Page 1

Professional Shop Manual

Commercial Z-Wing

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2006 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-02102

1/2006

Page 2

Page 3

TABLE OF CONTENTS

Introduction ........................................................................................................................................... 1

Spindles and Blades ............................................................................................................................. 1

PTO Belt ................................................................................................................................................ 3

Deck Belt ............................................................................................................................................... 4

Spindle Service ..................................................................................................................................... 5

Deck Belt and PTO Belt Tensioner ........................................................................................................ 7

Cutting Deck Removal: Early 2005 Production ..................................................................................... 8

Cutting Deck Removal: Commencing with late 2005 Production ........................................................ 11

Deck Leveling: Early 2005 Production ................................................................................................ 13

Deck Wing and Hinge Lock .................................................................................................................16

Hinge Lock: Late 2005 production ......................................................................................................20

Deck Wing Lift Mechanism:Early 2005 Production ............................................................................. 24

Deck Wing Lift Cable Adjustment ........................................................................................................ 29

Deck Lift Mechanism ........................................................................................................................... 30

Lap Bars .............................................................................................................................................. 34

Checking Neutral Adjustment .............................................................................................................35

Linkage Neutral Adjustment ................................................................................................................36

Hydro Neutral Adjustment ................................................................................................................... 37

Tracking Adjustment ........................................................................................................................... 38

Steering Pivot Shafts and Bushings .................................................................................................... 40

Brake Linkage Adjustment ..................................................................................................................41

Brake Pivot Shaft Removal .................................................................................................................46

Hydraulic Drive System: General Operation ....................................................................................... 48

Hydraulic Drive System: Diagnosis ..................................................................................................... 50

Hydraulic Drive System: Pump Removal ............................................................................................54

Hydraulic Drive System: Wheel Motor Removal ................................................................................. 58

Front Axle and Caster Wheels ............................................................................................................ 61

Electrical: Components ....................................................................................................................... 66

Electrical: Starter Circuit ......................................................................................................................73

Electrical: Engine Stop Circuit .............................................................................................................74

Electrical: Engine-Stopping Safety Circuits .........................................................................................75

Electrical: PTO Circuit .........................................................................................................................76

Electrical: Deck Wing Lift .................................................................................................................... 77

Electrical: Charging Circuit .................................................................................................................. 78

Charging System Diagnosis ................................................................................................................ 78

Resistance ..........................................................................................................................................80

1

Page 4

2

Page 5

1. INTRODUCTION

Cub Cadet Commercial Z-Wing

Cub Cadet Commercial Z-Wing

1.1. Purpose: Heavy-duty mowing in a compact

package.

• Until now, commercial cutters needing a

machine that would fit through a 36” gate had to

settle for a commercial walk-behind mower or a

homeowner-grade zero-turn.

• The Z-Wing’s unique folding deck gives it the

ability to pass through a 36” gate or opening, yet

provide a 48” cutting swath, increasing productivity.

• When folded, the deck wings of the Z-Wing takeup a smaller foot-print in a trailer or garage. This

enables the user to make more efficient use of

their trailer and garage space, and reduces the

chance of damage to other equipment during

loading or storage.

NOTE: When the deck of our standard TANK

line encounters other objects, it is seldom the

deck that gets damaged.

1.2. Means: The deck wings are lifted by an electric

actuator pulling on cables.

1.3. Safety: Safety switches that sense the position

of the deck wings prevent the PTO from being

engaged while the wings are up.

1.4. Drive System: Hydro-gear pumps drive White

Hydraulic wheel motors. These motors are new

to Cub cadet, and feature a unique roller stator

design.

See Figure 1.1.

Figure 1.1

NOTE: The information in this manual is derived

from prototype equipment. Although it is accu

rate at the time of writing, it is subject to change

without notice.

2. SPINDLES AND BLADES

2.1. Flail blades have been in use on “bat-wing”

mowers in a variety of applications for many

years. The unique thing about their use on the

Z-Wing mower is that they enable just the outer

portion of the deck (wing) to be raised, and the

blades fold back to clear obstacles while the

wings are raised.

Deck wing

(raised)

Blades

2.2. Things to know about flail blades:

• The individual blade elements can be removed

from each of the three blade assemblies.

• If one element on a blade assembly is worn or

damaged beyond a point that can be corrected

with a light sharpening, replace both elements to

maintain balance.

• Blade assemblies can be balanced, but not with

the ease nor the accuracy of single-piece

blades.

• Replace any suspect blade hardware before

operating the mower.

• The operator should cease operation immediately if any unusual deck vibration or noises

occur.

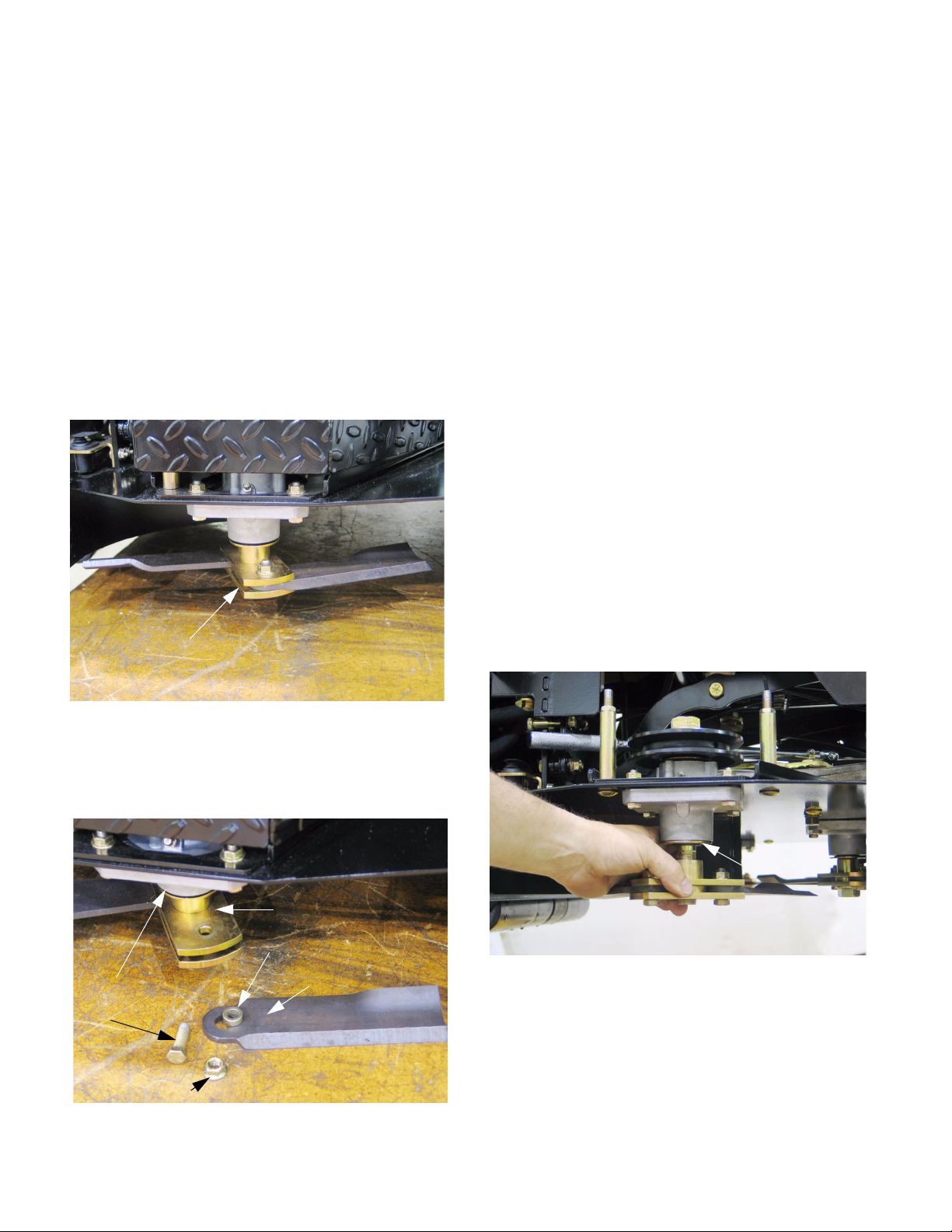

See Figure 2.1.

Figure 2.1

-

1

Page 6

Cub Cadet Commercial Z-Wing

2.3. Precautions:

• Disable the engine while working on the cutting

deck: Disconnect the sparkplug leads, disconnect the negative battery cable, and remove the

key from the key switch.

• Allow the engine to cool thoroughly before working near the exhaust system.

• Protect hands while working on sharp objects

like blades using gloves or rags.

2.4. With the wings raised the outer blades are easily

accessible for service. The center blade is as

accessible as it would be on a conventional

deck. Lift and safely support the mower to reach

the center blade.

See Figure 2.4.

2.6. When performing any blade or spindle service,

inspect the spindles, pulleys, and belts for wear

or damage.

2.7. Inspect the hardware that secures the blades to

the blade mount assemblies.

• Replace the locking nut if the locking feature has

degraded.

• If the bolt is replaced, use only a grade-8

replacement from a reputable source (Cub

Cadet).

• Replace the bushing if it shows signs of wear or

damage.

2.8. On installation, apply a small amount of thread

locking compound such as Loctite 262 (red) to

the threads, and tighten the nuts to a torque of

35-40 ft-lbs (47.5-54 Nm).

2.9. If the blade assembly is to be removed for sharpening and balancing, lower the deck to the lowest cutting position.

2.10. Remove the belt covers using a 9/16” wrench.

2.11. Hold the top of the spindle bolt using a 1 1/8”

wrench and turn the nut off the bottom using a

1 1/8” wrench.

Blade assembly in-place

Figure 2.4

2.5. The blades can be removed from the blade

mount assembly using a pair of 9/16” wrenches.

See Figure 2.5.

Blade spacer

and upper mounting plate

Bushing

Steel shield

Grade-8 bolt

Blade

2.12. Slide the blade assembly off the spindle bolt.

See Figure 2.12.

Steel shield

Figure 2.12

NOTE: The steel shield is part of the seal, not

the blade assembly. Do not remove it unless the

spindle requires service.

Self-locking nut

Figure 2.5

2

Page 7

Cub Cadet Commercial Z-Wing

2.13. The blade assemblies may be sharpened and

balanced similar to conventional blades, but a

straight-edge should be used to confirm that the

blades are straight out. If the blades are partially

folded during balance checking, the results will

be thrown-off.

2.14. On installation, apply thread locking compound

such as Loctite 262 (red) to the threads, and

tighten the nut to a torque of 100-120 ft-lbs (114136 Nm).

2.15. Install the belt covers and reconnect the battery.

2.16. Test the operation of the mower and its safety

features before returning it to service.

3. PTO BELT

3.1. Precautions:

• Disable the engine while working on the cutting

deck: Disconnect the sparkplug leads, disconnect the negative battery cable, and/or remove

the key from the key switch.

• Allow the engine to cool thoroughly before working near the exhaust system.

• Protect hands while working on sharp objects

like blades using gloves or rags.

• Apply the parking brake while working on the

mower.

3.2. Lower the deck wings.

3.3. Raise the cutting deck to the highest position.

This moves the deck as far back as possible,

reducing the amount of force on the PTO belt

tensioner.

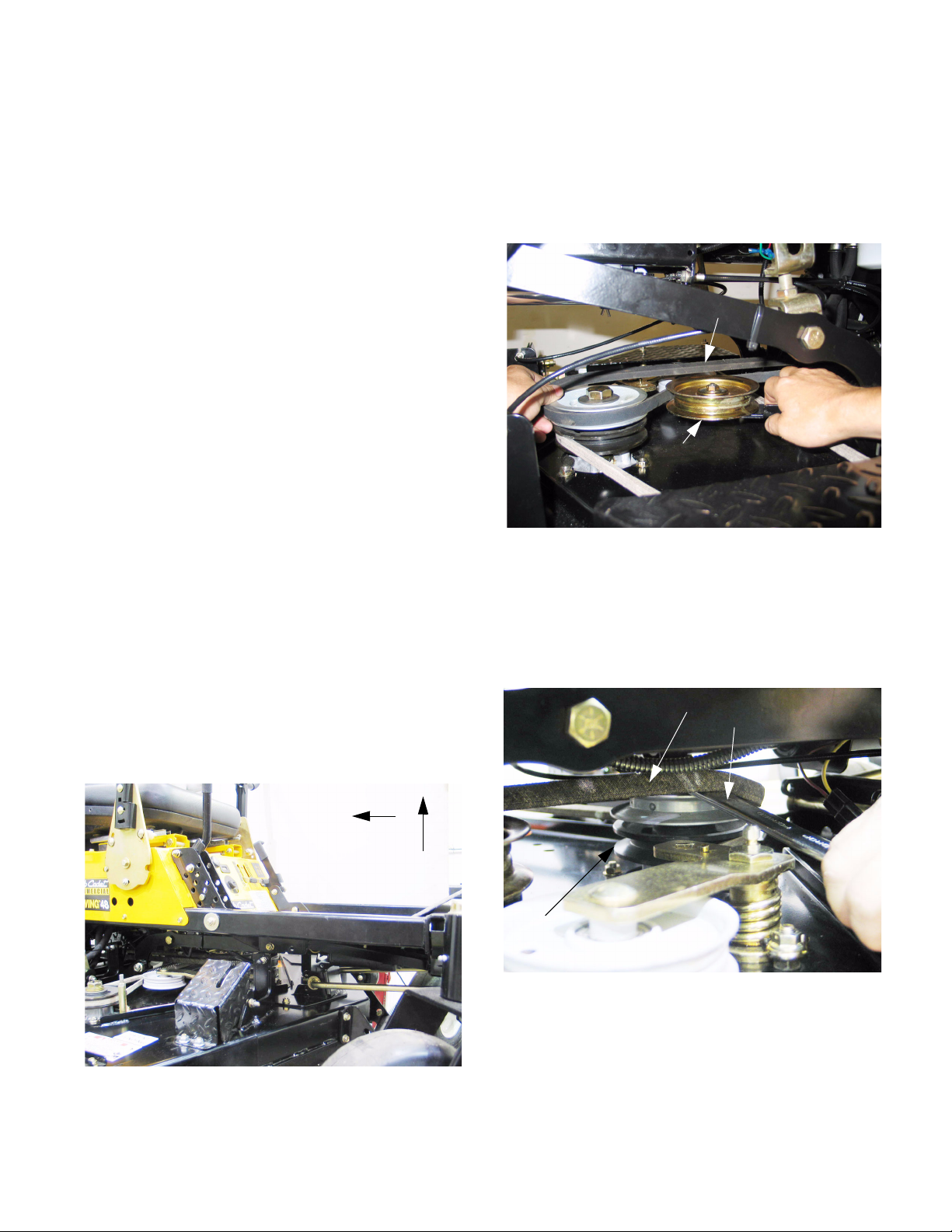

See Figure 3.3.

3.4. Remove the belt covers that protect the blade

spindles using a 9/16” wrench.

3.5. Working from the left side of the mower, relieve

tension from the belt tensioner pulley, and roll

the belt off of the pulley, allowing the tensioner

pulley to slip beneath the belt.

