CUMMINS C1750 N5C, C1400 N5C, C1200 N5C, C1160 N5C, C1000 N6C Owner's Manual

...

OwnersOwners ManualManual

Generator Set

QSK60G and QSV91 Engines with PowerCommand

3.3 Control

C995 N5C

C1160 N5C

C1200 N5C

C1400 N5C

C1540 N5C

C1750 N5C

C2000 N5C

C1000 N6C

C1100 N6C

®

C1250 N6C

C1400 N6C

C1540 N6C

C1750 N6C

C2000 N6C

C1000 N6

C1250 N6

C1350 N6

C1700 N6

English

Original Instructions

3-2016 0908-0209 (Issue 6)

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS.................................................................................. 1

1.1 Warning, Caution, and Note Styles Used in This Manual ................................................ 1

1.2 General Information........................................................................................................... 1

1.2.1 General Safety Precautions.................................................................................... 1

1.3 Generator Set Safety Code............................................................................................... 4

1.3.1 Moving Parts Can Cause Severe Personal Injury or Death................................... 4

1.3.2 Positioning of Generator Set - Open Sets .............................................................. 4

1.3.3 Moving the Generator Set ...................................................................................... 4

1.3.4 Alternator Operating Areas..................................................................................... 6

1.4 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death ............ 6

1.4.1 AC Supply and Isolation ......................................................................................... 7

1.4.2 Medium Voltage Equipment (601 V to 15 kV - North America).............................. 7

1.5 Fuel and Fumes Are Flammable ....................................................................................... 7

1.5.1 Natural Gas ............................................................................................................ 7

1.5.2 Spillage.................................................................................................................. 8

1.5.3 Fluid Containment ................................................................................................. 8

1.5.4 Do Not Operate in Flammable and Explosive Environments ................................. 8

1.6 Exhaust Gases Are Deadly ............................................................................................... 8

1.6.1 Exhaust Precautions.............................................................................................. 9

1.7 Decommissioning and Disassembly.................................................................................. 9

2. INTRODUCTION .................................................................................................................... 11

2.1 About This Manual .......................................................................................................... 11

2.2 Schedule of Abbreviations............................................................................................... 11

2.3 Related Literature ............................................................................................................ 13

2.3.1 Further Information - Literature............................................................................. 13

2.4 After Sales Services ........................................................................................................ 14

2.4.1 Maintenance........................................................................................................ 14

2.4.2 Warranty ............................................................................................................... 14

2.4.3 How to Obtain Service ......................................................................................... 14

2.5 Project Details ................................................................................................................. 15

3. SYSTEM OVERVIEW............................................................................................................. 17

3.1 Generator Set Identification............................................................................................. 17

3.1.1 Generator Set Rating............................................................................................ 17

3.1.2 Nameplate - Open Generator Set ........................................................................ 17

3.2 Generator Set Components ............................................................................................ 17

3.3 Air Cleaner....................................................................................................................... 19

3.3.1 Air Cleaner System............................................................................................... 19

3.4 Coolant Specification....................................................................................................... 20

3.5 Gas Train......................................................................................................................... 21

3.6 Heaters ............................................................................................................................ 21

3.6.1 Heater Supply and Isolation ................................................................................. 21

3.7 Mains (Utility) Powered Battery Charger ......................................................................... 22

3.8 Oil Specification............................................................................................................... 22

3.8.1 Low BTU Gas Engines ......................................................................................... 23

i0908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

Table of Contents 3-2016

3.9 Sensors ........................................................................................................................... 24

3.10 System Options ............................................................................................................. 24

3.10.1 PowerCommand Universal Annunciator............................................................. 24

3.10.2 Mains (Utility) Powered Battery Charger ............................................................ 25

3.10.3 Coolant Heater ................................................................................................... 26

4. CONTROL SYSTEM - POWERCOMMAND 3.3 .................................................................... 27

4.1 Control System Description............................................................................................. 27

4.1.1 Control System Panel........................................................................................... 27

4.1.2 Operating Modes .................................................................................................. 28

4.1.3 Power On and Sleep Modes ................................................................................ 30

4.2 Operator Panel ................................................................................................................ 30

4.2.1 Selection Buttons.................................................................................................. 31

4.2.2 Default Settings .................................................................................................... 32

4.2.3 Lamp Indicators .................................................................................................... 32

4.2.4 Lamp (LED) Test Button ...................................................................................... 32

4.2.5 Reset Button ........................................................................................................ 32

4.2.6 CB Open Button .................................................................................................. 32

4.2.7 CB Closed Button ................................................................................................ 33

4.2.8 Graphical Display and Buttons ............................................................................. 33

4.3 Operator Panel - Initial Operator Menu ........................................................................... 35

4.3.1 Initial Menu Data................................................................................................... 35

4.4 Operator Panel - Generator Set Data Operator Menu .................................................... 37

4.4.1 Generator Set Data .............................................................................................. 37

4.5 Operator Panel - Engine Data Operator Menu................................................................ 39

4.5.1 Engine Data.......................................................................................................... 39

4.5.2 History/About Menu .............................................................................................. 41

4.6 Operator Panel - Alternator Data Operator Menu ........................................................... 43

4.6.1 Alternator Data ..................................................................................................... 44

4.7 Operator Panel - Faults and Warnings Menus................................................................ 46

4.7.1 Fault Menu............................................................................................................ 46

4.7.2 Fault Messages .................................................................................................... 48

4.7.3 Fault Acknowledgement ....................................................................................... 48

4.7.4 Warning Fault Menu ............................................................................................. 48

4.7.5 Faults History Data Operator Menu...................................................................... 50

4.8 Operator Panel - Adjust Menu......................................................................................... 52

4.9 Operator Panel - Genset Setup Data Operator Menu..................................................... 53

4.10 Operator Panel - Paralleling Status Menu..................................................................... 54

4.11 Operator Panel - Paralleling/Basic Setup Menu............................................................ 61

4.12 Selecting Operating Modes ........................................................................................... 64

4.12.1 Passwords and Mode Change Access............................................................... 64

4.12.2 Selecting Manual Run Mode .............................................................................. 65

4.12.3 Selecting Auto Mode .......................................................................................... 66

4.12.4 Selecting Off Mode............................................................................................. 67

5. OPERATION - POWERCOMMAND 3.3................................................................................. 69

5.1 Safety .............................................................................................................................. 69

5.2 Introduction ...................................................................................................................... 69

5.3 Maintenance .................................................................................................................... 69

5.4 Operating Recommendations.......................................................................................... 70

Copyright © 2016 Cummins Inc.

ii 0908-0209 (Issue 6)

Table of Contents3-2016

5.4.1 Running-in ............................................................................................................ 70

5.4.2 No Load Operation ............................................................................................... 70

5.4.3 Exercise Period .................................................................................................... 70

5.4.4 Low Operating Temperatures............................................................................... 70

5.4.5 High Operating Temperatures.............................................................................. 70

5.4.6 Operating Conditions............................................................................................ 70

5.4.7 De-Rating Factors ............................................................................................... 72

5.5 Generator Set Operation ................................................................................................. 72

5.5.1 Sequence of Operation......................................................................................... 72

5.6 Starting ............................................................................................................................ 73

5.6.1 Operator’s Pre-start Checks ................................................................................. 73

5.6.2 Starting at Operator Panel (Manual Run Mode)................................................... 74

5.6.3 Starting from Remote Location (Auto Mode)........................................................ 75

5.6.4 Cold Starting with Loads ...................................................................................... 76

5.7 Stopping .......................................................................................................................... 76

5.7.1 Stopping at Operator Panel (Manual Mode)......................................................... 77

5.7.2 Stopping from Operator Panel (Auto Mode) ......................................................... 77

5.7.3 Stopping from Remote Location (Auto Mode)...................................................... 77

5.7.4 Emergency Stop (Code 1433 or 1434) ............................................................... 78

5.8 Paralleling Operation ....................................................................................................... 79

5.8.1 Speed and Voltage Matching ............................................................................... 79

5.8.2 Operation When in Parallel ................................................................................. 79

5.8.3 Generator Set Application Type ........................................................................... 79

5.8.4 Standalone Application......................................................................................... 80

5.8.5 Synchronize Only ................................................................................................. 81

5.8.6 Isolated Bus Only ................................................................................................. 82

5.8.7 Power Transfer Control ........................................................................................ 83

5.8.8 Conditions for Each Paralleling State................................................................... 87

6. MAINTENANCE...................................................................................................................... 97

6.1 Locking the Generator Set Out of Service ...................................................................... 98

6.1.1 Immobilizing for Safe Working.............................................................................. 98

6.2 Periodic Maintenance ...................................................................................................... 99

6.2.1 Periodic Maintenance Schedule........................................................................... 99

6.3 Maintenance Procedures - Daily ................................................................................... 100

6.3.1 General Information............................................................................................ 101

6.3.2 Engine Operation Report................................................................................... 101

6.4 Air Intake System .......................................................................................................... 101

6.4.1 Air Cleaner Service Indicator.............................................................................. 102

6.4.2 Air Cleaner System............................................................................................. 102

6.4.3 Air Cleaner System............................................................................................. 103

6.4.4 Air Cleaner System............................................................................................. 103

6.4.5 Air Cleaner Element Replacement ..................................................................... 104

6.5 Batteries ........................................................................................................................ 105

6.5.1 Storage ............................................................................................................... 105

6.5.2 Safety Precautions ............................................................................................. 105

6.5.3 Battery Maintenance........................................................................................... 106

6.5.4 Electrolyte - Specific Gravity and Temperature.................................................. 108

6.5.5 Electrolyte Levels and Bench Charging Rates................................................... 110

6.5.6 Battery Fault Finding .......................................................................................... 112

iii0908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

Table of Contents 3-2016

6.6 Cooling System ............................................................................................................. 113

6.6.1 Water Quality Check........................................................................................... 113

6.6.2 Radiator - Check................................................................................................. 113

6.6.3 Cooling Fan - Inspection .................................................................................... 114

6.7 DC Electrical System..................................................................................................... 114

6.8 Engine Oil ...................................................................................................................... 115

6.8.1 Oil Maintainer - Level Check and Fill ................................................................. 115

6.8.2 Crankcase Ventilation Re-circulator ................................................................... 116

6.9 Exhaust System............................................................................................................. 117

6.10 Fuel System................................................................................................................. 118

6.10.1 Fuel consumption ............................................................................................. 118

6.10.2 Methane Index.................................................................................................. 118

