CUMMINS C13N6H (Spec A), C17N6H (Spec A), C20N6HC (Spec A), C20N6H (Spec A) Installation Manual

InstallationInstallation ManualManual

Home Standby Generator Set

C13N6H (Spec A)

C17N6H (Spec A)

C20N6H (Spec A)

C20N6HC (Spec A)

English

Original Instructions

12-2016 A053X172 (Issue 6)

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS....................................................................................... 1

1.1 Save These Instructions ........................................................................................................ 1

1.2 General Information ................................................................................................................ 1

1.3 General Precautions .............................................................................................................. 1

1.4 Generator Set Voltage Is Deadly ........................................................................................... 5

1.5 Engine Exhaust Is Deadly ...................................................................................................... 5

1.6 Fuel and Fumes Are Flammable ............................................................................................ 6

1.7 Batteries Can Explode............................................................................................................ 6

1.8 Starting Batteries .................................................................................................................... 7

1.9 Moving Parts Can Cause Severe Personal Injury or Death .................................................. 7

1.10 The Hazards of Carbon Monoxide........................................................................................ 8

2. INTRODUCTION............................................................................................................................ 9

2.1 About This Manual.................................................................................................................. 9

2.2 Schedule of Abbreviations...................................................................................................... 9

2.3 Related Literature ................................................................................................................. 11

2.4 Before Installation ................................................................................................................. 12

2.5 Model Specifications............................................................................................................. 13

3. PRE-INSTALLATION CONSIDERATIONS.................................................................................. 17

3.1 Pre-Installation Considerations Introduction......................................................................... 17

3.2 Installation Codes and Standards for Safety ........................................................................ 18

3.3 Required Items for Installation.............................................................................................. 20

4. INSTALLATION............................................................................................................................ 27

4.1 Site Assessment and Preparation ........................................................................................ 27

4.2 Fuel Selection and Fuel System Connection........................................................................ 31

4.3 Engine Exhaust..................................................................................................................... 43

4.4 Electrical Connections .......................................................................................................... 44

5. STARTUP AND CONFIGURATION............................................................................................. 55

5.1 "Establishing Communications" Message ............................................................................ 55

5.2 "Clock Setup" Screen............................................................................................................ 55

5.3 "Exercise" Screen ................................................................................................................ 61

5.4 "Brightness and Contrast" Screen ........................................................................................ 64

5.5 "About" Screen...................................................................................................................... 66

5.6 "Event Log" Screen............................................................................................................... 68

5.7 "Fault Log" Screen................................................................................................................ 69

5.8 "System Status" Screen........................................................................................................ 70

5.9 "Mode" Screen...................................................................................................................... 71

5.10 Automatic Load Management............................................................................................. 74

5.11 Manual Start Sequence (Local).......................................................................................... 75

5.12 Checklist ............................................................................................................................. 75

iA053X172 (Issue 6) Copyright © 2016 Cummins Inc.

Table of Contents 12-2016

5.13 Startup ............................................................................................................................... 78

6. OPTIONAL REMOTE MONITORING SYSTEM (RMS) DESCRIPTION ..................................... 79

6.1 Introduction .......................................................................................................................... 79

6.2 Optional Remote Monitoring System (RMS) Account Setup and Generator Set Control

Connection ............................................................................................................................ 80

APPENDIX A. FUEL LINE SELECTION........................................................................................... 81

A.0 Fuel System Pipe Sizing Introduction................................................................................... 82

A.1 Gas Pipe Sizing.................................................................................................................... 83

APPENDIX B. OUTLINE AND SYSTEM DRAWINGS...................................................................... 95

APPENDIX C. WIRING DIAGRAMS............................................................................................... 101

C.0 Wiring Diagrams................................................................................................................. 102

ii A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

1 Important Safety Instructions

1.1 Save These Instructions

This manual contains important instructions for the generator set that should be

followed during installation, operation and maintenance of the generator set and

batteries.

Thoroughly read the operator manual before operating the generator set. Safe

operation and top performance can only be obtained when equipment is properly

operated and maintained.

The following symbols in this manual alert you to potential hazards to the operator,

service person and equipment.

DANGER

Alerts you to an immediate hazard that will result in severe personal injury or

death.

WARNING

Alerts you to a hazard or unsafe practice that can result in severe personal

injury or death.

Alerts you to a hazard or unsafe practice that can result in personal injury or

equipment damage.

1.2 General Information

This manual should form part of the documentation package supplied by Cummins

Power Generation with specific generator sets. In the event that this manual has

been supplied in isolation please contact your authorized dealer.

It is in the operator's interest to read and understand all warnings and

cautions contained in the documentation relevant to the generator set

operation and daily maintenance.

1.3 General Precautions

• Keep ABC fire extinguishers accessible.

CAUTION

NOTICE

• Make sure that all fasteners are secure and torqued properly.

1A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 12-2016

• Keep the generator set and its compartment clean. Do not store any items in

the generator set compartment.

• Before working on the generator set, make sure the generator set is shut down

and disabled.

1. Press the generator set's "O" (Off) button or the red STOP button on the

local display (whichever is applicable) to stop the generator set. Allow the

generator set to thoroughly cool to the touch.

2. If applicable, turn off and disconnect the battery charger from the AC

source before disconnecting the battery cables.

3. Disconnect the negative (–) cable from the battery and secure it from

contacting the battery terminals to prevent accidental starting.

• Use caution when making adjustments when the generator set is running, hot,

or when parts are electrically live, as all situations may cause personal injury or

death.

• Used engine oil has been identified by some state and federal agencies as

causing cancer or reproductive toxicity. Do not ingest, inhale, or come into

contact with used oil or its vapors.

• Do not work on the generator set when mentally or physically fatigued or after

consuming alcohol or drugs.

NOTICE

Only trained and authorized personnel shall maintain or service the

generator set.

NOTICE

The installation of the generator set shall provide enough ventilation to

ensure that gases generated by vented batteries during charging, or caused

by equipment malfunction, are removed.

General Safety Precautions

WARNING

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or

death.

Make sure that only a trained and experienced electrician makes generator

set electrical output connections, in accordance with the installation

instructions and all applicable codes.

2 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

1. Important Safety Instructions12-2016

WARNING

Electrical Generating Equipment

Faulty electrical generating equipment can cause severe personal injury or

death.

Generator sets must be installed, certified, and operated by trained and

experienced person in accordance with the installation instructions and all

applicable codes.

WARNING

Moving Parts

Moving parts can cause severe personal injury.

Use extreme caution around moving parts. All guards must be properly

fastened to prevent unintended contact.

WARNING

Toxic Hazard

Used engine oils have been identified by some state and federal agencies to

cause cancer or reproductive toxicity.

Do not ingest, breathe the fumes, or contact used oil when checking or

changing engine oil. Wear protective gloves and face guard.

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or

death.

Do not operate equipment when fatigued, or after consuming any alcohol or

drug.

Make sure that only suitably trained and experienced service personnel

perform electrical and/or mechanical service.

WARNING

Toxic Gases

Substances in exhaust gases have been identified by some state and federal

agencies to cause cancer or reproductive toxicity.

Do not breathe in or come into contact with exhaust gases.

WARNING

High Noise Level

Generator sets in operation emit noise, which can cause hearing damage.

Wear appropriate ear protection at all times.

3A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 12-2016

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

Wear appropriate PPE when working on hot equipment and avoid contact

with hot surfaces.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause

severe burns or death.

Do not store fuel, cleaners, oil, etc., near the generator set. Do not use

combustible liquids like ether.

WARNING

Combustible Gases

Generator sets in operation have combustible gases under pressure, which

if ignited can cause eye and ear damage.

• Wear appropriate eye and ear protection at all times.

• Do not operate the generator set with any doors open.

WARNING

Fire Hazard

Materials drawn into the generator set, as well as accumulated grease and

oil, are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from

obstructions. Make sure the generator set is mounted in a manner to prevent

combustible materials from accumulating under the unit.