PTO belt

PTO belt tensioner pulley

Figure 3.5

NOTE: belt routing and spring location

3.6. With the tension relieved, connect a 1 1/8”

wrench to the bolt at the top of the stack pulley.

Pass the wrench beneath the belt to reach the

bolt.

See Figure 3.6.

PTO Belt

See Figure 3.5.

1 1/8” wrench

Deck moves back

as deck moves up

Loosening belt slightly

Figure 3.3

Stack pulley

Figure 3.6

3.7. Draw the wrench forward to force the belt over

the top of the pulley.

3

Page 8

Cub Cadet Commercial Z-Wing

3.8. A second 1 1/8” wrench may be applied to the

top of the nearest blade spindle if more rotation

is needed.

Stack pulley

Second wrench on

near pulley

3.9. Lower the deck slightly to provide belt clearance

between the stack pulley and the wing lift motor,

and remove the belt from the mower.

See Figure 3.8.

Figure 3.8

4. DECK BELT

4.1. Remove the PTO belt as described in the PTO

Belt section of this manual, including all precau

tions.

4.2. Remove both deck belt covers using a 9/16”

wrench.

4.3. Working from the right of the mower, use a 1/2”

breaker bar to move the deck belt tensioner pul

ley arm, relieving tension from the deck belt.

See Figure 4.3.

Deck belt tensioner pulley

Deck belt

-

-

3.10. If the old belt exhibits any damage beyond normal wear, identify and correct the cause of the

damage before returning the mower to service.

3.11. Inspect the condition of the deck belt, and

replace it if it is suspect.

3.12. Position the new belt on the PTO clutch and

stack pulley.

3.13. Pull the tensioner pulley arm out to the left, and

slip the belt over the pulley.

3.14. Test the operation of the mower deck before

returning the mower to service.

Figure 4.3

NOTE: belt routing and spring location

4.4. Roll the belt off of the tensioner or s p i n d l e p u l l e y .

See Figure 4.4.

1/2” Breaker bar

Figure 4.4

4.5. If the old belt exhibits any damage beyond normal wear, identify and correct the cause of the

damage before returning the mower to service.

4

Page 9

Cub Cadet Commercial Z-Wing

4.6. Check the blade spindles for looseness while the

belt is off.

4.7. Reverse the removal process to install a new

belt or belts.

4.8. Test the operation of the mower and its safety

features before returning the mower to service.

5. SPINDLE SERVICE

5.1. Inspect all of the spindles for wear or damage

when performing regular deck belt and blade

maintenance. The recommended lubrication

interval for the deck spindles is 25 hrs., using

No.2 Multipurpose lithium base grease.

5.2. If repair or removal is required, remove the deck

belt as described in the Deck Belt section of this

manual.

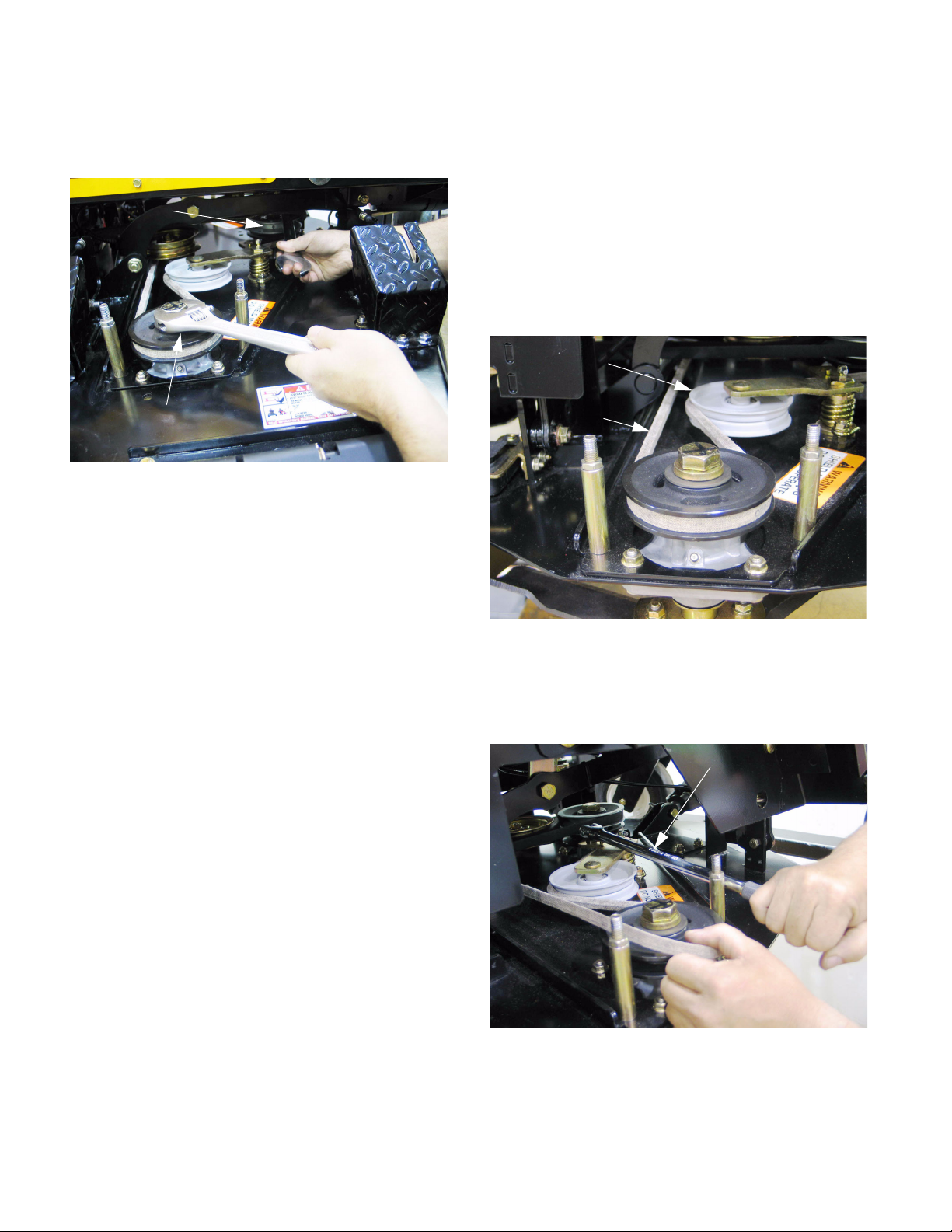

5.5. Withdraw the spindle bolt and washers, and

remove the pulley.

Thick hub boss

faces up on all

spindle pulleys

Figure 5.5

5.6. The center spindle has two pulleys, with a

spacer between them, but the procedure is oth

erwise similar to the outer two spindles.

See Figure 5.6.

Deck belt sheave PTO belt sheave

Steel shield

(top)

See Figure 5.5.

Heavy washer

Flat washer

-

5.3. Hold the top of the spindle bolt using a 1 1/8”

wrench and turn the nut off the bottom using a

1 1/8” wrench.

5.4. Slide the blade assembly off the spindle bolt.

See Figure 5.4.

Spindle bolt

Blade assembly

Figure 5.4

Figure 5.6

5.7. Once the pulley is removed, the spindle may be

unbolted from the deck using a pair of 9/16”

wrenches, or it may be repaired in place.

NOTE: If a warrantable repair is being made to

the spindle, replace the spindle as a complete

unit. Outside of warranty, the dealer may repair

or replace the spindle at their own discretion.

Spindle service parts may not be available dur

ing the first year of production.

-

5

Page 10

Cub Cadet Commercial Z-Wing

5.8. The steel shields are identical top and bottom,

and are easily removable. They do have barbed

lips that may damage the seal when removed.

they should not be removed unless the seals are

to be replaced.

Seal

Lip

Sealing surface

Steel shield

5.9. With the steel shields removed, the seals and

bearings also come out easily.

See Figure 5.8.

Figure 5.8

See Figure 5.9.

5.10. If the tapered roller bearings need to be

replaced, the races need to be driven-out and

replaced as well.

Race (upper spindle bearing)

Spindle housing

5.11. Assembly notes:

• Clean and inspect the bearings for signs of damage. Replace bearings and races if necessary.

• Pack the bearings with fresh No.2 multi-purpose

lithium base grease and install them in the spindle housings using new seals.

See Figure 5.10.

Figure 5.10

Tapere d

roller bearing

Seal

• Replace any suspect hardware.

• On installation of the spindle nuts, apply thread

locking compound such as Loctite 262 (red) to

the threads, and tighten the nut to a torque of

100-120 ft-lbs (114-136 Nm).

• Apply a small amount of thread locking compound such as Loctite 242 (blue), or replace the

nuts if the locking feature of the nuts are in question. Tighten the spindle mounting bolts (nuts) to

a torque of 20-25 ft-lbs (27-34 Nm).

Figure 5.9

6

Page 11

Cub Cadet Commercial Z-Wing

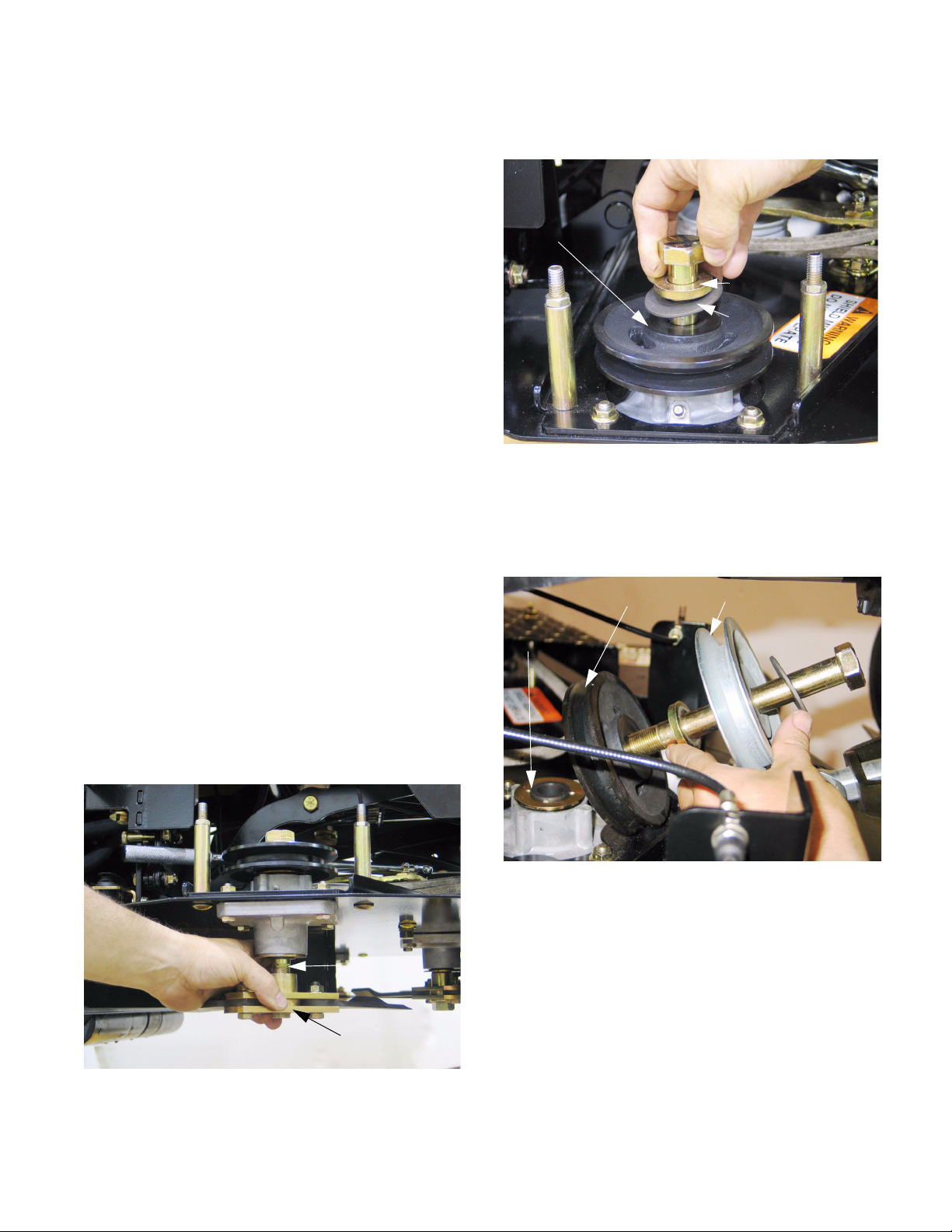

6. DECK BELT AND PTO BELT TENSIONER

6.1. The deck belt tensioner idler arm can be

removed using a 1” wrench on the bolt head

above the deck and an 11/16” wrench to remove

the nut, lock washer, and flat washer from

beneath the deck.

Deck belt

tensioner arm

Figure 6.1

6.2. The bolt is rifle-drilled to provide for grease

access to the bushing in the idler arm. The bush

ings are replaceable. See Figure 6.2.

See Figure 6.1.

Torsion spring

Heavy flat washer

Shoulder bolt (drilled)

6.5. The pulley is mounted to the idler arm using a

carriage bolt. It can be easily removed using a 9/

16” wrench.

6.6. Installation notes:

• Apply a small amount of thread locking compound such as Loctite 262 (red) to the torsion

spring retaining nut, or replace the nut if the locking feature of the nut is in question. Snug the nut

against the spring.

• Apply a small amount of thread locking compound such as Loctite 242 (blue), or replace the

nuts if the locking feature of the nuts are in question. Tighten the pulley mounting nut to a torque

of 20-25 ft-lbs (27-34 Nm).

• Apply a small amount of thread locking compound such as Loctite 242 (blue), or replace the

nut if the locking feature of the nut is in question.

Tighten the idler arm bolt to a torque of 30-35 ftlbs (41-48 Nm).

• Lubricate the idler arm bushings with #2 multipurpose lithium base grease.

6.7. The PTO belt tensioner is a simple idler arm with

an extension spring between the arm and the

-

deck weldment.

6.8. The spring may be detached without removing

the arm using a length of starter rope or a spring

removal tool.

See Figure 6.8.

Bushing

Hole for breaker bar

Hole for torsion spring

Figure 6.2

6.3. A heavy flat washer between the shoulder of the

bolt and the deck weldment distributes the

mounting load.

6.4. The torsion spring is mounted to a carriage bolt

using a nut and jam nut that can be easily

removed using a 9/16” wrench.

Label

“48”

Figure 6.8

6.9. The PTO idler arm can be removed from the

deck using two 9/16” wrenches.

7

Page 12

Cub Cadet Commercial Z-Wing

6.10. There are three mounting holes for the pulley on

the idler arm, use the one nearest the pivot point

as indicated by the “48” mark on the label.

See Figure 6.10.

Mounting holes

Figure 6.10

6.11. The bushings in the PTO belt tensioner idler arm

are replaceable.

7. CUTTING DECK REMOVAL: EARLY 2005 PRODUCTION

NOTE: Decks having U-shaped front lift rods

were used on all Z-Wings produced after Nov. 1,

2005 (S/N: 0K015Z00001). These decks are ret

rofitted to earlier production. Earlier decks are

easily identified by V-shaped front lift rods that

connect to the deck at a single point.