6.10.3 De-rate.............................................................................................................. 118

6.11 Gearbox Inspection ..................................................................................................... 119

6.12 Generator Set Output - AC Electric System ................................................................ 119

6.13 Hoses and Fuel Lines - Check .................................................................................... 120

6.14 Lubricating Oil Analysis ............................................................................................... 120

6.15 Storage and Lay-up of Generator Set ......................................................................... 121

7. TROUBLESHOOTING.......................................................................................................... 123

7.1 Control System .............................................................................................................. 123

7.2 Safety Considerations ................................................................................................... 123

7.3 Fault Finding.................................................................................................................. 124

7.4 Status Indicators - PowerCommand 3.3........................................................................ 125

7.4.1 Not in Auto ......................................................................................................... 125

7.4.2 Remote Start ..................................................................................................... 125

7.4.3 Warning ............................................................................................................. 125

7.4.4 Shutdown Status ............................................................................................... 125

7.4.5 Generator Set Running Lamp ........................................................................... 125

7.5 Fault/Status Codes - PowerCommand 3.3.................................................................... 125

7.5.1 Fault Messages .................................................................................................. 126

7.5.2 Fault Acknowledgement ..................................................................................... 126

7.5.3 Fault Codes - PowerCommand 3.3 .................................................................... 126

7.5.4 Troubleshooting Procedure for Fault Codes ...................................................... 161

7.6 Line Circuit Breaker....................................................................................................... 165

8. BATTERY CHARGER .......................................................................................................... 167

8.1 Mains (Utility) Powered Battery Charger - Wall-Mounted (24 VDC - 30 Amp) ............. 167

8.1.1 Boost................................................................................................................... 167

8.1.2 Specifications - 30 Amp...................................................................................... 168

8.2 Circuits........................................................................................................................... 168

9. MANUFACTURING FACILITIES .......................................................................................... 169

Copyright © 2016 Cummins Inc.

iv 0908-0209 (Issue 6)

1 Important Safety Instructions

Save these instructions. This manual contains important instructions that should be followed during

installation and maintenance of the generator set.

Safe and efficient operation can be achieved only if the equipment is properly operated and

maintained. Many accidents are caused by failure to follow fundamental rules and precautions.

1.1 Warning, Caution, and Note Styles Used in This Manual

The following safety styles and symbols found throughout this manual indicate potentially hazardous

conditions to the operator, service personnel, or equipment.

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

1.2 General Information

This manual should form part of the documentation package supplied by Cummins Power Generation

with specific generator sets. In the event that this manual has been supplied in isolation please

contact your authorized distributor.

NOTICE

It is in the operator’s interest to read and understand all warnings and cautions contained

within the documentation relevant to the generator set, its operation and daily maintenance.

1.2.1 General Safety Precautions

WARNING

Hot Pressurized Liquid

Contact with hot liquid can cause severe burns.

Do not open the pressure cap while the engine is running. Let the engine cool down before

removing the cap. Turn the cap slowly and do not open it fully until the pressure has been

relieved.

10908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 3-2016

WARNING

Moving Parts

Moving parts can cause severe personal injury.

Use extreme caution around moving parts. All guards must be properly fastened to prevent

unintended contact.

WARNING

Toxic Hazard

Used engine oils have been identified by some state and federal agencies to cause cancer or

reproductive toxicity.

Do not ingest, breathe the fumes, or contact used oil when checking or changing engine oil.

Wear protective gloves and face guard.

WARNING

Electrical Generating Equipment

Incorrect operation can cause severe personal injury or death.

Do not operate equipment when fatigued, or after consuming any alcohol or drug.

WARNING

Toxic Gases

Substances in exhaust gases have been identified by some state and federal agencies to

cause cancer or reproductive toxicity.

Do not breathe in or come into contact with exhaust gases.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause severe burns or

death.

Do not store fuel, cleaners, oil, etc., near the generator set.

WARNING

High Noise Level

Generator sets in operation emit noise, which can cause hearing damage.

Wear appropriate ear protection at all times.

WARNING

Hot Surfaces

Contact with hot surfaces can cause severe burns.

Wear appropriate PPE when working on hot equipment and avoid contact with hot surfaces.

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death

Make sure that only suitably trained and experienced service personnel perform electrical

and/or mechanical service.

Copyright © 2016 Cummins Inc.

WARNING

2 0908-0209 (Issue 6)

1. Important Safety Instructions3-2016

WARNING

Toxic Hazard

Ethylene glycol, used as an engine coolant, is toxic to humans and animals.

Wear appropriate PPE. Clean up coolant spills and dispose of used coolant in accordance

with local environmental regulations.

WARNING

Combustible Liquid

Ignition of combustible liquids is a fire or explosion hazard which can cause severe burns or

death.

Do not use combustible liquids like ether.

WARNING

Automated Machinery

Accidental or remote starting of the generator set can cause severe personal injury or death.

Isolate all auxiliary supplies and use an insulated wrench to disconnect the starting battery

cables (negative [–] first).

WARNING

Fire Hazard

Materials drawn into the generator set are a fire hazard. Fire can cause severe burns or death.

Make sure the generator set is mounted in a manner to prevent combustible materials from

accumulating under the unit.

WARNING

Fire Hazard

Accumulated grease and oil are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from obstructions. Repair oil

leaks promptly.

WARNING

Fire Hazard

Materials drawn into the generator set are a fire hazard. Fire can cause severe burns or death.

Keep the generator set and the surrounding area clean and free from obstructions.

NOTICE

Keep multi-class ABC fire extinguishers handy. Class A fires involve ordinary combustible

materials such as wood and cloth. Class B fires involve combustible and flammable liquid

fuels and gaseous fuels. Class C fires involve live electrical equipment. (Refer to NFPA No. 10

in applicable region.)

NOTICE

Before performing maintenance and service procedures on enclosed generator sets, make

sure the service access doors are secured open.

30908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 3-2016

NOTICE

Stepping on the generator set can cause parts to bend or break, leading to electrical shorts,

or to fuel, coolant, or exhaust leaks. Do not step on the generator set when entering or

leaving the generator set room.

1.3 Generator Set Safety Code

Before operating the generator set, read the manuals and become familiar with them and the

equipment. Safe and efficient operation can be achieved only if the equipment is properly operated

and maintained. Many accidents are caused by failure to follow fundamental rules and precautions.

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death.

Read and follow all Safety Precautions, Warnings, and Cautions throughout this manual and

the documentation supplied with the generator set.

1.3.1 Moving Parts Can Cause Severe Personal Injury or Death

• Keep hands, clothing, and jewelry away from moving parts.

• Before starting work on the generator set, disconnect the battery charger from its AC source,

then disconnect the starting batteries using an insulated wrench, negative (–) cable first. This will

prevent accidental starting.

• Make sure that fasteners on the generator set are secure. Tighten supports and clamps; keep

guards in position over fans, drive belts, etc.

• Do not wear loose clothing or jewelry in the vicinity of moving parts or while working on electrical

equipment. Loose clothing and jewelry can become caught in moving parts.

• If any adjustments must be made while the unit is running, use extreme caution around hot

manifolds, moving parts, etc.

1.3.2 Positioning of Generator Set - Open Sets

The area for positioning the set should be adequate and level, and the area immediately around the

set must be free of any flammable material.

1.3.3 Moving the Generator Set

WARNING

Heavy Load

Incorrect lifting or repositioning can cause severe personal injury or death.

Make sure that only suitably trained and experienced personnel transport and handle

generator sets and associated components.

Heavy Load

Incorrect lifting or repositioning can cause severe personal injury or death.

Do not lift the generator set by attaching to the engine or alternator lifting points. Do not

stand under or near the generator set when lifting.

Copyright © 2016 Cummins Inc.

WARNING

4 0908-0209 (Issue 6)

1. Important Safety Instructions3-2016

WARNING

Mechanical Hazard

Failed components may be ejected or operate incorrectly which can cause severe personal

injury or death.

Do not climb the generator set; this may damage critical parts.

NOTICE

Access or service doors must be closed and locked before repositioning, and they must

remain locked during transportation and siting.

It is essential that there are sufficient trained and experienced personnel in attendance to make sure

the lifting and transportation of the generator set is undertaken in a safe and appropriate manner, and

in accordance to local guidelines and legislation.

Before lifting the generator set, lifting points, angle of slings, mass, access to intended site, and the

distance of movement should all be taken into account when organizing a suitable crane/hoist. Consult

the generator set information supplied with the generator set for details of dimensions and mass.

• Make sure that the crane operating area is able to support the mass of the crane and the

generator set.

• Make sure the equipment used for lifting is adequate to support the weight of the generator set.

• Attach the lifting device to the lifting points only using suitable shackles, chains, and spreader

bars.

• Slowly tighten the slings. Inspect the lifting attachments before commencing a full lift to make

sure they are attached correctly.

• Hoist the generator set slowly using the indicated lifting points only.

• Guide the generator set with ropes at a safe distance to prevent uncontrolled rotation when

positioning the generator set.

• Move the generator set to the desired location and place in position, bringing the set down

slowly.

• Loosen the slings; unhook and remove the shackles.

1.3.3.1 Positioning a Generator Set Using a Forklift Truck

WARNING

Heavy Load

Incorrect lifting or repositioning can cause severe personal injury or death.

Make sure that only suitably trained and experienced personnel transport and handle

generator sets and associated components.

WARNING

Heavy Load

Incorrect lifting or repositioning can cause severe personal injury or death.

Do not attempt to lift a generator set with an undersized forklift truck.

NOTICE

Access or service doors must be closed and locked before repositioning, and they must

remain locked during transportation and siting.

When using a forklift truck to transport/position the generator set, the dimensions, mass, and route

must be taken into account when selecting an appropriate lifting truck.

50908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 3-2016

It is essential that there are sufficient trained and experienced personnel in attendance to make sure

the lifting and transportation of the generator set is undertaken in a safe and appropriate manner.

1. Insert the arms of the forklift into the forklift pockets. Make sure the generator set completely

rests on the forklift arms.

2. Lift and handle the equipment slowly.

3. Lower the generator set in position.

1.3.4 Alternator Operating Areas

WARNING

Ejected Debris

Debris ejected during catastrophic failure can cause serious injury or death by impact,

severing or stabbing.

To prevent injury:

• Keep away from the air inlet and air outlet when the alternator is running.

• Do not put operator controls near the air inlet and air outlet.

• Do not cause overheating by running the alternator outside rating plate parameters.

