Page 1

Professional Shop Manual

T65 Series Vertical Shaft Engines

NOTE: These materials are for use by trained technicians who are experi enced in the service and repair of outdo or power

equipment of the kind described in this publication, and are not intende d for use by untrained or in experienced indi viduals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experie nced and trained professio nal. Read, understand, and follow all

instructions and use common sense when working on powe r e quip ment. T his includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publ ication. However , due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2013 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

Professional Service Manual Intent.................................................................... 1

Safety .................................................................................................................1

Fasteners ...........................................................................................................3

Assembly Instructions ........................................................................................3

Model and Serial Number ...................................................................................5

Maintenance .......................................................................................................5

Spark Plugs ........................................................................................................6

Air Filter.............................................................................................................. 7

Oil Type and Capacity ........................................................................................8

Changing the oil ...............................................................................................10

Fuel system ......................................................................................................11

Servicing the Fuel System ................................................................................11

Fuel Filter .........................................................................................................11

Valve lash .........................................................................................................12

Exhaust system ................................................................................................14

Cleaning the Engine .........................................................................................14

General Torque Specifications .........................................................................14

Chapter 2: Basic Troubleshooting

Definitions ........................................................................................................15

Introduction ......................................................................................................15

Steps to Troubleshooting .................................................................................15

Define the Problem ..........................................................................................15

Identify Factors that Could Cause the Problem ................................................17

Repairing the Problem ..................................................................................... 21

Prime Test ........................................................................................................22

Leak-down Test ................................................................................................22

Compression Test ............................................................................................24

PCV Testing .....................................................................................................25

Troubleshooting Flow Charts ...........................................................................26

Chapter 3: Air Intake System

Air Filter ............................................................................................................31

Air Filter Housing ..............................................................................................32

Carburetor Insulator .........................................................................................33

Fuel Line ..........................................................................................................37

Inspect the Fuel Lines ......................................................................................37

I

Page 4

Chapter 4: The Fuel System and Governor

Inspecting the Fuel ...........................................................................................38

Test Fuel for Alcohol ........................................................................................38

The Fuel Filter ..................................................................................................39

Evaporative (EVAP) Emissions System........................................................... 39

Charcoal Canister Fuel Caps........................................................................... 39

Fuel Tank Vent .................................................................................................40

The Fuel Tank ..................................................................................................41

Autochoke ........................................................................................................42

Temperature Compensator ..............................................................................43

Primer ...............................................................................................................44

Carburetors ......................................................................................................45

Inspecting the Carburetor................................................................................. 45

Disassembly and Rebuilding the Carburetor ....................................................46

Governor ..........................................................................................................51

Governor Shaft .................................................................................................52

Governor Cup and the Governor Gear .............................................................54

Chapter 5: Lubrication

Oil Type and Quantity ...................................................................................... 55

Oil Dipstick .......................................................................................................56

Dipstick Tube Removal ....................................................................................57

Lubrication System ...........................................................................................58

PCV ..................................................................................................................59

Chapter 6: Starter and Charging Systems

Recoil Starter Removal ....................................................................................61

Starter Rope .....................................................................................................62

Starter Pulley and Recoil Spring ......................................................................64

Chapter 7: Ignition System 67

Troubleshooting the Ignition System ................................................................67

Troubleshooting the Stop Switch ..................................................................... 68

Troubleshooting the Module .............................................................................69

About the Spark Plug .......................................................................................72

Cleaning the Spark Plug .................................................................................. 72

Inspection of the Spark Plug ............................................................................72

Spark Plug Removal ........................................................................................72

Ignition Module................................................................................................. 73

Engine Brake and Stop Switch (if equipped) ....................................................74

Flywheel ...........................................................................................................75

II

Page 5

Chapter 8: Exhaust

Muffler ..............................................................................................................77

Chapter 9: Cylinder Head

Cylinder Head .................................................................................................. 79

Valves ..............................................................................................................82

Chapter 10: Crankshaft, piston and Connecting Rod

Engine Disassembly..........................................................................................85

Crankshaft Inspection ......................................................................................88

Piston Inspection ..............................................................................................89

Connecting rod Inspection ...............................................................................91

Cylinder Inspection ...........................................................................................92

Bearings ...........................................................................................................93

Reassembly .....................................................................................................94

Engine Specifications Chart .............................................................................98

Engine Torque Values Chart ............................................................................99

Chapter 11: Failure Analysis

Abrasive Ingestion ..........................................................................................101

Insufficient lubrication .....................................................................................104

Engine Overspeed .........................................................................................106

Engine Overheat ............................................................................................107

Mechanical Breakage/ Wear ..........................................................................108

Detonation/pre-ignition................................................................................... 108

III

Page 6

IV

Page 7

Introduction

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

! CA UTION! CA UTION

Warning indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury.

! WA RNI NG! WA RNI NG

! DANGER! DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent

This manual is intended to provide service dealers with an introduction to proven diagnostic and repair proce-

dures for MTD T65 series vertical shaft engines.

Disclaimer: The information contained in this manual is correct at the time of writin g. Both the prod u ct an d th e inf or -

mation about the product are subject to change without notice.

About the text format:

NOTE: Is used to point out information that is relevant to the procedure, but does not fit as a step in the proce-

dure.

• Bullet points: indicate sub-steps or points.

1. Numbered steps

1a. Substeps

the actions required to complete a step.

Disclaimer: This manual is intended for use by trained, professional technicians.

• Using common sense in operation and safety is assumed.

• In no event shall MTD be liable for poor text interpretation or poor execution of the pro cedures described

in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or MTD Technical Support.

Safety

This Service Manual is meant to be used along with the Operator’s Manual. Read the Operator’s Manual and

familiarize yourself with the safety and operational instructions for the equipment being worked on. Keep a copy of

the Operator’s Manual for quick reference. Operator’s manuals may be viewed for free at the brand support website.

It will be necessary to have the complete model and serial number for the equipment.

indicate specific things that should be done, and the orde r in whic h th ey sh ou ld be do ne.

will be lettered and nested within steps. Two or more substeps may be combined to describe

1

Page 8

T65 Series Vertical Shaft Engines

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very ser ious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

• Lift and support heavy objects sa fely and securely.

• Be aware of your surroundings and potential h azards that are inhe rent to all power

equipment. All the labels in the world cannot protect a technician from an in stant of

carelessness.

! CAUTION! CAUTION

• Grooming and attire:

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

! WARNING! WARNING

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

! DANGER! DANGER

2

Page 9

Introduction

Fasteners

• Most of the fasteners used on the MTD engine are metric. Some are fractional inches. For this reason,

wrench sizes are frequently identified in the text, and measurements are given in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners, like cotter pins, are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summa-

rized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manual is handy as a quick-r eference g uide as we ll as a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary pr ocedures. Th is avoids repeating

the same procedure two or three times in the manual.

3

Page 10

T65 Series Vertical Shaft Engines

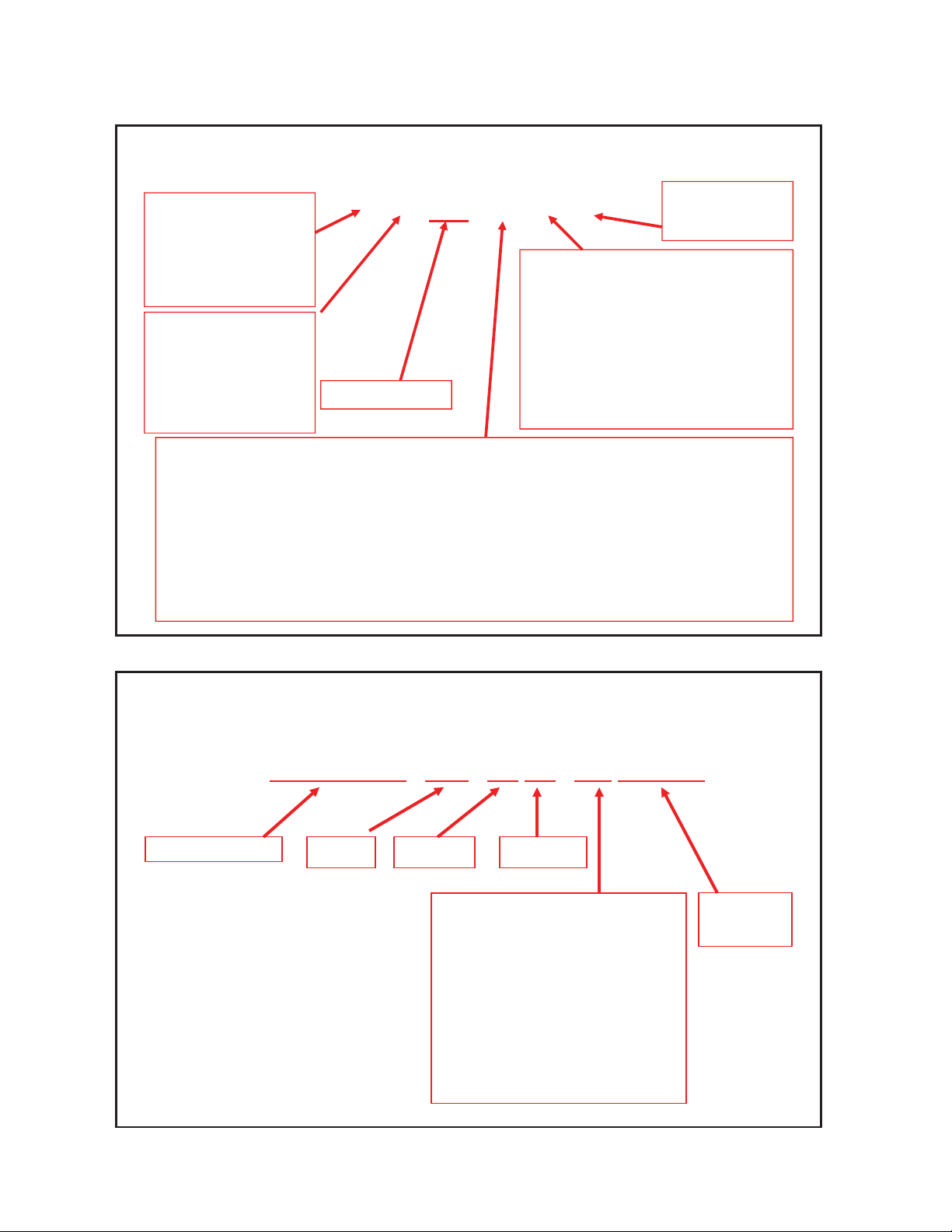

MTD Vertical Engine Model Designators

Starter/Alternators

1=Recoil start

2=Electric start (12V)

3=E. start/alt. 18W

4=E. start/alt. 3A/5A

5= AutoChoke/ Recoil

6= AutoChoke/Electric Start

7= AutoChoke/Electric Start/Alt

1 P 6 1 M U A

P= Vertical (1 cyl.)

Q= Vertical (2 cyl.)

T= Vertical (1 cyl.)

X= Vertical (1 cyl.)

Bore Dia. (mm)

End Product

rettilpsgoLL)relffum on( rediRA

B Mower (long shaft M0) R Mower (long shaft/no shroud)

)duorhs on/tfahs gnol( rewoMMredderhS/reppihCC

D Mower (long shaft M1) N Mower (short shaft M0)

E Mower (short shaft M1) P Mower (long shaft M0)

F Mower (short shaft/no shroud) Q Mower (short shaft M0)

G Garden Cart (Side Discharge) T Tiller

relliT dlroWW )relffu

m/w( rediRJ

Compliance

U United States (50 State)

H Europe

C California

0 (Zero) 49 State

L 49 State - Special

G U.S.(49) and Europe

T Australia (S.A.)

