CUMMINS 20GSBB-6714A, 14GSBB-6716B, 20GSBB-6717A, 20GSBB-6714B, 20GSBB-6927B Installation Manual

...Page 1

InstallationInstallation ManualManual

Home Standby Power Generator Set

GSBB (Spec A-D)

GSBC (Spec B-D)

English

Original Instructions 3-2015 A029V088 (Issue 19)

Page 2

Page 3

Table of Contents

1. IMPORTANT SAFETY INSTRUCTIONS ...................................................................................... 1

1.1 Save These Instructions ........................................................................................................ 1

1.2 General Precautions .............................................................................................................. 1

1.3 Generator Voltage is Deadly .................................................................................................. 2

1.4 Engine Exhaust is Deadly ...................................................................................................... 2

1.5 Fuel is Flammable and Explosive .......................................................................................... 2

1.6 Batteries Can Explode............................................................................................................ 2

1.7 Moving Parts Can Cause Severe Personal Injury or Death .................................................. 3

1.8 The Hazards of Carbon Monoxide.......................................................................................... 3

1.8.1 What Is Carbon Monoxide Poisoning? ........................................................................ 3

1.8.2 What Are the Special Risks of CO Near the Home?................................................... 3

1.8.3 Only You Can Protect Yourself From CO Poisoning!.................................................. 4

2. INTRODUCTION............................................................................................................................ 5

2.1 About this Manual................................................................................................................... 5

2.2 Model Specifications............................................................................................................... 5

2.3 Information For After Installation............................................................................................. 8

3. STEP-BY-STEP OUTLINE OF INSTALLATION............................................................................ 9

3.1 Pre-Installation Considerations............................................................................................... 9

3.1.1 Installation Codes and Standards for Safety ............................................................. 10

3.1.2 Required Items for Installation................................................................................... 10

3.1.3 Choosing A Transfer Switch ...................................................................................... 12

3.2 Generator Set Installation Requirements.............................................................................. 16

3.3 Generator Set Installation Suggestions/Guidelines.............................................................. 16

3.4 Preparing the Site................................................................................................................. 16

3.5 Lifting and Moving the Generator Set................................................................................... 17

3.6 Staking the Generator Set in Place ...................................................................................... 17

3.7 Electrical Wiring Connections ............................................................................................... 17

3.7.1 AC Power Supply Connections.................................................................................. 18

3.7.2 Grounding .................................................................................................................. 19

3.7.3 Automatic Transfer Switch......................................................................................... 21

3.7.4 Heater and Outlet Connections.................................................................................. 21

3.7.5 Operator Panel........................................................................................................... 21

3.7.6 Load Shed Communications Wires............................................................................ 23

3.7.7 Ethernet Connections Wire........................................................................................ 26

3.7.8 Battery ....................................................................................................................... 26

3.8 Fuel System.......................................................................................................................... 27

3.8.1 Fuel Line Connections ............................................................................................... 28

3.8.2 Fuel Line Connections (Model 14GSBB-6716B Only)............................................... 29

3.8.3 Natural Gas Fuel System........................................................................................... 29

3.8.4 Propane Fuel System ................................................................................................ 31

A029V088 (Issue 19) i

Page 4

Table of Contents 3-2015

3.8.5 Testing the Fuel System for Leaks ............................................................................ 36

3.9 Engine Exhaust..................................................................................................................... 37

4. OPTIONAL INTERNET/EMAIL INTERFACE DESCRIPTIONS................................................... 39

4.1 Introduction .......................................................................................................................... 39

4.2 Screen Descriptions ............................................................................................................. 40

4.2.1 Setting Time and Date .............................................................................................. 40

4.2.2 Set Exercise Schedule .............................................................................................. 40

4.2.3 Load Control (Management) ..................................................................................... 41

4.2.4 Event Log .................................................................................................................. 41

4.2.5 Fault Log ................................................................................................................... 42

4.2.6 Network Setup Screen Descriptions.......................................................................... 42

4.2.7 Email Setup Screen Descriptions .............................................................................. 43

4.2.8 Saving Changes......................................................................................................... 44

5. OPTIONAL INTERNET/EMAIL INTERFACE SETUP.................................................................. 45

5.1 Network Connectivity Options............................................................................................... 45

5.2 Material/Cable Routing ......................................................................................................... 45

5.3 Network Information Needed For Setup ............................................................................... 45

5.3.1 Network Router.......................................................................................................... 45

5.3.2 Email/Internet Service Provider (ISP)........................................................................ 45

5.4 In-Home Network Access to the Generator Set .................................................................. 46

5.5 Setting Up Internet Access and E-mail Alerts....................................................................... 49

5.6 Port Forwarding ................................................................................................................... 51

5.7 Remote Viewing IP Options Static IP .................................................................................. 51

5.8 Dynamic IP Monitoring ......................................................................................................... 52

5.9 Help Hotline ......................................................................................................................... 52

5.10 Frequently Asked Questions .............................................................................................. 53

6. OPERATION ............................................................................................................................... 55

6.1 3 Position Switch................................................................................................................... 55

6.2 In-Home Operator Panel ...................................................................................................... 56

6.2.1 BACK Button.............................................................................................................. 56

6.2.2 START STOP Button................................................................................................. 56

6.2.3 Standby ON/OFF Button............................................................................................ 56

6.3 Typical Operation.................................................................................................................. 57

6.3.1 Normal Operation: Utility Power Available and Connected....................................... 60

6.3.2 Emergency Operation: Utility Power Interrupted ....................................................... 61

6.4 To Enable/Disable Standby ................................................................................................. 62

6.5 To Manually Start/Stop Generator Set ................................................................................ 62

6.6 Fault, Maintenance and New Event Screens ....................................................................... 63

6.6.1 Fault Screen............................................................................................................... 63

6.6.2 Maintenance Due Screen .......................................................................................... 64

6.6.3 New Event Screen ..................................................................................................... 64

6.7 Genset Status ...................................................................................................................... 65

6.8 Display Setup and Software Info .......................................................................................... 66

6.8.1 Brightness and Contrast ............................................................................................ 66

ii A029V088 (Issue 19)

Page 5

3-2015 Table of Contents

6.8.2 Software Info.............................................................................................................. 67

6.9 Event Log.............................................................................................................................. 68

6.9.1 To Check Log of Last 20 Events................................................................................ 68

6.9.2 List of Recordable Events.......................................................................................... 68

6.10 Fault Log............................................................................................................................. 69

6.11 Exercise Settings ............................................................................................................... 70

6.12 Time Setup ......................................................................................................................... 71

6.13 Load Management.............................................................................................................. 72

6.13.1 Automatic Load Management.................................................................................. 72

6.13.2 Manual Load Management ...................................................................................... 73

7. STARTUP AND CONFIGURATION............................................................................................. 75

7.1 Installation Review ............................................................................................................... 75

7.2 Startup ................................................................................................................................. 75

7.3 Fuel Solenoid - First Startup................................................................................................. 76

7.4 Generator Set Configuration ................................................................................................ 76

7.5 Transfer Switch Configuration ............................................................................................. 78

7.6 Transfer Switch Parameter Adjustments ............................................................................. 80

7.7 Generator Adjustments......................................................................................................... 81

7.7.1 To Adjust the Output Voltage..................................................................................... 81

7.7.2 To Calibrate the Display Meter ................................................................................. 82

8. COMMUNICATION TROUBLESHOOTING................................................................................. 83

8.1 In-Home Network Access to Generator Set Troubleshooting .............................................. 83

8.2 Remote Internet Access to Generator Set Troubleshooting ................................................ 84

8.3 Email Alert Troubleshooting ................................................................................................. 85

APPENDIX A. OUTLINE AND SYSTEM DRAWINGS...................................................................... 89

A029V088 (Issue 19) iii

Page 6

Table of Contents 3-2015

This page is intentionally blank.

iv A029V088 (Issue 19)

Page 7

1 IMPORTANT SAFETY INSTRUCTIONS

1.1 Save These Instructions

This manual contains important instructions for the generator set that should be followed during

installation, operation and maintenance of the generator and batteries.

Thoroughly read the Operator Manual before operating the generator set. Safe operation and

top performance can only be obtained when equipment is properly operated and maintained.

The following symbols in this manual alert you to potential hazards to the operator, service

person and equipment.

DANGER

Alerts you to an immediate hazard that will result in severe personal injury or

death.

WARNING

Alerts you to a hazard or unsafe practice that can result in severe personal injury or

death.

CAUTION

Alerts you to a hazard or unsafe practice that can result in personal injury or equipment

damage.

1.2 General Precautions

• Keep ABC fire extinguishers handy.

• Make sure all fasteners are secure and torqued properly.

• Keep the generator set and its compartment clean. Do not store any items in the genset

compartment.

• Excess oil, oily rags (etc.) can catch fire.

• Dirt and gear stowed in the compartment will restrict cooling air flow.

• Before working on the generator set, move the Stop Switch (S2) to the Stop position,

disconnect the remote harness (P7) to disable the ATS mounted charger and then remove

the negative (-) battery cable to prevent starting.

• Use caution when making adjustments while the generator set is running, hot, moving or

when parts are electrically live, as all situations may cause personal injury or death.

• Used engine oil has been identified by some state and federal agencies as causing cancer

or reproductive toxicity. Do not ingest, inhale or come into contact with used oil or it's

vapors.

• Do not work on the generator set when mentally or physically fatigued or after consuming

alcohol or drugs.

A029V088 (Issue 19) 1

Page 8

1. IMPORTANT SAFETY INSTRUCTIONS 3-2015

1.3 Generator Voltage is Deadly

• Generator output connections must be made by a trained and experienced electrician in

accordance with all applicable codes.

• This standby generator set and the public utility may only be connected to the house

circuits by means of the automatic transfer switch.

• Improper connections can lead to electrocution of utility workers and damage to

equipment.

• Use caution when working on live electrical equipment. Remove jewelry, make sure

clothing and shoes are dry and stand on a dry wooden platform.

1.4 Engine Exhaust is Deadly

• See What Is Carbon Monoxide Poisoning? to learn the symptoms of Carbon Monoxide

poisoning.

• This generator set is for outdoor installation only.

• It must be located well away from doors, windows, other openings into the house and

where the exhaust gases will disperse away from the house.

1.5 Fuel is Flammable and Explosive

• Keep flames, cigarettes, sparks, pilot lights, electrical arc-producing equipment, switches

and all other sources of ignition well away from areas where fuel fumes are present and

areas sharing ventilation.

• Fuel lines must be secured, free of leaks and separated or shielded from electrical wiring.

• Leaks can lead to explosive accumulations of gas. Prevent leaks and the accumulation of

gas.

