Culligan G1 Series, G1-2S, G1-3L, G1-4L, G1-1F Installation, Operation And Service Instructions

...

CULLIGAN

Cat. No. 01021713

Rev. E 04/02/13

DCO 013630

Installation,

Operation and

Service

Instructions

®

Series G1 Reverse Osmosis

Water Treatment Systems

Models from 2011

©2013 Culligan International Com pa ny

Attention Culligan Customer:

Your local independently operated Culligan dealer employs trained service and maintenance personnel who are experienced in the installation, function and repair of Culligan equipment. This publication is written specifically for these individuals and is intended for their use.

We encourage Culligan users to learn about Culligan products, but we believe that product knowledge is best obtained by

consulting with your Culligan dealer. Untrained individuals who use this manual assume the risk of any resulting property

damage or personal injury.

NOTICE Please send any suggestions for improving this manual to productmanuals@culligan.com

WARNING! Electrical shock hazard! Prior to servicing equipment, disconnect power supply to

prevent electrical shock.

WARNING! If incorrectly installed, operated, or maintained, this product can cause severe injury.

Those who install, operate, or maintain this product should be trained in its proper

use, warned of its dangers, and should read the entire manual before attempting to

install, operate, or maintain this product. Failure to comply with any warning or

caution that results in any damage will void the warranty.

CAUTION! This product is not to be used by children or persons with reduced physical, sensory

or mental capabilities, or lack of experience or knowledge, unless they have been

given supervision or instruction.

CAUTION! Children should be instructed not to play with this appliance.

CAUTION! If the power cord from the transformer to the unit looks or becomes damaged, the

cord and transformer should be replaced by a Culligan Service Agent or similarly qualified person in order to avoid a hazard.

WARNING! This device complies with Part 15 of the FCC rules subject to the two following

conditions: 1) This device may not cause harmful interference, and 2) This device

must accept all interference received, including interference that may cause undesired

operation.

This equipment complies with Part 15 of the FCC rules. Any changes or modifications not expressly approved by the

manufacturer could void the user’s authority to operate the equipment. Changes or modifications not expressly approved

by the party responsible for compliance could void the user’s authority to operate the equipment.

CAUTION! To reduce the risk of fire, use only No. 26 AWG or larger telecommunications line

cord.

NOTE This system is not intended for use with water that is microbiologically unsafe or of unknown quality

without adequate disinfection either before or after the system.

NOTE Check with your public works department for applicable local plumbing and sanitation codes. Follow

local codes if they differ from the standards used in this manual. To ensure proper and efficient operation of the Culligan equipment to your full satisfaction, carefully follow the instructions in this manual.

Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates are protected by patents issued or pending in the United States and other countries. Culligan reserves the right to change the specifications

referred to in this literature at any time without prior notice. Culligan, Aqua-Sensor, Tripl-Hull, and SoftMinder are trademarks of Culligan International Company or its affiliates.

Culligan International Company

9399 West Higgins Road, Suite 1100

Rosemont, Illinois 60018

1-847-430-2800

www.culliganmatrixsolutions.com

Culligan®

Installation

and

Operation

Instructions

Series G1 Reverse Osmosis

Water Treatment Systems

Models From 2011

Contents

Introduction ........................................................................ 1

G1 RO Features ................................................................ 2

G1 RO Series Specifications ............................................. 4

G1 RO System Configurations .......................................... 5

G1 RO Installation ............................................................. 6

GBE RO Controller Program Data................................... 19

First Time Setup .............................................................. 20

Basic Operation ............................................................... 31

Setup ............................................................................... 32

Accessories ..................................................................... 41

Error Limits ...................................................................... 58

System Operating Information ......................................... 60

Service and Maintenance ................................................ 62

GBE RO Controller Menu Structure ................................ 76

G1 RO Parts Diagrams and Lists .................................... 80

Flow Diagram .................................................................. 99

Electrical Installation ...................................................... 101

GBE RO Controller Wiring ............................................. 102

Remote Display Template ............................................. 103

Appendix A G1 RO International ............................. 104

Appendix B Basic Principles ...................................... 121

Appendix C Menu and Key Navigation ...................... 123

Appendix D Quick Programming Guide .................... 125

Appendix E Data Port Output .................................... 129

Appendix F Programming Log ................................... 133

Index .............................................................................. 134

Cat. No. 01021713

i

Units of Measure Conversion: U.S. to Metric

Convert From To Multiplication Factor

gallons per minute (gpm) liters per minute (l/min) 3.785

gallons per day (gpd) cubic meters per hour (m^3/hr) 0.000158

gallons (gal) liters (l) 3.785

pounds per square inch (psi) bar 0.0689

degrees Fahrenheit (F) degrees Centigrade (C ) (F-32) x 0.556

pounds (lbs) kilograms (kg) 0.4536

Inches (in) millimeters (mm) 25.4

parts per million (ppm) mg/l 1.00

ii Culligan® Series G1 Reverse Osmosis

ii Cat. No. 01021713

Introduction

Read this Manual First

Before you operate the Culligan® Series G1 reverse osmosis systems, read this manual to become familiar with the

device and its capabilities.

®

Culligan

manual contains important information about the unit, including information needed for installation, operating, and maintenance procedures. A troubleshooting section provides a guide for quick and accurate problem solving.

In order for the water treatment system to continue to provide high quality water, you must develop a thorough understanding of the system and its operation. Review this manual before making any attempt to install, operate, or service

the system. Installation or maintenance done on this system by an untrained service person can cause major damage to

equipment or property damage.

About this Manual

This manual:

This publication is based on information available when approved for printing. Continuing design refinements could cause

changes that may not be included in this publication.

Series G1 reverse osmosis systems are designed to meet the needs of applications for high quality water. This

• Familiarizes the operator with the equipment

• Explains installation and setup procedures

• Provides basic programming information

• Explains the various modes of operation

• Gives specifications and troubleshooting information

Safe Practices

Throughout this manual there are paragraphs set off by special headings.

Notice

Notice is used to emphasize installation, operation or maintenance information which is important, but does not present

any hazard. For example,

NOTICE The nipple must extend no more than 1 inch above the cover plate.

Caution

Caution is used when failure to follow directions could result in damage to equipment or property. For example,

CAUTION! Disassembly while under water pressure can result in flooding.

Warning

Warning is used to indicate a hazard which could cause injury or death if ignored. For example,

WARNING! Electrical shock hazard! Unplug the unit before removing the timer mechanism or

cover plates!

The CAUTION and WARNING paragraphs are not meant to cover all possible conditions and situations that may occur. It

must be understood that common sense, caution, and careful attention are conditions which cannot be built into the equipment. These MUST be supplied by the personnel installing, operating, or maintaining the system.

Be sure to check and follow the applicable plumbing codes and ordinances when installing this equipment. Local codes

may prohibit the discharge of acid or caustic solutions to drain. An extra solution tank should be used to neutralize the

solution before discharging to drain.

Use protective clothing and proper face or eye protection equipment when handling chemicals or power tools.

Cat. No. 01021713

Introduction 1

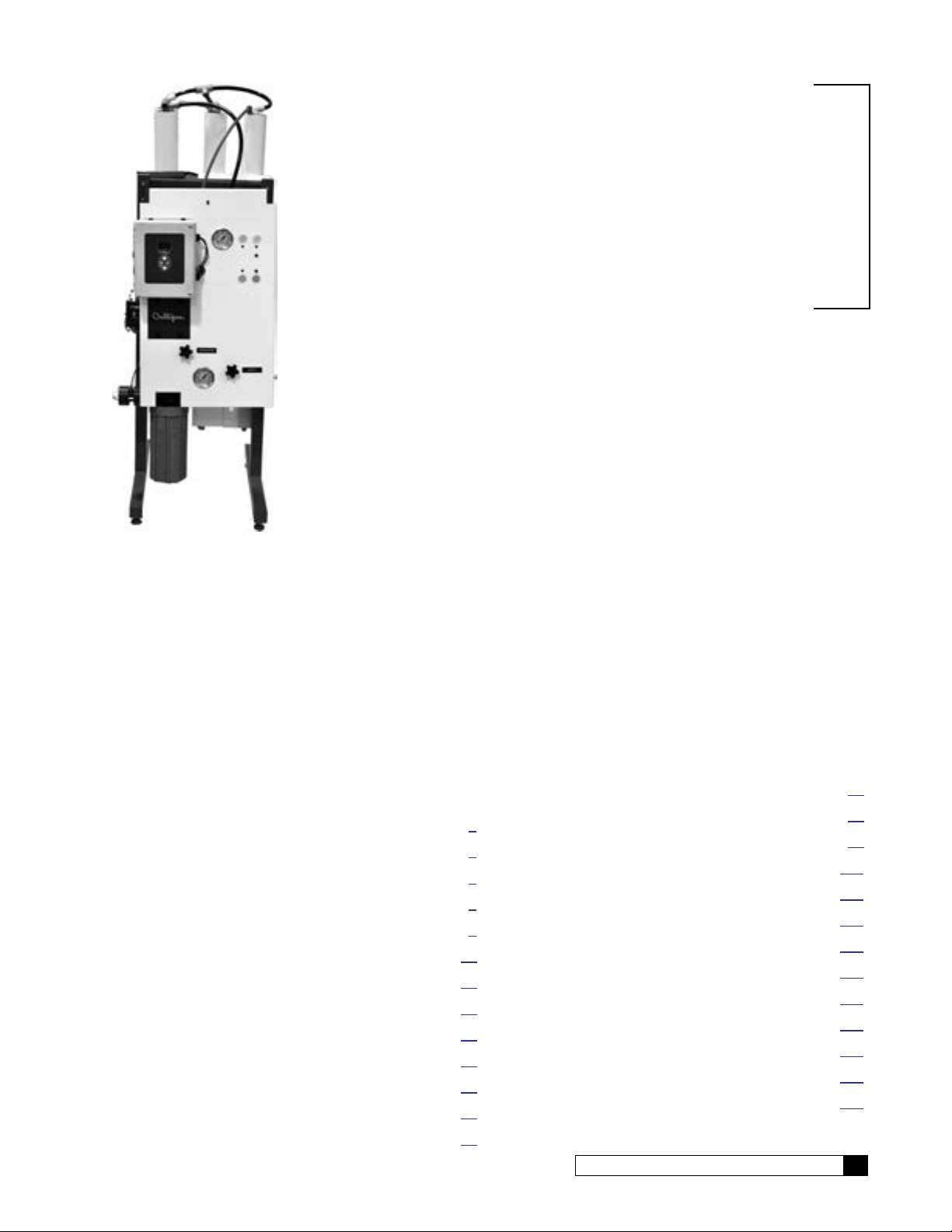

G1 RO Features

The Series G1 Reverse Osmosis systems are the direct result of Culligan’s long time experience in membrane applications around the world. From process water for any size business to treating water for an entire city, Culligan has the

knowledge and the range of products you need to get the job done.

The Series G1 reverse osmosis system is sized to serve many small-to-medium-sized applications that require high-quality reverse osmosis water. It is designed with the flexibility to closely match your treatment requirements from 0.35 to 2.8

gallons per minute (500 to 4,000 gallons per day). Mount the system on a wall to save floor space, or install it on the floor

using an optional floor stand. A rich standard feature set with multiple options can satisfy virtually any application. Select

the right size and choose any options needed to complete your system.

Key G1 RO System Features

• Simple System Integration

• Global Product Platform

• Flexible Configurations

• Quick Delivery/Easy Installation

• Exclusive Culligan Advanced Electronics

• Multiple Languages

• Historical Operating Data

• Alarm Recognitions

• US Standard and Metric Readings

• Remote Monitoring Options for connection to a control room PLC

• Telemetry Options

• Real Time Clock: tracks date and time has five-year battery back up.

• TDS Probe: TDS probe measures product water quality.

• Remote Alarm Output Connection (Optional): Provides either a N.O. or N.C. Dry Contacts. This feature can be

used to activate an alarm or programmed into a customers (DCS) building alarm system.

GBE RO Controller Features

System Computes Normalized Flow

The system computes normalized flow and can be set to trigger an alarm if the normalized flow drops below a specified

limit.

Power Up Mode

The system can be configured to either go to standby mode or to automatically return to making RO water in the event of

power loss and restoration.

Storage Tank and Pressure Logic

The system has the ability to monitor high and low level switches in an atmospheric storage tank and a pressure switch in

a pressurized storage tank to automatically put the system into standby mode when the tank is full.

Pretreatment Lockout

Allows for single softener or filter pretreatment that can be set to go into regeneration or backwash cycle at low water use

periods and have the RO in standby until cycle is completed. RO product water tank would need to be sized correctly

based on flow demand if continuous RO product water is required.

GBE Historical Data

The GBE RO Controller stores basic performance data over the lifetime of the membranes as an aid to optimizing RO

performance and determining when the membranes need to be cleaned or replaced.

2 Culligan® Series G1 Reverse Osmosis

2 Cat. No. 01021713

Flush Options

The system offers six different membrane flush modes to improve performance and extend membrane life.

NOTE Quality Flush and Permeate Flush are mutually exclusive optional features.

Target TDS

The RO system keeps track of the average product water TDS whenever the RO system is operating, mixing lower quality

water with product water to meet the average product water TDS.

Communications via Modem

An optional modem and monitoring service can be used to remotely monitor the RO performance over time. This service

can also be used to alert the customer and the Culligan dealer in the event that an alarm or error condition occurs.

Wireless Remote Communication

An optional wireless remote can display the current operational status and performance statistics up to 200 feet from the

G1 RO system.

PLC Outputs Available

The GBE Controller collects data once per minute and then streams the data to a customer-owned PLC for data collection

or monitoring. Customer would have to write code to take text information and convert the data for their data collection

system. For more information, see Culligan P/N 01021512 Advanced Communication Manual.

This data, once converted from a text stream, can easily be imported to an excel spreadsheet and the data logged can

then be graphed and trended.