Y China

W U.S.(50) and Europe

Major Revision

Change

MTD Engine Serial Numbers

Model number

1P65FH/0510271A0023

MonthYear

Producing Line# and Shift#:

1A=Line 1, 1

st

Shift

1B=Line 1, 2

nd

Shift

2A=Line 2, 1

st

Shift

2B=Line 2, 2

nd

Shift

3A=Line 3, 1

st

Shift

3B=Line 3, 2

nd

Shift

4A=Line 4, 1

st

Shift

4B=Line 4, 2nd Shift

Date

Engine

number

4

Page 11

Introduction

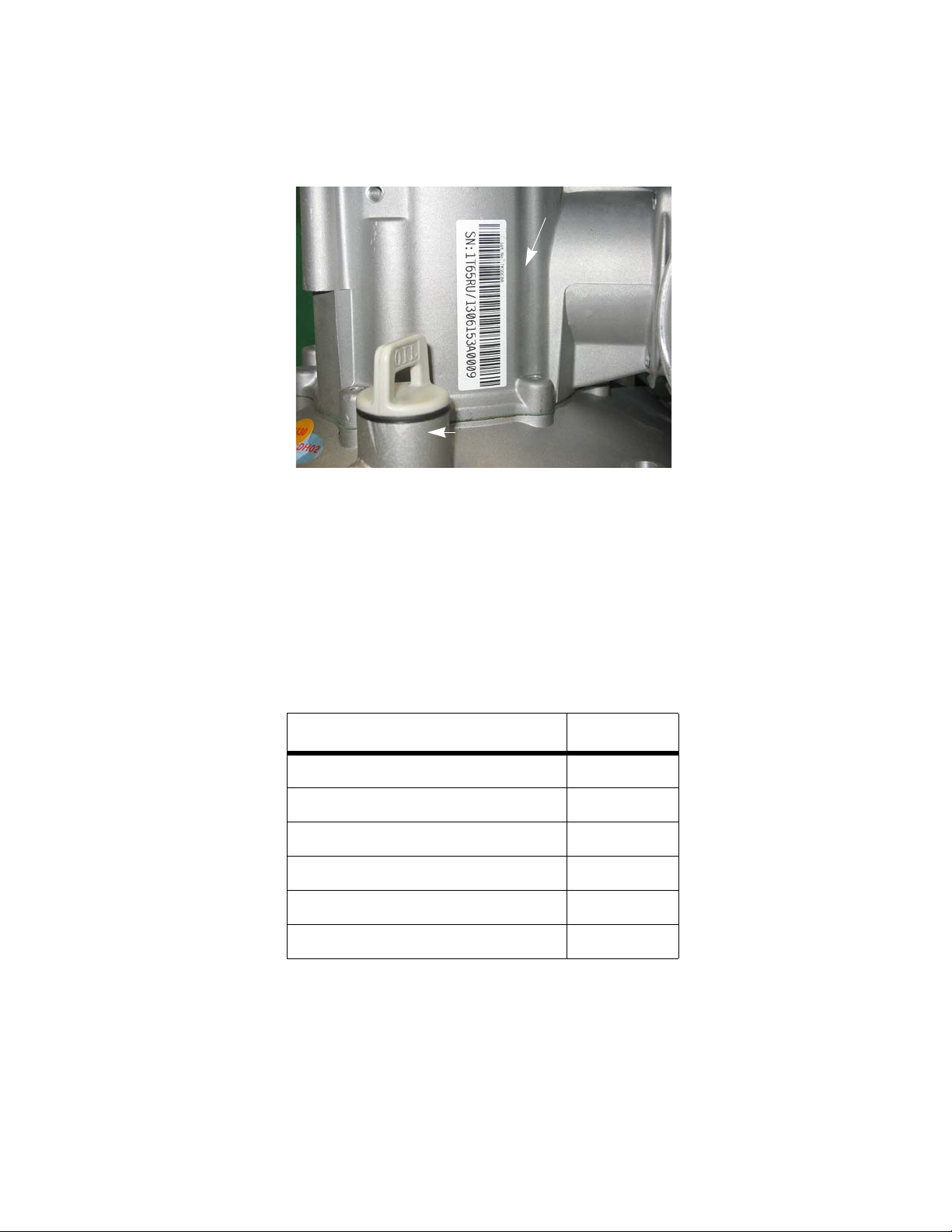

Figure 1.1

Model /serial number

Dipstick

Model and serial number

The model and serial number can be found on a white sticker with a bar code. The sticker is usually located near

the dipstick. See Figure 1.1.

NOTE: The serial number will always start with the model number.

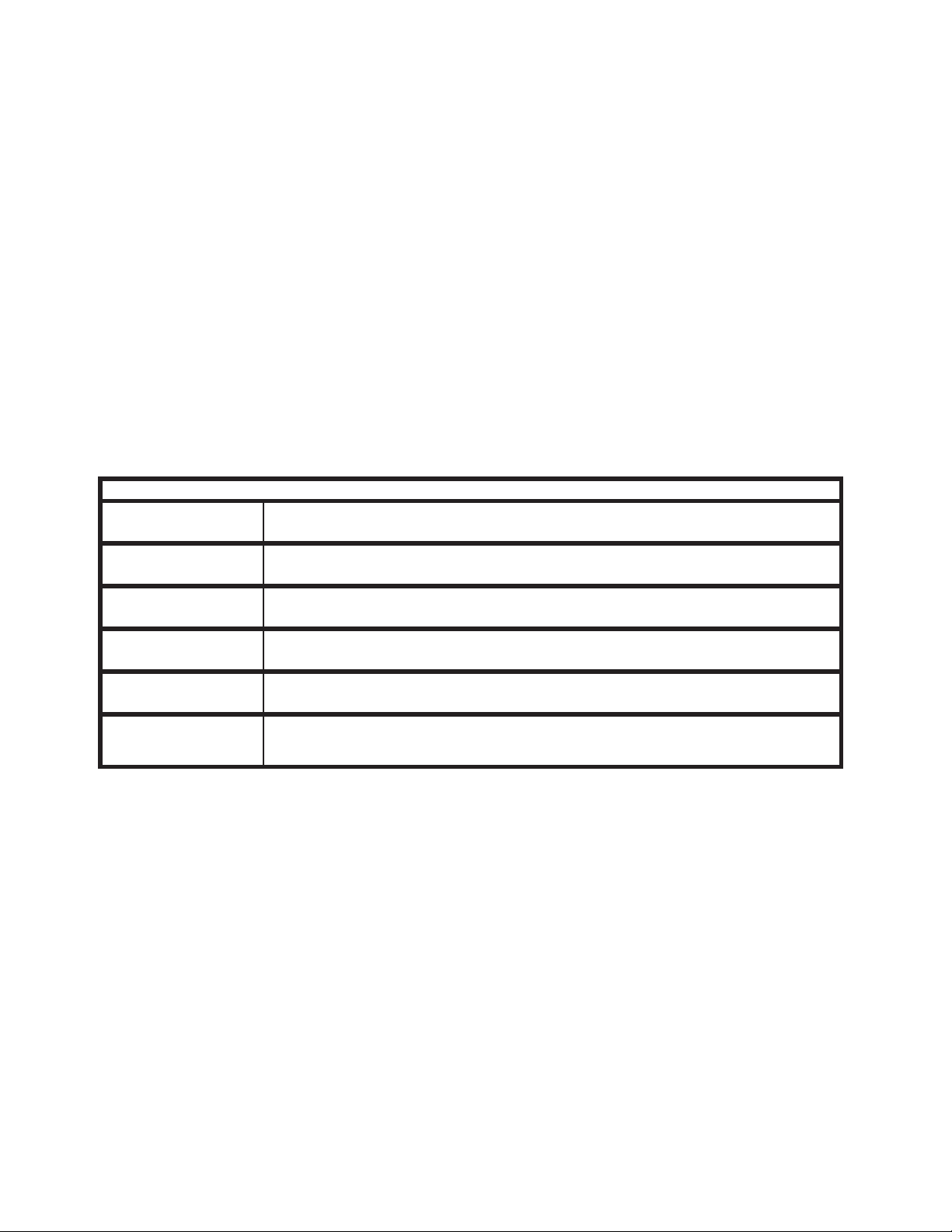

Maintenance

The recommended maintenance intervals listed in this manual are a guideline. Local conditions may require

shorter service intervals.

Maintenance items Interval

Oil Change* 25 hrs

Clean/replace spark arrestor** 25 hrs

Replace the air filter 25 hrs

Spark plugs 50 hrs

Fuel filter 50 hrs

Clean the engine 25 hours

* First oil change at 5 hours

**If equipped

5

Page 12

T65 Series Vertical Shaft Engines

Figure 1.2

Spark plugs

The information in this manual applies to the MTD

engine. Some basic principles may apply to engines produced by other manufacturers.

As the saying goes “an ounce of prevention is worth a

pound of cure”. The same can be said about preventive

maintenance on outdoor power equipment. By changing

the spark plug and oil at recommended intervals many fai lures can be avoided.

NOTE: Please refer to Chapter 7: Ignition for the

complete service instructions on spark

plugs.

1. The spark plug used in the T65 series engine is a

F5RTC (part # 951-14437) gapped to 0.024” -

0.031” (0.60 - 0.80 mm). See Figure 1.2.

2. Wear rate will vary somewhat with severity of use. If

the edges of the center electrode are rounded-off,

or any other apparent wear / damage occurs, replace the spark plug before operating failure (no start) occurs.

3. Cleaning the spark plug:

NOTE: MTD does not recommend cleaning spark plugs. Use of a wire brush may leave metal deposits on the

insulator that causes the spark plug to short out and fail to spark. Use of abrasive blast for cleaning

may cause damage to ceramic insulator or leave blast media in the recesses of the spark plug. When

the media comes loose during engine operation, severe and non-warrantable engine damage may

result.

4. Inspection of the spark plug can provide indicati on s of th e op er a ting con d ition of th e en gine .

• Light tan colored deposits on insulator and electrode s is nor mal.

• Dry , black deposits on the insulator and electrodes indicate an over-rich fuel / air mixture (too much fuel or

not enough air)

• Wet, black deposits on the insulator and electrodes indicate the presence of oil in the combustion cham-

ber.

• Heat damaged (melted electrodes / cracked insulator / metal transfer deposits) may indicate detonation.

• A spark plug that is wet with fuel indicates that fuel is present in the combustion chamber, but it is not

being ignited.

6

Page 13

Air filter

Figure 1.3

Foam filter

Paper-pleated element

The main function of the air filter is to trap air borne p articles before they reach the carburetor that can cause catastrophic internal engine damage.

MTD vertical shaft engines are equipped with one

of two different air filters. The first is a round paper pleated

filter. The second is a round foam filter. See Figure 1.3.

• Air filters used on the MTD engine are designed

to prevent particles larger than 3-5 micron from

passing through into the engine.

• The filter should be checked on a regular basis

possibly several times in a season.

• Typically an air filter should be changed before

every season.

• If a foam air filter is dirty, but not in bad of condition, it can be cleaned and reused. The paper

pleated filters can be shaken or lightly tapped to

free the debris from the filter.

Introduction

NOTE: Never use compressed air on a paper air filter . Compressed air will remove the tiny fibers that are used

to catch the dirt in the air. Without these fibers the filter is useless.

• Foam filters can be washed in warm soapy water.

NOTE: When drying a foam filter either squeeze it inside of a paper towel or let it air dry. DO NOT wring it.

Wringing the foam filter will cause damage to the foam.

NOTE: On foam filters, dry the filter throughly the n apply a couple of drops of motor oil. Gently work the oil

through the filter before installing it.

NOTE: Always check with factory specification prior to servicing/replacing any engine components.

7

Page 14

T65 Series Vertical Shaft Engines

SAE 40

SAE 30

SAE 10W30/SAE 10W40

SAE 5W20

-4°F

14°F

32°F 50°F 68°F 86°F 104°F

-20°C

-10°C

0°C

10°C 20°C

30°C

40°C

Oil Chart

Oil type and capacity

The recommended oil for MTD engines is an SAE 10W-30 oil with an SM API rating or better . The oil capacity is

20 fl.oz (0.6 liters).

• Check the oil level daily, before starting the engine. Change the oil more frequently in severe operating

conditions such as high ambient temperature, dusty conditions, or high load use in exceptionally thick

grass.

• Synthetic oil is a suitable alternative, but it does not extend service interva ls.

NOTE: MTD recommends the use of petroleum oil during the break in period to ensure the piston rings cor-

rectly break in.

• Synthetic vs. Petroleum based oil: To simply look at synthetic oil and to compare it with Petroleum based

oil there is very little difference. However, when you look at the two thro ugh a micro scope it is easy to see

the difference. Synthetic is made up of smaller molecules. This allows the oil to get into areas that petroleum based oil cannot.

• No oil additives or viscosity modifiers are recommended. The performance of a good oil meeting the API

specifications will not be improved by oil additives.

NOTE: Some oil additives may cause severe and non-warrantable engine damage, constituting a lubrication

failure.

NOTE: If the oil is noticeably thin, or smells of gasoline, a carburetor repair may be needed before the engine

can be run safely.

