Page 1

Professional Shop Manual

Z-Force S

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2010 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-05513

06/2010

Page 2

Page 3

Table of Contents

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Professional Shop Manual intent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description of the Z-Force-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model and Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Engine Related Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel tank removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 3: Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Brake system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Brake adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Brake puck/rotor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brake shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parking brake lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4: Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Floor pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Left control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Right control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Seat box assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5: Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Drive belt adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EZT transmission removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ZT 2800 transmission removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Drive pedal biasing adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hydro neutral control adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6: Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wheel alignment and drive control link adjustments . . . . . . . . . . . . . . . . . . . . 43

Steering gear box removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Steering gearbox installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rebuilding the steering gear box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Front wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Front yokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removal of the steering gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Tie rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Steering shaft, bushings and dampener removal . . . . . . . . . . . . . . . . . . . . . . 79

I

Page 4

Chapter 7: Electrical System ..............................................................................87

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

RMC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Key switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

RMC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

To identify a faulty RMC module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Parking Brake Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Reverse Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Seat Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Starter solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

PTO Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Lighting circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Run Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Run Circuit / Reverse Caution mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Engine shut-down circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Charging circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

PTO Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Reverse Mower Control (RMC) circuit operation . . . . . . . . . . . . . . . . . . . . . 109

Electrical diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Electrical environment: AC Vs. DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Ohm’s Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Kirchhoff’s current law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Kirchhoff’s voltage law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

How the system is wired together . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Types of circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Series/parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Shorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Increased resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

The Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Digital Multi-meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Wiring diagram or schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Fused jumper wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Test lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Self-powered continuity lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Ammeters and specialized charging system testers . . . . . . . . . . . . . . . . . . . 120

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Charging the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Checking battery condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Battery Testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Adjustable load testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

II

Page 5

Fixed load testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Conductance testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Battery discharge test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Storage of batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Electrical Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Voltage Drop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Testing switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Chapter 8: Decks And Lift Shaft....................................................................... 137

Cutting decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Cleaning the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

To clean the deck while it is removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

PTO belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Deck Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Belt tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Spindle pulleys and spindle shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Spindle removal/installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Spindle overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Leveling the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Side to Side Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Front To Rear (pitch) Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Deck Gauge Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Front and rear deck lift shaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Deck lift pedal lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Chapter 9: Maintenance Intervals .....................................................................155

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Engine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

The spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Air filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Oil filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Servicing the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Clean the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

III

Page 6

IV

Page 7

Introduction

CHAPTER 1: INTRODUCTION

Professional Shop Manual intent

This Manual is intended to provide service dealers with an introduction to the mechanical aspect s o f the Z-Force-

S riding mower.

• Detailed service information about the engine will be provided by the engine manufacturer, in most cases.

Disclaimer: The information contained in this manual is correct at the time of writing. Both the product and the information about the product are subject to change without notice.

About the text format:

NOTE: is used to point out information that is relevant to the pro cedure, bu t doe s not fit as a step in the pr oce dure.

• Bullet points: indicate sub-steps or points.

! CA UTION! CA UTION

! WA RNI NG! WA RNI NG

! DANGER! DANGER

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD or Cub Cadet be liable for poor text interpretation or poor execution of the procedures described in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or Cub Cadet Technical Support.

Fasteners

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

Warning indicates a potentially hazardous situation that, if not avoi ded, could result in death of

serious injury.

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

• Most of the fasteners used on these mowers are sized in fractional inches. The engine and transmissio ns

are metric. For this reason, wrench sizes are frequently identified in the text, and measur ements are given

in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

1

Page 8

Z-Force-S

Assembly

Torque specifications may be noted in the part of the text that covers assembly , they may also be summarized in

tables along with special instructions regarding locking or lubrication. Whichever method is more appropriate will be

used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-bystep procedure guide that does not require the user to hunt for information.

The level of assembly instructions provided will be determined by the complexity and of reassembly, and by the

potential for unsafe conditions to arise from mistakes made in assembly.

Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating the same

procedure two or three times in the manual.

Description of the Z-Force-S

The Z-Force-S combines a traditional Z-force lap bar

zero turn rider (ZTR) with Cub Cadet’s patented Syncro

TM

Steer

that turn the front wheels much further than conventional

systems. The steering control is linked to the traction drive

system control.

technology.

The magic of the system: variable ratio steering gears

The traction drive system synchronizes the steering

angle of the front tires

rear tires.

with the speed and direction of the

A true zero-turn is achieved when the operator turns

the steering wheel far enough that the inside rear wheel

spins in reverse just like a traditional lap-bar controlled

ZTR.

Figure 1.1

2

Page 9

Model and Serial Numbers

Introduction

The model and serial number tag can be found under

the seat. See Figure 1.2.

Model number

The model number is 17AI5BHB010. The break down of what the number mean is as follows:

1...............................................................................................Residential machine

....7...........................................................................................Residential zero turn mower

.......A...... ... ....................................... ... .... ... ... ... .... ....................Sales level

...........I....................................................... ... ... .... ... ... ... ... .... ....Engine code

.............5..................................................................................Frame

Serial number

Figure 1.2

The serial number is located to the right of the model n um ber as shown above. See Figure 1.2.

.................B..............................................................................Transmission (B = EZT, G = ZT2800)

....................H ..........................................................................Style series

.........................B......................................................................Deck (B = 48”, D = 60”)

.............................010..............................................................Customer number

The serial number is 0J149Z20021. The serial number reads as follows:

0...............................................................................................Engineering level

..J .............................................................................................Month of production (J = October)

.....14........................................................................................Day of the month

.........9......................................................................................Last digit of the year

...........Z......... ... ... .......................................... ... .... ....................Plant it was built in (Streetsboro, OH)

..............2.................................................................................Assembly line number

.................0005........................................................................Number of unit built

3

Page 10

Z-Force-S

4

Page 11

Engine Related Parts

CHAPTER 2: ENGINE RELATED PARTS

This chapter will cover the engine accessories that are manufactured by Cub Cadet.

IMPORTANT: The engine is manufactured by Kawasaki. Refer to the Kawasaki manual for engine specific

service information.

Muffler

Remove the muffler by following these steps:

Bumper

1. Remove the six nuts and bolts (three on each side)

that hold the rear bumper in place using a pair of 1/2”

wrenches.

2. Slide the bumper out from between the frame, the

fuel tank bracket on the right and utility bin bracket on

the left.

Fuel tank

support bracket

See Figure 2.1.

13 mm wrench size

Figure 2.1

Figure 2.2

Exhaust pipe

3. Remove the two nuts that hold each exhaust pipe to

the cylinder head using a 13 mm wrench.

See Figure 2.2.

4. Remove the muffler and exhaust pipes.

NOTE: The exhaust pipes are welded to the muffler. The

pipes and the muffler are serviced as one assem

bly.

5. Clean and remove all gasket material from the cylinder head (and the exhaust pipe if they are being

reused).

6. Using new gaskets, install the muffler by following the

previous steps in reverse order.

NOTE: Tighten the exhaust nuts to a torque of 120 ft lbs

(14Nm).

NOTE: When installing the bumper, insert all six bolts

before tightening them. Otherwise the bumper will

bind and the holes will not line up.

-

7. Test drive the mower in a safe area before returning it

to service.

5

Page 12

Z-Force-S

Fuel tank removal/replacement

Remove/replace the fuel tank by following these steps:

Gasoline and its vapors are extremely flammable. Use common sens e when working aroun d

! CAUTION! CAUTION

1. Clamp off the fuel line between the fuel tank and the

fuel filter.

2. Disconnect the fuel line from the fuel tank at the fuel

filter.

3. Drain the fuel into an approved container.

the fuel system

Fuel filter

4. Remove the fuel tank by removing the four screws

that hold it to the support brackets using a 9/16”

wrench.

5. Install the fuel tank by following the previous steps

in reverse order.

6. Test drive the mower in a safe area before returning

it to service.

See Figure 2.4.

Fuel line from the fuel tank

Figure 2.3

Support brackets

Figure 2.4

6

Page 13

Brakes

CHAPTER 3: BRAKES

Brake system description

The Z-Force-S uses twin HydroGear transmissions to drive the re ar wheels. The hydrau lic action of the tr ansmissions will provide the braking for the mower while it is in motion. There is a friction brake on the transmission, but it is

used as a parking brake.

NOTE: Mowers equipped with a 48” deck have HydroGear EZT transmissions with the brakes on the inboa rd

side of the transmissions (shown below). Mowers with the 60” deck are equipped with HydroGear

ZT2800 transmissions. The brakes for the ZT2800 transmissions are mounted to the frame of the

mower on the outboard side of the transmissions. The brakes for both the EZT and the ZT2800 trans

missions function and are serviced the same way.

