Page 1

Operator’s Manual

ZERO TURN TRACTOR

Model Numbers

ZT 42 w/42” Mower Deck

ZT 50 w/50” Mower Deck

IMPORTANT:

READ SAFETY RULES

AND INSTRUCTIONS

CAREFULLY.

P. O. Box 1386, 97 Kent Avenue, Kitchener, Ontario N2G 4J1

PRINTED IN U.S.A.

769-02895A

(4/08)

Page 2

TABLE OF CONTENTS

TRACTOR PREPARATION ................................................................................................... 2

IMPORTANT SAFE OPERATION PRACTICES .................................................................... 4

SAFETY DECALS AND LABELS ........................................................................................... 7

RECORDING MODEL AND SERIAL NUMBER INFORMATION ........................................... 9

CUSTOMER SUPPORT ......................................................................................................... 9

TO THE OWNER..................................................................................................................... 9

SLOPE GAUGE .................................................................................................................... 10

SECTION 1: CONTROLS AND FEATURES ........................................................................ 11

SECTION 2: OPERATION ................................................................................................... 15

SECTION 3: ADJUSTMENTS .............................................................................................. 22

SECTION 4: MAINTENANCE .............................................................................................. 23

SECTION 5: MOWER DECK ............................................................................................... 28

SECTION 6: TROUBLE SHOOTING .................................................................................... 33

SECTION 7: REPLACEMENT PARTS ................................................................................. 34

SECTION 8: WARRANTY ...................................................................................................... 35

TRACTOR PREPARATION

Remove the upper crating material from the shipping

pallet, and cut any bands or tie straps securing the tractor to the pallet.

Use the lift handle to raise the deck to its highest position; engage the transmission bypass rods (Refer to

SECTION 1, page 10 CONTROLS AND FEATURES);

and carefully roll the tractor off the shipping pallet. Disengage the bypass rods.

Remove the deck wash system nozzle adapter and oil

drain tube from the manual bag and store for future use.

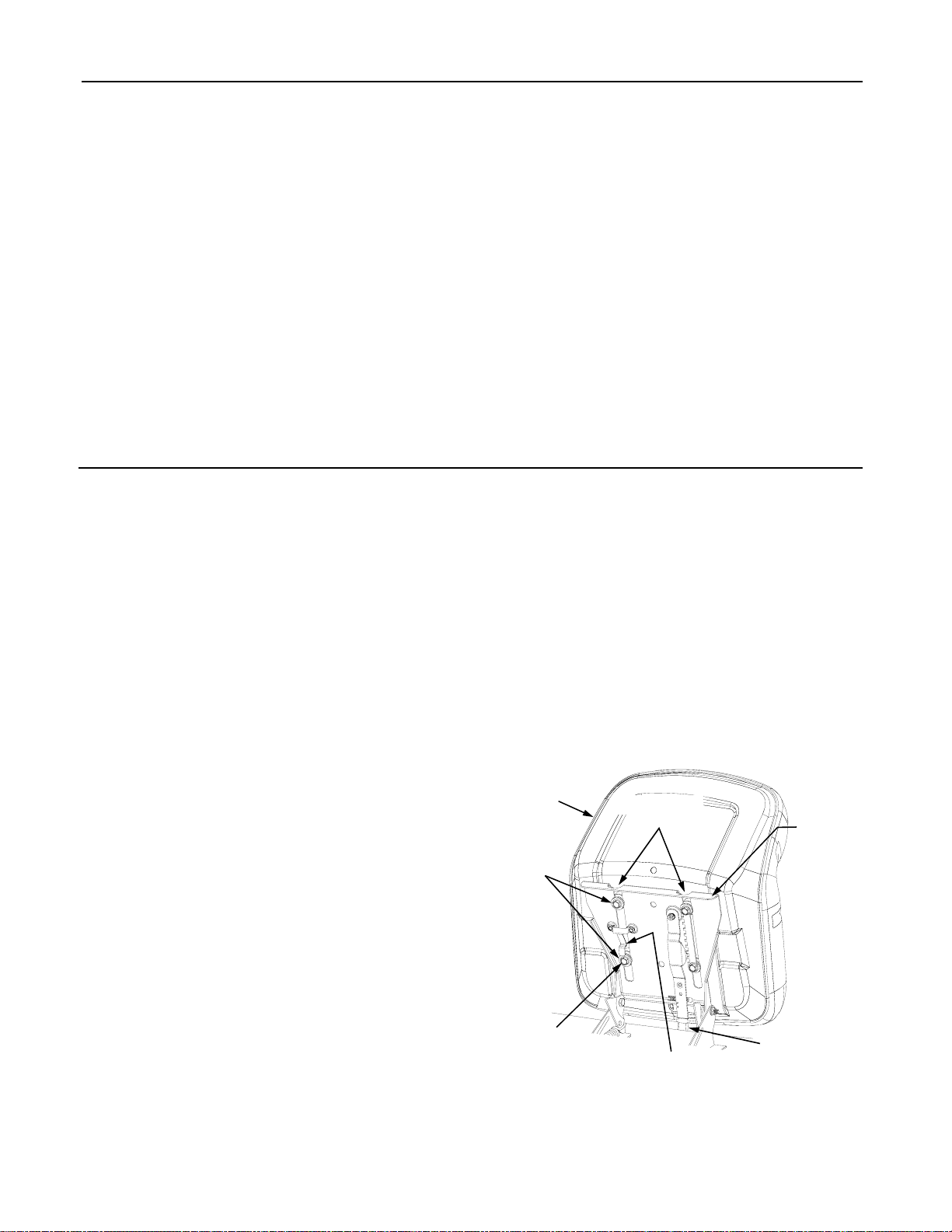

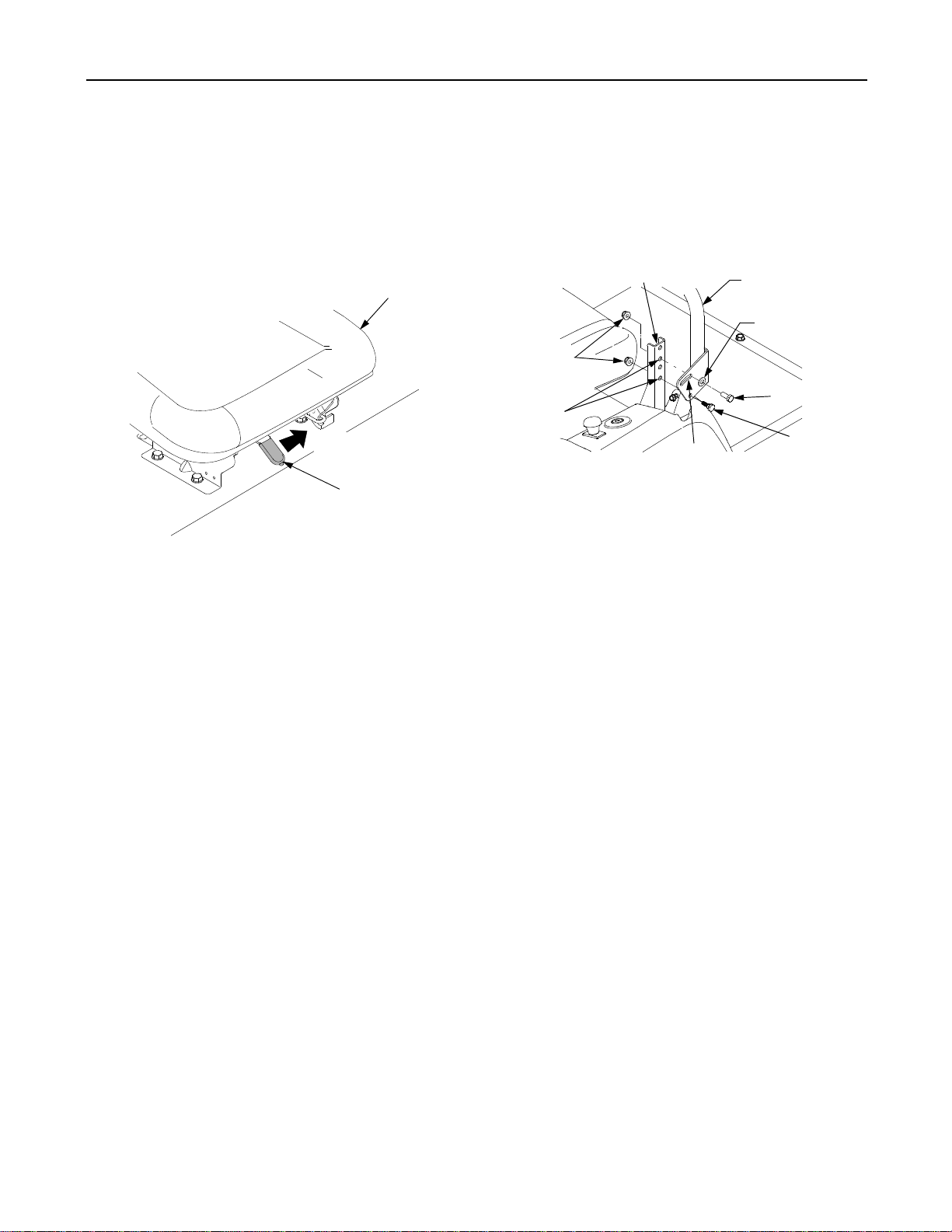

INSTALL OPERATOR’S SEAT

The operator’s seat was partially inserted into the seat

pivot bracket for shipping purposes. To install the seat

proceed as follows:

1. Cut any straps securing the seat assembly and the

drive control levers. Remove any packing material.

NOTE: The seat is partially inserted into the slot s of th e

seat pivot bracket. If the seat does not become disengaged from the pivot bracket when removing the packaging material, the pivot bracket may be pivot ed upward

and the seat pushed into place as described in ste p 6. If

the seat does disengage the pivot bracket, install the

seat as instructed in steps 2 through 6.

2. Pivot the seat pivot bracket partially upward. Refer

to Figure 1.

3. Note the grooves in the seat adjust spacers

attached to the bottom of the seat, then lift the seat

and position above and to the rear of the pivot

bracket.

4. Align the grooves in the seat adjust spacers with

the sides of the adjustment slots in the pivot

bracket.

5. Slide the seat adjust spacers into the slots of the

pivot bracket.

6. Continue to push the seat forward in the pivot

bracket until the front/left shoulder bolt of the seat

assembly passes forward of the stop bracket on

the seat pivot bracket. See Figure 1.

Use the seat adjust lever to adjust the seat position. Refer to "Adjusting the Operator’s Seat" in Section 3 for

seat adjustment instructions.