Cat. No. 01021713

G1 RO Features 3

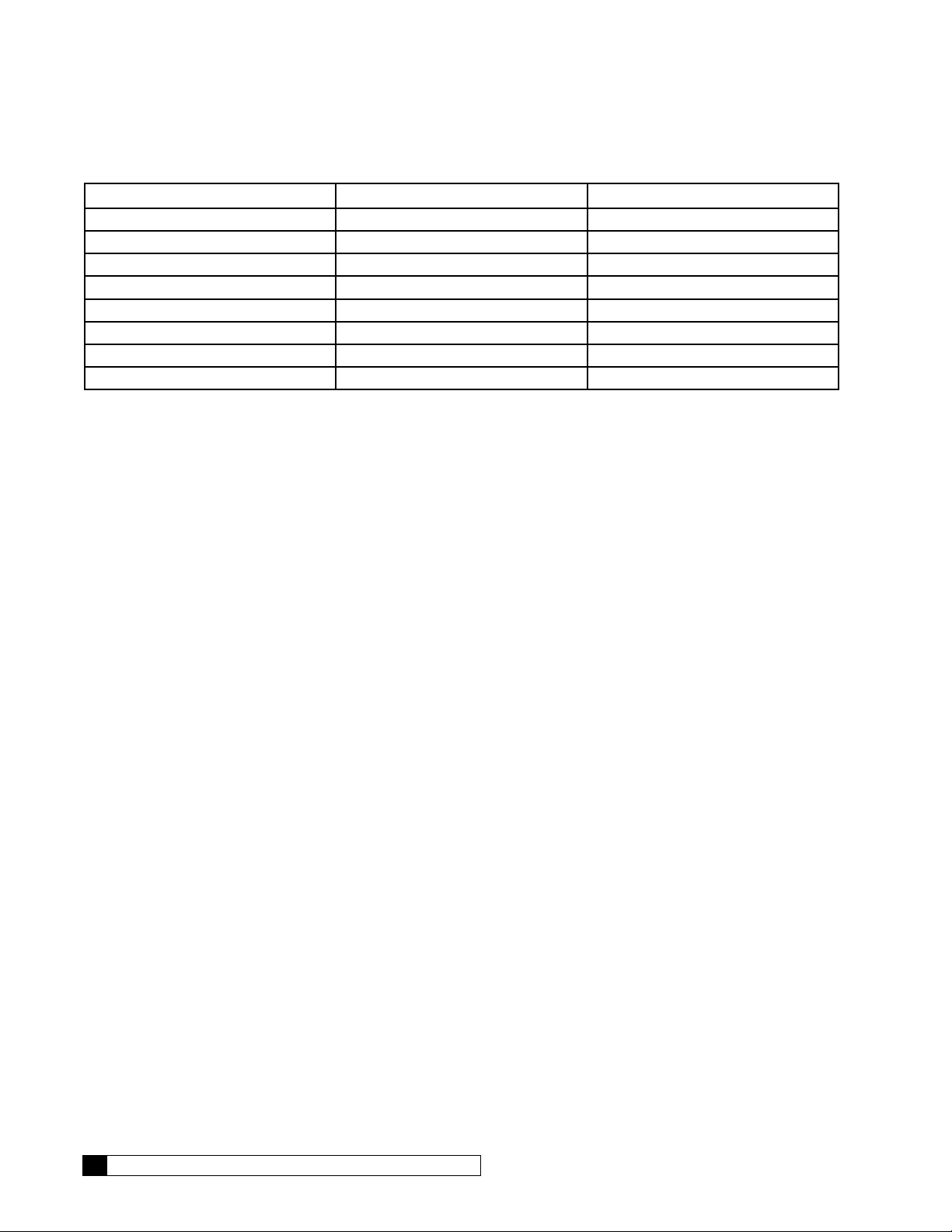

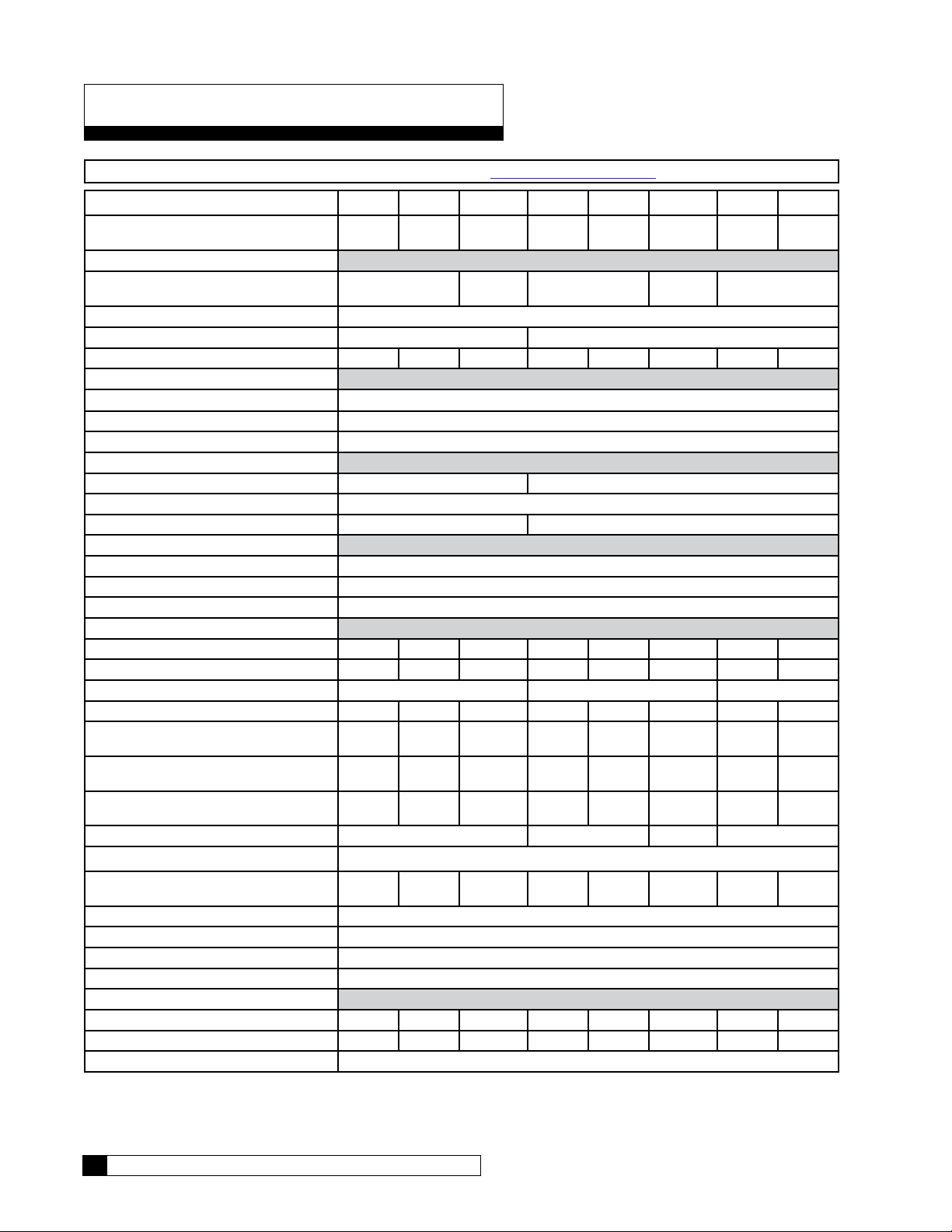

G1 RO Series Specifications

NOTE Specifications for G1 RO 230V (international) are in Appendix A on page 104.

G1-2S G1-3S G1-4S G1-2L G1-3L G1-4L G1-1F G1-2F

Nominal Capacity, GPD [m³/hr]* 500

[0.08]

Dimensional, Series G1 Units

Width - in [mm] 34.5 [876] 38.5

Depth - in [mm] 8.7 [221]

Height - in [mm] 34.8 [884] 45.5 [1156]

Operating Weight, lb [kg] 81 [37] 92 [42] 96 [44] 88 [40] 103 [47] 111 [50] 97 [44] 129 [59]

Unit Connections

Inlet (Tube) - in. 1/2

Product (Tube) - in. 1/2

Concentrate (Tube) - in. 3/8

Electrical

Motor Horsepower, hp [kW] 0.333 [0.25] 0.75 [0.56]

Power Requirement (VAC/Hz/phase) 115/60/1

Full Load Current, amp (@115V) 8 12

Hydraulic - Prefilter

Housing Quantity 1

Cartridge Rating, micron 5

Cartridge Length - in [mm] 10 [254]

Hydraulic - RO

RO Housing Quantity 2 3 4 2 3 4 1 2

RO Element Quantity 2 3 4 2 3 4 1 2

RO Element Size - in 2.5x21 2.5x40 4x40

RO Array 1:1 1:1:1 1:1:1:1 1:1 1:1:1 1:1:1:1 1 1:1

Product Flow - gpm [L/min]* 0.35

[1.32]

Concentrate Flow - gpm [L/min]* 0.35

[1.32]

Required Inlet Feed Flow gpm [L/min] 0.7

[2.65]

Pump Flow @ 150 psi, gpm [Lmin] 1.6 [6.06] 2.7 [10.44]

Maximum Module Feed Pressure psig [kPa] 150 [1034]

Nominal Module Feed Pressure psig [kPa]† 100

[689]

Max. Product Pressure psig [kPa] 40 [275.6]

Inlet Pressure Min., dynamic psig [kPa] 20 [137.8]

Maximum, dynamic psig [kPa] 50 [344.5]

Operating Temp °F [°C] 33-100 [1-38]

Recovery (%)*

Design 50 50 50 50 50 50 25 50

Minimum 40 40 40 40 40 40 15 40

Salt Rejection, Nominal (%) 98

†Calculated using a 0.85 fouling factor

*Nominal capacity based on new RO membranes operating on a properly pretreated feed water of 500 ppm TDS as NaCl,

77 °F (25 °C), Silt Density Index (SDI) below 3, and supplying water to atmosphere. Productivity will vary depending on

the actual feed water quality and temperature.

4 Culligan® Series G1 Reverse Osmosis

750

[0.12]

0.52

[1.97]

0.52

[1.97]

1.04

[3.94]

103

[709.7]

1000

[0.16]

[978]

0.69

[2.61]

0.69

[2.61]

1.38

[5.22]

104

[716.6]

1200

[0.19]

0.83

[3.14]

0.83

[3.14]

1.66

[6.28]

96

[661.4]

1700

[0.27]

34.5 [876] 38.5

1.18

[4.47]

1.18

[4.47]

2.36

[8.93]

97

[668.3]

2200

[0.35]

[978]

1.53

[5.79]

1.53

[5.79]

3.06

[11.58]

3.1 [11.73]

101

[695.9]

4 Cat. No. 01021713

2000

[0.32]

34.5 [876]

1.40

[5.30]

4.17

[15.78]

5.56

[21.04]

5.6 [21.2]

95

[654.6]

4000

[0.63]

2.8

[10.6]

2.78

[10.52]

5.56

[21.04]

101

[695.9]

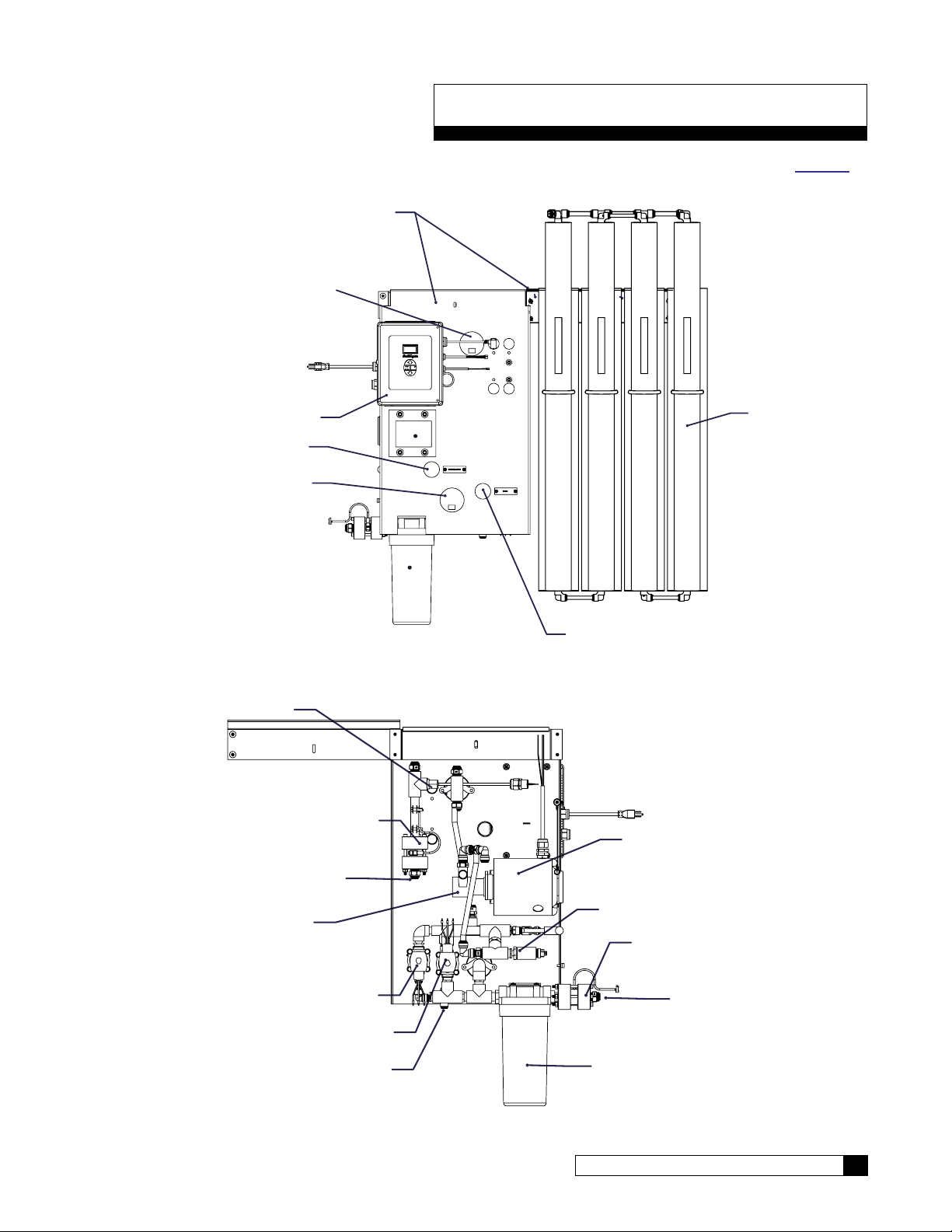

G1 RO System Configurations

A G1-4L is pictured in Figure 1 and Figure 2. Width of membrane rack varies with model. See parts section on page 80

for a list of component part numbers.

MOUNTING BRACKETS

MEMBRANE FEED PRESSURE

GBE RO CONTROLLER

RECIRCULATION CONTROL

INLET FEED PRESSURE

TDS SENSOR

PRODUCT FLOW METER

MEMBRANES

WASTE CONTROL

Figure 1. G1 RO front view.

MOTOR

PRODUCT WATER OUTLET

Cat. No. 01021713

PUMP

FAST FLUSH SOLENOID

INLET SOLENOID

WASTE WATER OUTLET

PRESSURE SWITCH

FEED FLOW METER

FEED WATER INLET

PREFILTER

Figure 2. G1 RO back view.

G1 RO System Configurations 5

G1 RO Installation

Unpacking the G1 RO

This manual, the warranty, and registration card are packed in the control assembly box. Please complete the registration

card and mail it promptly.

NOTICE Examine each component carefully to check for loose or damaged parts. Report any apparent or

concealed shipping damage to the freight carrier immediately.

Materials Required

To install the system, the following items are required:

• Level

• Drill

• Screws for mounting the bracket for the main plumbing assembly

• Screwdrivers, including a small, flat-bladed (1/8” wide) screwdriver for wiring

• Adjustable wrench

• Tubing;

All—Nat 1/2” Feed Water and Product Water Tubing, P/N 00901801

All—Nat 3/8” Product Concentrate (Waste) Water Tubing, P/N 00444973

• 1-Gallon Bucket calibrated for taking flow rates

• Stopwatch

• Calculator

• Clean rags

• Thermometer

• Portable Total Dissolved Solids meter

• Safety glasses

Unpacking

The G1 reverse osmosis unit requires some assembly. Please check your order thoroughly to make sure you have the

following items. Refer to the table for box quantities.

• Pump/Motor Panel

• Housing Assemblies

• Membranes

• Fitting Kit

Location

The Series G1 unit is designed for wall mounting so that all components are accessible for maintenance and monitoring.

The wall you choose for mounting the unit must be capable of supporting at least 130 pounds. See the assembly section

below for installation detail.

A 120 VAC/60 Hz/1 Phase grounded electrical receptacle with 15 amp fuse protection is required for use with the six-foot,

three-wire power cord.

NOTICE Do NOT use any bolt size smaller than 1/4" diameter.

The unit must be located near a drain able to handle 10 gallons per minute (37.9 liters/min). This is in addition to the flow

from any other water treatment equipment.

CAUTION! The system must not be located near any corrosive chemicals which may cause fail-

ure of the plastic or metal parts of the unit. In addition, do not locate the unit where the

temperature may exceed the feed water temperature limits.