• Do not overload the alternator.

• Do not run an alternator with excessive vibration.

• Do not synchronize parallel alternators outside the specified parameters.

Always wear suitable PPE when working in the hatched areas shown in the diagram or directly in-line

with any air inlet/outlet.

Make sure this consideration is captured in your risk assessment.

1.4 Electrical Shocks and Arc Flashes Can Cause Severe Personal Injury or Death

• Only qualified service personnel certified and authorized to work on power circuits should work

on exposed energized power circuits.

• All relevant service material must be available for any electrical work performed by certified

service personnel.

• Exposure to energized power circuits with potentials of 50 VAC or 75 VDC or higher poses a

significant risk of electrical shock and electrical arc flash.

• Refer to standard NFPA 70E, or equivalent safety standards in corresponding regions, for details

of the dangers involved and for safety requirements.

Copyright © 2016 Cummins Inc.

6 0908-0209 (Issue 6)

1. Important Safety Instructions3-2016

1.4.1 AC Supply and Isolation

NOTICE

Local electrical codes and regulations (for example, BS EN 12601:2010 Reciprocating internal

combustion engine driven generating sets) may require the installation of a disconnect

means for the generator set, either on the generator set or where the generator set

conductors enter a facility.

NOTICE

The AC supply must have the correct over current and earth fault protection according to

local electrical codes and regulations. This equipment must be earthed (grounded).

It is the sole responsibility of the customer to provide AC power conductors for connection to load

devices and the means to isolate the AC input to the terminal box; these must comply with local

electrical codes and regulations. Refer to the wiring diagram supplied with the generator set.

The disconnecting device is not provided as part of the generator set, and Cummins Power

Generation accepts no responsibility for providing the means of isolation.

1.4.2 Medium Voltage Equipment (601 V to 15 kV - North America)

• Medium voltage acts differently than low voltage. Special equipment and training is required to

work on or around medium voltage equipment. Operation and maintenance must be done only

by persons trained and experienced to work on such devices. Improper use or procedures will

result in severe personal injury or death.

• Do not work on energized equipment. Unauthorized personnel must not be permitted near

energized equipment. Due to the nature of medium voltage electrical equipment, induced voltage

remains even after the equipment is disconnected from the power source. Plan the time for

maintenance with authorized personnel so that the equipment can be de-energized and safely

grounded.

1.5 Fuel and Fumes Are Flammable

Fire, explosion, and personal injury or death can result from improper practices.

• Do not fill fuel tanks while the engine is running unless the tanks are outside the engine

compartment. Fuel contact with hot engine or exhaust is a potential fire hazard.

• Do not permit any flame, cigarette, pilot light, spark, arcing equipment, or other ignition source

near the generator set or fuel tank.

• Fuel lines must be adequately secured and free of leaks. Fuel connection at the engine should

be made with an approved flexible line. Do not use copper piping on flexible lines as copper will

become brittle if continuously vibrated or repeatedly bent.

• Make sure all fuel supplies have a positive shutoff valve.

• Make sure the battery area has been well-ventilated prior to servicing near it. Lead-acid batteries

emit a highly explosive hydrogen gas that can be ignited by arcing, sparking, smoking, etc.

1.5.1 Natural Gas

Pipeline Natural Gas is lighter than air. If leakage occurs the gas will first accumulate at high levels,

including ceiling voids. Gas detection equipment should be installed at high level to be effective. If

leakage occurs isolate the gas supply, do not operate any equipment (electrical or otherwise) that may

cause a spark or may be a source of ignition, evacuate the building and completely ventilate the area.

Only suitable qualified personnel who are adequately trained to manage natural gas emergencies are

to be allowed near the plant room or generator set(s) in such emergencies.

70908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 3-2016

Non-Pipeline Gas Generator Sets are designated by Cummins, Inc. as Low Btu Generator Sets. NonPipeline Gas classification includes Landfill Gas, Digester Gas, Well Head Gas and Coal Bed

Methane. Non-pipeline gas, depending on its properties, can be lighter than air, neutral, or heavier

than air. If leakage occurs the gas can accumulate either at high level, mid-level or low level. Gas

detection equipment siting is dependant upon the properties of the gas.

Non-pipeline gases may also contain other substances which may be harmful and can cause personal

injury or death. Analysis of the non-pipeline gas available at site should be performed to identify the

gases properties and consistencies.

Shut down the generator set by following the shut down procedure as described in this manual. Fully

shut the gas train shut-off valve(s). Fully shut all external gas supply valves to the generator set. Alert

the emergency services and local gas supplier.

1.5.2 Spillage

Any spillage that occurs during fueling or during oil top-off or oil change must be cleaned up before

starting the generator set.

1.5.3 Fluid Containment

NOTICE

Where spillage containment is not part of a Cummins supply, it is the responsibility of the

installer to provide the necessary containment to prevent contamination of the environment,

especially water courses and sources.

If fluid containment is incorporated into the bedframe, it must be inspected at regular intervals. Any

liquid present should be drained out and disposed of in line with local health and safety regulations.

Failure to perform this action may result in spillage of liquids which could contaminate the surrounding

area.

Any other fluid containment area must also be checked and emptied, as described above.

1.5.4 Do Not Operate in Flammable and Explosive Environments

Flammable vapor can cause an engine to over speed and become difficult to stop, resulting in

possible fire, explosion, severe personal injury, and death. Do not operate a generator set where a

flammable vapor environment can be created, unless the generator set is equipped with an automatic

safety device to block the air intake and stop the engine. The owners and operators of the generator

set are solely responsible for operating the generator set safely. Contact your authorized Cummins

Power Generation distributor for more information.

1.6 Exhaust Gases Are Deadly

• Provide an adequate exhaust system to properly expel discharged gases away from enclosed or

sheltered areas, and areas where individuals are likely to congregate. Visually and audibly

inspect the exhaust system daily for leaks per the maintenance schedule. Make sure that

exhaust manifolds are secured and not warped. Do not use exhaust gases to heat a

compartment.

• Make sure the unit is well ventilated.

Copyright © 2016 Cummins Inc.

8 0908-0209 (Issue 6)

1.6.1 Exhaust Precautions

Hot Exhaust Gases

Contact with hot exhaust gases can cause severe burns.

Wear personal protective equipment when working on equipment.

Hot Surfaces

Contact with hot surfaces can cause severe burns.

Wear appropriate PPE when working on hot equipment and avoid contact with hot surfaces.

Toxic Gases

Inhalation of exhaust gases can cause asphyxiation and death.

Pipe exhaust gas outside and away from windows, doors, or other inlets to buildings. Do not

allow exhaust gas to accumulate in habitable areas.

1. Important Safety Instructions3-2016

WARNING

WARNING

WARNING

WARNING

Fire Hazard

Contaminated insulation is a fire hazard. Fire can cause severe burns or death.

Remove any contaminated insulation and dispose of it in accordance with local regulations.

The exhaust outlet may be sited at the top or bottom of the generator set. Make sure that the exhaust

outlet is not obstructed. Personnel using this equipment must be made aware of the exhaust position.

Position the exhaust away from flammable materials - in the case of exhaust outlets at the bottom,

make sure that vegetation is removed from the vicinity of the exhaust.

The exhaust pipes may have some insulating covers fitted. If these covers become contaminated they

must be replaced before the generator set is run.

To minimize the risk of fire, make sure the following steps are observed:

• Make sure that the engine is allowed to cool thoroughly before performing maintenance or

operation tasks.

• Clean the exhaust pipe thoroughly.

1.7 Decommissioning and Disassembly

NOTICE

Decommissioning and disassembly of the generator set at the end of its working life must

comply with local guidelines and legislation for disposal/recycling of components and

contaminated fluids. This procedure must only be carried out by suitably trained and

experienced service personnel. For more information contact your authorized distributor.

90908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

1. Important Safety Instructions 3-2016

This page is intentionally blank.

Copyright © 2016 Cummins Inc.

10 0908-0209 (Issue 6)

2 Introduction

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or death.

Make sure that only a trained and experienced electrician makes generator set electrical

output connections, in accordance with the installation instructions and all applicable codes.

Electrical Generating Equipment

Faulty electrical generating equipment can cause severe personal injury or death.

Generator sets must be installed, certified, and operated by trained and experienced person

in accordance with the installation instructions and all applicable codes.

2.1 About This Manual

The purpose of this manual is to provide the users with sound, general information. It is for guidance

and assistance with recommendations for correct and safe procedures. Cummins Power Generation

(CPG) cannot accept any liability whatsoever for problems arising as a result of following

recommendations in this manual.

WARNING

WARNING

The information contained within the manual is based on information available at the time of going to

print. In line with Cummins Power Generation policy of continuous development and improvement,

information may change at any time without notice. The users should therefore make sure that before

commencing any work, they have the latest information available. The latest version of this manual is

available on QuickServe Online (https://quickserve.cummins.com).

Users are respectfully advised that, in the interests of good practice and safety, it is their responsibility

to employ competent persons to carry out any installation work. Consult your authorized distributor for

further installation information. It is essential that the utmost care is taken with the application,

installation, and operation of any engine due to their potentially hazardous nature. Careful reference

should also be made to other Cummins Power Generation literature. A generator set must be

operated and maintained properly for safe and reliable operation.

For further assistance, contact your authorized distributor.

2.2 Schedule of Abbreviations

This list is not exhaustive. For example, it does not identify units of measure or acronyms that appear

only in parameters, event/fault names, or part/accessory names.

AmpSentry, INSITE, and InPower are trademarks of Cummins Inc. PowerCommand is a registered

trademark of Cummins Inc.

