Cultured Stone SUBMITTAL PACKET Installation Manual

CULTURED

TECHNICAL SUBMITTAL PACKET 2020

SUBMITTAL PACKET

WELCOME

COMPANY NAME:

CONTACT NAME:

PROJECT TITLE:

STREET ADDRESS:

CITY, STATE, ZIP:

We would like to congratulate you on your upcoming project which incorporates adhered concrete

masonry veneer products. Enclosed in this packet are the required Cultured Stone submittal forms

and technical documents. We have also enclosed additional support materials and installation details

commonly requested by architects and contractors.

Visit culturedstone.com/resources to view all digital materials available for download.

SUBMITTAL FORM

TECHNICAL DATA SHEET

50-YEAR WARRANTY

CERTIFICATE OF QUALITY

STONE INSTALLATION

As part of our commitment to service, we would like to recommend that you take advantage of our consulting services.

We have trained Technical Field Service representatives that will walk through your project with you prior

to installation. This can help prevent improper installations and in some cases identify where additional

stone or accessories may be needed.

Thank you again for choosing Cultured Stone. Should you have any questions, please do not hesitate in

contacting us. We are grateful for the opportunity to be a part of your project needs.

Sincereley,

BRICK INSTALLATION

3-PART SPEC

ICC-ES EVALUATION REPORT

SAFETY DATA SHEET

Sales Representative

Cultured Stone

1.800.255.1727 | culturedstone.com

SUBMITTAL PACKET

SUBMITTAL FORM

Cultured Stone Representative:

PROJECT DETAILS CULTURED STONE

PROJECT NAME:

PROJECT ADDRESS:

CITY, STATE, ZIP:

Please fill in all known information:

OWNER ARCHITECT BUILDER MASON

COMPANY NAME:

CITY, STATE:

CONTACT NAME:

CONTACT PHONE:

COMPANY NAME:

CITY, STATE:

CONTACT NAME:

CONTACT PHONE:

PROJECT NOTES:

PROFILE: COLOR:

APPROX SQ FOOTAGE:

MANUFACTURING LOCATION:

COMPANY NAME:

CITY, STATE:

CONTACT NAME:

CONTACT PHONE:

COMPANY NAME:

CITY, STATE:

CONTACT NAME:

CONTACT PHONE:

Pre-Installation Project Team Meeting Scheduled? Y N Date Scheduled:

Your signature below acknowledges receipt of Cultured Stone’s “Submittal Packet” and the above

information is accurate to the best of your knowledge.

Received By: Date:

Company: Phone:

Cultured Stone Representative: Date:

Email completed form to: BoralStoneAnswers@Boral.com

1.800.255.1727 | culturedstone.com

TECHNICAL DATA

The Cultured Stone® collection of manufactured stone veneers is engineered to meet or exceed specifications

for all major code approvals. Manufacturers who oer ”just like” or a so-called “equivalent” to Cultured Stone

manufactured stone veneer products should be asked to document claims of test results and research reports.

Complete copies of these Cultured Stone manufactured stone veneer building code evaluation reports, research

reports, approvals and listings are available upon request:

• ICC-ES ESR-1364 • Florida Product Approval FL15047

• Tested and listed by Underwriters Laboratories, Inc. • HUD Materials Release No. 1316

• Texas Department of Insurance– • BMEC Authorization

Product Evaluation Report, EC-21

Note: Local building codes may vary; always check with your local building code authority prior to installation.

Results of tests conducted by an independent testing agency confirm that the Cultured Stone collection of

manufactured stone veneers conforms to or exceeds the following test requirements as specified in ICC

Evaluation Service Acceptance Criteria 51 for Precast Stone Veneer:

MATERIALS

CEMENT ASTM C 150 or ACI 318 Section 3.2.1

SAND ASTM C 144 or C 33

AGGREGATE ASTM C 33 or C 330 (except gradation), C 331

TESTING

SHEAR BOND TEST

(ADHESION)

WATER ABSORPTION Tested in accordance with UBC 15-5 9%–22% depending on texture

FREEZE/THAW

CHARACTERISTICS

COMPRESSIVE

STRENGTH

UNIT WEIGHT

TENSILE STRENGTH Tested in accordance with ASTM C 190 Reported

FLEXURAL STRENGTH Tested in accordance with ASTM C 348 Reported

THERMAL

PROPERTIES

NONCOMBUSTIBLE

Tested in accordance with ASTM C 482 > 50 psi

Testing procedures follow those outlined

in ASTM C 67

Tested in accordance with ASTM C 39 > 1800 psi @ 28 days

Density is determined in accordance

with ASTM C 567

Tested in accordance with ASTM C 177-71

Tested and listed by Underwriters

Laboratories, Inc.

< 3% mass loss

< 15 lbs. per square foot

R-value is .620 based on a 1.75" thick sample.

Average thickness may vary on dierent

Cultured Stone veneer products, and the

R-value will vary accordingly.

Cultured Stone brand products showed zero

flame spread and zero smoke development.

052918

1.800.255.1727 | culturedstone.com

50-YEAR TRANSFERABLE

LIMITED WARRANTY

LIMITATIONS ON THE TRANSFERABILITY OF THIS

WARRANTY ARE SET FORTH HEREIN

INTRODUCTION

Thank you for your recent purchase of Cultured Stone® by Boral® manufactured stone veneer products (“Product(s)”). This

express limited warranty (“Warranty”) only covers Cultured Stone manufactured stone veneer products manufactured by Boral

Stone Products LLC (“Boral”).

WHO IS COVERED & FOR HOW LONG

Subject to the following terms, Boral warrants its Products for fi fty (50) years to the original purchaser (the “Purchaser”) (based

upon the date of retail purchase, date of substantial completion of the installation if professionally installed, or date of settlement

of the purchase of a newly constructed building, whichever is applicable). This Warranty is personal to you; however, the

Warranty may be transferred to any subsequent purchaser(s) of your home or building during the fi rst fi fteen (15) years after the

original purchase date (as described above), but the warranty period as to such subsequent owners is limited to fi fteen (15) years

from the original purchase date (as described above).

WHAT BORAL WARRANTS

Boral, subject to the conditions and limitations listed herein, warrants its Products to be manufactured in compliance with

the International Code Council Acceptance Criteria 51 (“ICC AC 51) for Precast Stone Veneer; however, Products that are

accessories and Products that are not wall veneer shall not meet the weight, density and dimension parameters of ICC AC 51.

WHAT IS NOT COVERED

We do not cover damage to the Product due to any cause not expressly covered herein. This Warranty does not cover any

problems with non-defective material caused by conditions or handling beyond our control.

Some examples of conditions not covered by this Warranty include:

1. Improper application, use of accessories which do not properly receive and/or secure our Products, or installation

not in strict adherence to the applicable installation instructions or installation not in accordance with local building

code requirements.