6 Culligan® Series G1 Reverse Osmosis

6 Cat. No. 01021713

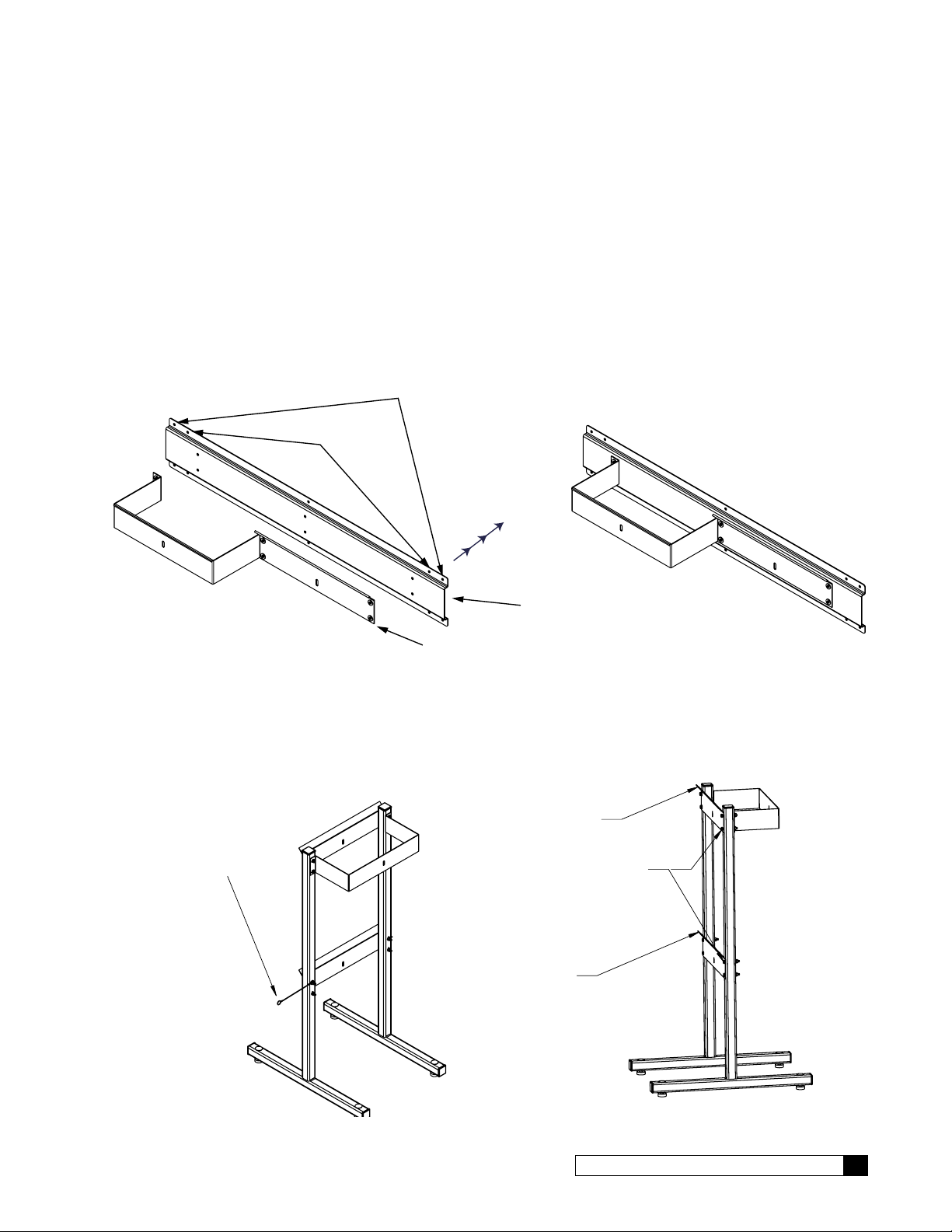

Assembly

Bracket

Concrete Wall Installation

Refer to Figure 3 to install the G1 RO system to a concrete wall. Place the unit against the wall, level the unit and mark

the wall through the mounting holes. Drill the holes in the wall and mount the unit. Horizontal holes are on 16" centers.

Vertical holes are on 2" centers.

Wall Mounting Kit (optional)

If the wall is not concrete and wall mounting is necessary, a wall mounting bracket kit is available. The bracket has holes

for mounting on 18” and 20”centers. Use bracket P/N 01023017 for all models.

Place the bracket adapter on the wall with the flat side towards the wall. Level the bracket adapter and mark the wall

through the appropriate holes. Drill holes in the wall. Assemble the wall brackets to the bracket adapter. Mount the adapter and wall brackets to the wall. Mount the pump/motor assembly and the membrane assembly to the brackets.

Align with 20" studs

Align with 18" studs

Mount

To Wall

Wall Mount

Bracket Adaptor

Mounting

Figure 3. G1 RO wall mount bracket kit, P/N 01022077 (included with unit) and optional bracket adapter.

Stand Mounting (optional)

If the RO unit requires floor mounting, a rigid steel stand (P/N 01021987, Figure 4) is available. Wall mount brackets are

used with floor stand to mount unit and membranes.

NOTE DIRECTION

ANGLED FACE UP

LANYARD

NOTE DIRECTION

ANGLED FACE UP

BOLT HEADS

THIS SIDE

Cat. No. 01021713

Figure 4. G1 RO floor assembly.

G1 RO Installation 7

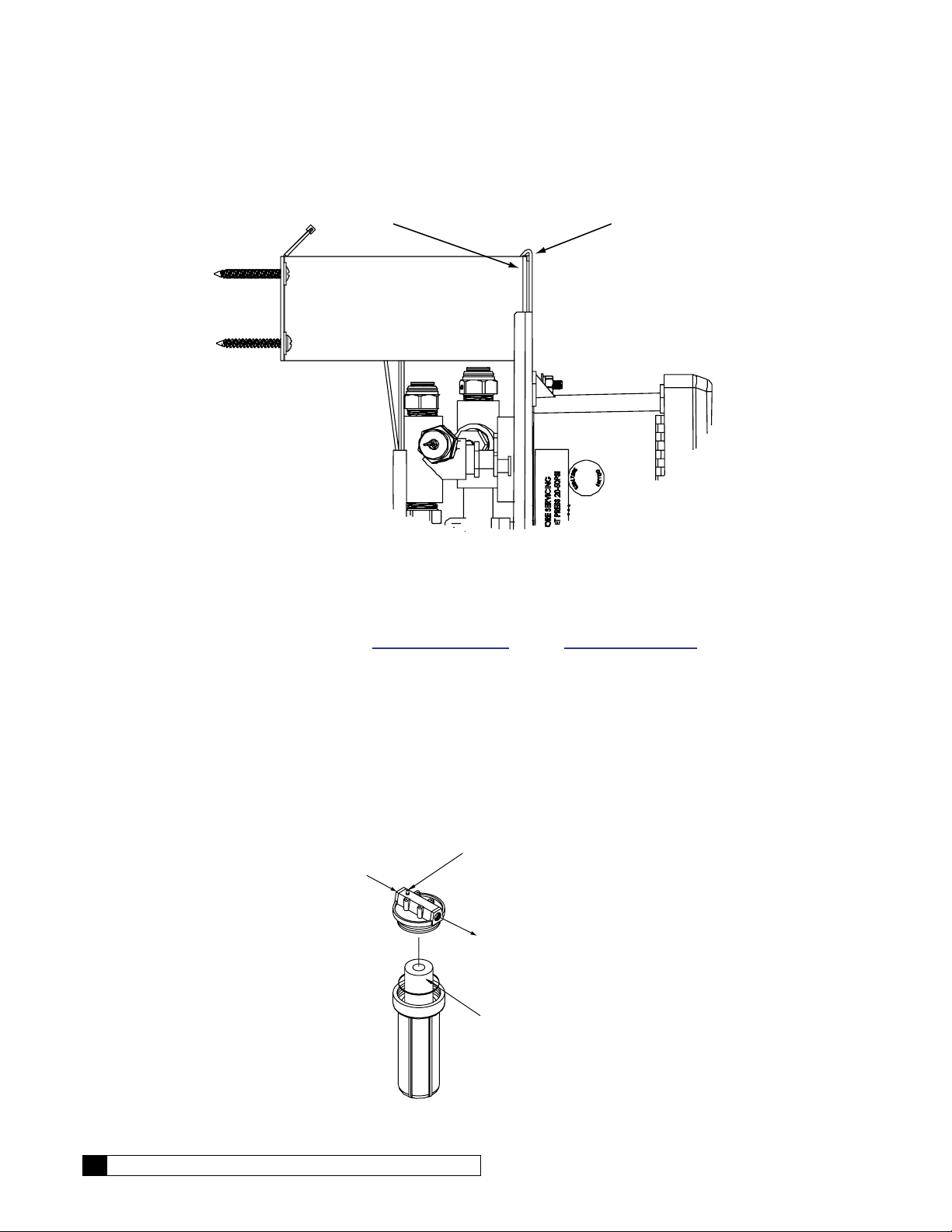

Pump/Motor Panel

Mounting Bracket

Pressure

Hang the pump motor panel on the mounting bracket. The top edge of panel hooks on to the bracket. See Figure 5.

Motor Panel

Figure 5. Pump motor panel hanging on mounting bracket.

Fittings

Locate the Membrane Fitting Kit that was shipped with the unit. This kit includes all the fittings needed to connect the

membranes to the pump/motor panel. Refer to Figure 11 on page 13 through Figure 15 on page 17 for the model

you are installing and follow the tubing diagram. Detailed drawings of the fittings and housings can be found in the parts

section.

Prefilter Cartridge

1. Locate the prefilter cartridge packed with the main unit.

2. Unscrew the prefilter bowl.

3. Lubricate the seal ring with silicone lubricant as required.

4. Remove the paper wrapper from the cartridge, place the cartridge in the bowl, and screw the bowl onto the

head.

Inlet

Figure 6. Installing the Prefilter.

Relief

Button

Outlet

Filter Cartridge

8 Culligan® Series G1 Reverse Osmosis

8 Cat. No. 01021713

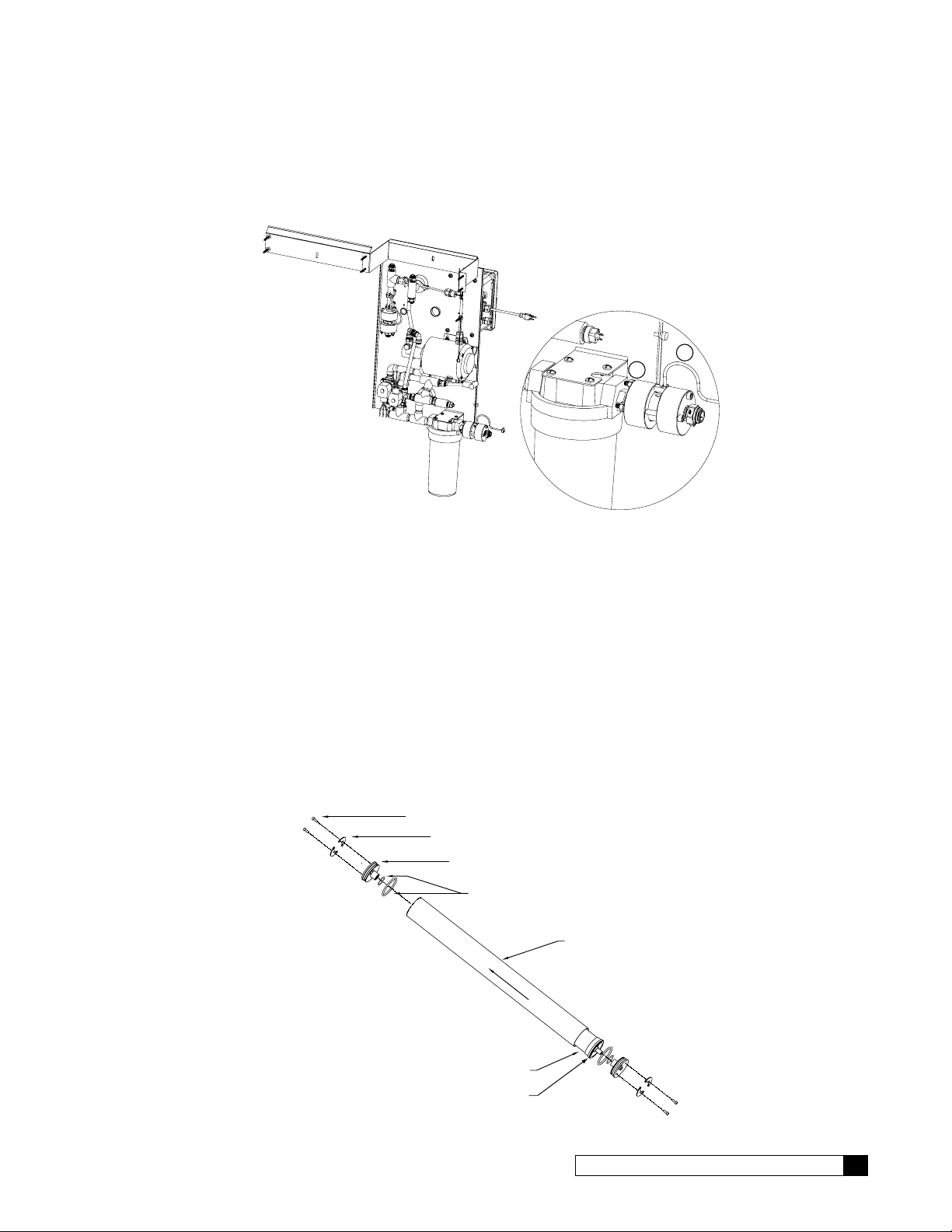

Feed Flow Meter

Screws

1. Install the feed flow meter on the prefilter.

2. Install the flow meter cable.

2

1

Figure 7. Feed flow meter installed on prefilter.

Membranes

Before mounting the membrane housings, the membranes must be inserted into the housings. Take care to not damage

the end cap O-rings or membrane brine seal.

The membranes are shipped in a sealed package. Use extreme caution when opening the package with a sharp instrument. Any damage to the membrane can cause poor quality coming from the unit.

1. The membrane housings have directional arrows on them that indicate direction of flow. Install the membranes

in the direction of flow. Open the housing end opposite the direction of flow.

2. Remove the end caps from all vessels by removing the two Allen head screws that hold down the retaining

clips. The clips are pushed into an internal groove in the housing, so completely remove the screws so the clip

can be slid out of the groove. Note placement of the caps to assure reinstallation in the same orientation.

3. Check the O-ring seals on the membrane and end plug, and the membrane brine seal for damage. If an O-ring

is cut or crimped, it may cause high flow and poor quality. Replace any suspicious O-rings.

Cat. No. 01021713

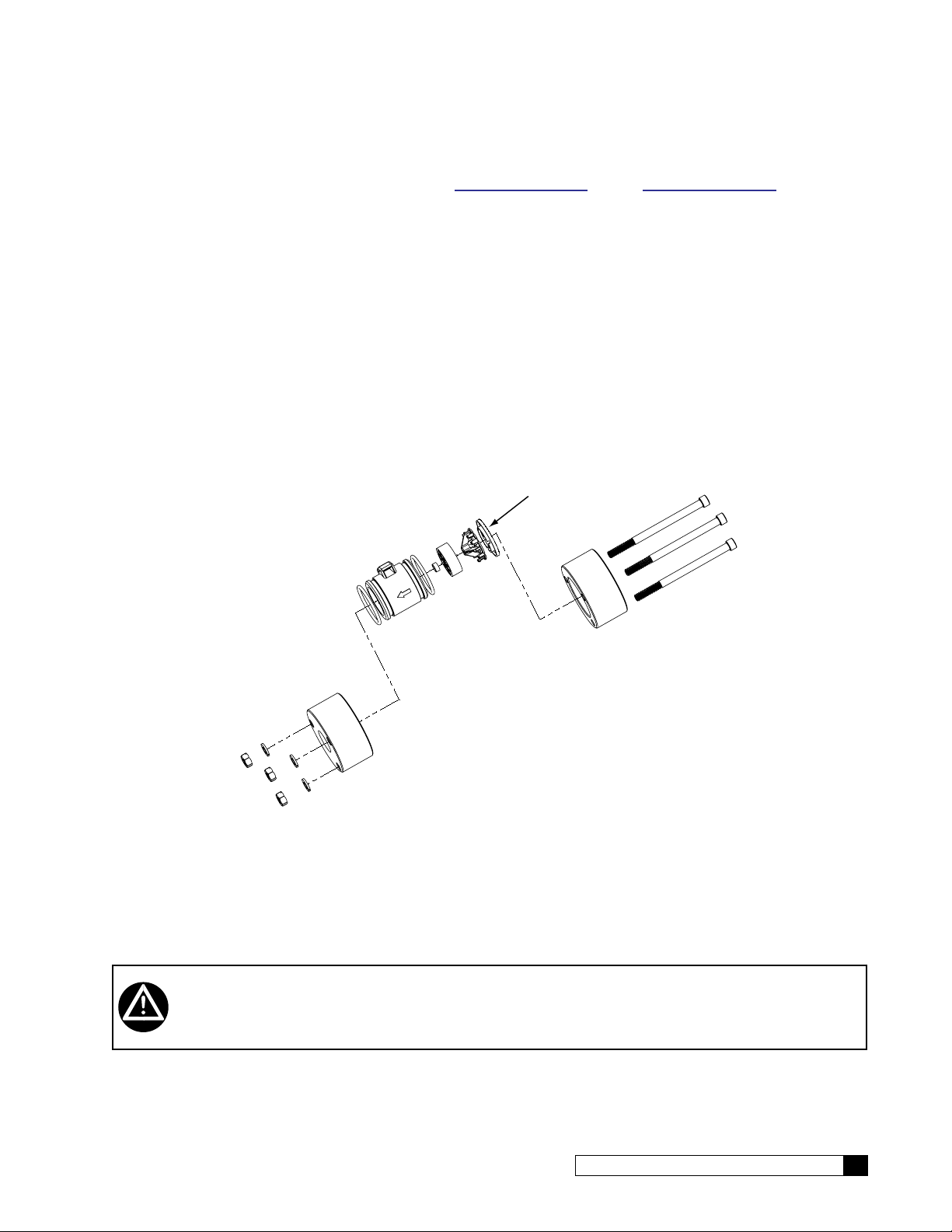

Retaining Rings

End Cap

O-Rings

Housing

FLOW

Membrane

Brine Seal

Figure 8. Membrane and its housing.

