Page 1

Service Manual

1000/1500 Series Riding Tractors

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2006 MTD Products Inc. All Rights Reserved

MTD Products Inc. - Product Training and Education Department

FORM NUMBER - 769-02100

1/2006

Page 2

Page 3

Table of Contents

1. INTRODUCTION ........................................................................................................................1

2. NEW HOOD DESIGN . ........................................................... ... ... ... .... ... ... ... ... .... ... .....................3

3. HOOD PANEL REMOVAL: 1500 SERIES ................................................................................5

4. HOOD AND HINGE REMOVAL: 1500 SERIES ........................................................................6

5. REAR FENDER REMOVAL .......................................................................................................7

6. FUEL SYSTEM ...........................................................................................................................9

7. FUEL SHUT-OFF SOLENOID .................................................................................................11

8. FUEL RELATED NO-START ISSUES ..................................................................................... 11

9. MUFFLER REMOVAL ..............................................................................................................12

10. CUTTING DECK REMOVAL ....................................................................................................13

11. DECK LIFT SHAFT ASSEMBLY .............................................................................................15

12. LIFT SHAFT BUSHINGS .........................................................................................................16

13. DECK LIFT CABLES AND PULLEYS .....................................................................................17

14. LEVELING THE CUTTING DECK ........................................................................................... 18

15. DASH PANEL REMOVAL ....................................................................................................... 20

16. CRUISE CONTROL AND PARK BRAKE LINKAGES ............................................................22

17. TRACTION DRIVE BELT REPLACEMENT: CVT ................................................................... 24

18. DRIVE SYSTEM ADJUSTMENT: CVT ....................................................................................27

19. BRAKE ADJUSTMENT: CVT .................................................................................................. 30

20. SERVICING THE BRAKE PEDAL SHAFT BUSHINGS: ......................................................... 32

21. TRANSAXLE REPLACEMENT: CVT ......................................................................................34

22. TRANSAXLE SERVICE AND INTERNALS: CVT ................................................... ... .... ... ... ... 36

23. TRACTION DRIVE BELT REPLACEMENT: HYDROSTATIC LT ...........................................36

24. DRIVE SYSTEM ADJUSTMENT: HYDROSTATIC LT ...........................................................39

25. HYDRO CONTROL ROD ADJUSTMENT ........... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... 42

26. BRAKES AND BRAKE ADJUSTMENT: HYDROSTATIC LT .................................................43

27. PEDAL BUSHING REPLACEMENT .................... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... .........46

28. TRANSAXLE SERVICE AND MAINTENANCE: HYDROSTATIC LT ......................................47

29. TRANSAXLE REPLACEMENT: HYDROSTATIC LT ..............................................................49

30. TRACTION DRIVE BELT REPLACEMENT: HYDROSTATIC GT........................................... 52

31. DRIVE SYSTEM ADJUSTMENT: HYDROSTATIC GT............................................................ 54

32. BRAKES AND BRAKE ADJUSTMENT: HYDROSTATIC GT ................................................. 58

33. TRANSAXLE SERVICE AND MAINTENANCE: HYDROSTATIC GT .....................................62

34. TRANSAXLE REPLACEMENT: HYDROSTATIC GT .............................................................. 64

35. STEERING GEAR AND STEERING PINION GEAR REPLACEMENT ................................... 67

36. STEERING ADJUSTMENT / ALIGNMENT .............................................................................68

37. PIVOT BAR SERVICE .............................................................................................................69

38. ELECTRICAL SYSTEM ...........................................................................................................71

39. UNDERSTANDING THE PTO SWITCH ................................................................................... 77

1

Page 4

2

Page 5

#

#

0

Series 1000 and 1500

Series 1000 and 1500

1. INTRODUCTION

Disclaimer: This service manual is intended to be

used by trained technicians.

Disclaimer: The information contained in this manual

is current and accurate at the time of writing, but is subject to change without notice.

1.1. Intent: This manual is intended to:

• Provide specific service and repair procedures

for a range of Cub Cadet 1000 and 1500 Series

tractors manufactured for the 2005/2006 season.

• Highlight significant changes to the Cub Cadet

1000 Series since it’s introduction.

1.2. Engines: A variety of single cylinder and V-twin

engines have been used in the 1000 series trac

tors. Kohler Courage line of single-cylinder and

V-Twin engines is presently the most heavily

used power source in the 1000 Series line

1.3. For specific engine service information, refer to

the engine manufacturer’s service publications.

1.4. The engine is partially identified by the 4th digit

of the factory number:

•13AX11CG756 - Kohler Courage single cylinder

•13AP

11CP756 - Kohler courage V-Twin

1.5. Refer to the table provided for engine applications in the 1000 series range. See Figure 1.5.

1000 Series Engine Applications

Year Model

Factory

Engine

2001 1027 13A -328-101 9.0 HP BS

1170 13CD608G101 17.5 HP BS

1180 13AT608H 101 18 HP BS

1212 14AJ808H101 21 HP B S

2002 1027 13A -328-101 9.0 HP BS

1170 13CD608G101 17.5 HP BS

1515 13A-201F100 15 H P KO H

1517 13A-231G100 17 HP KO H

2003 1525 13A-221F100 15 HP KAW

1527 13A-241G100 17 H P K AW

1529 13A-261H100 19 HP KA W

2004 LT 1018 13AL11CG 710 18.5 HP BS

LT 1022 13AB11C H 710 22 HP B S

LT 1024 13AR 11CP 710 24 HP B S

GT 1222 14A B13C H710 22 HP BS

2005 LT 1042 13BX 11C G 710 19 HP KO H

LT 1045 13AX 11C H710 20 HP KOH

LT 1046 13AP11C H 710 23 HP KOH

-

LT 1050 13AQ11CP71

26 HP K OH

SLT 1554 13AK11C K710 27 HP KOH

2006 LT 1042 13AX 11C G 756 19 HP H OH

LT 1045 13AX 11C H756 20 HP KOH

LT 1050 13AP11C P756 23 HP KOH

SLT 1550 13AQ 11BP 756 25 HP KOH

GT 1554 14AK13BK 756 27 HP K OH

Figure 1.5

1

Page 6

Series 1000 and 1500

1.6. Decks: Cutting decks ranging in width from 38”

to 54” have been used on the 1000 Series plat

form.

1.7. There have been multiple versions of some

decks, most particularly the 42”. Check the serial

number when researching for parts or service

information.

1.8. The deck size is identified by the 8th digit of the

factory number:

See Figure 1.8.

1000 Series Deck Applicatio n s

Year Width Deck Deck/PTO Belts

2001 27.5" CYB /ST D 754-0754

42" G 754-0472

46" H 754-0349/754-0476

2002 27.5" CYB /ST D 754-0754

42" G 754-0472

38" F 754-0641

42" G 754-0645/754-0644

2003 38" F 754-0641

42" G 754-0645/754-0644

46" H 754-04011

2004 42" G 754-0498/754-0499

46" H 754-04033

50" P 754-04048

2005 42" G 754-04060B

46" H 754-04033

50" P 754-04077

54" K 754-0642

2006 42" G 754-0349

46" H 754-0349

50" P 754-0349

54" K 754-0349

Figure 1.8

• 13AX11CG756 - 42” 2-blade deck

• 13AX11CH

756 - 46” 3-blade deck

1.9. Drive Systems: A variety of hydrostatic and

-

CVT drive systems have been used on the 1000

Series tractors.

1.10. A Two-belt CVT system driving an MTD singlespeed transaxle is presently used only on the

LT1040 model. This system can be distin

guished by the gear selector (F-N-R) on the left

rear fender, and the simple drive pedal.

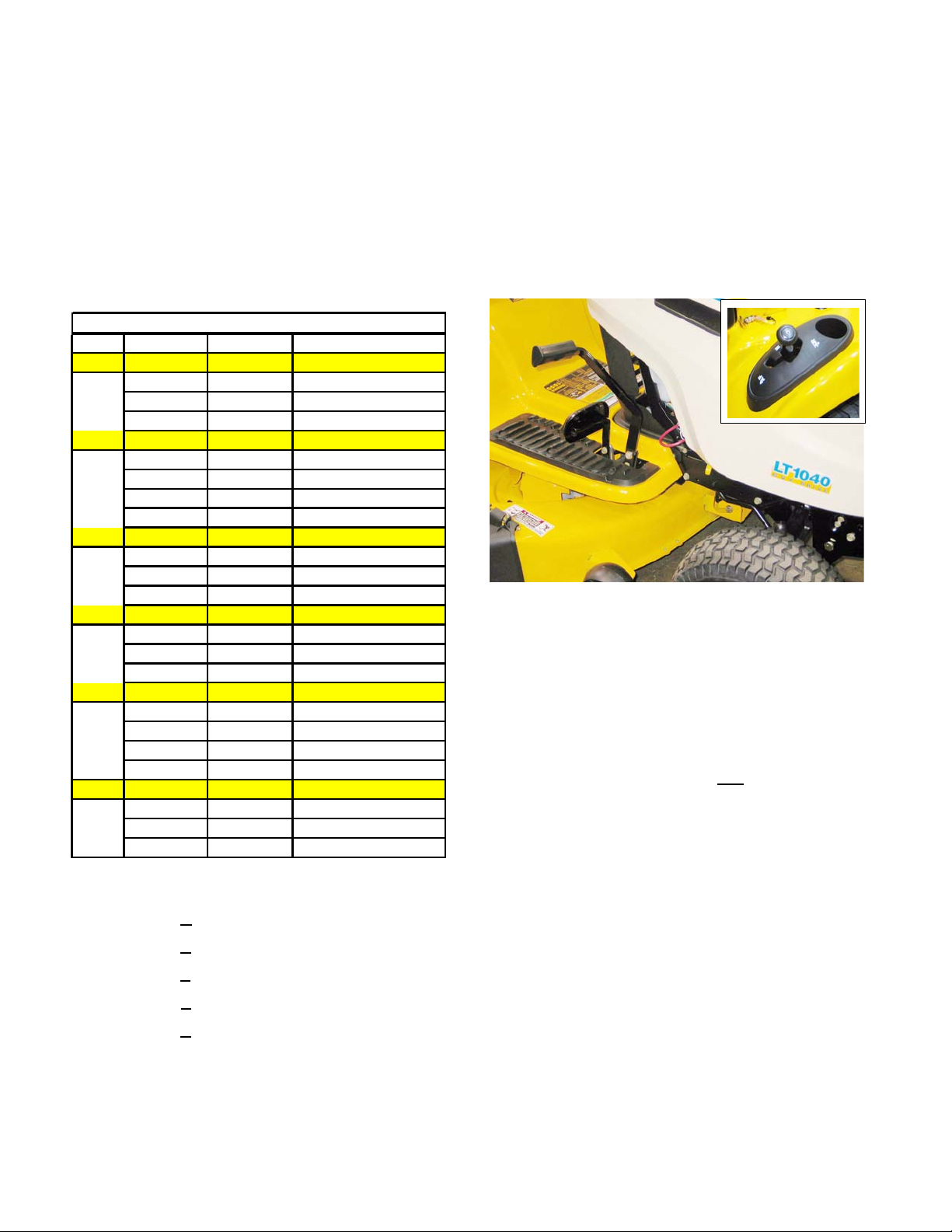

See Figure 1.10.

Figure 1.10

1.11. A similar two-belt CVT system was employed to

drive a heavy-duty transaxle in some 2002 and

2002 models having two forward speed ranges.

These are easy to identify by the presence o f the

gear selector lever between the operators knees

rather than on the fender.

1.12. All CVT driven 1000 and 1500 Series tractors

have a gear selector lever

the right side, near the brake pedal.

1.13. All Hydrostatic transaxles on the 1000 and 1500

Series are operated by a rocker pedal on the

right side, near the brake pedal.

1.14. A Hydro-Gear 310-0510 hydrostatic transaxle is

used on LT models having 20” rear tires. Hydro

static transaxles have a rocker pedal to control

forward and reverse direction and speed.

and a drive pedal on

-

-

• 13AP11CP

• 13AQ11BP

• 14AK13BK

756 - 50” 3-blade deck

756 - 50” 3-blade deck

756 - 54” 3-blade deck

2

Page 7

Series 1000 and 1500

1.15. A Hydro-Gear 314-0610 hydrostatic transaxle

with a different final drive ratio is used on LT

models having 22” rear tires. Hydrostatic tran

saxles have a rocker pedal to control forward

and reverse direction and speed.

1.15.

Figure 1.15

See Figure

2. NEW HOOD DESIGN

-

2.1. Early 1000 and 1500 Series tractors used a variety of steel hoods and side panels. Later ones

resembled those used on the 2000 and 2500

Series tractors.

2.2. The hood presently used on the 1000 series

tractors is a molded 1-piece design.

2.2.

See Figure

1.16. A Hydro-Gear 320-3000 hydrostatic transaxle is

used on GT designated models. This is a sub

stantially heavier duty IHT than the one used in

the LT models. Hydrostatic transaxles have a

rocker pedal to control forward and reverse

direction and speed.

See Figure 1.16.

Figure 1.16

-

Figure 2.2

2.3. The 1000 Series hood opens from the back.

See Figure 2.3.

Figure 2.3

3

Page 8

Series 1000 and 1500

2.4. The 1000 Series hood can be easily removed:

See Figure 2.4.

Figure 2.4

• Disconnect the headlight wires

• Release the retaining springs

• Align the bolts in the hood with the slots in the

hinge.

• A pair of gas charged cylinders provide lift assist.

See Figure 2.5.

Gas lift Cylinders

Pivot Rod

Figure 2.5

2.6. A new spring-loaded latch was added to hold the

hood closed.

See Figure 2.6.

• Lifting the hood off of the tractor.

2.5. The hood used on the 1500 Series tractors for

2005 and 2006 is more substantial than that

used on the 1000 Series. It is a one-piece

molded design very similar to the one used on

the much larger 5000 and 6000 series tractors.

See Figure 2.5.

Figure 2.5

Figure 2.6

• It opens from the front.

4

Page 9

Series 1000 and 1500

2.7. A torsion spring keeps the latch secure until the

lower pivot latch is intentionally pulled up, to

open the hood.

Upper

Pivot

Latch

Cotter

Pin

Lower

Pivot

Latch

2.8. The hood latches to a sturdy rod that is mounted

to the front of the frame.

See Figure 2.7.

Torsion Spring

Pivot

Rod

Figure 2.7

See Figure 2.8.