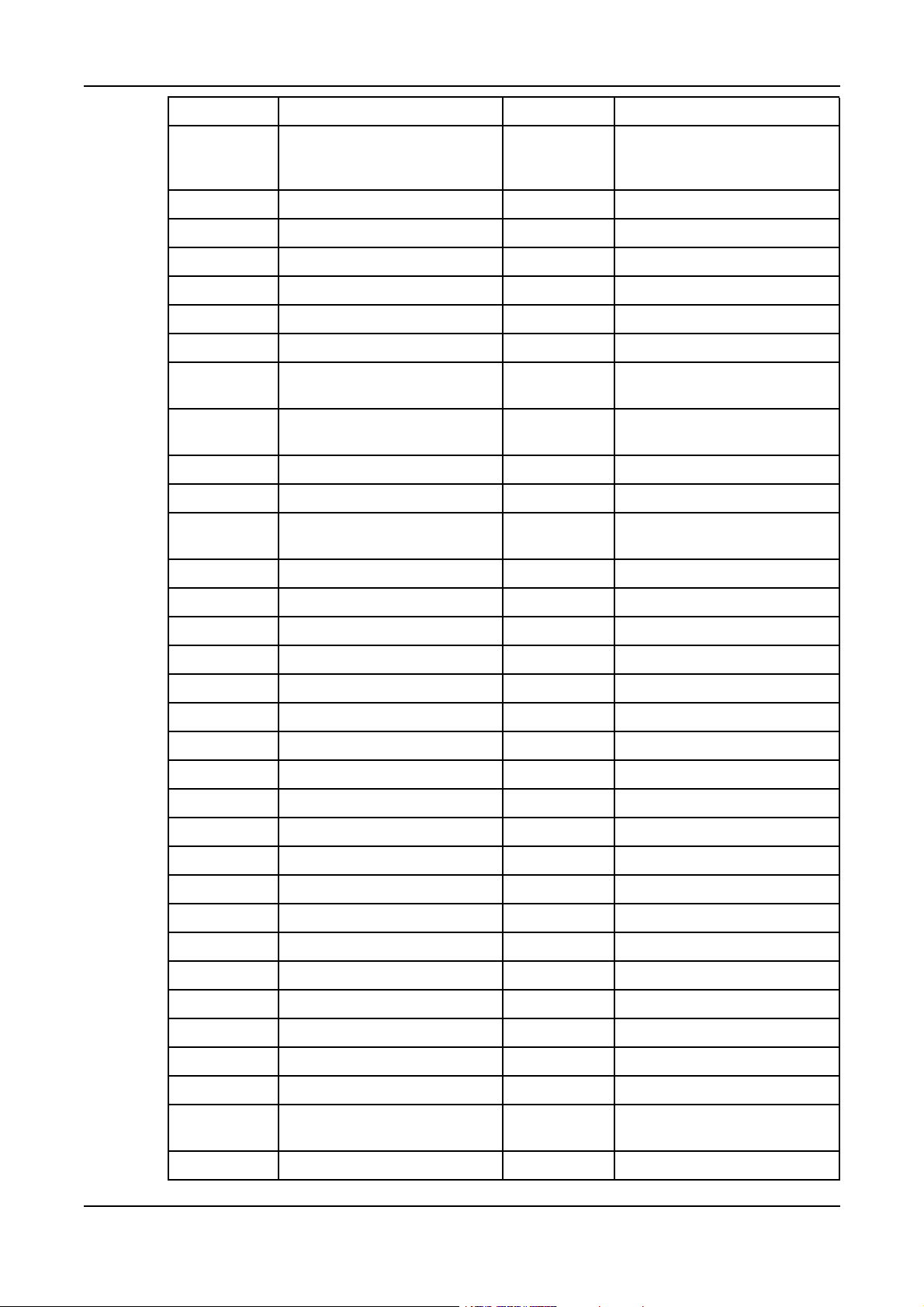

ABBR. DESCRIPTION ABBR. DESCRIPTION

AC Alternating Current LED Light-emitting Diode

AMP AMP, Inc., part of Tyco

Electronics

ANSI American National Standards

Institute

ASOV Automatic Shut Off Valve MFM Multifunction Monitor

110908-0209 (Issue 6)

LTS Long Term Storage

LVRT Low Voltage Ride Through

Copyright © 2016 Cummins Inc.

2. Introduction 3-2016

ABBR. DESCRIPTION ABBR. DESCRIPTION

ASTM American Society for Testing

and Materials (ASTM

International)

ATS Automatic Transfer Switch MLD Masterless Load Demand

AVR Automatic Voltage Regulator NC Normally Closed

AWG American Wire Gauge NC Not Connected

CAN Controlled Area Network NFPA National Fire Protection Agency

CB Circuit Breaker NO Normally Open

CE Conformité Européenne NWF Network Failure

CFM Cubic Feet per Minute OEM Original Equipment

CGT Cummins Generator

Technologies

CMM Cubic Meters per Minute OORH / ORH Out of Range High

CT Current Transformer OORL / ORL Out of Range Low

D-AVR Digital Automatic Voltage

Regulator

DC Direct Current PCC PowerCommand®Control

Mil Std Military Standard

Manufacturer

OOR Out of Range

PB Push Button

DEF Diesel Exhaust Fluid PGI Power Generation Interface

DPF Diesel Particulate Filter PGN Parameter Group Number

ECM Engine Control Module PI Proportional/Integral

ECS Engine Control System PID Proportional/Integral/Derivative

EMI Electromagnetic interference PLC Programmable Logic Controller

EN European Standard PMG Permanent Magnet Generator

EPS Engine Protection System PPE Personal Protective Equipment

E-Stop Emergency Stop PT Potential Transformer

FAE Full Authority Electronic PTC Power Transfer Control

FMI Failure Mode Identifier PWM Pulse-width Modulation

FRT Fault Ride Through RFI Radio Frequency Interference

FSO Fuel Shutoff RH Relative Humidity

Genset Generator Set RMS Root Mean Square

GCP Generator Control Panel RTU Remote Terminal Unit

GND Ground SAE Society of Automotive Engineers

LCT Low Coolant Temperature SCR Selective Catalytic Reduction

HMI Human-machine Interface SPN Suspect Parameter Number

IC Integrated Circuit SWL Safe Working Load

ISO International Organization for

Standardization

LBNG Lean-burn Natural Gas UL Underwriters Laboratories

Copyright © 2016 Cummins Inc.

SW_B+ Switched B+

12 0908-0209 (Issue 6)

ABBR. DESCRIPTION ABBR. DESCRIPTION

LCD Liquid Crystal Display UPS Uninterruptible Power Supply

2.3 Related Literature

Before any attempt is made to operate the generator set, the operator should take time to read all of

the manuals supplied with the generator set, and to familiarize themselves with the warnings and

operating procedures.

A generator set must be operated and maintained properly if you are to expect safe and

reliable operation. The Operator manual includes a maintenance schedule and a

troubleshooting guide.

The Health and Safety manual must be read in conjunction with this manual for the safe

operation of the generator set:

• Health and Safety Manual (0908-0110)

The relevant manuals appropriate to your generator set are also available, the documents below are in

English:

2. Introduction3-2016

NOTICE

• Operator Manual for QSV91 & QSK60G Generator Sets with PowerCommand 3.3 control (0908-

0209)

• Installation Manual for QSV91 & QSK60G Generator Sets with PowerCommand 3.3 control

(A029R140)

• Recommended Spares List (RSL) for QSK60G (A046W059)

• Recommended Spares List (RSL) for QSK60G (A046W060)

• Recommended Spares List (RSL) for QSV91 (<2MW) (A046W061)

• Recommended Spares List (RSL) for QSV91 (>2MW) (A046W064)

• Service Manual for PowerCommand 3.3 Control (0900-0670_

• Parts Manual for QSK60G (A029C810)

• Parts Manual for QSV91 (A029B383)

• Service Tool Manual (A043D529)

• Failure Code Manual (F1115C)

• Application Manual T-030, Liquid Cooled Generator Sets - for application information

(A040S369)

• Engine Operation & Maintenance Manual for QSV81/91 (4021313)

• Engine Operation & Maintenance Manual for QSK60G (4021395)

• Engine Owners Manual for QSV81/91 (4915546)

• Engine Owners Manual for QSK60G (4915558)

• Warranty Manual (A040W374)

• ESB Warranty Statement - Lean-Burn Gaseous Fuel Generating Set (A050L829)

2.3.1 Further Information - Literature

Contact your authorized distributor for more information regarding related literature for this product.

130908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

2. Introduction 3-2016

2.4 After Sales Services

Cummins Power Generation offers a full range of maintenance and warranty services.

2.4.1 Maintenance

WARNING

Electrical Generating Equipment

Incorrect operation and maintenance can result in severe personal injury or death

Make sure that only suitably trained and experienced service personnel perform electrical

and/or mechanical service.

For expert generator set service at regular intervals, contact your local distributor. Each local

distributor offers a complete maintenance contract package covering all items subject to routine

maintenance, including a detailed report on the condition of the generator set. In addition, this can be

linked to a 24-hour call-out arrangement, providing year-round assistance if necessary. Specialist

engineers are available to maintain optimum performance levels from generator sets. Maintenance

tasks should only be undertaken by trained and experienced technicians provided by your authorized

distributor.

2.4.2 Warranty

For details of the warranty coverage for your generator set, refer to the Global Commercial Warranty

Statement listed in the Related Literature section.

In the event of a breakdown, prompt assistance can normally be given by factory trained service

technicians with facilities to undertake all minor and many major repairs to equipment on site.

Extended warranty coverage is also available.

For further warranty details, contact your authorized distributor.

Damage caused by failure to follow the manufacturer's recommendations will not be covered

by the warranty. Please contact your authorized distributor.

2.4.2.1 Warranty Limitations

For details of the warranty limitations for your generator set, refer to the warranty statement applicable

to the generator set.

2.4.3 How to Obtain Service

When a product requires servicing, contact the nearest Cummins Power Generation distributor. To

locate the distributor, refer to power.cummins.com and select Distributor Locator. When contacting

the distributor, always supply the complete model, specification, and serial number as shown on the

nameplate.

NOTICE

2.4.3.1 Locating a Distributor

In North America

To easily locate the nearest certified distributor/dealer for Cummins generator sets in your area, or for

more information, contact us at 1-800-344-0039 or visit power.cummins.com.

If unable to contact a distributor using the automated service, consult the Internet.

If unable to arrange a service or resolve an issue, contact the Service Manager at the nearest

Cummins Power Generation distributor for assistance.

Copyright © 2016 Cummins Inc.

14 0908-0209 (Issue 6)

When contacting the distributor, always supply the complete Model, Specification, and Serial Number

as shown on the product nameplate.

Outside North America

Refer to power.cummins.com and select Distributor Locator, or send an email to

ask.powergen@cummins.com.