Seat

Seat

Adjust

Spacer

Front/Left

Shoulder Bolt

Adjustment

Slots

Stop Bracket

Figure 1

Seat

Pivot

Bracket

Seat Adjust

Lever

2

Page 3

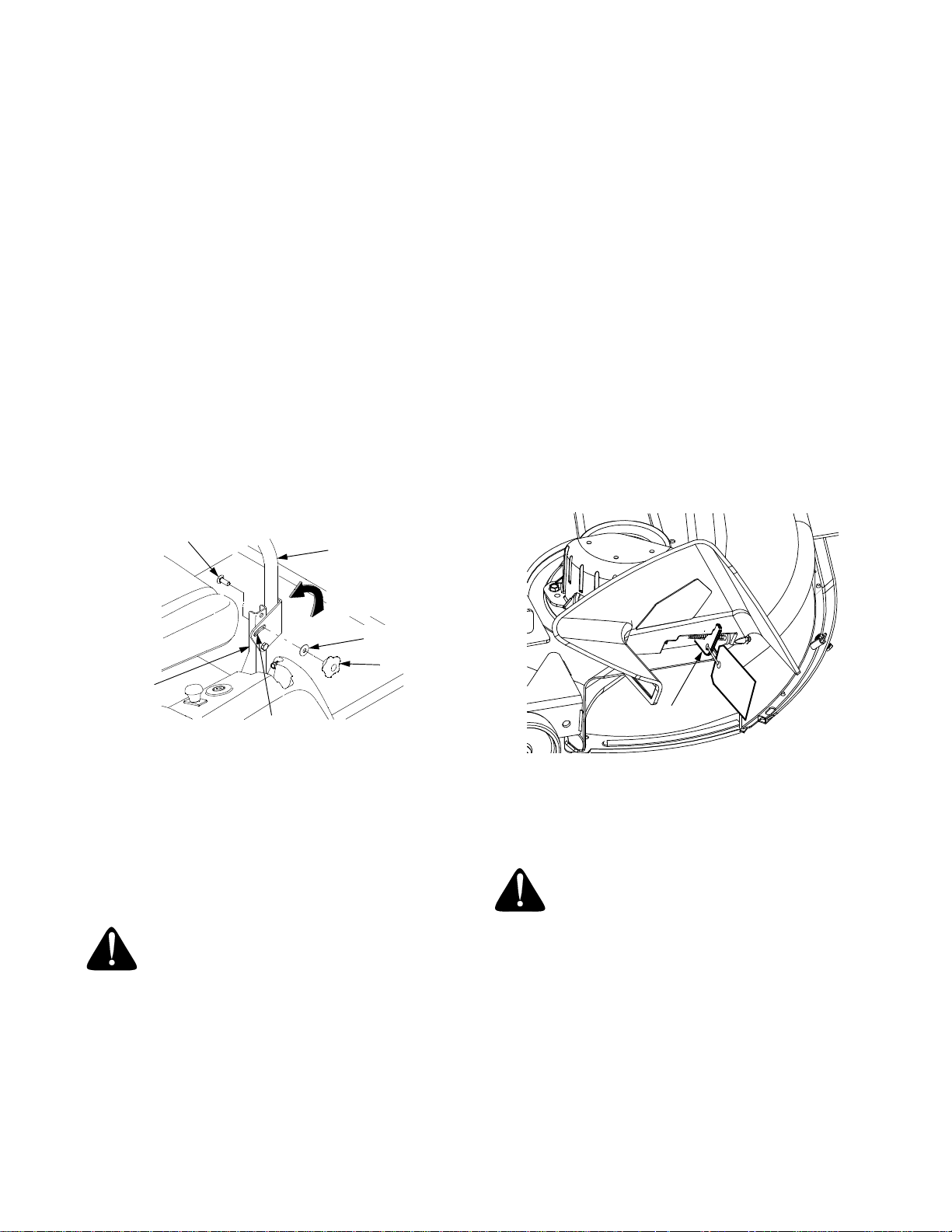

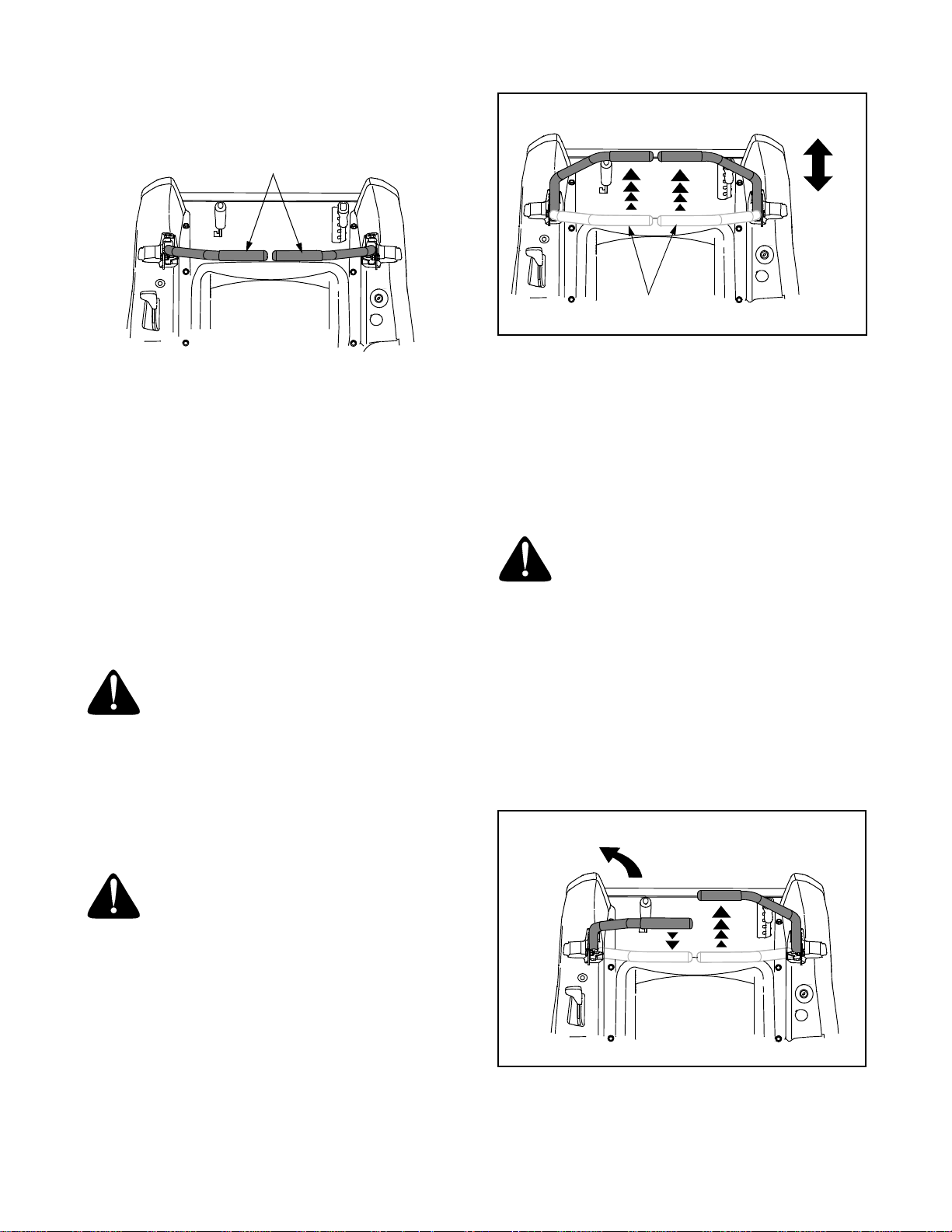

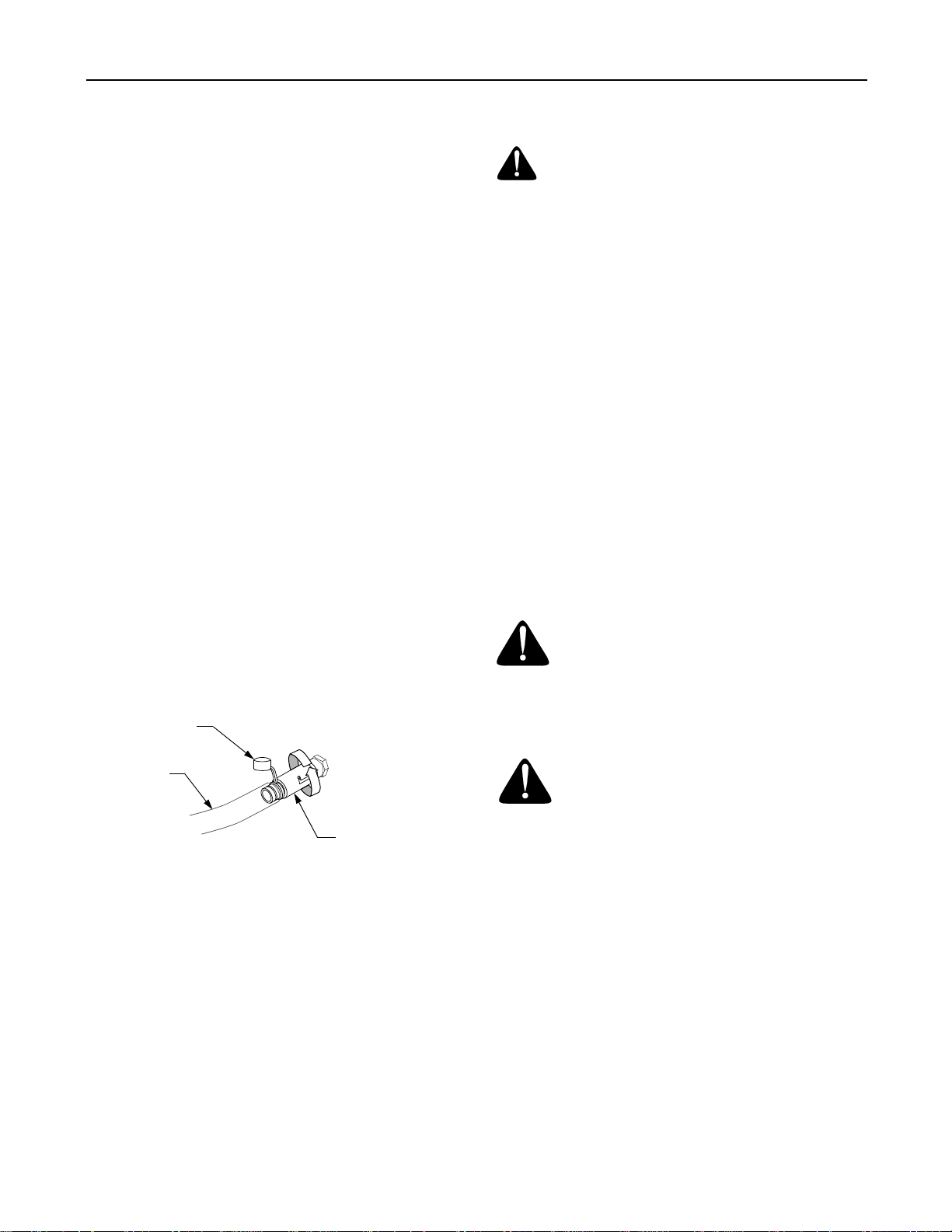

POSITION DRIVE CONTROL LEVERS

The drive control levers are unfastened from their respective pivot brackets and lowered for shipping purposes. The control levers must be repositioned and

secured to the pivot bracket to operate the tractor. Reposition the control levers as follows:

• Remove the nut knob, bell washer, and carriage

bolt from either of the two control lever pivot

brackets. Refer to Figure 2.

• Lift and swing that control lever upward until the

slotted hole in the lever bracket aligns with one of

the holes in the pivot bracket. Refer to Figure 2.

• From the inside, insert the carriage bolt into the

pivot bracket and through the control lever slot. See

Figure 2.

• Slide the bell washer onto the carriage bolt, then

thread the nut knob onto the bolt. Fully tighten the

knob to temporarily secure control lever (See Figure

2). Refer to "Adjusting the Drive Control Levers" in

Section 3 for instructions on final adjustment of the

levers.

Carriage Bolt

Control Lever

The tractor is shipped with an activated sealed battery,

with the positive battery cable factory connected. The

negative cable must be connected.

NOTE: Make sure the ignition switch is in the "OFF" position before attaching the battery cable.

1. Pull the protective cap off the negative terminal of

the battery, and remove the hex cap screw and nut

from the free end of the negative battery cable.

2. Connect the negative battery cable (heavy black)

to negative terminal (NEG) of the battery using the

hex cap screw and nut. Slide the black terminal

cover over the negative terminal of the battery.

MODEL ZT42 ONLY

Remove The Chute Stop

• Locate the chute stop on the right side of the

mower, between discharge chute and cutting deck.

• While holding the discharge chute up, rotate the

chute stop clockwise and remove.

• Discard the chute stop.

Lift control

lever upward

Bell Washer

Nut Knob

Pivot

Bracket

Slotted

Hole

Figure 2

• Note the relative position of the control lever to the

pivot bracket, then repeat the previous steps to

reposition the other control lever in approximately

the same position.

CONNECT THE BATTERY

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds. Wash hands after handling.

Chute Stop

Figure 3

MODEL ZT50 ONLY

Lower Deck Discharge Chute

WARNING: Never operate the mower deck

without the discharge chute installed and

in the down position.

Locate the cable tie holding the deck discharge chute in

the up position for shipping purposes. Cut the cable tie

and lower the discharge chute.

3

Page 4

IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out impor-

tant safety instructions which, if not followed,

could endanger the personal safety and/or

property of yourself and others. Read and fol-

DANGER: This machine was built to be operated according to the rules for safe operation in this man-

ual. As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

GENERAL OPERATION

1. Read, understand, and follow all instructions on

the machine and in the manual(s) before

attempting to assemble and operate. Keep this

manual in a safe place for future and regular

reference and for ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. To help avoid blade contact or a thrown object

injury, keep bystanders, helpers, children and pets

at least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

6. Thoroughly inspect the area where the equipment

is to be used. Remove all stones, sticks, wire,

bones, toys, and other foreign objects which could

be picked up and thrown by the blade(s). Thrown

objects can cause serious personal injury.

7. Plan your mowing pattern to avoid discharge of

material toward roads, sidewalks, bystanders and

the like. Also, avoid discharging material against a

wall or obstruction which may cause discharged

material to ricochet back toward the operator.

8. Always wear safety glasses or safety goggles

during operation and while performing an

adjustment or repair to protect your eyes. Thrown

objects which ricochet can cause serious injury to

the eyes.

9. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes and

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

10. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without the discharge cover or

entire grass catcher in its proper place.

low all instructions in this manual before attempting to

operate this machine. Failure to comply with these instructions may result in personal injury. When you see

this symbol—heed its warning.

11. Do not put hands or feet near rotating parts or

under the cutting deck. Contact with the blade(s)

can amputate hands and feet.

12. A missing or damaged discharge cover can cause

blade contact or thrown object injuries.

13. Stop the blade(s) when crossing gravel drives,

walks, or roads and while not cutting grass.

14. Watch for traffic when operating near or crossing

roadways. This machine is not intended for use on

any public roadway.

15. Do not operate the machine while under the

influence of alcohol or drugs.

16. Mow only in daylight or good artificial light.

17. Never carry passengers.

18. Back up slowly. Always look down and behind

before and while backing to avoid a back-over

accident. Be aware and pay attention to the safety

system function that stops power to the blades

when driving in reverse. If not functioning properly,

contact an authorized dealer for safety system

inspection and repair.

19. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

20. Disengage blade(s), set parking brake, stop

engine and wait until the blade(s) come to a

complete stop before removing grass catcher,

emptying grass, unclogging chute, removing any

grass or debris, or making any adjustments.

21. Never leave a running machine unattended.

Always turn off blade(s), place transmission in

neutral, set parking brake, stop engine and

remove key before dismounting.

22. Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down ramp(s), because the unit

could tip over, causing serious personal injury.

The unit must be pushed manually on ramp(s) to

load or unload properly.

23. Muffler and engine become hot and can cause a

burn. Do not touch.

24. Check overhead clearances carefully before

driving under low hanging tree branches, wires,

door openings etc., where the operator may be

struck or pulled from the unit, which could result in

serious injury.

4

Page 5

25. Disengage all attachment clutches, set parking

brake to the ’ON’ position and move the RH and

LH drive levers fully outward to the neutral position

before attempting to start engine.

26. Your machine is designed to cut normal residential

grass of a height no more than 10”. Do not attempt

to mow through unusually tall, dry grass (e.g.,

pasture) or piles of dry leaves. Dry grass or leaves

may contact the engine exhaust and/or build up on

the mower deck presenting a potential fire hazard.

27. Use only accessories and attachments approved

for this machine by the machine manufacturer.

Read, understand and follow all instructions

provided with the approved accessory or

attachment.

28. Data indicates that operators, age 60 years and

above, are involved in a large percentage of riding

mower-related injuries. These operators should

evaluate their ability to operate the riding mower

safely enough to protect themselves and others

from serious injury.