2. Damage resulting from accident, misuse, neglect, casualty, fi re, vandalism, plant growth, impact of foreign objects,

salt or de-icing chemicals, excessive exposure to water due to things such as standing water, water backups,

improper fl ashing, leaks, seepage or irrigation systems, failure of or damage to the wall substrate on which the

Product was applied caused by movement, distortion, cracking, or settling of such wall or the foundation of the

building, surface discoloration due to airborne stains, pollutants, algae, fungi, lichens or cyanobacteria, exposure

to harmful chemicals, external heat sources (including, but not limited to, a barbecue grill, fi re, or refl ection from

windows and doors), acts of God, or other such occurrences beyond the control of Boral;

3. Product or material that has been painted, varnished, sealed with non-breathable sealer, or similarly coated over the

manufacturer’s original fi nish; and

4. The use of sandblasting, power washing, silicone treatments, or any other form of chemical wash.

Products shall not be in breach of this Warranty if they contain or exhibit (i) minor chipping, as defi ned under ASTM C1364,

Section 8.2; or (ii) minor cracks, as defi ned under ASTM C 90-05, Section 7.2.1, incidental to the usual methods or materials of

manufacture or minor chipping resulting from customary methods of handling in shipment and delivery which do not a˛ ect

the proper placement of the unit or signifi cantly impair the strength or permanence of the construction.

Products are not warranted against discoloration caused by air pollution, exposure to harmful chemicals, or “normal weathering”

resulting from exposure to the elements. “Normal weathering” is defi ned as the damaging e˛ ects of sunlight and extremes of

weather and atmosphere that may cause any colored surface to oxidize, fade, or become soiled or stained over time.

Boral strives to accurately reproduce the colors of its masonry stone veneer Products in its marketing literature and sample

boards. The Product colors that you see are as accurate as technology allows. Boral makes no warranty with respect to any

real or perceived color di˛ erences between those depicted in its marketing literature and sample boards and those of the

actual Products that will be installed on or within the home or building. Boral recommends that you look at actual Product

samples before making a color selection for your home or building.

50˜YEAR TRANSFERABLE LIMITED WARRANTY

WHAT IS YOUR REMEDY

If the Products are not in conformance with our Warranty, Boral will, in its sole discretion, either (i) repair or replace the

nonconforming Products at no charge to you, or (ii) refund the price paid for the Products. Labor costs for removal or

installation are not covered. Any Products repaired or replaced hereunder will continue to be covered under the terms

of this Warranty for the remainder of the original warranty period.

SUBMITTING A WARRANTY CLAIM

To obtain performance under this Warranty, the Purchaser(s) shall notify Boral of the claim promptly following its discovery,

and shall submit with such notifi cation proof of date of purchase and/or installation, and proof of property ownership, in order

to provide Boral an opportunity to investigate the claim and examine the material claimed to be defective. All notifi cations

shall be provided to Boral at Boral Stone Products Warranty Department, 2256 Centennial Road, Toledo, Ohio 43617 or call

1-800-255-1727. Shortly after we receive your communication, we will contact you regarding your claim. To fully evaluate your

claim, we may ask you to provide pictures of your Products or samples for us to test. If you have any questions, do not hesitate

to write us at the address above or call 1-800-255-1727.

REPLACEMENT & PRODUCT VARIATIONS

As a result of our ongoing e˛ orts to improve and enhance our product line, we reserve the right to discontinue or modify

our Products, including their colors, without notice to the Purchaser(s) and shall not be liable to the Purchaser(s) as a

result of such discontinuance or modifi cation. We are not liable to you if you make a warranty claim in the future and any

replacement Products you receive vary in color or fi nish because of normal weathering or changes in our product line.

You should understand that if we replace any Products under this Warranty, we reserve the right to provide you with

substitute Products that are comparable only in quality and price to your original Products.

LIMITATIONS

EXCEPT AS SET FORTH ABOVE, BORAL MAKES NO EXPRESS OR IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO ANY PRODUCT SOLD. ORAL STATEMENTS CONCERNING

THE PRODUCT˝S˙ COVERED BY THIS WARRANTY, OR STATEMENTS CONTAINED IN BORAL’S GENERAL ADVERTISING,

PAMPHLETS OR OTHER PRINTED MATERIALS DO NOT CONSTITUTE WARRANTIES, AND PURCHASER ACKNOWLEDGES

THAT IT HAS NO RIGHT TO RELY UPON SAME. BORAL, WHETHER AS A MANUFACTURER OR CARRIER, SHALL NOT BE

LIABLE FOR ANY COMMERCIAL LOSSES, SPECIAL, INCIDENTAL, CONSEQUENTIAL, PUNITIVE OR EXEMPLARY DAMAGES,

OR FOR ANY LOSS, DAMAGE OR EXPENSE ARISING UNDER OR IN CONNECTION WITH ANY SALE OF PRODUCT.

BORAL’S LIABILITY FOR DAMAGES OF ANY KIND SHALL IN NO EVENT EXCEED THE ORIGINAL PURCHASE PRICE OF THE

PARTICULAR ORDER, LOT OR SHIPMENT ˝OR THE ORIGINAL PURCHASE PRICE OF THAT PORTION THEREOF WHICH IS

NOT REPAIRED OR REPLACED˙ WITH RESPECT TO WHICH A CLAIM IS ASSERTED. IN PARTICULAR, BORAL SHALL NOT BE

LIABLE FOR LOSS OF SALES, REVENUES OR PROFITS OR CLAIMS OF ANY THIRD PARTIES.

LEGAL RIGHTS

Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

Some states do not allow the exclusion or limitation on incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This Warranty gives you specifi c legal rights, and you may also have other rights which vary

from state to state. If the laws of a particular state require terms other than or in addition to those contained in this Warranty,

this Warranty shall be deemed modifi ed so as to comply with the appropriate laws of such state, but only to the extent

necessary to prevent the invalidity of this Warranty or any provision of this Warranty or to prevent the imposition of any fi nes,

penalties or any liability.

1.800.255.1727 | culturedstone.com ©2018 Cultured Stone 053018

Certificate of Quality

DATE:

ATTN:

PROJECT

TITLE:

PROJECT

CITY+STATE:

PRODUCT/STONE

COLOR+PROFILE (1):

PRODUCT/STONE

COLOR+PROFILE (2):

ARCHITECT:

GENERAL

CONTRACTOR:

MASONRY

CONTRACTOR:

This document certifies that the product manufactured by Cultured Stone, for the project

listed above, meets the Acceptance Criteria AC-51 for Precast Stone Veneer established

by ICC Evaluation Service and as specified in the Evaluation Report No. ESR-1364.

Sincerely,

Rick Garagliano

Director of Quality, Cultured Stone

MANUFACTURER’S

STONE INSTALLATION

INSTRUCTIONS

METHODS TO COMPLY WITH ASTM C1780

Cultured Stone® and Cultured Brick® Installation Instructions are available separately from your dealer and can

also be found at www.culturedstone.com.

Building code requirements vary from area to area. Check with local authorities for building code requirements

in your area. Carefully read all Installation Instructions before proceeding with your Cultured Stone products

application. Observe safety precautions. Cultured Stone products are covered by a 50-Year Limited Warranty

when installed in accordance with the manufacturer’s Installation Instructions. See the complete warranty on

our website at www.culturedstone.com.