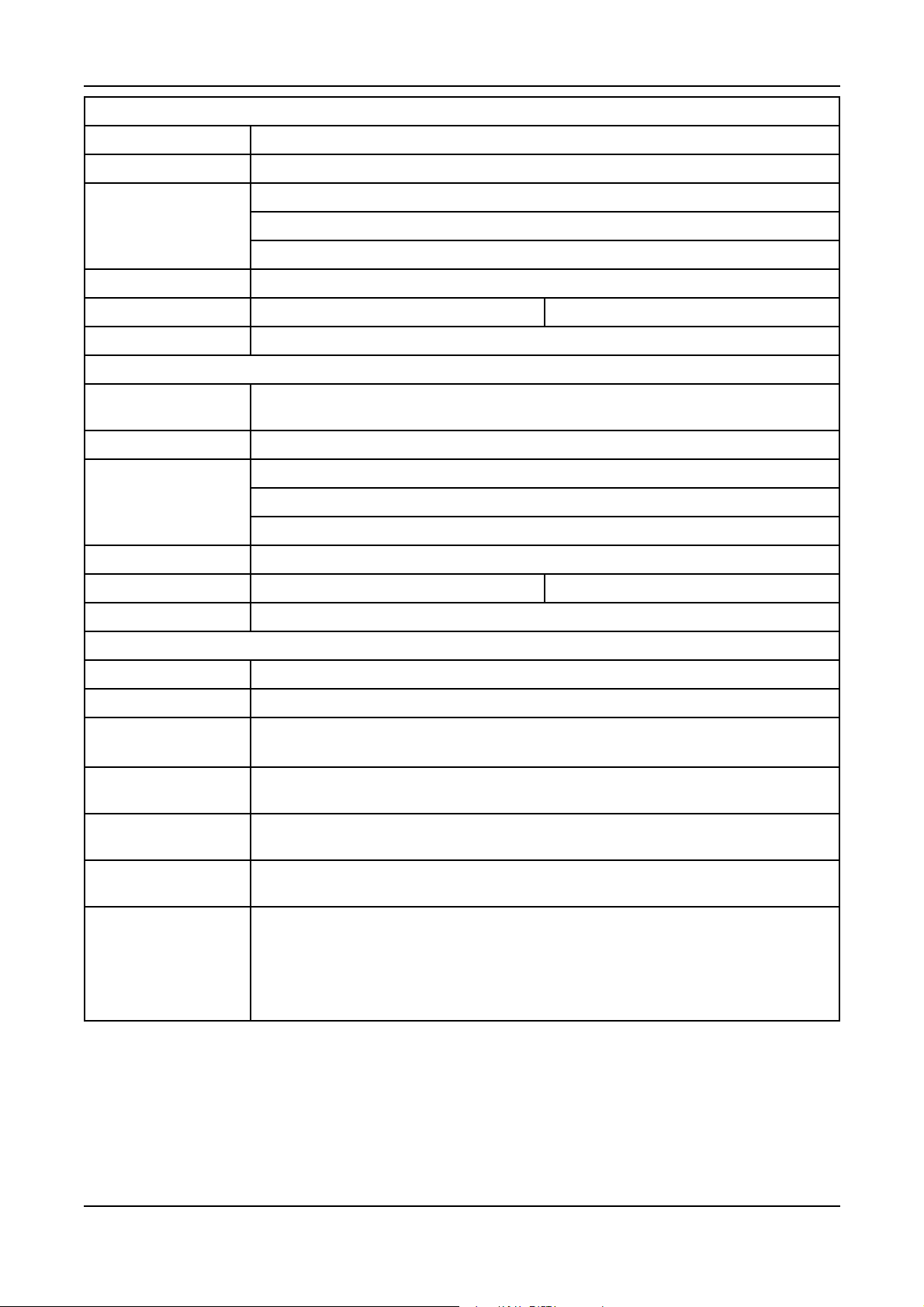

2.5 Project Details

It is important when contacting your authorised distributor to have project information at hand.

Complete this form in order to assist you and the distributor when referencing the installation. (Make

duplicate copies of this page as required.)

2. Introduction3-2016

150908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

2. Introduction 3-2016

Balance of Plant Details

Project Title

Company Name

Address

Contact Name

Phone Numbers Tel: Mobile:

Email

Site Details

Customer Order

Number

Site Name

Address

Contact Name

Phone Numbers Tel: Mobile:

Email

Equipment Details

Generator Model(s)

Number of Sets

Generator Set Serial

Number(s)

Engine Serial

Number(s)

Alternator Serial

Number(s)

Date of

Commissioning

Additional Information

Copyright © 2016 Cummins Inc.

16 0908-0209 (Issue 6)

3 System Overview

This section provides an overview of the generator set.

3.1 Generator Set Identification

Each generator set is provided with a nameplate similar to that shown below. The nameplate provides

information unique to the generator set.

3.1.1 Generator Set Rating

Refer to the generator set nameplate for generator set rating. Refer to Section 5.4 on page 70 for

operation at temperatures or altitudes above those stated on the nameplate.

3.1.2 Nameplate - Open Generator Set

FIGURE 1. TYPICAL OPEN GENERATOR SET NAMEPLATE

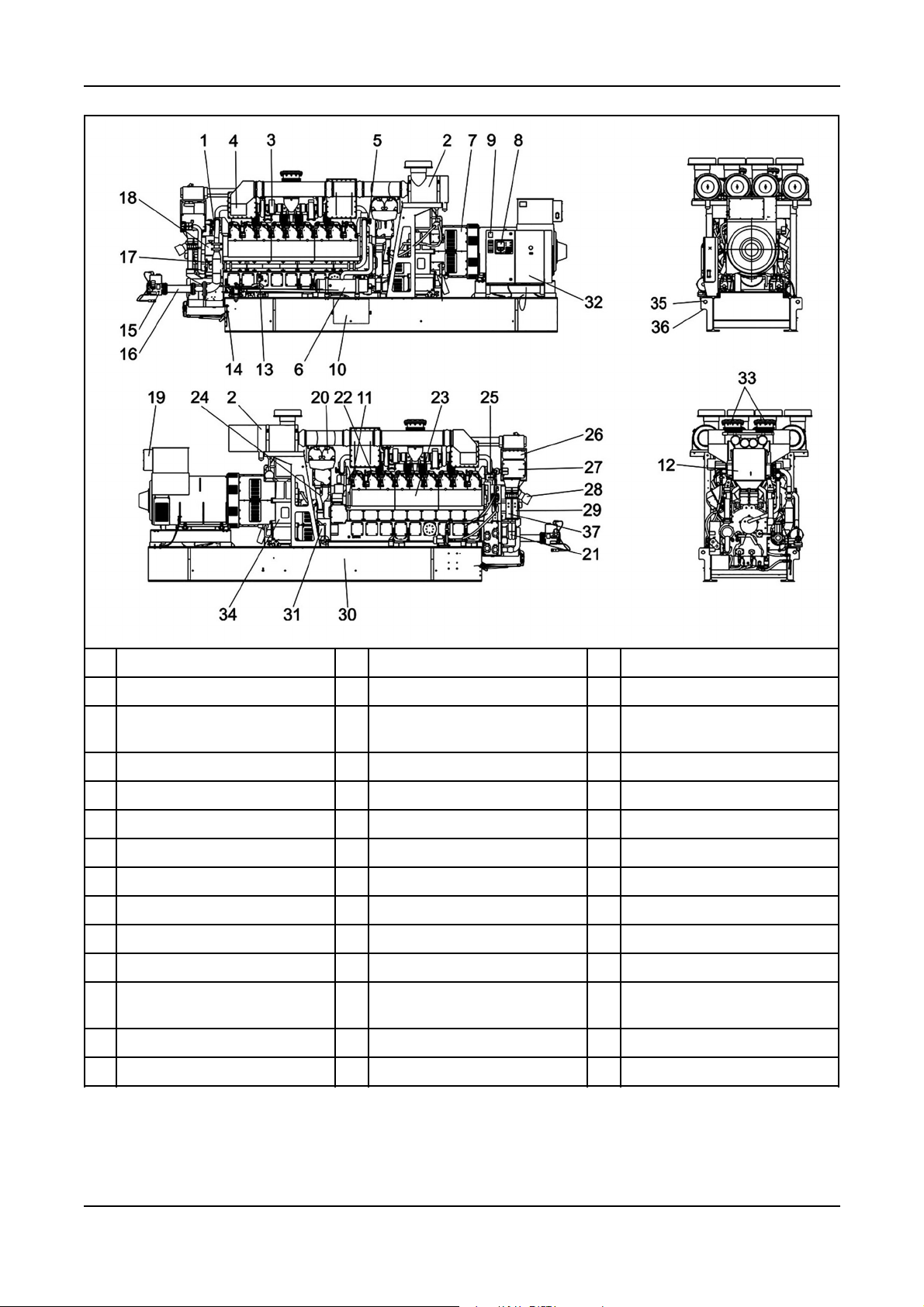

3.2 Generator Set Components

The main components of a typical QSV91G engine generator set are shown below, and referred to

within this section.

There are various options listed although they may not be available for all models.

170908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

3. System Overview 3-2016

No Description No Description No Description

1 Gas Mass Flow Valve 14 Lube-oil Make-up Valve 27 CENSE Module

2 Air Filter 15 DSSOV Solenoid Shut Off

Valve

3 Turbocharger 16 Gas Pipe 29 Low Temp Water Coolant pipe

4 Fuel/Air Mixer 17 Vent Valve 30 Steel Bedframe

5 Gas Mass Flow Valve 18 Centrifugal Oil Filter 31 Electric Starter Motor

6 Crankcase Breather Filter 19 AVR/Controls Box 32 AC Auxiliaries Box

7 Alternator 20 Lube Oil Filters 33 Exhaust Bellows

8 Generator Set Terminal Box 21 Coolant Water Pump 34 Gearbox

9 Generator Set Dataplate 22 Spark Plugs & Ignition Coils 35 Lifting Point

10 Dirty Oil Leak-off Tank 23 Multihousing Cover 36 Jacking Point

11 Engine Dataplate 24 Lube Oil Cooler Coolant Return

Pipe

12 Aftercooler 25 Flotech Gas Valve

13 Lube-oil Dipstick 26 Governor Driver Modules

FIGURE 2. TYPICAL QSV91G ENGINE GENERATOR SET

28 Governor Actuator Module

37 High Temp Water Coolant pipe

Copyright © 2016 Cummins Inc.

