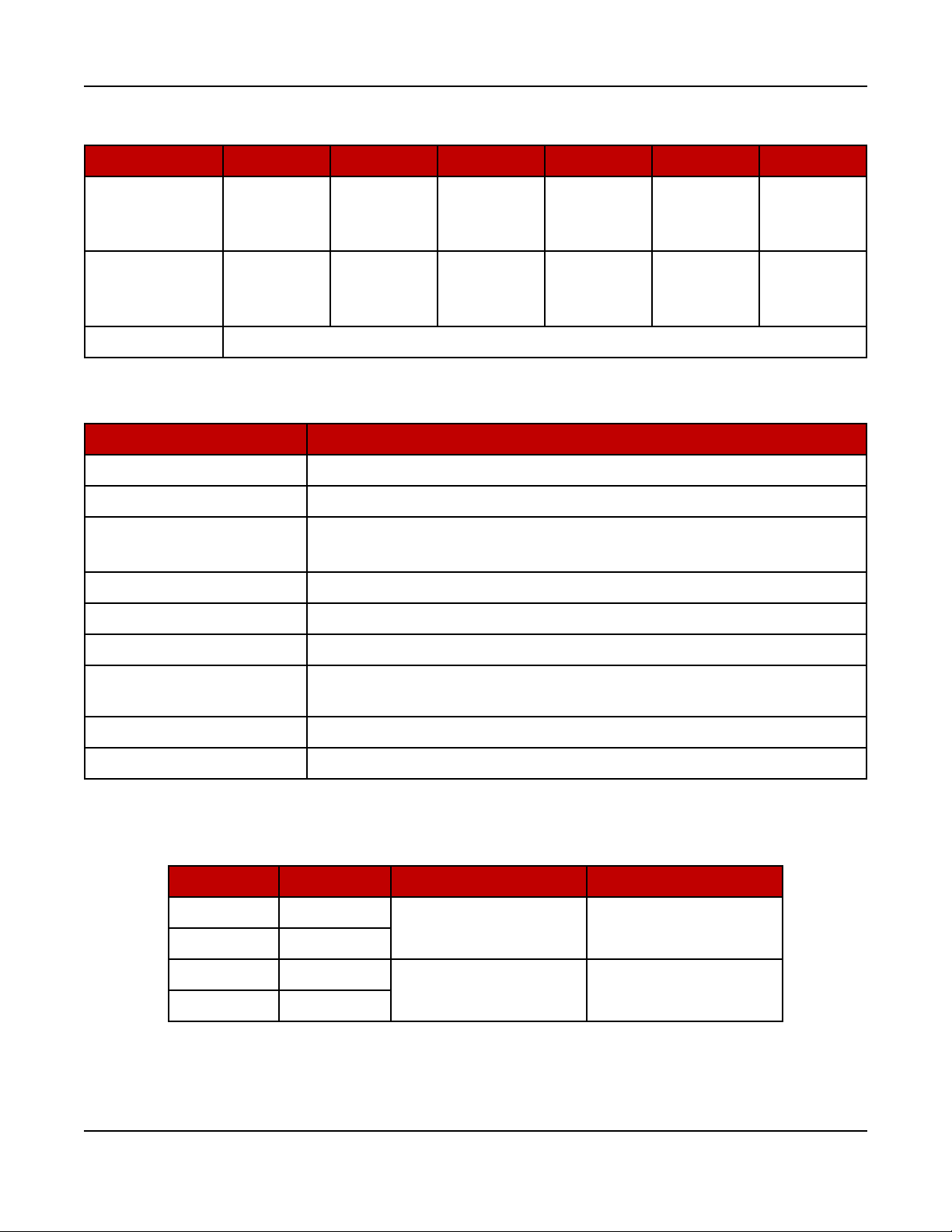

TABLE 1. 2.4L MODEL VARIATIONS

Models Description

C20 N6, C22 N6, C25 N6, C30 N6, C36 N6, C40 N6 60 Hz, 1800 RPM

C30 N6H, C36 N6H, C40 N6H, C45 N6H, C50 N6H, C60 N6H 60 Hz, 3600 RPM

TABLE 2. COLD WEATHER SPECIFICATIONS (ALL MODELS)

Temperature Description Battery Type Group

Above 4 °C (40 °F) No starting aids required. Standard 26

Additional coolant heater and

-17 to 4 °C (0 to 40 °F)

Below -17 °C (0 °F)

For NFPA 110 applications, a coolant heater is required. A factory option is

available.

TABLE 3. FUEL SPECIFICATIONS 60 HZ, 1800 RPM

C20 N6 C22 N6 C25 N6 C30 N6 C36 N6 C40 N6

Full Load

(Propane)

105.1 scfh

265,000

BTU/hr

battery charger recommended for

starting. Factory options available.

All starting aides (battery heater,

coolant heater, battery charger)

recommended. Factory options

available.

NOTICE

112.7 scfh

285,000

BTU/hr

125.4 scfh

315,000

BTU/hr

164.1 scfh

410,000

BTU/hr

Standard 26

Larger 34

182.7 scfh

460,000

BTU/hr

193.6 scfh

490,000

BTU/hr

Full Load

(Natural Gas)

Fuel Pressure 6-13 inches of water column (1.5 - 3.2 kPa) under any condition

259.6 scfh

270,000

BTU/hr

278.8 scfh

290,000

BTU/hr

309.5 scfh

320,000

BTU/hr

15A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

380.9 scfh

395,000

BTU/hr

472.3 scfh

490,000

BTU/hr

519 scfh

540,000

BTU/hr

Page 20

2. Introduction 8-2017

TABLE 4. FUEL SPECIFICATIONS 60 HZ, 3600 RPM

C30 N6H C36 N6H C40 N6H C45 N6H C50 N6H C60 N6H

Full Load

(Propane)

Full load

(Natural Gas)

195.5 scfh

490,000

BTU/hr

476.1 scfh

495,000

BTU/hr

219.6 scfh

550,000

BTU/hr

533.3 scfh

555,000

BTU/hr

236.2 scfh

595,000

BTU/hr

573.2 scfh

595,000

BTU/hr

256.9 scfh

645,000

BTU/hr

623.0 scfh

645,000

BTU/hr

289.5 scfh

725,000

BTU/hr

704.7 scfh

730,000

BTU/hr

324.6 scfh

820,000

BTU/hr

814.2 scfh

840,000

BTU/hr

Fuel Pressure 6-13 inches of water column (1.5 - 3.2 kPa) under any condition

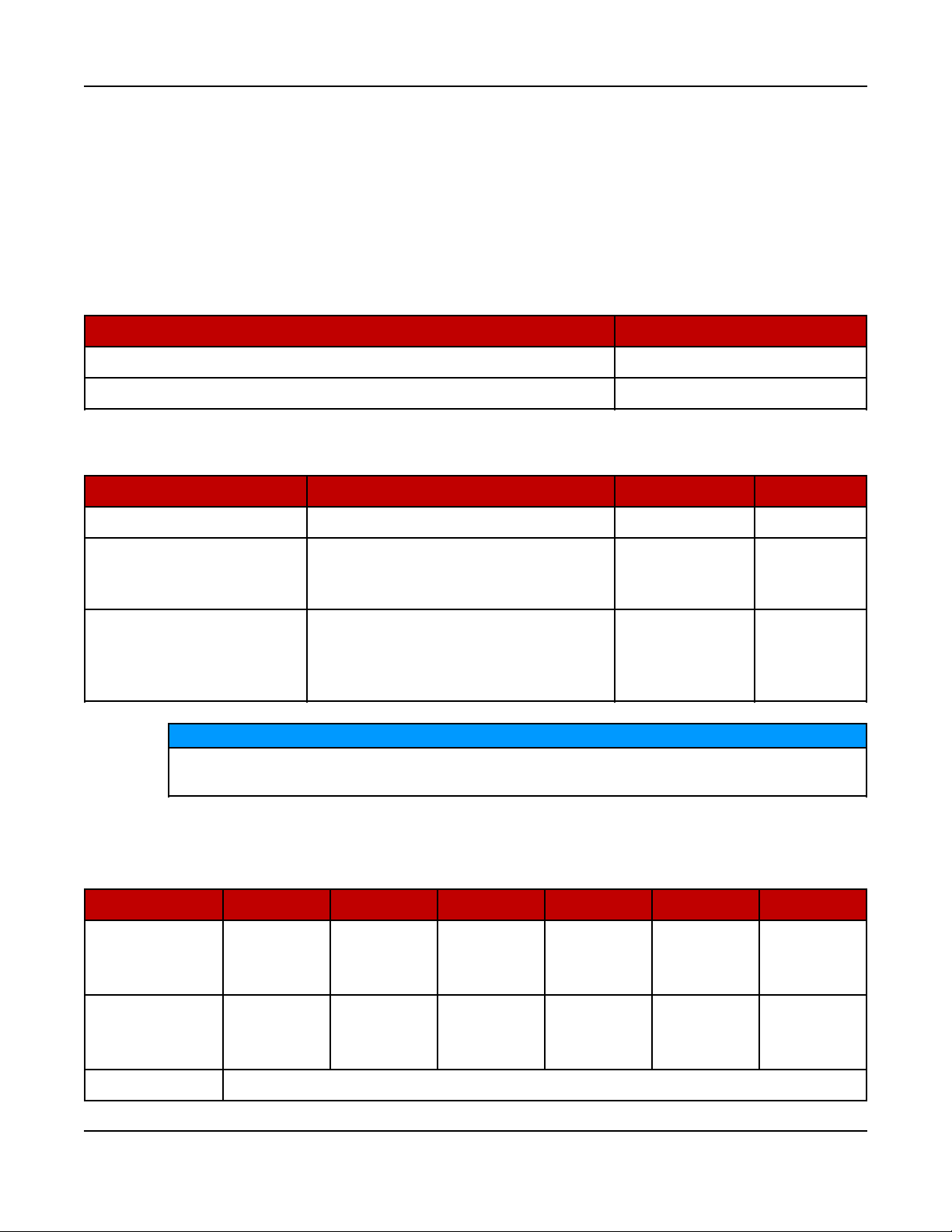

TABLE 5. ENGINE SPECIFICATIONS (ALL MODELS)