8

Page 15

Introduction

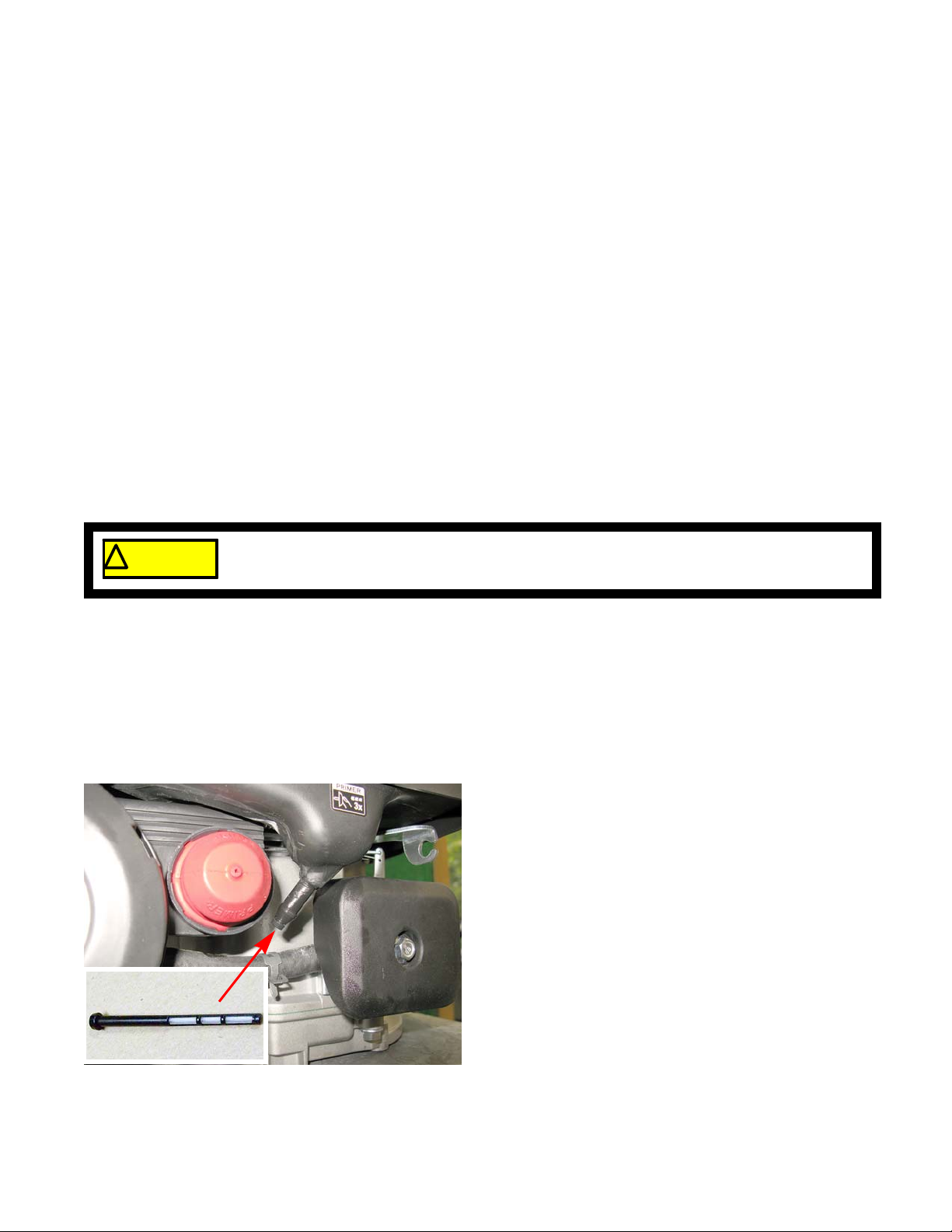

Figure 1.4

1/4 turn

Threaded

1/4 turn

Threaded

Figure 1.5

Dip stick

Figure 1.6

Fully seat the

dip stick before

reading it

NOTE: There are two types of dip sticks that can be found

on the T series engine; a short threaded dip stick

and a quarter turn extended dip stick See Figure

1.4.

To check the oil with a threaded dip stick:

1. Twist and remove the dip stick from the engine.

2. Clean the oil off of the tip of the dipstick.

3. Re-insert the dipstick without threading it in to get

the oil level reading. See Figure 1.5.

4. The oil level is determined by the lowest point on the

dipstick that is completely covered with oil.

To check the oil with a 1/4 turn dip stick:

1. Twist and remove the dip stick from the engine.

2. Clean the oil off of the tip of the dipstick.

3. Re-insert the dipstick and turn it until it is fully

seated to get the oil level reading. See Figure 1.6.

4. The oil level is determined by the lowest point on the

dipstick that is completely covered with oil.

9

Page 16

T65 Series Vertical Shaft Engines

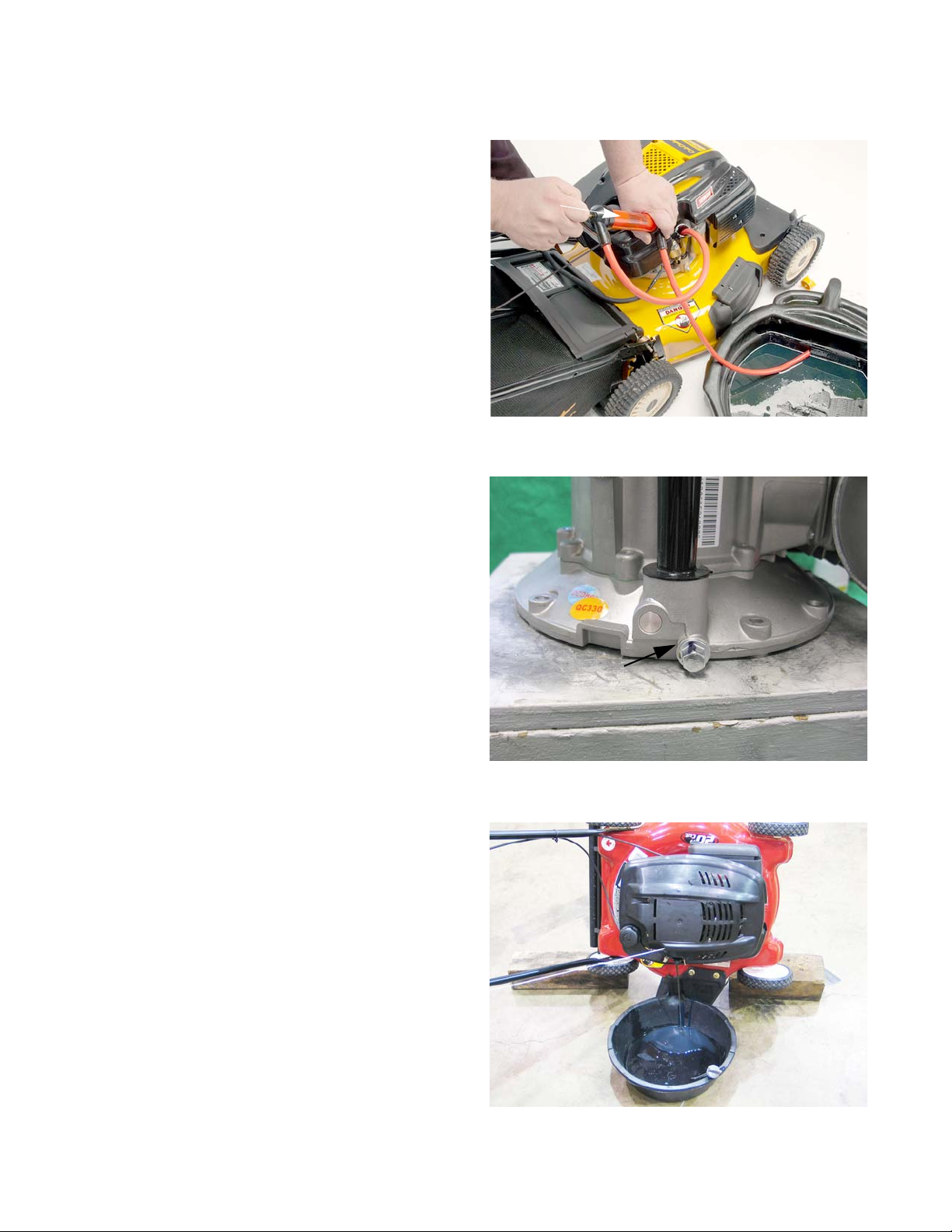

Figure 1.7

Siphon

Figure 1.8

Drain Plug

Figure 1.9

Changing the oil

NOTE: If the engine has been running, allow the

engine to cool before doing any maintenance work.

NOTE: The oil should be changed after the first 5

hours of operation and every 25 hours there

after.

NOTE: There are three methods o f changing the oil.

Siphon the oil out through the dip stick tube

A. Insert the siphon hose into the dip stick tube. See

Figure 1.7.

B. Siphon the oil out of the engine by following the pro-

cedures provided by the siphon manufacturer.

Drain Plug in the bottom of the dipstick tube

A. Place an approved oil drain pan next to the base of

the dip stick.

B. Remove the drain plug using a 1/4” extension. See

Figure 1.8.

C. Allow all of the oil to drain into the oil pan.

D. Apply a small amount of releasable thread sealing

compound such as Loctite® 565 to the threads of

the drain plug.

E. Install the drain plug, tightening it to a torque of 124

- 150 in lbs (14 - 17 Nm).

Tip the engine and application over

A. Drain the fuel out of the fuel tank.

B. Place an approved oil drain pan on the ground.

C. Lean the unit over on to the muffler side of the

engine. See Figure 1.9.

D. Leave the application in this position until all of the

oil has drained out.

E. Tip the unit back to its normal operating position.

10

Page 17

Introduction

! CAUTION! CAUTION

Gasoline and its vapors are extremely flammable. Use common sense when working around

the fuel system. Avoid sparks, open flames or heat sources that can ignite the fuel vapors.

Figure 1.10

Fuel filter

Fuel system

What you should know about fuel.

Most of the fuel presently available in North America is oxygenated to some extent. This is commonly done

through the addition of ethanol. Most engines offered for sale on outdoor power equipment in the North American

markets are designed to tolerate no more than 10% ethanol by volume

Ethanol is hygroscopic, meaning it absorbs water. If left exposed to air, it will draw water out of the air.

Ethanol is an oxygenator, which means that it will oxidize (corrode) metal that it comes into contact with. Exposure to air causes fuel to go bad quickly, leaving gum and varnish deposits.

Fuel used in MTD outdoor power equipment should be no more than 30 days old. Because it may already have

been stored at the refinery or gas st ation for a week or mo re, fu el should be purchased in small quan tities and stored

in safety approved gas cans with the caps closed.

For storage, all fuel should be run out of the tank and engine. Anti-oxidation additives will help keep the fuel

fresher.

Servicing the fuel system

Inspect the fuel system every time the engine is operated. If dirty fuel is found in the fuel tank or fuel that does not

smell “right”, drain the fuel tank and replace the fuel filter. Dispose of bad fuel in a safe and legal manner.

Refer to the units service manual for the procedures to drain the fuel tank.

Fuel filter

1. The fuel filter is installed in the fuel tank where the

fuel line connects. See Figure 1.10.

11

Page 18

T65 Series Vertical Shaft Engines

Figure 1.11

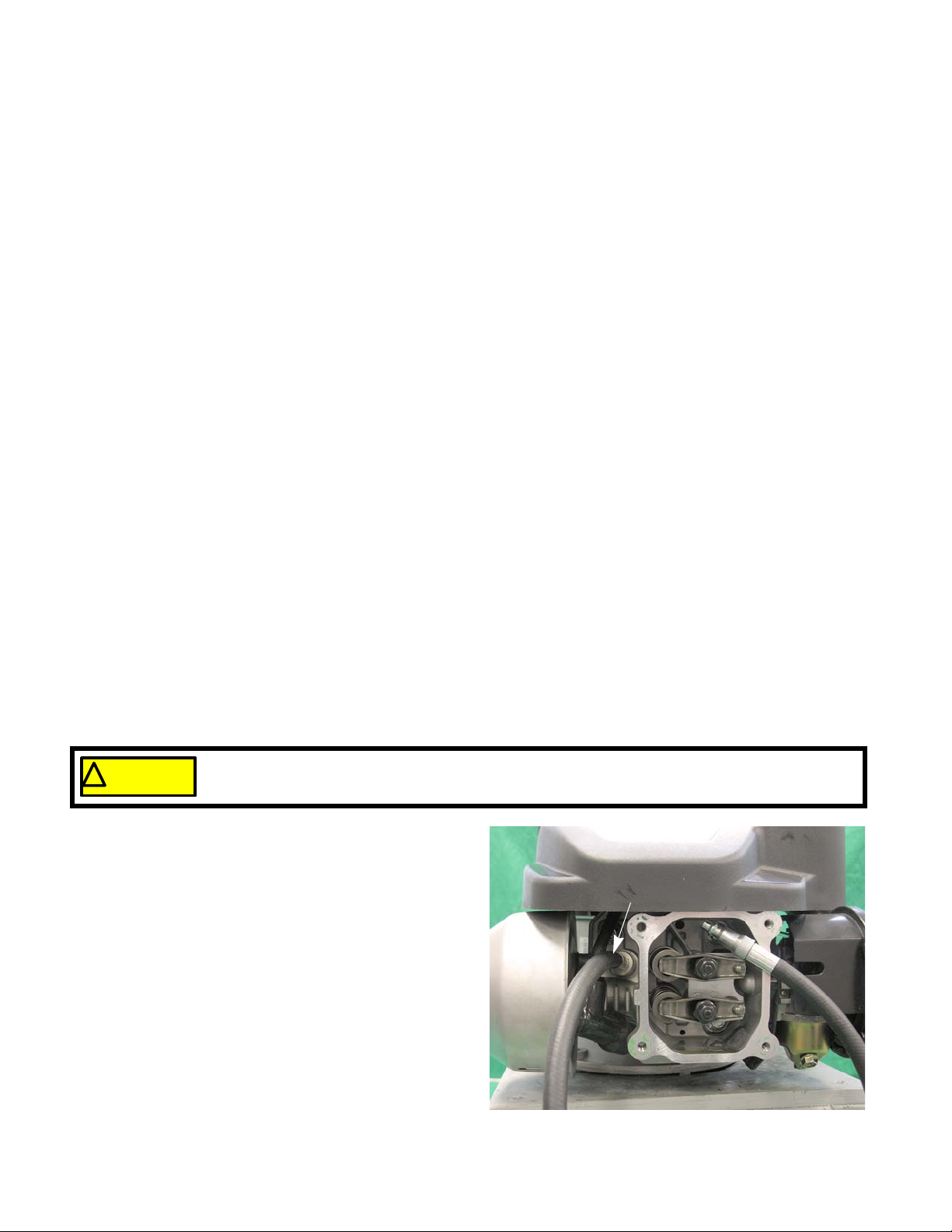

Spark plug hole

High tension lead

Muffler

(plug removed)