• A "rotten egg" smell indicates a possible Natural Gas or Propane leak:

• Natural Gas rises when released and can accumulate under hoods and inside

housings and buildings.

• Propane sinks when released and can accumulate inside housings and

basements and other below-grade spaces.

1.6 Batteries Can Explode

Batteries can explode, causing severe skin and eye burns and can release toxic electrolytes.

• Wear safety glasses.

• Do not smoke.

• Do not dispose of the battery in a fire.

• The battery is capable of exploding.

2 A029V088 (Issue 19)

Page 9

3-2015 1. IMPORTANT SAFETY INSTRUCTIONS

• Do not open or mutilate the battery.

• Released electrolytes have been known to be harmful to the skin and eyes and to be

toxic.

• Batteries present the risk to high short circuit current:

• Remove watches, rings or other metal objects and use tools with insulated handles.

• To prevent arcing when disconnecting the battery:

• Move the Stop Switch (S2) to the Stop position, disconnect the remote harness (P7)

to disable the ATS mounted charger and then remove the negative (-) battery cable to

prevent starting.

• To prevent arcing when reconnecting the battery:

• First, reconnect the positive (+) cable, then the negative (-) cable, and finally

reconnect the battery charger.

• When replacing the generator set battery, always replace it with a battery as specified in

the Model Specifications section of this manual.

1.7 Moving Parts Can Cause Severe Personal Injury or Death

• Do not wear loose clothing or jewelry near moving parts such as fans.

• Keep hands away from moving parts.

• Keep guards in place, over fans.

1.8 The Hazards of Carbon Monoxide

Engine-driven generators can produce harmful levels of carbon monoxide that can injure or kill

you.

1.8.1 What Is Carbon Monoxide Poisoning?

Carbon Monoxide (CO) is an odorless, colorless, tasteless and non-irritating gas. You cannot

see it or smell it. Red blood cells, however, have a greater affinity for CO than for Oxygen.

Therefore, exposure even to low levels of CO for a prolonged period can lead to asphyxiation

(lack of Oxygen) resulting in death. Mild effects of CO poisoning include eye irritation, dizziness,

headaches, fatigue and the inability to think clearly. More extreme symptoms include vomiting,

seizures and collapse.

1.8.2 What Are the Special Risks of CO Near the Home?

Residents can be exposed to lethal levels of CO when the genset is running. Depending on air

temperature and wind, CO can accumulate in or near the home.

To protect yourself and others from the dangers of CO poisoning, it is recommended that

reliable and approved CO detector alarms be installed in the home.

WARNING

Carbon Monoxide (CO) gas can cause nausea, fainting or death.

A029V088 (Issue 19) 3

Page 10

1. IMPORTANT SAFETY INSTRUCTIONS 3-2015

1.8.3 Only You Can Protect Yourself From CO Poisoning!

• Locate the generator in an area where there are no windows, doors or other access points

into the home.

• Make sure all CO detectors are working properly.

• Pay attention to the signs of CO poisoning.

• Check the exhaust system for corrosion, obstruction and leaks each time you start the

generator set and every eight hours if you run it continuously.

4 A029V088 (Issue 19)

Page 11

2 Introduction

This generator set application is intended for stationary emergency use.

Important note for Brazil applications: The manufacturer warns that the installation, operation

and maintenance of equipment by the user must fully comply with the Manual's guidelines and

current Brazilian laws, including those of the Brazilian Agency of Petroleum, Natural Gas and

Fuels (ANP) and the Brazilian Energy Agency (ANEEL).

2.1 About this Manual

This manual is a guide for the installation of the generator set models listed on the front cover.

Proper installation is essential for top performance, reliable operation and safety. Read through

this manual before starting the installation.

The installation must comply with all applicable building codes.

See the generator set Operator Manual (A029V089) for operation and maintenance and the

Service Manual (A030A239) for service.

Manuals are updated from time to time to reflect changes in the equipment and its

specifications. The most up-to-date version of this manual will be found on the

QuickServe website (https://quickserve.cummins.com/info/index.html).

NOTICE

NOTICE

2.2 Model Specifications

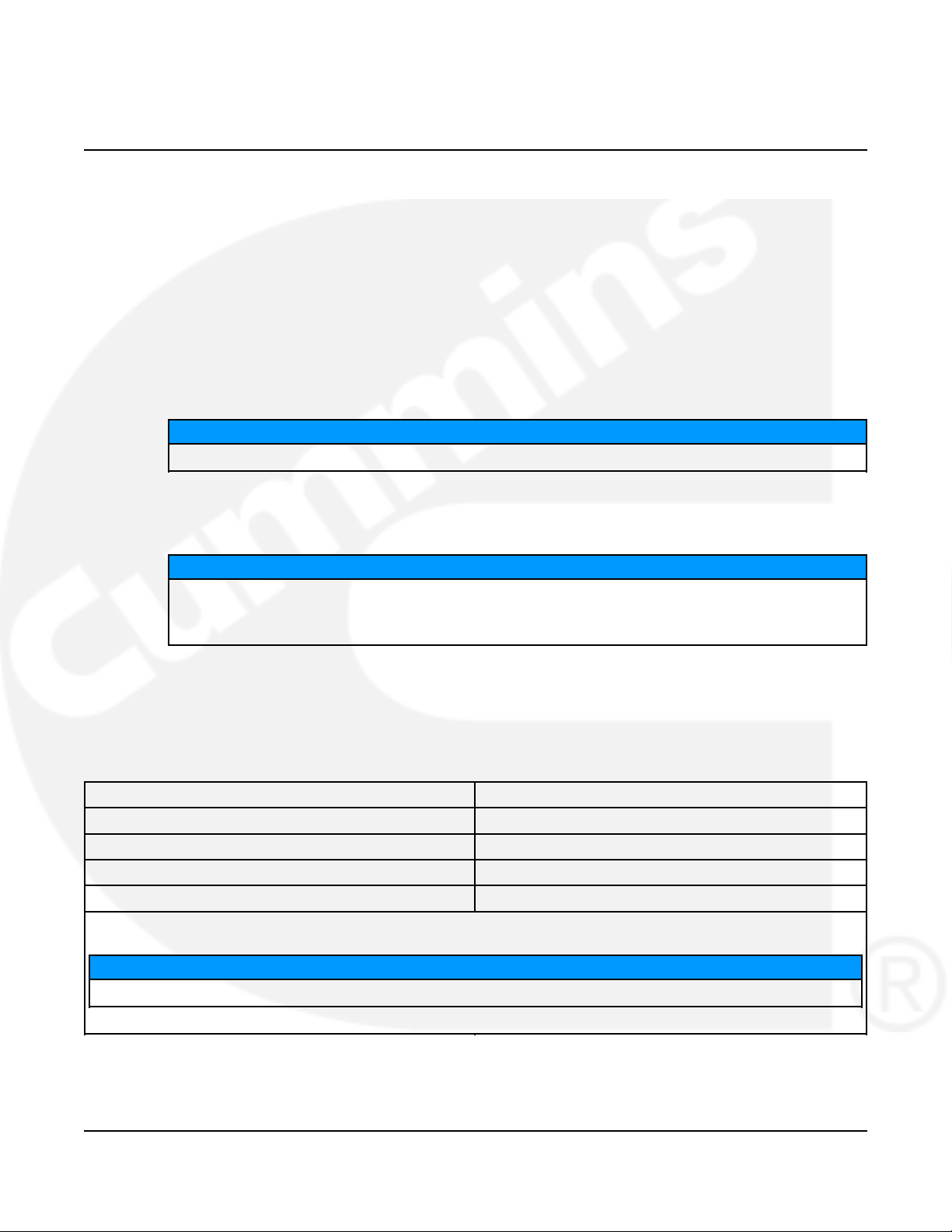

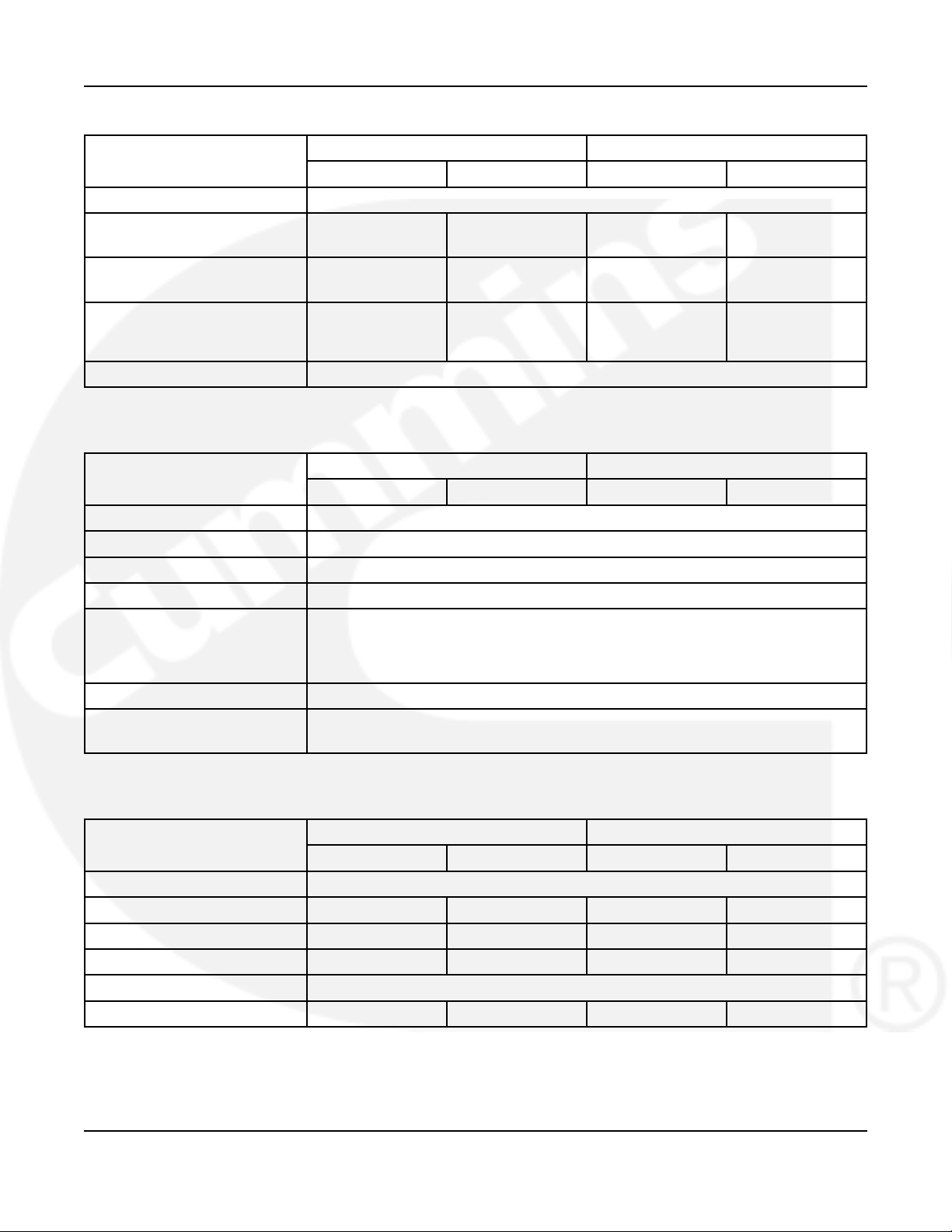

TABLE 1. GSBB AND GSBC MODEL VARIATIONS

Product Description

20GSBB-6713A\B 60 Hz Warm

20GSBB-6714A\B 60 Hz Cold *

14GSBB-6716A\B 50 Hz (AU/NZ)

20GSBB-6717A\20GSBC-6927B 60 Hz CSA Cold *

* Includes an engine oil heater.