29. If situations occur which are not covered in this

manual, use care and good judgment. Contact

your authorized dealer for assistance.

SLOPE OPERATION

Slopes are a major factor related to loss of control and

tip-over accidents which can result in severe injury or

death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not

mow it.

For your safety, use the slope gauge included as part

of this manual to measure slopes before operating this

unit on a sloped or hilly area. If the slope is greater

than 15 degrees as shown on the slope gauge, do not

operate this unit on that area or serious injury could

result.

DO:

1. Mow up and down slopes, not across. Exercise

extreme caution when changing direction on

slopes.

2. Watch for holes, ruts, bumps, rocks, or other

hidden objects. Uneven terrain could overturn the

machine. Tall grass can hide obstacles.

3. Use slow speed. Choose a low enough speed

setting so that you will not have to stop or shift

while on the slope. Tires may lose traction on

slopes even though the brakes are functioning

properly.

Always keep machine in gear when going down

slopes to take advantage of engine braking action.

4. Follow the manufacturer’s recommendations for

wheel weights or counterweights to improve

stability.

5. Use extra care with grass catchers or other

attachments. These can change the stability of the

machine.

6. Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed or

direction. Rapid engagement or braking could

cause the front of the machine to lift and rapidly flip

over backwards which could cause serious injury.

DO NOT:

1. Do not turn on slopes unless necessary; then, turn

slowly and gradually downhill, if possible.

2. Do not mow near drop-offs, ditches or

embankments. The mower could suddenly turn

over if a wheel is over the edge of a cliff, ditch, or if

an edge caves in.

3. Do not try to stabilize the machine by putting your

foot on the ground.

4. Do not use a grass catcher on steep slopes.

5. Do not mow on wet grass. Reduced traction could

cause sliding.

6. Do not tow heavy pull behind attachments (e.g.

loaded dump cart, lawn roller, etc.) on slopes

greater than 5 degrees. When going down hill, the

extra weight tends to push the tractor and may

cause you to loose control. (e.g. tractor may speed

up, braking and steering ability are reduced,

attachment may jack-knife and cause tractor to

overturn).

CHILDREN

1. Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the mowing activity.

They do not understand the dangers. Never

assume that children will remain where you last

saw them.

a. Keep children out of the mowing area and in

watchful care of a responsible adult other

than the operator.

b. Be alert and turn machine off if a child

enters the area.

c. To avoid back-over accidents, always look

behind and down for small children.

d. Never carry children, even with the blade(s)

shut off. They may fall off and be seriously

injured or interfere with safe machine

operation.

e. Use extreme care when approaching blind

corners, doorways, shrubs, trees or other

objects that may block your vision of a child

who may run into the machine.

f. Keep children away from hot or running

engines. They can suffer burns from a hot

muffler.

g. Remove key when machine is unattended

to prevent unauthorized operation.

5

Page 6

2. Never allow children under 14 years old to operate

the machine. Children 14 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

TOWING

1. Tow only with a machine that has a hitch designed

for towing. Do not attach towed equipment except

at the hitch point.

2. Follow the manufacturers recommendation for

weight limits for towed equipment and towing on

slopes.

3. Never allow children or others in or on towed

equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast downhill.

SERVICE

SAFE HANDLING OF GASOLINE:

1. To avoid personal injury or property damage

use extreme care in handling gasoline. Gasoline

is extremely flammable and the vapors are

explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes

which can ignite. Wash your skin and change

clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner.

Always place containers on the ground

away from your vehicle before filling.

c. When practical, remove gas-powered

equipment from the truck or trailer and

refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with

a portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times until fueling is complete. Do not use a

nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while the

engine is hot or running. Allow engine to

cool at least two minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more

than ½ inch below bottom of filler neck to

allow space for fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine

and equipment. Move unit to another area.

Wait 5 minutes before starting the engine.

k. To reduce fire hazards, keep machine free

of grass, leaves, or other debris build-up.

Clean up oil or fuel spillage and remove any

fuel soaked debris.

l. Never store the machine or fuel container

inside where there is an open flame, spark

or pilot light as on a water heater, space

heater, furnace, clothes dryer or other gas

appliances.

m. Allow a machine to cool at least 5 minutes

before storing.

GENERAL SERVICE:

1. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless, and deadly gas.

2. Before cleaning, repairing, or inspecting, make

certain the blade(s) and all moving parts have

stopped. Disconnect the spark plug wire and

ground against the engine to prevent unintended

starting.

3. Periodically check to make sure the blades come

to complete stop within approximately (5) five

seconds after operating the blade disengagement

control. If the blades do not stop within the this

time frame, your unit should be serviced

professionally by an authorized dealer.

4. Regularly check the safety interlock system for

proper function, as described later in this manual.

If the safety interlock system does not function

properly, have your machine serviced

professionally by an authorized dealer.

5. Check the blade(s) and engine mounting bolts at

frequent intervals for proper tightness. Also,

visually inspect blade(s) for damage (e.g.,

excessive wear, bent, cracked).

Replace the blade(s) with the original equipment

manufacturer’s (O.E.M.) blade(s) only, listed in

this manual. “Use of parts which do not meet the

original equipment specifications may lead to

improper performance and compromise safety!”

6. Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing

them.

7. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

8. Never tamper with the safety interlock system or

other safety devices. Check their proper operation

regularly.

9. After striking a foreign object, stop the engine,

disconnect the spark plug wire(s) and ground

against the engine. Thoroughly inspect the

machine for any damage. Repair the damage

before starting and operating.

10. Never attempt to make adjustments or repairs to

the machine while the engine is running.

6

Page 7

11. Grass catcher components and the discharge

cover are subject to wear and damage which could

expose moving parts or allow objects to be thrown.

For safety protection, frequently check components and replace immediately with original equipment manufacturer’s (O.E.M.) parts only, listed in

this manual. “Use of parts which do not meet the

original equipment specifications may lead to

improper performance and compromise safety!”

12. Do not change the engine governor settings or

over-speed the engine. The governor controls the

maximum safe operating speed of the engine.

13. Maintain or replace safety and instruction labels,

as necessary.

14. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

Spark Arrestor

WARNING: This machine is equipped with

an internal combustion engine and should

not be used on or near any unimproved forest-covered, brushcovered or grass-covered

land unless the engine’s exhaust system is

equipped with a spark arrester meeting applicable local or provincial laws (if any).

If a spark arrester is used, it should be maintained in

effective working order by the operator.

A spark arrester for the muffler is available through

your nearest engine authorized service dealer.

Do not modify engine

To avoid serious injury or death, do not modify engine

in any way. Tampering with the governor setting can

lead to a runaway engine and cause it to operate at unsafe speeds. Never tamper with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California

and federal EPA emission regulations for SORE (Small

Off Road Equipment) are certified to operate on regular unleaded gasoline, and may include the following

emission control systems: Engine Modification (EM)

and Three Way Catalyst (TWC) if so equipped.

Average Useful Life

According to the Consumer Products Safety Commission (CPSC) and the U.S. Environmental Protection

Agency (EPA), this product has an

Average Useful Life of

seven (7) years, or 60 hours of operation. At the end of

verage Useful Life, buy a new machine or have the

the

machine inspected annually by an authorized service

dealer to ensure that all mechanical and safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or

death.

WARNING: YOUR RESPONSIBILITY Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this manual and on the machine.

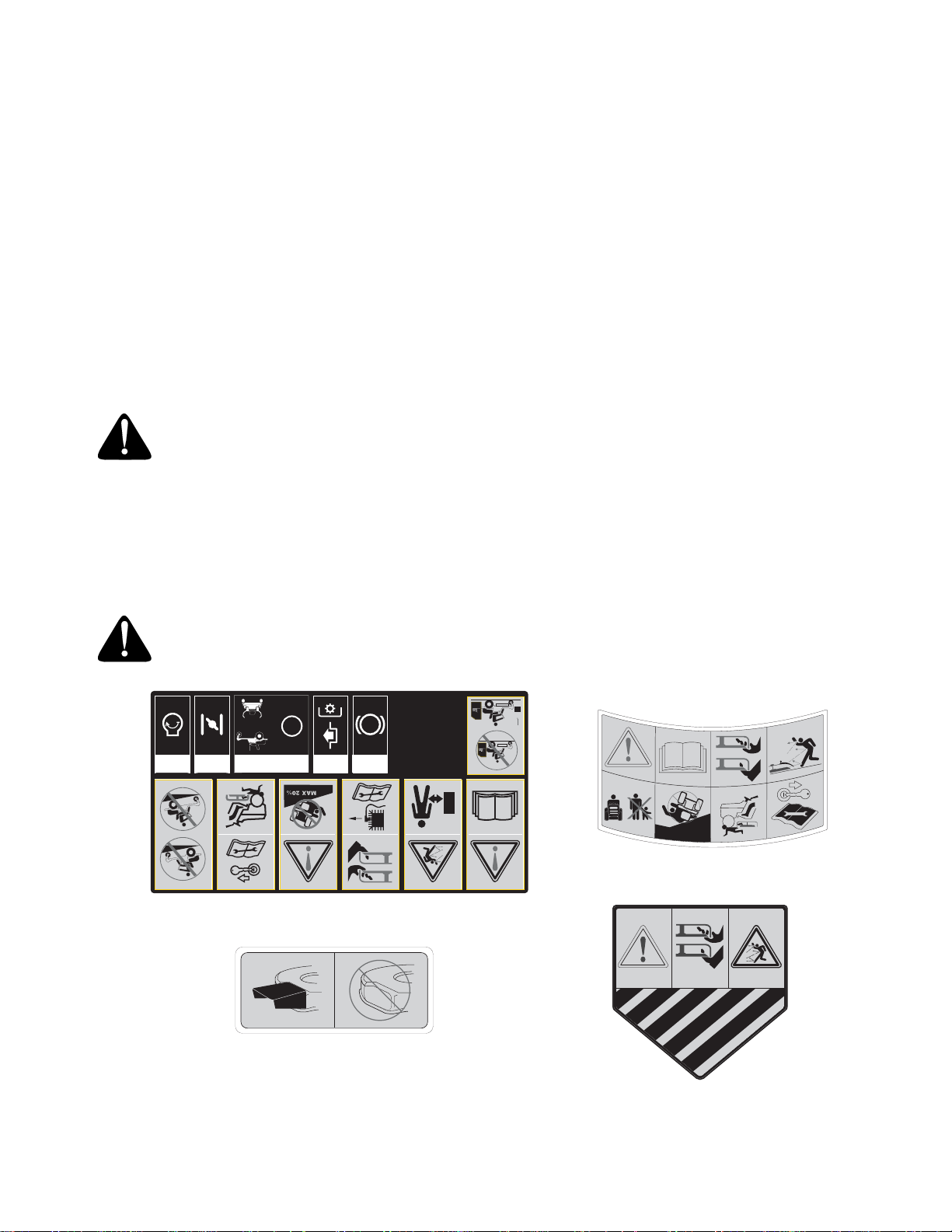

R

+

N

=

F

4

3 51

P

2

S30296

kg

MAX 20

%

S30544

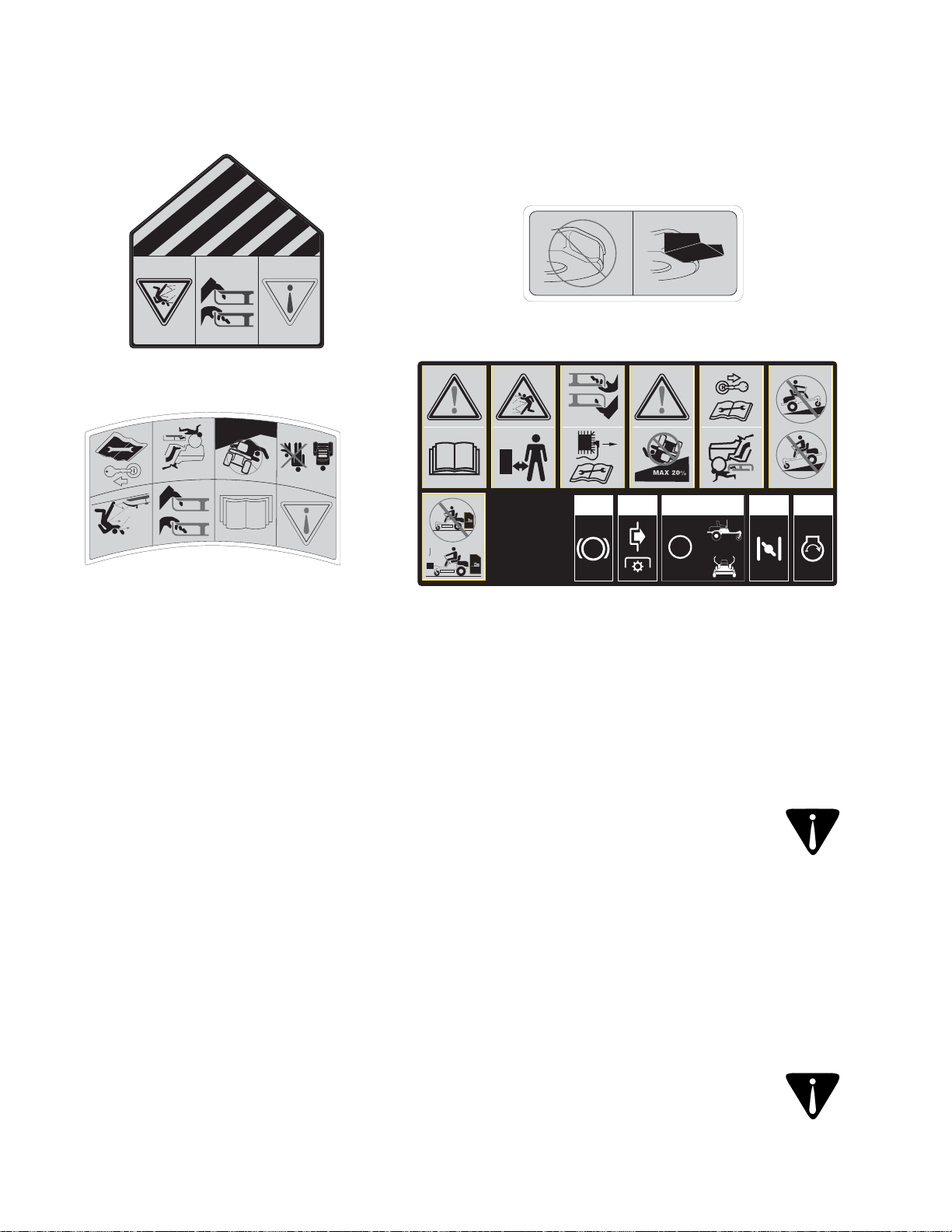

Safety Labels found on your unit

7

Page 8

RECORDING MODEL AND SERIAL NUMBER

This Operator’s Manual is an important part of your new lawn tractor. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on the

model plate is very important if you need help from your authorized dealer.