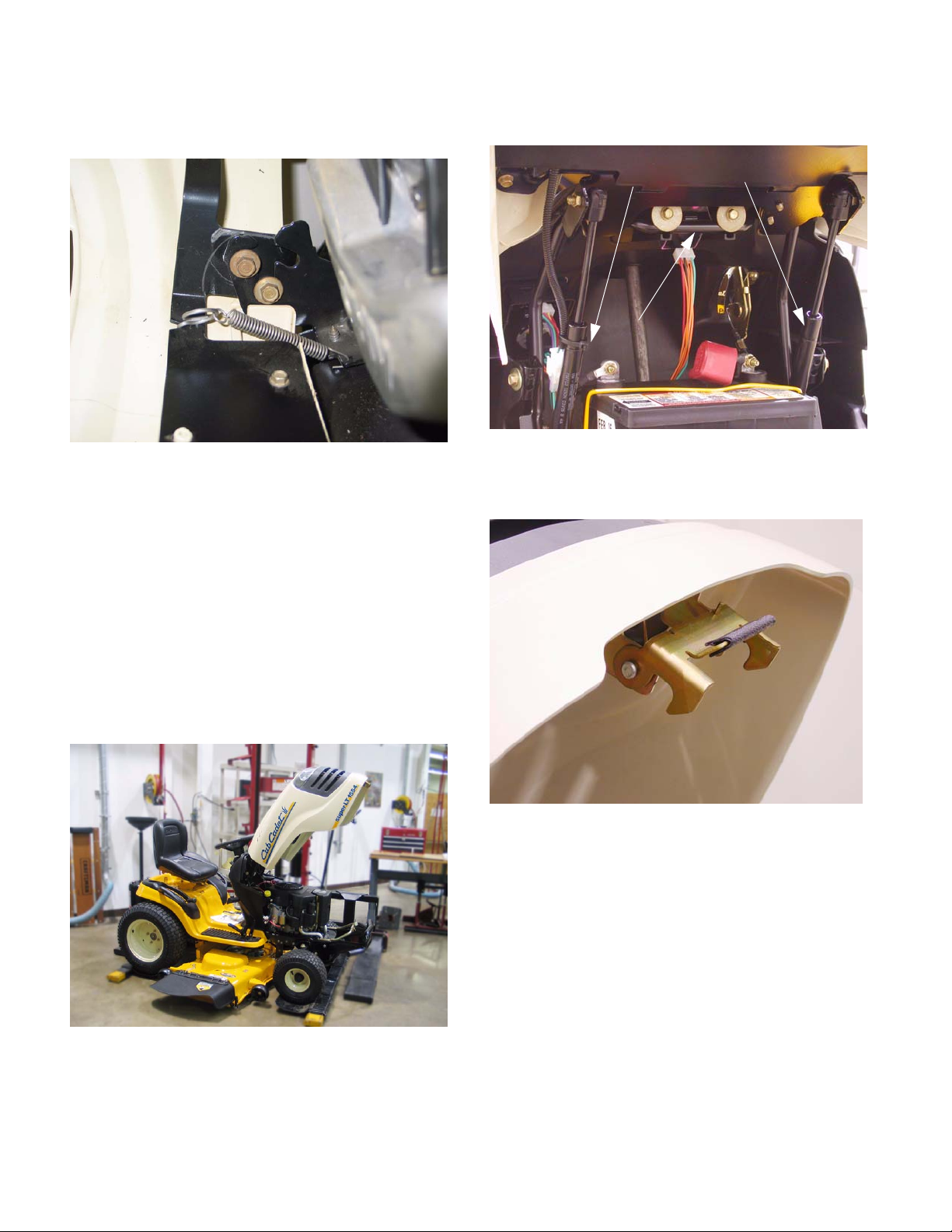

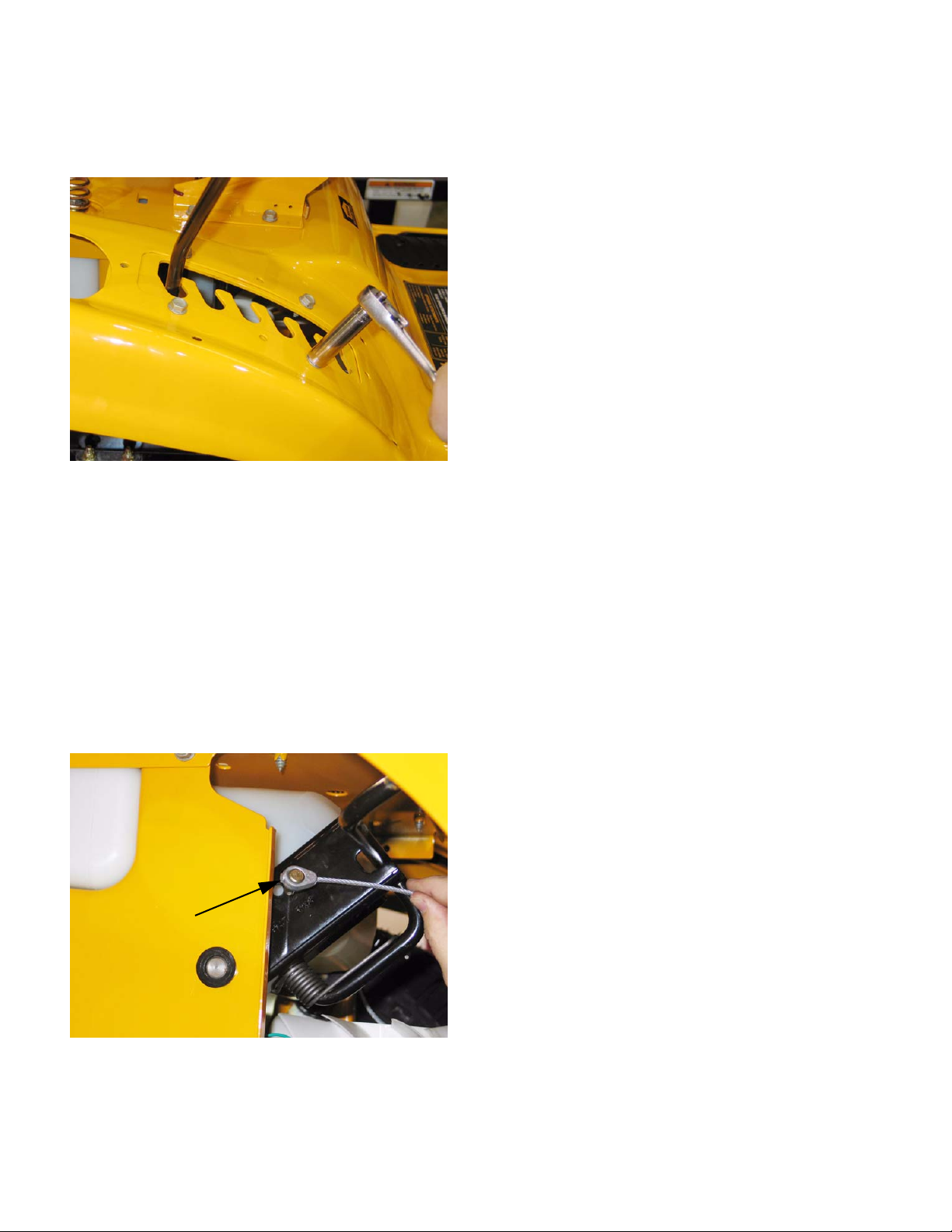

3.2. Disconnect headlight harness (plugged secured

to hood lift cylinder).

Headlight

Harness

3.3. Remove the air deflector baffle using a 3/8”

wrench.

See Figure 3.2.

Figure 3.2

See Figure 3.3.

Hood Latch Rod

Figure 2.8

3. HOOD PANEL REMOVAL: 1500 SERIES

NOTE: Use this procedure if the hood alone is to

be removed. Typical reasons might include

replacement because of damage to the hood, or

to ease access for other service.

3.1. Disconnect ground cable from battery using a

7/16” wrench.

Figure 3.3

3.4. Support the hood as it is being loosened.

3.5. Separate hood from hinge using a 3/8” wrench.

3.6. Lift hood off of tractor.

5

Page 10

Series 1000 and 1500

4. HOOD AND HINGE REMOVAL: 1500 SERIES NOTE: Use this procedure for more extensive

repairs. T ypical reasons may include dash p anel

removal, or the need for more working room

than simply removing the hood will provide.

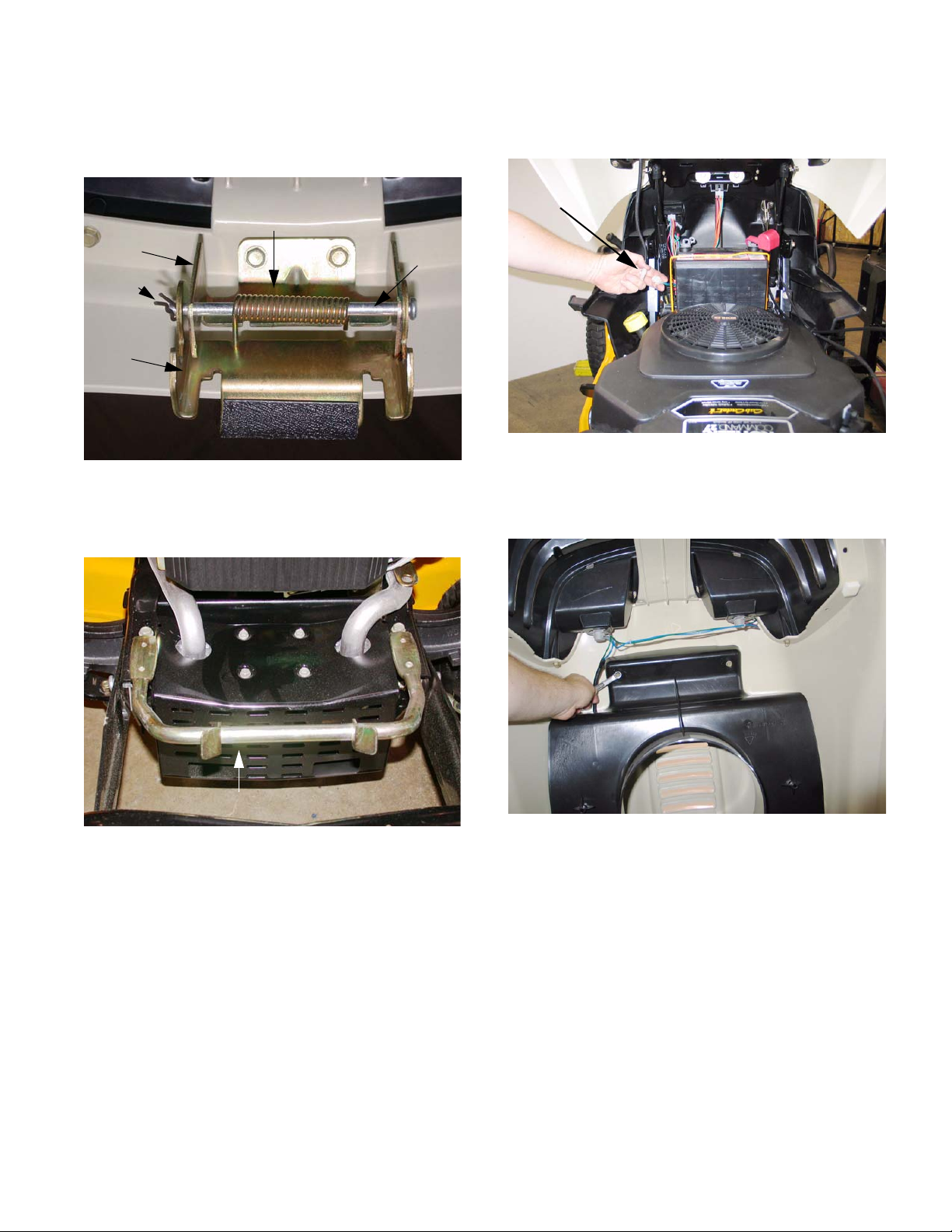

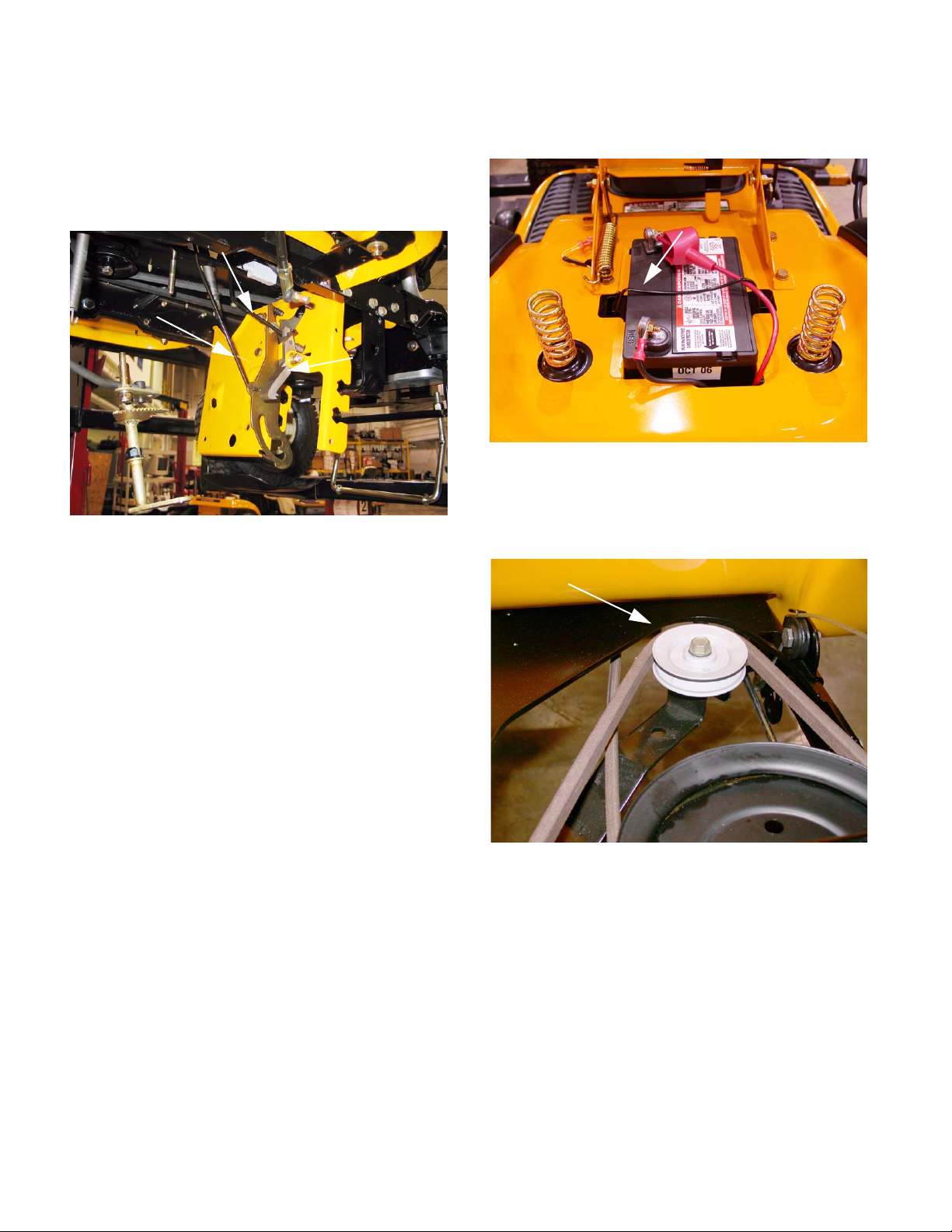

4.1. Remove the battery: See Figure 4.1.

Figure 4.1

4.8. Hood installation notes: See Figure 4.8.

Figure 4.8

• Position the hinge support bar over the two

spacers that partially cover the threads of the

balls that the that hood support struts attach to.

The slots in the ends of the bar will fit over the

spacers.

• Disconnect the negative battery cable (black)

first, using a 7/16” wrench.

• Disconnect the positive battery cable (red) using

a 7/16” wrench.

• Remove the battery hold-down.

• Lift the battery from the tractor.

4.2. Disconnect the headlight harness. (Plug secured

to the hood lift cylinder).

4.3. Support the hood with an improvised prop-rod to

prevent damage.

4.4. Remove screws holding hinge support bar to

dash support using a 1/2” wrench.

4.5. Disconnect and remove the hood lift cylinders

using a small straight-blade screwdriver.

4.6. Remove screws & flat washers holding hinge

support bar to dash panel using a 3/8” wrench.