-

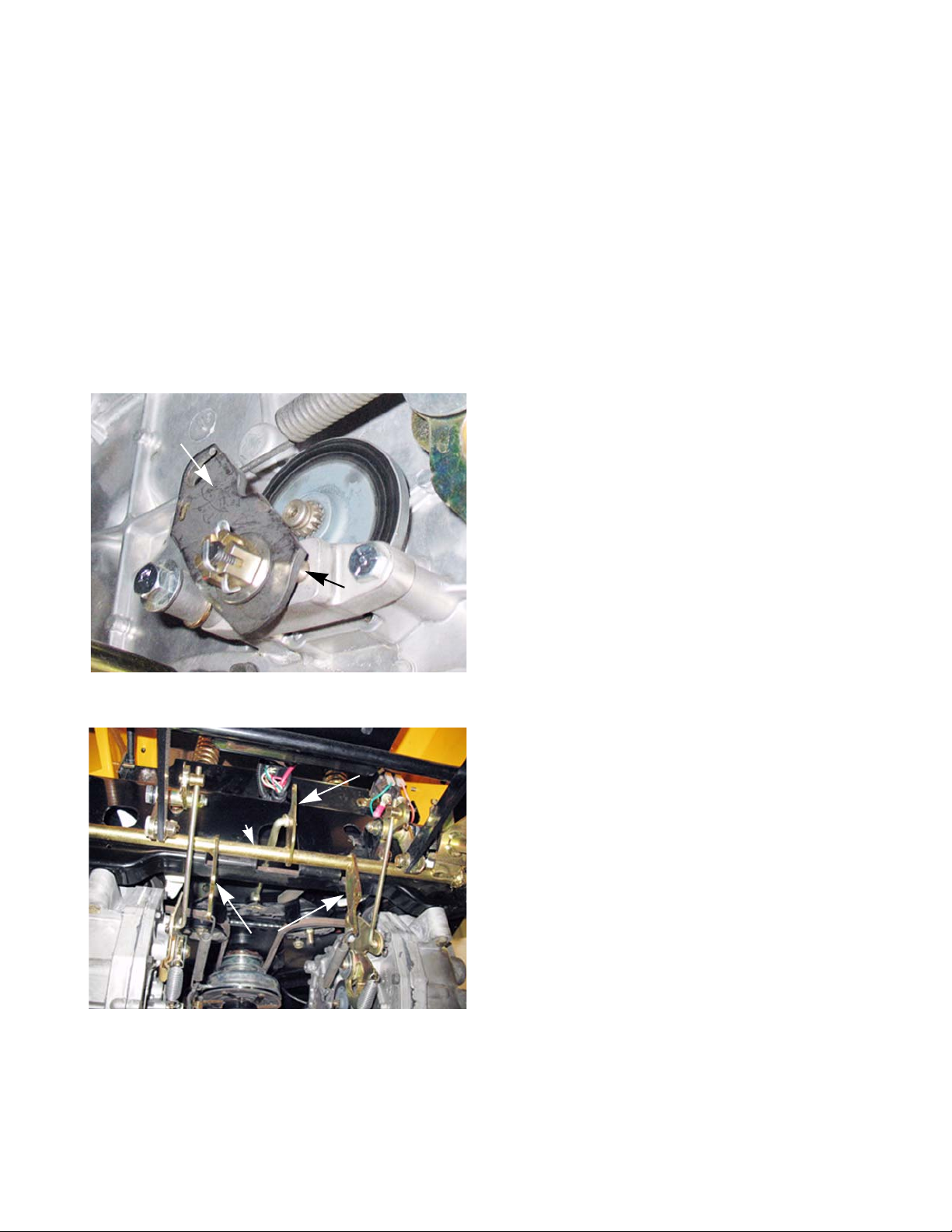

Cam arm

Brake

shaft

Figure 3.1

Brake pins

Center bell

crank

• There is a brake for each transmission.

• They are activated by moving the parking brake

lever to the “ON” position.

• The parking brake lever operates the brake shaft.

• The brake shaft has three bell cranks. The two

outer bell cranks are for applying the brakes. They

are connected to the brake caliper cam arms by

extension springs.

• When the cam arms are pulled forward, they push

on the brake pins with a cam action applying pres

sure to the brake pads. See Figure 3.1.

• The center bell crank on the brake cross shaft

assembly has a link that is connected to the drive

belt idler pulley bracket. When the parking brakes

are applied, the idler pulleys are pulled away from

the drive belt. This de-tensions the belt, disengag

ing drive to the transmissions. See Figure 3.2. The

adjustment procedure for the brake link is covered

in the drive belt adjustment section of Chapter 5:

Drive.

-

-

Brake bell

cranks

Figure 3.2

7

Page 14

Z-Force-S

Brake adjustment

NOTE: When performing a brake adjustment, inspect the brake components for signs of wear or damage.

1. Block the front wheels.

2. Lift and safely support the rear of the mower.

NOTE: Make sure the parking brake is released.

3. Remove the cotter pin locking the castle nut on the

brake caliper.

4. Back the castle nut off a few turns using a 9/16”

wrench.

NOTE: Even if the brakes are set to the correct

5. Insert a 0.030” (0.8 mm) feeler gauge between the

brake rotor and the outboard brake puck.

See Figure 3.4.

NOTE: The tolerance for the brake clearan ce is

See Figure 3.3.

clearance, inserting a feeler gauge between

the rotor and the brake puck can be very dif

ficult. Loosen the castle nut first, then insert

the feeler gauge and tighten the nut to set

the proper clearances

0.020” - 0.040” (0.5 - 1.0mm). The 0.030

feeler gauge will set the clearance at the

midpoint.

Castellated nut

-

Cotter pin

Figure 3.3

6. Tighten the nut un til there is slig ht drag on the feeler

gauge.

NOTE: For even braking, both sides should be set

to the same clearance.

7. Install a new cotter pin.

8. Repeat same procedure on the other side.

9. Take the mower off of the jack stands.

10. Open the by-pass valves and check the parking brake before ret urnin g th e mo we r to serv ice .

• With the brakes released, the mower should have only hydraulic drag when it is pushed.

• With the brakes engaged, the wheels should slide before they rotate when the mower is pushed.

11. Test drive the mower in a safe area before returning it to service.

0.030” feeler

gauge

Figure 3.4

8

Page 15

Brakes

Brake puck/rotor replacement

On HydroGear transmissions, the brake pucks are wearing parts that will need to be serviced from time to time. If

a mower is operated with the parking brake dragging, the pucks will wear out rapidly and the brake rotor will develop

hot spots. If the mower is operated long enough, the rotor may have grinding marks on it with excessively worn

pucks.

! CA UTION! CA UTION

The brake pucks and the rotors are serviced at the same time. To service the brake pucks:

If the rotor shows hot spots or any other signs of damage, including warpage, it must be

replaced. Failure to do so can result in the failure of the brakes

Brake spring

Figure 3.5

1. Lift and safely support the rear of the mower.

2. Make sure the parking brake is released.

3. Disconnect the brake springs. See Figure 3.5.

Loosen this bolt

4. Loosen the rear mounting bolt. See Figure 3.6.

Remove this

bolt

Figure 3.6

9

Page 16

Z-Force-S

5. Remove the front mounting bolt, allowing the caliper

to swing down.

6. The outboard brake puck should fall out when the

brake caliper swings down. If it did not, it can be

removed now.

7. Slide the brake rotor off to reach the inboard brake

puck.

See Figure 3.8.

See Figure 3.7.

Caliper

Figure 3.7

8. Remove the caliper for inspection when servicing

the brake pucks. To do this, remove the rear bolt

loosened in step 4.

9. With the caliper on a work bench, remove the brake

puck, backing plate and the two brake pins.

See Figure 3.9.

10. Check for free movement of the brake pins. A dry

lubricant can be used on the brake pins sparingly.

Never put grease or anti-seize on

! CA UTION! CA UTION

of the pucks.

brake pins. It can migrate to the brake

pucks, preventing the braking action

Inboard brake

puck

Figure 3.8

Brake caliper

Brake pins

Backing plate

11. Slide the brake pins into the caliper.

12. Place the backing plate in the caliper.

10

Brake puck

Figure 3.9

Page 17

Brakes

13. Place a new puck into the caliper. See Figure 3.10.

NOTE: A piece of scotch tape may be used to hold the

new brake pucks in place for assembly. The tape

will grind away when the brakes are applied.

14. Place a new brake puck into the recess in the transmission. Use a piece of scotch tape to hold it in place.

15. Slide the brake rotor in place, shoulder out.

Brake caliper re-assembled

Figure 3.10

19. Repeat steps 4-19 on the other side.

20. When both sides are completed, take the mower off of the jack stands.

21. Open the by-pass valves and check the parking brake before ret urnin g th e mo we r to serv ice .

• With the brakes released, the mower should have only hydraulic drag when it is pushed.

• With the brakes engaged, the wheels should slide before they rotate when the mower is pushed.

22. Test drive the mower in a safe area before returning it to service.

16. Mount the brake caliper to the transmission. Apply a

small amount of releasable thread locking compound

such as Loctite® 242 (blue) to the mounting bolt s and

tighten to a torque of 80 - 120 in-lbs (9 - 13.5Nm).