• You can locate the model number by looking beneath the seat. A sample model plate is explained below.

Model Number

Numéro de modèle

XXX-XXXXXX

Serial Number

Numéro de série

XXXXXXXXXXX

CUB CADET CANADA

KITCHENER, ON N2G 4J1

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed separately with your unit for

more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

1. Visit www.cubcadet.ca for many useful suggestions, click on Customer Support button.

2. Call a Customer Support Representative at 1-800-668-1238.

Please have your unit’s model number and serial number ready when you call. See previous section to locate

this information. You will be asked to enter the serial number in order to process your call.

8

Page 9

(Keep this sheet in a safe place for future reference.)

A CORNER OF A BUILDING

A POWER POLE

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

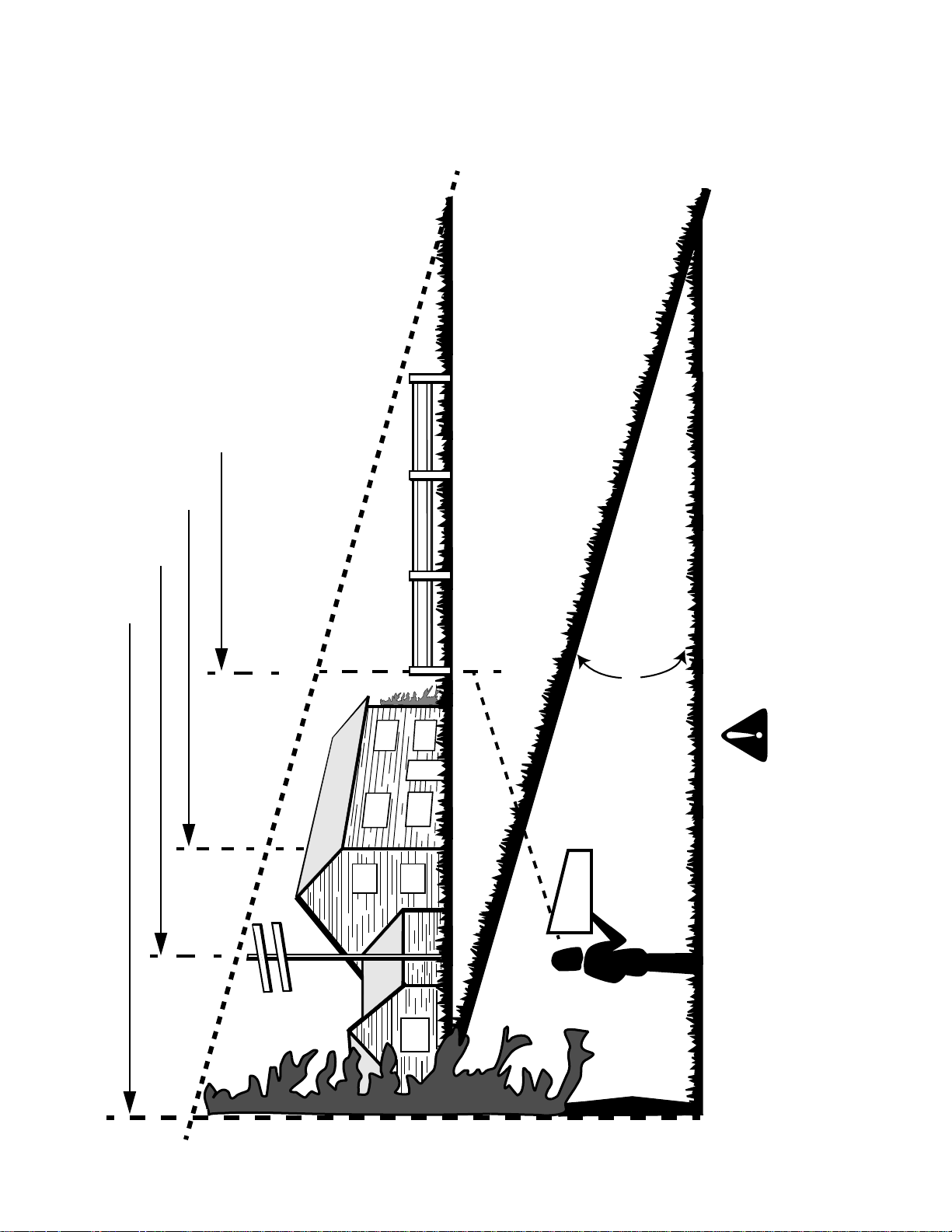

SLOPE GAUGE

E

OP

L

S

°

E

P

R

E

S

E

N

5

1

A

G

N

I

T

OR A FENCE POST

OT

D

R

,

E

N

I

L

D

E

T

15°

WARNING

USE THIS PAGE AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

F

O

D

L

ON

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet).

A riding mower could overturn and cause serious injury. If operating a walk-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RZT zero turn tractors across the face of slopes rather than up and down. Begin with the first pass

across the bottom of the slope and turn uphill at the end of each pass whenever possible.

9

Page 10

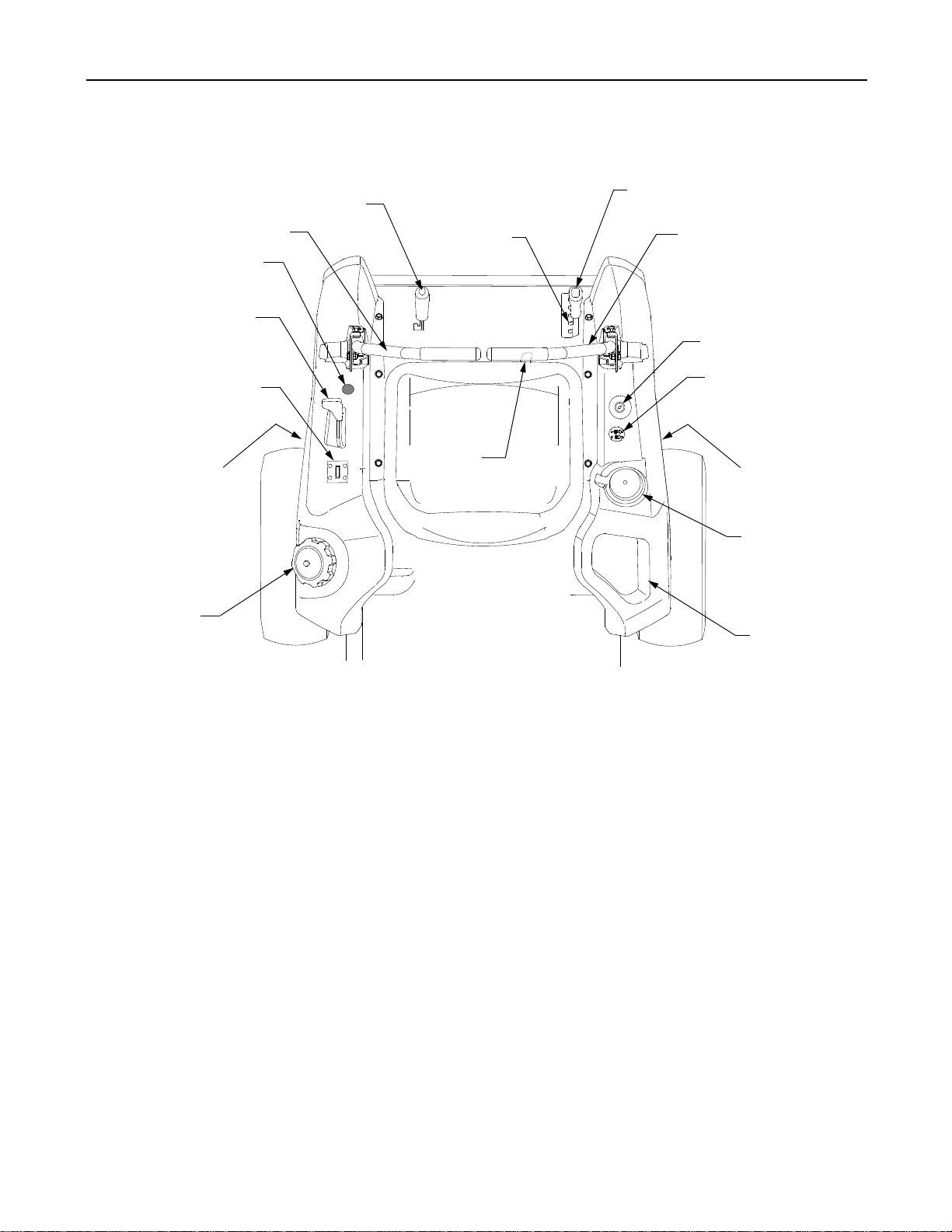

SECTION 1: CONTROLS AND FEATURES

O

C

N

M

L

F

K

A

J

B

C

D

E

F

G

H

A.

Deck Lift Handle

B.

RH and LH Drive Control Levers

C.

D.

Ignition Switch

E.

PTO Switch

F.

Transmission Bypass Rod (Not Shown)

G. Cup Holder

Figure 4

H.Deck Height Index

J.

K.

L.

M.

N.

O. Parking Brake Engagement Lever

10

Storage Tray

Seat Adjustment Lever (Not Seen)

Fuel Tank Cap

Hour Meter /Indicator Panel

Throttle Control

Choke Control—Model ZT50 ONLY

Page 11

NOTE: References to LEFT, RIGHT, FRONT, and

REAR indicate that position on the tractor when

facing forward while seated in the operator’s seat.

A. Deck Height Index

The deck height index consists of six index notches

located on the front/right of the seat box frame. Each

notch corresponds to a 1/2 inch change in the deck

height position ranging from 1-1/2 inches at the lowest notch to 4 inches at the highest notch.

B. Deck Lift Handle

The deck lift handle is located on the front/right of the

seat box frame, and is used to raise and lower the

mower deck.

Pull the handle to the left out of the index notch and

push downward to lower the deck, or pull upward to

raise the deck. When the desired height is attained,

move the lift handle to the right until fully in the index

notch.

C. RH and LH Drive Control Levers

The RH and LH control levers are located to each

side of the operator’s seat. These hinged levers open

out to the side in the neutral position to permit the

operator to be seated or to leave the tractor seat. The

levers must be fully opened out in the neutral position

to start the tractor engine.

Each lever controls the respective RH or LH transmission. Consequently, these levers control all of the

movements of the tractor. Driving and steering utilizing these control levers is quite different from

conventional tractors, and will take some practice to

master. Refer to SECTION 2: OPERATION for

instructions on using the control levers.

D. Ignition Switch

The ignition switch is located on the RH console to

the right of the operator’s seat.

The ignition switch has three positions as follow:

OFF

STOP

ON

NOTE: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the tractor is not in use.

E. Power Take-Off (PTO) Switch

The PTO switch is located on the RH console to the

right of the operator’s seat.

Figure 6

The PTO switch operates the electric PTO clutch

mounted on the bottom of the engine crankshaft. Pull

the switch knob upward to engage the PTO clutch, or

push the knob downward to disengage the clutch.

The PTO switch must be in the "disengaged" position

when starting the engine.

F. Transmission Bypass Rods (Not Shown)

The transmission bypass rods (one for each the RH

and LH transmission) are located beneath the frame

platform, just inside each rear wheel.

When engaged, the two rods open a bypass within the

hydrostatic transmissions, which allows the tractor to

be pushed short distances by hand. Refer to

SECTION 4: MAINTENANCE for instructions on

using the bypass feature.

WARNING: Never tow your tractor.

Towing the tractor with the rear wheels

on the ground may cause severe damage

to the transmissions.

G. Cup Holder

The cup holder is located toward the rear of the RH

console to the right of the operator’s seat.

START

Figure 5

OFF - The engine and electrical system is turned off.

ON - The tractor electrical system is energized.

START- The starter motor will turn over the engine.

Release the key immediately when the

engine starts

H. Storage T ray

The storage tray is located at the rear of the RH

console.

J. Seat Adjustment Lever (Not Seen)

The seat adjustment lever is located below the front/

left of the seat. The lever allows for adjustment of the

fore to aft position of the operator’s seat. Refer to

SECTION 3: ADJUSTMENTS for instructions on

adjusting the seat position.

11

Page 12

K. Fuel Tank Cap

The fuel tank cap is located at the rear of the LH

console. Turn the cap counterclockwise to unscrew

and remove from the fuel tank. Always re-install the

fuel cap tightly onto the fuel tank after removing.

WARNING: Never fill the fuel tank when

the engine is running. If the engine is hot

from recently running, allow to cool for

several minutes before refueling. Highly

flammable gasoline could splash onto

the engine and cause a fire.