STEP ONE:

DETERMINE BACK-UP WALL &

SURFACE PREPARATION REQUIREMENTS

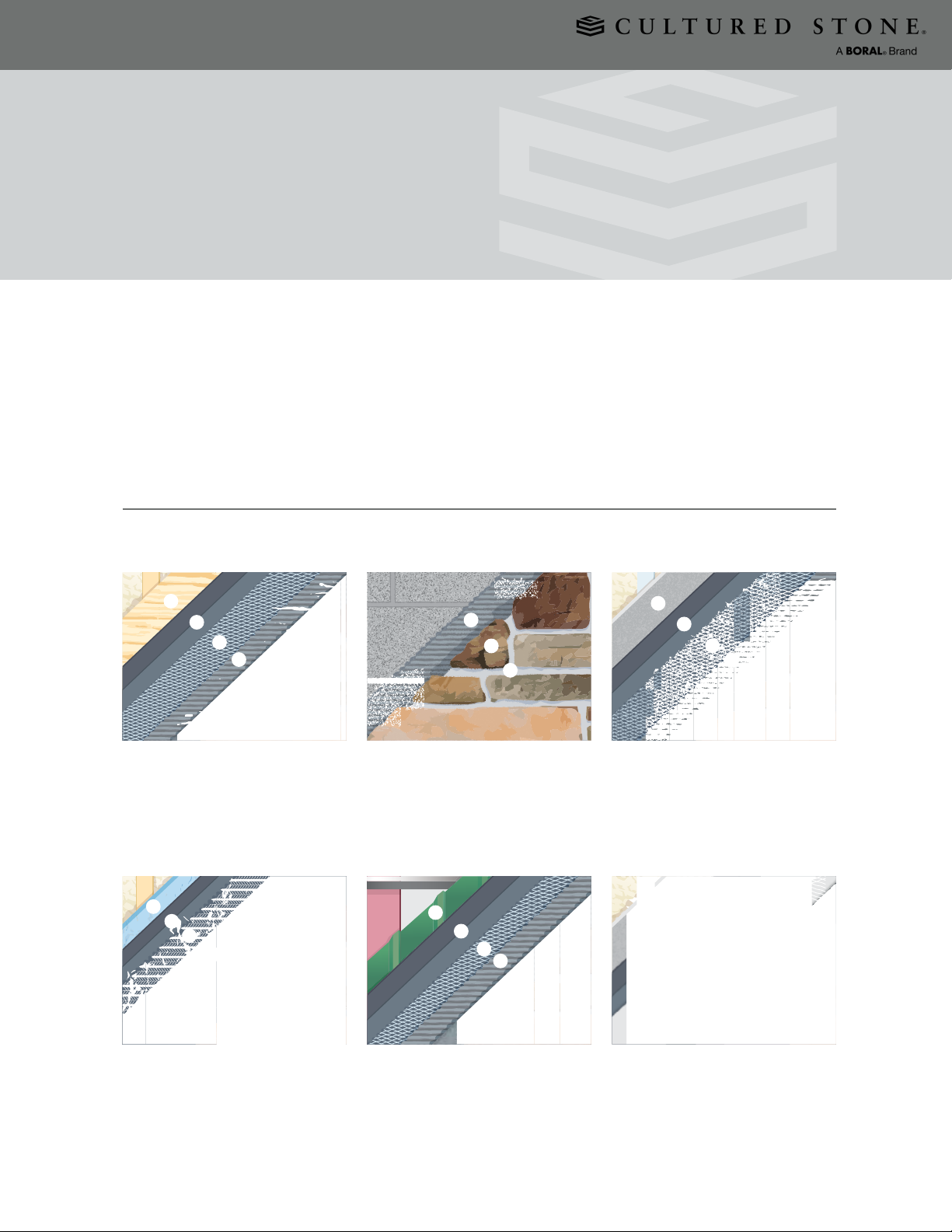

Typical back-up systems include:

WOOD FRAME

UNIT MASONRY/CONCRETE

1

2

3

1

2

4

5

7

6

In sequence: (1) sheathing, (2) two layers of

water resistive barrier (WRB), (3) galvanized

metal lath, (4) scratch coat, (5) mortar setting

bed, (6) Cultured Stone manufactured stone

veneer, (7) mortar joint.

In sequence: (1) mortar applied directly to

untreated, unpainted masonry, concrete or

stucco, (2) Cultured Stone manufactured stone

veneer, (3) mortar joint.

Note: Painted, sealed, dirty & smooth surfaces/

walls will require additional preparation to

address these conditions.