7.1. Remove the PTO belt as described in the PTO

Belt section of this manual, including all precau

tions.

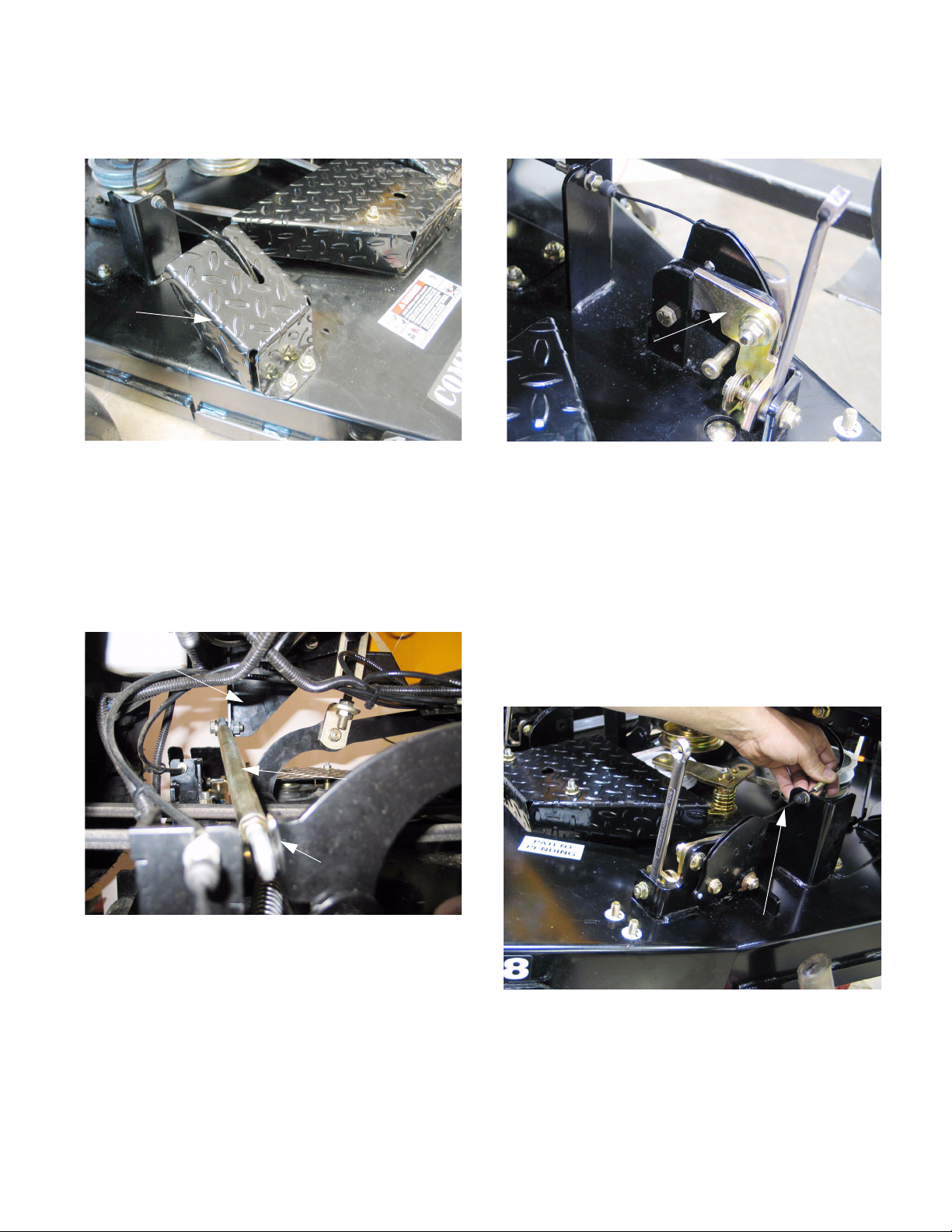

7.2. Trap the deck lift in the lowest position using the

clevis pin so that the cutting deck rests on the

ground and the lift handle does not imitate a cat

apult when the weight of the deck is removed

from the lift assist springs.

Lift handle

See Figure 7.2.

-

-

-

6.12. Assembly notes:

• Apply a small amount of threadlocking compound such as Loctite 242 (blue), or replace the

nuts if the locking feature of the nuts are in question. Tighten the pulley mounting nut to a torque

of 20-25 ft.-lbs (27-34 Nm).

• Apply a small amount of threadlocking compound such as Loctite 242 (blue), or replace the

nut if the locking feature of the nut is in question.

Tighten the pulley mounting nut to a torque of

20-25 ft.-lbs (27-34 Nm).

• Lubricate the idler arm bushings with No. 2 multipurpose lithium base grease.

Clevis pin

Figure 7.2

8

Page 13

Cub Cadet Commercial Z-Wing

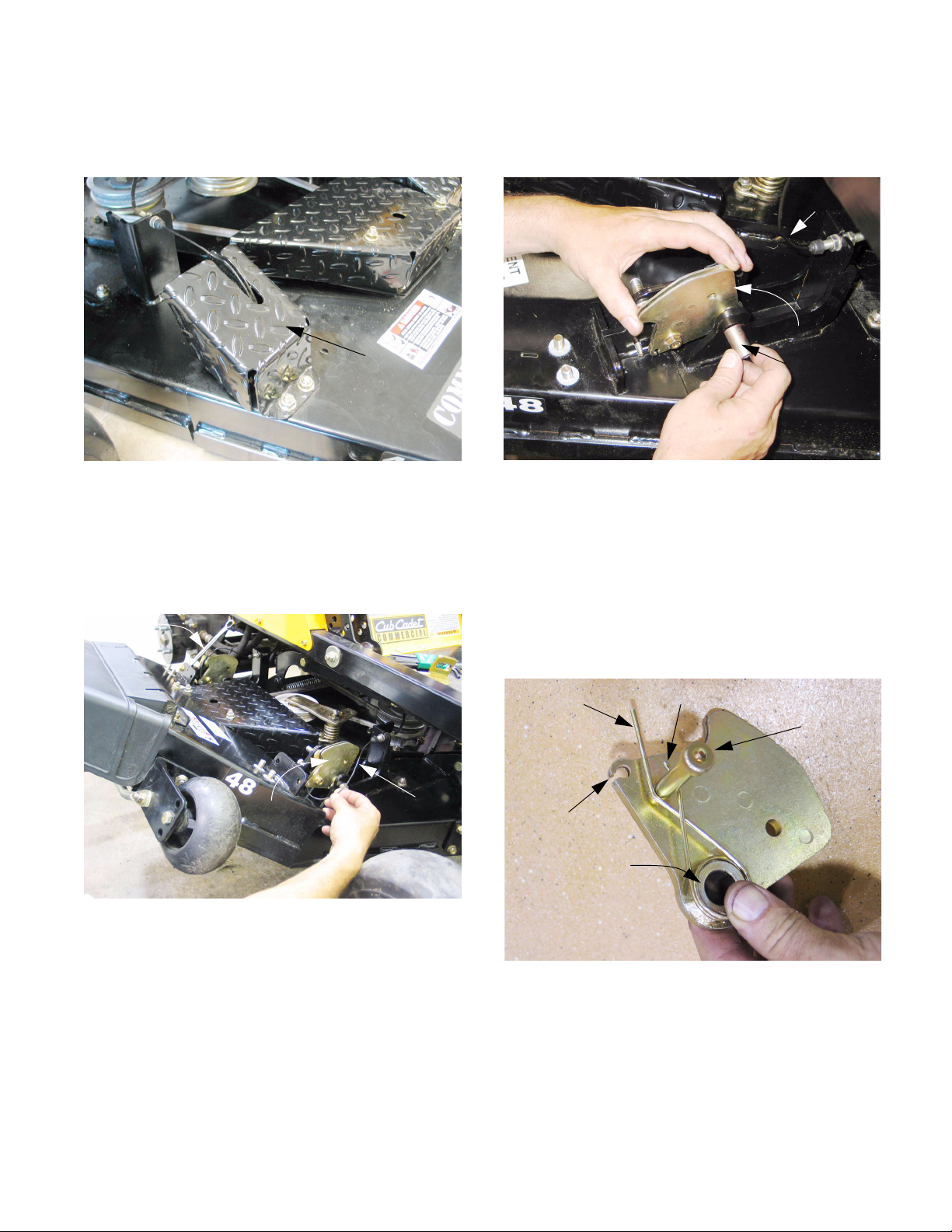

7.3. Remove the wing lift shield using a 9/16”

wrench.

Wing lift

shield

7.4. Mowers produced after mid-season 2005 (2005/

2) are equipped with a lateral brace between the

frame and the mowing deck, similar to a panhard

rod in the rear suspension of a car or truck. Dis

connect or remove the lateral brace as required

by the task at-hand using a 5/8” wrench and an

11/16” wrench.

Frame

mounting point

See Figure 7.3.

Figure 7.3

See Figure 7.4.

7.5. Block all four hinge locks into the unlatched position using extra wrenches. See Figure 7.5.

Hinge lock

Figure 7.5

NOTE: Wrenches are handy to insert, easy to

spot, and unlikely to be forgotten.

-

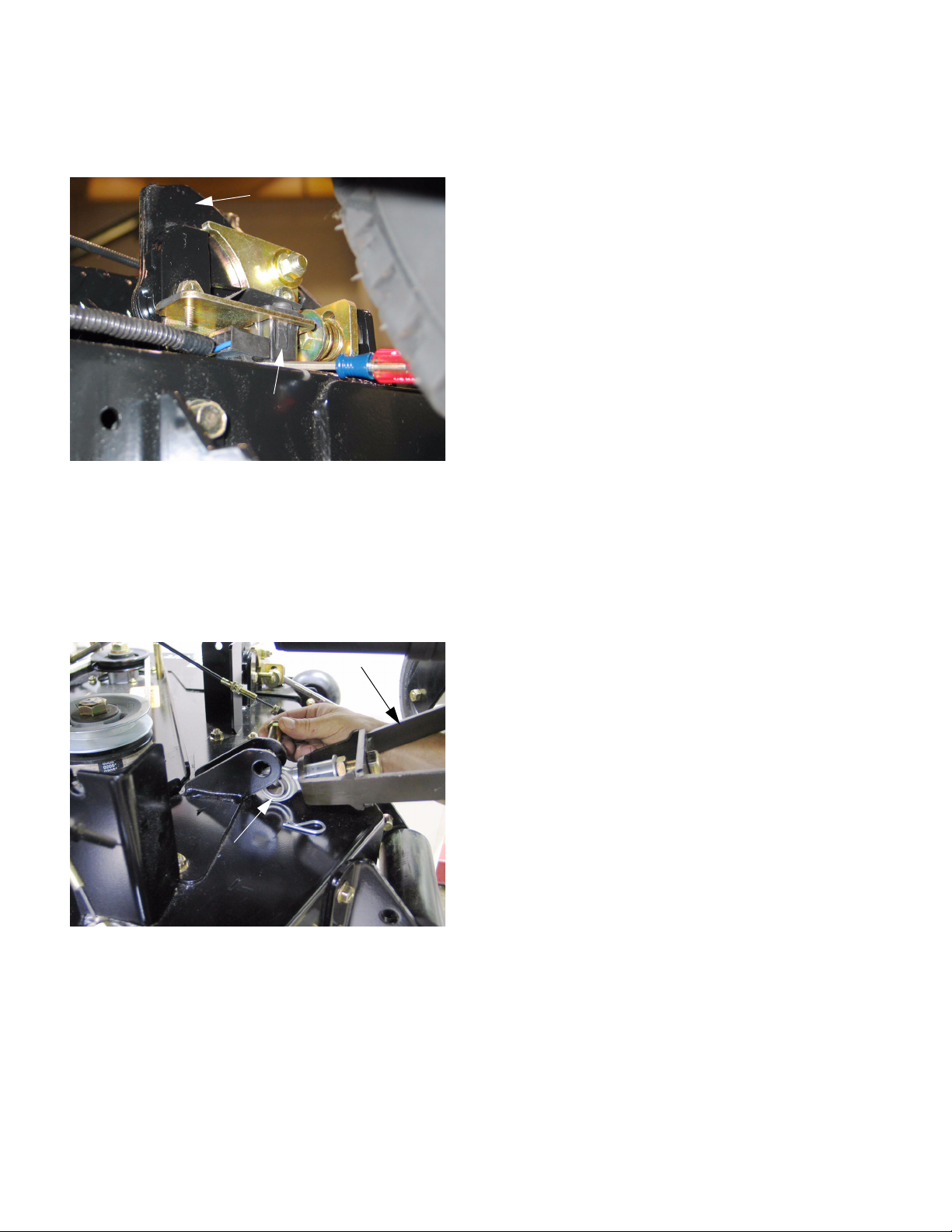

7.6. Slide the rubber boot back from the cable end,

and remove the end jam nut on the cable using a

pair of 1/2” wrenches.

7.7. With the wings unlatched, they can be lifted

manually. Lift the wings manually to put slack in

the lift cable so that the end of the cable can be

slipped-out of the hole and slot in the bracket.

See Figure 7.7.

Figure 7.4

lateral link

Deck

mounting point

Lift wing to provide

slack in the cable

Figure 7.7

7.8. Once the cable housing is released from the

bracket on the deck, the barrel on the end of the

cable core can be maneuvered out of the hole

and slot in the wing lift bracket.

9

Page 14

Cub Cadet Commercial Z-Wing

7.9. Disconnect the wires from the deck wing position

switches on each rear deck wing bracket.

See Figure 7.9.

Rear deck wing hinge

Deck Wing position switch

Figure 7.9

7.10. Cut any cable ties holding wing lift cables and

wing position switch wires to the cutting deck.

7.11. Remove the hairpin clip and clevis pin that

secure the front of the cutting deck to the spheri

cal rod end on the front lift arm assembly.

See Figure 7.11.

Front lift arm Ass’y.

• Hold the lift handle down

• Carefully remove the hairpin clip and clevis pin

that kept the lift handle in the lowest position.

• Carefully allow the lift handle to rise to the transport position under the force of the lift assist

springs.

• Turn the front caster wheels sideways for deck

clearance.

7.15. Remove the cutting deck from the mower.

7.16. Installation is done by reversing the removal process. Installation notes:

• Confirm the correct operation of all safety features, including the wing-latch mechanisms

before returning the mower to service.

• Confirm that the cables ar correctly adjusted

after deck installation.

• Confirm that the cables and wires are routed and

fastened in such a way that they will not be damaged during operation of the mower.

• If the locking feature of the removed lateral

-

brace mounting nut has worn, replace the nut or

apply a small amount of thread locking compound such as Loctite 242 (blue).

• Tighten the mounting bolt to a torque of 40 ft-lbs.

(54.25 Nm).

Spherical rod end

Figure 7.11

7.12. Remove the hairpin clips that secure the cutting

deck to the lift arms.

NOTE: 914-0147 hairpin clips are an acceptable

replacement for the originals.

7.13. Move the deck to the right to disengage the pins

that connect the deck to the lift arms.

