Page 1

ST23

ST26

ST35

Trimmers

Operator's Manual

Page 2

TABLE OF CONTENTS

Table of Contents .............................................. 1

Foreword ...........................................................1

Safety Precautions ............................................ 2

Metal Blade Use................................................6

Decal Information .............................................. 7

Specifications .................................................... 8

Parts Description............................................... 9

Trimmer Assembly .......................................... 10

Fueling Instructions ......................................... 12

Operation ........................................................ 14

Maintenance ...................................................17

Maintenance Chart..................................... 17

Troubleshooting Guide.................................... 24

Warranty........................................... Back Cover

FOREWORD

This Operator’s Manual contains safety precautions and operating procedures for the Cub Cadet

Commercial line of trimmers. You must read and understand this Operator’s Manual and especially the

Safety Precautions for proper and safe operation.

Cub Cadet Commercial's philosophy is to continually improve all of its products. As a result, engineering

changes and improvements are made from time to time. If the operating characteristics or the appearance

of your trimmer differ from those described in this Operator’s Manual, please contact your Cub Cadet

Commercial dealer for information and assistance. Contact your Cub Cadet Commercial dealer if you do

not understand any of the instructions in this manual.

Although hazard control and accident prevention are partially dependent upon the design and

configuration of the trimmers, these factors are also dependent upon the awareness, concern, prudence

and proper training of the personnel involved in the operation, transport, maintenance and storage of the

trimmers.

WARNING

Indicates a strong possibility of severe personal injury or death if instructions are not followed.

CAUTION

Indicates a possibility of personal injury or equipment damage if instructions are not followed.

IMPORTANT:

This enclosed message provides information necessary for the protection of the unit.

NOTE:

This enclosed message provides tips for use, care and maintenance of the unit.

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

1

Page 3

SAFETY PRECAUTIONS

GENERAL:

1. It is important that you read, fully understand and

observe the following safety precautions and

warnings. Read the Operator's Manual and the

safety instructions periodically.

2. Do not lend or rent out your trimmer without the

Operator’s Manual. Be sure that anyone using

your trimmer understands the information

contained in this Operator’s Manual.

3. Careless or improper use of this trimmer may

cause serious or even fatal injury.

4. The use of the trimmer can be hazardous. If the

rotating cutting line or a blade comes in contact

with your body, it will cut you. When it comes in

contact with solid foreign objects such as rocks

or bits of metal, it may fling them directly or by

ricochet in the direction of bystanders or the

operator.

5. Cub Cadet Commercial does not recommend the

use of rigid blades when cutting in stony areas.

Thrown objects or damaged blades may result in

serious or fatal injury to the operator or bystanders.

PHYSICAL CONDITION: You must be in good

physical condition and mental health and not under

the influence of any substance (drugs, alcohol, etc.)

which might impair vision, dexterity or judgment. Do

not operate the trimmer when you are fatigued.

1. Be alert - if you get tired while operating your

trimmer, take a break. Fatigue may result in loss

of control. Working with the trimmer can be

strenuous. If you have any condition that might

be aggravated by strenuous work, check with

your doctor before operating the trimmer.

2. Prolonged use of the trimmer (or other machines) exposing the operator to vibrations may

produce whitefinger disease (Raynaud's

phenomenon) or carpal tunnel syndrome. These

conditions reduce the hand's ability to feel and

regulate temperature, produce numbness and

burning sensations and may cause nerve and

circulation damage and tissue necrosis.

Antivibration systems do not guarantee that you

will not sustain whitefinger disease or carpal

tunnel syndrome. Therefore, continual and

regular users should monitor closely the

condition of their hands and fingers. If any of the

above symptoms appear, seek medical advice

immediately.

PROTECTIVE CLOTHING: Trimmer operation can

cause serious injury to eyes, ears and body. The

deflector provided with your trimmer may not

protect the operator from all foreign objects (gravel,

glass, wire, etc.) thrown by the rotating cutting line

or blade. Thrown objects may also ricochet and

strike the operator.

1. Clothing must be sturdy and snug-fitting, but

allow complete freedom of movement. Avoid

loose-fitting jackets, scarfs, neckties, jewelry,

flared or cuffed pants, unconfined long hair or

anything that could become caught on branches,

brush or moving parts of the unit. Wear long

pants made of heavy material to protect your

legs. DO NOT WEAR SHORTS.

2. To reduce the risk of injury to your eyes, never

operate the trimmer unless wearing goggles or

properly fitted safety glasses with adequate top

and side protection complying with ANSI Z 87.1.

3. To reduce the risk of injury to your face Cub

Cadet Commercial recommends that you also

wear a face shield or face screen over your

goggles or safety glasses.

4. Trimmer noise may damage your hearing. Wear

sound barriers (ear plugs or ear mufflers) protect

your hearing. Continual and regular user should

have their hearing checked regularly.

5. Protect your hands with gloves when handling

the trimmer. Heavy-duty, nonslip gloves improve

your grip and protect your hands.

6. Good footing is most important in trimmer work.

Wear sturdy boots with nonslip soles. Steel-toed

safety boots are recommended.

7. Wear an approved safety hard hat to reduce the

risk of injury to your head.

PROTECTING OTHERS:

1. Minors should never be allowed to use the

trimmer.

2

Page 4

2. Spectators, children, fellow workers and animals

must be warned to stay back 50 feet (15m) while

the trimmer is in use. Stop the engine and cutting

head immediately if you are approached.

SAFETY PRECAUTIONS

fuel.

3. Fuel your trimmer outdoors or in a well-ventilated

area.

3. People working in the area near you should wear

the same protective equipment as the operator.

PREPARATION FOR THE USE OF THE

TRIMMER:

1. Never modify the trimmer in any way. Only

attachments supplied by Cub Cadet Commercial

or expressly approved by Cub Cadet Commercial for use with the specific Cub Cadet Commercial trimmer models are authorized. Although

certain unauthorized attachments are usable

with the Cub Cadet Commercial trimmer, their

use may, in fact, be extremely dangerous.

2. When transporting your trimmer in a vehicle,

properly secure it to prevent turnover, fuel

spillage and damage to the trimmer.

3. Always use the shoulder harness when using

rigid blades.

4. Adjust the shoulder harness and hand grips to

suit your size before starting work.

5. Always check your trimmer for proper condition

and operation before starting, particularly the

throttle trigger, throttle trigger interlock, stop

switch, cutting head or blade, deflector and

harness.

6. The throttle trigger must move freely and always

spring back to the idle position. The cutting head

must be properly tightened and in safe operating

condition. Inspect for loose parts (nuts, screws,

etc.).

HANDLING FUEL: The Cub Cadet Commercial

trimmer uses an oil-gasoline

mixture for fuel.

4. Select bare ground for fueling and move at least

10 feet (3 m) from the fueling spot before starting

the engine.

5. Gasoline vapor pressure may build up inside the

gas tank of a two cycle engine depending on the

fuel used, the weather conditions, and the

venting system of the tank. In order to reduce the

risk of personal injury from escaping gas vapor

and fumes, remove the fuel filler cap on your

trimmer carefully so as to allow any pressure

buildup in the tank to release slowly.

6. Never remove the fuel filler cap while the engine

is running.

7. Unit vibrations can cause an improperly

tightened fuel cap to loosen or come off

permitting fuel to spill. In order to reduce the risk

of fuel spillage and fire, tighten the fuel cap by

hand with as much force as possible.

8. Wipe off any spilled fuel before starting your

trimmer.

9. Check for fuel leakage while refueling and during

operation. If fuel or oil leakage is found, do not

start or run the engine until the leak is fixed and

spilled fuel has been wiped away.

10. If fuel spills on your clothing, change your

clothing immediately.

CARBON MONOXIDE HAZARDS:

1. If you operate the trimmer in an area that is

confined, or even partially enclosed, the air you

breathe could contain a dangerous amount of

exhaust gas. To keep exhaust gas from building

up, provide adequate ventilation.

1. Gasoline is an extremely flammable fuel. If

spilled and ignited by a spark or other ignition

source, it can cause fire, serious burn injury and

property damage. Use extreme caution when

handling gasoline or an oil-gasoline fuel mixture.

2. Do not smoke or bring any fire or flame near the

2. The exhaust gas contains carbon monoxide, a

poisonous, colorless and odorless gas. Breathing the exhaust gas can cause loss of consciousness and may lead to death.

3

Page 5

SAFETY PRECAUTIONS

STARTING: Your trimmer is a one-person machine.

1. Start and operate your trimmer without assistance. When starting, place the trimmer on firm

ground or a solid surface in an open area.

Maintain good balance and secure footing.

2. To reduce the risk of injury from loss of control,

be absolutely sure that the cutting head or blade

is clear of you and all other obstructions and

objects, including the ground when starting,

because when the engine starts, the engine

speed will be fast enough for the clutch to

engage and turn the cutting head or blade.

3. When you pull the starter grip, do not wrap the

starter rope around your hand. Do not allow the

grip to snap back, but guide the starter rope to

rewind properly. Failure to follow this procedure

may result in injury to your hand or fingers and

may damage the starter mechanism.

OPERATION:

1. Work carefully.

2. To reduce the risk of injury from thrown objects

or blade contact, never operate the trimmer

without a properly mounted deflector.

3. Operate the trimmer under good visibility and

daylight conditions only.

4. Always hold the trimmer firmly with both hands.

Wrap your fingers tightly around the handles,

keeping the handles cradled between your

thumb and forefinger. Keep your hands in this

position, to have your trimmer under control at all

times.

5. Make sure your trimmer handles and grips are in

good condition and free of moisture, pitch, oil or

grease.

6. Never attempt to operate the trimmer with one

hand. You might lose control of the trimmer

resulting in serious or fatal injury.

7. To reduce the risk of bodily injury resulting from

loss of control and contact with the cutting head,

always attach and wear the shoulder harness on

those trimmers equipped with a straight shaft

and loop handle.

8. Before trimming, inspect the area for stones,

glass, pieces of metal, trash or other solid

objects. The cutting line could throw objects of

this kind.

9. This trimmer is to be used normally at ground

level with the cutting head or blade parallel to the

ground. Using the trimmer above ground level or

with the cutting head or blade perpendicular to

the ground may increase the risk of injury, since

the cutting line or blade is more fully exposed

and the trimmer may be more difficult to control.

Never use your trimmer as a hedge trimmer.

10. When using rigid blades, avoid cutting close to

fences, sides of buildings, tree trunks, stones or

other such objects that could cause the trimmer

to kick out or could cause damage to the blade.

Cub Cadet Commercial recommends use of the

nylon line heads or Polycut head for such jobs.

In addition, be alert to an increased possibility

of ricochets in such situations.

11. Do not use the starting throttle lock when you

are trimming as you do not have control of the

engine speed. For the proper use of the throttle

lock, see “Starting” in the Operation Section.

12. If the cutting tool or deflector becomes clogged

or stuck, always turn off the engine and make

sure the cutting tool has stopped, before

cleaning. Grass,weeds, etc. should be cleaned

off the cutting tool at regular intervals.

13. During cutting, check the tightness and the

condition of the cutting tool at regular intervals.

If the behavior of the tool changes, stop the

engine immediately, and check the bolt

securing the tool for tightness and the cutting

tool for cracks and damage.

14. Replace cracked, bent, warped, damaged or

dull cutting blades immediately. Such tools may

shatter at high speed and cause serious or fatal

injury.