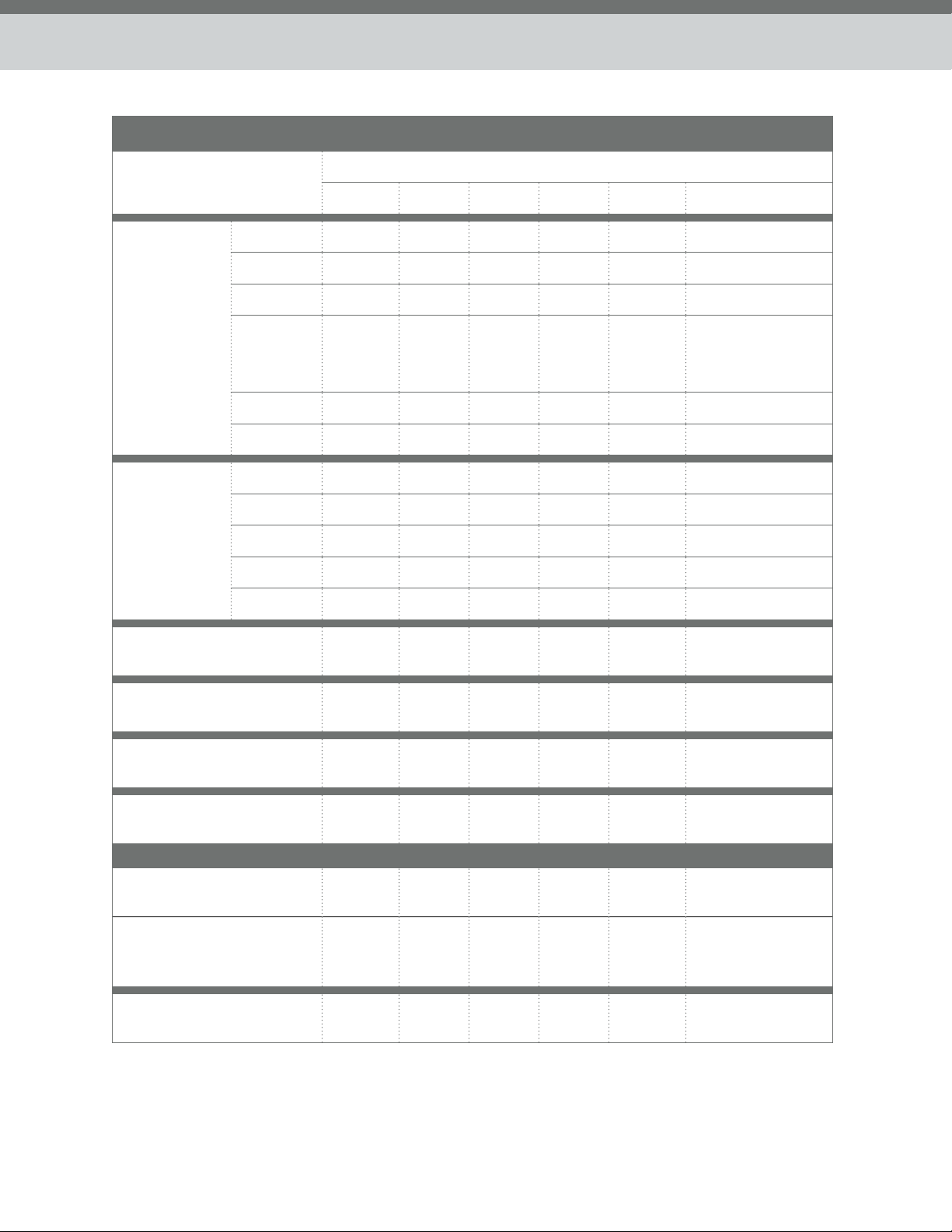

RIGID FOAM INSULATION METAL BUILDINGS

1

2

3

4

5

7

1

2

3

4

6

METAL FRAME

1

2

3

3

4

5

7

6

In sequence: (1) sheathing, (2) two layers of

water resistive barrier (WRB), (3) galvanized

metal lath, (4) scratch coat, (5) mortar setting

bed (6) Cultured Stone manufactured stone

veneer, (7) mortar joint.

CEMENT BOARD

1

2

3

5

7

6

4

6

5

In sequence: (1) rigid foam insulation,

(2) two layers of water resistive barrier (WRB),

(3) galvanized metal lath (Ribbed Lath shown),

(4) scratch coat, (5) mortar setting bed,

(6) Cultured Stone manufactured stone veneer,

(7) mortar joint.

See the special Technical Evaluation Report

regarding installation over continuous

insulation for more information.

In sequence: (1) sheathing, (2) two layers of

water resistive barrier (WRB), (3) galvanized

metal lath, (4) scratch coat, (5) mortar setting

bed, (6) Cultured Stone manufactured stone

veneer, (7) mortar joint.

In sequence: (1) sheathing, (2) two layers of

water resistive barrier (WRB), (3) cement board,

(4) mortar setting bed, (5) Cultured Stone

manufactured stone veneer, (6) mortar joint.