Specification Value

Engine 4 cylinder-in-line, SOHC, liquid-cooled, 4-stroke, spark ignited

Displacement 2351 cc (144 in3)

Spark Plug Gap

1.0 mm (0.040 in) (NA)

0.76 mm (0.030 in) (T/TAA)

Spark Plug Torque 20 Nm (15 ft-lb)

Coolant 50/50 coolant solution (50% pure water and 50% ethylene glycol)

High Crankcase Pressure No higher than 1.5 kPa

Low Compression

135 psi (dry test) or higher with less than 15 psi range between

cylinders

Oil Capacity 4.3 L (4.54 quarts)

Oil Recommendation 5W30 API SM

TABLE 6. GENERATOR SET SIZE SPECIFICATIONS WITH SOUND LEVEL 1

ENCLOSURE (L X W X H)

kW RPM mm in

20-25 1800

1830 x 864 x 1152 72 x 34 x 45.2

30 3600

30-40 1800

2384 x 864 x 1152 94 x 34 x 45.2

36-60 3600

16 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 21

2. Introduction8-2017

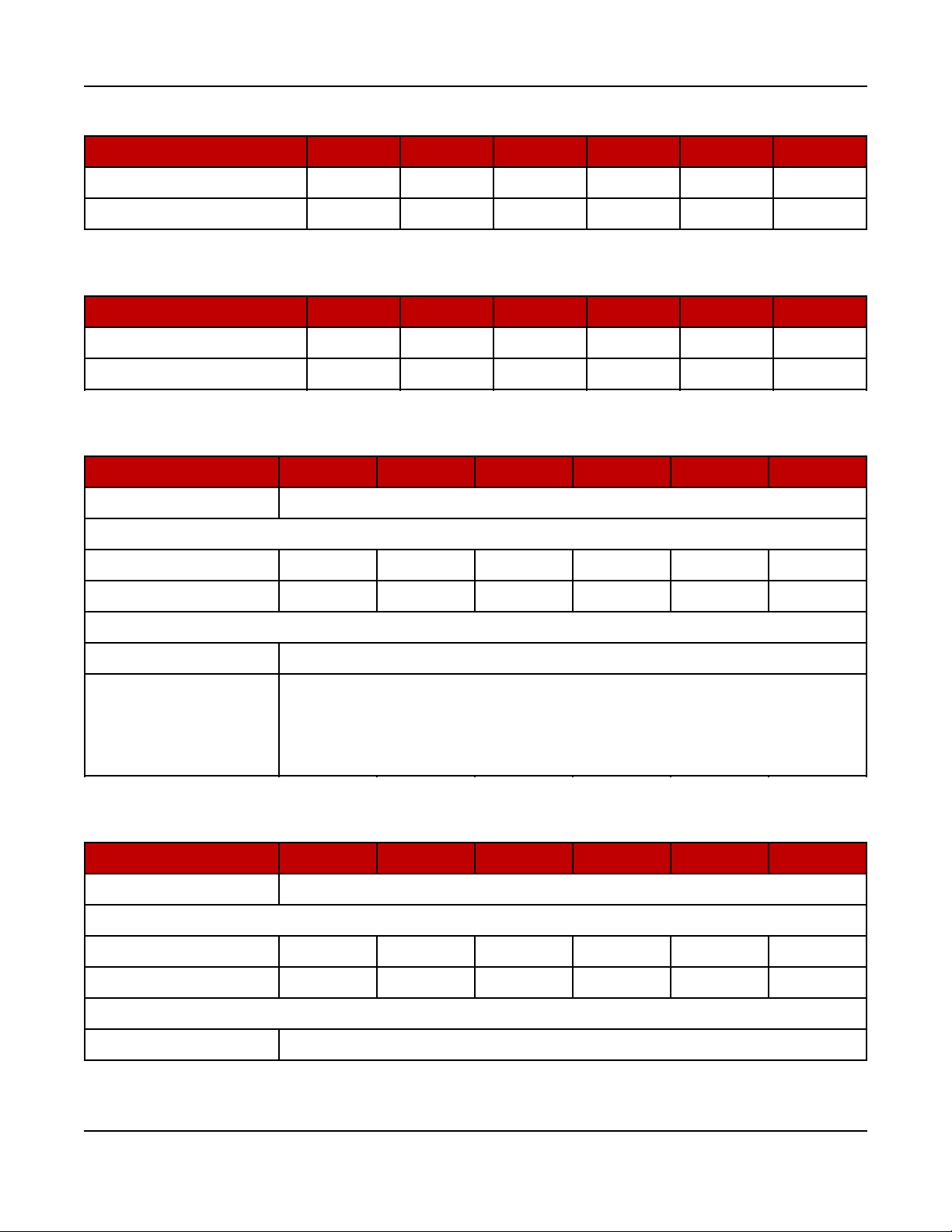

TABLE 7. GENERATOR SET WEIGHT 60 HZ, 1800 RPM

Sound Level 1 (Wet) C20 N6 C22 N6 C25 N6 C30 N6 C36 N6 C40 N6

kg 503 503 520 580 615 646

lb 1109 1109 1147 1279 1356 1424

TABLE 8. GENERATOR SET WEIGHT 60 HZ, 3600 RPM

Sound Level 1 (Wet) C30 N6H C36 N6H C40 N6H C45 N6H C50 N6H C60 N6H

kg 514 567 635 635 635 648

lb 1134 1249 1399 1399 1399 1429

TABLE 9. ALTERNATOR SPECIFICATIONS 60 HZ, 1800 RPM

C20 N6 C22 N6 C25 N6 C30 N6 C36 N6 C40 N6

Alternator Brushless, 4-pole rotating field, single bearing

Power (kVa):

1-Phase 20 22 25 30 36 40

3-Phase 25 27.5 31.3 37.5 45 50

Rated Voltages (V):

1-Phase 120/240

120/240

3-Phase

120/208

277/480

347/600

TABLE 10. ALTERNATOR SPECIFICATIONS 60 HZ, 3600 RPM

C30 N6H C36 N6H C40 N6H C45 N6H C50 N6H C60 N6H

Alternator Brushless, 2-pole rotating field, single bearing

Power (kVa):

1-Phase 30 36 40 45 50 60

3-Phase 37.5 45 50 56.3 62.5 75

Rated Voltages (V):

1-Phase 120/240

17A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 22

2. Introduction 8-2017

C30 N6H C36 N6H C40 N6H C45 N6H C50 N6H C60 N6H

120/240

3-Phase

120/208

277/480

NOTICE

Maximum I2= 8%.