G1 RO Installation 9

4. Remove a new membrane from its plastic bag. Lightly lubricate the O-rings with a silicone-based lubricant or

TO MEMBRANE

use a mixture of 70% glycerin and 30% water.

CAUTION! Do not use a petroleum-based lubricant. It will damage the synthetic rubber and the

membrane.

5. Install the membrane in the same direction as indicated by the arrow on the outside of the membrane vessel.

The brine seal end should go in last.

6. Repeat for the remaining membrane housings. There may be from one to four housings on each model.

G1 Tubing Configuration

A

FEED (1/2" TUBE)

FROM MEMBRANE

C

PRODUCT 1/2" TUBE

B

FROM MEMBRANE

CONCENTRATE 3/8" TUBE

SYSTEM PRODUCT

OUTLET 1/2" TUBE

SYSTEM INLET

1/2" TUBE

SYSTEM WASTE

(CONCENTRATE) 3/8" TUBE

Figure 9. G1 tubing configuration.

WARNING! The system must be grounded. An improperly grounded unit could cause injury from

electrical shock!

10 Culligan® Series G1 Reverse Osmosis

10 Cat. No. 01021713

Plumbing Installation

Low Flow Nozzle

Refer to the appropriate tubing installation instructions (Figure 11 on page 13 through Figure 15 on page 17) for

further information.

Feed Water Connections

Connect tubing to the Feed water inlet. Observe the following:

1. To minimize pressure loss, the tubing size should be at least 1/2”.

2. Install an optional pressure gauge (P/N D1006272) before the pre-filter. This allows you to measure the pres-

sure differential across the filter cartridge.

3. Install a tee, with a shutoff valve on the branch, before the feed flow meter to provide a connection for introduc-

ing cleaning solutions.

4. If necessary, install a pressure regulator (50 psi downstream max. setting) in the inlet plumbing, to assure con-

stant pressure and to prevent harmonic vibration.

5. Install a shutoff valve in the inlet plumbing to simplify maintenance and service.

6. If the feed water can be used for a short period, install bypass plumbing around the unit.

Figure 10. Feed meter and nozzle.

Concentrate Water Connections

1. Direct 3/8" piping to drain from the outlet of the unit.

2. To prevent siphoning of the water in the unit to drain, raise the concentrate piping above the level of the mod-

ules and provide an anti-siphon loop.

WARNING! An air gap must be provided between the end of the concentrate tubing and the drain

to prevent back-siphoning of drain contents.

Cat. No. 01021713

G1 RO Installation 11

Product Water Connections

The product water exits the unit at the product flow meter on the back side of the unit. Connect the product tubing to the

fitting on the flow meter assembly. The product water flow meter contains a nozzle that is used with all models EXCEPT

G1-1F and G1-2F.

CAUTION! This unit produces high quality product water. This water can be contaminated by

plumbing following the unit or it can corrode the plumbing. Use only plumbing components of inert material that are compatible with the application.

The connection of the main product tubing to service plumbing will depend on how the product water will be stored.

CAUTION! Reverse osmosis elements will fail immediately if pressurized product water is allowed

to flow backward into the Series G1 unit.

12 Culligan® Series G1 Reverse Osmosis

12 Cat. No. 01021713

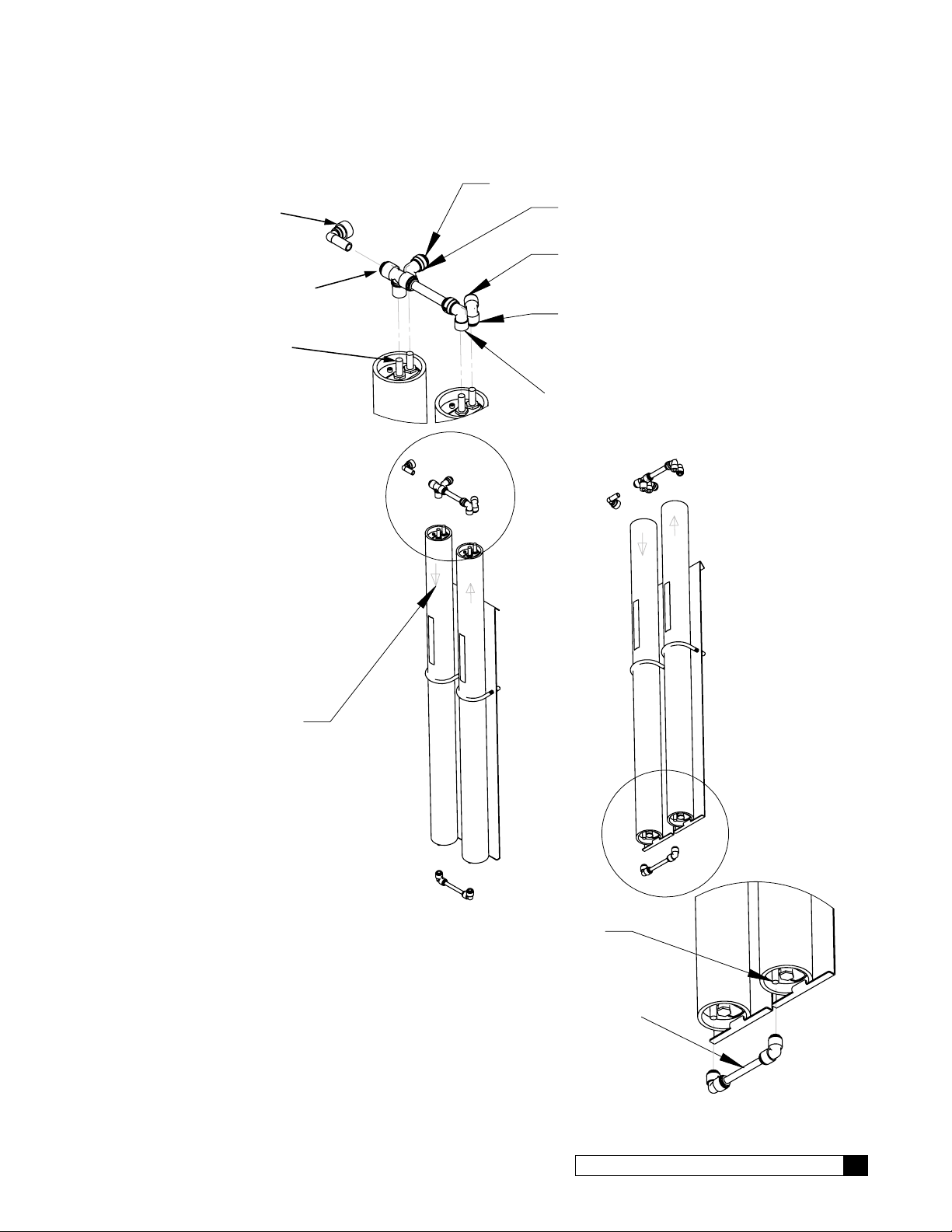

2S/2L Tubing Assembly Instructions

1/2" TUBE FOR FEED

USED FOR FLOOR

STAND APPLICATION

1/2" TUBE

FOR PRODUCT

REMOVE CAPS

ON 3/8" STEMS

INSERT 1/2"X3/8" ELBOW

OVER 3/8" STEM

3/8" TUBE FOR RECIRCULATION/WASTE

INSERT 3/8"X3/8" ELBOW

OVER 3/8" STEM

INSERT PRODUCT FITTING

ASSEMBLY OVER 3/8" STEMS

NOTE DIRECTION

OF FLOW

Cat. No. 01021713

REMOVE CAPS

ON 3/8" STEMS

INSERT FEED FITTING

ASSEMBLY OVER 3/8" STEMS

(BOTTOM SIDE OF MEMBRANES)

Figure 11. RO 2S/2L tubing assembly instructions.

G1 RO Installation 13

3S/3L Tubing Assembly Instructions

STAND APPLICATION

NOTE DIRECTION

OF FLOW

3/8 STEM ELBOWS, TO

BE INSERTED INTO

RECIRCULATION ASSEMBLY

ON MOTOR PANEL (M1/G1-ONLY)

3/8" TUBE FOR

RECIRCULATION/WASTE

INSERT 1/2"X3/8" ELBOW

OVER 3/8" STEM

1/2" TUBE FOR FEED

USED FOR FLOOR

INSERT FEED FITTING

ASSEMBLY OVER

3/8" STEMS

1/2" TUBE

FOR PRODUCT

Figure 12. RO 3S/3L tubing assembly instructions.

REMOVE CAPS

INSERT PRODUCT FITTING

ASSEMBLY OVER 3/8" STEMS

ON 3/8" STEMS

REMOVE CAPS

ON 3/8" STEMS

INSERT 3/8" FITTING ASSEMBLY

OVER 3/8" STEM

ASSEMBLY OVER 3/8" STEMS

(BOTTOM SIDE OF MEMBRANES)

INSERT FEED FITTING

14 Culligan® Series G1 Reverse Osmosis

14 Cat. No. 01021713

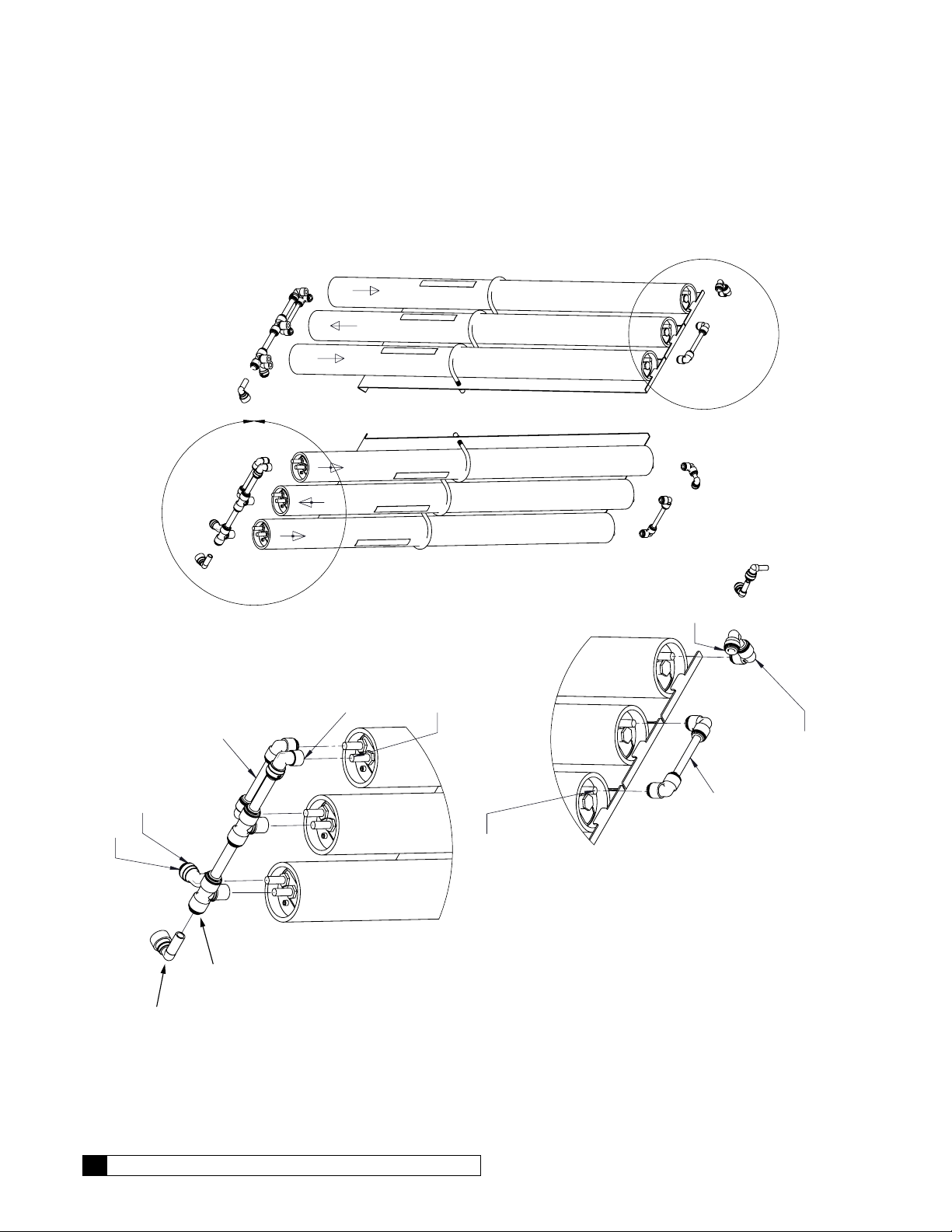

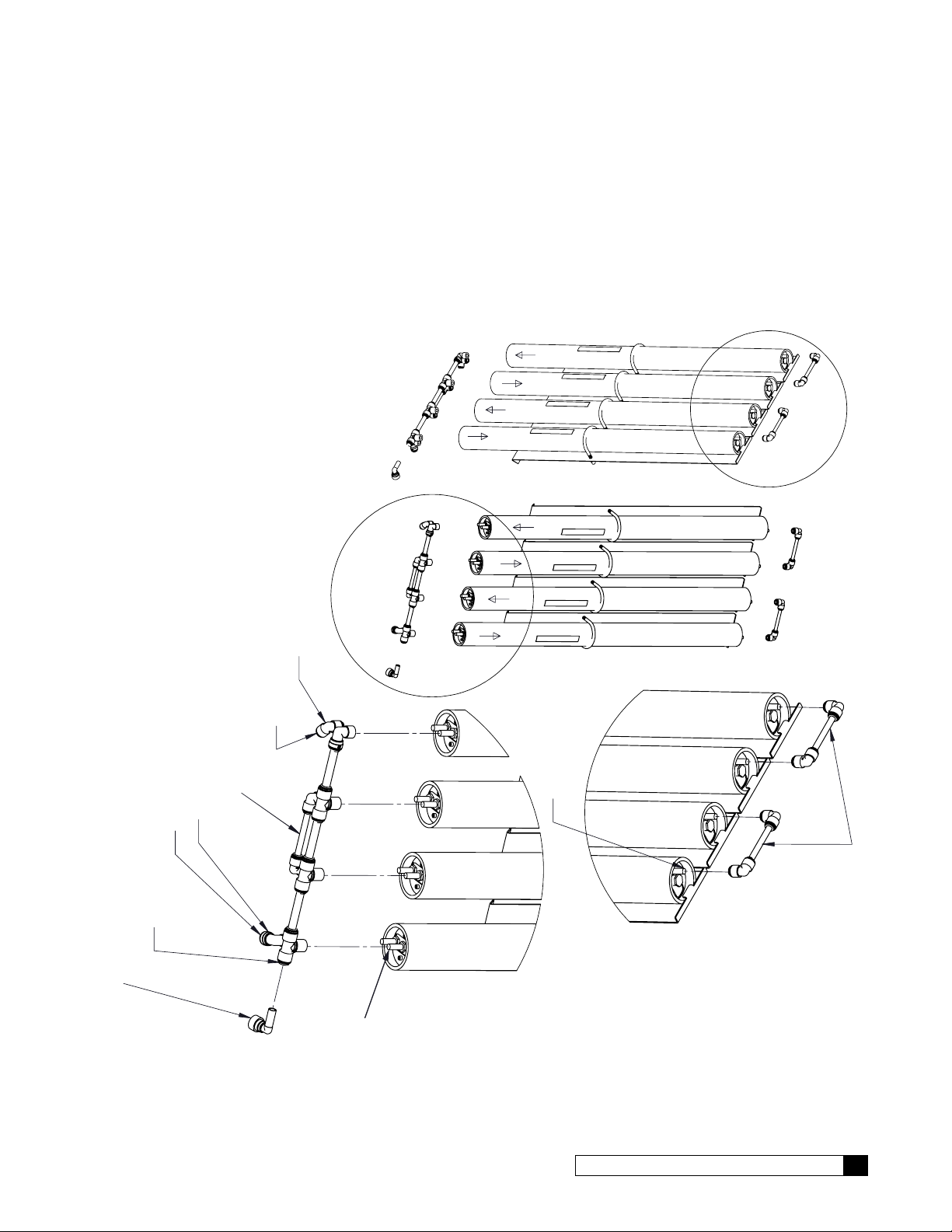

4S/4L Tubing Assembly Instructions

NOTE DIRECTION OF FLOW

REMOVE CAPS

ON 3/8" STEMS

INSERT 3/8"X3/8" ELBOW

OVER 3/8" STEM

3/8" TUBE FOR RECIRCULATION/WASTE

INSERT FEED FITTING

ASSEMBLY OVER 3/8" STEMS

INSERT 1/2"X3/8" ELBOW

OVER 3/8" STEM

1/2" TUBE FOR FEED

1/2" TUBE FOR PRODUCT

USED FOR FLOOR STAND APPLICATION

REMOVE CAPS

ON 3/8" STEMS

INSERT FEED FITTING

ASSEMBLIES OVER 3/8" STEMS

(BOTTOM SIDE OF MEMBRANES)

Cat. No. 01021713

Figure 13. RO 4S/4L tubing assembly instructions.