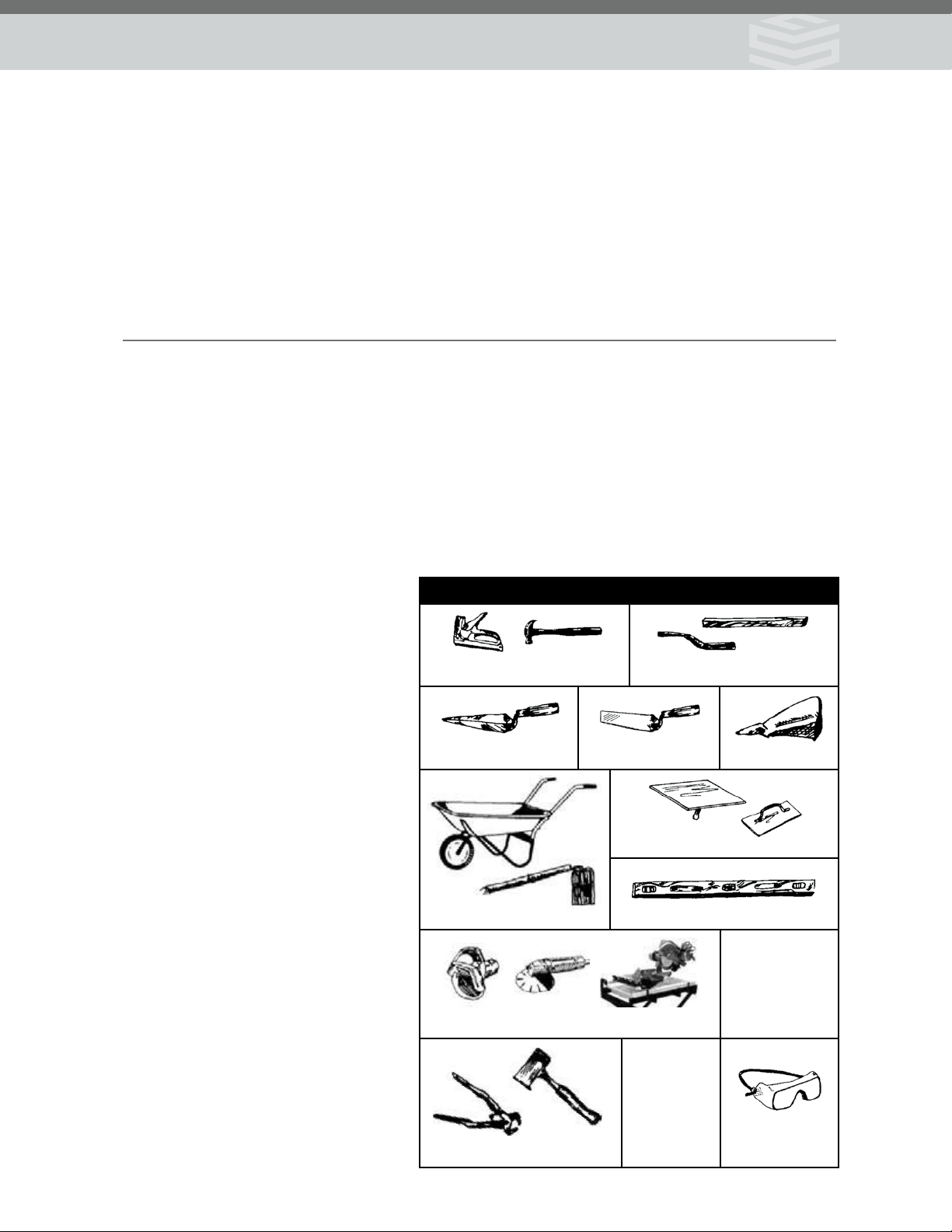

STONE INSTALLATION INSTRUCTIONS

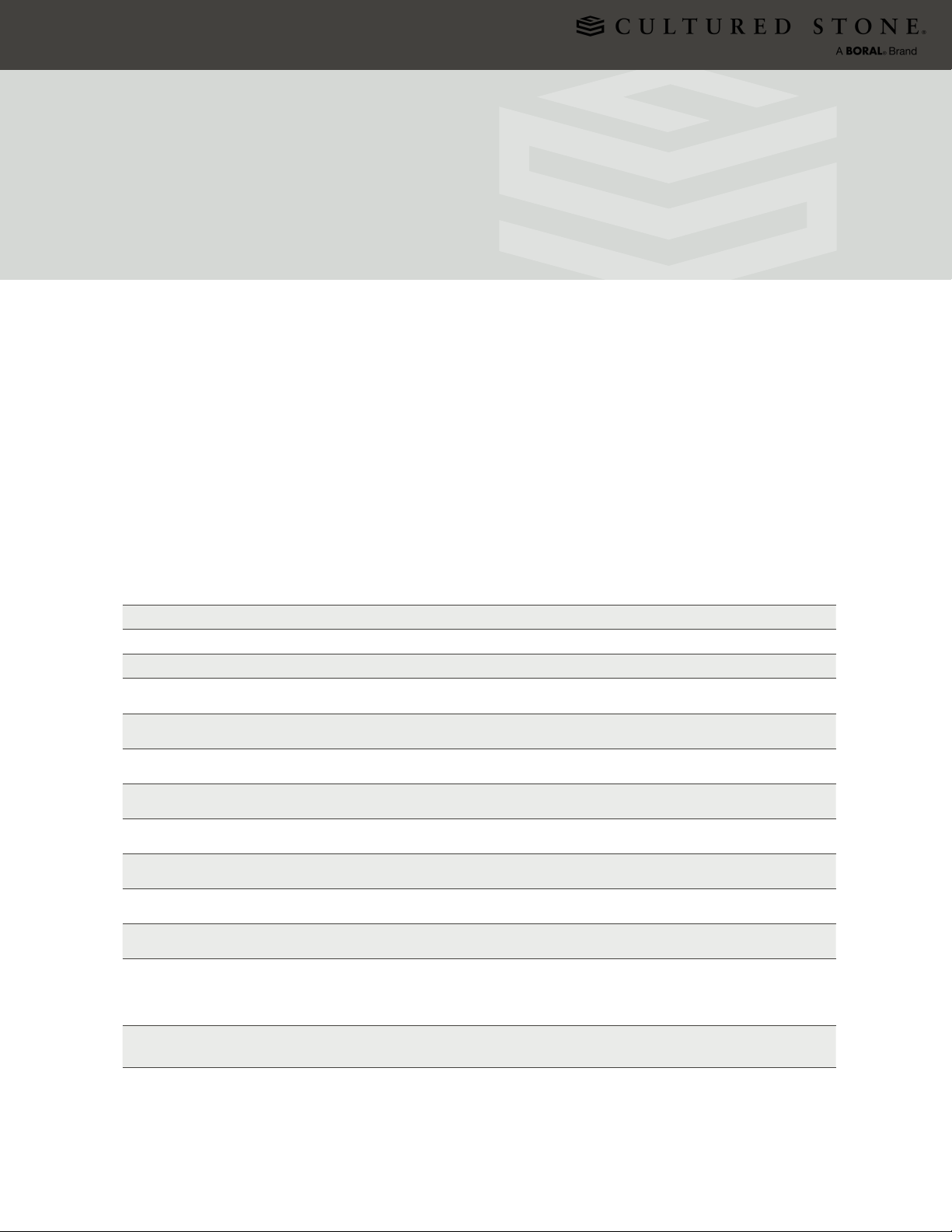

WALL SYSTEM/BACK UP

SURFACE PREPARATION TABLE 1

PREPARATION REQUIREMENTS

CLEANING

2 LAYERS

WRB

LATH

SCRATCH

COAT

ROUGHEN/

TEXTURE

NOTES

WOOD FRAME

16"oc

METAL FRAME

16"oc

UNIT MASONRY

(BRICK OR BLOCK)

SHEATHING

PLYWOOD

OSB

CEMENT

BOARD

WALLBOARD

½" FOA M

BOARD

SHEATHING

EXTERIOR

GYPSUM

OSB

PLYWOOD

½" FOA M

BOARD

✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓

OPTIONAL OPTIONAL N/A

✓ ✓ ✓

*

✓

✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

*

✓

OPTIONAL OPTIONAL OPTIONAL

**

✓ ✓

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

SITE

EVALUATION

Requires modified mortar

to bond units. Proprietary

coatings between bonding

mortar & cement board

may compromise warranty.

Engineer review

recommended for existing

unit masonry.

POURED CONCRETE OR

“TILT UP” CONSTRUCTION

OPEN STUD CONSTRUCTION

METAL BUILDING

INTERIOR INSTALLATION

CONTINUOUS INSULATION

STUCCO

Notes: Designer must consider and detail movement joints. Do not bridge movement joints with stone units. Optional surface

preparation utilizing a rainscreen may be added. See General Information (page 8) for more information. Designer must

consider a detail movement joint. Do not bridge movement joints with stone units

Some foam products may qualify as WRB. See foam manufacturer instructions.

**

Cleaning can be as simple as rinsing dust o the surface with clear water or as involved as bead blasting. You are

**

removing form release agents, dirt, paint, sealers or anything that may inhibit bond. This process may also be the

method to roughen the surface to create bond ready texture. See ASTM C1780 for more information.

See cement board section for option to eliminate scratch coat application

***

✓

✓

OPTIONAL OPTIONAL OPTIONAL

**

✓ ✓ ✓

✓ ✓ ✓

SPECIAL CONDITIONS

**

1 LAYER

*

✓

✓ ✓ ✓

✓ ✓

✓ ✓

✓

N/A

N/A

N/A

See ASTM C1780 for

roughness evaluation.

48 hour scratch coat cure.

Use paper backed 3.4 lb

rib lath.

48 hour scratch coat cure.

Use paper backed 3.4 lb

rib lath.

See TER for lath fastener

selection available for

framed or masonry

applications.

Engineer review

recommended for existing

stucco.

Spacing per ASTM C1063

STEP TWO:

WALL SURFACE PREPARATION

EXTERIOR APPLICATIONS

Make sure that the application of Cultured Stone products and the structure they are being applied to incorporate

good building practices. Corrosion-resistant flashing shall be installed at all wall penetrations. Flashing type and

locations shall be in accordance with the requirements of the applicable building code. On exterior applications,

the incorrect installation or absence of flashing, cant strips, gutters, kick out flashing and downspouts may result

in diversion of water run-o onto finished surface areas. Masonry and other building products subjected to these

conditions may develop staining and, when combined with severe freeze-thaw conditions, may eventually cause

damage. The application of Cultured Stone products under these conditions is not recommended.

Flashing

1. To maintain the weather-resistance of the exterior wall on which stone products are installed,

corrosion-resistant flashing/weep screed and a means of drainage shall be installed at all penetrations

and terminations of the stone cladding. Flashing type and locations shall be in accordance with the

requirements of the applicable building code.

2. For additional recommendations regarding flashing, refer to the following trade associations, standards,

organizations and resources:

a. National Concrete Masonry Association - Manufactured Stone Veneer (NCMA-MSV) installation

guide for adhered concrete masonry veneer, available at www.ncma.org

b. Architect or engineer

c. ASTM E 2112

d. Asphalt Roofing Manufacturers Association (ARMA)

e. Brick Institute of America (BIA)

f. The American Plywood Association (APA)

g. Local building department

h. Consult window manufacturer warranty as a perimeter soft joint/gap may be required

Clearance

Maintain a 4" clearance between Cultured Stone and grade or 2" clearance above a paved surface.

Most building codes require the use of a weep screed in framed applications. In framed applications,

this distance is measured from the “beak” of the weep screed. When a weep screed is not required—

application over masonry as an example—a 2" × 4" leveling/ledger board may be used as a temporary

level straight edge to start your installation. See the NCMA Installation Guide for conditions that

allow a reduction in clearance requirements.