Figure 1.12

Valves closed

(push rods slack)

Probe to confirm piston

is at top of travel

Valve lash

Valve lash is the clearance between the top of the valve stem and the rocker arm. The valve lash should be

checked after the first 25 hours of use and ever y 100 hour s a f ter th at. Valve lash can be checked and adjusted using

the following steps:.

1. If the engine has been run, allow it to cool thor-

oughly. Position the mower for easy access to the

cylinder head.

2. Disconnect the high-tension lead from the spark

plug and ground it well away from the spark plug

hole.

3. Remove the spark plug using a 13/16” or 21mm

wrench. A flexible coupling or “wobbly” extension

may help. See Figure 1.11.

4. Remove the four bolts that secure the valve cover

using a 10mm wrench, and remove the valve cover

from the engine.

NOTE: If care is used not to damage the valve

cover gasket, it can be re-used.

5. Confirm that the piston is at T

on the compression stroke. See Figure 1.12.

NOTE: An old plastic dip stick makes a nice probe

to check for TDC.

• The compression stroke can be distinguished

from the overlap stroke by the presence of air

pressure at the spark plug hole and the fact that

neither of the valves should move significantly

on the compression stroke.

• There is an automatic compression release mechanism that “bump s” the exhaust valve a s the piston rises

on the compression stroke. At TDC, th e exhaust valve should be fully closed.

op-Dead-Center (TDC)

12

Page 19

Introduction

Figure 1.13

0.005” feeler

gauge

Setting intake valve lash

Figure 1.14

Setting exhaust valve lash

gauge

0.007” feeler

6. Check valve lash between each valve stem and

rocker arm using a feeler gauge.

7. Intake valve lash (top valve) should be 0.004” -

0.006” (0.10 - 0.15 mm). See Figure 1.13.

8. Exhaust valve lash (bottom valve) should be 0.006” -

0.008” (0.15 - 0.20 mm). See Figure 1.14.

11. Double-check the clearance after tightening the jam nut, to confirm that it did not shift. Re-adjust if necessary.

12. Rotate the engine through several compression cycles:

13. Clean-up any oil around the valve cover opening, clean the valve cover, replace the valve cover gasket if nec-

14. Install the valve cover, tightening the valve cover screws to a torque of 62 - 80 in-lbs (7 - 9 Nm).

9. Use a 10mm wrench to loosen the jam nut, and a

14mm wrench to adjust the rocker arm fulcrum nut.

See Figure 1.14.

• Tighten the rocker arm fulcrum nut to close-up the

clearance between the end of the valve stem and

the contact point on the rocker arm.

• Loosen the rocker arm fulcrum nut to open-up the

clearance between the end of the valve stem and

the contact point on the rocker arm.

10. Hold the fulcrum nut with a 14mm wrench, tighten the

jam nut to a torque of 80 - 106 in-lb. (9 - 12 Nm) using

a 10mm wrench.

• Observe the movement of the valve gear.

• Return the piston to TDC compression stroke and re-check the valve lash.

essary.

IMPORTANT: Over tightening the valve cover will cause it to leak.

15. Install the spark plug.

16. Te st ru n th e en gin e befo r e returning it to service.

13

Page 20

T65 Series Vertical Shaft Engines

41M 21M 01Mezis 8M 6M 5M

4Mezis

347261sbl-tf398322

1

1sbl-ni8.4 edarG

856.637.12mN5.013.45.22.1mN

5553

02sbl-tf021058251sbl-ni8.5

675.741.72mN6.317.52

.3

7

.1

mN

791653sbl-tf612881562sbl-ni8.8

2317.285.74mN

4.4

29

.

98.5

9.2

mN

6316894sbl-tf0034212763sbl-ni

9.0

1

4816.6114.6

6

mN9.3

3

41

1.8

1.4

mN

261

30

1

0

6sbl-

tf063641

6

8

44sbl-ni

9.2

1

02

2

7.93

1

4.18

m

N

7.0

4

5.61

7.9

5

m

N

075452sbl-tf051065381sbl-ni

m

N

59169.33mN7

1

8.6

4

2

lacitircno

N

ni srenetsa

F

munimulA

Exhaust system

The exhaust system is a frequently overlooked component of an engine. It is important to make sure the muf f ler is in

good condition and free of blockage.

NOTE: A blocked muffler will result in poor performance. If a muffler is completely blocked, the engine may not

start.

Cleaning the engine

1. To maintain a proper operating temperature and to keep the equipment looking good, all debris should be

removed from around the engine.

2. It is recommended to use compressed air to blow all of the debris off of the engine.

NOTE: A pressure washer may be used to clean outdoor power equipment but only after the unit has been

allowed to properly cool.

General torque specifications

14

Page 21

Definitions

! CA UTION! CA UTION

The first two rules in troubleshooting is to cause no further harm to the engine and prevent

injuries. Always make sure to check the oil for level and condition before starting an engin e.

Also check attachments for damage and make sure they are firmly mounted.

Basic Troubleshooting

CHAPTER 2: BASIC TROUBLESHOOTING

Troubleshooting

Diagnosis

shooting.

Introduction

Diagnosing an engine is an art form that is built upon several factors. First and most importantly is a good understanding of how the engine works. The second is skills that have been honed by experience. Finally the use of visual

observations and a structured, systematic approach to troubleshooting a problem.

The first part of this chapter will outline the steps of troubleshooting an engine so a technician can form a proper

diagnosis. The second half of this chapter will describe specific procedures and tests to perform while troubleshooting.

Steps to troubleshooting

NOTE: The steps and the order of the steps that follow are a suggested approach to troubleshooting the MTD

Define the problem

The first step in troubleshooting is to define the problem:

- The act of gathering information by preforming tests and direct observations.

- Developing and testing theories of what the problem is, based on the information gathered in trouble-

engine. The technician does not necessarily have to follow them as described in this chapter.

• Crankshaft will not turn.

A. Starter not working.

B. Engine in a bind (external - attachment jammed).

C. Engine in a bind (internal - engine seized).

• Crankshaft turns, no start.

• Starts, runs poorly.

A. Starts, then dies.

B. Runs with low power output.

C. Makes unusual smoke when running.

I. Black smoke, usually heavy.

II. White smoke, usually heavy.

III. Blue smoke. usually light.

D. Makes unusual sounds when running.

I. Knock

II. Click

III. Chirp

15

Page 22

T65 Series Vertical Shaft Engines

IV. Unusual exhaust tone.

There are tools that the technician can use in order to define the problem, such as:

1. Interview the customer.

1a. Get a good description of their complaint.

1b. If it is an intermittent problem, verify what conditions aggravate the problem as best as possible.

1c. Get an accurate service history of the equipment.

1d. Find out how the customer uses and stores the equipment.

2. Direct observation:

2a. Do not automatically accept that the customer is correct with their description of the problem. Try to

duplicate the problem.

2b. Check the general condition of the equipment (visually).

I. Cleanliness of the equipment will indicate the level of care the equipment has received.

II. Make sure the engine and attachments are securely fastened.

III. The tune-up factors.

NOTE: Most hard starting and poor running conditions can be solved by performing a tune-up.

a. Check the conditio n and amount of oil in the crankcase.

b. Check the level and condition of the fuel.

c. Check the ignition and “read” the spark plug.

d. Look for obvious signs of physical damage, exhaust system blockage or cooling system block-

age.

16

Page 23

Identify factors that could cause the problem

This is the second step in the troubleshooting process.

1. Crankshaft will not turn.

Basic Troubleshooting

A. Starter not working

I. A dead battery.

II. A bad ground.

III. A failure in the electrical circuit.

IV. A failure of the starter itself.

B. Engine in a bind (external - atta ch men t jamme d)

the engine either failed or has something jammed in it, locking up the system.

C. Engine in a bind (internal - engine seized)

likely suspects are:

I. Complete hydraulic lock (easy fix).

II. Bent crankshaft.

III. Interna l binding, crankshaft, connecting rod or piston.

2. Crankshaft turns, no start.

2a. Most gasoline engine diagnosis involves isolating problems in the four critical factors an engine needs to

run properly:

I. Ignition

II. Compression

needs sufficient sealing to generate the vacuum needed to draw in and atomize the next intake

charge.

- sufficient spark to start combustion in the cylinder, occurring at the right time.

. This can be an electrical failure or a mechanical failure. The likely suspects are:

. This usually indicates that the unit being powered by

. This is usually either a quick fix or a catastrophic failure. The

- enough pressure in the cylinder to convert combustion into kinetic motion. It also

III. Fuel

IV. Flow

2a. Isolate the ignition system and compression from the fuel system by preforming a prime test.

I. Burns prime and dies. This would indicate a fuel system issue.

II. Does not burn prime. Not a fuel system issue. Check for an ignition, compression or flow problem.

2c. Compression or ignition problem.

I. Check the engine stop and safety switch.

II. Test the ignition system using a proper tester.

III. Replace the spark plug with a new one or a known good one.

IV. Check compression or leak down.

V. Check valve lash.

VI. Check valve timing/actuation.

VII. Check exhaust.

3. Starts, runs poorly.

3a. Starts, then dies.

- correct type and grade of fresh gasoline; in sufficient q uantity, atomized (tiny droplets) and in

correct fuel/air proportions.

- if all of the above conditions are met but the flow of air is constricted on the inlet or exhaust

side, it will cause the engine to run poorly or not at all. This also includes ensuring the valves are

timed to open at the proper time.

17

Page 24

T65 Series Vertical Shaft Engines

I. Run the engine with a spark tester in-line between the sp ark plug wire and the sp ark plug or use an

oscilloscope and see if the spark goes away at the same time the engine dies.

II. Check choke operation.

a. Black smoke?

b. Wet plug?

III. Prime test immediately after engine dies. If it restarts, this may indicate a problem with fuel flow to

the carburetor. Check the gas cap, fuel line, fuel filter, and the float in the carburetor.

3b. Runs with low power output.

I. Look for unusual exhaust color (smoke).

II. Unusually hot muffler (may glow red).

a. Retarded ignition.

b. Exhaust valve opening ea rly (lash too tight).

III. Mechanical bind.

a. A slightly bent crankshaf t. In some cases the drag may increase and decrease as the crankshaf t

rotates. This produces a pulsing feeling that is different than a jerk back.

b. Parasitic external load. A bind in the equipment the engine is powering.

c. Internal drag from a scored piston or similar damage.

IV. Low governor setting or stuck governor.

a. Check RPMs using a tachometer.

b. RPMs should not droop under moderate to heavy loads.

V. Low comp re ss ion .

a. Check valve lash.

b. Check compression.

c. Check leak down to identify the source of the compression loss.

VI. Flow blockage.

a. Exhaust blockage, usually accompanied by an unusual exhaust sound.

• Just as a throttle on the carburetor controls the engine RPMs by limiting the amount of air an

engine can breathe in, an exhaust blockage will limit engine performance by constricting the

other end of the system.

• The muffler itself my be blocke d.