G1 RO Installation 15

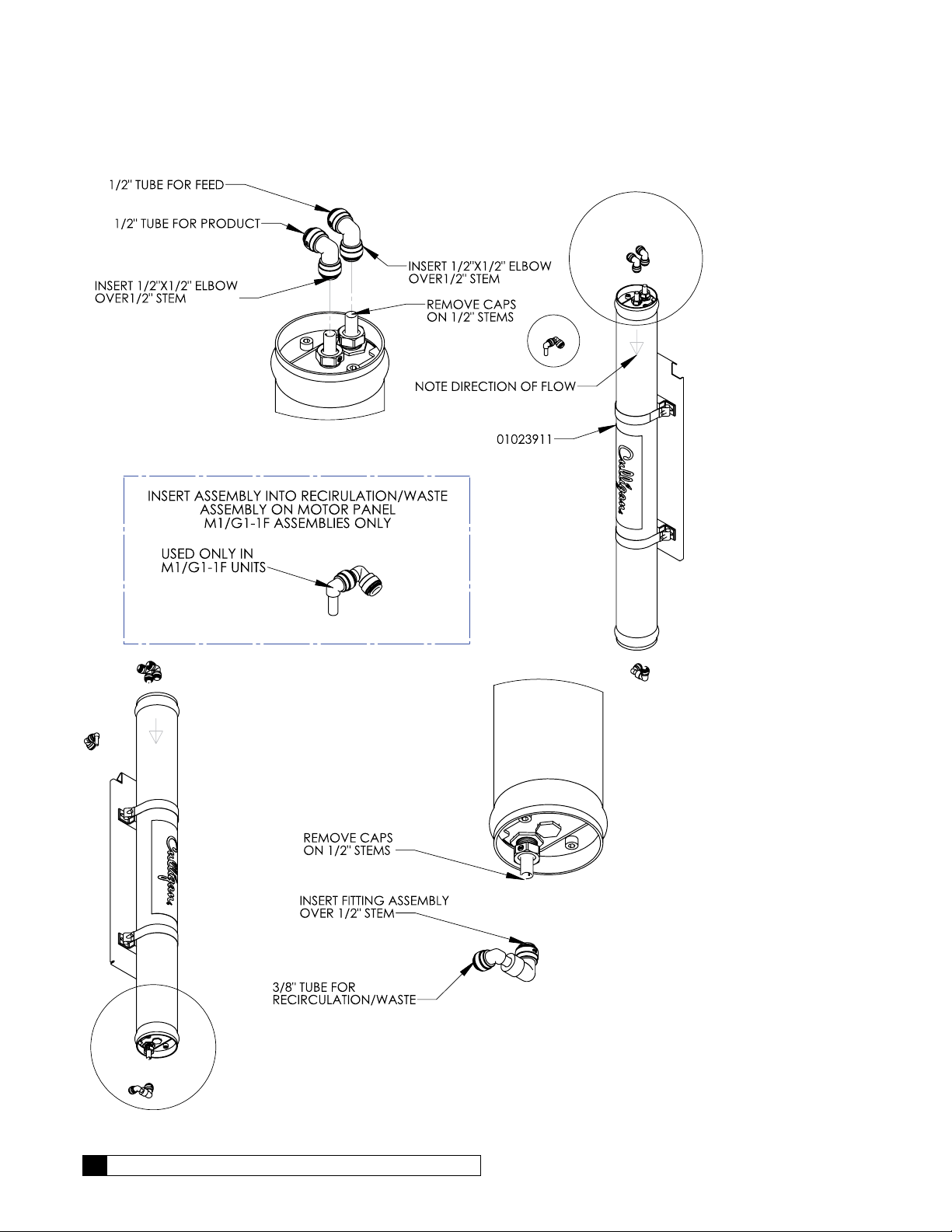

1F Tubing Assembly Instructions

Figure 14. RO 1F tubing assembly instructions.

16 Culligan® Series G1 Reverse Osmosis

16 Cat. No. 01021713

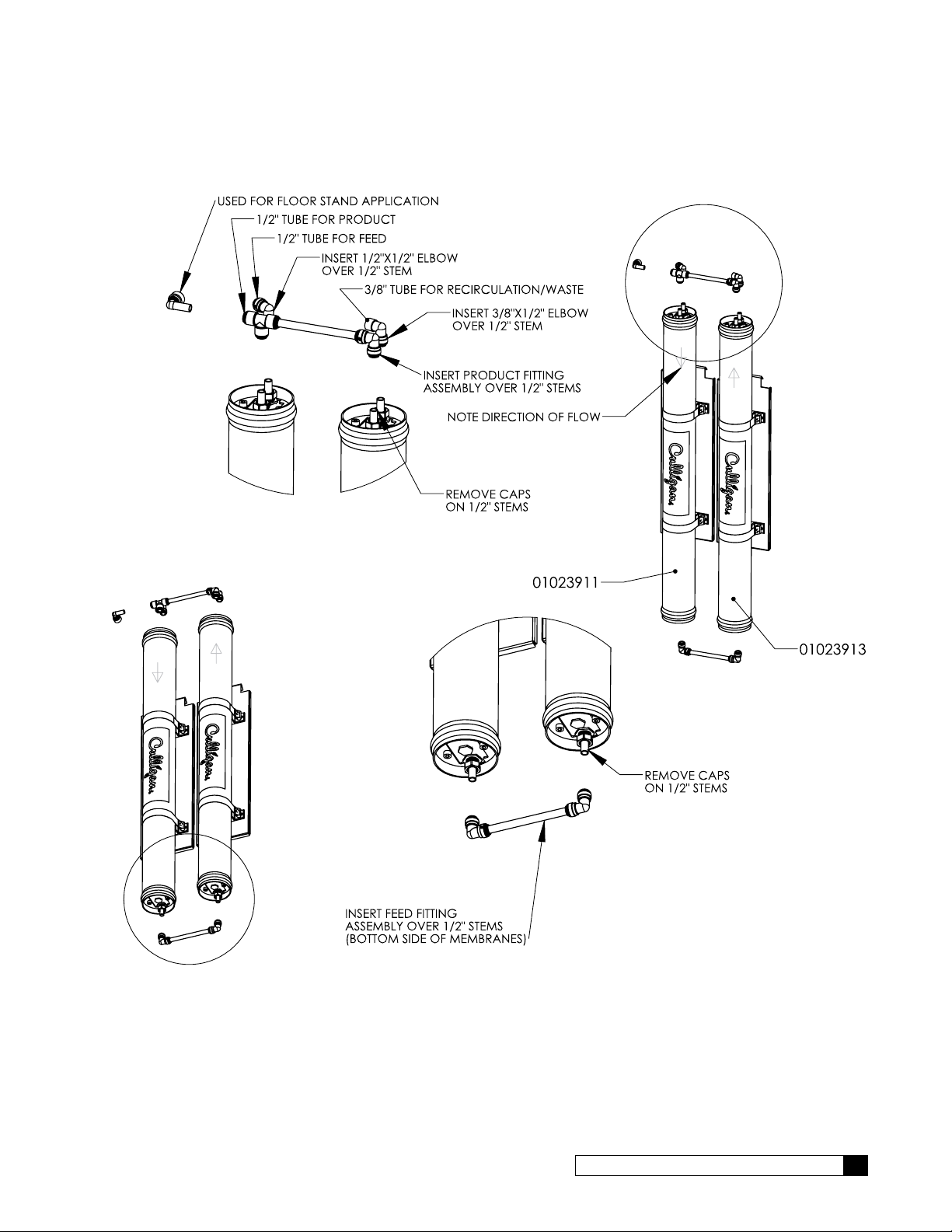

2F Tubing Assembly Instructions

Cat. No. 01021713

Figure 15. RO 2F tubing assembly instructions.

G1 RO Installation 17

Pressurized Storage Tank

The product water can be stored in a pressurized storage tank with the reverse osmosis unit controlled by a pressure

switch. Use the same components used for direct feed (see Figure 16). The pressure switch needs to be wired to the control panel as a float switch (see Figure 57 on page 105 for G1 standard wiring). A pressurized water storage kit is available for the G1 under P/N D1013880 (110V) or P/N D1018976 (220V). Connect the product tubing to a bulkhead fitting at

the top of the storage tank such as P/N 01005095 (2-gallon), P/N 01004776 (3-gallon), or P/N 01004765 (9-gallon).

Non-Pressurized Product Water Storage Tank

Depending on the type of application, a level control may be required to turn the unit off when the storage tank is full.

Install the level control according to the instructions provided with the control. See “GBE RO Controller Basic sub-panel

wiring.” on page 105 for electrical connections.

NOTICE If a repressurization pump is used, an additional level control is recommended to prevent the

pump from running dry if the storage tank is empty.

To maintain high water quality, a hydrophilic air vent filter, vacuum breaker, pop-off valve, ultraviolet lamp, and pressure

relief valve may be required.

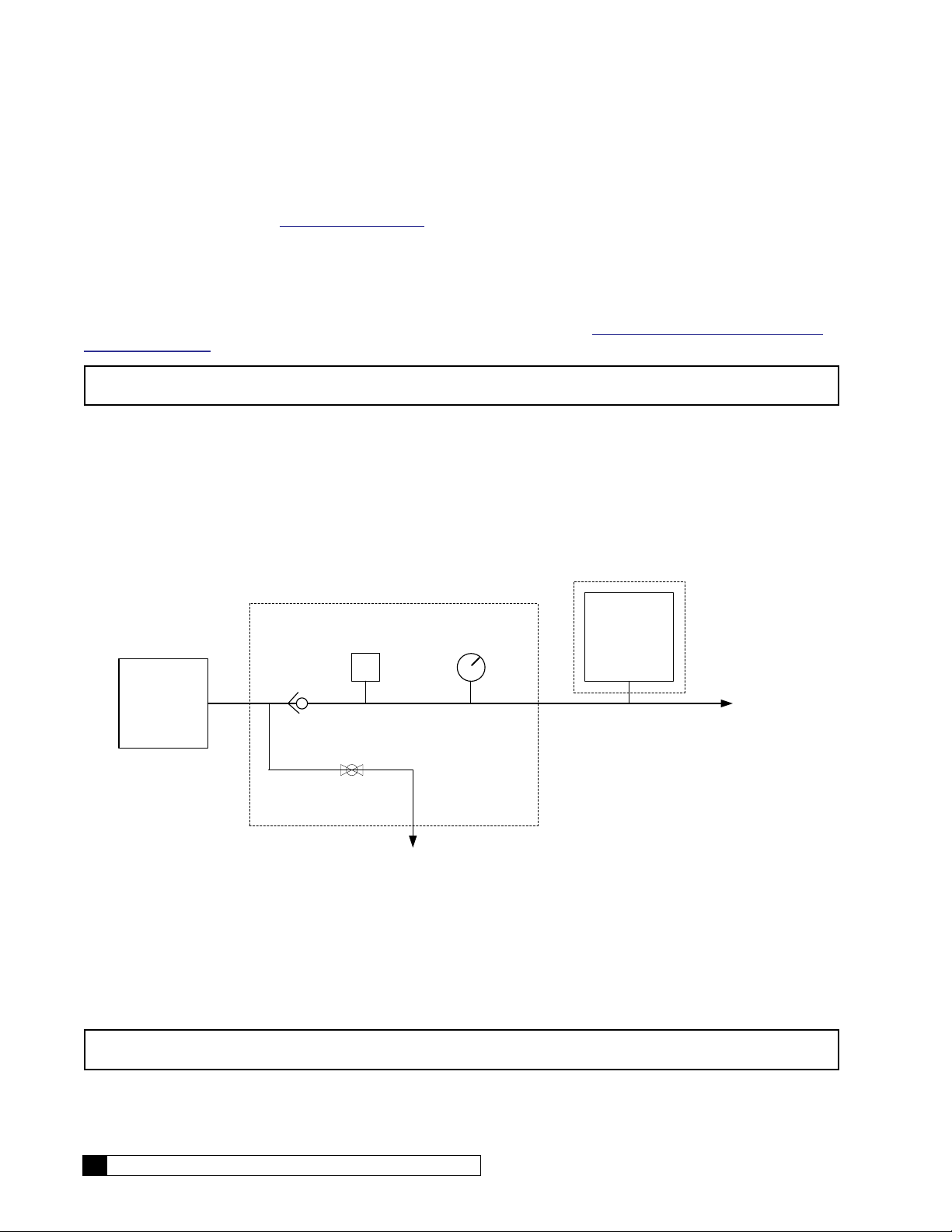

Direct Feed

If the product water is to be used directly, without storage, a few precautions are necessary to prevent damage to the

elements. Install a pressure gauge, pressure relief valve, and a normally-open (“dump”) solenoid in the product water

line as shown in Figure 16, or use pressurized storage kit (P/N D1013880). The pressure gauge will allow the operator to

monitor the product water pressure. The relief valve, which should be set to open at 40 psig, will prevent the product water

pressure from exceeding 40 psi. The dump solenoid will relieve all pressure when the unit is off.

2SWLRQDO

3UHVVXUL]HG

6WRUDJH

7DQN

7R 6HUYLFH

52 6\VWHP

&KHFN

9DOYH

3UHVVXUH 6ZLWFK

36

3UHVVXUH *DXJH

69

3UHVVXUL]HG

6WRUDJH .LW

'

7R 'UDLQ

8VH RI 3UHVVXUL]HG 6WRUDJH7DQN UHTXLUHVXVH RI 3UHVVXUL]HG 6WRUDJH .LW'

Figure 16. Direct feed connection.

Wire the direct feed/pressurized storage solenoid valve in parallel with the motor.

Valve SV4 closes when the RO pump runs; SV4 opens when the pump stops, allowing all membrane back proessure to

be relieved.

NOTICE Product back pressure will decrease the net pressure pushing water through the reverse osmosis

elements. Therefore, the flow of product water will decrease.