WATER RESISTIVE BARRIER (WRB) INSTALLATION

Where a WRB is required, it should be installed as two separate layers, in shingle fashion. Fasteners, fastening

schedule, vertical and horizontal lap requirements should follow the manufacturer’s installation instructions. The

WRB layers must be continuous through inside and outside corners, typically extending 16" to the next framing

member. See Material Selection (page 4) for specific WRB material requirements. Example for building paper:

2" horizontal lap, 6" vertical lap.

Interior Gypsum Board

Batt Insulation

Wood Framing

Exterior Grade Sheathing

2 Layers Of WRB

Lath

Lath Fasteners–Type &

Mortar Scratch Coat

Mortar Setting Bed

Manufactured

Stone Veneer

Mortar Joint

WRB Lapped Over

Weep Screed

Weep Screed

CORNER CONSTRUCTION

1

2

3

Water resistive barrier & lath must continuously

wrap a minimum of 16" at outside and inside

corners and fasten at a framing member. In

sequence: (1) wall substrate, (2) two layers of

water resistive barrier, (3) metal lath

3

STONE INSTALLATION INSTRUCTIONS

LATH INSTALLATION

Where lath is required, it shall be installed in accordance with ASTM C1063. Typically this will require corrosion

resistant fasteners every 6" on center vertically, and 16" on center horizontally, fastened to framing. If an alternative

lath is used, install it in accordance with the manufacturer’s installation instructions and evaluation report. See the

following Material Selection section for more specific lath requirements.

Note: Fasteners installed between framing should be limited as they may extend into the wall’s insulation cavity.

SCRATCH COAT

Using a trowel or spray application, install mortar scratch coat of minimum

thickness of ½" up to ¾." Use sucient material and pressure to fully

engage and encapsulate the lath. No lath material should be visible after

scratch coat installation.

Note: Proper encapsulation and scratch coat thickness are key aspects to

lath corrosion resistance and physical performance characteristics.

STEP THREE:

MATERIAL SELECTION

WATER RESISTIVE BARRIER (WRB)

Select a material meeting one or more of the following standards:

• ASTM D226 Type 1 No.15 Asphalt Felt, intended for wall application

• ASTM E2556/E2556M

• ICC ES AC-38. Current Evaluation Report, by an ANSI accredited evaluation service, showing

compliance to ICC ES Acceptance Criteria #38

• ILiquid WRB/Air Barrier–Current Evaluation Report by an ANSI accredited evaluation service showing

compliance to code requirements for WRB

LATH

Select a material meeting one or more of the following standards:

• ASTM C847, minimum 2.5 lb/yard expanded metal lath

• ASTM C847, minimum 3.4 lb/yard, 3⁄8" rib, expanded metal lath

• Non-metallic lath, with a current evaluation report, confirming compliance to ICC-ES AC 275 by an

ANSI accredited evaluation service, confirming alternative to one of the above lath products

• Liquid WRB/Air Barrier–Current Evaluation Report by an ANSI accredited evaluation service showing

compliance to code requirements for WRB

• Alternate lath products showing compliance with ICC-ES AC 275, or equivalent. Drain-N-Dry

best in class ventilated rainscreen and superior integral Alkali Resistant glass lath combined meeting AC

275. For more information visit www.DrainNDryLath.com

All lath products must be self-furred, or use furring fasteners, to provide ¼" clearance between lath and substrate,

for the purposes of mortar embedded encapsulating lath.

LATH FASTENERS

Select fasteners that meet the requirements of the following standard:

• ASTM C1063

1. Galvanized nails, staples, concrete nails. Penetration depth into wood framing is ¾" minimum.

2. Corrosion-resistant, self-drilling, self-tapping pancake-head screw with 7⁄16" head, of 1¼" length

or suitable to obtain 3⁄8" penetration beyond inside surface of metal. (Used for installing to metal

surfaces such as metal studs or metal building siding.)

Applications over continuous insulation, refer to Technical Evaluation Reports 1312-02 or 1302-01 available

at www.culturedstone.com.

• ASTM C1032, minimum 18 gauge, woven wire mesh

• ASTM C933, welded wire lath

™

Lath is a

MORTAR

Select a material meeting one or more of the following standards:

• ASTM C270 Type N or Type S

• ASTM C1714 Type N or Type S

• ANSI 118.4 and 115.15

MORTAR (CONTINUED)

Mortar Admixtures: Comply with ASTM C1384

Bonding Agents: Comply with ASTM C1059 or C932

Coloring Pigment: Comply with ASTM C979

All mortar, additives, bonding agents and pigments must be stored, mixed and used in strict accordance with the

manufacturer’s instructions and appropriate standards referenced above.

Notes: Refer to NCMA Installation Guide (www.ncma.org) for additional guidance with mortar selection by

application. Under mixing, over mixing, tempering and open times of mortar can impact bond. Follow mortar

manufacturer’s instructions.

STEP FOUR:

ESTIMATING THE STONE REQUIRED

Determine the amount of Cultured Stone products needed by measuring the area to be covered. Measure the

length times the height to arrive at the gross square footage of flat stone needed. Subtract square footage for

window, door and other openings. Measure the linear feet of outside corners to determine the amount of corner

pieces needed. One linear foot of corner pieces covers approximately 3⁄4 of a square foot of flat area. Subtract

the flat area covered by the linear feet of corner pieces from the square footage of flat stone required. You may

wish to obtain some extra stone to allow for cutting and trimming, or tighter joints. In addition, be sure to verify

whether the texture chosen is sold based on coverage with a ⁄" mortar joint or tight-fitted. Most texture coverages

are listed for a 1⁄2" joint, the exceptions being dry-stack Ledgestone, European Castle Stone, Pro-Fit

®

Pro-Fit

Hewn Stone

Alpine Ledgestone, Pro-Fit® Terrain™ Ledgestone, Pro-Fit® Modera™ Ledgestone,

™

, and Cast-Fit®.