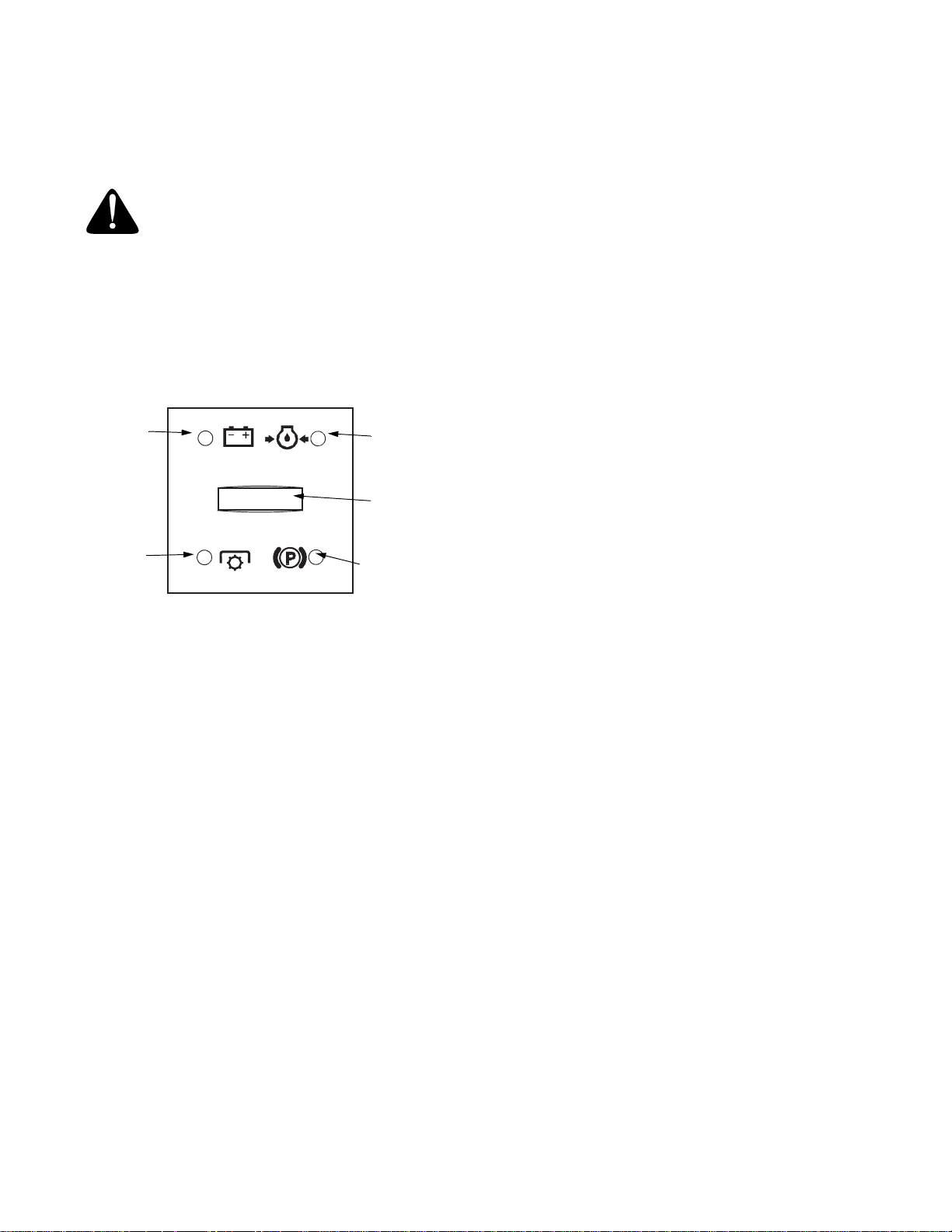

L. Hour Meter/Indicator Panel

The hour meter/indicator panel is located on the LH

console to the left of the operator’s seat.

52, 100-102, 150-152, etc.). The LCD will flash as

described for five minutes every time the tractor’s engine is started during this maintenance

interval. Follow the oil change intervals pro-

vided in the engine owner’s manual.

Indicator Panel Feature

Battery Indicator (Refer to Figure 7)

• Illuminates and the battery voltage is displayed

briefly when the ignition switch it turned to the

"ON" position.

• Illuminates to indicate the battery voltage has

dropped below 11.5 (+0.5/-1.0) volts. The battery

voltage is also displayed on the hour meter. If this

indicator and display come on during operation,

check the battery and charging system for possible causes and/or contact your dealer.

Battery

Indicator

PTO

Engaged

Indicator

Oil Pressure

Indicator

(optional)

Hour

Meter

Parking Brake

Engaged

Indicator

Figure 7

Hour Meter Feature

The hour meter records the hours that the tractor has

been operated in the digital display (tenths of an

hour-right most digit).

NOTE: The hour meter is activated whenever the igni-

tion switch is turned to the "ON" position. Keep a

record of the actual hours of operation to assure all

maintenance procedures are completed according to

the instructions in this manual and the engine manual.

• When key is turned to the "ON" position, the

battery indicator light briefly illuminates and the

battery voltage is briefly displayed. The display

then changes to the accumulated hours.

• The Indicator Monitor will also remind the operator of maintenance intervals for changing the

engine oil. The LCD will alternately flash, “CHG” ;

“OIL” and the recorded hours for five minutes

after every 50 hours of recorded operation. The

maintenance interval lasts for two hours (from 50-

Oil Pressure Indicator (Refer to Figure 7) (optional)

• This warning lamp indicates low engine oil pressure. If the indicator comes on while the engine

is running, stop the engine immediately and

check for possible causes. Do not run the engine

while this indicator is illuminated. Contact your

dealer to have the tractor and engine inspected.

NOTE: The oil pressure indicator may illuminate

when the ignition switch is in the ON position, but

should turn off when the engine is started.

PTO Engaged Indicator (Refer to Figure 7)

• This indicator illuminates when the PTO switch is

pulled upward in the "ENGAGED" position and

the ignition switch is turned to the "START"

position. Check this indicator if the engine will not

crank with the ignition switch in the "START"

position. If necessary, move the PTO switch to

the "DISENGAGED" position.

Parking Brake Engaged Indicator (Refer to Figure 7)

• This indicator illuminates when the parking brake

is in the DISENGAGED position and the ignition

switch is turned to the "START" position. Check

this indicator if the engine will not crank with the

ignition switch in the "START" position. If necessary, move the parking brake to the ENGAGED

position.

This indicator also illuminates when the ignition

switch is turned to the "START" position and the

RH and/or LH drive control levers are in a position other than the fully out in neutral position.

Move the control levers fully outward.

12

Page 13

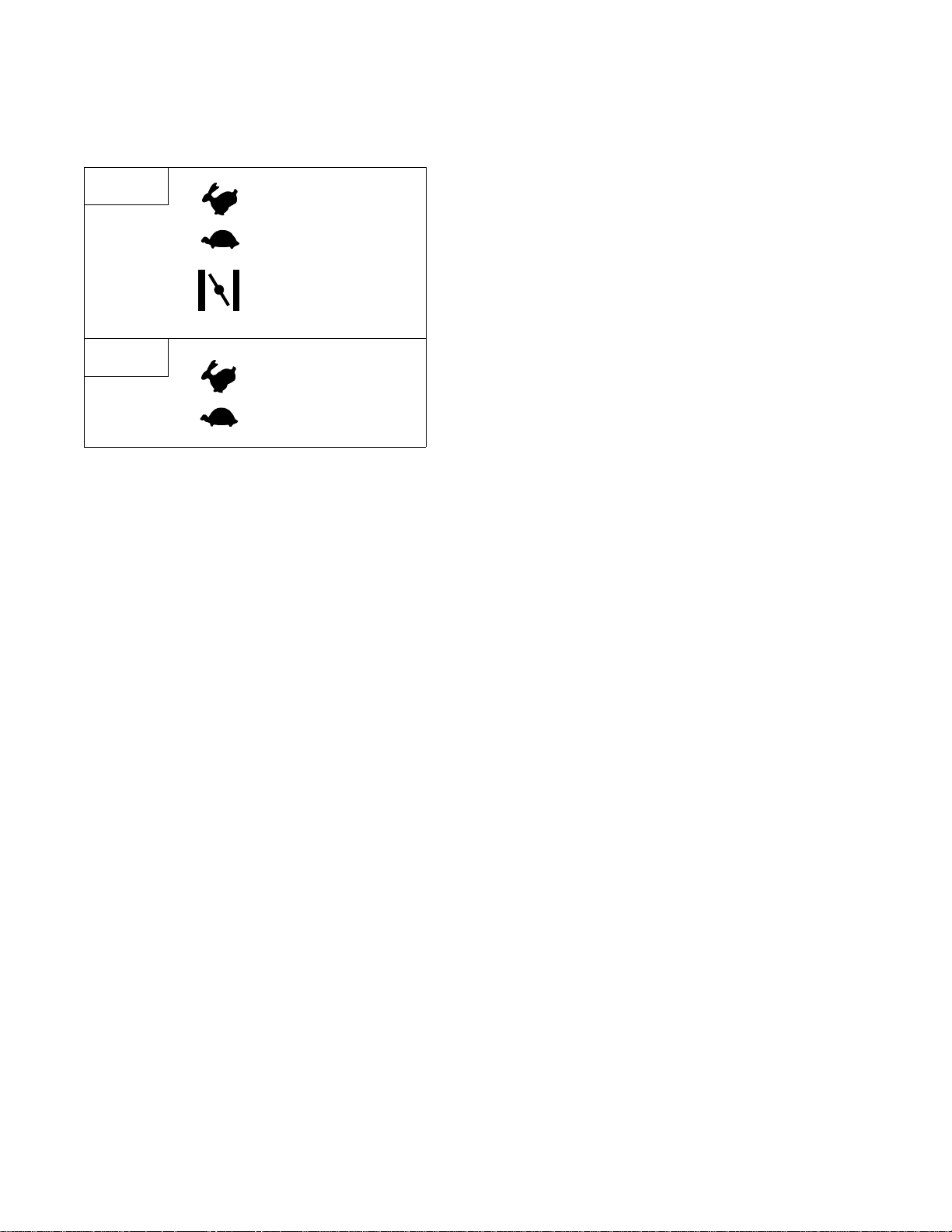

M. Throttle Control

The throttle control is located on the LH console to

the left of the operator’s seat. When set in a given

position, a uniform engine speed will be maintained.

ZT42

CHOKE

ZT50

This symbol indicates the

fast position.

This symbol indicates the

slow position.

This symbol indicates the

choke position.

This symbol indicates the

fast position.

This symbol indicates the

slow position.

Figure 8

• Push the throttle control handle forward to increase the engine speed. The tractor is designed

to operate with the control handle in the fast

position (full throttle) when the tractor is driven

and the mower deck is engaged.

• Pull the throttle control handle rearward to decrease the engine speed.

• Model ZT42 ONLY — When starting the engine,

push the control handle fully forward into the

"CHOKE" position. See Figure 8. After starting

and warming the engine, move the control handle

rearward until you feel it move past the choke

detent.

N. Choke Control - Model ZT50 ONLY

The choke knob controls the position of the engine

choke. Pull the knob out to choke the engine; push the

knob in to open the choke.

O. Parking Brake Engagement Lever

The parking brake engagement lever is located on

the front/left of the seat box frame, and is used to

engage the parking brake.

• Pull the lever fully upward and to the left and

lower into the "J" slot to engage the parking

brake.

• Pull the lever up out of the "J" slot and to the

right; then lower completely to disengage the

parking brake.

IMPORTANT: If the LH and RH drive control levers

are not fully opened out in the ne utral position when

engaging the parking brake, the engine will stop. The

parking brake must be placed in the engaged position

when starting the tractor engine.

13

Page 14

SECTION 2: OPERATION

GENERAL SAFETY

• RECEIVE INSTRUCTION - Read the operator’s

manual. Learn to operate this machine SAFELY.

Don’t risk INJURY or DEATH. Allow only those

who have become competent in its usage to

operate this tractor .

• Before starting the engine or beginning operation,

be familiar with the controls. The operator should

be in the operator’s seat. The PTO switch must

be in the disengaged position, the parking brake

engaged, and the RH and LH drive control levers

moved fully outward in the neutral position.

• Keep all shields in place. Keep away from moving

parts.

• NO RIDERS! Keep all people and pets a safe

distance away. Look behind and down to both

sides of the tractor before and while backing up.

• DO NOT direct the mower discharge at people.

• Avoid slopes where possible. Never operate on

slopes greater than 15°. Slopes with a greater

incline present dangerous operating conditions.

Tractors can be rolled over.

• Before leaving the operator’s seat: Shut off the

PTO, move the RH and LH drive control levers

fully outward in the neutral position, engage the

parking brake, shut off the engine and remove

the ignition key. Wait for all movement to stop

before servicing or cleaning.

• Operate the drive control levers smoothly and

avoid any sudden movements of the levers

when starting and stopping. Keep a firm grip on

the control levers.

• Be careful when operating near roadways. Stop

the tractor motion and wait for vehicles to pass

before operating along the road.

• Do not operate the tractor with the mower deck

removed. Removal of the deck will change the

balance of the tractor, and could contribute to a

tractor rollover.

• Avoid operation on traction surfaces that are

unstable; use extreme caution if the surface is

slippery.

• Slow down before turning and come to a

complete stop before any zero turn maneuver.

• Do not stop the tractor or park the tractor over

combustible materials such as dry grass, leaves,

debris, etc.

• Do not fill the fuel tank when the engine is

running or while the engine is hot. Allow the

engine several minutes to cool before refueling.

Tighten the fuel cap securely.

BEFORE OPERATING YOUR TRACTOR

• Before you operate the tractor, study this manual

carefully. It has been prepared to help you

operate and maintain your tractor efficiently.

• This engine is certified to operate on unleaded

gasoline. For best results, fill the fuel tank with

only clean, fresh, unleaded regular or premium

gasoline. DO NOt use leaded gasoline.