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal

injury or death.

The generator set must be off and locked out of service whenever the air

inlet, air outlet, or any interior panels are removed.

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal

injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the

starting battery cables (negative [–] first).

4 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

1. Important Safety Instructions12-2016

NOTICE

Keep multi-class ABC fire extinguishers handy. Class A fires involve

ordinary combustible materials such as wood and cloth. Class B fires

involve combustible and flammable liquid fuels and gaseous fuels. Class C

fires involve live electrical equipment. (Refer to NFPA No. 10 in applicable

region.)

NOTICE

Before performing maintenance and service procedures on enclosed

generator sets, make sure the service access doors are secured open.

NOTICE

Stepping on the generator set can cause parts to bend or break, leading to

electrical shorts, or to fuel, coolant, or exhaust leaks. Do not step on the

generator set.

1.4 Generator Set Voltage Is Deadly

• Generator set output connections must be made by a trained and experienced

electrician in accordance with all applicable codes.

• This generator set and the public utility may only be connected to house circuits

by means of the automatic transfer switch.

CAUTION

Improper connections can lead to electrocution of utility workers and

damage to equipment. Make sure that the connections are installed

properly by a trained technician.

• Use caution when working on live electrical equipment. Remove jewelry, and

make sure clothing and shoes are dry. Stand on a dry wooden platform.

1.5 Engine Exhaust Is Deadly

• See The Hazards of Carbon Monoxide to learn the symptoms of Carbon

Monoxide poisoning.

• Locate the generator set away from doors, windows, other openings into the

house, and where exhaust gases will disperse away from the house.

5A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 12-2016

1.6 Fuel and Fumes Are Flammable

Fire, explosion, and personal injury or death can result from improper practices.

• DO NOT permit any flame, cigarette, pilot light, spark, arcing equipment, or

other ignition source near the generator set or fuel system.

• Fuel lines must be adequately secured and free of leaks. Fuel connection at the

engine should be made with an approved flexible line. Do not use copper piping

on flexible lines because copper will become brittle if continuously vibrated or

repeatedly bent.

• Be sure all fuel supplies have a positive shutoff valve.

• Be sure the battery area has been well-ventilated prior to servicing near it.

Lead-acid batteries emit a highly explosive hydrogen gas that can be ignited by

arcing, sparking, smoking, etc.

1.7 Batteries Can Explode

Batteries can explode, causing severe skin and eye burns and can release toxic

electrolytes.

WARNING

Combustible Gases

Batteries can explode, causing severe skin and eye burns, and can release

toxic electrolytes.

Do not dispose of the battery in a fire, because it is capable of exploding. Do

not open or mutilate the battery.

WARNING

Electric Shock Hazard

Batteries present the risk of high short circuit current.

Remove watches, rings, or other metal objects. Use tools with insulated

handles.

NOTICE

Servicing of batteries must be performed or supervised by personnel

knowledgeable of batteries and the required precautions. Keep unauthorized

personnel away from batteries.

• Wear safety glasses.

• Do not smoke.

• To prevent arcing when disconnecting the battery:

1. Press the Off switch from the display and then press the E-Stop button.

2. Disconnect AC power from any battery chargers.

6 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3. Remove the negative (-) battery cable to prevent starting.

• To prevent arcing when reconnecting the battery:

1. Reconnect the positive (+) cable.

2. Reconnect the negative (-) cable.

3. Reconnect the battery charger to AC power supply.

• When replacing the generator set battery, always replace it with a battery as

specified in this manual.

1.8 Starting Batteries

Toxic Hazard

The electrolyte in starting batteries is a dilute sulfuric acid that is harmful to

the skin and eyes. It is also electrically conductive and corrosive.

Always:

1. Wear full eye protection and protective clothing;

2. If the electrolyte contacts the skin, wash it off immediately with water;

3. If the electrolyte contacts the eyes, flush them thoroughly and

immediately with water and seek medical attention; and

4. Wash spilled electrolyte down with an acid neutralizing agent. A

common practice is to use a solution of one pound (500 grams)

bicarbonate of soda (also known as baking soda or sodium bicarbonate)

to one gallon (4 liters) of water.

5. Continue to add the bicarbonate of soda solution until the evidence of

reaction (that is, foaming) has stopped.

6. Flush the resulting liquid with water and dry the area.

1. Important Safety Instructions12-2016

WARNING

1.9 Moving Parts Can Cause Severe Personal Injury or Death

• Do not wear loose clothing or jewelry near moving parts, such as fans.

• Keep hands away from moving parts.

• Keep guards in place over fans.

7A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 12-2016

1.10 The Hazards of Carbon Monoxide

Carbon monoxide (CO) is an odorless, colorless, tasteless and non-irritating gas.

You cannot see it or smell it. Red blood cells, however, have a greater affinity for

CO than for oxygen. Therefore, exposure even to low levels of CO for a prolonged

period can lead to asphyxiation (lack of oxygen) resulting in death. Mild effects of

CO poisoning include eye irritation, dizziness, headaches, fatigue and the inability to

think clearly. More extreme symptoms include vomiting, seizures and collapse.

Engine-driven generator sets produce harmful levels of carbon monoxide that can

injure or kill you.

Special Risks of CO near the Home

WARNING

Toxic Gases

Carbon monoxide (CO) gas can cause nausea, fainting, or death. Residents

can be exposed to lethal levels of CO when the generator set is running.

Depending on air temperature and wind, CO can accumulate in or near the

home.

To protect yourself and others from the dangers of CO poisoning, it is

recommended that reliable, approved, and operable CO detector alarms are

installed in proper locations in the home as specified by their manufacturer.

Protecting Yourself from CO Poisoning

• Locate the generator set in an area where there are no windows, doors, or

other access points into the home.

• Make sure all CO detectors are installed and working properly.

• Pay attention for signs of CO poisoning.

• Check the exhaust system for corrosion, obstruction, and leaks every time you

start the generator set and every eight hours when you run it continuously.

8 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

2 Introduction

2.1 About This Manual

Improper installation can result in severe personal injury, death and damage

to equipment. The installation must comply with all applicable building

codes (including project permits and inspections). The installer should be

properly trained and licensed to perform electrical and mechanical

equipment installations (including gaseous fuel installation).

Manuals are updated from time to time to reflect changes in the equipment

and its specifications. The most up-to-date version of this manual is found

on the QuickServe website

(https://quickserve.cummins.com/info/index.html).

This manual is a guide for the installation of the generator set models listed on the

front cover. Proper installation is essential for top performance, reliable operation,

and safety. Read through this manual before starting the installation. This manual

covers outdoor applications only; this product must never be installed indoors.

WARNING

NOTICE

NOTICE

The installation must comply with all applicable building codes.

See the generator set's specific Operator Manual for operation and maintenance

and specific Service Manual for service.

Refer to the Model Specifications section for specific information about the system

and its components.

Refer to the Outline and System Drawings appendix and the Wiring Diagrams

appendix for specific information about installation and wiring connections.

2.2 Schedule of Abbreviations

This list is not exhaustive. For example, it does not identify units of measure or

acronyms that appear only in parameters, event/fault names, or part/accessory

names.

