INSTALLATION AND OPERATION MANUAL

MF3500 Model

NORMAL CARE & MAINTENANCE

CLEANING THE GLASS

When the fire is first started, it will produce some smoke.

The smoke might accumulate on the glass surface. Before

the fire gets hot, open the door and wipe the glass surface

off with a damp rag.

If after constant use, the glass might fill with ash deposits.

You must clean the glass after the glass has cooled down.

Do not touch the surface with your hands. Take a damp rag

and wipe the glass clean. If this does not clean the glass

use any non-abrasive liquid spray.

DISPOSAL OF ASHES

Ashes should be placed in a metal container with a

tight fitting lid. The closed container of ashes should

be placed on a noncombustible floor or on the ground,

well away from all combustible materials, pending final

disposal. If the ashes are disposed of by burial in soil

or otherwise locally dispersed, they should be retained

in the closed container until all cinders have been

thoroughly cooled.

REMOVAL OF CERAMIC GLASS

Open the door and lift off of hinges. If the door is tight, tap

gently on the bottom of the door with your hand or rubber

hammer. Lay door down on newspaper with glass clips

facing you. Loosen the screws and take off the glass clips.

Remove the broken glass carefully and discard.

Reverse the above procedure for replacing new glass with

new gasket.

CAUTION

DO NOT OPERATE STOVE WITH BROKEN GLASS.

DO NOT SLAM THE DOOR SHUT.

DO NOT STRIKE GLASS.

DO NOT USE ABRASIVE CLEANERS.

DO NOT CLEAN HOT GLASS.

RE P L A C E CE R A M IC G LA S S W I T H FAC T O R Y

AUTHORIZED REPLACEMENT PARTS ONLY.

THE CLINKER WILL REMAIN HOT FOR SEVERAL

MINUTES AFTER IT IS PULLED OUT OF THE BURNER

POT.

FUEL POT REMAINS

The “clinker” is the solid mass that remains unburned in

the burner pot. It contains the inorganic parts of the fuel

and is safe to use as fertilizer or dispose of in a proper

container.

SOOT AND FLY ASH

The products of combustion will contain small particles of fly

ash. The fly ash and soot will collect in the exhaust venting

system and restrict the flow of flue gasses. Incomplete

combustion, such as occurs during startup, shutdown, or

incorrect operation of the parlor stove will lead to some soot

formation which will collect in the exhaust venting system.

The exhaust venting system should be inspected at least

once per month (during heavy use) to determine if cleaning

is necessary. Corn has a high ash content.