7.14. If working on the ground:

10

Page 15

Cub Cadet Commercial Z-Wing

8. CUTTING DECK REMOVAL: COMMENCING WITH LATE 2005 PRODUCTION

NOTE: Decks having U-shaped front lift rods

were used on all Z-Wings produced after Nov. 1,

2005 (S/N: 0K015Z00001). These decks are ret

rofittable to earlier production. Earlier decks are

easily identified by V-shaped front lift rods that

connect to the deck at a single point.

8.1. Remove the PTO belt as described in the PTO

Belt section of this manual, including all precau

tions.

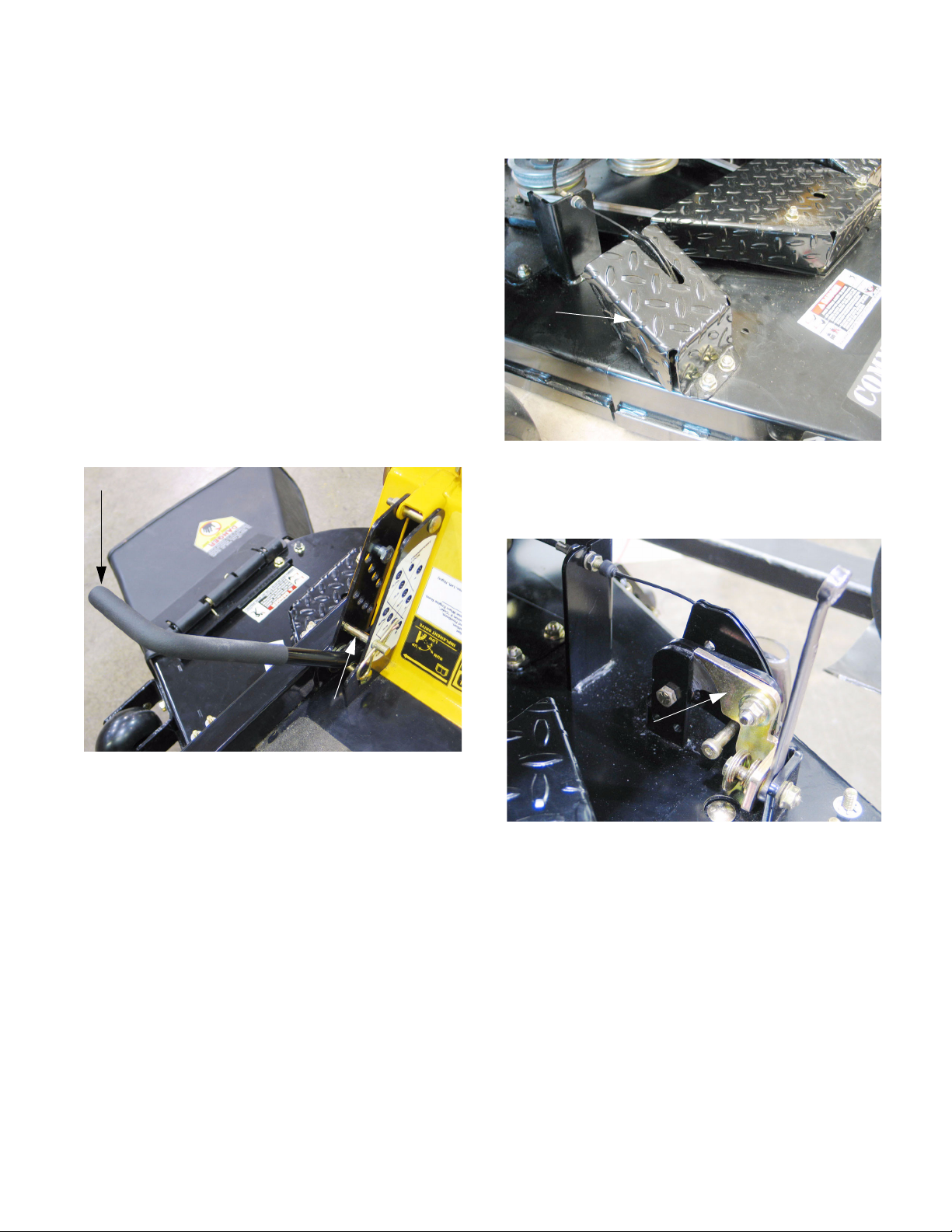

8.2. Trap the deck lift in the lowest position using the

clevis pin so that the cutting deck rests on the

ground or a purpose-built cart, and the lift handle

does not imitate a catapult when the weight of

the deck is removed from the lift assist springs.

See Figure 8.2.

Lift handle

8.3. Remove the wing lift shield using a 9/16”

wrench.

-

-

Wing lift

shield

8.4. Block all four hinge locks into the unlatched position using extra wrenches. See Figure 8.4.

See Figure 8.3.

Figure 8.3

Figure 8.2

Clevis pin

Hinge lock

Figure 8.4

NOTE: Wrenches are handy to insert, easy to

spot, and unlikely to be forgotten.

8.5. Slide the rubber boot back from the cable end,

and remove the end jam nut on the cable using a

pair of 1/2” wrenches.

11

Page 16

Cub Cadet Commercial Z-Wing

8.6. With the wings unlatched, they can be lifted

manually. Lift the wings manually to put slack in

the lift cable so that the end of the cable can be

slipped-out of the hole and slot in the bracket.

See Figure 8.6.

Lift wing to provide

slack in the cable

Figure 8.6

8.7. Once the cable housing is released from the

bracket on the deck, the barrel on the end of the

cable core can be maneuvered out of the hole

and slot in the wing lift bracket.

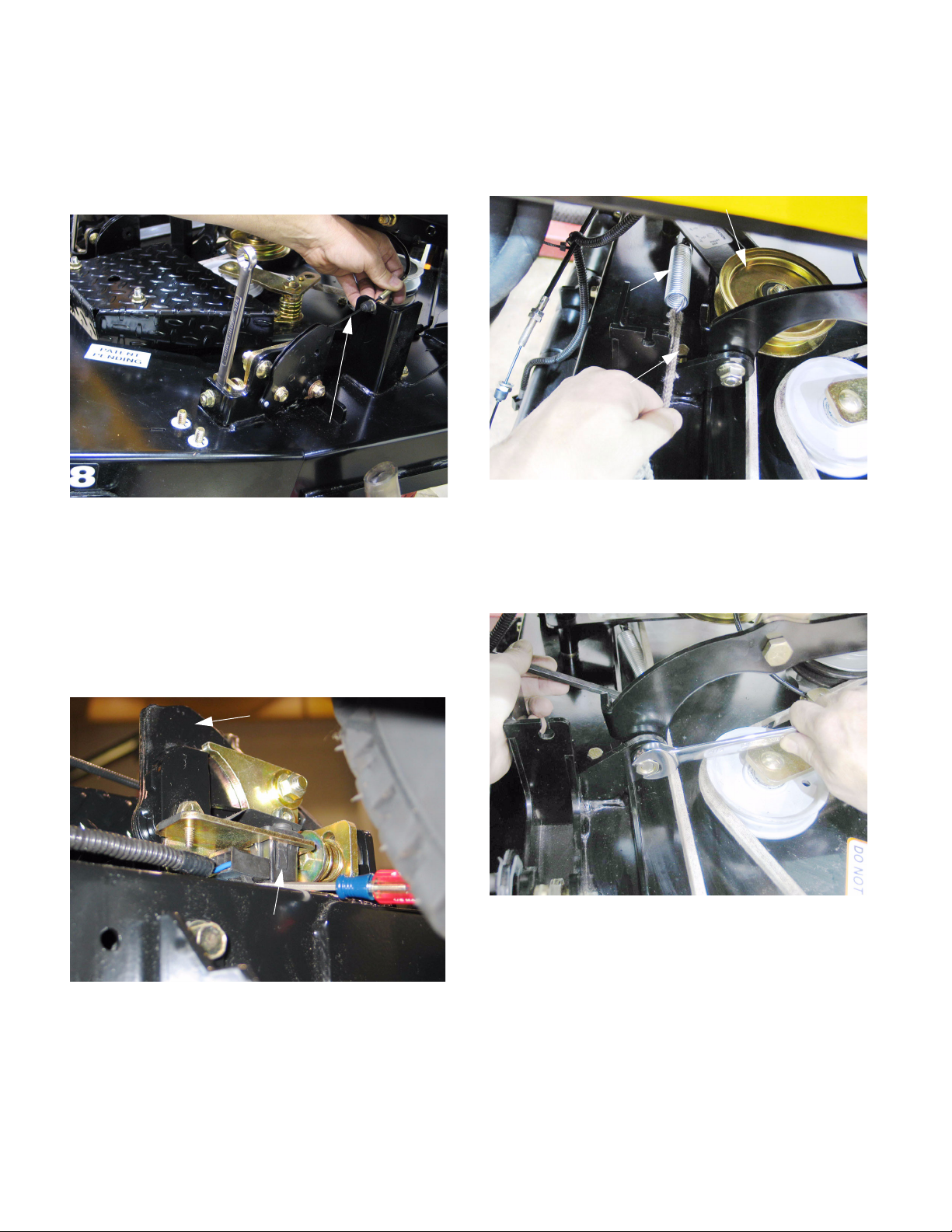

8.10. Release the extension spring that maintains tension on the PTO belt tension arm and pulley.

Use a length of starter rope or a spring removal

tool.

Extension

spring

Bolt

(anchor point

for spring)

Figure 8.10

8.11. Remove the nuts and socket-head shoulder

bolts that connect the deck to the lift arms using

a 5/16” Allen wrench and a 3/4” wrench.

See Figure 8.11.

See Figure 8.10.

PTO belt tensioner pulley

8.8. Disconnect the wires from the deck wing position

switches on each rear deck wing bracket.

See Figure 8.8.

Rear deck wing hinge

Deck Wing position switch

Figure 8.8

8.9. Cut any cable ties holding wing lift cables and

wing position switch wires to the cutting deck.

Figure 8.11

12

Page 17

Cub Cadet Commercial Z-Wing

8.12. Move the deck forward to disengage the front

deck lift bar from the hooks on the front of the

deck.

See Figure 8.12.

Figure 8.12

8.13. Raise the mower and remove the deck from

beneath it.

8.14. If working on the ground:

8.16. Installation is done by reversing the removal process. Installation notes:

• Confirm the correct operation of all safety features, including the wing-latch mechanisms

before returning the mower to service.

• Confirm that the cables ar correctly adjusted

after deck installation.

• Confirm that the cables and wires are routed and

fastened in such a way that they will not be damaged during operation of the mower.

• If the locking feature of the removed laterally

brace mounting nut has worn, replace the nut or

apply a small amount of thread locking compound such as Loctite 242 (blue).

• Tighten the mounting bolt to a torque of 40 ft-lbs.

(54.25 Nm).

• Hold the lift handle down

• Carefully remove the hairpin clip and clevis pin

that kept the lift handle in the lowest position.

• Carefully allow the lift handle to rise to the transport position under the force of the lift assist

springs.

• Turn the front caster wheels sideways for deck

clearance.

• Remove the cutting deck from the mower.

8.15. If the mower is to be moved while the cutting

deck is off of it:

• Secure the wires and cables that are associated

with the wing lift mechanism.

• Secure or remove the front lift bar assembly.

9. DECK LEVELING: EARLY 2005 PRODUCTION

NOTE: Decks having U-shaped front lift rods

were used on all Z-Wings produced after Nov. 1,

2005 (S/N: 0K015Z00001). These decks are ret

rofittable to earlier production. Earlier decks are

easily identified by V-shaped front lift rods that

connect to the deck at a single point.

9.1. Preparation:

• Park the mower on a flat, level, paved surface,

set the parking brake and lower the deck wings.

• Safety: disable the engine by removing the key

from the key switch and disconnecting the high

tension leads from the spark plugs.

• Setting the mower deck height to 4” provides the

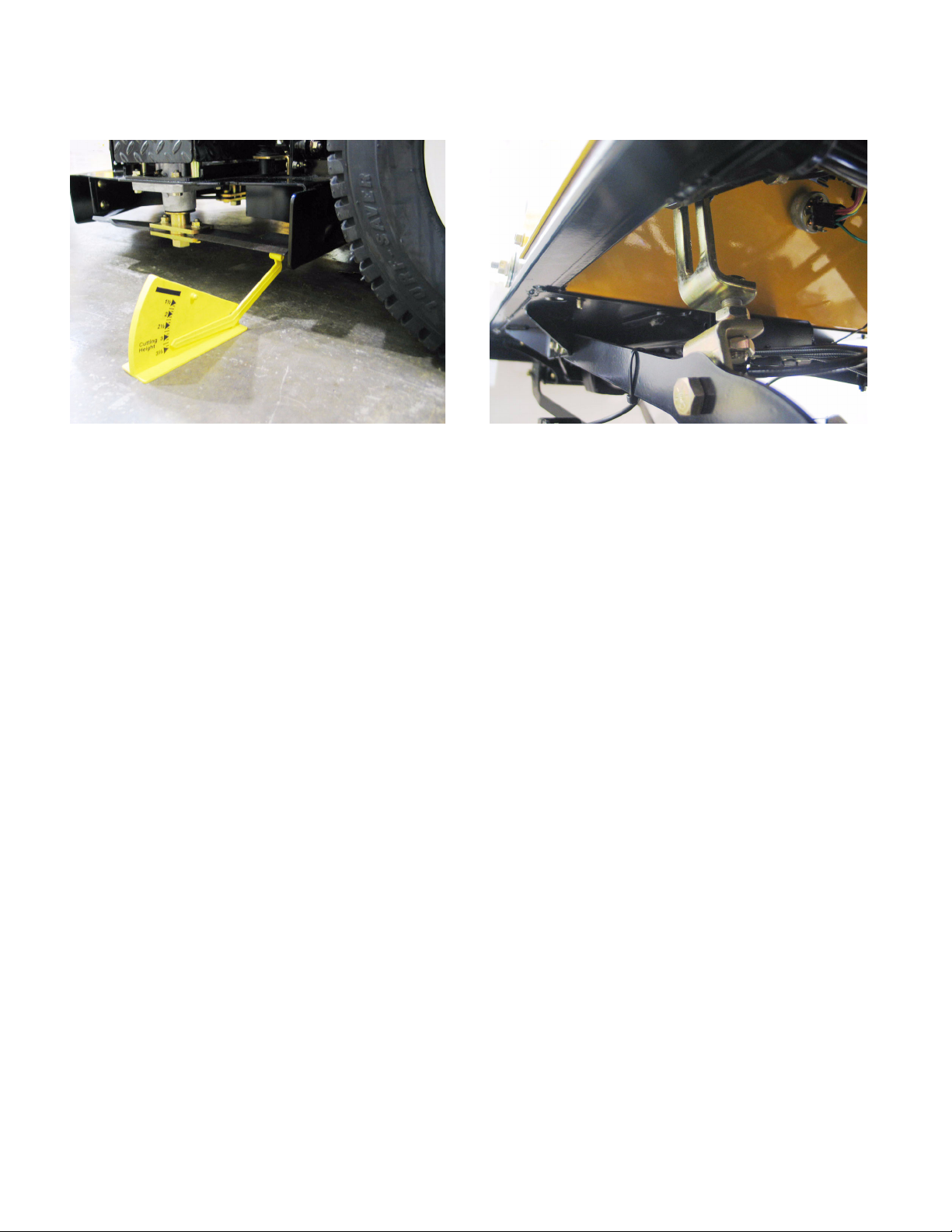

best combination of access above and below the

deck.

