Page 1

3URIHVVLRQDO6KRS0DQXDO

3URIHVVLRQDO6KRS0DQXDO

LTX Series Riding Tractors

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are no t intended for use by untrained or inexperienced individu als.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accurate as possible at the time of publication. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2012 MTD Products Inc. All Rights Reserved

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

Professional Shop Manual intent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description of the 900 series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Model and Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Engine related parts

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel tank removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuel Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Evaporative (EVAP) emissions system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Roll over valve vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 3: Steering

Steering alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Axles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sector gear and steering pinion gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Steering shaft and hex bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pivot bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 6B: Electronic Power Steering

Rubber Torsion Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EPS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EPS motor & gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting the EPS (without the 725-05419 EPS tester) . . . . . . . . . . 27

EPS removal/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 4: Body panels

What is covered by this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Hood components: Headlight removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Hood components: side vent removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hood components: grill removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Hood components: pivot bracket removal . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Seat and Fenders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dash Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

I

Page 4

Chapter 5: Hydro. Drive and brake system

About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Externally repairable drive system problems . . . . . . . . . . . . . . . . . . . . . . . . 56

Indications that a transaxle is not warrantable . . . . . . . . . . . . . . . . . . . . . . . 61

Brake adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Neutral control adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Linkage: pedal shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Pedal shaft assembly removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Belt control; tensioner and idler pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Drive belt replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Changing transaxle hydraulic fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Transaxle removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Chapter 6: CVT Drive and brake system

About this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

About the variable speed drive system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Externally repairable drive system problems: . . . . . . . . . . . . . . . . . . . . . . . . 94

Indications that a transaxle is not warrantable . . . . . . . . . . . . . . . . . . . . . . . 97

Brake adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Gear selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Tensioner pulley control rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Linkage: pedal shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Pedal shaft assembly removal: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Linkage: pedal tie strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Belt control: tension make-up pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Belt control: variable speed pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Belt control: tensioner pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Drive belt replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Transaxle removal and replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Transaxle repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Chapter 7: electrical system

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

RMC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Key switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

RMC Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

RMC module plug test (electric PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

RMC module plug test (manual PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Electric PTO switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

PTO relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

PTO switch (manual PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Brake switch (manual PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Brake switch (electric PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Park brake switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Reverse Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Seat Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Starter solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

II

Page 5

Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Run Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Run Circuit / Reverse Caution mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Engine shutdown circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Charging circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

PTO Circuit (electric PTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Reverse Mower Control (RMC) circuit operation . . . . . . . . . . . . . . . . . . . . 170

Electrical diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Electrical environment: AC Vs. DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Ohm’s Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Kirchhoff’s Current Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Kirchhoff’s Voltage Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

How the system is wired together . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Types of circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Series/parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Shorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Increased resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

The Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Digital multimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Wiring diagram or schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Fused jumper wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Test lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Self-powered continuity lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Ammeters and specialized charging system testers . . . . . . . . . . . . . . . . . 181

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Charging the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Checking battery condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Battery Testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Adjustable load testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Fixed load testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Conductance testers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Battery discharge test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Storage of batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Electrical Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Voltage Drop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Testing switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

III

Page 6

Chapter 8: Cutting Decks and lift shaft

Cutting decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Deck removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Cleaning the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

To clean the deck while it is removed:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Spindles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

PTO belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Leveling the deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Side to Side Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Front To Rear Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Deck Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Deck lift shaft assembly bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Deck lift shaft assembly removal/replacement . . . . . . . . . . . . . . . . . . . . . . 218

Deck lift links and cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Engine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Chapter 9: Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

The spark plug(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Air filter and foam pre-cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Servicing the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Clean the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Lubricate the pedal shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Hydro-gear Appendix

IV

Page 7

Introduction

CHAPTER 1: INTRODUCTION

Professional Shop Manual intent

This Manual is intended to provide service dealers with an introduction to the mechanical aspects of the LTX

series of tractors.

• Detailed service information about the engine will be provided by the engine manufacturer, in most cases.

Disclaimer: The information contained in this manual is correct at the time of writin g. Both the prod u ct an d th e inf or mation about the product are subject to change without notice.

About the text format:

NOTE: is used to point out information that is relevant to the procedure, but does not fit as a step in the pr oce dure.

• Bullet points: indicate sub-steps or points.

! CA UTION! CA UTION

! WA RNIN G! WA RNIN G

! DANGER! DANGER

Disclaimer: This manual is intended for use by trained, professional technicians.

• Common sense in operation and safety is assumed.

• In no event shall MTD or Cub Cadet be liable for poor text interpretation or poor execution of the procedures described in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician or Cub Cadet Technical Support.

Fasteners

Caution is used to point out potential danger to the technician, operator, bystanders, or surrounding property.

Warning indicates a potentially hazardous situation that, if not avoided, could result in death

of serious injury.

Danger indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury. This signal word is to be limited to the most extreme situations.

• Most of the fasteners used on these mowers are sized in fractional inches. The engine and transmissions

are metric. For this reason, wrench sizes are frequently identified in the text, and measurement s are given

in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of re leasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

1

Page 8

LTX Tractors

! CAUTION! CAUTION

• Be prepared in case of emergency:

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Grooming and attire:

! WARNING! WARNING

! CAUTION! CAUTION

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection ................................ while working around any machinery

Protective gloves ..................................... where necessary

Armored footwear.................................... when working around any machinery

Hearing protection ................................... in noisy environments

Chemically resistant gloves..................... when working with chemicals or solvents

Respirator................................................ when working with chemical or solvents

Appropriate tinted eye protection............. when cutting or welding

Flame resistant headgear, jacket, chaps. when cutting or welding

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious

harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

! DANGER! DANGER

2

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all power

equipment. All the labels in the world cannot protect a technician from an instant of

carelessness.

• Exhaust fumes from running engines contain carbon monoxide (CO). Carbon

monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity.

Only run engines in well ventilated areas. If running engines indoors, use an

exhaust evacuation system with adequate make-up air ventilated into the shop.

Page 9

Introduction

Assembly

Torque specifications may be noted in the part of the text that covers assembly, they may also be summarized in

tables along with special instructions regarding locking or lubrication. Whichever method is more appropriate will be

used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-bystep procedure guide that does not require the user to hunt for information.

The level of assembly instructions provided will be determined by the complexity of disassembly/reassembly,

and by the potential for unsafe conditions to arise from mistakes made in assembly.

Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating the

same procedure two or three times in the manual.

Description of the 900 series

The 900 series is a new tractor platform intr oduced in the 2009 season. This plat form replaces the traditional 600

series tractor.

New for the 900 series is:

• New stronger frame

See Figure 1.1.

Figure 1.1

• New hood and grill designs

• A new 42” timed deck

• A new 2 blade 46” deck

• Tighter turning radius

3

Page 10

LTX Tractors

Model and Serial Numbers

The model and serial number tag can be found under

the seat.

number as shown above.

The model number is 13AX90AR010 The break down of what the character mean is as follows:

See Figure 1.2.

The serial number is located to the right of the model

See Figure 1.2.

Model number

Figure 1.2

Serial number

1 ..............................................................................................Cuts grass

....3 ..........................................................................................Lawn tractor

.......A....................................................................................... Sales level/type of create

...........X............................ ... ... ... .... ... ... ... .... ............................. Engine code

.............9. ................................................................................Frame

.................0 ......................................... ... .... ... ... .......................Drive system

....................A.......................................................................... Hood style

.........................R.....................................................................Deck (S = 42”, T = 46”, P=50”, R=42” timed deck)

.............................056 ............................................................. Customer number

The serial number is 1J078H30003. The serial number reads as follows:

1 ..............................................................................................Engineering level

..J............................................................................................. Month of production (J = October)

.....07 .......................................................................................Day of the month

.........8 .....................................................................................Last digit of the year

...........H............................................................ ... .... ... .............Plant it was built in (Martin, TN)

..............3 ................................................................................Assembly line number

.................0003 ....................................................................... Build number of unit

4

Page 11

CHAPTER 2: ENGINE RELATED PARTS

This manual will cover the engine accessories that are manufactured by Cub Cadet.

IMPORTANT: Refer to the engine manufacturer’s manual for engine specific service information.

Muffler

Remove the muffler by following these steps:

NOTE: The muffler and the exhaust pipes are welded

together . They are replaced as one assembly.

1. Remove the hood and bumper by following the steps

described in Chapter 4: Body/Chassis.

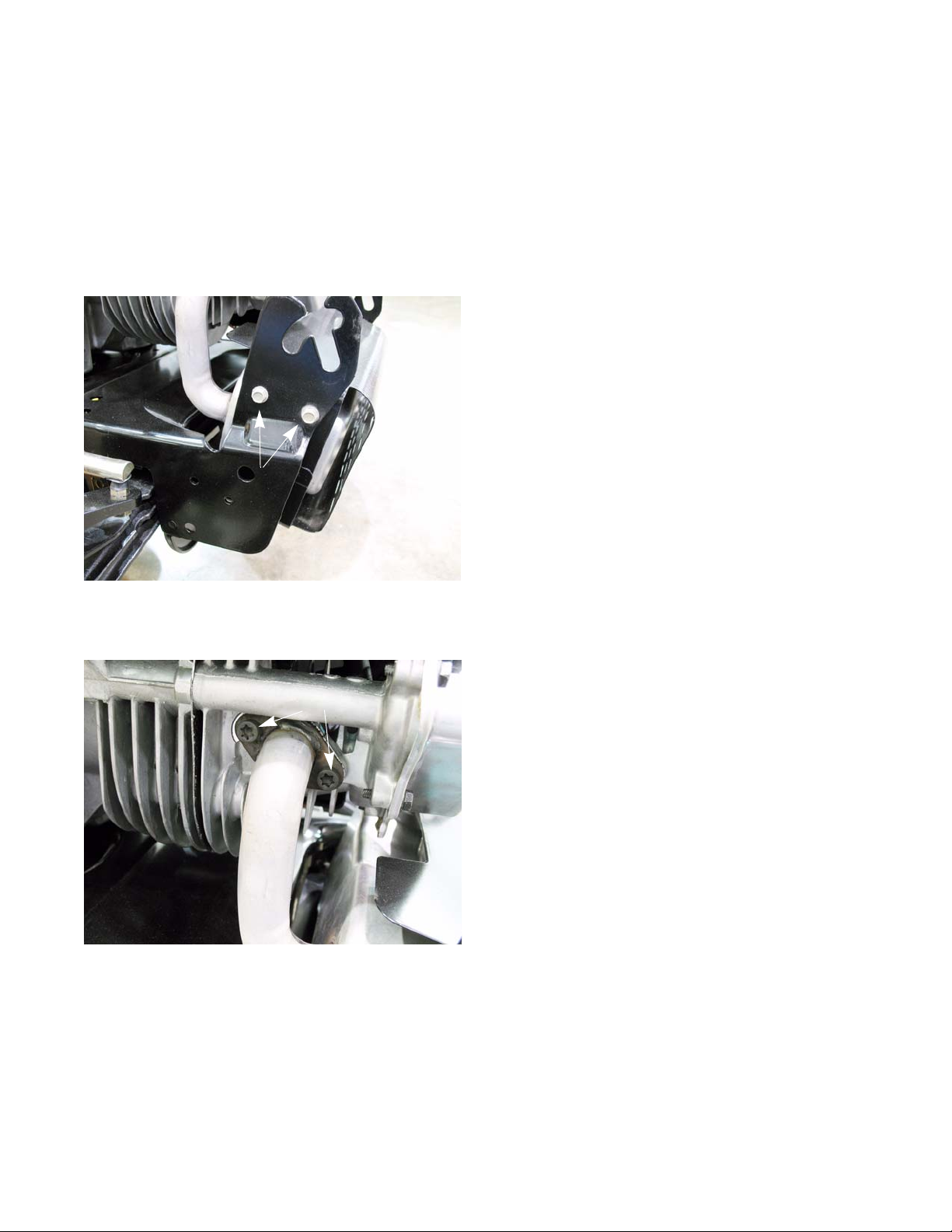

2. Remove the two screws on each side that secure th e

muffler guard bracket.