®

Ledgestone,

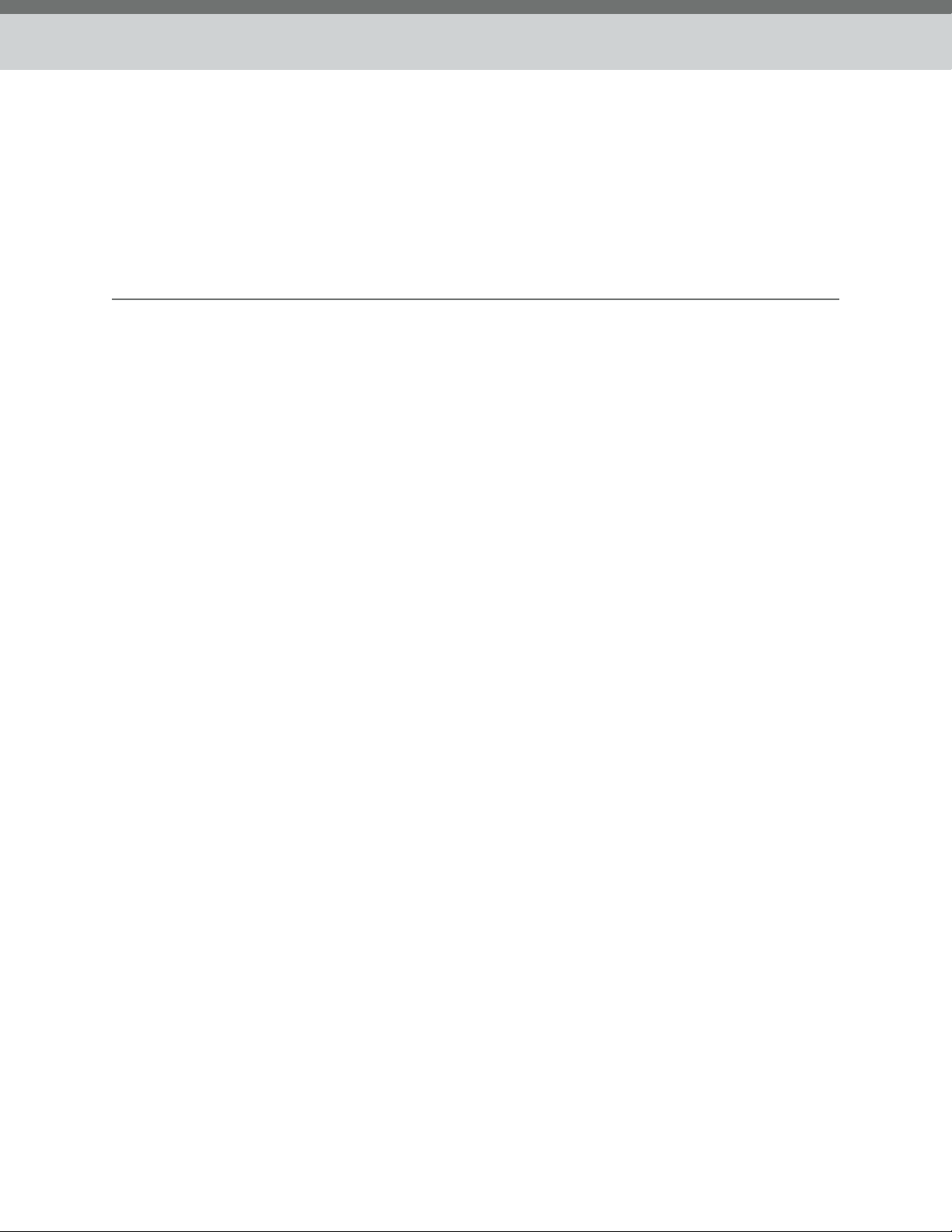

TOOLS REQUIRED

Choose the tools required for your

installation:

• Safety Glasses and other personal

protective equipment

• Staple Gun or Hammer

• Wheelbarrow & Hoe

• Hock & Trowel

• Mason’s Trowel

• Margin Trowel

• Masonry, Circular, Table, Wet Saw or

Grinder with Carborundum or Diamond

Blade Wide-Mouth Nippers or Hatchet

• Dust Mask

(1)

• Level

• Metal Jointing Tool or Wood Stick

• Grout Bag

• Whisk Broom

Note: Cutting dust mitigation steps include

but are not limited to: wet saw, dust vac

system and respirator systems. OSHA may

be required due to specific site conditions.

(1) Caution: Product contains Crystalline Silica. Dust from

cutting or sawing may create possible cancer hazard.

Dust may cause irritation of the nose, throat and

respiratory tract. Avoid prolonged or repeated inhalation

of dust. A properly fitted, particulate-filtering disposable

NIOSH approved N-95 series face piece respirator (“dust

mask”) should be used when mechanically altering this

product (e.g., sawing, cutting, drilling or similar dust

generating processes). Wear a long-sleeved shirt, long

pants, gloves and safety glasses with side shields when

handling and installing material. Wash hands and face

with soap and warm water immediately after handling.

TOOLS REQUIRED

Staple Gun/Hammer

(Applying water-resistive barrier

and/or metal lath)

Mason’s Trowel

(Applying mortar)

Wheelbarrow & Hoe

(Mixing mortar)

Masonry, Circular, Table, Wet Cut Saw or Grinder

with Carborundum or Diamond Blade

Wide-Mouth Nippers/Hatchet

(Trimming stone)

(Applying masonry adhesive)

Margin Trowel

Dust Mask

Metal Jointing Tool/Wood Stick

(Finishing joints)

Grout Bag

Hock & Trowel

Level

Whisk Broom

(Cleaning finished work)

(1)

Safety Glasses

(1)

5

STONE INSTALLATION INSTRUCTIONS

STEP FIVE:

APPLICATION OF CULTURED STONE UNITS

PREPARE YOUR WORK AREA

Spread Cultured Stone wall veneer out at the job site so you have a good variety of sizes, shapes and colors to

choose from. Plan for some variety and contrast in the overall design. Use small stones next to large ones, heavytextured pieces next to smooth, thick stones next to thinner ones. Mixing Cultured Stone wall veneer from dierent

boxes during application will allow you to achieve a desirable balance of stones on your finished project.

LEVEL & PLUMB JOINT LINES

When applying Cobblefield

Ledgestone, endeavor to maintain level and plumb joint lines. Also, long rectangular pieces will look most natural if

applied horizontally.

INSTALL CORNER PIECES FIRST

If your application requires corner pieces, apply these first. Notice

that the corner pieces have a long and a short leg. Alternate these

in opposite directions (Fig. 1).

INSTALL FLAT PIECES

After the corner pieces are in place, flat pieces are applied working

toward the wall center (Fig. 2).

STARTING POINT

Apply mortar and stone working from the bottom up, or most stones can also be applied from the top down.

Working from the top down may help avoid splashing previously applied stone with dripping mortar. Ledgestone

types should be installed from the bottom up.

®

manufactured stone veneer, European Castle Stone, Limestone, Rockface, Coral or

FIG. 1

FIG. 2

JOINT WIDTH

In order to obtain the most natural look, joints should be as narrow as possible. The average should not exceed

1⁄2" in width. An attractive look can also be achieved by fitting stones tightly together if desired. If using tight fit/

dry-stack method, figure in additional stone material. It is important to make sure scratch coat/backing has been

covered completely by the setting bed of mortar. This will conceal the scratch coat/backing and prevent pockets

from forming behind stones that could trap water.

SETTING UNITS

Units shall be installed using Method A or Method B or a

combination of both to achieve setting bed with complete

coverage of the back of the unit and full contact between the

mortar setting bed, unit and prepared backing surface.

Method A

Back butter the unit, using sucient mortar and pressure

to fill texture and voids in the back of unit. While 1⁄2" to 3⁄4"

setting bed mortar is wet, press and work the unit onto the

prepared backing with enough pressure to force mortar to

squeeze out around the entire perimeter of the unit.

Method B

The mortar setting bed shall be installed by trowel application 1⁄2" to 3⁄4" thick directly to the prepared

surface. Plus back butter the unit using sucient mortar and pressure to fill texture on and voids in

the back of the unit. While the setting bed on the prepared backing surface is plastic, press and work

the unit into the setting bed with enough pressure to force mortar to squeeze out around the entire

perimeter of the unit. Limit mortar setting bed open time and work only an area that can be covered

before the mortar skins over. Time and area will depend on mortar and weather conditions.