• The exhaust valve may not be opening fully, possibly because of extremely loose valve lash

settings.

• The exhaust valve seat may have come loose in the cylinder head. This may cause a loss of

compression, a flow blockage or it may randomly alternate between the two.

NOTE: The cause of an exhaust valve coming loose is usually over heating.

b. Intake blockage.

• An intake blockage up-stream of the carburetor will cause a rich fuel/air mixture and constrict

the amount of air that the engine can dr aw in, limitin g pe rf or ma n ce .

• The intake valve not fully opening. A possible cause of this is loose valve lash.

18

Page 25

V. Makes unusual smoke when running.

Basic Troubleshooting

a. Black smoke

• Not enough air: air flow blockage or a partially closed choke.

• Too much fuel: carburetor float or float valve stuck or metering / emulsion issues with the carburetor.

b. White smoke

• Oil in muffler, usually the result of improper tipping. The engine will “fog” for a minute or so,

then clear-up on its own.

• Massive oil dilution with gasoline. It may be caused by improper tipping. It can also be caused

by leaky carburetor float valve, if there is a down-hill path from the carburetor to the intake port.

Check oil for gasoline smell, repair carburetor.

c. Blue smoke,

PCV system.

• May be blocked or unplugged.

• May be over-come by massive over-filling or oil dilution with gasoline.

• Will cause oil to exit the engine via any low-resistance paths.

Piston rings.

• Confirm with leak-down test.

• Smoke will be more pronounced under load.

, usually heavy, usually indicates a rich air fuel mixture.

, usually heavy.

usually light.

• Repair may not make economic sense.

Valve gu ide s (a nd intake valve ste m sea l).

• Smoke will be more pronounced on over-run.

VI. Makes unusual noise when running.

a. Knock

• Check for loose mounting of engine or driven implement.

• Rotate crankshaft back-and-forth to check for loose connecting rod.

b. Click

• Clicks and pops on engine shut-down: Compression release coming into play as the engine

RPMs cross the activation threshold. This will have no ill effects on engine performance.

• Half-engine speed clatter: loose valve lash.

• Half-engine speed clatter, slightly heavier: wrist-pin.

• Rhythmic heavy-light engine speed click: piston slap.

c. Spark-knock

• Advanced ignition timing.

• Low octane fuel.

• Over-heating engine (check for blocked cooling air flow).

• Carbon build-up in cylinder: glowing carbon chunks pre-igniting air fuel mix.

d. Chirp

• Compression, blowing-by the fire-ring of a damaged head gasket will sometimes produce a

19

Page 26

T65 Series Vertical Shaft Engines

chirping noise.

• Confirm with a compression test and leak-down test.

e. Unusual exhaust tone.

Splashy

• Splashy idle usually indicates a slight rich condition.

• May indicate an exhaust blockage, usually slightly muffled.

Backfire

• On over-run: unburned fuel igniting pa st ex haust valve . Mixture no t bur ning com pletely in combustion chamber. It may be too rich or it may be spark-plug or ignition problem.

• Occasional, under load: engine momentarily runs lean, usually will cycle with float bowl level or

governor pull-in, sometimes sounds like a slight stumble. Ethanol content exceeding 10% will

make the engine run artificially lean.

Skip

• Usually ignition related.

• Run the engine with a spark tester in-line between the spark plug wire and the spark plug or

use an oscilloscope and see if the spark goes away at the same time the engine dies.

4. Engine over-speed

A. Continual over-speed.

• Binding or damaged external governor linkage or carburetor thro ttle.

• Mis-adjusted governor arm.

• Internal governor failure.

B. Momentary over-speed.

• Intermittent bind (very unusual).

• Interference: This is fairly common when debris can fall on the governo r linkage d uring n ormal

operations.

5. Engine RPMs surge (hunting).

A. Over-governed condition- Return spring replaced with wrong part or hooked into wrong hole.

NOTE: This is an extremely rare condition, usually created by tampering.

B. Lean Air-fuel mixture condition- When AFR (Air Fuel Ratio) is significantly below stoichiometric ratio

(14.7:1) engine RPMs sink until they reach a po int tha t can be su pp or te d by the availa b l e fuel . Th is

causes a momentary surge in power until the available fuel is consumed, then the RPMs fall again,

repeating the cycle.

• Too much air: look for an air leak in the intake tract.

• Not enough fuel: look for fuel supply or carburetor problems.

20

Page 27

Basic Troubleshooting

Repairing the problem

The third step in the troubleshooting process is to repair the problem. This step consists of:

A. Form a diagnosis by using all of the information gathere d from the tro ub leshoo ting th at was p erforme d.

B. Physically perform the repair.

The fourth, and hopefully final, step in the troubleshooting process is the follow through. This step consists of:

A. Thoroughly test the repaired equipment: confirming that the initial diagnosis was correct. If it was

wrong, start the troubleshooting process over again.

NOTE: Sometimes the engine will have multiple problems at the same time. By performing one repair, other

issues may show up that are unrelated to the first repair.

B. Delivery to customer: We are not just repairing equipment, we are repairing customers.

• Inoculate against recurring problem with educa tion, e.g.: if the problem was caused by stale

fuel, make sure the customer is aware that fuel go es bad ove r tim e.

• Make sure the customer understands the repair, preventing “superstitious” come-backs.

21

Page 28

T65 Series Vertical Shaft Engines

! CA UTION! CAUTION

If the engine is not centered at top dead center, the engine will rotate when compressed air is

introduce to the combustion chamber.

Figure 2.1

Leak-down

tester adapter

Prime test

To perform a prime test:

1. Prime the engine through the carburetor throat using a squirt bottle, filled with clean fresh gasoline.

2. Make sure the throttle is in the run position.

3. Attempt to start the engine.

4. If the engine starts and runs long enough to burn the prime, the problem is effectively isolated to the fuel system. Proceed to Chapter 4: The Fuel System and Governor.

5. If the engine did not start, check ignition system as described in Chapter 7: Ignition System.

6. If the ignition system is working, check the compression or perform a leak down test.

Leak-down test

A leak-down test is the preferred method to test the engine’s ability to compress the charge. It will also show

where pressure is leaking from.

To perform a leak-down test:

NOTE: A leak down test pressurizes the combustion chamber with an external air source and will allow the

technician to listen for air “leaking“ at the valves, piston rings and the head gasket.

NOTE: These are general instructions. Read and follow the instruc tions that came with the tester before

attempting to perform this test.

• If possible, run the engine for 3-5 minutes to warm up the engine.

• Remove the spark plug and air filter.

• Find top dead center of the compression stroke.

1. Find top dead center by following the steps

described in the valve lash section of Chapter 1:

Introduction.

2. Thread the leak down tester adapter into the spark

plug hole. See Figure 2.1.

22

Page 29

Basic Troubleshooting

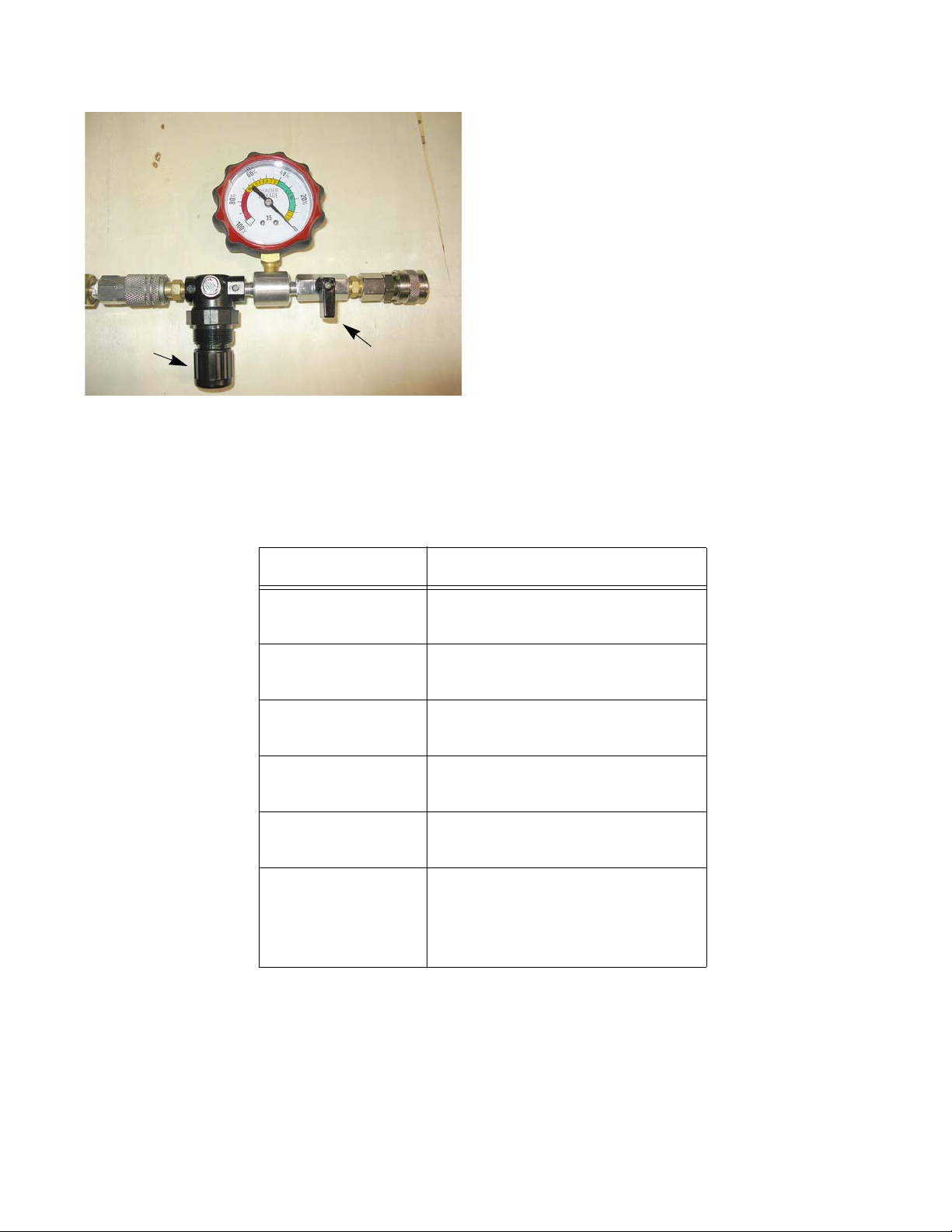

Figure 2.2

Regulator

knob

Valve

3. Connect tester to compressed air.

4. Adjust the regulator knob until the needle on the

gauge is in the yellow or set area of the gauge. See

Figure 2.2.

5. Connect the tes te r to th e ad ap te r.

NOTE: Open the valve, if equipped.

NOTE: If the engine rotates it was not at top dead center.

6. Check the reading on the gauge.

7. Compare the results to the following chart.

Leak-down Testing Results

Symptom Possible cause

Air escaping from

the breather

Air escaping from

Worn cylinder or piston rings.

Possible blown head gasket

Leaking exhaust valve

the exhaust

Air escaping from

Leaking intake valve

the carburetor

Gauge reading

low

Gauge reading

moderate

Gauge reading

high

Cylinder and piston rings are in

good condition

There is some wear in the

engine, but it is still usable

excessive wear of cylinder and/

or piston rings. Engine should

be short blocked or it could be a

blown head gasket.