4.7. Lift hood and hinge assembly off of the tractor,

and remove it to a safe place.

• Support the hood with an improvised prop rod.

• Install the screws that hold the hinge support bar

to the dash support and instrument panel.

• Snap the hood support cylinder into place, and

remove the prop rod.

• The remainder of the installation process is simply the reversal of the removal steps.

6

Page 11

Series 1000 and 1500

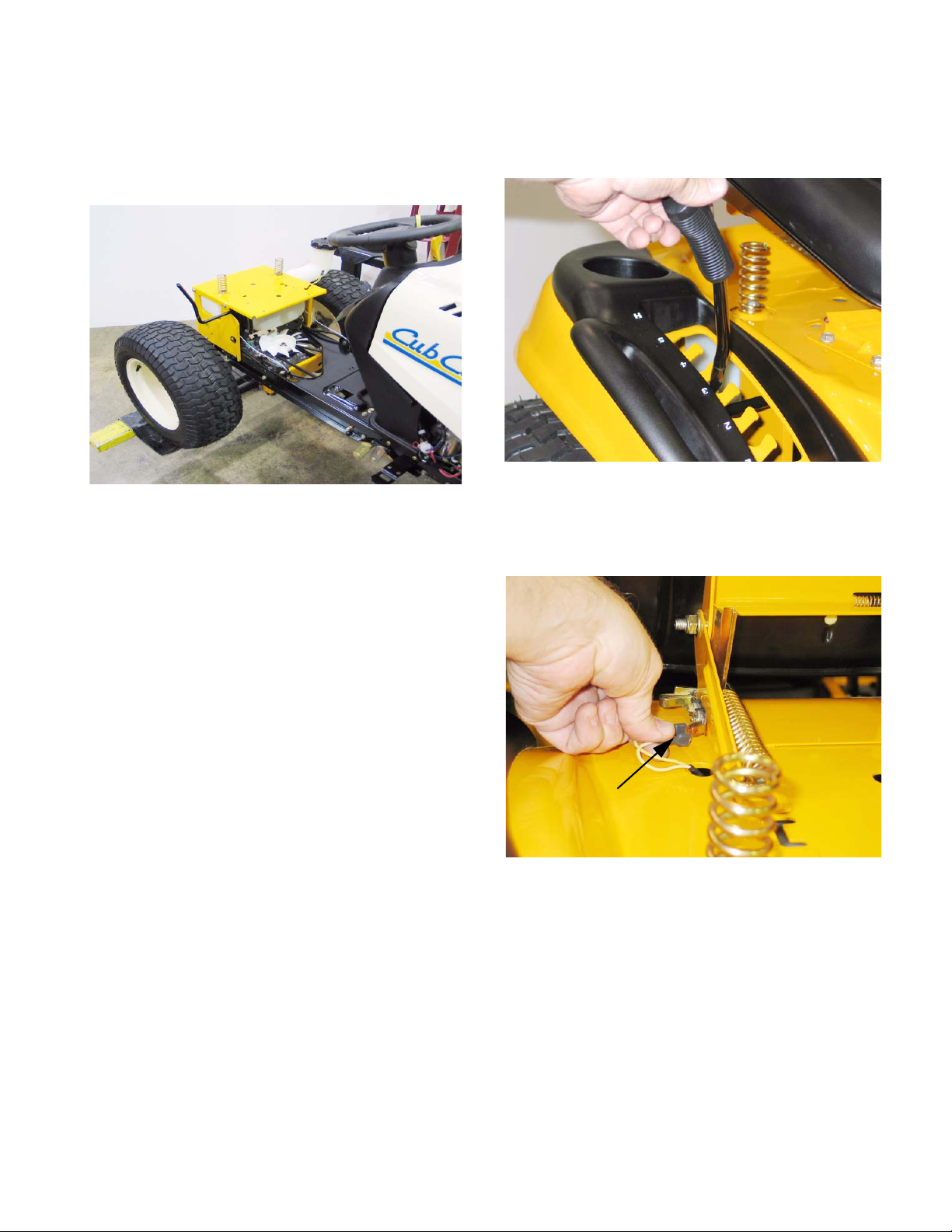

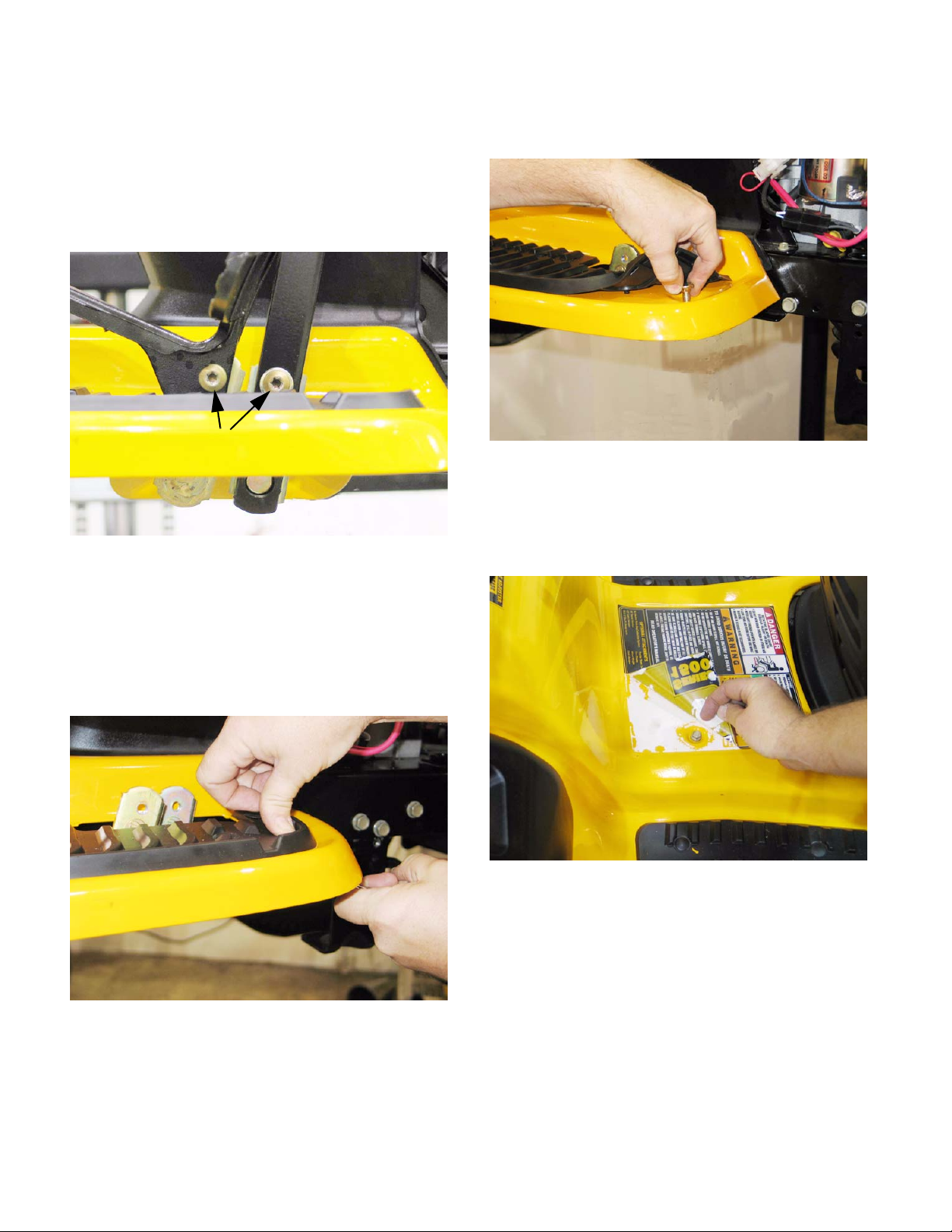

5. REAR FENDER REMOVAL

5.1. It is necessary to remove the fender assembly

for access to the following service areas:

Figure 5.1.

Figure 5.1

• Fuel tank (hydrostatic drive riders)

• Lift-shaft assembly (except bushings)

See

5.4. Remove the rubber grip from the cutting deck

height control handle atop the right rear fender.

See Figure 5.4.

Figure 5.4

5.5. Disconnect the two yellow wires from the seat

safety switch mounted to the left side seat

bracket.

See Figure 5.5.

• Deck lift cable removal

• Wiring harness inspection or removal

• Dash panel removal

• Traction drive belt idler pulley removal

• Traction drive belt tension arm removal

NOTE: At first-glance, fender removal appears

to be a substantial job. Skilled mechanics can

typically remove the fenders from a 1000 Series

Cub Cadet tractor in about 15 minutes, with an

equal amount of time required for installation.

5.2. Disconnect the ground cable from the negative

battery post using a 7/16” wrench.

5.3. Remove the cutting deck from the tractor.

Safety Switch Connectors

Figure 5.5

5.6. Release the gold colored extension spring from

the left side seat bracket using a length of starter

rope or a spring removal tool.

• gold colored spring: left seat bracket

• red spring: right seat bracket

• Only the gold colored spring must be removed

because it blocks access to the bolts that hold

the seat bracket to the frame.

7

Page 12

Series 1000 and 1500

5.7. Remove the four bolts that hold the seat brackets to the frame using a 1/2” wrench.

5.8. Remove the seat to a safe location.

5.9. Remove the hydro control pedal (or speed control pedal on CVT equipped models) using a T40 driver.

See Figure 5.9.

T-40 Screws

Figure 5.9

5.12. Peel-back the rubber foot pad to reach and

remove the carriage bolt.

Figure 5.12

5.13. Carefully peel-up each rear corner of the larger

instruction label located between the foot pads,

revealing two screws that hold the fender

assembly to the frame.

See Figure 5.12.

See Figure 5.13.

5.10. Remove the brake pedal using a T-40 driver

(upper screw) and a 9/16” wrench (lower screw).

5.11. Remove the nuts from the carriage bolts that

secure the front edge of each running board to

the frame bracket that supports it.

See Figure 5.11.

Figure 5.11

Figure 5.13

NOTE: If the previous steps are done with care,

the label can be reapplied, using some spray-on

contact adhesive if necessary.

• If the label shows signs of becoming damaged

by the peeling-back process, it should be

replaced during reassembly.

• Apply thumb pressure to the rubber foot pad,

directly above the nut / carriage bolt to hold the

square boss on the nut into the bracket, to prevent rotation.

• To identify and order a replacement label, note

the number printed on the lower right corner of

the label (“S32484 AC” typical). That number,

with a 777 prefix (777-S32484 AC) is usually the

part number of the label.

8

Page 13

Series 1000 and 1500

5.14. Remove the two screws that were revealed by

peeling-back the label. This can be done using a

3/8” wrench.

5.15. Remove the fuel filler cap.

5.16. Lift the fenders off of the tractor, maneuvering

them to clear the cutting deck height control

lever.

See Figure 5.16.

See Figure 5.14.

Figure 5.14

• When installing a large panel, start all of the

threaded fasteners, then go back and tighten

each after the panel is in position.

• Test the operation of all controls and safety features in a safe place, free of obstacles and bystanders before returning the tractor to service.

6. FUEL SYSTEM

6.1. While the 1000 and 1500 Series tractors are

built on the same frame, the fuel systems differ

substantially in layout.

6.2. The 1000 Series tractors have the fuel tank

beneath the hood, with the battery located under

the seat.

See Figure 6.2.

Figure 5.16

5.17. Remove the fenders to a safe place.

5.18. Replace the fuel filler cap.

5.19. Installation notes:

• Confirm that the seat safety switch wires are

accessible before securing the fender.

• 144 in-lbs is adequate tightening torque for the

5/16”-18 screws and bolts removed in this procedure. (1/2” wrench or T-40 driver)

Figure 6.2

6.3. This positioning is necessary to provide easy

service access to the CVT drive system used on

the 1000 series tractors. The rear mounted bat

tery, and the tray that supports it are easily

removable.

6.4. The battery of the 1500 Series tractor is located

under the hood, with the fuel tank mounted

under the rear fenders.

-

9

Page 14

Series 1000 and 1500

6.5. On current models of the 1000 and 1500 Cub

Cadet, the fuel is moved from the tank to the car

buretor by a vacuum-driven fuel pump that is

mounted to the engine.

Figure 6.5

6.6. The fuel line runs from a barbed fitting on the

bottom of the fuel tank to the fuel pump.

See Figure 6.5.

Fuel Pump

6.9. In the event that it is necessary to remove the

-

fuel tank, begin by removing the fenders as

described in the REAR FENDER REMOVAL

section of this manual.

6.10. Make provisions for draining any fuel that

remains in the gas tank: 24” of 1/4” fuel line, and

a suitable catch pan will be sufficient.

6.11. Pinch the fuel line about 6” from the fuel tank to

prevent the line from emptying (unless it needs

to be drained or replaced).

• Position the catch pan under the fitting on the

fuel tank.

• Have the extra length of fuel line handy.

6.12. Remove the hose clamp that secures the fuel

line to the fitting on the gas tank.

See Figure 6.12.

6.7. The 1500 series fuel line should be routed as

shown.

6.8. The fuel cap is vented.

• There are a few non-vented fuel caps that will fit

the filler neck of the 1000 and 1500 Series tractor.

See Figure 6.7.

Fuel Line

Figure 6.7

Figure 6.12

6.13. Quickly pull the fuel line off of the fitting, and

replace it with the extra hose. Direct the hose

into the catch pan.

6.14. When the tank is empty, dispose of any unusable fuel in a safe and responsible manner.

• Non-vented caps are used on the Cub Cadet Big

Country line of utility vehicles.

• Use of a non-vented cap on a 1000 or 1500

Series tractor will cause fuel supply issues.