17. Reconnect the brake spring.

18. Adjust the brakes as described in the previous section of this chapter.

11

Page 18

Z-Force-S

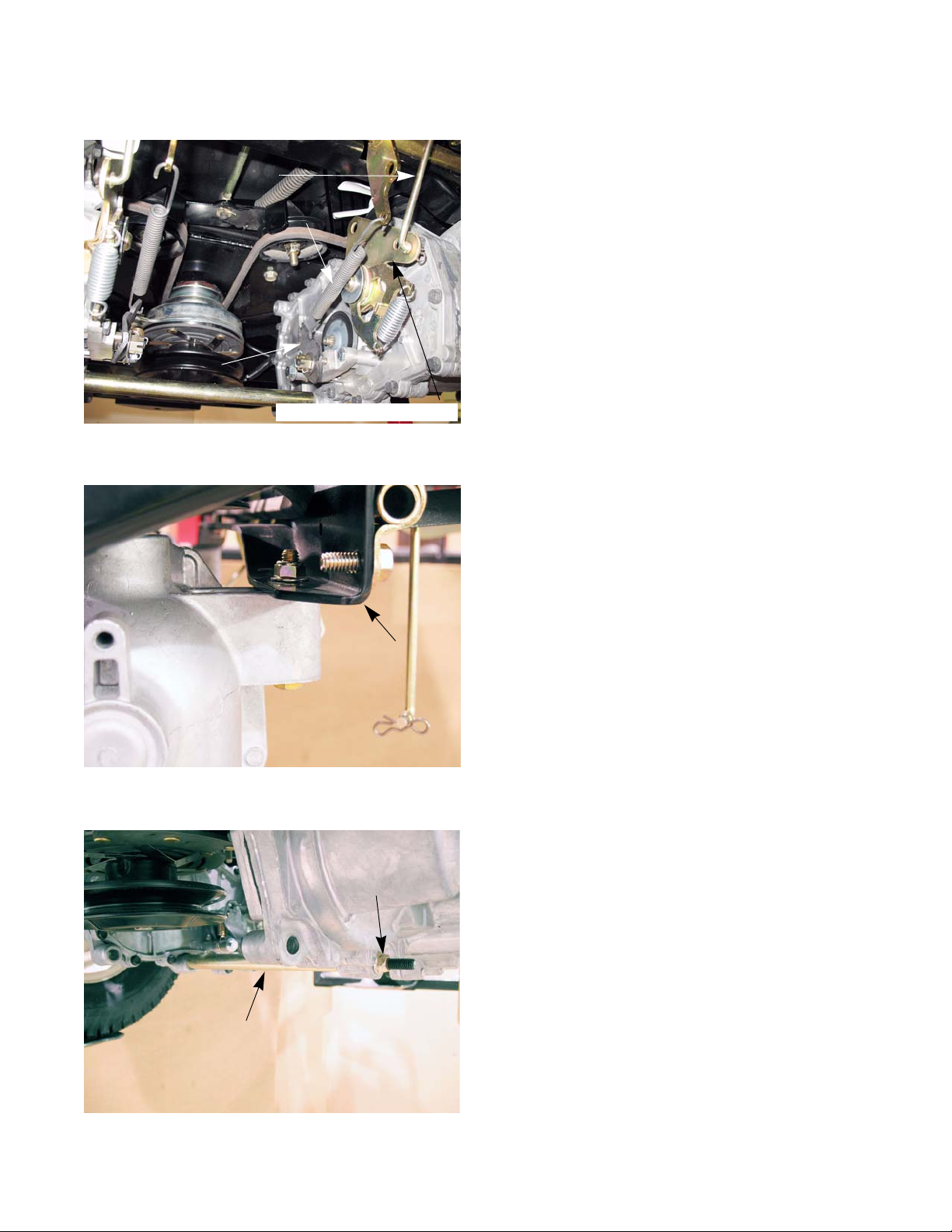

Brake shaft assembly

To remove/replace the brake shaft:

1. Remove the cutting deck by following the procedures described in Chapter 8: Cutting Decks and

Lift shaft.

2. Lift and safely support the rear of the mower.

3. If the parking brake is set, release it.

4. Disconnect the brake springs. See Figure 3.11.

5. Disconnect the link that runs from the idler bracket

to the brake shaft by removing the cotter pin.

See Figure 3.12.

Brake springs

Figure 3.11

Cotter pin

Link

6. Disconnect the adjustable drive links from the pivot

arms by removing the bow tie clips at the ferrule end

of the link.

12

See Figure 3.13.

Figure 3.12

bow tie clip

Adjustable drive

links

Figure 3.13

Page 19

Brakes

Spring

9/16” wrench

3/4” wrench

Figure 3.14

Clamp

Brake lever

Brake shaft

7. Remove the extension spring that runs from the

brake lever to the brake shaft.

8. Remove the nut and shoulder bolt that attaches the

brake lever to the brake shaft using a 9/16” wrench

and a 3/4” wrench.

9. Remove the clamps (one on each side) that hold the

brake shaft to the frame of the mower. Use a 1/2”

wrench.

10. Install the brake shaft by following the previous step s

in reverse order.

See Figure 3.15.

See Figure 3.14.

Figure 3.15

1 1. T est drive the mower in a safe area before returning it

to service.

13

Page 20

Z-Force-S

Parking brake lever

To remove/replace the parking brake lever:

1. Remove the cutting deck by following the procedures described in Chapter 8: Cutting Decks and

Lift shaft.

Spring

2. Move the parking brake lever to the “OFF” position.

3. Remove the extension spring that runs from the

brake lever to the brake shaft.

NOTE: When the parking brake lever is in the “ON”

position, this spring pulls on the lever apply

ing pressure to the parking brake switch.

4. Remove the two screws from the underside of the

left control panel using a T-30 torx driver.

See Figure 3.17.

See Figure 3.16.

Brake lever

Brake shaft

-

Figure 3.16

5. Remove the grip from the parking brake lever.

See Figure 3.18.

6. Remove the two screws that hold the left control

panel to the seat box assembly using a T-30 torx

driver.

See Figure 3.18.

7. Remove the two screws that hold the control panel

to the control pods using a T-30 torx driver.

Left control panel

Figure 3.17

Grip

Screws

Figure 3.18

14

Page 21

Parking brake spring

9/16” wrench

3/4” wrench

Figure 3.19

Brakes

8. Carefully raise the control panel enough to gain

access to the inside of the control pod.

9. Disconnect the spring that runs from the parking

brake lever to the frame of the mower.

See Figure 3.19.

10. Remove the nut and shoulder bolt that attach the

brake lever to the brake shaft using a 9/16” wrench

and a 3/4” wrench.

11. Remove the parking brake lever.

See Figure 3.20.

Figure 3.20

Parking brake lever

Clamp

Plastic bushings

12. Remove and inspect the plastic bushings for signs of

wear or damage.

NOTE: If there are signs of damage or wear, replace the

bushings.

13. Install the parking brake lever by following the previous steps in reverse order.

14. Test drive the mower in a safe area before returning it

to service.

Shoulder bolt

Nylock nut

Figure 3.21

15

Page 22

Z-Force-S

16

Page 23

Floor pan

Body

CHAPTER 4: BODY

Screws

Figure 4.1

Deck lift pedal

Tilt steering pedal

Clevis pin

Spacer

To remove/replace the floor pan:

1. Remove the deck by following the procedures

described in Chapter 8: Decks and Lift Shafts.

2. Remove the two screws that hold the tilt steering

pedal using a T-30 torx driver.

3. Remove the tilt steering pedal.

4. Remove the rear nut, bolt and spacer from the deck

lift indexing bracket using a pair of 9/16” wrenches.

See Figure 4.2.

5. Remove the clevis pin from the deck lift indexing

bracket.

See Figure 4.2.

See Figure 4.1.

Shoulder bolt

Lift pedal arm

Deck lift indexing bracket

Figure 4.2

6. Lower the deck lift pedal.

7. Remove the pedal by removing the shoulder bolt and

nut using a pair of 9/16” wrenches.

NOTE: On mowers equipped with a 60” deck, there are

two lift assist springs. With the deck removed,

these springs will hold the lift pedal arm in the for

ward position with great force.

-

17

Page 24

Z-Force-S

8. Remove the reverse pedal using a 7/16” wrench.

See Figure 4.3.

9. Remove the drive pedal using a 1/2” wrench.

See Figure 4.3.

Drive pedal

Reverse pedal

Figure 4.3

10. Remove the eight screws that hold the floor pan to

the frame using a T-30 torx driver.

NOTE: The two outboard screws next to the seat

box are longer than the rest. They also pass

through a pair of spacers.

11. Lift the floor pan off of the mower.

NOTE: Under the floor pan there are two spacers.

See Figure 4.5.

12. Install the floor pan by following the previous steps

in reverse order.

See Figure 4.4.

Long screw

Long

screw

Figure 4.4

Spacers

18

Figure 4.5

Page 25

Left control console

Body

left control panel

Screws

Figure 4.6

To remove/replace the left side control console:

1. Disconnect the negative battery cable.

2. Remove the deck by following the procedures

described in Chapter 8: Decks and Lift Shafts.

Release the parking brake before

! CA UTION! CA UTION

3. Remove the two screws from the underside of the left

control panel using a T-30 torx driver.

NOTE: Technicians with good dexterity can remove the

RMC module, PTO switch and hour meter with out

removing the left control panel.

• Release the parking brake

• Remove the four screws that hold the park brake

locking plate to the control panel.

• Gentle lower the locking bracket to prevent dam-

age to the parking brake switch.

• Reach into the opening to access the switches.

the control panel.

See Figure 4.6.

Ground cable

Figure 4.7

PTO clutch harness

4. Disconnect the PTO clutch harness. See Figure 4.7.

5. Disconnect the ground cable from the frame.

See Figure 4.7.

19

Page 26

Z-Force-S

6. Disconnect the engine harness from the main harness. See Figure 4.8.

7. Disconnect the starter cable. See Figure 4.8.

8. Remove the grip from the parking brake lever.

See Figure 4.9.

9. Remove the two screws that hold the left control

panel to the seat box assembly using a T-30 torx

driver.

See Figure 4.9.

10. Remove the two screws that hold the control panel

to the control consoles using a T-30 torx driver.