NOTICE

See the Cold Weather Specifications Table for recommendations.

A029V088 (Issue 19) 5

Page 12

2. Introduction 3-2015

TABLE 2. COLD WEATHER SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Operating Temperature Range

Above 32 °F (0 °C) and low No dryers or starting aids required.

humidity

High humidity Alternator drying heater recommended.

Below 20 °F (-7 °C) Additional oil heater recommended for starting. Factory-installed model available.

Below 0 °F (-18 °C) Additional accessory breather shield/shroud required to avoid possible engine

Below -10 °F (-23 °C) Additional accessory battery blanket recommended for starting.

Below -20 °F (-29 °C) Not warranted. See warranty statement.

damage. See warranty statement.

TABLE 3. GENERATOR SET SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Dimensions

Weight (With Oil) 540 lbs (245 kg)

Size (L x W x H) 48 x 43 x 34.6 in (1219 x 864 x 880 mm)

Noise 62 dB(A) at 23 ft (7 m) at normal load. (Normal load is equal to the typical

household consumption of 3 KW.)

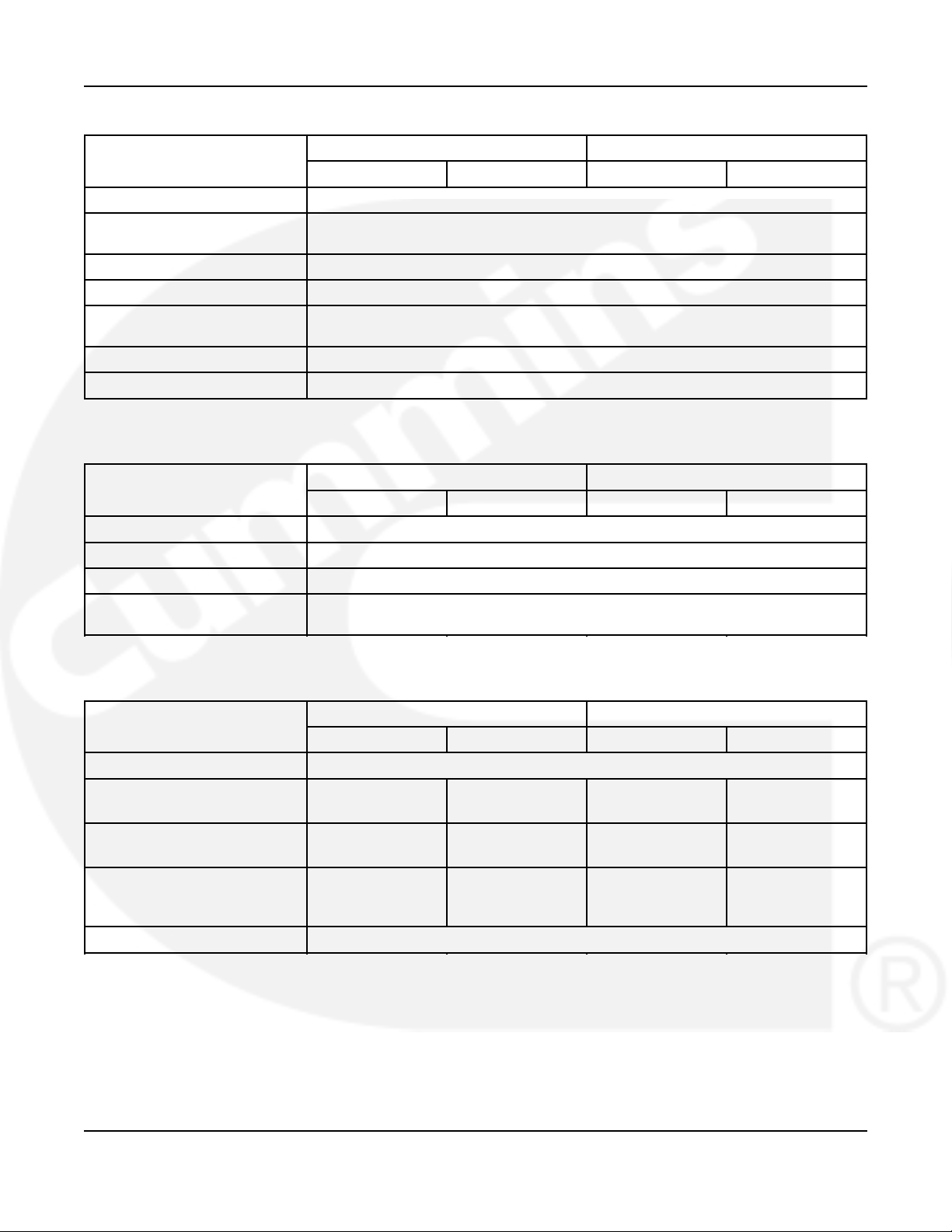

TABLE 4. FUEL SPECIFICATIONS TABLE (SPEC A AND CANADIAN GSBB SPEC B)

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Fueling

1/2 Load 132,500 Btu/Hr 135,000 Btu/Hr 122,000 Btu/Hr 114,000 Btu/Hr

53 ft3/Hr 135 ft3/Hr 48 ft3/Hr 111 ft3/Hr

Full Load 275,000 Btu/Hr 240,000 Btu/Hr 229,000 Btu/Hr 213,000 Btu/Hr

109 ft3/Hr 233 ft3/Hr 91 ft3/Hr 207 ft3/Hr

Fuel Pressure (all loads)

As measured at genset fuel

regulator service port

Tank Size Contact your local gas company to verify the tank size required for your application.

7-11 inches WC 5-11 inches WC 7-11 inches WC 5-11 inches WC

6 A029V088 (Issue 19)

Page 13

3-2015 2. Introduction

TABLE 5. FUEL SPECIFICATIONS TABLE (US GSBB SPEC B AND CANADIAN GSBC SPEC B)

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Fueling

1/2 Load 195,000 Btu/Hr 177,000 Btu/Hr 165,000 Btu/Hr 150,000 Btu/Hr

78 ft3/Hr 172 ft3/Hr 66 ft3/Hr 146 ft3/Hr

Full Load 310,000 Btu/Hr 255,000 Btu/Hr 262,500 Btu/Hr 217,000 Btu/Hr

123 ft3/Hr 248 ft3/Hr 104 ft3/Hr 211 ft3/Hr

Fuel Pressure (all loads)

As measured at genset fuel

regulator service port

Tank Size Contact your local gas company to verify the tank size required for your application.

12-14 inches WC 5-7 inches WC 12-14 inches WC 5-7 inches WC

TABLE 6. ENGINE SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Engine 2 Cylinder-V Twin, OHV, Air-Cooled, 4-Stroke, Spark Ignited, 3600 RPM

Displacement 60.59 in3(993 cc)

Spark Plug Gap .020 inch (.51 mm)

Spark Plug Torque 15 ft-lb (20 N-m)

Intake and Exhaust Cold Valve 0.004-0.006 inch (0.10 - 0.15 mm)

Lash

(Measure at 0.25" (6.35mm)

past top dead center)

Oil Capacity Approximately 80 oz (2.3 Liters)

Oil Recommendation 5W-30 Synthetic Engine Oil

(See Operator Manual)

TABLE 7. GENERATOR SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Generator Brush-Type, 2-Pole Rotating Field, Single Bearing