18 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 23

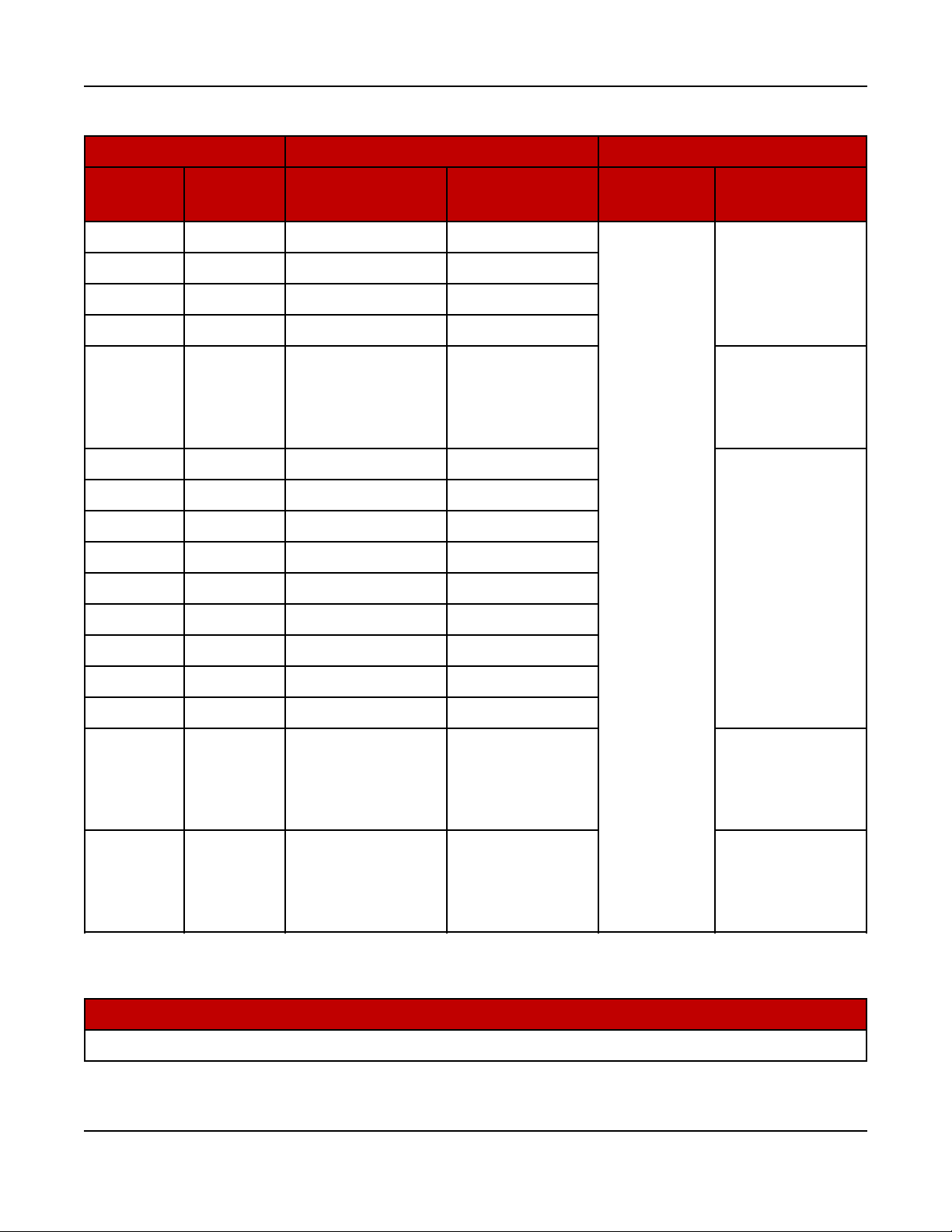

TABLE 11. GENERATOR SET DERATING GUIDELINES

Engine Power Available Up To... Derate At…

2. Introduction8-2017

Model Fuel Elevation

Ambient

Temperature

C20 N6 NG, LP 1005 m (3300 ft) 40 °C (104 °F)

C22 N6 NG 670.5 m (2200 ft) 40 °C (104 °F)

C22 N6 LP 1005 m (3300 ft) 40 °C (104 °F)

C25 N6 NG 0 m (0 ft) 25 °C (77 °F)

C25 N6 LP 114 m (375 ft) 25 °C (77 °F)

C30 N6 NG 762 m (2500 ft) 40 °C (104 °F)

C30 N6 LP 1005 m (3300 ft) 40 °C (104 °F)

C36 N6 NG, LP 1005 m (3300 ft) 40 °C (104 °F)

C40 N6 NG, LP 114 m (375 ft) 40 °C (104 °F)

C30 N6H NG, LP 945 m (3100 ft) 40 °C (104 °F)

C36 N6H NG, LP 1005 m (3300 ft) 40 °C (104 °F)

Elevation Temperature

2% per 10 °C

(18 °F)

above 40 °C

(104 °F)

2% per 10 °C

(18 °F)

above 25 °C

(77 °F)

4% per

305 m

(1000 ft)

2% per 10 °C

(18 °F)

above 40 °C

(104 °F)

C40 N6H NG, LP 1005 m (3300 ft) 40 °C (104 °F)

C45 N6H LP 1005 m (3300 ft) 40 °C (104 °F)

C45 N6H NG, LP 914 m (3000 ft) 40 °C (104 °F)

C50 N6H NG, LP 114 m (375 ft) 25 °C (77 °F)

C60 N6H NG, LP 114 m (375 ft) 40 °C (104 °F)

TABLE 12. CONTROL SPECIFICATION (ALL MODELS)

Specification

Integrated microprocessor based engine, generator, transfer switch control

2% per 10 °C

(18 °F)

above 25 °C

(77 °F)

2% per 10 °C

(18 °F)

above 40 °C

(104 °F)

19A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 24

2. Introduction 8-2017

TABLE 13. DC SYSTEM SPECIFICATIONS (ALL MODELS)

Specification Value

Nominal Battery Voltage 12 VDC

Battery Group

26 standard, 34 high capacity (a high capacity battery requires an

accessory battery tray)

Battery Type Maintenance free

Minimum Cold Crank

Amps

545 standard, 850 high capacity (a high capacity battery requires

an accessory battery tray)

20 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 25

3 Pre-Installation Considerations

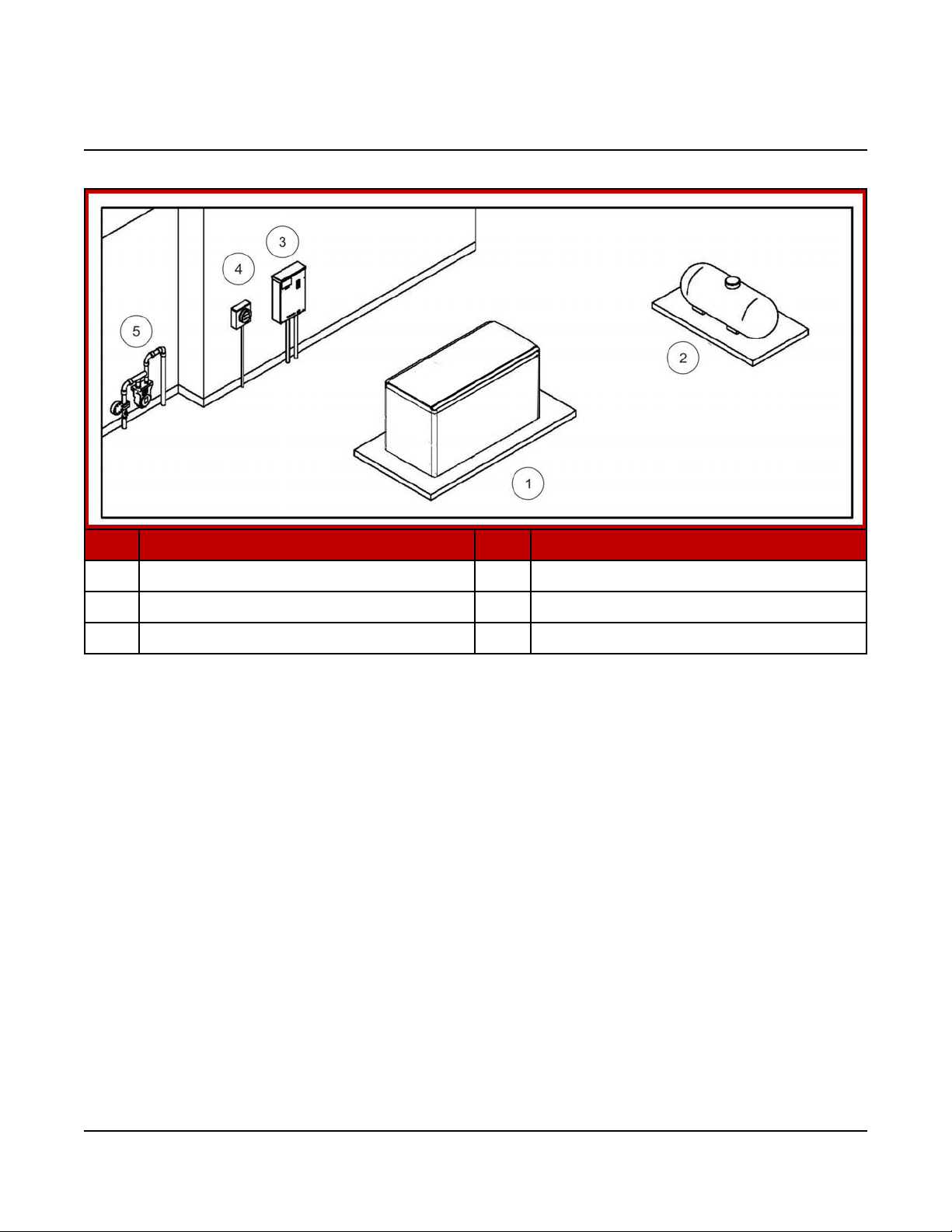

No. Description No. Description

1 Generator Set 4 Electrical Meter

2 Propane Tank 5 Natural Gas Meter

3 Transfer Switch

FIGURE 1. SITE PREPARATION EXAMPLE

Areas of consideration:

• Location of the generator set - this is one of the first decisions to be made, as it

affects all other aspects of the installation, such as:

◦ Length of electric wiring

◦ Length of gas lines (natural gas or propane - must be inspected by the gas

utility inspectors and building inspectors)

◦ Site preparation:

▪ Access to the site

▪ Trenches

▪ Site preparation materials needed

• Fuel supply pressure

• Automatic transfer switch location and connections

• Tools and materials required

21A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 26

3. Pre-Installation Considerations 8-2017

• Minimum distance from the propane tank fill (verify the legal minimum distance

with local code officials)

• Accessories required (if any) for the customer's application (utility power may

be required at the generator set; make plans accordingly)

NOTICE

Depending on the locality and use of the generator set, it may be necessary

to obtain an air quality emissions permit before installation begins. Check

with local pollution control or air quality authority to determine permit

requirements.