18 Culligan® Series G1 Reverse Osmosis

18 Cat. No. 01021713

GBE RO Controller Program Data

Program Data Input

There are a few items to note that can make programming the Culligan® Global RO Controller easier:

Slew Rates This term refers to the speed at which the display moves through the input of material. For ex-

ample, holding down the up arrow key for (5) seconds when inputting minutes for Time of Day

will cause the minutes to pass in (10) minute blocks of time. Press the up arrow or down arrow

keys for shorter periods (less than 5 seconds) will slow the rate. To move through the programming slowly, do not hold down the up arrow or the down arrow keys.

Beeper A beeper is available to assist the user by providing an audible tone (about 70 decibels) to signi-

fy valid (one beep) and invalid (three beeps) key presses. The beeper can be deactivated in the

programming mode. (If error occurs, beep will still sound even if set to “No” programming.)

Programming

Mode Timeout

Program Input

Acceptance

If there is no keypad activity for a one (1) minute period while in the programming mode, the

controller will exit the programming mode and return to the main display. Any setting that was

changed prior to the control timing out will revert to the original value. Pressing the CHECK

MARK button saves the setting.

For programming information to be accepted, the check mark key must be depressed prior to

programming mode timeout.

Cat. No. 01021713

GBE RO Controller Program Data 19

First Time Setup

First Time Setup Procedure

If at any time you need to re-run the First Time Setup, refer to “Menu Default—Rerun First Time Setup” on page 22.

After completing the plumbing connections to the water softener, turn on and program the Global RO Controller.

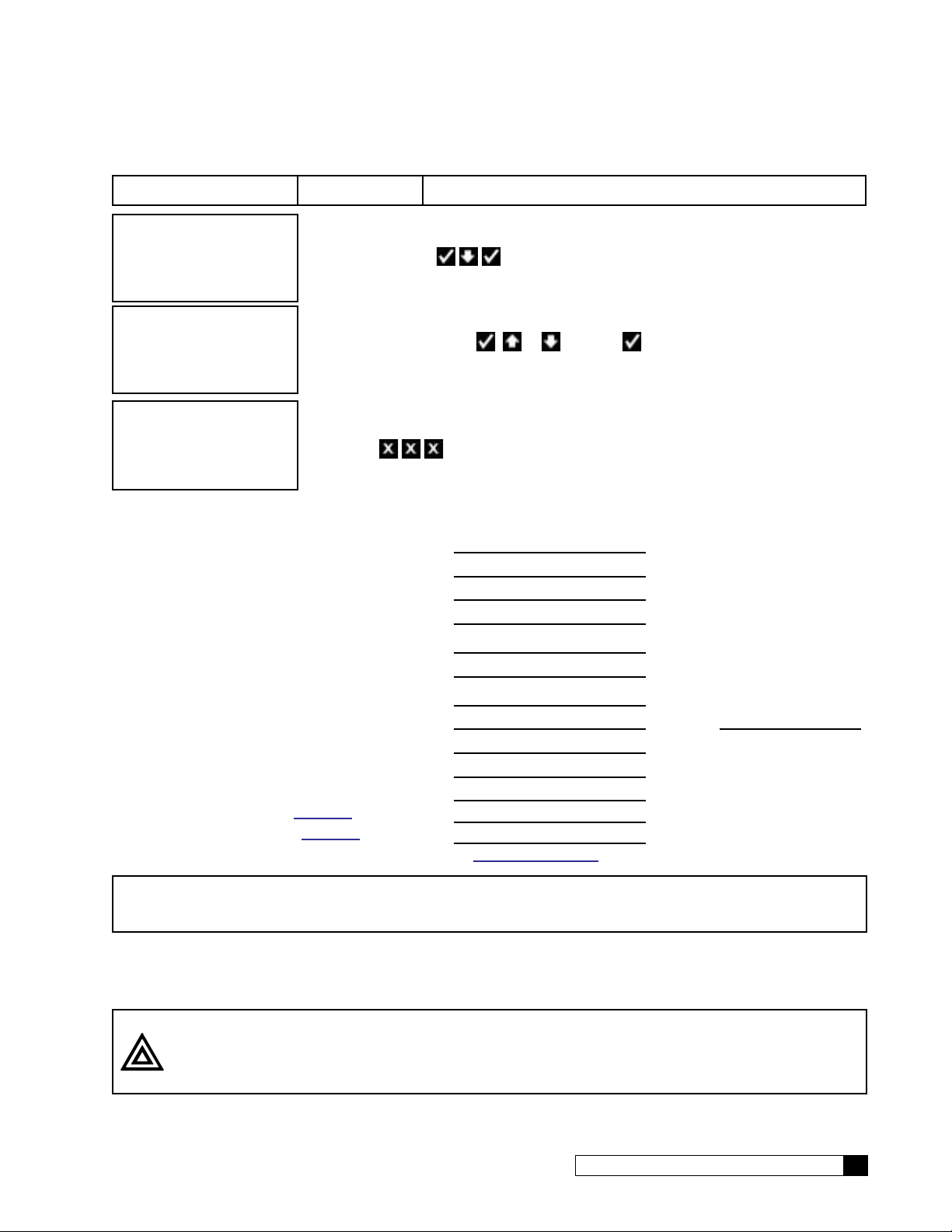

Select Language (English, French, Italian, Spanish)

LANGUAGE

ENGLISH

1. Apply power to the unit. When a new controller is first turned on, the screen dis-

plays LANGUAGE. Press

gin first time setup in your preferred language.

NOTE You also can change the language setting after first-time setup from

the Setup menu. See “Set Up Language” on page 33.

or and then to change the value and be-

Serial Number

FIRST TIME SETUP

PRESS DOWN ARROW

S/N:00012345

FWR***LT04

1. Plug in the wall transformer. When a new controller is first turned on, the screen

displays FIRST TIME SETUP. Press

2. The screen displays the serial number and firmware version and date installed for

this GROC. Press

ting, month.

to accept this information. The screen displays the first set-

.

MON DD YEAR

NOTE The S/N, firmware, and date displayed in this manual are examples only.

NOTE If this unit will be installed with a modem, it is required that this electronic serial number be reported to

Culligan on the IQR form.

Setting Up Date and Time

SET

MONTH JAN

1. The screen displays the month setting. Press to accept this information and

view the day setting.

SET

MONTH >JAN

SET

MONTH >FEB

2. Press to select the item. The screen displays a cursor next to the value. This

indicates that the value may be changed by pressing the

3. Press to select a new value. The screen displays the new setting value next to

the cursor.

4. Press to select the next available value. You may press or to scroll

through all available options for this setting.

SET

DAY 1

20 Culligan® Series G1 Reverse Osmosis

5. Press to accept the selected screen value. The controller accepts the new value and displays the next setting.

or button.

20 Cat. No. 01021713

Other First Time Setup Settings

Screen Display Range Procedure

SET

DAY 1

SET YEAR

2012

CLOCK TYPE

12 HR

SET HOUR

12PM

SET

MINUTES 25

1–31

2010–2040

12 or 24

12AM–11PM

0–59

1. The screen displays the day setting. Press

then

2. The screen displays the year setting. Press

then

3. The screen displays the clock type setting. Press

4. The screen displays the hour setting. Press

then

5. The screen displays the minutes setting. Press

and then

to change the value and see the next setting.

to change the value and see the next setting.

and then to change the value and see the next setting.

to change the value and see the next setting.

to change the value and see the next setting.

or and

or and

or and

or

or

POWERON MODE

OFFLINE

Running

Offline

SYSTEM UNITS

US INCH

US INCH

METRIC

Completed First Time Setup

STARTING

JAN-01-12 12:01P

RUNNING

JAN-01-12 12:01P

Cat. No. 01021713

1. When the setup is complete, the circuit board microprocessor automatically calcu-

lates the water conditioner capacity. The screen displays the initializing status and

the current date and time, and then transitions to the home screen.

2. The screen displays the current state of the RO system (RUNNING or OFFLINE)

and the date/time set for the unit. This is the default home screen.

6. The screen displays the selected status of the RO when pow-

ered on. Press

ue and see the next setting.

7. The screen displays the units of measure setting. Press

or and then to change the value and complete the

first-time setup.

NOTE This setting does not automatically change to metric

if you select a language other than English.

or and then to change the val-

First Time Setup 21

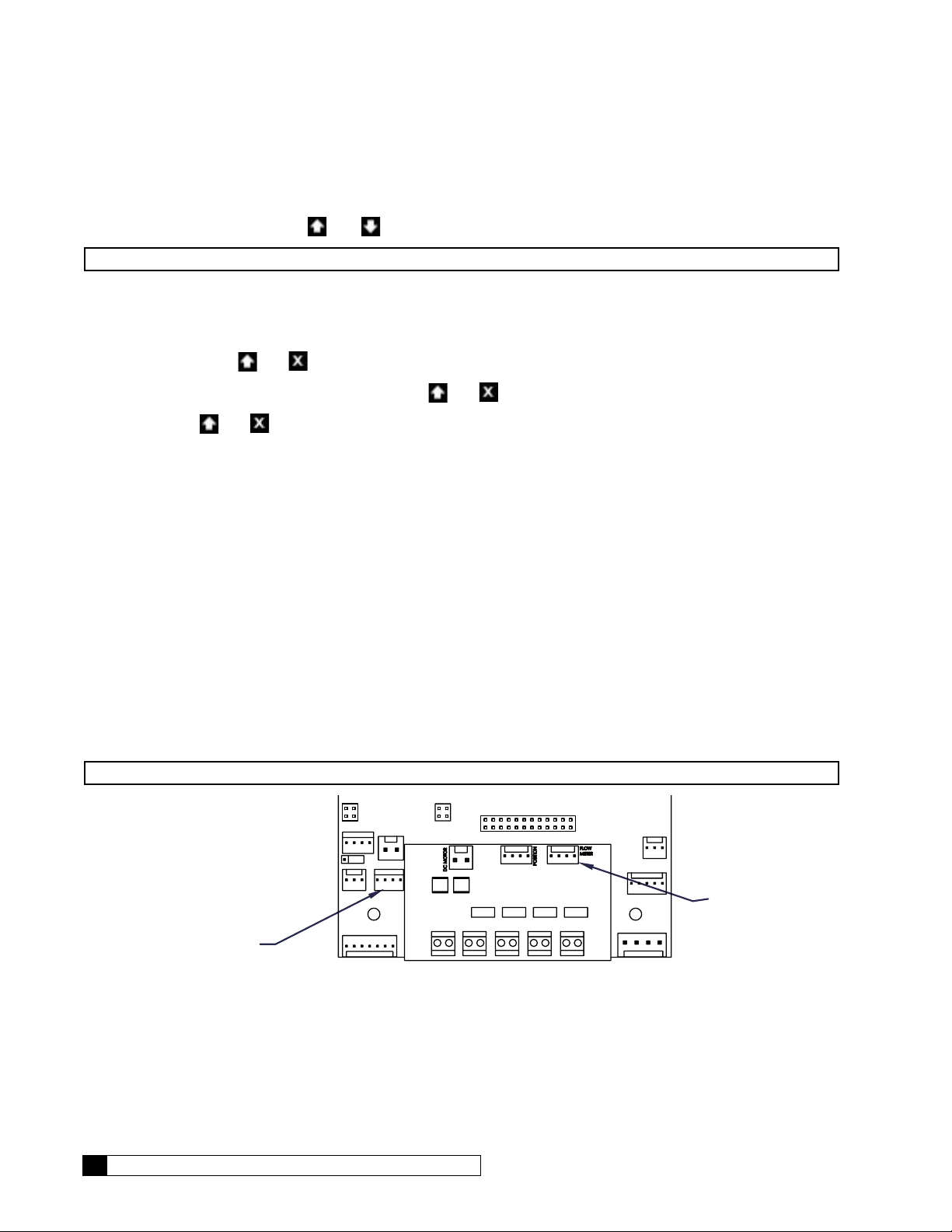

Menu Lockout

J7

J5 J6

4 = n/c, 3 = ground, 2 = flow pulse signal, 1 = 5 VDC supply

It is possible to lock the keypad of the Global RO controller so that users will only have access to the INFORMATION, GO

TO RUNNING, and GO TO OFFLINE menu screens.

To lock the system, press and hold

NOTE Menu lockout may be completed only from the home screen.

and for 10 seconds. Repeat this process to unlock the keypad.

Menu Default—Rerun First Time Setup

Below is the procedure to default the board to factory settings and begin the first time setup.

1. Power down the control.

2. Press and hold

3. Power up the control while continuing to hold

4. Release

5. Power down the control.

6. Power up the control again. The screen lights up for two seconds and then displays the home screen.

7. Follow the first time setup process.

and .

and for at least five (5) seconds.

and . The display should be blank—if not go back to step 1.

Flow Meters

There are two flow meters on the G1 RO system, the feed flow meter (FM1) and the product flow meter (FM2). Before

using the G1 RO it is necessary to first calibrate both flow meters. See Table 1.

Connect the wires of both flow meters to the CIB board using the 4 - pin connections provided. The feed flow meter connects to FM1 (J11) and the product flow meter connects to FM2 (J12). See Figure 17.

The pins are:

Pin 4 = not connected

Pin 3 = ground

Pin 2 = flow pulse signal

Pin 1 = 5 VDC power supply

NOTE Pin 1 on the GBE board is identified with a small WHITE dot.

J16

J17

J10

J1—PRODUCT

FLOW

J15—INLET FLOW

METER

The 4 - Pin Connections are:

NOTE: Pin 1 is identified with a small WHITE dot.

Figure 17. Flow Meter Connections on GBE Board

22 Culligan® Series G1 Reverse Osmosis

22 Cat. No. 01021713

METER

1. Start with both the recirc valve and the waste valves fully open (turn the valve all the way in a counter-clockwise

direction).

2. Start the RO.

3. When the pump turns on, slowly close the waste and recirc valves clockwise.

4. Try to close the waste valve until the flow rates to product and to drain are approximately even, then begin to

close the recirc valve, to bring the membrane feed pressure within the range of 80–120 psi.

5. Set the K-Factor for both FM1 and FM2 at the values listed in Table 1. See “G1 Tubing Configuration” on page

10.

6. On the GBE RO controller, select 3)INFORMATION and observe the FFLOW and PFLOW rates.

7. Using a stopwatch and a bucket, measure and record the time elapsed (in seconds) to fill a one-gallon bucket

with product water.

8. Meaure and record the time elapsed (in seconds) to fill a one-gallon bucket with waste water.

NOTE Convert your stopwatch readings to minutes (for gallons per minute) by dividing the number of sec-

onds by 60. For example, if you measure 45 seconds to fill a 1-gallon bucket, the fill time is 45/60 = 0.75

minutes, and the flow rate is 1/0.75 = 1.33 gpm.

Feed Flow Meter Product Flow Meter

Model FM1 Initial Nozzle Needed/K Factor FM2 Initial Nozzle Needed/K Factor

2S 500 500

3S 500 500

4S 500 500

2L 80 500

3L 80 500

4L 80 500

1F 80 80

2F 80 80

Table 1. K factor for FM1 and FM2.

9. Calculate the values for “A” and “B” using the following equations:

A =

(FM1 INITIAL) x (FFLOW DISPLAYED)

FFLOW ACTUAL

Where

FM1 INITIAL is from Table 1

FFLOW DISPLAYED

is displayed on the GBE RO controller

FFLOW ACTUAL = (Actual Product Flow) + (Actual Waste), in gallons per minute

(FM2 INITIAL) x (PFLOW DIS-

B =

PLAYED)

PFLOW ACTUAL

Where

FM2 INITIAL is from Table 1

PFLOW DISPLAYED is displayed on the GBE RO controller

PFLOW ACTUAL = (Actual Product), in gallons per minute

10. Use the directions in the next section to change the K factor for FM1 to the value for A, and then change the K

factor for FM2 to the value calculated for B.

11. Verify that the displayed values of FFLOW and PFLOW in the information screen on the GBE RO controller

match the actual measured flow rates from steps 7 and 8 while the RO is running.

Cat. No. 01021713

First Time Setup 23

RUNNING

JAN-01-12 12:01P

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

2) LANGUAGE

3) POWERON MODE

4) FLUSH MODES

>5) ACCESSORIES

1) WIRELESS REM

2) MODEM

>3) FLOW METERS

4) SWITCH INPTS

1. From the default home screen, press . The screen displays the main menu.

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

4. Press to select 5)ACCESSORIES. The screen displays the accessories menu.

5. Press to select 3)FLOW METERS. The screen displays the flow meter

settings.