• Some fuels are gasoline blended with alcohols or

ethers. The maximum alcohol percentage for ethanol and gasahol blends is 10%. The maximum

ether percentage for MTBE or ETBE blends is

15%. If undesirable operating symptoms occur,

use gasoline with a lower percentage of alcohol

or ether. Do not use gasoline that contains

Methanol.

• Check the engine oil level. See Engine Manual.

IMPORTANT: Your tractor is shipped with motor

oil in the engine. However, you MUST check the

oil level before operating. The capacity of the

engine and oil filter is approximately 62 oz. (1.83

liters) for the model ZT42 and 80 oz. (2.36 liters).

for the model ZT50. Be careful not to overfill.

• Clean the air cleaner element if necessary. See

Engine Manual.

• Check the tire inflation pressures.

• Adjust the seat for operator’s maximum comfort,

visibility, and for maintaining complete control of

the tractor.

SAFETY INTERLOCK SYSTEM

This tractor is equipped with a safety interlock system

for the protection of the operator. If the interlock system

should ever malfunction, do not operate the tractor.

Contact your authorized Dealer.

• The safety interlock system prevents the engine

from cranking or starting unless the RH and LH

drive control levers are moved fully outward in the

neutral position, the parking brake is engaged,

and the PTO is disengaged.

• To avoid sudden movement when disengaging

the parking brake, the safety interlock system will

shut off the engine if the RH and/or LH drive

control levers are moved to a position other than

the fully out in neutral position when the parking

brake is engaged

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

14

Page 15

• The safety interlock system will shut off the

engine if the operator leaves the seat with the

PTO engaged, regardless of whether the parking

brake is engaged.

NOTE: The PTO switch must be moved to the

“OFF” position to restart the engine.

• The safety interlock system will shut off the PTO

and the mower blades will stop if both drive control levers are moved into the reverse position.

The PTO will re-engage when one or both of the

levers are moved back to the neutral or forward

position.

STARTING THE ENGINE

WARNING: For personal safety, the

operator must be sitting in the tractor

seat when starting the engine.

WARNING: This unit is equipped with a

safety interlock system designed for the

protection of the operator. Do not operate the tractor if any part of the interlock

system is malfunctioning. Periodically

check the functions of th e interlock system for proper operation.

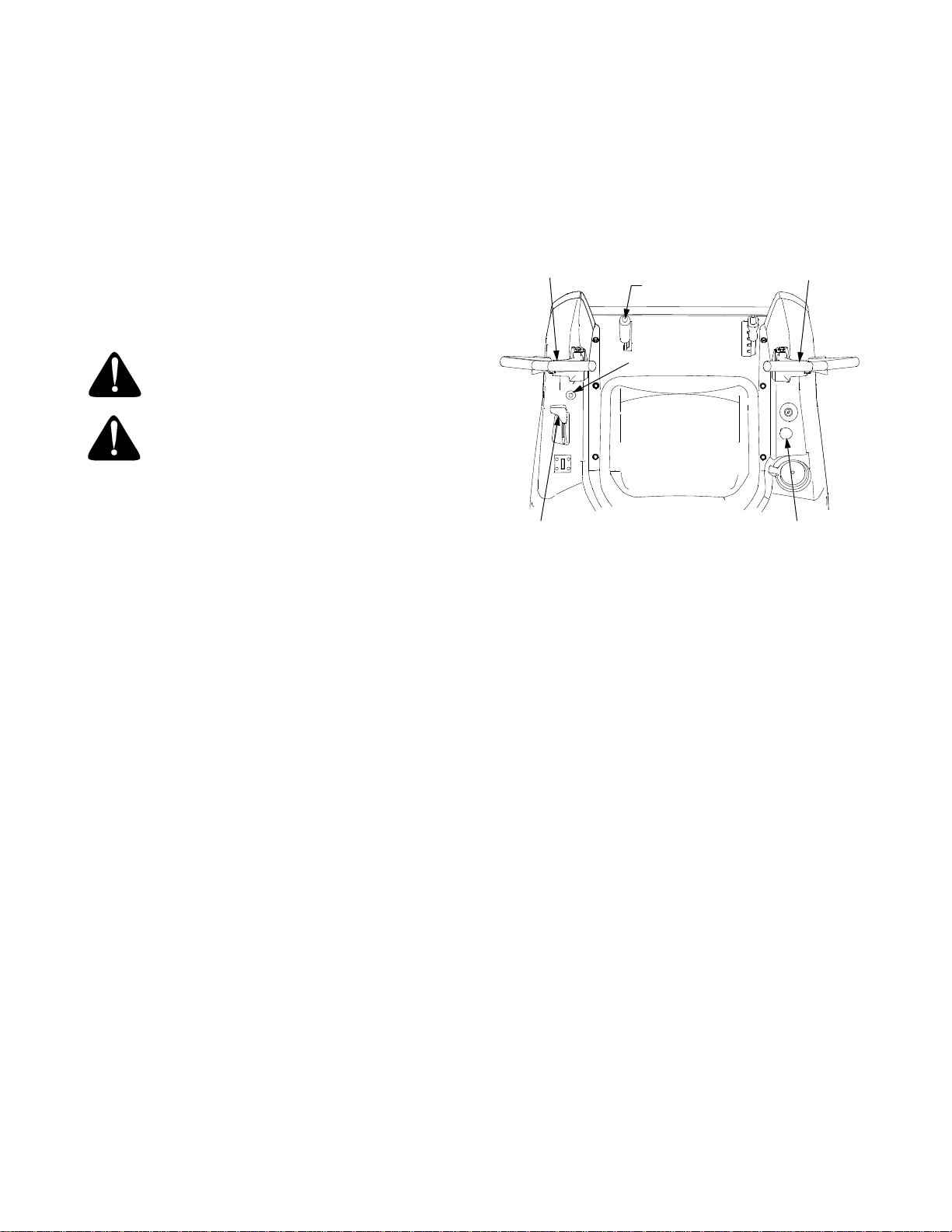

• Move the RH and LH drive control levers fully

outward in the neutral position. Refer to Figure 9.

• Operator must be sitting in the tractor seat.

• Engage the parking brake. Refer to Figure 9.

• Make certain the PTO switch is in the disengaged (down) position. Refer to Figure 9.

• Model ZT42 ONLY

1. Move the throttle control lever fully forward

into the "CHOKE" position. NOTE: If the

engine is warmed up, it may not be ne cessary

to place the throttle control in the choke

position.

2. Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine continuously for more than 5 seconds at a time. If

the engine does not start within this time, turn

the key to “OFF” and wait a minute. Try again

after waiting.

3. After the engine starts, gradually pull the

throttle control lever rearward past the choke

detent position to the FAST position. Do not

use the choke to enrich the fuel mixture,

except as necessary to start the engine.

• Model ZT50 ONLY

1. Pull the choke control knob upward to the full

choke position. NOTE: If the engine is warmed

up, it may not be necessary to choke the

engine.

2. Move the throttle control lever fully forward to

the "fast" position.

LH Control Lever

Out in Neutral

ZT42 - Move Throttle

Control to Choke

ZT50 - Move Throttle

Control to "FAST"

Parking Brake

Engaged

ZT50 - Pull Choke

RH Control Lever

Out in Neutral

PTO Switch in Down

(Disengaged) Position

Figure 9

3. Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine

continuously for more than 5 seconds at a

time. If the engine does not start within this

time, turn the key to “OFF” and wait a minute

to allow the engine’s starter motor to cool. Try

again after waiting.

4. As the engine warms up, gradually push the

choke knob downward to open the choke. Do

not use the choke to enrich the fuel mixture,

except as necessary to start the engine.

• Allow the engine to run for a few minutes at mid

throttle before putting the engine under load.

• Observe the hour meter/indicator panel. If the

battery indicator light comes on, immediately stop

the engine. Have the tractor inspected by your

dealer.

15

Page 16

COLD WEATHER STARTING

When starting the engine at temperatures near or

below freezing, ensure the correct viscosity motor oil

is used in the engine and the battery is fully charged.

Start the engine as follows:

• Be sure the battery is in good condition. A warm

battery has much more starting capacity than a

cold battery.

• Use fresh winter grade fuel. Winter grade

gasoline has higher volatility to improve starting.

Do not use gasoline left over from summer.

• Follow the previous instruction for STARTING

THE ENGINE.

USING JUMPER CABLES TO START ENGINE

WARNING: Batteries contain sulfuric acid

and produce explosive gasses. Make

certain the area is well ventilated, wear

gloves and eye protection, and avoid

sparks or flames near the battery.

If the battery charge is not sufficient to crank the

engine, recharge the battery. If a battery charger is

unavailable and the tractor must be started, the aid of

a booster battery will be necessary. Connect the

booster battery as follows:

• Connect the end of one cable to the disabled

tractor battery’s positive terminal; then connect

the other end of that cable to the booster

battery’s positive terminal.

• Connect one end of the other cable to the booster

battery’s negative terminal; then connect the

other end of that cable to the frame of the disabled tractor, as far from the battery as possible.

• Start the disabled tractor following the normal

starting instructions previously provided; then

disconnect the jumper cables in the exact reverse

order of their connection.

• Have the tractor’s electrical system checked and

repaired as soon as possible to eliminate the

need for jump starting.

STOPPING THE ENGINE

• Place the PTO switch in the “OFF” position.

• Move the RH and LH drive control levers fully

outward in the neutral position.

• Engage the parking brake.

• Place the throttle control lever in the slow (idle)

position. Run the engine for a short time to let

engine speed stabilize at the idle speed.

• Turn the ignition key to the “OFF” position and

remove the key from the ignition switch.

NOTE:

switch to prevent accidental starting or battery

discharge if the equipment is left unattended.

PRACTICE OPERATION (INITIAL USE)

Operating a zero-turn tractor is not like operating a

conventional type riding tractor. Although and because a zero-turn tractor is more maneuverable, getting used to operating the control levers takes some

practice.

We strongly recommend that you locate a reasonably large, level and open "practice area" where there

are no obstructions, pedestrians, or animals. You

should practice operating the tractor for a minimum of

30 minutes.

Carefully move (or have moved) the tractor to the

practice area. When performing the practice session,

the PTO should not be engaged. While practicing,

operate the tractor at approximately 1/2-3/4 throttle

and at less than full speed in both forward and

reverse.

Carefully practice maneuvering the tractor using the

instructions in the following section "Driving the Tractor." Practice until you are confident that you can

safely operate the tractor.

DRIVING THE TRACTOR

• Adjust the operator’s seat to the most

• Release the parking brake.

Always remove the key from the ignition

WARNING: Avoid sudden starts, excessive speed and sudden stops.

WARNING: Do not leave the seat of the

tractor without disengaging the PTO,

moving drive control levers fully outward

in the neutral position, and engaging the

parking brake. If leaving the tractor

unattended, turn the ignition key off and

remove key.

comfortable position that allows you to operate

the controls. See seat adjustment in the

ADJUSTMENTS section.

16

Page 17

• Move the RH and LH drive control levers inward

in the neutral position. See Figure 10.

Control Lever Moved

Inward and in Neutral

Figure 10

NOTE: If the control levers are not e ven in the neu tral

position, refer to Section 3 and adjust the levers so

that they are even.

• Move the throttle control lever forward to the full

throttle position (3500-3600 RPM).

NOTE: The tractor and engine are designed to run at

full throttle. If performing a practice session, it is

preferable that the tractor is operated at less than full

throttle (approximately 2500-3000 RPM), but this only

applies to practice operation.

NOTE: For Model ZT42, make certain the throttle

control has not been moved too far forward into the

"Choke" position.

WARNING: Always maintain a firm grip

on the control levers. DO NOT release the

control levers to slow or stop the tractor;

move the levers to the neutral position

using your hands.

• To drive the tractor, firmly grasp the respective

drive control levers with your right and left hands

and proceed as follows :

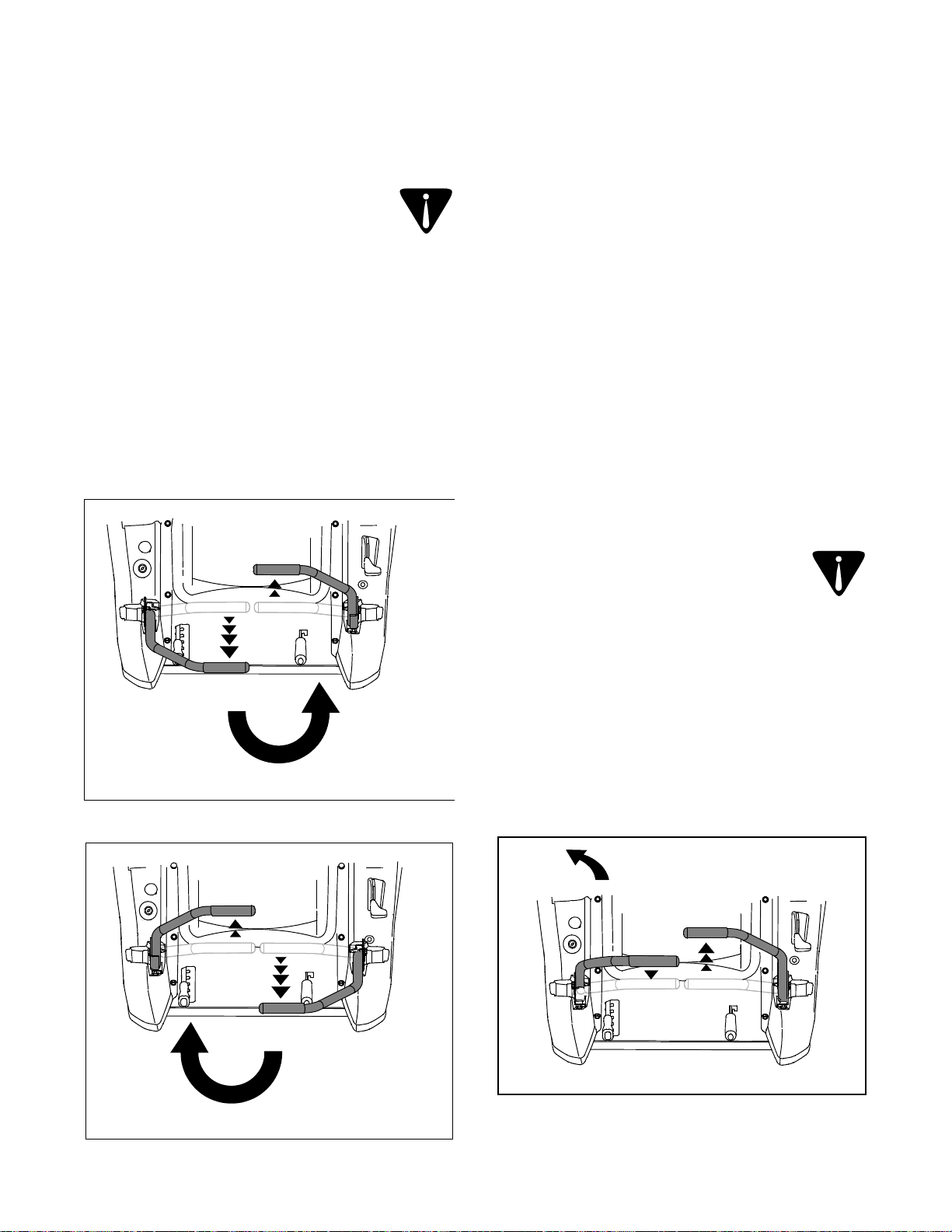

Driving the Tractor Forward

WARNING: Keep all movement of the

drive control levers slow and smooth.