Screws

See Figure 2.1.

Engine Ralated Parts

Figure 2.1

Screws

Figure 2.2

3. Disconnect the muffler from the engine:

For single cylinder engines:

• Remove the two screws that secure the exhaust

pipe to the cylinder head.

See Figure 2.2.

5

Page 12

LTX Tractors

• Remove the screw that fastens the muffler support bracket to the cylinder head.

See Figure 2.3.

For twin cylinder engines:

Screw

Support bracket

Figure 2.3

• Remove the two nuts that secure each exhaust

pipe to the cylinder head. See Figure 2.4.

Nuts

Figure 2.4

6

Page 13

Figure 2.5

Engine Ralated Parts

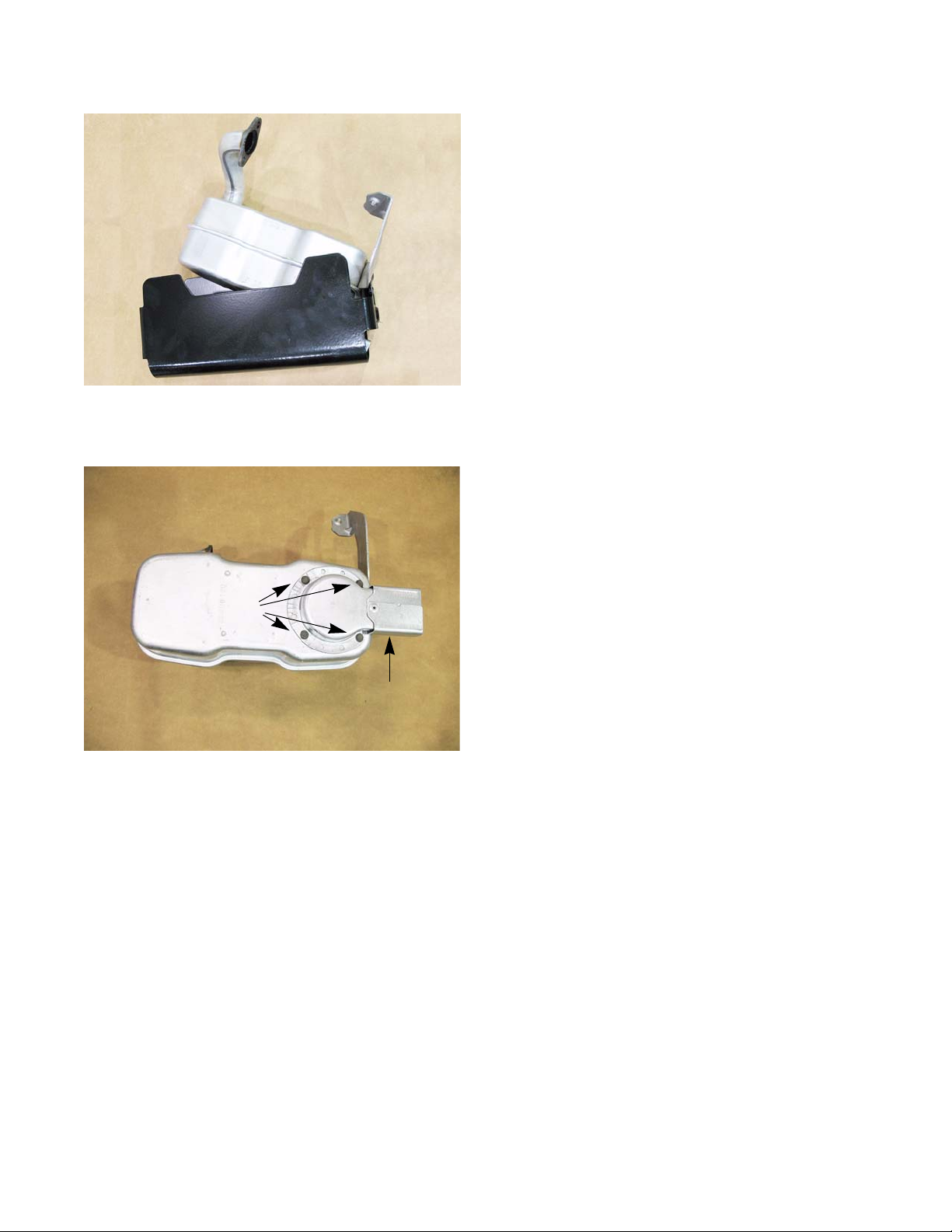

4. Pull the muffler cover and muffler out together.

5. Rotate the muffler out of the muffler cover.

See Figure 2.5.

6. With the muffler on a work bench, remove the four

screws that hold the muffler deflector to the muffler.

See Figure 2.6.

Screws

Figure 2.6

7. Install the muffler by following the above steps in

reverse order.

8. Test run the tractor before returning to service.

Muffler deflector

7

Page 14

LTX Tractors

Fuel tank removal/replacement

Remove/replace the fuel tank by following these steps:

Gasoline and its vapors are extremely flammable. Use common sense when working around

! CAUTION! CAUTION

• Work in a well-ventilated area.

• Allow the engine to cool fully before starting work on the tractor.

• Eliminate any sources of possible ignition from the work area, including but not limited to: heat sources,

open flame, potential sparks.

• Clean-up any spilled fuel quickly and properly, disposing of cleaning materials in a way that will not produce a further fire hazard.

• Hold any drained fuel in an approved and safe

container.

1. Open the hood.

2. Drain the fuel in the fuel tank into an approved container.

the fuel system.

NOTE: The tank may be drained by mechanical

syphon or by disconnecting the fuel line from

the fuel filter.

3. Disconnect the fuel tank vent hose from the roll over

valve (if equipped).

4. Remove the four screws that secure the fuel tank

support rod.

5. Work the fuel tank support bracket off of the tractor

6. Slide the fuel tank out from between the dash and

the engine.

7. Remove the fuel line clamp and slide the fuel line off of the fuel tank nipple.

NOTE: The fuel tank has a barbed fitting. Anytime a fuel line is removed from a barbed fitting it should be

8. Install the fuel tank by following the above steps in reverse order.

9. Test run the tractor and check for leaks before returning to service.

See Figure 2.7.

replaced because of the damage caused to the fuel line liner.

Screws

Figure 2.7

8

Page 15

Fuel Line

Engine Ralated Parts

CSM Cover

Picture courtesy of Avon Automotive

NBR intermediate layer

Reinforcement

Figure 2.8

THV barrier layer

NBR inner liner

The fuel line used by Cub Cadet is GREENbarTM. This

is a multi-layer fuel line that meets the current EPA guidelines.

NOTE: This fuel line has a thin inner liner. If a tear forms in

this inner liner, fuel can get between the liner and

the hose. This will cause the liner to collapse, cut

ting off the fuel flow.

NOTE: Replace the fuel line only with GREENbarTM 700

series fuel line.

-

9

Page 16

LTX Tractors

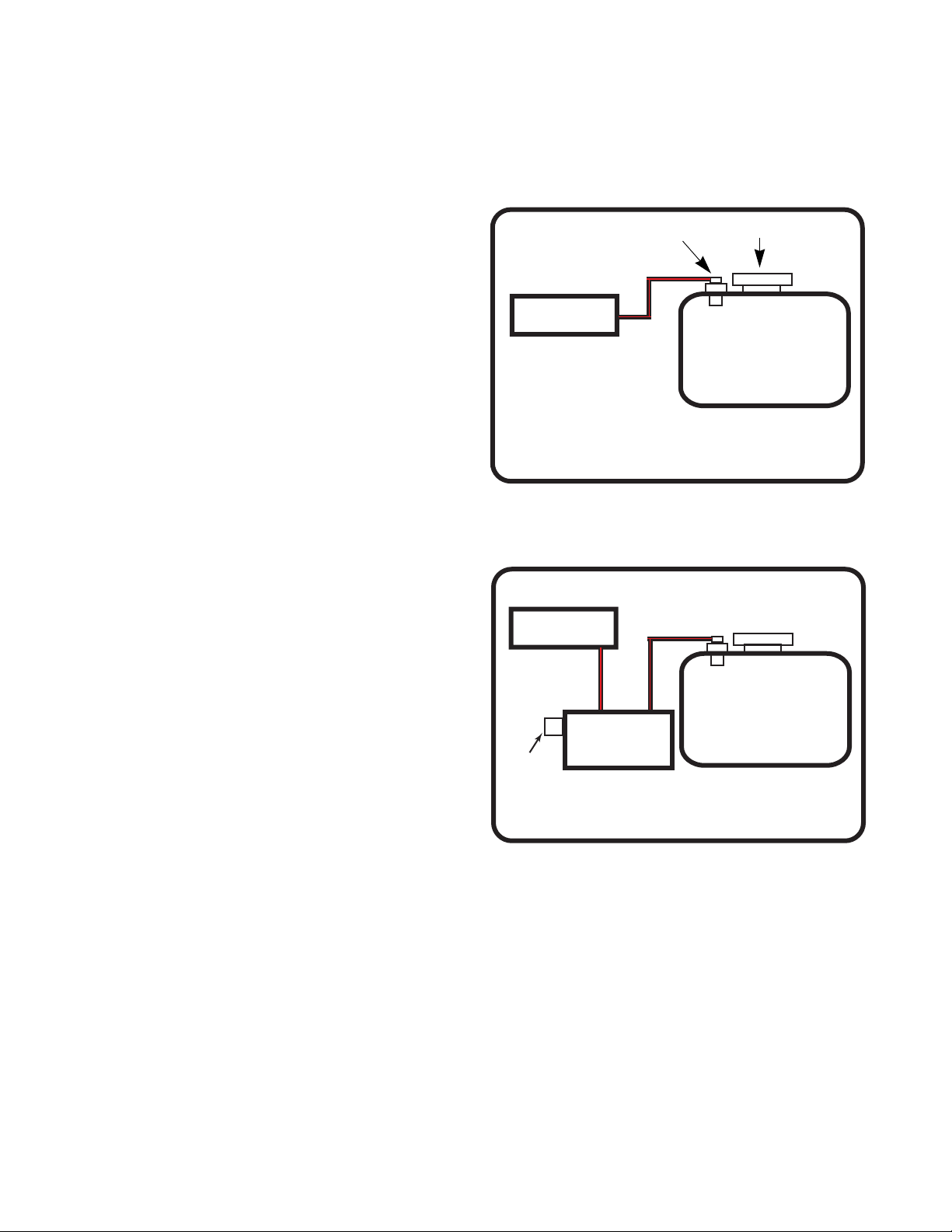

%NGINE

%NGINE

#HARCOAL

CANISTER

6ENT

Evaporative (EVAP) emissions system

The EPA has enacted rules that regulate the amount of vapors an engine’s fuel system is allowed to vent to the

atmosphere. The rules are know as Tier III Emissions Standards. These rules apply to all engines built on or after 1/

1/2012. Some of the requirements of tier III emissions include:

• Tethered fuel caps.

• Unvented fuel caps.