Starter

cable

Engine harness

connector

Figure 4.8

Grip

11. Carefully lift up on the control panel to gain access

to the wiring under it.

12. Disconnect the wiring harness from the switches

and modules.

13. Lift the control panel off of the mower.

NOTE: If the control panel is being replaced,

See Figure 4.10.

remove the switches and modules from it

and install them on the new control panel.

Screws

Figure 4.9

RMC module

Hour meter

Key switch

PTO switch

Figure 4.10

20

Page 27

Lift assist spring

Figure 4.11

Body

14. Disconnect the deck lift assist spring.

See Figure 4.11.

NOTE: The lift assist spring exerts a lot of force.

15. Remove the nuts and bolts that hold the utility bin

bracket to the control console using a pair of 1/2”

wrenches.

See Figure 4.12.

Nuts

1/2” wrench

Figure 4.12

Figure 4.13

Screws

16. Remove the two screws that hold the rear of the control console to the seat box assembly using a T-30

torx driver and a 7/16” wrench.

NOTE: The upper screw goes through a reinforcement

plate for the lift assist spring.

See Figure 4.13.

21

Page 28

Z-Force-S

17. Remove the screws that hold the front of the control

console to the front of the seat box assembly using

a T-30 torx driver and a 7/16” wrench.

4.21.

18. Gently pull the harness through the hole in the console while lifting it off of the mower.

See Figure

19. Install the control console by following the previous

steps in reverse order.

20. Test drive the mower in a safe area before returning

it to service.

Screws

Figure 4.14

22

Page 29

Right control console

right control panel

Choke cable

Throttle cable

Figure 4.15

Body

To remove/replace the right side control console:

1. Disconnect the choke and throttle cables from the

engine.

NOTE: Paint marking and color coding the cables will

NOTE: On mowers equipped with the 60” decks, remove

2. Remove the two screws from the underside of the

right control panel using a T-30 torx driver.

See Figure 4.16.

See Figure 4.15.

make reassembly easier.

the deck by following the procedures described in

Chapter 8: Decks and Lift Shafts.

Screws

Figure 4.16

Right control panel

Screws

Figure 4.17

Seat

box

assembly

3. Remove the two screws that hold the right control

panel to the seat box assembly using a T-30 torx

driver.

See Figure 4.17.

4. Remove the two screws that hold the control p anel to

the control consoles using a T-30 torx driver.

5. Lift the control panel off of the control console.

NOTE: If the control panel is being replaced, remove the

throttle and choke cables from it and install them

on the new control panel.

23

Page 30

Z-Force-S

NOTE: On mowers equipped with a 60” deck, dis-

connect the deck lift assist spring.

6. Remove the nuts and bolts that hold the fuel tank

bracket to the control console using a pair of 1/2”

wrenches.

See Figure 4.19.

Lift assist spring

Figure 4.18

7. Remove the two screws that hold the rear of the

control console to the seat box assembly using a T30 torx driver and a 7/16” wrench.

NOTE: On mowers equipped with a 60” deck, the

upper screw will go through a reinforcement

plate for the lift assist spring.

See Figure 4.20.

1/2” wrenches

Figure 4.19

7/16” wrench

T-30 driver

24

Figure 4.20

Page 31

Body

8. Remove the screws that hold the front of the control

console to the front of the seat box assembly using a

T-30 torx driver and a 7/16” wrench.

9. Lift the control console off of the mower.

See Figure 4.21.

7/16”wrench

10. Install the control console by following the previous

steps in reverse order.

1 1. T est drive the mower in a safe area before returning it

to service.

T-30 torx

Figure 4.21

25

Page 32

Z-Force-S

Seat

To remove/replace the seat:

1. Disconnect the seat switch.

2. Remove the four nuts that hold the seat track to the

seat base using a 1/2” wrench.

3. Lift the seat off of the base.

NOTE: The track is serviced as part of the seat and

is not available separately.

4. Remove the seat switch using a 3/8” wrench.

See Figure 4.23.

5. Install the seat by following the previous steps in

reverse order.

See Figure 4.22.

Nuts

Seat switch

Figure 4.22

Seat switch

6. Test drive the mower in a safe area before returning

it to service.

Figure 4.23

26

Page 33

Seat box assembly

Pivot bolt

Body

Battery

To remove/replace the seat box assembly:

1. Remove the battery and battery box. See Figure 4.24.

2. Disconnect the seat switch.

Figure 4.24

3. Remove the seat pivot bolts. See Figure 4.25.

4. Remove the seat from the mower.

PTO relay

Figure 4.25

Figure 4.26

Starter solenoid

5. Disconnect the fuse holder/PTO relay from the seat

box.

See Figure 4.26.

6. Remove the two screws and nuts that hold the st arter

solenoid to the seat box.

NOTE: The wires do not need to be disconnected. The

solenoid can be left hanging.

7. Remove the left control console by following the procedures described in the left control console section

of this chapter.

8. Remove the right control console by following the

procedures described in the right control console

section of this chapter.

27

Page 34

Z-Force-S

9. Disconnect the reverse switch harness from the

conduit clip on the right side of the seat box.

See Figure 4.27.

10. Remove the four screws (two on each side) that

hold the seat box assembly to the frame using a 1/

2” wrench.

11. Lift the seat box assembly off of the mower.

12. Install the seat box by following the previous steps

in reverse order.

See Figure 4.28.

Reverse switch harness

Figure 4.27

Screws

13. Test drive the mower in a safe area before returning

it to service.

Figure 4.28

28

Page 35

Drive

CHAPTER 5: DRIVE

The Z-Force S is built using two different models of HydroGear transmissions. The 48 ” de ck vers ion is equip ped

with two HydroGear EZT transmissions. The 60” version is equipped with two ZT2800 transmissions.

The Hydro-gear shop manual for the EZT transmissions is form number BLN-52622. The Hydro-gear shop man-

ual for the ZT2800 transmissions is form number BLN-52441. These manuals are available through HydroGear.

Drive belt

The drive belt is the most common drive system component that will need attention. To remove/replace the drive

belt:

NOTE: The procedure to re place the drive belt is the same

for both transmission models.

1. Remove the deck as described in chapter 8: Cutting

Decks and Lift Shaft.

2. Set the parking brake.

3. Lift and safely support the rear of the mower.

Jack stands

Figure 5.1

Figure 5.2

Idler pulleys

4. Remove one of the rear wheels. See Figure 5.1.

5. Loosen the idler pulleys using a pair of 9/16”

wrenches.

6. Slip the belt past the belt guides and off of the idler

pulleys.

See Figure 5.2.

29

Page 36

Z-Force-S

7. Remove the two screws that secure the fan cover to

the frame using a 1/2” wrench.

NOTE: On the mowers equipped with a 60” deck,

the screw on the left side also goes through

the harness clamp.

8. Slide the fan cover out of the mower on the side that

has the tire removed.

9. Remove the transmission fans using a 3/8” wrench.

10. Slide the drive belt off of the transmission pulleys.

See Figure 5.3.

See Figure 5.3. Insert.

Harness clamp

Figure 5.3

11. Unplug the electric PTO harness. See Figure 5.1.

12. Unbolt the electric PTO using an impact wrench and

a 5/8” socket.

NOTE: If the PTO clutch will not slide off of the

NOTE: If the PTO will not come off using the steps

See Figure 5.5.

crankshaft, thread the bolt half way into the

crankshaft. Make sure the belt keeper is in

place to prevent the clutch from rotating.

Star t the engine a nd turn th e P T O on and of f

several times to shake it loose.

above, remove the engine mounting bolts

and slide the engine forward. This will give

enough clearance to slide the belt off of the

engine pulley.

PTO harness

Transmission fans

Figure 5.4

PTO clutch

Figure 5.5

30

Page 37

Drive

Engine pulley

Figure 5.6

Cub Cadet belts are designed to fit our equipment and are not standard lengths. Use of a

! CA UTION! CA UTION

14. The belt can now be snaked out of the mower.

15. Install the belt following the above steps in reverse order.

non-OEM belt may prevent the de-clutching mechanism from working properly when the

brakes are applied.

13. Slide the engine pulley down far enough to slip the

NOTE: Note the direction of the key in the engine pulley. It

NOTE: When installing the engine pulley and electric PT O,

NOTE: If the engine pulley is seized to the crankshaft, the

belt off of the pulley.

should be facing down. If the pulley is installed

upside down, the belt alignment will be off.

coat the crank shaft with anti-seize. This will ease

pulley and clutch removal in the future.

engine bolts can be removed to slid e the engine to

the rear. This will provide enough clearance to

remove the belt.

See Figure 5.6.

NOTE: Tighten the electric PTO clutch bolt to a torque of 450 - 600 in-lbs (51 - 68 Nm).

16. Test dr ive the m owe r befo re returning to service.

31

Page 38

Z-Force-S

Drive belt adjustment

The drive belt is tensioned by a spring loaded idler pulley. When the brakes are applied, the drive belt is declutched. An adjustable linkage connects the tensioning pulley to the brake shaft. A brake link that is out of adjust

ment will prevent the moveable idler from correctly tensioning and de-tensioning the belt.

As the belt wears and stretches, the moveable idler need s to p ush the be lt in furthe r to kee p prop er be lt ten sion.

To do this, the ferrule at the end of the brake link needs to be at the middle of the slot in the idler pulley bracket. To

adjust this brake link:

NOTE: The brake link is properly adjusted when the

belt is fully de-clutched as the brake is

applied and fully tensioned when the brake

is released.