23

Page 30

T65 Series Vertical Shaft Engines

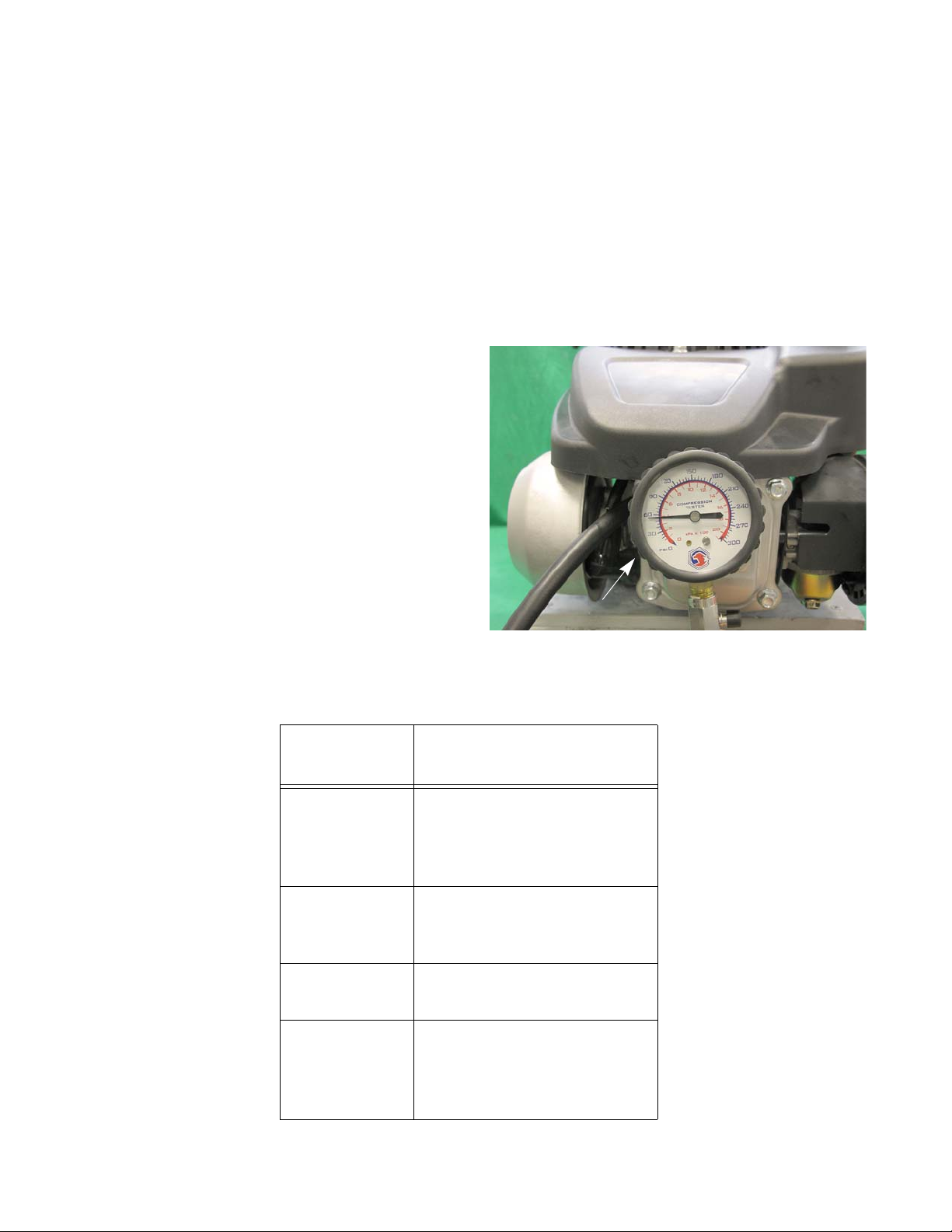

Figure 2.3

Compression gauge

Compression test

To perform a compression test:

NOTE: Compression should be in the range of 55 - 85 PSI (3.8 - 5.9 Bar).

• Disconnect the high-tension lead from the spark plug and ground it well away from the spark plug hole.

• Remove the spark plug using a 13/16” or 21mm wrench. A flexible coupling or “wobbly” extension may

help.

• Pull the starter rope several times to purge any fuel or oil from the combustion chamber.

NOTE: Air compresses readily, liquid does not. Liquid in the combustion chamber will result in an artificially

high compression reading.

1. Install a compression gauge in the spark plug hole.

2. Confirm that the gauge is “zeroed”, then pull the

starter rope repeatedly, until the needle on the

gauge stops rising. See Figure 2.3.

3. Interpreting compression readings.

Readings in

psi

<20

(1.4 Bar)

20 - 55

(1.4-3.8 Bar)

55 - 85

(3.8-5.9 Bar)

>85

(>5.9 Bar)

Compression Readings

Possible causes

Most likely a stuck valve or

too tight of a valve lash,

provided the starter rope

pulls with normal effort.

Valve seat damage or piston ring and/or cylinder

wear.

Normal readings

Excessive valve lash, a

partial hydraulic lock, a bad

cam or a bad automatic

compression relief.

24

Page 31

PCV testing

Figure 2.4

Breather

Breather hose

Figure 2.5

Basic Troubleshooting

The PCV (Positive Crankcase Ventilation) valve is

located in the engine block and allows the crankcase pressure to escape.

Leakage and blockage are the two failure modes for a

PCV system. Either mode will cause crankcase pressure

to build-up, though the effects of a blocked PCV are gene rally more dramatic. Increased case pressure will result in

oil entering the combustion chamber.

NOTE: The PCV chamber is vented to the air filter th rough

a molded rubber hose. The rubber hose directs

crankcase fumes to a covered duct within the air

filter housing. See Figure 2.4.

To measure the crankcase pressure:

1. Remove the dipstick.

2. Attach a manometer to the dipstick tube.

3. Start the engine.

4. Read the measurement on the manometer. See Figure 2.5.

NOTE: Less than (between zero and -1”) (-2.54cm) of

water is a typical reading.

NOTE: Experimentation by MTD’s Training and Education

Department has revealed the following characteristics of MTD engines:

• A leaky PCV system will not build-up substantial

case pressure.

• A leaky PCV system will allow the engine to ingest

contaminants through the system, accelerating

engine wear.

• A blocked PCV system will allow crankcase pres-

sure to build very rapidly. Noticeable oil fumes will

be evident in the exhaust within several minutes of

normal operation.

25

Page 32

T65 Series Vertical Shaft Engines

Ignition Troubleshooting

Engine will

not start

Engine runs

erratically or shuts

off, restarts

Check for spark

Spark No Spark

Check for the correct spark

plug

Check flywheel and key for

damage or sheared key

Set proper air gap on

ignition module

Test ignition module

for intermittent or

weak spark

Check electric starter and

battery if applicable

Replace spark plug

Isolate engine from

equipment and repeat

test

Spark No Spark

Equipment problem,

check switches, wiring

and equipment controls

Engine problem, check

for shorts or grounds in

wiring

Disconnect ignition

ground-out wire at

the ignition module &

repeat test

Check for proper air gap

on ignition module

and repeat test

Check flywheel magnets

for strength

Test ignition module

Troubleshooting flow charts

26

Page 33

Engine Operation Problems

Excessive engine loading

OVERHEATS

Low oil level or wrong viscosity oil

Cooling air flow obstructed or

clogged cooling fins

Carburetor improperly adjusted or

improper RPM setting*

Ignition timing or

incorrect spark plug

Carbon in the combustion

chamber

ENGINE KNOCKS

Check for excessive carbon in

combustion chamber

Loose flywheel examine key, key way

and proper flywheel nut torque

Ignition timing or

incorrect spark plug

Loose or worn connecting rod

Worn cylinder

Associated equipment loose or

improperly adjusted

Basic Troubleshooting

27

Page 34

T65 Series Vertical Shaft Engines

SURGES OR RUNS UNEVENLY

Fuel cap vent obstructed

Dirty carburetor or air filter

Carburetor improperly adjusted

Governor sticking, binding or

improper RPM setting

Carburetor linkage, shafts or

shutters sticking or binding

Intermittent spark, check ignition

or incorrect spark plug

Oil level above full

Wrong viscosity oil

Engine cooling fins dirty causing

overheating

Breather damaged, dirty or

improperly installed

Excessive engine speed

Damaged gaskets, seals or "O" rings

EXCESSIVE OIL CONSUMPTION

Valve guides worn excessively

Worn or glazed cylinder

Piston rings worn

Lean carb setting causing

overheating (adjustable carb)

Engine Operation Problems

28

Page 35

ENGINE MISFIRES

Improper Valve Lash

Weak valve spring

Excessive carbon build up

Carburetor improperly adjusted

Ignition timing or

incorrect spark plug

Valves sticking or not

seating properly

Wrong or fouled spark plug

Bent crankshaft

ENGINE VIBRATES

EXCESSIVELY

Attached equipment out

of balance

Loose mounting bolts

If applicable counter balance not

properly aligned

Engine Operation Problems

Basic Troubleshooting

29

Page 36

T65 Series Vertical Shaft Engines

BREATHER PASSING OIL

Oil level too high

Breather damaged, dirty or

improperly installed

Damaged gaskets, seals

or "O" rings

Excessive RPM or improper

governor setting

Angle of operation too severe

Piston rings not properly seated

or ring end gaps are aligned

LACKS POWER

Air intake obstructed

Lack or lubrication or improper

lubrication

Carburetor improperly adjusted

Exhaust Obstructed

Improper valve lash

Loss of compression (worn rings,

blown head gasket)

Engine Operation Problems

30

Page 37

Air filter

Figure 3.1

Figure 3.2

Air filter

AIR INTAKE SYSTEM

CHAPTER 3: AIR INTAKE SYSTEM

To access the air filter:

NOTE: The T65 engine comes equipped with either a

pleated paper filter or a foam filter. The procedure

to access the filter is the same for both types.

1. Rotate air filter cover counter-clockwise. See Figure

3.1.

2. Pull cover off of the engine.

3. Remove the air filter. See Figure 3.2.

4. Install by following the above steps in reverse order.

31

Page 38

T65 Series Vertical Shaft Engines

Figure 3.3

Nuts

Figure 3.4

Primer line

Breather hose

Figure 3.5

Squeeze the barbs together,

then push

Air Filter Housing

To remove the air filter housing:

1. Remove the air filter by following the steps

described in the previous section.

2. Remove the two nuts that hold the air filter body to

the carburetor mounting studs. See Figure 3.3.

3. Disconnect the breather hose. See Figure 3.4.

4. Disconnect the primer line, if equipped. See Figure

5. Lift away the filter housing.

6. The primer can be removed from the air filter hous-

3.4.

ing by squeezing together the two sets of barbs

while pushing the primer out of the housing. See

Figure 3.5.

32

Page 39

Carburetor Insulator

To avoid personal injury or property damage, use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. Serious personal injury can occur

when gasoline is spilled on yourself and/or your clothes which can ignite. Wash your skin

and change clothes immediately

! WAR N IN G! WAR N IN G

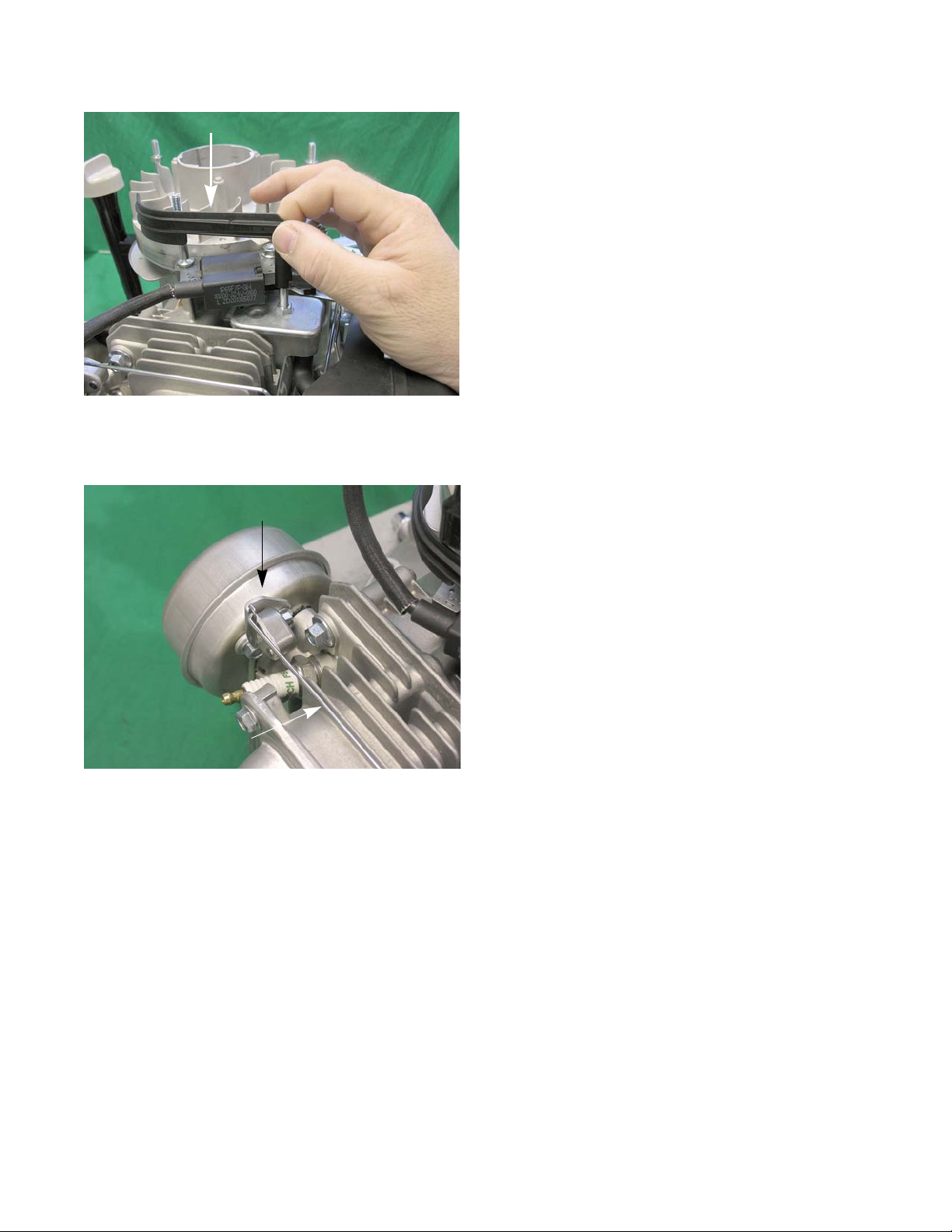

Figure 3.6

Figure 3.7

Tin gasket

Autochoke Linkage Bracket

AIR INTAKE SYSTEM

To remove/replace the carburetor insulator:

1. Remove the air filter housing by following the previously described steps.

2. Remove the carburetor.

2a. Clamp off the fuel line.