-

• Check the rear tire pressure: they should be

between 10-12 PSI (.69-.84 Bar). Be aware that

adjustments to rear tire pressure will also cause

a change in tracking.

13

Page 18

Cub Cadet Commercial Z-Wing

9.2. Side-to-side measurement: See Figure 9.2.

Figure 9.2 Figure 9.4

• Orient the outer pair of blades fore-and-aft.

• Check the vertical play on each element of the

blade assemblies to be measured. There will be

some up and down travel at the blade tips, generally between 1/8” and 1/4” (3.175mm and

6.35mm). If the amount of play significantly

exceeds this range, or is not consistent between

blade elements, identify the cause and correct it.

• Aerodynamic down-force overcomes the centrifugal force that keeps the blades perpendicular to

the spindle axis at mowing speeds: the blades

operate at the lower end of the available play.

• Measure the distance to the ground from the left

and right rear blade tips. It should be equal.

9.3. If the distance from the left and right rear blade

tips to the ground is equal, proceed to fore-andaft pitch measurement. If the distance is not

equal, level the deck as described under the

Side-to-side leveling sub-heading.

9.4. Side-to-side leveling: See Figure 9.4.

Adjustable link:

left-hand side

• The right side deck lift link is fixed in length,

while the left side link is adjustable.

• Loosen the jam nut that locks the adjustment on

the left lift link using a 3/4” wrench.

• Move the adjustment nut up or down as necessary to level the deck, using a 3/4” wrench.

• Tighten the jam nut, and double-check the level.

Readjust if necessary.

9.5. Fore-and-aft pitch measurement:

• Measure the distance to the ground from the

front and rear tips of the right side blade.

• The front blade tip should be between 1/8” and

1/4” (3.175mm and 6.35mm) closer to the

ground than the rear blade tip.

• This measurement should be the same for the

left side blade too. If it is not, identify and correct

the cause.

• If adjustment is necessary, proceed as

described in the deck pitch adjustment subheading.

14

Page 19

Cub Cadet Commercial Z-Wing

9.6. Deck pitch adjustment: Mowers produced

before November 2005.

Spherical rod end

Figure 9.6

• Loosen the jam nut that locks against the spherical rod-end connecting the front of the cutting

deck to the front lift arm assembly using a 15/16”

wrench.

See Figure 9.6.

Adjustment

bolt

Jam nut

• Loosen the jam nuts that lock against the front

rod lift tube using a 15/16” wrench.

• Tighten or loosen the pitch adjustment nuts as

required to achieve a nose-down blade attitude

(lower at the front of the blade than at the back)

of 1/8” to 1/4” (3.175mm and 6.35mm) using a

15/16” wrench.

• Tension on the adjusting nuts should be even.

If it is not, the looser side will amplify deck vibrations.

• Secure the adjustment by tightening the jam nut.

• The effect of adjustment is greater at lower cutting heights because the front deck lift arm is

closer to horizontal at higher cutting levels. It is

important to make this adjustment at the level

used most frequently by the operator.

9.9. Run and test the mower, inspecting cut quality,

before returning the mower to service.

9.10. Lateral brace adjustment: See Figure 9.10.

• Tighten or loosen the pitch adjustment bolt as

required to achieve a nose-down blade attitude

(lower at the front of the blade than at the back)

of 1/8” to 1/4” (3.175mm and 6.35mm) using a

15/16” wrench.

• Secure the adjustment by tightening the jam nut.

9.7. Run and test the mower, inspecting cut quality,

before returning the mower to service.

9.8. Deck pitch adjustment: Mowers produced after

November 2005, or retrofitted with a new deck

after November 2005:

U-shaped deck lift

bar has two adjustment points

See Figure 9.8.

Lateral

brace

Figure 9.10

• Mowers produced after mid-season 2005, but

before November of 2005 are equipped with a

lateral brace between the frame and the mowing

deck, similar to a panhard rod in the rear suspension of a car or truck.

• The lateral brace length should be adjusted so

that at the middle of the deck’s height travel it

exerts no force on the deck: if one of the mounting bolts is removed it will slip back-in without

force.

Figure 9.8

15

Page 20

Cub Cadet Commercial Z-Wing

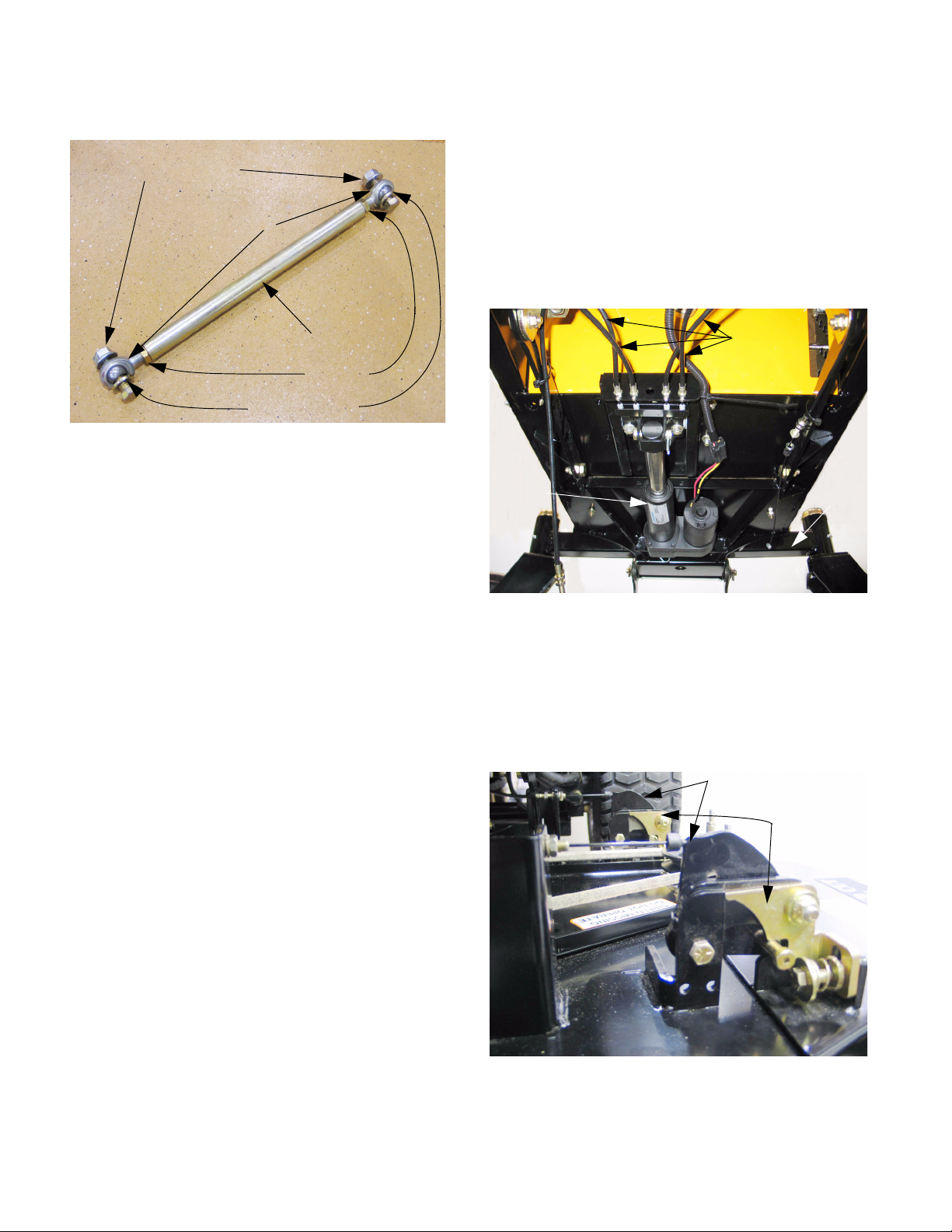

9.11. To adjust the lateral brace: See Figure 9.11.

Mounting nuts / bolts

Spherical rod ends

Center section

Jam nuts

Safety washers

Figure 9.11

NOTE: Safety washers prevent the lateral brace

from becoming disconnected if one of the spher

ical rod-ends fails.

• Loosen the jam nuts at each spherical rod-end

using an 11/16” wrench before disconnecting the

brace.

• Disconnect one end of the lateral brace, and

lengthen or shorten the brace as needed by

rotating the tubular center section.

• Both spherical rod ends are connected to the

center section with right-hand threads, so one

end must be disconnected for adjustment.

• Reconnect the end, and tighten the jam nuts.

• If the locking feature of the removed mounting

nut has worn, replace the nut or apply a small

amount of thread locking compound such as

Loctite 242 (blue).

10. DECK WING AND HINGE LOCK

NOTE: Mowers produced after mid-season 2005

use a different hinge lock mechanism than the

early 2005 production mowers. While the two

hinge locks are similar in operation, the actual

components differ substantially. The revised

hinge locks will be described in a sub-section

that follows the early hinge lock section.

10.1. How it works: See Figure 10.1.

Wing lift

cables

-

Linear

actuator

Figure 10.1

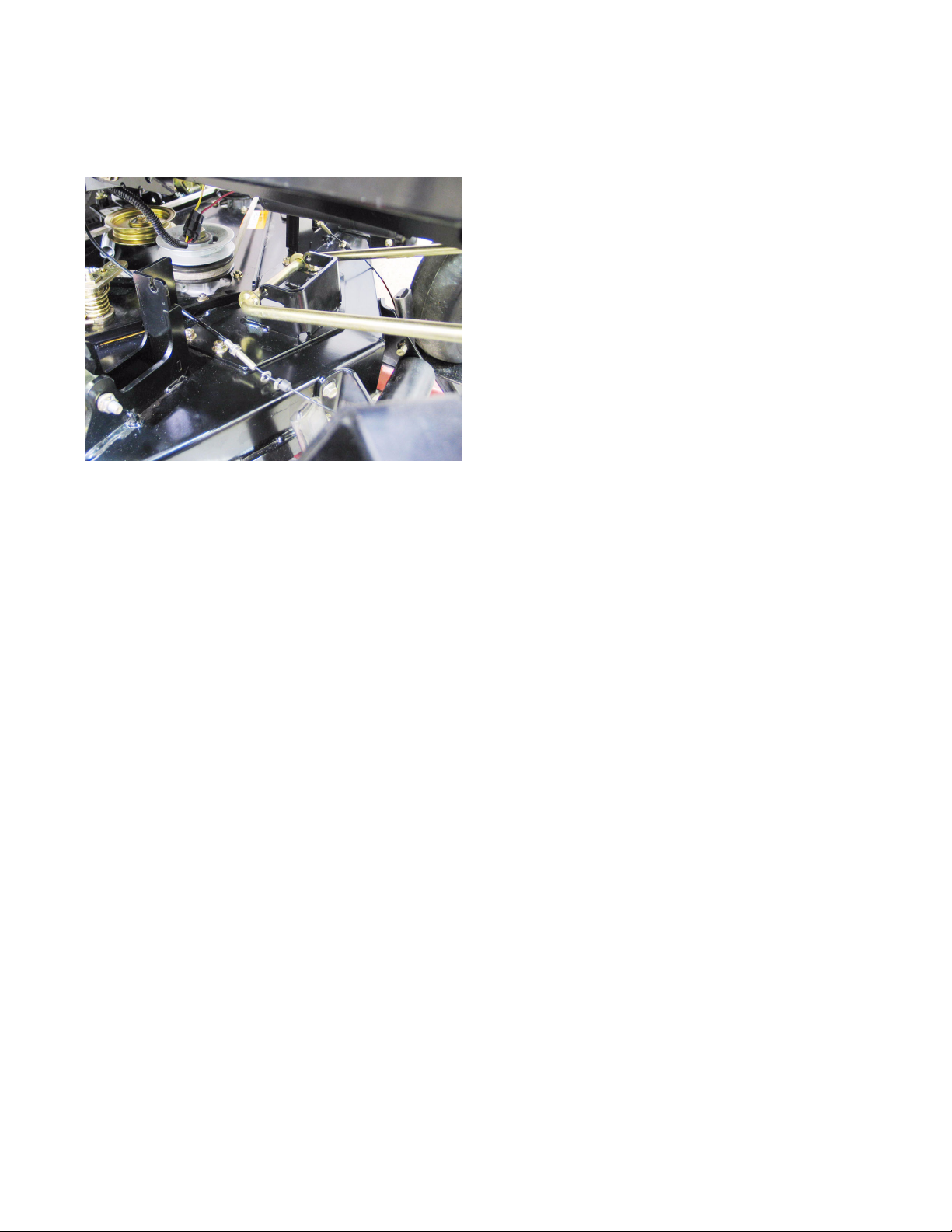

• A linear actuator mounted under the floor pulls

on a brace of cables. Each pair of two cables

unlatch and lift one deck wing.

10.2. Each deck wing has two hinge locks and lift

cable brackets, protected by lift wing shields.

See Figure 10.2.

Lift cable brackets

Hinge locks

Pivot

bar

• Tighten the mounting bolt to a torque of 40 ft.lbs. (54.25 Nm).

Figure 10.2

16

Page 21

NOTE: All four sets of hinge locks and brackets

are identical: the parts are interchangeable leftto-right and front-to-rear.

10.3. When the wing lift is activated, all four cables,

hinge locks, and lift mechanisms should work in

unison:

See Figure 10.3.

Cable bracket

Hinge lock

Cub Cadet Commercial Z-Wing

10.4. The lift mechanism can be reached by removing

the lift wing shield using a 9/16” wrench.

See Figure 10.4.

Socket-head

cap screw

Wing position switch Compression spring

Figure 10.3

• The force applied through the cable rotates the

cable bracket inward.

• The socket head cap screw attached to the

cable bracket moves upward, releasing the

plunger on the safety switch and rotating the

hinge lock clear of the corner of the deck hinge

• The force of a compression spring keeps the

hinge lock applied when the cable is slack.

• When the spring is compressed and the hinge

lock is clear of the hinge, the cable will begin to

lift the deck wing.

Lift wing shield

Figure 10.4

10.5. If the cable bracket is to be removed, it can be

unbolted with the cable attached using two 9/16”

wrenches. Once loose, the cable can be discon

nected from the bracket. See Figure 10.5.

Cable bracket

(unbolted)

-

• A clutch within the actuator prevents over-travel

when the wings reach the fully raised position.

• The safety switches prevent the operation of the

PTO with the deck wings raised.

• Proper adjustment is very important: refer to the

DECK WING CABLE ADJUSTMENT section of

this manual for the correct procedure.

• Proper hinge alignment is very important. If a

hinge becomes bent or damaged, it must be

repaired before the mower is used.