15. A loose blade may cause the blade to crack,

vibrate, break or come off the trimmer, which

may result in serious or fatal injury. Make sure

that the blade is properly tightened. Use the

wrench supplied or one of sufficient length to

obtain the proper torque. If the blade loosens

after being properly tightened, stop work

4

Page 6

immediately. The retaining bolt may be worn or

damaged and should be replaced. Never use

unauthorized parts to secure the blade. If the

blade continues to loosen, see your Cub Cadet

Commercial dealer. Never use a trimmer with a

loose blade.

16. To reduce the risk of personal injury from loss of

control, do not use an incorrect idle adjustment.

At correct idle speed, the head and line or

blade should not move. For instructions on

adjusting the idle speed, see “Carburetor

Adjustment” in the Maintenance Section.

17. Never touch a rotating cutting tool with your

hand or any part of your body. It continues to

rotate for a short period after the throttle trigger

is released.

18. Always turn off the engine and make sure the

cutting line has stopped before putting the

trimmer down.

SAFETY PRECAUTIONS

5

Page 7

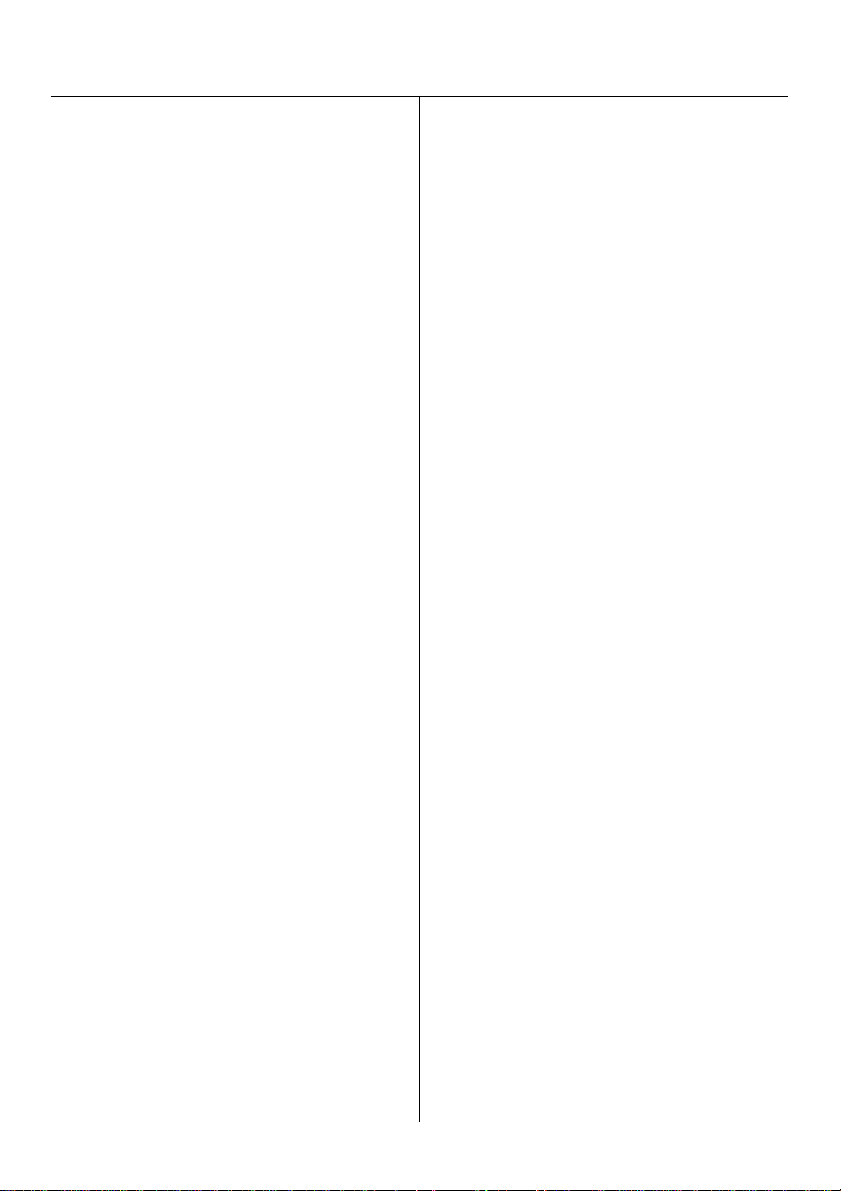

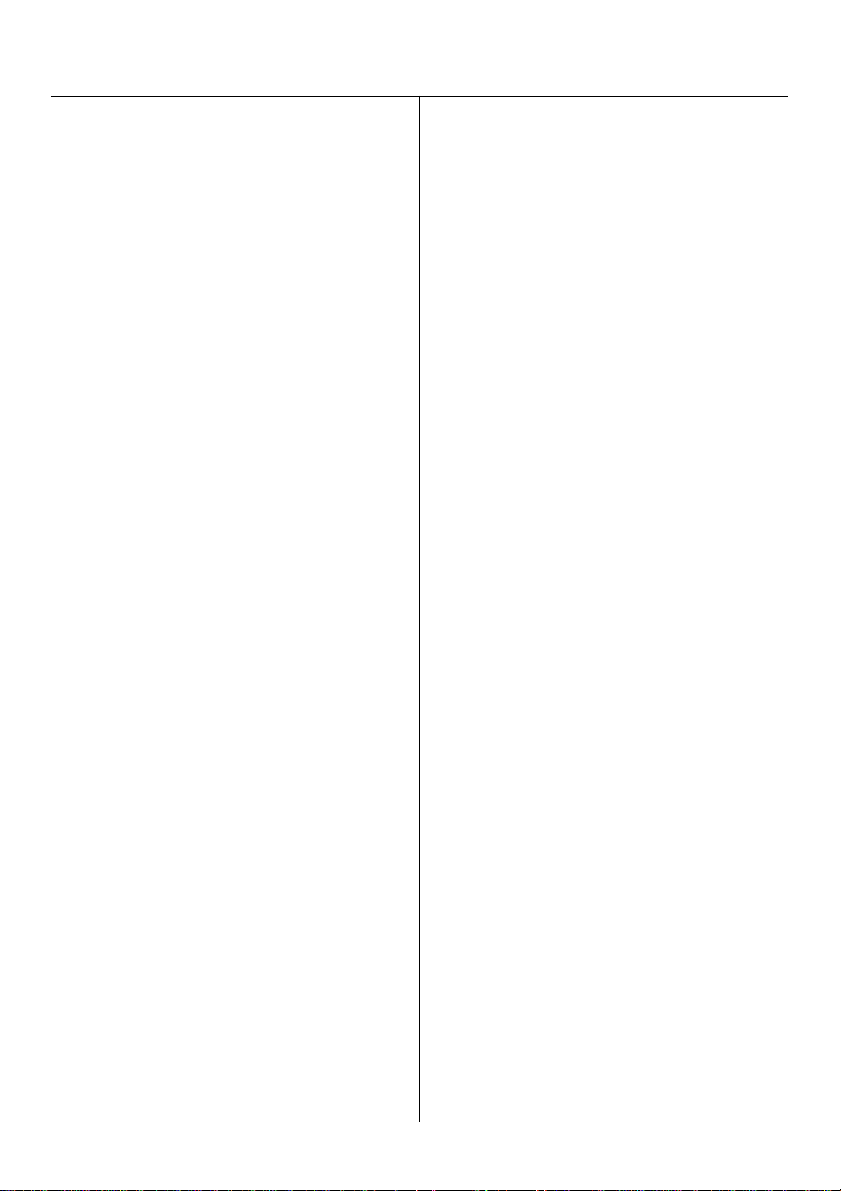

METAL BLADE USE

WARNING

Specified deflector shield, bicycle handle and shoulder harness MUST be used on brushcutter with

metal blades. Operating the brushcutter without specified deflector, shield, bicycle handle, and

shoulder harness can cause serious personal injury.

WARNING

If blade is mounted improperly, it may come loose during operation and cause serious or fatal injury.

REQUIRED PARTS………………Parts List on 3,4 page

A. Blades; 23,26cc; 1.IM-195833140 2.IM-195833170 3.IM-195833230

B. Deflector; 4.IM-720463430

C. Handle; 5.590541

D. Shoulder Harness; 6.IM-720853461

35cc; 1.IM-195833150 2.IM-195833070 3.IM-195833160

1

C

Blades

2

3

Bicycle Handle Shoulder Harness

5

Metal Shield

(Deflector)

6

4

D

B

A

WARNING

Always wear hearing, eye, foot and leg protection when operating trimmer.

WARNING

Blade coasts after throttle release, maintain control and stop blade by contact with cut materials

before the unit is set down.

WARNING

Read Operator’s manual. Follow ALL warning and safety instructions. Failure to do so can result

in serious personal injury to the operator and / or bystanders.

6

Page 8

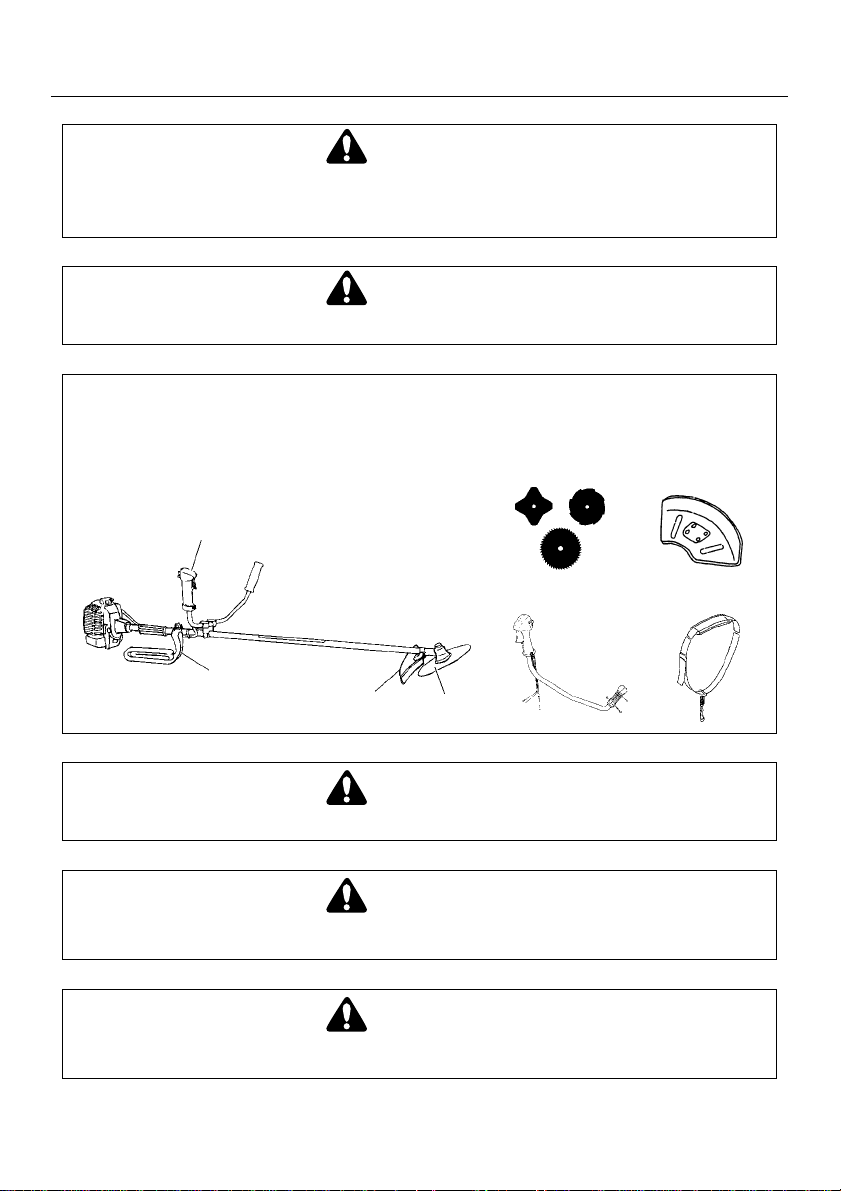

DECAL INFORMATION

WARNING

LOCATE THE SAFETY DECALS ON YOUR TRIMMER. MAKE

SURE THE DECALS ARE LEGIBLE AND THAT YOU UNDER-

STAND AND FOLLOW THE INSTRUCTIONS ON THEM.