Abbr. Description Abbr. Description

AC Alternating Current LED Light-Emitting Diode

AMP AMP, Inc. (part of Tyco

Electronics)

MFM Multifunction Monitor

9A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

2. Introduction 12-2016

Abbr. Description Abbr. Description

ANSI American National

Mil Std Military Standard

Standards Institute

ASOV Automatic Shut Off Valve MPU Magnetic Pickup

ASTM American Society for

NC Normally Closed

Testing and Materials

(ASTM International)

ATS Automatic Transfer

NC Not Connected

Switch

AVR Automatic Voltage

Regulator

NFPA National Fire Protection

Agency

AWG American Wire Gauge NO Normally Open

CAN Controlled Area Network NWF Network Failure

CB Circuit Breaker OEM Original Equipment

Manufacturer

CE Conformité Européenne OOR Out Of Range

CCA Cold Cranking Ampere OORH/

Out Of Range High

ORH

CFM Cubic Feet per Minute OORL/ORL Out Of Range Low

CGT Cummins Generator

PB Push Button

Technologies

CMM Cubic Meters per Minute PCC PowerCommand®Control

CT Current Transformer PGI Power Generation

Interface

DC Direct Current PGN Parameter Group

Number

DEF Diesel Exhaust Fluid PI Proportional/Integral

DPF Diesel Particulate Filter PID Proportional/Integral/

Derivative

EBS Excitation Boost System PLC Programmable Logic

Controller

ECM Engine Control Module PMG Permanent Magnet

Generator

ECS Engine Control System PPE Personal Protective

Equipment

EMI Electromagnetic

Interference

PT Potential Transformer

10 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

2. Introduction12-2016

Abbr. Description Abbr. Description

EN European Standard PTC Power Transfer Control

EPS Engine Protection

System

E-Stop Emergency Stop RFI Radio Frequency

FAE Full Authority Electronic RH Relative Humidity

FMI Failure Mode Identifier RMS Remote Monitoring

FSO Fuel Shutoff RMS Root Mean Square

Genset Generator Set RTU Remote Terminal Unit

GCP Generator Control Panel SAE Society of Automotive

GND Ground scfh Standard Cubic Feet of

HMI Human-Machine

Interface

IC Integrated Circuit SPN Suspect Parameter

PWM Pulse-Width Modulation

Interference

System

Engineers

gas per Hour

SCR Selective Catalytic

Reduction

Number

ISO International Organization

for Standardization

LBNG Lean-Burn Natural Gas UL Underwriters

LCD Liquid Crystal Display UPS Uninterruptible Power

LCT Low Coolant

Temperature

2.3 Related Literature

Before any attempt is made to operate the generator set, the operator should take

time to read all of the manuals supplied with the generator set and familiarize

themselves with the warnings and operating procedures.

SW_B+ Switched B+

Laboratories

Supply

11A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

2. Introduction 12-2016

NOTICE

A generator set must be operated and maintained properly if you are to

expect safe and reliable operation. The Operator manual includes a

maintenance schedule and a troubleshooting guide.

The Health and Safety manual must be read in conjunction with this manual

for the safe operation of the generator set, as well as the Warranty

Statements.

The literature provided with the generator set is as follows:

• Installation Manual (A053X172)

• Operator Manual (A053X174)

• Quick Start Installation Guide (A053X181)

• Quick Start Operator Guide (A053X183)

• Health and Safety Manual (0908-0110-00)

• Global Warranty Statement (A056F206)

• Emission Warranty Statement (Federal Emissions EPA Title 40 CFR Part 90

Component Warranty) (A028X278)

The relevant manuals appropriate to your generator set are also available. The

documents below are in English:

• Generator Set Service Manual (A053X177)

• RA Series RA112L1 Automatic Transfer Switch Owner Manual (A052S254) - if

applicable

• RA Series 100A/200A/400A Automatic Transfer Switch Owner Manual

(A046S594) - if applicable

• Parts Manual (A053X179)

• Standard Repair Times - HO Family (A053X186)

• Service Tool Manual (A043D529)

• Warranty Failure Code Manual (F1115C)

• Engineering Application Manual T-030: Liquid Cooled Generator Sets

(A040S369)

2.4 Before Installation

Before beginning the installation of the generator set, verify that the unit was

correctly selected. Check the following features:

• Model

• Specifications

• Options

12 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

• Fuel Supply

◦ The gas supplied to the generator set must be of acceptable quality.

◦ The gas supply must have sufficient pressure. Care must be taken to be

sure that the gas supply at the generator set, not just at the source, is of

proper pressure for operation. The specified pressure must be available

while the generator set is starting and running at full load.

◦ The gas must be supplied to the generator set in sufficient volume to

support operation of the generator set. This is normally a matter of

selecting fuel line size to be large enough to transport the volume of fuel

needed. For liquid propane vapor-withdrawal fuel systems the size and

temperature of the fuel tank also affects this requirement.