• Low permeation (GREENbar

• Roll over valve vents

The fuel tank has an unvented fuel cap. The fuel tank

vents through the roll over valve. The vapors will flow

through the vent hose (black hose with a red trace) to the

engine.

connector, is a Cub Cadet system, meaning warranty and

parts are handled by Cub Cadet.

facturer, but on most engines the vent hose will go to the

air intake manifold.

See Figure 2.9.

The EVAP system, from the fuel tank up to the engine

The engine side of the system varies by engine manu-

TM

) fuel line

Roll over valve

49 state fuel system

Figure 2.9

Fuel cap

Fuel tank

NOTE: Units sold in California will have a charcoal

canister to further reduce the amount of

emissions that escape from the fuel system.

The fuel tank will vent through the charcoal

canister. The charcoal in the canister will act

as a filter and remove some of the vapors

that are venting out of the fuel tank.

A second vent hose connects the canister to

the engine. As the engine runs, the vacuum

in the intake manifold will draw the vapors

out of the charcoal, recharging it.

See Figure 2.10.

NOTE: A leak in the vent hose will allow dirt injec-

tion into the engine. This will not affect

engine performance until the dirt ingestion

has cause damage inside the engine.

Fuel tank

California fuel system

Figure 2.10

10

Page 17

Engine Ralated Parts

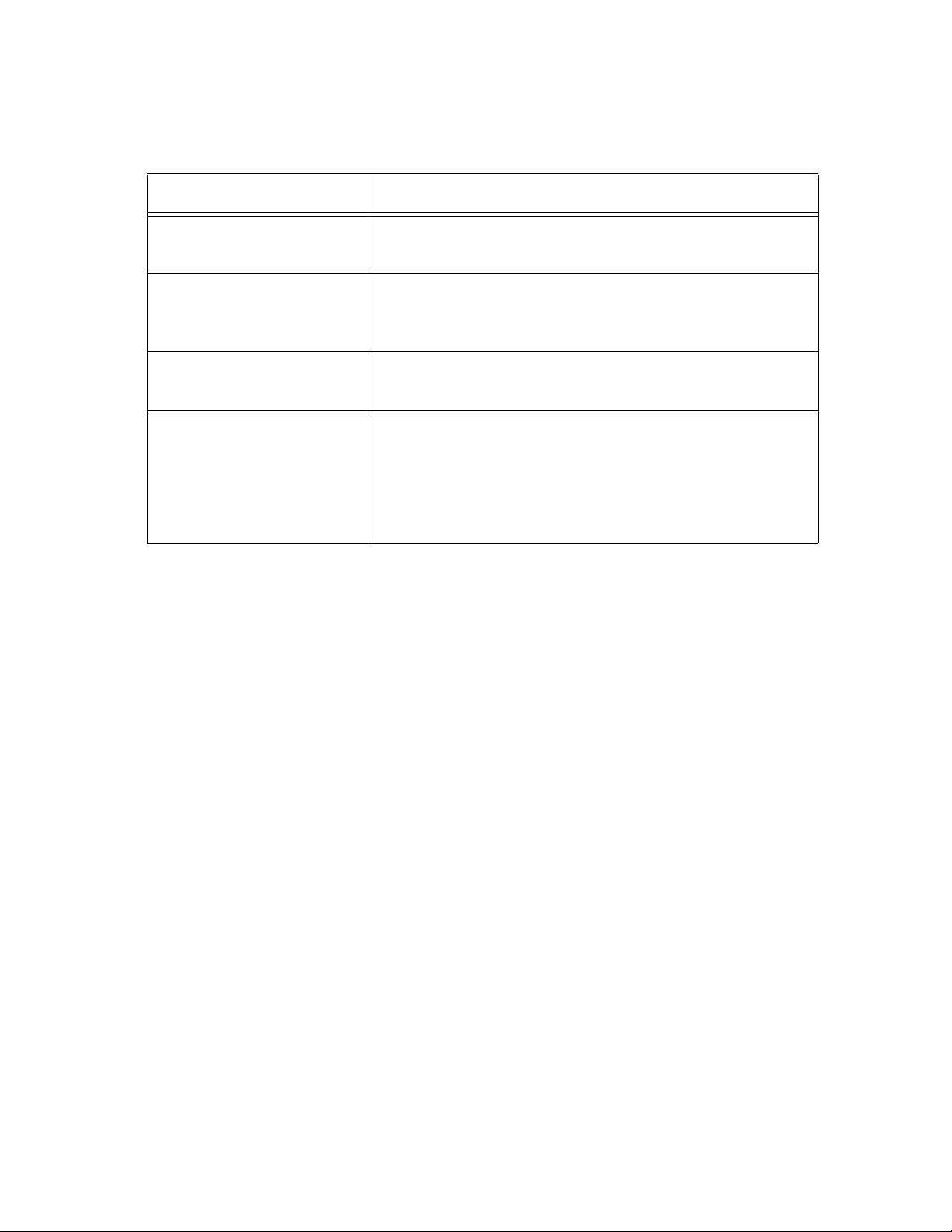

T roubleshooting

Symptom Cause

Engine starts, then dies A blockage in the vent hose.

The roll over valve is stuck closed.

Engine runs rich Raw gasoline in the charcoal canister (if equipped).

A blockage in the line between the charcoal canister (if

equipped) and the intake manifold.

Engine runs lean Wrong fuel cap installed.

Leak in the vacuum lines.

Gasoline vapor escaping from

the engine

The charcoal canister (if equipped) is saturated.

A blockage in the line between the charcoal canister (if

equipped) and the intake manifold.

Wrong fuel cap installed.

Leak in the vacuum lines.

11

Page 18

LTX Tractors

Roll over valve vent

To remove the roll over valve:

1. Open the hood.

2. Disconnect the vent hose. See Figure 2.11.

NOTE: The vent hose will have a red trace.

3. Gently pry the roll over valve out of the fuel tank.

See Figure 2.12.

4. Inspect the rubber grommet, replace if damaged.

To install the roll over valve:

Vent hose

Figure 2.11

Roll over valve

1. With the grommet on the roll over valve, install the

roll over valve by pressing it into the opening in the

tank.

2. Attach the vent hose to the roll over valve.

3. Test run the engine in a safe area befo re retur nin g

to service.

Figure 2.12

12

Page 19

Testing the roll over valve

15 in.Hg.

Figure 2.13

Engine Ralated Parts

The roll over valve vent has two functions. The first

function is to vent the tank and the second function is to

close off the vent if the tank is inverted.

Test the roll over valve by:

1. Remove the roll over valve by following the steps pre viously described in this section.

2. Connect a vacuum pump to the roll over valve.

3. Hold the roll over valve in an inverted position.

4. Apply a vacuum to the roll over valve.

See Figure 2.13.

NOTE: The roll over valve should hold 15 in.Hg. for 15

seconds.

Zero reading

Figure 2.14

5. With the vacuum still applied, turn the roll over valve

over.

See Figure 2.14.

NOTE: The vacuum should be relieved.

6. If the results do not match what is listed above,

replace the roll over valve.

13

Page 20

LTX Tractors

14

Page 21

Steering alignment

Center the sector gear

CHAPTER 3A: STEERING

IMPORTANT: The front tires will have a “TOE-IN” between

1/16” and 1/4” to allow the unit to track properly.

1. Check the tire pressure in the front tires and make

certain that they are at approximately 14 PSI. The

rear tires should be at 10 PSI.

2. Place the unit on level ground.

3. Lower the deck lift lever to the lowest position.

4. Line up the centering hole in the sector gear with the

centering hole in the support plate, and insert a 1/4”

Phillips screw driver up through both.

See Figure 3A.1.

Steering

Figure 3A.1

Measure rim-to-rim at the front and back of rim

Measure rim-to-rim at the front and back of rim

Figure 3A.2

NOTE: The steering wheel should be in the straight for-

ward position. If it is not, remove the steering

wheel and reinstall it so that it is.

5. In front of the axle, measure the distance horizont ally

from the inside of the left rim to the inside of the right

rim.

See Figure 3A.2.

6. From behind the axle, measure the distance horizontally from the inside of the left rim to the inside of the

right rim.

7. The measurement taken in front of th e axle should be

between 1/16” and 5/16” less than the measurement

taken behind the axle. If not, perform the following

steps:

15

Page 22

LTX Tractors

8. Loosen the jam nut at the rear of the right ball joint

that secures the ball joint to the drag link, using a 1/

2” wrench and an 11/16” wrench.

9. Remove the hex nut and lock washer, that secures

the right ball joint to the right axle assembly, using a

1/2” wrench and a 9/16 wrench.

10. Remove the right hand ball joint from the right hand

drag link.

1 1. Remove the left hand ball joint performing steps 8, 9

and 10 above.

12. Place the left and right tire assemblies in the straight

forward position.

13. Set the toe-in for the rim assemblies to 3/16”.

14. Thread the right hand ball joint onto the right hand

drag link until the mounting hole in the right hand axle assembly lines up with the ball joint.

NOTE: Count the number of turns the ball joint was rotated onto the drag link. This number should be within a

couple of turns of the left side. If there is more than a couple turns difference, then one or both of the

drag links are bent.

See Figure 3A.3.

Jam nut

Figure 3A.3

15. Secure the right hand ball joint to the right hand axle assembly with the lock washer and nut removed earlier,

using a 1/2” wrench and a 9/16” socket

16. Secure the right hand ball joint jam nut to the right hand drag link using a 1/2” wrench and an 11/16” wrench.

17. Install the left hand ball joint using steps 14, 15 and 16.

16

Page 23

Axles

Figure 3A.4

Identification mark

Steering

NOTE: The left and right axle have a “L” or a “R” stamped

on the end of the shaft for identification.

See Figure 3A.4.

1. Jack up the front end of the tractor and securely place

on jack stands.

2. Remove the front wheel by popping the hub cap off

with a flat head screw driver.

Castellated washer

Figure 3A.5

1/2” wrench

3. Remove the cotter pin and the castellated washer.

See Figure 3A.5.

NOTE: When installing the wheel, install a new cotter pin

in between the uprights of the castellated washer.

4. Remove the nut holding the drag link to the steering

block using a 1/2” and 9/16” wrench.

See Figure 3A.6.

Figure 3A.6

9/16” wrench

17

Page 24

LTX Tractors

5. Support the axle and remove the steering block

using two 1/2” wrenches.

NOTE: The SLT models do not have a spacer.

See Figure 3A.7.

Steering block

Spacer

Figure 3A.7

6. Remove the spacer and lower the axle out of the

pivot bar.

NOTE: Starting in the 2010 season, some tractors

will be equipped with a stamped pivot bar.

These tractors will have plastic bushing

where the axle rides inside the pivot bar.

See Figure 3A.8.

NOTE: The procedure to remove this axle is the

same as previously described. When install

ing the axle, install new upper and lower

bushings.

7. Install the axle by following the previous steps in

reverse order.