Abrubt movement of the control levers

can affect the stability of the tractor and

could cause the tractor to flip over,

which may result in serious injury or

death to the operator.

• Slowly and evenly move both drive control levers

forward. The tractor will start to move forward.

See Figure 11.

• As the control levers are pushed farther forward

the speed of the tractor will increase.

DRIVING FORWARD

Faster

Slower

Neutral

Position

Figure 11

• To slow the tractor move the controls lever

rearward to attain the desired speed, or move the

levers to the neutral position to stop the tractor.

IMPORTANT: Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral.

Turning the Tractor While Driving Forward

WARNING: When reversing the direction

of travel, we recommend performing

gradual ‘U’ turns where possible.

Sharper turns increase the possibility of

turf defacement, and could affect control

of the tractor. ALWAYS slow the tractor

before making sharp turns.

• To turn the tractor while driving forward, move the

control levers as necessary so that one lever is

rearward of the other. The tractor will turn in the

direction of the rearward control lever.

- To turn to the left, move the left drive control

lever rearward of the right lever. See Figure 12.

FORWARD LEFT TURN

Figure 12

17

Page 18

- To turn to the right, move the right drive control

lever rearward of the left lever. See Figure 13.

FORWARD RIGHT TURN

Figure 13

• The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

• To execute a "pivot turn," move the turn side

drive control lever to the neutral position, while

moving the other control lever forward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

IMPORTANT: Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral.

Turning While Driving Rearward

• To turn the tractor while driving rearward, move

the control levers as necessary so that one lever

is forward of the other. The tractor will turn in the

direction of the forward control lever.

- To turn to the left while traveling in reverse,

move the left drive control lever forward of the

right lever. See Figure 15.

REARWARD LEFT TURN

Driving the Tractor In Reverse

WARNING: Always look behind and

down on both sides of the tractor before

backing up. Always look behind while

traveling in the reverse direction.

• Slowly and evenly move both drive control levers

rearward. The tractor will start to move in the

reverse direction. See Figure 14.

DRIVING REARWARD

Neutral

Position

Slower

Faster

Figure 14

• As the control levers are pushed farther rearward

the speed of the tractor will increase.

• To slow the tractor move the controls lever

forward to attain the desired speed, or move the

levers to the neutral position to stop the tractor.

Figure 15

- To turn to the right while traveling in reverse,

move the right drive control lever forward of the

left lever. See Figure 16.

REARWARD RIGHT TURN

Figure 16

• The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

• To execute a "pivot turn," move the turn side

drive control lever to the neutral position, while

moving the other control lever rearward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

18

Page 19

Executing a Zero Turn

WARNING: When executing a zero turn,

the tractor MUST BE STOPPED.

Executing a zero turn while the tractor is

moving can significantly reduce your

control of the tractor and will cause

severe turf defacement to occur.

• Stop the forward or reverse motion of the tractor

by moving the two drive control levers to neutral.

• To turn clockwise, slowly move the left control

lever forward while simultaneously moving the

right control lever rearward. See Figure 17.

CLOCKWISE ZERO TURN

Figure 17

• To turn counterclockwise, slowly move the right

control lever forward while simultaneously moving

the left control lever rearward. See Figure 18.

COUNTERCLOCKWISE ZERO TURN

Figure 18

STOPPING THE TRACTOR

• Move both drive control levers to the neutral

position to stop the motion of the tractor.

• Push the PTO switch downward to the

disengaged position.

• Use the deck lift handle to raise the deck to its

highest position.

• If dismounting the tractor:

- Move the drive control handles fully outward in

the neutral position.

- Engage the parking brake.

- Move the throttle control lever to the fast

position if operating a ZT42 tractor, or to the

slow position if operating a ZT50 tractor.

- Turn the ignition switch to “OFF’” and remove

the key from the switch.

DRIVING ON SLOPES

Refer to the SLOPE GAUGE on page 10 to help

determine slopes where you may not operate safely.

WARNING: Do not operate on inclines

with a slope in excess of 15 degrees (a

rise of approximatel y 2-1/2 feet every 10

feet). The tractor could overturn and

cause serious injury.

• Always drive across slopes, never up and down.

Control the speed and direction of the tractor

using primarily the control lever on the downhill

side of the tractor, with the uphill control lever

remaining essentially in a fixed position.

• Avoid turning downhill if possible. Start at the

bottom of a slope and work upward. Always slow

down before turning.

• Use extra care and go slowly when turning

downhill.

OPERATING THE PTO

Operate the PTO clutch as follows:

• Move the throttle control lever to approximately

the mid throttle position.

• Pull the PTO switch upward to the “ENGAGED”

position.

• Advance the throttle lever to the operating speed

(full engine speed).

• The operator must remain in the tractor seat at all

times. If the operator should leave the seat

without turning off the power take-off switch, the

tractor’s engine will shut off.

• The PTO clutch cannot be operated when the

tractor is driving in the reverse direction. The

PTO will disengage when both drive control

levers are moved to the reverse position, and will

re-engage when one (or both) control levers are

moved to the neutral or forward position.

19

Page 20

USING THE MOWER DECK

WARNING: Make certain the area to be

mowed is free of debris, sticks, stones,

wire or other objects that can be thrown

by the rotating blades.

IMPORTANT: Do not engage the mower deck

when lowered in grass. Premature wear and

possible failure of the ‘V” belt and PTO clutch will

result. Fully raise the deck or move to a non

grassy area before engaging the mower deck.

• Mow across slopes, not up and down. If mowing

a slope, start at bottom and work upward to

ensure turns are made uphill.

• On the first pass pick a point on the opposite side

of the area to be mowed.

• Engage the PTO clutch using the PTO switch and

move the throttle control to the fast position.

• Lower the mower deck to the desired height

setting using the lift handle.

• Slowly and evenly push the RH and LH drive

control levers forward to move the tractor

forward, and keep the tractor headed directly

toward the alignment point.

NOTE: The speed of the tractor will affect the

quality of the mower cut. Mowing at full speed will

adversely affect the cut quality. Control the

ground speed with the control levers.

• When approaching the other end of the strip,

slow down or stop before turning. A U-turn is

recommended unless a pivot or zero turn is

required.

• Align the mower with an edge of the mowed strip

and overlap approximately 3 inches.

• Direct the tractor on each subsequent strip to

align with a previously cut strip.

• To prevent rutting or grooving of the turf, if

possible, change the direction that the strips are

mowed by approximately 45° for the next and

each subsequent mowing.

WARNING: Be careful when crossing

gravel paths or driveways. Disengage

the PTO and raise the deck to the

highest position before crossing.

IMPORTANT: When stopping the tractor for any

reason while on a grass surface, always:

• Place the shift lever in neutral,

• Engage the parking brake,

• Shut engine off and remove the key.

Doing so will minimize the possibility of having your

lawn ‘‘browned’’ by hot exhaust from your tractor’s

running engine.

CHECKING THE SAFETY INTERLOCK CIRCUITS

Periodically check the safety interlock circuits to

ensure they are working properly. If a safety circuit is

not working as designed, contact you dealer to have

the tractor inspected. DO NOT operate the tractor if

any safety circuit is not functioning properly. To check

the safety circuits, proceed as follows:

• Sitting in the tractor seat with both drive control

levers opened fully outward, disengage the

parking brake and momentarily turn the ignition

switch to the start position. The engine should not

crank.

• Engage the parking brake and pull the PTO

switch upward to the engaged position.

Momentarily turn the ignition switch to the start

position; the engine should not crank.

• Push the PTO switch downward to the disengaged position and engage the parking brake.

Start the engine and move one of the drive control levers from the fully outward neutral position.

The engine should stop running. Repeat the procedure with the opposite control lever.

• Move both control levers fully outward in the neutral position and disengage the parking brake;

then lift upward from the operator’s seat. The

engine should stop.

• With both control levers fully outward in the neutral position and the parking brake engaged,

engage the PTO. Lift upward from the operator’s

seat; the engine should stop.

• Start the tractor, disengage the parking brake,

and move the control levers inward to the neutral

operating position. Engage the PTO and move

both control lever slowly into the slow reverse

position; the PTO should disengage and the

mower deck should stop until one or both of the

control levers are moved to the neutral or forward position.

20

Page 21

SECTION 3: ADJUSTMENTS

ADJUSTING THE OPERATORS SEAT

• To adjust the position of the seat, move and hold

the seat adjustment lever toward the left. Slide

the seat forward or rearward to the desired

position; then release the adjustment lever. Make

sure seat is locked into position before operating

the tractor. See Figure 19.

Seat

Move Lever

to Left

Adjustment

Lever

Figure 19

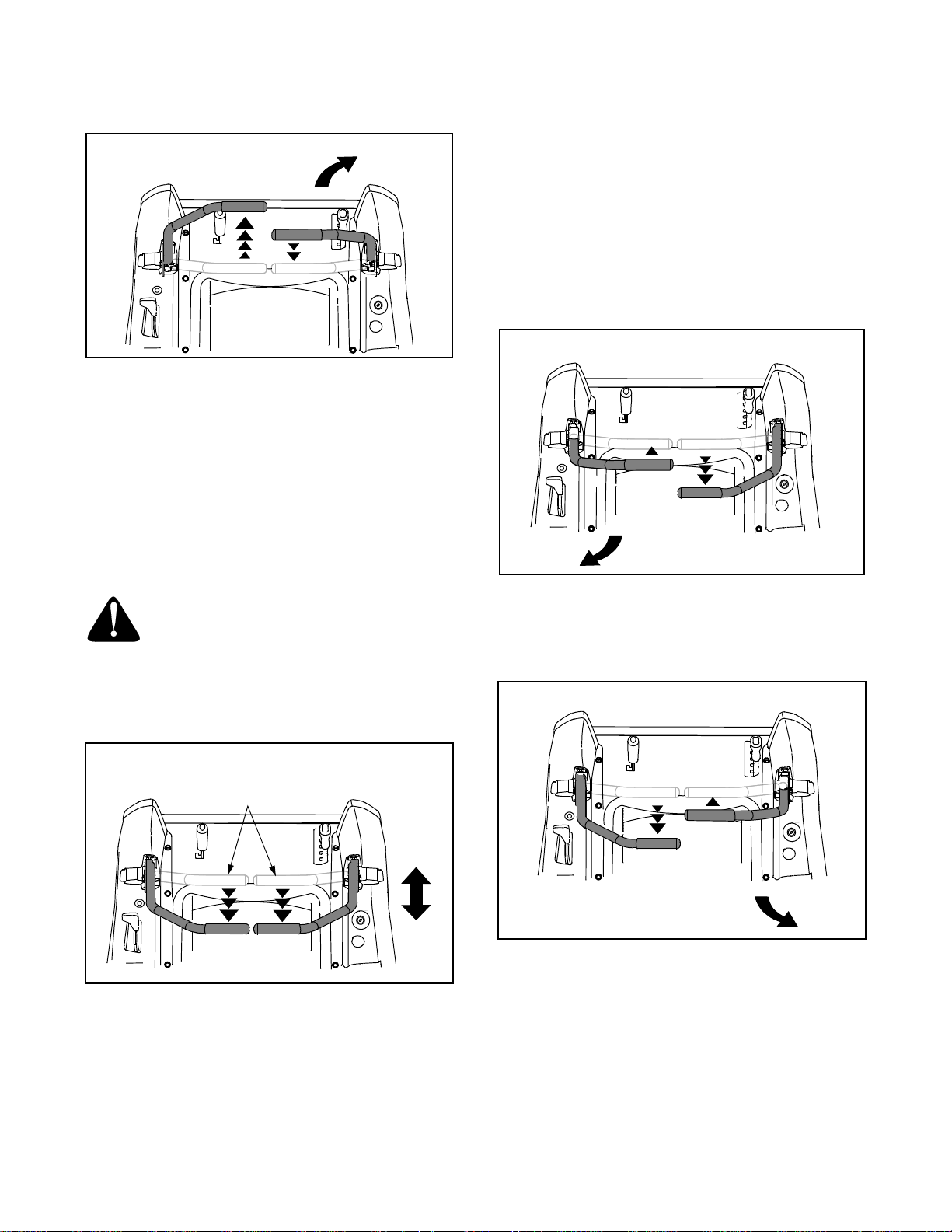

ADJUSTING RH & LH DRIVE CONTROL LEVERS

The RH and LH drive control levers can be adjusted

up or down and fore-and-aft for the comfort of the

operator. The drive control levers can be placed in

either of two height positions, or can be moved

forward or rearward within the range of the slot in

each control lever mounting bracket.