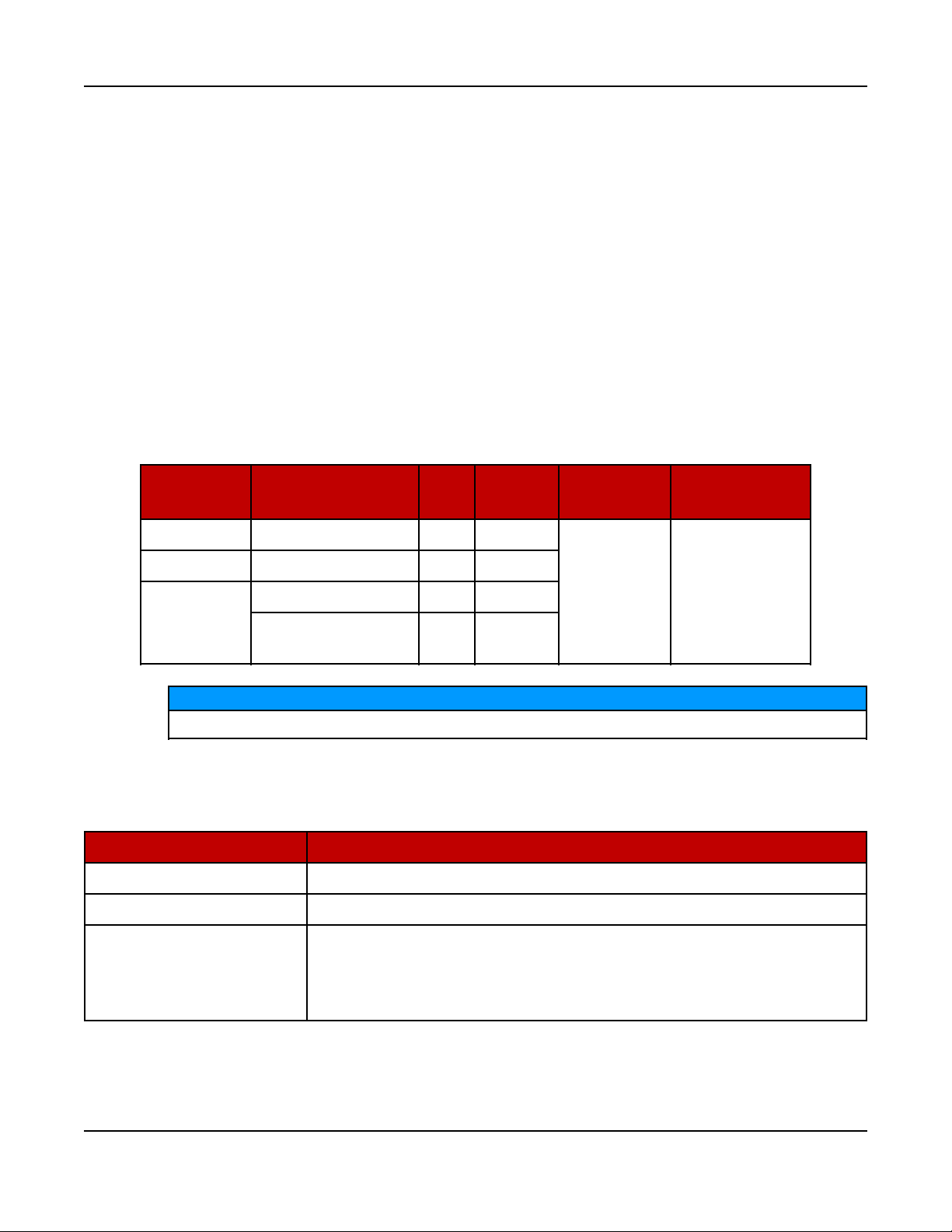

2.5 Model Specifications

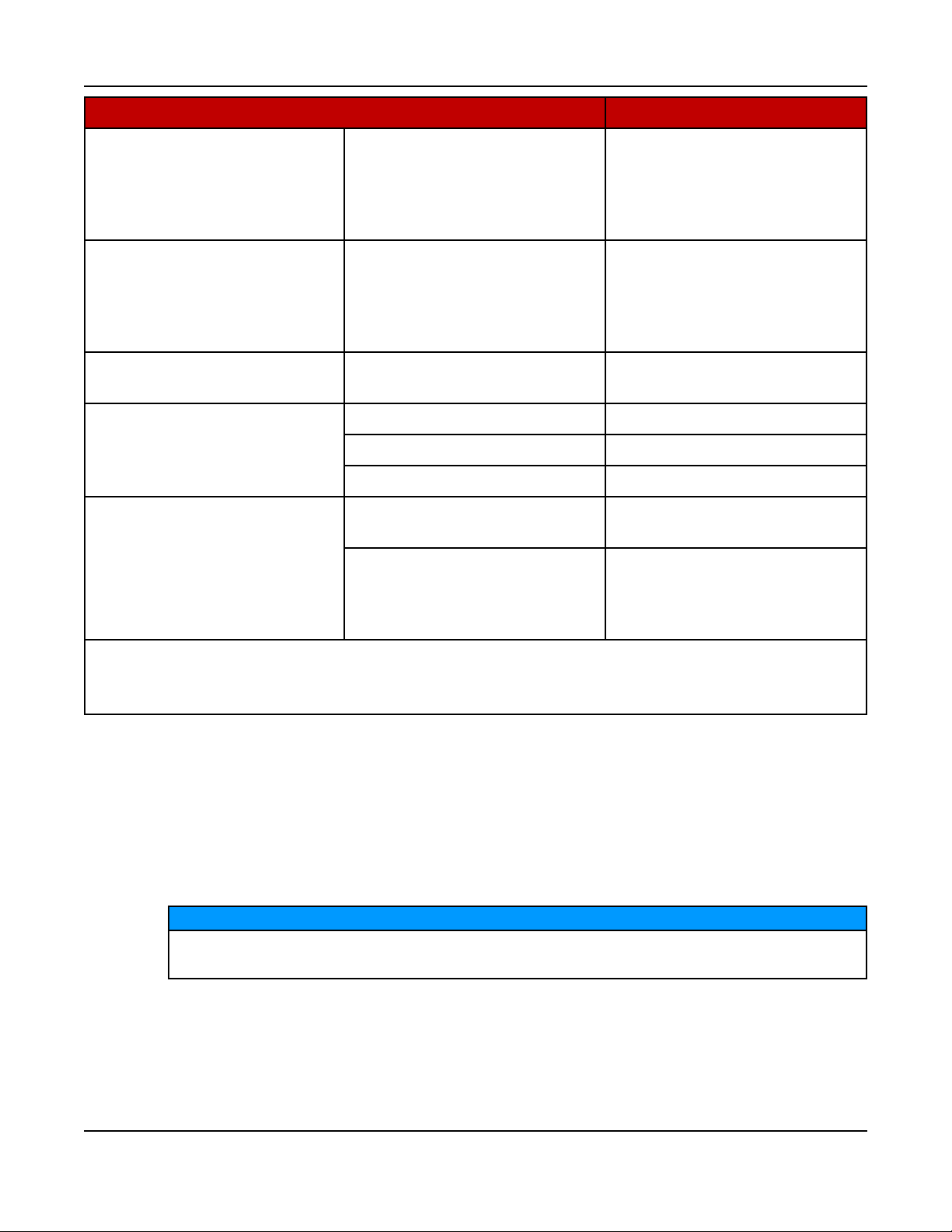

TABLE 1. MODEL VARIATIONS

2. Introduction12-2016

Model

C13N6H Both 13 54.2

C17N6H Both 17 70.8

C20N6H,

C20N6HC

Maximum load imbalance allowed is 50% of generator set rating.

TABLE 2. COLD WEATHER SPECIFICATIONS (ALL MODELS)

Temperature Description

Above 40 °F (4 °C) No starting aids required

0 to 40 °F (-17 to 4 °C) Alternator heater (supplied with the generator set)

Natural Gas or

Propane Vapor

Natural Gas Only 18 75

Propane Vapor

Only

kW Amps Frequency Voltage

20 83.3

NOTICE

60 Hz

120/240 VAC

Single Phase

Below 0 °F (-17 °C)

• Alternator, battery, oil and regulator heaters

• 0W30 oil (see Lubricating Oil System Specifications)

• Accessory kit available

13A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

2. Introduction 12-2016

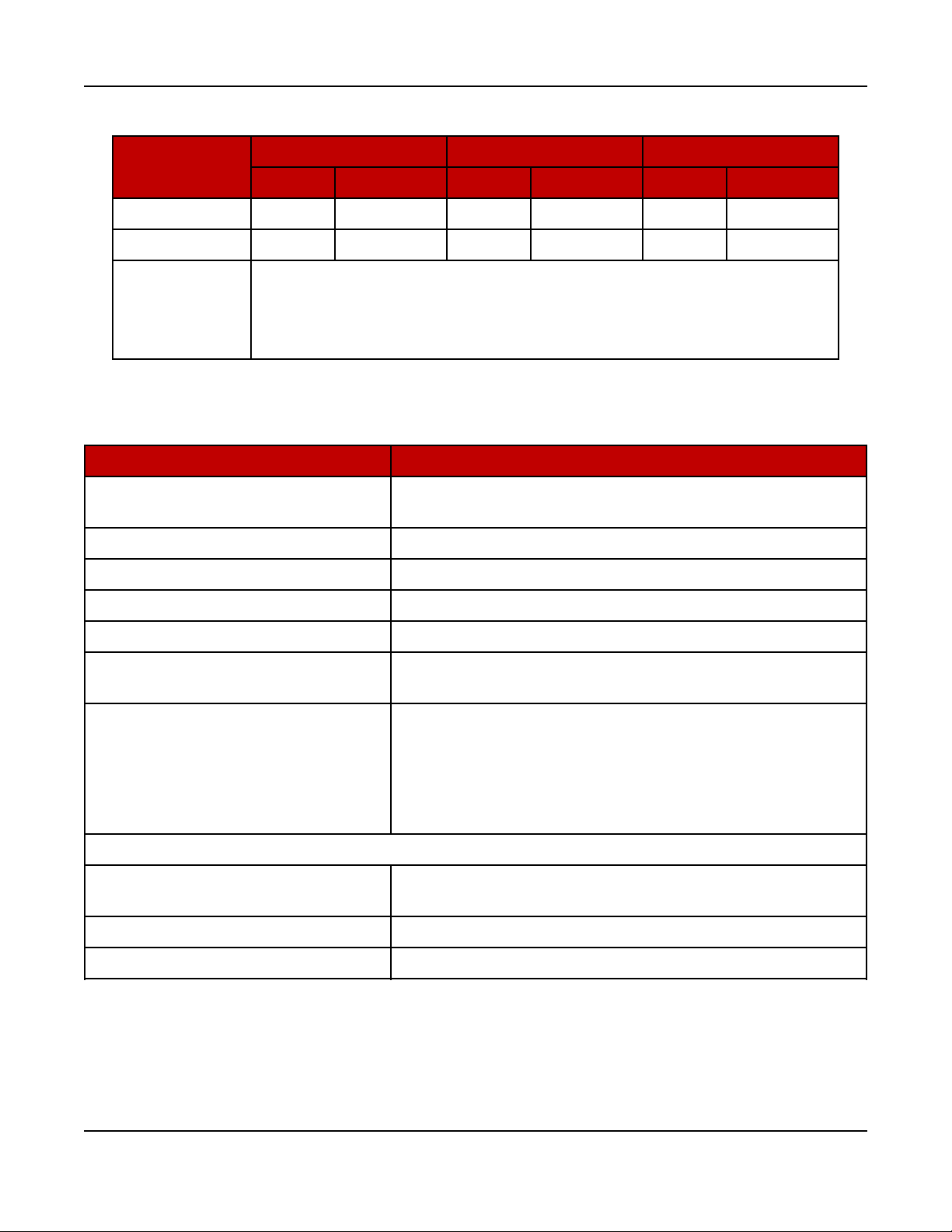

TABLE 3. FUEL SPECIFICATIONS (AT FULL LOAD) (ALL MODELS)