24 Culligan® Series G1 Reverse Osmosis

24 Cat. No. 01021713

Flow Meter Settings

Screen Display Range Changing the Setting

FLOW METERS

INSTALLED

Installed

Not Installed

The screen displays the installation status of the flow meter. Press

to change the state to installed if a flow meter is in-

stalled in the RO system.

FM1 K FACTOR

80.0

0–9999

Press

calculated value for the flow meter FM1 and/or FM2.

or and then to change the K-Factor to the

RUNNING

JAN-01-12 12:01P

6. Press to save the settings and return to the home screen.

12. Once all the desired flows are set, allow the system to run for approximately 30 minutes, and then record the

following measurements using the units gauges (U), GROC information screens (G), and your instruments (I):

a. Feed Flow Rate, gpm (G)

b. Feed Water Temperature, °F (I)

c. Feed Water SDI (I)

d. Feed TDS, ppm (I)

e. Inlet Pressure, psig (U)

f. System (pump outlet) pressure, psig (U)

g. Product TDS, ppm (G)

h. Product Flow, gpm (G) x TCF

i. Product Temperature, °F (G)

j. Product Pressure, psig (I)

k. Concentrate (waste) flow, gpm (a–h)

l. % Recovery (see page 121)

m. % Rejection (see page 121)

1

TCF = Temperature Correction Factor. Refer to Table 2 on page 26 for this value.

1

=

NOTICE The Global RO Controller has a feature which records historical data. The intial startup data is kept

in the controllers memory. It is still a good idea to record the values on a separate sheet of paper

and keep the data near the unit in case of electrical problems.

13. Choose GO TO OFFLINE from the main menu. Connect the product tubing to the service plumbing.

14. Test the operation of the pressure switch by closing the inlet water supply valve. The unit should shut off immediately.

CAUTION! If the unit does not shut off, turn the unit OFF immediately to prevent pump damage.

Disconnect electrical power source, then check the wiring and replace the switch, if

necessary.

15. Open the inlet water supply valve. The unit should restart.

16. If connected, test the storage tank level control shutdown and the pretreatment lockout function.

Cat. No. 01021713

First Time Setup 25

Normal Operation

During normal operation, the system usually will start up and shut down based on signals from a level control or pressure

switch. Adjust the feed pressure as required (no higher than 150 psig) to maintain a constant product flow. Record the

performance data regularly and compare it to the performance on initial start up. If any changes are noticed, the product

flow should be normalized to determine if cleaning is required (see Product Flow Calculations below).

Product Flow Calculations

The product flow rate depends primarily on feed water pressure, product water pressure, and temperature. All 1-Series

RO water conditioners have specified nominal flow rates based on approximately 105 psig net pressure and 77°F temperature. However, in most applications the temperature and pressure are lower, so the product flow rate is lower than the

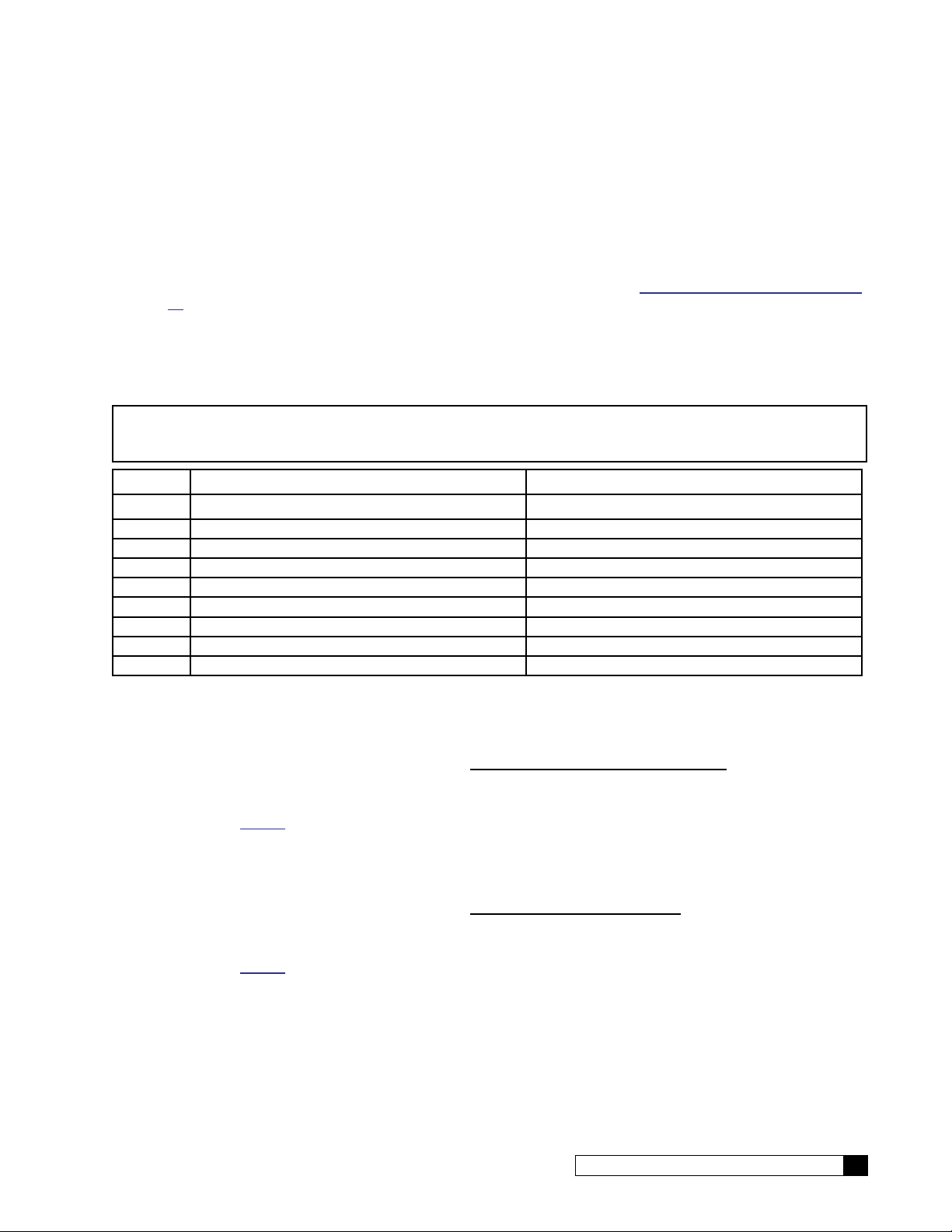

nominal flow rate. The actual flow rate must be converted to flow under standard conditions, then compared to the initial

performance (also converted to standard conditions) to determine whether the system is still working properly.

To convert the data to standard conditions,

1. Measure the product flow. Example: 1000 ml/min

2. Measure the feed pressure. Example: 120 psig

3. Measure the product pressure. Example: 5 psig

4. Subtract the product pressure from the feed pressure. Example: 115 psig

5. Divide the product flow by the result from step 4. Example: 1000 ÷ 115 = 8.69 ml/min/psi

6. Multiply the result from step 5 by 105. Example: 8.69 x 105 = 913 ml/min

7. Measure the temperature of the feed water, then determine the temperature correction factor from Table 2.

Example: At a temperature of 55°F , the factor is 1.54.

Temp. °F Temp. °C Correction Factor Temp. °F Temp. °C Correction Factor

40 4.4 2.12 75 24 1.04

45 6.7 1.90 80 27 0.95

50 10 1.71 85 29 0.86

55 13 1.54 90 32 0.79

60 16 1.39 95 35 0.72

65 18 1.26 100 38 0.66

70 21 1.14

Table 2. Temperature Correction Factors

8. Multiply the result of step 6 by the temperature correction factor. Example: 913 ml/min x 1.54 = 1406 ml/min.

NOTICE To convert ml/min to gallons per day, multiply by 0.38. For example, 1406 ml/min x 0.38 = 534 gpd.

9. Compare the current standardized flow to the initial standardized flow. If the flow has decreased by 15% or

more, it is time to clean the elements.

Example: If the initial standardized flow was 570 gpd, and the current standardized flow is 470 gpd, the flow has

decreased by 100 gpd, or 18% (100/570) = 0.18. The elements should be cleaned.

10. If the problem cannot be corrected with the troubleshooting guide and assistance is required, please have the

following information available when calling the Culligan dealer:

• Product flow rate

• Concentrate flow rate

• Feed pressure

• Product water quality

• Feed water quality

• Feed water temperature

• Prefilter outlet (and inlet if the optional prefilter inlet gauge was installed)

• Product pressure

26 Culligan® Series G1 Reverse Osmosis

26 Cat. No. 01021713

Switch Inputs

Several switch types may be installed in an RO system, including

• Low Pressure Switch

• Pretreatment Lockout Switch

• Float (Level Control) Switch

See “GBE RO Controller Wiring” on page 102 for a diagram of all three switches.

Low Pressure Switch

The GBE RO Controller is equipped with a low pressure switch to protect the pump from starvation/cavitation. If the inlet

pressure switch goes LOW and stays there for at least XX seconds (set at setup/accessories/switch inputs), the pump will

turn off. For a positive displacement pump, XX should be specified at 1–5 seconds. The controller keeps track of how many

times this happens: if fewer than five times since the most recent of either midnight or the last time the operator manually selected GO TO RUNNING from the main menu, then the system will attempt to restart. If this is the fifth time it has happened,

then the system goes to OFFLINE and throws the LOW INLET PRESSURE error condition.

NOTE This five-time counter on the number of restarts allowed resets to zero every night at midnight and

every time that the operator selects YES from the Main Menu/Go to Running screen.

The pressure switch is prewired at the factory to the GBE RO controller AUX board POSITION (J1) pins utilizing pins 2

and 4. The switch is factory set to 18 psi. The pressure can be adjusted from 6 psi to 30 psi by turning the knurled ring on

the body of switch clockwise to increase the pressure and counter-clockwise to decrease. One revolution is approximately

6.5 psi.

Pretreatment Lockout

The GBE RO controller allows an external contact closure to cause the RO to go into a “pre-treat lockout” condition. If the

GBE RO controller state was in any state other than OFFLINE, the state will change to STANDBY as soon as the pretreat

lockout is engaged. When pretreat lockout is disengaged, the system will either move to STARTING or stay in STANDBY

based upon the status of the float switches and the settings specified at main menu/ setup/ accessories/ switch inputs.

The pretreat lockout can be engaged by either a normally open or normally closed input signal to the pretreat lockout

terminals from the main menu/setup/accessories/switched inputs menus. The factory default is that CLOSED will specify

pretreat lockout.

Note that the pre-treat lockout input switch must move to, and stay in its new position for a continuous period of at least

two (2) seconds for the pretreat lockout to be triggered

®

Timeclock controlled softeners, such as the Hi-Flo

treatment, they should be duplexed, or regenerated by a timeclock so that regeneration can occur when the unit is not in

operation.

3, do not offer pretreatment lockout. If these units are used for pre-

Cat. No. 01021713

First Time Setup 27

Wiring for Softeners and Filters with MVP Controller

For these systems, you must add a 24V relay P/N 01016156, to provide the pretreatment contact.

MVP to Relay: Connect a wire from Terminal 5 of the relay to the left terminal of P8 (Aux 2) on the MVP circuit board.

Connect another wire from terminal 1 of the relay to the right terminal of P8. Refer to Figure 18.

Relay to GBE RO controller: Connect a wire from the POSITION (J2), PIN 3 terminal on the AUX board to terminal 3 on

the relay. Connect another wire from the POSITION (J2), PIN 4 terminal on the AUX board to terminal 4 on the relay.

LCD

SW6 Dip Switch

P11

Battery

P6

Motor

P9 Power

2.5VAC 24V

MVP

P5

Aux1

P7 Sol

Valve

P8

Aux2

P1

Cam

Aqua

Sensor

Flow

Meter

Relay

P3

Comm

GROC BOARD

Figure 18. MVP to GBE RO controller relays.

28 Culligan® Series G1 Reverse Osmosis

28 Cat. No. 01021713

Wiring for Softeners and Filters with GBE RO Controller

For these systems, you must add a 24 VAC relay, part number 01016156, to provide the pretreatment contact.

GBE to Relay: Connect a wire from terminal 5 of the relay to the left terminal of Aux 4 on the GBE softener/filter circuit

board. Connect another wire from terminal 1 of the relay to the right terminal of Aux 4. Refer to Figure 19.

Relay to GBE RO controller: Connect a wire from the POSITION (J2), PIN 3 terminal on the AUX board to terminal 3 on

the relay. Connect another wire from the POSITION (J2), PIN 4 terminal on the AUX board to terminal 4 on the relay. Use

the GBE RO controller Aux cable kit, P/N 01021830, to connect cables to the GBE RO controller board.

J5 J6

J7

GBE SOFTENER/FILTER

J16

AUX OUT 4

J17

J10

J2

Relay

GROC BOARD

Cat. No. 01021713

Figure 19. GBE to GBE RO controller relays.

First Time Setup 29

Float Level Control

P/N: XXXXXXXX rev. X

VENDOR: XXXXXX

DATE CODE: WK/YY

HEX FILE: XXXXXXXX rev. X

Remote Display

RF Board Connector

Modem

Connectors

Product Flow Meter (J1)

The GBE RO controller provides a Level Control High switch as well as a Level Control Low switch. You can use the Level

Control High switch alone, or with the Level Control Low switch.

The Level Control connections are located on the GBE RO controller board. They are labeled POSITION (J12) on the

main GBE RO controller board. Pin 4 is common and Pin 2 is for HIGH level and Pin 3 is for LOW level.

These switches can be specified to be either “OPEN WHEN LEVEL IS ABOVE SWITCH” or “CLOSED WHEN LEVEL IS

ABOVE SWITCH” when the level of water is above the switches. Both switches must have the same OPEN or CLOSED

specification. For example, you can specify (main menu/setup/accessories/switch inputs) that the float switches will be

CLOSED when the level of water is above the level of the switches. The system assumes that a float switch is “off” when

the water is below the switch and it is on when the state of the switch matches to user specified OPEN or CLOSED condition. Use the GBE RO controller switch accessory kit (P/N 01022360) to connect Float Switch and Pretreatment Lockout

to the controller board. The kit contains four connectors (P/N 01021838) with wire leads. See page 102 for wiring information.

Float Switch (J12)

Plug into J12

and Pretreat Lockout

Connectors for Float Switch

Figure 21. J12 float switch.

Figure 20. GROC plug-on connector with wire leads.

4 3 2 1

Storage Tank Setup When Using Both a High and Low Level Float Switch (Two Floats)

When two floats are used, the behavior of the controller is such that it will switch from RUNNING to STANDBY when the

water reaches the upper float switch and it changes state from being off to on. The system will stay in STANDBY until the

LOWER float switch transitions from on to off. When this LOWER switch transitions from on to off, the system will switch

back into RUNNING unless it is also in Pretreat Lockout at this point in which case it will transition to RUNNING when the

Pretreat Lockout disengages.

In order for the system to operate correctly using two float switches, it is necessary to specify a value of 0 (zero) as the Hi

Float Restart Delay time (main menu/steup/accessories/switch inputs).

Storage Tank Setup When Using a Single High Level Float Switch

Connect the level control to the FLTHI terminals. The system will switch from RUNNING to STANDBY when the water

reaches the upper float switch and it changes state from being off to on. The system will transition back to RUNNING a

specified number of minutes after the upper float switch transitions from on back to off. The specified number of minutes

to delay must be greater than 0 (zero). If it is specified as zero, then the system will operate as described in the previous

paragraph for two-float switches. The delay can be specified in whole minutes up to a maximum of 999 minutes. Note that

it is necessary to select this delay carefully, based upon the size of the storage tank and the maximum rate of draw-down

on the storage tank in comparison to the maximum rate of producing RO water or it is possible that the storage tank could

run dry.

NOTICE Do not apply power to these terminals. Use dry contacts only.