8. Perform a wheel alignment by following the steps described in the steering a lignment section of this chapter.

9. Test run the tractor in a safe area before ret ur ning it to ser vice.

Bushings

-

Figure 3A.8

18

Page 25

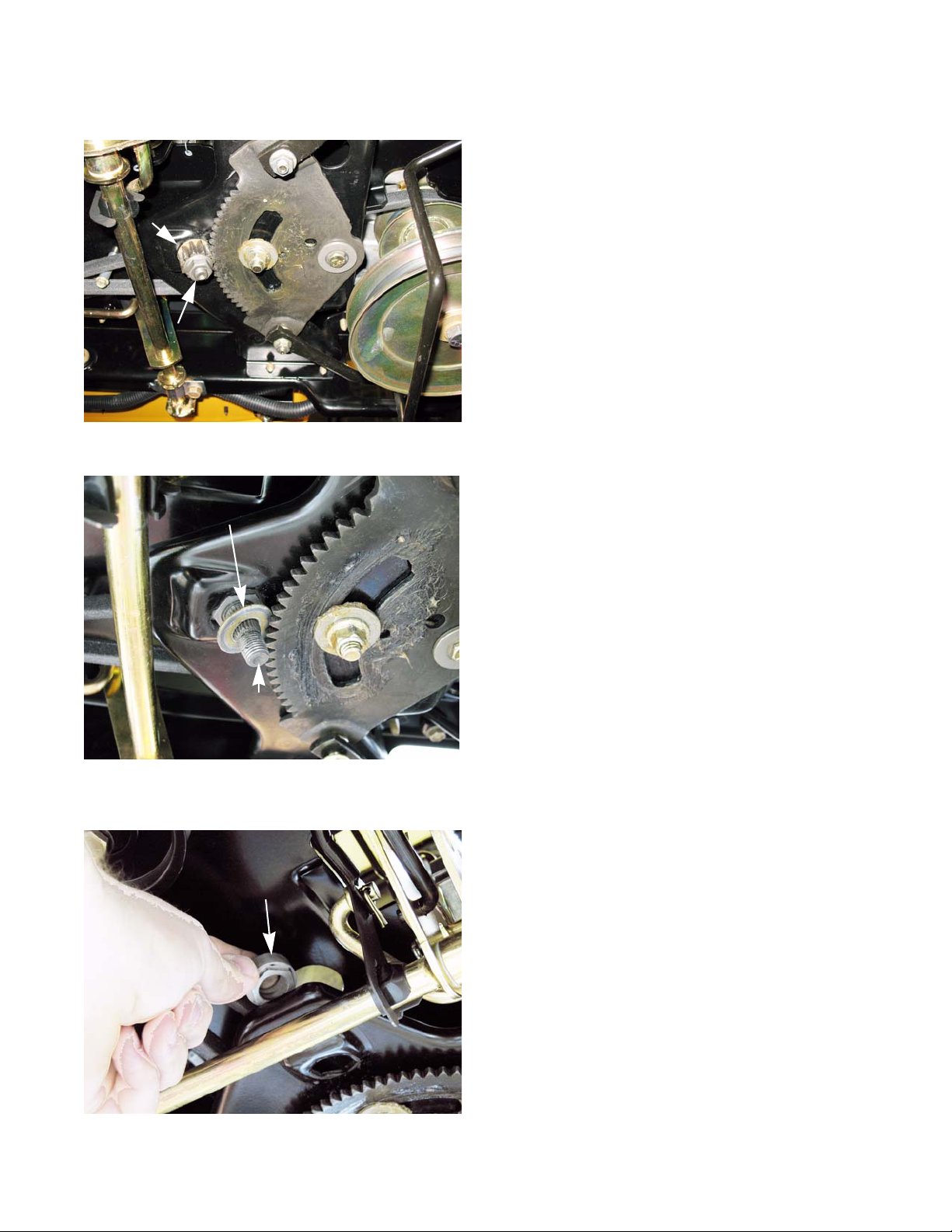

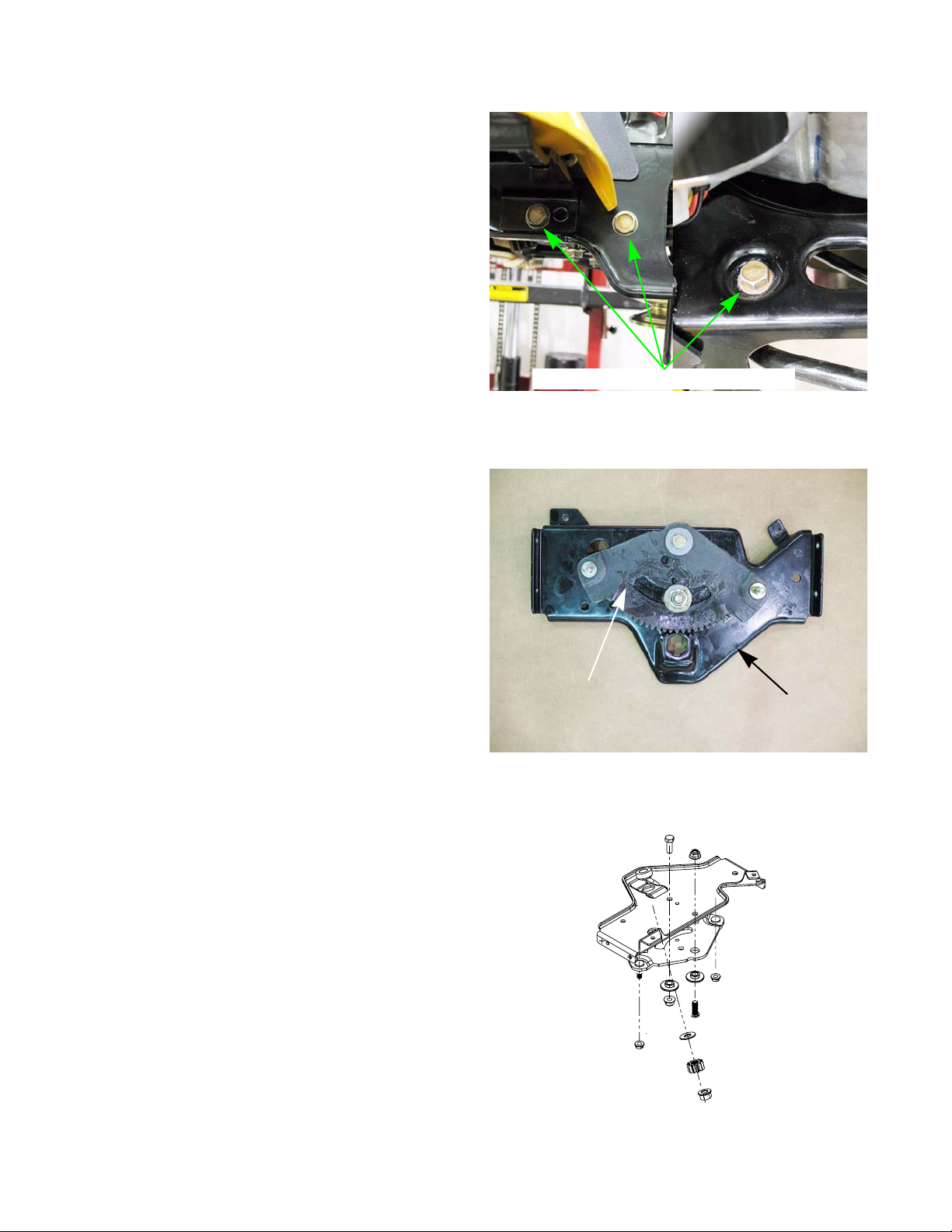

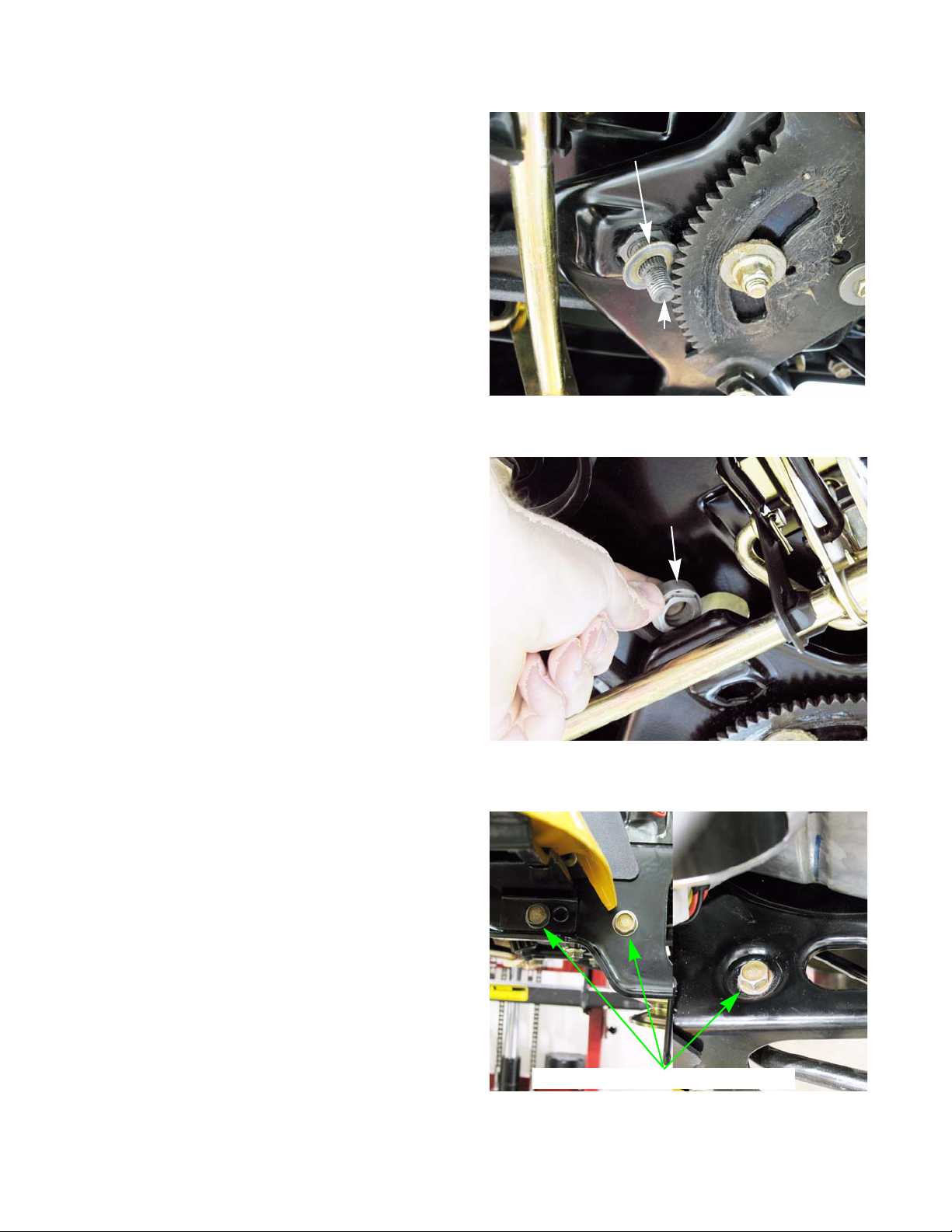

Sector gear and steering pinion gear

Steering Pinion Ge ar

Flange Lock Nut

Figure 3A.9

Remove the washer

Steering

If you are replacing the sector gear or steering pinion

gear, check the condition of both gears for any wear or

damage. It may be wise to replace both as a set.

1. Remove the cutting deck by following the steps

described in Chapter 8: Cutting Decks and Lift Shaft

2. Jack up the front end of the tractor and securely

place on jack stands.

3. Remove the flange lock nut securin g the stee ring pi nion gear to the steering shaft using an 1 1/16” socket.

See Figure 3A.9.

Lift up on the steering shaft

Figure 3A.10

Remove the hex

bushing

4. Slide the steering pinion gear off of the steering shaf t.

5. Lift up on the steering shaft an d remove the washer.

See Figure 3A.10.

6. Push the steering shaft up through the frame of the

tractor.

7. Remove the hex bushing. See Figure 3A.11.

Figure 3A.11

19

Page 26

LTX Tractors

8. Remove the drag links from the sector gear.

9. Remove the six screws that secure the steering

plate to the frame.

10. Remove the steering plate.

See Figure 3A.12.

Remove these screws on each side

Figure 3A.12

11. Remove the hex cap screw, shoulder spacer and

hex nut in the middle of the sector gear using two 9/

16” wrenches.