Power (kVA) --- --- 13.5 13.5

Rated Voltage (V) 120/240 120/240 115/230 115/230

Rated Current (Amps) 162/81.25 144/72 117.4/58.7 117.4/58.7

Phase Type Single Phase

Circuit Breaker (Amps) 100 100 60 60

A029V088 (Issue 19) 7

Page 14

2. Introduction 3-2015

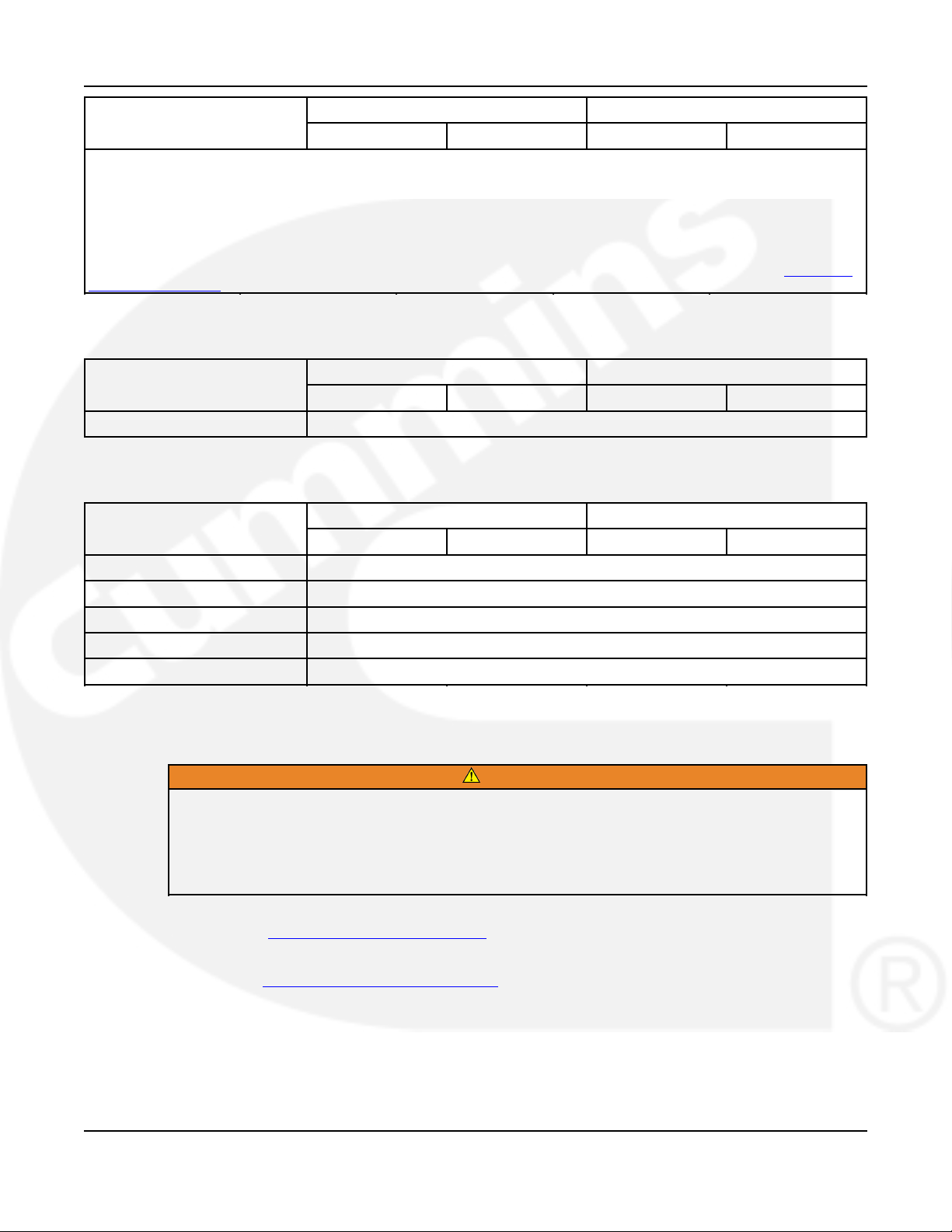

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

De-rating Guidelines: Maximum wattage or maximum current are subject to and limited by such factors as fuel Btu

content, ambient temperature, altitude, engine power and condition, etc. Full rated power is available at 60 °F (15.5

°C) at sea level. De-rate 3.5% for each 1000 ft (304.8 m) above sea level and 3% for each 10 °F (5.5 °C) increase in

ambient temperature above 60 °F (15.5 °C).This generator is rated in accordance with UL 2200 (Stationary Engine

Generator Assemblies) or CSA C22.2 No. 100-04 (Motors and Generators). The maximum continuous current values

that are listed on the generator set nameplate and specification tables occur at the lower limit of acceptable voltage.

Maximum current occurs at 108 and 216 volts, 10% below nominal voltage 120/240. The voltage set point of this

generator set can be adjusted from the operator panel if desired. Refer to the Operator manual procedure To Adjust

the Output Voltage.

TABLE 8. CONTROL SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

Controller Integrated Microprocessor-Based Engine, Generator, Transfer Switch Controller

TABLE 9. DC SYSTEM SPECIFICATIONS TABLE

60 Hz 50 Hz

Propane Vapor Natural Gas Propane Vapor Natural Gas

DC System

Nominal Battery Voltage 12 Volts DC

Battery Group 26 R

Battery Type Maintenance Free

Minimum Cold Crank Amps 545

2.3 Information For After Installation

WARNING

Improper installation can result in severe personal injury, death and damage to

equipment. The installation must comply with all applicable building codes. It is

strongly recommended that the installer be properly trained and licensed to perform

electrical and mechanical equipment installations, however a person with the proper

knowledge and experience in installing electrical and mechanical equipment

installations may also install this genset.

Refer to the GSBB Specifications Sheet for specific information about the system and it's

components.

Refer to the Outline and System Drawings for specific information about the installation and

wiring connections.

See the Operator Manual (A029V089) for proper operation and maintenance instructions.

8 A029V088 (Issue 19)

Page 15

3 Step-By-Step Outline of Installation

WARNING

The installer is responsible for complying with all applicable installation codes and

safety requirements. See the Installation Codes and Standards section of this manual

for more information.

The following sections create a step-by-step overview of a typical generator set installation.

Review these sections to become familiar with specific procedures and important safety

precautions before beginning the installation.

NOTICE

For information on pre-installation considerations (tools, materials, locating the genset,

codes and standards and specifications) see the Introduction chapter of this manual.

3.1 Pre-Installation Considerations

Before installation begins, certain actions must be considered. Prior coordination will reduce

delays and the amount of time power has to be interrupted.

Areas of consideration:

• The location of the generator set is one of the first decisions to be made, as it affects all

other aspects of the installation, such as:

• the length of electric wiring

• the length of gas lines

• Natural Gas or Propane - both of which must be inspected by the gas utility

inspectors and building inspectors

• the site preparation

• access to the site

• trenches

• site preparation materials needed

• Fuel supply pressure.

• The installation cannot be completed without connections to an automatic transfer

switch. Decide where to locate the automatic transfer switch

• Decide what tools and materials will be needed

• Maintain the minimum distance from the Propane tank fill.

• Verify the legal minimum distance with local code officials.

• Determine what (if any) accessories will be required for the customer's application. Utility

power may be required at the generator set, make plans accordingly.

A029V088 (Issue 19) 9

Page 16

3. Step-By-Step Outline of Installation 3-2015

NOTICE

Depending on the locality and use of the generator set, it may be necessary to obtain

an air quality emissions permit before installation begins. Check with local pollution

control or air quality authority to determine whether or not a permit is needed.

3.1.1 Installation Codes and Standards for Safety

WARNING

The generator set installer bears sole responsibility for following all applicable local

codes and regulations.

The following list of Installation Codes and Standards for Safety applies to the installation and

operation of standby generator sets. This list is for reference only and not intended to be

inclusive of all applicable codes and standards. The address of each agency is listed so that

copies of the codes may be obtained for reference. Installation codes and recommendations are

subject to change, and may vary by location or over time.

TABLE 10. INSTALLATION CODES AND STANDARDS FOR SAFETY RECOMMENDATIONS

NFPA 70 - National Electric Code National Fire Protection Association

NFPA 37 - Installation and Use of Stationary Combustion Engines 470 Atlantic Avenue

and Gas Turbines

NFPA 54 - National Fuel Gas Code

NFPA 58 - Storage and Handling of Liquefied Petroleum Gases

CSA Electrical Bulletin Canadian Standards Association

CSA C22.2 No. 100 Housing and Construction Materials Section

CSA C22.2 No. 14 178 Rexdale Blvd.

California Administrative Code - Title 25 Chapter 3 State of California

Underwriters Laboratories Underwriters Laboratories, Inc.

UL2200 333 Pfingsten Road

Boston, MA 02210

Rexdale, Ontario, Canada M9Q 1R3

Documents Section

P.O. Box 1015

North Highlands, CA 95660

Northbrook, IL 60062-2096

3.1.2 Required Items for Installation

Specific tools and materials are required for the installation of this generator set. These items

are identified in the following sections.

10 A029V088 (Issue 19)

Page 17

3-2015 3. Step-By-Step Outline of Installation

3.1.2.1 Materials Required

TABLE 11. ELECTRICAL MATERIALS

Required Optional

Appropriately-sized gauge and length AC wires with 75 °C insulation. 4 wires; L1, X

L2, N and Gnd.

Appropriate conduit for all AC wires. X

Cummins Power Generation Plug-n-Play harness from Genset to ATS. (1', 50' and X

100' lengths available for purchase)

Appropriate conduit for DC communications wires. X

Cummins Power Generation Plug-n-Play harnesses for Generator Set to in home X

display (if installing in the house). (1', 50' and 100' lengths available for purchase)

Three conductor 75 °C 300V minimum-rated wiring appropriately sized to 120 volt X

GFCI installation or to Alternator/Oil heaters (if equipped).

Appropriately-sized junction box and cover for heater/GFCI wiring (if installing). X

Provided on cold weather model.

Code compliant GFCI outlet and "While in Use - Wet Location" cover. X

Cat 5e for Internet installation. X

Two conductor 300V wire (18AWG) per Load Management relay. X

Low Voltage: SPDT relay min 1A 24VAC. X

High Voltage: SPDT relay sized to load (amp and voltage). X

TABLE 12. MOUNTING MATERIALS

Required Optional

Four base mounting spikes. Provided with generator. X

Cummins Power Generation Installation Wheel Kit is available for easy on-site X

generator transportation.

TABLE 13. FUEL MATERIALS

Required Optional

12" Flexible fuel line. Provided with generator. X

UL Listed pipe thread sealant. X

Size Fuel line. NG: 5-7" H20, LP: 12-14" H20 fuel pressure (as measured at genset X

fuel regulator service port). See Installation Manual guidelines.

Fuel regulator - as required.

Manual fuel shut-off at Genset (preferred). X

A029V088 (Issue 19) 11

Page 18

3. Step-By-Step Outline of Installation 3-2015

TABLE 14. IN-HOME DISPLAY MATERIALS

Required Optional

In-home display. One (1) provided with generator. X

Four wall anchors and screws (no. 6) if mounting on stud wall. X

Standoffs and mounting fasteners if mounting on block or brick wall. X

3.1.2.1.1 Loose Parts Shipped With the Generator

The following loose parts are shipped with the generator set:

• Oil drain hose

• Flexible fuel hose assembly

• Welch plug tied to fuel regulator (US GSBB Spec B and Canadian GSBC Spec B only)

• Four base spikes (ground stakes)

• In-home display

• Two keys

• Literature - Operator Manual (A029V089), Installation Manual (A029V088) and Warranty

Statement

3.1.2.2 Tools Required

Use a forklift to move the generator set and set it in place. Alternatively, a one-man hand dolly

designed to fit the generator set base is available to move the generator set and set it in place.

Hand tools required include the following:

• Wire stripper for terminating the communications wires

• Torque wrench

• Jewelers screwdriver

• Allen wrench

• Ratchet set with 10 mm socket and extension

• Two pipe wrenches for gas connections

• Phillips-head and flat-blade screwdrivers

• Ball peen hammer

• Fuel meter (operates down to 5 in. WC)

3.1.3 Choosing A Transfer Switch

Block diagrams showing partial or full load coverage are shown on the following pages:

• UL 1008 listed, Service Entrance Rated Automatic Transfer Switch (without controller):

• RSS 100-6868

• RSS 200-6869

• CSA Approved and UL 1008 listed (with controller):

• RSS 100-6634

12 A029V088 (Issue 19)

Page 19

3-2015 3. Step-By-Step Outline of Installation

• RSS 200-6635

• UL 1008 listed, Service Entrance Rated (without controller):

• RSS 100-6868

• RSS 200-6869

NOTICE

If the transfer switch is connected for full load coverage which exceeds the generator

set rating, it may be necessary to shed large loads such as air conditioners.