C13N6H C17N6H C20N6H, C20N6HC

Type

scfh BTU/hr scfh BTU/hr scfh BTU/hr

Natural Gas 253 260,000 289 297,000 300 309,000

Propane 85 212,000 101 252,000 116 290,000

Natural Gas: 3.5 - 12 inch water column (0.9 - 3.0 kPa)

Fuel Pressure

Propane Vapor: 6 - 12 inch water column (1.5 - 3.0 kPa)

Maximum pressure for either fuel under any condition: 13 inch water

column (3.2 kPa)

TABLE 4. ENGINE SPECIFICATIONS (ALL MODELS)

Type Value

Engine

2 cylinder v-twin, OHV, air-cooled, 4-stroke, spark

ignited

Displacement 999 cc (60.9 in3)

Spark Plug Gap 0.7 - 0.8 mm (0.027 - 0.031 in)

Spark Plug Torque (Cold Engine) 25 - 30 Nm (18 - 22 ft-lb)

RPM 3600

Lubricating Oil Pressure at Rated

Speed (Minimum)

45 psi (310 kPa)

Full synthetic gasoline engine oil which meets or

exceeds API service SN/SN-RC and ILSAC GF-5:

Oil Recommendation

• 5W30: Temperatures above 0 °F (-18 °C)

• 0W30: All temperatures, required below 0 °F (-18

°C)

Lubricating Oil Capacity:

Lubricating Oil Pressure at Rated

Speed (Minimum)

310 kPa (45 psi)

--Full at High Mark on Dipstick 2.3 L (2.4 qt)

--Low Mark on Dipstick 1.3 L (1.4 qt)

14 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

Model

2. Introduction12-2016

TABLE 5. GENERATOR SET SIZE (ALL MODELS)

Dimension Value

Length 877 mm (34.5 in)

Width 915 mm (36 in)

Height 694 mm (27.3 in)

TABLE 6. GENERATOR SET WET WEIGHT (INCLUDING BATTERY)

Model Value

C13N6H 218 kg (479 lb)

C17N6H, C20N6H, C20N6HC 241 kg (531 lb)

TABLE 7. GENERATOR SET DERATING GUIDELINES

Engine Power Available Up To... Derate At…

Elevation Ambient Temperature Elevation Temperature

C13N6H 2100 m (6900 ft) 25 °C (77 °F)

C17N6H 300 m (1000 ft) 25 °C (77 °F)

C20N6H,

C20N6HC

0 m (0 ft) 15 °C (60 °F)

NOTICE

Derating guidelines: This product's output power is limited by factors such

as BTU content of fuel, ambient temperature, altitude, humidity, engine

condition, etc. The derating guidelines are based on properly maintained

product, using the appropriate fuel. Derate values are based on expected

engine power changes from elevation and temperatures listed.

TABLE 8. ALTERNATOR SPECIFICATIONS (ALL MODELS)

Type Specification

Design Rotating field

Poles 2

3.5% per

300 m

(1000 ft)

1% per

5.5 °C (10 °F)

RPM 3600

Voltage 240

Hz 60

15A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

2. Introduction 12-2016

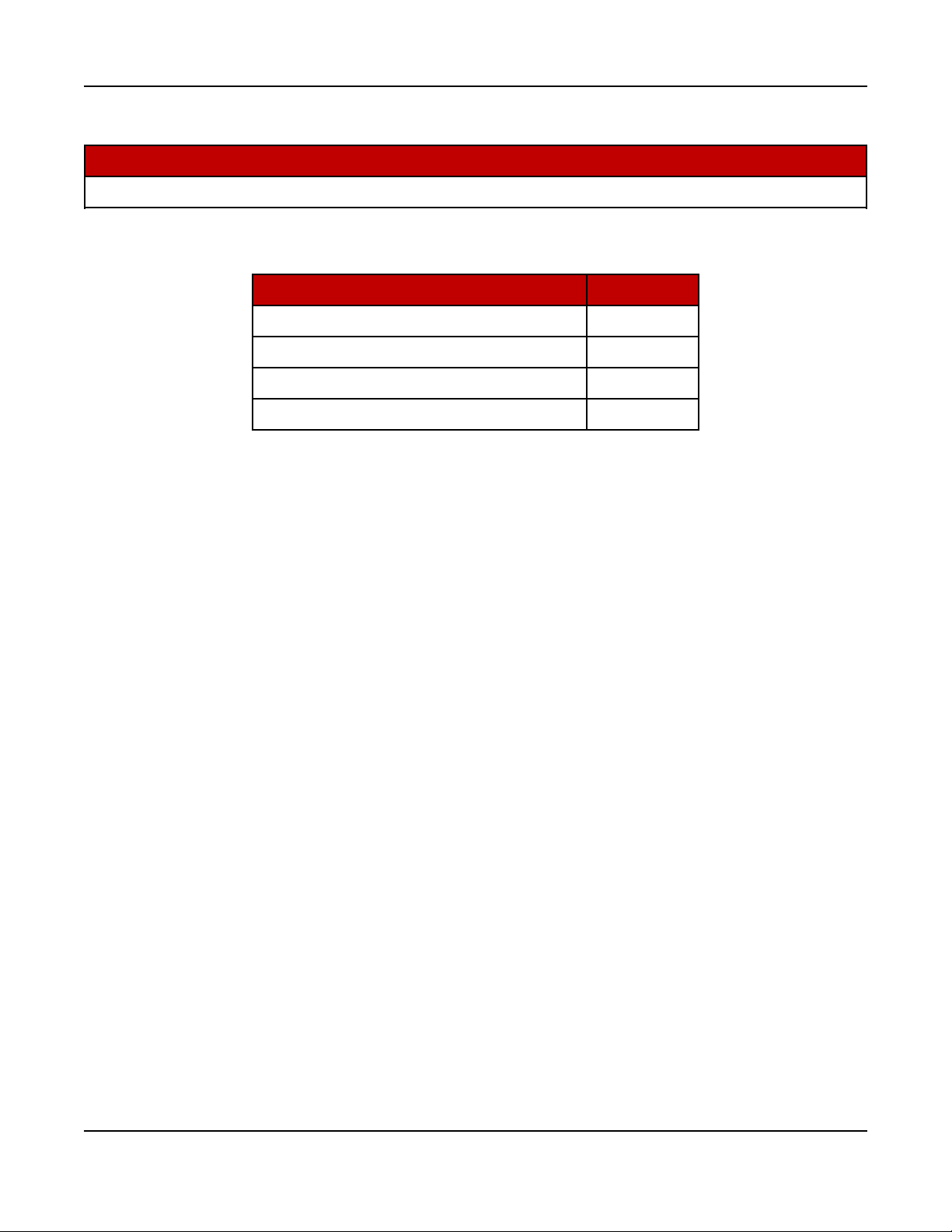

TABLE 9. CONTROL SPECIFICATIONS (ALL MODELS)

Control

Integrated Microprocessor-Based Engine, Alternator, Transfer Switch Controller

TABLE 10. DC SYSTEM SPECIFICATIONS (ALL MODELS)

Type Value

Nominal Battery Voltage 12 VDC

Battery Group 51 R

Battery Type Lead Acid

Minimum Cold Crank Amps (CCA) 450

16 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3 Pre-Installation Considerations

3.1 Pre-Installation Considerations Introduction

WARNING

The installer is responsible for complying with all applicable installation

codes and safety requirements. See the Installation Codes and Standards for

Safety section of this manual for more information.