DEFLECTOR DECAL:

SHAFT DECALS:

This trimmer can be can be

dangerous and cause serious injury

if improperly used. To reduce injury

risk to operator, helpers and

bystanders, read and understand the

Operator's Manual.

Blindness can occur from objects

that are thrown or ricochet even with

a shield in place. Operators, helpers

and by-standers must wear ANSI

Z87.1 approved eye protection.

Always wear hearing protection

when operating a trimmer.

Prevent accidental contact

with the trimmer and any

cutting attachment. Maintain a

50 ft. (15m) radius, DANGER

ZONE surrounding the

operator. ONLY the operator,

dressed in proper protective

clothing should be in the

DANGER ZONE.

SHAFT DECALS: (Continued)

Beware of KICKOUT (blade thrust)

when using blades. Special

precautions are necessary for blade

KICKOUT

INSPECT BLADES BEFORE USE.

DO NOT USE DAMAGED, CRACKED, BENT,

DULL, OR IMPROPERLY SHARPENED BLADES.

Do not remove shields or decals, modify the unit or

install unapproved attachments or parts. Approved

attachments and replacement Operator's Manuals

are available from your Cub Cadet Commercial

dealer or by writing:

CUB CADET CORPORATION

P.O.Box 368023, Cleveland,OH 44136-9723

operation, see your Operator's

Manual. Install ONLY Cub Cadet

Commercial approved blades on ST

model trimmers equipped with

proper blade shield, loop handle,

shoulder harness, blade collar, nut

and cotter pin.

The blade/cutting attachment does

not stop immediately after releasing

the throttle. Keep hands and feet

clear of the blade/cutting attachment

unless the engine is shut off and the

cutting attachment is not moving.

7

Page 9

SPECIFICATIONS

Model ST23 ST26 ST35

Loop Handle Loop Handle Loop Handle

Length (mm) 1783 1783 1818

(in.) 70.1 70.1 71.5

Width (mm) 260 260 260

(in.) 10.2 10.2 10.2

Height (mm) 250 264 277

(in.) 9.84 10.4 10.9

Weight (kg) 4.8 5.1 6.7

(lb.) 10.5 11.2 14.7

Type of Engine Air-cooled, two-stroke, single cylinder gasoline engine.

Bore (mm) 33 33 37

(in.) 1.3 1.3 1.46

Stroke (mm) 26 30 32

(in.) 1.02 1.18 1.26

Displacement (cc) 22.2 25.6 34.4

(cu. in.) 1.35 1.56 2.1

Engine Power (ps/rpm) 1.02/8000 1.22/7500 1.63/7500

Carburetor All position diaphragm carburetor with priming pump.

Exhaust System Spark arrester muffler.

Ignition System Flywheel magneto. (Electronic)

Spark Plug NGK BPMR7A

Fuel Mixed (gasoline and oil).

Fuel/Oil Ratio 50:1 Using Cub Cadet Commercial 2-Stroke Engine Oil.

25-30:1 Using Other Brands of TC Oil.

Fuel Tank Capacity (lit) 0.45 0.55 0.65

(U.S. fl. oz.) 15.2 18.6 22.0

8

Page 10

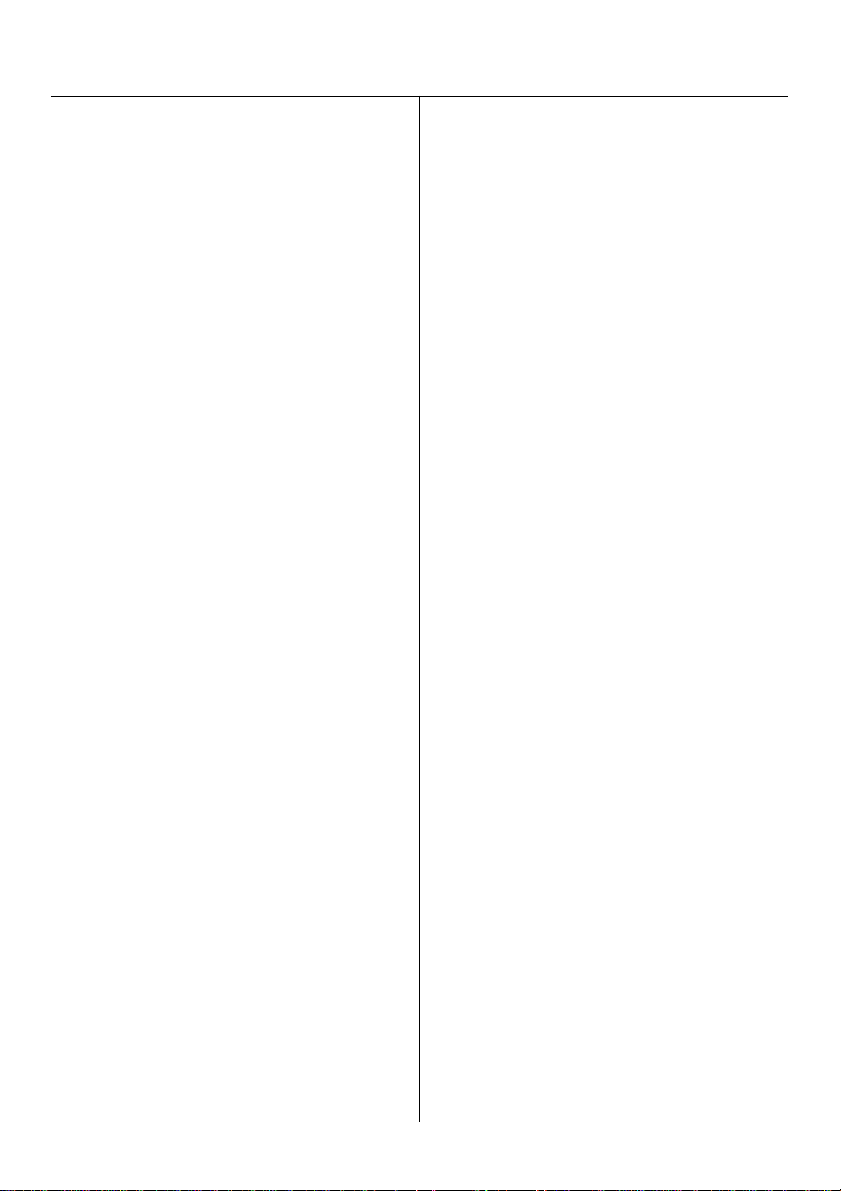

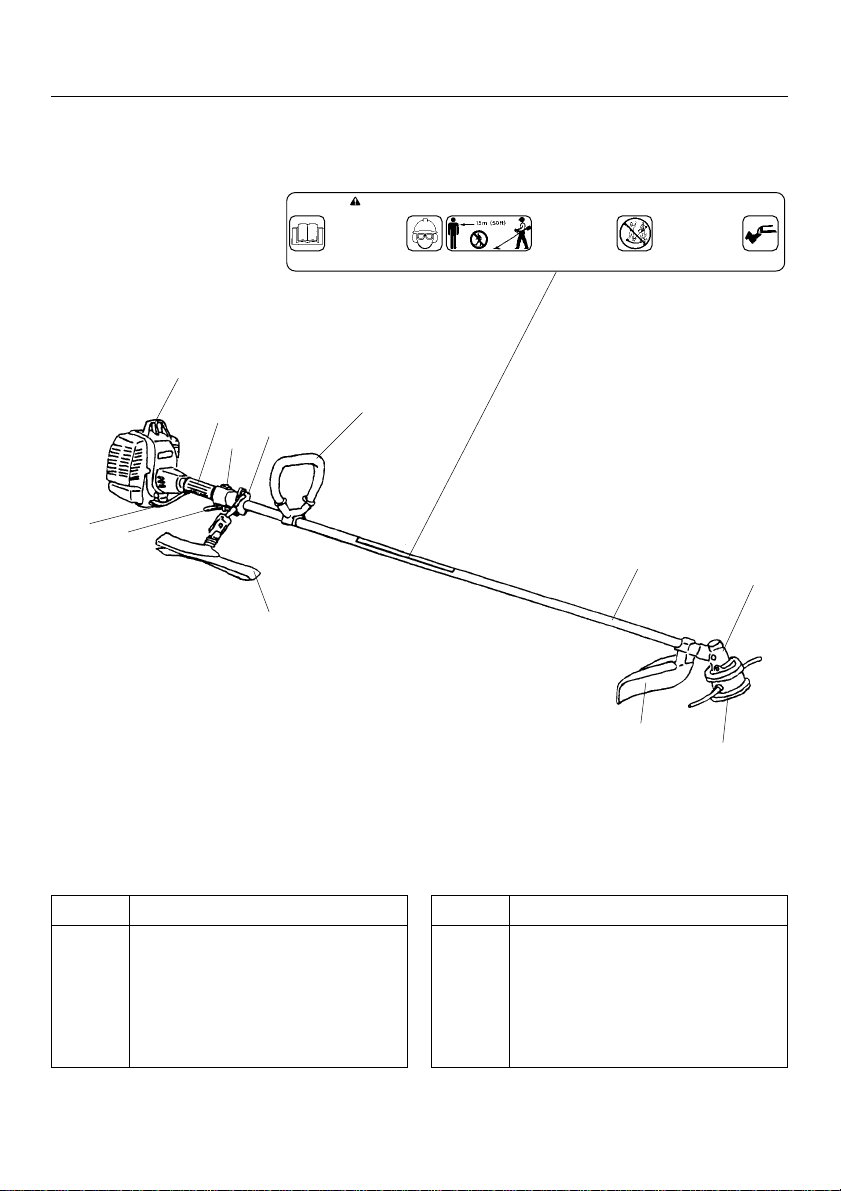

PARTS DESCRIPTION

WARNING

• This unit can be dangerous and cause serious

injury if improperly used. To reduce injury risk to

operator, helpers and bystanders, read and

understand the Operator and Safety Manual.

• Blindness can occur from objedts that are thrown

or ricochet even with shield in place. Operators,

helpers and bystanders must wear eye protection, ANSI Z87.1 approved.

• Always wear hearing protection when operating

unit.

• Use caution when refueling hot engine. Never

refuel while engine is on.