18 0908-0209 (Issue 6)

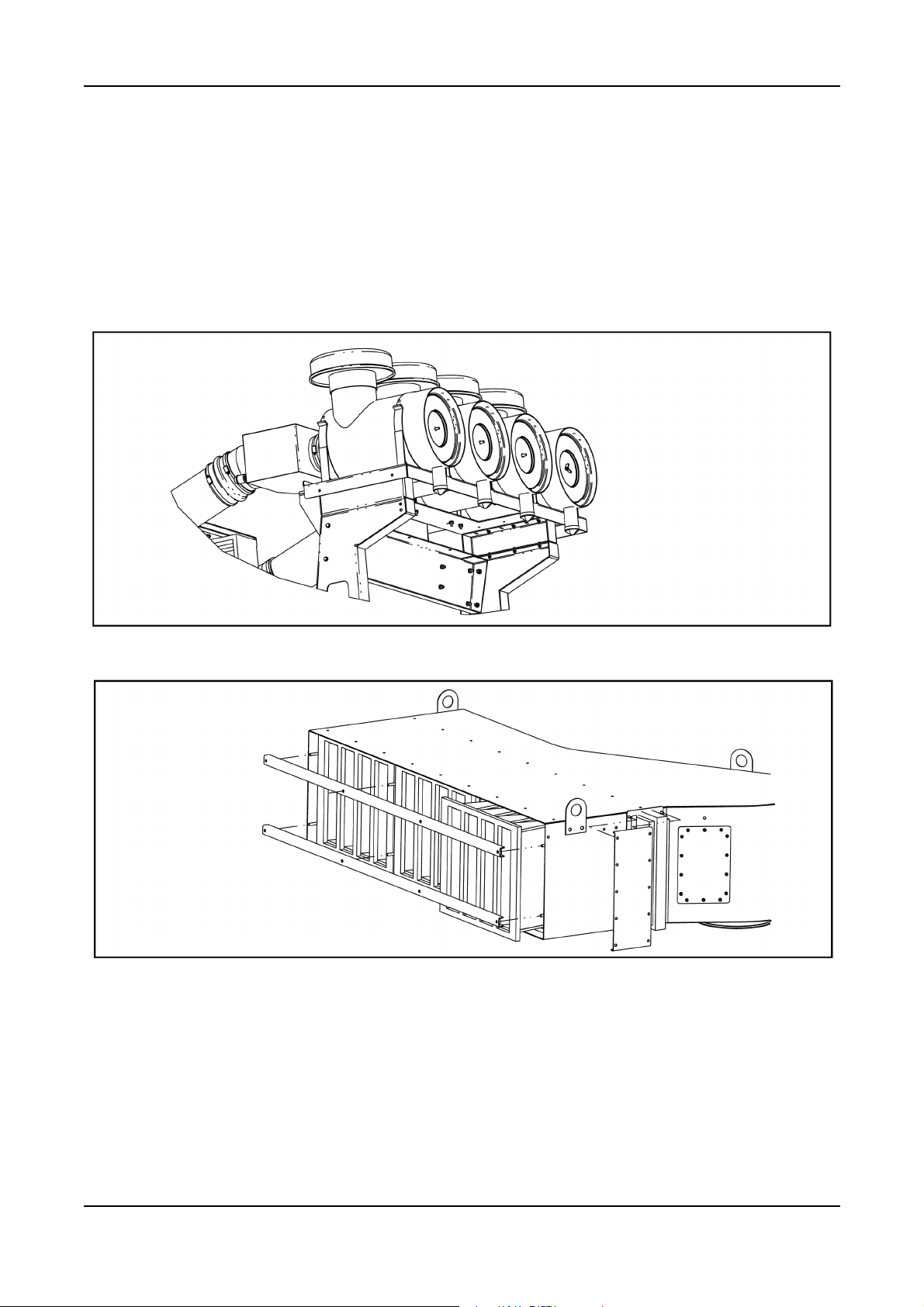

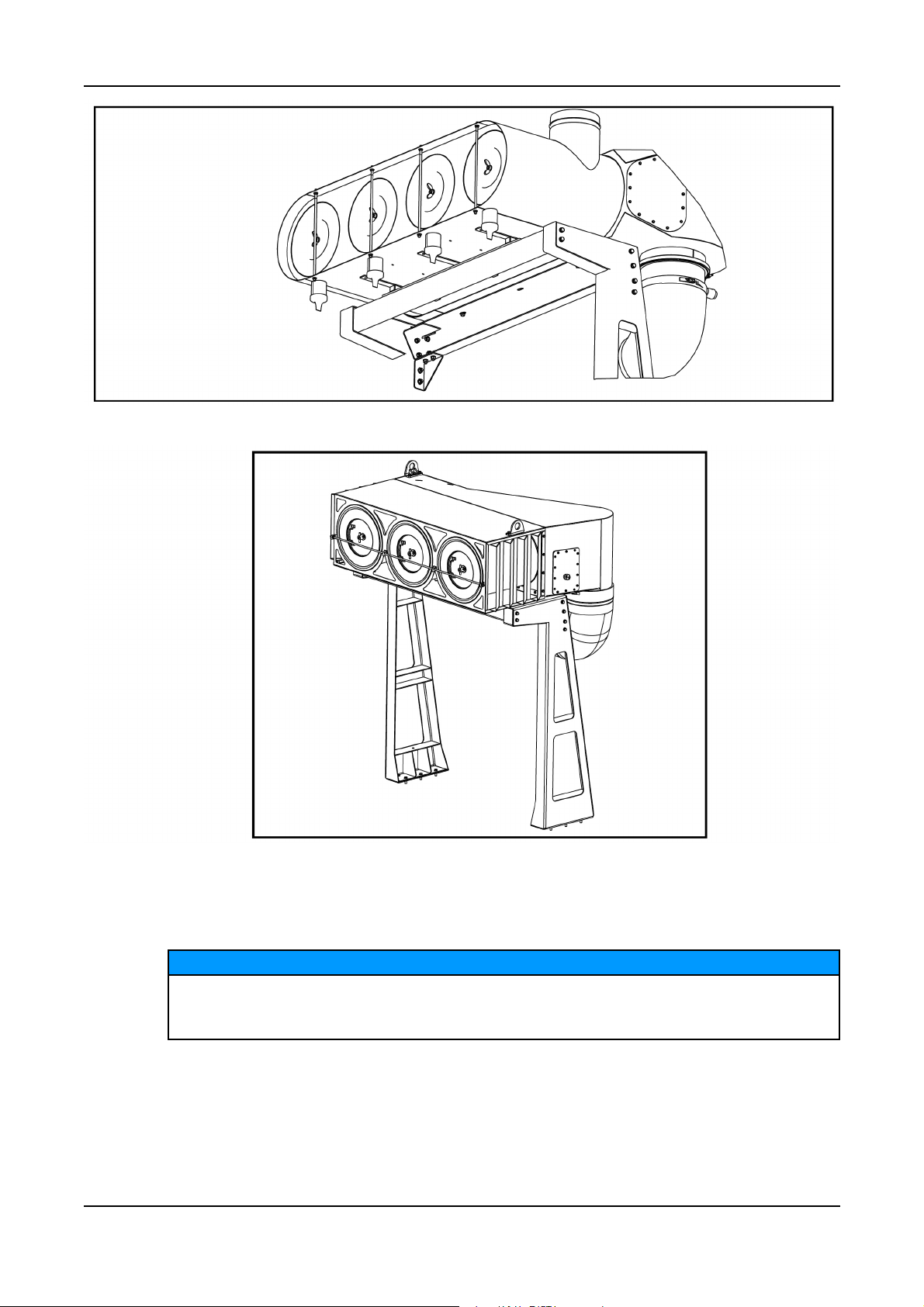

3.3 Air Cleaner

An air cleaner includes an element that must be replaced periodically. Some air cleaners include a

service indicator that indicates when an air cleaner element is dirty and must be replaced.

3.3.1 Air Cleaner System

An air cleaner is used to filter particles from the air supply to the engine. Regular maintenace is critical

in achieving optimum performance of the generator set.

Depending on the requirements, one of the following air cleaner systems will be fitted on the generator

set.

3. System Overview3-2016

FIGURE 3. AIR CLEANER ASSEMBLY

FIGURE 4. AIR CLEANER ASSEMBLY

190908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

3. System Overview 3-2016

FIGURE 5. AIR CLEANER ASSEMBLY

FIGURE 6. AIR CLEANER ASSEMBLY

3.4 Coolant Specification

Incorrect coolant concentration or level may allow an engine to overheat without protection

of shutdown device, and cause severe damage to the engine. Maintain coolant level for

proper operation of high engine temperature shutdown system.

It is important that the quality of coolant used in Cummins engines meets the Cummins recommended

specifications (Consult your authorised distributor). A premixed fully formulated coolant or a 50/50

mixture of high quality water and fully formulated concentrated anti-freeze must meet Cummins

Engineering Standard 14603.

Cummins recommend the use of Fleetguard®Antifreeze Coolant ES Compleat containing DCA4 Plus.

Copyright © 2016 Cummins Inc.

NOTICE

20 0908-0209 (Issue 6)

For filling and maintenance of Cooling Systems refer to the Operation and Maintenance Manual, or

consult your authorised distributor.