-

NOTE: The belt must be on when performing this

adjustment.

1. Release the parking brake.

2. Remove the deck as described in chapter 8 Cutting

Decks and Lift Shaft.

3. Remove the cotter pin and washer from the ferrule

on the end of the brake link.

4. Slide the ferrule out of the idler bracket.

5. Adjust the ferrule so that it lines up with the middle

of the slot and slides in without pulling on the spring.

See Figure 5.8.

6. Install the washer and a new cotter pin.

7. Test drive the mower before returning to service.

8. Re-attach the deck.

See Figure 5.7.

Tensioning spring

Cotter pin

Brake link

Ferrule

Figure 5.7

Ferrule

32

Figure 5.8

Page 39

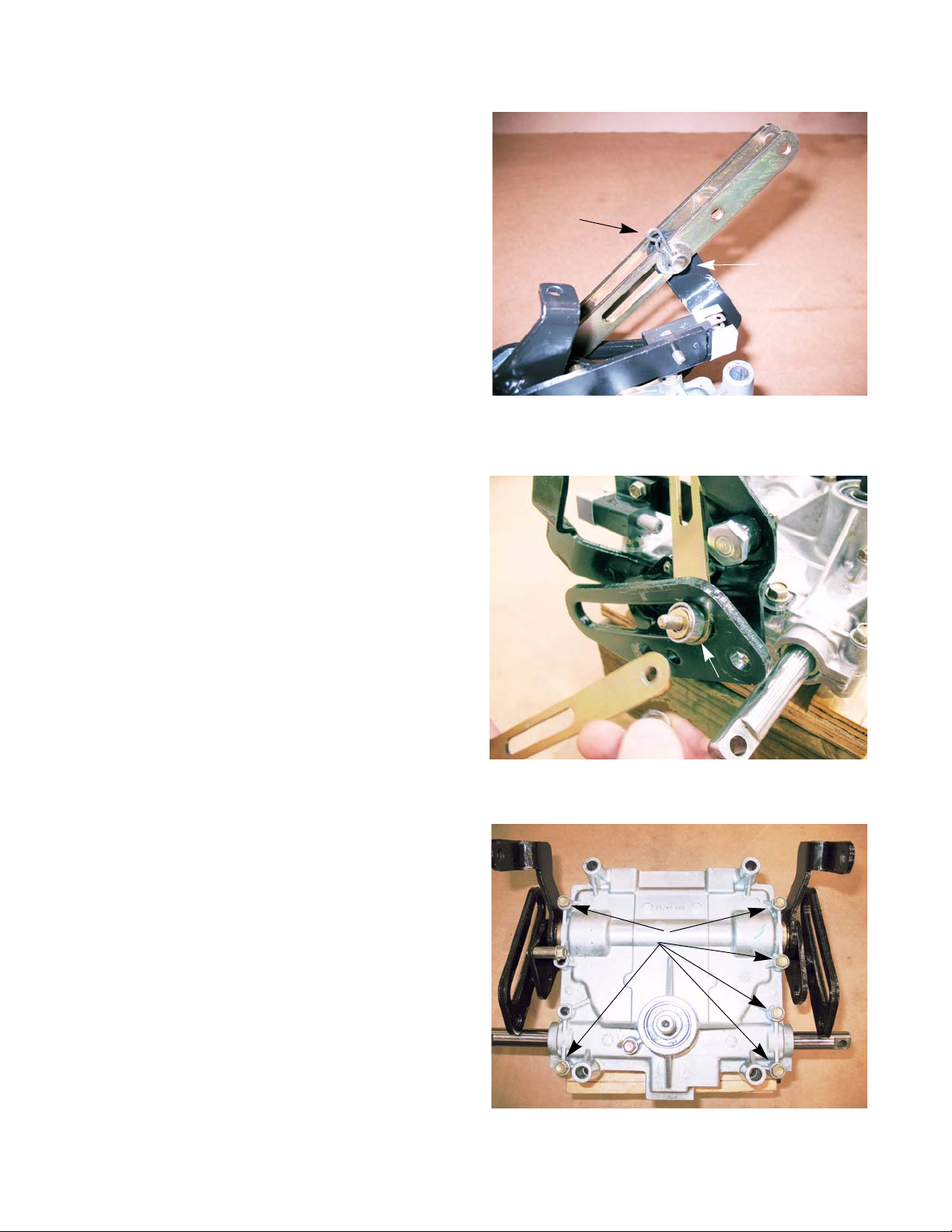

EZT transmission removal/replacement

Drive

Bad

Drive control rod

Cam arm

spring

Speed selector plate

Figure 5.9

1. Remove the deck as described in Chapter 8 Cutting

Decks and Lift Shaft.

2. Lift and safely support the rear of the mower.

3. Remove the drive belt by following the procedures

described previously in this chapter.

NOTE: When removing the belt, remove the wheel of the

transmission to be removed.

4. Disconnect the brake rod spring from the cam arm.

See Figure 5.9.

5. Remove the bowtie clips that secure the drive control

rods to the speed selector plates.

6. Slide the rods out of the selector plate.

7. Remove the nut and bolt that hold the front of the

transmission to the frame cross member using a pair

of 1/2” wrenches.

See Figure 5.10.

Figure 5.10

Spacer

Frame cross

member

Nut

8. Remove the nut, T -bolt and spacer that connect the

transmissions to each other.

See Figure 5.11.

Figure 5.11

33

Page 40

Z-Force-S

9. Remove the bolt holding the rear of the transmission to the torque bracket. See Figure 5.12.

10. Support the transmission to prevent it from falling

while the mounting bolts are removed.

11. Remove the two bolts that fasten the transmission

to the frame.

See Figure 5.15.

Torque br acket

Bolt

Figure 5.12

Transmission bolts

12. Lower the transmission enough to gain access to

the by-pass rod.

13. Remove the hair pin clip that secure the by-pass rod

to the by-pass lever.

14. Lift the by-pass rod off of the by pass lever.

15. Remove the transmission from the mower.

16. Install the transmission by following the previous

steps in reverse order.

NOTE: Before lowering the mower to the ground

purge the transmission by:

• Move the by-pass rod to the by-pass position.

• Start the engine.

• Cycle the drive pedal from full forward to full

reverse six times.

• Move the by-pass rod to the drive position.

• Cycle the drive pedal from full forward to full

reverse six times.

17. Perform a neutral adjustment and wheel alignment

by following the steps described in 6: Steering.

18. Test dr ive the m owe r befo re returning it to service.

See Figure 5.14.

Figure 5.13

By-pass rod

Figure 5.14

34

Page 41

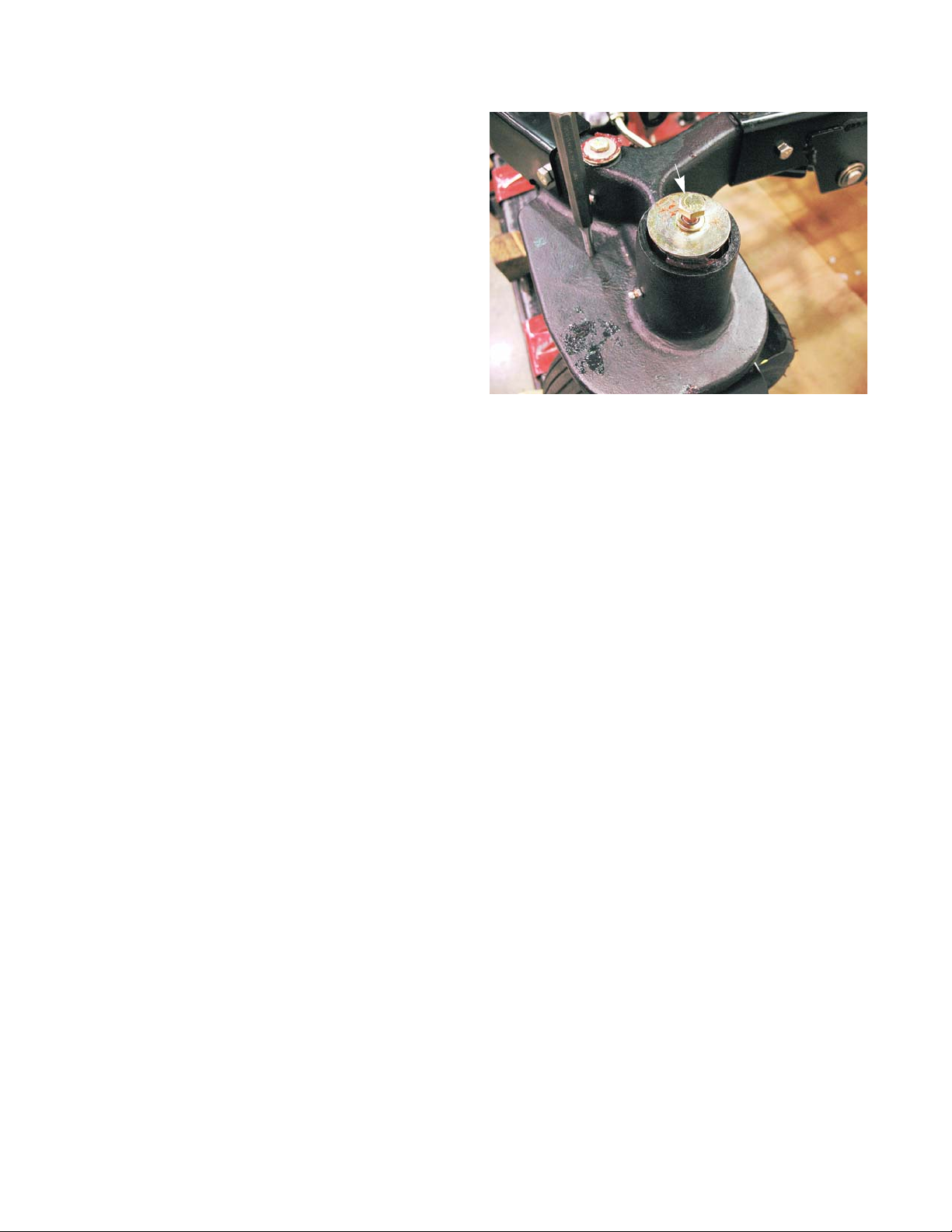

ZT 2800 transmission removal/replacement

Jack stands

Figure 5.15

Expansion tank

Drive

1. Remove the deck as described in chapter 8 Cutting

Decks and Lift Shaft.