• Prevent accidental contact with unit and any cuting

attachment. Maintain a 50 ft. (15 m) radius,

GER ZONE surrounding the operator. ONLY the

operator, dressed in proper protective clothing

should be in the DANGER ZONE.

• Beware of KICKOUT【blade thrust】when using

blades. Special precautions are necessary for

blade operation, see your Operator and Safety

Manual. ONLY install manufacturer approved

blades on Brushcutter models equipped with proper blade shields, harness, blade collar, nut and cotter pin.

DAN-

kickout

• Blade/Cutting attachment does not stop immediately

after releasing throttle. Keep hands and feet clear of

blade/cutting attachment unless engine is shut off

and cutting attachment is not moving.

• INSPECT BLADES BEFORE USE.

• DO NOT USE DAMAGED, CRACKED, BENT, DULL

OR IMPROPERLY SHARPENED BLADES.

• Do not remove shields modify the unit or install

attachments or parts not approved by manufacturer.

Approved attachment information and replacement

Operator and Safety Manual are available from manufacturer.

7

2

5

10

3

4

12

11

1

6

9

8

REF NO. DESCRIPTION

1 Gear Case

2 Grip

3 Throttle Wire

4 Throttle Lever

5 Hanger

6 Shoulder Band (Standard on ST35)

REF NO. DESCRIPTION

7 Engine

8 Head/Blade

9 Deflector

10 Stop Switch

11 Drive Tube

12 Loop Handle

9

Page 11

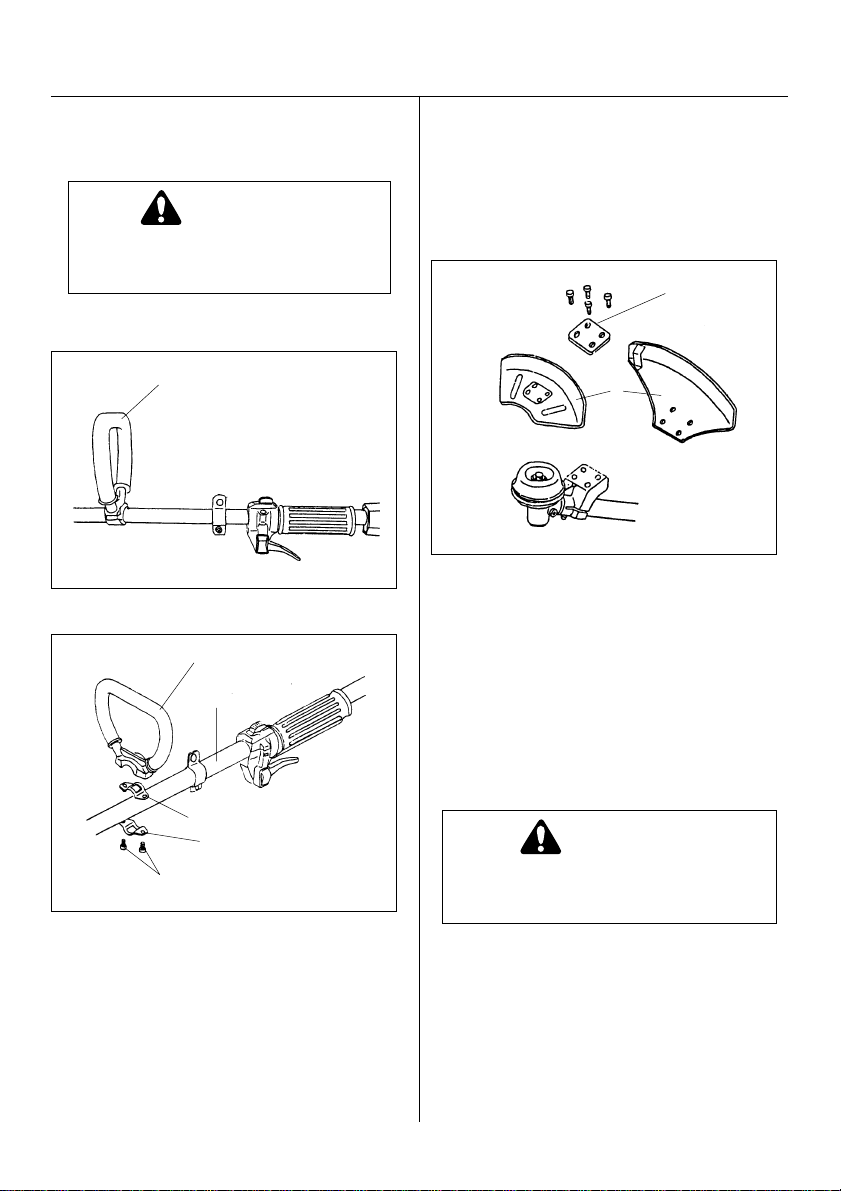

TRIMMER ASSEMBLY

The trimmer is partly disassembled for ease of

shipment and must be assembled before it can be

used for the first time.

WARNING

Because of the increased risk of accidents

the powerhead must not be started while it

is detached from the trimmer.

A. MOUNTING THE LOOP HANDLE:

6. Line up the loop handle and tighten the screws

firmly.

B. MOUNTING THE DEFLECTOR:

1. To mount the deflector, lay the trimmer on its

back with the cutting tool head facing upward.

2

1

1. Mount the loop handle (Ref. 1) .

1

5

2

3

4

2. Position the clamp (Ref. 2) in the loop handle

(Ref. 1).

3. Place both parts on the drive tube (Ref. 5).

4. Position the clamp (Ref. 3).

1

(A)

(B)

2. Place the deflector (Ref. 1) inside pointing

upward, on the bracket already fitted to the drive

shaft. Fit the plate (Ref. 2) on the inside of the

deflector and line it up. Insert the four screws

and tighten them down.

3. When using the nylon line trimmer, attach the

deflector (B) with a chopper blade on your

brushcutter in order to keep the line at the proper

length. Failure to follow this procedure may

damage your brushcutter.

WARNING

To reduce the risk of injury from thrown objects

or blade contact, never operate the trimmer

without a properly mounted deflector.

C. MOUNTING THE CUTTING TOOL:

1. Install the nylon line trimmer head or the cutting

blade as illustrated.

5. Insert the screws (Ref. 4) hand tight.

10

Page 12

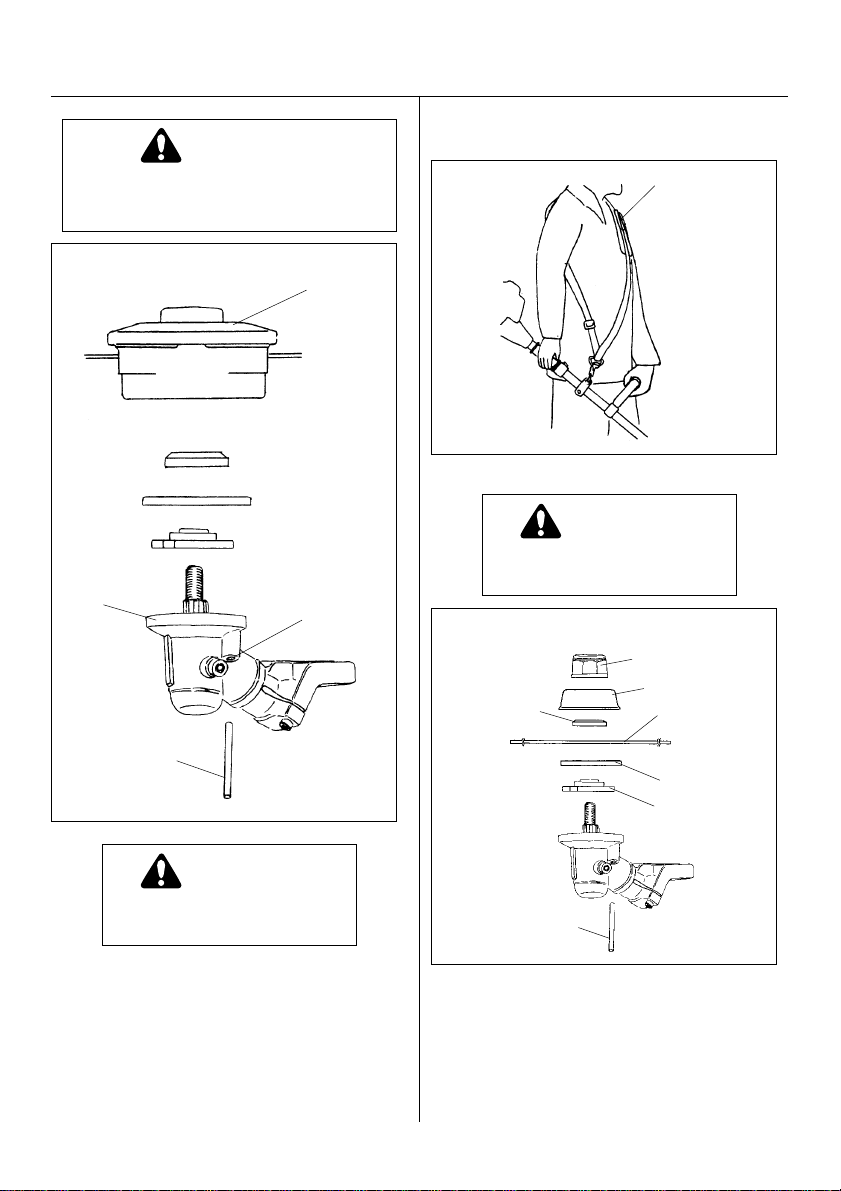

WARNING

If the nylon line trimmer head or the blade is

fitted improperly, it may come loose during

operation and cause serious or fatal injury.

Installing the Nylon Line Trimmer Head

4

2

3

TRIMMER ASSEMBLY

D. USING THE SHOULDER HARNESS (Standard

on ST35):

1

1. Put on the shoulder strap (Ref. 1).

WARNING

Always use the shoulder harness

when using rigid blades.

Installing steel blade

7

6

5

4

1

WARNING

Protect your hands with gloves if

mounting a rigid blade.

2. Align the hole in the holder (Ref. 3) with the hole

in the gear case (Ref. 2) and install the locking

tool (Ref. 1).

3. Fit the nylon line trimmer head (Ref. 4) onto the

shaft (turning it counterclockwise) until it is tight.

4. Remove the locking tool.

3

2

1

1. Install the selected cutting blade as illustrated.

2. Align the hole in the holder (Ref.2) with the hole

in the gearcase and install the locking tool

(Ref.1).

3. Install cover (Ref.3).

4. Install cutting blade (Ref.4).

5. Install holder (Ref.5).

11

Page 13

FUELING INSTRUCTIONS

6. Install the bolt cover (Ref.6).

7. Install the left hand nut (Ref.7) tighten to 18.5

•

m).

(N

WARNING

Reread the Safety Precautions relating

to “Handling Fuel” on Page 3.

The Cub Cadet Commercial trimmer uses an oilgasoline mixture as fuel. The engine is certified to

operate on unleaded gasoline.

Use regular name-brand unleaded gasoline with a

minimum octane number of 89. If the octane

number of the regular grade gasoline in your area

is lower use premium unleaded fuel. Fuel with a

lower octane number may result in preignition

(causing “pinging”) which is accompanied by an

increase in engine temperature. This, in turn,

increases the risk of piston seizure and damage to

the engine.