The following sections create a step-by-step overview of a typical generator set

installation. Review these sections to become familiar with specific procedures and

important safety before beginning the installation.

NOTICE

For information on tools and materials, see the Required Items for

Installation section. For information on locating the generator set, see the

Installation section. For codes and standards, see the Installation Codes

and Standards for Safety section. For specifications, see the Model

Specification section.

Areas of consideration:

• Location of the generator set: this is one of the first decisions to be made, as it

affects all other aspects of the installation, such as:

◦ Length of electric wiring

◦ Length of gas lines (natural gas or propane - must be inspected by the gas

utility inspectors and building inspectors)

◦ Site preparation:

▪ Access to the site

▪ Trenches

▪ Site preparation materials needed

• Fuel supply pressure

• Automatic transfer switch location and connections

• Tools and materials required

• Minimum distance from the propane tank fill:

◦ Verify the legal minimum distance with local code officials.

◦ Verify the minimum distance from the service pressure regulator to the

generator set.

17A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations 12-2016

◦ Verify any minimum clearance requirements to the generator set that the

gas supplier or equipment supplier may have.

• Accessories required (if any) for the customer's application (utility power is

required at the generator set for the battery charger and may be required for

the heaters; make plans accordingly)

NOTICE

Depending on the locality and use of the generator set, it may be necessary

to obtain an air quality emissions permit before installation begins. Check

with local pollution control or air quality authority to determine permit

requirements.

3.2 Installation Codes and Standards for Safety

NOTICE

The generator set installer bears sole responsibility for following all

applicable local codes and regulations.

The following list of codes and standards may apply to the installation and operation

of the generator set. This list is for reference only and not intended to be inclusive of

all applicable codes and standards. The address of each agency is listed so that

copies of the codes may be obtained for reference. Installation codes and

recommendations are subject to change, and may vary by location or over time.