2. Lift and safely support the rear of the mower.

3. Remove the drive belt by following the procedures

described previously in this chapter.

NOTE: When removing the belt, remove the wheel of the

transmission to be removed.

4. Release the parking brake.

5. Remove the two screws that hold the expansion t ank

to the seat box using a 7/16” wrench.

See Figure 5.16.

6. Follow the vent hose from the transmission to be

removed up to the expansion tank.

Vent h ose

Figure 5.16

Drive control rod

7. Using a pair of pliers, squeeze the tabs on the hose

clamp together while sliding the clamp down the

hose.

8. Carefully remove the vent hose from the expansion

tank.

NOTE: The expansion tank should be empty when the

transmission is cold.

9. Remove the bowtie clip that secures the drive cont rol

rod to the speed selector plate.

10. Slide the rod out of the selector plate.

Speed selector plate

Figure 5.17

35

Page 42

Z-Force-S

11. Remove the nut and bolt that hold th e front of the

transmission to the frame cross member using a

pair of 1/2” wrenches.

12. Remove the nut, T -b olt and spacer that connect the

transmissions to each other.

See Figure 5.18.

See Figure 5.19.

Front transmission

bolt

Figure 5.18

13. Remove the bolt holding the rear of the transmission to the torque bracket. See Figure 5.20.

Spacer

Nut

Figure 5.19

Torque bracket

36

Figure 5.20

Page 43

Drive

Transmission mount

bolts

Figure 5.21

14. Support the transmission to prevent it from falling

while the mounting bolts are removed.

15. Remove the two bolts that fasten the transmission to

the frame.

16. Lower the transmission enough to gain access to the

by-pass rod.

17. Remove the hair pin clip that secure the by-pass rod

to the by-pass lever.

18. Lift the by-pass rod off of the by pass lever.

See Figure 5.21.

See Figure 5.14.

By-pass rod

Figure 5.22

20. Install the transmission by following the previous steps in reverse order.

NOTE: Before lowering the mower to the ground purge the transmission by:

• Move the by-pass rod to the by-pass position.

• Start the engine.

• Cycle the drive pedal from full toward to full reverse six times.

• Move the by-pass rod to the drive position.

• Cycle the drive pedal from full forward to full reverse six times.

NOTE: Removal of the brake caliper will make installing the transmission easier, but is not required.

21. Perform a neutral adjustment and wheel alignment by following the steps described in 6: Steering.

22. Test dr ive the m owe r befo re returning it to service.

19. Remove the transmission from the mower.

NOTE: If replacing the transmission, Inspect the vent

hose. If it is in good condition remove it from the

old transmission and install it on the new transmis

sion. If it cracked, brittle or damaged, install a new

vent hose on the new transmission.

-

37

Page 44

Z-Force-S

Drive pedal biasing adjustment

The Z-Force-S is equipped with a pedal biasing

cam. This cam allows the pedals to be adjuste

increase forward travel speed or reverse travel speed.To

adjust the pedal biasing:

1. Remove the floor pan by following the procedures

described in Chapter 4 Body.

2. Inspect the bushings that support the forward drive

pedal shaft.

NOTE: Any wear in the bushings will affect pedal

See Figure 5.23.

travel. Replace worn bushings before adjust

ing pedal biasing cam.

d to

Forward drive pedal shaft

-

Bushings

Figure 5.23

3. Loosen the biasing cam lock bolt using a 9/16”

wrench while holding the biasing cam with a 3/4”

wrench.

4. Rotate the cam using a 3/4” wrench while watching

the forward drive pedal arm.

NOTE: Adjusting the forward drive arm towards the

front of the mower will give more reverse

pedal travel and less forward pedal travel.

Adjusting the forward drive pedal arm

towards the rear of the mower will increase

forward pedal travel and decrease reverse

pedal travel.

NOTE: When the bolt hole in the biasing cam in at

the top center or bottom center position, The

cam is in the neutral bias position.

ure 5.25.

5. Tighten the biasing cam lock bolt using a 9/16”

wrench while holding the biasing cam in place with a

3/4” wrench.

See Figure 5.24.

See Fig-

More forward

Biasing cam

Neutral biasing position

More reverse

9/16” bolt

forward drive

pedal arm

Figure 5.24

6. Install the floor pan by following the procedures

described in Chapter 4: Body.

7. Test drive the mower in a safe area before returning

it to service.

38

Biasing cam

Figure 5.25

Page 45

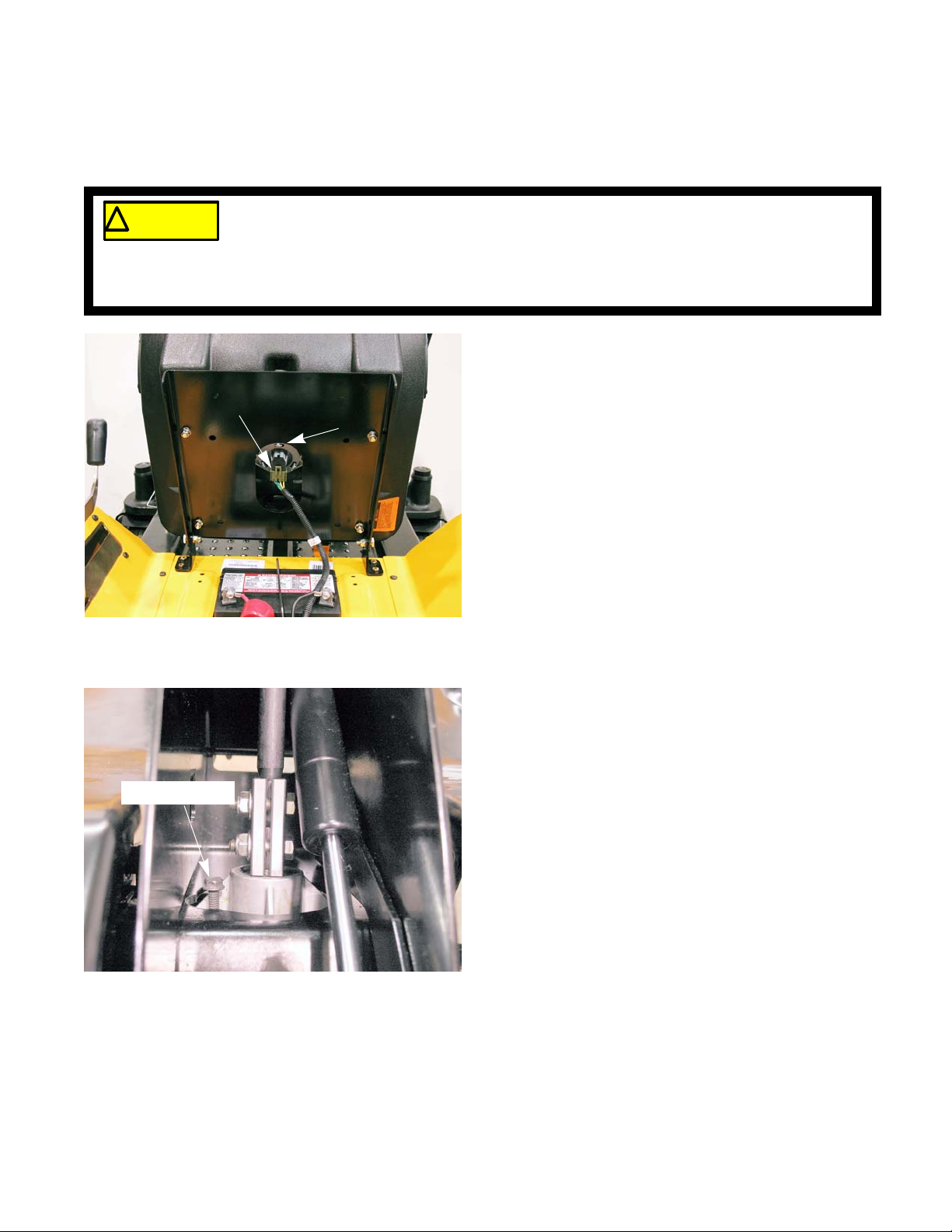

Hydro neutral control adjustment

NOTE: Neutral control rarely goes out of adjustment on its own. If it needs adjustment, check for damaged

linkage or signs of tampering.

Drive

! CAUTION! CAUTION

• Work in a well vented area to prevent carbon monoxide poiso ning or asphyxiation.