The chemical composition of the fuel is also

important. Some fuel additives not only

detrimentally affect elastomers (carburetor

diaphragms, oil seals, fuel lines etc.), but

magnesium castings as well. This could cause

running problems or even damage the engine. For

this reason it is essential that you use only namebrand fuels!

IMPORTANT:

Do not use any gasoline containing alcohol.

Serious engine or fuel system damage will occur.

Use only quality two-stroke, air-cooled engine oil

with the classification TC. The mix ratio is 25-30:1.

We recommend Cub Cadet Commercial brand 2Stroke Engine Oil since it is specially tested for use

in all Cub Cadet Commercial two-stroke engines.

The mix ratio is 50:1

IMPORTANT:

Do not use BIA or TCW (two-stroke water cooled)

mix oils!

Directions for Mixing: (See Chart for Amounts)

1. Put one-half of the gasoline in a safety approved

container.

2. Add the proper amount of two-stroke oil and mix

thoroughly.

3. Add the remainder of the gasoline and mix

thoroughly.

Take care when handling gasoline. Avoid direct

contact with the skin and avoid inhaling fuel vapor.

The gasoline container should be kept tightly

closed in order to prevent any moisture getting into

the mixture.

Only mix sufficient fuel for a few days work, not to

exceed 30 days of storage. Store in a safety

approved fuel container only.

Fuel Mixes:

Gasoline Oil (50:1) Oil (25-30:1)

(Cub Cadet (Other Name-

2-Stroke Brand TC Oils)

Engine Oil)

Liters Liters Liters

(U.S. gal.) (U.S. fl. oz.) (U.S. fl. oz.)

1 0.02 0.04-0.033

(1) (2.6) (5.12-4.27)

10 0.2 0.4-0.33

(2.5) (6.4) (12.8-10.66)

20 0.4 0.8-0.67

(5) (12.8) (25.6-21.33)

Dispose of empty two-stroke oil containers at

authorized disposal locations only.

CAUTION

The engine used on this trimmer is of a 2-cycle

design. The internal moving parts of the engine,

f.e., crankshaft bearings, piston pin bearings and

piston to cylinder wall contact surfaces, require

oil mixed with the gasoline for lubrication. Failure

to add oil to the gasoline or failure to mix oil with

the gasoline at the appropriate ratio will cause

major engine damage which will void your

warranty. For your fuel premix, only use Cub

Cadet Commercial brand 50:1 2-cycle oil or a

quality oil designed for 2-cycle air cooled

engines.

12

Page 14

FUELING INSTRUCTIONS

FUEL MIXTURE :

When using Cub Cadet Commercial 50:1 2-cycle

brand oil, or a quality oil designed for 2-cycle aircooled engines, oil ratio is 50 parts gasoline to 1

part oil or 50:1.

CAUTION

Never use a mixing ratio greater than 50:1

regardless of the oil package mixing instructions.

Ratios greater than 50:1,(for example, 60:1,

80:1, 100:1), reduce the amount of lubrication to

the internal moving parts of the engine and can

cause damage.

MIXING INSTRUCTIONS :

Always mix fuel and oil in a clean container

approved for gasoline. Mark the container to

identify it as fuel mix for the trimmer. Use regular

unleaded gasoline and fill the container with half

therequired amount of gasoline. Pour the correct

amount of oil into the container then add the

remaining amount of gasoline. Close the container

lightly and shake it momentarily to evenly mix the

oil and the gasoline before filling the fuel tank on

the trimmer.

When refilling the trimmer fuel tank, clean around

the fuel tank cap to prevent dirt and debris for

entering the tank during cap removal. Always shake

the premix fuel container momentarily before filling

the fuel tank.

Always use a spoul or funnel when fueling to

reduce fuel spillage. Only fill the tank to within 1/41/2 inch from the top of the tank. Avoid filling to the

top of the tank filler neck.

NOTE:

1. Never mix gasoline and oil directly in the

trimmer fuel tank.

2. Check for fuel leakage around the tank cap

and the fuel tank before the operation.

CAUTION

1. Do not use National Marine Manufacturer’s

Association (NMMA) or BIA certified oils. This

type of 2-cycle engine oil does not have the

proper additives for air-cooled, 2-cycle

engines and can cause engine damage.

2. Do not use automotive motor oil. This type of

oil does not have the proper additives for aircooled, 2-cycle engines and can cause

engine damage.

Fill Mark

Gas

Half Gasoline

➪

Oil

Gas

➪

Add Oil Add Remaining

13

Gasoline

➪

Shake

(Mix Oil and Gasoline)

Page 15

OPERATION

A. STARTING:

WARNING

Reread the Safety Precautions relating

to “Starting” on Page 3.

WARNING

When the engine starts, the cutting tool may

rotate even with the throttle trigger in the

low-speed position possibly causing injury.

3

1. When the Engine is Cold.

STOP

START

a. Slide the ignition switch (Ref.1) to the “START”

position. (Away from the arrow.)

1

2

c. Close the choke (Ref.3) completely.

5

4

d. Grasp the throttle trigger (Ref.4) fully, then

release it slowly while pushing the lock button

(Ref.5). This sets the throttle trigger at halfthrottle.

6

b. Push the priming pump (Ref. 2) several times.

14

Page 16

e. Put the unit on the ground:

It must rest securely on the engine support and

deflector. Check that the cutting tool is not

touching the ground or any other obstacles.

f. Make sure you have a firm footing:

Hold the unit with your left hand and press it

down firmly. Do not stand or kneel on the drive

shaft.

g. Pull the starter grip:

When pulling the starting rope (Ref. 6), use short

pulls, 1/2 to 2/3 of the rope length.

Do not let the starter grip snap back - guide it

slowly into the housing so that the starter rope

can rewind properly.

OPERATION

7

b. Remove the spark plug wire (Ref. 7).

h. Grasp the trigger immediately after the engine is

started. This releases the lock button and

automatically sets the engine to idle.

2. When the Engine is Warm.

Restarting the engine after it has been stopped.

a. Slide the ignition switch to the “START” position.

b. Push the priming pump several times.

c. Set the choke lever to the “FULL OPEN”

position.

d. Pull the starter grip.

NOTE:

If the engine does not start after four pulls, use

the cold start procedure.

3. If the Engine Doesn't Start.

a. If you did not move the choke lever to the “FULL

OPEN” position quickly enough after the engine

began to fire, the combustion chamber has

flooded.

c. Unscrew and dry off the spark plug.

d. Set the ignition switch to “STOP”.

e. Open the throttle fully .

f. Pull the starter rope several times to clear the

combustion chamber .

g. Refit the spark plug and connect the spark plug

wire.

h. Set the ignition switch to “START”.

i. Set the choke lever to “FULL OPEN”.

j. Now start the engine.

15

Page 17

OPERATION

B. STOPPING:

STOP

START

1. Return the throttle to the “IDLE” position and let

the engine run for 2 or 3 minutes until it has

cooled down.

2. Slide the ignition switch (Ref.1) to the “STOP”

position.

1

WARNING

Reread the Safety Precautions relating

to “Operation” on Page 4.

16

Page 18

MAINTENANCE

NOTE:

MAINTENANCE, REPLACEMENT, OR REPAIRE OF THE EMISSION CONTROL DEVICE AND

SYSTEMS MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIRE ESTABLISHMENT OR

INDIVIDUAL.

MAINTENANCE CHART

PART MAINTENANCE BEFORE

Complete Machine Visual Inspection X

(Condition, Leaks)

Clean X

Control Handle Check Operation X 10

Fuel Filter Check X 23

Replace X

Carburetor Adjust X 18,19

Cooling System Clean X 21,22

Muffler Check X 22

Clean X

Fuel Leakage Check X 3

Repair X

Fuel Lines Check X 23

Replace X

Clutch and Check/Clean X 22

Clutch Drum Replace X

All Accessible Screws

and Nuts

(Not Adjusting Screws)

Cutting Tools Sharpen Metal X 4

Gearbox Lubrication Check X 23

Drive Shaft Lubrication

Retighten X 3

Visual Inspection X 4,5,6

Replace X

Cutting T ools

Check Tightness X 4,9,10,11

of Cutting Tool

Fill Full X

Check X 23

Replenish X

MONTHLY

USE FAULTY

YEARLY IF IF SEE

DAMAGED

PAGE

24

17

Page 19

MAINTENANCE

EMISSION PARTS MAINTENANCE CHART

PART MAINTENANCE BEFORE

USE

Air Filter Clean X

Element Replace X

Spark Plug Check / Clean / Adjust X

Replace X

Carburetor Clean (*1) X

Overhaul (*2) / Replace (*3)

(*1) • At an authorized Cub Cadet Commercial servicing facility to be charged.

(*2) • For consumer use / At an authorized Cub Cadet Commercial servicing facility to be charged.

(*3) • For commercial use / At an authorized Cub Cadet Commercial servicing facility to be charged.

NOTE:

Time intervals shown are a maximum. Actual use and your experience will determine the frequency of

required maintenance.

You should be charged for the cost of any required replacement except warranty replacement under

LIMITED WARRANTY and/or EMISSION CONTROL WARRANTY.

MONTHLY or

50 HOURS USE

THREE MONTHS or

150 HOURS USE

SIX MONTHS or

300 HOURS USE

YEARLY or

600 HOURS USE

X

SEE

PAGE

21

20

18,19

A. CARBURETOR ADJUSTMENT.

The carburetor is preset at the factory. This is the

optimum setting under the barometric pressure and

climatic conditions at the factory and is suitable for

most operating sites.

It ensures that your machine will run smoothly, be

fuel efficient, operate reliably and produce low

emissions.

If the engine runs unsatisfactorily at high altitudes

or at sea level, slight readjustment of the carburetor

may be necessary:

NOTE

Every unit is run at the factory and the carburetor is

set in compliance with EPA. In addition, the

carburetor is equipped with H and L needle

adjustment limiters that prevent settings outside

acceptable limits.

1. Check the air filter and clean it if necessary.

2. Check the spark arresting screen (if fitted) and

clean it if necessary.

H

I

3. Mount the cutting tool.

a. Nylon line trimmer head:

Trim lines to the correct length. (The lines must

extend as far as the line limiting blade on the

deflector.

4. Start the engine and adjust the idling speed

correctly with the idle speed adjusting screw

(Ref. I). The cutting tool must not rotate.

5. Warm up the engine.

18

L

Page 20

6. Adjusting the idle speed:

It is usually necessary to change the setting of

the idle speed adjusting screw (Ref. I) after every

correction to the low speed adjusting screw (Ref.

L).

7. Proper idling speed:

ST23,26............. 2,800-3,000 rpm

ST35.................. 2,500-2,700 rpm

8. The engine stops while idling:

Turn the idle speed adjusting screw (Ref. I)

clockwise until the engine runs smoothly, but the

cutting tool must not rotate.

9. The cutting tool rotates when the engine is

idling:

Turn the idle speed adjusting screw (Ref. I)

counterclockwise until the cutting tool stops

rotating then return the screw about another half

turn from that position.

10. Erratic idling behavior, poor acceleration:

The idle setting is too lean. Turn the low speed

adjusting screw (Ref. L) counterclockwise until

the engine runs and accelerates smoothly.

11. Adjusting high speed:

Adjust the low adjustment screw (Ref. L) for the

smooth engine idling. Then increase the engine

speed and adjust the high speed adjustment

screw (Ref. H) for stable engine rotation. The

engine acceleration should be smooth with

proper adjustment.