30 Culligan® Series G1 Reverse Osmosis

30 Cat. No. 01021713

Basic Operation

After the first-time setup has been completed, the RO system will be online (RUNNING) or offline (OFFLINE). You can

change the operation status of the system from the main menu on the Global RO Controller.

RUNNING

JAN-01-12 12:01A

Go To Running

>1)GO TO RUNNING

2)GO TO OFFLINE

3)INFORMATION

4)SETUP

1. This is the home screen. Press any button except to display the main menu.

2. Press to select 1)GO TO RUNNING.

GO TO RUNNING

NO

STARTING

JAN-01-12 12:01P

STARTUP FLUSH

RUNNING

JAN-01-12 12:01A

Go To Offline

1)GO TO RUNNING

>2)GO TO OFFLINE

3)INFORMATION

4)SETUP

GO TO OFFLINE

NO

3. The GROC screen displays the GO TO RUNNING command. Press or

and then

(select NO to cancel the command and return to the main menu).

4. The screen displays the status of the unit as it initiates the startup process.

5. The home screen displays the operational status (RUNNING).

1. Press to select 1)GO TO OFFLINE.

2. The GROC screen displays the GO TO OFFLINE command. Press or

and then

(select NO to cancel the command and return to the main menu).

to change the value to YES if you want the system to start running

to change the value to YES if you want the system to stop running

OFFLINE

JAN-01-12 12:01A

Cat. No. 01021713

3. The screen displays the main menu. Press repeatedly to return to the home

screen, which displays the operational status (OFFLINE).

Basic Operation 31

Setup

After completing the first time setup for the RO, you must also complete the system setup for flush modes, accessories,

and error limits before completing the initial startup.

Flow Meter K-Factor setting is required during setup. All other RO settings are optional depending on the accessories

installed. The RO controller does not require any specific setup to run unless accessories are installed or will be installed.

RO accessories include:

Accessory Global RO Controller (GROC) Setting

Flush Valves Setup—>Flush Modes

Flow Meters Setup—>Accessories—>Flow Meters

Modem Setup—>Accessories—>Modem

Wireless Remote, RF Board Setup—>Accessories—>Wireless Rem—>Channel #

Level Controls Setup—>Accessories—>Switch Inputs

Repressurization System Setup—>Accessories—>Switch Inputs

Pretreatment Lockout Setup—>Accessories—>Switch Inputs

Pressure Transducers (G2, G3 only) Setup—>Accessories—>Press Gauges

System Setup

Set Up Time/Date

If the unit loses time for some reason, you can use this setting to reset the correct date and time. Please note that if you

have a modem installed and connected to the phone line, the unit will check for the correct time each time it calls in.

RUNNING

JAN-01-12 12:01P

1. From the default home screen, press . The screen displays the main menu.

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

>1) TIME/DATE

2) LANGUAGE

3) POWERON MODE

4. Set Time/Date is the first menu item, so press to select 1) SET TIME/DATE.

The screen displays the first setting that can be changed.

4) FLUSH MODES

Time/Date Settings

Screen Display Range Procedure

SET

MONTH JAN

Jan–Dec

1. The screen displays the month setting. Press

and then

to change the value and see the next setting.

or

SET

DAY 1

32 Culligan® Series G1 Reverse Osmosis

1–31

2. The screen displays the day setting. Press

then

to change the value and see the next setting.

32 Cat. No. 01021713

or and

Screen Display Range Procedure

SET YEAR

2012

CLOCK TYPE

12 HR

SET HOUR

12PM

2010–2040

12 or 24

12AM–11PM

3. The screen displays the year setting. Press

then

4. The screen displays the clock type setting. Press

5. The screen displays the hour setting. Press

then

to change the value and see the next setting.

and then to change the value and see the next setting.

to change the value and see the next setting.

or and

or

or and

SET

MINUTES 25

DAYLIGHT SAVING

YES

0–59

YES

NO

6. The screen displays the minutes setting. Press

and then

7. The screen displays whether you observe daylight savings

time where the RO unit is installed. Press

then

menu.

to change the value and see the next setting.

or and

to change the value and return to the Time/Date

RUNNING

JAN-01-12 12:01P

8. Press to return to the home screen.

Set Up Language

Use the language setting to change the displayed language on the RO controller.

NOTE Ensure the units of measure (US, Metric) are appropriate. See page 21 to change if necessary.

RUNNING

JAN-01-12 12:01P

1. From the default home screen, press . The screen displays the main menu.

or

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

1) TIME/DATE

>2) LANGUAGE

3) POWERON MODE

4) FLUSH MODES

Cat. No. 01021713

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

4. Press to select 2)LANGUAGE. The screen displays the last selected lan-

guage of the RO controller.

Setup 33

LANGUAGE

ENGLISH

1) HEURE/DATE

>2) LANGUE

3) EN MARCHE

4) MODES FLUSH

Set Up Power On Mode

RUNNING

JAN-01-12 12:01P

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

1) TIME/DATE

2) LANGUAGE

>3) POWERON MODE

4) FLUSH MODES

5. Press or and then to change the display to your preferred

language.

6. The screen displays the setup menu in the selected language of the RO controller.

1. From the default home screen, press . The screen displays the main menu.

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

4. Set Time/Date is the first menu item, so press to select 3)POWERON

MODE.

POWERON MODE

5. Press or and then to select Power On Mode options.

OFFLINE

RUNNING

OFFLINE

RUNNING

JAN-01-12 12:01P

6. Press to return to the home screen.

The RO system will start whenever power is supplied.

The RO system will go into standby when power is supplied to the unit.

Flush Modes

The GBE RO controller can be programmed to operate up to six different flush modes. Multiple flush modes can be specified and operating at any one time. If any one or more flush modes are calling for flushing to happen at a certain time, the

flush will take place. Some flush modes require additional plumbing and components such as solenoid valves.

Startup Flush

In this mode the fast flush solenoid (SV-2) opens for a specified number of minutes each time that the pump turns on.

Standby Flush

In this mode any time that the system state is in STANDBY, the inlet AND fast flush solenoids open for a specified number of

minutes every specified number of hours. This is a line-pressure-level flush (ie the pump does NOT turn on during this flush).

34 Culligan® Series G1 Reverse Osmosis

34 Cat. No. 01021713

Time Trigger Flush

'UDLQ

3XPS

In this mode, any time that the system state is in RUNNING, the fast flush solenoid (SV-2) will open for a specified number

of minutes every specified number of hours. Note that the pump is ON during this flush.

Flow Trigger Flush

In this mode, any time that the system state is in RUNNING, the fast flush solenoid (SV-2) will open for a specified number

of minutes every specified number of PRODUCT RO water generated. Note that the pump is ON during this flush.

Quality Flush

If this mode is enabled, the product diversion solenoid (SV-3, NOT INCLUDED) is opened as soon as the pump turns on

when the RO system is RUNNING. This solenoid will remain open until the measured product TDS drops below the specified quality flush TDS setpoint or until the quality flush time period expires. If the TDS does not drop below the setpoint

during this period, the unit will switch to OFFLINE and the “product TDS High” error will be thrown. The Quality Flush solenoid valve is wired to the AUX board on the GBE RO controller at terminal AUX4. The solenoid valve must be 24 VAC.

7'6

7R 6HUYLFH

69

,QOHW

9DOYH

3XPS

0(0%5$1( +286,1*6

Figure 22. RO quality flush.

69

At startup, SV1 opens, and then the pump turns on. SV3 opens while the system monitors the product TDS level. The

user programs the maximum allowable product TDS and the number of minutes allowed following startup to reach the allowable TDS level. Usually at startup, the TDS level starts high and then drops. If the level drops below the allowable level

within the allowed time, then SV3 will close, and the unit is now in service. If the allowable TDS level cannot be reached,

the unit will shut down and generate an error message.

Permeate Flush

If this mode is enabled, the permeate flush solenoid (SV-3, NOT INCLUDED) is opened as soon as the pump turns off.

This solenoid will remain open until the permeate flush time period expires and permits water from an optional permeate

storage tank to flush the membranes. The Permeate Flush solenoid valve is wired to the AUX board on the GBE RO controller at terminal AUX4 (G1). The solenoid valve must be 24 Volt.

&KHFN

9DOYH

69

36

)(('

69

&KHFN

9DOYH

69

'UDLQ

Cat. No. 01021713

Figure 23. RO permeate flush.

Setup 35

At shutdown, the pump turns off and SV1 closes. Then fast flush solenoid valve SV2 and permeate valve SV3 open for a

programmed number of minutes. During this time, RO product water stored either in an elevated atmospheric tank or in a

pressurized storage tank floods through the pump and the feed side of the membrane, and then SV2 and SV3 close. This

process provides RO-quality water during shutdown on both sides of the membrane to keep the membrane clean. This

process also ensures that the RO will provide high quality product water the next time the pump is turned on.

NOTE Quality Flush and Permeate Flush are mutually exclusive optional features.

Flush Mode RO Pump Inlet Valve Waste (Fast) Flush Valve Product Flush Valve

Start Up On Open Open Closed

Standby Off Open Open Closed

Time On Open Open Closed

Flow On Open Open Closed

Quality On Open Closed Open

Permeate Off Closed Open Open

Table 3. RO pump and valve states during flush modes.

Any time that a Flush is actually taking place while the system state is RUNNING, the system will ignore the following error limits: delivered product TDS high, %recovery low, %recovery high, %reject low, membrane pressure drop, pump feed

pressure low. Once the flush ends, the error checking will resume. If the inlet pressure switch reports LOW pressure for

at least XX (XX is programmable at 1-30 seconds, at the main menu/setup/accessories/switch inputs menu) continuous

seconds, even if this is during or even partially during a flush time, the system will still recognize this instance as an error

condition, and it will begin the LOW PRESSURE process.

Flush Mode Setup

RUNNING

JAN-01-12 12:01P

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

1) TIME/DATE

2) LANGUAGE

3) POWERON MODE

>4) FLUSH MODES

1. From the default home screen, press . The screen displays the main menu.

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

4. Set Time/Date is the first menu item, so press to select 4)FLUSH

MODES.

36 Culligan® Series G1 Reverse Osmosis

36 Cat. No. 01021713

Flush Mode Settings

Screen Display Range Procedure

>1) STARTUP

2) STANDBY

3) TIME TRIGGER

4) FLOW TRIGGER

START UP MODE

OFF

FLUSH DURATION

3

MINUTES

STANDBY MODE

OFF

FLUSH DURATION

3

MINUTES

Startup

Standby

Time Trigger

Flow Trigger

Qual Flush

Perm Flush

Off

On

1–180

Off

On

1–180

5. The screen displays the Flush Modes menu. Press

to scroll through the menu and then

setting.

6. The screen displays the Start Up Mode setting. This will flush

the drain prior to starting the pump. Press

then

sure flush.

7. If startup mode is set to ON, the screen displays the flush

duration of the drain. Press

change the value and then return to the Flush Mode menu.

8. The screen displays the Standby Mode setting. This will flush

the drain when the unit is in standby mode. Standby mode

may be triggered manually, by a STORAGE TANK FULL error, by a pretreatment lockout command, or other states. This

is a low pressure flush. Press

change the value if necessary.

9. If standby mode is set to ON, the screen displays the flush du-

ration setting. Press

value and then display the next setting.

to change the value if necessary. This is a line pres-

or and then to

or and then to change the

to select a flush mode

or and

or and then to

or

FLUSH EVERY

3

HOURS

TIME TRIG MODE

OFF

FLUSH DURATION

3

MINUTES

FLUSH EVERY

4

HOURS

Cat. No. 01021713

1–24

Off

On

1–180

1–24

10. If standby mode is set to ON, the screen displays the flush in-

terval setting. Press

value and then return to the Flush Mode menu.

11. The screen displays the Time Trigger Mode setting. A flush

will be triggered after a specified amount of time has passed.

Press

necessary.

12. If time trigger mode is set to ON, the screen displays the flush

duration setting. Press

the value and then display the next setting.

13. If time trigger mode is set to ON, the screen displays the flush

interval setting. Press

the value and then return to the Flush Mode menu.

or and then to change the value if

or and then to change the

or and then to change

or and then to change

Setup 37

Screen Display Range Procedure

FLOW TRIG MODE

OFF

FLOW TRIG MODE

OFF

FLUSH DURATION

3

MINUTES

FLUSH EVERY

100

GALLONS

QUAL FLUSH MODE

DISABLE

Off

On

Off

On

1–180

100–1000

Disable

14. The screen displays the Flow Trigger Mode setting. Press

or and then to change the value and see the flow

trigger mode settings.

15. The screen displays the Flow Trigger Mode setting. If the system is running, the unit will flush after generating a specified

amount of reverse osmosis water. Press

then

16. If flow trigger mode is set to ON, the screen displays the flush

duration setting. Press

the value and then display the next setting.

17. If flow trigger mode is set to ON, the screen displays the flush

interval setting. Press

the value and then return to the Flush Mode menu.

18. The screen displays the Quality Flush Mode setting. When the

system is running, the system sends all water to drain until a

preset quality is reached, at which time the water will flow to

the product outlet. This is a high pressure flush (pump is on).

The quality flush mode is disabled and can not be changed.

Press any button to return to the Flush Mode menu.

to change the value if necessary.

or and then to change

or and then to change

or and

PERM FLUSH

OFF

FLUSH DURATION

10

SECONDS

RUNNING

JAN-01-12 12:01P

38 Culligan® Series G1 Reverse Osmosis

1–180

21. Press to return to the home screen.

Off

On

19. The screen displays the Permeate Flush setting. This flush

requires an optional solenoid valve and permeate storage tank

from where the flush water is drawn. Press

then

20. If permeate flush mode is set to ON, the screen displays the

flush duration setting. Press

change the value and then display the next setting.

to change the value if necessary.

or and then to

38 Cat. No. 01021713

or and

Switch Inputs Programming

RUNNING

JAN-01-12 12:01P

1) GO TO RUNNING

2) GO TO OFFLINE

3) INFORMATION

>4) SETUP

2) LANGUAGE

3) POWERON MODE

4) FLUSH MODES

>5) ACCESSORIES

1) WIRELESS REM

2) MODEM

3) FLOW METERS

>4) SWITCH INPTS

Switch Inputs Settings

Screen Display Range Changing the Setting

1. From the default home screen, press . The screen displays the main menu.

2. Press to scroll to 4) SETUP.

3. Press to select the SETUP menu.

4. Press to select 5)ACCESSORIES. The screen displays the accessories menu.

5. Press to select 4)SWITCH INPTS. The screen displays the switch

inputs settings.

PRESSURE SWITCH

NORMALLY OPEN

PS Sw

Delay: 5

SECONDS

SV1 Delay:

10

SECONDS

PRETREAT SWITCH

NORMALLY OPEN

FLOAT SWITCHES

NORMALLY OPEN

Normally Open

Normally Closed

0–9,#

each digit

0–300

Normally Open

Normally Closed

Normally Open

Normally Closed

Used with the inlet pressure switch. Standard pressure switch is

normally open. Press

state if necessary.

Sets the pressure switch delay time. This is the number of seconds

the low pressure must exist before activating the switch. Press

or and then to change.

The number of seconds elapsed from the inlet solenoid valve (SV-

1) opening until the motor starts. Press

to change.

Used with the inlet pressure switch. Standard pressure switch is

normally open. Press

state if necessary.

Used to set whether float switches (level control) are normally

open or closed. There are two float switch contacts; they both must

be normally open or closed. Press

change the state if necessary.

or and then to change the

or and then

or and then to change the

or and then to

Cat. No. 01021713

Setup 39

Screen Display Range Changing the Setting

FS Hi

Delay: 0

MINUTES

RUNNING

JAN-01-12 12:01P

Used only when using the float switch high contacts. This sets how

0–120

6. Press to save the settings and return to the home screen.

long the float switch stays closed after transitioning from high to

low level.

40 Culligan® Series G1 Reverse Osmosis

40 Cat. No. 01021713

Accessories

5 3/8”

There are several components of the G1 RO that can be configured from the Accessories manu, including:

• Wireless Remote

• Modem

• Flow Meter

• Pressure and Level Control Switches

• Pressure Gauges

• Total Dissoved Solids Probes

• Error or Status Monitor

• SV3 or Target TDS Monitor

Wireless Remote