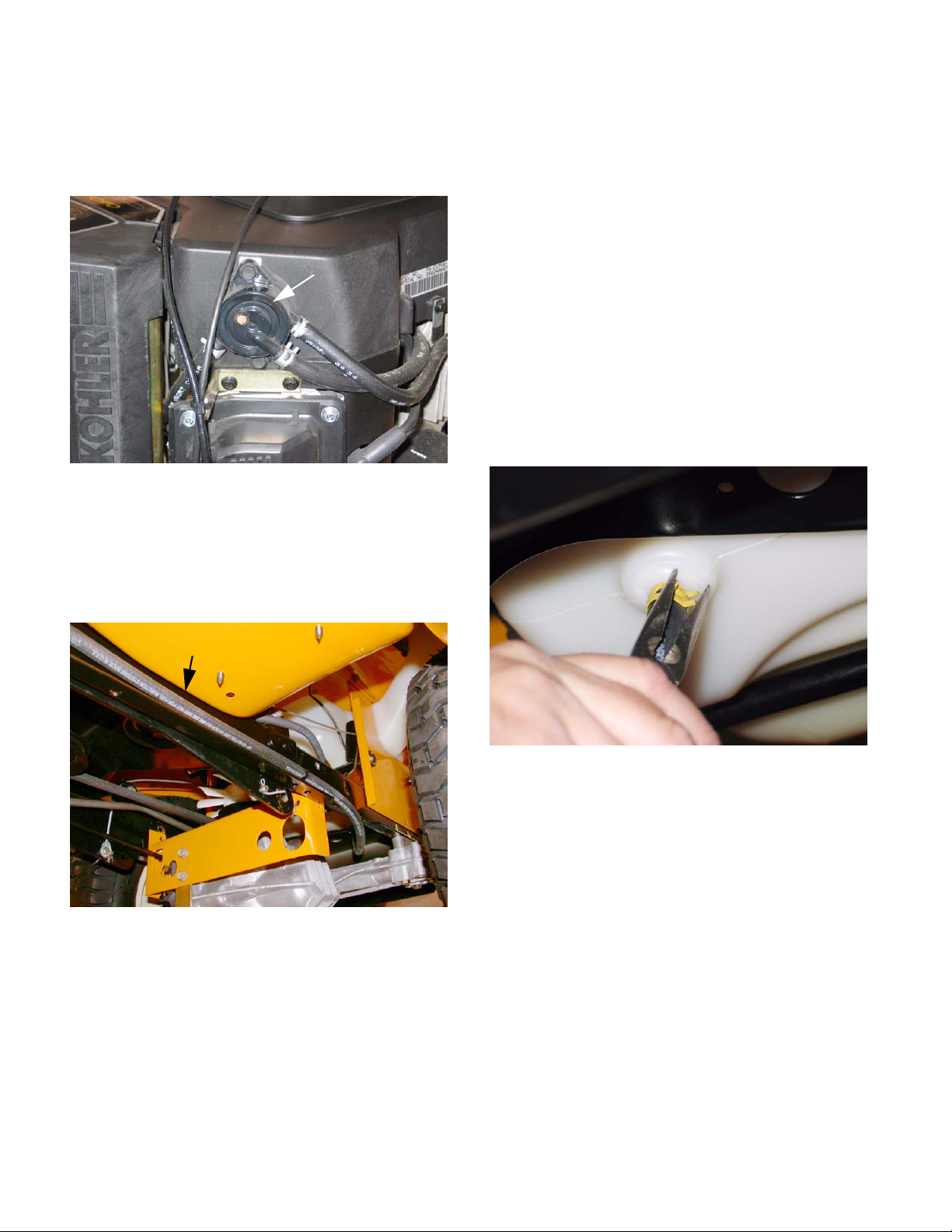

10

Page 15

Series 1000 and 1500

6.15. Remove the plate that supp orts the seat brackets using a 1/2” wrench. See Figure 6.15.

Seat Bracket Plate

Figure 6.15

6.16. Lift the fuel tank out of the tractor.

7. FUEL SHUT-OFF SOLENOID

7.1. In all models of the 1000 and 1500 Series Cub

Cadet riders, there is a fuel shut-off solenoid

mounted to the carburetor.

See Figure 7.1.

• When the solenoid does not have power, it

closes, stopping the flow of fuel.

• The solenoid usually emits an audible “click”

when power is applied or discontinued.

• If the solenoid does not click, it is not working. If

it does click, it cannot be assumed to be working

properly.

8. FUEL RELATED NO-START ISSUES

8.1. The leading industry cause of no-start and

engine performance problems is stale or out

dated fuel.

• In temperate regions of the country, fuel purchased during the summer may not be volatile

enough to ignite during the winter months.

• Similarly, “Winter” fuel may be cause performance issues if used into the summer months.

The gasoline companies taylor the contents of

their fuel blends to optimize performance, ta king

climate and geography into account.

• As fuel goes stale, the lighter end hydrocarbons

(more volatile elements) tend to evaporate, leaving the fuel less volatile.

-

Fuel Shutoff Solenoid

Figure 7.1

7.2. The fuel shut-off solenoid is a valve that is actuated by an electric coil.

• The fuel shut-off solenoid helps prevent “afterboom” when a hot engine is turned-off.

• The solenoid has power when the key is in the

run position and the safety switches on the tractor do not sense any unsafe conditions. When it

has power, the solenoid opens, allowing fuel to

reach the carburetor.

• In extreme cases, semi-solid residue will accumulate, damaging the fuel system.

• If a piece of equipment will sit unused during the

dormant season, the fuel system should be

drained completely, or preservative should be

added to the fuel according to the preservative

manufacturer’s instructions.

8.2. Alcohol content of the fuel should not exceed

10%.

• Small amounts of ethanol are fairly common in

fuel.

• Methanol is more destructive than ethanol, and

should be avoided.

• Alcohol absorbs water. Fuel that contains alcohol will also contain a certain amount of water.

The water will corrode any metallic parts of the

fuel system, and may cause freezing damage in

low temperatures.

• Products that purport to “dry” the fuel system are

generally isopropyl alcohol. The object is to resuspend the water that has settled out of the

alcohol the fuel already contains.

11

Page 16

Series 1000 and 1500

• Ether-based starting fluids should not be used,

and may void engine warranties if their use is

detected.

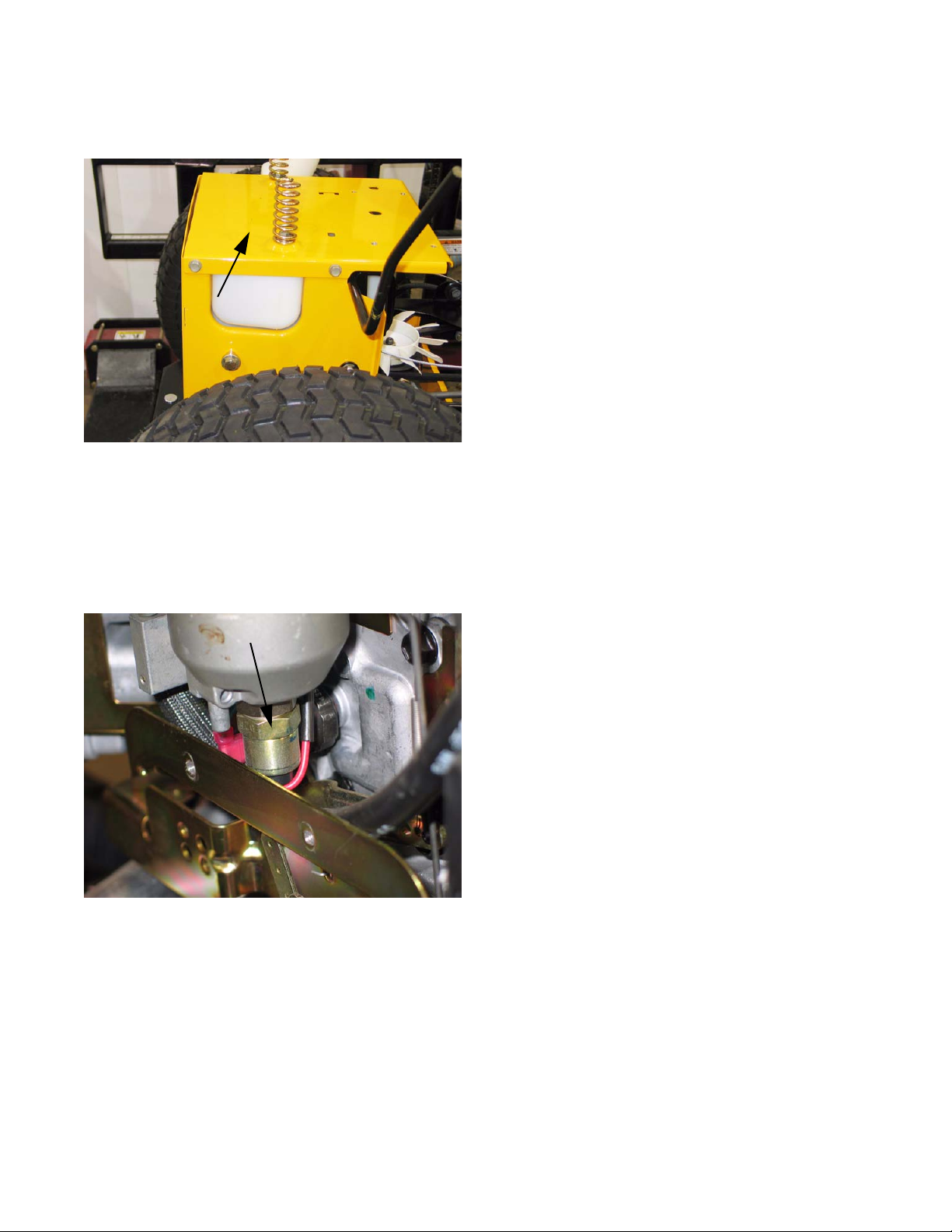

9. MUFFLER REMOVAL NOTE: There are a variety of mufflers on this

series of tractor depending on the year and

engine of the unit. this chapter will cover a few

different mufflers to give you the basics of muf

fler removal on this series.

NOTE: For all tractors, remove the bumper first.

• On units with side panels:

9.1. Remove the hood, side panels and grill.

NOTE: Make sure to disconnect the headlight

harness when you remove the grill and side pan

els.

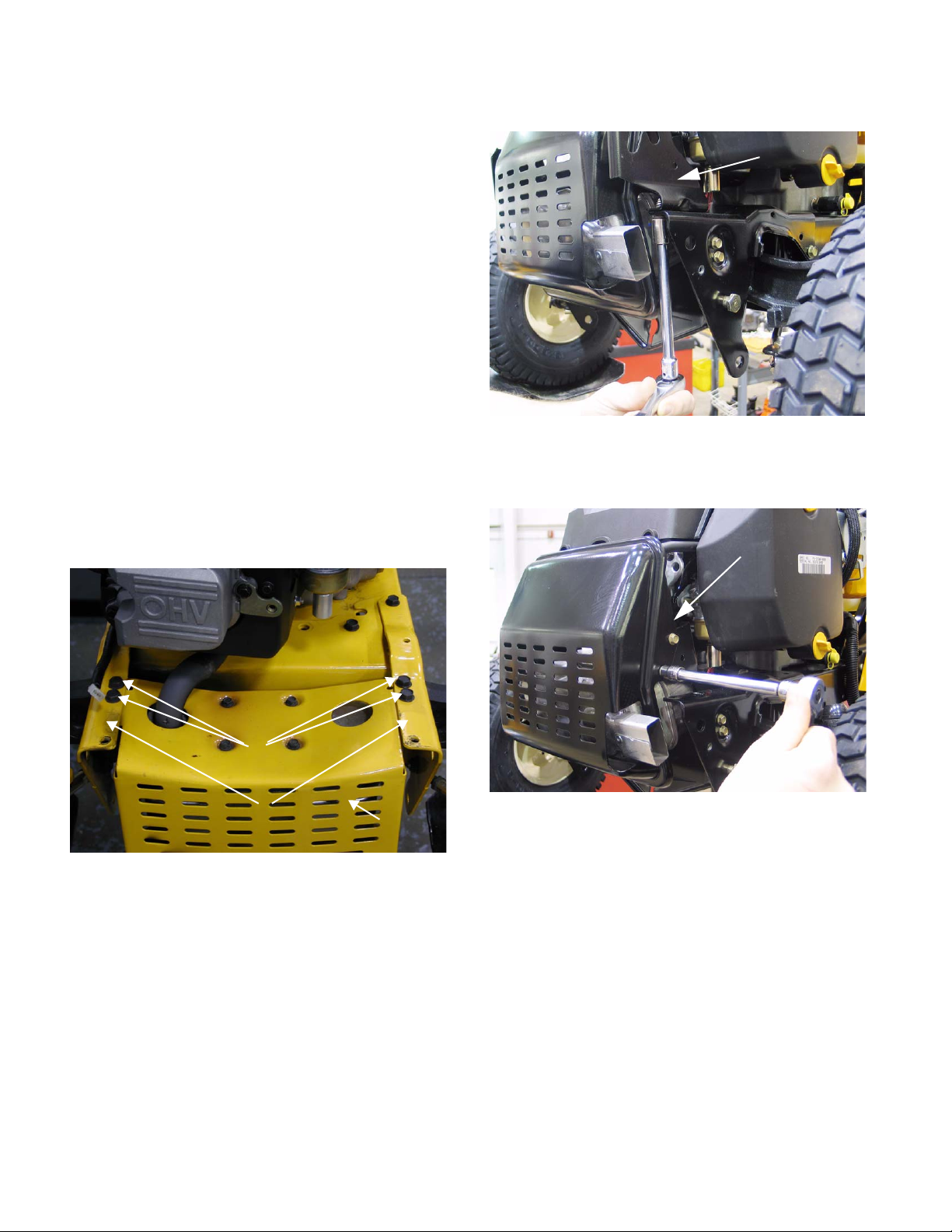

9.2. Remove the self tapping hex cap screws securing the front frame assembly to the muffler shield

and muffler using a 1/2" socket.

See Figure 9.2.

9.7. Remove both hinge brackets. See Figure 9.7.

Hinge Bracket

-

-

9.8. Remove the four screws in the sides of the muf-

fler guard. Slide the muffler and muf fler guard of f

of the exhaust pipe(s).

Figure 9.7

See Figure 9.8.

Muffler Guard

Hex Cap Screws

Frame

Muffler Shield

Figure 9.2

9.3. Remove the muffler and guard.

NOTE: Muffler slides off of the ex haust pipe. It is

NOT fastened to the pipe.

9.4. Remove the four screws in the top of the muffler

guard. the muffler and muffler guard will now

separate.

9.5. Reassemble in reverse order.

• 1000 Series with one piece hood.

9.6. Remove hood as shown in section 2.

Figure 9.8

NOTE: You may have the tail pipe stickin g out of

the left side. If so slide the guard off of it first.

12

Page 17

Series 1000 and 1500

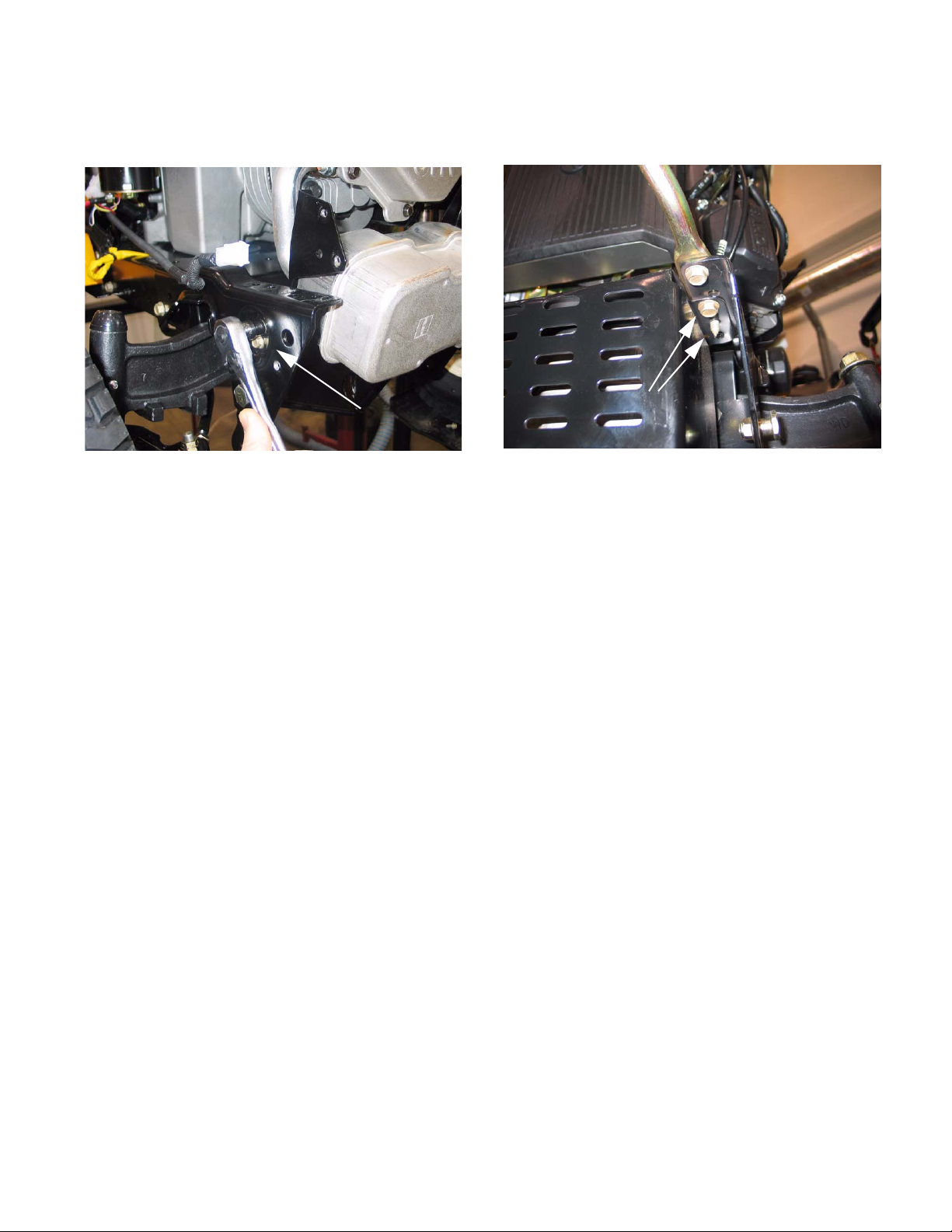

9.9. Remove the four screws going through the muffler support brackets into the muffler mounting

bracket.