(High Engine Speed..........10,000-11,000 rpm)

MAINTENANCE

19

Page 21

MAINTENANCE

B. THE THROTTLE WIRE ADJUSTMENT

C. CHECKING THE SPARK PLUG.

0.5mm-0.6mm

A

0.020”-0.024”

The wrong fuel mix (too much engine oil in the

gasoline), a dirty air filter or unfavorable running

conditions (mostly at low throttle) affect the

condition of the spark plug. These factors cause

deposits to form on the insulator nose which may

result in faulty operation.

1

2

1. Maintain a wire end-play of about 1/16 inch (12mm) with the adjuster and fix it with the

tightening bolt (Ref.2).

WARNING

To reduce the risk of injury from loss of control,

maintain the wire end-play at about 1/16 inch

(1-2mm). If the wire end-play is not maintained,

engine speed may be enough for the clutch to

engage and turn the cutting tool.

1. If the engine doesn't seem to have any power, is

difficult to start or runs poorly at idling speed, first

check the spark plug.

2. Remove the spark plug and see "3. If the Engine

Doesn't Start" on page 14.

3. Clean the dirty spark plug.

4. Check the electrode gap.

It should be 0.20in.(0.5mm) - 0.024in.(0.6mm)

Re-gap if necessary.

5. Use only a suppressed spark plug of the

approved type:

NGK BPMR7A

Correct the problems which caused the fouling of

the spark plug:

Incorrect carburetor setting, too much oil in the

fuel mix, dirty air filter, unfavorable running

conditions, e.g. operating at partial load.

20

Page 22

MAINTENANCE

D. CLEANING THE AIR FILTER.

Dirty air filters reduce engine power, increase fuel consumption and make starting more difficult.

If there is a noticeable loss of engine power:

ST23, 26

1

5

1. Turn the choke lever (Ref. 1) to “CLOSE”.

Loosen the screw (Ref. 2) and remove the air

filter cover (Ref. 3).

2. Remove the foam element (Ref 4) and felt

element (Ref.5).

3. Wash the air filter in warm, soapy water and dry.

4. Always replace a damaged foam element.

5. Fit the foam element in the filter housing.

3

4

ST35

4

5

IMPORTANT

To maintain proper engine operating

temperatures, cooling air must pass freely

through the cylinder fin area. This flow of air

carries combustion heat away from the engine.

Air out flow

3

Air out flow

6. Fit the filter cover and engage it in position.

7. Tighten the screw firmly.

E. COOLING SYSTEM MAlNTENANCE.

The cooling system relies on cooling air entering

the engine through the bottom engine grille located

between the fuel tank and starter. The

cooling fan pushes this air through the cylinder fin

area and out the rear grille openings in the engine

cover.

Air intake

Overheating and engine seizure can occur when:

1. Air intakes are blocked, preventing cooling air

from reaching the cylinder.

21

Page 23

MAINTENANCE

2. Dust and grass build up on the outside of the

cylinder. This buildup insulates the engine and

prevents the heat from leaving.

2. Place the piston at top dead center. Clean any

deposits from the muffler and the cylinder

exhaust port with a nonmetallic scraper.

Removal of cooling passage blockages or cleaning

of cylinder fins is considered “Normal

Maintenance”. Any resultant failure attributed to

lack of maintenance is not warranted.

F. CLEANING THE CYLINDER FINS.

(Check Periodically)

1. Remove any dust and dirt from between the fins.

2. If greater access is needed to thoroughly clean

the fins, remove the engine cover as illustrated.

Cylinder fins

G. CLEANING THE EXHAUST PORT.

This procedure requires specialized engine service

techniques and the proper tools. Contact the

authorized Cub Cadet Commercial dealer where

you bought your trimmer or your nearest Cub Cadet

Commercial Service Center.

IMPORTANT

Do not use a metal tool to scrape carbon from

the exhaust port. Be careful not to scratch the

cylinder or piston when cleaning the cylinder

exhaust port.

3. Inspect the gasket, and replace it if necessary.

4. Install the muffler.

5. Fit the gasket and cover.

H. CLEANING THE CLUTCH AND

CLUTCH DRUM.

Clutch

Clutch drum

Exhaust port

Gasket

1. Remove the muffler and gasket.

Muffler

Plate

1. Loosen the four screws and remove the fan

housing.

2. Clean the dirty clutch and clutch drum.

3. Always replace a damaged clutch and clutch

drum.

22

Page 24

I. FUEL SYSTEM.

1. Change the fuel pick up body every year.

MAINTENANCE

1. Remove the filler plug.

2. Check the level and add grease, if necessary,

using a pressure pump. Leave about 5-10 g (1/4

oz.) for any expansion of grease.

NOTE:

Use a good quality lithium multipurpose grease.

DO NOT overfill the housing.

3. Tighten the filler plug firmly.

K. LUBRICATING THE DRIVE SHAFT.

Shaft

2. Before storing your machine for a long period,

drain and clean the fuel tank and run the engine

until the carburetor is dry.

3. The fuel tank and the container in which the fuel

mix is stored should be cleaned from time to

time.

J. LUBRICATING THE GEAR HEAD.

Filler plug

Drive shaft

1. Pull the shaft out of the drive tube.

2. Use a good quality lithium multipurpose grease

to coat any dry areas of the shaft. Do not apply

too much grease. Never pump grease into the

drive tube.

23

Page 25

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

No Fuel at Carburetor Fuel Filter Dirty Replace

Fuel Line Clogged Clean

Carburetor See your Cub Cadet dealer

No Fuel at Cylinder Carburetor See your Cub Cadet dealer

Muffler Wet with Fuel Fuel Mixture is too Rich Open Choke

Clean/Replace Air Filter

Adjust Carburetor

See your Cub Cadet dealer

No Spark at Plug End of Wire Ignition Switch Off Turn Switch On

Electrical Problem See your Cub Cadet dealer

No Spark at Spark Plug Spark Gap Incorrect Re-gap 0.22in.(0.55mm)

Covered with Carbon Clean or Replace

Fouled with Fuel Clean or Replace

Spark Plug Defective Replace

Engine Does Not Crank or Turn Over Internal Engine Problem See your Cub Cadet dealer

Engine Dies or Accelerates Poorly Air Filter Dirty Clean or Replace

Fuel Filter Dirty Replace

Fuel Vent Plugged Clean Fuel Vent

Spark Plug Clean and Adjust or Replace

Carburetor Adjust

Cooling System Plugged Clean

Exhaust Port Fouled Clean

Spark Arrestor Screen Plugged

Clean

No Rotation of Cutting Tool Incorrect Mounting Remount

Twining of String or Grass Clean

Around Cutting Tool

Wear of Clutch Shoe or Drum Replace

Grass or Brush Not Being Cut Dull Cutting Tool Resharpen and Remount

Tool Not Mounted Properly Remount Tool Properly

Excessive Vibration

Loosened Bolt Securing the Tool

Incorrect Mounting Remount

Bent or Damaged Cutting Tool Replace Tool

Cutting Tool Out of Balance Replace Tool

Loosened Bolt And Nut Tighten

Tighten

24

Page 26

MANUFACTURER’S LIMITED WARRANTY FOR:

Cub Cadet Corporation's limited warranty promises to you, the original retail purchaser, that the unit of Cub Cadet Commercial hand held power

equipment you purchased (the "Product") will be free from defects in material and workmanship for, as applicable: a period of one (1) year from the

date of retail purchase for commercial purchasers and/or users, and a period of two (2) years from the date of retail purchase for residential purchasers

and/or users (the "Warranty period"). Cub Cadet Commercial agrees to repair or replace, at Cub Cadet Commercial's option, any defective Product free

of charge during the applicable Warranty Period. Upon completion of your purchase, the Serial Number of the Product will be registered with Cub

Cadet Corporation. This will initiate and validate your limited warranty and the applicable Warrnty Period. Please keep your purchase receipt and

present it to an authorized Cub Cadet Commercial servicing facility for warranty service. Parts replaced or repaired under this limited warranty are

warranted only to the end of the Warranty Period. All defective parts replaced under this Limited Warranty become the property of Cub Cadet

Corporation. For warranty service, you must, at your own expense, deliver the Product to, and pick it up from, an authorized Cub Cadet Commercial

servicing facility. To locate your nearest authorized Cub Cadet Commercial servicing facility, call Cub Cadet Corporation at 330-273-4550.

EXTENDED LIFETIME OF THE PRODUCT LIMITED WARRANTY FOR STRING TRIMMER SHAFT AND TUBE.

If applicable, Cub Cadet Corporation’s limited warranty further promises to you, the original retail purchaser, that the shaft and tube of the string

trimmer unit you purchased will be free from defects in material and workmanship for the expected life of the Products not to exceed ten (10) years

from the date of retail purchase (“Extended Warranty Period”). Cub Cadet Commercial agrees to repair or replace at Cub Cadet Commercial’s option,

any defective shaft and/or tube of a string trimmer unit free of charge during the Extended Warranty Periond. Parts replaced or repaired under this

limited warranty are warranted only to the end of the Extended Warranty Period.

This limited warranty is given by Cub Cadet Commercial to the original retail purchaser only, and is not transferable to subsequent owners. This

warranty does not cover damage to the Product resulting from any cause other than defects in material or workmanship. This warranty specifically

does not cover

damage caused by:

1. Lack of lubrication or engine failure due to the use of oils other than Cub Cadet Commercial-approved oils.

2. The use of gasohol containing methyl (wood) alcohol or gasoline containing less than 89 octane. Only use gasoline which contains 89 octane or

higher or gasohol which contains a maximum 10% ethyl (grain) alcohol or 15% MTBE (methyl tertiary-butyl ether). (The prescribed mixing

ratio of gasoline to oil is listed on the Cub Cadet Commercial oil label.)

3. Defects, malfunctions or failures resulting from abuse, misuse, modifications, alterations, improper servicing or maintenance, improper storage,

use of unauthorized attachments, including, without limitation, failure to provide or perform required maintenance services as described in the

Operator's Manual.

4. Tampering with engine speed governors or running engines above specified and recommended engine speeds.

5. Dirt, salt water corrosion, rust, varnish and moisture.

6. Operation of the Product with improperly serviced, damaged or removed air filter.

7. Failure to follow the set-up, pre-delivery service and adjustments outlined in the Operator's Manual.

8. Parts which are not warranted. (This limited warranty does not cover parts which are normal wear or maintenance items, including, without

limitation, spark plugs, filters, lubricants, engine tune-up parts, spark arrestor screen, cutting line and starter cords.)

9. Engine damage caused by the use of ether or any starting fluids.

10. Damage caused by the pressure of steam cleaning the Product.

11. Repairs or alterations made to the Product by an unauthorized party.

THIS LIMITED WARRANTY IS IN PLACE OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES. ANY IMPLIED WARRANTY , SUCH

AS FITNESS FOR A PAR TICULAR PURPOSE OR MERCHANTABILITY, IS EXCLUDED. REPAIR OR REPLACEMENT UNDER THIS

LIMITED WARRANTY IS EXPRESSLY AGREED TO BE THE EXCLUSIVE REMEDY. CUB CADET CORPORATION WILL NOT BE LIABLE

FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY T O YOU. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER LEGAL RIGHTS WHICH VARY FROM STATE TO STATE.