• Be careful to avoid contact with hot parts or moving parts.

Seat safety switch

The mower engine and drive system must be operated to complete this procedure. Confirm

that no hazards will be incurred by running the engine or operating the drive system.

To perform the hydro neutral control adjustment:

NOTE: The procedure to perform the hydro neutral contro l

adjustment is the same for the ZT 2800 and the

Tang

1. Lift and safely support the rear of the mower.

2. By-pass the seat safety switch. See Figure 5.26.

Figure 5.26

EZT transmissions.

2a. Slide the seat to the full forward position.

2b. Flip the seat up.

2c. Press in the seat bottom until the tang on the

seat switch is fully extended.

2d. Place a spring clamp on the tang to hold the

seat switch in this position.

Locking screw

Figure 6.27

3. Remove the four screws that hold the steering column cover in place using a T-30 torx driver.

4. Lock Steering Gear Box in Neutral Position:

4a. Remove the 1/4”-20 plug screw from the steer-

ing gear box centering port using a 3/8” wrench.

See Figure 6.27.

4b. Thread a 1/4”-20x2” bolt into the steering box

centering port until you feel it touch the steering

rack.

4c. Wh ile tr ying t o gent ly thr ea d the bo lt fu rth e r,

slowly rotate the steering shaft back and forth

until the bolt seats into the detent in the steering

rack.

4d. Finger tighten the screw to set the screw fully

into the detent. The steering gear box is now

centered and locked.

39

Page 46

Z-Force-S

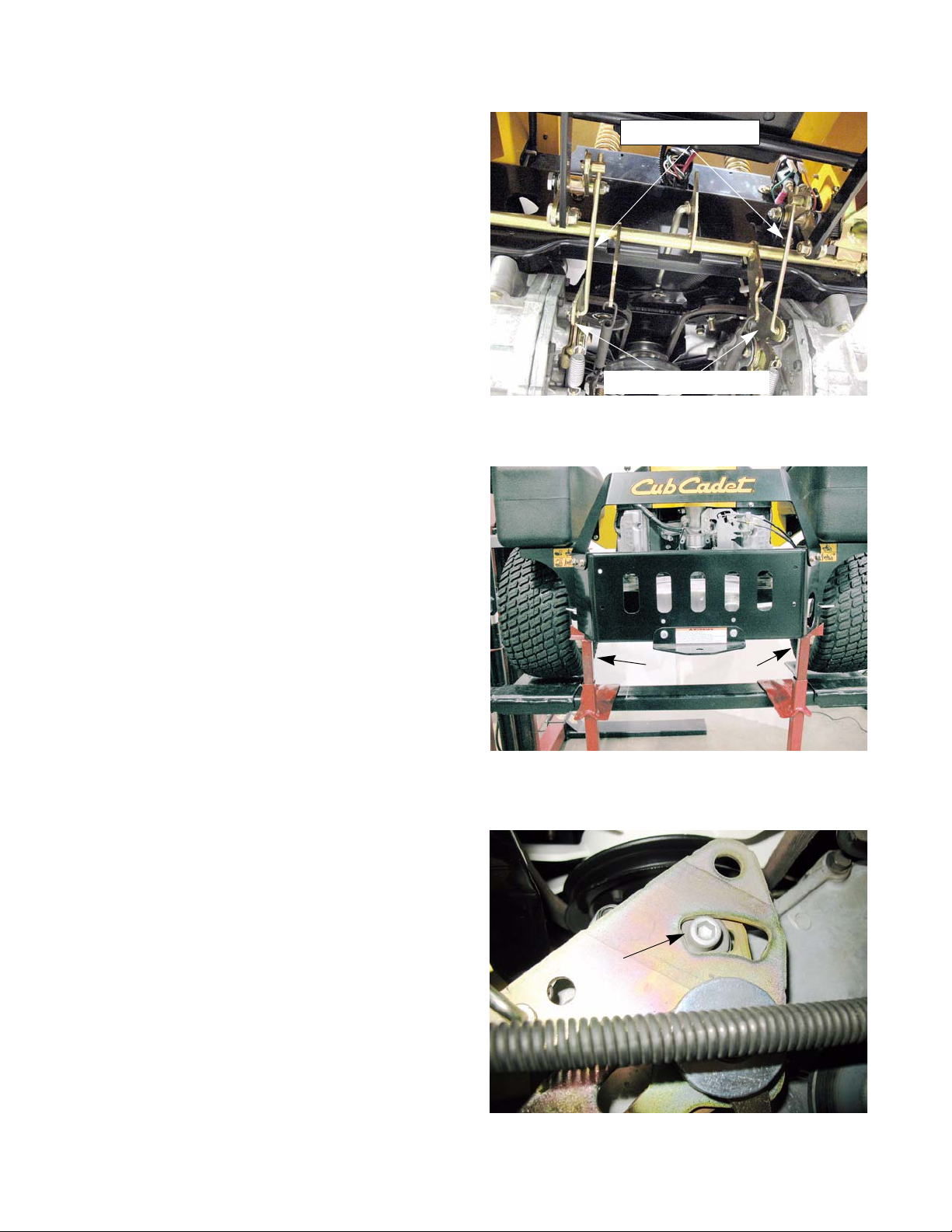

5. Disconnect both of the drive control arms from the

speed selector plates.

6. Start the engine and advance throttle to maximum

RPM.

7. Release the parking brake.

8. Watch both rear tires for movement.

See Figure 5.29.

See Figure 5.28.

Drive control rods

Speed selector plates

Figure 5.28

NOTE: If there is no wheel movement, the hyrdo

transmissions are in neutral and don’t need

to be adjusted. Skip ahead to step 13.

NOTE: If one or both rear wheels move, the hydro

transmissions need to be adjusted. Continue

on to step 9.

9. With the engine still running, locate the socket head

cap screw in the slot of the speed selector plate on

the transmission that needs to be adjusted.

10. Loosen the socket head cap screw using a 1/4” hex

key.

See Figure 5.30.

1 1. Adjust the speed selector plate until the wheel stops

moving.

12. Tighten the socket head cap screw using a 1/4” hex

key.

13. Turn-off the engine.

No movement

Figure 5.29

socket head

cap screw

40

Figure 5.30

Page 47

Drive

14. Adjust the drive control rods so they slide freely into the hole in the selector plate. Inst all the hairpin clips.

15. Remove the spring clamp from the seat switch.

16. Lower the mower to the ground.

17. Test the drive system and all safety features before retur nin g the unit to se rvice.

41

Page 48

Z-Force-S

42

Page 49

Steering

CHAPTER 6: STEERING

Introduction

The steering on the Z-Force-S mower works in two phases.

• First it will steer like any other riding mower by turning the front wheels.

• Second and more importantly, the steering linkage will control the drive output of the rear wheels through

the use of two HydroGear transmissions.

The steering gear box is connected to the front wheels by tie rods. When the steering wheel is turned, the gear

box will turn the front wheels. The gear box will also slow the drive speed of the rear wheels. The inside wheel is

slowed more than the outside wheel. When the insi de front wheel reaches an an gle of 90

will stop driving. Turning the wheel past that point will make the inside rear wheel go in reverse. The inside front

wheel can reach a 108

o

angle with the transmission on the inside of the turn driving in reverse. The riding mower will

then make a zero radius turn.

Because the steering gear box is linked to the transmissions, the transmission adjustments and the wheel alignment must be done together. A transmission that is out of adjustment can make the steering look out of adjustment

just as a steering linkage that is out of adjustment will affect the transmissions.

IMPORTANT: Check the tire air pressure and wear before attempting to diagnose any problems with the steer-

ing or tracking of a Z-Force-S riding mower. If the tires are not equal across the same axles, it

will greatly affect the performance of the riding mower.

o

, the rear wheel on that side

IMPORTANT: All zero turn mowers must have matching tires across the same axle (both front wheels and

both back wheels).

Wheel alignment and drive control lin k adj ustments

The wheel alignment and transmission link adjustment are performed together on the Z-force S.

1 Remove the four screws that hold the steering col-

umn cover in place using a T-30 torx driver.

See Figure 6.1.

Screws

Figure 6.1

43

Page 50

Z-Force-S

2. Lock Steering Gear Box in Neutral Position:

2a. Remove the 1/4”-20 plug screw from th e

steering gear box centering port using a 3/8”

wrench.

2b. Thread a 1/4”-20x2” bolt into the steering box

centering port until you feel it touch the steer

ing rack.

2c. While trying to gently thread the bolt further,

slowly rotate the steering shaft back and forth

until the bolt seats into the detent in the steer

ing rack.

2d. Finger tighten the screw to set the screw fully

into the detent. The steering gear box is now

centered and locked.

3. Remove the hairpin clips that secure the drive control rods to the speed selector plates.

See Figure 6.3.

See Figure 6.2.

Locking screw

-

-

Figure 6.2

4. Slide the rods out of the selector plate.

5. Insert two 5/16” pins through th e ho les in the axle

castings. The pins should pass through the casting

down to the wheel yokes.

NOTE: If both pins slide in, the wheels are aligned;

go to step 12. If one or both pins do not slide

in, proceed to the next step.

NOTE: The pins should slide in and out without

binding. As the drag links are being

adjusted, rock the tires back and forth to

remove the load created from the tires twist

ing on the floor.

See Figure 6.4.