3.2 Installation Codes and Standards for Safety

NOTICE

The generator set installer bears sole responsibility for following all

applicable local codes and regulations.

The following list of codes and standards may apply to the installation and operation

of the generator set. This list is for reference only and not intended to be inclusive of

all applicable codes and standards. The address of each agency is listed so that

copies of the codes may be obtained for reference. Installation codes and

recommendations are subject to change, and may vary by location or over time.

22 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 27

3. Pre-Installation Considerations8-2017

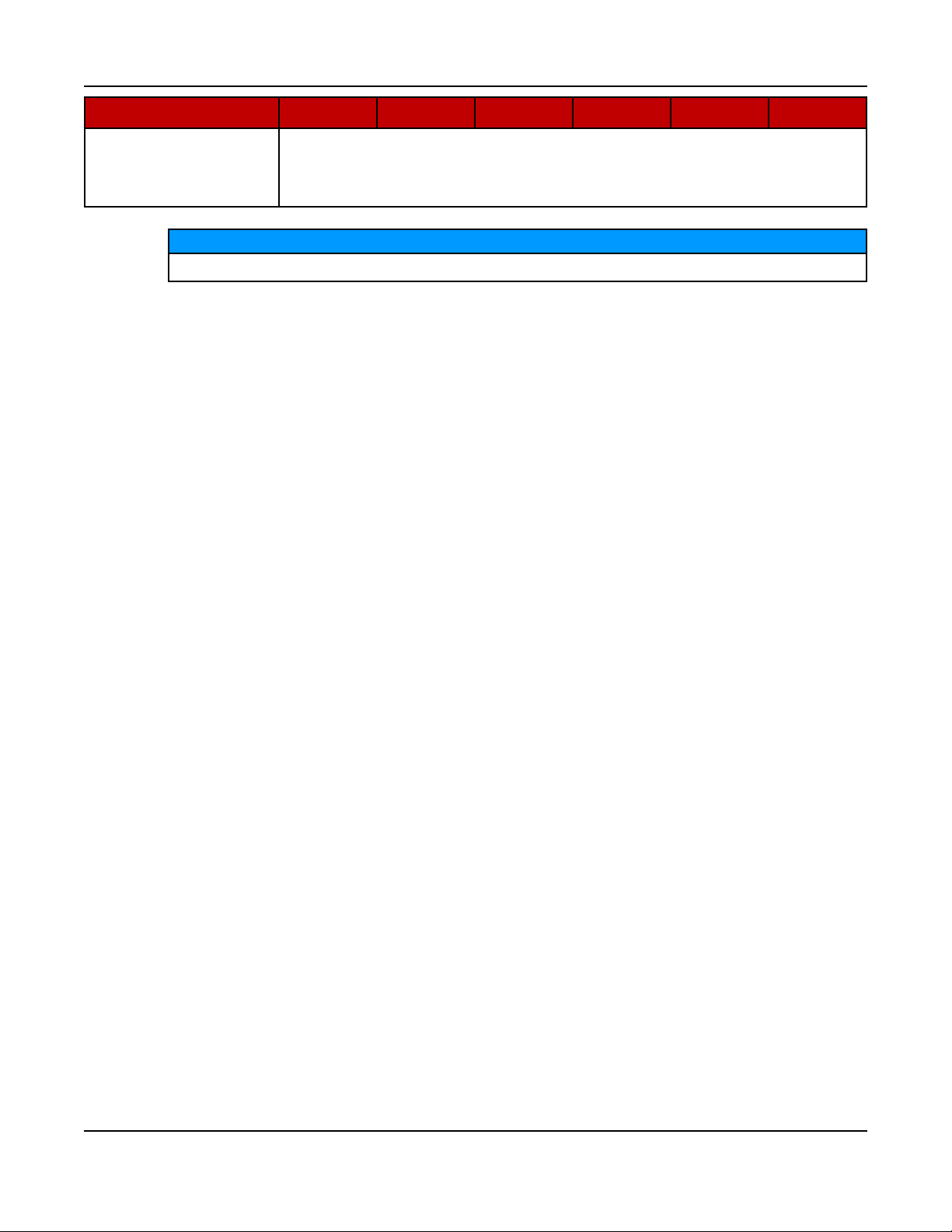

TABLE 14. INSTALLATION CODES AND STANDARDS FOR SAFETY

RECOMMENDATIONS

Type

US

Code or

Standard

Code

NFPA 70 - National Electrical

Code

Title Organization

NFPA 37 - Installation and Use

Code

of Stationary Combustion

Engines and Gas Turbines

Code

NFPA 54 - National Fuel Gas

Code

NFPA 58 - Storage and

Code

Handling of Liquefied Petroleum

Gases

NFPA 110 - Standard for

Code

Emergency and Standby Power

Systems

Code CSA Electrical Bulletin

Code

CSA 22.1 Canadian Electrical

Code

National Fire Protection

Association

470 Atlantic Avenue

Boston, MA 02210

Code

Canada

Standard

Standard

Code

Code

California Code

CSA B149 Installation Code for

Gas Burning Appliances and

Equipment

CSA C22.2 No. 100 Motors and

Generators

CSA C22.2 No. 14 Industrial

Control Equipment

CSA C282 Emergency Electrical

Power Supply for Buildings

CSA Z32 Electrical Safety in

Health Care Facilities

California Administrative Code Title 25 Chapter 3

Canadian Standards

Association

Housing and Construction

Materials Section

178 Rexdale Blvd.

Rexdale, Ontario, Canada M9Q

1R3

State of California

Documents Section

P.O. Box 1015

North Highlands, CA 95660

23A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 28

3. Pre-Installation Considerations 8-2017

3.3 Required Items for Installation

Tools and materials are used for the installation of this generator set. These items

are identified in the following sections. Please refer to local codes and standards,

because they may affect the materials required.

Materials Required

NOTICE

Refer to local codes and standards, which may affect material requirements.

NOTICE

If a 100% rated breaker is used, 90 °C wire must be used for L1, L2, and L3

with the wire size determined by the 75 °C ampacity tables.

NOTICE

A UL-listed grounding electrode terminal within its ratings and suitable for

the application must be installed and labeled “Grounding Electrode

Terminal”.

Electrical Materials:

NOTICE

Class 1 wiring methods must be used for connecting the generator set.

• Four code compliant AC power wires will be needed: L1, L2, N and Gnd (add

another wire for 3-phase for a total of 5 AC wires)

• For RA switches, 4 DC control wires will be needed from the generator to the

transfer switch.

• Wire sizes (DC control and power and AC sense only):

◦ DC control or AC sense wires under 1000 feet circuit length => 18-14

AWG of the insulation type below

◦ DC control or AC sense wires 1000-2000 feet circuit length => 16-14 AWG

of the insulation type below

• All AC and DC wires and cables shall be rated 75 °C minimum, stranded

copper, and rated for wet locations.

◦ For wire sizes 14 AWG and larger, use insulation types including but not

limited to: RHW, RHW-2, THHW, THW, THW-2, THWN, THWN-2, XHHW,

XHHW-2, USE-2, ZW-2

24 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 29

3. Pre-Installation Considerations8-2017

◦ For wire sizes 16 and 18 AWG, use insulation types including but not

limited to: FFH-2, KFF-2, PAFF, PFF, PGFF, PTFF, RFH-2, RFHH-2,

RFHH-3, SFF-2, TFF, TFFN, ZFF

• Code compliant 20 A, 120 VAC, GFCI protected circuit for alternator heaters,

battery charger, coolant heater, oil heater, and/or battery heater (if equipped)

• Code compliant conduit for all wires

Mounting Materials:

• Four base tie-down bolts

NOTICE

Seismic zone installations require compliance to specific mounting

configurations.

Fuel Materials:

• Flexible fuel line (provided with the generator set, attached to the radiator

guard)

• UL listed pipe thread sealant

• Fuel line (natural gas and propane: 6-13 inches of water column [1.5 - 3.2 kPa]

fuel pressure) at generator set

• Fuel pressure regulator (as required)

• Manual fuel shut-off at generator set ahead of automatic valves on generator

set fuel system

Tools Required

Use appropriate lifting techniques to position the generator set in place.

Transfer Switch Requirements

A transfer switch must be a part of every generator set installation. Transfer

switches transfer loads to the generator set during power outages.

NOTICE

Cummins offers a variety of transfer switches, including residential and light

commercial options.