9.10. The muffler will now slide off of the exhaust

pipe(s).

9.11. Remove the screws in the muffler mounting

brackets and lift the brackets off of the muffler.

9.12. Reassemble in reverse order.

• 1500 with one piece hood:

9.13. Open hood.

9.14. Remove bumper

See Figure 9.9.

Muffler Support Bracket

Figure 9.9

9.16. Remove the four screws holding the muffler

guard to the front muffler support brackets.

Figure 9.16.

Remove these hex screws. (two on each side)

Figure 9.16

NOTE: The rear two screws will be accessible

from the top. the front two screws will be acces

sible from the bottom.

9.17. Slide the muffler and muffler guard off of the

exhaust pipe(s).

9.18. Remove the four screws in the top of the muf fler

guard. Lift the muffler guard off of the muffler.

9.19. Reassemble in reverse order.

See

-

9.15. Remove the two clevis pins in the deck front stabilizer bracket.

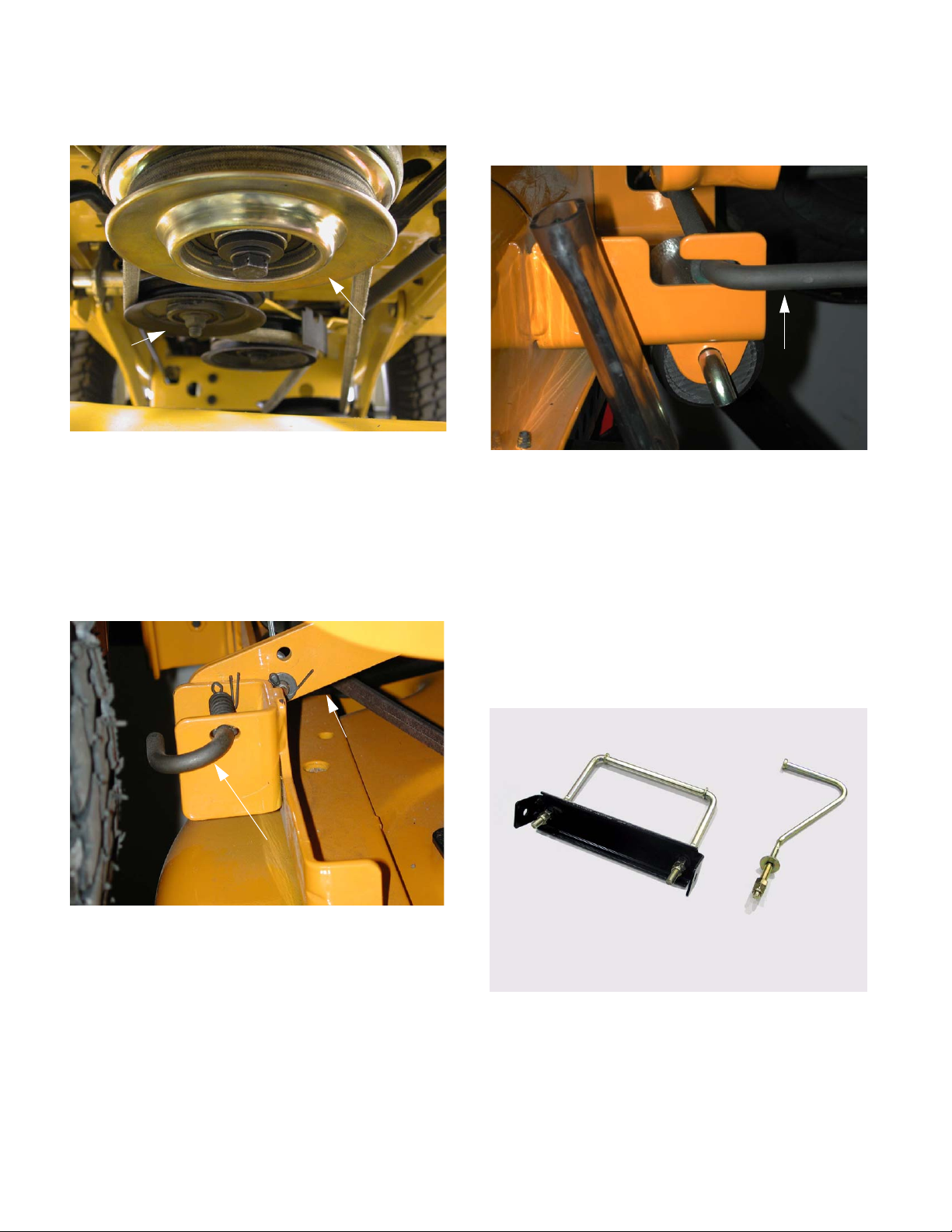

10. CUTTING DECK REMOVAL

10.1. Place the PTO switch in the off position.

10.2. Lower the lift lever to the lowest setting.

13

Page 18

Series 1000 and 1500

10.3. Remove the PTO belt from electric P TO clutch.

See Figure 10.3.

Idler

Electric PTO

clutch

(earlier production)

Figure 10.3

NOTE: On some models you will need to

remove the belt guide first.

NOTE: On earlier production models you need

to slip the belt off of the idler pulley before you

remove the belt from the PT O clutch.

10.7. Slide the deck forward and release the front stabilizer rod. DO NOT DROP the deck to the

ground.

See Figure 10.7.

Front

stabilizer

rod

Figure 10.7

10.8. Slide the deck toward the right side of he tractor

and remove it from under the tractor.

CAUTION: Remove the deck stabilizer assembly from the tractor prior to moving the unit.

10.4. Pull the rear deck support pins outward from the

deck lift arms.

See Figure 10.4.

Lift arm

Deck support

pin

Figure 10.4

10.5. Pivot the deck support pins to the rear.

10.6. Raise the lift lever to the highest setting. This will

raise the lift arms up and out of the way of the

deck assembly.

NOTE: Depending on the model and deck, some

units have a J-bolt for the front stabilizer bar

instead of the U-bolt. On those units you can line

up the coined spot stamped in the middle of the

bolt with the slot in the bracket and slide it off.

See Figure 10.8.

U-Bolt Stabilizer

J-Bolt Stabilizer

Figure 10.8

14

Page 19

Series 1000 and 1500

11. DECK LIFT SHAFT ASSEMBLY

11.1. If the deck lift shaft itself requires removal, first

remove the cutting deck.

11.2. Remove the fenders as described in the

FENDER REMOVAL section of this manual.

11.3. Disconnect the deck lift assist spring that

extends from the deck lift shaft to the transaxle

torque bracket using a length of starter rope or a

spring tool.

Deck Lift Assist Spring

See Figure 11.3.

1 1.6. With the deck height control lever all the way for-

ward, remove the hairpin clips that secure the

deck lift cables to the arms on the deck lift shaft.

See Figure 11.6.

Deck Lift Cable

Figure 11.6

1 1.7. Remove the E-clip from each end of the lift-shaft.

See Figure 11.7.

Figure 11.3

11.4. On models built in 2004 and prior, the lift assist

springs extend rearward to a pair of openings

with mounting tabs in the back surface of the

upper frame.

See Figure 11.4.

Mounting Tabs

Figure 11.4

E-clip

Figure 11.7

11.8. Pry the bushings that support the lift shaft out of

the frame.

11.5. Unbolt the seat bracket mounting plate from the

frame (4 screws) using a 1/2” wrench. This will

allow the fuel tank to be lifted slightly for clear

ance, but the tank need not be removed.

-

15

Page 20

Series 1000 and 1500

11.9. Slide the lift shaft assembly to the right, providing clearance to remove the left end of the shaft

from the frame.

11.10.Slide the lift shaft back to the left to remove it

from the tractor.

11.11.On the bench, relieve torsion spring pressure

between the lift shaft and the lever that controls

it using a length of starter rope.

11.11.

See Figure 11.9.

Lift Shaft

Figure 11.9

See Figure

bushing, it should be a dry graphite or PTFE

based lube.

• Replace the bushings an E-clips if they show

signs of wear.

• Reverse the removal process to install the lift

shaft.

• Connect the cables and install the bushings prior

to connecting the tension spring between the lift

shaft arm and the transaxle torque bracket.

12. LIFT SHAFT BUSHINGS

12.1. The most common item on the lift shaft assembly to require service is likely to be the bushings

that support the shaft. These bushings are visi

ble beneath the fender. See Figure 12.1.

Bushing

-

Start er Rope

Torsion Spring

Figure 11.11

11.12.Rotate the lever to align the coined “ears” with

the slots in the lift shaft arm, allowing separation

of the lever from the arm.

11.13.Assembly notes:

• Because of the dusty environment that many

mowers operate in, grease applied to this bushing may accelerate wear rather than prevent it. If

any lubricant is used between the shaft and the

Figure 12.1

12.2. When performing normal maintenance that

requires deck removal, inspect the lift shaft

bushings while the weight of the deck is

removed from them.

• These bushings are normal wear items.

• Grasp the lift shaft and apply up and down force.

• Watch for shaft motion within the bushings.

• Larger decks, such as the 50” and 54” ( P and K)

decks will place a greater load on the bushings.

• Worn bushings may cause deck leveling issues.

12.3. To replace the bushings, the weight of the deck

should be removed from the deck lift cable.

Remove the cutting deck before attempting to

remove the bushings.

16

Page 21

Series 1000 and 1500

12.4. Disconnect the deck lift assist spring that

extends from the deck lift shaft to the transaxle

torque bracket using a length of starter rope or a

spring tool.

Deck Lift Assist Spring

12.5. Remove the E-clip that holds each shouldered

hex bushing into the tractor frame. Replace one

bushing at a time.

12.6. Pry the worn bushing out of the hole.

See Figure 12.4.

Figure 12.4

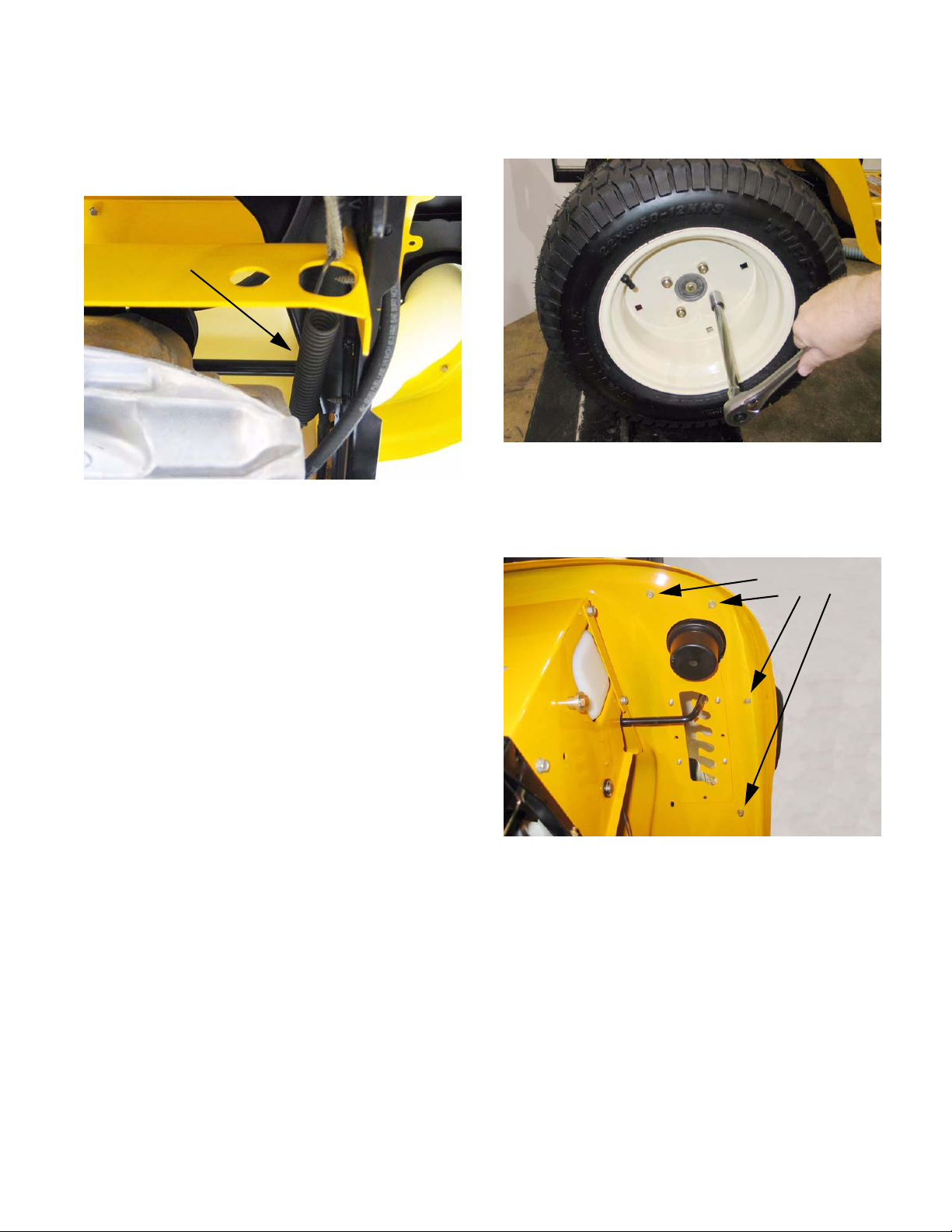

13.3. Remove the rear tires using a 3/4” wrench.

See Figure 13.3.

Figure 13.3

13.4. Remove the handle from the rear fenders using

a 3/8” wrench. The screws are accessible from

inside the rear fender.

See Figure 13.4.

Handle Screws

12.7. Clean any dirt or corrosion from the surface of

the lift shaft that contacts the bushing.

NOTE: Because of the dusty environment that

many mowers operate in, grease applied to this

bushing may accelerate wear rather than pre

vent it. If any lubricant is used between the shaft

and the bushing, it should be a dry graphite or

PTFE based lube.

12.8. Insert the new bushings, and secure them with

the E-clips.

12.9. Check deck levelness, and make any necessary

adjustments before returning the tractor to ser

vice.

13. DECK LIFT CABLES AND PULLEYS NOTE: The deck lift cables and pulleys can be

replaced without removing the rear fenders.