Figure 10.5

NOTE: The bolt and bushing that hold the

bracket are also the pivot point for the deck

wing.

17

Page 22

Cub Cadet Commercial Z-Wing

10.6. Orientation: on all four cable brackets, one side

of the bushing shoulder is thicker than the other.

The socket head cap screw always goes on the

side with the thicker shoulder.

Cable bracket Socket head cap screw

Figure 10.6

10.7. Assembly notes:

• Reverse the disassembly process to install the

cable bracket.

• Lubricate the pivot point with anti-seize compound.

• Apply a small amount of thread locking compound such as Loctite 242 (blue), or replace the

nut if the locking feature of the nut is in question.

Tighten the nut to a torque of 20-25 ft-lbs (27-34

Nm).

• Confirm correct operation and adjustment of the

wing lift mechanism and all associated safety

features before returning the mower to service.

10.8. To remove the hinge lock, the compression

spring that holds the hinge lock against the

bracket on the deck wing must first be discon

nected.

See Figure 10.6.

-

10.10.Once the spring is released, remove the nut

from the carriage bolt that secures the hinge lock

and its shouldered bushing to the bracket on the

deck wing.

Carriage bolt (captive)

Shouldered bushing

Hinge

lock

Figure 10.10

10.11. The hinge lock assembly can then be removed

from the deck, except for the carriage bolt. The

cable bracket must be removed to release the

carriage bolt.

Carriage bolt

Hinge lock

Shouldered

bushing

Self locking nut

Compression spring Small flat washer

Bolt Self locking nut

Large flat washer

See Figure 10.11.

See Figure 10.10.

10.9. Remove the nut that secures bolt, flat washer,

and the compression spring using a pair of 9/16”

wrenches. The spring will still be captive, but it

can be removed when the hinge lock is unbolted

from the bracket on the deck wing.

Figure 10.11

18

Page 23

Cub Cadet Commercial Z-Wing

Hi

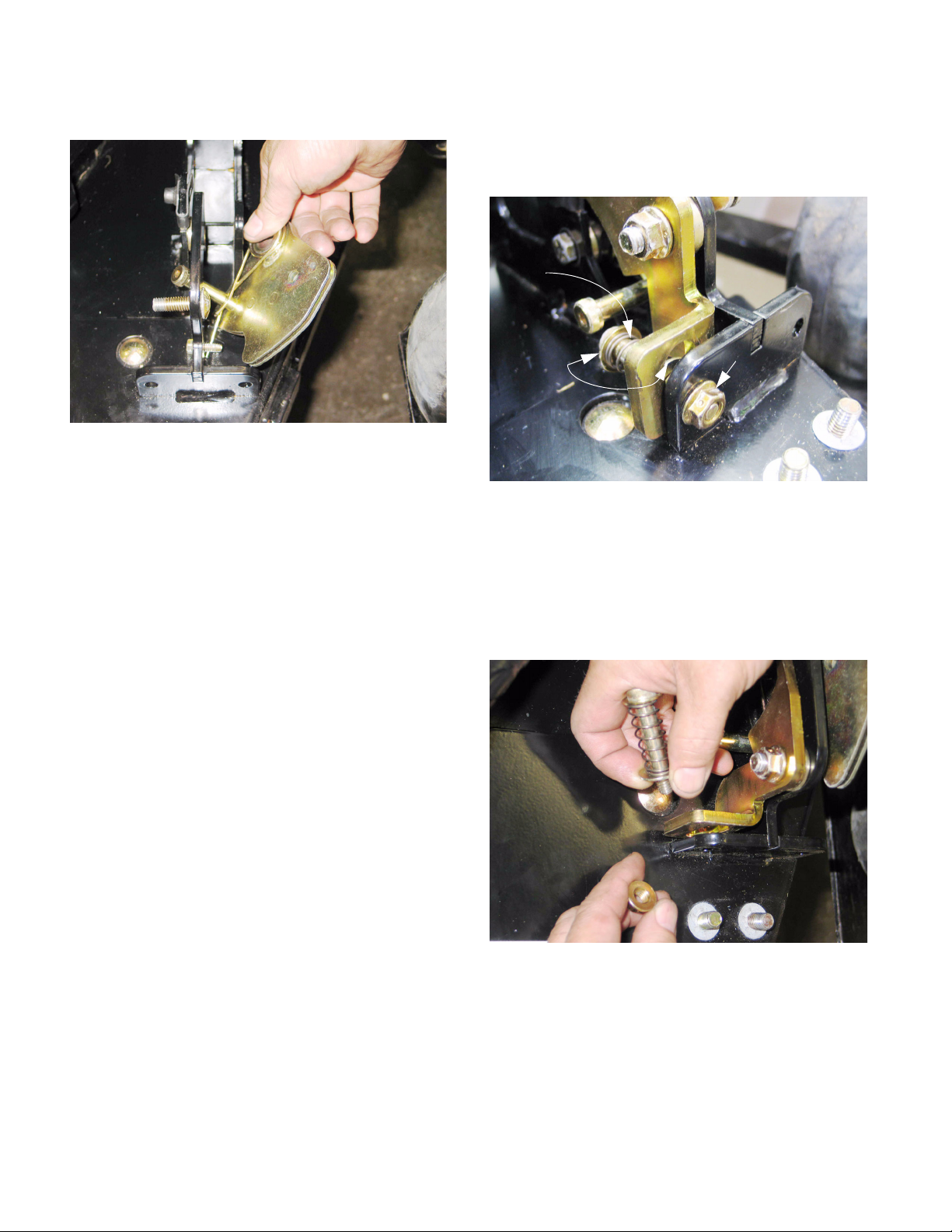

10.12.Assembly notes: See Figure 10.12.

1”

Figure 10.12

• Reverse the disassembly process to install the

hinge lock.

• Lubricate the pivot point (shoulder bushing) with

anti-seize compound.

• Tighten the nut on the carriage bolt to a torque of

20-25 ft-lbs (27-34 Nm). Apply a small amount of

thread locking compound such as Loctite 242

(blue), or replace the nut if the locking feature of

the nut is in question.

• Tighten the nut that holds the compression

spring until the distance between the head of the

bolt and the near edge of the bracket on the

deck wing is 1” (2.54 cm), with the hinge lock

pressed firmly against the bracket. Apply a small

amount of thread locking compound such as

Loctite 242 (blue), or replace the nut if the locking feature of the nut is in question.

• Confirm correct operation and adjustment of the

wing lift mechanism and all associated safety

features before returning the mower to service.

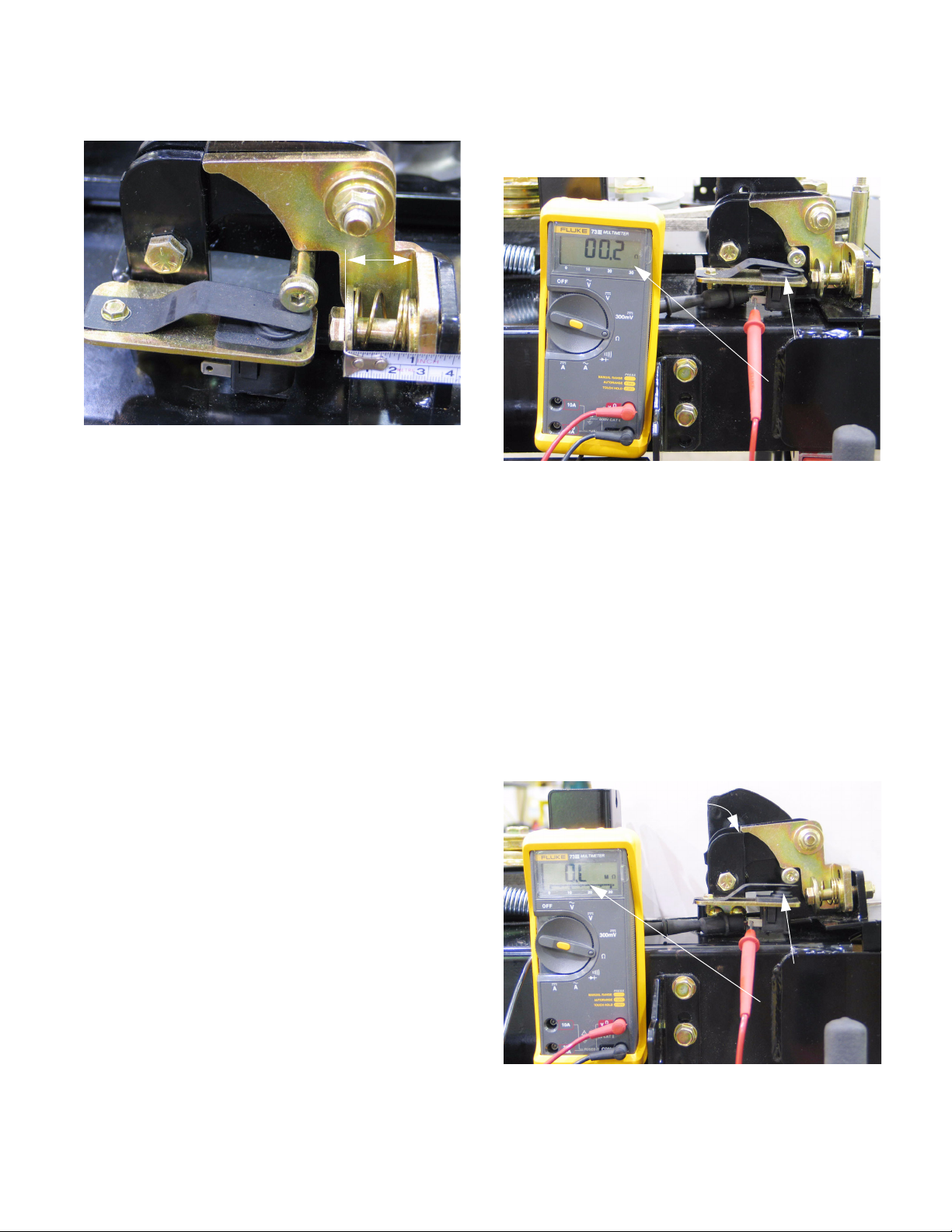

10.14.The switch contacts are normally open (N.O.),

meaning that the internal contacts are broken

when the plunger is extended.

Figure 10.14

• If the contacts fail to close when the plunger is

depressed, the PTO will not work.

• If the contacts fail to open when the plunger is

extended, an unsafe condition will exist.

• The switches should be tested whenever mower

deck maintenance is being performed.

10.15.The switches are mounted to a slotted bracket

using carriage bolts: they are adjustable.

10.16.The switches are correctly adjusted when the

contacts break just as the corner of the hinge

lock clears the corner of the hinge.

See Figure 10.16.

nge lock

just clears

corner of

hinge

See Figure 10.14.

Plunger down

Contacts closed

10.13.There is a safety switch mounted to the rear

hinge on each side of the deck.

• The switch is actuated by the socket head cap

screw that releases the hinge lock.

• If the switch contacts of both switches do not

close, the PTO will be disabled.

• Disabled PTO may be caused by a disconnected

switch, damaged wires, damaged switch, or a

misadjusted switch.

Plunger up

Contacts open

Figure 10.16

19

Page 24

Cub Cadet Commercial Z-Wing

11. HINGE LOCK: LATE 2005 PRODUCTION

11.1. When the wing lift is activated, all four cables,

hinge locks, and lift mechanisms should work in

unison:

Cable

J-nut

Torsion spring

Shouldered

cap screw

• The force applied through the cable rotates the

cable bracket inward.

See Figure 11.1.

Figure 11.1

Cable bracket

Hinge lock

NOTE:

new profile

Compression

spring

• There is a torsion spring connecting the hinge to

the cable bracket, giving the cable bracket more

positive return action.

• A J-nut has been positioned in a notch on the

hinge. The J-nut is hardened. This provides a

hard flat surface for the hinge lock to operate

against. The wear resistance of the J-nut will

provide more consistent locking action over

time, and is easily replaced.

• The compression spring that engages the hinge

lock is mounted on shouldered socket head cap

screw, eliminating the possibility of misadjustment.

11.3. The Safety switch that is mounted to each rear

hinge lock prevents the electric PTO from

engaging when the wings are not latched in the

down position.

See Figure 11.3.

• The socket head cap screw attached to the

cable bracket moves upward, releasing the

plunger on the safety switch and rotating the

hinge lock clear of the corner of the deck hinge

• The force of a compression spring keeps the

hinge lock applied when the cable is slack.

• When the spring is compressed and the hinge

lock is clear of the hinge, the cable will begin to

lift the deck wing.

• A clutch within the actuator prevents over-travel

when the wings reach the fully raised position.

• The safety switches prevent the operation of the

PTO with the deck wings raised.

• Proper adjustment is very important: refer to the

DECK WING CABLE ADJUSTMENT section of

this manual for the correct procedure.

• Proper hinge alignment is very important. If a

hinge becomes bent or damaged, it must be

repaired before the mower is used.

11.2. The revised hinge lock (2005/2) differs from the

original hinge lock (2005/1) in the following

ways:

Safety switch on

each rear hinge lock

Figure 11.3

• There is greater range of motion between the

point that the socket head cap screw releases

the plunger on the safety switch and the point

that it contacts the hinge lock.

20

Page 25

Cub Cadet Commercial Z-Wing

11.4. The lift mechanism can be reached by removing

the lift wing shield using a 9/16” wrench.

See Figure 11.4.

Lift wing shield

Figure 11.4

11.5. While the earlier cable brackets can simply be

unbolted with the cable attached, the torsion

spring on the revised cable brackets makes

them easier to remove if the cable is first discon

nected. See Figure 11.5.

11.6. The cable bracket can then be removed using

two 9/16” wrenches. Unbolt it and remove the

bushing.

Figure 11.6

11.7. The bolt and bushing that hold the bracket are

also the pivot point for the deck wing: If the deck

wing is to be completely removed, taking-off

-

both cable brackets will separate the deck wing

from the rest of the deck.

See Figure 11.6.

Cable

Cable bracket

Bushing

Wrench

Cable

bracket

Figure 11.5

• One hinge lock on the wing to be serviced can

be blocked open using an open-end wrench.

• The hinge lock nearest the cable bracket to be

removed can be manually unlatched.

• With both hinge locks released, the deck wing

can be lifted manually to slacken the cable.

• Slack in the cable allows the cable-end barrel to

be slipped out of the key-hole opening in the

cable bracket.

Cable

11.8. Orientation: on all four cable brackets, one side

of the bushing shoulder is thicker than the other.

See Figure 11.8.

Long arm Short arm

Key hole

opening

Shoulder that

surrounds the

bushing

Figure 11.8

• The socket head cap screw always goes on the

side with the thicker shoulder.

• The long arm of the torsion spring should be

nearer the cable bracket than the short arm.

• The long arm of the torsion spring fits under the

socket head cap screw.

Socket head

cap screw

21

Page 26

Cub Cadet Commercial Z-Wing

11.9. Assembly notes: See Figure 11.9.

Figure 11.9

• Reverse the disassembly process to install the

cable bracket: hook the long arm of the torsion

spring under the machine screw on the deck

wing hinge, and position the socket head cap

screw under the hinge lock.