NOTICE

• The RSS 100 transfer switch models can be connected for full or partial load coverage

equal to the capacity of the generator set.

• The RSS 200 transfer switch models can be connected for full load coverage greater than

the capacity of the generator set.

TABLE 15. TRANSFER SWITCH CONNECTION VS. LOAD COVERAGE

Transfer Switch Model Connection Capabilities

Full Load Full or Partial Load

(Greater Than Capacity of Genset) (Equal to Capacity of Genset)

RSS 100-6634 X

RSS 200-6635 X

RSS 100-6868 X

RSS 200-6869 X

NOTICE

Model RSS 100-6634 and RSS 200-6635 transfer switches do not incorporate a utility circuit

breaker and therefore must be connected through a Service Entrance Utility Panel incorporating

the utility circuit breaker.

Perform Generator Set Configurationwhen ready to start up the generator set.

A029V088 (Issue 19) 13

Page 20

3. Step-By-Step Outline of Installation 3-2015

FIGURE 1. PARTIAL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITHOUT

CONTROLLER)

FIGURE 2. FULL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITHOUT

CONTROLLER, ONE CIRCUIT BREAKER)

14 A029V088 (Issue 19)

Page 21

3-2015 3. Step-By-Step Outline of Installation

FIGURE 3. PARTIAL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITH CONTROLLER)

FIGURE 4. FULL COVERAGE LOAD CONNECTIONS (TRANSFER SWITCH WITH CONTROLLER)

A029V088 (Issue 19) 15

Page 22

3. Step-By-Step Outline of Installation 3-2015

3.2 Generator Set Installation Requirements

WARNING

EXHAUST GAS IS DEADLY! Install the generator set out-doors only. The generator set

must be located away from doors, windows and other openings to the house and where

exhaust gases will disperse away from the house.

Generator set location is critical for safety and performance. Follow the guidelines below

• Must comply with applicable codes (NFPA, NEC, etc.).

• Install out-doors only.

• Call the local utilities to mark the locations of buried utility services (gas, electric or

telephone) before digging trenches for fuel and electrical lines.

• Ask the homeowner for locations of any other buried components (gas, electric or

telephone) before digging trenches for fuel and electrical lines.

Clearances:

• The exhaust side of the generator set must be located 5 feet from combustible materials

(NFPA 37).

• The exhaust side of the generator must be located 5 feet from any opening in a wall

(window, door, vent, etc.).

• The generator must be located such that the exhaust is not able to accumulate in an

occupied area.

• The generator must have access for installation, service and maintenance as deemed

appropriate by a Cummins Power Generation authorized dealer or installer.

• The generator must be located to ensure ventilation openings are not blocked.

3.3 Generator Set Installation Suggestions/Guidelines

• Locate the generator set on stable ground, not subject to flooding.

• Locate and orient the generator set such that prevailing winds will carry exhaust gases and

fuel leaks away from the house or occupied area.

• Make sure engine vent port on the side of the enclosure is not blocked and is free of

debris.

3.4 Preparing the Site

Steps to preparing a proper/safe generator set site:

1. Create a level area.

Add a layer of sand or pea gravel that is deep enough that the generator set will sit level.

2. Be sure that the area is at least 48 in by 34 in (1219 mm by 864 mm).

Sites on an incline require more area.

3. Be sure that the area is on firm ground.

16 A029V088 (Issue 19)

Page 23

3-2015 3. Step-By-Step Outline of Installation

4. Remove any combustible material that would be under and around the generator set.

5. Be aware of water/sprinkler systems to prevent water intrusion into enclosure openings.

3.5 Lifting and Moving the Generator Set

WARNING

The generator set is heavy. Dropping the generator set can cause severe personal

injury or death. Keep feet and hands clear when lifting the generator set.

CAUTION

The generator is shipped with oil in the crankcase. Keep the generator set upright.

The generator set is heavy and must be handled with care.

• Use a fork lift to move the generator set and set it in place.

• The lifting eyes on the engine and alternator should not be used for lifting the entire

generator set.

• Alternatively, a one-person hand dolly designed to fit the generator set base is

available to move the generator and set it in place.

3.6 Staking the Generator Set in Place

WARNING

Pounding the stakes into electric, gas or telephone service lines can result in severe

personal injury or death. Observe the utility company markings and discuss any other

buried lines with the home owner.

Set the generator set in place and pound the four corner stakes into the ground to secure the

generator set in place.

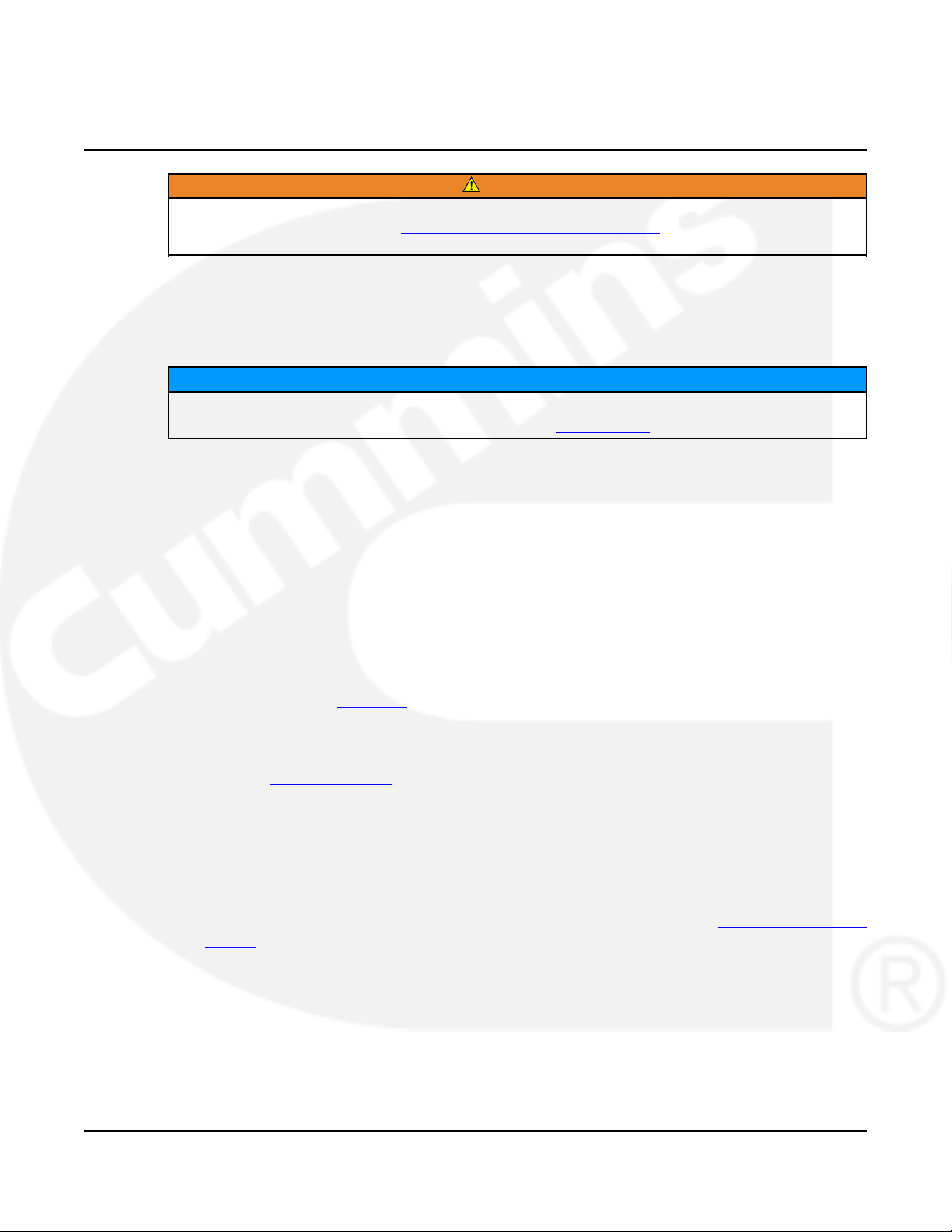

3.7 Electrical Wiring Connections

Refer to the Outline and Systems Drawings for the locations of the electrical conduit openings

on the side of the generator set and the alternative stub-up opening in the base for all power

and communications wiring connections between the generator set and transfer switch.

Route the wires from the transfer switch through the conduit and connect the wires to the mating

terminals on the generator set terminal block.

Two separate conduits are required:

• One is for all AC voltage connections on TB2 or in the AC junction box

• One is for all communications cables on P7, J4 or Ethernet cables.

A029V088 (Issue 19) 17

Page 24

3. Step-By-Step Outline of Installation 3-2015

Callout Component

Number

1 Electrical Stub-up Area Through Plastic Skid

2 Manual/Stop/Remote Switch

3 Installer Access

4 Removable Service Panel

5 Battery Location

FIGURE 5. STUBUP OPENING

3.7.1 AC Power Supply Connections

WARNING

Electrical connections must be made by a licensed electrician. Improper installation can

lead to electrocution and damage to property.

WARNING

Automatic startup of the generator set during installation can cause severe personal

injury or death. Push the control switch OFF and disconnect the negative (-) cable from

the battery to keep the generator set from starting.

18 A029V088 (Issue 19)

Page 25

3-2015 3. Step-By-Step Outline of Installation

3.7.1.1 Main Wiring

WARNING

Refer to the requirements of The National Electrical Code (NFPA No. 70) for all AC

wiring connections.

For access to the wiring connection terminal block (TB2):

• Open the top of the generator set

• Swing the service door wide open, or gently lift up on each side of the front cover to

remove it completely

• Remove the finger guard cover from the terminal block compartment

Connections:

• Consult the local electric code for wire size (L1, L2, N and GND). Wire size is determined

by the length of the run.

• Connect them to the AC output terminal block (TB-2)

• Torque the terminals per the table on the side of TB-2

• The wires must be routed to the transfer switch in approved liquid-tight conduit

• The conduit can be stubbed up through the bottom stub-up opening or connected to

the conduit opening on the side of the generator set

• If the stub-up opening is used, fill in the stub-up opening with duct seal or mastic tape

to keep out insects and rodents

AC wiring can induce false signals in control and communications wiring. Do not route

in the same conduit.

3.7.2 Grounding

Use the Typical System Grounding One-Line Diagrams in this section to be sure that the

generator set, transfer switch, power supply wiring and all connected electrical equipment are

bonded to a common grounding point in accordance with the applicable codes and standards.

The generator set grounding terminal (TB2-4) must be connected to the grounding terminal in the

transfer switch. Do not provide a separate grounding rod for the generator set.

CAUTION

WARNING

NOTICE

Generator neutral is not grounded at the generator set, but at the common system grounding

point.