25A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 30

3. Pre-Installation Considerations 8-2017

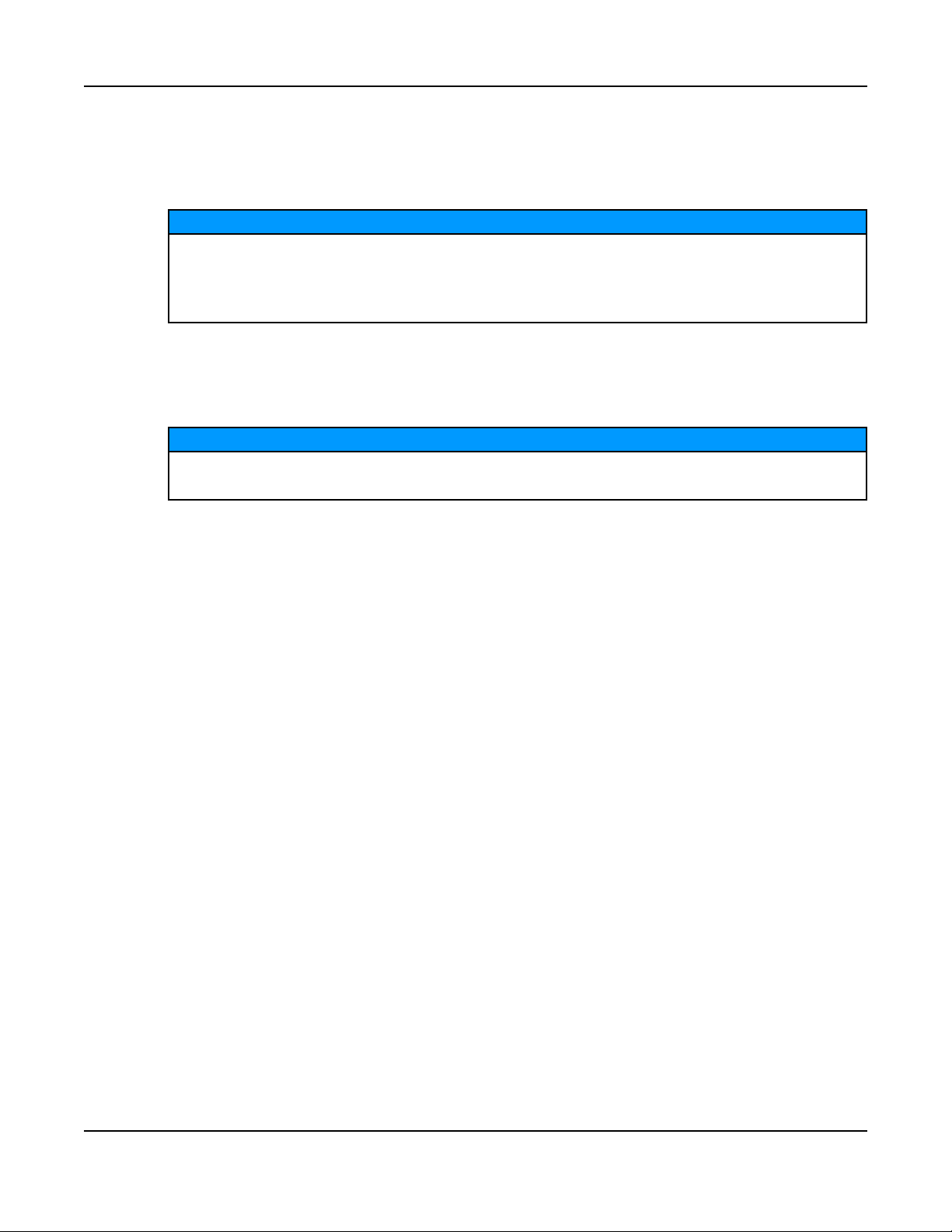

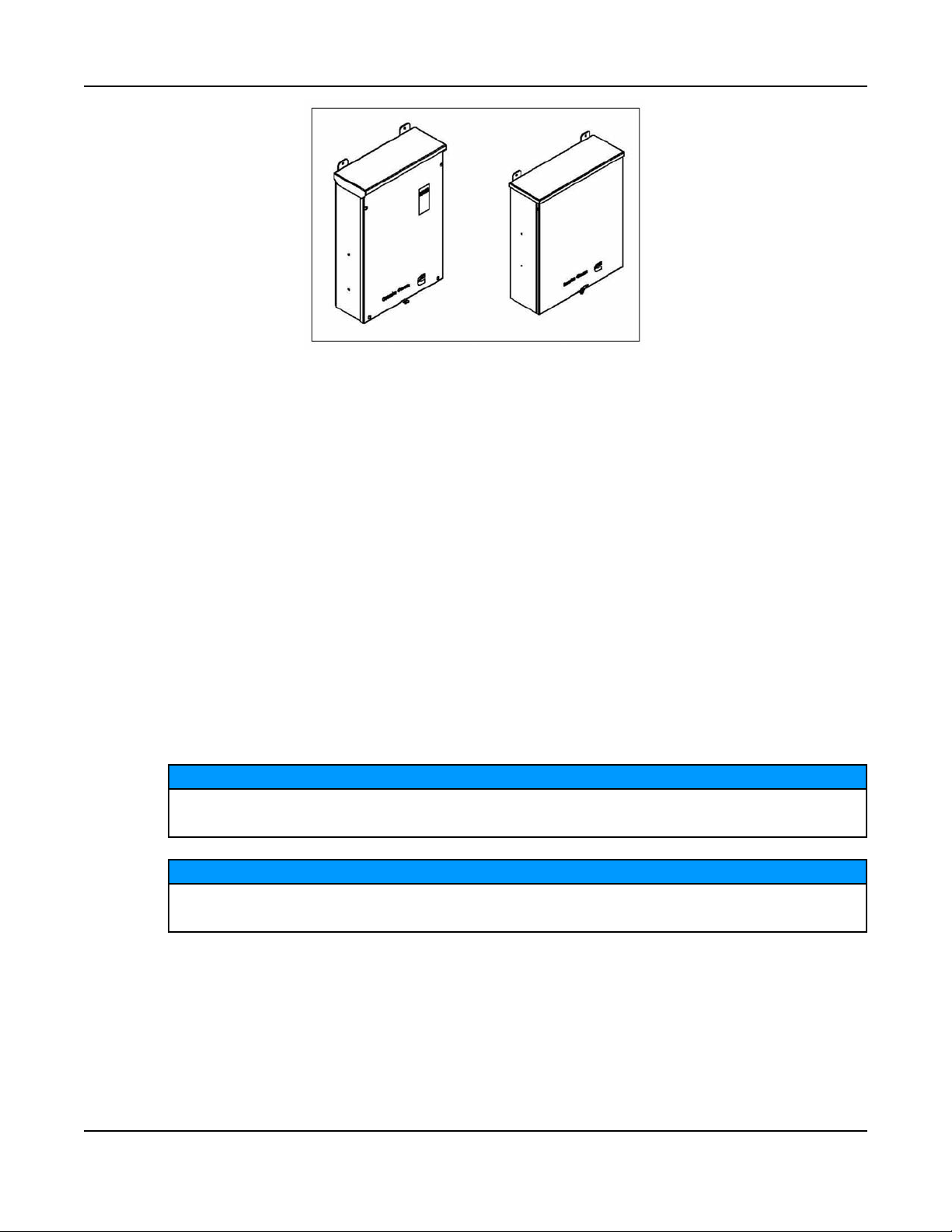

FIGURE 2. CUMMINS TRANSFER SWITCH (RA SERIES)

Before beginning the installation of the transfer switch, verify that the unit was

correctly selected. Check the following features:

• Specifications (voltage, amperage, frequency, poles, and phases)

• Enclosure (indoor vs. outdoor)

• Model

Refer to the RA Series Transfer Switch Owner Manual (A046S594) for more

detailed information. The RA Series transfer switch is the recommended ATS for

use with these generators.

Choosing a Transfer Switch

This section includes block diagrams showing partial or full load coverage for the

Cummins RA Series transfer switches. For more information, see the RA Series

RA112L1 Automatic Transfer Switch Owner Manual (A052S254) or the RA Series

Automatic Transfer Switch Owner Manual (A046S594) (models RA112N3,

RA212N3, RA112S3, RA212S3, RA412N3, and RA412S3).

NOTICE

These generator sets can be used with either service entrance transfer

switches or non-service entrance transfer switches.

NOTICE

If the load exceeds the generator set rating, it may be necessary to use

Cummins’ load management kit (A051C329).