Drive control links

Speed selector plates

Figure 6.3

5/16” pin

-

44

Figure 6.4

Page 51

Steering

Figure 6.5

Straight edges

NOTE: The flat side of the yoke should be parallel to the

box section of the frame when the pins are

installed.

NOTE: A couple of straight edges can be used to check

the alignment of the yoke to the frame.

See Figure 6.5.

If they are not:

• Check for a bent yoke.

• Remove the yoke and check the gear timing. See

the yoke section of this chapter for the proper pro

cedures.

6. Loosen the jam nuts on both ends of the tie rod(s).

See Figure 6.6.

See Figure 6.5.

-

Jam nuts

Figure 6.6

7. Disconnect one end of the tie rod. See Figure 6.7.

8. Manually move the front wheel yoke until the alignment holes line up.

9. Insert the 5/16” pin.

Tie rod

end

Figure 6.7

45

Page 52

Z-Force-S

10. Adjust the tie rods until the ends line up with their

mounting point.

11. Re-attach the tie rod(s).

12. Tighten the jam nuts.

13. Adjust the drive control rods so they slide freely into

the hole in the selector plate. Install the hairpin clips.

14. Remove the 1/4”-20x2” screw from the steering

gear box.

15. Reinstall the original plug screw in the steering gear

box.

16. Install the steering column cover.

17. Remove the 5/16” pins.

18. Test drive the riding mower in a safe area before

returning it to service.

See Figure 6.8.

Mounting point

Figure 6.8

46

Page 53

Steering gear box removal

Steering shaft

coupler

Locking screw

Figure 6.9

Steering

To remove/replace the gear box:

1 Remove the deck by following the procedures

described in Chapter 8: Decks and Lift Shaft.

2. Remove the floor pan by following the steps

described in Chapter 4: Body/Chassis.

3. Remove the four screws that hold the steering column cover in place using a T-30 torx driver.

4. Loosen the top clamp bolt in the steering shaft coupler using a pair of 1/2” wrenches.

5. Remove the bottom bolt in the steering shaft coupler .

See Figure 6.9.

NOTE: The clamp bolts pass through grooves in the steer-

ing shaft and the steering gearbox input shaft.

NOTE: It is not necessary to lock the steering gearbox for

removal, but it will need to be centered and locked

for installation.

Return to neutral spring

Figure 6.10

Pedal biasing cam

6. Disconnect the return to neutral spring.

See Figure 6.10.

NOTE:

7. Disconnect the front side of the drive input link using

a 9/16” wrench and a 15/16” wrench.

See Figure 6.11.

NOTE: The rear end of the drive input link is attached to

the drive pedal shaft by a pedal biasing cam.

Removing it will change the pedal travel.

Figure 6.11

Drive input link

47

Page 54

Z-Force-S

8. Disconnect both of the tie rods from the steering

gearbox using a pair of 1/2” wrenches.

See Figure 6.12.

NOTE: There is a spacer between the tie rod end

and the steering rack.

NOTE: The bolt has a special tapered shoulder. Do

not replace it with a standard bolt.

9. Disconnect the reverse switch. See Figure 6.13.

Spacer

Tie rod end

Figure 6.12

10. Disconnect both of the drive control links by removing the nuts and bolts that attach the connector

plates to the drive control link using a pair of 7/16”

wrenches.

See Figure 6.14.

Reverse switch

Figure 6.13

Connector plate

48

Drive control link

Figure 6.14

Page 55

Gear box mounting bolts

Figure 6.15

hairpin clip

Steering

11. Remove the four nuts and bolts (two on each side)

that hold the gearbox to the frame using a pair of 1/

2” wrenches.

12. Lower the steering gearbox out of the mower, sliding

it out of the steering shaft coupler.

NOTE: If replacing the gearbox:

13. Remove the drive control connector plates by:

See Figure 6.15.

Connector

plate

Reverse

switch

Roller

Figure 6.16

13a. Remove the cotter pins, washers and clevis

pins in the linkages.

13b. Remove the nuts and bolts connecting the

transmission linkage s to th e le vers o n t he st eer

ing gear box.

NOTE: There are rollers in the slots. Take care not to lose

them when removing the bolts.

14. Remove the reverse switch.

See Figure 6.16.

-

49

Page 56

Z-Force-S

Steering gearbox installation

1. Attach the drive control link connector plates to the

steering gearbox.

2. Install the reverse switch.

3. Lock the steering gearbox in the cente r ed pos ition :

3a. Remove the 1/4”-20 plug screw from the

steering gear box centering port using a 3/8”

wrench.

See Figure 6.17.

See Figure 6.18.

hairpin clip

Reverse

switch

Connector

plate

Roller

Figure 6.17

3b. Thread a 1/4”-20x2” bolt into the steering box

centering port until you feel it touch the steer

ing rack.

3c. While trying to gently thread the bolt further,

slowly rotate the input shaft back and forth

until the bolt seats into the detent in the steer

ing rack.

3d. Finger tighten the screw to set the screw fully

into the detent. The steering gear box is now

centered and locked.

4. Remove the hairpin clips that secure the drive control links to the speed selector plates.

See Figure 6.19.

5. Slide the rods out of the speed selector plates.

Locking screw

-

Figure 6.18

50

Drive control rods

Figure 6.19

Page 57

5/16” pin

Axle casting

Figure 6.20

Steering

6. Insert two 5/16” pins through the holes in the axle

castings. The pins should pass through the casting

down to the wheel yokes.

NOTE: The flat side of the yoke should be parallel to the

box section of the frame when the pins are

installed.

See Figure 6.21.

See Figure 6.20.

Figure 6.21

Center the steering wheel

The yoke is parallel

to the frame

If they are not:

• Check for a bent yoke.

• Remove the yoke and check the gear timing. See

the yoke section of this chapter for the proper pro

cedures.

7. Center the steering wheel. See Figure 6.22.

-

Figure 6.22

51

Page 58

Z-Force-S

8. Lift the steering gearbox into the frame while sliding

the gearbox input shaft into the steering shaft cou

pler. See Figure 6.23.

9. Install the four mounting nut s and bolt s. T ighten to a

torque of 17 ft lbs (23 Nm).

10. Install the lower coupler bolt.

11. Tighten both coupler bolts to a torque of 72 in lbs (8

Nm).

NOTE: Once the steering gearbox is mounted, the

locking screw can be backed out to allow the

steering shaft to be rotated for easier access

to the coupler bolt. The steering gearbox

must be locked again once the coupler bolts

are torqued.

12. Attach the tie rods to the steering rack.

See Figure 6.24.

-

coupler bolts

Figure 6.23

NOTE: The spacer must be between the tie rod end

and the steering rack.

NOTE: If necessary, adjust the tie rod ends so that

the hole in the rod end lines up with the hole

in the steering rack.

13. Remove the 5/16” pins.

14. Attach the front side of the drive input link using a 9/

16” wrench and a 15/16” wrench.

NOTE: If the pedal biasing cam was moved, the

drive pedal adjustment will need to be per

formed by following the steps described in

the drive pedal adjustment section of Chap

ter 5: Drive System.

See Figure 6.25.

-

Spacer

Figure 6.24

Pedal biasing cam

-

52

Drive input link

Figure 6.25

Page 59

Steering

Return to neutral spring

Figure 6.26

Reverse switch

15. Install the return to neutral spring. See Figure 6.26.

16. Connect the reverse switch. See Figure 6.27.

Figure 6.27

Figure 6.28

Connector plate

Drive control link

17. Connect both of the drive control links by installing

the nuts and bolts that attach the connector plates to

the drive control link using a pair of 7/16” wrenches.

See Figure 6.28.

18. Adjust the drive control links so they slide freely into

the hole in the selector plate. Install the hairpin clips.

19. Remove the locking bolt from the steering gearbox,

and install the plug screw.

20. Install the floor pan by following the steps described

in Chapter 4: Body/Chassis.

21. Install the steering column cover.

22. Test drive the riding mower in a safe area before

returning it to service.

23. Install the deck.

53

Page 60

Z-Force-S

Rebuilding the steering gear box

To take the steering gear box apart:

1. Remove the steering gear box by following the procedures described in the previous section of this

chapter.

2. Remove the drive control link connector plates:

2a. Remove the hairpin clip and clevis pin.

See Figure 6.29.

2b. Remove the nut, while leaving the bolt in

place.

Hairpin clip

Clevis pin

Figure 6.29

2c. Remove the connector plate on the nut side.

2d. Remove the bolt, washers and the roller with

the other connector plate.

3. Remove the brackets from the steering gearbox

using a 3/8” wrench.

4. Remove the six remaining case screws using a 3/8”

wrench.

See Figure 6.31.

See Figure 6.30.

Roller

Figure 6.30

Screws

54

Figure 6.31

Page 61

Using one of the pry

points to separate the

housings

Figure 6.32

Steering

5. Lift the upper housing off of the lower housing.

NOTE: There is no sealant between the two housings.

They should easily slip apart. If they are stuck

together, there are three pry points cast into the

housings that can be used to separate the hous

ings. See Figure 6.32.

6. Remove the steering rack. See Figure 6.33.

-

Wear block

7. Remove the wear block and spring.

Steering

rack

Figure 6.33

8. Remove the speed cam assemblies.

See Figure 6.34.

Speed cam assemblies

Figure 6.34

55

Page 62

Z-Force-S

9. Separate the speed cam assemblies by driving out

the two roll pins using a 5/32” pin punch and a ham

mer. See Figure 6.35.

10. Slide the output bevel gear assemblies off of the

speed cams.