A029V088 (Issue 19) 19

Page 26

3. Step-By-Step Outline of Installation 3-2015

WARNING

Contact with electrical equipment can result in severe personal injury or death. It is extremely

important that bonding and equipment grounding be properly done. All metallic parts that could

become energized under abnormal conditions must be properly grounded.

FIGURE 6. TYPICAL SYSTEM GROUNDING ONE-LINE DIAGRAMS

20 A029V088 (Issue 19)

Page 27

3-2015 3. Step-By-Step Outline of Installation

3.7.3 Automatic Transfer Switch

Install the transfer switch in accordance with its Installation Manual and make connections to the

generator set in accordance with the Electrical Connections section of this manual.

3.7.3.1 Transfer Switch Communications Wires

WARNING

Interconnecting the generator set and the public utility can lead to the electrocution of

personnel working on the utility lines, damage to equipment and fire. An approved

switching device must be used to prevent interconnections.

Install the transfer switch in accordance with its Installation Manual.

Wiring harnesses are available in various lengths for quick connection between the generator

set and transfer switch. See the Outline and System Drawings Appendix for harness details.

3.7.4 Heater and Outlet Connections

3.7.4.1 120 Volt Optional Accessories

NOTICE

Engine oil heaters are factory installed on models 20GSBB-6714, 20GSBC-6727,

15GSBB-6720

To supply 120 VAC to power the following accessories, connect 12 AWG 75 °C wires to the

accessory wires in the 120 volt junction box from a 15 amp protected circuit in the main

distribution panel in the house.

• Optional battery heater

• Optional engine heater and alternator drier assembly

• Optional installer-supplied GFCI outlet

• Optional breather shroud/heater

NOTICE

The wires my be run through the same conduit as the AC power output wires.

3.7.5 Operator Panel

3.7.5.1 Operator Panel Communication Wires

NOTICE

There are two unmarked connectors on the back of the display, either one may be used

for connecting the display to the generator set.

Wiring harnesses are available in various lengths for quick connection between the generator

set and in-home display. See the Outline and System Drawings Appendix for harness details.

A029V088 (Issue 19) 21

Page 28

3. Step-By-Step Outline of Installation 3-2015

Class 1 wiring methods should be used for the in-home display, Ethernet and transfer switch

communication conductors between the generator set and transfer switch. Separation of Class 2

and power circuits should be maintained per Article 725.136 of 2008 NFPA 70: National

Electrical Code.

See the Operator Manual (A029V089) for information regarding using the operator panel to

operate and monitor the generator set.

3.7.5.2 Operator Panel Installation In The Home

Mount the generator set operator panel on a wall, in a convenient location such as next to the

house thermostat.

To install the operator panel:

• In drywall or paneled walls:

1. Drill a hole that is large enough to clear the harness connector on the back of the

operator panel.

2. Route the wires inside the wall, to hide the wires.

3. Mount the operator panel with four No. 6 wood screws or wall anchors.

• On brick, stone or block walls:

1. Mount with spacers to clear the harness connector on the back of the operator panel.

2. Mount with the appropriate wall anchors.

3. Connect the operator panel to the generator set harness using either of the two 8 pin

connectors on the back of the operator panel.

Refer to the Outline and System Drawings Appendix of this manual for guidelines on how to

connect the operator panel to the generator set.

3.7.5.3 Operator Panel Installation In The Generator Set

The operator panel may be installed inside of the generator set.

To install the operator panel in the generator set:

NOTICE

The control panel bezel must be removed for installation in the generator set.

1. Remove the bushing in the 1" hole on the control panel.

2. Remove the 4 small screws from the control panel.

3. Pulling the harness through the 1" hole, connect J4 directly to the back of the operator

panel into the connector that lines up with the hole in the metal panel.

4. Replace the 4 small screws.

22 A029V088 (Issue 19)

Page 29

3-2015 3. Step-By-Step Outline of Installation

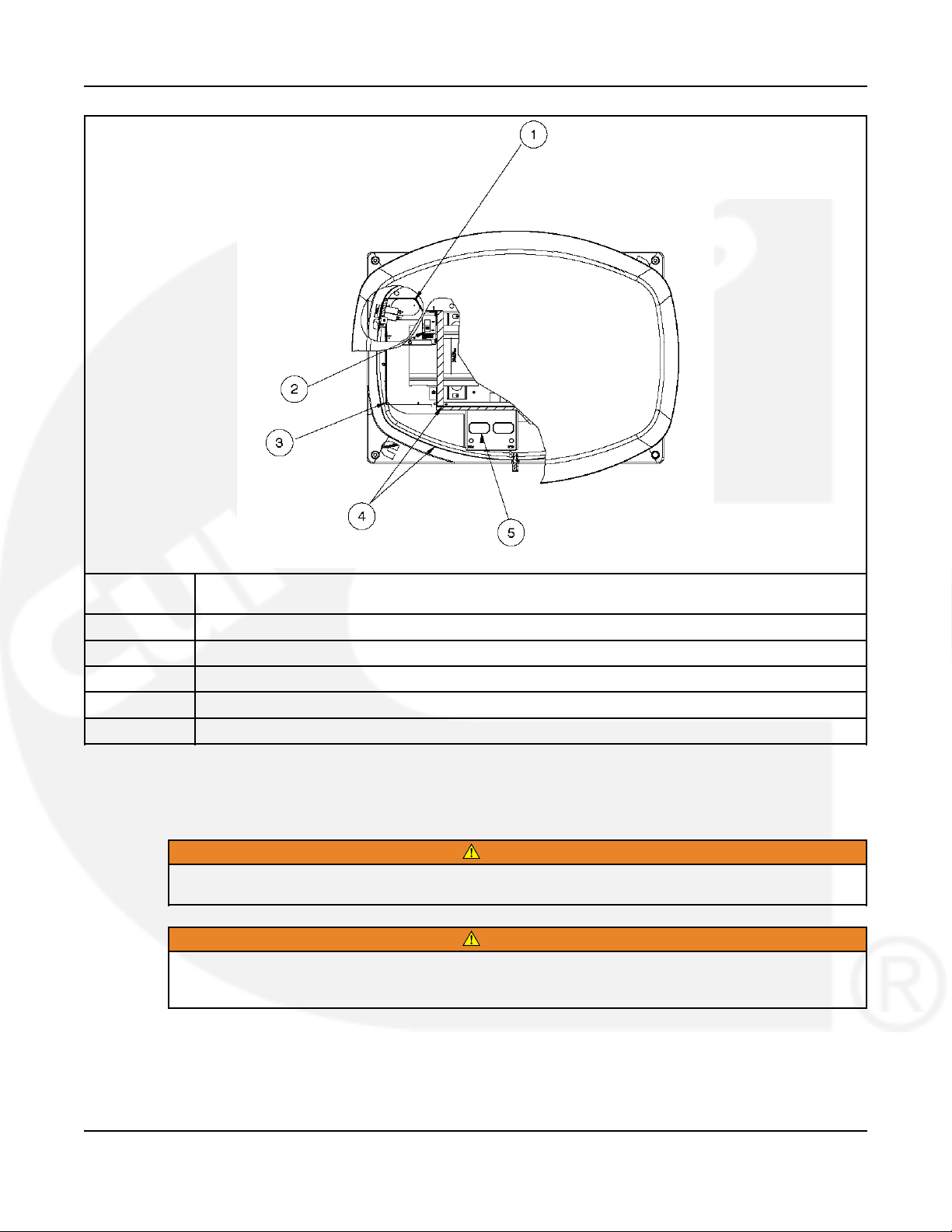

FIGURE 7. OPERATOR PANEL BEZEL

3.7.6 Load Shed Communications Wires

The control cable has the load control wires brought out of the genset (P7-7 and P7-8). Class 1

wiring methods should be used for the in-home display, Ethernet and transfer switch

communication conductors between the generator set and transfer switch. Separation of Class 2

and power circuits should be maintained per Article 725.136 of 2008 NFPA 70: National

Electrical Code.

Use 300V 18 gauge 75 °C wire for wiring the relay.

See the following figures for the different ways the relays can be wired.

A029V088 (Issue 19) 23

Page 30

3. Step-By-Step Outline of Installation 3-2015

No. Description No. Description

1 Normally Closed 2 Load control pin 7 or 8

3 Ground pin 4 4 From thermostat

5 To air conditioner (load)

Relay Requirement:

• Input: 12Vdc, Max 0.5 Amp

• Contact: Low voltage current, < 40 Amp

• Mounting: No restrictions

FIGURE 8. LOW VOLTAGE RELAY SPDT

24 A029V088 (Issue 19)

Page 31

3-2015 3. Step-By-Step Outline of Installation

No. Description No. Description

1 Normally Closed 2 Load Control Pin 7 or 8

3 Ground Pin 4 4 From Circuit Breaker

5 To Load

Relay Requirement:

• Input: 12Vdc, Max 0.5 Amp

• Contact: 120 V AC, Amp rating for load

• Mounting: Typically in distribution panel

FIGURE 9. HIGH VOLTAGE RELAY SPDT 120V AC LOAD

A029V088 (Issue 19) 25

Page 32

3. Step-By-Step Outline of Installation 3-2015

No. Description No. Description

1 Normally Closed 2 Load Control Pin

3 Ground Pin 4 4 From Circuit Breaker

5 To Load

Relay Requirements:

• Input: 12Vdc, Max 0.5 Amp

• Contact: 120 V AC, Amp rating for load

• Mounting: Typically in distribution panel

FIGURE 10. HIGH VOLTAGE RELAY DPDT 220V AC LOAD

3.7.7 Ethernet Connections Wire

The generator set control board has a connector for Cat 5 Ethernet cable for connection to a

remote modem/router. See Ethernet/Email Interface for setup and operation.

Use Cat 5 Ethernet cable and 300V 18 gauge 75 °C wire for wiring the relay.

Class 1 wiring methods should be used for the in-home display, Ethernet and transfer switch

communication conductors between the generator set and transfer switch. Separation of Class 2

and power circuits should be maintained per Article 725.136 of 2008 NFPA 70: National

Electrical Code.

The Internet/Email interface requires “high speed" or “broadband" cable or DSL service

to the house. See Ethernet/Email Interface for a full list of requirements.

NOTICE

3.7.8 Battery

The generator set has a 12 VDC, negative-ground control and engine cranking system. The

engine has a battery charger for recharging during generator set operation.

A battery charger located in the transfer switch keeps the battery charged during generator set

standby.

Refer to the GSBB Specifications Table for battery specifications.

26 A029V088 (Issue 19)

Page 33

3-2015 3. Step-By-Step Outline of Installation

An optional thermostatically controlled battery heater is available for more reliable starting in

ambient temperatures down to -20 °F (-28.8 °C). The heater wraps around the battery. The

heater cord is connected to the 120V, accessory junction box. Install the heater in accordance

with the kit instructions.