NOTE: Note the order the sp acers and washer were

removed so that they can be installed prop

erly. See Figure 3A.14.

12. Remove the bolt that the sector gear pivots on using

two 9/16” wrenches.

NOTE: When installing the sector gear, coat the

sector gear and the steering plate with a

high quality lithium grease.

13. Install the steering and steering pivot gears by following the previous steps in reverse order.

See Figure 3A.13.

-

See Figure 3A.13.

sector gear

Steering plate

Figure 3A.13

14. Perform a wheel alignment by following the steps

described in the steering alignment section of this

chapter.

15. Test run the tractor in a safe area before returning it

to service.

20

Figure 3A.14

Page 27

Steering shaft and he x bushing

Figure 3A.15

Steering

To remove the steering shaft or to replace the hex bushing:

1. Remove the cutting deck by following the steps

described in Chapter 8: Cutting Decks and Lift Shaft

2. Jack up the front end of the tractor and securely

place on jack stands.

3. Remove the steering wheel

3a. Remove the cover from the center of the steer-

ing wheel. See Figure 3A.15.

Figure 3A.16

Steering Pinion Ge ar

Flange Lock Nut

Alignment hole

NOTE: The cover can be released by prying-in on the

lock-tabs on the under-side of the steering wheel.

See Figure 3A.16.

3b. Remove the bolt that holds the steering wheel

to the steering shaft using a 1/2” wrench.

3c. Lift the steering wheel off of the steering shaft.

.

4. Remove the flange lock nut securin g the stee ring pi nion gear to the steering shaft using an 11/16” socket.

See Figure 3A.17.

NOTE: If the steering shaft rotates while removing the nut,

insert a pin punch or a #2 phillips screwdriver into

the alignment hole in the sector gear. This will lock

the steering shaft in place, allowing the nut to be

removed.

5. Slide the steering pinion gear off of the steering

shaft.

Figure 3A.17

21

Page 28

LTX Tractors

6. Lift up on the steering shaf t and remove the washer.

See Figure 3A.18.

7. Push the steering shaft up thro ugh the frame of the

tractor.

8. Remove the hex bushing. See Figure 3A.11.

NOTE: Replace the hex bushing every tim e th e

steering shaft is removed.

9. Remove the drag links from the sector gear.

Remove the washer

Lift up on the steering shaft

Figure 3A.18

Remove the hex

bushing

10. Remove the six screws that secure the steering

plate to the frame.

11. Remove the steering plate.

NOTE: The steering shaft will come out with the

steering plate..

12. Install the steering shaft by following the above

steps in reverse order.

13. Test run the tractor in a safe area before returning it

to service.

22

See Figure 3A.12.

Figure 3A.19

Remove these screws on each side

Figure 3A.20

Page 29

Pivot bar

Remove this bolt

Figure 3A.21

Steering

To remove/replace the pivot bar:

1. Jack up the front end of the tractor and securely place

on jack stands.

2. Remove the axles by following the procedures

described in the axle section of this chapter.

3. Slide the front deck link out of the frame.

4. Support the pivot bar.

5. Remove the pivot bar pivot bolt using two 3/4”

wrenches.

6. Slide the pivot bar out of the frame.

See Figure 3A.21.

Spacer

Figure 3A.22

NOTE: There is a spacer in the center of the pivot bar. It

must be in place when installing the pivot bar.

See Figure 3A.22.

NOTE: Starting in the 2010 season, there will be a

stamped pivot bar on some models. The proce

dure to remove it is the same as the cast iron pivot

bar described in the previous steps.

See Figure 3A.23.

7. Install the pivot bar by following the previous steps in

reverse order.

-

Stamped pivot bar

Figure 3A.23

NOTE: Apply high quality grease to the frame, spacer an d

the pivot bar.

8. Preform a wheel alignment by following the steps

described in the steering alignment section of this

chapter.

9. Test run the tractor in a safe area before returning it

to service.

23

Page 30

LTX Tractors

24

Page 31

Electronic Power Steering

CHAPTER 3B: ELECTRONIC POWER STEERING

NOTE: The basic steering system, such as the tie rod ends, drag links axles, etc., is covered in Chapter 3A:

Steering.

In 2012, Cub Cadet introduced the Electronic Power Steering (EPS) system on the Cub select models of the LTX

series of tractors. The EPS provides an electric assist to the steering wheel.

The EPS is a system consisting of three sub-assemblies: the rubber torsion coupling, the EPS module and

the EPS motor & gearbox. They form an assembly that is inserted between the steering shaft and sector gear. The

EPS system is treated as one part.

DO NOT loosen or separate any of

EPS Module

! CAUTION! CAUTION

sion coupler when the EPS assembly is built at

the factory . Once it has been calibrated, it can no t

be re-calibrated. Any shift between the coupling

and the module will result in the EPS auto-steering, which is a very unsafe condition.

the EPS components.

The module is calibrated to the tor-

EPS motor & gearbox

Rubber torsion coupling

Figure 3B.1

Rubber Torsion Coupling

The steering shaft connects the steer ing wheel to the EPS system through the rubber torsion coupling. As the

steering wheel is turned, it applies force to the coupling. The force causes the torsion coupling to twist or torque. The

amount the coupling torques is determined by the amount of force applied to the steering wheel, the more force

applied to the steering wheel, the more the coupling twists.

NOTE: The rubber torsion coupling has hard stops bui lt into it. If the force applied to the steering wheel causes

the coupling to hit its hard stops, the steering input will transfer through the module into the steering

gearbox. This allows manual steering if the EPS system fails.

EPS Module

The EPS module controls the power supplied to the EPS motor. It senses the amount of force that is being

applied to the steering wheel by monitoring the torsion coupling. The module will ramp up the power supplied to the

EPS motor as the force applied to the steering wheel increases. The EPS motor will reach full power within a couple

of degrees of deflection of the torsion coupling.

NOTE: Auto-steering is a condition were

the EPS will turn the wheels to one

direction, once the engine is

started. This happens because the

calibration is off and the EPS thinks

there is a steering input when there

isn’t.

The EPS comes with a 4 year warranty. If there is

a failure with the system, replace the entire system as an assembly.

25

Page 32

LTX Tractors

EPS motor & gearbox

The steering input passes through the torsion co upling

and module into the gearbox. The gearbox then passes

the input force to the output shaft connected to the steer

ing housing.

-

EPS module

The EPS motor assists in turning the input shaft by

driving a set of planetary gears. The planet ary gears drive

a worm shaft. The worm shaft drives a worm gear on the

output shaft.

IMPORTANT: DO NOT open or service the steering

gearbox.

DO NOT drop or hammer on any of

! CA UTION! CA UTION

trapped between the torsion coupling and the

EPS module. If this sensor shifts, it can cause an

auto-steer condition.

the EPS components.

There is a torque senor that is

Steering shaft

coupler

Torsion coupling

EPS motor

EPS motor

output shaft

EPS gearbox

Worm gear

Figure 3B.2

Planetary gears

Worm shaft

26

Worm gear

Figure 3B.3

Page 33

Troubleshooting the EPS (without the 725-05419 EPS tester)

The first step in troubleshooting the EPS system is to

understand how it works.

Electronic Power Steering

See Figure 3B.4.

(QJLQHVKXW

GRZQFLUFXLWV

,JQLWLRQPRGXOH

Figure 3B.4

,JQLWLRQPRGXOH

*5281'

0$*1(72

%$77(5<

*5281'

0$*1(72

%$77(5<

• A constant 12 volts is supplied by the battery

through a 40 amp fuse in the fuse box.

• The EPS is grounded through the green wire.

• The EPS senses the ignition pulses from the ignition module primary windings throug h th e ye llow

wire with a white trace.

NOTE: On tractors with Kohler engines with a Digital

Spark Advance (DSA) ignition, A diode is installed

to protect the ignition module from any stray volt

age that may come from the engine shut down circuits. A white wire carries a clean spark signal to

the EPS to turn it on.

See Figure 3B.5.

• Once the EPS determines that the engine is running (by sensing the ignition pulses from the ignition coil) it will turn on.

• The EPS will power the EPS motor as it senses

input from the steering wheel.

To troubleshoot the EPS assembly:

1 Check the 40 amp fuse in the fuse box.

See Figure 3B.6.

NOTE: If the fuse is blown, check for a short in the red

wire that goes to the EPS assembly before replac

ing the fuse.

-

-

40 amp fuse

Figure 3B.5

Figure 3B.6

The technician needs to determine if there is a mechanical bind in the steering system or an EPS issue. The easiest way to rule out a binding steering system is to:

2. Remove the steering pinion gear by following the

procedures described in Chapter 3: Steering.

3. Start the engine.

4. Operate the steering wheel.

• If the steering wheel now moves freely , th e issue is

downstream of the pinion gear. The most likely

suspect would be axles frozen to the pivot bar.

• If the steering wheel is still hard to operate, isolate

the problem to either the EPS assembly or the cir

cuits that go to the EPS assembly.

NOTE: To protect the EPS module, it will turn off if the

steering input is held at a hard stop for more than 2

seconds. The EPS will turn back on once the input

is released from the hard stop.

-

27

Page 34

LTX Tractors

NOTE: Before troubleshooting any electrical circuit on a tractor, always make sure the battery is fully charged.

NOTE: The EPS assembly has constant battery power and is not controlled by the ignition switch.

To troubleshoot the EPS assembly:

5. Place the tractor on flat, level ground.

6. Remove any attachments that may be on the tractor.

7. Set the parking brake.

8. Turn the steering wheel so that the wheels are

pointing straight forward.

9. With the ignition key in the off position, open the

hood.

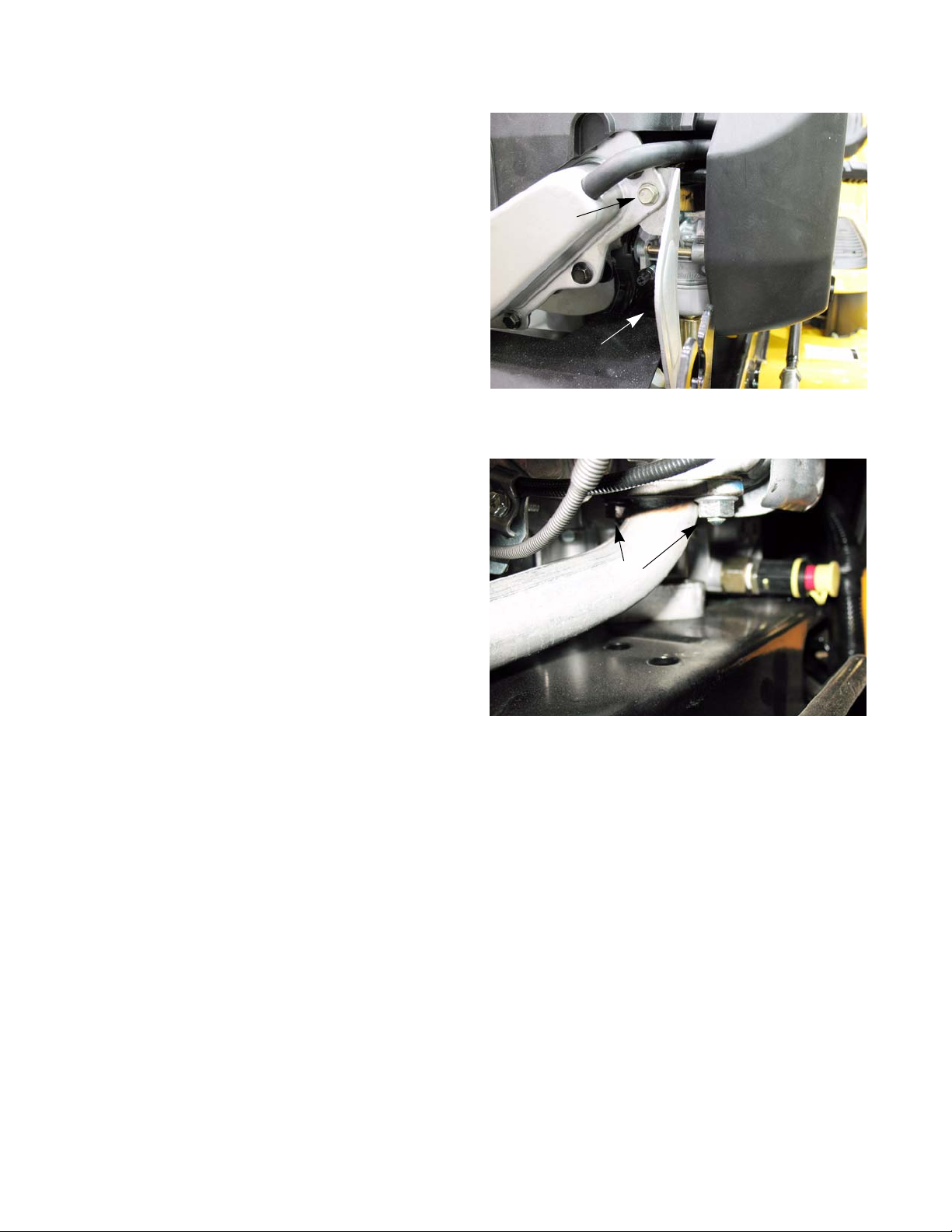

10. Locate, but do not disconnect, the EPS harness

connector underneath the fuel tank.