26 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 31

3. Pre-Installation Considerations8-2017

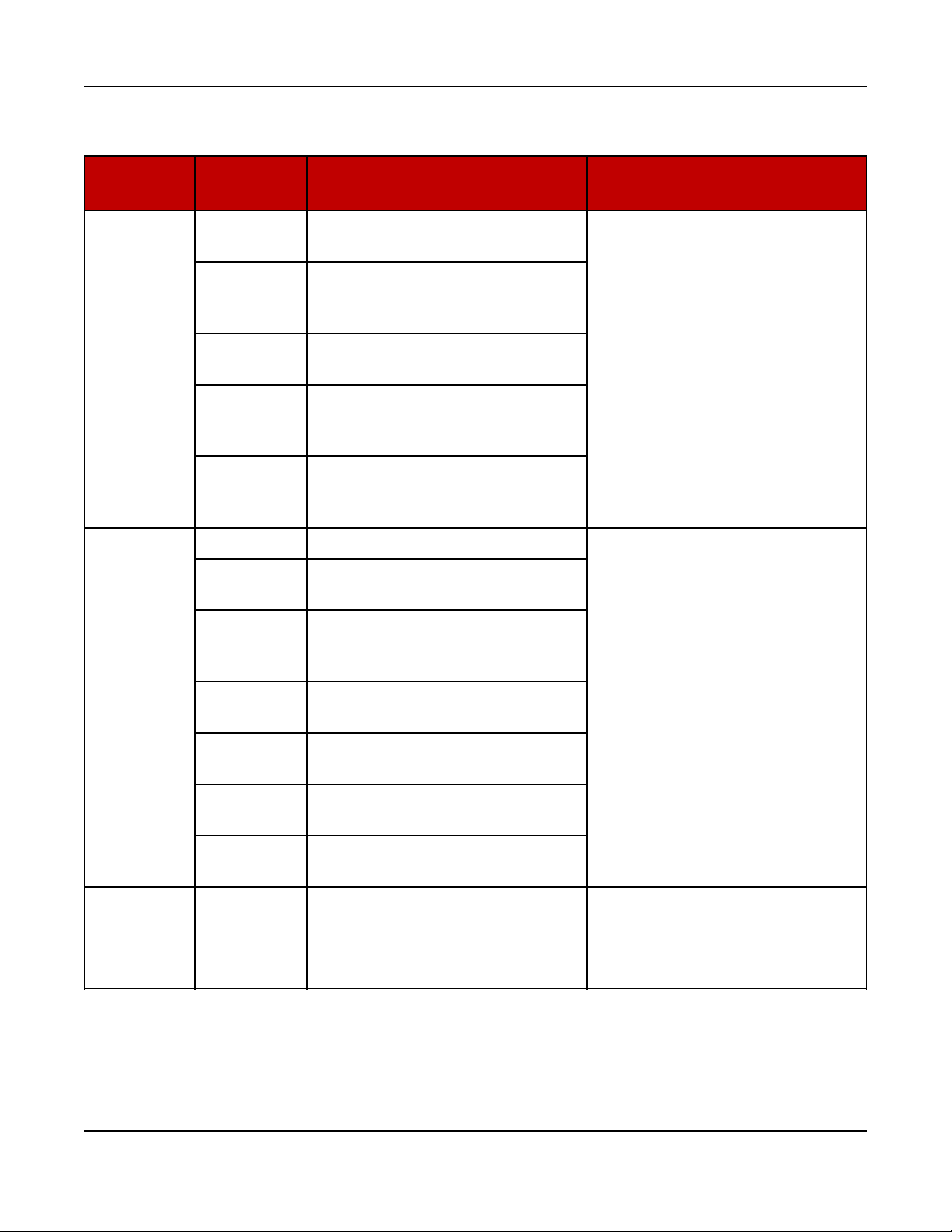

FIGURE 3. TRANSFER SWITCH CONNECTIONS FOR PARTIAL COVERAGE LOAD

FIGURE 4. TRANSFER SWITCH CONNECTIONS FOR FULL COVERAGE LOAD

Loose Parts Shipped with the Generator Set

The following loose parts are shipped with the generator set:

• Flexible fuel hose assembly (attached to the radiator guard)

27A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 32

3. Pre-Installation Considerations 8-2017

• One enclosure key (where applicable)

• Battery tie-down

• Sound level 2 baffle (where applicable)

• Weather enclosure exhaust elbow (where applicable)

• Literature (operator manual, installation manual, health and safety manual, and

warranty statements)

28 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 33

4 Installation

4.1 Site Assessment and Preparation

Proper component location and site preparation have a very important impact on

completing a successful installation. The major components and sources of power

needed for installation include the following items:

• Generator set

• Transfer switch

• Electrical utility

• Fuel source

• Accessories (may be required under certain conditions)

Generator Set Installation Suggestions and Guidelines

• Locate the generator set on stable ground, not subject to flooding. Generator

set should not be installed where significant water runoff from a roof or

downspouts is present. Sump pump discharge should be routed away from the

generator set.

• Locate and orient the generator set such that prevailing winds will carry exhaust

gases and fuel leaks away from the house or occupied areas.

• This unit is to be installed so that the risk of contact by people is minimized.

Picking a Location

WARNING

Exhaust gas is deadly. Locate the generator set away from doors, windows,

and other openings to the house and where exhaust gases will disperse

away from the house.

29A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 34

4. Installation 8-2017

No. Description No. Description

1 Cool Air In 3 Hot Air Out (Weather Enclosure)

2 Hot Air Out

FIGURE 5. EXAMPLE OF GENERATOR SET LOCATION

The generator set location is critical for safety and performance. Follow the

guidelines below:

• Must comply with applicable codes (NFPA, NEC, IBC, etc.).

• Use this manual for outdoor installations only. For other applications, contact

your local Cummins dealer or refer to the application manual at the following

link: http://www.cumminspower.com/www/literature/applicationmanuals/t030.pdf

• Consider access to utilities, such as electric/gas meters, transfer switch, remote

fuel tank location (for liquid propane if applicable), etc.

• Call the local utilities to mark the locations of buried utility services (gas,

electric, or telephone) before digging.

• Verify the locations of any other buried components (gas, electric or telephone)

with the homeowner before digging.

Follow the clearance guidelines below:

• The generator set must be located 5 feet from combustible materials (NFPA 37)

and any opening in a wall (window, door, vent, etc.).

• The generator set must be located such that the exhaust is not able to

accumulate in an occupied area.

• The generator set must have enough room for installation, service, and

maintenance.

• The generator set must be located to ensure ventilation openings are not

blocked.

30 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 35

4. Installation8-2017

• Position the generator set so that cooling air is free to enter and leave the area.

• Locate and position the generator set so that prevailing winds carry exhaust

gases and potential fuel leaks away from the house or occupied area.

NOTICE

For all clearance requirements, refer to the Outline and System Drawings

section.

Laying the Foundation

When laying the foundation:

1. Clear obstructions, and make sure that there is adequate clearance for access.

2. Level the ground, and make sure that the ground is compact and settled.

Ensure that it is stable ground, not subject to flooding.

3. Prepare the concrete pad.

• The pad should be constructed of reinforced concrete with a 28-day

compressive strength of at least 2500 psi (17,237 kPa).

• The pad dimensions should be the same as those indicated in the Outline

and System Drawings appendix.

NOTICE

Seismic installations may require a different pad and securing

devices.

NOTICE

Local codes and standards may have different requirements.

4. Lift the generator set onto the pad, and secure it.

Lifting and Moving the Generator Set

WARNING

Heavy Load

The generator set is heavy. Handle with care.

Dropping the generator set can cause severe personal injury or death. Use

appropriate lifting techniques to move the generator set. Keep feet and

hands clear when lifting the generator set.

CAUTION

The generator set is shipped with oil in the engine crankcase. Keep the

generator set upright.

31A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 36

4. Installation 8-2017

Mounting the Generator Set

Mount the generator set on a substantial and level base such as a concrete pad. A

non-combustible material must be used for the pad. Verify that the mounting pad is

level by length, by width, and diagonally.

NOTICE

Seismic installation may require specific anchorage.

4.2 Fuel Selection and Fuel System Connection

This generator set has a convertible fuel system. The generator may run on natural

gas or propane, depending on the preferences of the owner. All generator sets

come preconfigured from the factory for natural gas fuel. For more information on

converting the fuel system type, see the Service Manual.

NOTICE

Fuel systems must be installed by qualified service technicians. Improper

installation presents hazards of fire and improper operation, resulting in

severe personal injury or property damage.

NOTICE

In some jurisdictions fuel system installations to the generator set must be

performed by licensed or registered personnel. Check with the authority

having jurisdiction for requirements.

WARNING

Gaseous fuels are flammable, explosive, and can cause severe personal

injury or death. Do not smoke if you smell gas, are near fuel tanks for fuelburning equipment, or are in an area sharing ventilation with such

equipment. Keep flames, sparks, pilot lights, electrical arcs, arc-producing

equipment and all other sources of ignition well away. Keep a type ABC fire

extinguisher handy.

In all fuel system installations, cleanliness is extremely important.

• Make every effort to prevent fuel contamination from:

◦ Moisture

◦ Dirt

◦ Excess thread sealant

◦ Contaminants of any kind

• Clean all fuel system components before installing.

32 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 37

4. Installation8-2017

Gaseous-fuel supply system design, materials, components, fabrication, assembly,

installation, testing, inspection, operation, and maintenance must comply with the

applicable codes. See NFPA Standards No. 37, 54, and 58. If this is a seismic

installation, refer to IBC codes and standards. Where seismic installation is

required, there may be specific anchorage requirements for the generator set and

other installed components.