To prevent injury due to accidental start-up, do not connect the battery cables to the battery until

the installation has been completed and it is time to start the set.

WARNING

Before working on the generator set, move the Switch (S2) to the Stop Position, disconnect the

remote harness (P7) to disable the ATS mounted charger, and remove the negative (-) battery

cable from the battery to prevent starting.

FIGURE 11. BATTERY INSTALLATION

3.8 Fuel System

WARNING

Fuel systems must be installed by qualified service technicians. Improper installation

presents hazards of fire and improper operation, resulting in severe personal injury or

property damage.

A029V088 (Issue 19) 27

Page 34

3. Step-By-Step Outline of Installation 3-2015

WARNING

Gaseous fuels are flammable, explosive and can cause severe personal injury or death.

Do not smoke if you smell gas, are near fuel tanks for fuel-burning equipment or are in

an area sharing ventilation with such equipment. Keep flames, sparks, pilot lights,

electrical arcs, arc-producing equipment and all other sources of ignition well away.

Keep a type ABC fire extinguisher handy.

In all fuel system installations, cleanliness is extremely important.

• Make every effort to prevent fuel contamination of:

• moisture

• dirt

• excess thread sealant

• contaminants of any kind

• Clean all fuel system components before installing.

Gaseous-fuel supply system design, materials, components, fabrication, assembly, installation,

testing, inspection, operation and maintenance must comply with the applicable codes. See

NFPA Standards No. 37, 54 and 58.

Most codes require a manual shutoff valve ahead of a flexible fuel hose. The manual valve

should be of the indicating type. The generator set has an electric (battery-powered) shutoff

valve included.

It is recommended that a shutoff valve be located near the generator set as well, for

emergency shut off or servicing the generator set.

Until the generator set is connected, cap the fuel line stub-up at the generator set to prevent dirt

from entering and gas from discharging if the gas supply shutoff valve is opened inadvertently.

3.8.1 Fuel Line Connections

Fuel presents the hazard of fire or explosion that can result in severe personal injury or

death. Do not smoke or allow any flame, spark, pilot light or other ignition sources near

fuel or in the installation area. Read the important safety precautions in the Fuel System

section of this manual.

Refer to the Outline and System Drawings for the location of the fuel supply connection

through the side of the generator set.

NOTICE

WARNING

NOTICE

The low fuel pressure switch connection comes standard on the 50 Hz. model and is an

option on the 60 Hz. model of this generator set.

A flexible fuel hose is packaged inside the generator set.

28 A029V088 (Issue 19)

Page 35

3-2015 3. Step-By-Step Outline of Installation

The section of flexible fuel hose supplied with the generator set must be used between the

engine's fuel system and fuel supply line to protect the fuel system from damage caused by

vibration, expansion and contraction. The fuel hose must be installed according to all applicable

codes and standards.

Connect it between the 3/4 NPT fitting on the generator set and the fuel supply line.

Callout Component

Number

12 Fuel Connection (Female) 3/4 NPT & NG & LPV

13 4x Anchoring Spike

FIGURE 12. FUEL LINE CONNECTIONS

3.8.2 Fuel Line Connections (Model 14GSBB-6716B Only)

The factory installed, UL approved valve must be removed and an Australian Gas Association

(AGA) approved shutoff valve must be installed prior to generator set installation in Australia or

New Zealand. Adaptation from NPT to BSPT may be required, depending on the valve used.

The maximum amperage of the valve selected must be less than 1.0 amp at 12 VDC.

3.8.3 Natural Gas Fuel System

The generator set requires an adequate fuel supply to operate correctly at full load. The length

of the fuel supply pipe from the gas service entrance to the generator set must be known to

determine the correct fuel pipe size. Refer to the Natural Gas Pipe Capacity - Cubic Feet of Gas

Per Hour table, located within the Natural Gas Supply Line Size section of this manual to find

the fuel supply requirement for your generator set. The Pipe must be a minimum of schedule 40

subject to the authority having jurisdiction.

A029V088 (Issue 19) 29

Page 36

3. Step-By-Step Outline of Installation 3-2015

3.8.3.1 Natural Gas Supply

NOTICE

The Natural Gas supply meter may need to be exchanged for a higher capacity meter to

supply the additional gas consumed by the generator set.

See the Generator Set Specifications Table for fuel specifications, such as BTU. To

determine the required meter capacity, generator set consumption must be added to the gas

consumed for heating, cooking, clothes drying, etc.

• A typical installation might require a 400,000 BTU meter.

Consideration should also be given to utilizing high pressure gas supply (2 psi) if available. This

will reduce the required size, and therefore cost, of gas piping, especially if the location of the

generator set requires a long supply line.

NOTICE

An older site might require upgrading and repair of the gas supply system, which

should be scheduled to minimize power and gas supply interruptions.

3.8.3.2 Natural Gas Supply Line Size

See the Generator Set Specifications Table for fuel specifications (such as BTU/hr).

The Natural Gas meter may not be adequate if the meter serves other gas appliances, such as

a:

• Furnace

• Water heater

• Stove

To correctly size the fuel pipe, you must also take other loads operated from the fuel supply line

into consideration, such as:

• Space heating equipment

• Water heating equipment

Use the total load requirement of the fuel supply line to determine the size of the fuel supply

pipe. Use the Natural Gas Pipe Capacity - Cubic Feet of Gas Per Hour table to determine the

correct pipe size.

For Spec A and Canadian GSBB Spec B, make sure the fuel supply pressure at the inlet to the

generator regulator (at service port) is set between 5–11 in. WC for all operating loads (no load to

full load).

For US GSBB Spec B and Canadian GSBC Spec B, make sure the fuel supply pressure at the

inlet to the generator regulator (at service port) is set between 5–7 in. WC for all operating loads

(no load to full load).

NOTICE

30 A029V088 (Issue 19)

Page 37

3-2015 3. Step-By-Step Outline of Installation

FIGURE 13. TYPICAL NATURAL GAS INSTALLATION

NOTICE

Typically, 1 ft3/hr = 1000 BTU/hr. When the fuel delivery value falls between two

columns, use the larger value.

TABLE 16. NATURAL GAS PIPE CAPACITY - CUBIC FEET OF GAS PER HOUR

Normal Iron Length of Pipe in Feet

Pipe Size

(Inches)

3/4 360 250

1 680 465 375 320 285 260 240

1 1/4 1400 950 770 660 580 530 490 460 430 400 360 325 300 280

Maximum pipe capacity in cubic feet per hour of 0.60 specific gravity Natural Gas with a pressure drop of 0.5 inches

(1.27 mm) WC over the length.

10 20 30 40 50 60 70 80 90 100 125 150 175 200

3.8.4 Propane Fuel System

WARNING

NFPA Standard No. 58 requires all persons handling and operating Propane to be

trained in proper handling and operating procedures.

WARNING

Fuel leaks can lead to explosive accumulations of gas. Propane sinks in air and can

accumulate inside housings, basements and other below-grade spaces. Prevent gas

leaks and the accumulation of gaseous fuel in the event of a leak.

A029V088 (Issue 19) 31

Page 38

3. Step-By-Step Outline of Installation 3-2015

3.8.4.1 Recommended Fuel (Propane)

WARNING

Propane presents the hazard of fire or explosion that can cause severe personal injury

or death. Do not permit any flame, spark, arc-producing equipment, switch, pilot light,

cigarette or other ignition source near the fuel system. Keep an ABC type fire

extinguisher nearby.

Use clean, fresh HD-5 grade Propane or equivalent product consisting of at least 90% Propane.

NOTICE

Commercial Propane may contain more than 2.5% butane, which can result in poor fuel

vaporization and low tank pressure - resulting in poor engine staring in below 32 °F (O

°C) temperatures.

3.8.4.2 Propane Tank Size

First, some Propane tank facts to bear in mind when figuring the proper Propane tank size:

• Propane tanks are sized by the number of gallons of water they can hold, not the amount

of fuel they can hold.

• Propane tanks are generally filled to only 80% of their water capacity. Therefore, a 500 lb.

tank results in 400 lb. tank capacity.

• Low ambient temperatures affect the amount of fuel available from the Propane tank.

• Approximately 60% of the fuel (in gallons) filled in the tank can be effectively used.

Therefore, a 500 lb. tank results in 300 gallon capacity.

To assist in the proper selection of the Propane tank, follow the guidelines below.

• Propane tanks must be fitted with a pressure reducing regulator before connection to the

generator set to prevent fuel system damage.

• Propane tanks must be located at least 10 ft. (3048 mm) from any source of combustion

(including the generator set).

TABLE 17. REQUIRED PROPANE TANK SIZE IN GALLONS (LITERS) FOR INDICATED

TEMPERATURES WHEN KEPT AT LEAST HALF FULL

Withdrawal Lowest Average Winter Temperature

Rate

100 cfg 250 250 250 400 500 1000 1500

(250,000

BUT/hr)

[2.8 m3/hr (264

MJ/hr)]

150 cfg 300 400 500 500 1000 1500 2500

(375,000

BUT/hr)

[4.2

m3/hr(395.6

MJ/hr)]

32 °F (0 °C) 20 °F (-7 °C) 10 °F (-12 0 °F (-18 °C) -10 °F (-23 -20 °F (-29 -30°F (-34

°C) °C) °C) °C)

(945) (945) (945) (1515) (1890) (3785) (5675)

(1135) (1515) (1890) (1890) (3785) (5675) (9640)

32 A029V088 (Issue 19)

Page 39

3-2015 3. Step-By-Step Outline of Installation

Withdrawal Lowest Average Winter Temperature

Rate

200 cfg 400 500 750 1000 1200 2000 3500

(500,000

BUT/hr)

[5.7 m3/hr

(527.5 MJ/hr)]

300 cfg 750 1000 1500 2000 2500 4000 5000

(750,000

BUT/hr)

[8.5 m3/hr

(791.2 MJ/hr)]

32 °F (0 °C) 20 °F (-7 °C) 10 °F (-12 0 °F (-18 °C) -10 °F (-23 -20 °F (-29 -30°F (-34

°C) °C) °C) °C)

(1515) (1890) (2840) (3785) (4540) (7570) (13250)

(2840) (3785) (5675) (7570) (9640) (15140) (18925)

3.8.4.3 Propane Vapor Fuel Supply Line Size and Pressure

Fuel line size depends on the amount of fuel needed to run the generator set at full load at the

distance the fuel must be moved.

• See the Generator Set Specifications Table for fuel system specifications, such as the

amount of propane vapor at certain loads.