See Figure 3B.7.

EPS connector

11. Check for battery voltage at the red wire:

11a. Set the Digital Multimeter (DMM) to the DC

volts scale.

11b. Measure the battery voltage across the battery terminals

NOTE: If the battery voltage is < 12.6 volts, charge the battery before continuing.

11c. Connect the black (-) lead of the DMM to the negative post of the battery.

1 1d. Back probe EPS harness connector at the red wire with a black trace, using the red (+) lead of the DMM.

NOTE: The DMM should read battery voltage.

12. Check the ground to the EPS: See Figure 3B.8.

12a. Set the DMM to the DC volts scale.

12b. Connect the red (+) lead to the p ositive post of

the battery.

12c. Back probe EPS harness connector at the

green or black wire, using the black (-) lead of

the DMM.

NOTE: The DMM should read battery voltage. If it

does not, disconnect the EPS harness. If

you now have battery voltage at the EPS

harness connector (tractor side), there is a

short in the EPS assembly. If not, repair the

tractor harness.

Black wire

Figure 3B.7

Figure 3B.8

28

Page 35

Red wire

with black trace

Electronic Power Steering

13. Check the current draw of the EPS assembly.

13a. Leave the DMM connected to the ground wire

on the EPS and the battery.

13b. Place an amp clamp meter on the red wire with

a black trace.

NOTE: Cut the tape that seals the loom at the EPS con-

nector end of the harness and slide th e loom off of

the wires to attach the amp clamp.

13c. Start the tractor.

NOTE: The voltage reading on the DMM should now read

over 13 volts. If it does not, repair the charging cir

cuit before proceeding with troubleshooting the

EPS system.

See Figure 3B.9.

-

Figure 3B.9

NOTE: If the voltage drop s below 13 volt s and the current draw does no t rise above 15 amp s, repair the circuit

suppling voltage to the EPS before proceeding with tr oubleshooting the EPS system.

NOTE: If the voltage drops below 13 volts and current draw is more than 15 amps, the problem is inside the

EPS assembly and it must be replaced.

13e. Turn off the tractor.

5 volt

reticle

13d. Without sitting on the tractor, turn the steering

wheel a quarter turn back and forth. Watching

the voltage reading on the DMM and the current

reading on the amp clamp while doing this.

14.Remove the DMM and the amp clamp meter.

15.Check the input from the ignition module.

15a. Connect the ground lead of an oscilloscope to a

good ground on the engine block.

15b. Back probe the EPS harness connector at the

yellow wire with a white trace using the positive

(+) lead of the oscilloscope.

15c. Start the engine.

16. The oscilloscope should show a pulsed signal. The

bottom or resting phase of each pulse must be below

5 volts. The peak of each pulse must be over 5 volts.

See Figure 3B.10.

Figure 3B.10

17. The pulses must be at 9 Hertz (cycles/second) or

higher (engine needs to be >490 RPM).

18. If the resting phase of the pulse is above 5 volts,

there is a short in the safety circuit of the tractor that

is pulling up the voltage of the ignition module.

29

Page 36

LTX Tractors

NOTE: A voltage spike over 18.5vdc +/- 1.2v @70°F will cause the voltage regulator to shut down. The regula-

tor must be disconnected, then re-connected to reset it.

NOTE: A sustained voltage over 25 volts will damage the EPS module.

IMPORTANT: Loose battery cables or disconnecting jumper cables while the engine is running will create a

high voltage spike that will damage the EPS system.

NOTE: If the results are within the specified ranges or if the amperage draw is higher the n expected, check for

a mechanical bind by:

19. Remove the EPS assembly.

20. Check the steering shaft bushings.

NOTE: Cocked steering shaft bushing will bind the steering shaft, mimicking a bad EPS. Fix the bushings

before condemning the EPS.

21. If nothing is in a bind, replace the EPS assembly.

Troubleshooting the EPS (with the 725-05419 EPS Tester)

To troubleshoot the EPS using the 725-05419 EPS Tester:

1. Connect the red lead of the EPS Tester to the positive post of the battery .

2. Connect the black lead of the EPS Tester to the

negative post of the battery.

NOTE: A green LED and a blue LED should be illu-

minated. If they are not, the tester is malfunctioning.

NOTE: If a red LED illuminates when the tester is

connected to the EPS, the EPS has a short

and has blown the fuse on the tester.

3. Disconnect the EPS harness connector underneath

the battery.

4. Plug the EPS Tester into the connector on the EPS

assembly.

NOTE: The 725-05419 EPS Tester comes with a jumper harness, to be used on tractors with the battery unde r

the seat, so that the tester can reach the EPS assembly.

5. Start the engine.

6. Operate the steering wheel.

• If the steering wheel turns easily, the EPS is not the issue. Refer to the previous section to check the trac-

tor’s electrical system.

Green LED

Blue LED

Figure 3B.11

• If the steering wheel is still hard to turn:

a. Remove the EPS assembly.

b. Reconnect the EPS tester to the EPS assembly by following the procedures described in the EPS

removal section of this chapter.

c. Rotate the input shaft of the torsion coupler. If it rotates with minimal effort the EPS is working.

d. Check for a mechanical bind in the steering system. If it’s hard to turn, the EPS is faulty.

30

Page 37

EPS motor

Figure 3B.12

Electronic Power Steering

To remove/replace and test the EPS motor:

NOTE: The EPS system has a 4 year warranty. DO NOT

remove the EPS motor to test it within the warranty

period. Outside of the warranty period, the EPS

motor can be replaced separately from the EPS

assembly.

1 Remove the EPS assembly by following the proce-

dures described in the EPS removal section of this

chapter.

2. Disconnect the EPS motor harness from the EPS

module.

3. Remove the two screws that secure the motor base

to the EPS, indicated by the arrows in

using a 3/8” wrench.

4. Lif t the motor assembly off of the EPS.

Figure 3B.12,

Red wire

Black wire

Figure 3B.13

5. Mount the motor in a vise.

NOTE: Position the motor so that the vise jaws clamp the

motor base, to prevent damage to the motor.

6. Attach the black wire from the motor to the negative

side of a 12 volt power supply capable of producing

40 amps.

NOTE: The tractor’s battery or a jum p er box ca n be use d

as a power supply.

7. Attach the red wire from the motor to the positive

side of the power source.

NOTE: The motor should spin. If it does not, replace the

motor.

31

Page 38

LTX Tractors

8. Inspect the EPS motor gasket. If it is damaged,

replace it.

NOTE: Do not use a gasket sealant/adhesive on the

EPS motor gasket.

9. Remove the sun gear from the EPS motor.

10. Install the sun gear into the planetary gear set.

Sun gear

Figure 3B.14

11. Install the EPS motor.

NOTE: While installing the EPS motor, align the

motor pigtail with the EPS motor harness.

12. Install the EPS assembly in the tractor by following

the procedures described in the EPS removal sec

tion of this chapter, in re verse order.

13. Test run the tractor in a safe area before returning it

to service.

NOTE: Do not put a tractor into service with any

safety or control features that are not work

ing properly.

-

-

EPS motor pigtail

Harness

Figure 3B.15

32

Page 39

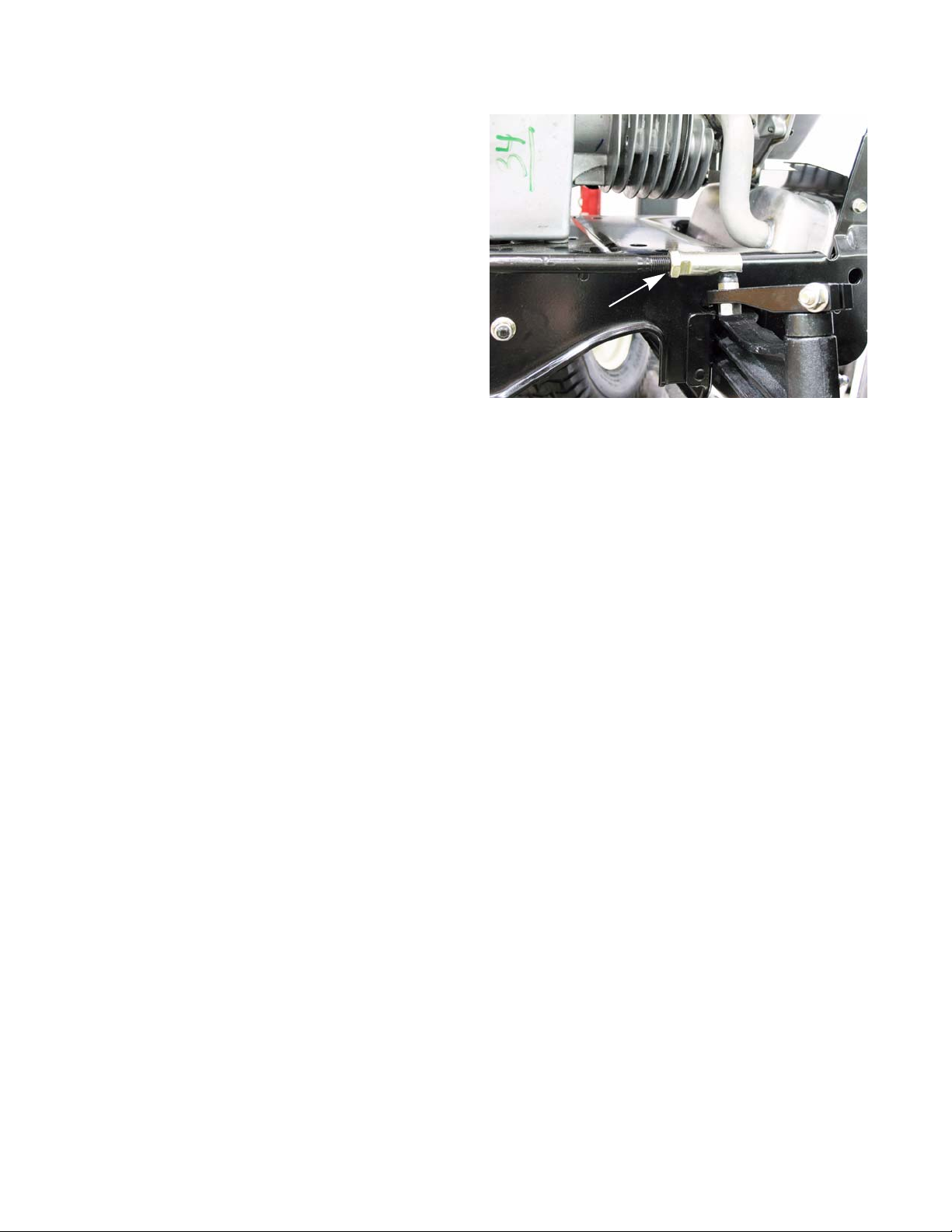

EPS removal/replacement

Loosen

Electronic Power Steering

To remove/replace the EPS assembly:

1 Remove the hood, dash and fender by following the

procedures described in Chapter 4: Body Panels.