• Lubricate the pivot point with anti-size compound.

• Insert the bushing, and secure the assembly

with nut and bolt.

11.10. To remove the hinge lock, the compression

spring that holds the hinge lock against the

bracket on the deck wing must first be discon

nected. See Figure 11.10.

Spring

Flat

washers

Figure 11.10

11.11. Remove the nut that secures bolt, flat washer,

and the compression spring using a pair of 9/16”

wrenches.

11.12. The shoulder bolt, spring, and flat washers can

all be removed if the spring is compressed with

finger pressure.

Nut

See Figure 11.12.

-

• Apply a small amount of thread locking compound such as Loctite 242 (blue), or replace the

nut if the locking feature of the nut is in question.

Tighten the nut to a torque of 20-25 ft-lbs (27-34

Nm).

• Confirm correct operation and adjustment of the

wing lift mechanism and all associated safety

features before returning the mower to service.

Figure 11.12

22

Page 27

Cub Cadet Commercial Z-Wing

11.13. The hinge lock and the bushing that it pivots on

can then be removed from the deck using a 9/

16” wrench.

Hinge lock

NOTE: The cable bracket must be removed to

release the carriage bolt.

11.14. Assembly notes:

• Reverse the disassembly process to install the

hinge lock.

• Lubricate the pivot point (shoulder bushing) with

anti-seize compound.

• Tighten the nut on the carriage bolt to a torque of

20-25 ft-lbs (27-34 Nm). Apply a small amount of

thread locking compound such as Loctite 242

(blue), or replace the nut if the locking feature of

the nut is in question.

• Tighten the nut that holds the compression

spring until the shoulder bottoms-out against the

bracket. Apply thread locking compound such as

Loctite 242 (blue), or replace the nut if the locking feature of the nut is in question. Tighten the

nut to a torque of 20-25 ft-lbs (27-34 Nm).

See Figure 11.13.

Carriage bolt

Bushing

Figure 11.13

11.16. The switch contacts are normally open (N.O.),

meaning that the internal contacts are broken

when the plunger is extended.

Contacts closed

Hinge lock latched

Plunger down

Figure 11.16

• If the contacts fail to close when the plunger is

depressed, the PTO will not work.

• If the contacts fail to open when the plunger is

extended, an unsafe condition will exist.

• The switches should be tested whenever mower

deck maintenance is being performed.

11.17. Each switch is mounted to a bracket that can be

rotated for adjustment:

• Loosen the switch bracket mounting bolt using a

pair of 9/16” wrenches.

• Rotate the switch bracket until the contacts open

and when the hinge lock is unlatched and close

when the hinge lock latches.

• Secure the bracket by tightening the bolt.

See Figure 11.16.

• Confirm correct operation and adjustment of the

wing lift mechanism and all associated safety

features before returning the mower to service.

11.15. There is a safety switch mounted to the rear

hinge on each side of the deck.

• The switch is actuated by the socket head cap

screw that releases the hinge lock.

• If the switch contacts of both switches do not

close, the PTO will be disabled.

23

Page 28

Cub Cadet Commercial Z-Wing

11.18. The switches are correctly adjusted when the

contacts break just as the corner of the hinge

lock clears the corner of the hinge.

See Figure 11.18.

Corner of hinge

Hinge lock

Figure 11.18

11.19. Test the operation of the switches after service is

complete, but before the lift wing shields are

reinstalled.

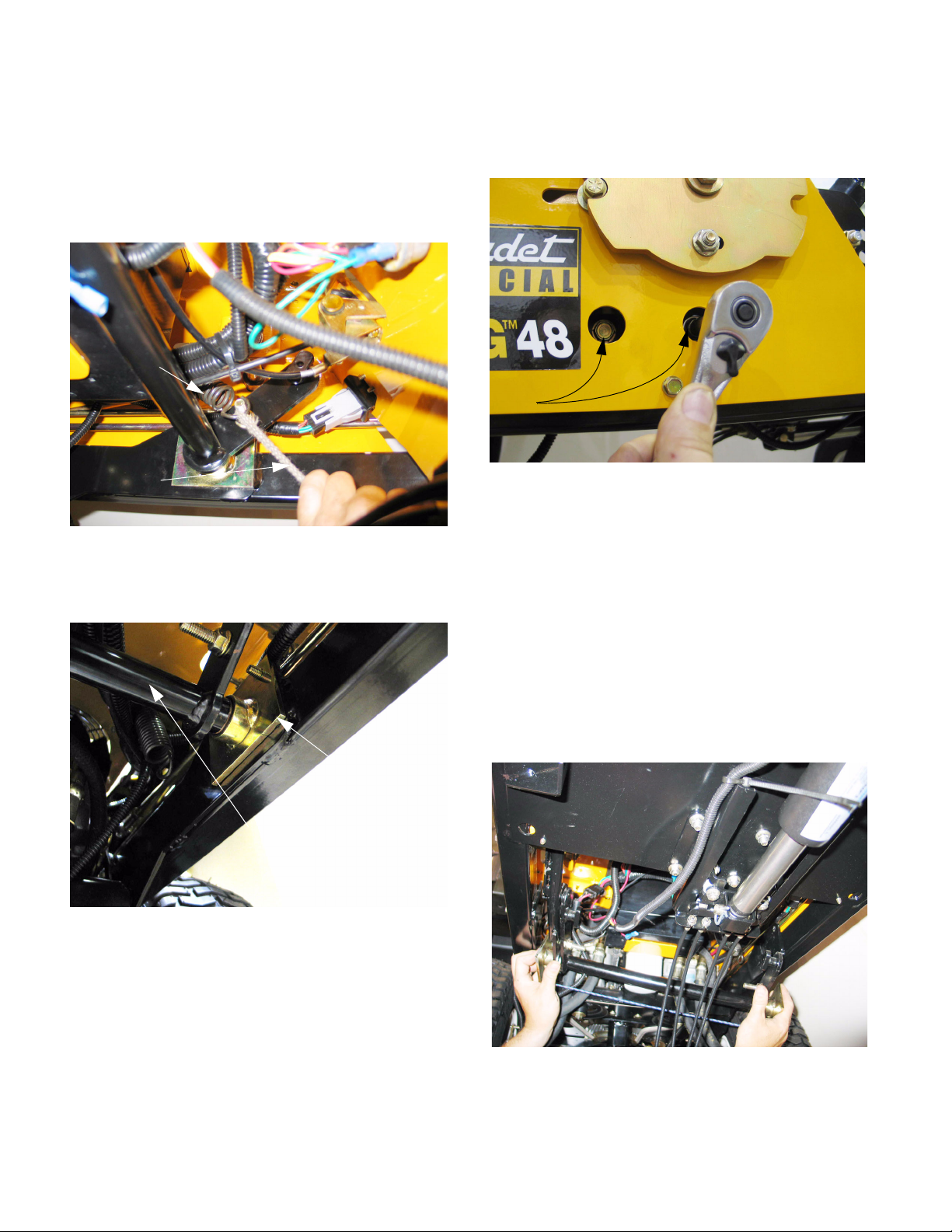

12.4. To remove the wing lift actuator, remove the cutting deck as described in the CUTTING DECK

REMOVAL section of this manual.

12.5. Retract the actuator:

• Insert the key in the key switch and turn it to ON.

• Work the rocker switch to lift the deck wings (disconnected), retracting the ram on the actuator.

• Turn the key switch OFF and remove the key.

• If the actuator has failed in the fully extended

position, or if the cable bracket is to be removed,

follow the steps described later in this section.

12.6. Disconnect the electric plug joining the actuator

to the rest of the harness.

Disconnect

See Figure 12.6.

12. DECK WING LIFT MECHANISM: EARLY 2005 PRODUCTION

NOTE: Decks having U-shaped front lift rods

were used on all Z-Wings produced after Nov. 1,

2005 (S/N: 0K015Z00001). These decks are ret

rofittable to earlier production. Earlier decks are

easily identified by V-shaped front lift rods that

connect to the deck at a single point.

12.1. Refer to the electrical section of this manual for

electrical diagnosis of the wing lift actuator.

12.2. The cable cores are all nylon jacketed, and

should have long service lives.

• Lubrication may be detrimental to the cables in

some operating conditions, adhering grit to the

cable or softening the cable core jacket.

• If any lubricant is applied, use a dry product like

graphite or dry Teflon (PTFE) such as Tri-flo

brand.

12.3. If one cable needs replacement, and it has not

suffered from some identifiable damage or

cause for accelerated wear, a good case can be

made for replacing all four cables.

Figure 12.6

-

12.7. Remove the hairpin clip and clevis pin and connecting the rear (ram) of the actuator to the

cable bracket.

Cable bracket

See Figure 12.7.

Clevis pin

Figure 12.7

Ram end of

actuator

24

Page 29

Cub Cadet Commercial Z-Wing

12.8. Disconnect the front of the actuator:

• Remove the hairpin clip from the clevis pin that

secures the front of the actuator to the frame of

the mower.

• Hold the actuator to keep it from rotating.

• Drive the clevis pin up, releasing the actuator.

12.9. Carefully slide the actuator toward the back of

the mower to release it from the front bracket,

and lower it to remove it.

Slide back

then down

Actuator

See Figure 12.9.

Installation notes, continued:

• Lubricate the pivot points (clevis pins) with antiseize compound.

• Confirm correct operation and adjustment of the

hinge lift mechanism and associated safety features before returning the mower to service.

12.11. If the actuator has failed in the fully extended

position, or if it is necessary to remove the cable

bracket, the following sequence of instructions

will be more useful.

12.12.To remove the wing lift actuator, remove the cutting deck as described in the CUTTING DECK

REMOVAL section of this manual.

12.13.Disconnect the electric plug joining the actuator

to the rest of the harness.

12.14.Remove the rear hairpin clip and clevis pin that

hold the actuator to the cable bracket assembly.

12.15.Remove the four nuts that secure the cable

bracket assembly to the frame of the mower

using a 1/2” wrench.

See Figure 12.15.

Figure 12.9

12.10.Installation notes: See Figure 12.10.

Flat ground on pin

Index mark

Figure 12.10

• Reverse the disassembly process to install the

actuator.

Nuts (securing cable bracket to frame)

Figure 12.15

• It is acceptable to grind a small flat on one side

of the head of the front clevis pin, perpendicular

to the bore for the hairpin clip, for ease of installation.

25

Page 30

Cub Cadet Commercial Z-Wing

12.16.If the nuts are loosened from their carriage bolts

in small increments and slight downward force is

applied to the bracket, the square bosses on the

carriage bolts will remain engaged to the frame.

Tape placed over the heads of the carriage bolts

will also help keep them in place.

See Figure 12.16.

Tape to temporarily secure carriage bolts

Figure 12.16

12.17.Cut any cable ties that secure the lift cables to

the mower.

12.18.Lower the cable bracket assembly slightly to

clear the bolts, draw it rearward to clear the actu

ator, and remove it. See Figure 12.18.

12.19.Disconnect the front of the actuator:

See Figure 12.19.

Removing clevis pin

Figure 12.19

• Remove the hairpin clip from the clevis pin that

secures the front of the actuator to the frame.

• Hold the actuator to keep it from rotating.

• Lift the clevis pin up, releasing the actuator.

12.20.Carefully slide the actuator toward the back of

the mower to release it from the front bracket,

and lower it to remove it.

-

12.21. If the cables need to be replaced, remove them

as described in the following steps:

Cable bracket assembly

Figure 12.18

NOTE: Cable replacement can be accomplished

without removing the cable bracket assembly.

12.22.Remove the jam nuts from the end of each cable

using a 7/16” wrench and a 3/8” wrench.

See Figure 12.22.

Jam nuts

Figure 12.22

26

Page 31

Cub Cadet Commercial Z-Wing

12.23.With the jam nuts removed, the threaded end of

the cable housings will pass through the keyhole shaped slots in the end to the cable

bracket.

12.24.With the cables free of the cable bracket, the

actuator mounting bracket can be rolled out the

end of the cable bracket.

Cable bracket

Actuator mounting bracket

Figure 12.24

See Figure 12.24.

12.26.While the cable bracket and actuator mounting

bracket are disassembled, inspect the rollers

and their mounting hardware.

Roller

Shoulder bolt

Figure 12.26

NOTE: To judge the amount of wear on the roll-

ers, the new measurements are as follows:

O.D.= .880”, I.D.= .375”, Thickness= .283”

(O.D.= 2.24cm, I.D.= .95cm, Thickness= .72cm)

See Figure 12.26.

Washers

(horizontal axis

rollers only)

12.25.To separate Z-fittings on the end of the cables

from the actuator mounting bracket, remove one

of the vertical-axis rollers, and loosen the sec

ond one using a 1/2” wrench and a 3/16” allen

wrench. This will allow the cable retainer to

pivot, releasing the Z-fittings from the actuator

mounting bracket.

See Figure 12.25.

Vertical axis rollers

Cable

Retainer

Figure 12.25

NOTE: The 4 horizontal-axis rollers can be

removed in similar fashion, but there is a washer

-

between each roller and the actuator bracket.

12.27.On mowers produced after November of 2005,

the cable bracket assembly was changed. The

bottom lip of the current brackets flares outward,

while the earlier ones are bent in.

See Figure 12.27.

Figure 12.27

27

Page 32

Cub Cadet Commercial Z-Wing

12.28.On the early design, the rollers of the actuator

mounting bracket rode in a channel formed by

the bottom lip of the cable mounting bracket,

supporting the lift actuator.

12.29.The rollers on actuator mounting brackets made

since November of 2005 only contact the top

surface of the cable mounting bracket.

See Figure 12.29.

Rollers not enclosed in channel

Figure 12.29

12.30.The lift actuator is supported by a separate

bracket.

See Figure 12.30.

12.31.Installation notes: See Figure 12.31.

Ground flat

Index mark

Figure 12.31

• It is acceptable to grind a small flat on one side

of the head of the front clevis pin, perpendicular

to the bore for the hairpin clip, for ease of installation.

12.32.Assembly notes, continued:

• Reverse the disassembly process to install the

cables, brackets, and actuator.

• Lubricate the pivot points (clevis pins) with antiseize compound.

Figure 12.30

NOTE: Removal of the actuator and the actuator

mounting bracket are much easier on the mow

ers produced after November of 2005.

• Test to confirm correct operation and adjustment

of the hinge lift mechanism and associated

safety features before returning the mower to

service.

-

28

Page 33

13. DECK WING LIFT CABLE ADJUSTMENT

Cub Cadet Commercial Z-Wing

NOTE: The bat wing feature of the Z-Wing

mower is a key element in the sales of the

mower. Safe and dependable operation of the

feature is crucial to customer satisfaction. Cor

rect adjustment of the cables is vitally important

to the safe and dependable operation of the bat

wing feature.

13.1. Lower the deck wings all the way.

13.2. Remove the shields that cover each wing lift

mechanism using a 9/16” wrench.

See Figure 13.2.

Nuts securing wing

lift shields

Bolts are

captive

NOTE: Whether the tightest cable is on the left

or right wing, front or rear hinge, does not matter.