13.1. To remove the deck lift cables, remove the cutting deck.

13.2. Lift and safely support the rear of the tractor.

-

-

Figure 13.4

17

Page 22

Series 1000 and 1500

13.5. Remove the notched plate that the deck height

control lever seats against in the fender, using a

1/2” socket.

13.6. Push the deck height control lever as far forward

as it will go, and secure the lever in that position.

13.7. Remove the pulley that carries the deck lift cable

using a 1/2” wrench and a 5/8” wrench.

13.8. Remove the E-clip from the same end of the lift

shaft that the cable is being removed from. This

will allow the lift shaft to be pushed-in slightly,

providing clearance for the pin.

13.9. Remove the hairpin clip that secures the pin on

the top end of the cable to the arm on the deck

lift shaft.

See Figure 13.5.

Figure 13.5

See Figure 13.9.

13.10.Remove the hairpin clip that secures the pin to

the lift arm, and remove the cable.

13.11.Installation notes:

• Reverse the removal process to install the

cables and pulleys.

• Because of the dusty environment that many

mowers operate in, grease applied to the ca ble

or pulley may accelerate wear rather than prevent it. If any lubricant is used on the pulley, it

should be a dry graphite or PTFE based lube.

• Replace the pulleys and cables if they show

signs of wear.

• Check deck level before returning the tractor to

service.

• Tighten fasteners to the following torques:

Lug nuts 75ft-lbs (Nm)

Screws, handle to fender 60 in-lbs (Nm)

Screws, plate to fender 144in-lbs (Nm)

Shoulder bolts, pulley 144 in-lbs (Nm)

14. LEVELING THE CUTTING DECK NOTE: Prior to leveling the mowing deck, per-

form the following steps:

• Check the tire pressure. The front tires will be

approximately 14 PSI, and the rear tires will be

approximately 10 PSI.

• Place the tractor on a level surface.

• Depress and lock the parking brake.

Deck Lift Cable

Figure 13.9

NOTE: Early models used a removable clevis

pin. Current production cables have captive

pins.

• Place the cutting deck in cutting position 3 or 4.

SIDE TO SIDE ADJUSTMENT

IMPORTANT: The cutting deck must be even

side to side.

18

Page 23

Series 1000 and 1500

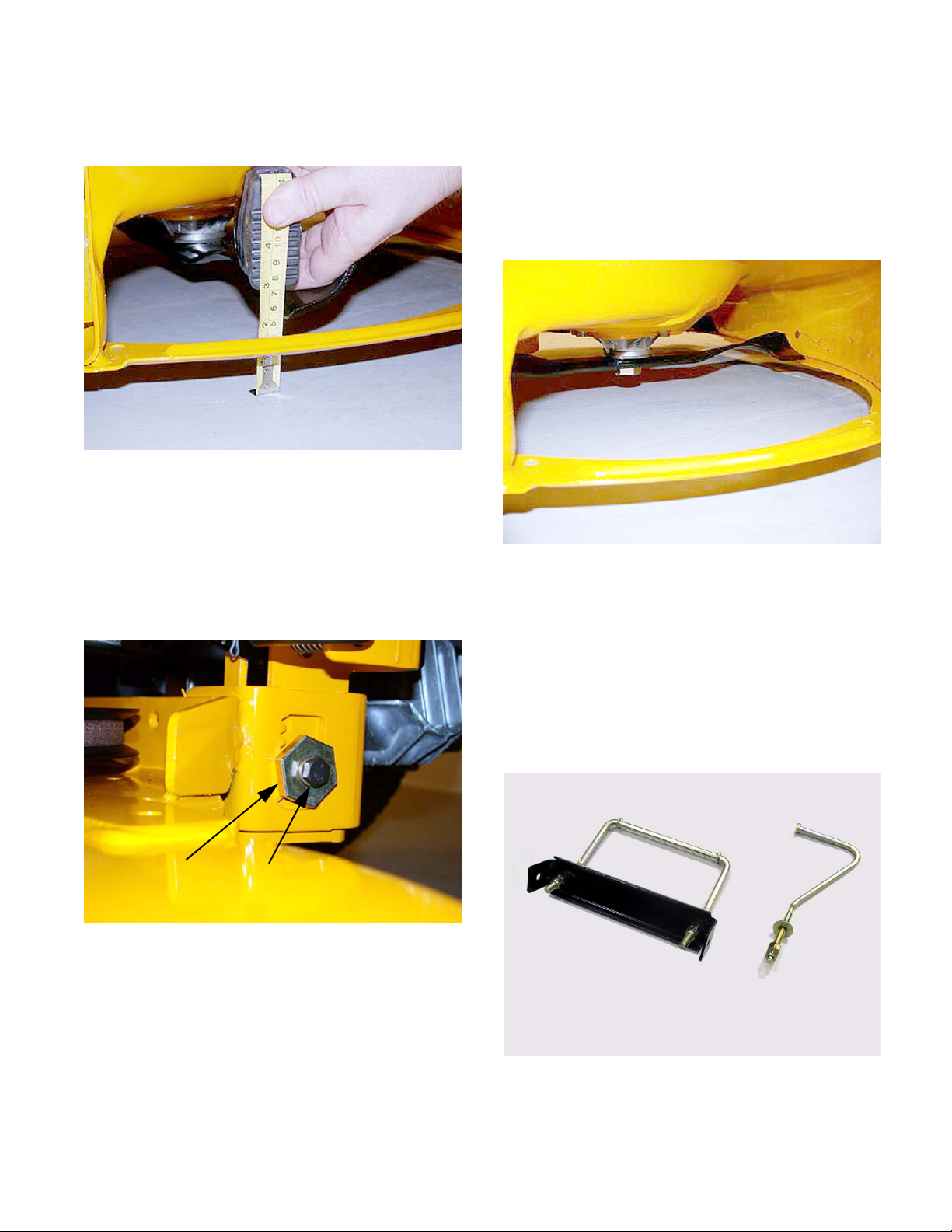

14.1. Using a work glove or rag, rotate the blades until

they are cutting edge tip to cutting edge tip (per

pendicular) to the tractor. See Figure 14.1.

Figure 14.1

14.2. Measure the outer blade tips to ground. Both

measurements taken should be equal.

NOTE: If an adjustment is needed, perform the

following steps:

FRONT TO REAR ADJUSTMENT

-

IMPORTANT: The front of the deck will be

between 1/4” and 3/8” lower in the front than the

rear of the deck.

14.6. Using a work glove or a rag, rotate the blades

until they are parallel with the tractor frame.

Figure 14.6.

Blades parallel with frame

Figure 14.6

See

14.3. Loosen (DO NOT REMOVE) the hex cap screw

on the left deck hanger bracket using a 1/2” an d

a 3/4” wrench.

Adjustment Gear Hex Cap Screw

14.4. Rotate the 3/4” deck adjustment gear right or left

until the deck is level side to side and both blade

tips to ground are equal in measurement.

14.5. Retighten the hex cap screw on the left deck

hanger using a 1/2” and a 3/4” wrench wh en th e

proper adjustment has been achieved.

See Figure 14.3.

Figure 14.3

14.7. Measure the front blade tips to the ground.

14.8. Measure the rear blade tips to the ground.

14.9. Make certain the front blade tips are 1/4” to 3/8”

lower than the rear blade tips.

NOTE: If an adjustment is needed, perform the

following steps:

14.10.There two types of stabilizer rods. A U-bolt type

and a J-bolt type.

U-Bolt Stabilizer

See Figure 14.10.

J-Bolt Stabilizer

Figure 14.10

19

Page 24

Series 1000 and 1500

• For the U-bolt style:

14.11.Loosen both lock nuts securing the adjustment

nuts on the front of the deck stabilizer bracket

using a two 3/4” wrenches.

Lock Nuts

Adjustment Nuts

Figure 14.11

14.12.Locate both adjustment nuts on the front side of

the deck stabilizer bracket.

14.13.Tighten both nuts to r aise the front of the deck or

loosen both nuts to lower the front of the deck

using a 3/4” wrench.

NOTE: Make sure you count the numbe r of turns

you put on the first nut and put the same number

on the second nut. both nuts must be moved

equally.

14.14.Retighten both lock nuts to jam the adjustment

nuts into position when the proper adjustment

has been achieved.

See Figure 14.11.

• For the J-bolt Style:

14.15.The J-bolt style stabilizer is adjusted in a similar

fashion. Loosen the single lock nut away from

the adjustment nut using two 3/4” wrenches.

Lock Nut Adjustment Nut

Figure 14.15

14.16.To lower the front of the deck loosen the adjustment nut on the J-bolt. To raise the front of the

deck tighten the lock nut. Tighten the lock nut

against the adjustment nut when finished.

15. DASH PANEL REMOVAL

15.1. Remove fender, as described in the FENDER

REMOVAL section of this manual.

15.2. For the 1500 remove the hood and battery, as

described in the HOOD REMOVAL section of

this manual.

• For the 1000 remove the fuel tank by first removing the fuel cap. place a piece of plastic over fuel

tank opening and put fuel cap back on.

• Remove the four 1/2” screws holding the fuel

tank in place.

• Lift the fuel tank and place on top of engine or

clamp the fuel line and remove it from the fuel

pump and remove fuel tank from unit.

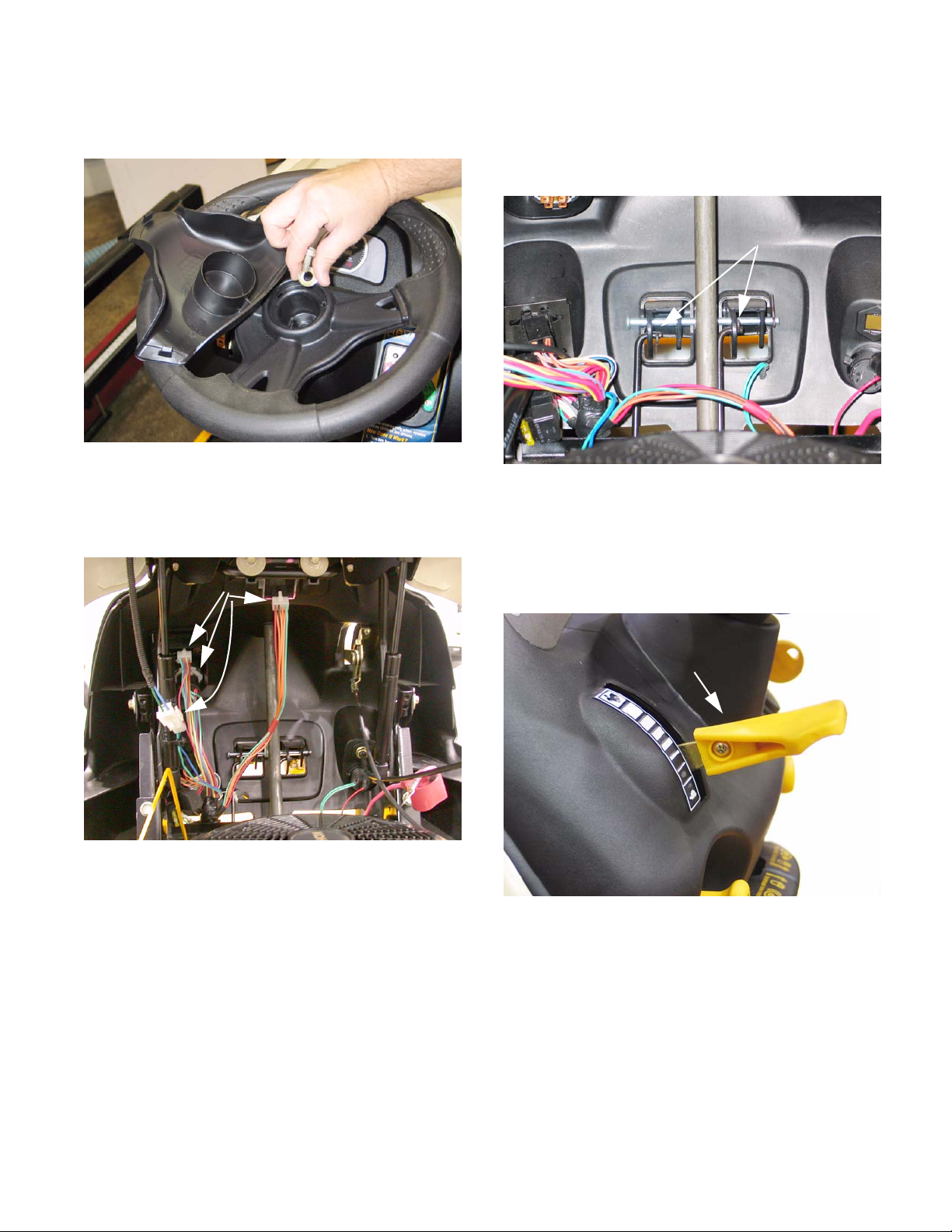

15.3. Pry the cap off the center of the steering wheel.

20

Page 25

Series 1000 and 1500

15.4. Remove the steering wheel from the steering

shaft using a 1/2” wrench.

Figure 15.4

15.5. Disconnect the following dash-mounted electrical devices by unplugging the molded connectors: See Figure 15.5.

Molded connectors

See Figure 15.4.

15.6. Disconnect the rods that connect the Park Brake

and Cruise Control mechanisms to the levers on

the dash that control those features by removing

the hairpin clips.

15.7. Remove the knob from the throttle lever using a

phillips head screwdriver, then remove the

screws that hold the throttle assembly to the

dash panel.

See Figure 15.6.

Hairpin clips

Figure 15.6

See Figure 15.7.

Figure 15.5

NOTE: Image shows 1500 dash. 1000 ser ies

dash components are in a similar location.

• Key switch and OCR module

• PTO Switch

• Hour meter / Monitor

• Accessory power port - if present.

Throttle

Lever

Figure 15.7

15.8. On models with a separate choke cable, disconnect the choke cable at the engine end. If the

technician prefers, they may also choose to dis

connect the throttle cable at the engine end.

15.9. Remove the remaining screws that hold the

dash panel to the tractor, and remove the dash.

• Two socket-head cap scre ws (T -40) at each side

of the base of the dash panel (four total).

-

21

Page 26

Series 1000 and 1500

• Two hex-head cap screws holding the rear

flange of the dash to the frame (1/2” wrench)

• Two hex-head cap screws holding the top of the

dash to the dash support (3/8” wrench).

See Figure 15.9.

Hex-head cap screw

Figure 15.9

15.10.Reverse the removal process to install the dash

panel.

16.4. Remove the hair pin clips holding the linkages to

the levers in the dash.

Figure 16.4

16.5. Remove the screw holding the pivot rod in place.

See Figure 16.5.

Pivot Rod Hex Screw

See Figure 16.4.

Hairpin Clips

• Test the operation of all safety features in a safe

area that is clear of obstacles and bystanders

before returning the tractor to service.

• Test the operation of all controls in a safe area

that is clear of obstacles and bystanders before

returning the tractor to service.

16. CRUISE CONTROL AND PARK BRAKE LINKAGES

16.1. Open the hood.

16.2. On the 1000 series you need to remove the fuel

tank. on the 1500 series you need to remove the

battery.

16.3. The procedure for removing the park brake linkage and the cruise control linkage is the same.

you can remove both at the same time.

Figure 16.5

16.6. Remove the hair pin clip in the pivot rod.

16.7. Work the pivot rod out. sliding it out to the right.

the levers will fall out as the rod clears them.