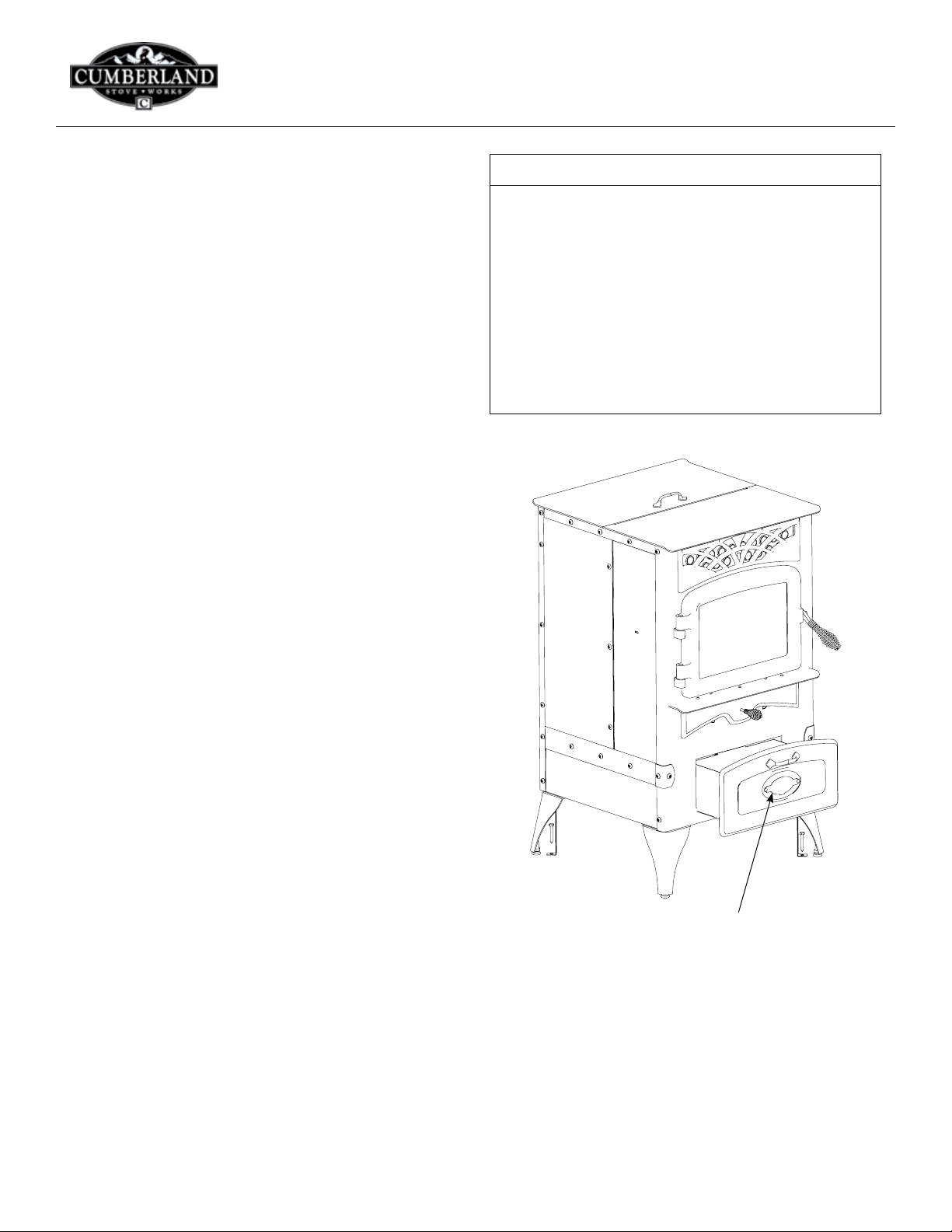

Ash Pan Location

EXHAUST AND CONVECTION AIR FILTER

• Remove air filter and replace regularly

• Clean exhaust vent

Page 22 800-345-6007

CumberlandStoveWorks.com

INSTALLATION AND OPERATION MANUAL

AIR FILTER

MF3500 Model

DAILY MAINTENANCE

• Surfaces on the front of the stove will be extremely

hot during operation. Always wear heat resistant

gloves to perform periodic maintenance.

• Remove heat shield. Using a wooden stick, tap the side

heat exchangers that are located on the left and right

sides of the firebox. When you open the door, they are

located directly inside to the left and right. When you

tap the sides with the wooden stick the loose fly ash will

drop out of these holes.

• Inspect inside stove for excessive ash build up. You will

learn some fuels produce more ash than others.

WEEKLY MAINTENANCE

• Remove the ash pan and dump the ash into a metal

container.

• Cleaning of the exhaust system will depend upon the

ash and debris content of your fuel. If your fuel has

a high ash content and/or significant debris in it, the

exhaust system will require weekly cleaning. Cleaner

fuels will allow for monthly cleaning of the exhaust

system. Remove the exhaust pipe from the back of the

stove and remove any ash that may have collected in

the pipes. Replace the pipes to the stove and seal with

high temperature seal tape. If you have installed proper

clean out tees you will not have to take the chimney

sections apart.

NOTE: A clean unit bums efficiently and will remain

trouble free!

WARNING

WHEN PERFORMING ANY INTERNAL ELECTRICAL

MAINTENANCE

• MOVING PARTS INSIDE OF THE CABINET MAY

CAUSE INJURY. DO NOT OPERATE UNIT WITH

PANELS REMOVED OR OPEN.

• HOT PARTS. DO NOT OPERATE THE UNIT WITH

PANEL OPEN.

• RISK OF ELECTRIC SHOCK. DISCONNECT POWER

BEFORE SERVICING UNIT.

• IN THE EVENT OF COMPONENT FAILURE, REPLACE

WITH THE ORIGINAL FACTORY EQUIPMENT.

CAUTION

TH I S IS A MINIMUM RE QUIREM E NT FOR SOOT

AND FLY ASH REMOVA L . ASHES SH O U L D B E

PLACED IN A METAL CONTAINER WITH A TIGHT

FITTING LID. THE CONTAINER SHOULD BE PLACED

ON A NON-C OMBU S TIBL E FLOOR , WEL L AWAY

FROM COMBUSTIBLE MATERIALS, PENDING FINAL

DISPOSAL. IF ASHES ARE DISPOSED OF BY BURIAL

IN SOIL OR OTHERWISE LOCALLY DISPERSED, THEY

SHOULD BE RETAINED IN THE CLOSED CONTAINER

UNTIL ALL CINDERS ARE NO LONGER WARM.