Most codes require a manual shutoff valve ahead of a flexible fuel hose. The

generator set includes electric (battery-powered) shutoff valves.

NOTICE

It is recommended that a shutoff valve be located near the generator set for

emergency shut off or servicing the generator set. Follow applicable codes.

Until the generator set is connected, cap the fuel line stub-up at the generator set to

prevent dirt from entering and gas from discharging if the gas supply shutoff valve is

opened accidentally.

To determine the required capacity, refer to the Fuel Line Selection section.

Fuel Line Connections

WARNING

Fuel presents the hazard of fire or explosion that can result in severe

personal injury or death. Do not smoke or allow any flame, spark, pilot light

or other ignition sources near fuel or in the installation area. Read the

important safety precautions in this manual.

1. Refer to the Outline and System Drawings appendix for the location of the fuel

supply connection through the side of the generator set.

2. Install a flexible fuel hose, which must be used between the engine's fuel

system and fuel supply line to protect the fuel system from damage caused by

vibration, expansion and contraction. The fuel hose must be installed according

to all applicable codes and standards.

Installing Fuel Lines

The basic components required for fuel line installation are as follows:

• Flexible fuel line (attached to the radiator guard)

• Fuel line

• Shutoff valve

• Fuel supply

To install the fuel lines:

1. Connect a flexible fuel line to the fuel connection ports on the generator set.

2. Connect the opposite end of the flexible fuel line to the fuel source line near the

shutoff valve.

33A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 38

4. Installation 8-2017

NOTICE

A shutoff valve is recommended and often required by local and state codes.

Natural Gas Fuel System

Requirements for a natural gas generator set are as follows:

TABLE 15. NATURAL GAS GENERATOR SET REQUIREMENTS

Component Description

Gas Pipeline quality

Fuel Supply Adequate fuel supply to operate correctly and run at full load

Shutoff Valve Manual

Fuel Pipe Size The length of the fuel supply pipe from the gas service entrance to the

generator set must be known to determine the correct fuel pipe size.

Refer to the charts in the Fuel Line Selection appendix.

Iron pipe must be a minimum of Schedule 40 subject to the authority

having jurisdiction.

Flexible Fuel Line Attached to the radiator guard. Protects the fuel system from vibration,

expansion, and contraction.

WARNING

Fuel leaks can lead to explosive accumulations of gas. Prevent gas leaks

and the accumulation of gaseous fuel in the event of a leak.

34 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 39

No. Description No. Description

1 Shutoff Valve 3 Meter

4. Installation8-2017

2 Flexible Fuel Line (Attached to

Radiator Guard)

FIGURE 6. TYPICAL NATURAL GAS INSTALLATION

Natural Gas Supply Line Size

The natural gas supply meter may need to be exchanged for a higher capacity

meter to supply the additional gas consumed by the generator set.

Use the total load requirement of the generator set to determine the size of

the fuel supply pipe. Use the tables and charts in the Fuel Line Selection

appendix to determine the correct pipe size.

An older site might require upgrading and repair of the gas supply system.

Schedule an upgrade or repair to minimize power and gas supply

interruptions.

Make sure the full load fuel supply pressure at the inlet to the generator fuel

shutoff valves matches the requirements in the Model Specifications section.

Propane Fuel System

Propane vapor can be used as a primary fuel source or as a backup fuel source for

the generator sets with two independent fuel sources connected to the generator

set.

4 Secondary Regulator

WARNING

Fuel leaks can lead to explosive accumulations of gas. Propane sinks in air

and can accumulate inside housings, basements, and other below-grade

spaces. Prevent gas leaks and the accumulation of gaseous fuel in the event

of a leak.

35A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 40

4. Installation 8-2017

NOTICE

NFPA Standard No. 58 requires all persons handling and operating propane

to be trained in proper handling and operating procedures.

The required components in a propane vapor fuel system are as follows:

Component Description

Propane Tank Make sure to identify and use the correct tank size based on fuel flow

requirements and the lowest average temperature for your region. If the

tank is sized incorrectly, the generator set could run out of fuel. Refer to

the Fuel Line Selection appendix.

Shutoff Valve Useful during installation or in the event of a leak (may be required to

meet local codes).

Primary Regulator Located at the tank outlet, the primary regulator reduces the tank

pressure to the working pressure in the fuel supply line. Primary and

secondary regulators must be properly matched for a safe and functional

system. Consult with your propane supplier to ensure that the regulators

are properly sized.

Secondary

Regulator

Located near the generator set, the secondary regulator reduces the

higher line pressure to a working pressure that matches the

requirements in the Model Specifications section. Higher pressure before

the secondary regulator is necessary to ensure that there is enough fuel

available at the secondary regulator for a fully loaded generator set.

Fuel Line Connects to the fuel supply. It must be sized properly using the propane

fuel line sizing charts (refer to the Fuel Line Selection appendix).

Installation must comply with all national, state, and local codes.

Cummins Flexible

Fuel Line

Attached to radiator guard. Protects the fuel system from vibration,

expansion, and contraction.

36 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 41

No. Description No. Description

1 Generator Set 4 Secondary Regulator

4. Installation8-2017

2 Flexible Fuel Line (Attached to

Radiator Guard)

3 Shutoff Valve

FIGURE 7. TYPICAL PROPANE INSTALLATION

Propane Fuel Requirements

Propane presents the hazard of fire or explosion that can cause severe

personal injury or death. Do not permit any flame, spark, arc-producing

equipment, switch, pilot light, cigarette, or other ignition source near

the fuel system. Keep an ABC type fire extinguisher nearby.

Fuel leaks can lead to explosive accumulations of gas. Propane sinks

in air and can accumulate inside housings, basements and other

below-grade spaces. Prevent gas leaks and the accumulation of

gaseous fuel in the event of a leak.

Use clean, fresh HD-5 grade propane or equivalent product consisting of at

least 90% propane.

5 Propane Tank

WARNING

WARNING

NOTICE

NFPA Standard No. 58 requires all persons handling and operating

propane to be trained in proper handling and operating procedures.

37A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 42

4. Installation 8-2017

NOTICE

Commercial propane may contain more than 2.5% butane, which can

result in poor fuel vaporization and low tank pressure, resulting in poor

engine starting and operation in below 32 °F (O °C) temperatures.

Propane Tank Size

When propane is used, size the tank correctly to ensure successful generator

set operation.

Considerations when figuring the proper propane tank size:

• Temperature is a critical factor that affects the size of the tank.

◦ Ambient temperatures can affect how quickly liquid is converted to

gas.

◦ Generator set fuel consumption is the same regardless of the

surrounding temperatures.

◦ Colder weather climates require larger fuel tanks. Larger tanks have

greater surface area, allowing more liquid propane to vaporize and

maintain the required fuel rate.

◦ Propane is stored as liquid. Keep the fuel tank at least 50% full to

operate properly. Fuel tanks that are less than 50% full may not have

the capacity to vaporize enough propane to operate the generator set

and other LP appliances.

• Propane tanks are sized by their internal volume in gallons, not the

amount of fuel they can hold (which is less).

• Propane tanks are generally filled to only 80% of their capacity.

Therefore, a 500-gallon (1892 L) tank results in 400-gallon (1514 L) tank

capacity.

• Low ambient temperatures affect the amount of fuel available from the

propane tank.

• Approximately 60% of the fuel (in gallons) filled in the tank can be

effectively used. Therefore, a 500-gallon (1892 L) tank results in 240gallon (908 L) usable capacity.

To assist in the proper installation of the propane tank, follow the guidelines

below.

• Consult your tank and propane supplier for assistance in all aspects of

determining tank size, selection of components and installation

requirements.

• Fit the propane tanks with a pressure reducing regulator before

connection to the generator set to prevent fuel system damage.

• Locate the propane tanks and all other fuel system components at least

10 feet (3 meters) from any source of combustion (including the generator

set). The fuel supplier or local code may require a larger distance

between the tank and source of combustion.

38 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 43

4. Installation8-2017

• Install the propane tanks according to all national and local codes and

standards, and as required by the fuel tank and fuel supplier.

Refer to the Fuel Line Selection appendix for propane figures and tables.

Propane Vapor Fuel Supply Line Size and Pressure

Fuel line size depends on the amount of fuel needed to run the generator set

at full load at the distance the fuel must be moved.

To correctly size the fuel pipe, you must also take other loads operated from

the fuel supply line into consideration, such as space heating and water

heating equipment.

Use the total fuel requirement of the generator set and other connected

appliances to determine the size of the fuel supply pipe. Use the tables and

charts in the Fuel Line Selection appendix to determine the correct pipe size.

See the Model Specifications section for fuel system specifications, including

fuel consumption and required fuel system pressure at the generator set.

See the Propane Fuel System section for a typical propane vapor installation.

See the Fuel Line Selection appendix for fuel capacity at given distances and

pipe size.

NOTICE

Make sure the fuel supply pressure at the inlet of the generator set fuel

regulator (at service port) matches the requirements in the Model

Specifications section.