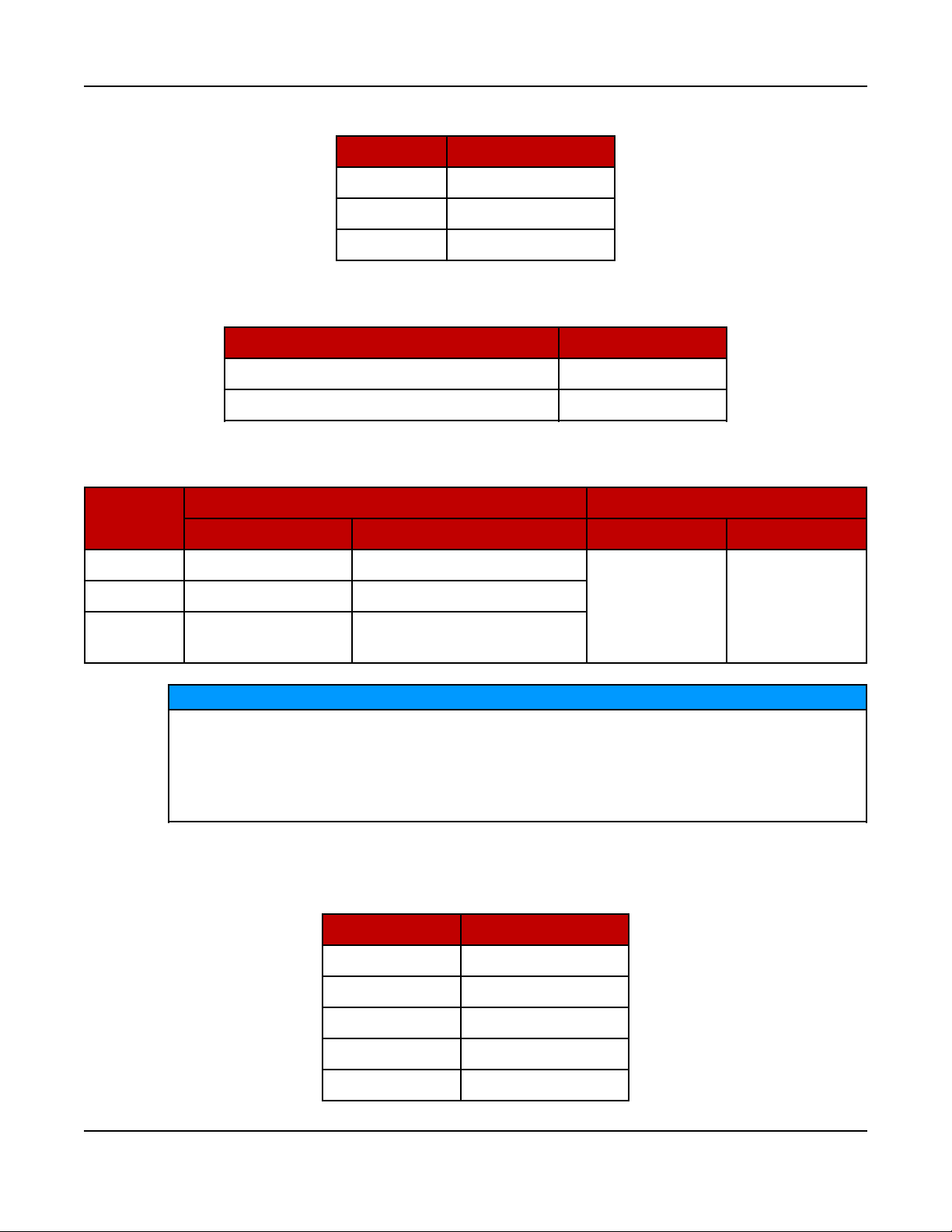

TABLE 11. INSTALLATION CODES AND STANDARDS FOR SAFETY

RECOMMENDATIONS

Code or Standard Organization

NFPA 37 - Installation and Use of Stationary

Combustion Engines and Gas Turbines

NFPA 54 - National Fuel Gas Code

NFPA 58 - Storage and Handling of Liquefied

Petroleum Gases

NFPA 70 - National Electrical Code

CSA Electrical Bulletin

CSA 22.1 Canadian Electrical Code

CSA B149

CSA C22.2 No. 100

CSA C22.2 No. 14

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02210

Canadian Standards Association

Housing and Construction Materials

Section

178 Rexdale Blvd.

Rexdale, Ontario, Canada M9Q 1R3

18 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations12-2016

Code or Standard Organization

California Administrative Code - Title 25 Chapter 3 State of California

Documents Section

P.O. Box 1015

North Highlands, CA 95660

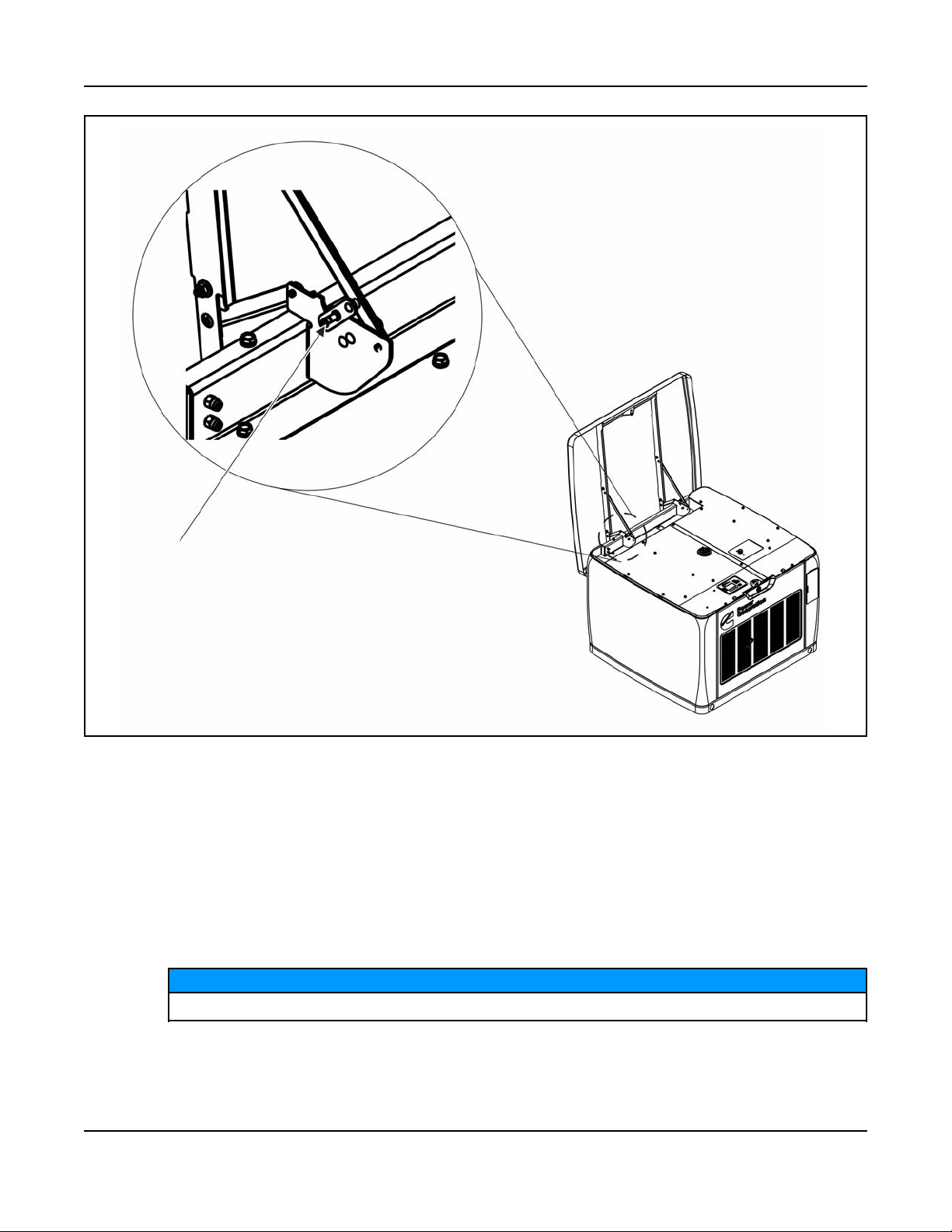

Operating the Generator Set Cover Safely

To configure the local display or access the generator set, you will need to lift the

cover (lid). The cover of the generator set is designed to latch securely into the "up"

position to prevent accidental closure.

• To open: Lift the cover until the hinge pin drops into the hinge pin slot. Test

that the cover is secure by gently pressing down on the cover.

• To close: Lift up on the cover while pressing upward on the hinge pin and slide

the pin upwards out of the hinge pin slot. Carefully push the cover downward

and let go of the hinge pin allowing it to ride along the hinge until the cover is

closed.

19A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations 12-2016

FIGURE 1. HINGE LOCATION

3.3 Required Items for Installation

Tools and materials are used for the installation of this generator set. These items

are identified in the following sections. Please refer to local codes and standards,

because they may affect the materials required.

Materials Required

NOTICE

Refer to local codes and standards, which may affect material requirements.

20 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations12-2016

NOTICE

A UL-listed grounding electrode terminal within its ratings and suitable for

the application must be installed and labeled “Grounding Electrode

Terminal”.

NOTICE

Class 1 wiring methods must be used for connecting the generator set.

TABLE 12. MATERIALS REQUIRED

Requirement Specification

Electrical Materials

Code compliant AC power wires Four (L1, L2, N and Gnd)

For accessories (alternator heater, oil heater, battery heater,

and/or regulator heater) (if equipped)

Code compliant 20 A, 120

VAC, GFCI protected circuit,

copper wire only

RA switches only: Control wires from the generator set to the

Four DC wires

transfer switch

Ethernet cable for Internet installation (as required) Cat 5, Cat 5e or Cat 6

All AC and DC wire and cable ratings Must be 75 °C minimum with

600 V minimum insulation,

stranded copper, rated for wet

1

Wire sizes (for all DC customer connections): Under 1000 ft

locations.

18-14 AWG

wire length

Conduit Code compliant for all wires

Mounting Materials

Bolts or anchor assemblies Two base tie-down

Fuel System Materials

Fuel line Flexible

Pipe thread sealant UL listed

Fuel service pressure regulator (as required) -Manual fuel shut-off at generator set ahead of automatic

--

valves on generator set fuel system

Remote Display Materials (if Applicable)

Remote display --

21A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations 12-2016

Requirement Specification

Hardware, Cummins

provided:

Pigtail harnesses Two (one for local display and

one for remote display); 5wire (RS485-A2, RS485-B2,

B+, WAKEUP and B-), 1 ft

long each

Hardware, customer provided: Intermediate wires of required

Five wires, 600V insulation

length to connect to the pigtail

harnesses using splices

provided in the remote display

kit

Wire sizes (RS485-A2,

Under 1000 ft wire length 20-14 AWG

RS485-B2, B+, WAKEUP):

Wire sizes (B+ and B-): Under 100 ft wire length 18 AWG

Under 200 ft wire length 16 AWG

Under 300 ft wire length 14 AWG

Hardware, Miscellaneous If wires can be concealed in a

wall cavity:

If wires cannot be concealed

in a wall cavity:

3 wall anchors and screws

(number 6 or number 8)

3 wall anchors and screws

(number 6 or number 8),

standoffs, and conduit or wire

raceway

1

300V insulation is acceptable for Ethernet and DC cables if routed in a separate conduit

from AC wiring.

2

Use twisted pair wires for RS485-A and RS485-B wires.

1, 2

Tools Required

Use appropriate lifting techniques to position the generator set in place.

Transfer Switch Requirements

A transfer switch must be a part of every generator set installation. Transfer

switches transfer loads to the generator set during power outages.

NOTICE

Cummins offers a variety of transfer switches, including residential and light

commercial options.