2. Remove the fuel tank by following the procedures

described in Chapter 2: Engine Related Parts.

3. Remove the steering pinion gear by following the

procedures described in Chapter 3: Steering

4. Disconnect the EPS harness connector.

Steering coupler

Steering shaft

Remove

Figure 3B.16

Figure 3B.17

5. Loosen the top nut a nd bolt of the stee ring shaf t coupler using a pair of 1/2” wrenches.

6. Remove the lower nut and bolt from the steering

shaft coupler.

NOTE: It may be necessary to drive the bolt out with a

punch.

7. Lift the steering shaft off of the EPS.

NOTE: It will probably be necessary to pry the steering

shaft coupler off of the EPS.

! CAUTION! CAUTION

nents can cause the calibration of the EPS to

shift, resulting in an auto-steer condition.

See Figure 3B.16.

See Figure 3B.17.

DO NOT hammer on any of the

EPS components.

Hammering on the EPS compo-

33

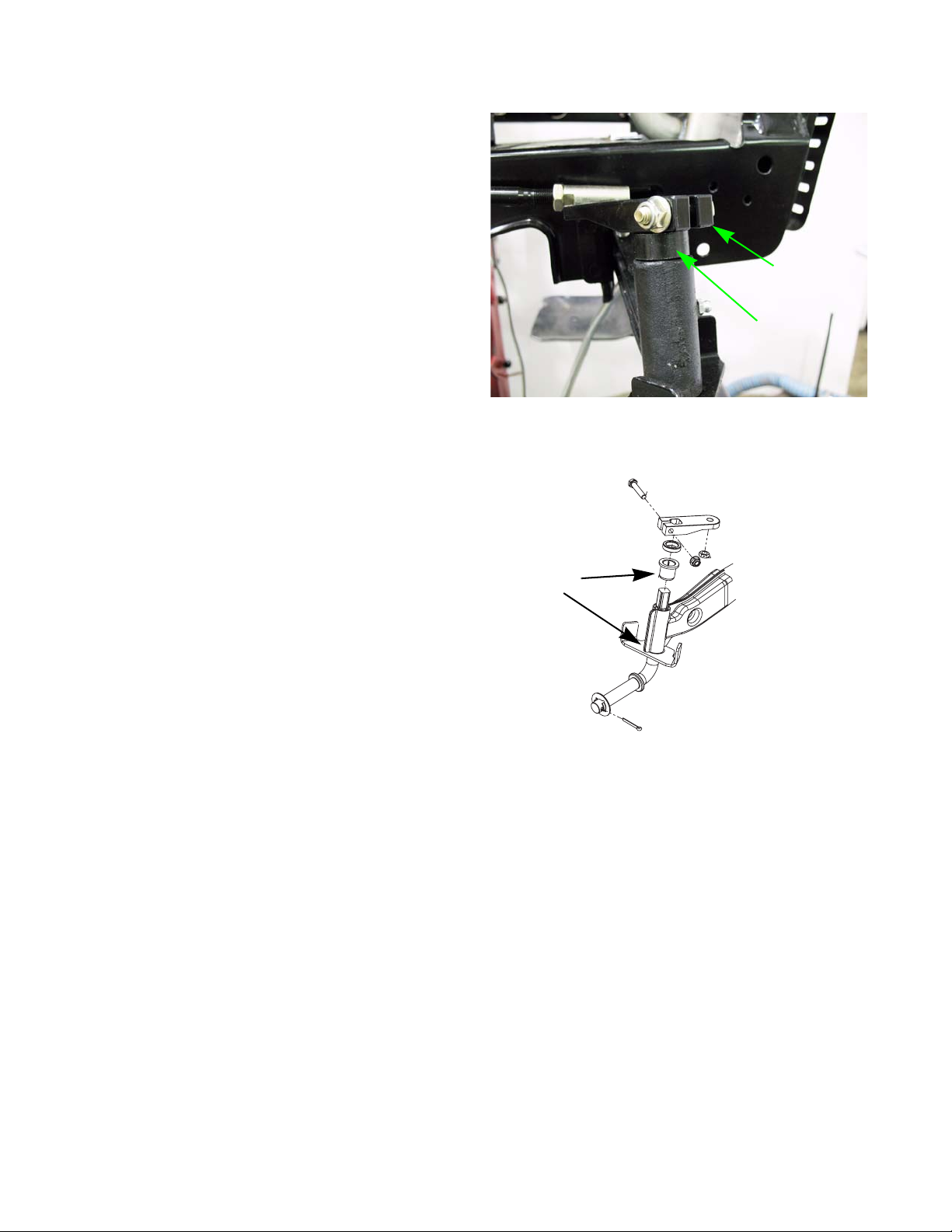

Page 40

LTX Tractors

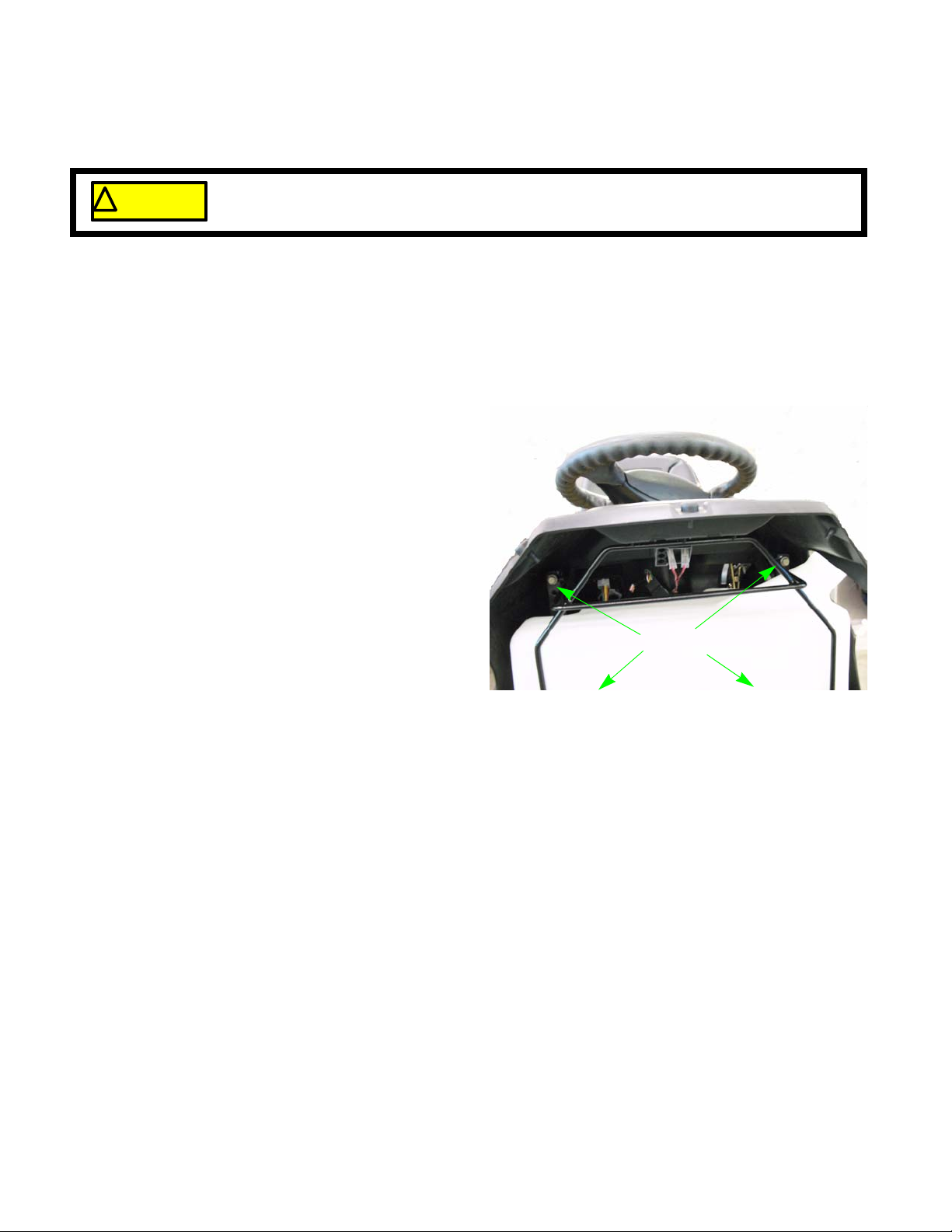

8. Remove the two screws securing the left dash support to the frame using a 3/8” wrench.

See Figure 3B.18.

9. Slide the left dash support off of the EPS motor.

10. Remove the two screws securing the EPS bracket

to the frame.

Screws

Figure 3B.18

11. Lift the EPS out of the tractor.

NOTE: The EPS output shaft will pass through a

spacer, and a bushing.

12. Install the EPS by following the previous steps in

reverse order.

NOTE: The washer that goes in-between the pinion

gear and the steering housing must be held

in place, under the tractor, while inserting the

EPS into the steering housing.

13. Test drive the tractor in a safe area before returning

it to service.

NOTE: Do not put a tractor into service with any

safety or control features that are not work

ing properly.

See Figure 3B.19.

-

Spacer

Bushing

Figure 3B.19

34

Page 41

Body Panels

CHAPTER 4: BODY PANELS

What is covered by this chapter

The intent of this chapter is to describe the removal and disassembly of the major body panels on the tractor.

•Hood

•Seat

• Fenders

• Dash panel

Figure 4.1

“A” style hood

NOTE: It is not absolutely necessary to remove the mow-

ing deck for any procedures covered in this section. The technician may choose to remove the

mowing deck so that it is easier to reach some

parts of the tractor.

NOTE: The hood described in this section is the “A” style

hood. Other styles may be produced for different

markets (e.g.: over-seas) or future style changes.

See Figure 4.1.

35

Page 42

LTX Tractors

Hood

Hood removal:

1. The hood is front-hinged. See Figure 4.2.

2. Open the hood by lifting the rear edge to tilt it forward.

3. Disconnect the headlight wires. See Figure 4.3.

NOTE: The ground terminals and powe r te rm ina l s

on the headlights are two different sizes.

The green wires (ground) fit the larger termi

nals. The red wires (power) fit the smaller

terminals.

Lift here

Figure 4.2

Inset: headlight detail

4. The hood hinges on a pair of shoulder bolts th at fit

into slots in the hood bracket.

5. The hinge travel is limited by a tab that fits into a

channel in the hood bracket.

6. Open the hood far enough to align the tabs with the

slots, then lift the hood off of the tractor.

See Figure 4.4.

36

Figure 4.3

Tab

Figure 4.4

Slot

Channel

Shoulder bolt

Page 43

Hood components: Headlight removal

Figure 4.5

Single-pin 1156-style lamp

Socket

Body Panels

1. With the spade terminals disconnected, rotate the

lamp holder (socket) to release it from the grill

assembly.