The following figure shows a typical Propane vapor installation and the table below lists fuel

capacity for given distances and pipe size.

Size the fuel line so that the Propane vapor pressure drops no more than 1.5 inches WC from

no load to full load.

NOTICE

For Spec A and Canadian GSBB Spec B, make sure the fuel supply pressure at the inlet of the

generator fuel regulator (at service port) is set between 7–11 in. WC for all operating loads (no

load to full load).

For US GSBB Spec B and Canadian GSBC Spec B, make sure the fuel supply pressure at the

inlet of the generator fuel regulator (at service port) is set between 12–14 in. WC for all operating

loads (no load to full load).

A029V088 (Issue 19) 33

Page 40

3. Step-By-Step Outline of Installation 3-2015

TABLE 18. PROPANE VAPOR PIPE CAPACITY - CUBIC FEET OF GAS PER HOUR

Nominal Iron Length of Pipe in Feet

Pipe Size

(Inches)

3/4 227 157 126

1 428 293 236 201 179 164 151 138 129 123 110

1 1/4 882 598 485 416 365 333 308 289 207 252 230 204

1 1/2 1323 920 743 624 567 570 472 434 409 390 346 315

2 2488 1732 1386 1197 1058 958 882 819 768 724 642 598

Maximum pipe capacity in cubic feet per hour of Propane vapor with a pressure drop of 0.5 inches (1.27 mm) WC

over the length

10 20 30 40 50 60 70 80 90 100 125 150

FIGURE 14. TYPICAL PROPANE VAPOR WITHDRAWL INSTALLATION

3.8.4.4 Converting From Natural Gas to Propane (Vapor Withdrawal)

The generator set leaves the factory set up for Natural gas.

For use with Propane, the generator must be converted by configuring the control for

Propane.

For US GSBB Spec B and Canadian GSBC Spec B, additional steps must be taken when

converting to Propane.

1. The manual fuel selector must be adjusted to the LP setting.

2. Once the manual fuel selection is set, install the welch plug tied to the front of the fuel

regulator by hammering the plug into the fuel selector until the plug distorts and cannot be

removed. Once the plug is installed, the fuel type cannot be changed unless the welch plug

is physically removed. If the welch plug is removed, it will most likely be damaged and will

need to be replaced with a new welch plug.

34 A029V088 (Issue 19)

Page 41

3-2015 3. Step-By-Step Outline of Installation

No. Description No. Description

1 Manual Fuel Selector 2 Welch Plug (in bag)

FIGURE 15. MANUAL FUEL SELECTOR AND WELCH PLUG (US GSBB SPEC B AND CANADIAN

GSBC SPEC B ONLY)

FIGURE 16. MANUAL FUEL SELECTOR (US GSBB SPEC B AND CANADIAN GSBC SPEC B ONLY)

A029V088 (Issue 19) 35

Page 42

3. Step-By-Step Outline of Installation 3-2015

FIGURE 17. WELCH PLUG INSTALLATION (US GSBB SPEC B AND CANADIAN GSBC SPEC B

ONLY)

3.8.5 Testing the Fuel System for Leaks

WARNING

Fuel presents the hazard of explosion or fire which can result in severe personal injury

or death. Do not smoke or allow any flame, spark, pilot light, arc-producing equipment,

switch or other ignition sources around fuel or fuel components.

Before operating the generator set, test the fuel system for leaks.

• Energize the fuel solenoid from a separate 12-volt DC source before testing the fuel

system

NOTICE

Testing for gas leaks with a flame can cause a fire or explosion that can lead to severe

personal injury or death. Use approved methods only.

After assembly, and before initial operation, all fuel system connections, hose valves, regulators

and fittings must be tested and proven free of leaks using a soap-and-water (or equivalent)

solution while the system is under gas or air pressure of at least 1.5 times the supply pressure

or 3 psi (20.7 kPa) minimum.

• Apply the soap-and-water solution to all fuel system connections, hose valves, regulators

and fittings.

• When the system is running, bubbles will form where air/pressure is leaking from the

system.

Other approved methods of detecting leaks can be used if appropriate. DO NOT use a flame to

test for gas leaks.

36 A029V088 (Issue 19)

Page 43

3-2015 3. Step-By-Step Outline of Installation

3.9 Engine Exhaust

The exhaust system for this generator set is complete and was designed specifically for this

engine. Do not modify or add to the exhaust system of this generator set.

WARNING

EXHAUST GAS IS DEADLY! The exhaust system must terminate away from building

vents, windows, doors and sheltered spaces that may not have ample fresh air

ventilation.

WARNING

Engine discharge air and exhaust carry carbon monoxide gas (odorless and invisible)

which can cause asphyxiation and death. Never use engine discharge air or exhaust for

heating a room or enclosed space.

A029V088 (Issue 19) 37

Page 44

3. Step-By-Step Outline of Installation 3-2015

This page is intentionally blank.

38 A029V088 (Issue 19)

Page 45

4 Optional Internet/Email Interface

Descriptions

4.1 Introduction

This feature allows for in-home or remote access to your generator set through a web page.

NOTICE

An Internet browser (i.e., Internet Explorer) is required for this option.

On this web page, you can start or stop the generator set, adjust the exerciser day and time,

determine if utility power is available and view the last 20 events/faults on the generator set.

This feature is useful for homeowners who travel or have a second home and want to be able to

remotely interface with their generator set. This feature can also help to reduce troubleshooting

time and service calls when the service technician has access to the same web page.

Use of the Ethernet is not required if you do not use web access. To set up your generator set

for web access, complete installation instructions are included in the Network Setup Guide

instruction sheet, included with your generator set literature package.

The Internet/Email Interface can make the same fault, maintenance and event notices available

to you and to your generator set service contract agency with appropriate Internet Service and

email account.

NOTICE

Technical support for setup and troubleshooting of the hardware used for in-home

network access to the generator set is available through the selling Cummins Power

Generation dealer/distributor.

The owner may be required to contact their ISP and/or email provider for technical support of the

email notification feature setup and troubleshooting.

Due to the variations in network equipment, network configurations and ISPs, the owner is

responsible for acquiring the needed support/service from a qualified network specialist to

properly and securely set up the owner's network for remote monitoring of the generator set.

Cummins Power Generation does not provide technical support for setup and troubleshooting of

the owner's network and email service.

A029V088 (Issue 19) 39

Page 46

4. Optional Internet/Email Interface Descriptions 3-2015

4.2 Screen Descriptions

FIGURE 18. HOME PAGE

4.2.1 Setting Time and Date

Select the Genset Time/Date Tab on the Home Screen to set the time and date for the

generator set control.

FIGURE 19. SET GENSET TIME AND DATE

4.2.2 Set Exercise Schedule

Select the Exercise Schedule Tab on the Home Screen to set the generator set exercise

schedule.

40 A029V088 (Issue 19)

Page 47

3-2015 4. Optional Internet/Email Interface Descriptions

NOTICE

The generator set will exercise on the first scheduled day for which it is programmed. After that it

exercises on that day at the scheduled interval. For example, if the generator set is scheduled on

a Wednesday for Saturdays with a monthly interval, the generator set starts on the next available

Saturday. After that it exercises on Saturdays one month apart.

FIGURE 20. SET EXERCISE SCHEDULE

4.2.3 Load Control (Management)

Select the Load Control Tab on the Home Screen to enable Automatic or Manual Load Control.

In Automatic mode, the user can only view which loads are connected. In Manual mode, the

user can view loads and also connect or disconnect them. See Load Management for details.

4.2.4 Event Log

Select the Event Log Tab on the Home Screen to review the last 20 events. See the Event Log

screen capture below for a list of all of the recordable events.

FIGURE 21. GENSET LOAD MANAGEMENT

A029V088 (Issue 19) 41

Page 48

4. Optional Internet/Email Interface Descriptions 3-2015

FIGURE 22. EVENT LOG

4.2.5 Fault Log

Select the Fault Log Tab on the Home Screen to review the last 5 faults.

FIGURE 23. FAULT LOG

4.2.6 Network Setup Screen Descriptions

An owner-custom password can be defined in the Network Setup screen shown below. The

user will be prompted to enter the User Name and Password to access this screen.

The Network Setup Parameters screen allows dynamic addresses to be changed to static

addresses. This screen allows the user to configure the static address for the in-home network.

See the Network Setup Parameters screen shown below.

42 A029V088 (Issue 19)

Page 49

3-2015 4. Optional Internet/Email Interface Descriptions

FIGURE 24. NETWORK SETUP SCREEN

FIGURE 25. NETWORK SETUP PARAMETERS

4.2.7 Email Setup Screen Descriptions

The user must determine what events will trigger an email notification of the event:

• Never

• All Events

• Maintenance and Attention Required or Attention Required Only

This screen is also used to set up e-mail configuration.

The user may enter up to three email addresses for receiving notifications of the home-standby

generator set status. See the Email Addresses figure below.

A029V088 (Issue 19) 43

Page 50

4. Optional Internet/Email Interface Descriptions 3-2015

FIGURE 26. EMAIL SETUP PARAMETERS

FIGURE 27. EMAIL ADDRESSES

4.2.8 Saving Changes

After the email addresses are added and Done is selected, this screen will appear, verifying that

all changes have been saved.

FIGURE 28. SAVE SCREEN

44 A029V088 (Issue 19)

Page 51

5 Optional Internet/Email Interface Setup

5.1 Network Connectivity Options

Network connectivity includes in-home Network access to the generator set, e-mail notification,

and remote access to the generator set.

5.2 Material/Cable Routing

Route the category 5 Ethernet cable from the generator in the same conduit as the control lines

and display cable (for in-home mounted displays) to the transfer switch and into the house.

Ensure the cable is long enough to reach the network router. Attach the cable end connectors at

each end.

5.3 Network Information Needed For Setup

The following sections will help with gathering information required for a successful installation.

5.3.1 Network Router

The following information is needed to configure the generator set with a static IP address.

• Router User Name:_______________________________

• Router Password:________________________________

• Available Static IP Address:________________________

5.3.2 Email/Internet Service Provider (ISP)

This information is used when configuring email notifications. The internet service provider (ISP)

may need to be contacted for this information.

NOTICE

If these items cannot be verified or provided, email communication and/or remote

Internet access may not work. If the service provider will not verify or provide the

installer with this information, it is the responsibility of the customer to provide this

information.

Email Account Provider (May Be ISP):____________________________________________

Email Account Provider Contact Number:__________________________________________

Email Provider Allows SMTP Communications Via Port: ___

Email Provider Supports Authenticated and Unauthenticated Email: Yes/No (circle one)

A029V088 (Issue 19) 45

Page 52

5. Optional Internet/Email Interface Setup 3-2015

NOTICE