2b. Disconnect the fuel line from the carburetor.

2c. Drain the fuel tank in to an approved container .

2d. Remove and discard the fuel line. See Figure

3.6.

NOTE: Disconnecting the fuel line causes tiny tears in the

inner lining of the fuel line. These tears will collapse the inner lining, cutting off fuel flow.

NOTE: If the engine is not equipped with an autochoke,

skip ahead to step 2l.

2e. Remove the recoil starter by following the pro-

cedures described in Chapter 6: Starters

2f. Lift the blower housing off of the engine.

2g. Remove the tin gasket. See Figure 3.7.

2h. Remove the Autochoke Linkage Bracket.

2i. Remove the carburetor gasket.

33

Page 40

T65 Series Vertical Shaft Engines

Figure 3.8

Air vane

Choke rod

Figure 3.9

Mounting studs

Carburetor gasket

Figure 3.10

Throttle arm

Governor rod

2j. Lift the Autochoke Air Vane off of the its pivot.

2k. Unhook the choke rod from the carburetor.

See Figure 3.8.

2l. If the engine is not equipped with an auto-

choke, remove the carburetor gasket.

2m. Slide the carburetor off of the mounting studs.

See Figure 3.9.

2n. Rotate the throttle arm until it meets the idle

speed screw, then pivot the carburetor slightly

to disengage the 90 degree bend at the end of

the governor rod. See Figure 3.10.

2o. Unhook the stabilizer spring that takes-up the

play between the governor arm, the governor

rod, and the throttle arm on the carburetor.

34

Page 41

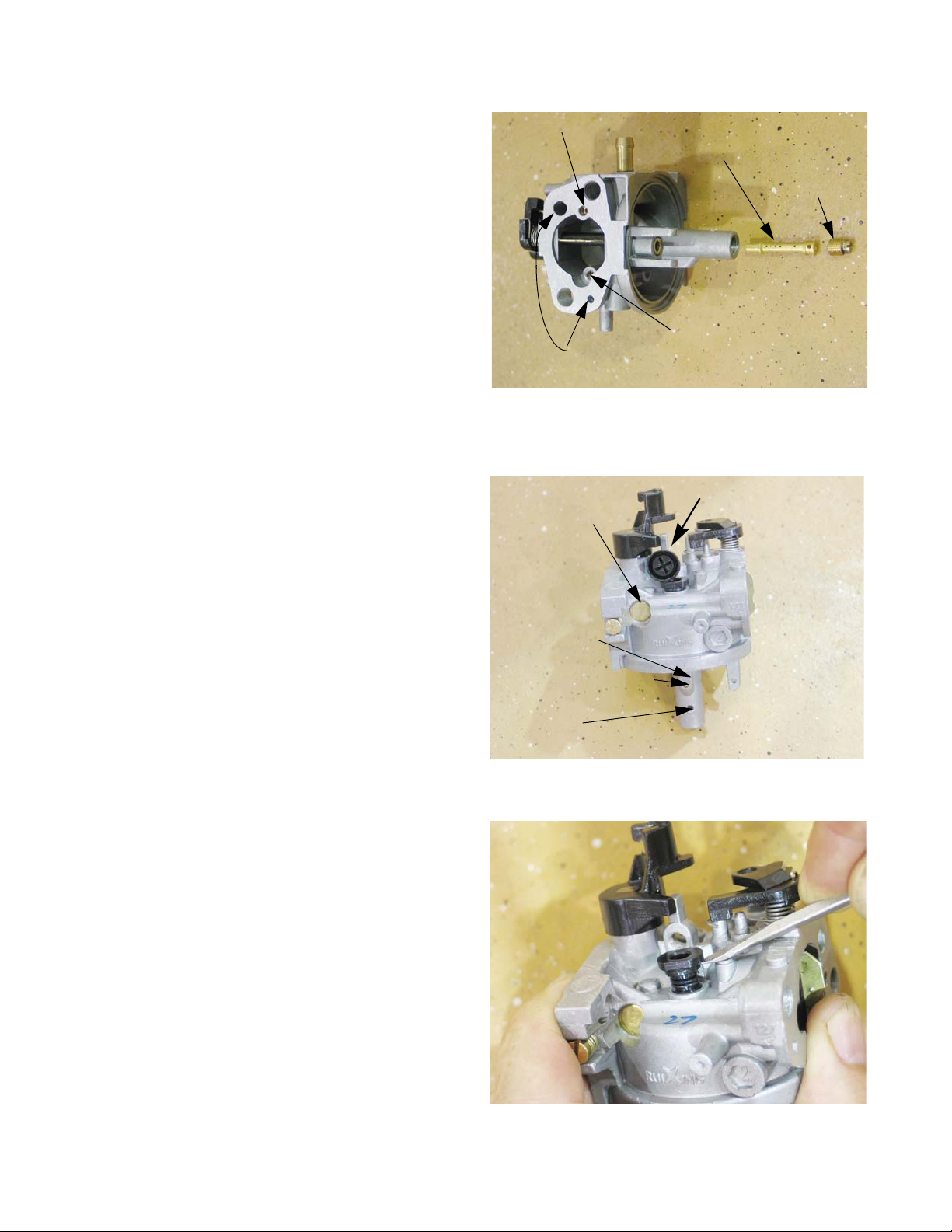

AIR INTAKE SYSTEM

Figure 3.11

Carburetor Calibration Number

Figure 3.12

Suppler trademark

Alphanumeric code

Calibration code

Serial code

Figure 3.13

Gasket: insulator

to cylinder head

Gasket: Insulator

to carburetor

Insulator

NOTE: The carburetors are not inter -changeable from one

engine model to another. To help prevent carburetor mix-ups, the Carburetor Calibration Number is

stamped on the carburetor by the fuel nipple. Calibration numbers are similar or the same as the

engine number. See Figure 3.11.

NOTE: MTD gets carburetors from several suppliers.

When ordering carburetor kits, the carburetor’s

manufacturer, calibration code and serial number

are needed. All of this information is located on the

carburetor. See Figure 3.12.

3. The insulator is sandwiched between two gaskets

which are located between the carburetor and the

cylinder head. See Figure 3.13.

NOTE: The gaskets are different, and there is an orienta-

tion to the insulator.

NOTE: The front gasket also acts as a heat shield.

4. Install the insulator by following the above steps in

reverse order.

NOTE: Tighten the carburetor mounting nuts to a torque of

80 - 106 in lbs (9 - 12 Nm).

5. Test run the engine before returning to service.

35

Page 42

T65 Series Vertical Shaft Engines

36

Page 43

FUEL SYSTEM AND GOVERNOR

Figure 4.1

NBR inner liner

THV barrier layer

NBR intermediate layer

Reinforcement

CSM Cover

Picture courtesy of Avon Automotive

When working around the fuel system, do not bring any source s of hea t, spark, or open flame

near the work area.

! WA RNI NG! WA RNI NG

CHAPTER 4: THE FUEL SYSTEM AND GOVERNOR

The function of the fuel system is to store fuel, mix the fuel with air in the correct ratio and deliver it to the intake

port. The fuel system consists of the following components:

• Fuel tank

• Fuel lines

• Fuel filter

• Carburetor and insulator block

NOTE: When working on the fuel systems, look at the whole system. A problem will rarely be isolated to one

component.

Fuel Line

The fuel line used by MTD is GREENBAR

a multi-layer fuel line that meets the current EPA guidelines.

TM

. This is

NOTE: This fuel line has a thin inner liner. If a tear

forms in this inner liner, fuel can get be tween

the liner and the hose. This will cause the

liner to collapse, cutting off the fuel flow.

NOTE: The fuel line must be replaced every time it

is disconnected from the brass barb on the

carburetor.

NOTE: Replace the fuel line only with GREEN-

TM

BAR

Inspect the fuel lines

• Are they cracked?

• Are they clogged?

• Are they brittle?

NOTE: If the answer to any of the above is yes,

replace the fuel lines. When replacing fuel lines, GREENBAR

order to meet EPA and CARB standards.

700 series fuel line.

TM

700 series fuel line must be used in

NOTE: The carburetor nipple has a sharp edge that will damage the inner lining of the fuel line. Replace the

fuel line every time it is removed from the nipple.

• Drain the fuel tank or clamp the fuel line before starting work to preven t sp illa g e.

• Dispose of drained fuel in a safe and responsible manner.

37

Page 44

T65 Series Vertical Shaft Engines

Figure 4.2

Figure 4.3

Inspecting the fuel

NOTE: Fuel is the maintenance item most often overlooked by consume rs. A lot of f uel systems prob lems are

caused by gas that is out of date or fuel with too much alcohol in it. When inspecting the fuel:

• Look for water.

• Look for dirt.

• Look for discoloration.

• Sniff carefully to see if it smells like varnish or kerosene.

• Look for oil in the fuel.

• Test the fuel for alcohol content.

NOTE: Save a sample of the fuel collected to show the customer.

NOTE: Customers pouring engine oil into the fuel tank seems to be a growing problem.

Test fuel for alcohol

Fuels currently on the market contain a wide array of

additives. Some of these additives oxygenate the fuel.

Oxygenated fuel reduces emissions, and is required in

some parts of the United States. Fuel make-up varies seasonally and geographically. Ethanol is the primary additive

used to oxygenate fuel.

Ethanol in fuel creates a lot of problems for gasoline

engines. The biggest problem is that alcohol attracts and

holds water. This corrodes the metal components of the

fuel system, especially the carburetor. Alcohol also does

not produce as much heat as gasoline when burned and it

burns at a different stoichiometric ratio. This results in less

power for the engine.

A 10% ethanol (E10) mix is acceptable for MTD

engines. Anything higher than that will result in performance issues and is not covered by warranty.

NOTE: E15 and E85 fuels are not to be used in any

MTD engines.

There are several alcohol test kit available commercially. See Figure 4.2.

Generally these kits involve mixing a measured

amount of water and gas together and seeing were the

boundary layer is. See Figure 4.3.

The test kit should come with a chart to compare the

boundary layer height to alcohol percentage.

38

Page 45

The fuel filter

Figure 4.4

Figure 4.5

Charcoal canister fuel cap

Evaporative (EVAP) emissions system

FUEL SYSTEM AND GOVERNOR

The fuel filter is located in the fuel tank. It can be remo ve d

and cleaned with a can of carburetor cleaner or replaced.

See Figure 4.4.

Gasoline is made from the graduated distillation of crude oil. It consists of a multitude of individual hydrocarbons and

has a boiling range of 86 - 410

gasoline an ideal fuel for spark ignited, internal combustion eng ines. However, the hydrocarbons are not good for the

environment. To reduce or eliminate the release of fuel vapors into the atmosphere, an evaporative (EVAP) emissions system is used. St arting with the 2008 season, an EVAP system has been offered in areas that require it. MTD

uses a charcoal canister fuel cap on the T65 series engines.

NOTE: All fuel caps must be tethered to the fuel tank as part of the EPA Tier III emissions. A broken tether on

the fuel cap must be repaired before the unit can be put back into service.

Charcoal canister fuel caps

o

F (30-210oC)1. The large quantity of hydrocarbons and the low boiling range makes

The simplest and most common EV AP system used on

an MTD engines is the charcoal canister fuel cap. The fuel

cap has charcoal that will absorb most of the vapors that

try to escape through the vent.

When the engine is running and the fuel level drops, a

vacuum is created. The clean air that is drawn in through

the vent will pull the vapors out of the charcoal, refreshing

it for the next cycle.

A charcoal canister fuel cap can be identified by its

height. See Figure 4.5.

1. Dr. Ullmann, J, Fuels, Automotive Ha ndbook, seventh edition. Bosch, Robert distributed by SAE Society of

Automotive Engineers, 2007. 320.