2. Rotate the bulb to release it from the socket. See

Figure 4.6.

See Figure 4.5.

Ground terminal

Power terminal

Figure 4.6

3. Install the replacement lamp following the above

steps in reverse order.

37

Page 44

LTX Tractors

Hood components: side vent removal

1. Carefully pry the vent free of the lock tabs.

See Figure 4.7.

2. Pull the vent out of the hood assembly.

3. Install the hood side vent by pressing it into the

hood side opening until the lock tabs click into

place, securing the vent.

2 lock tabs on top

2 lock tabs on bottom

Figure 4.7

38

Page 45

Hood components: grill removal

Body Panels

Slotted mounting hole

Screw +

washer

Large Screws

Figure 4.8

Grill

Pivot bracket

1. Remove the hood assembly from the tractor, and

place it on a stable work surface.

2. Loosen, but do not remove the screws that hold the

upper corners of the grill to the hood using a 3/8”

wrench.

3. Remove the two screws that hold the pivot bracket

and grill to the hood assembly using a 1/2” wrench.

See Figure 4.9.

See Figure 4.8.

Hood

Grill

Locating tab

Figure 4.9

Figure 4.10

Lock tabs

4. Once removed, the headlight lens may be removed

for cleaning by carefully prying the two lock tabs at

the inner edge.

NOTE: The locating tab at the outer edge of each len s has

no locking feature.

5. Assemble and install the grill by reversing the steps

used to remove it.

• Tighten the small screws to a torque of 15-35 in-

lbs. (1.7-4.0 N-m).

• Tighten the large screws to a torque of 35-50 in-lbs

(4.0-5.7 N-m).

See Figure 4.10.

39

Page 46

LTX Tractors

Hood components: pivot bracket removal

1. Remove the four screws that hold the outer arms of

the pivot bracket to the hood using a 3/8” wrench.

See Figure 4.11.

2. Remove the two screws that hold the pivot bracket

and grill to the hood assembly using a 1/2” wrench.

See Figure 4.12.

Small

screws

Small

screws

pivot bracket

Figure 4.11

Pivot bracket

Large Screws

3. Assemble and install the grill by reversing the steps

used to remove it.

• Tighten the small screws to a torque of 15-35

in-lbs. (1.7-4.0 N-m).

• Tighten the large screws to a torque of 25-45

in-lbs (2.80-5.1 N-m).

Hood

Grill

Figure 4.12

40

Page 47

Body Panels

Seat and Fenders

The battery will be removed in this procedure. Review the Operator’s Manual and the Chapter

! CA UTION! CAUTION

There are four variants of fender used on the Cub Cadet Series 1000 for the model year 2009 and after:

• Manual PTO models have two levers on the right fender: one for the deck height control and one for the

PTO.

• Electric PTO models have one lever on the right fender to control the deck height.

• CVT-drive tractors (single-speed transmission + variable speed pulleys) use fenders with a single pedal

opening on each side: clutch/brake on the left, drive pedal on the right. In addition, a forward-neutralreverse lever is on the left fender.

• Hydrostatic-drive tractors use fenders with a single pedal opening on the left, and two openings on the

right. The clutch/brake pedal is on the left, with two pedals on the right; one to control forward drive, and

the other to control reverse drive.

7: Electrical Systems for important safety information about handling batteries before proceeding.

IMPORTANT: Do not return an unsafe mower to service.

Dash

mounting

bolts

Drive belt tensioner

bracket pivot bolt

Figure 4.13

NOTE: Removing the fenders provides access to:

• The bolts that hold the base of the dash panel to

the frame.

• The nut that holds the drive belt tensioner pivot

bracket to the frame.

• The travel stop pin that must be taken-off to

remove the control pedal cross-shaft.

See Figure 4.13.

41

Page 48

LTX Tractors

Removal procedures for fenders are very similar on all

variants. Where necessary , notes will be included to cover

slight differences in procedures.

1. Seat removal: It is necessary to remove the seat

before removing the fenders, primarily because of

the seat safety switch connection.

1a. Tilt the seat up, and disconnect the negative

battery cable.

See Figure 4.14.

Negative

battery

cable

Figure 4.14

NOTE: The seat slides in three “T” slots in the seat

bracket. A single bolt threads into one of the

forward bosses on the seat base, locking it

into the slots. On installation, tighten the bolt

to a torque of 60-80 in-lbs. (7-9 N-m).

1b. Remove the locking bolt using a 9/16” wrench.

See Figure 4.15.

1c. Slide the seat forward to the end of its travel,

then lift it up to disengage the slide blocks

from the “T” slots.

1d. Disconnect the seat safety switch from the

harness plug to remove the seat.

1e. Lift the seat off of the tractor.

See Figure 4.16.

Locking bosses

Bolt

Figure 4.15

Seat safety switch

Harness plug

42

Figure 4.16

Page 49

Correct spring location

Body Panels

1f. The seat adjuster lever and spring will come

easily off the bottom of the seat.

See Figure 4.17.

• The lever is located by a tab that fits into a slot on

the bottom of the seat.

Seat adjuster lever

Figure 4.17

1 Push in

2 slide

forward

• The spring fits into a toroidal (doughnut shaped)

recess in the bottom of the seat.

1g. To remove the seat safety switch: squeeze the

tabs on the side of the switch, and push it into

the seat base.

1h. Slide the switch to the wider end of the hole in

the seat base, and pull it out.

See Figure 4.18.

Positive cable

Negative

cable

Figure 4.18

Figure 4.19

Hold down

2. Remove the battery and tray:

NOTE: Battery tray removal provides easy access to the

following service points:

• Fluid check point on hydrostatic transaxles.

• Electrical: Solenoid, main fuse, battery cables

• Drive belt inspection

• Deck lift linkage inspection

2a. Disconnect the positive battery cable from the

battery (the negative battery cable was discon

nected in an earlier step). See Figure 4.19.

-

43

Page 50

LTX Tractors

2b. Remove the battery hold-down by prying the

end of the hold-down out of the “U” shaped

slot.

2c. Lift the battery out of the tractor.

See Figure 4.20.

2d. Lift the battery tray out of the tractor.

When reinstalling a battery in

! CAUTION! CAUTION

the tractor.

NOTE: It is not necessary to remove the seat

bracket when removing the fenders.

2e. The seat bracket may be removed using a pair

of 1/2” wrenches.

NOTE: Later production units will use self tapping

screws instead of a nut and bolt.

this tractor, use only the original

type of battery. The negative terminal must

go toward the rear of

See Figure 4.21.

Slot

Battery tray

Figure 4.20

Battery

hold-down

3. Remove the grips from the fender-mounted control

levers.

3a. Pull the shift knob off of the forward-neutral-

reverse lever (on CVT-equipped tractors).

See Figure 4.22.

44

Figure 4.21

F-N-R

lever

Figure 4.22

Page 51

Body Panels

Lift assist spring

Figure 4.23

3b. If the tractor has a deck lift assist spring,

remove the deck or lift the mower deck to the

highest position and support it with wood

blocks.

NOTE: Tractors equ ipped with the 3 8” deck and 42” tim ed-

blade R-deck will not have lift assist springs.

3c. Unhook and gently release the lift assist spring

from the back of the tractor frame.

See Figure 4.24.

See Figure 4.23.

PTO

lever

Figure 4.24

Figure 4.25

Deck height

lever

3d. Remove the grips from the deck lift lever and

PTO engagement lever (on manual PTO mod

els). See Figure 4.25.

-

45

Page 52

LTX Tractors

NOTE: A blow-gun with air pressure regulated to

less than 25 PSI (1.72 Bars). may be

inserted into the small hole at the end of a

rubber grip to inflate it slightly, easing

removal.

4. Remove the rubber foot pads. See Figure 4.27.

See Figure 4.26.

Air blow gun

Figure 4.26

5. Remove the drive pedals.

5a. Remove the reverse pad from the drive pedal

(hydrostatic drive tractors only).

See Figure 4.28.

46

Figure 4.27

Reverse pedal pad

Figure 4.28

Page 53

Drive pedal

Drive linkage

Figure 4.29

Body Panels

5b. Unbolt the drive pedal using a 1/2” wrench, and

maneuver it out of the tractor.

5c. Remove the brake pedal using a 1/2” wrench.

See Figure 4.29.

Wax paper

Figure 4.30

Bolts

under label

6. Remove the fender panel.

6a. Carefully peel-up the large operating instruc-

tions label from the floor portion of the fender

panel.

See Figure 4.30.

• Gentle application of heat will help loosen the

adhesive.

• Start at the back: the back edge is closer to the

fasteners that are concealed by the label.

• Use wax paper to preserve the adhesive.

6b. Remove the two bolts that are found under the

label using a 3/8” wrench.

6c. Remove the four bolts that hold the fender to

the seat-box portion of the frame using a 1/2”

wrench.

See Figure 4.31.

Bolts

Figure 4.31

47

Page 54

LTX Tractors

6d. Remove the nuts and bolts that hold th e front

edge of each fender to the frame outriggers

using a pair of 7/16” wrenches.

See Figure 4.32.

6e. Carefully lift the fender assembly off of the

tractor.

NOTE: On tractors equipped with a Kohler s ing le

cylinder engine, the front of the fender

mounts to the outrigger using a rubber bush

ing and steel spacer. See Figure 4.33.

Nut, bolt, and washer

Figure 4.32

Steel spacer

Rubber

bushing

Figure 4.33

48

Page 55

Screws that hold

the handle assembly

Figure 4.34

Steel reinforcement plate

Body Panels

NOTE: The handle assemblies can be removed from the

rear fenders using a 3/8” wrench, from b eneath the

fender.

NOTE: With the handle assembly removed, the steel rein-

forcement plate can be unbolted from the top side

of the fender using a 3/8” wrench.

See Figure 4.34.

See Figure 4.35.

Reinforcement plate

mounting screws

Figure 4.35

49

Page 56

LTX Tractors

Dash Panel

The dash panel may be removed to provide easier

access to the cruise-control and drive system linkag e s, or

to

replace the dash or dash support brackets.

1. Remove the fenders.

2. Remove the steering wheel:

2a. Remove the cover from the center of the

steering wheel.

NOTE: The cover can be released by prying-in on

the lock-tabs on the under-side of the steer

ing wheel. See Figure 4.37.

See Figure 4.36.

Figure 4.36

-

2b. Remove the bolt that holds the steering wheel

to the steering shaft using a 1/2” wrench.

2c. Lift the steering wheel off of the shaft.

! CA UTION! CA UTION

The following steps involve working with gasoline. Gasoline is flammable, and steps should be

taken to avoid fire hazard;

• Work in a well-ventilated area.

• Allow the engine to cool fully before starting work on the tractor.

• Eliminate any sources of possible ignition from the work area, including but not limited to:

heat sources, open flame, potential sparks.

• Clean-up any spilled fuel quickly and properly, disposing of cleaning materials in a way that

will not produce a further fire hazard.

Figure 4.37

50

• Hold any drained fuel in an approved and safe container.

Page 57

Top tank bracket mounting screw

Figure 4.38

Body Panels

3. Remove the fuel tank.

3a. Drain the fuel tank to a level that will not allow

fuel to spill.

NOTE: The tank may be drained by mechanical syphon or

by disconnecting the fuel line from the fuel filter.

3b. Remove the two screws that hold the top of the

wire form fuel tank bracket to the dash support

brackets using a 3/8” wrench.

3c. Support the fuel tank.

See Figure 4.38.

Figure 4.39

3d. Remove the two screws that hold the bottom of