22 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations12-2016

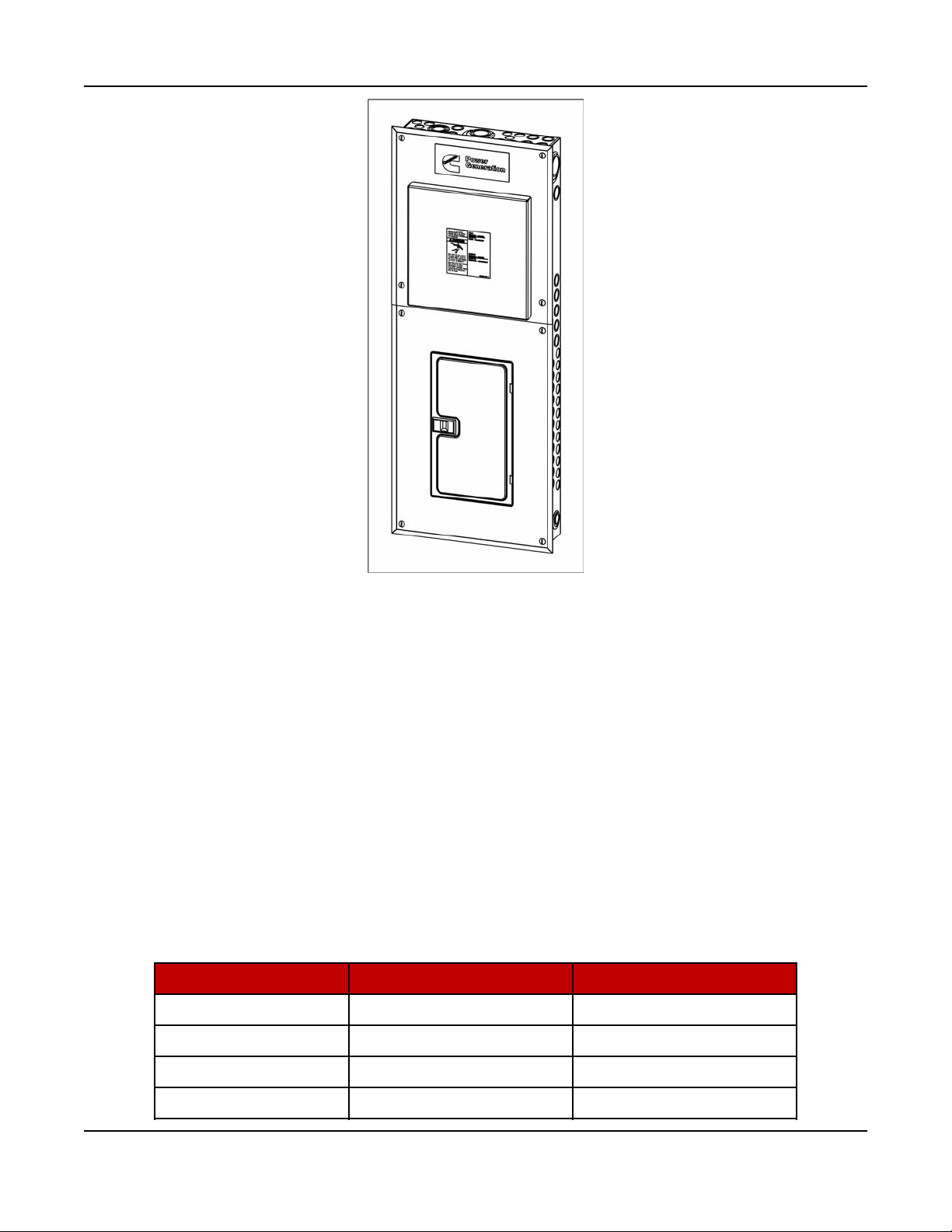

FIGURE 2. CUMMINS AUTOMATIC TRANSFER SWITCH (ATS)

Before beginning the installation of the transfer switch, verify that the unit was

correctly selected. Check the following features:

• Specifications (voltage, amperage, frequency, poles, and phases)

• Enclosure (indoor vs. outdoor)

• Model

Cummins recommends that any RA series transfer switch be used with these

generator sets. Refer to the appropriate RA series ATS owner manual for more

detailed information.

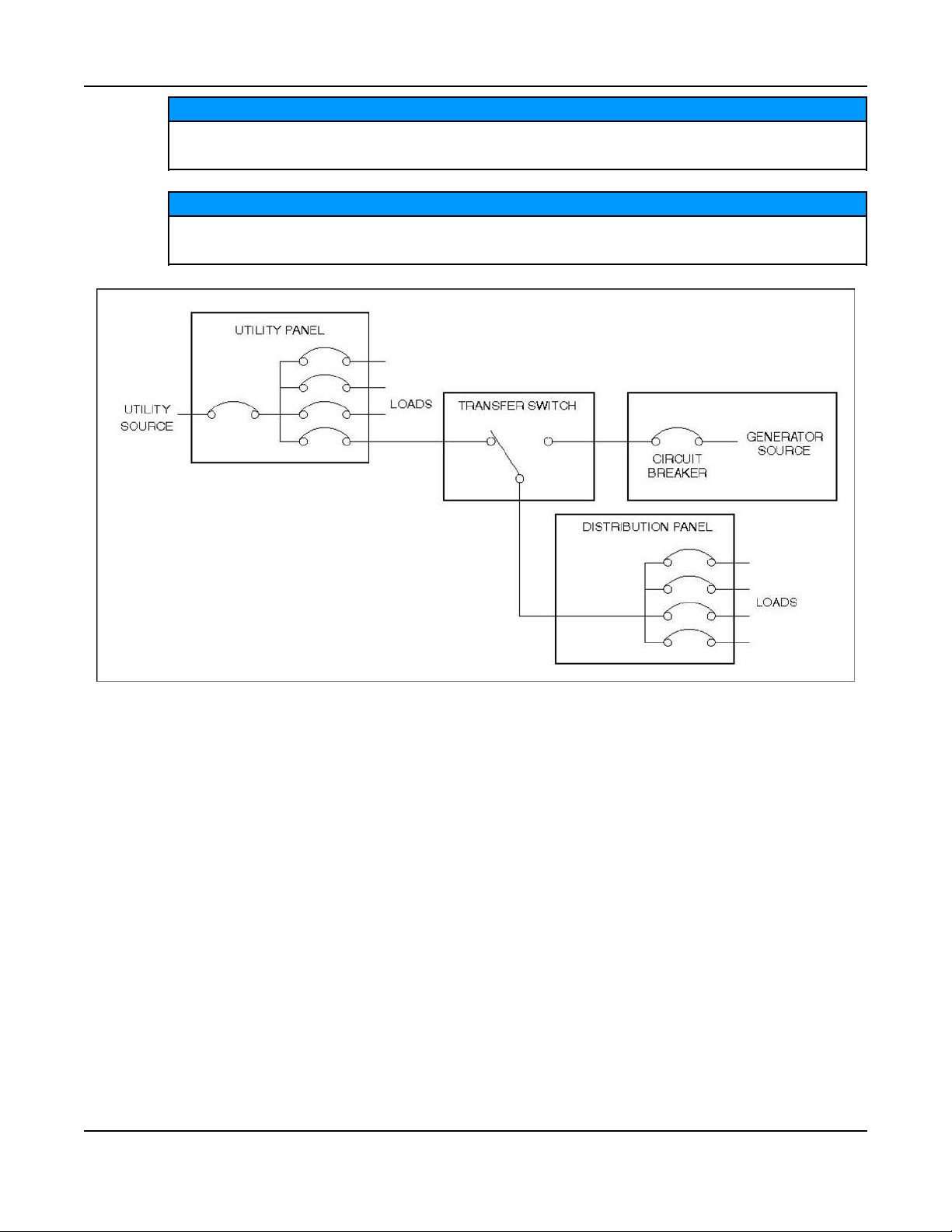

Choosing a Transfer Switch

This section includes block diagrams showing partial or full load coverage for the

following Cummins UL 1008 listed transfer switches:

TABLE 13. CUMMINS TRANSFER SWITCH MODELS

Model Non-Service Entrance Service Entrance

RA 100A ■ ■

RA 200A ■ ■

RA 400A ■ ■

RA112L1 ■

23A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations 12-2016

NOTICE

These generator sets can be used with either service entrance transfer

switches or non-service entrance transfer switches.

NOTICE

If the load exceeds the generator set rating, it may be necessary to use

Cummins’ load management kit (A051C329).

FIGURE 3. TRANSFER SWITCH CONNECTIONS FOR PARTIAL COVERAGE LOAD

24 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations12-2016

FIGURE 4. TRANSFER SWITCH CONNECTIONS FOR FULL COVERAGE LOAD

Loose Parts Shipped with the Generator Set

The following loose parts are shipped with the generator set:

• Two enclosure keys

• Generator set mounting spacers

• Circuit breaker cover and screw

• Chassis plugs

• Transfer switch TB4 jumper

NOTICE

This jumper must be installed in the RA series transfer switch according

to the interconnect diagram in the RA series transfer switch owner

manual.

• Literature (Operator Manual, Quick Start Operator Guide, Installation Manual,

Quick Start Installation Guide, Health and Safety Manual, and Warranty

Statements)

25A053X172 (Issue 6) Copyright © 2016 Cummins Inc.

3. Pre-Installation Considerations 12-2016

This page is intentionally blank.

26 A053X172 (Issue 6)Copyright © 2016 Cummins Inc.

Loading...

Loading...