Note: Method B is recommended for tight fit applications to ensure full setting bed of mortar. In tight fit

applications, before placing next unit, compact or remove the squeezed out mortar to allow adjoining unit

to butt tightly. There shall be mortar between the units but the joint will be less than 3/8."

CUTTING & TRIMMING

Stones can be cut and shaped for fit. Use wide-mouth nippers or a

hatchet (Fig. 3 & 4). (Refer to page 5, Tools Required section.) Some

broken stones may be found in the box. These also may be used in

FIG. 3

TRIM WITH

WIDEMOUTH NIPPERS

FIG. 4

TRIM WITH A HATCHET

filling gaps between large stones. For best finished appearance, coat

cut or broken edges with mortar. If possible, position cut edges up

when they are above eye level, down when below eye level. Placing

a cut edge next to a thick/larger stone will also help conceal the cut.

Safety glasses and a dust mask

(1)

should always be worn when

cutting any Cultured Stone product.

MORTAR & WEATHER CONDITIONS

If stone is being applied in hot or dry weather, the back of each piece should be moistened with a fine spray of

water or a wet brush to adequately prevent excessive absorption of moisture from the mortar. If being installed

over concrete, masonry or scratch coat substrate, the substrate surface area should also be dampened before

applying mortar. Surfaces should appear damp but free of surface water. Applications should be protected

from temperatures below 40°F as mortar will not cure properly under such conditions. See ASTM C1780 for

Hot & Cold Weather Requirements.

If using a modified mortar, follow mortar manufacturer’s recommendations regarding wetting of

stone and scratch coat.

ADDITIONAL INSTRUCTIONS FOR PRO-FIT

PRO-FIT

®

ALPINE LEDGESTONE & EUROPEAN CASTLE STONE

®

LEDGESTONE,

Fit the Joints Tightly

Install all these products with tight-fitted joints. Generally, components should be placed butting

each other and aligned for level and plumb. When installing, the backs of all these components

must be wet.* They should be noticeably damp, but free from surface water. Mortar may be tinted

to match the color of the stone you are installing to help conceal the joint lines. If while setting a

stone, a previously installed stone is disturbed, that stone must be removed, cleaned and re-installed.

* If using a modified mortar, follow mortar manufacturer’s recommendations regarding wetting of

stone and scratch coat. Consider using Method B for mortar setting bed application

of tight fitted installations

Starting Point

Products are applied starting from the bottom and working up. Start each ProFit Ledgestone

course level and continue horizontally completing each course before starting the next. European

Castle Stone is done in a similar sequence to achieve a random ashlar pattern. If required, cut the

appropriate size component to fit at the end or top of the finish area. Frequently check the installation

for level and alignment.

STEP SIX:

GROUTING & FINISHING JOINTS

GROUTING JOINTS

When additional mortar is required, use a grout bag to fill in joints completely. Care must be taken to avoid

smearing mortar on surface of stone. Accidental smears or mortar droppings should be removed only after mortar

has become crumbly using a whisk broom or dry bristle brush. Never use a wet brush or wire brush.

FINISHING JOINTS

When the mortar joints have become firm or “thumb-print” dry

(setting time will vary depending on wall surface and climatic

conditions), they should be pointed up with a wood stick or

metal jointing tool. Rake out excess mortar, compact and seal

edges around stones (Fig. 6). Careful attention to proper and

even jointing will result in a professional looking finish.

FIG. 5

GROUT JOINTS

FIG. 6

FINISHING THE JOB

7

STONE INSTALLATION INSTRUCTIONS

CLEANING FINISHED JOB

When the mortar is suciently set up, the finished job should be broomed or brushed to remove loose mortar and

to clean the face of the stone. A wet brush or sponge should never be used to treat the mortar joints as this will

cause staining that will be dicult, or impossible, to remove. Do not use acid or acid-based products.

MORTAR COLOR

Tinting mortar complements the color of the stone being installed. Example: Use tan mortar with earth-tone stones.

This will greatly enhance the appearance of the finished installation. Regular mortars can be tinted to complement

your Cultured Stone product using iron oxide pigments available from your dealer.

GENERAL INFORMATION

CLEANING

Dirt, etc., may be removed by using a solution of granulated soap or detergent and water with a bristle brush. Do

not use a wire brush as it will cause damage to the surface. Rinse immediately with fresh water. Do not attempt to

clean using acid or acid-containing products, power-washing, sandblasting or wire-brush cleaning.

ENHANCED BOND

Refer to NCMA Installation Guide for application specific mortar recommendations. Pre-blended modified

mortars, bonding agents and enhancers may provide greater bond strength. Enhanced bond strength capability

may be desired for tight fit applications, tilt up construction or where code jurisdictions require higher bond

strength. These products must be compatible with manufactured stone and used in strict accordance with

manufacturer’s instructions. These products may also have specific requirements regarding hot or cold weather,

exposure to rain/water while curing or water used to dampen the stone units prior to installation.

SALT & DE-ICING CHEMICALS

Because concrete and masonry are vulnerable to damage by salt, Cultured Stone products are not warranted

against damage incurred from salt or other chemicals used to remove snow or ice. Do not use de-icing chemicals

on areas immediately adjacent to a Cultured Stone manufactured stone veneer application.

SCUFFING

Scung occurs on all natural stone. Occasionally some scung will occur on the surface of Cultured Stone

products. This can enhance the natural appearance of your Cultured Stone manufactured stone veneer installation.

Some scu marks can be removed by cleaning as described above.

EFFLORESCENCE

Eorescence is a water-soluble salt that is deposited on the surface of stucco, concrete, brick and other masonry

products by the evaporation of water from the wall. On rare occasions eorescence will occur on Cultured Stone

products. To remove eorescence, allow the stone to dry thoroughly, then scrub vigorously with a sti bristle

brush and clean water. Rinse thoroughly—do not use a wire brush. For more dicult eorescence problems, scrub

thoroughly with a solution of 1 part white household vinegar to 5 parts water. Rinse thoroughly.

WATER REPELLENT TREATMENTS/SEALERS

Sealers are not necessary on Cultured Stone products. However, some customers use sealers to help prevent

staining in applications prone to smoke, soot, dirt or water splashing. If you choose to use a sealer, make sure it

is a Silane, Siloxane or Silane-Siloxane blend breathable sealer. Take note that sealers may darken the color of the

stone. A sealer may also slow the natural movement of moisture out of the stone and increase the possibility of

eorescence and/or spalling. For information regarding actual performance or application of sealers, contact the

manufacturer of the sealer directly. Craftshield

beauty of the installation while safeguarding the surface from the elements.

™

is a protective treatment that preserves the intended artistry and

RAINSCREEN STATEMENT

Some building codes require a rainscreen behind cladding materials, including manufactured stone veneer. If

you are installing manufactured stone/brick veneer in one of these jurisdictions, or are concerned about extreme

weather conditions, it is recommended that you choose a rainscreen system that can achieve the following:

• The system should create a space with a minimum depth of 3/16" (5 mm) & max depth of ¾" (19 mm).

• The materials should be corrosion and rot resistant.

Loading...

Loading...