16.8. Raise the unit off of the ground.

16.9. Remove the brake and drive pedals.

22

Page 27

Series 1000 and 1500

16.10.Remove the cotter pins in the brake pedal shaft

and the drive pedal shafts.

Cotter Pins

Figure 16.10

16.11.Slide the drive pedal to the right. The inboard

bushing and washer can now be removed. Con

tinue working the drive pedal shaft to the right

and slip it out of the unit.

16.12. Remove the hair pin clip in the brake rod and

disconnect it from the brake pedal shaft.

16.13.Remove the return spring from the brake pedal

shaft.

16.14.Slide the brake pedal shaft to the right and

remove the inboard bushing and washer. Con

tinue sliding the brake pedal shaft to the right

and work it off of the unit.

16.15.Remove both drag links from the tractor.

See Figure 16.10..

-

16.16.Remove the lock nut from the bottom of the

steering shaft. Then slide off the steering shaft

gear.

See Figure 16.16.

Lock Nut

Hex Nut

Figure 16.16

-

16.17.Reaching up through the open in g whe r e the

pedal shafts were, place a 9/16” wrench on the

head of the bolt located in the center rear of the

subframe. Using a 9/16” socket, remove the nut.

See Figure 16.16.

NOTE: There is a sleeve on this bolt that acts as

a spacer between the sub-frame and frame. Be

aware of this sleeve when you lower the sub

frame in a later step.

16.18.There are four screws holding the subframe to

the tractor.Two on each side. Loosen the two

front screws and remove the two rear screws.

See Figure 16.18.

-

NOTE: Make sure to keep the drag links separate so the you know which one is for the left and

which one is for the right. they are not marked

and they are not interchangeable.

Loosen these two.

Sub Frame Hex Screws

Remove these two.

Figure 16.18

23

Page 28

Series 1000 and 1500

16.19.Pivot the subframe down. Be careful of the

spacer on the bolt and the hex flange bushing for

the steering shaft, they will fall out.

16.20.You now have access to the cruise linkage and

cam lock. You also have access the park brake

linkage and locking plate.

Cruise Control Rod.

Parking Brake Rod

Figure 16.20

16.21.Remove the hair pin clips on the linkages.

Remove the linkages.

See Figure 16.20.

Cam Lock

17.3. Remove the battery hold-down, remove the battery and the battery tray. See Figure 17.3.

Battery Hold Down

Figure 17.3

17.4. Pull the upper drive belt tensioner pulley rearwards to provide slack in the belt, and roll the

belt off of the tensioner pulley.

Tensioner pulley

See Figure 17.4.

16.22.Remove the nut and bolt holding the cruise cam

and/or the park brake locking plate.

16.23.Reassemble in reverse order.

CAUTION: Make sure the linkage rods are

routed properly before you swing the subframe

17. TRACTION DRIVE BELT REPLACEMENT: CVT

NOTE: There are two drive belts in the CVT sys-

tem. Because they work together on the variable

speed pulley, wear to one belt effects the perfor

mance of the other belt. It is strongly recommended that the belts be replaced as a set.

17.1. Remove the cutting deck from the tractor.

17.2. Tilt-up the seat and disconnect the battery

cables (ground cable first) using a 7/16” wrench.

-

Figure 17.4

17.5. Carefully release the tensioner pulley.

24

Page 29

Series 1000 and 1500

17.6. Using the slack created by taking the b elt off the

tensioner pulley, slip the belt off of the transaxle

input pulley and the upper sheave of the variable

speed pulley and remove the belt from the trac

tor. You may need to remove the transmission

input pulley to get enough clearance to remove

the belt.

Transmission input pulley

See Figure 17.6.

Figure 17.6

-

17.8. Lift the sliding center partition of the variable

speed pulley as far as it will go. This should pro

vide enough clearance to slip the lower belt off of

the variable speed pulley.

Variable speed pulley

17.9. Locate the double idler pulley bracket beneath

the tractor.

See Figure 17.9.

-

17.7. Loosen but do not remove the bracket that supports the variable speed pulley using a 1/2”

wrench.

NOTE: On 2004 and earlier CVT models, the

variable speed pulley was mounted directly to

the transaxle housing. On those tractors,

remove the variable speed pulley from the trac

tor using a pair of 9/16” wrenches.

See Figure 17.7.

Loosen these bolts

Figure 17.7

Double

idler

Figure 17.9

NOTE: This is the pair of pulleys that moves in

reaction to drive pedal input from the operator.

The further the pedal is depressed, the further

-

the bracket pivots, applying more tension to

the

belt.

17.10.Slip the lower drive belt off of the pulleys.

NOTE: On some 2004 and earlier models, it

may be necessary to loosen but not remove the

rear-most of the two pulleys (riding against the

flat side of the belt) to provide clearance to

remove the belt.

25

Page 30

Series 1000 and 1500

17.1 1.Disconnect the plug for the PT O clutch wire. It is

located on the right side of the tractor , just above

the opening in the frame that the wire passes

through to reach the PTO clutch.

See Figure 17.11.

PTO clutch plug

NOTE: On some models you may have to

remove the belt guide on the engine. Remo ve

the 1/2” bolt securing the belt guide to the frame

on the left hand side and slide the guide out of

the hole on the right hand side.

17.12.

Bolt

See Figure

Figure 17.11

17.12.Remove the bolt that holds the PTO clutch to the

crankshaft using a 5/8” wrench.

See Figure 17.12.

Figure 17.12

NOTE: If an impact wrench is unavailable it may

be necessary to use an improvised piston stop

or to hold the flywheel.

Figure 17.12

17.13.Carefully lower the PTO clutch and any associated hardware off of the crankshaft.

17.14.Lower the drive pulley far enough to allow the

belt to slip past the keepers that are stamped

into the frame. Slip the belt off of the pulley and

remove the pulley.

See Figure 17.14.

Figure 17.14

Stamped

belt

keepers

26

NOTE: Keep track of the position of any spacers

or washers that accompany the PTO clutch and

crankshaft pulley. Several different configura

tions have been used.

-

Page 31

Series 1000 and 1500

17.15.Remove the belt from the tractor.

NOTE: There were a small number of tractors

made using a CVT drive and a 2-speed

(L-H-N-R) G T transaxle. The belt must pass over

the center mounted gear selector on these mod

els for removal. Remove the knob from the gear

selector, and remove the shift gait from the

fender assembly to provide clearance.

17.16.Assembly notes:

• Install the belts by reversing the order of the

removal process.

• The engine drive pulley is installed on the drive

shaft with the key side facing down.

• Line up the key on the PTO clutch during assembly.

• There is a large flat washer that goes on top of

the PTO clutch during assembly.

• Torque the PT O clutch bolt during assembly.

• When installing the belt guide, make sure that it

passes through the cutout in the P TO clutch . this

acts as a anti-rotation bracket. Se e Figure 1 7.16.

• The tractor’s forward ground speed should vary

smoothly between 0 and 5.2 MPH when the

drive pedal is depressed progressively to the

end of it’s travel.

-

• It is normal for the cruise control to hold a mowing speed that is about 10% less than the 5.2

MPH transport speed.

• If the tractor performs as described, no adjustment is required.

18.2. Diagnosis: If the tractor does not move at all,

and the engine does not seem to be laboring as

the pedal is depressed, the issue may be in the

CVT belt system, the shift linkage leading to the

transaxle, or within the transaxle itself.

18.3. To isolate the CVT belt system:

• Turn-off the engine.

• Release the parking brake.

• Place the gear selector in any motion gear.

• Attempt to push the tractor.

• If the tractor rolls, examine the shift linkage.

• If the wheels lock when a gear is engaged, the

transaxle and shift linkage are not likely to be the

problem.

Cutout

Figure 17.16

18. DRIVE SYSTEM ADJUSTMENT: CVT

18.1. Make an operational test of the tractor:

• The tractor should not “creep” when the transmission is in gear and the drive pedal is not

depressed.

• On level ground, with the brake released, the

gear selector should slip smoothly into gear. It is

normal for gear engagement to be more difficult

on a grade, or with the brakes applied because it

is more difficult for the drive dogs to engage

under load or bind.

18.4. If the tractor does not move at all, and the

engine seems to be laboring as the pedal is

depressed, the issue may be in the brake, or

within the transaxle itself:

• Turn-off the engine.

• Release the parking brake.

• Place the gear selector in Neutral.

• Attempt to push the tractor.

• If the tractor rolls with difficulty, examine the

brakes as described in the “BRAKE ADJUSTMENT: CVT” section of this manual.

18.5. If the problem can be isolated to CVT belt drive

system, make a visual inspection of the CVT belt

drive system:

• Turn the engine off, and allow it to cool before

starting to work on the tractor.

• Remove the cutting deck.

• Lift the seat.

• Disconnect the battery cables, negative cable

first, using a 7/16” wrench

• Remove the battery hold-down.

27

Page 32

Series 1000 and 1500

• Remove the battery and battery tray from the

tractor.

18.6. Inspect the upper drive belt: See Figure 18.6.

Figure 18.6

• Is the upper drive belt correctly positioned on the

tensioner pulley , transaxle input shaf t pulley , an d

the upper sheave of the variable speed pulley?

loads (from torquing the nut) directly to the pul

ley, not the adaptor.

18.8. Repair any problems found. If the upper drive

belt is correct and in serviceable condition, rein

stall it. If the upper drive belt needs to be

replaced, the lower drive belt should be replaced

as well. Refer to the “TRACTION DRIVE BELT

REPLACEMENT” section of this manual.

18.9. Operate the drive pedal while observing the

movement of the components controlled by the

drive pedal.

See Figure 18.9.

Observe

movement

-

-

• Inspect the type and condition of the belt.

• Check the bearing on the tensioner pulley.

• Check the tensioner pulley arm: it should return

readily to static position under spring tension.

• The center partition of the variable speed pulley

should move up with light force and down under

it’s own weight.

18.7. The pulley on the transaxle input shaft should be

firmly attached.

• Early production tractors used a splined joint

between the pulley and the input shaft.

• Current production tractors carry the pulley on a

separate hub that fits over the splined shaft.

NOTE: The nut securing the pulley should be

tightened to a torque of 10-15 ft.-lbs using an 11/

16” wrench. Over-torquing the nut ma y shear the

input shaft. Replace the belleville washer

between the nut and the pulley if it is flattened.

NOTE: Some models used a special “fully finished” nut with an extended washer face. Do not

replace this nut with a standard nut unless a

washer is added between the nut and the pulley.

The washer must have a big enough O.D. to fit

over the star shape on the pulley adaptor, and

must be sufficiently thick to transfer compression

Figure 18.9

18.10.The double idler bracket should move with about

10 lbs pressure applied to the pedal, and retu rn

under spring pressure as the pedal is released.

See Figure 18.10.

Figure 18.10

28

Page 33

Series 1000 and 1500

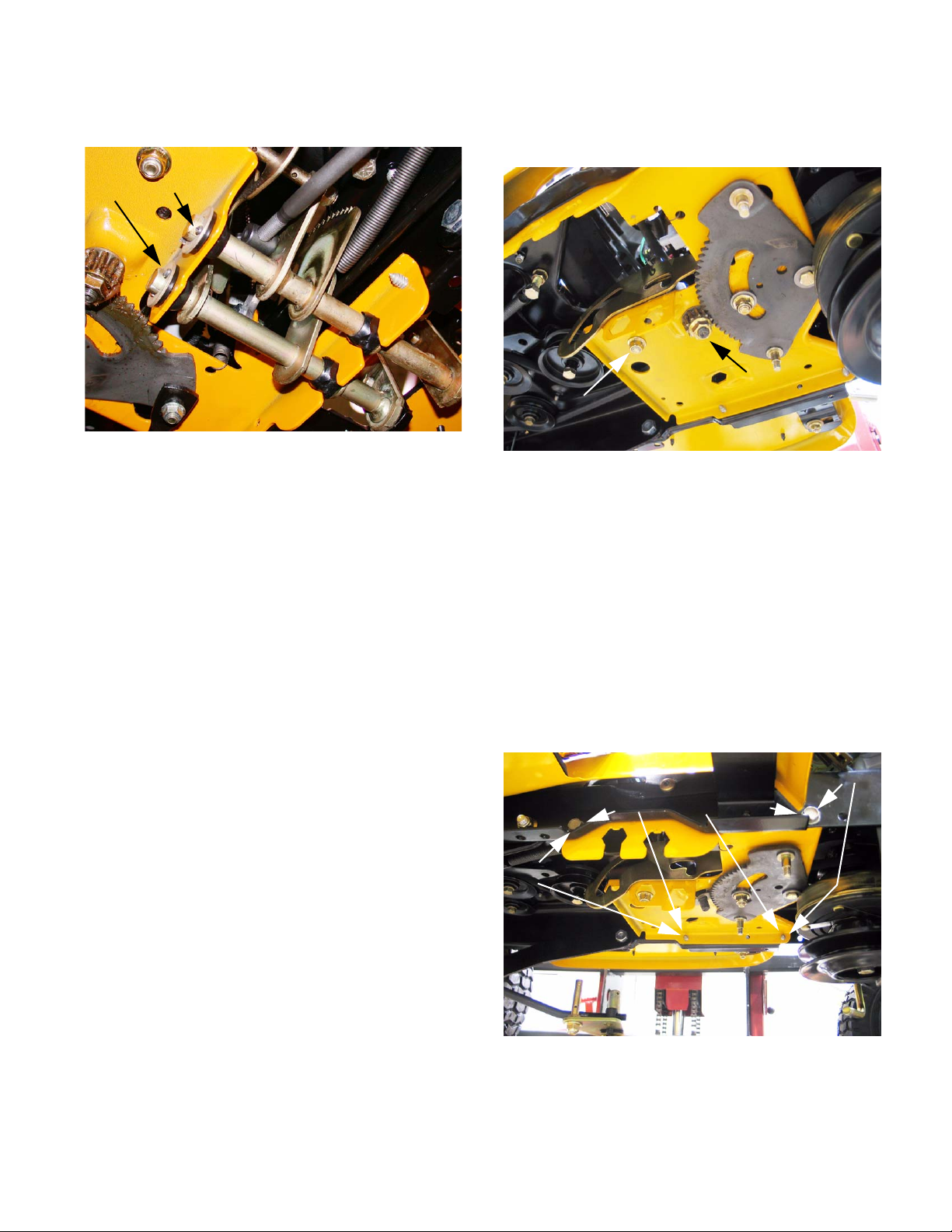

18.11.The empty hole in the double idler bracket

should swing through an arc of 1 3/8” when 10

lbs. of force is applied to the drive pedal.

See Figure 18.11.

1 3/8” movement

Figure 18.11

18.12.If the measurement is not 1 3/8”, check the type

and condition of the lower drive belt. If the lower

drive belt is worn or incorrect, replace both drive

belts before adjusting the speed control. Refer to

the “TRACTION DRIVE BELT REPLACEMENT:

CVT” section of this manual.

18.13.If the belts are serviceable and correct, adjust

the length of the speed control rod to achieve the

correct double idler bracket travel as desc rib ed

in the following steps:

18.14.Loosen the jam nut that locks the speed control

rod into the rod-end joint at the double idler

bracket with a pair of 9/16” wrenches.

See Figure 18.14.

18.15.The forward end of the speed control rod connects to a pin attached to the speed contr ol

assembly.

NOTE: On 2005 production units you can

remove the nut on the ball joint and lift it out of

the idler bracket on an angle, then skip to step

15.16.

See Figure 18.15.

2005 production

Figure 18.15

• Early production models may have a hairpin clip

and washer adjacent to the cam plate that prevents the speed control linkage from moving

when the parking brake is applied.