HOW TO ORDER PARTS

Contact your Cub Cadet Commercial Salesperson, OR phone us (use the numbers below), OR write us (use the address below).

We will need the following information:

1. Your account number if available.

2. Your name and address and the address where you want the parts to be shipped.

3. The Model/Serial No. of the equipment.

4. The Cub Cadet Commercial Part No. and the quantity desired. (Please do not use reference numbers.)

NOTE: Inspect all shipments on receipt for damage or missing parts. File a claim with the carrier before accepting a damaged shipment.

We reserve the right to change designs, specifications and equipment at any time without notice and without incurring any obligations.

CUB CADET CORPORATION, P.O.Box 368023,

Cleveland, OH 44136-9723

Phone (330) 273-4550, Fax (330) 225-9133

Page 27

U. S. EPA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The U.S. Environmental Protection Agency (EPA), Cub Cadet Corporation and the engine manufacturer for this

equipment, Ishikawajima Shibaura Machinery Co., Ltd. (ISM), are pleased to explain the federal emission control

systems warranty on your engine.

In the U. S. (exclude the state of California), new 1997 and later model year engines must be designed, built, and

equipped, at the time of sale, to meet the EPA regulations for small nonroad engines. The engine must be free from

defects in materials and workmanship during the period of warranty coverage (see PERIOD OF WARRANTY

COVERAGE below). ISM must warrant the emission control system on your engine for that period provided there has

been no abuse, neglect or improper maintenance of your engine.

Your emission control system may include parts such as the carburetor and the ignition system (see EMISSION

CONTROL WARRANTY PARTS LIST below).

Where a warrantable condition exists, Cub Cadet Corporation will repair your engine at no cost to you, including

diagnosis, parts, and labor, on behalf of ISM. While ISM is ultimately responsible for this warranty, Cub Cadet

Corporation has agreed to carry out ISM’s warranty repair responsibilities, and Cub Cadet Corporation should be your

primary contact for emission-related warranty service.

PERIOD OF WARRANTY COVERAGE

1997 and later utility and small nonroad engines are warranted for two years. If any emission-related part on your

engine is defective, the part will be repaired or replaced by Cub Cadet Commercial on behalf of ISM.

OWNER’S RESPONSIBILITIES

(a) As the engine owner, you are responsible for the performance of the required maintenance listed in your Operator’s

Manual. Cub Cadet Commercial and ISM recommend that you retain the original purchase documentation and all

receipts covering maintenance on your engine, but Cub Cadet Commercial and ISM cannot deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

(b) As the engine owner, you should be aware, however, that Cub Cadet Commercial and ISM may deny you warranty

coverage if your engine or a part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

(c) You are responsible for presenting your engine to an authorized Cub Cadet Corporation servicing facility as soon

as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights and responsibilities, call Cub Cadet Corporation at 330-273-

4550. You may also contact ISM’s representative at 1-916-431-6677.

WARRANTY STATEMENT

The warranty period referred to above begins on the date the equipment (or engine if sold separately) is first soled to a

retail purchaser.

ISM warrants to the initial retail purchaser and each subsequent owner that this engine is designed, built, and equipped

to conform at the time of initial sale to all applicable regulations of EPA, and that the engine is free of defects in

materials and workmanship that would cause it to fail to conform with EPA regulations during its warranty period.

For the parts listed under EMISSION CONTROL WARRANTY PARTS LIST below, an authorized Cub Cadet Commercial servicing facility will, at no cost to you, make the necessary diagnosis, repair, or replacement of any defective part

to ensure that the engine complies with applicable EPA regulations.

Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled only for

regular inspection, is warranted for the warranty period. Any part repaired or replacement part installed under this

warranty shall be warranted for the remainder of the warranty period.

Page 28

WARRANTY STATEMENT (continued)

Any warranted part which is scheduled for replacement as required maintenance is warranted for the period of time up

to the point of first scheduled replacement. A replacement part installed prior to the first scheduled replacement due

to a defect in the original part shall be warranted until the date of the first scheduled replacement. The owner is

responsible for the performance of all required maintenance listed in the Operator’s Manual.

EMISSION CONTROL WARRANTY PARTS LIST

The parts listed below are covered by this warranty.

- Carburetor

- Ignition system (ignition module)

- Spark plug

- Air filter element

- Insulator (intake manifold)

- Fasteners for emission-related parts

Any parts replaced under this warranty become the property of Cub Cadet Commercial and ISM.

WHAT IS NOT COVERED

This warranty shall not cover any of the following:

(a) Conditions resulting from tampering, misuse, abuse, improper adjustment, engine alteration, use of add-on or

modified parts, use of replacement parts that are not approved by ISM, accident, failure to use the recommended

fuel or oil, use of additives to fuel or oil, use of stale fuel more than 30 days old, or not performing required

maintenance.

(b) Replacement parts used for required maintenance.

(c) Consequential damages such as loss of time, inconvenience, or loss of use of this engine or equipment; however,

Cub Cadet Commercial and ISM are liable for damages to other engine components caused by the failure of a

warranted part while it is still under warranty.

(d) Damages or repair costs caused by the owner’s unreasonable delay in making the engine available for inspection

and repair.

(e) Fees for diagnosis or inspection that does not result in eligible warranty service being performed.

(f) Any replacement parts that are not approved by ISM, or malfunction of approved parts due to use of unapproved

parts.

Subject to the limitation above,

Manual may be performed by the owner, or by any repair establishment or individual, without affecting coverage under

this warranty; however, warranty repairs must be performed by an authorized Cub Cadet Commercial servicing facility.

The use of parts that are not equivalent in performance and durability to ISM-approved parts may impair the

effectiveness of the emission control system and prevent coverage under this warranty. If non ISM-approved parts are

used for non-warranty maintenance or replacement on this engine, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to ISM-approved parts in performance and durability.

HOW TO OBTAIN WARRANTY SERVICE

To obtain service under this warranty, promptly take your engine to the nearest authorized Cub Cadet Commercial

servicing facility. If available, bring the original purchase receipt (showing the initial date of purchase) and all available

maintenance records.

If you need assistance in locating the nearest authorized Cub Cadet Commercial servicing facility or have any

questions regarding your warranty rights and responsibilities, call Cub Cadet Corporation at 330-273-4550. You may

also contact ISM’s representative at 1-916-431-6677.

non-warranty maintenance of emission control parts that is required in Operator’s

Page 29

ST23

ST26

ST35

Trimmers

Parts List

Page 30

ENGINE, ST23 TRIMMER

37

41 38

34

36

40

1

69

35

70

66

67

68

87

63

64

65

47

28

31

30

32

21

23

29

27

33

10

62

61

72

73

24

25

22

26

6

2

12

19

13

1

59

81

82

80

79

83

4

3

5

6

7

13

9

11

8

76

50

52

58

57

91

14

15

10

78

77

75

74

48

42

51

55

56

90

88

18

49

47

33

35

43

44

46

53

54

89

16

17

35

45

33

20

84

85

71

Page 31

ENGINE, ST23 TRIMMER – PARTS LIST

Ref. Parts No.

No. No. Description Used

1 IM-115253421 Crankshaft ........................ 1

2 IM-034309031 Key ................................... 1

3 IM-115013300 Piston Assembly (Includes

4 IM-115113650 Ring, Piston ...................... 2

5 IM-115323130 Pin, Piston ........................ 1

6 IM-198343210 Clip, Piston Pin ................. 2

7 IM-042709007 Bearing, Needle ................ 1

8 IM-110035180 Crankcase Assembly

9 IM-040106000 Bearing, Ball, 6000 ........... 1

10 IM-050209097 Seal, Oil ............................ 2

11 IM-030500512 Pin, Dowel ........................ 2

2

12 IM-110035131 Crankcase Assembly

13 IM-199283050 Shim, 0.1mm .......As Req’d.

IM-199283060 Shim, 0.2mm .......As Req’d.

14 IM-155353090 Pulley Assembly, Starter

15 IM-155163110 Ratchet ............................. 1

16 IM-155103461 Recoil Assembly (Includes

17 IM-155213050 Rope, Starter .................... 1

18 IM-155223061 Knob, Starter .................... 1

19 IM-040106200 Bearing, Ball, 6200 ........... 1

20 IM-190285420 Name Plate ....................... 1

21 IM-150053291 Coil Assembly, Ignition...... 1

22 IM-199513451 Insulator ............................ 1

23 IM-010709018 Bolt, M4x20 ....................... 2

24 IM-198213300 Spring ............................... 1

25 IM-150413033 Cap, Plug .......................... 1

2 Ref. 4) ............................ 1

(Includes 1 ea. Ref. 9,10

and 2 ea. Ref. 11) ............. 1

(Includes 1 ea. Ref. 10

and 19) ............................. 1

(Includes 1 ea. Ref.15 and

91) .................................... 1

1 ea. Ref.17, 18, 88, 89

and 90) ............................. 1

Ref. Parts No.

No. No. Description Used

26 IM-150265091 Spark Plug ........................ 1

27 IM-150103460 Flywheel, Magneto ........... 1

28 IM-170033220 Clutch Assembly ............... 1

29 IM-199213150 Spacer .............................. 2

30 IM-199213221 Spacer .............................. 2

31 IM-199433071 Bolt ................................... 2

32 IM-020109118 Nut .................................... 1

33 IM-010709009 Bolt, M5x20 ....................... 5

34 IM-175103460 Housing, Blower ............... 1

35 IM-010709008 Bolt, M5x16 ....................... 8

36 IM-170333220 Drum, Clutch ..................... 1

37 IM-036100010 Snap Ring, S-10 ............... 1

38 IM-298111010 Grommet........................... 1

40 IM-010709011 Bolt, M5x30 ....................... 1

41 IM-020109131 Nut .................................... 1

42 IM-110213550 Cylinder ............................ 1

43 See Ref.86 - Gasket, Muffler ..................... 1

44 IM-135403500 Muffler ............................... 1

45 IM-135493090 Arrester ............................. 1

46 IM-110993390 Gasket, Cylinder ............... 1

47 IM-010709016 Bolt, M5x48 ....................... 4

48 IM-175154060 Cowling, Cylinder .............. 1

49 IM-135433470 Baffle Plate ....................... 1

50 IM-190333330 Trade Mark ....................... 1

51 See Ref.86 - Gasket, Insulator .................. 1

52 IM-199513501 Insulator ............................ 1

53 IM-125543100 Adjuster ............................ 1

54 IM-010709006 Bolt, M5x12 ....................... 4

55 IM-020100005 Nut .................................... 1

56 IM-026100005 Washer ............................. 2

57 IM-010709010 Bolt, M5x25 ....................... 2

58 See Ref.86 - Gasket .................................. 1

59 IM-130104240 Carburetor Assembly

(Includes 1 ea. Ref. 60, 61,

62, 63, 64 and 65) ............ 1

Ref. Parts No.