SEASONAL CLEANING

Once every year you must clean out all of the fuel in the

hopper, firebox area, ash pan and fire pot area. Corn and

any ash can accumulate moisture over the summer months

causing the unit to rust and the fuel to mold.

It is recommended that prior to shutting down the unit in

the spring it is run on the high setting for about six hours to

help clean out the heat exchanger system, venting system

and firebox area.

When the unit is cleaned out, empty the hopper, take the

venting apart and clean out the fly ash, rinse and let dry.

Take the draft blower off and clean out all areas such as

back heat exchanger and lubricate the auger, auger tube,

and fire pot area. (Something like vegetable spray works

great to coat the inside of the unit and the moving parts).

Clean the glass, doors and outer cabinet so that you are

ready for the next heating season. Use of a wet/dry vacuum

makes the clean out easier and faster.

CumberlandStoveWorks.com

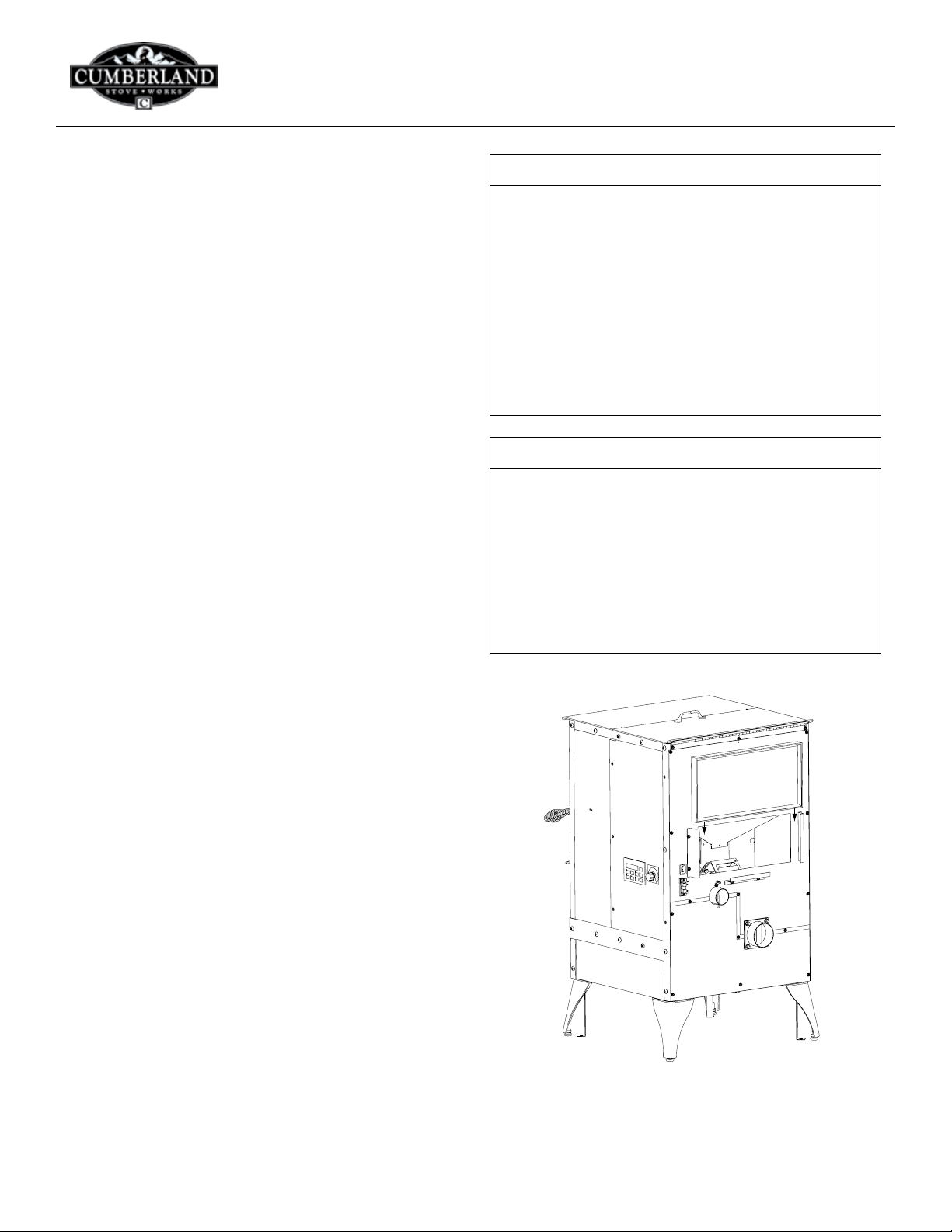

Air Filter Placement - back view

Page 23800-345-6007

Loading...

Loading...