-

NOTE: Usually an exposed thread length of 1/2”

to 5/8” (12.7mm - 15.9mm) is a good starting

point if a new cable has been installed.

13.4. Tighten the second cable on the same wing until

the hinge lock is at the same point of disengage

ment as the first, using a pair of 1/2” wrenches.

See Figure 13.4.

Jam nut

Adjusting nuts

-

Figure 13.2

13.3. Turn the key switch to the RUN position, and

“Blip” the wing lift switch until the tightest cable

moves the hinge lock it is connected to just far

enough to free that hinge.

See Figure 13.3.

Adjustment needed: rear

lock is further disengaged

than front hinge lock.

Figure 13.4

13.5. Lower the deck wings, then begin to raise them:

• Watch the movement of the hinge locks to confirm that they are working at the same time.

• If the hinge locks or hinges are binding in any

way, repair them before proceeding.

• Make any necessary adjustments if they are not.

13.6. Adjust the cables on the second wing so that the

hinge locks both move in unison with the hinge

locks on the first wing.

Figure 13.3

29

Page 34

Cub Cadet Commercial Z-Wing

13.7. Operate the wings through 20 complete raise/

lower cycles:

• Confirm smooth and consistent operation of the

deck wings.

• Confirm that all four hinge locks are locking and

unlocking in sync. Jerky operation of 1 wing may

indicate that 1 lock is unlocking later than the

others.

• Confirm that both deck wings are operating in

sync.

• Confirm that all four cables are secured in such

a way that they will not be damaged by normal

belt or linkage movement.

• Make any adjustments or repairs necessary to

achieve 20 trouble-free cycles.

• Tighten the jam nuts when testing is completed.

• Check the safety switches that are used to confirm that the wings are down. Make any repairs

or adjustments necessary for the correct operation of the safety switches, as described in the

DECK WING AND HINGE LOCK section of this

manual.

14. DECK LIFT MECHANISM

14.1. If the deck lift shaft, the hubs it rides in, or any

associated linkage need repair, the following

procedure will provide guidance in removal and

installation of those parts.

14.2. Begin by removing the cutting deck as described

in the CUTTING DECK REMOVAL section of

this manual.

14.3. Disconnect the front of each lift arm from the

mower frame using a 9/16” wrench and a 3/4”

wrench.

See Figure 14.3.

Lift arms

48” deck uses rear set of holes

Figure 14.3

NOTE: There are two sets of holes in the

bracket that the front of the lift arm mounts to.

They are correctly positioned in the rear set of

mounting holes.

NOTE: The lift links mount inboard of the lift

arms: the left side lift link is adjustable, the right

side lift link is fixed-length.

30

Page 35

Cub Cadet Commercial Z-Wing

14.4. The deck lift arms and their connection points to

the deck were modified in November of 2005.

The new arms feature a bushing at the connec

tion point to the cutting deck. See Figure 14.4.

Bushings

Figure 14.4

14.5. The bushings on both lift arms are off-set to the

left. The right side arm has a tab for the connec

tion of a lateral brace that was introduced at midseason, 2005. The lateral brace was disused in

November 2005.

See Figure 14.5.

14.7. Disconnect and remove each lift arm and lift link

assembly.

-

Lift arm

Lift link

14.8. Confirm that the deck height control is in the

highest (Transport Lock) position, minimizing

tension on the lift-assist springs. When raising

-

the deck lift handle, remove the clevis pin from

above it with caution because the handle will be

under tension from the lift-assist springs.

See Figure 14.8.

See Figure 14.7.

T-head

Figure 14.7

Connecting point

for lateral brace

Figure 14.5

14.6. With the front of each lift arm disconnected from

the frame, the lift links can be angled-back so

that the slot in the lift link fits through the T-head

weldment on the lift-shaft assembly.

Deck lift handle

Shoulder bolt

securing deck lift

handle in Transport

Lock position

Figure 14.8

31

Page 36

Cub Cadet Commercial Z-Wing

14.9. Remove the locking nuts from each bolt that

connects the lift assist springs to the bellcranks

on the lift shaft assembly using a 9/16” wrench.

14.10.Disconnect the springs from the bolts using a

length of recoil rope or an appropriate hook tool.

See Figure 14.10.

Lift assist spring

Recoil

starter rope

Figure 14.10

14.12.The bolts that hold the lift hub assemblies to the

control housing are accessible through openings

in the sides of the housing.

Bolts

holding lift hub assemblies

Figure 14.12

NOTE: Have a length of bungee cord capable of

maintaining light pressure across an 18” span

handy before removing the lift hub bolts.

See Figure 14.12.

14.11. Each end of the lift shaft assembly is carried by a

hub assembly.

See Figure 14.11.

Lift hub

assembly

Lift shaft assembly

Figure 14.11

14.13.Loosen, then remove the pair of bolts that

secures each lift hub to the control housing

using a 9/16” wrench.

14.14. Carefully maneuver the lift shaft assembly out of

the control housing, between the two frame

channels. As it clears the frame, attach the

shock cord between the two left hubs, holding

the lift shaft assembly together.

See Figure 14.14.

32

Figure 14.14

Page 37

Cub Cadet Commercial Z-Wing

14.15. Rotate the left end of the lift shaft rearward to

free the deck height control handle from the

index assembly, and remove the assembly to a

workbench.

14.16.Once on the bench, the bungee cord can be

removed.

See Figure 14.15.

Bungee cord

Figure 14.15

See Figure 14.16.

14.17.The left side hub will simply slip off of the shaft.

See Figure 14.17.

T-head

for lift link

Left lift hub

Figure 14.17

14.18.The right side hub will slip off of the shaft as well,

but it also retains the deck height control lever.

See Figure 14.18.

Lift handle

Carriage bolt

Lift shaft assembly

Deck lift handle

Lift shaft assembly

Lift hubs

Figure 14.16

Lift shaft assembly

Carriage bolt

Flat washers

Lift hub

Figure 14.18

33

Page 38

Cub Cadet Commercial Z-Wing

14.19.Assembly notes: See Figure 14.19.

Figure 14.19

• Apply anti-seize compound to the friction surfaces where the lift shaft assembly rides on the

lift hubs and the lift links.

• Use the shock cord technique to hold the

assembly together for installation.

• Tighten the bolt to a torque of 20-25 ft-lbs (27-34

Nm). Apply a small amount of thread locking

compound such as Loctite 242 (blue).

• A magnetic socket, or the gun patch technique

may be used to get the lift hub bolts started.

15. LAP BARS

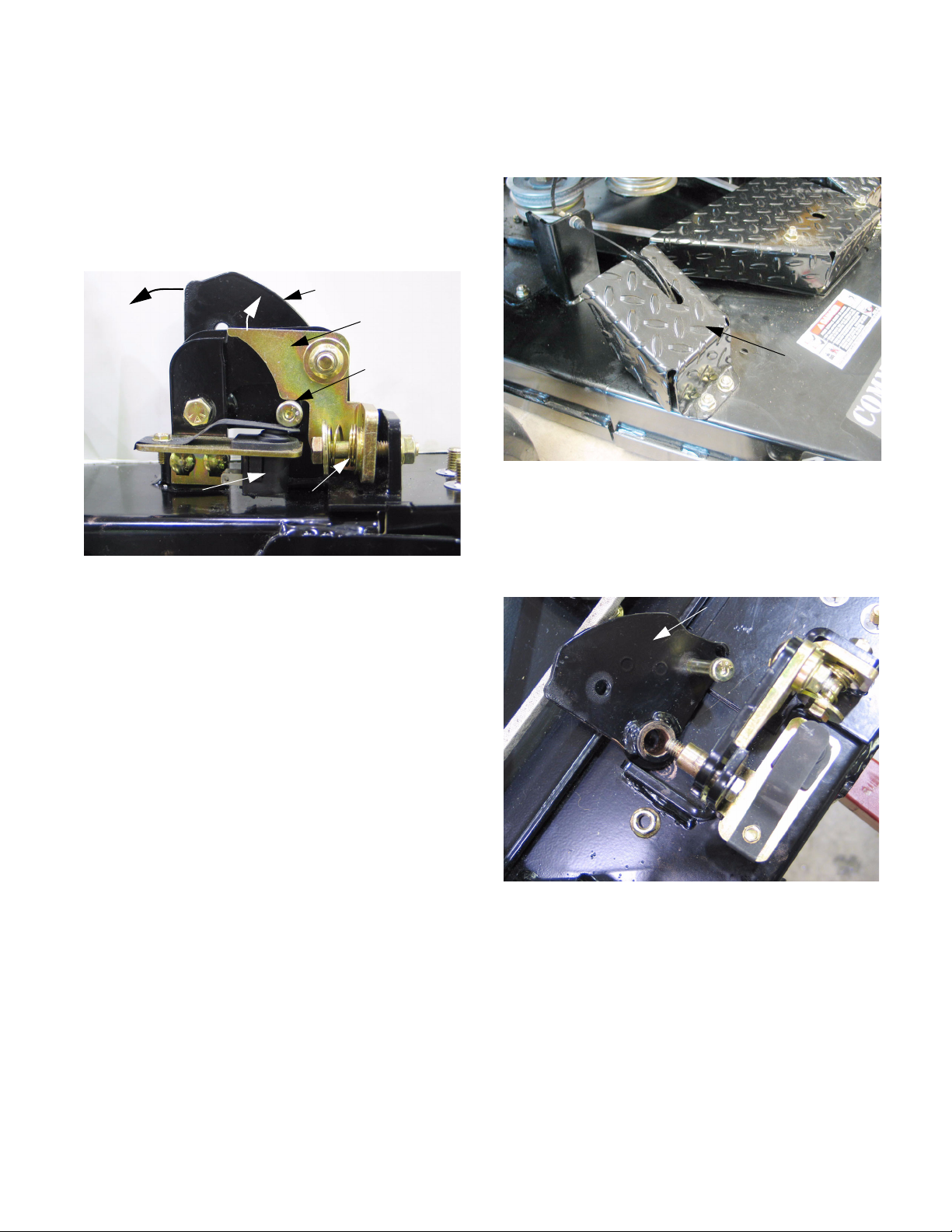

15.1. The lap bars do not have room to pivot outward

in the conventional manner because they would

interfere with the deck wings in the raised posi

tion. For this reason, separate pivot handles

articulate on the lap bar pivot brackets which

fasten to the steering pivot plate.

See Figure 15.1.

Pivot handle

Figure 15.1

15.2. The pivot handles are bolted to the lap bar pivot

brackets, with washer on each side of the pivot

bar handle.

See Figure 15.2.

-

• Install the cutting deck as described in the CUTTING DECK REMOVAL section of this manual.

• If a lift hub should loosen, or the threads should

get stripped in the field, it is possible to reinforce

the installation with 3/8-16 nuts until a more permanent repair can be effected.

Washers

Figure 15.2

• The bolts should be tight enough to eliminate

play, but loose enough that they do not bind.

• Periodic tightening may be necessary using two

9/16” wrenches.

• Lubricate the joints weekly, per the Operator’s

Manual.

34

Page 39

Cub Cadet Commercial Z-Wing

L

t

15.3. The lap bar pivot brackets are adjustable to suit

individual operators.

Two Square

holes

Two slots

Tracking adjustment:

travel limiters

Steering pivot plate

neutral adjustment

• Carriage bolts in two square holes and two slots

provide adjustment for height and rake using a

single 1/2” wrench.

• A mechanical interlock with the parking brake

locks the steering pivot plates when the brake is

applied.

• High speed tracking adjustment is done by

adjusting rollers up or down on the steering pivot

plate to limit travel.

• The slotted connection between the steering

pivot plate and the hydrostatic pump control

allows “interlock neutral” to be aligned with true

neutral for the pump.

See Figure 15.3.

ap bar pivo

bracket

Steering

pivot plate

Brake interlock

Figure 15.3

16. CHECKING NEUTRAL ADJUSTMENT

CAUTION: Releasing the parking brake with the

engine at top no-load speed and loose or misadjusted control linkages can result in unpredict

able or uncontrolled movement of the mower.

• If the drive system makes a pronounced whining

sound, indicating that it may be severely out of

adjustment, do not release the parking brake.

• Perform the tests in a safe area that is free of

hazards, obstacles, other personnel, or pets.

• In cases where the misadjustment is pronounced, the tests may be performed at reduced

throttle settings, to help identify the nature and

location of the misadjustment.

16.1. With the engine warm and running at full throttle,

the hydro relief valves closed, and the parking

brake set: there should not be any abnormal

whining noise from the drive system.

16.2. With the engine warm and running at full throttle,

the hydro relief valves closed, and the parking

brake released: there should not be any ten

dency for either rear wheel to creep.

16.3. If either of these issues exist, neutral adjustment

is necessary.

16.4. The creeping action will provide clues about the

adjustment that is required:

• If both wheels tend to creep, both neutral settings may need to be adjusted.

• If only one wheel tends to creep, only that side

may need adjustment.

-

-

• The direction of the creepage will dictate the

direction of adjustment that is required.

16.5. Before adjusting the linkage, inspect it for any

bent, broken, stripped, worn, or loose compo

nents. This is particularly true if a mower that

was previously operating well has suddenly

35

gone out of adjustment.

-

Page 40

Cub Cadet Commercial Z-Wing

17. LINKAGE NEUTRAL ADJUSTMENT

17.1. Preliminary steps:

• Repair or replace any worn or damaged linkage

components before attempting to adjust the

steering linkage.

• Confirm that the parking brake interlock is working properly-repair it if it is not.

17.2. To isolate the problem to either the linkage or the

hydro pumps, loosen the nut and bolt that

secure the linkages to the steering pivot plates

using two 1/2” wrenches.

See Figure 17.2.

Steering

pivot plate

Slotted hole

Connection to

steering link rods

17.5. If the bolt that makes the connection between

the steering link rod and the steering pivot plate

is against the end of the slot in the plate, then

the steering link rod will need adjustment.

17.6. To reach the steering link rod adjustment point,

remove the hydro service plate:

Negative battery

Hydro service

plate

• Disconnect the cable from the negative terminal

on the battery using a 10 mm wrench.

cable and post

Figure 17.6

See Figure 17.6.

Figure 17.2

17.3. Repeat the test of neutral adjustment, as

described in the CHECKING NEUTRAL

ADJUSTMENT section of this manual.

• If the mower still creeps, or the drive system is

working against the brakes when it should be in

neutral, and the linkage is loose enough not to

interfere with the return to neutral action: the

adjustment must be made at the hydro.

• After adjustment at the hydro, the linkage is still

likely to need adjustment.

• If the mower does not creep, and the drive system is not working against the brakes (as indicated by a whining or groaning noise), then the

problem lies in the linkage.

17.4. If the problem lay in the connection between the

steering link rod and the steering pivot plate, the

simple act of loosening the connection and care

fully re-tightening it with the parking brake

applied should correct the adjustment.

• Remove the seven perimeter bolts from the

hydro service plate using a 7/16” wrench.

• Carefully lift the plate off of the mower.

17.7. Loosen both jam nuts that lock the adjustment

on the steering link rod using a 1/2” wrench

(nuts) and a 7/16” wrench to hold the spherical

rod end.

Spherical

-

rod end