No. No. Description Used

60 IM-130153240 Valve, Float....................... 1

61 IM-130123350 Gasket .............................. 1

62 IM-130283357 Diaphragm, Metering ........ 1

63 IM-130513409 Diaphragm, Pump ............. 1

64 IM-130513413 Gasket .............................. 1

65 IM-198113900 Rubber .............................. 1

66 IM-135713490 Case, Air Silencer ............. 1

67 IM-135263310 Element “B”, Air Filter ....... 1

68 IM-135263300 Element “A”, Air Filter ....... 1

69 IM-135713480 Cap, Case......................... 1

70 IM-125504680 Wire Complete, Throttle.... 1

71 IM-160113270 Tank, Fuel......................... 1

72 IM-160033200 Cap Assembly, Fuel Tank

(Includes 1 Ref. 73) ......... 1

73 IM-160993100 Gasket .............................. 1

74 IM-130303290 Filter, Fuel......................... 1

75 IM-198343181 Clip ................................... 1

76 IM-130983060 Hose ................................. 1

77 IM-198113730 Rubber .............................. 1

78 IM-068209150 Hose ................................. 1

79 IM-198113560 Rubber .............................. 1

80 IM-068209177 Hose ................................. 1

81 IM-160043121 Valve, Reversing............... 1

82 IM-198343060 Clip ................................... 1

83 IM-198483100 Connector ......................... 1

84 IM-198113701 Rubber .............................. 2

85 IM-198113740 Rubber .............................. 1

86 IM-135994150 Gasket Kit (Includes 1 ea.

Ref. 43, 51 and 58) ........... 1

87 IM-125683061 Wire Holder....................... 1

88 IM-155183121 Reel .................................. 1

89 IM-155263270 Spring, Spiral .................... 1

90 IM-155343050 Screw ................................ 1

91 IM-155263261 Spring, Return .................. 1

Page 32

SHAFT, ST23 TRIMMER

14

32

28

Optional

10

16

15

47

3

20

49

21

22

23

24

25

26

27

48

17

18

19

20

4

5

6

31

30

7

9

33

29

2

3

8

38

41

1

11

10

13

12

40

39

54

55

56

53

57

35

36

37

58

50

51

52

Page 33

SHAFT, ST23 TRIMMER – PARTS LIST

Ref. Parts No.

No. No. Description Used

1 IM-720113160 Shaft, Drive ....................... 1

2 IM-720124320 Pipe, Complete (Includes

3 IM-720133160 Metal ................................. 6

4 IM-720203082 Hanger .............................. 1

5 IM-720973178 Bolt, M6x14 ....................... 1

6 IM-720623400 Grip ................................... 1

7 IM-125034130 Lever Assembly, Throttle

8 IM-125504820 Wire Complete, Throttle .... 1

9 IM-720473180 Plate ................................. 1

10 IM-010709009 Bolt, M5x20 ....................... 6

11 IM-720043511 Deflector Assembly , Plastic

4

12 IM-720493060 Cutter ................................ 1

13 IM-010709008 Bolt, M5x16 ....................... 1

14 IM-720023990 Case Assembly, Gear

15 IM-720973663 Bolt, M6x8 ......................... 1

16 IM-720973175 Bolt, M5x10 ....................... 1

17 IM-036500024 Snap Ring, R-24 ............... 1

18 IM-036100009 Snap Ring, S-9 ................. 1

19 IM-720973161 Bearing, Ball, 609ZZ ......... 1

20 IM-720973159 Bearing, Ball, 609 ............. 2

21 IM-040146001 Bearing, Ball, 6001LL ....... 1

22 IM-036500028 Snap Ring, R-28 ............... 1

23 IM-720333630 Holder ............................... 1

24 IM-720343890 Cover ................................ 1

25 IM-720333610 Holder ............................... 1

26 IM-720343780 Cover, Nut......................... 1

27 IM-720973715 Nut, LH M10x1.25 ............. 1

6 Ref. 3) ............................ 1

(Includes 1 Ref. 8) ............ 1

(Includes 1 Ref.12 and 13) 1

(Includes 1 ea. Ref. 15, 16,

17, 18, 19, 21, 22, 47, 48,

49 and 2 ea. Ref. 10 and

20) .................................... 1

Ref. Parts No.

No. No. Description Used

28 IM-720053800 Handle, Loop (Includes

2 Ref. 29) .......................... 1

29 IM-720973177 Bolt, M6x12 ....................... 2

30 IM-720983371 Wrench, Spanner Box 19 . 1

31 IM-090500004 Wrench, Key, 4mm ........... 1

32 IM-720983420 Bag, Tool........................... 1

33 IM-100814820 Manual, Operator’s ........... 1

38 IM-198113780 Rubber .............................. 1

39 IM-720973673 Bolt, 5x8 ............................ 1

40 IM-199233430 Collar ................................ 1

41 IM-026100005 Washer, 5mm.................... 1

47 IM-720263660 Case ................................. 1

48 IM-720273190 Gear Assembly ................. 1

49 IM-720293360 Shaft ................................. 1

Ref. Parts No.

No. No. Description Used

Optional

35 IM-195833140 Blade, 4 Tooth................... 1

36 IM-195833170 Blade, 8 Tooth................... 1

37 IM-195833230 Blade, Circular .................. 1

50 IM-720463430 Deflector, Steel ................. 1

51 IM-720053910 Handle Assembly, Loop

(Includes 2 Ref. 52) .......... 1

52 IM-720973183 Bolt, M6x18 ....................... 2

53 IM-720613420 Handle .............................. 1

54 IM-125034241 Lever Assembly, Throttle .. 1

55 IM-720623520 Grip Assembly .................. 1

56 IM-720063260 Holder Assembly, Handle . 1

57 IM-720973147 Coller ................................ 1

58 IM-720853461 Harness, Shoulder ............ 1

Page 34

ENGINE, ST26 TRIMMER

35

33

30

34

31

32

56

54

55

1

57

58

59

64

27

28

29

60

61

62

63

65

44

25

53

67

68

19

20

24

12

9

11

75

71

72

70

69

78

21

22

81

23

47

51

5

8

1

8

76

73

74

77

79

66

12

3

2

4

6

52

10

7

14

86

13

85

9

17

42

36

45

46

50

82

83

84

15

16

43

41

26

38

37

28

48

49

18

26

39

Page 35

ENGINE, ST26 TRIMMER – PARTS LIST

Ref. Parts No.

No. No. Description Used

1 IM-115253470 Crankshaft ........................ 1

2 IM-11501331 1 Piston Assembly (Includes

3 IM-115113650 Ring, Piston ...................... 2

4 IM-115323040 Pin, Piston ........................ 1

5 IM-198343210 Clip, Piston Pin ................. 2

6 IM-042709008 Bearing, Needle ................ 1

7 IM-110035190 Crankcase Assembly

8 IM-040106201 Bearing, Ball, 6201 ........... 2

9 IM-050209070 Seal, Oil ............................ 2

10 IM-030500512 Pin, Dowel ........................ 2

11 IM-110035200 Crankcase Assembly

2

12 IM-010709010 Bolt, M5x25 ....................... 5

13 IM-155353090 Pulley Assembly, Starter

14 IM-155163110 Ratchet ............................. 1

15 IM-155103461 Recoil Assembly (Includes

16 IM-155213050 Rope, Starter .................... 1

17 IM-155223061 Knob, Starter .................... 1

18 IM-190285440 Name Plate ....................... 1

19 IM-150053330 Coil Assembly, Ignition...... 1

20 IM-010709018 Bolt, M4x20 ....................... 2

21 IM-198213300 Spring ............................... 1

22 IM-150413033 Cap, Plug .......................... 1

23 IM-150265091 Spark Plug ........................ 1

24 IM-150103500 Flywheel, Magneto ........... 1

25 IM-170033370 Clutch Assembly ............... 1

2 Ref. 3) ............................ 1

(Includes 1 ea. Ref. 8,9

and 2 ea. Ref. 10) ............. 1

(Includes 1 ea. Ref. 8 and

9) ...................................... 1

(Includes 1 ea. Ref.14 and

86) .................................... 1

1 ea. Ref.16, 17, 83, 84

and 85) ............................. 1

Ref. Parts No.

No. No. Description Used

26 IM-010709009 Bolt, M5x20 ....................... 4

27 IM-175103470 Housing, Blower ............... 1

28 IM-010709008 Bolt, M5x16 ....................... 5

29 IM-170333240 Drum, Clutch ..................... 1

30 IM-036100012 Snap Ring, S-12 ............... 1

31 IM-199233470 Collar ................................ 1

32 IM-010709011 Bolt, M5x30 ....................... 1

33 IM-020109131 Nut .................................... 1

34 IM-175423050 Plate ................................. 1

35 IM-198113890 Rubber .............................. 1

36 IM-110213560 Cylinder ............................ 1

37 See Ref.80 - Gasket, Muffler ..................... 1

38 IM-135403670 Muffler (Includes 1 Ref.39) 1

39 IM-135493090 Arrester ............................. 1

41 IM-010709016 Bolt, M5x48 ....................... 2

42 IM-175154070 Cowling, Cylinder .............. 1

43 IM-135433630 Baffle Plate ....................... 1

44 IM-190333330 Trade Mark ....................... 1

45 See Ref.80 - Gasket, Insulator .................. 1

46 IM-010109433 Bolt, M5x56 ....................... 2

47 IM-199513510 Insulator ............................ 1

48 IM-125543100 Adjuster ............................ 1

49 IM-010709006 Bolt, M5x12 ....................... 1

50 IM-020100005 Nut .................................... 1

51 IM-026100005 Washer ............................. 2

52 See Ref.80 - Gasket .................................. 1

53 IM-130104240 Carburetor Assembly

(Includes 1 ea. Ref. 54, 55,

56, 57, 58 and 59) ............ 1

54 IM-130153240 Valve, Float ....................... 1

55 IM-130123350 Gasket .............................. 1

56 IM-130283357 Diaphragm, Metering ........ 1

57 IM-130513409 Diaphragm, Pump ............. 1

58 IM-130513413 Gasket .............................. 1

Ref. Parts No.

No. No. Description Used

59 IM-198113900 Rubber .............................. 1

60 IM-135713490 Case, Air Silencer ............. 1

61 IM-023100005 Nut .................................... 2

62 IM-135263310 Element “B”, Air Filter ....... 1

63 IM-135263300 Element “A”, Air Filter ....... 1

64 IM-135713450 Cap, Case......................... 1

65 IM-125504790 Wire Complete, Throttle.... 1

66 IM-160113261 Tank, Fuel......................... 1

67 IM-160033200 Cap Assembly, Fuel Tank

(Includes 1 Ref. 78) .......... 1

68 IM-160993100 Gasket .............................. 1

69 IM-130303290 Filter, Fuel......................... 1

70 IM-198343181 Clip ................................... 1

71 IM-198163080 Hose ................................. 1

72 IM-198113730 Rubber .............................. 1

73 IM-068209150 Hose ................................. 2

74 IM-198113560 Rubber .............................. 1

75 IM-160043121 Valve, Reversing............... 1

76 IM-198343060 Clip ................................... 1

77 IM-198483100 Connector ......................... 1

78 IM-198113620 Rubber .............................. 2

79 IM-198113740 Rubber .............................. 1

80 IM-135994160 Gasket Kit (Includes 1 ea.

Ref. 37, 45 and 52) ........... 1

81 IM-125683061 Wire Holder....................... 1

82 IM-110993420 Gasket, Cylinder ............... 1

83 IM-155183121 Reel .................................. 1

84 IM-155263270 Spring, Spiral .................... 1

85 IM-155343050 Screw ................................ 1

86 IM-155263261 Spring, Return .................. 1

Page 36

SHAFT, ST26 TRIMMER

14

32

28

Optional

10

16

15

43

3

20

45

21

22

23

24

25

26

27

44

17

18

19

20

4

5