To adjust the drive control lever height, proceed as

follows:

• Remove the nut knob, bell washer, and carriage

bolt securing the lever to the pivot bracket.

• While supporting the control lever to keep it from

falling, remove the hex insert flange lock nut and

shoulder screw from the bottom of the control

lever and pivot bracket. Refer to Figure 20.

• Reposition the control lever to align with the other

set of holes in the pivot bracket and insert the

shoulder screw removed earlier. Fasten with the

hex insert flange lock nut and tighten until snug.

• Insert the hex screw w/washer through the

control lever slot and the pivot bracket.Thread the

flange lock nut onto the screw, but do not tighten

now.

• If you are going to adjust the control levers

forward or rearward, proceed to the next step. If

not, fully the flange lock nut.

Pivot Bracket

Flange

Lock Nut

Height

Adjust

Holes

Slot

Control Lever

Flat Washer

Hex Screw

Shoulder

Screw

Figure 20

To adjust the drive control levers forward or rearward,

proceed as follows:

If not already loose, loosen the flange lock nut and

rotate the control lever either forward or rearward to

the desired position. See Figure 20.

NOTE: If the control lever is too tight to move, slightly

loosen the hex insert flange lock nut and shoulder

screw at the bottom of the control lever.

• Tighten the flange lock nut to fix the control lever

in the adjusted position

• Repeat the above procedure to adjust the other

control lever into the same position. Adjust so

that both levers are even with each other when in

the neutral position.

21

Page 22

SECTION 4: MAINTENANCE

ENGINE MAINTENANCE

Engine maintenance procedures and schedules can

be found in the engine manual. Follow those instructions for performing engine maintenance.

Using the Engine Oil Drain Valve

• Run the engine for a short time to warm the

engine oil. The oil will flow more freely and carry

away more impurities Use care to avoid burns

from hot oil.

• Locate the oil drain hose on the RIGHT side of

the engine. Refer to Figure 21.

• Route the free end of the oil drain hose toward an

appropriate oil collection container with at least a

2.5 quart capacity, to collect the used oil.

Remove the oil fill cap/dipstick from the oil fill

tube.

• While holding the free end of the oil drain hose

over the oil collection container, unscrew the

square head hose plug from the end of the hose.

See Figure 21. Drain the engine oil into the

collection container.

• After draining the oil, wipe any residual oil from

the oil drain hose. Thread the square head plug

into the drain hose fitting and fully tighten the

plug.

• Replace the oil filter, and refill the engine with

new oil as instructed in the separate engine

manual.

Protective

Cap

GENERAL BATTERY INFORMATION

WARING

• Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands

after handling.

• Should battery acid accidentally splatter into the

eyes or onto the skin, rinse the affected area

immediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

• If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia/

water or baking soda/water.

• NEVER connect (or disconnect) battery charger

clips to the battery while the charger is turned on,

as it can cause sparks.

• Keep all sources of ignition (cigarettes, matches,

lighters) away from the battery. The hydrogen

gas generated during charging can be

combustible.

• As a further precaution, only charge the battery in

a well ventilated area.

• Always shield eyes and protect skin and clothing

when working near batteries.

WARNING: Batteries contain sulfuric

acid and may emit explosive gases. Use

extreme caution when handling batteries. Keep batteries out of the reach of

children.

BATTERY REMOVAL

Oil Drain

Hose

Turn and

Pull Out

Oil Drain

Valve

Figure 21

HYDROSTATIC TRANSMISSION MAINTENANCE

The zero turn tractor is equipped with dual integrated

hydrostatic pumps, motors, and transaxles that are

sealed and do not require regular maintenance. All

service work on the hydrostatic transmissions should

be performed by your dealer.

WARNING: Battery posts, terminals and

related accessories contain lead and

lead compounds. Wash hands after

handling.

The battery is located on the right/rear of the tractor

beneath the seat box frame.

To remove the battery:

• Remove the two hex tapping screws from the battery holddown bracket and remove the bracket.

Use care to avoid losing the trim strip from the

bottom of the bracket.

• Remove the hex cap screw and sems nut securing the black negative battery lead to the negative

battery post (marked NEG). Move the cable away

from the negative battery post.

• Remove the hex cap screw and sems nut securing the red positive battery lead to the positive

battery post (marked POS).

22

Page 23

• Carefully lift the battery out of the tractor.

Install the battery by repeating the above steps in the

reverse order.

WARNING: Always connect the positive

lead to the battery before connecting the

negative lead. This will prevent sparking

or possible injury from an electrical short

caused by contacting the tractor body

with tools being used to connect the

cables.

CHARGING THE BATTERY

Test and, if necessary, recharge the battery after the

tractor has been stored for a period of time.

• A voltmeter or load tester should read 12.6 volts

(DC) or higher across the battery terminals.

• Charge the battery with a 12-volt battery charger

at a MAXIMUM rate of 10 amps.

• Recharge the battery before returning to service.

Although the tractor may start, the engine charging

system may not fully recharge the battery.

SERVICING ELECTRICAL SYSTEM

A fuse is installed to protect the tractor’s electrical

system from damage caused by excessive amperage. Always use the same capacity fuse for

replacement. If the electrical system does not function, check for a blown fuse. See Figure 22

If you have a recurring problem with blown fuses,

have the tractor’s electrical system checked by your

dealer.

GOOD

BAD

Figure 22

Voltmeter

Reading

12.7 100% Full Charge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

State of

Charge

Charging

Time

BATTERY MAINTENANCE

The battery is filled with battery acid and then sealed

at the factory. However, even a “maintenance free”

battery requires some maintenance to ensure its

proper life cycle.

• Spray the terminals and exposed wire with a

battery terminal sealer, or coat the terminals with

a thin coat of grease or petroleum jelly, to protect

against corrosion.

• Always keep the battery cables and terminals

clean and free of corrosion.

• Avoid tipping. Even a sealed battery will leak

electrolyte when tipped.

BATTERY STORAGE

• When storing the tractor for extended periods,

disconnect the negative battery cable. It is not

necessary to remove the battery.

• All batteries discharge during storage. Keep the

exterior of the battery clean, especially the top. A

dirty battery will discharge more rapidly.

• The battery must be stored with a full charge. A

discharged battery can freeze sooner than a

charged battery. A fully charged battery will store

longer in cold temperatures than hot.

Relays and Switches

There are several safety switches in the electrical

system. If a function of the safety interlock system

described earlier is not functioning properly, have the

electrical system checked by your dealer.

LUBRICATION

• Using a pressure lubricating gun, lubricate the

front castor axles and pivot axle with a No. 2

multi-purpose grease after every 10 hours of

service.

• Refer to the "MOWER DECK" section later in this

manual for deck lubrication procedures.

• Periodically lubricate all other pivot points with a

quality lubricating oil.

TIRE MAINTENANCE

Check the tire air pressure after every 50 hours of

operation or weekly. Keep the tires inflated to the

recommended pressures. Improper inflation will

shorten the service life of a tire. See the tire side wall

for proper inflation pressures. Observe the following

guidelines:

• Do not inflate a tire above the maximum pressure

shown on the sidewall of the tire.

• Do not reinflate a tire that has been run flat or

seriously under inflated. Have a qualified tire

mechanic inspect and service the tire.

23

Page 24

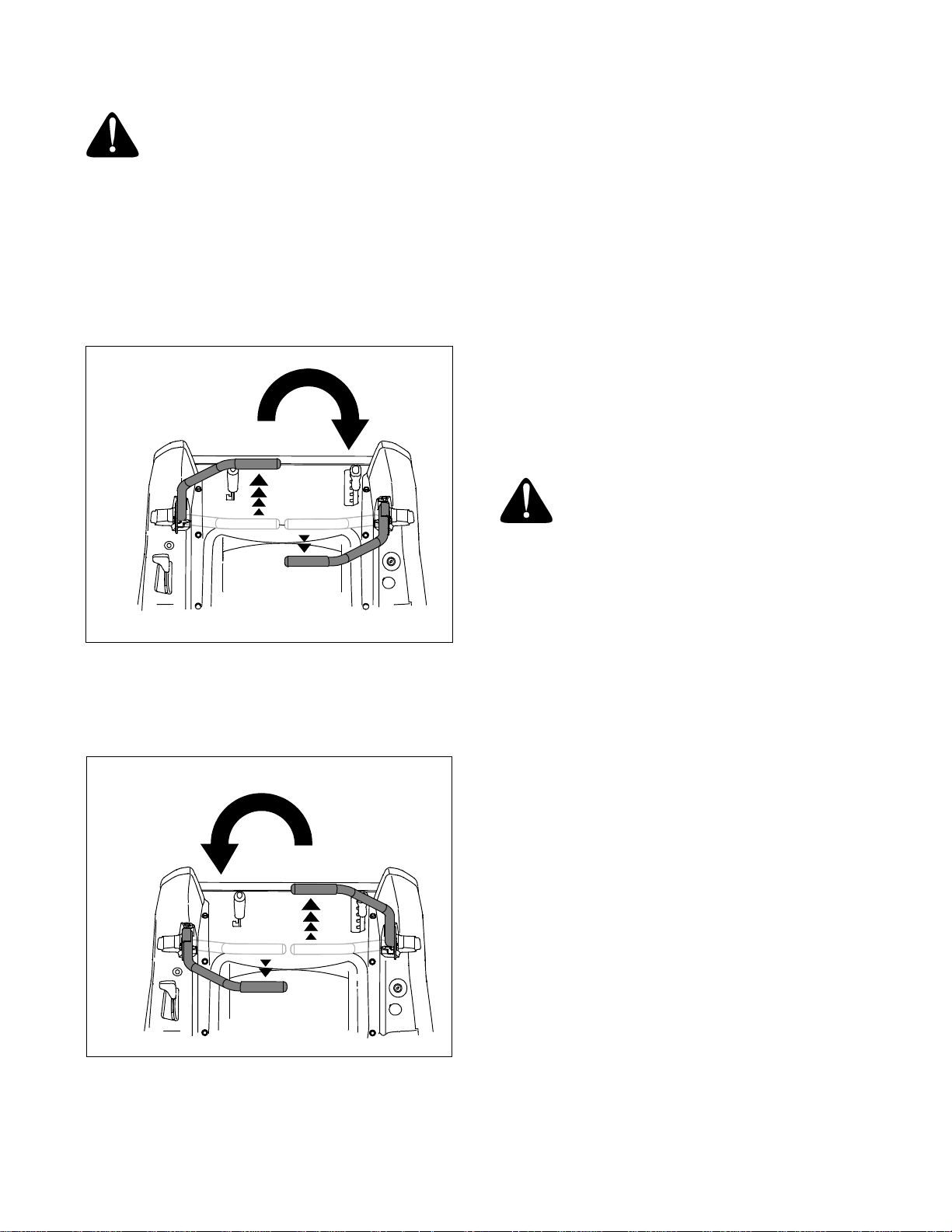

USING THE TRANSMISSION BYPASS RODS

If for any reason the tractor will not drive or you wish

to move the tractor, the two hydrostatic transmissions are equipped with bypass rod that will allow you

to manually move the tractor short distances.

WARNING: Do not tow the tractor, even

with the bypass rod engaged. Serious

transmission damage will result from

doing so.

• From just in front of the two rear tires, locate the

transmission bypass rods. See Figure 23.

• Pull one rod toward the front of the tractor until

the flange on the rod is forward of the keyhole

slot in the frame assembly.

• Lower the bypass rod into the keyhole slot and

release so the rod flange is against the front of

the frame bracket.

• Repeat the above procedure to engage the other

bypass rod.

RH Transmission

Bypass Rod

Pull out

Bypass Rod

Then Lower

In Slot

TRACTOR CREEPING

Creeping is the slight forward or backward movement

of the tractor when the engine is running at high idle

and the drive control levers are opened out in the

neutral position.

If after operating the tractor for some time, it begins to

creep while in the neutral position, adjust the

transmission control rods as follows.

• Place the front of the tractor against an

immovable object (e.g. wall, post, etc.).

• Jack up the rear of the tractor so that both rear

wheels are approximately one inch of the ground.

• With the engine running at high idle and the drive

control levers opened out in the neutral position,

and the parking brake disengaged, check the rear

wheels for rotation.

• If only one wheel is rotating, locate the transmission control rod beneath the frame at the front of

the rear tire. If both wheels rotate, locate both

control rods. See Figure 24.

RH Transmission

Control Rod

Internal

Cotter Pin

Keyhole

Slot

Figure 23

• After moving the tractor, disengage both bypass

rods. Lift the rod and guide the flange of the rod

back through the larger circular opening of the

keyhole, then release the rod.

IMPORTANT: The tractor will not drive with the

bypass rods in the engage position.

Ferrule

Transmission

Control Arm

Figure 24

• Remove the internal cotter pin securing the

ferrule to the transmission control arm and

withdraw the ferrule. Wheel rotation should stop.

If it does not, contact your White Outdoor dealer.

• If the rotation stops, adjust the ferrule up or down

the control rod as necessary to align with the hole

in the transmission control arm. Re-insert the

ferrule into the hole in the control arm and secure

with the internal cotter pin.

• If necessary, repeat the previous two steps to

adjust the other transmission control rod.

• Lower the tractor and remove the jack.

24

Page 25

TRACTOR HIGH SPEED TRACKING

If the tractor tracks to one side with both drive control

levers fully forward, adjust the control levers as

follows:

• Check for proper and balanced air pressure in

both front and rear tires. Refill tires if necessary.