Converting the Fuel System Type

For single-fuel systems, the generator set leaves the factory configured for

natural gas. No mechanical parts are required for fuel conversion. To convert

the fuel system type, configure the control.

1. Enter the Fuel System Menu.

a. From any Info Menu, hold down the up and down arrows

simultaneously for two seconds. The Service Menu appears.

b. Select Setup Menus.

c. Enter the password 574 on the Password screen. The Setup Menu

appears.

d. Select Genset Service.

e. Select Genset.

f. Advance through the screens until the Fuel System Setup Menu

appears.

2. Update the Fuel System Type on the Fuel System Setup Menu. See the

figure below.

a. Press Adjust on the Fuel System Menu.

39A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 44

4. Installation 8-2017

b. Edit the Fuel System using the horizontal arrow key. Change the field

value by using the +/- keys.

FIGURE 8. FUEL SYSTEM TYPE

40 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 45

4. Installation8-2017

3. Update the Gas Fuel Type on the Fuel System Menu.

a. When changing the Fuel System, a second Fuel System Menu is

enabled. Advance to this menu by pressing the down arrow after

saving any changes.

b. Press Adjust on the Fuel System Menu.

c. Edit the Gas Fuel Type by using the horizontal arrow key. See the

figure below.

FIGURE 9. GAS FUEL TYPE

d. Change the field value to Natural Gas, Liquid Propane, or Dual by

using the +/- keys.

e. Select Save to save the changes.

41A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 46

4. Installation 8-2017

Testing the Fuel System for Leaks

After assembly and before initial operation, all of the fuel system components must

be tested and proven free of any leaks.

WARNING

Fuel presents the hazard of explosion or fire which can result in severe

personal injury or death. Do not use an open flame to check for leaks. Do not

smoke or allow any flame, spark, pilot light, arc-producing equipment, switch

or other ignition sources around fuel or fuel components. Keep multi-type

ABC fire extinguishers close by.

NOTICE

Follow any local codes and standards, as they may require a different

method or documentation of a leak test.

Perform the following fuel piping system leak check:

1. After assembly and before initial operation of generator set, test all fuel system

components as required per the National Fuel Gas Code (NFPA 54).

2. The National Fuel Gas Code requires that the generator set be isolated from

the piping system by disconnecting it and capping the outlet prior to test. The

test pressure required is the greater of 1.5 times the supply pressure or 3 psi

(20.7 kPa) minimum.

3. After successfully completing the previous step, connect the generator set to

the fuel piping system.

4. To verify that all connections from the fuel piping system to the generator set

are free of leaks, conduct a bubble test using an approved leak detection

solution (or equivalent method) with the system pressure of 0.8 to 1.0 psi (5.5 to

7.0 kPa).

5. Spray the bubble solution on all of the joints.

6. Inspect all of the joints and monitor the line pressure. If bubbles appear, there is

a leak.

7. If any leaks are found, repair the joint or replace components as needed.

8. Verify the leak has been fixed.

NOTICE

The leak detection solution (that is, bubble solution) must be non-corrosive

and be free of ammonia and chlorine.

42 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 47

4.3 Engine Exhaust

The exhaust system for this generator set is complete and was designed specifically

for this generator set. Do not modify or add to the exhaust system of this generator

set.

WARNING

Exhaust gas is deadly. Make sure that the exhaust system terminates away

from building vents, windows, doors, and sheltered spaces that may not

have ample fresh air ventilation.

WARNING

Engine discharge air and exhaust carry carbon monoxide gas (odorless and

invisible) which can cause asphyxiation and death. Never use engine

discharge air or exhaust for heating a room or enclosed space.

4.4 Electrical Connections

4. Installation8-2017

WARNING

Improper installation can lead to electrocution and damage to property.

Electrical connections must be made by a licensed electrician.

WARNING

Automatic startup of the generator set during installation can cause severe

personal injury or death. Make sure the generator set is shut down and

disabled:

1. Press the generator set's "O" (Off) button to stop the generator set.

Allow the generator set to thoroughly cool to the touch.

2. Turn off and disconnect the battery charger from the AC source before

disconnecting the battery cables.

3. Disconnect the negative (–) cable from the battery and secure it from

contacting the battery terminals to prevent accidental starting.

NOTICE

Refer to regional codes and the National Electrical Code (NFPA 70) for all

electrical installation requirements.

NOTICE

Class 1 wiring methods must be used for connecting the generator set.

43A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 48

4. Installation 8-2017

Electrical Preparations

1. Run all wires through a single conduit (unless prohibited by the authority having

jurisdiction).

NOTICE

Be sure to account for any needed accessories, such as a remote

display, etc.

2. Connect the conduit to the generator set. Refer to the specific outline drawing in

the Outline and System Drawings section for the size and location of the hole

provided for electrical conduit connection. The existing hole may be increased

in size to match conduit used.

AC Connections

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal

injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the

starting battery cables, negative (–) cable first.

NOTICE

If a 100% rated breaker is used, 90 °C wire must be used for L1, L2, and L3

with the wire size determined by the 75 °C ampacity tables.

NOTICE

When using a circuit breaker with an adjustable, electronic trip unit, the

amperage and trip curve settings may need adjustment to match the

generator set load wiring, or downstream loads and circuit breakers. An

accessory seal kit (part number A026M166) is available to tamper-proof the

adjustable settings.

1. Make sure the generator set is shut down and disabled:

a. Press the Off switch from the display and then press the E-Stop button to

stop the generator set. Allow the generator set to thoroughly cool to the

touch.

b. Turn off and disconnect the battery charger from the AC source before

disconnecting the battery cables.

c. Disconnect the negative (–) cable from the battery and secure it from

contacting the battery terminals to prevent accidental starting.

2. Remove the enclosure side panel to access the main circuit breaker box.

3. Place the circuit breaker handle in the OFF position.

44 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 49

4. Installation8-2017

4. Remove the four bolts holding the circuit breaker cover.

5. Connect the conductors to the circuit breaker load-side terminals, neutral lug,

and equipment grounding lug. For grounding and neutral connections, look for

the symbols on the generator set circuit breaker box (shown below, and in the

next image at the bottom).

Equipment Grounding Conductor Symbol Equipment Neutral Connection Symbol

FIGURE 10. SYMBOLS ON CIRCUIT BREAKER BOX

45A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 50

4. Installation 8-2017

FIGURE 11. CIRCUIT BREAKER AC LOAD CONNECTIONS LOCATION (SYMBOLS

SHOWN AT BOTTOM)

6. Torque the circuit breaker terminals per specifications on the circuit breaker

label.

7. Torque the neutral lug to 31.1 Nm (275 in-lb).

8. Torque the equipment grounding lug to 13.8 Nm (120 in-lb).

9. Fill in the stub-up openings with an approved duct seal or mastic tape to keep

out insects and rodents.

10. Install the circuit breaker cover.

46 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 51

4. Installation8-2017

Automatic Transfer Switch AC Connections

WARNING

Failure to use an approved transfer switch can lead to the electrocution

of personnel working on the utility lines, damage to equipment, fire, or

personal injury. An approved switching device must be used to prevent

interconnection to the public utility.

Install the transfer switch in accordance with the appropriate RA Series

Transfer Switch Owner Manual.

Factory Option and Accessory Connections

NOTICE

Use copper conductors only.

AC powered options or accessories available:

• Battery charger

• Engine coolant heater

• Alternator heater

• Battery warmer

• CCV heater

47A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 52

4. Installation 8-2017

No. Description No. Description

1 AC Distribution Connector(s)

FIGURE 12. AC ACCESSORY CONNECTIONS

The battery charger, engine coolant heater, alternator heater, CCV heater,

and battery warmer require power from a 120 VAC, 20 Amp protected circuit

from the Main Distribution Panel. Use 12 AWG 75 °C (167 °F) conductors to

make connection to the generator set AC distribution connector.

DC Connections

NOTICE

When selecting and installing conduit to the generator set, account for any

needed accessories, such as a remote display, etc.

48 A045R241 (Issue 10)Copyright © 2017 Cummins Inc.

Page 53

4. Installation8-2017

FIGURE 13. DC CUSTOMER CONNECTIONS

Automatic Transfer Switch DC Connections

WARNING

Failure to use an approved transfer switch can lead to the electrocution

of personnel working on the utility lines, damage to equipment, fire, or

personal injury. An approved switching device must be used to prevent

interconnection to the public utility.

49A045R241 (Issue 10) Copyright © 2017 Cummins Inc.

Page 54

4. Installation 8-2017

Install the transfer switch in accordance with the appropriate RA Series

Transfer Switch Owner Manual.

The following image is an example that shows the location of the connectors

in the generator set where the ATS DC control wires terminate. This is also

the location of the connectors where load management control wires (if

applicable) terminate.

Refer to the Wiring Diagrams appendix for generator set to RA transfer switch

DC customer connections.

NOTICE

Class 1 wiring methods should be used for connecting the generator

set and transfer switch signal wiring.

FIGURE 14. EXAMPLE OF RA SERIES TRANSFER SWITCH DC CONNECTIONS

LOCATION