39

Page 46

T65 Series Vertical Shaft Engines

Figure 4.6

Vent hole

Figure 4.7

Hand-pump vacuum

/pressure tester

Fuel tank vent

The fuel tank vent performs the important task of allowing air into the fuel tank. As fuel is being used by the

engine, the fuel level in the tank drops. The dropping fuel

level then creates a vacuum in the tank. If the fuel tank

could not allow air through the vent, the vacuum would

prevent the fuel from getting to the carburetor.

The tank is vented through the cap. See Figure 4.6.

NOTE: This is a charcoal canister fuel cap. If the

vent is not functioning, the whole fuel cap

must be replaced.

To test the cap vent:

1. Drain the fuel out of the fuel tank into an approved

container.

2. Attach a hand-pumped vacuum/pressure tester to

the fuel barb on the fuel tank. See Figure 4.7.

3. Attempt to pull a vacuum on the fuel tank with the

fuel cap in place.

4. Attempt to pressurize the fuel tank with the fuel cap

in place.

NOTE: The tank should not hold any pressure nor

any vacuum.

• Replace the cap if either pressure or vacuum

builds using the hand-pump tester.

• A cap that maintains pressure will cause the

engine to run rich as the fuel in the tank heats

and expands, forcing it’s way past the float

valve in the carburetor.

• A cap that maintains vacuum will cause the

engine to run lean as the fuel is depleted and

no air comes in to replace it.

• The two conditions may both be present, but

the symptoms vary with fuel, fuel level, and

operating conditions.

• Usually presents as a “Runs and quits” scenario.

40

Page 47

The fuel tank

When working around the fuel system, do not bring any source s of hea t, spark, or open flame

near the work area.

! WA RNI NG! WA RNI NG

Figure 4.8

Tether

Figure 4.9

Gland nut

Rubber washer

FUEL SYSTEM AND GOVERNOR

To remove the fuel tank:

1. Drain the fuel out of the fuel tank into an approved

container.

2. Disconnect the fuel line from the tank.

3. Remove the recoil starter by following the procedures

described in Chapter 6: Starters

4. Lift the blower housing off of the engine.

5. Remove the fuel cap and tether by unscrewing them.

See Figure 4.8.

6. Remove the fuel tank gland nut.

7. Remove the rubber washer.

8. Slide the tank out of the blower housing.

9. Install the fuel tank by following the previous step in

reverse order.

41

Page 48

T65 Series Vertical Shaft Engines

Figure 4.10

Choke

closed

Air vane

Figure 4.11

Choke

open

Air flow

Figure 4.12

Temperature compensator

Choke Compensator rod

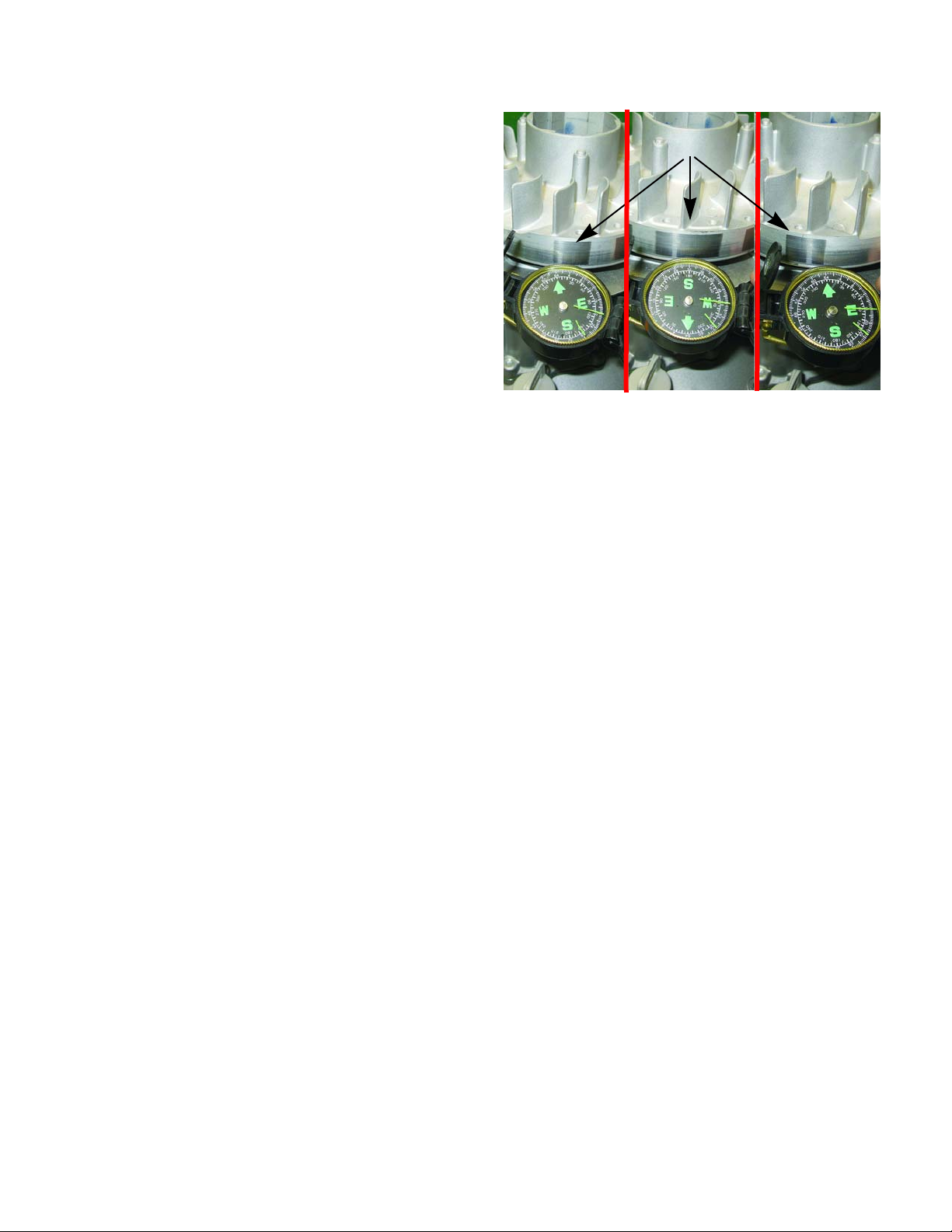

Autochoke

The MTD engine uses a simple autochoke system that

is similar to the old style air vane governors. When the

engine is at rest a spring holds the choke in the closed

position. See Figure 4.10.

When the engine starts, the air flow from the flywheel

fan pushes on an air vane. The air vane in turn moves the

choke lever, opening the choke. See Figure 4.11.

The Autochoke System also has a temperature compensator installed on the muffler . As the muffler heat s up, a

bi-metallic coil inside will expand. The expanding coil will

rotate a lever towards the muffler , pulling on a rod. This rod

will override the autochoke, holding the choke open on hot

restarts. It will also keep the choke from fully closing until

the engine heats up.

42

Page 49

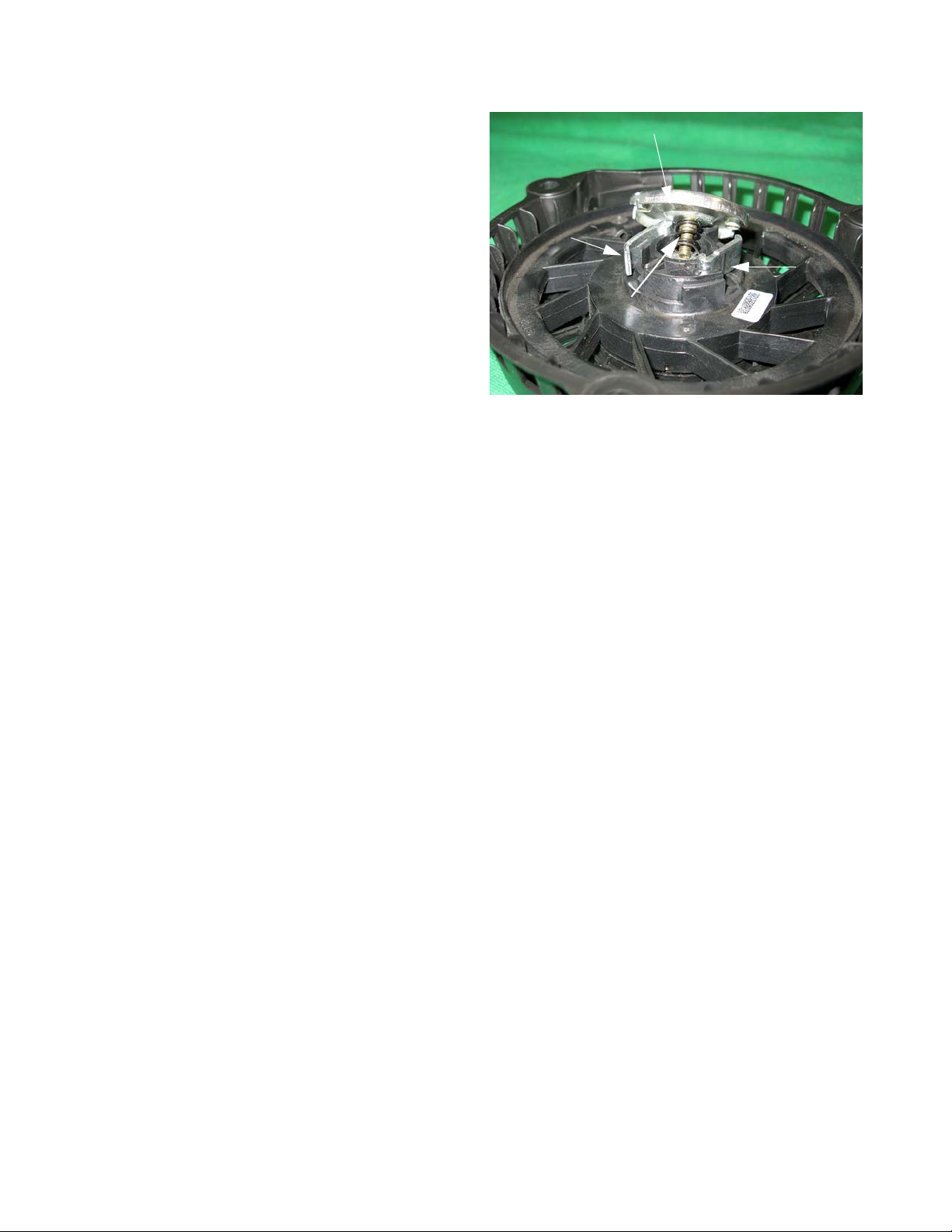

Temperature compensator

Figure 4.13

Air Vane

Figure 4.14

Temperature Compe nsa to r

Choke rod

FUEL SYSTEM AND GOVERNOR

To remove/replace the air vane:

1. Unplug the spark plug.

2. Drain the fuel out of the fuel tank into an approved

container.

3. Disconnect the fuel line from the tank.

4. Remove the recoil starter by following the procedures

described in Chapter 6: Starters

5. Lift the blower housing off of the engine.

6. Lift the air vane off of the bracket. See Figure 4.13.

7. Unhook the choke linkage.

8. Install by following the above steps in reverse order.

To remove/replace the temperature compensator:

1. Remove the muffler cover by following the p rocedures

described in Chapter 8: Exhaust.

2. Remove the two screws that hold the compensator to

the muffler using a 10 mm wrench. See Figure 4.14.

3. Unhook the compensator from the choke rod.

4. Install the compensator by following the previous

steps in reverse order.

43

Page 50

T65 Series Vertical Shaft Engines

Figure 4.15

Primer

Primer

Carburetor

Air pressure

Figure 4.16

Choke is

removed

Primer port

Figure 4.17

Remove the

primer line

Primer

Another way to enrichen the fuel air mixture for startup is the primer. The primer is a simple pump that pressurizes the float chamber, forcing fuel out the main nozzle.

See Figure 4.15.

Carburetors that use a primer are ea sily ide n tifie d by

the lack of a choke plate and the addition of a primer port.

See Figure 4.16.

To remove/replace the primer:

1. Remove the air filter housing by following the steps

described in Chapter 3: Air Intake And Filter.

2. Disconnect the primer line from the primer bulb. See

Figure 4.17.

44

Page 51

FUEL SYSTEM AND GOVERNOR

Figure 4.18

Squeeze the barbs together,

then push

3. Squeeze the two sets of tabs together and push the

primer out of the housing. See Figure 4.18.

4. Install the primer by following the above steps in

reverse order.

5. Test run the engine before returning to service.

Carburetors

Troubleshooting the carburetor is a process of elimination. If everything else on the engine checks out, the carbu-

retor is probably bad.

NOTE: It is important to perform a compression or leak down te st befor e conde mnin g a car bur etor. An engine