• Remove the hairpin clip and washer if so

equipped.

• Disconnect the pin from the speed control

assembly using a pair of 9/16” wrenches.

18.16.Thread the rod in or out of the rod-end as

required to achieve the correct linkage travel.

Jam nut

Figure 18.14

18.17.When adjustment is complete:

• Secure the linkage and tighten any loosened

fasteners.

• Install the battery tray and battery.

• Test the operation of the drive system in a safe

area that is free of obstacles, hazards, and bystanders.

• After successful testing, install the cutting deck,

test all safety features, and return the mower to

service.

29

Page 34

Series 1000 and 1500

19. BRAKE ADJUSTMENT: CVT

19.1. On CVT-driven lawn and garden tractors, most

of the braking force is generated within the tran

saxle: when the drive pedal is released, the drive

ratio changes, slowing the tractor. The brake

brings the tractor to a complete stop, and func

tions as a parking brake.

19.2. When properly adjusted, the brake should do

two things: it should stop and hold the tractor

when applied, and it should not drag when

released.

19.3. To check that the brakes hold the tractor:

• Place the gear selector in Neutral.

• Set the parking brake.

• Attempt to push the tractor.

• The wheels should skid without rotating.

• If the brakes do not hold the tractor, the brake

needs to be adjusted or repaired.

19.4. To check that the brakes do not drag:

• Place the gear selector in Neutral.

• Release the parking brake.

• Attempt to push the tractor - it should move with

less than 20 lbs. of force. More force indicates

drag.

-

19.8. CVT-driven transaxles use a self locking nut on

the brake adjustment.

-

Figure 19.8

19.9. Insert a .013” feeler gauge between the brake

rotor and the outer brake pad. There should be

slight drag on the feeler gauge.

19.10.If the feeler gauge is too loose, or will not go in,

brake caliper adjustment is necessary.

19.1 1.A 1/2” wrench will turn the adjustment nut.

See Figure 19.11.

See Figure 19.8.

Lock nut

• If the brakes drag, they need to be adjusted or

repaired.

19.5. There is no linkage adjustment. All adjustment is

done at the brake caliper.

19.6. To reach the brake caliper, lift and safely support

the right rear corner of the tractor.

19.7. Remove the right rear wheel of the tractor using

a 3/4” socket.

Figure 19.11

19.12.Tighten the nut to reduce the clearance. Loosen

the nut to increase the clearance.

30

Page 35

Series 1000 and 1500

19.13.Check the movement of the brake arm:

• The brake arm should move forward as the

brake is applied.

• The return spring should draw the br ake arm

back against the spacer when the brakes are

released.

19.14.Visually check the thickness of the brake pads:

they are visible within the caliper.

19.15.Check the brake rotor:

• Confirm that the brake rotor floats on the splined

shaft by sliding it in and out with light finger pressure.

• If it binds on the shaft it may cause brake drag

and reduced holding performance.

• A rotor that has been dragging will frequently be

discolored by the heat (blue).

19.16.If the brakes are dragging or worn, or if the rotor

needs to be removed from the shaft, r emove the

two bolts that hold the caliper to the transaxl e

using a 3/8” wrench.

See Figure 19.16.

19.17.Remove the caliper from the transaxle. The

brake actuator arm can now be unhooked from

the spring that connects it to the linkage.

Figure 19.17.

Figure 19.17

19.18.The rotor should slip-of f of th e sp lined sh aft, providing access to the fixed brake pad.

See Figure 19.18.

See

Caliper

2 Bolts

Fixed brake pad

Figure 19.16

Figure 19.18

31

Page 36

Series 1000 and 1500

19.19.A crease in the brake arm acts as a cam. At rest,

the ends of the two pins ride in the peak of the

crease:

• The brake arm pivots on a square-headed stud.

• The two pins are forced against the backing

plate when force is applied to the arm.

• The backing plate rides between the pins and

the pad, to prevent the pins from damaging the

brake pad.

See Figure 19.19.

Figure 19.19

20. SERVICING THE BRAKE PEDAL SHAFT BUSH-

INGS:

• If there is insufficient travel in the linkage to fully

apply the brakes, a simple visual inspection

should identify the cause.

20.1. Confirm that the brake pedal is firmly att ached to

the pedal shaft.

20.2. Remove the cutting deck to re ac h th e brake

pedal shaft, bushings, and bracket.

See Figure 20.1.

Brake Pedal

Figure 20.1

19.20.Replace the pads if they are worn. They frequently last many years unless the brakes have

been dragging.

19.21.Be sure the pin bores are clear of dirt and corrosion: either may cause the pins to bind and the

brakes to drag.

19.22.On assembly, apply a small amount of dry

graphite lubricant to the pins and the spots on

the brake arm that they contact. Do not allow

any lubricant to get on the brake pad.

19.23.Install the brake caliper, tightening the two nuts

to 7 to 10 ft.-lbs., then check and adjust the padto-rotor clearance.

19.24.Install the rear wheel, tightening the lug nuts to a

torque of 350 to 500 In.-lbs. Lower the tractor to

the ground.

19.25.After any brake service is performed, test the

brakes as described in steps 24.2 through 24.4,

then test-drive the tractor in a safe area that is

free of hazards, obstacles, and by-standers

before returning the tractor to service.

20.3. Check for excessive play in the bushings.

Replace them if they are worn.

NOTE: It is suggested that if any of these bushings need to be replaced, replace all of the pedal

shaft bushings at this time. The speed control

pedal shaft bushings are replaced in a similar

manner.

32

Page 37

Series 1000 and 1500

20.4. The inboard brake pedal shaft bushing can be

removed by removing the cotter pin and washer

that secure it.

20.5. The brake rod must be disconnected to remove

the outboard brake pedal shaft bushing.

Remove and discard the cotter pin that holds the

brake rod to the brake pedal shaft.

See Figure 20.5.

See Figure 20.4.

Bushing

Figure 20.4

Brake rod

20.6. Press the brake pedal shaft as far outward as

possible, and pry the worn bushing out of the

bracket.

NOTE: A pair of vice-grips and a plate can be

used to press the end of the shaft flush with the

edge of the bracket

NOTE: The inner bushing is a hex flange bushing. The outer bushing is similar, but has one

open side. The “tooth” in the top facet of the

bracket that supports the bushing registers in

open side of the bushing.

See Figure 20.6.

Figure 20.6

Figure 20.5

20.7. Clean any corrosion or dirt from the surfaces

where the pedal shaft contacts the bushing, and

slip the new bushings into place.

20.7.

Figure 20.7

See Figure

33

Page 38

Series 1000 and 1500

NOTE: Lubrication with grease may accelerate

bushing wear. If lubrication is applied it should

be in dry form such as graphite or PTFE (Teflon).

21.2. Remove the battery hold down, battery and battery tray from the unit. See Figure 21.2.

20.8. Secure the inner bushing with a new cotter pin

and the flat washer that was previously

removed.

20.9. Move the pedal through it’s range of travel to

check for binding. If binding is encountered:

• Bind in just a portion of the travel may be caused

by a bent pedal shaft.

• Constant bind is likely to be caused by a bent

bracket.

• Also check for interference between the parking

brake and cruise control interlocks.

20.10.Correct any binding condition.

20.11.Connect the brake rod to the brake pedal shaft,

and secure it with a new cotter pin.

20.12. After any brake service is performed, test the

brakes as described in steps 14.2 through 14.4,

then test-drive the tractor in a safe area that is

free of hazards, obstacles, and by-standers

before returning the tractor to service.

21. TRANSAXLE REPLACEMENT: CVT

Battery hold down

Figure 21.2

21.3. Take tension off of the transmission belt idler

and remove the belt from around the idler pulley.

See Figure 21.3.

Idler pulley

• The single speed transaxles used in our CVT

riders has evolved over the years. Internals ha ve

changed. Some have had the Variable Speed

Pulley integrated into the transaxle. If you are

replacing a transaxle it is very important to carefully match the transmission part numbers

between the old and new. A part number on the

transmission case might be the number of the

case half. Visually compare the IPL drawing with

the actual transaxle to assure a match .

• Before condemning a transaxle, check to make

sure the brake is not locking up the transaxle.

• Check the drive belts for damage or wear and

make sure they are the correct belts and ar e not

the cause of drive problems.

• When replacing a transaxle within the warranty

period, we have a like-kind exchange program.

• Out of warranty transaxles can be serviced.

21.1. Disconnect the battery cables (negative first and

then positive).

Figure 21.3

34

Page 39

Series 1000 and 1500

21.4. Using a 7/8 socket and extension, remover the

nut securing the transmission pulley to the trans

mission. See Figure 21.4.

Transmission pulley

Figure 21.4

21.5. Remove the pulley from the unit.

21.6. Support the frame of the unit to allow removal of

both rear wheels.

See Figure 21.6.

21.7. Disconnect the brake linkage where it connects

-

to the brake spring.

Brake linkageBrake linkage

21.8. Use white-out to mark the position of the ferrule

on the transmission shift rod.

21.9. Remove the hairpin clip securing the transmission shift rod to the transmission. See Figure

21.9.

See Figure 21.7.

Figure 21.7

Figure 21.6

NOTE: Leave room under the rider to allow low-

ering the transaxle from the unit.

Hairpin clip

Figure 21.9

21.10.Using a 1/2” socket, remove the two hex screws

securing the front of the transmission housing to

the transmission support bracket.

21.9.

21.11.Support the transmission from below.

35

See Figure

Page 40

Series 1000 and 1500

21.12.Using a 1/2” socket and 1/2” wrench, remove the

four hex nuts securing the transmission to the

frame.

See Figure 21.12.

Nuts

Figure 21.12

CAUTION: The transmission must be supported

during removal of the bolts. Use a helper if nec

essary.

22. TRANSAXLE SERVICE AND INTERNALS: CVT

• Transaxles needing service within the warranty

period qualify for like-kind exchange.

• If you are servicing transaxle internals, keep in

mind that different transaxles/components have

been used over the years.

• Carefully compare the transaxle with the illustrated parts list when ordering components.

23. TRACTION DRIVE BELT REPLACEMENT: HYDROSTATIC LT

23.1. Turn-off the engine and allow all parts to cool

before beginning work.

23.2. Remove the cutting deck.

23.3. Identify and unplug the wires leading to the elec-

-

tric PTO clutch. See Figure 23.3.

21.13.Lower the transmission from the rider. See Figure 21.13.

Figure 21.13

NOTE: There is a backing plate on the top of th e

frame. There may be a spacer between the

frame and the transmission housing.

21.14.Reassemble in the reverse order of disassembly.

PTO clutch wires

Figure 23.3

NOTE: If it appears that the drive belts a re worn,

we recommend replacing both of them when

servicing the transaxle. Use original OEM belts

to assure proper operation of the rider.

36

Page 41

Series 1000 and 1500

23.4. Remove the electric PTO clutch from the engi ne

crankshaft using a 5/8” wrench.

Figure 23.4

NOTE: Lower the clutch carefully, keeping track

of the hardware on the crankshaft. There are

variations between engines, clutches and years:

• Spacer s above or below the traction drive pulley.

• Integral or separate key on traction drive pulley.

• Different PTO clutch anti-rotation brackets.

23.5. Slip the belt off of the single fixed idler.

See Figure 23.5.

See Figure 23.4.

5/8” Head bolt

23.6. Carefully release the spring that maintains tension on the double idler bracket using a length of

starter rope or an appropriate tool.

See Figure 23.6.

Figure 23.6

23.7. Slip the drive belt from between the double idler

pulleys.

NOTE: On some early models, the rear-most

pulley (rides against V side of belt) was large

enough that the double idler bracket acted as a

belt keeper. On those models, it is necessary to

loosen the nut and bolt that secure that pulley to

the bracket in order to slip the belt past th e edge

of the bracket.

Figure 23.5

NOTE: Pulleys may be steel or plastic, depend-

ing on when the tractor was built.

37

Page 42

Series 1000 and 1500

23.8. Slip the crankshaft pulley down far enough to get

the belt off of the pulley, and remove the belt

from the crankshaft.

Stamped Belt Guards

NOTE: Belt keepers that are part of the tractor

frame prevent the belt from being removed with

out lowering the pulley.

NOTE: The pulley may be removed from the

crankshaft at the discretion of the technician.

• If there is a spacer above the pulley, the end with

the radiused inside edge mates with the radiused step on the crankshaft.

• If one end of the pulley has a radiused inside

edge, that is the end that mates with the radiused step on the crankshaft.

23.9. Carefully work the belt over the top of the cooling

fan on the transaxle, and remove it from the trac

tor. See Figure 23.9.

See Figure 23.8.

Figure 23.8

23.10.The belt for the G.T. models of the 1500 Series

line is Kevlar wrapped. Substituting the polywrapped belt used on the L.T. models is not rec

ommended, but the Kevlar belt is an acceptable

premium upgrade for the L.T. tractors.

See Figure 23.10.

-

23.11.If the traction drive belt failed prematurely, identify the cause of it’s demise before installing a

replacement. Check the condition of all of the

idler pulleys.

23.12.The fixed idler pulley can be removed from later

models using a single 1/2” wrench. The bolt that

holds the fixed idler to earlier models threads

into a 3/8” nut above the tractor frame. The bolt

can be removed from the nut using a pair of

9/16” wrenches without removing the fenders.

-

See Figure 23.12.

Kevlar wrapped belt

Figure 23.10

-

Figure 23.9

Fixed idler

Figure 23.12

38

Page 43

Series 1000 and 1500

23.13.The double idler pivot bracket is held to the

frame by the same bolt that holds the fore-most

of the two pulleys. The rear pulley can be easily

removed from the bracket. It is necessary to take

the fenders off to remove the front pulley or the

bracket itself.

23.14.Install the drive belt by reversing the order of the

removal process.

• Apply anti-seize compound to the crankshaft

before installing the PTO clutch.

• Tighten the crankshaft bolt to a torque of 38-50

ft.-lbs. on assembly.

• Test the drive system and all tractor safety features in a clear area that is free of hazards and

by standers before returning the tractor to service.

24. DRIVE SYSTEM ADJUSTMENT: HYDROSTATIC LT

24.1. The relief valve is operated using a small rod

that is visible at the bottom right corner of the

rear of the tractor frame.

See Figure 24.1.

24.3. There is no adjustment to the relief valve, but full

travel of the linkage should be checked if the

drive system is losing power or ground speed.

See Figure 24.3.

Relief valve linkage

Figure 24.3

24.4. Symptoms of a linkage that is out of adjustment

include:

Relief valve rod

Figure 24.1

24.2. Pulling the rod out and locking it in the upper

portion of the keyhole enables the tractor to be

pushed, but disables the hydraulics of the drive

system by opening a valve that releases the

hydraulic pressure from the motor circuit.

• Low ground speed in either direction with no

unusual noises from the transaxle. One possible

cause for low ground speed is a linkage that

does not transfer all of the pedal travel to the

input arm on the transaxle.

• “Creeping” when the transaxle is in neutral

position.

• Whining or growling when the tractor is in Neutral with the brake applied.

• The creeping and whining symptoms usually

accompany one-another, indicating that the linkage is not properly centered around Neutral.

• Low ground speed in one direction only (For ward or Reverse) may accompany whining,

growling or creeping in Neutral if the linkage is

out of adjustment.

• Low ground speed, accompanied by excessive

noise is likely to be an internal problem or a

brake that is dragging or out of adjustment.

24.5. Begin linkage adjustment by inspecting the linkage. Linkages on equipment that has been in the