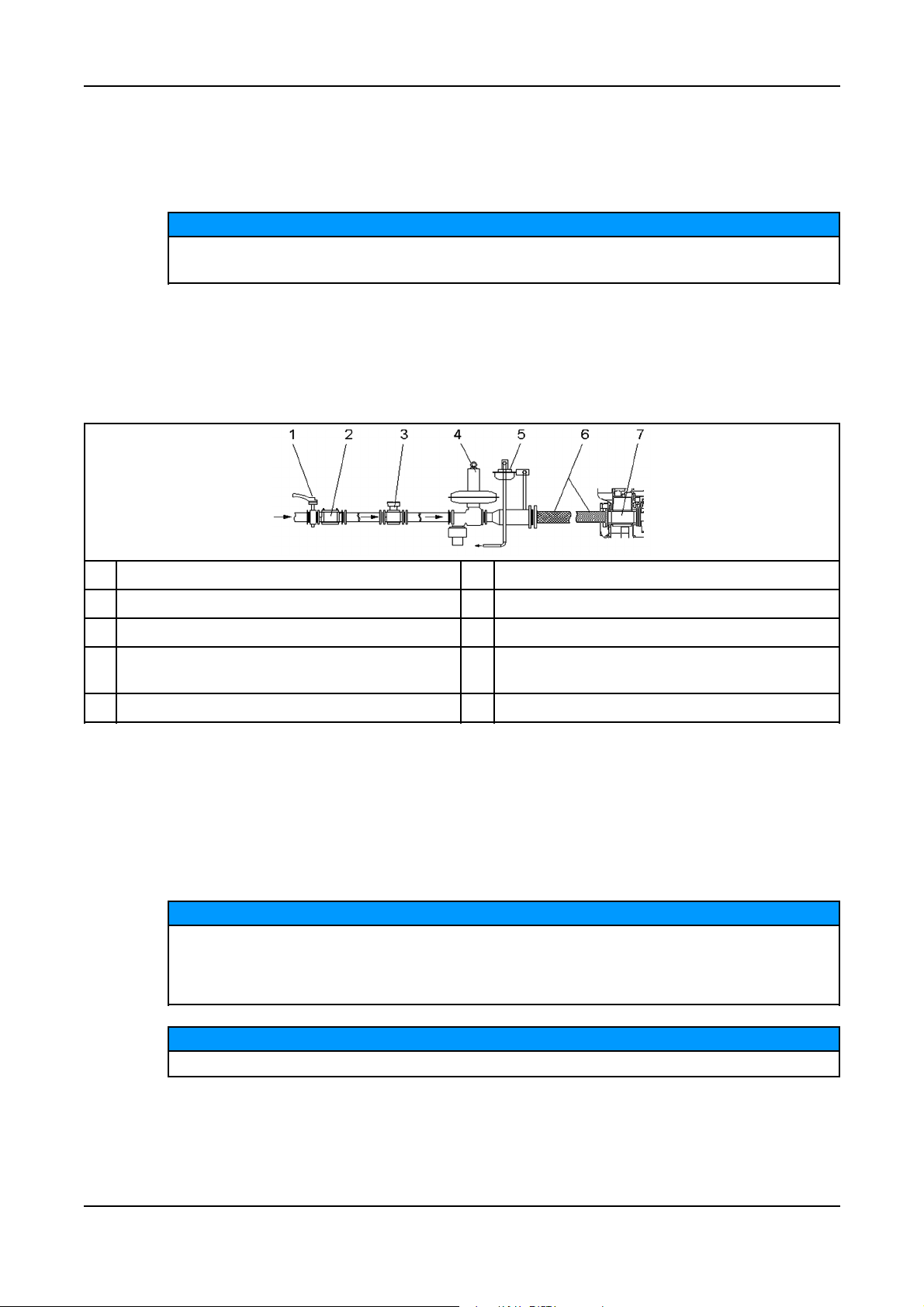

3.5 Gas Train

Installation, maintenance and testing of gas pipe work system must be carried out by suitably

trained and experienced personnel.

Natural Gas is supplied to the engines’ fuel management system through a flexible pipe attached to a

gas train. The gas train includes a main shut-off valve and other gas control components. Control

equipment for the fuel/air ratio and engine speed, are provided on the generator set.

A typical gas train, starting at the gas main supply point, includes the components shown below.

3. System Overview3-2016

NOTICE

No Description No Description

1 Gas Shut-off Valve (GSOV) 5 Pressure Relief Valve (PRV)

2 Filter 6 Flexible Pipe

3 Flowmeter (optional) 7 Double Block & Double Solenoid Shut Off Valve

(DSSOV) (Mounted off-genset - Option)

4 Pressure Regulator

FIGURE 7. TYPICAL GAS TRAIN

3.6 Heaters

3.6.1 Heater Supply and Isolation

A power supply is required for the operation of the engine, coolant, and alternator heaters (if fitted).

NOTICE

It is the sole responsibility of the customer to provide the power supply and the means to

isolate the AC input to the terminal box. Cummins Power Generation accepts no

responsibility for providing the means of isolation. Contact your distributor for more

information.

NOTICE

This disconnecting device is not provided as part of the generator set.

210908-0209 (Issue 6)

Copyright © 2016 Cummins Inc.

3. System Overview 3-2016

3.7 Mains (Utility) Powered Battery Charger

CAUTION

Hazardous Voltage

Contact with high voltages can cause severe electrical shock, burns, or death.

Disconnect the battery charger before isolating the battery.

This unit maintains the battery in a fully charged condition without over-charging. The unit also

provides rapid charging, when necessary, at a current up to the rated output.

The charger’s electronic control circuit allows the charger to be left in circuit during engine cranking

and to operate in parallel with the charge alternator.

The charger will supply current to the battery system until the battery terminal voltage becomes equal

to the set float voltage, at which point only a trickle charge current is present. When the battery

becomes discharged due to a load being present and the terminal voltage falls, the charger will again

supply current to restore the voltage of the battery to the float voltage.

3.8 Oil Specification

NOTICE

High quality engine oil, approved by Cummins should be used only. The use of unapproved

oil may cause severe damage to the engine.

Selecting and using the correct grade of engine oil is critical for achieving engine service life, engine

reliability and performance.

It is important to understand that the generator set must be operated and maintained in accordance to

Cummins published recommendations. Failure to follow applicable service intervals and

recommendations in the Operation and Maintenance Manual applicable to the engine can result in

severe engine damage. Consult your authorised distributor for more information.

Use high-quality SAE40 (mono-grade) NG engine oils, such as Valvoline® Premium Blue GEO LA or

its equivalent. The use of the ‘Premium Grade – Long Change Interval’ oils are strongly

recommended. The SAE40 oils approved for use in Cummins HHP natural gas fuelled engines are as

follows:

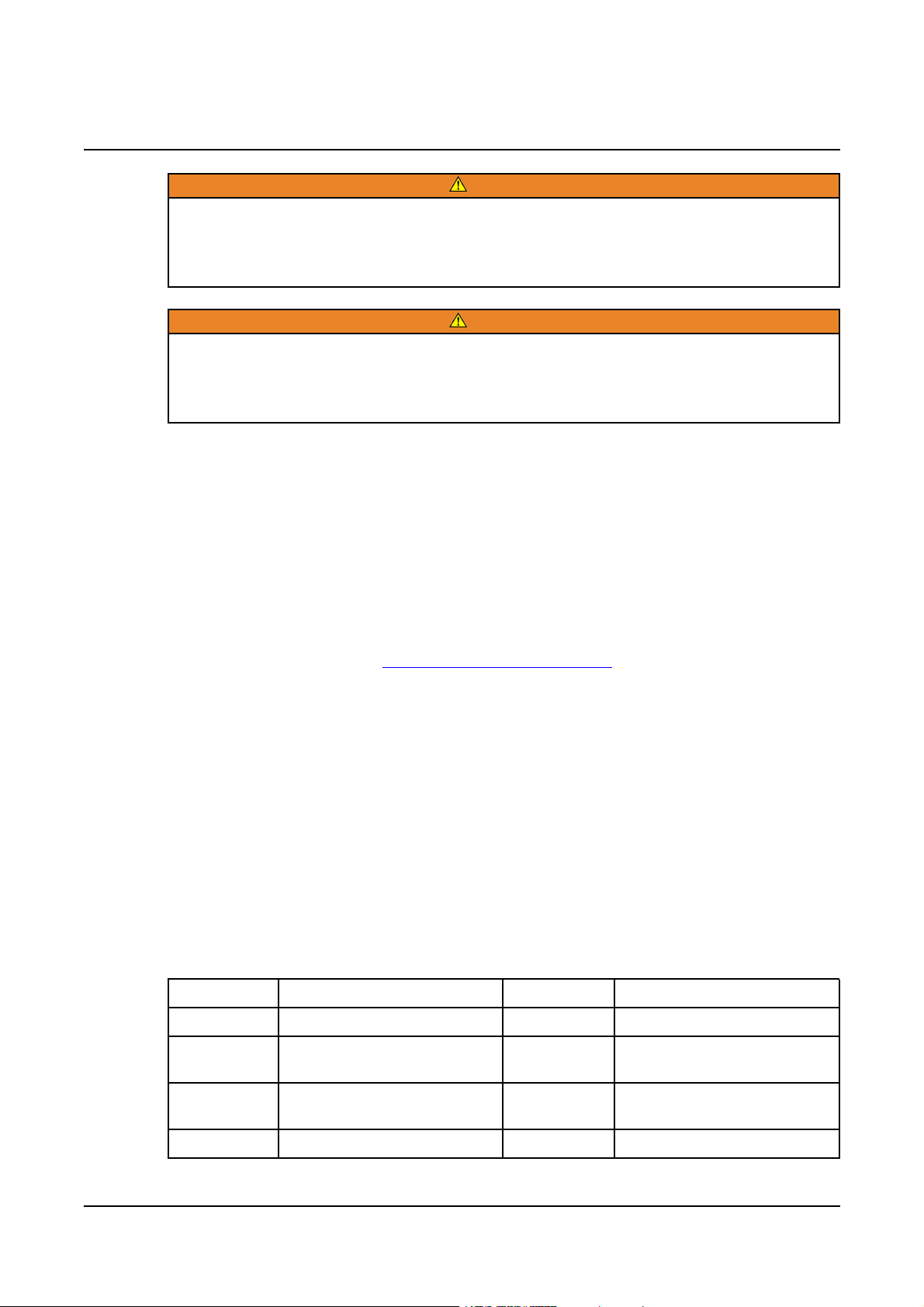

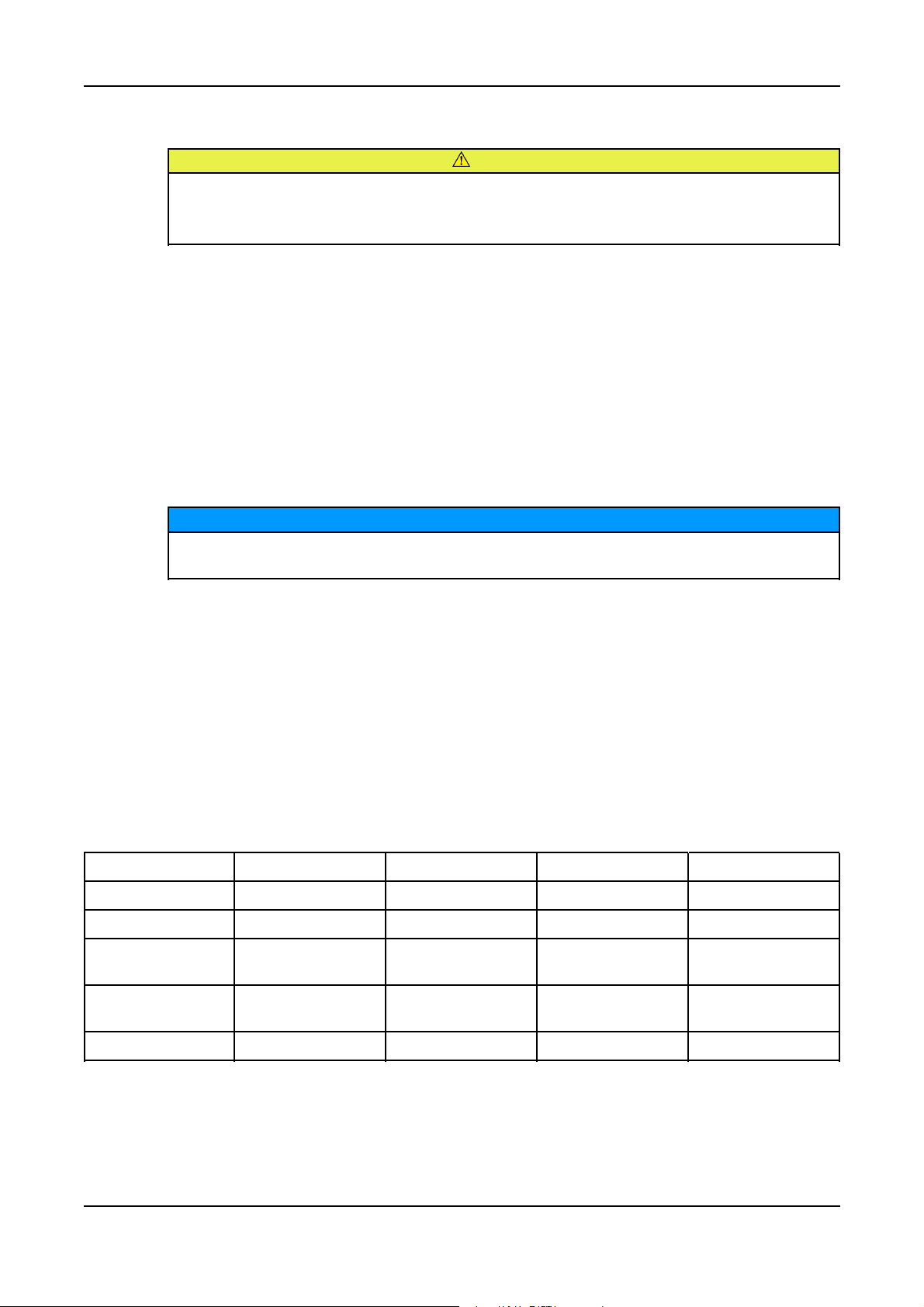

TABLE 1. QSV91G 2MWE ENGINE (18.2BAR BMEP MODELS): C2000 N5C, C2000 N6C

Manufacturer Oil Names Grade TBN Sulphated Ash %

Manufacturer Oil Names Grade TBN Sulphated Ash %

Mobil Pegasus 805* SAE40 6.2 0.54

Valvoline Premium Blue GEO

LA*

SAE40 5.5 0.44

Valvoline Premium Blue GEO

MA*

Shell Mysella XL* SAE40 4.5 0.48

*Premium grade oil

Copyright © 2016 Cummins Inc.

SAE40 7.2 0.7

22 0908-0209 (Issue 6)

3. System Overview3-2016

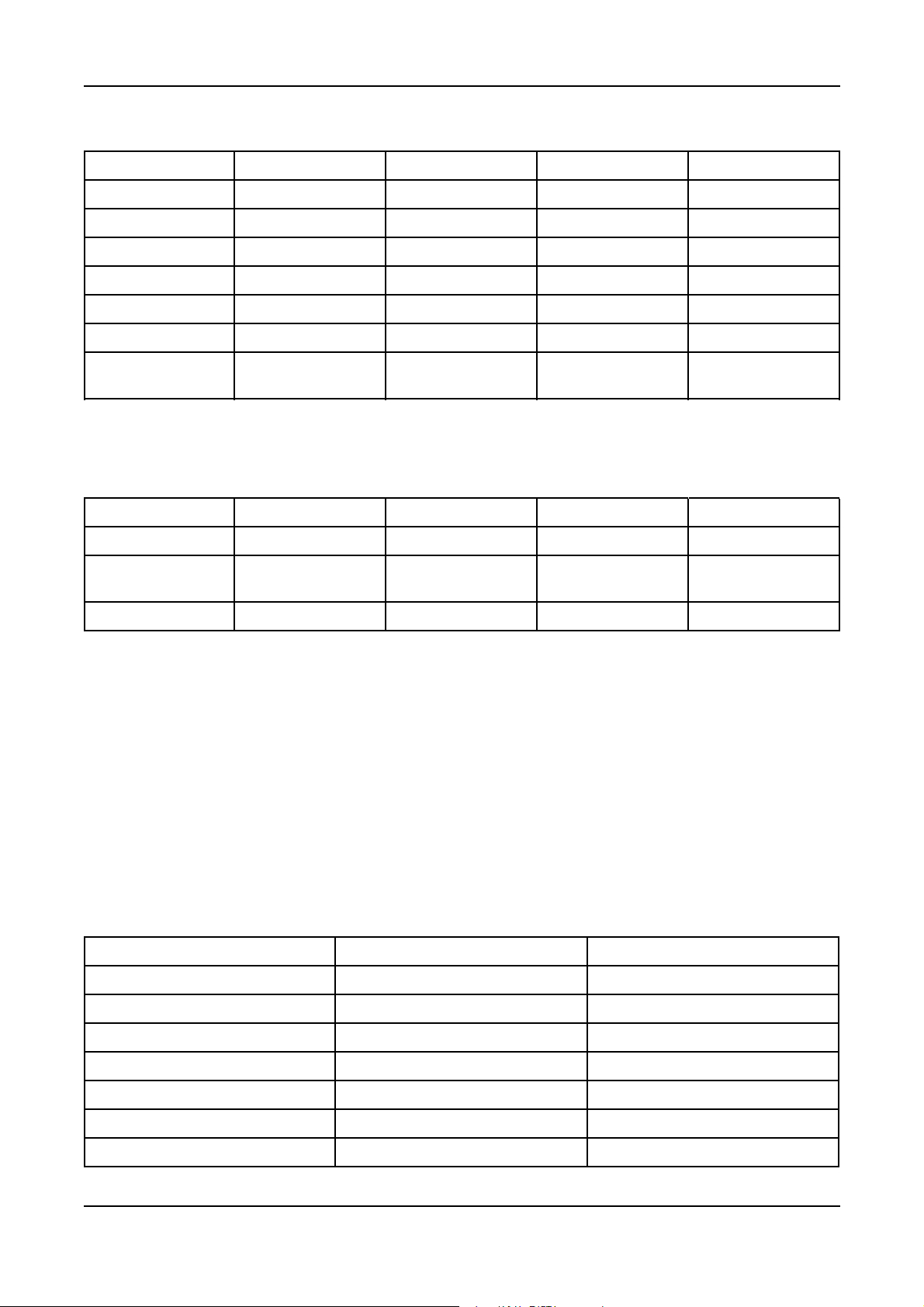

TABLE 2. QSV81/91G ENGINE (14 & 16BAR BMEP MODELS): C1540 N5C, C1750 N5C, C1250 N6C, C1540

N6C, C1750 N6C, C1700 N6

Manufacturer Oil Names Grade TBN Sulphated Ash %

Mobil Pegasus 805* SAE40 6.2 0.54

Mobil Pegasus 705 SAE40 5.6 0.52

Elf Nateria MH40 SAE40 5.2 0.45

Shell Mysella LA SAE40 5.0 0.45

Shell Mysella XL* SAE40 4.5 0.48

Caltex Geostar LA SAE40 5.2 0.49

Valvoline Premium Blue GEO

SAE40 5.5 0.44

LA*

*Premium grade oil

TABLE 3. QSK60G ENGINE (MULTI AND SINGLE-TURBOCHARGER MODELS): C995 N5C, C1160 N5C,

C1200 N5C, C1400 N5C, C1000 N6C, C1100 N6C, C1400 N6C, C1000 N6, C1250 N6, C1350 N6

Manufacturer Oil Names Grade TBN Sulphated Ash %

Mobil Pegasus 805* SAE40 6.2 0.54

Valvoline Premium Blue GEO

SAE40 5.5 0.44

LA*

Shell Mysella XL* SAE40 4.5 0.48

*Premium grade oil

Regularly sample the oil and perform oil analysis. If regular oil analysis is not performed, then the oil

change interval is reduced and oil analysis must be carried out immediately prior to the oil change to

determine that the oil contamination was within acceptable limits at the time of the oil change. Refer to

the engine specific Operation and Maintenance manual for guidance on intervals and procedures.

3.8.1 Low BTU Gas Engines

Cummins Inc., recommends the use of a high quality SAE40 lubricating oil specifically formulated for

use in Low BTU and aggressive gaseous fueled engines.

Various lubricating oil brands are available worldwide and careful selection is required to match the

product with the type of fuel in use. Cummins Inc. has Low BTU engines operating experience with

ChevronTexaco and ExxonMobil who offer a wide range of products for the various categories of fuel.

The more acidic fuel sources require oil with a higher Total Base Number (TBN) to protect the engine.

Supplier Product Fuel

Chevron Texaco (Caltex) Geotex LA

Geotex HD

Geotex LF

®

®

®

Geotex HDAX LA

Geotex HDAX LFG

ExxonMobil Pegasus 805

Pegasus 605

Pipeline Natural Gas

Non-Pipeline Natural Gas

Non-Pipeline Natural Gas

®

®

®

®

230908-0209 (Issue 6)

Natural Gas

Non-Pipeline Natural Gas

Natural Gas

Non-Pipeline Natural Gas

Copyright © 2016 Cummins Inc.

3. System Overview 3-2016

Supplier Product Fuel

Pegasus 610

®

Non-Pipeline Natural Gas

3.9 Sensors

Various generator set parameters are measured by sensors, and the resulting signals are processed

by the control board.

Engine-mounted sensors monitor a number of different systems, such as:

• Lube Oil Pressure

• Cooling System Temperature

3.10 System Options

3.10.1 PowerCommand Universal Annunciator

A universal annunciator provides lamps and a horn to annunciate the operating status and fault

conditions of an emergency power system. It is designed for connection to either a 12 VDC or a 24

VDC control system. It can be configured to be either a positive or negative signal device.

Two versions of the PowerCommand universal annunciator are available.

• Panel Mounted

• Panel with Enclosure

The universal annunciator can communicate using either a PCCNet or a Modbus network.

Refer to the annunciator owner's manual for more information.

Copyright © 2016 Cummins Inc.

24 0908-0209 (Issue 6)

Loading...

Loading...